Self counter force balance loading test method of engineering pile bearing capacity

A technology of reaction force balance and testing method, applied in the direction of foundation structure engineering, foundation structure test, construction, etc., can solve the problems of waste, long construction period, affecting the normal use of engineering piles, etc., to achieve the effect of saving costs and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

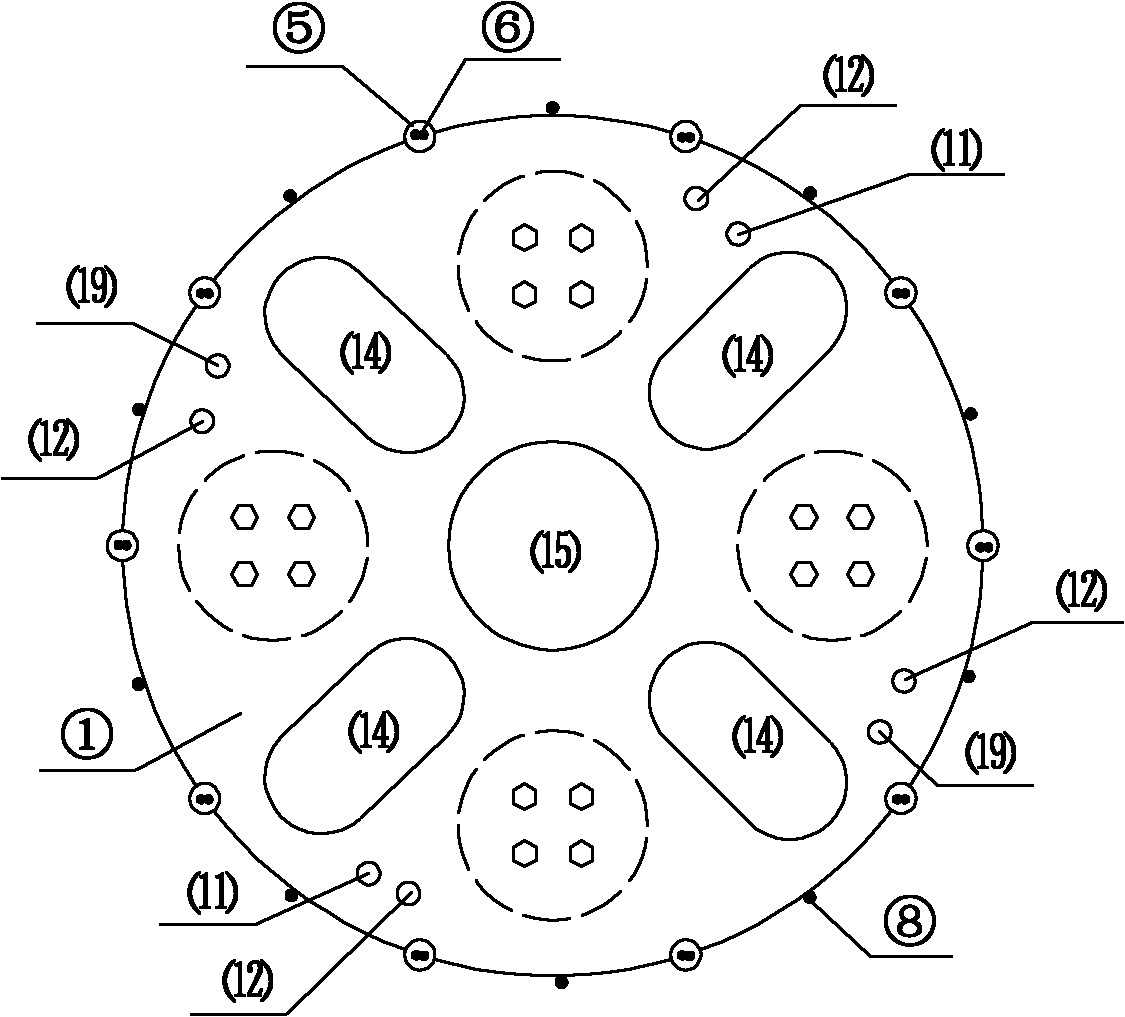

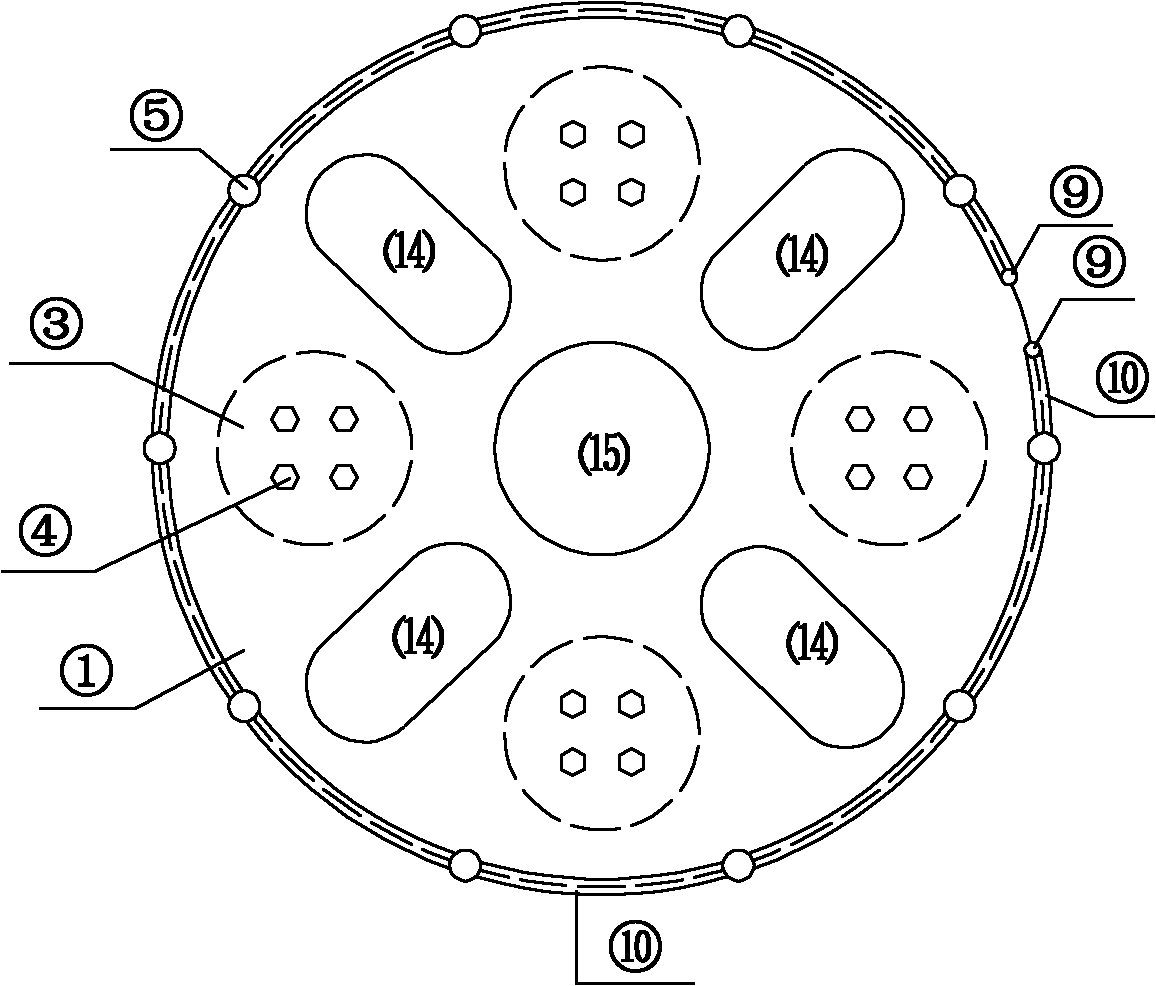

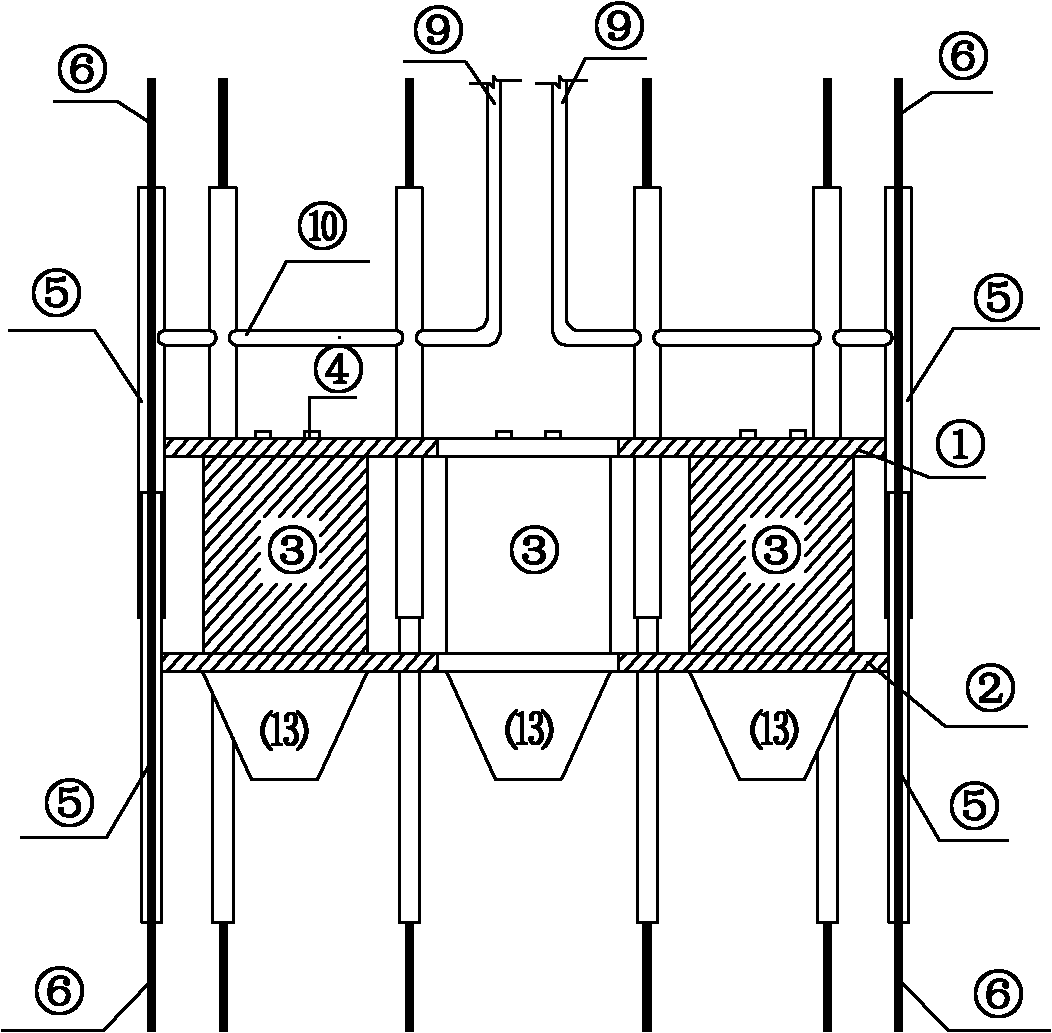

[0024] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described, and this embodiment is the engineering pile that design bearing capacity is 20000kN, and pile length 56m, and pile diameter is 2500mm, and pile body main reinforcement diameter 28mm, pile length 28.5m above set 40 There are 20 main reinforcements below the pile length of 28.5m. The load box is buried at a distance of 12.5m from the pile end, and the stirrup spacing within the range of 3m below the top and bottom cover plates of the load box is increased to 10cm. The horizontal force at the top of the pile is 5000kN, the bending moment is 1200kN m, the bending moment at the load box is 150kN m, and the maximum one-way jacking force of the load box is designed to be 24000kN.

[0025] figure 1 It is a schematic plan view of accessories such as the load box, the main reinforcement of the reinforcement cage and the threaded reinforcement in the embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com