Through-flow double channel blower fan

A dual-channel, fan technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of uneven wind speed, non-adjustable wind speed at the air outlet, and inability to achieve graded winnowing, etc., to achieve a uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

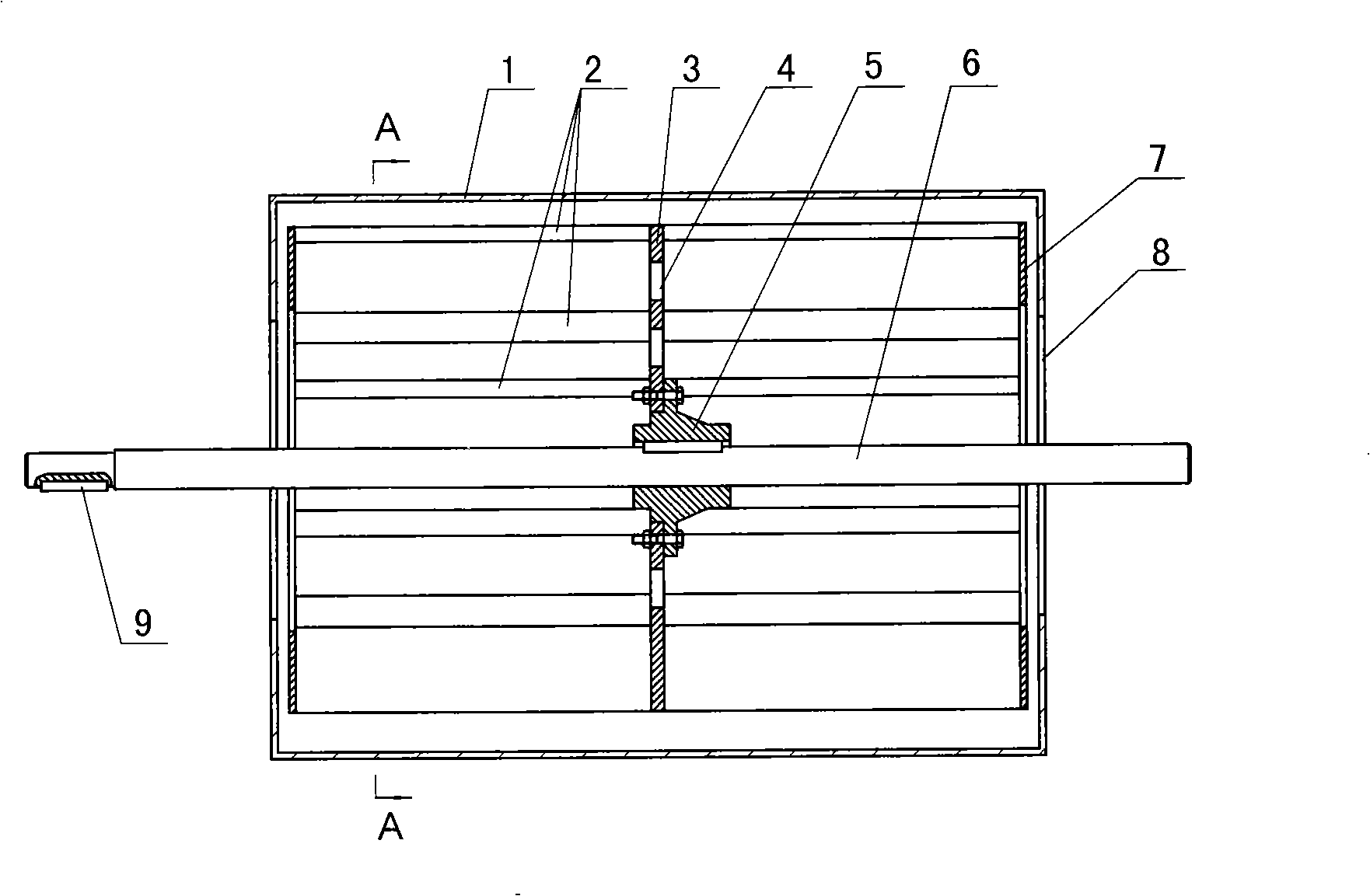

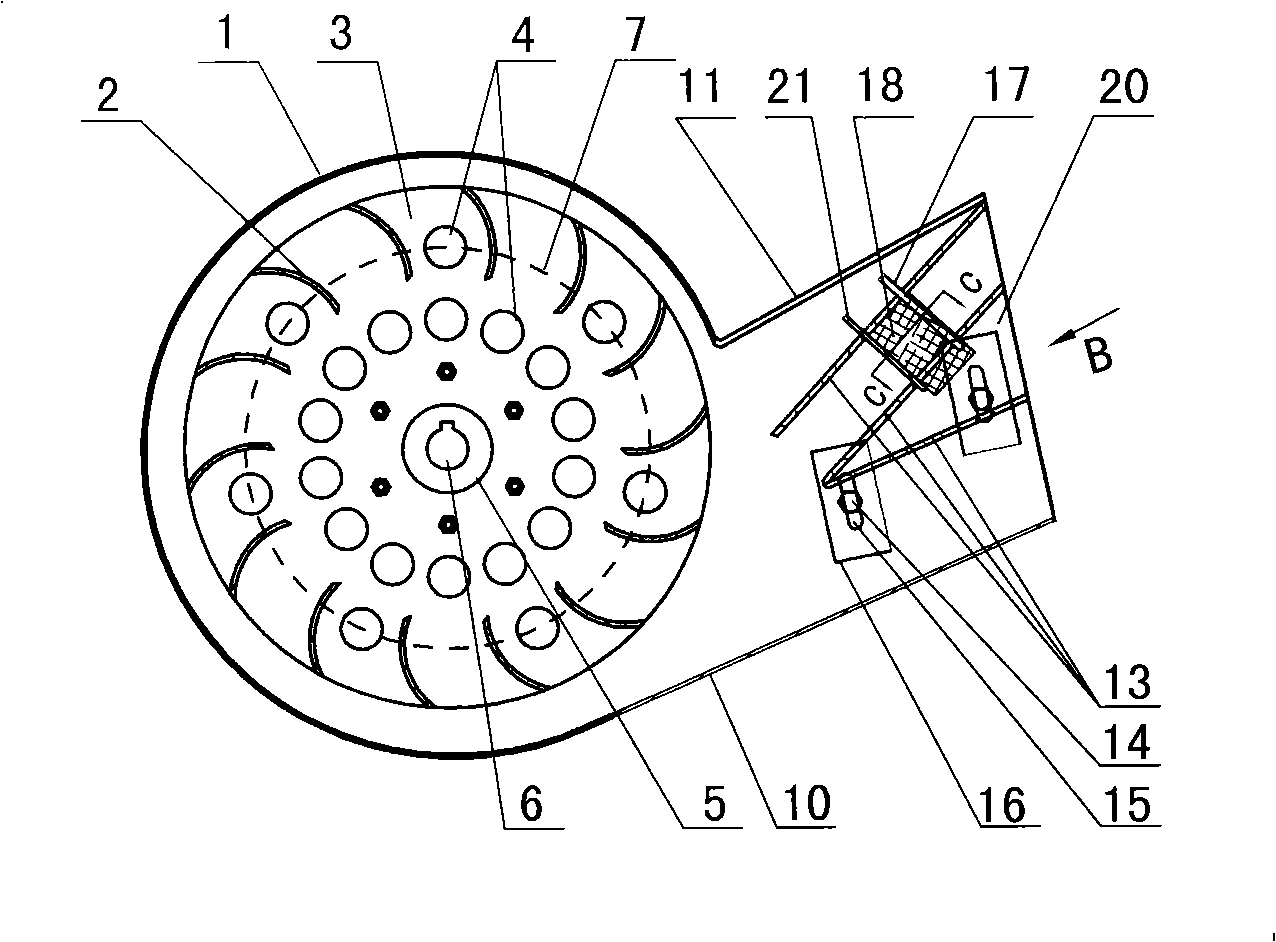

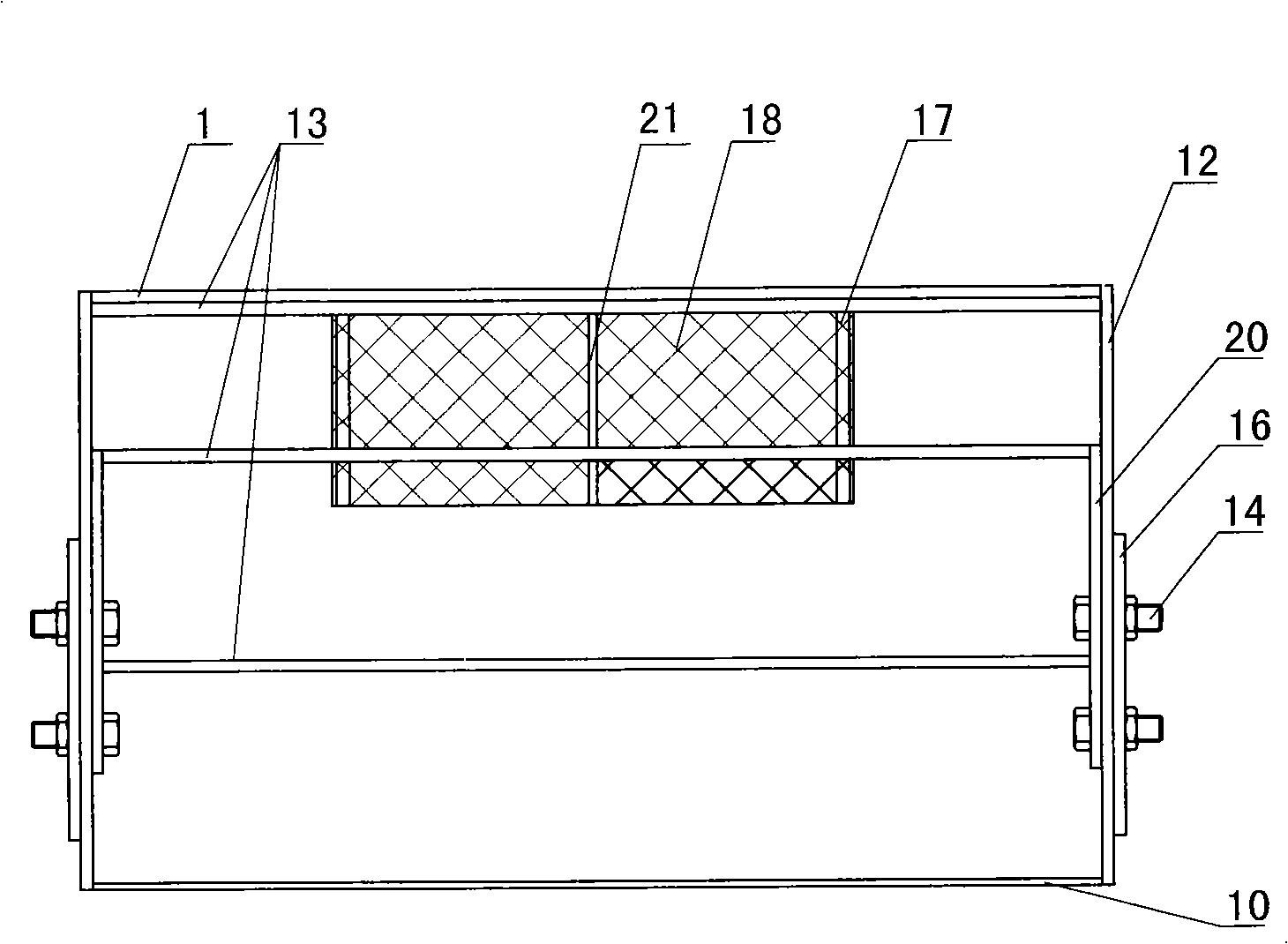

[0018] exist Figure 1-4 In the shown embodiment, it includes a volute 1 with an air inlet 8 and an air outlet and an impeller assembly, wherein the cross section of the air outlet and the outer port are square, and the bottom plate 10 forming the air outlet is at an angle of 25 degrees to the horizontal , from the outer end of the air outlet, three partitions 13 are respectively arranged inwardly, wherein the outer end of the first partition 13 is fixedly connected with the outer end of the top plate 11 constituting the air outlet, and the included angle with the top board 11 of the air outlet is 18 degrees, the second partition 13 is located between the first and third partitions 13, and is parallel to the first partition 13, and the third partition 13 is parallel to the bottom plate 10 forming the air outlet, and its probe The inner end of the air inlet and outlet is fixedly connected with the inner end of the second partition 13, and the side plate 12 close to the air outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com