Patents

Literature

76 results about "Horizontal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In genetics, the term horizontal resistance was first used by J.E. Vanderplank to describe many-gene resistance, which is sometimes also called generalized resistance. This contrasts with the term vertical resistance which was used to describe single-gene resistance. Raoul A. Robinson further refined the definition of horizontal resistance. Unlike vertical resistance and parasitic ability, horizontal resistance and horizontal parasitic ability are entirely independent of each other in genetic terms.

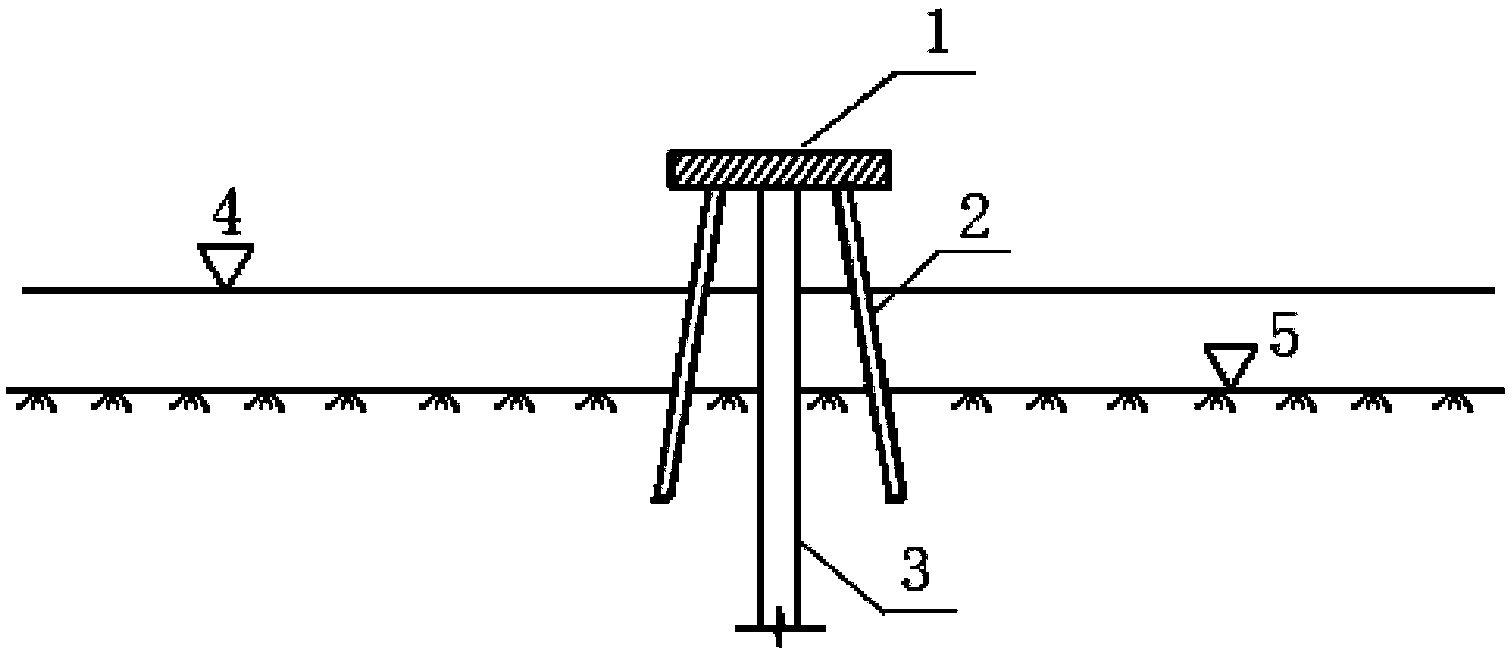

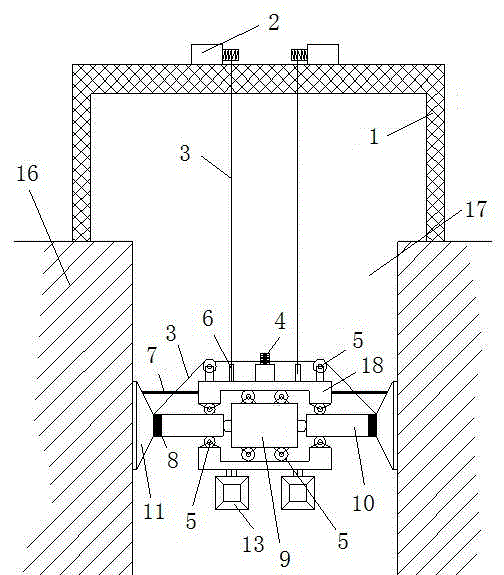

Construction process of open sea fan foundation rock-socketed pile

ActiveCN106120839ASolve the problem of eccentricityImprove the immunityFoundation testingBulkheads/pilesOpen seaEngineering structures

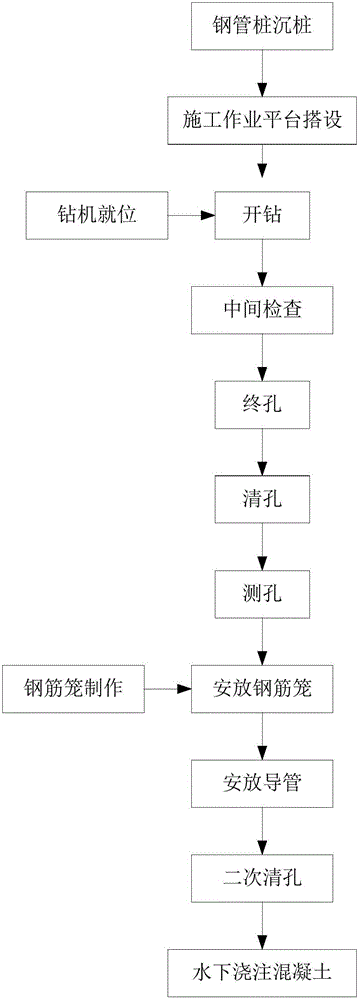

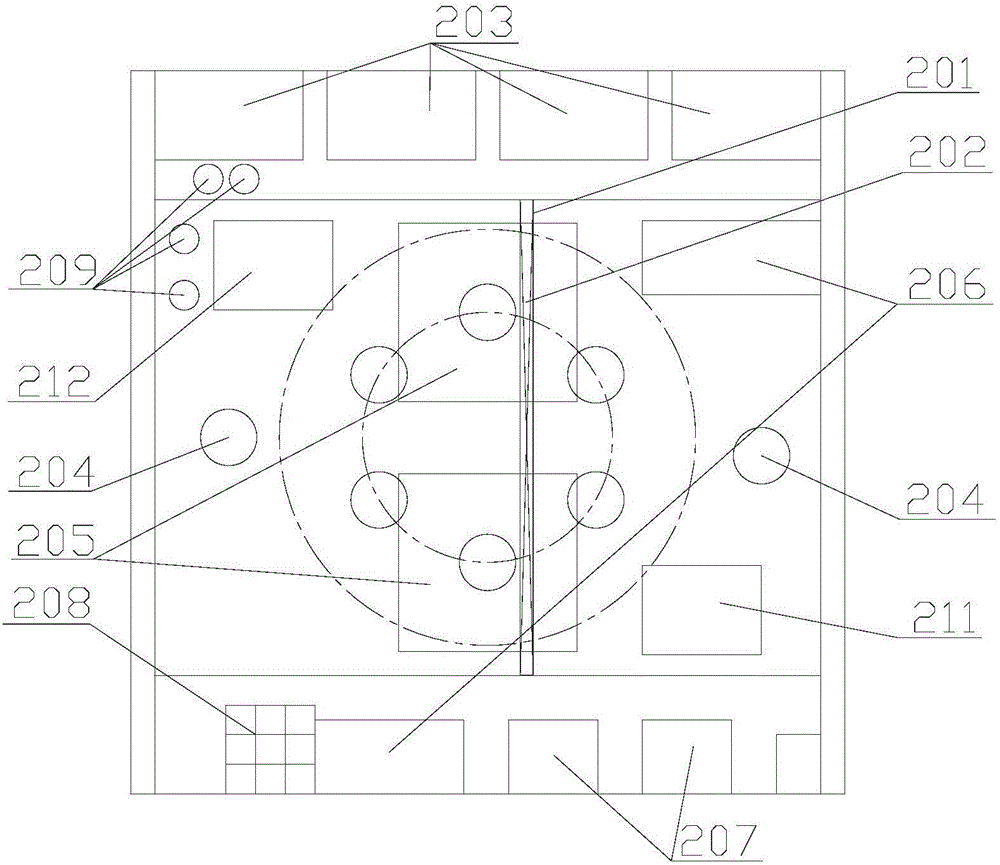

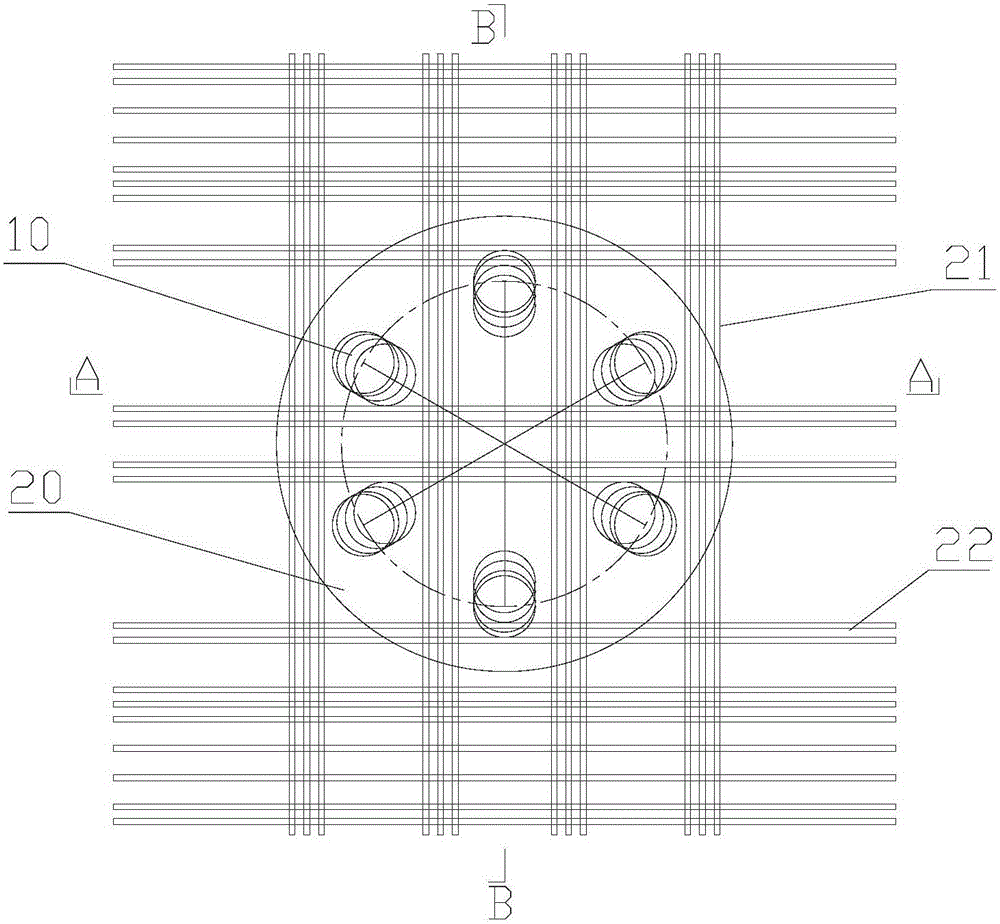

The invention discloses a construction process of an open sea fan foundation rock-socketed pile. The construction process comprises the steps of pile sinking of a steel pipe pile, setting a construction operation platform, drilling, performing intermediate inspection, finishing a drilled hole, clearing the hole, measuring the hole, placing a steel reinforcement cage, placing a guide pipe, clearing the hole for the second time and performing underwater concrete pouring procedure. In the pile sinking procedure of the steel pipe pile, six steel pipe piles with the inclination of 5:1 which are uniformly distributed on the circular track curve are sunken into the foundation in the pile driving way by a special pile driving boat; in the setting procedure of the construction operation platform, the construction of a bearing platform bottoming concrete layer is performed and the construction operation platform is erected on the bearing platform bottoming concrete layer; the concrete of the bearing platform bottoming concrete layer is performed by the steel pipe piles; the construction operation platform is square and comprises an upper bailey frame, a lower bailey frame, a steel platform panel and a safety fence. According to the construction process, the construction efficiency of the pile socketing into rock can be improved, the horizontal resistance and the anti-shifting capability of the rock-embedded piles can be effectively improved, and the requirements of engineering structure design and construction are met.

Owner:CCCC THIRD HARBOR ENG +2

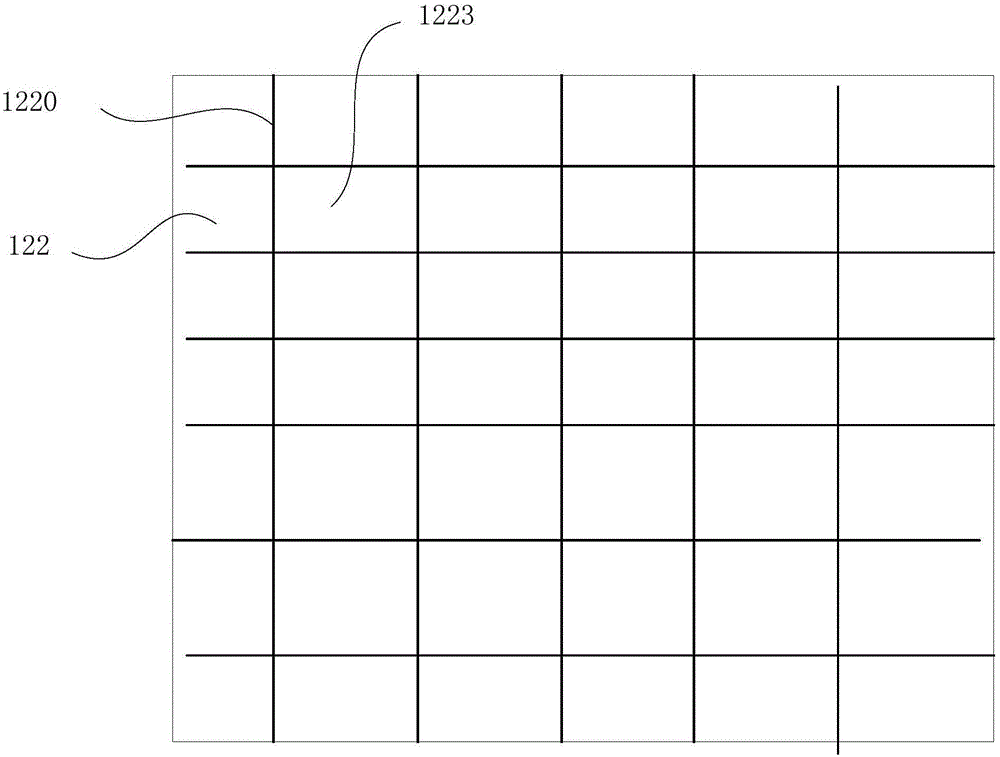

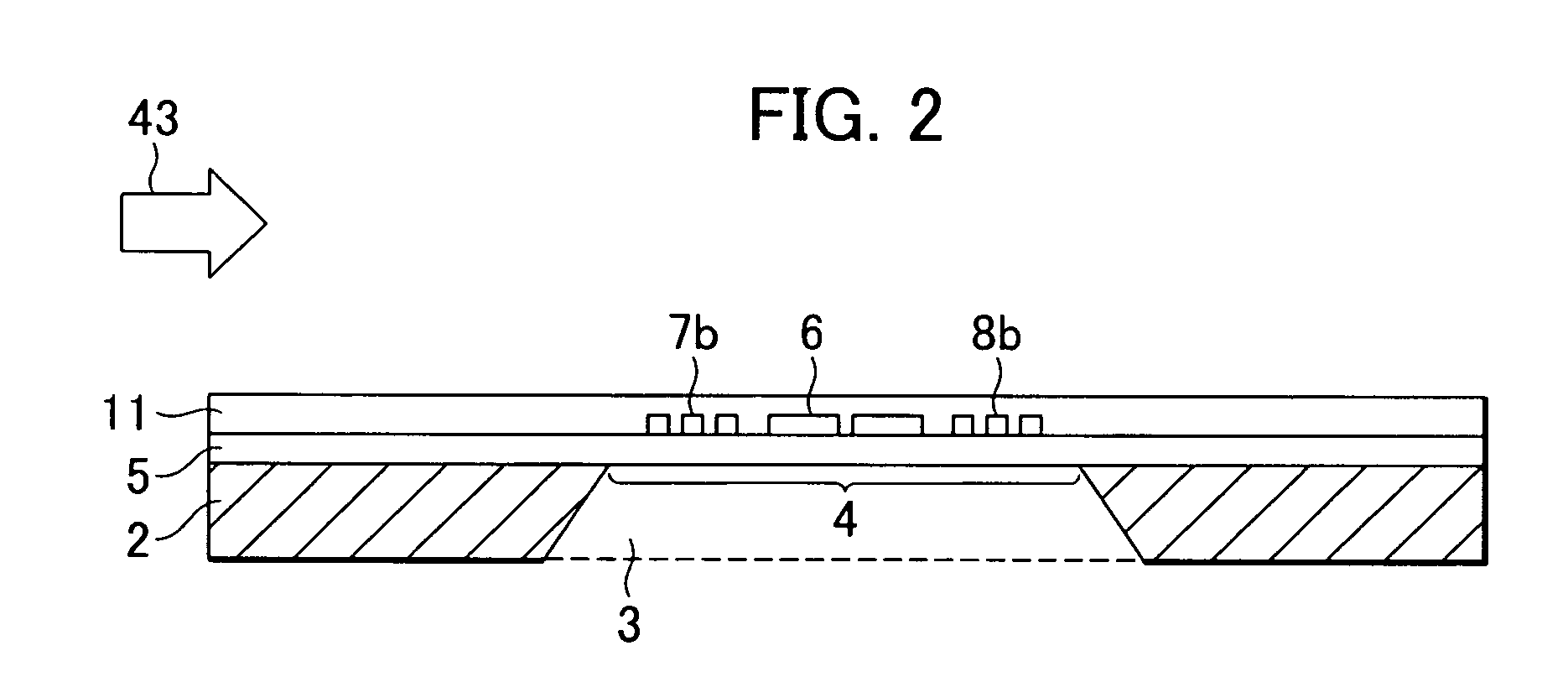

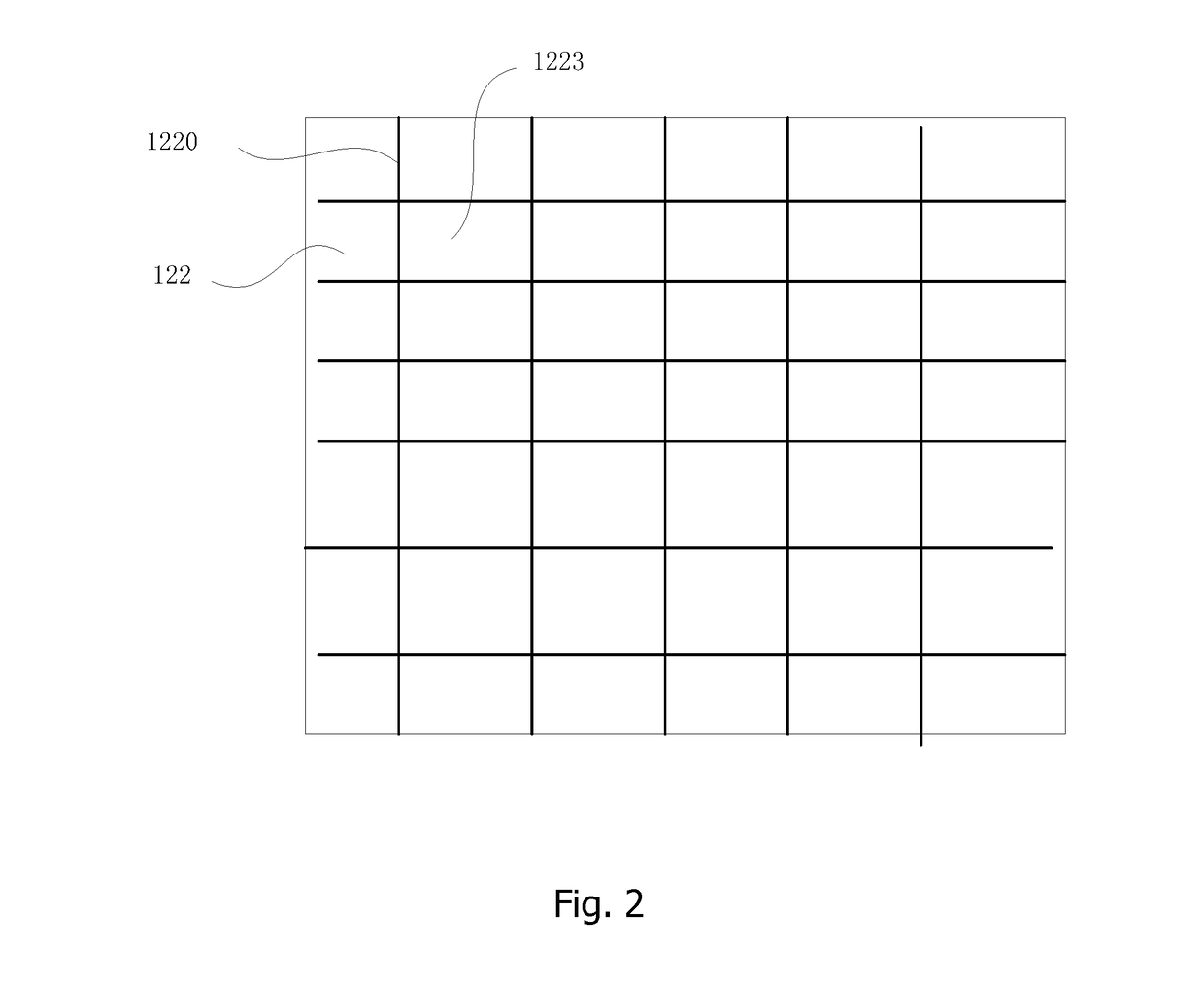

OLED device and array substrate

InactiveCN105140414ASolve uneven lightingLower resistanceSolid-state devicesSemiconductor/solid-state device manufacturingLight emissionHorizontal resistance

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

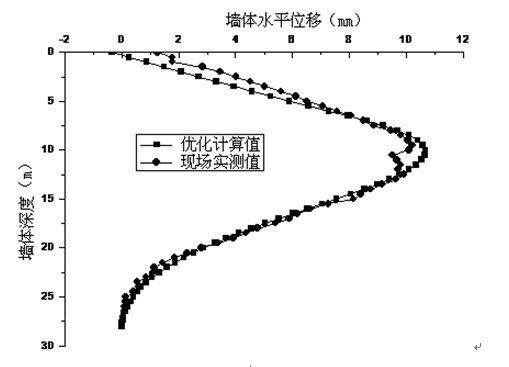

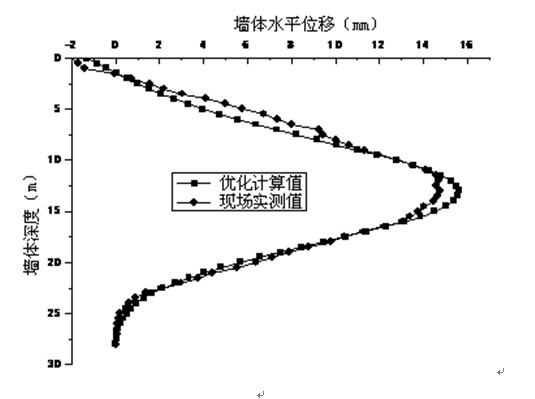

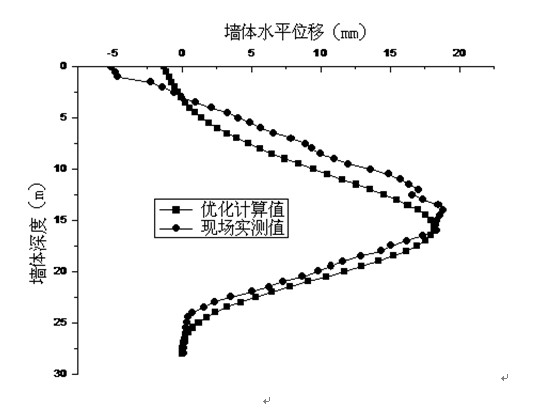

Method for solving solution of elastic foundation beams and for back analysis of value m

InactiveCN102087677AEasy programmingImprove efficiencyArtificial islandsUnderwater structuresPartial differential equationEngineering

The invention provides a method for solving solution of elastic foundation beams and for back analysis of value m, belonging to the technical field of geotechnical engineering. The method comprises the following steps of: 1, firstly, converting a fourth order partial differential equation of the elastic foundation beam into a low order partial differential equation set, and setting iteration times and admissible errors; 1, taking a minimum error function of a displacement value sol.y obtained in the step one and an actually-measured displacement value as an objective function, wherein the minimum error function is the sum of squares of difference values; 3, optimizing the objective function in the second step by the application of MATLAB nonlinear optimization algorithm fmincon functions, when reaching the iteration times or the admissible errors set in the first step, stopping iteration, and in this case, the objective function reaching the minimum value; and 4, the parameters corresponding to the minimum value of the objective function being the optimum solution of horizontal resistance factor value m of the to-be-determined soil layer foundation soil. The method provided by the invention is simple in analysis process and easy for programming.

Owner:SOUTHEAST UNIV

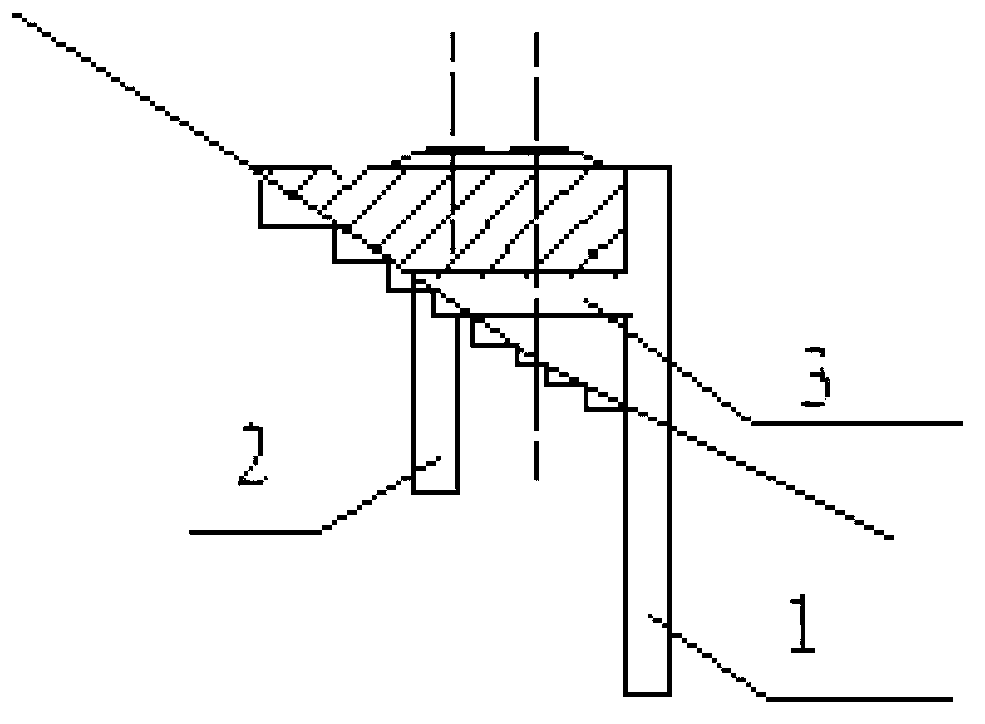

Self counter force balance loading test method of engineering pile bearing capacity

The invention provides a method for ensuring the position of a load box and pile quality and effectively transmitting axial force, shearing force and bending moment in self counter force balance loading test of engineering pile bearing capacity. A built-in jack of the load box is connected with a top cover plate and a bottom cover plate through high strength bolts, without being affected for normal loading, and consequently the load box transmits certain bending moment. The periphery of the load box is provided with twisted steels that are mutually lapped together and protected by a telescopic pipe, and mudjacking and solid joints are conducted after test, so that a reinforcing cage achieves the effect of overall equivalent connection and bears great shearing force and bending moment. The load box and the reinforcing cage are connected by means of inside cutting, and the horizontal resistance of a pile is increased at the load box. The surrounding gap of the pile is mudjacked at the load box after test to keep the continuity and integrity of pile concrete and ensure the axial force transmission of the pile and the vertical bearing capacity. The bottom of the bottom cover plate of the load box is provided with a conical flow guide body in order to avoid mud and sediments remaining on the bottom of the bottom cover plate when the pile concrete passes through the load box in pouring and ensure the pile quality and test accuracy.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

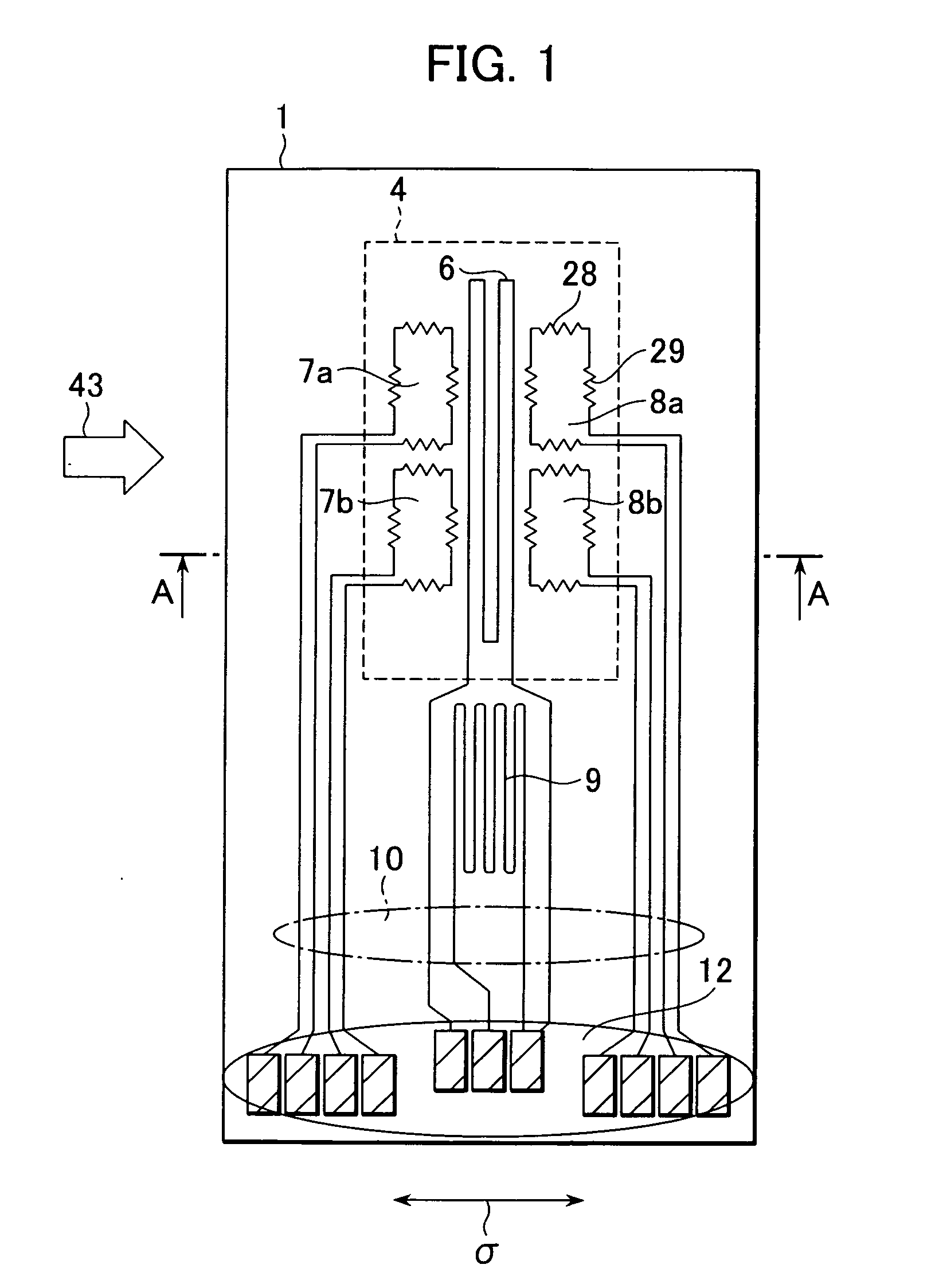

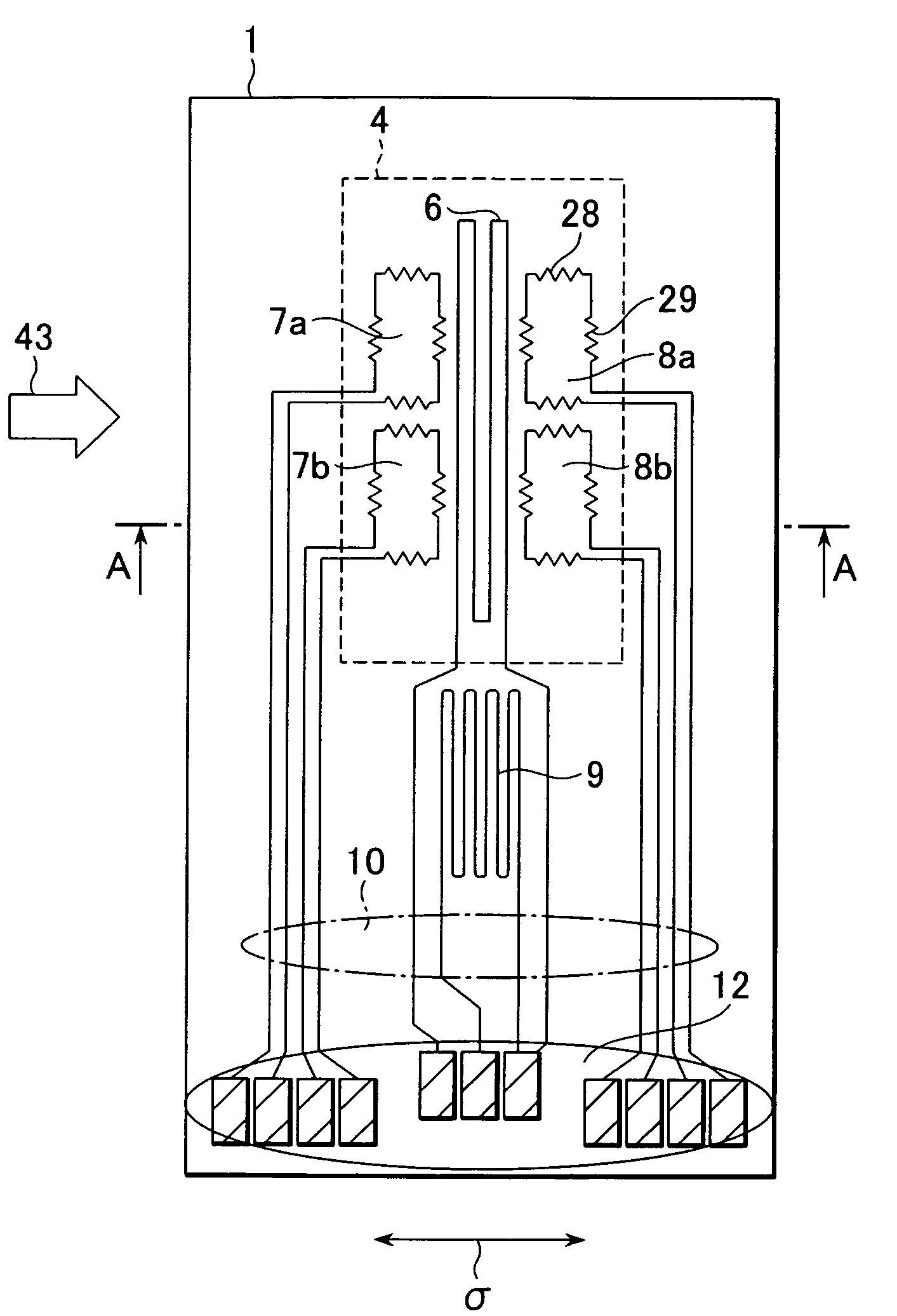

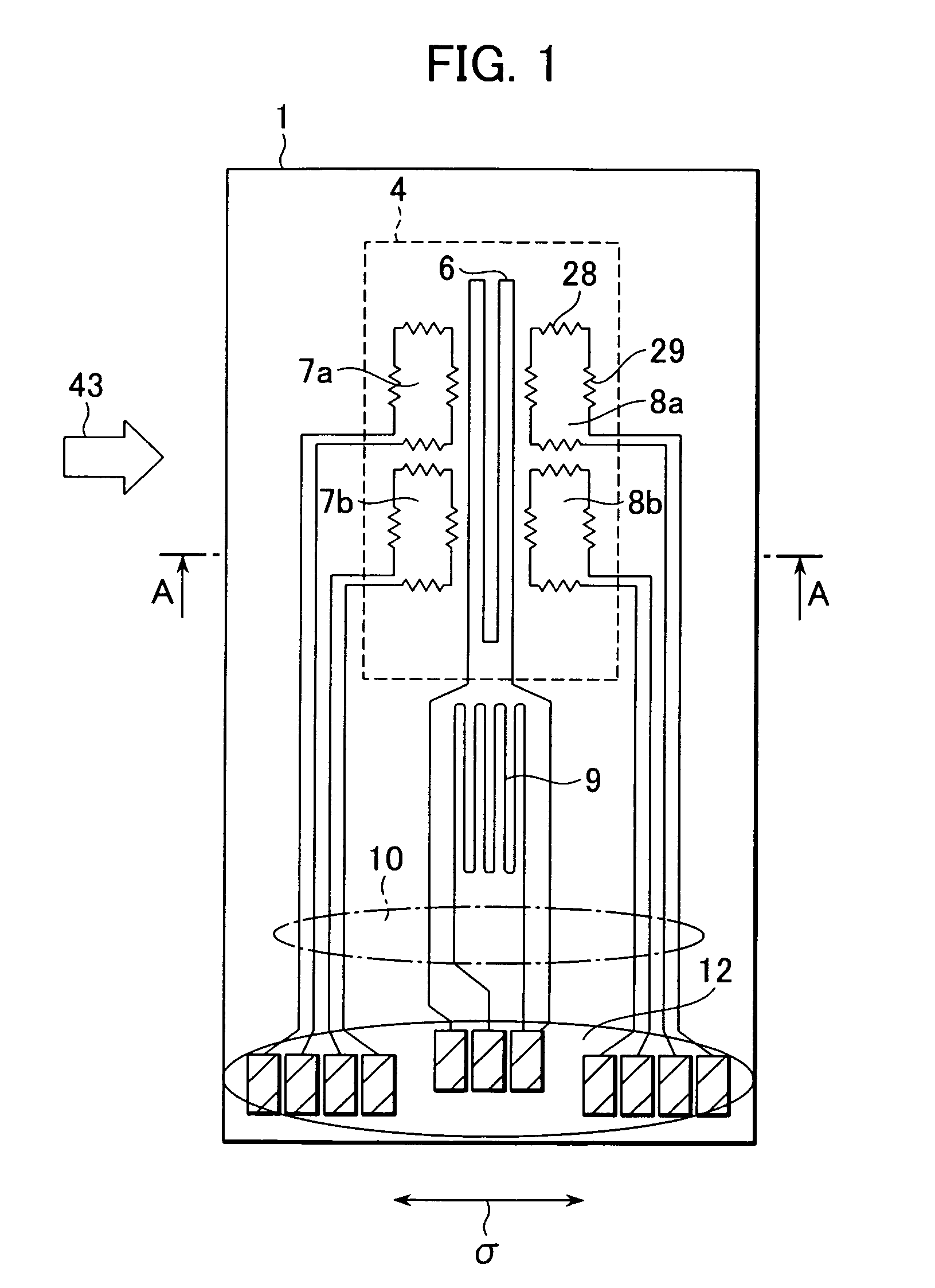

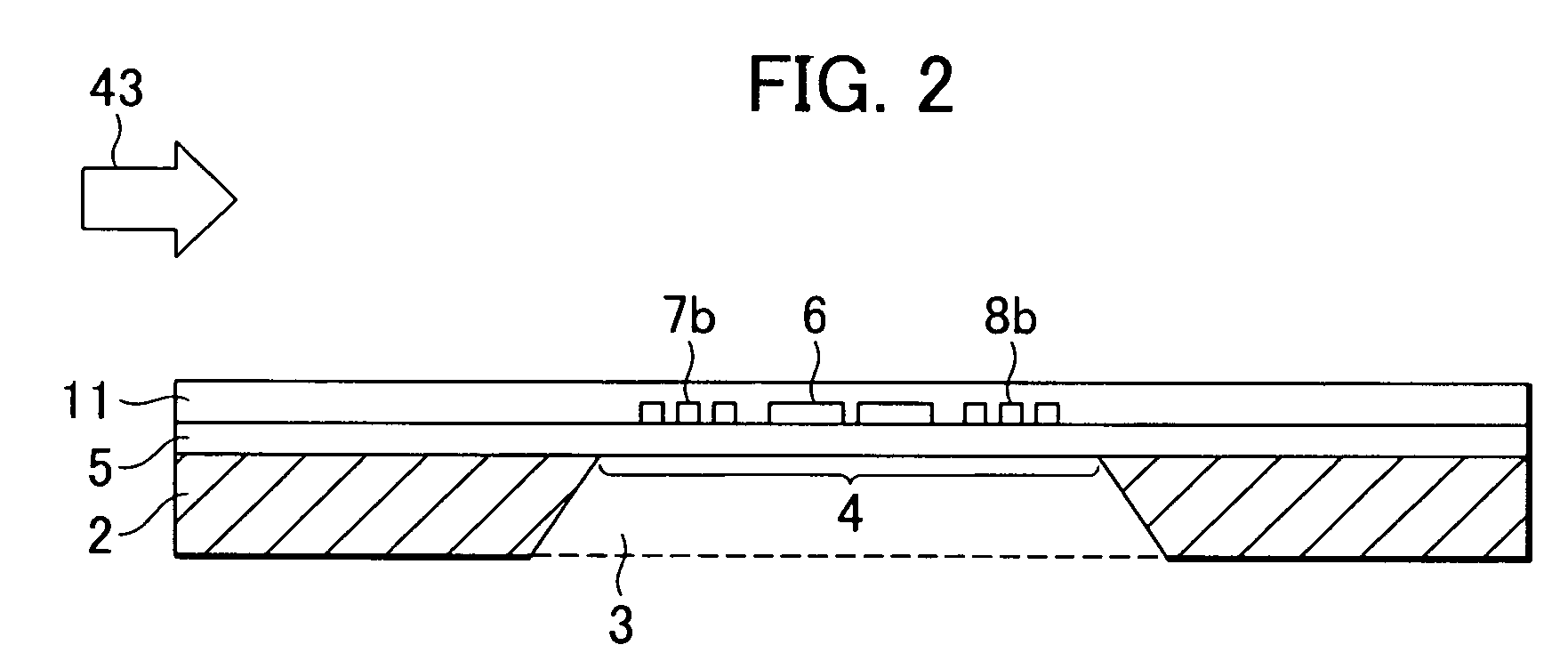

Physical quantity sensor

ActiveUS20060220662A1Reduce the impactHigh precision measurementResistance/reactance/impedenceVolume/mass flow by thermal effectsElectrical resistance and conductanceEngineering

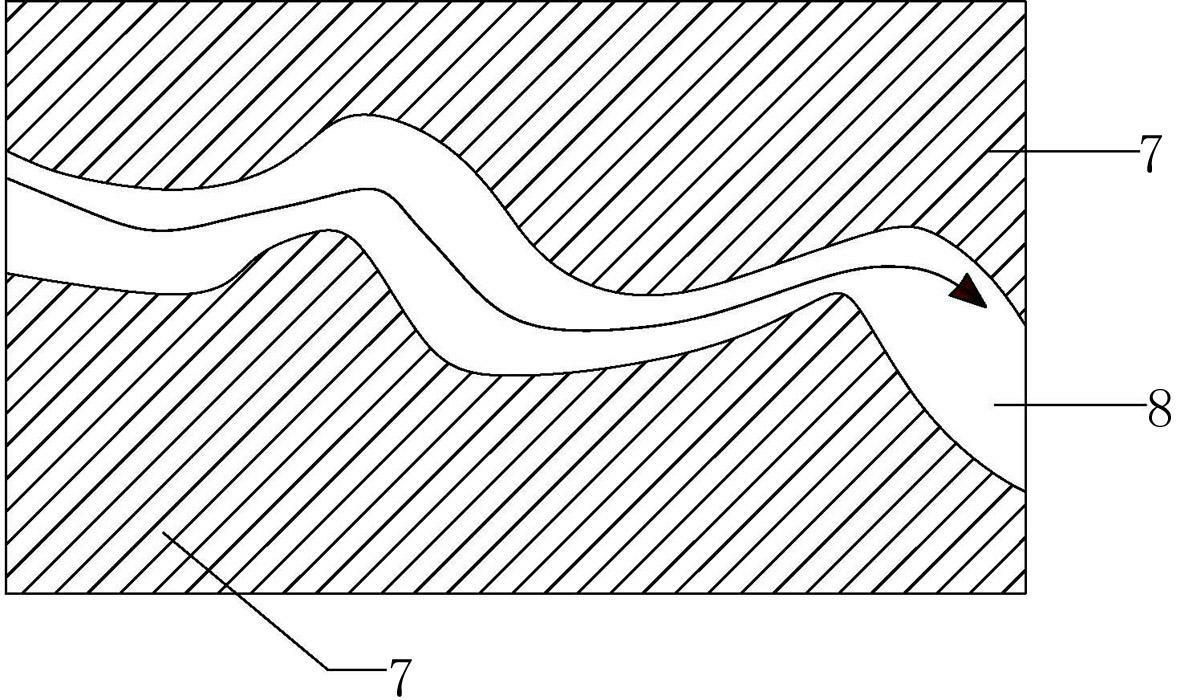

A highly accurate physical quantity sensor which can ensure reliability in strength and reduce resistance changes caused by stresses. Assuming, with respect to stress σ imposed on a substrate in a predetermined direction (e.g., direction in which maximum stress is imposed), a parallel direction to be a horizontal direction and a perpendicular direction to be a vertical direction, each of resistors of the sensor has a horizontal resistance component Rl and a vertical resistance component Rt. When a ratio of a piezoresistance coefficient πl of the horizontal resistance component Rl, which is provided when the stress imposed on the substrate is applied to the horizontal resistance component Rl, to a piezoresistance coefficient πt of the vertical resistance component Rt, which is provided when the stress is applied to the vertical resistance component Rt, is πl:πt=−n:1 (n:integer), a resistance value ratio of the vertical resistance component Rt to the horizontal resistance component Rl is set substantially equal to the ratio of the piezoresistance coefficient πl to πt.

Owner:HITACHI ASTEMO LTD

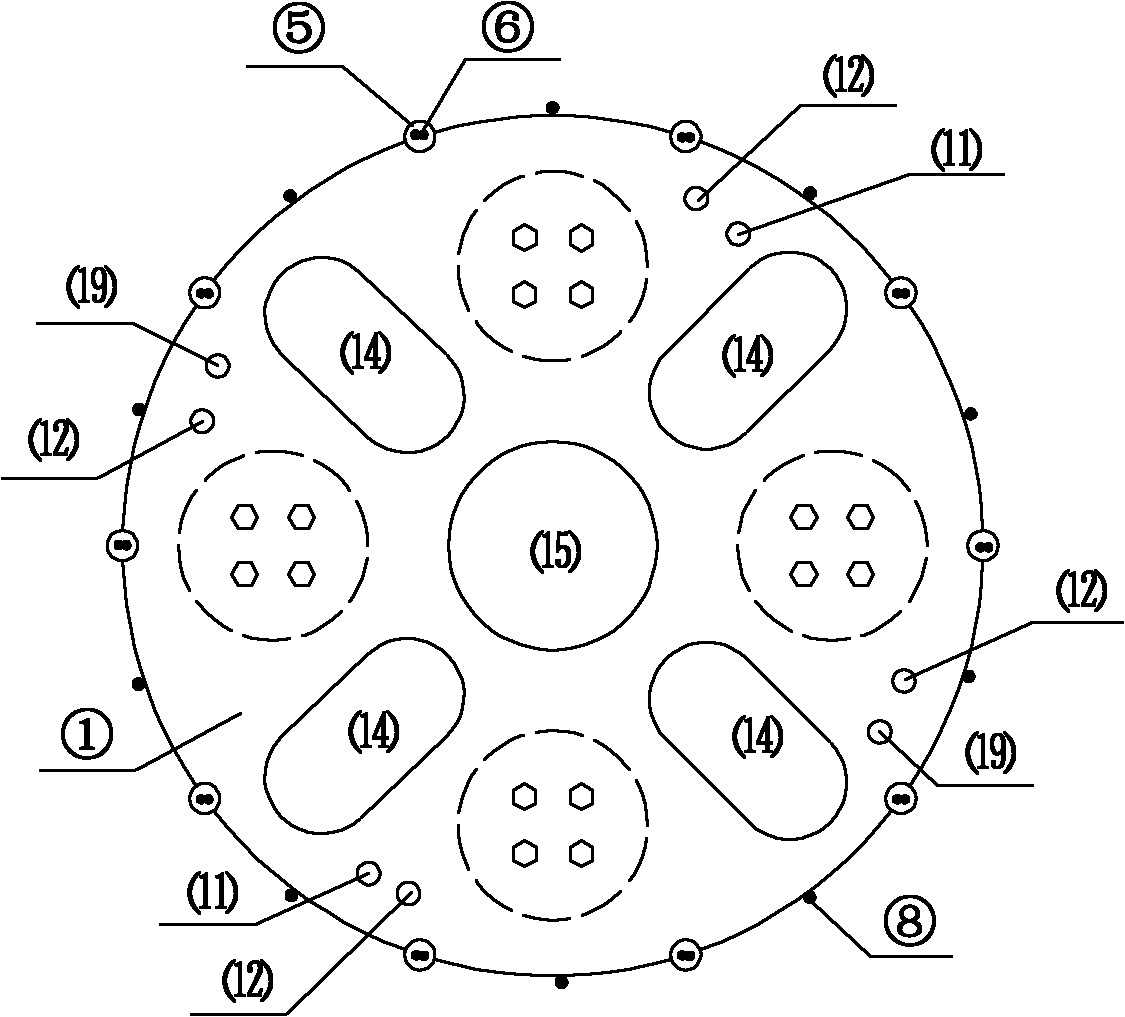

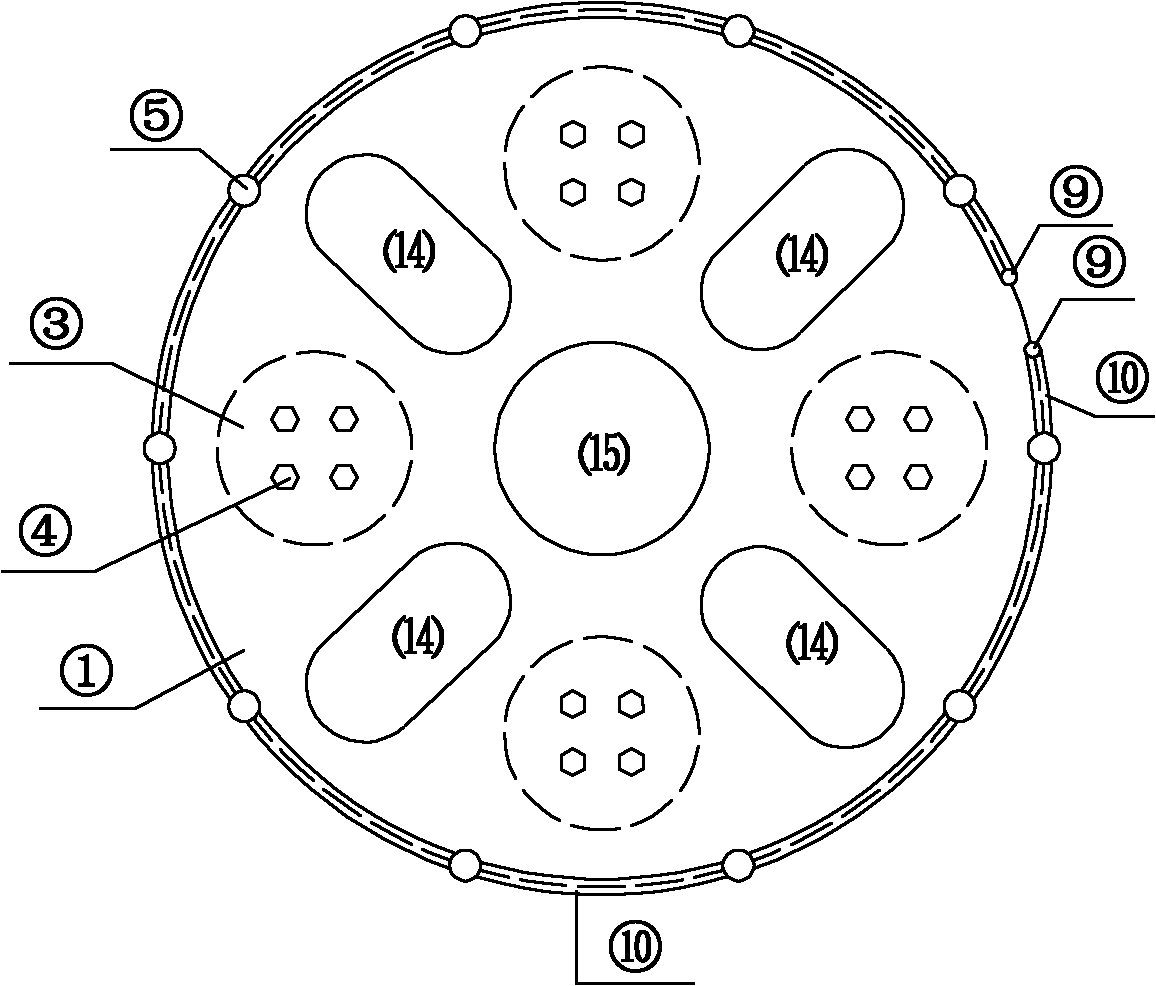

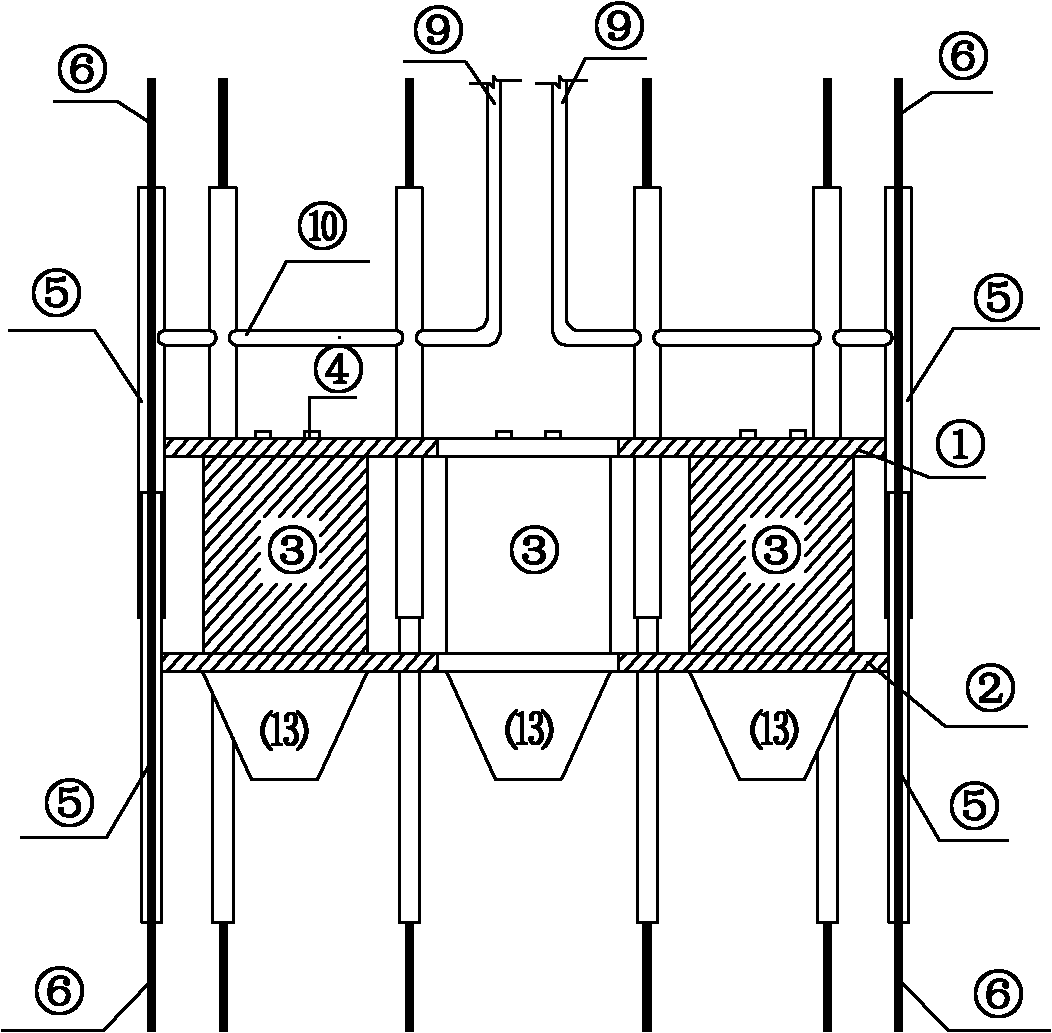

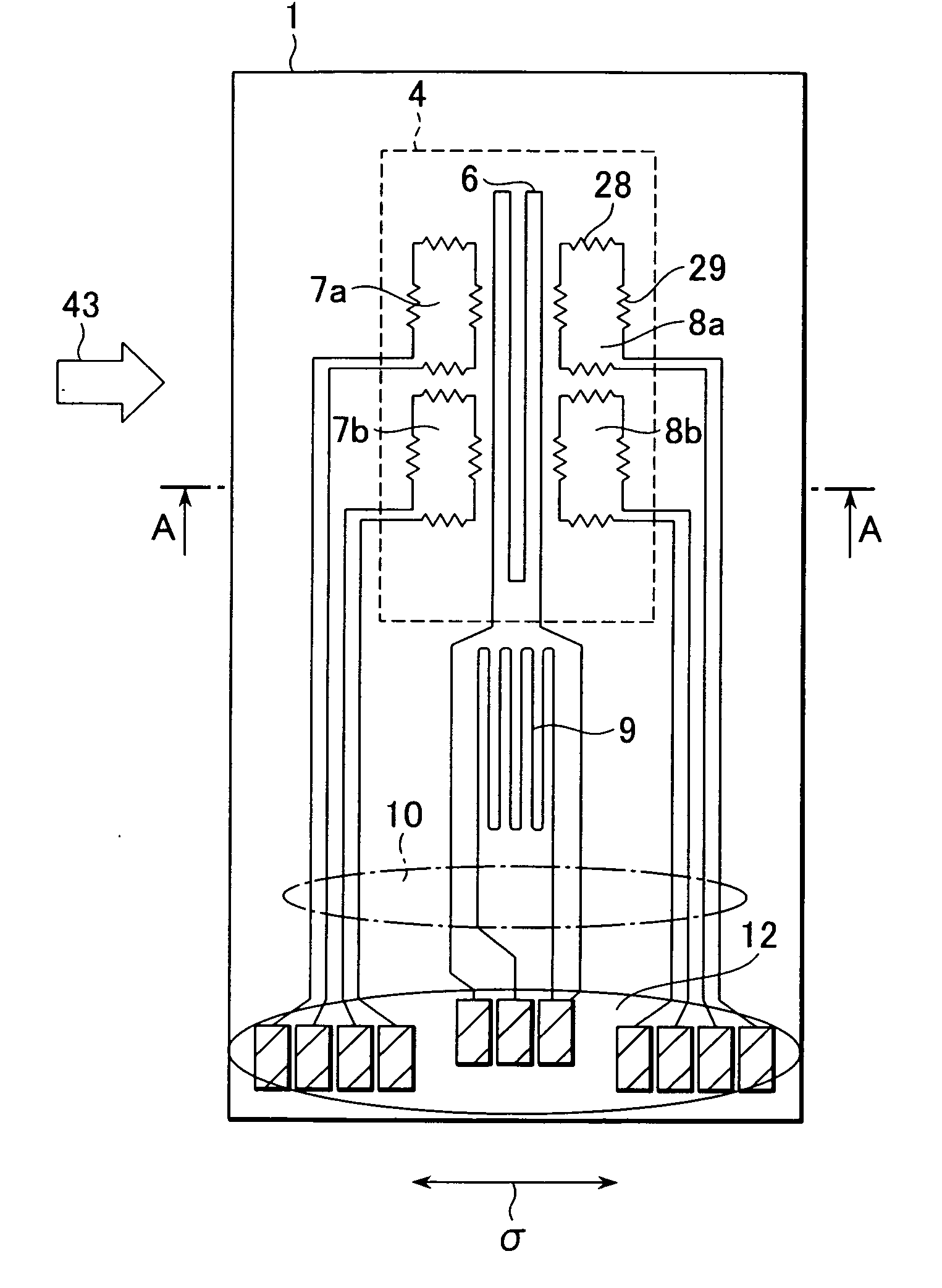

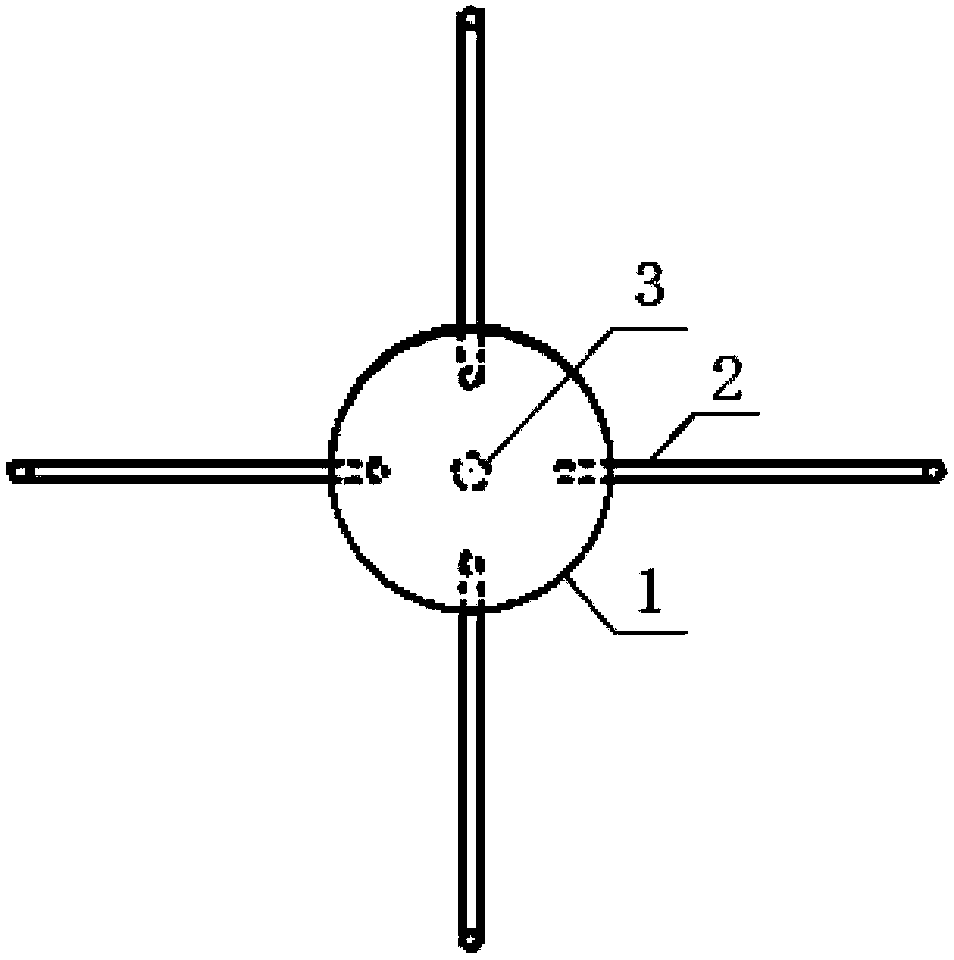

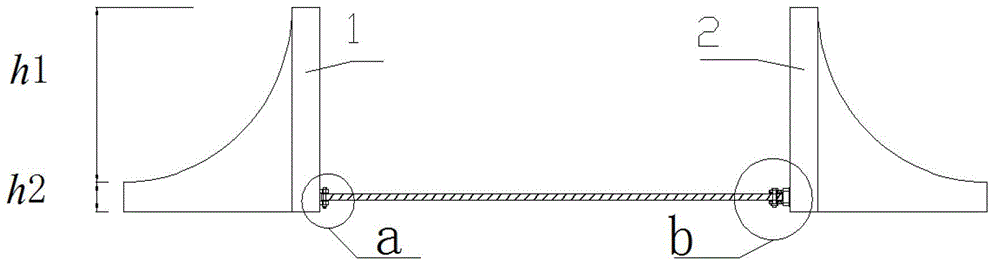

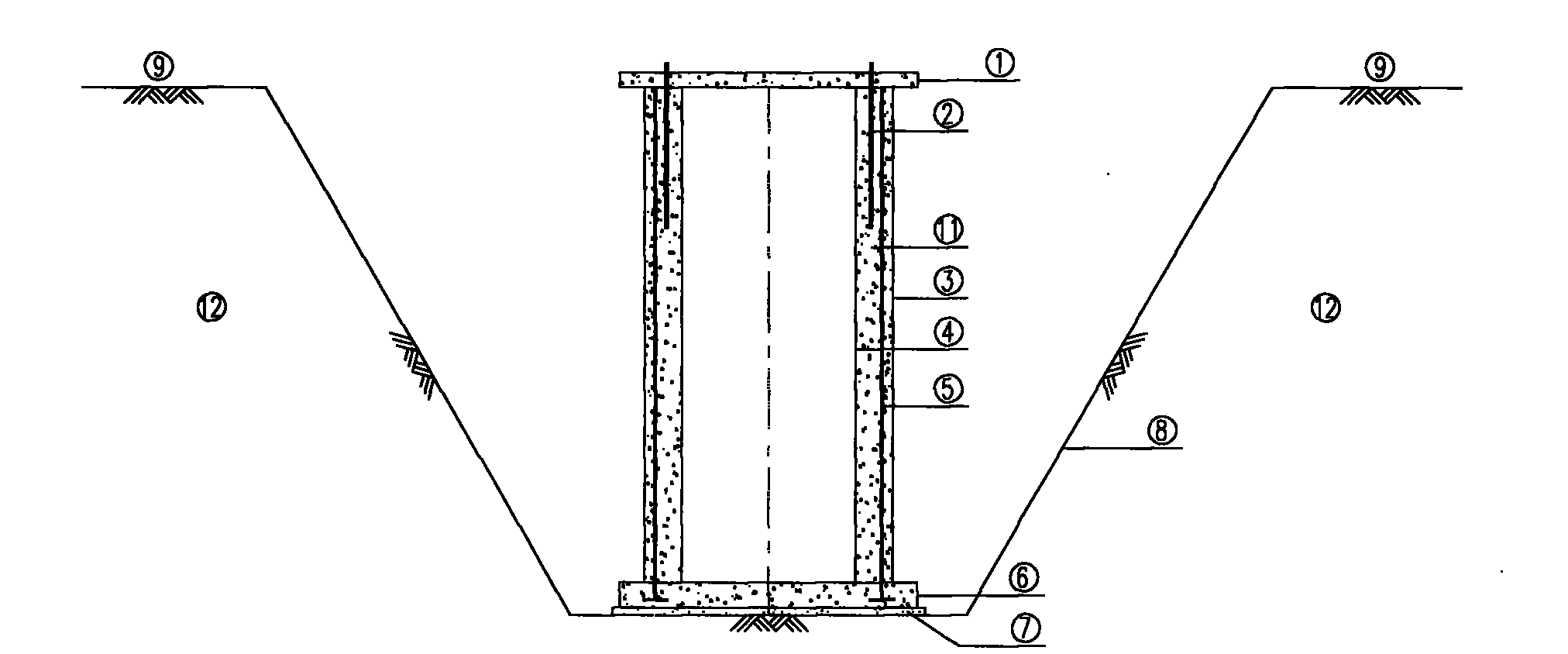

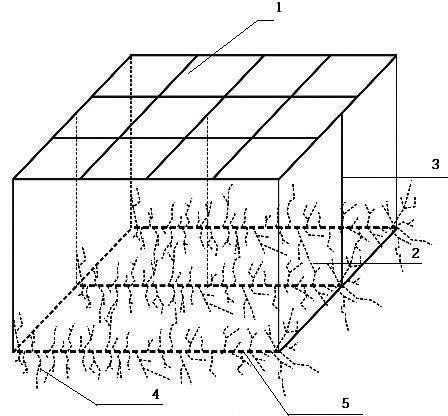

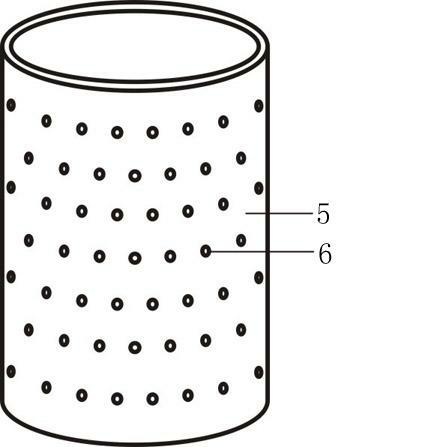

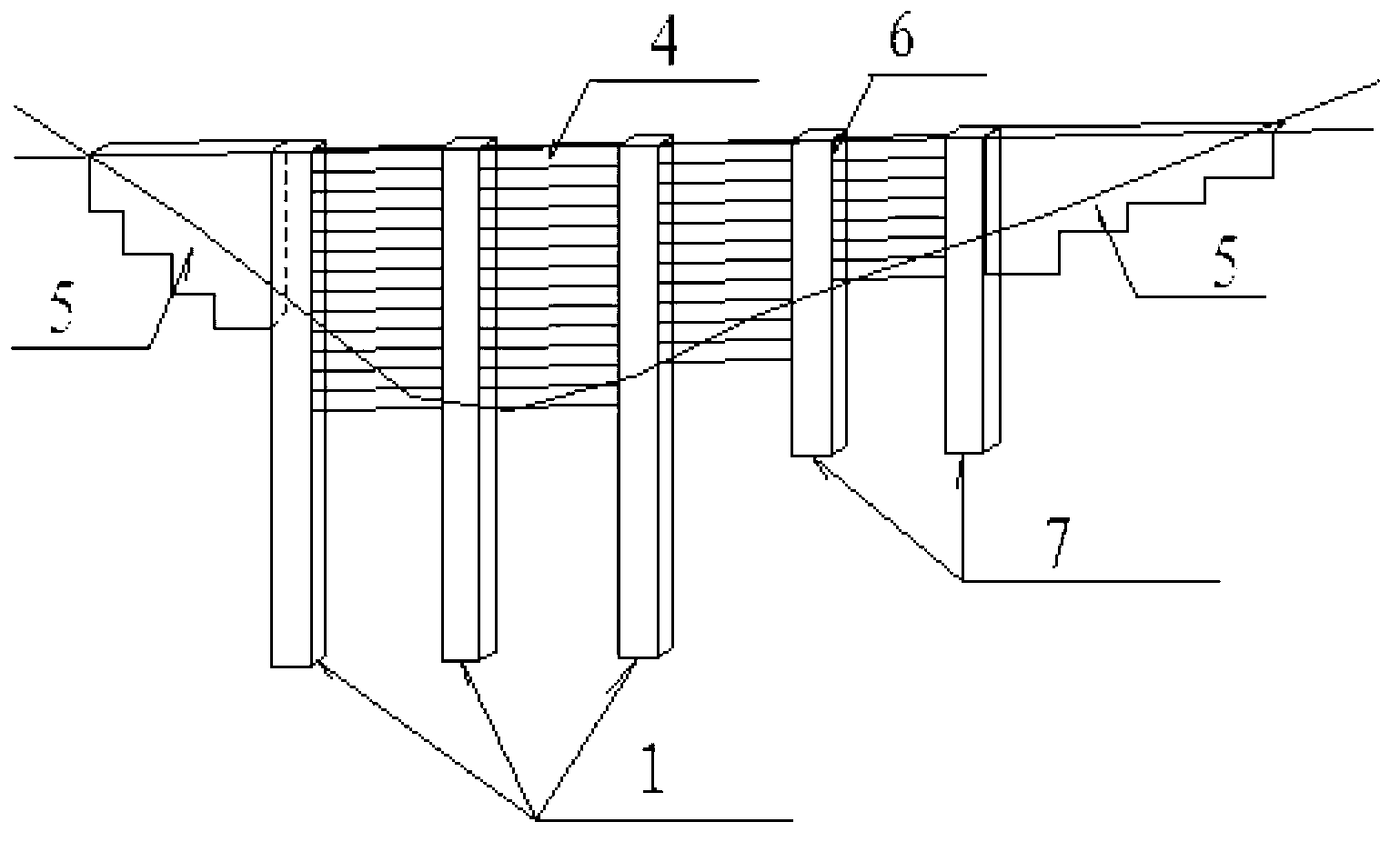

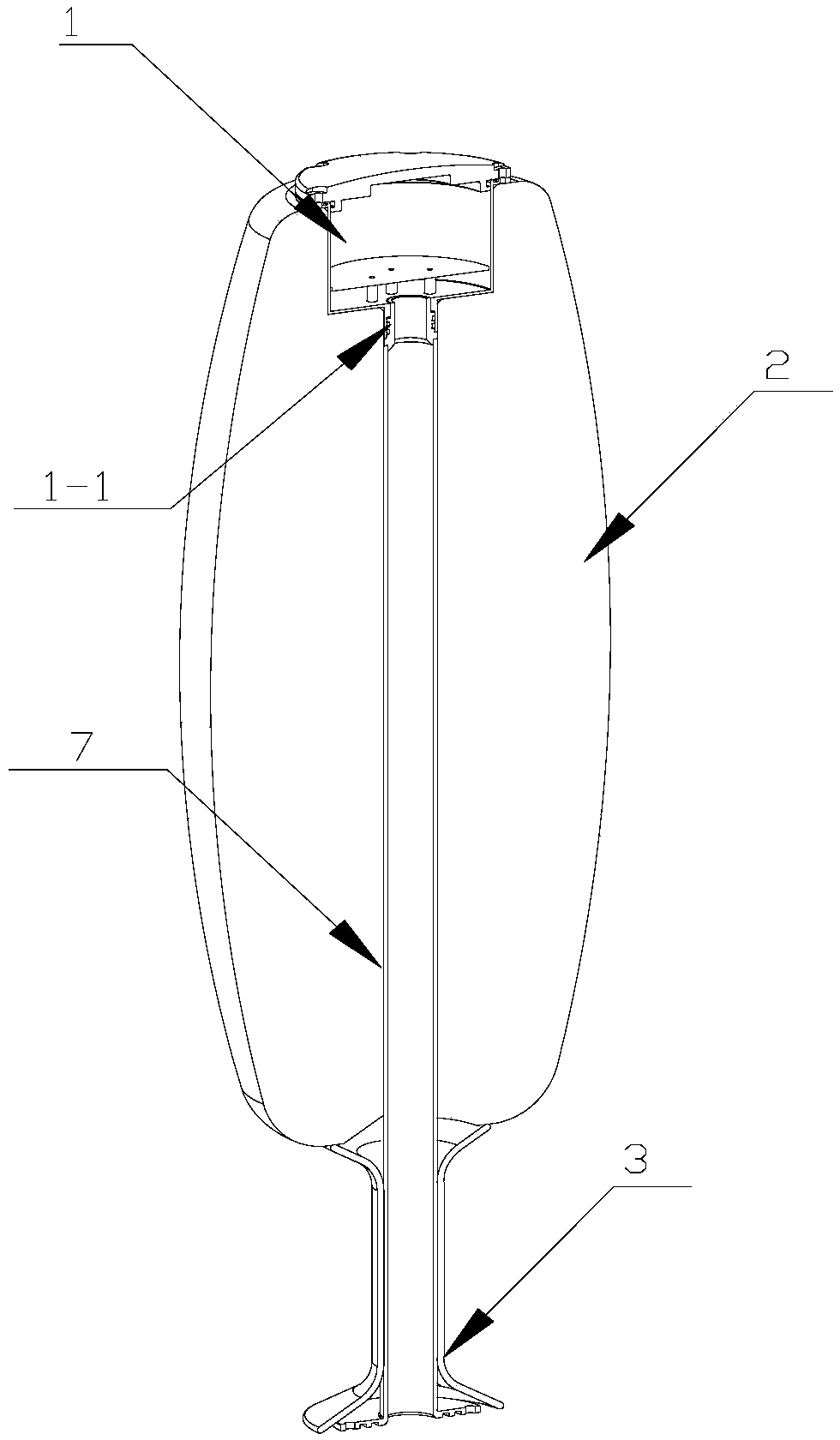

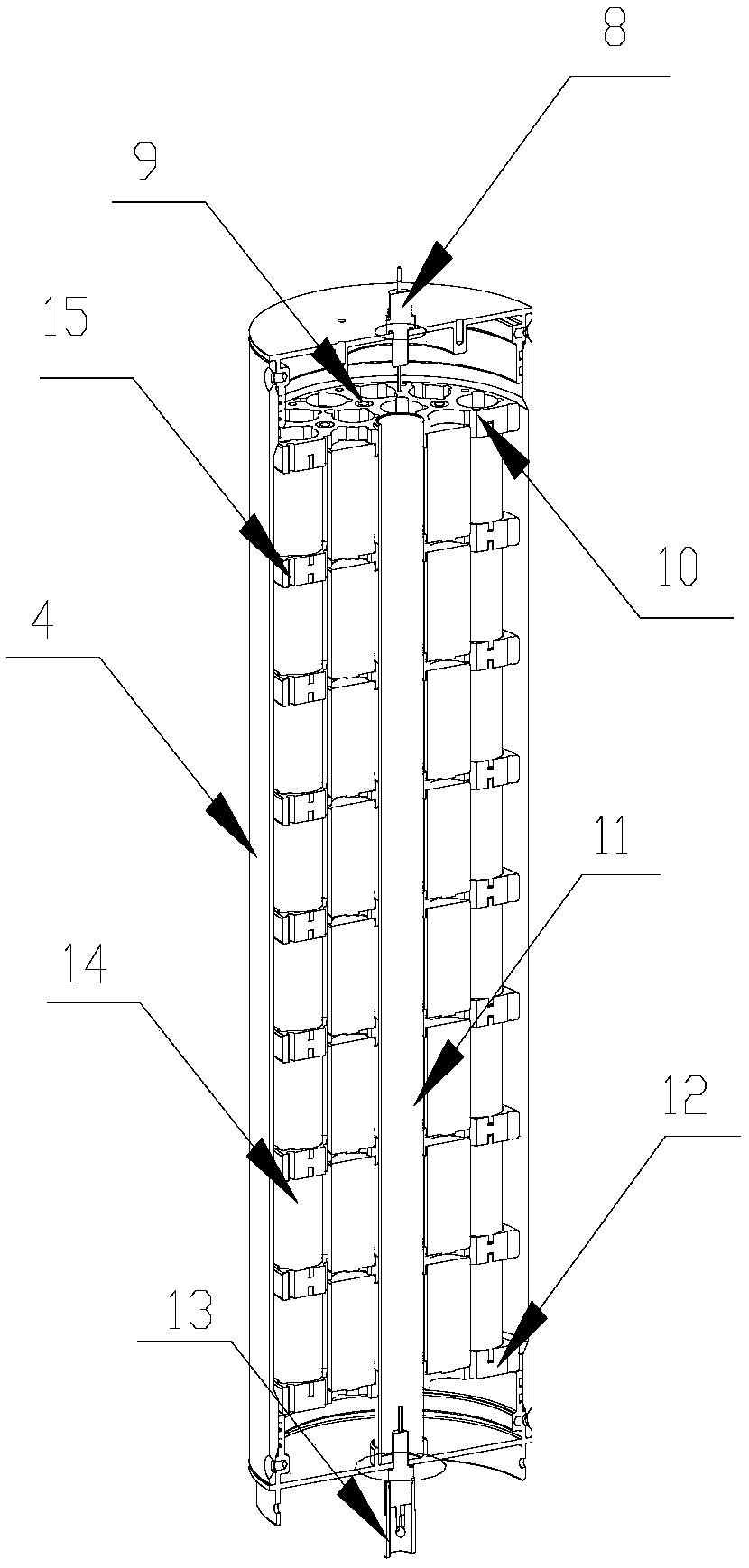

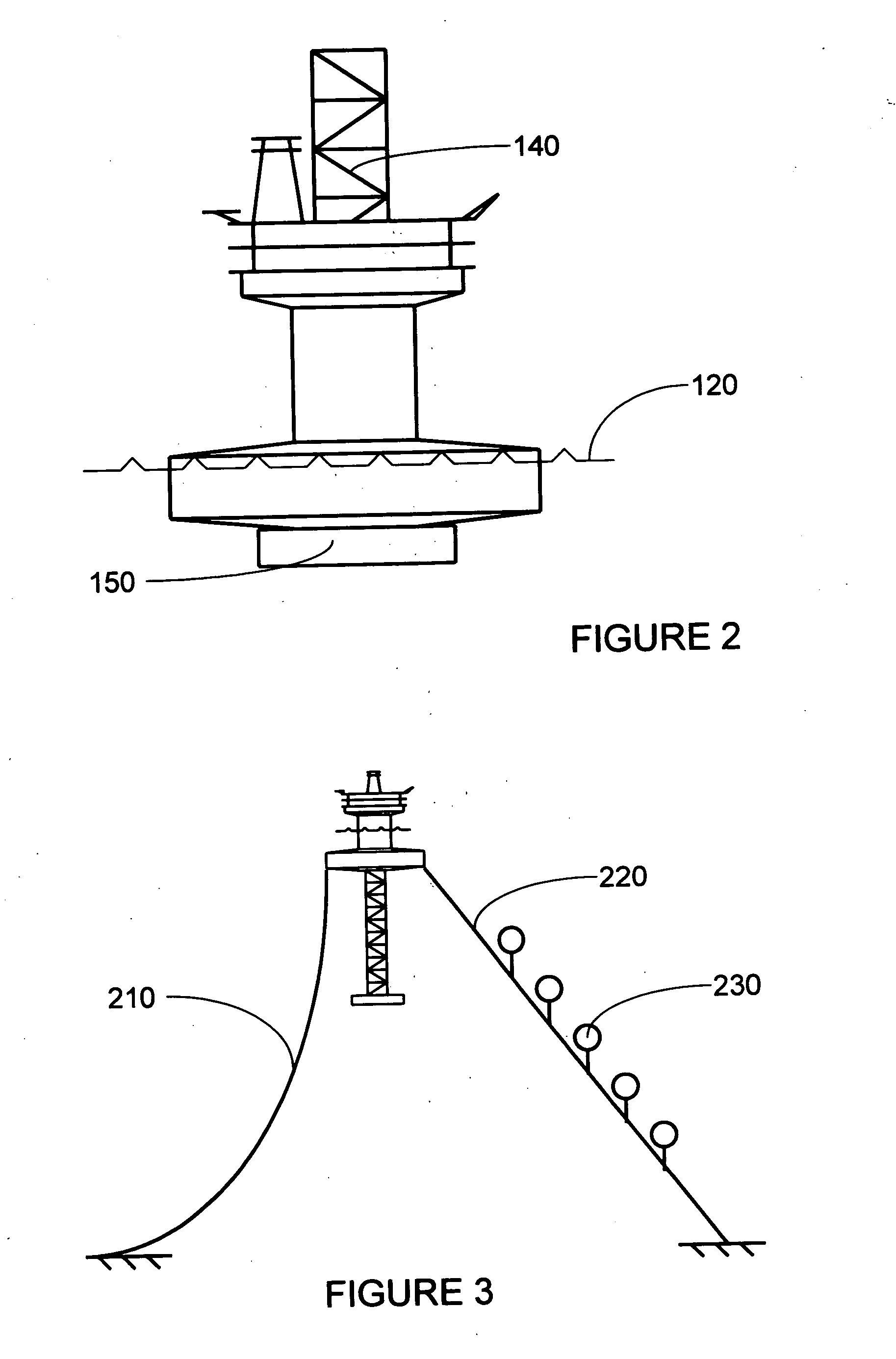

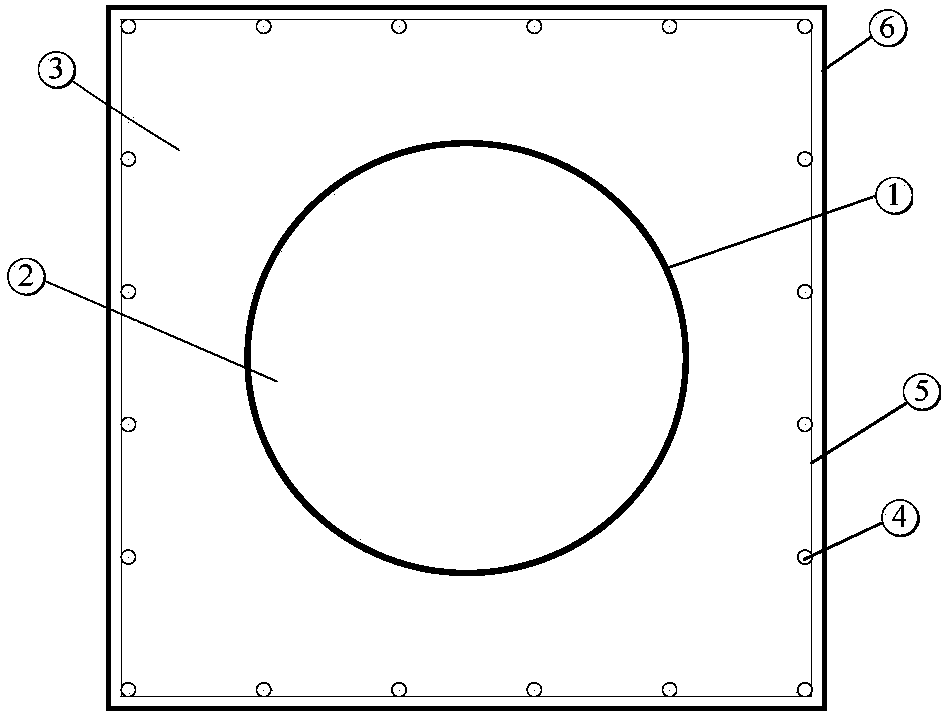

High-rise pile cap offshore wind power foundation combining vertical single pile and multiple raking piles

InactiveCN103352474AImprove horizontal carrying capacityImprove anti-overturn performanceFoundation engineeringSea levelHigh rise

The invention discloses a high-rise pile cap offshore wind power foundation combining a vertical single pile and multiple raking piles. The foundation comprises a bearing platform, the multiple raking piles and the single pile, wherein the upper ends of the raking piles and the upper end of the single pile are positioned above the sea level, the lower ends of the raking piles and the lower end of the single pile are inserted below the sea level, the multiple raking piles are uniformly distributed on a circumference with the single pile serving as a circle center, and the top ends of the multiple raking piles and the top end of the single pile are fixedly connected onto the lower end surface of the bearing platform. Besides, the upper end surface of the bearing platform is connected with a blower tower through a flange; and the number of the raking piles is 3-8, and the multiple raking piles are radially and uniformly distributed on the circumference with the single pile serving as a circle center. With the adoption of the high-rise pile cap offshore wind power foundation combining the vertical single pile and the multiple raking piles, the defect of a single pile foundation in the aspect of resisting to great horizontal force and bending moment load is overcome, the problem that a pile group foundation has more foundation piles and larger diameters can be effectively solved, and meanwhile, the construction difficulty and the construction cost are low; soil mass in larger range can be enabled to be involved in resistance to horizontal force and bending moment, horizontal resistance of the foundation soil mass can be sufficiently played, the horizontal bearing performance of a foundation pile is improved, and the antidumping capacity of the foundation is improved.

Owner:TIANJIN UNIV

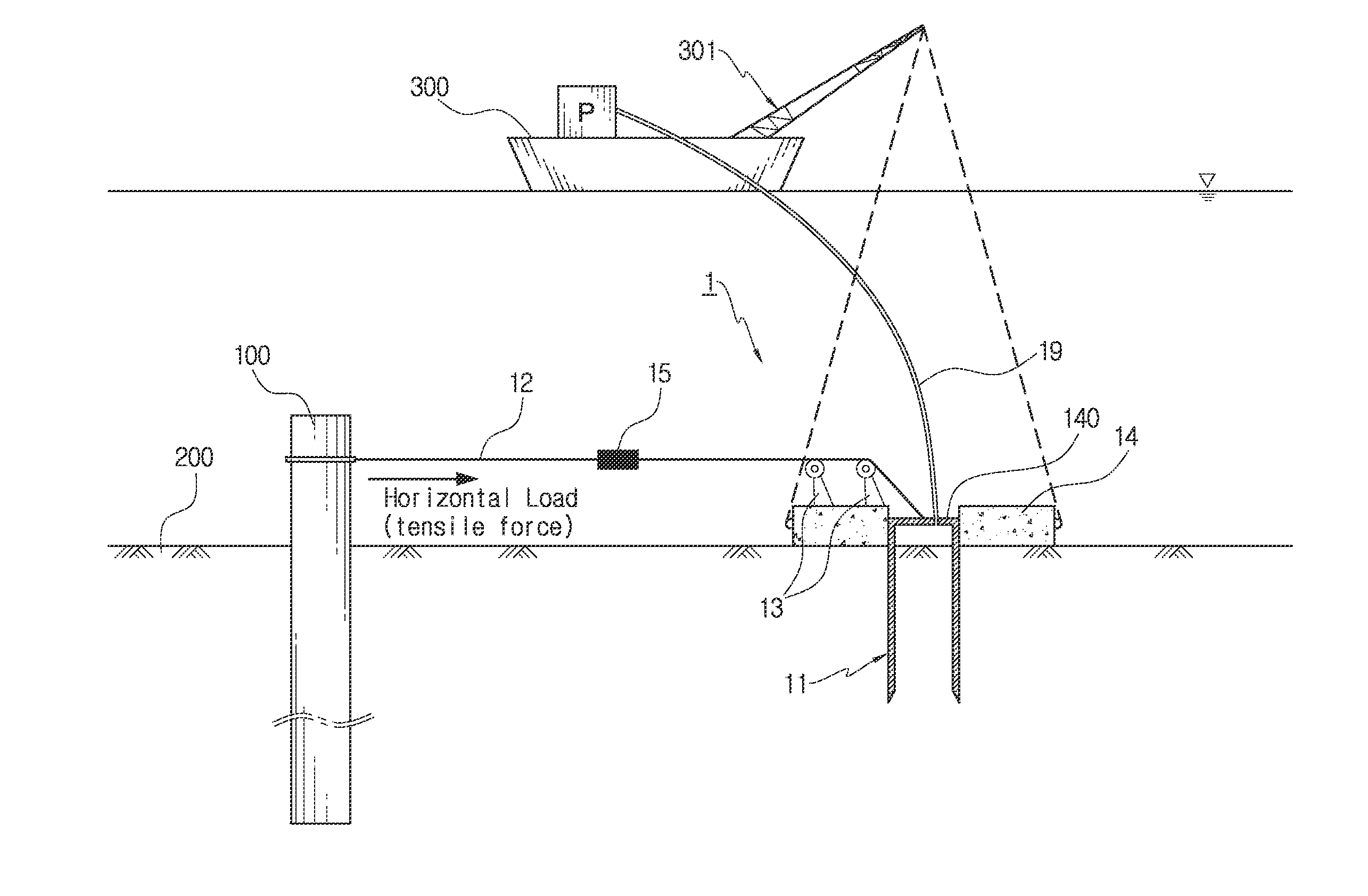

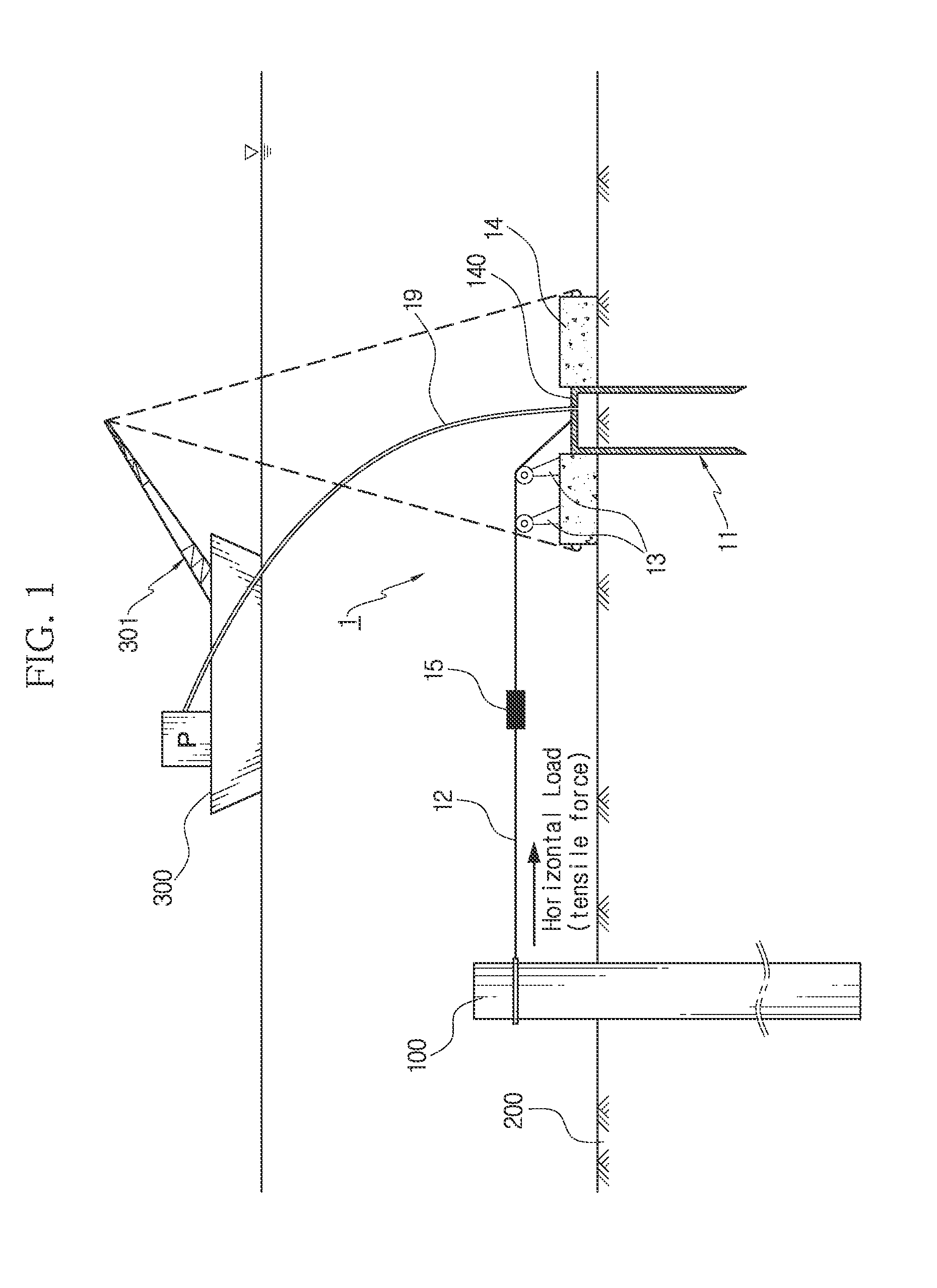

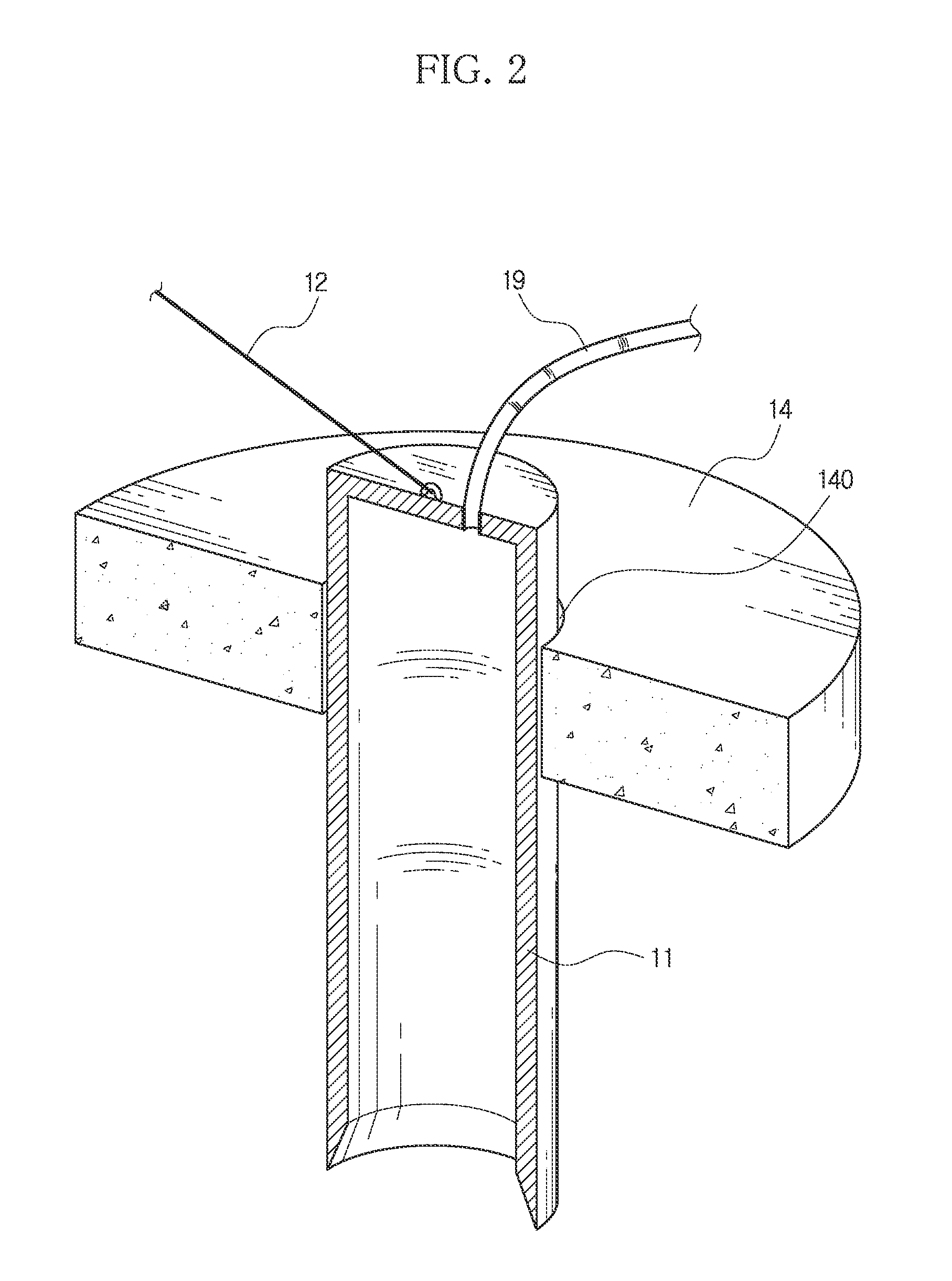

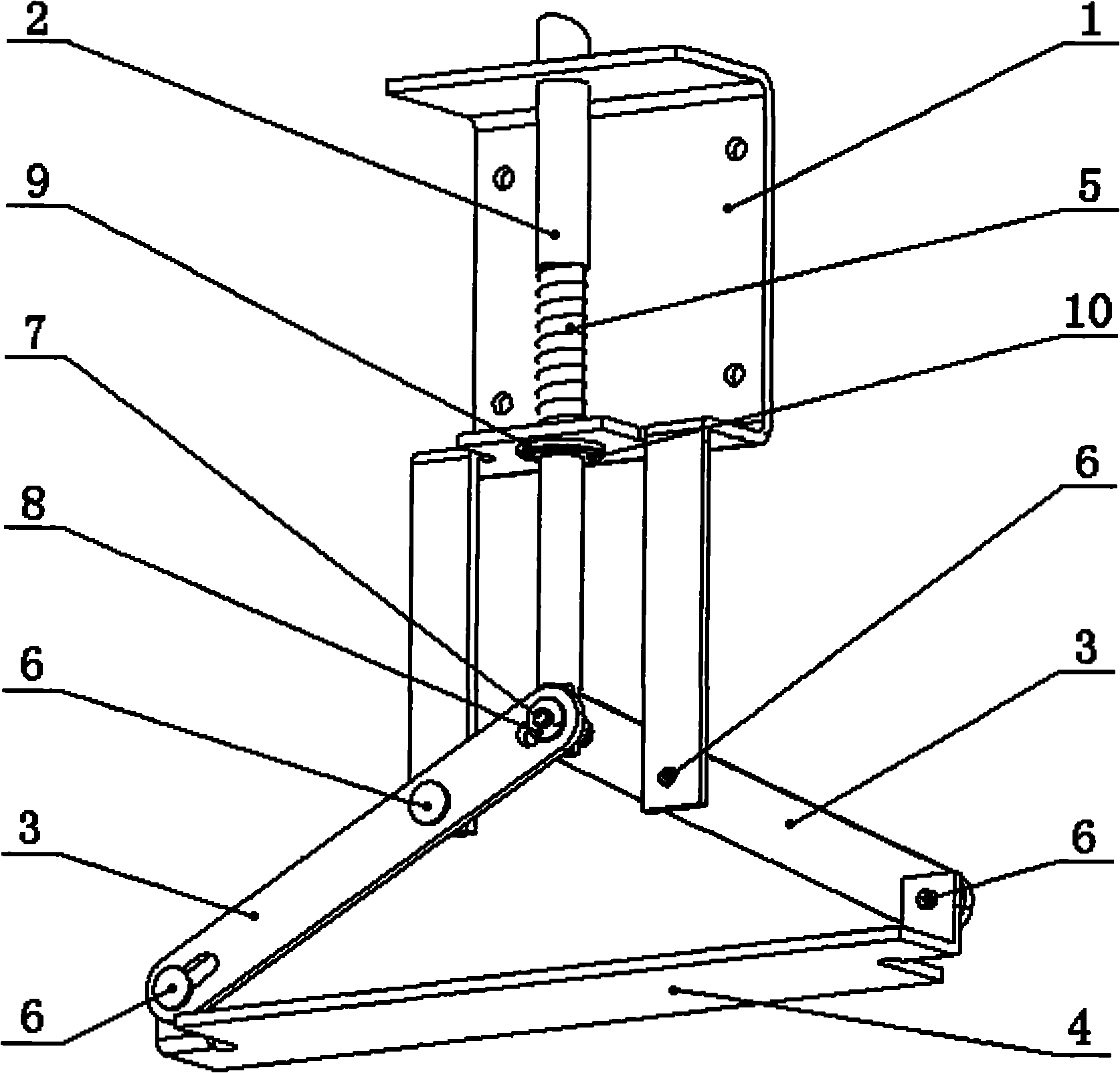

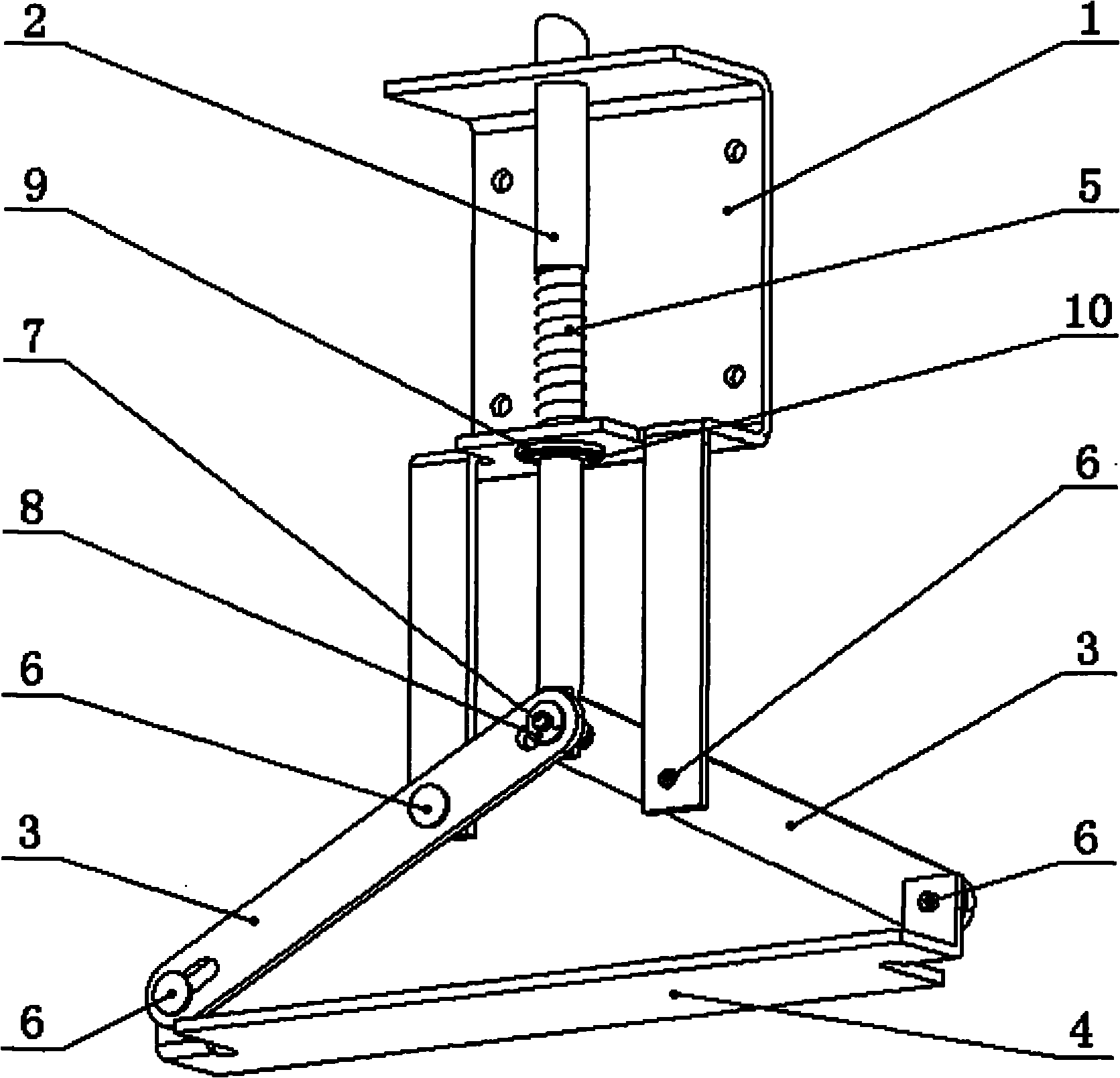

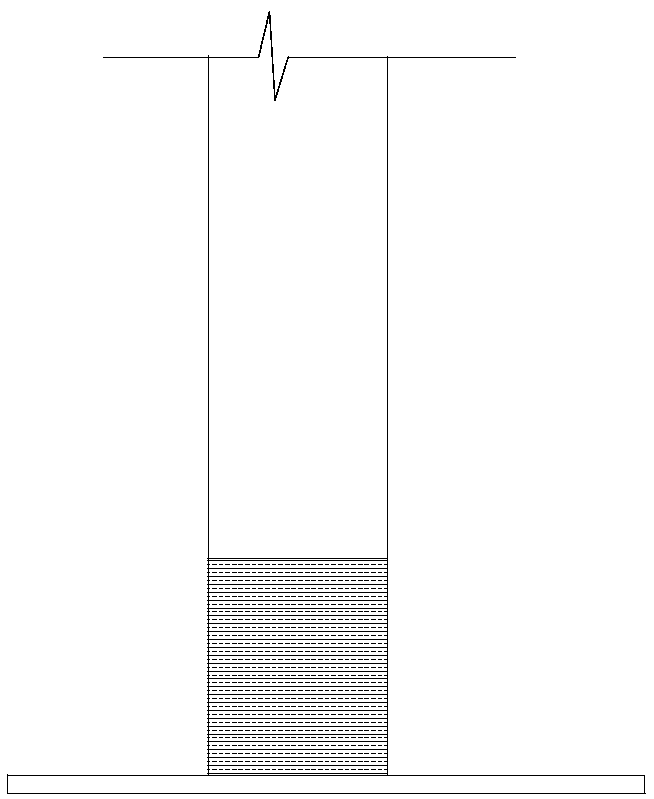

Apparatus for applying horizontal load to underwater pile using ground penetration of suction pile and method for measuring horizontal resistance of underwater pile using the same

InactiveUS20140290379A1Easy to installEasy to fixFoundation testingMaterial strength using tensile/compressive forcesPenetration forceMarine engineering

A horizontal resistance of an underwater pile is measured using a horizontal load applying apparatus which applies a horizontal load to the underwater pile to measure a horizontal resistance of the underwater pile by changing a direction of a penetration force generated when a suction pile penetrates an underwater ground.

Owner:KOREA INST OF CIVIL ENG & BUILDING TECH

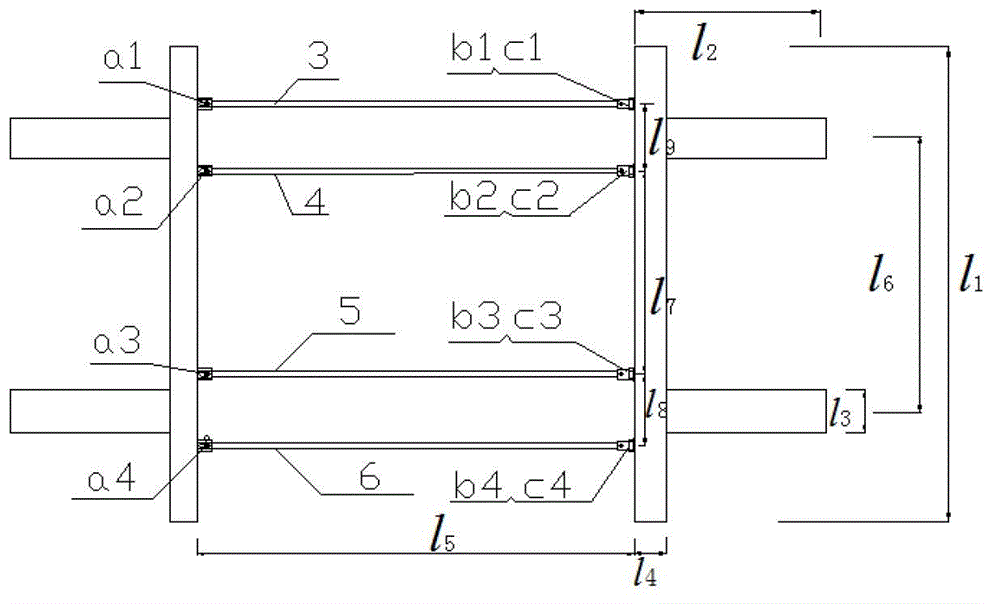

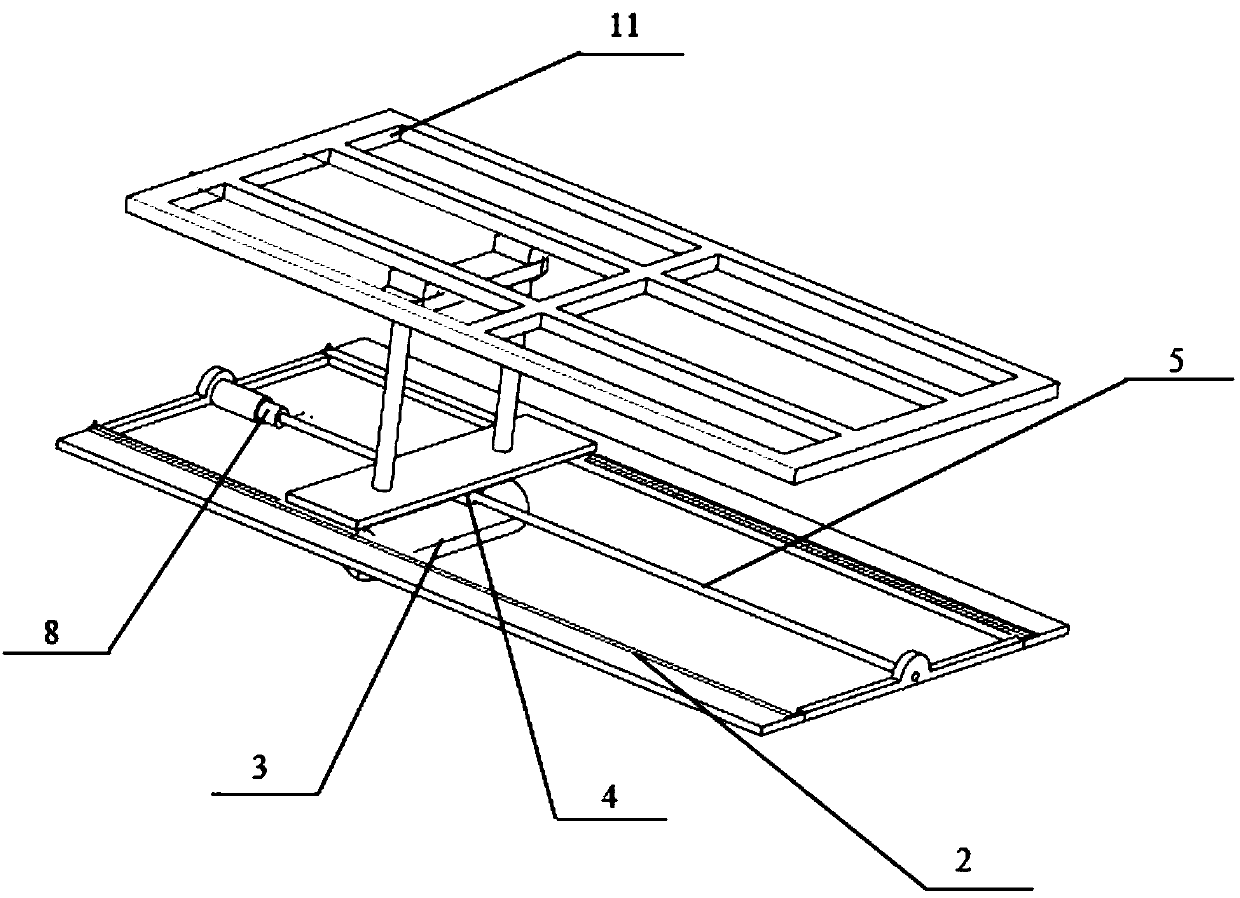

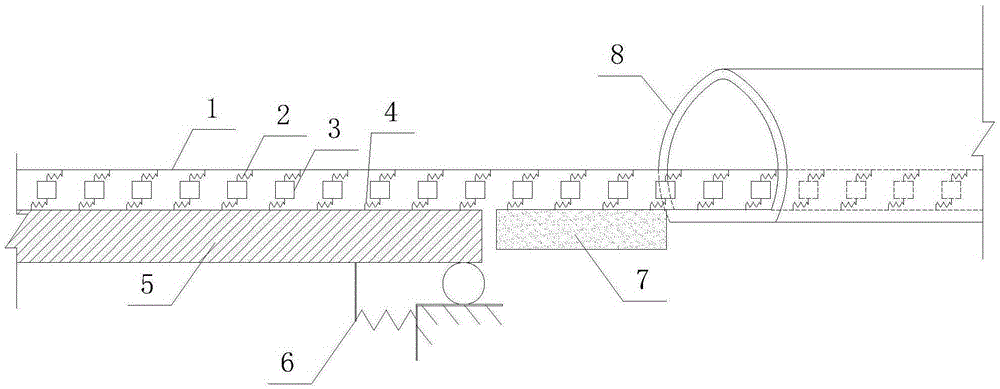

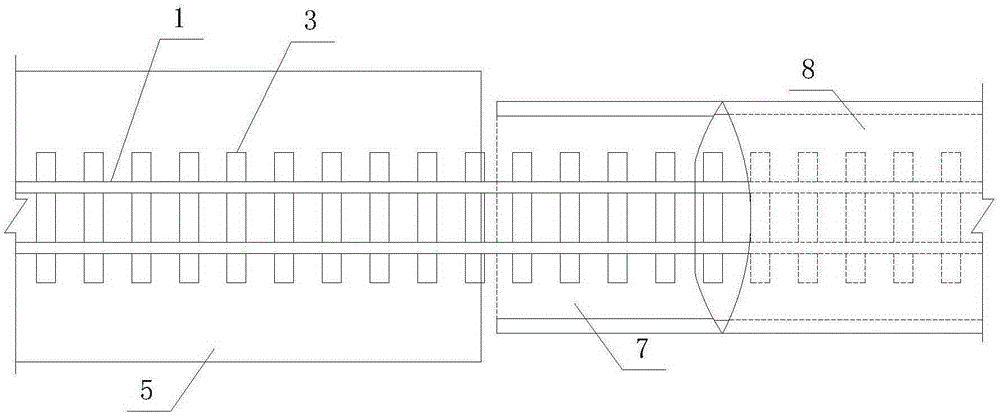

Integral ballast bed lateral restraining device

An integral ballast bed lateral restraining device belongs to the field of rail traffic, is suitable for reinforcing a heavy-duty or high-speed ballast bed structure, and solves the problems that the existing ballast bed structure has insufficient lateral restraint, insufficient vertical and horizontal resistance and short ballast bed maintenance period. First to fourth left connecting pieces (a1,a2,a3 and a4) are prefabricated at the lower end of the ballast stopping surface of a left integral reinforced concrete baffle plate (4); the first to fourth internal thread sleeves (c1,c2,c3 and c4) are prefabricated at the lower end of the ballast stopping surface of a right integral reinforced concrete baffle plate (2); and first to fourth right connecting pieces (b1,b2,b3 and b4) are in threaded connection with the first to fourth internal thread sleeves respectively. When the integral ballast bed lateral restraining device is in use, the end rings at one ends of first to fourth epoxy resin steel wire ropes are inserted into the holes of the first to fourth left connecting pieces and fixed through bolts and nuts; and the end rings at the other ends of the first to fourth epoxy resin steel wire ropes are inserted into the holes of the first to fourth right connecting pieces and fixed through bolts and nuts.

Owner:BEIJING JIAOTONG UNIV

In-situ pipe-soil test system and method on the basis of hydraulic suction cylinder

PendingCN109556653AAchieving Stable Loading RequirementsAvoid experimental errorMeasurement devicesOcean bottomWorking environment

Owner:TIANJIN UNIV

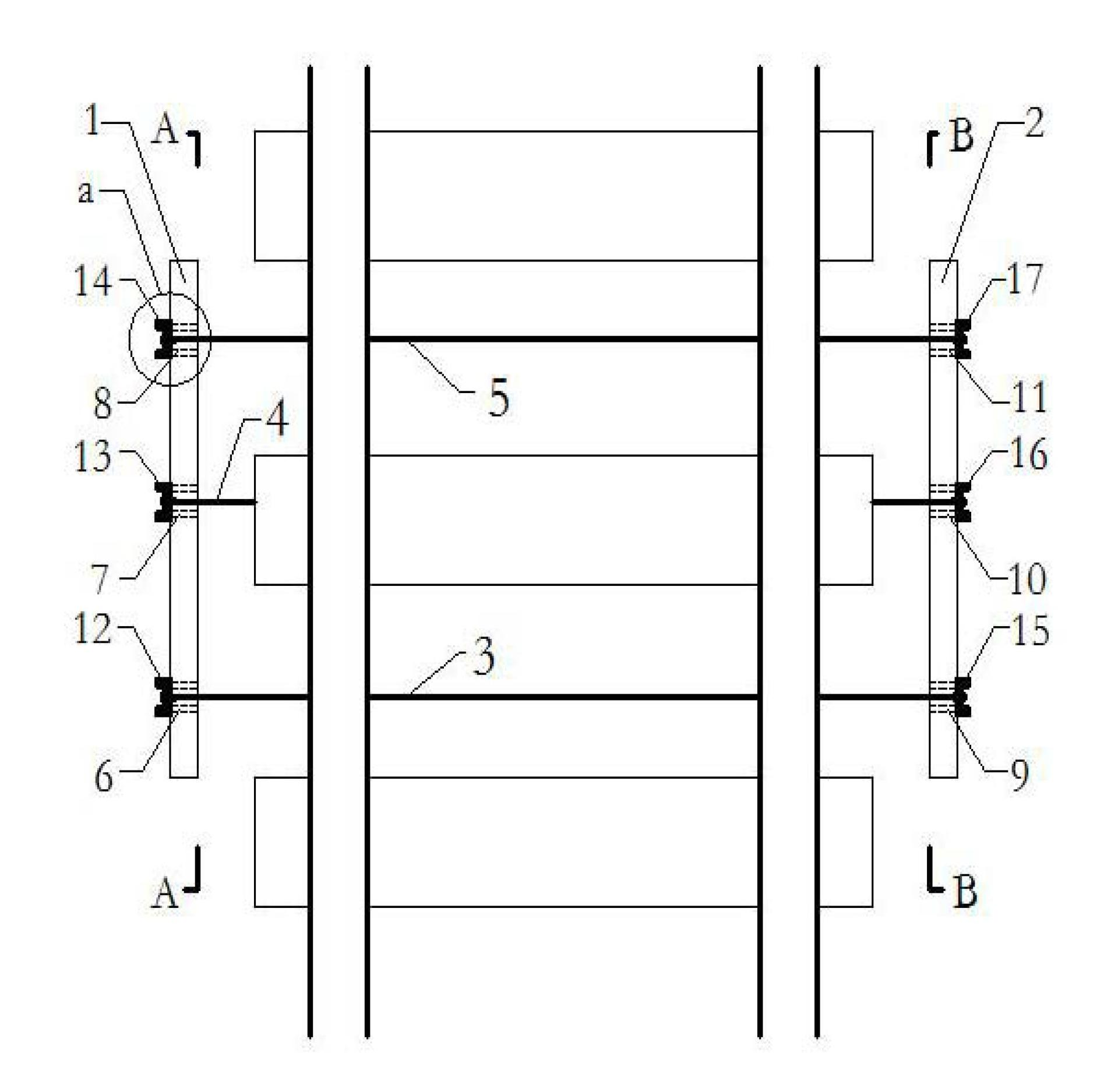

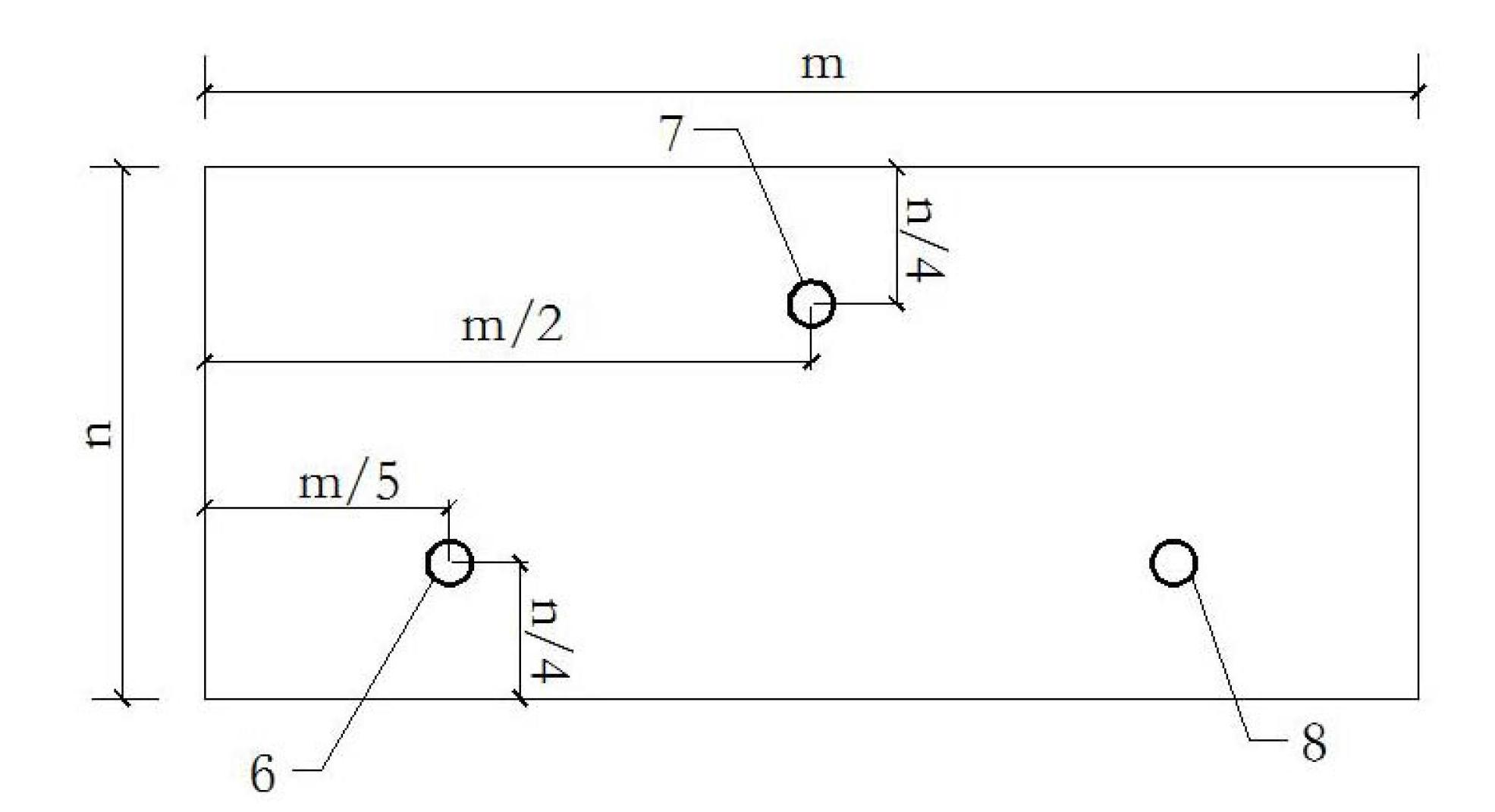

Horizontal restraint device of ballast bed

InactiveCN102628243AImprove bearing capacityIncrease resistanceBallastwayReinforced concreteEngineering

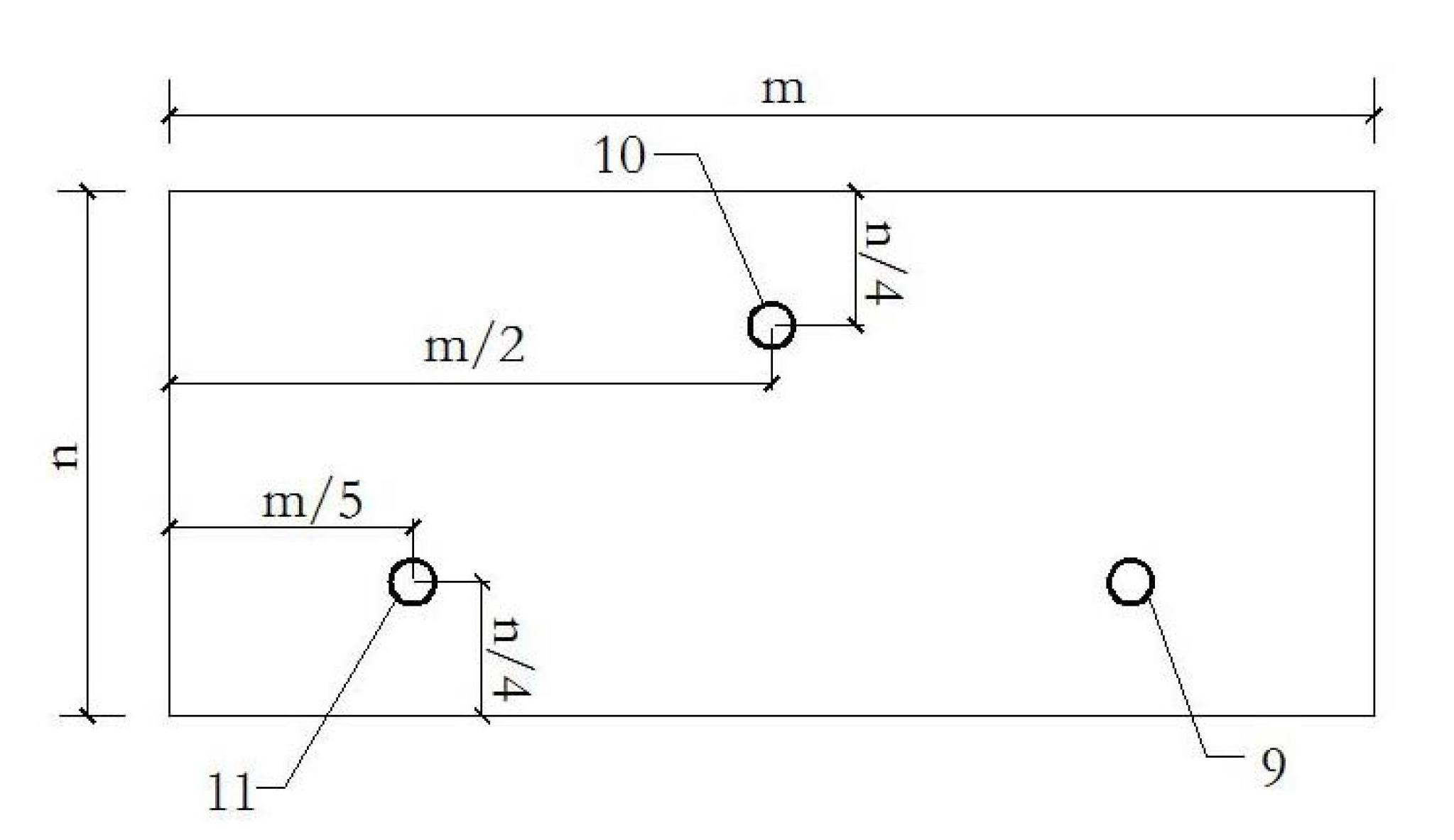

A horizontal restraint device of a ballast bed belongs to the field of track traffic and resolves the problems that an existing ballast bed structure is not sufficient in horizontal restraint, and a ballast bed is short in maintenance cycle and not sufficient in longitudinal and horizontal resistance. One ends of a first steel wire rope rig, a second steel wire rope rig and a third steel wire rope rig (3, 4 and 5) of the horizontal restraint device respectively penetrate through a first iron casing sleeve, a second iron casing sleeve and a third iron casing sleeve (6, 7 and 8) on a reinforced concrete plate (1) on the left side of a line. A first U-type bolt, a second U-type bolt and a third U-type bolt (12, 13 and 14) are inserted into annular connectors of one ends of the first steel wire rope rig, the second steel wire rope rig and the third steel wire rope rig (3, 4 and 5). The other ends of the first steel wire rope rig, the second steel wire rope rig and the third steel wire rope rig (3, 4 and 5) respectively penetrate through a fourth iron casing sleeve, a fifth iron casing sleeve and a sixth iron casing sleeve (9, 10 and 11) on a reinforced concrete plate (2) on the right side of the line. A fourth U-type bolt, a fifth U-type bolt and a sixth U-type bolt (15, 16 and 17) are inserted into annular connectors of the other ends of the first steel wire rope rig, the second steel wire rope rig and the third steel wire rope rig (3, 4 and 5).

Owner:BEIJING JIAOTONG UNIV

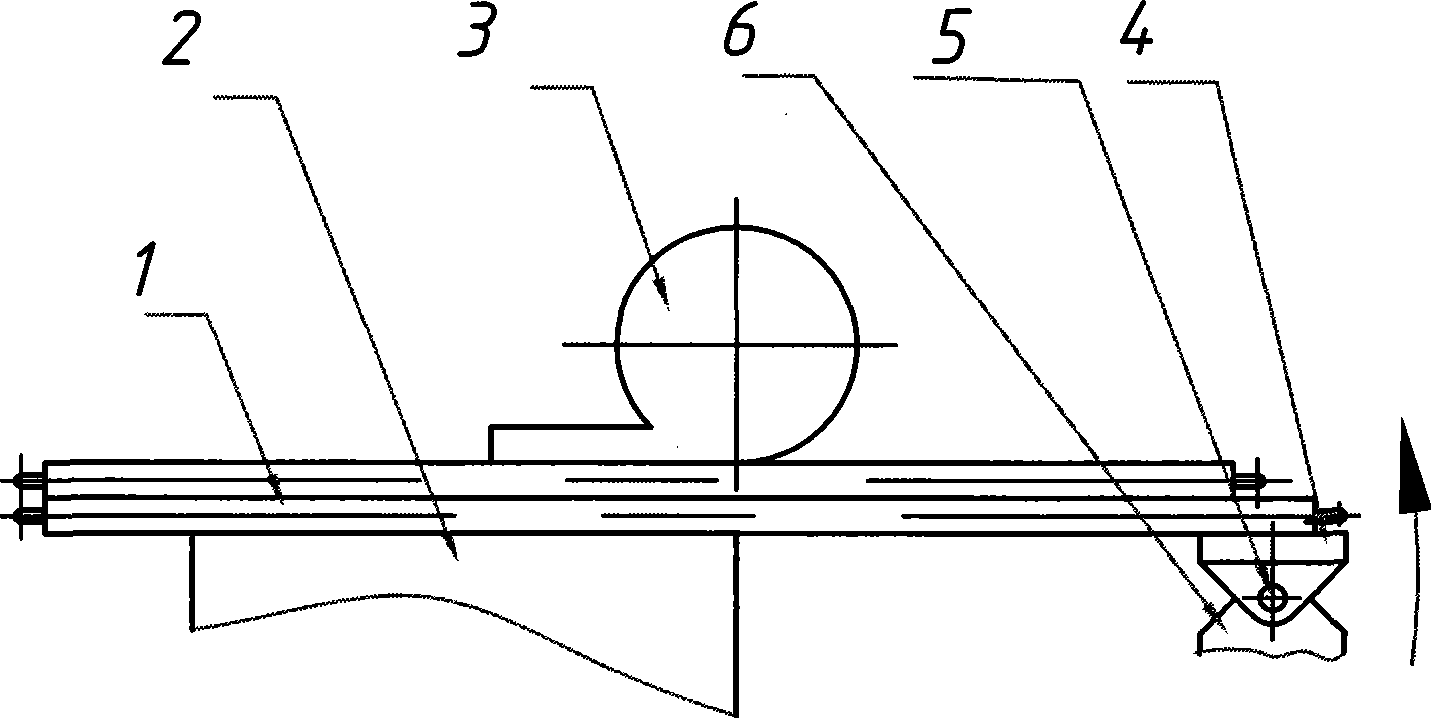

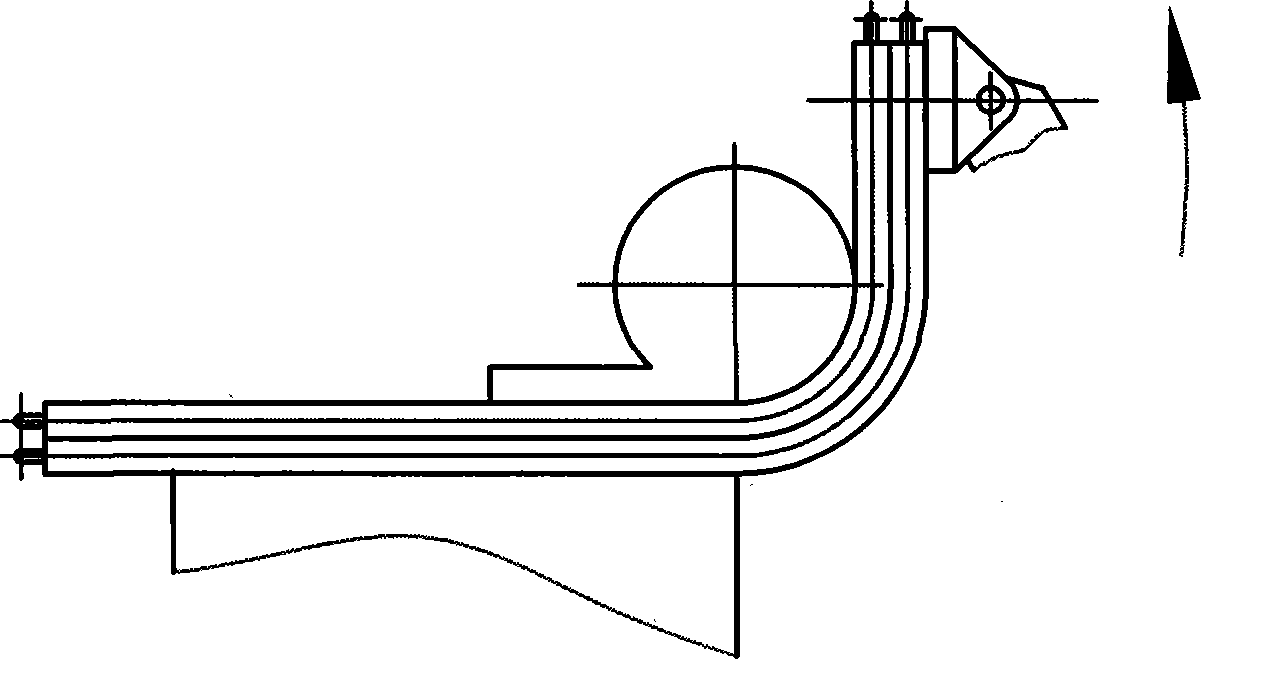

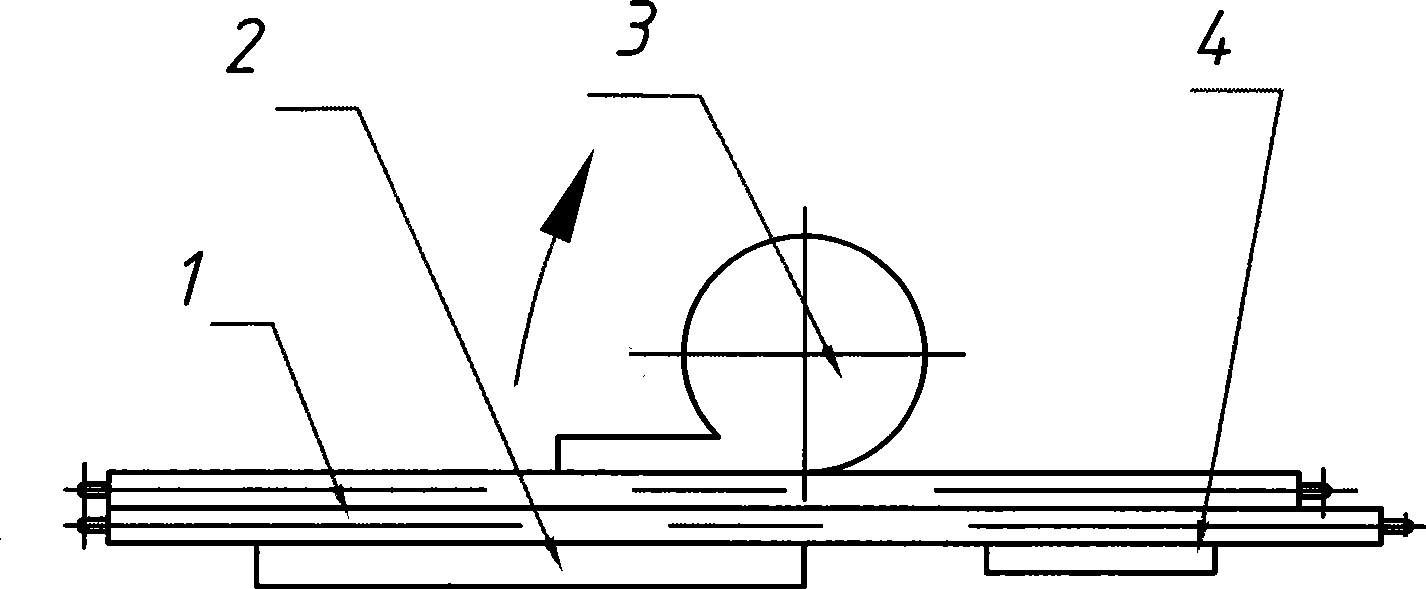

Bending method for air-conditioning condenser and bender

A bending method for an air-conditioning condenser, the bending plate can be moved horizontally by a moving device. The invention has the advantages: when the condenser sheet is bent, a horizontal moving force is increased, and the horizontal moving speed is equal to the linear velocity of the bottommost condenser sheet in the revolution on the bending mould, so that the condenser sheet has no horizontal resistance in the bending, thus preventing the rewinding. The needed total bending moment is small, the relative pressure between the condenser sheet and the bending mould, and between the layers of the condenser sheet is also small, the condenser sheet can not be rewound.

Owner:JDM JINGDA MASCH (NINGBO) CO LTD

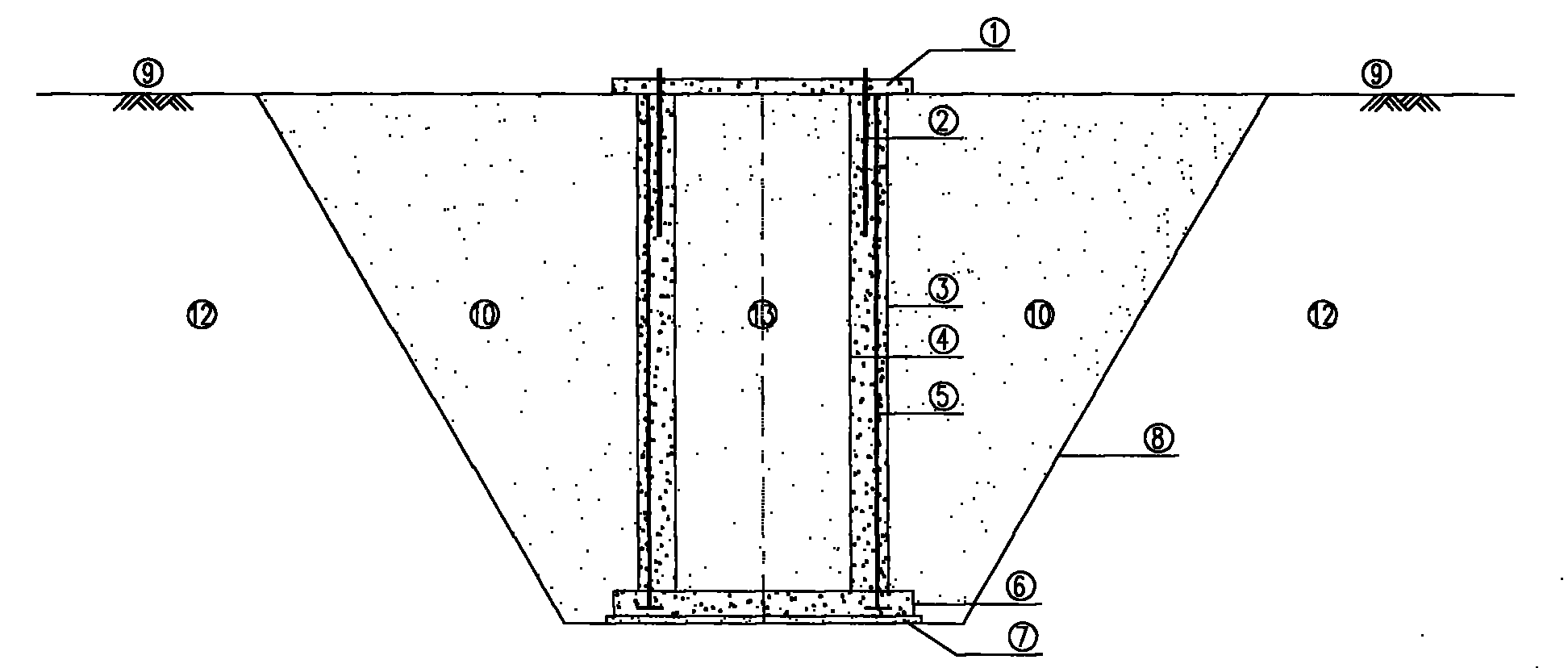

Two-ring grouted single pile foundation

A two-ring grouted single pile foundation is a foundation which is made up of hard components of an internal ring and an external ring. Part areas of the internal and external rings are connected by grouting. The foundation can provide great horizontal resistance and basic stiffness, and is suitable for basic fields of wind power generation, ports, offshore platforms and the like. On the basis of a behavior of a laterally loaded pile under load and making full use of material properties of steel and concrete, two rings or steel pipes with different inner and outer diameters are adopted. The internal and external rings are successively sunk into foundation soil in various ways (excavating and placing, driving, pressing and shocking). The foundation soil of the area which is close to the ground (soil surface) between the internal and external rings is excavated and materials such as concrete are grouted. If necessary, a reinforcing body can be inserted. Thus, the two-ring grouted single pile foundation is formed. The foundation makes full use of the concrete compressive property and the steel tensile property, and compared with a large-diameter steel pipe pile can effectively reduce an outer diameter of the pile foundation and steel consumption. When in water environment such as in the sea, an environmental load on the foundation is greatly reduced and construction difficulty is correspondingly reduced. The foundation can provide great horizontal resistance and basic stiffness, and can be applied to situations of bearing great horizontal load or passive earth pressure by using the foundation and can be applied to basic designs of onshore wind power generation, offshore wind power generation, ports, and offshore oil platforms.

Owner:上海同济启明星科技发展有限公司

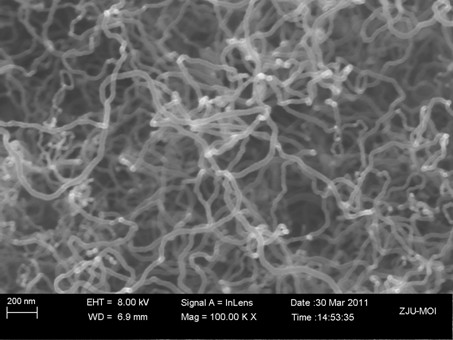

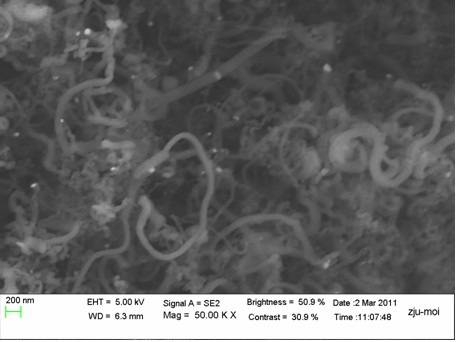

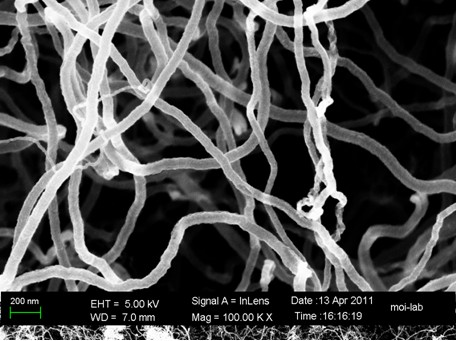

Preparation method for synthesizing carbon nanotubes in quantity and with low cost

InactiveCN102161481ASimple preparation processReduce energy consumptionNanotechnologyChemical platingCarbon nanotube

The invention discloses a preparation method for synthesizing carbon nanotubes in quantity and with low cost. The method comprises the following steps of: plating and coating nano-grade metal catalysts such as iron, cobalt, molybdenum and the like on foamed nickel by a chemical plating process; placing the foamed nickel plated with the catalysts into a quartz boat; heating the foamed nickel plated with the catalysts by using the common horizontal resistance furnace; introducing nitrogen with flow of 200 ml / min to remove air from a quartz tube; when the temperature reaches 650 DEG C, introducing hydrogen with flow of 50 ml / min to reduce the metal catalysts for 10 minutes; when the temperature reaches 690 to 720 DEG C, introducing acetylene gas with flow of 50 to 100 ml / min, wherein the hydrogen flow can be set to be 25 to 100 ml / min; closing an acetylene valve and a hydrogen valve after the reaction is performed for 30 minutes; introducing nitrogen with the flow of 20 ml / min; when the temperature is reduced to 300 DEG C, closing a nitrogen valve; and after the hearth is cooled to room temperature, taking out the quartz boat, wherein black products are found to be generated on the foamed nickel and are the carbon nanotubes according to electron microscope and Raman spectrum detection. By the method, the preparation process is simple; energy consumption is small; cost is low; time is saved; and preparation conditions are easy to implement.

Owner:ZHEJIANG UNIV

Soil non-excavation grounding resistance reduction method

InactiveCN102610935ADoes not affect damageWill not affect trafficLine/current collector detailsConnection contact member materialEngineeringHigh pressure

The invention relates to a soil non-excavation grounding resistance reduction method, in particular to a non-excavation project resistance reduction technology. The soil non-excavation grounding resistance reduction method is characterized in that two layers of horizontal resistance reduction ground screens are arranged on the grounding soil; one layer of the horizontal resistance reduction ground screen is arranged on the soil surface to form a surface ground screen, and the other layer is located in the underground soil layer with the soil resistance smaller than 300 ohm meters to form an underground ground screen; the surface ground screen is steel fabric; the underground ground screen is formed by spraying a resistance reducing agent into the soil through holes formed on the pipes laid by a directional drilling non-excavation pipe laying method so as to bind with the soil; and the surface ground screen is connected with the underground ground screen through a vertical grounding connection wire. The non-excavation resistance reduction method provided by the invention does not affect the traffic nor destroy the environment, and has the advantages of short construction period, low comprehensive cost, significant resistance reduction effect, and high social and economic value.

Owner:云南省昆明农业气象试验站 +1

Physical quantity sensor

ActiveUS7555944B2Inhibition of bucklingReduce internal stressVolume/mass flow by thermal effectsResistance/reactance/impedenceElectricityElectrical resistance and conductance

Owner:HITACHI ASTEMO LTD

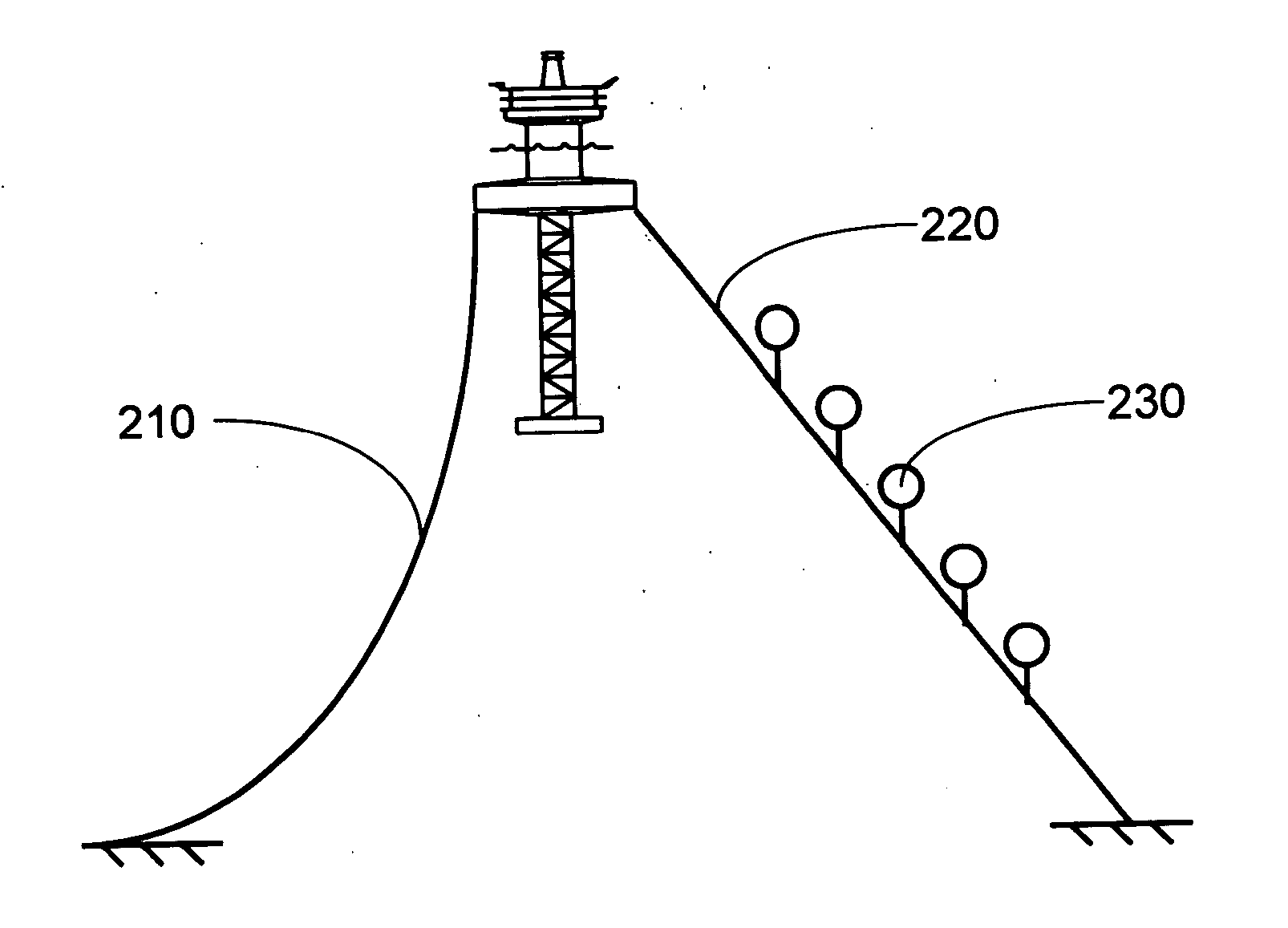

Rigid frame pile supporting and blocking structure

The invention relates to the construction field of abrupt slope square sections and provides a rigid frame pile supporting and blocking structure which comprises a plurality of h-type piles distributed parallelly, wherein each h-type pile comprises an outer anchoring pile, an inner anchoring pile and a beam, the pile tops of the inner anchoring piles and the pile bodies of the outer anchoring piles are connected through the beams, adjacent outer anchoring piles are connected through earth blocking plates, the outer anchoring piles penetrate a rock-soil body to be anchored in a stable foundation, the inner anchoring piles and the beams are all embedded in the rock-soil body, the outer anchoring piles are arranged on the outer side of an abrupt slope, and the inner anchoring piles are arranged on the inner side of the abrupt slope. The rigid frame pile supporting and blocking structure optimizes the existing h-type pile design, has high rigidity and good horizontal resistance, can bear high soil pressure or sliding force on highfill sections of the abrupt slope, has high safety and reliability and effectively solves the problem of difficult supporting of highfills of the abrupt slope.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

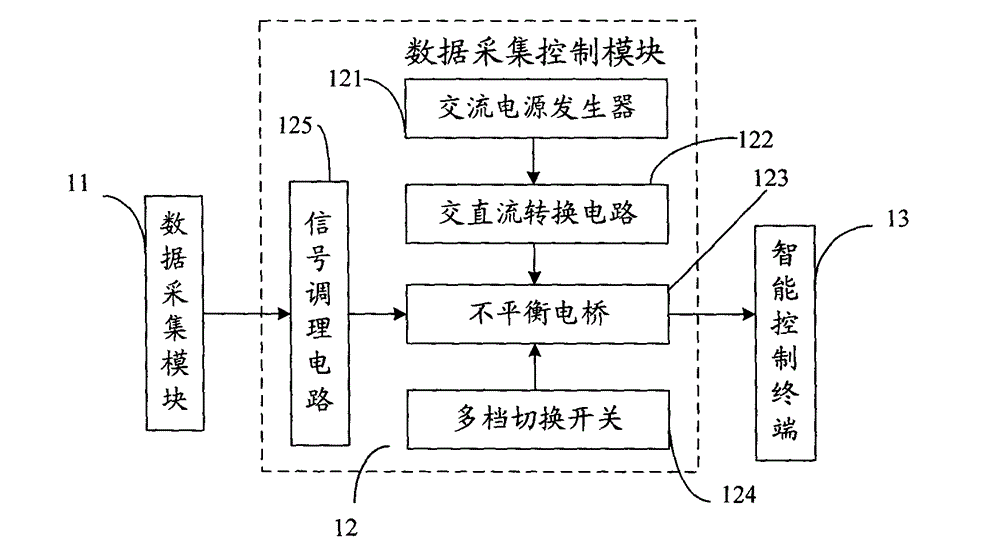

Landfill resistivity irregular factor test and engineering safety warning method and system

InactiveCN102944748AReal-time monitoring of internal structure changesEasy to operateResistance/reactance/impedenceElectrical resistance and conductanceData acquisition

The invention discloses a landfill resistivity irregular factor test and engineering safety warning method and system. The method comprises the following steps that in the whole process of landfill stacking body construction, operation and maintenance period, a data acquiring probe acquires a horizontal resistance signal and a vertical resistance signal of a landfill body which is tested by a landfill; a data acquiring control module calculates a horizontal resistance value and a vertical resistance value of the landfill which is tested by the landfill according to an unbalanced bridge principal; an intelligent control terminal calculates a resistivity irregular factor according to the horizontal resistance value and the vertical resistance value of the tested landfill body, thereby monitoring the change situation of the internal structure of the landfill stacking body in the whole process of construction, operation and maintenance period, and further performing landfill engineering safety warning. The system provided by the invention can be used throughout the construction of the landfill work, and has the advantages of simple and fast operation, continuousness and non-destructiveness, reliable result, low cost, easiness in promotion and the like, and filling the blank of landfill work risk evaluation and engineering safety warning, and has strong promotion and application values.

Owner:YANCHENG INST OF TECH

Lever type drawer lock

The invention relates to a lever type drawer locking mechanism which can lock and unlock a drawer without a key. The mechanism mainly comprises a support, a locking dog, link levers, a push plate, a pressure spring, a riveting shaft, a shaft sleeve, a gasket and a retainer ring which form a symmetric lever mechanism. The invention is characterized in that the upper end of the locking dog is an inclined plane (a wedge of 45 degrees from side view), the locking dog is always at high position under the action of the pressure spring, the locking dog is blocked by the edge of a drawer frame when being pushed into a drawer, horizontal resistance is applied on the inclined plane thereof, the resistance can be decomposed to be two component forces which are upward parallel with the inclined plane and downward vertical to the horizontal plane respectively, the component force downward vertical to the horizontal plane presses the locking dog and the locking dog contracts downward to low position, the drawer is smoothly pushed in place, and the locking dog is reset and enters into a locking hole on the drawer frame under the action of the pressure spring, so that the drawer is locked. When opening the drawer, the push plate is pressed upward, the push plate drives two link levers to rotate around respective pivot, and the other end of the link lever simultaneously drives the locking dog to move downward, so as to be separated from the lock hole, thus unlocking is realized and the drawer can drawn out. The invention can be applied to any furniture provided with drawer, locking and unlocking of drawer can be realized without a key, and a lock can not be found from the outside.

Owner:崔西武

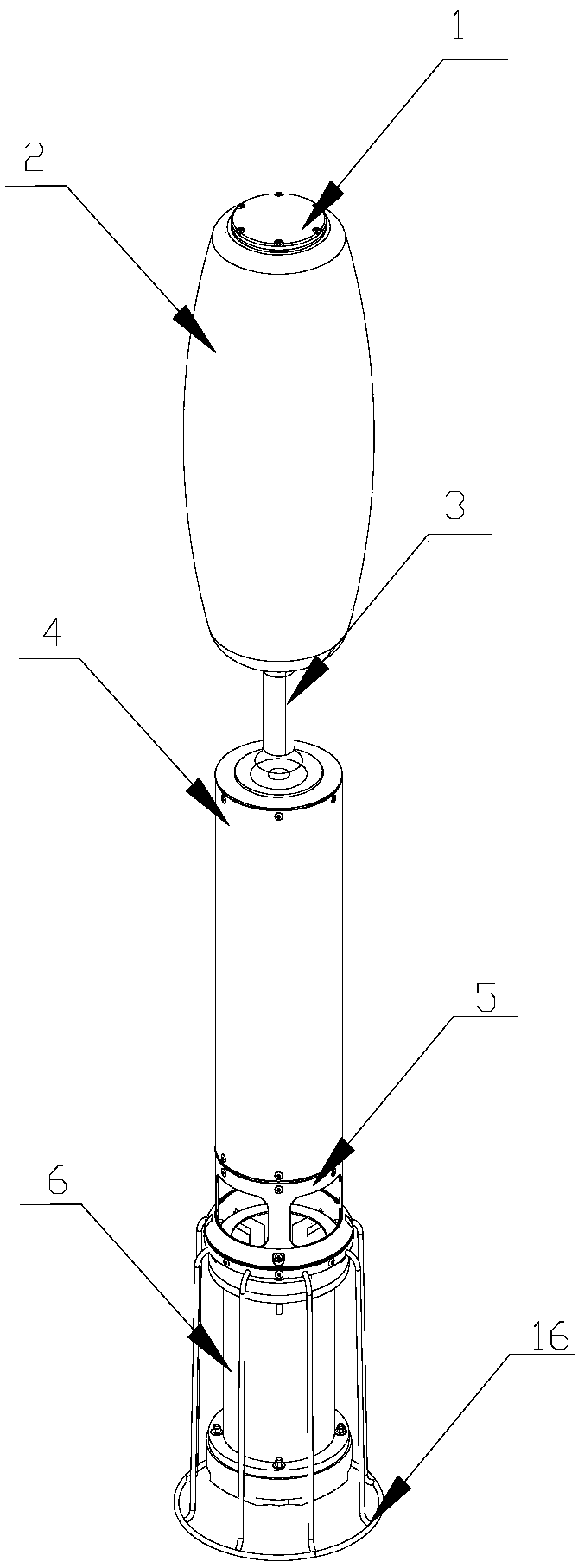

Dragging vertical stable flow velocity profile measuring buoy for wave glider

PendingCN109374922AReduce horizontal resistanceSmall vertical motion displacement effectsSpeed/acceleration/shock instrument detailsFluid speed measurementVertical stabilityData acquisition

The invention discloses a dragging vertical stable flow velocity profile measuring buoy for a wave glider. The dragging vertical stable flow velocity profile measuring buoy comprises a long round floating body, a cylindrical battery sealing chamber and an ADCP which are coaxially and vertically arranged from top to bottom. The top of the floating body is provided with an electrical sealing chamber, a data acquisition module, a GPS positioning module, a satellite communication module and a control module are installed in the electrical sealing chamber, a battery pack is installed in the batterysealing chamber, the bottom of the floating body is provided with a floating body bracket, the ADCP is connected to the lower end of the battery sealing chamber, the ADCP is connected to the data acquisition module and the control module, the data acquisition module receives the data of the ADCP and the GPS positioning module, and wireless communication is performed with a shore-based monitoringcenter through the satellite communication module to realize data transmission. The dragging vertical stable flow velocity profile measuring buoy has the advantages of high vertical stability and small horizontal resistance, the function of a floating buoy on a sea surface can be achieved, the dragging vertical stable flow velocity profile measuring buoy is suitable for dragging, and the real-timeremote communication of measurement data can be realized.

Owner:OCEAN UNIV OF CHINA +1

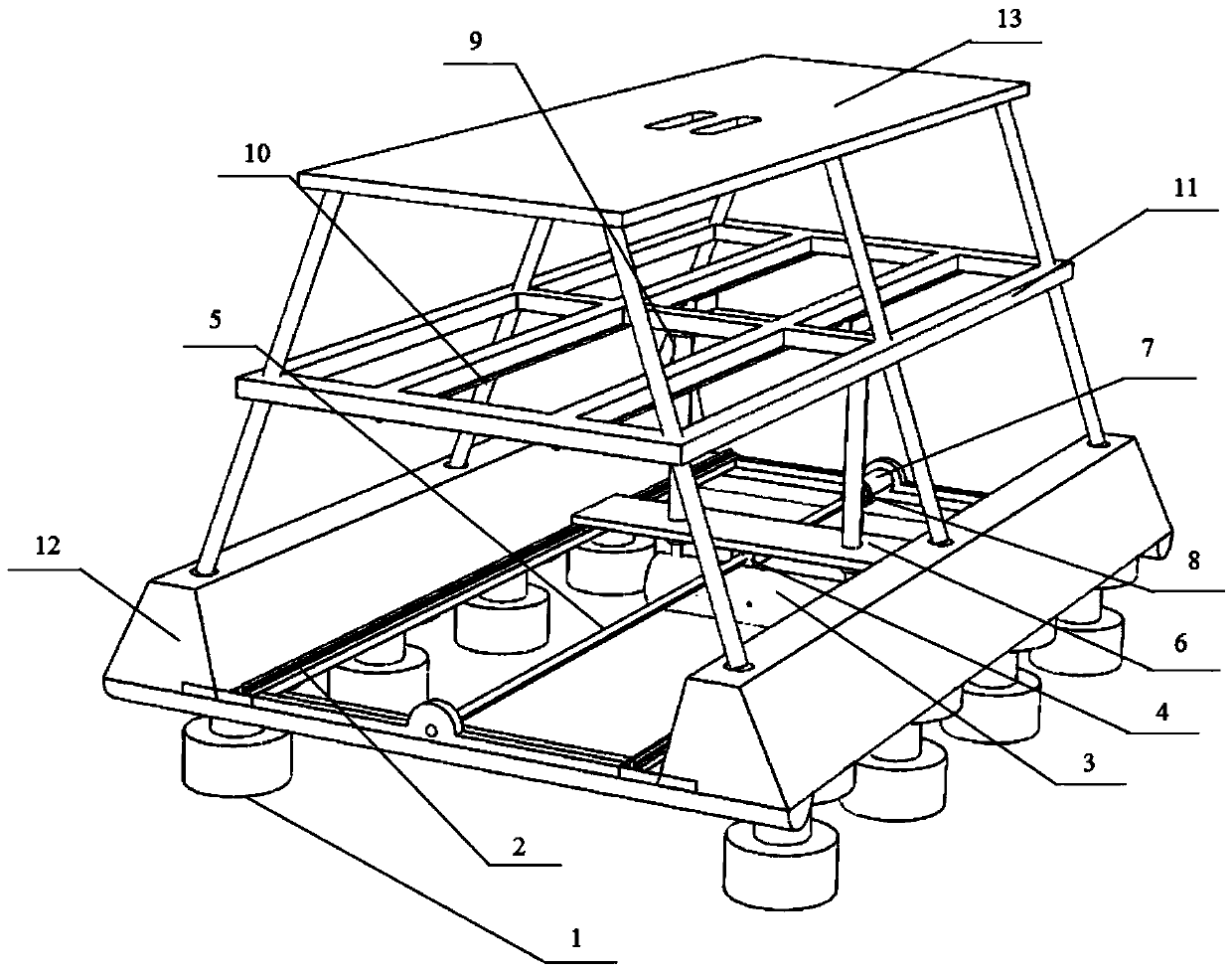

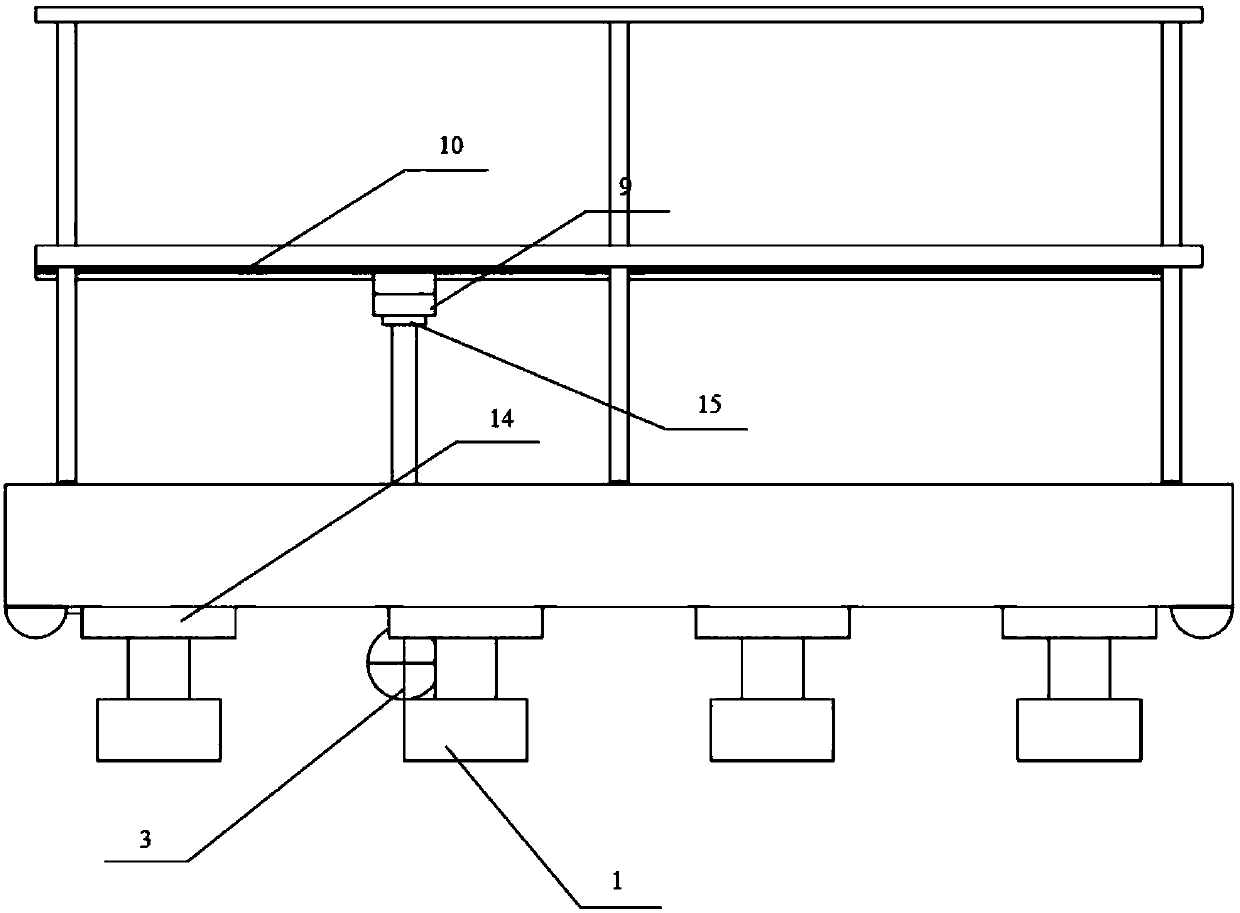

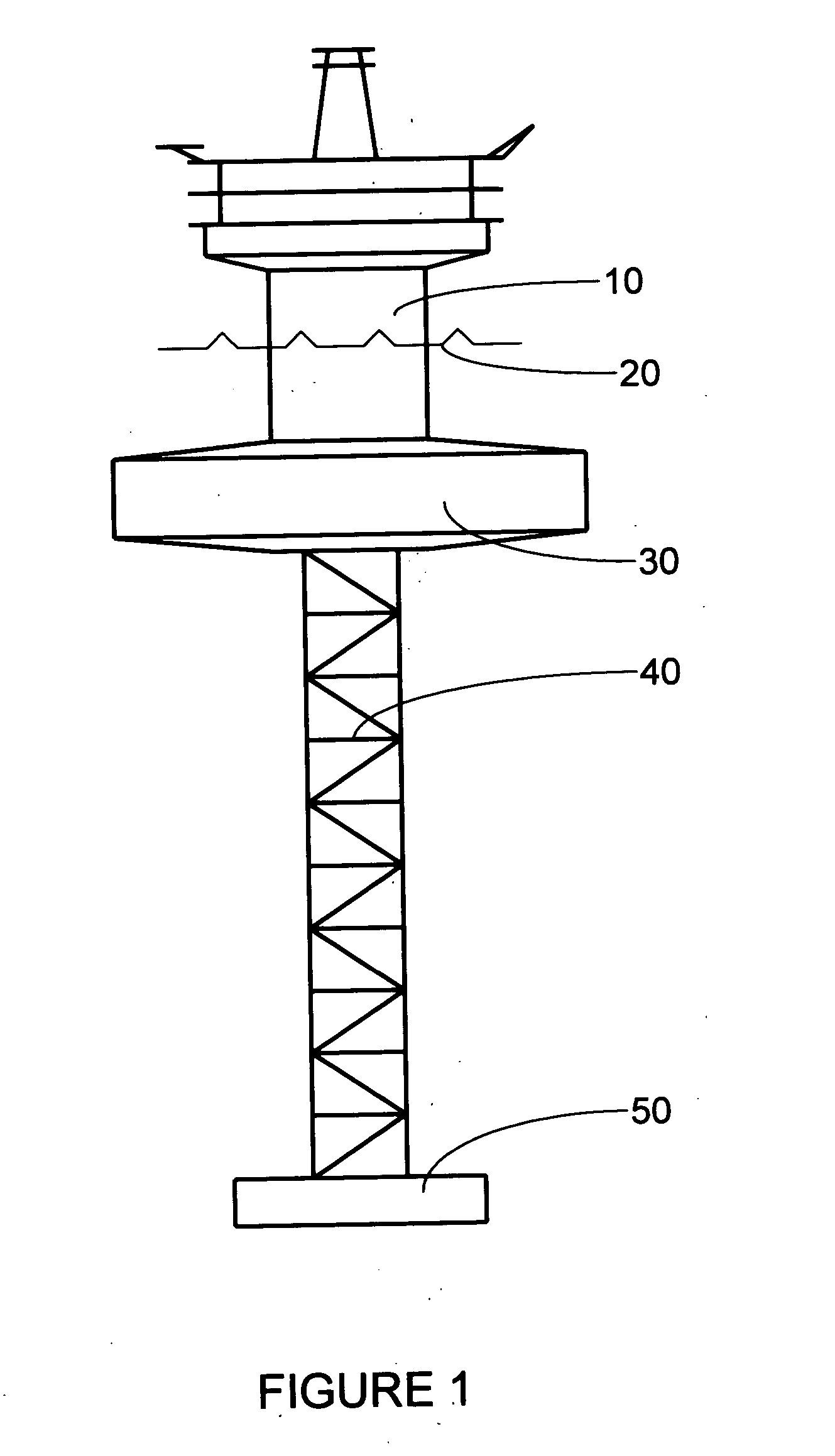

Ballast extension-submersion truss stable platform

InactiveUS20070204785A1Easy towingMinimized wave-zone buoyancyMovement controllersFloating buildingsDrill siteOperational stability

To overcome high construction and deployment / installation costs of spar platforms that are typically employed in deep waters for oil and gas production, Ballast Extension-Submersion Truss Stable Platform (BEST Stable Platform) capitalizes on a minimized wave-zone buoyancy design to control platform water-plane area. With a truss connected ballast that could be positioned at different depths, the Best Stable Platform can be constructed in shallow water near a fabrication yard, and the entire assembly could be towed to a drill site where the extended and submerged ballast would provide operational stability. For horizontal stability, mooring lines are floated by water neutral-density means to remove anchor line curvature. Accordingly, mooring lines could be pulled straight under water to provide optimal horizontal resistance, thereby reducing the need for excessive mooring line pretension that increases platform loads. Savings are realized by not having to design floating platforms that must have extra capacity to accommodate added pretension.

Owner:CHOW ANDREW W

Method for preparing graphene chemically modified electrode through in-situ growth

InactiveCN103529099AEasy to operateImprove production efficiencyMaterial electrochemical variablesOxygenMaterials science

Owner:SOUTHWEST JIAOTONG UNIV

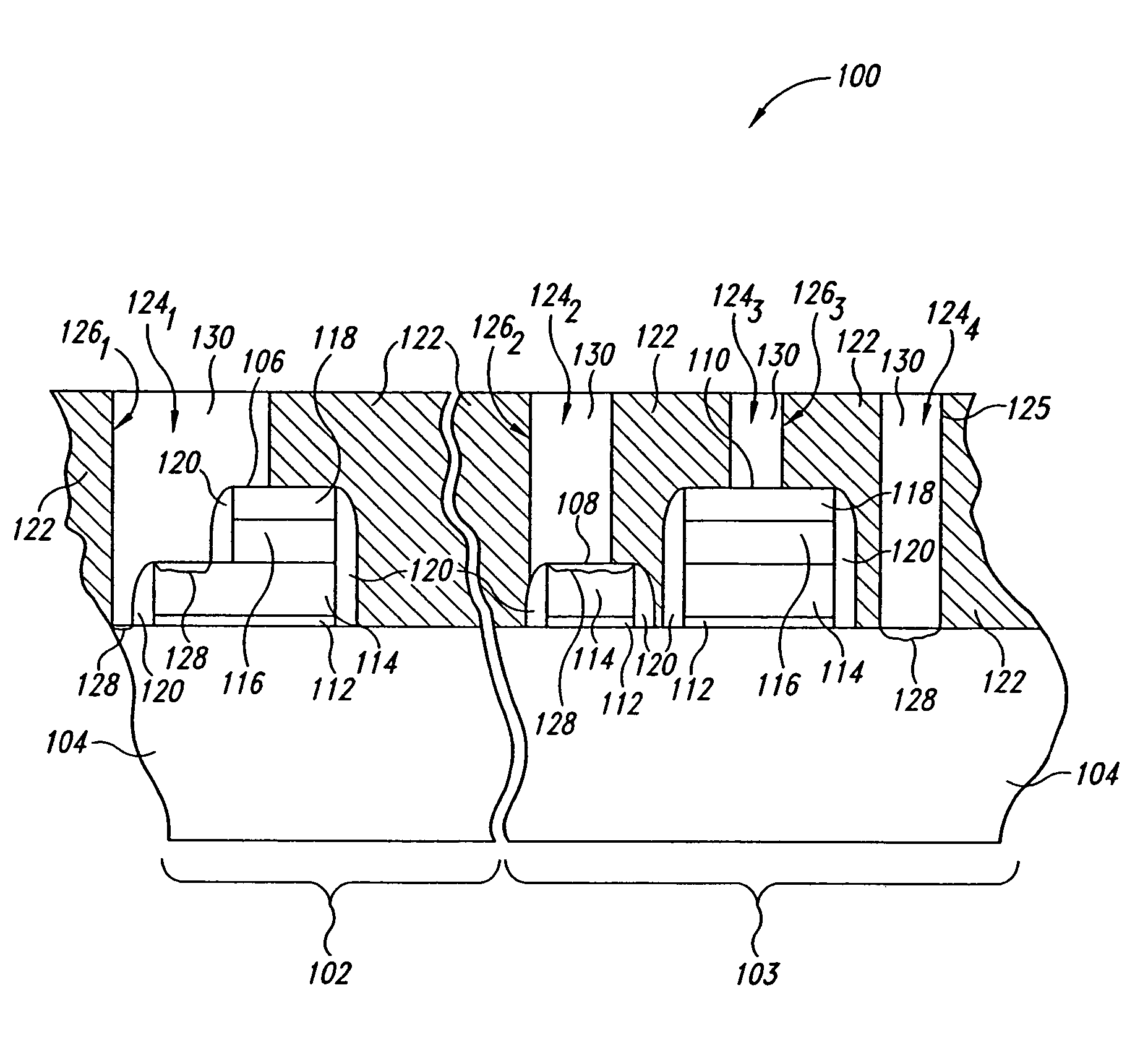

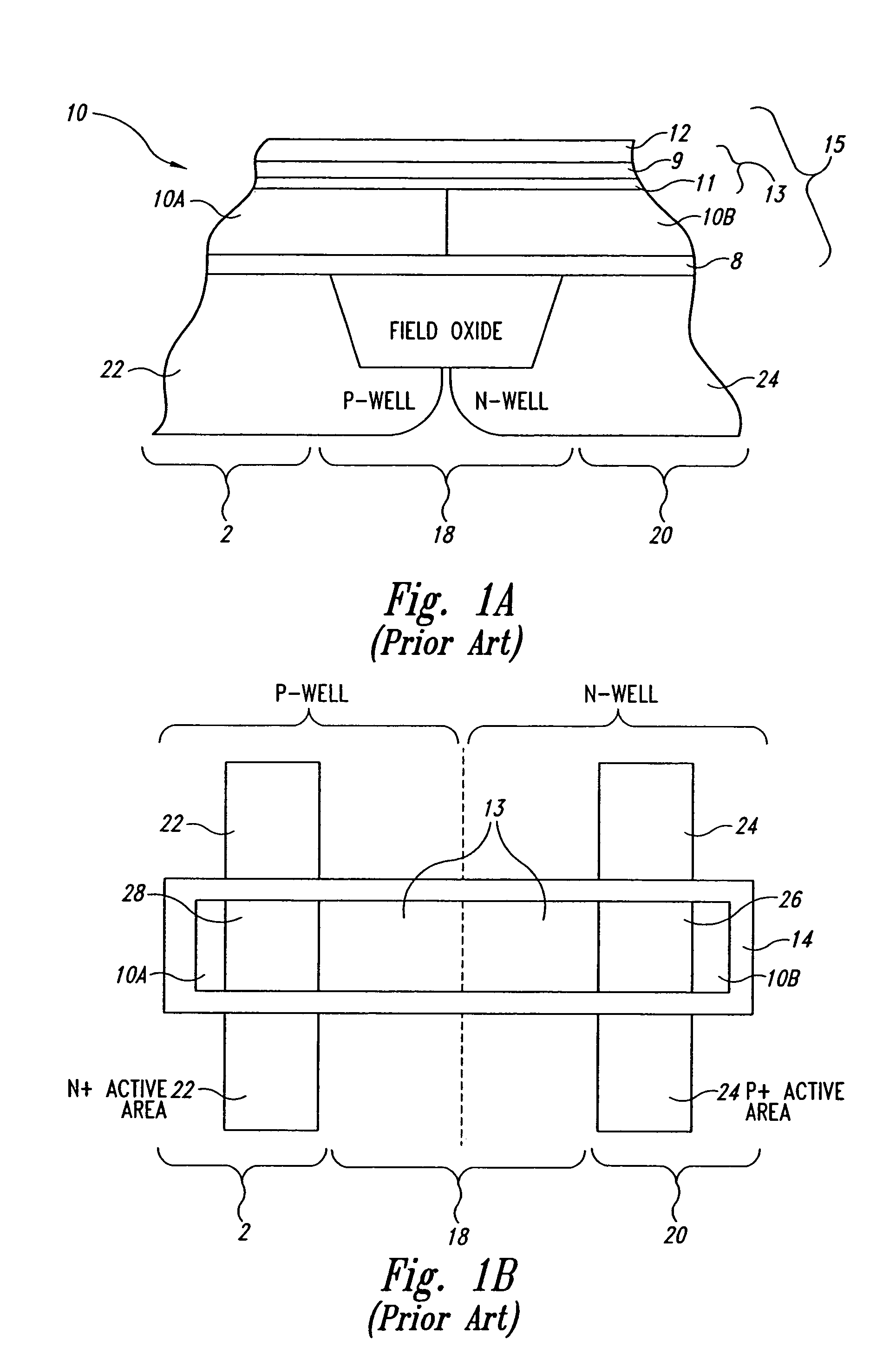

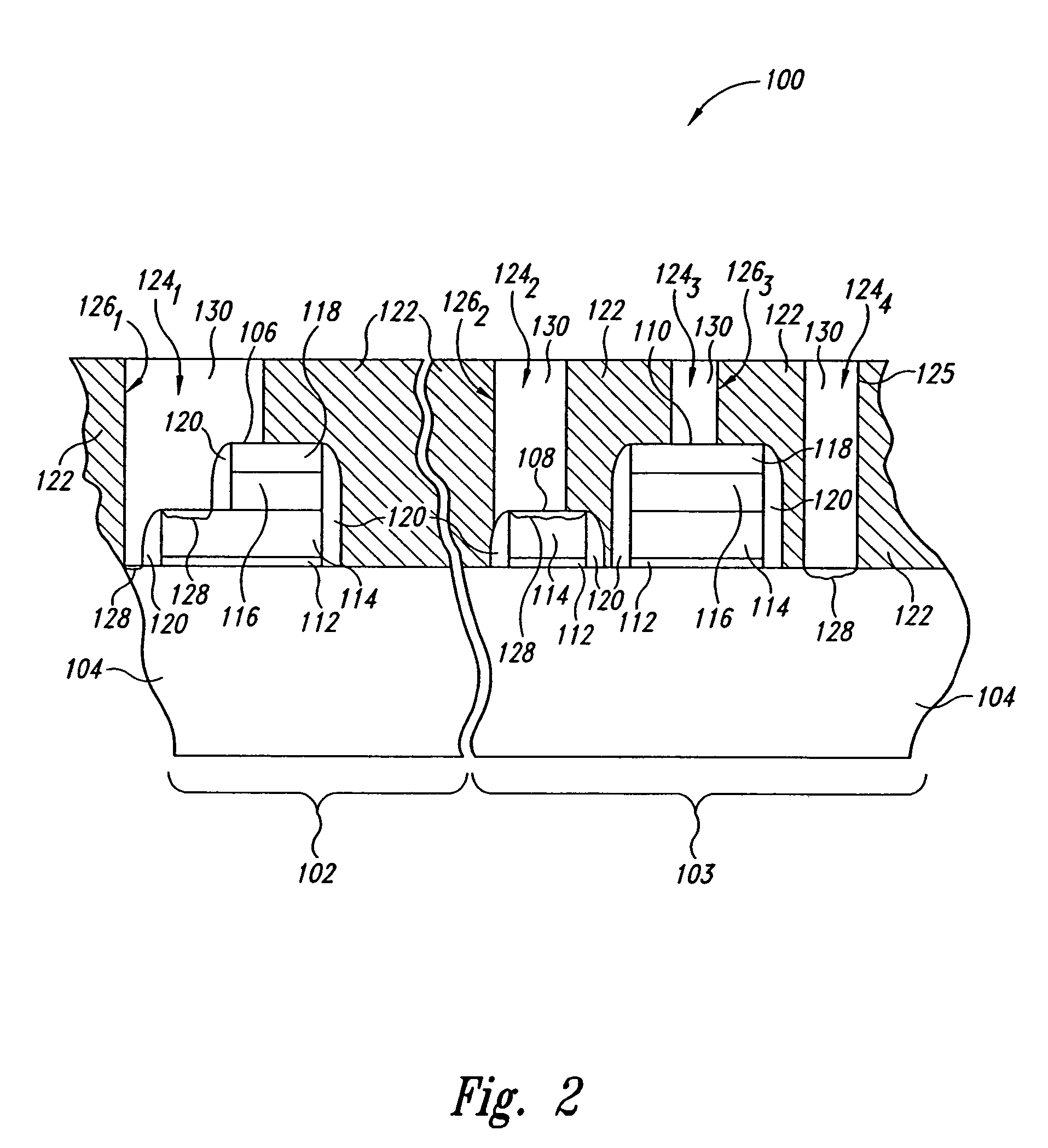

Methods for making semiconductor structures having high-speed areas and high-density areas

InactiveUS7095083B2Reduce resistanceImprove performanceSemiconductor/solid-state device detailsSolid-state devicesElectrical resistance and conductanceHigh density

Methods for making a semiconductor structure are discussed. The methods include forming openings in a high-density area and a high-speed area, and forming a metallization layer simultaneously into the high-density area and the high-speed area. The metallization layer includes a combination of substances and compounds that reduce vertical resistance, reduce horizontal resistance, and inhibit cross-diffusion.

Owner:MICRON TECH INC

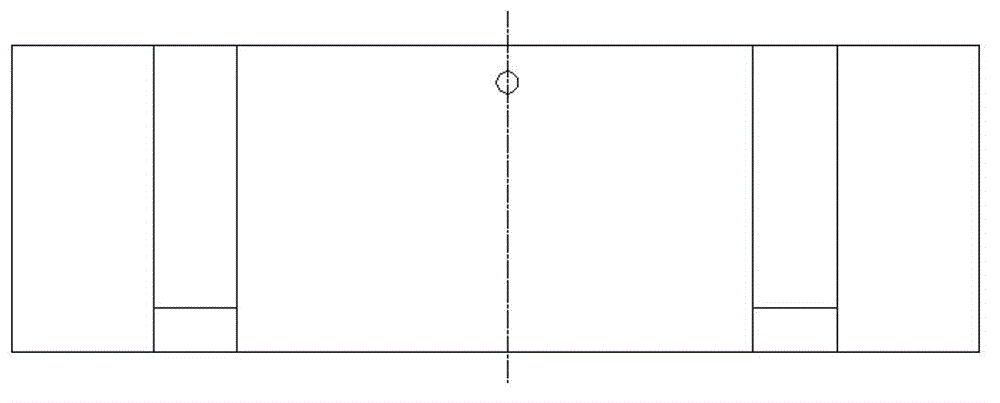

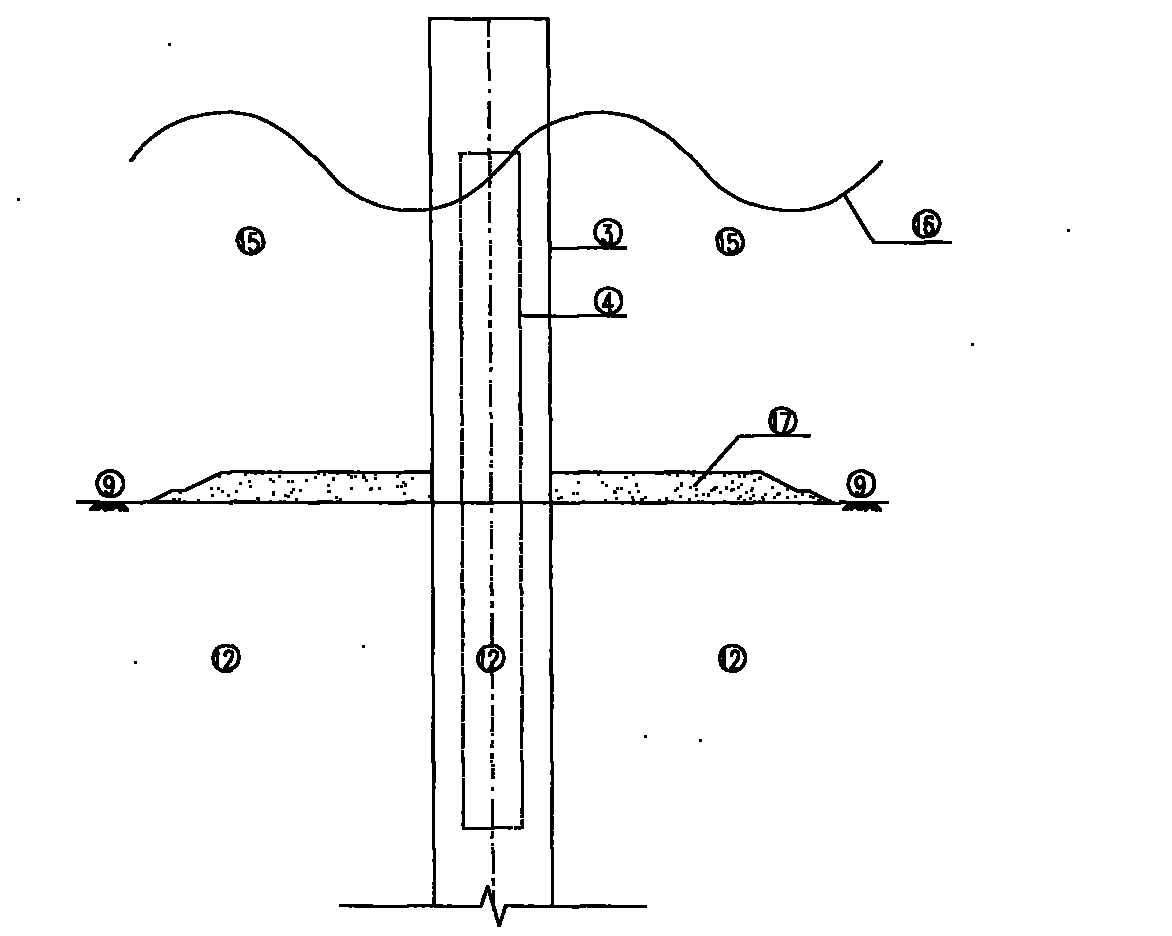

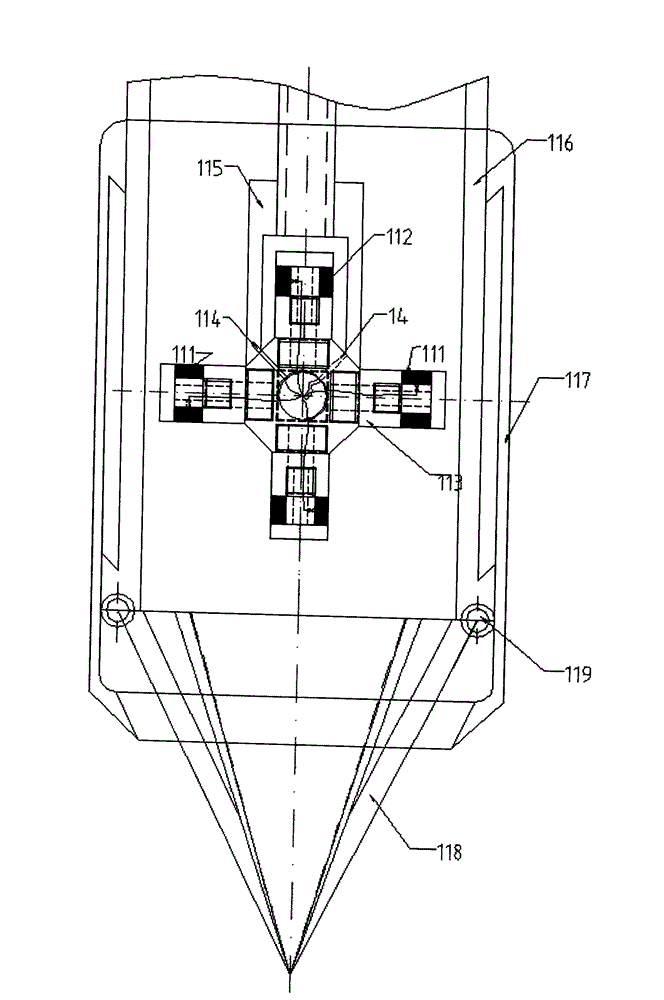

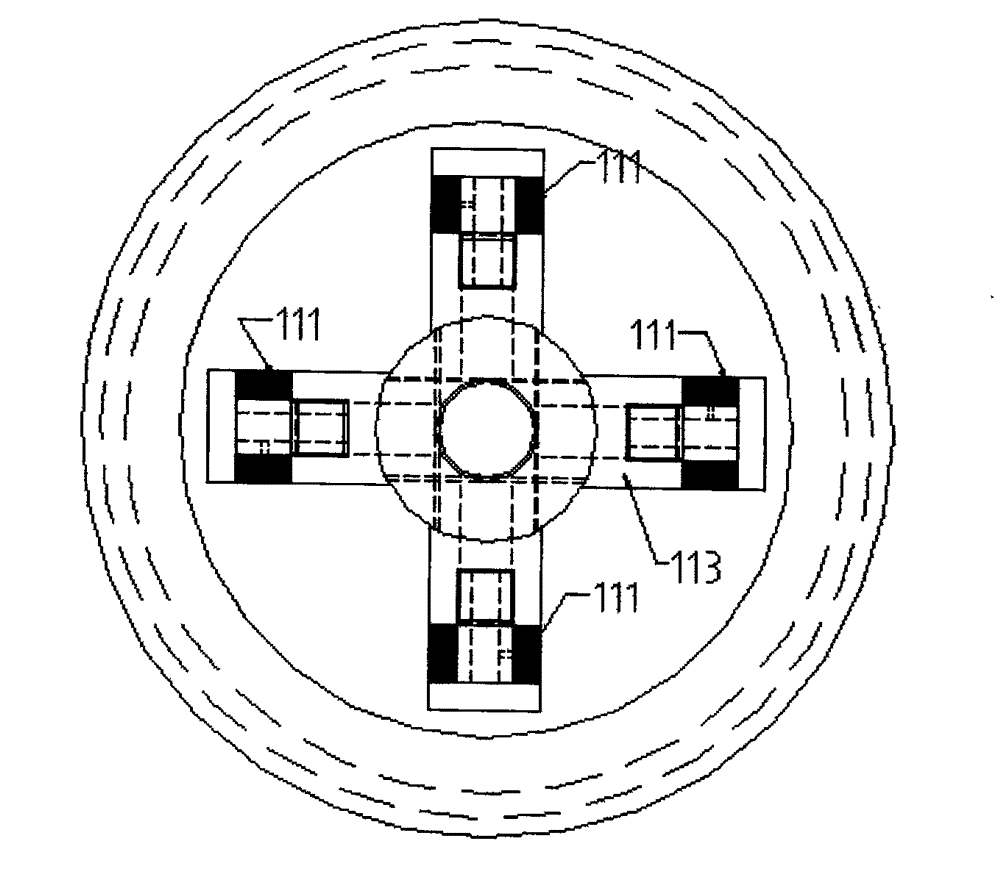

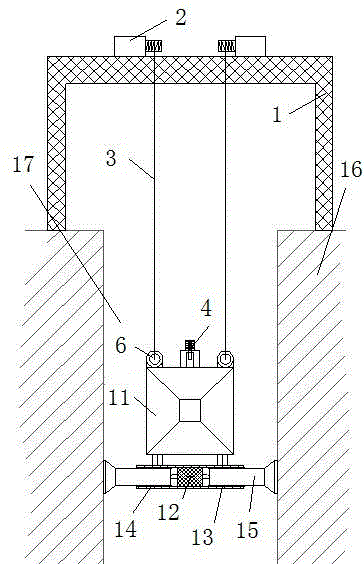

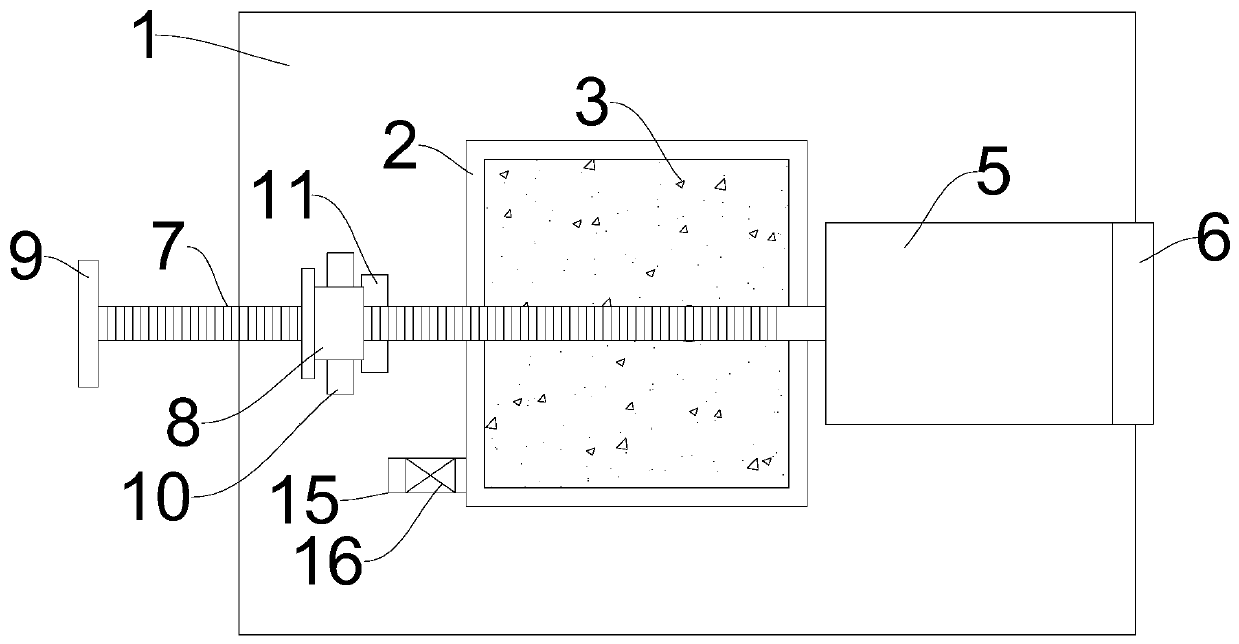

Deep stratum horizontal resistance coefficient in-situ tester

The invention discloses a deep stratum horizontal resistance coefficient in-situ tester. The deep stratum horizontal resistance coefficient in-situ tester comprises an elevating mechanism, a loading mechanism, a positioning mechanism, a test mechanism and a controller; the elevating mechanism comprises a truss, the truss is provided with a hoisting machine, and the hoisting machine is connected with the loading mechanism through a steel cable; the loading mechanism comprises a rectangular cabin connected with the steel cable, a bidirectional hydraulic jack is disposed in the rectangular cabin, two ends of the bidirectional hydraulic jack are respectively connected with force transmission beams, and the force transmission beams pass through openings of the rectangular cabin and then are connected with pressure bearing plates; the positioning mechanism comprises bidirectional hydraulic jacks, and two ends of each bidirectional hydraulic jack are connected with cross supports; and the test mechanism comprises stress sensors and displacement sensors, the controller controls the hoisting machine and the bidirectional hydraulic jacks to work, and the stress sensors and the displacement sensors are connected with the controller through data lines. A deep stratum horizontal resistance coefficient can be directly tested, and a guarantee is provided for anti-slide pile design and construction safety.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

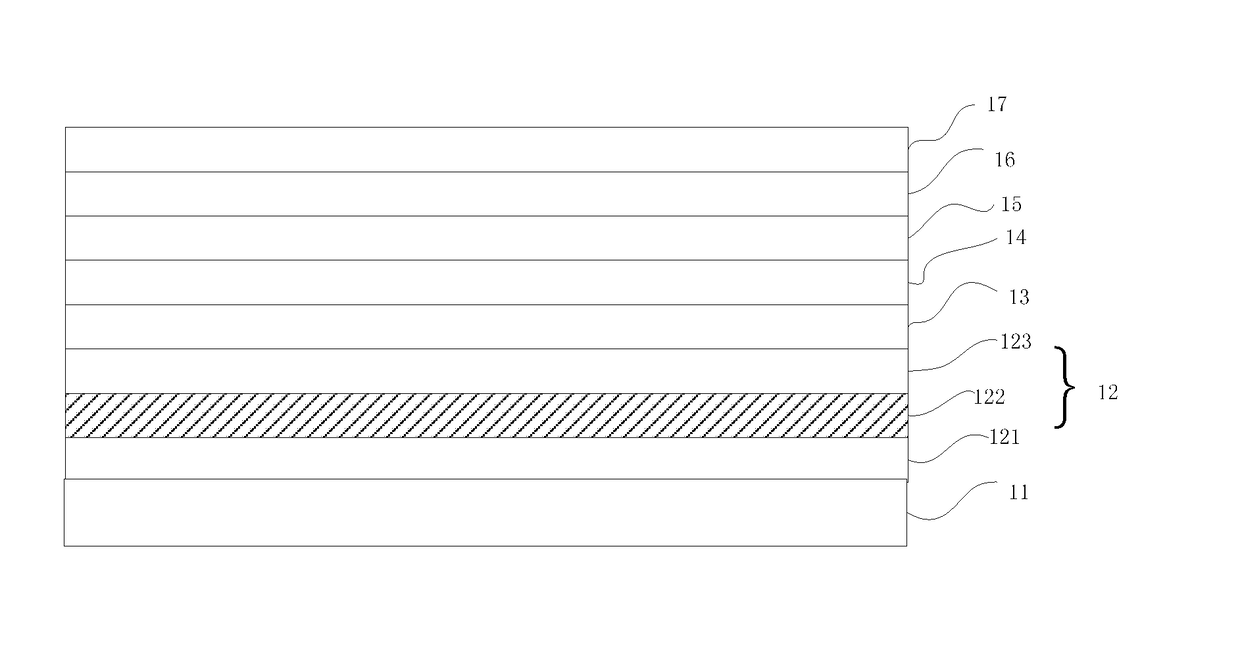

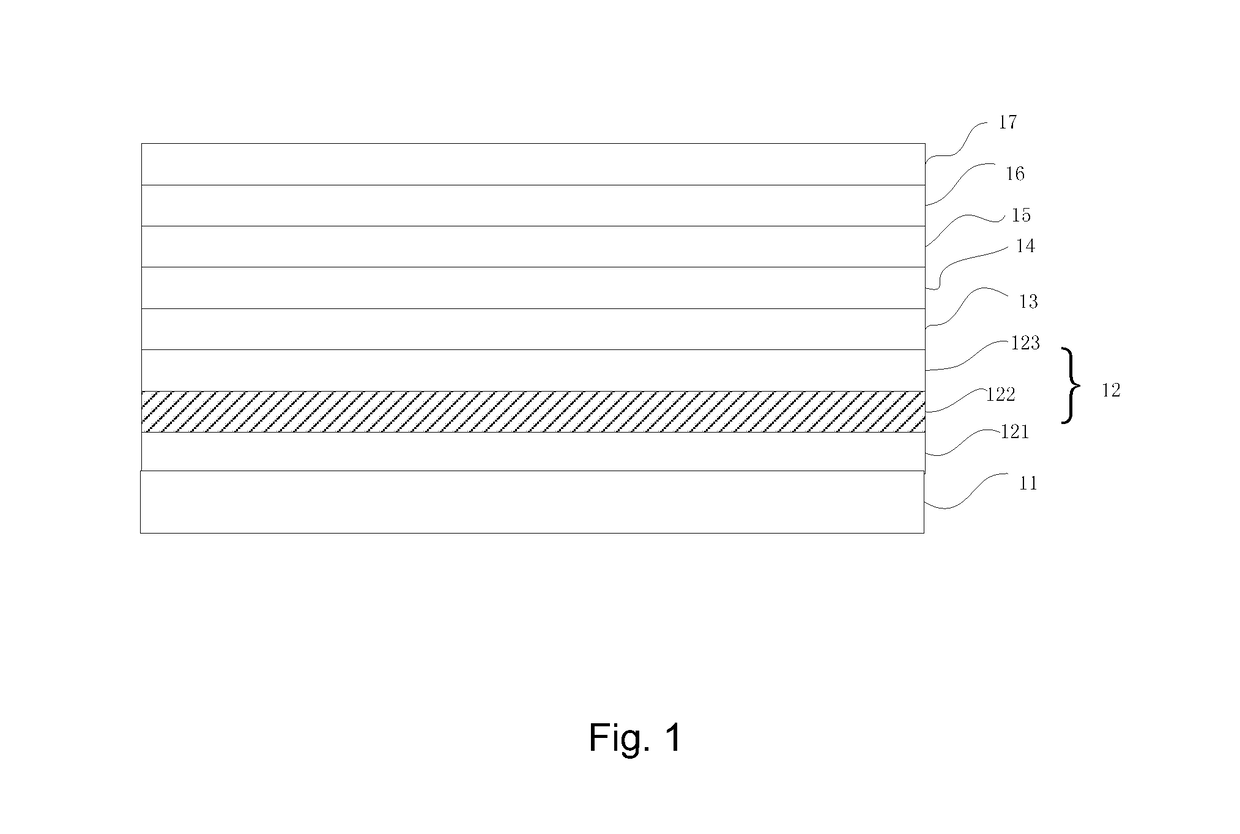

Organic Light Emitting Diode Device and Array Substrate

InactiveUS20170263883A1Reduce resistanceImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingLight emissionLight-emitting diode

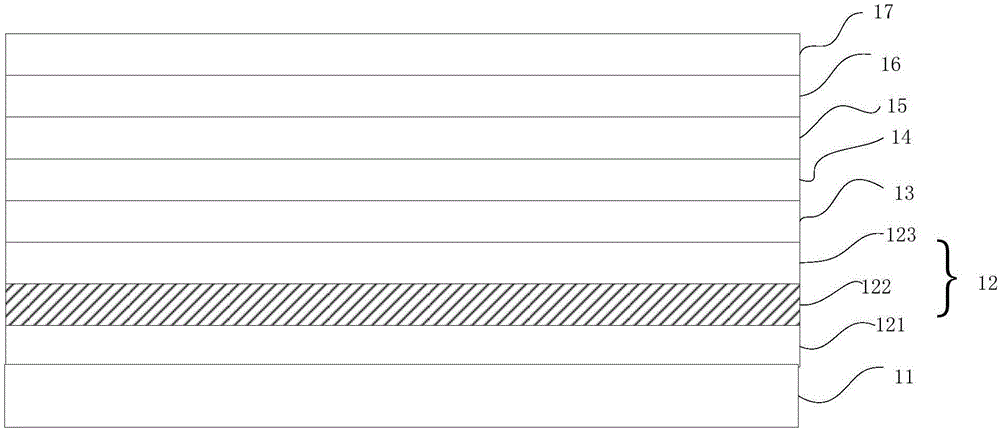

An organic light emitting diode device and array substrate having the organic light emitting diode are provided. The organic light emitting diode device of the embodiment of the present invention can reduce a resistance of the transparent anode, which is used for providing holes, in a horizontal direction through setting two transparent anode layers and disposing a metal layer therebetween, and further can improve a horizontal conductivity of the transparent anode, thereby solving the problem of uneven light emission of the organic light emitting diode device due to the greater horizontal resistance of the transparent anode for improving the quality of the screen display having the array substrate.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

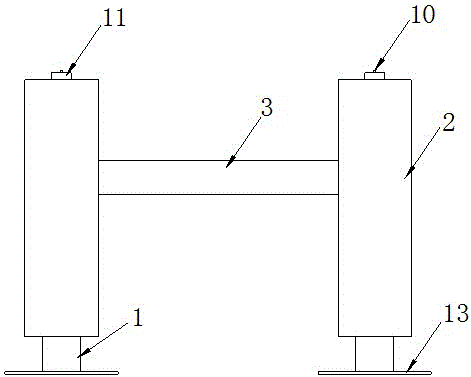

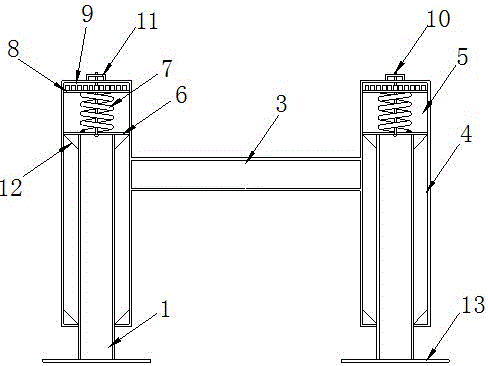

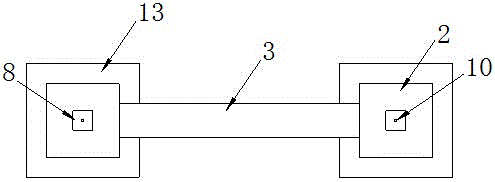

Spring damping vibration attenuation pipeline support with adjustable prestress

InactiveCN105042196APlay the function of vertical vibration dampingEliminate the disadvantage of low horizontal resistancePipe supportsNon-rotating vibration suppressionVibration attenuationVertical vibration

The invention provides a spring damping vibration attenuation pipeline support with the adjustable prestress. The spring damping vibration attenuation pipeline support comprises two uprights and upright sleeves, wherein the upper ends of the uprights are sleeved with the upright sleeves. The upright sleeves are connected through a connecting beam. Vibration attenuation cavities are formed in the upright sleeves. Damping springs are arranged in the vibration attenuation cavities. The upper ends of the uprights pass through upright channels and buffering vibration attenuation is achieved through the damping springs in the vibration attenuation cavities. Pull rods are arranged between the uprights and the upright sleeves. The distances between the uprights and the upright sleeves are adjusted through nuts at the screw ends of the pull rods, so that the prestress applied by the pull rods is adjusted. Through the adoption of the spring damping vibration attenuation pipeline support, the springs and a common support are combined together to form the spring damping vibration attenuation pipeline support; the vertical vibration attenuation effect is achieved through the springs; the uprights and the sleeves provide horizontal resistance; the defect that a common vibration attenuator is small in horizontal resistance in the prior art is overcome; the effective length of the pull rods with screws arranged at the ends can be adjusted through the nuts; the prestress adjusting purpose is achieved; and the prestress adjusting function which cannot be achieved by the common vibration attenuator is added.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

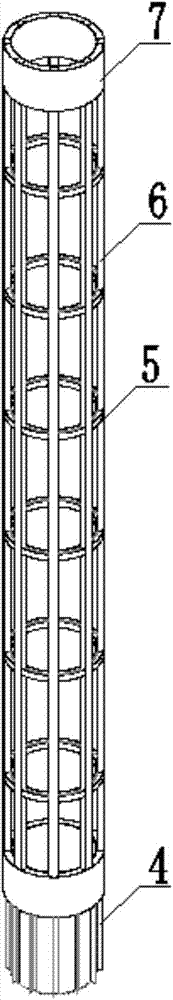

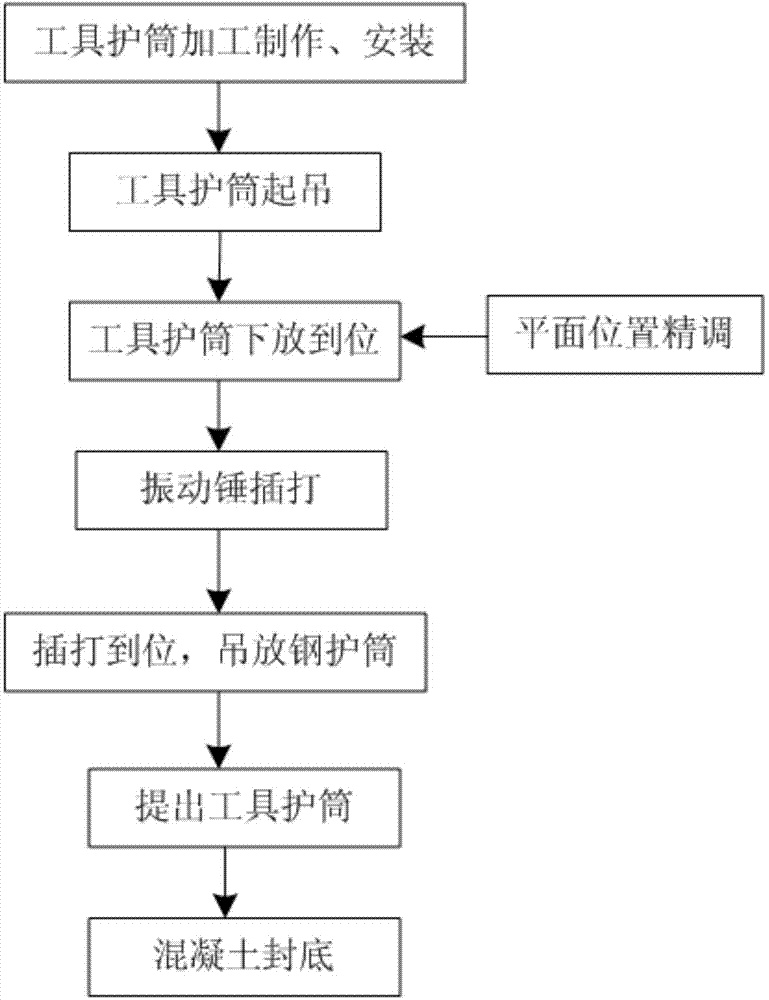

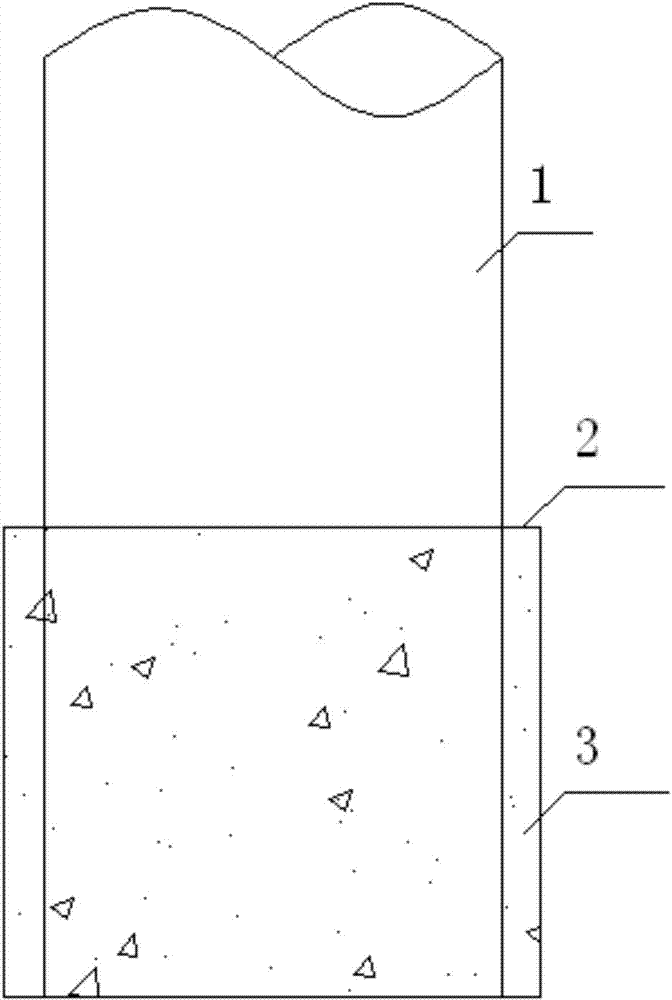

Method for accurately implanting large-diameter pile casing into strong wave flow force inclined bare rock

The invention creatively provides a method for accurately implanting a large-diameter pile casing into a strong wave flow force inclined bare rock. The method includes the following steps that the tool pile casing is machined, manufactured and installed in place; the tool pile casing is hoisted to the position of a corresponding pile foundation and placed in water until the seabed surface; the position of the tool pile casing is monitored and accurately adjusted; the tool pile casing is inserted and hit; after the tool pile casing enters a rock stratum by a certain depth, a cast-in-situ bored pile steel pile casing is implanted into a hole along the tool pile casing; the tool pile casing is pulled out; the hole is filled with installing guide pipe pouring high-diffusion self-flowing concrete, and then the bottom of the steel pile casing is fixedly connected with the rock stratum. Due to the fact that in the tool pile casing, steel pipe concrete pipes mainly serve as bearing force dowel steel pieces, the water facing and wind facing areas are reduced, impact of tides and wave force on the tool pile casing is reduced, it is guaranteed that the position of the tool pile casing is adjusted accurately, the influence of horizontal resistance on the pile casing can be reduced, the plane position of the large-diameter steel pile casing is effectively controlled, and the steel pile casing is accurately implanted into the rock stratum.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

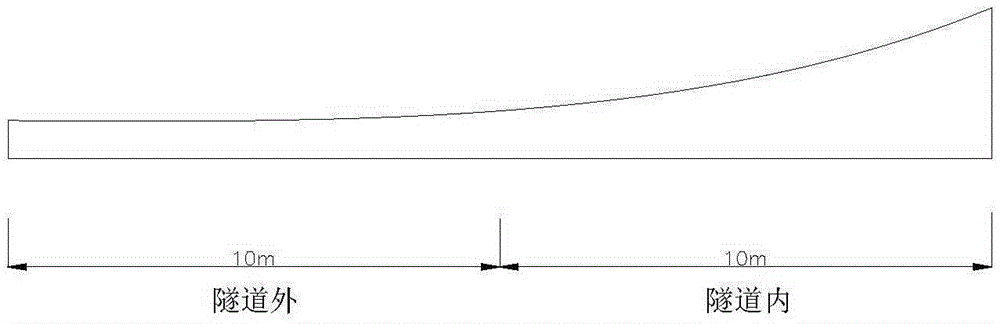

Bridge-tunnel transition section continuously welded rail track stability analysis method under extreme temperature condition

ActiveCN105354391AResearch forceStudy the law of deformationSpecial data processing applicationsEngineeringExtreme temperature

The invention discloses an analysis method of bridge-tunnel transition section continuously welded rail track stability under an extreme temperature condition. The method comprises the following steps: (1) establishing a bridge-tunnel transition section continuously welded rail track complete model, wherein steel rails, sleepers and bridges are simulated through the adoption of beam units, fastener longitudinal-horizontal resistance and railway ballast longitudinal-horizontal resistance are simulated through the adoption of nonlinear springs, pier top anti-pushing rigidity is simulated through the adoption of a linear spring, a roadbed packing layer and the tunnel part are simulated through the adoption of entity units; (2) applying initial bending on a track structure through the whole model buckling mode analysis; (3) applying longitudinal nonlinear temperature load on the model aiming at an extreme temperature feature so as to research the horizontal deformation rule of the bridge-tunnel transition section continuously welded rail track. In fully consideration of nonlinear interaction among various structures, the initial defect is applied to the model based on the buckling mode, the analysis result is more suitable for the actual condition, and an important method for analyzing the stability of the continuously welded rail track under the extreme temperature condition is provided.

Owner:CENT SOUTH UNIV

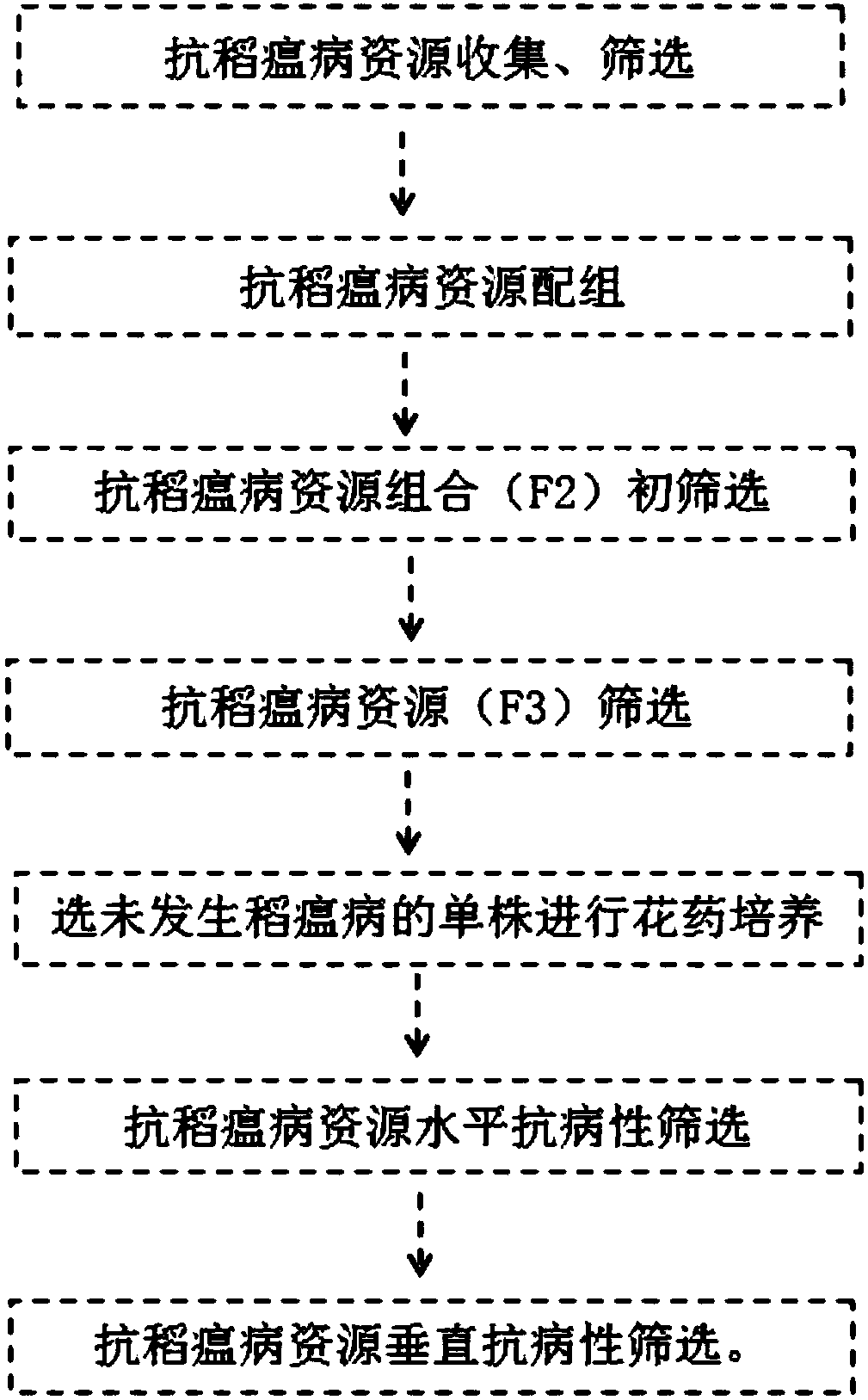

Breeding method for rice with high and stable resistance to rice blast

ActiveCN107593427AReduce workloadImprove the breeding effectPlant tissue cultureHorticulture methodsDiseaseCell division

The invention discloses a breeding method for rice with high and stable resistance to rice blast. By means of high-density direct seeding of F2 in the earlier stage, construction of rice blast resistant hybridized combinations, induction of rice blast with an environmental induction method and quantitative seeding of F3, the hybridized combination with rice blast resistant potential is effectivelyscreened, screening workload is reduced, and breeding effect is improved; furthermore, seedling cultivation density has no difference in the seedling stage, influence of cultivation density on rice blast induction is reduced, and single-plant rice blast resistant breeding effect is improved; by the aid of all-region planting, induction and screening of the rice blast resistant combination, loss of horizontal resistance resource of rice blast is prevented, and the combination has general and stable resistance to physiological strains; resistance level of the selected rice combination to localdominant physiological strains is improved through vertical disease resistance screening, and characteristics of stable resistance is further improved under inoculation identification of the local dominant physiological strains of rice blast; besides, under the action of medium optimization, callus differentiation and cell division are effectively promoted, and anther-culture breeding efficiency is improved.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

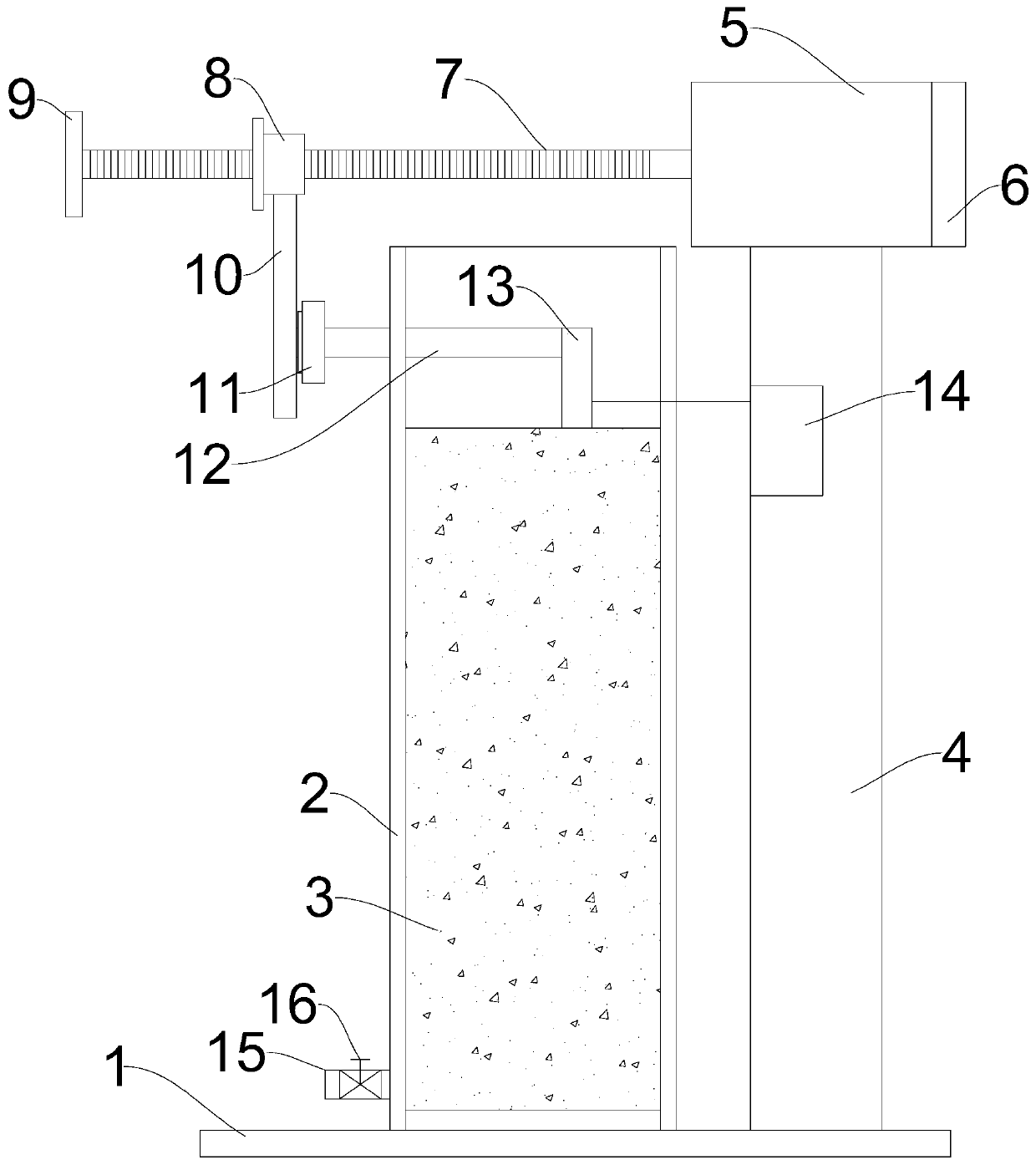

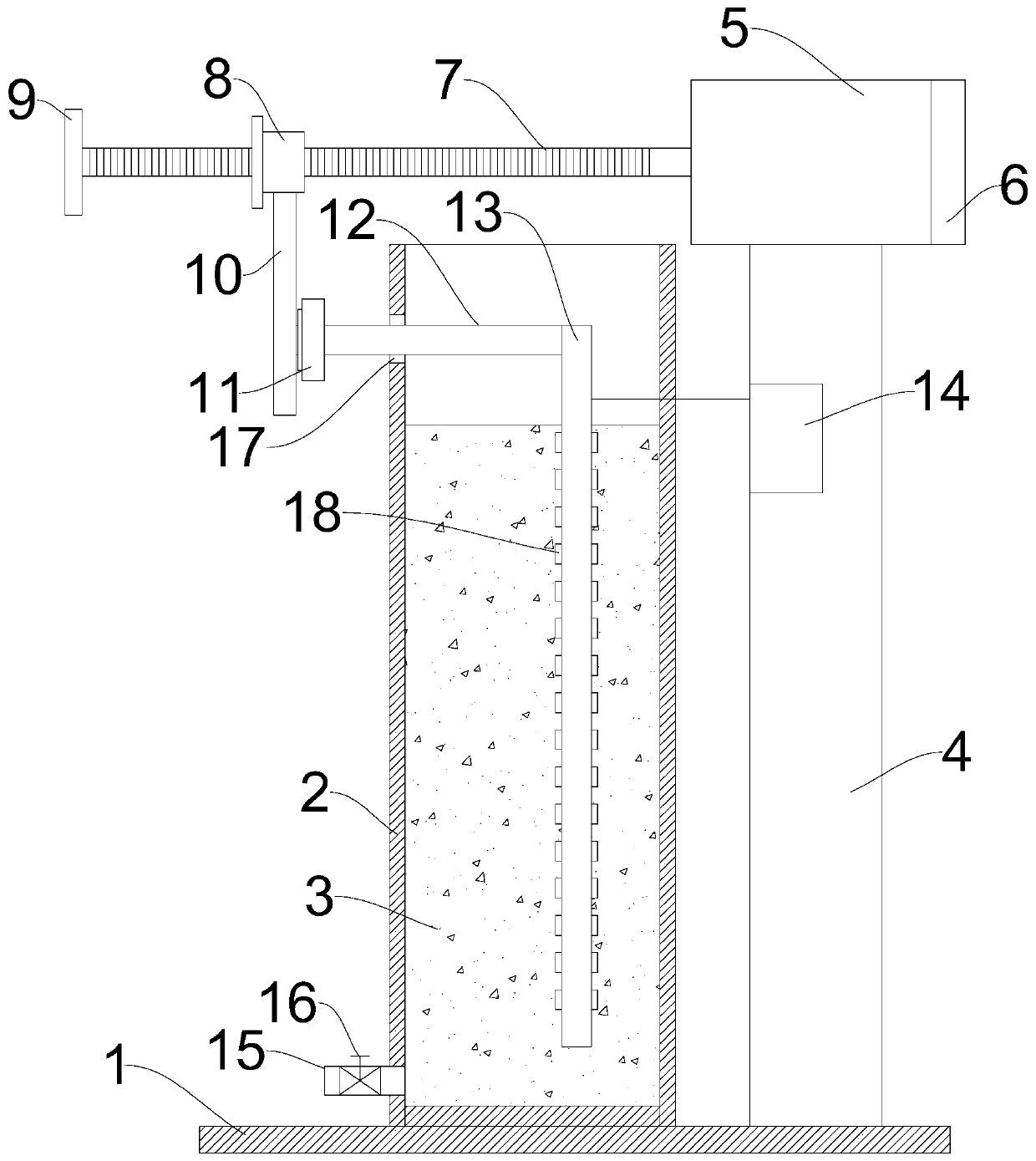

Horizontal static load test device for CT scanning, and method

PendingCN109883822ASimple structureImprove stability researchMaterial analysis using wave/particle radiationMaterial strength using tensile/compressive forcesComputed tomographyData acquisition

The invention relates to a horizontal static load test device for CT scanning, and a method, and belongs to the technical field of geotechnical engineering and geological engineering testing. The horizontal static load test device in the invention comprises a base, a transparent test box, a servo motor, a transmission device and a vertically arranged model pile; the transparent test box is filledwith a soil sample; a vertically arranged transparent support column is arranged at one side of the transparent test box; the top of the transparent support column is fixedly connected with the servomotor; the output end of the servo motor is fixedly connected with the top of the model pile through the transmission device; multiple strain gages are arranged on the outer wall of the model pile; and a data acquirer is also fixedly arranged at the side edge of the transparent support column. The test device in the invention has the benefits that: the test device can be used for monitoring the horizontal resistance of the soil sample at the side of the model pile and the horizontal load of the model pile, so that a p-y curve is obtained; and, the test device can be used for scanning by beingput on an industrial CT turntable, so that deformation of the soil sample and evolution of a shear zone can be observed.

Owner:GUIZHOU MINZU UNIV

Novel by-stage construction carbon fiber confined concrete laminated column

InactiveCN108316559AImprove bearing capacityImprove seismic performanceStrutsPillarsFiberCarbon fibers

The invention discloses a by-stage construction carbon fiber confined concrete laminated column. The by-stage construction carbon fiber confined concrete laminated column is the combination of internal carbon fiber and core concrete, and the combination of carbon fiber in a bottom area and peripheral reinforced concrete, and is a multi-combination confined carbon fiber concrete laminated column. External carbon fiber cloth in the bottom area facilitates improving of horizontal resistance, ductility and the energy dissipation ability of the laminated column; due to the fact that column damage generally occurs at the reinforced concrete part on the periphery of the bottom, through strengthening of the bottom, the cross section area of the laminated column can be effectively decreased, the building using area is increased, and the self-weight is reduced. As for the by-stage construction carbon fiber confined concrete laminated column, the core concrete and internal carbon fiber cloth areconstructed first to bear first-stage axial force, after a certain number of floors is constructed, and the peripheral reinforced concrete part and the carbon fiber cloth at the bottom area are constructed to form the carbon fiber confined concrete laminated column to together bear the horizontal load effect and second-stage axial force; and the by-stage construction carbon fiber confined concretelaminated column can well solve the problem that the column-shaft compression ratio of several floors at the bottom of a high-rise building structure exceeds the limit.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com