Patents

Literature

43results about How to "Increase horizontal resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

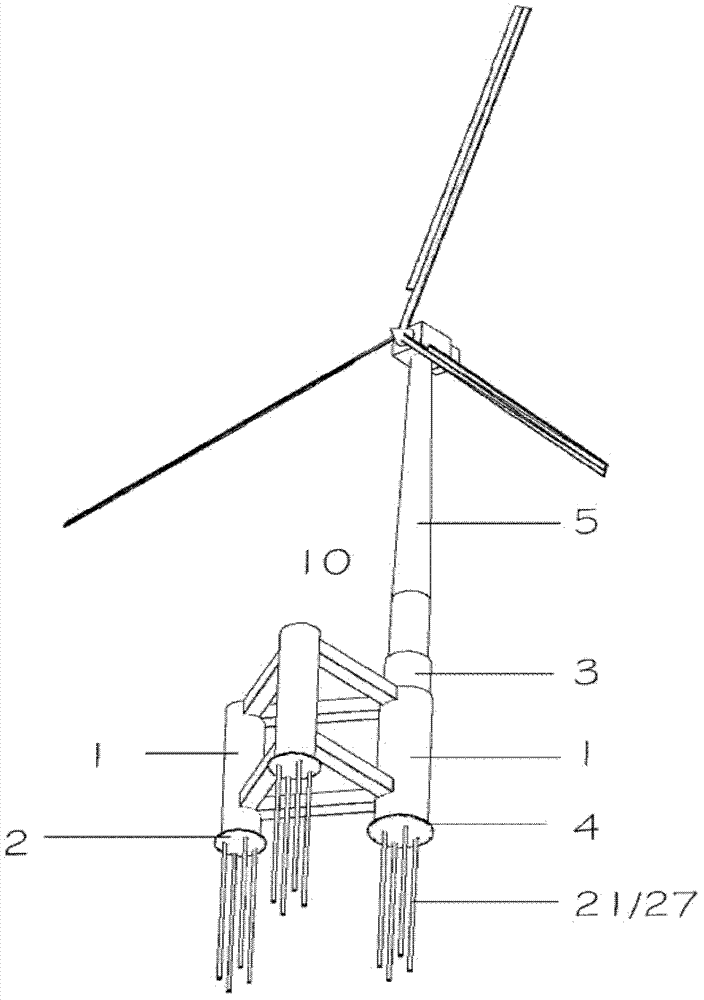

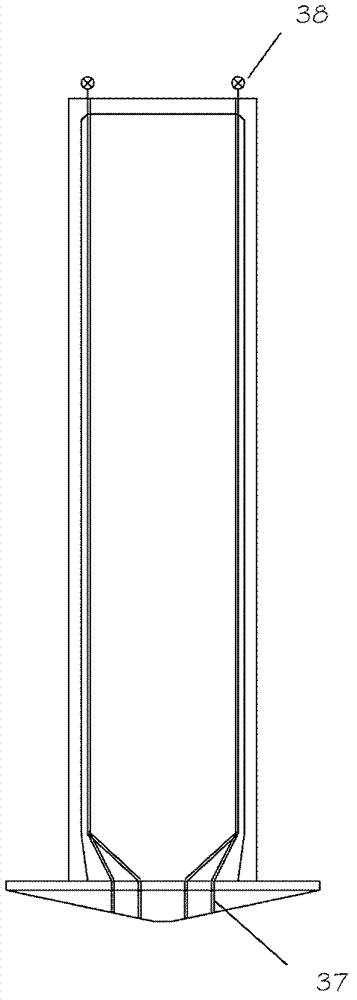

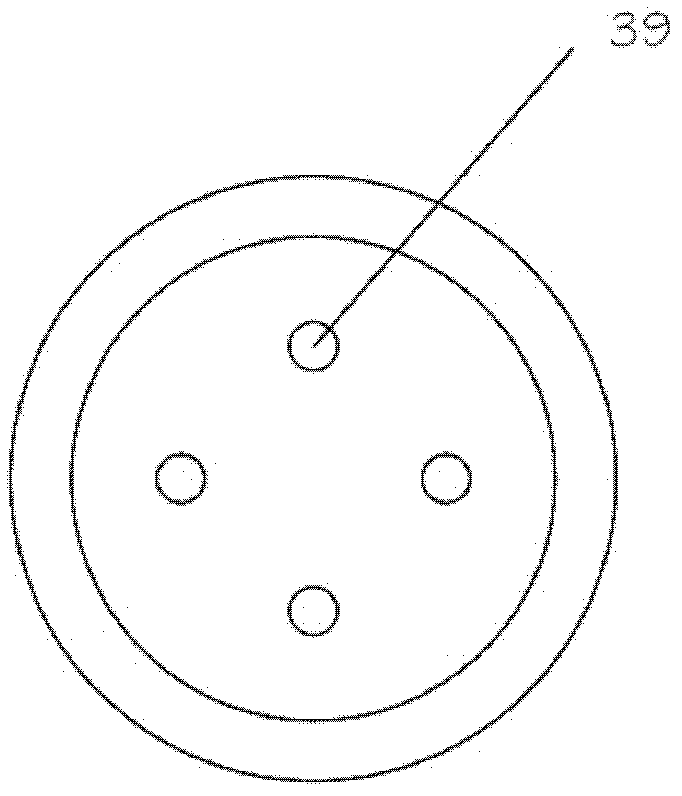

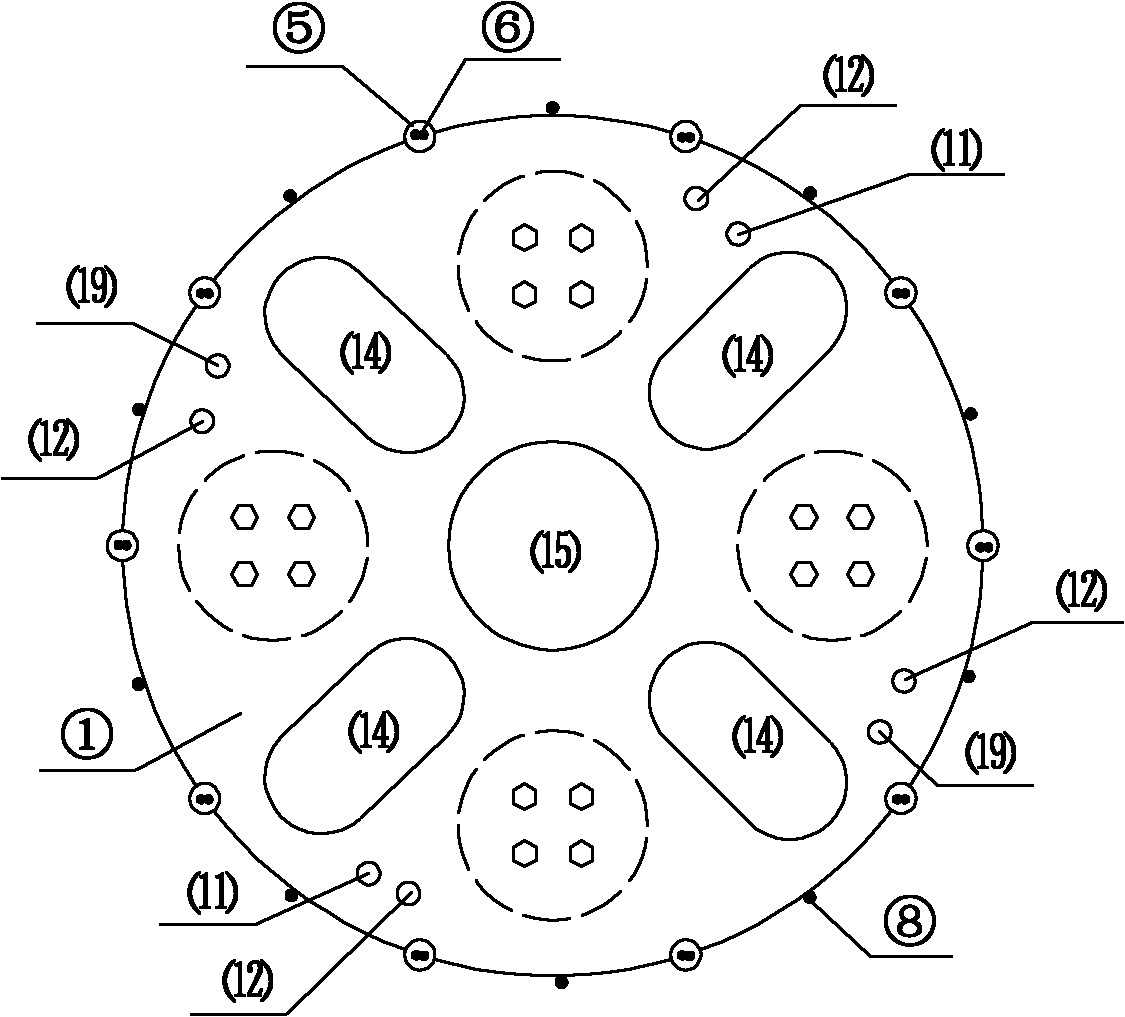

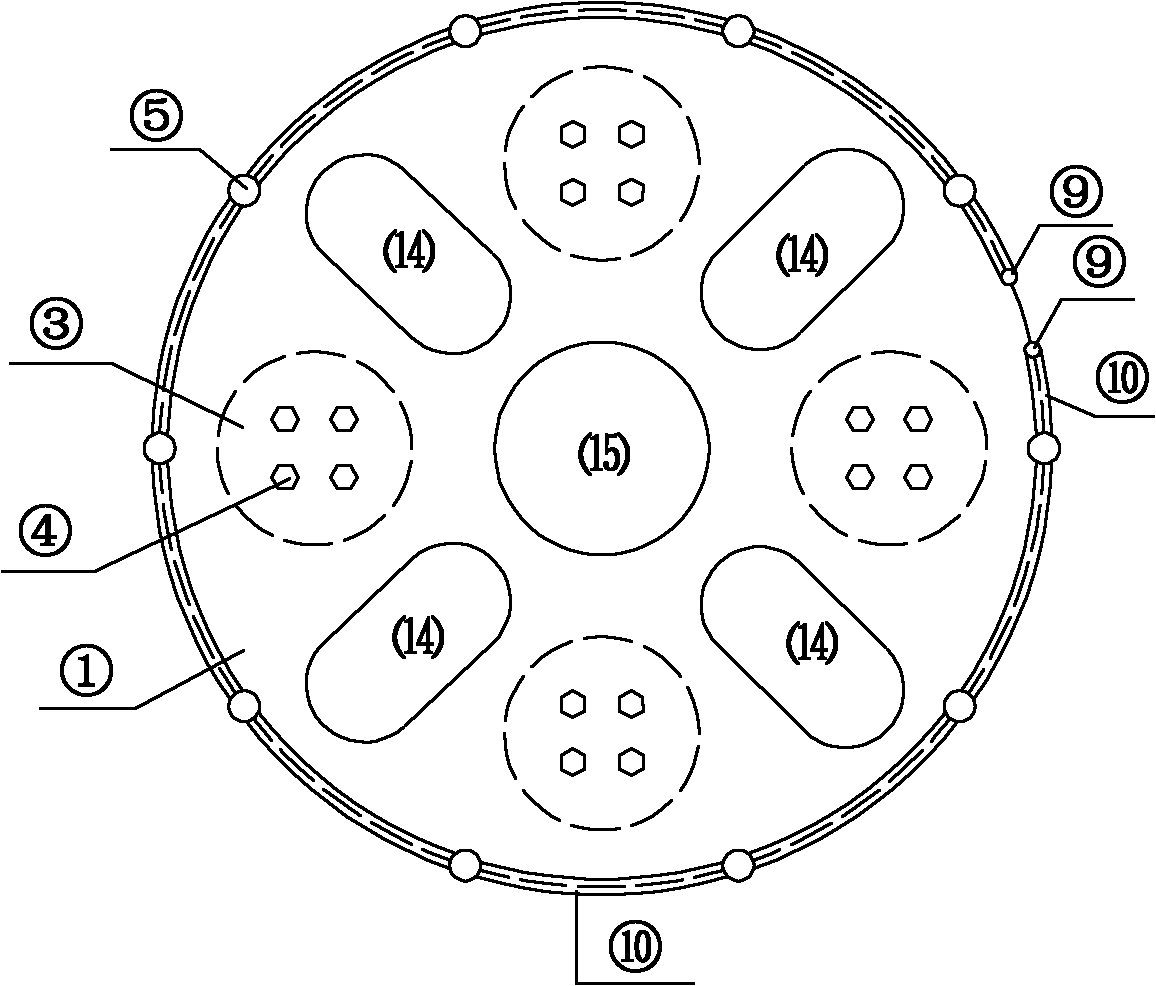

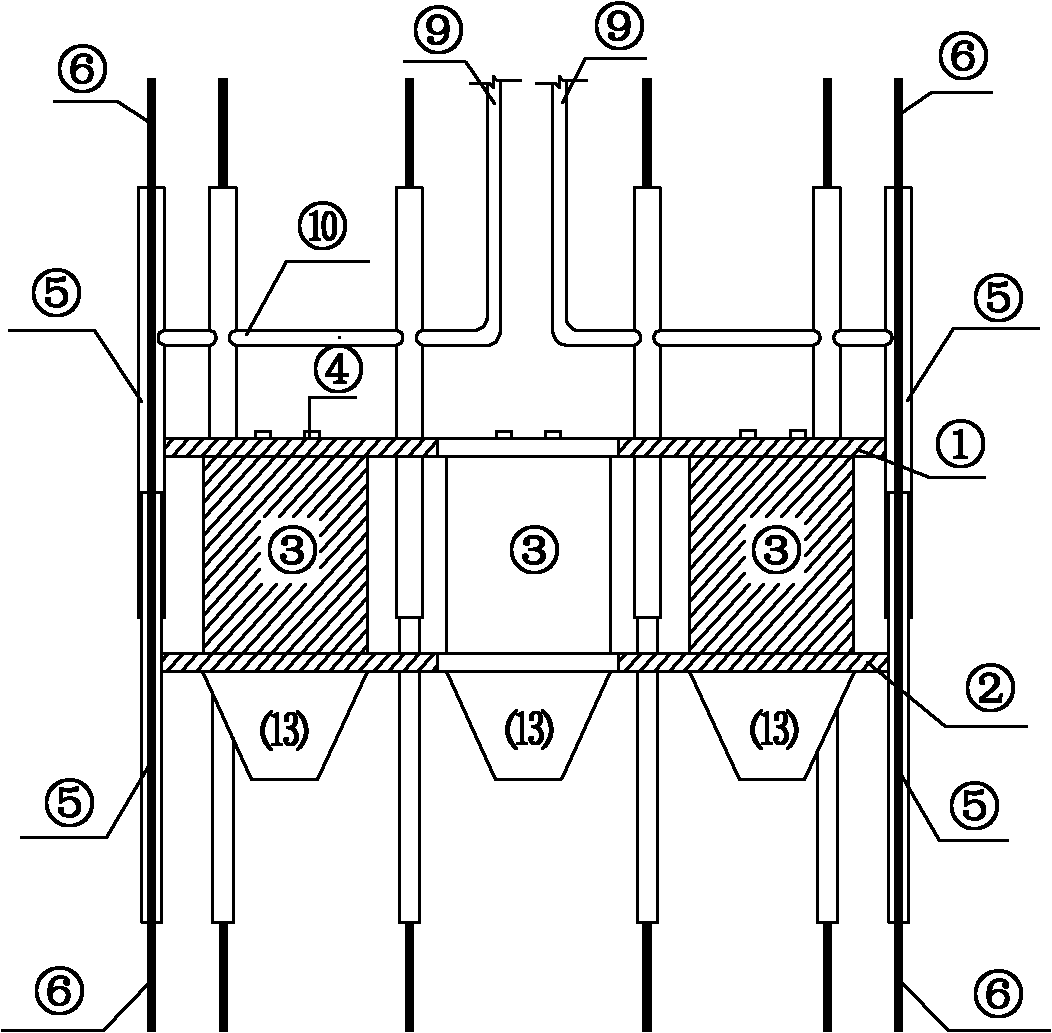

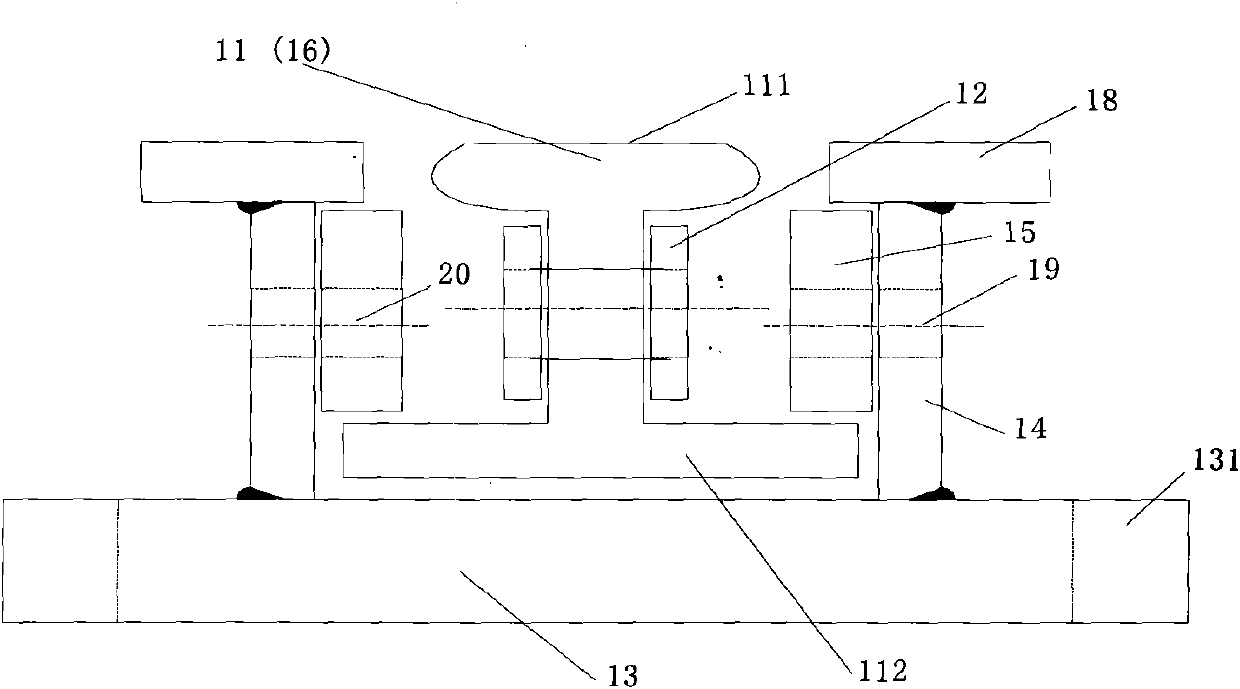

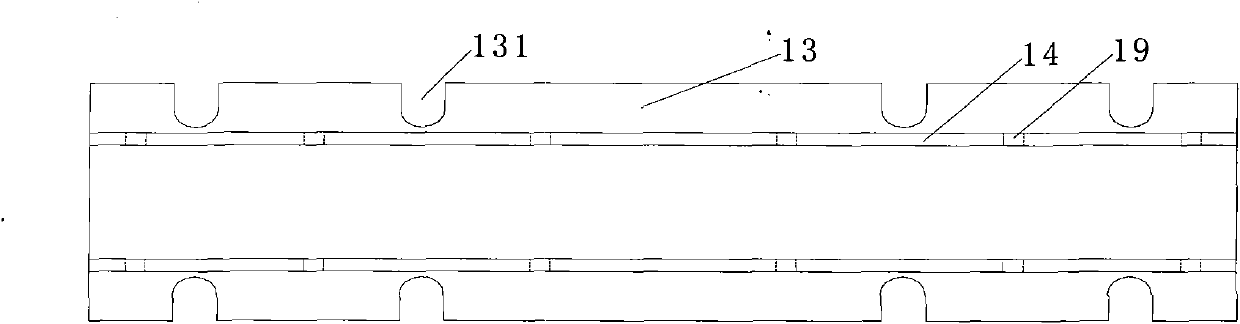

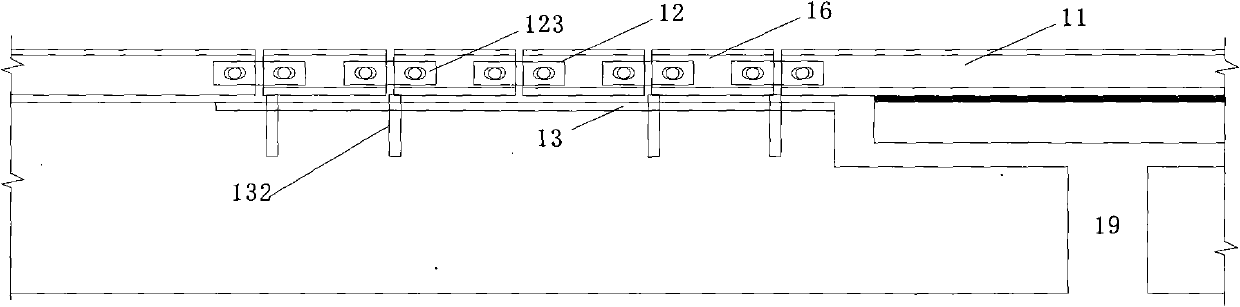

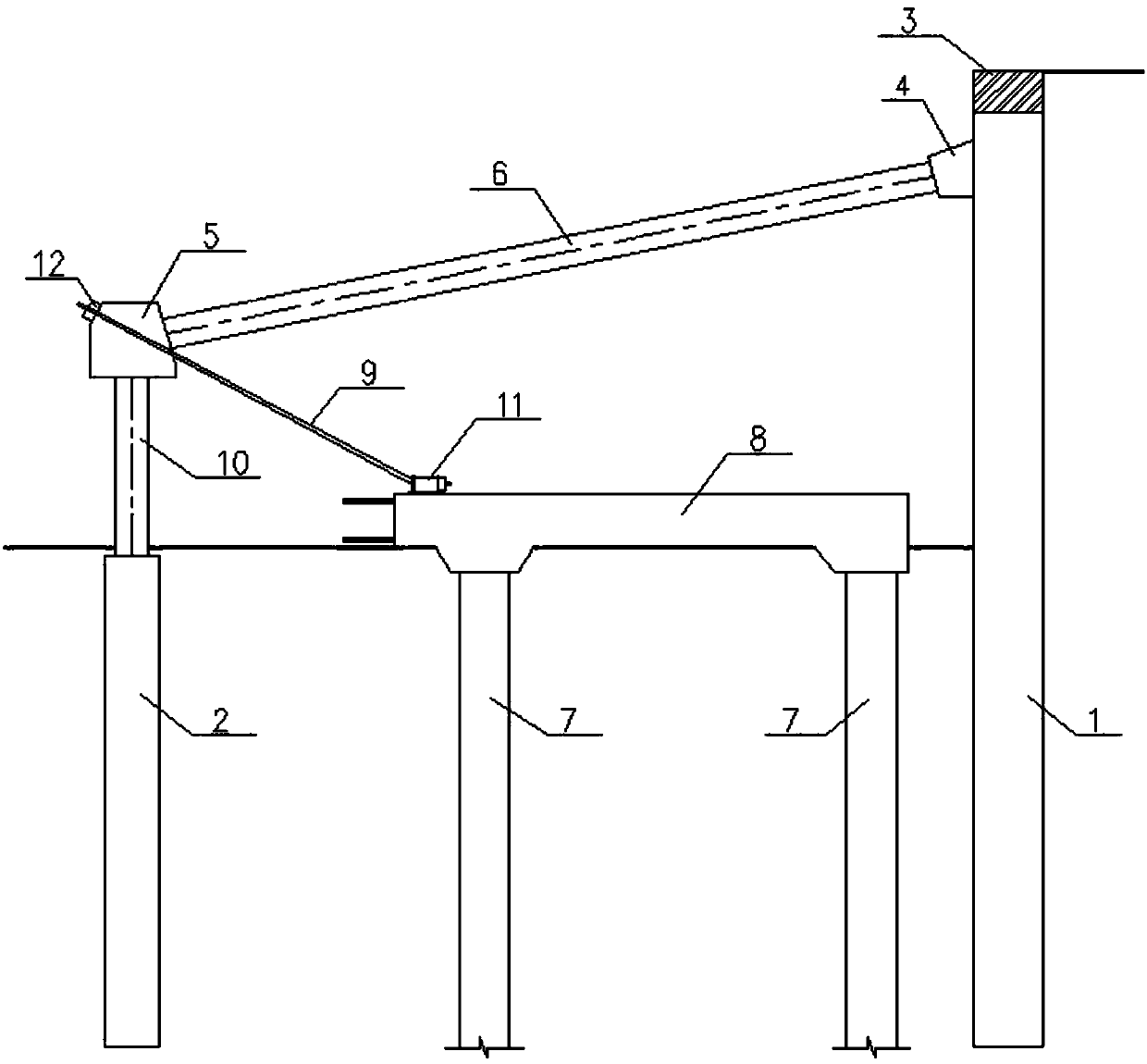

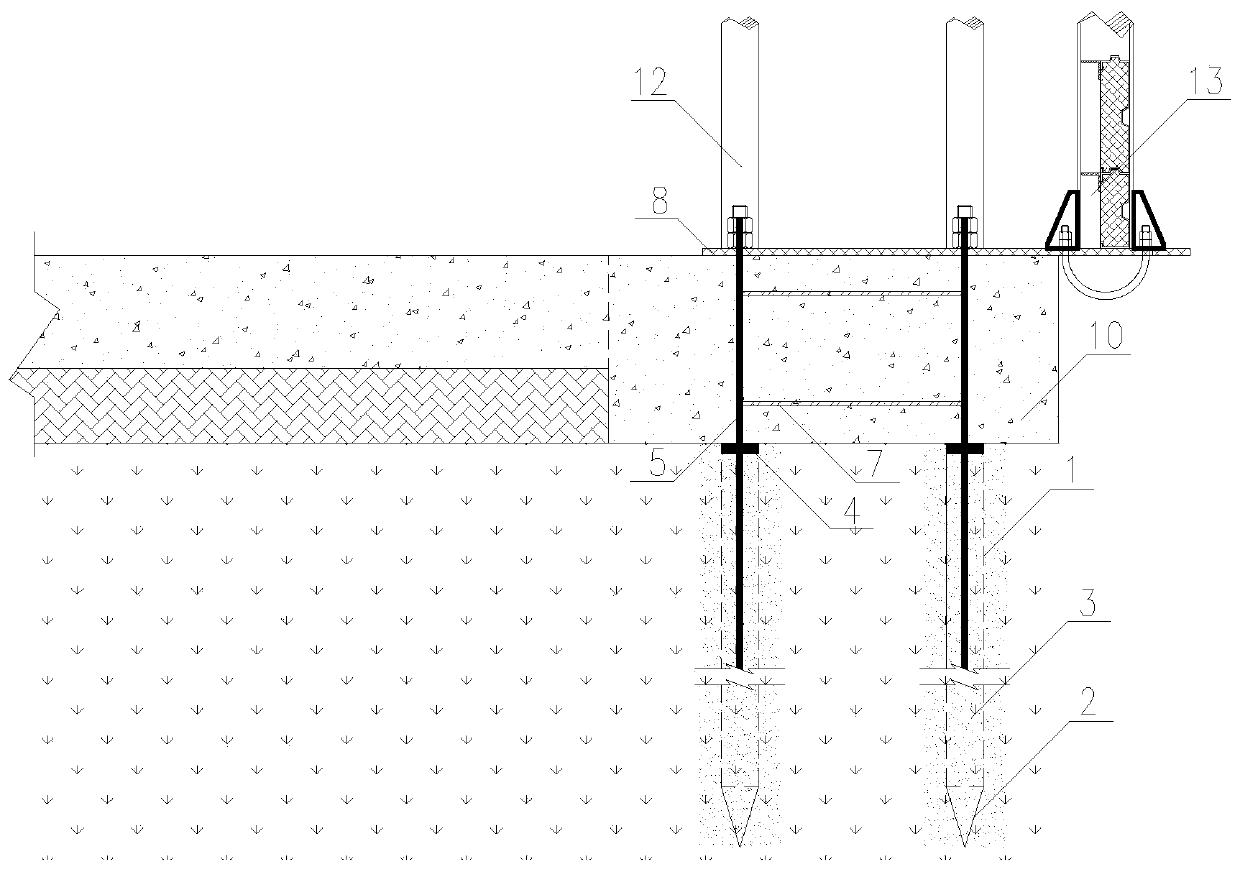

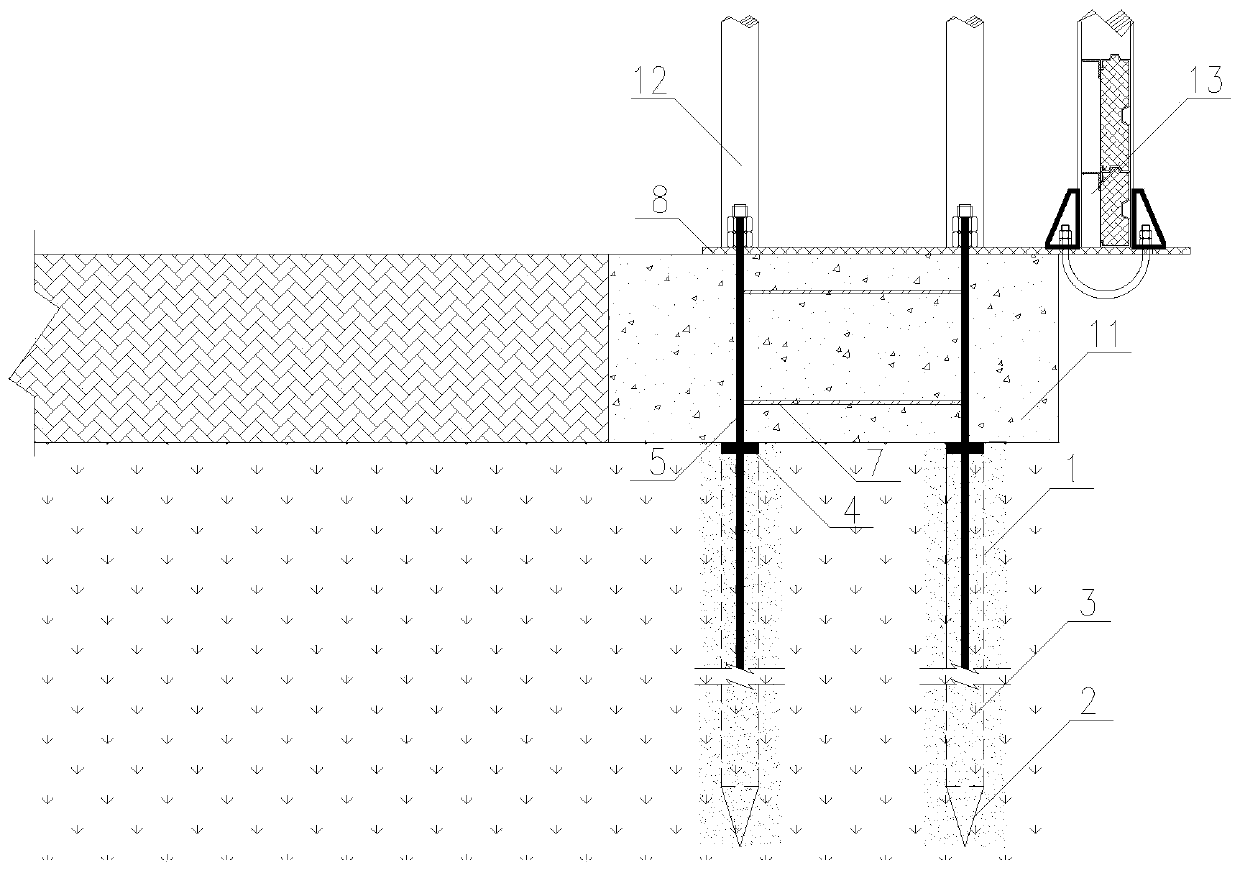

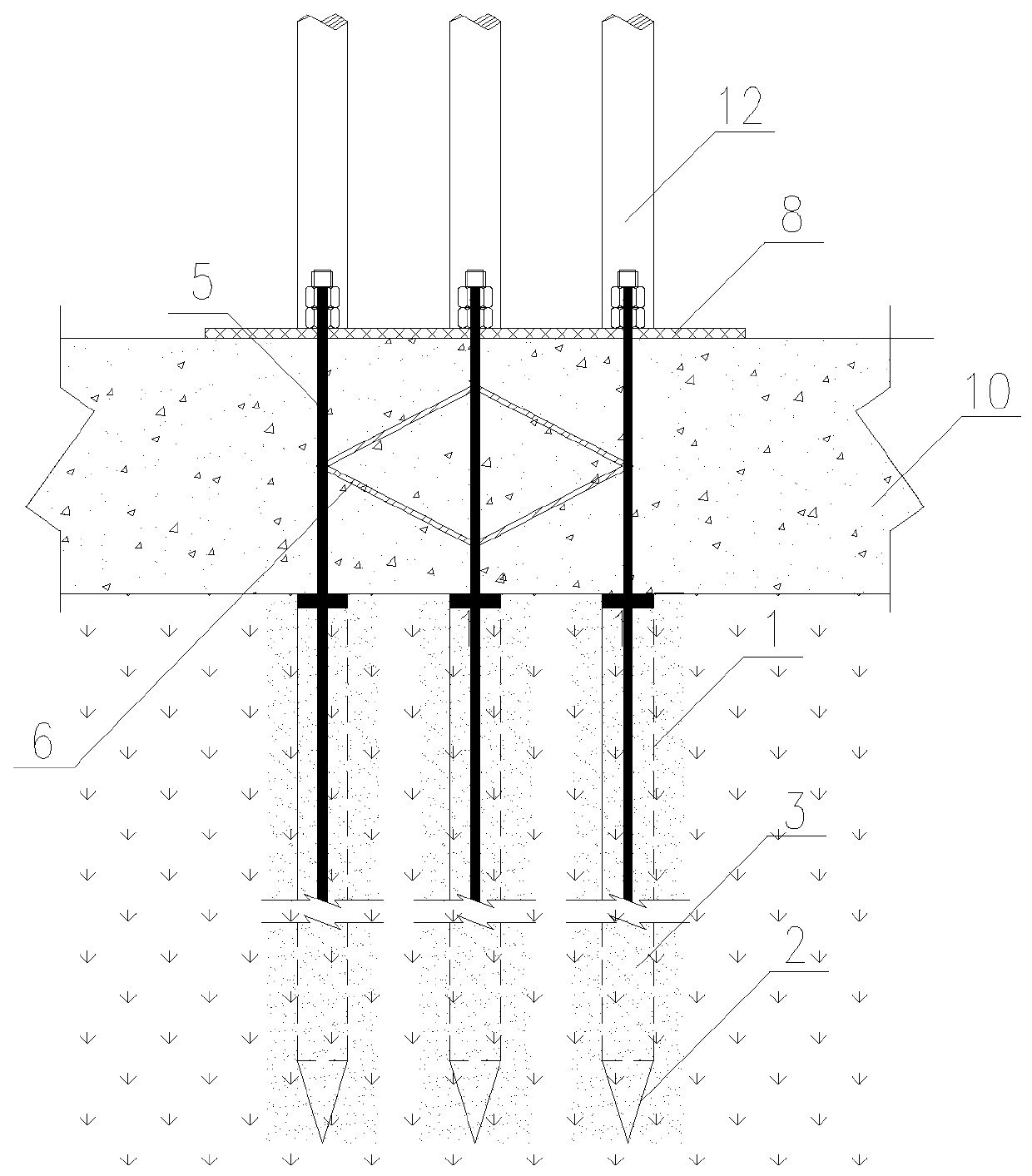

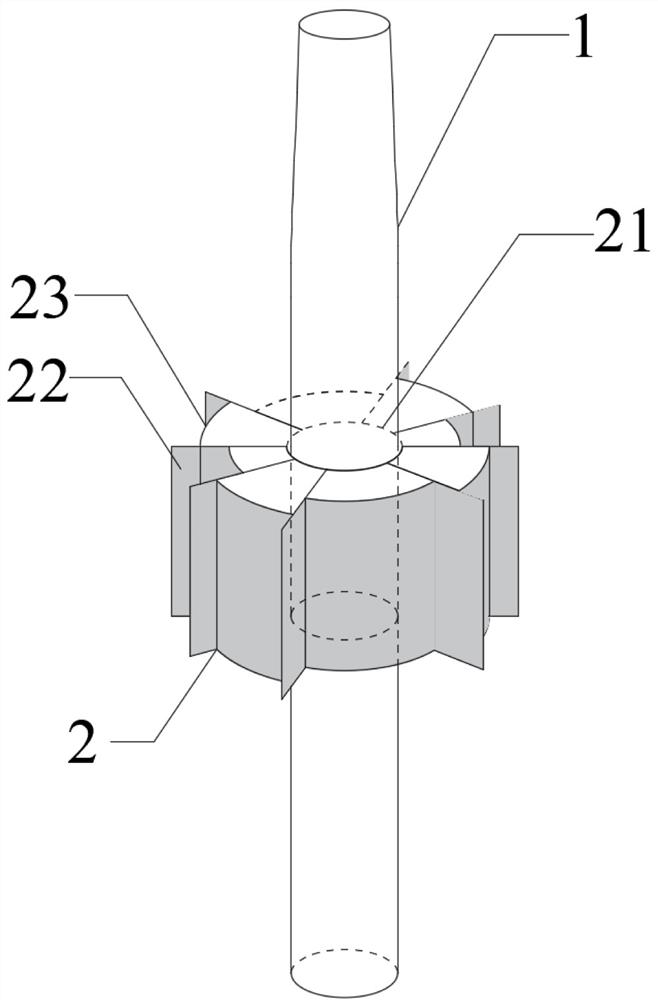

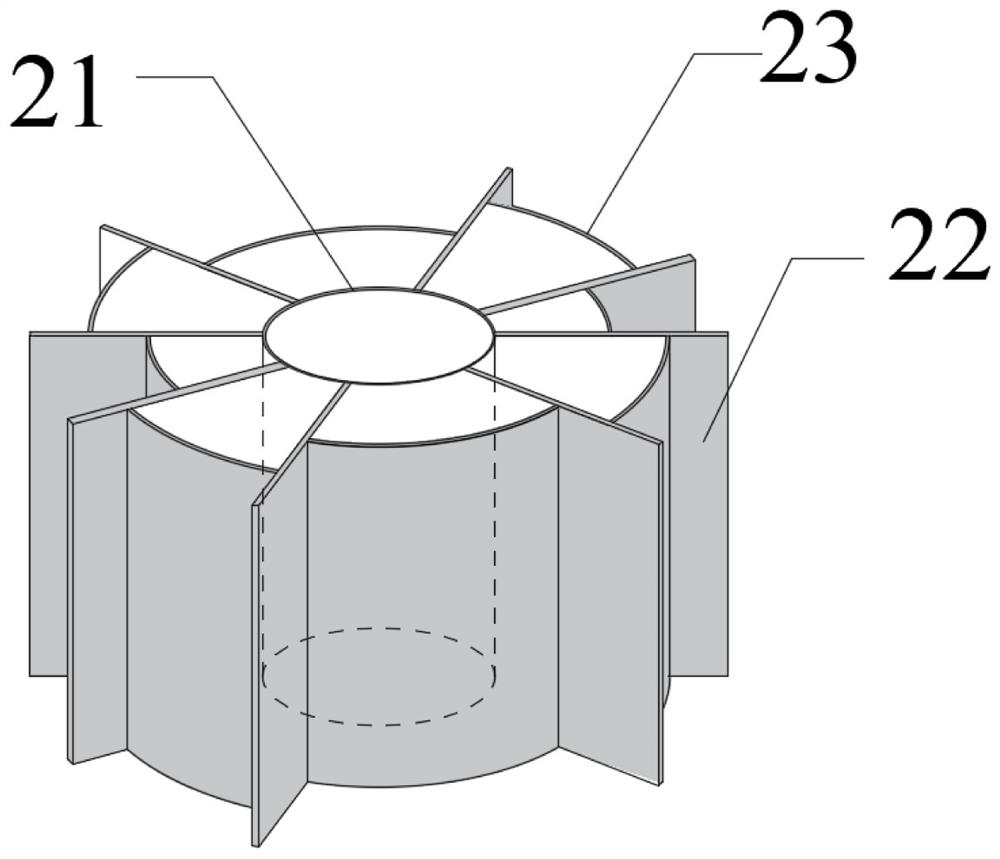

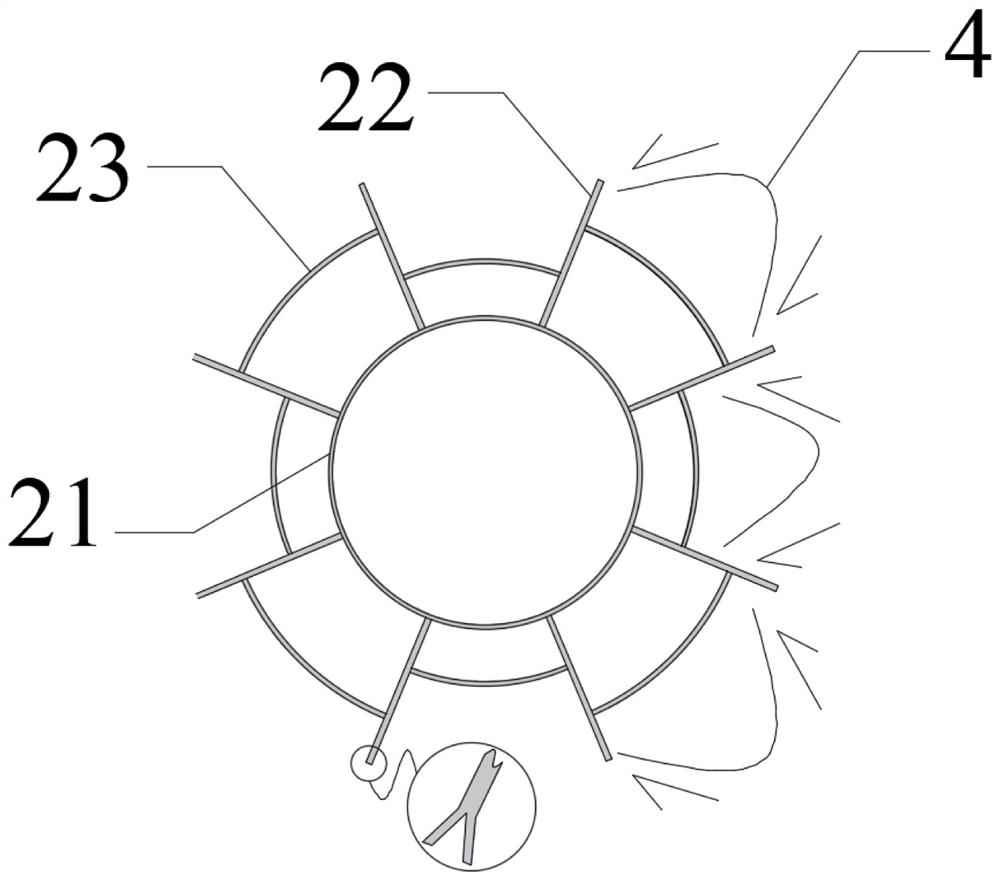

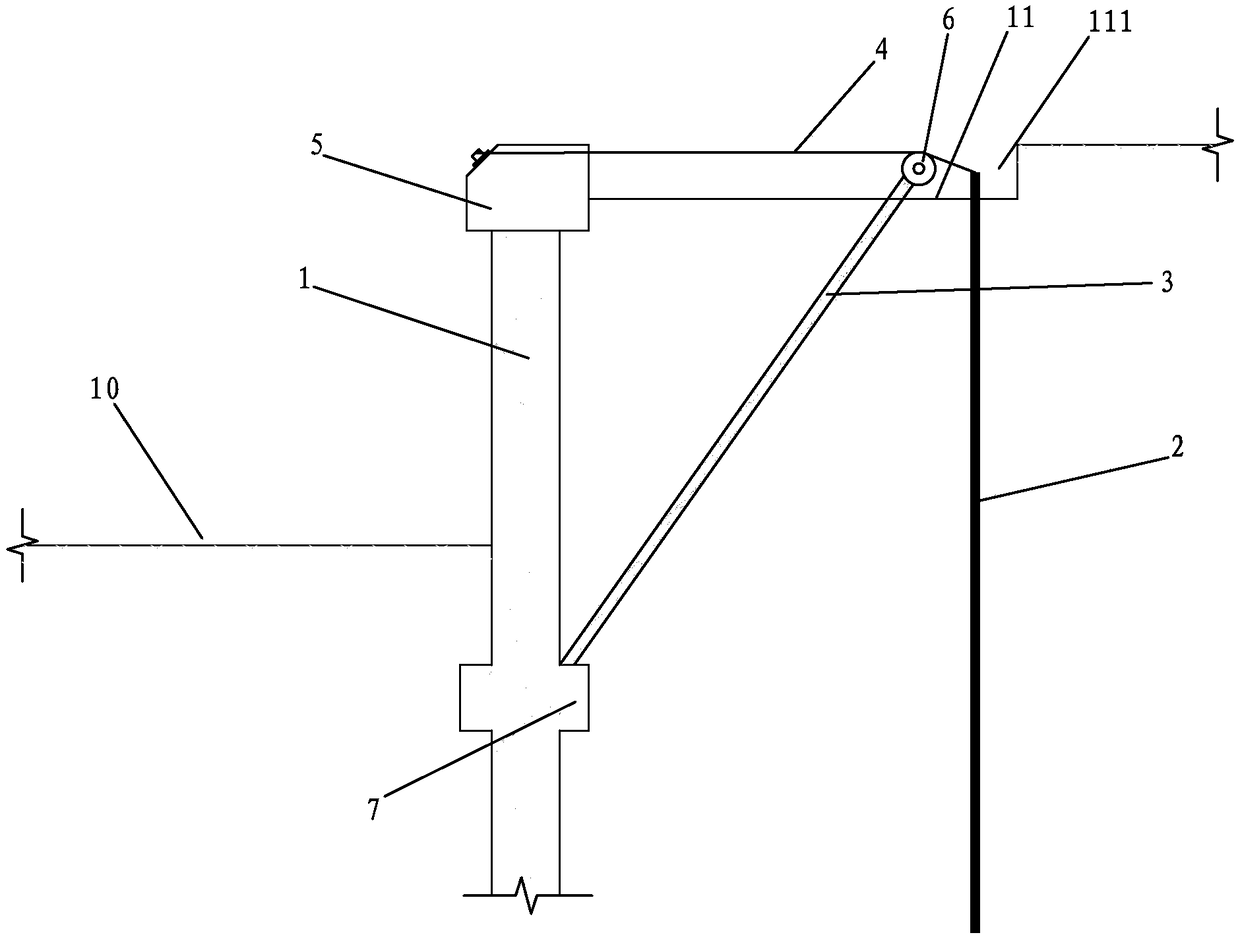

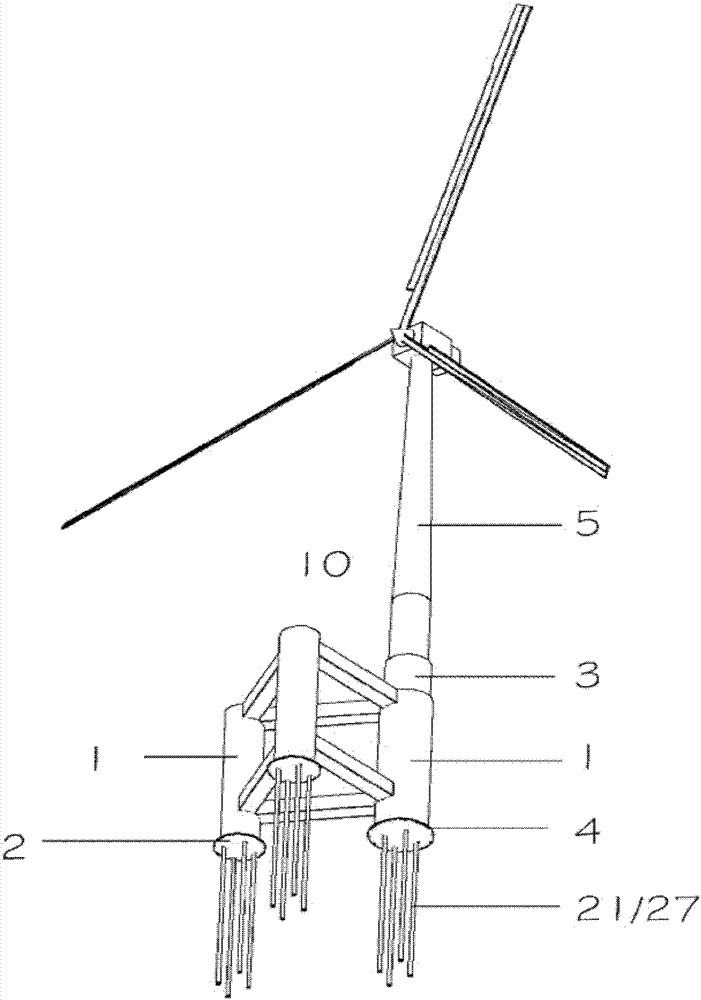

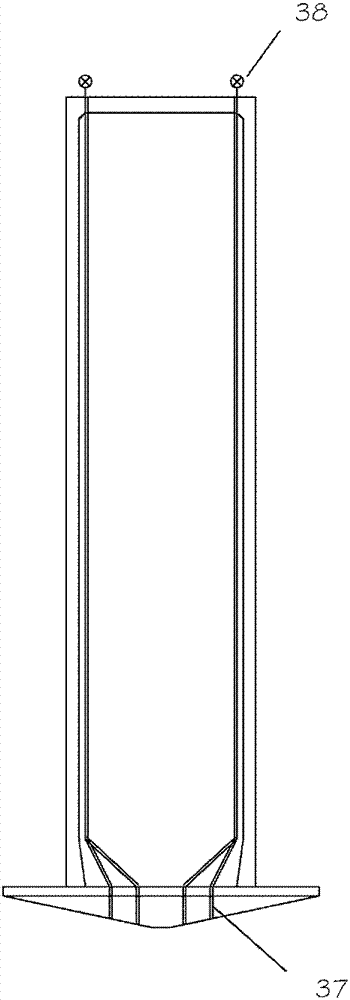

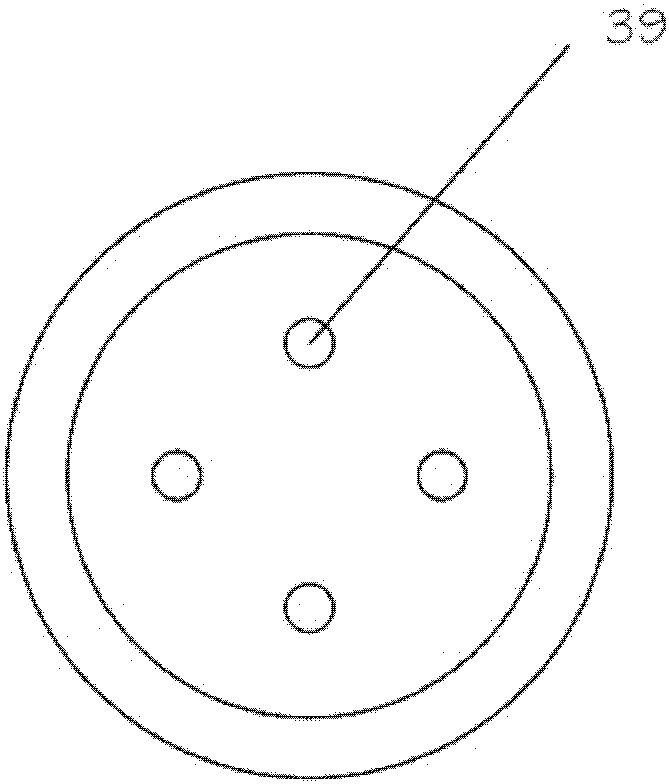

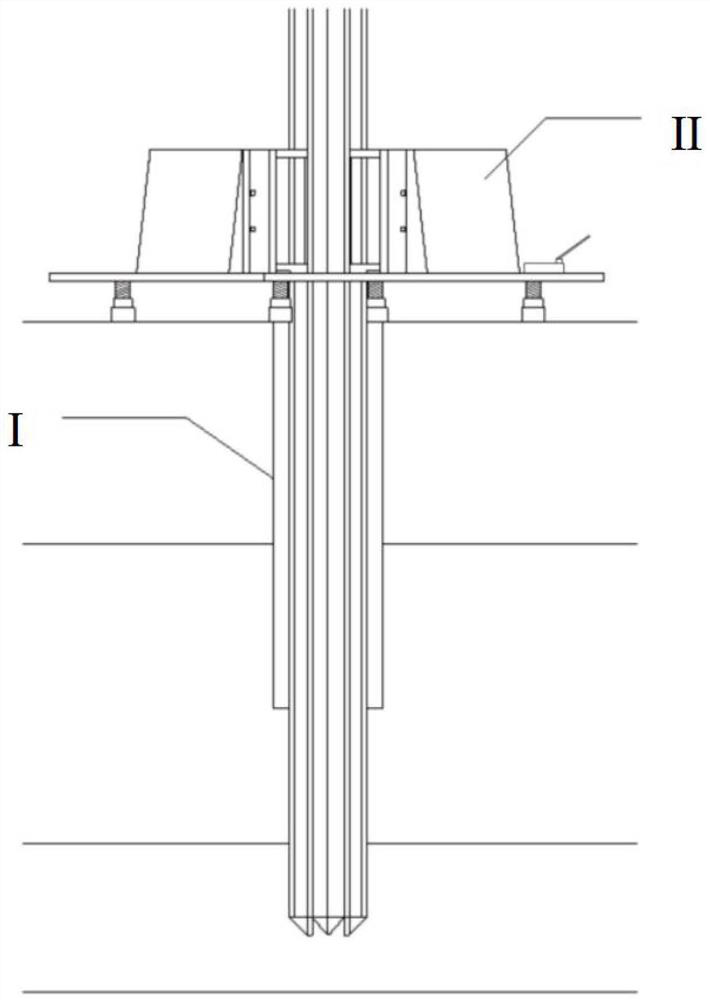

Local buoyancy ocean platform of offshore wind power, bridge and ocean structure, and construction method

ActiveCN103362113AIncrease horizontal resistanceImprove stabilityArtificial islandsUnderwater structuresMarine architectureMulti platform

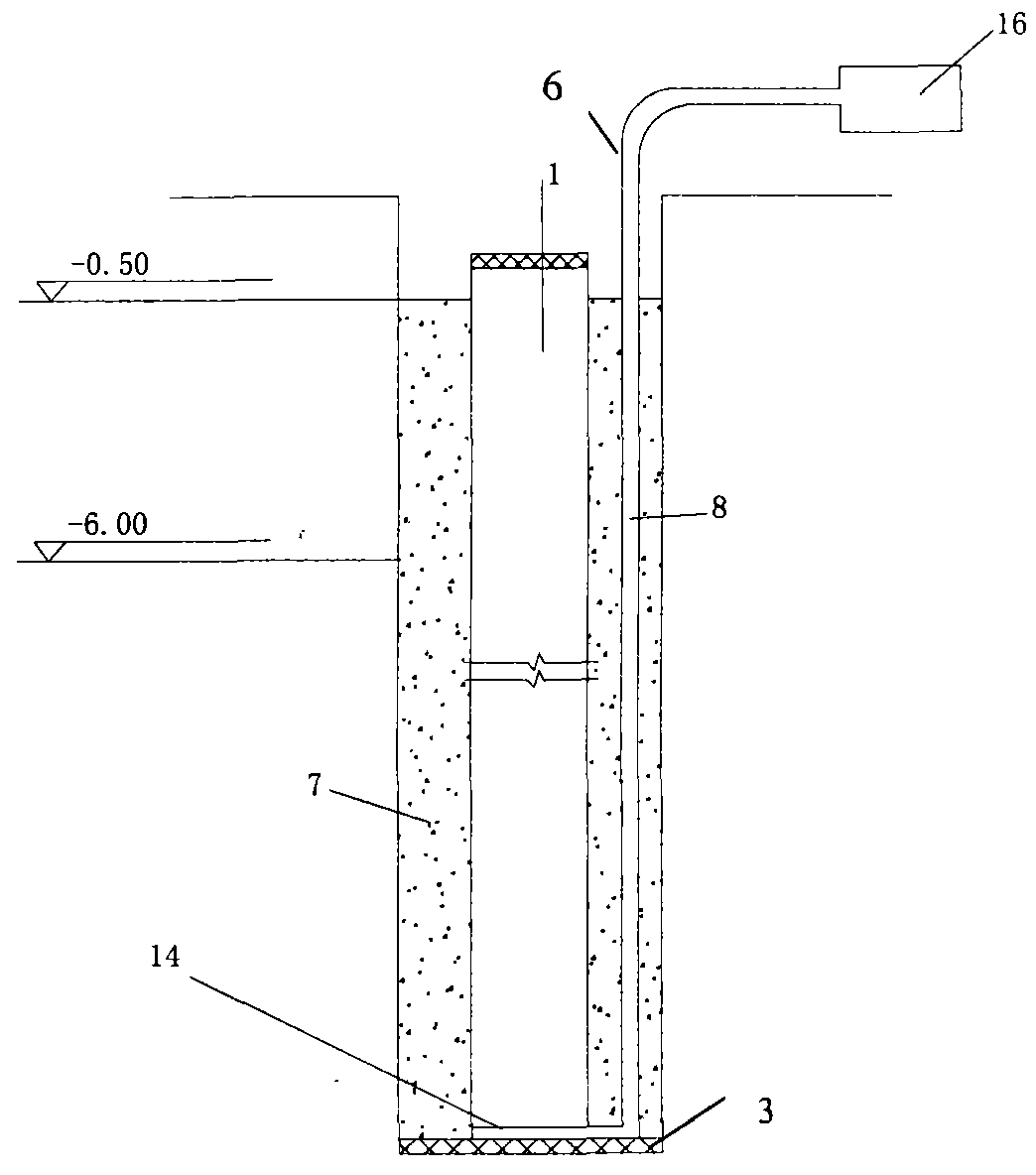

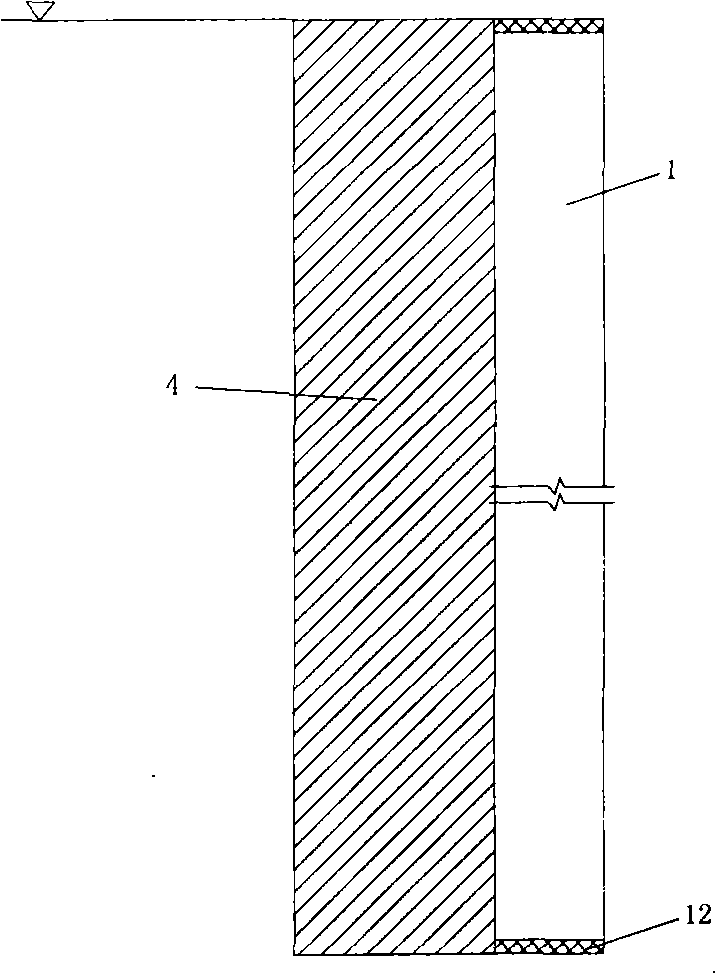

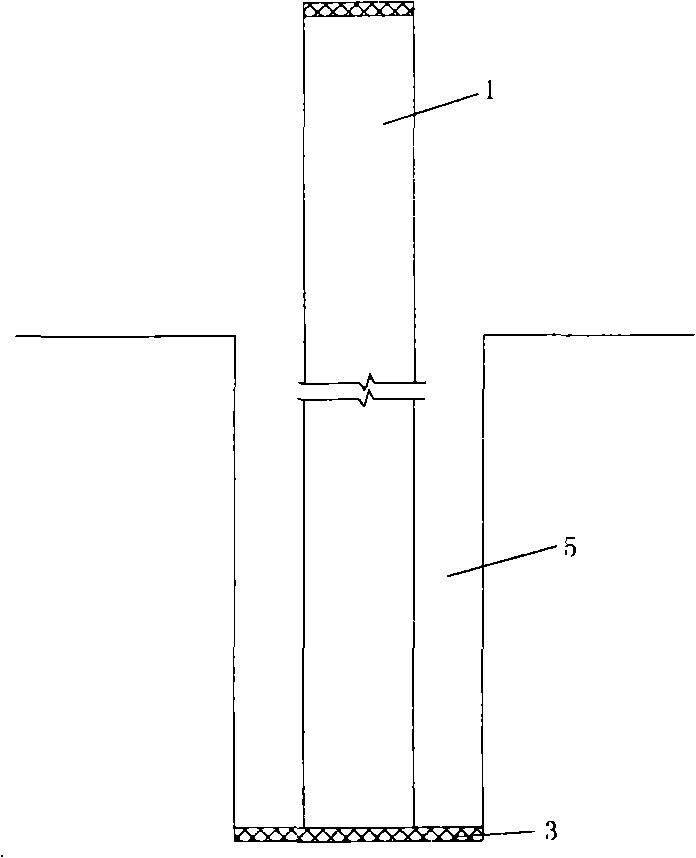

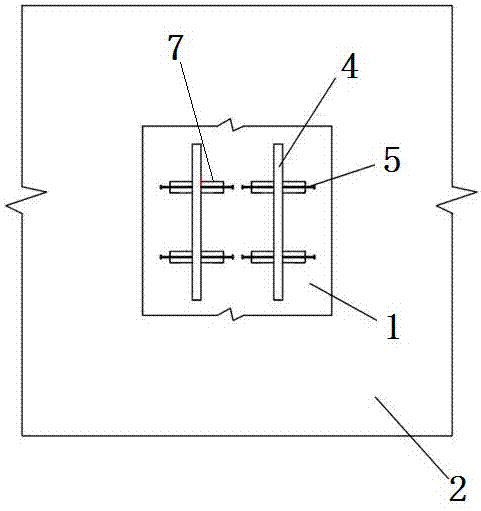

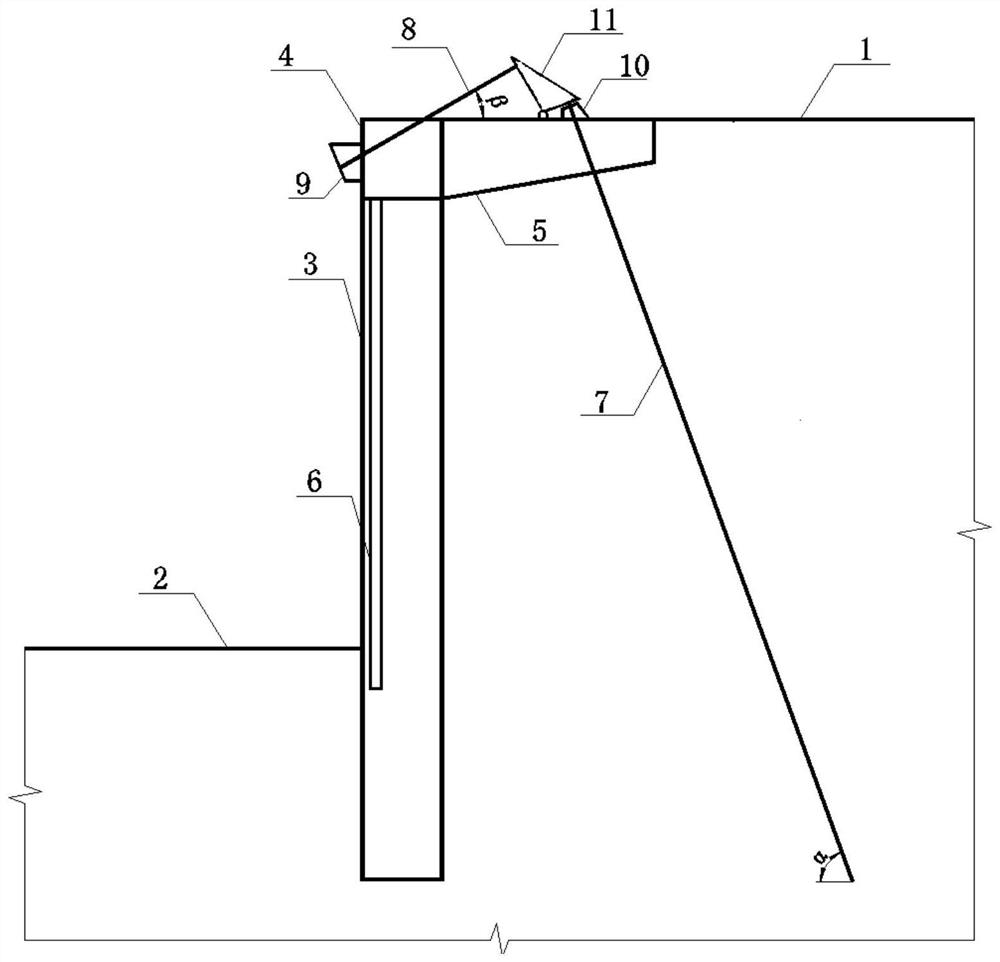

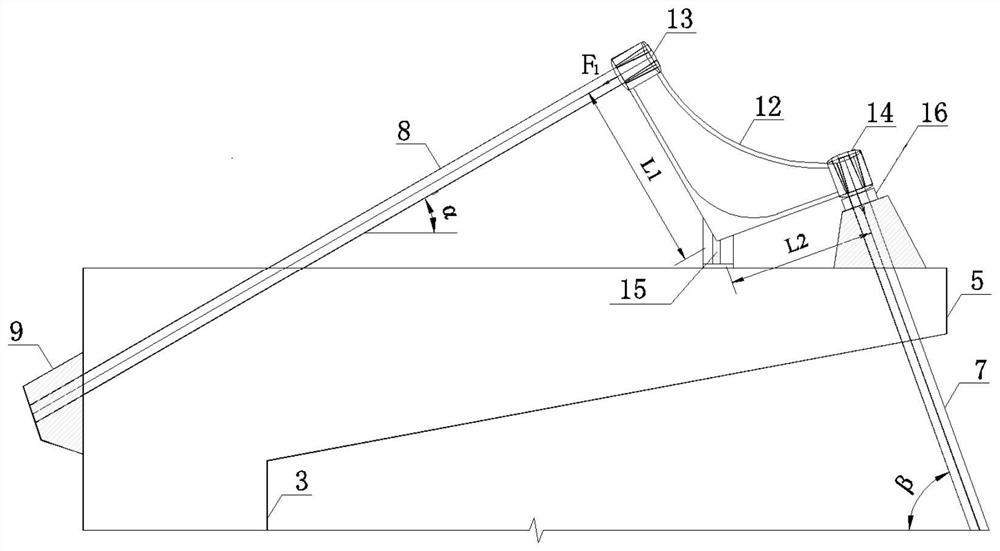

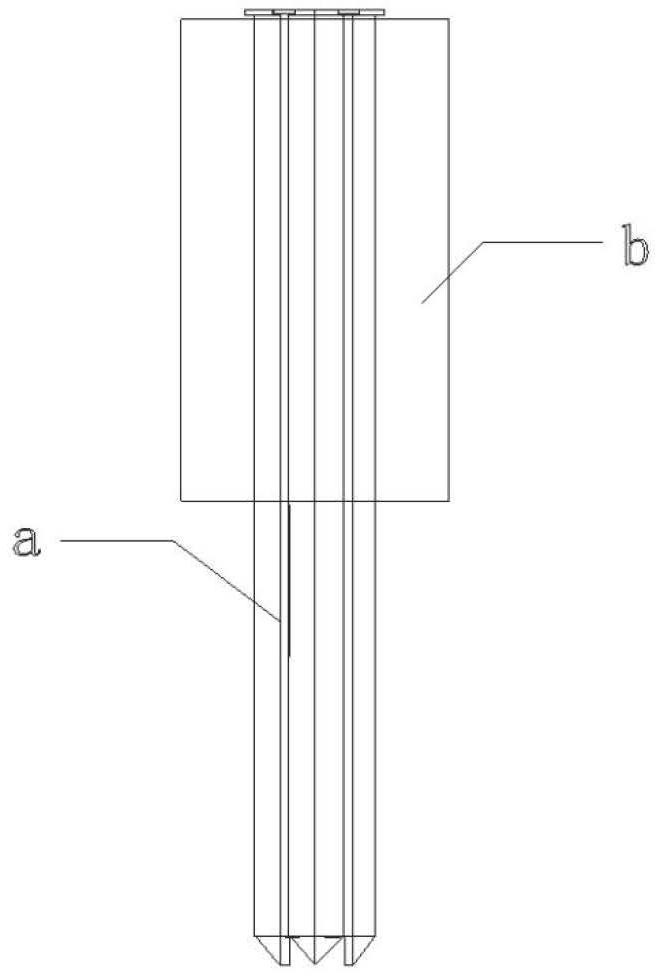

The invention discloses a local buoyancy ocean platform of offshore wind power, a bridge and an ocean building, and a construction method. The platform comprises at least one buoyancy cylinder, wherein the buoyancy cylinders are arranged vertically; the bottoms of the buoyancy cylinders are conical; and the buoyancy cylinders are hollow cylinders. Buoyancy of the buoyancy cylinders can be used for offsetting the weight of partial hydraulic buildings; small-bore bored piles or small-bore driven piles are arranged at the bottoms of the buoyancy cylinders, and fixed with seabed bed rock or a supporting layer, and support an external force together with a soil layer at the conical bottoms of the buoyancy cylinders; a tilting load borne by a whole foundation is converted into a vertical pressing and up-pull load of a single buoyancy cylinder foundation by a multi-buoyancy-cylinder space structure; the bearing capacity and the tilting resistance of the foundation are very high; multiple platforms can be connected into a multi-platform system; the platform can be cast in land, prefabricated, or assembled on a coast, and then hauled, towed and floated to a mounting position; and the platform is applied to ocean green energy sources such as the offshore wind power, the bridge and the ocean building with a soil layer of above 5m and water depth of about 5m to 50m, and has great potential economic benefits.

Owner:黄灿光 +1

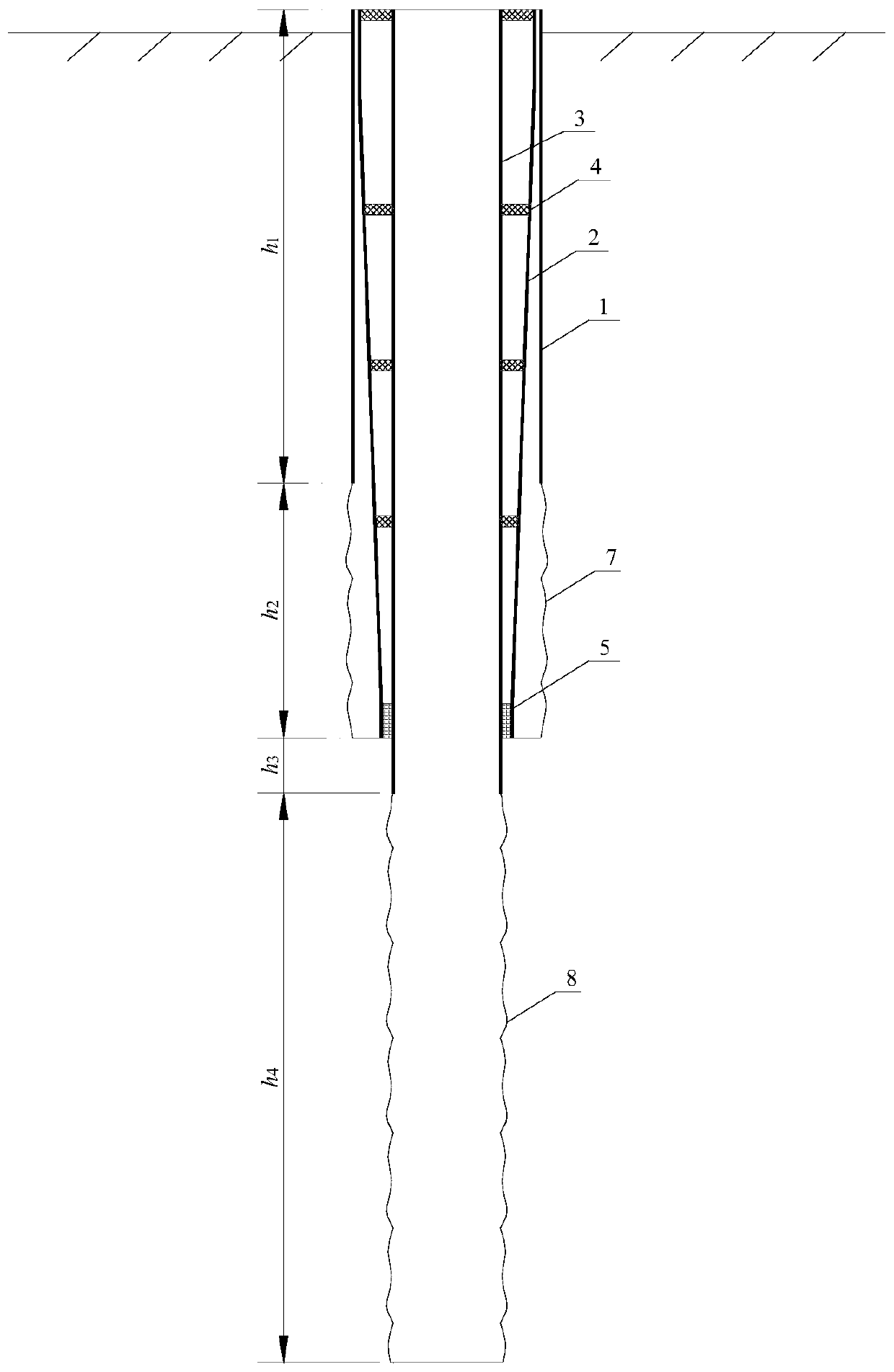

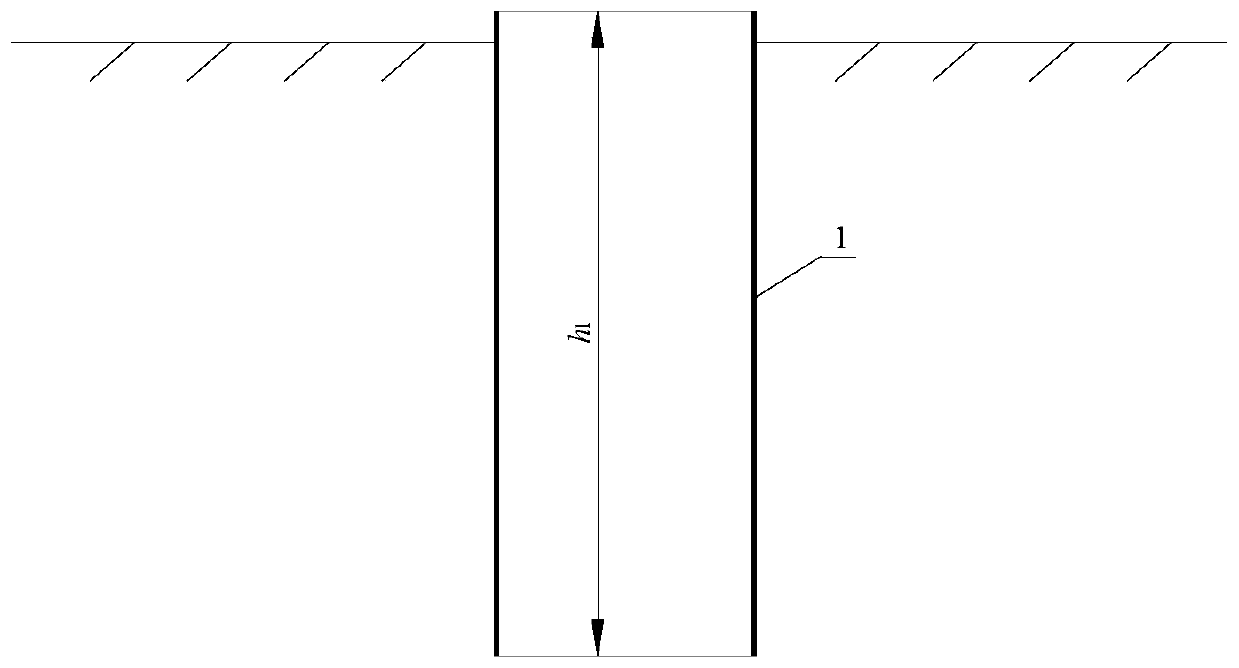

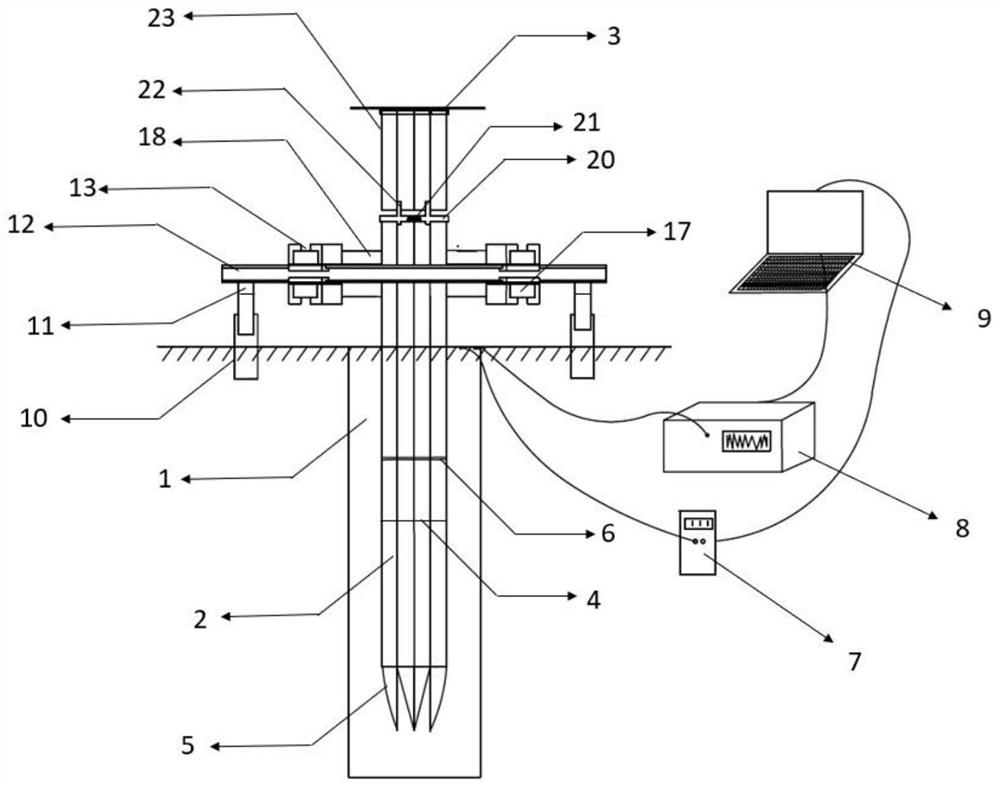

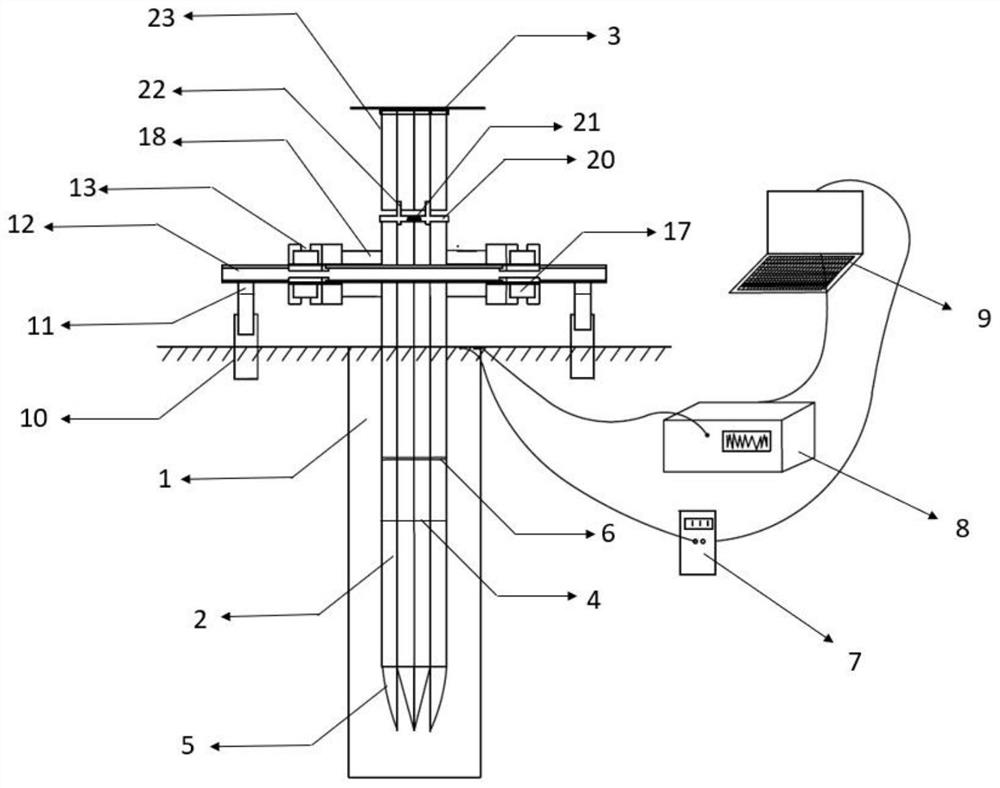

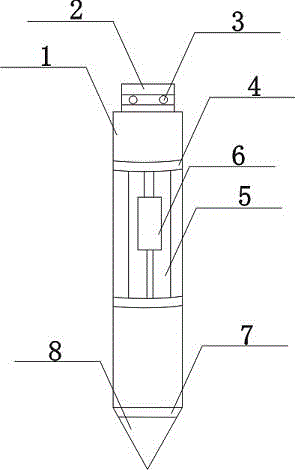

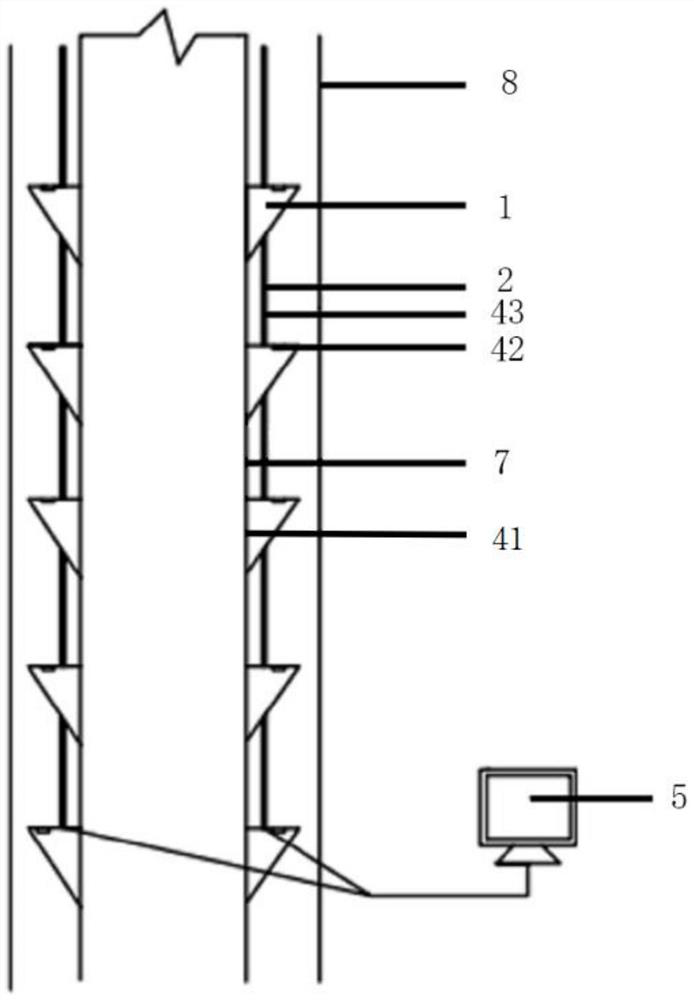

Self counter force balance loading test method of engineering pile bearing capacity

The invention provides a method for ensuring the position of a load box and pile quality and effectively transmitting axial force, shearing force and bending moment in self counter force balance loading test of engineering pile bearing capacity. A built-in jack of the load box is connected with a top cover plate and a bottom cover plate through high strength bolts, without being affected for normal loading, and consequently the load box transmits certain bending moment. The periphery of the load box is provided with twisted steels that are mutually lapped together and protected by a telescopic pipe, and mudjacking and solid joints are conducted after test, so that a reinforcing cage achieves the effect of overall equivalent connection and bears great shearing force and bending moment. The load box and the reinforcing cage are connected by means of inside cutting, and the horizontal resistance of a pile is increased at the load box. The surrounding gap of the pile is mudjacked at the load box after test to keep the continuity and integrity of pile concrete and ensure the axial force transmission of the pile and the vertical bearing capacity. The bottom of the bottom cover plate of the load box is provided with a conical flow guide body in order to avoid mud and sediments remaining on the bottom of the bottom cover plate when the pile concrete passes through the load box in pouring and ensure the pile quality and test accuracy.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

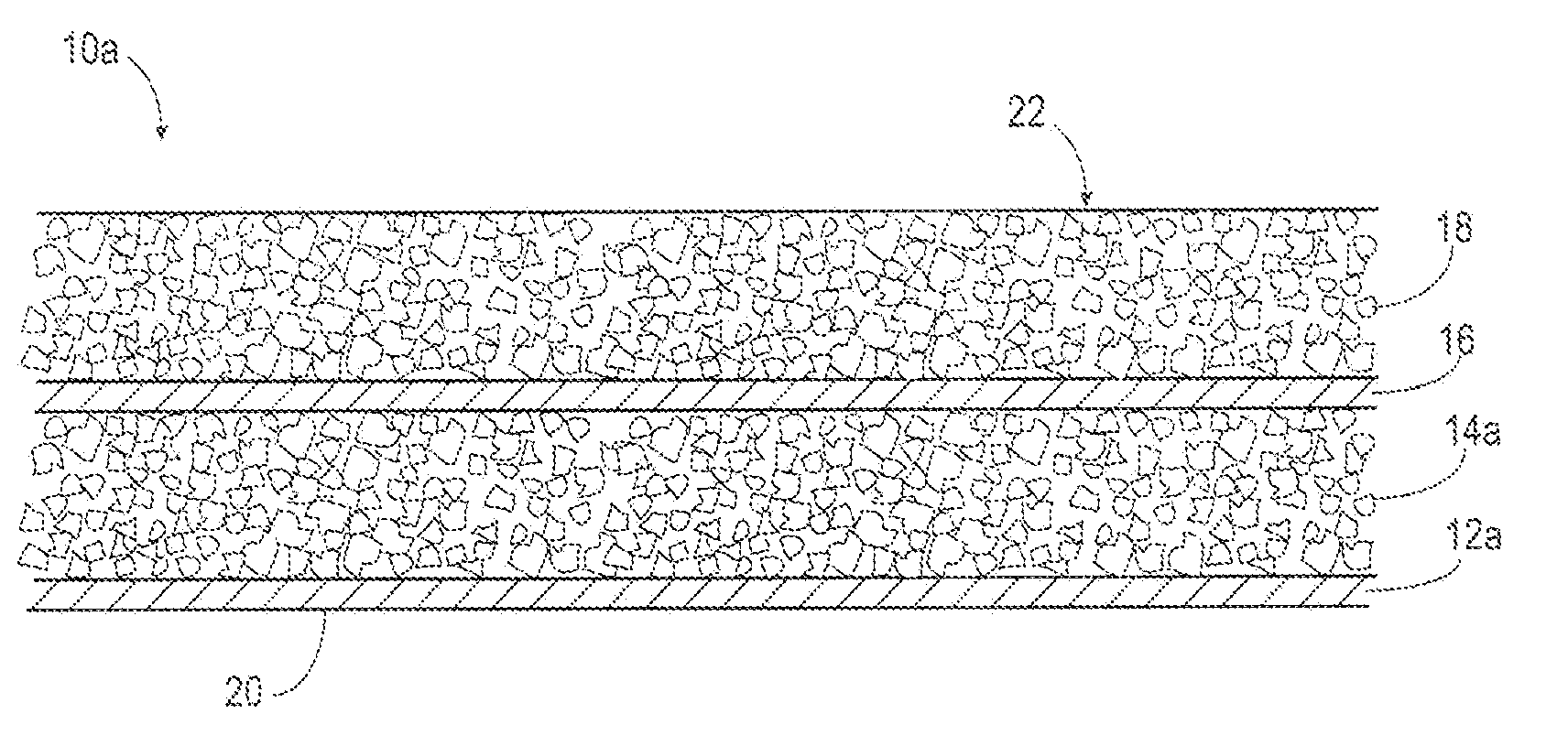

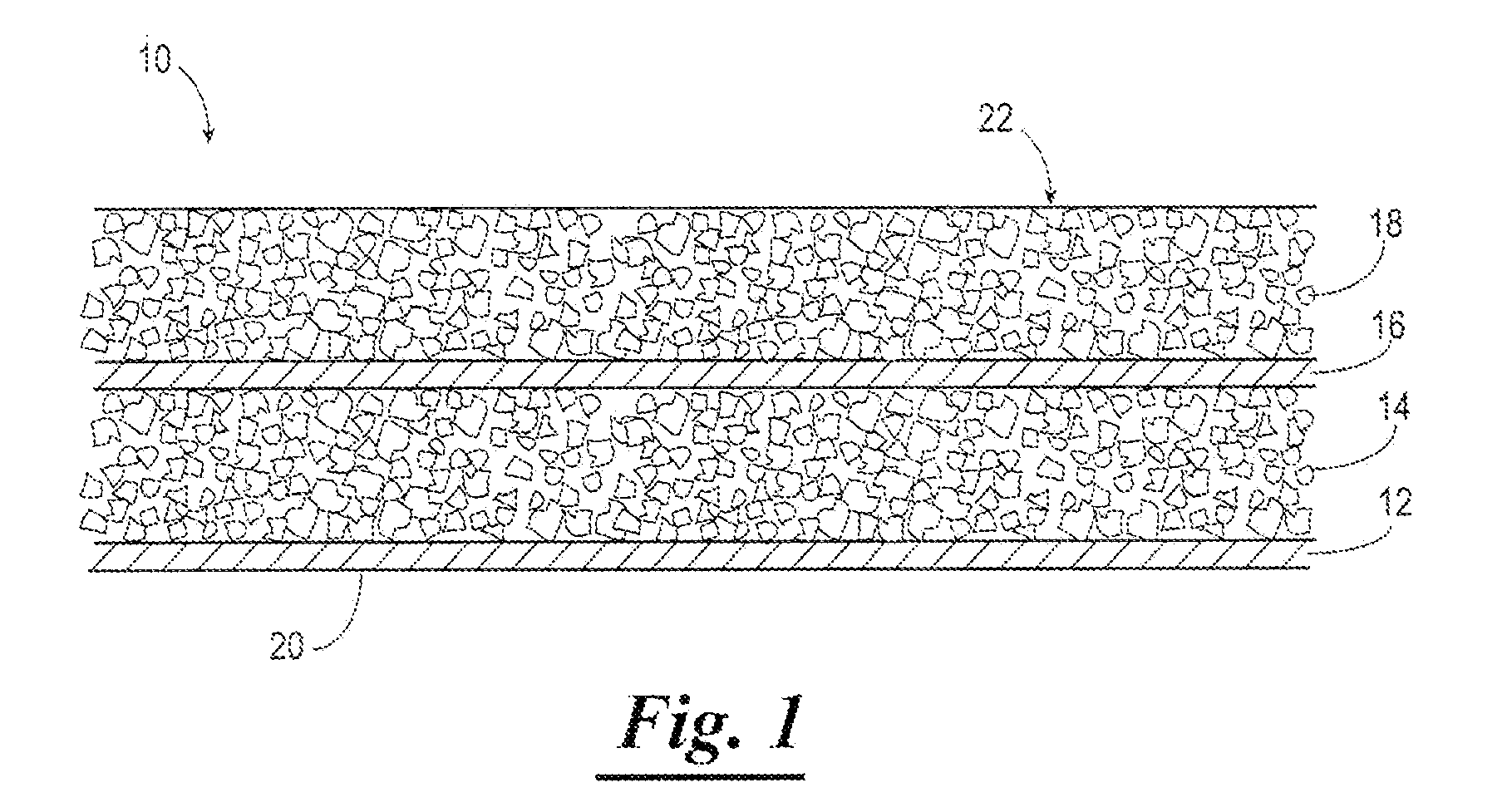

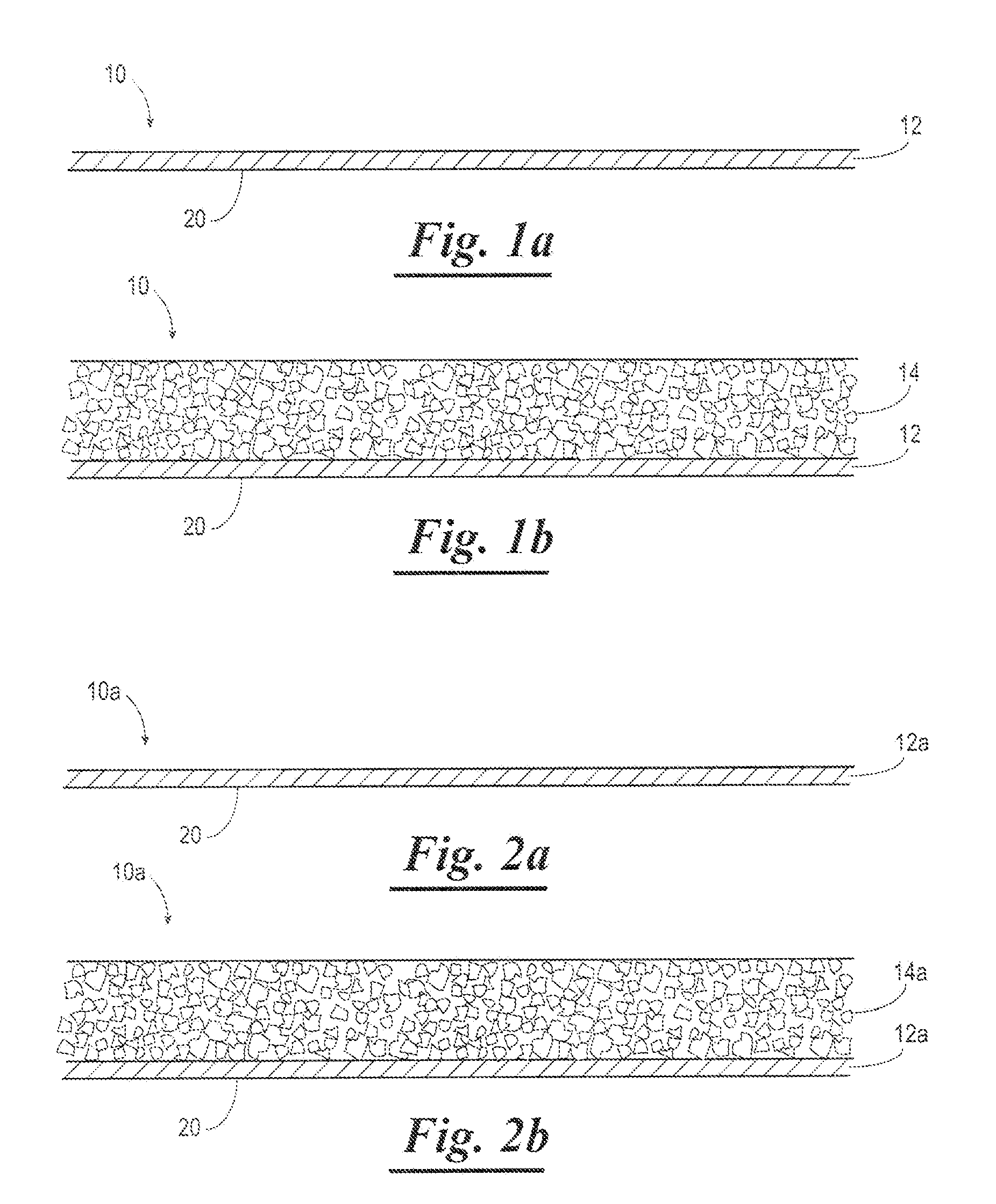

Crack resistant coating and method of applying crack resistant coating

InactiveUS20110038668A1Increase to horizontal movementIncrease horizontal resistanceIn situ pavingsPaving detailsAir voidsMaterials science

The present invention relates to a method for applying a crack resistant coating on a surface, where the crack resistant coating increases resistance to high vertical and horizontal movements and high shear stresses on the surface. The method comprises the steps of applying a binding material to the surface and applying an aggregate mixture within 15 seconds of applying the binding material to the surface, where the aggregate mixture comprises aggregate particles and an asphalt solution and where the aggregate mixture has a plurality of air voids, and where the binding material fills at least 15% of the air voids in the aggregate mixture (AVFA).

Owner:ARR MAZ PRODS

Long segmental structure of offshore high-piled wharf

InactiveCN101949142AReduce bending momentAdapt to connection requirementsBreakwatersQuaysHorizontal forceEngineering

The invention discloses a long segmental structure of an offshore high-piled wharf; pile tops adopt a hinge joint mode to reduce the bending moment of piles generated by temperature deformation and meet the requirement of pile top connection of construction under the severe condition of offshore deep water and storms; fork piles or inclined piles more than 25 m away from a temperature deformation balanced line are arranged by adopting small horizontal included angles to reduce the axial force of the piles generated by the temperature deformation; fork piles or inclined piles less than or equal to 25 m away from the temperature deformation balanced line can be longitudinally arranged to improve the capability of resisting longitudinal horizontal force of the wharf; the first bent span space of two segmental edges is appropriately reduced to reduce the design internal force of stringers, beams and piles; and rail connection structures of a plurality of small segments, with intervals of less than or equal to 20 mm, are adopted at an expansion joint to meet the working requirement of the expansion joint for the mechanical smooth transition of a rail. The long segmental structure of the offshore high-piled wharf successfully solves the technical problem of the long segmentation of the wharf, and the segmentation length is usually more than 120 m so as to reduce the horizontal force loaded by the bents, reduce the construction cost, and facilitate replacing steel pipe piles by adopting large tubular piles (which contain PHC piles).

Owner:CCCC THIRD HARBOR CONSULTANTS

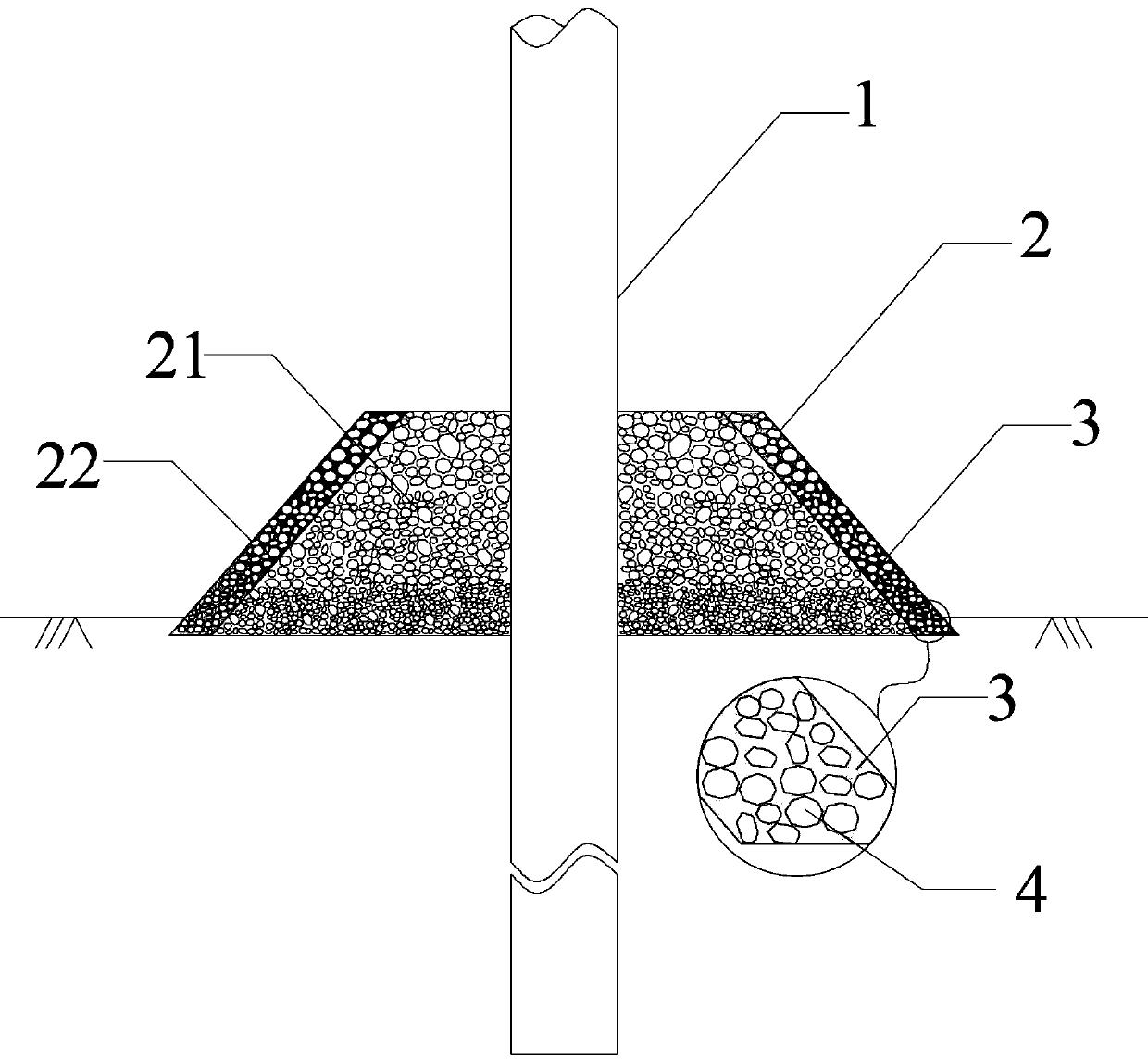

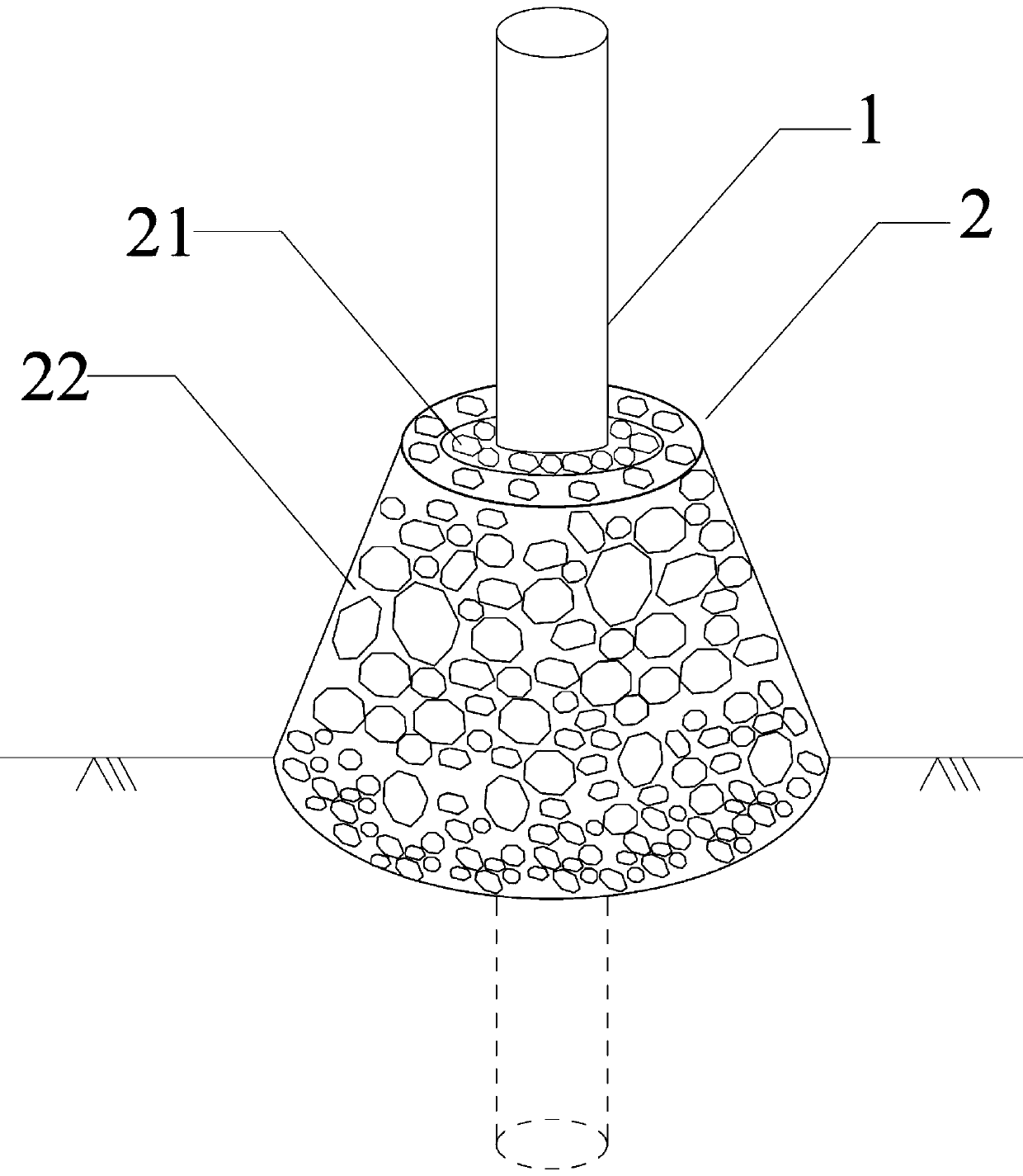

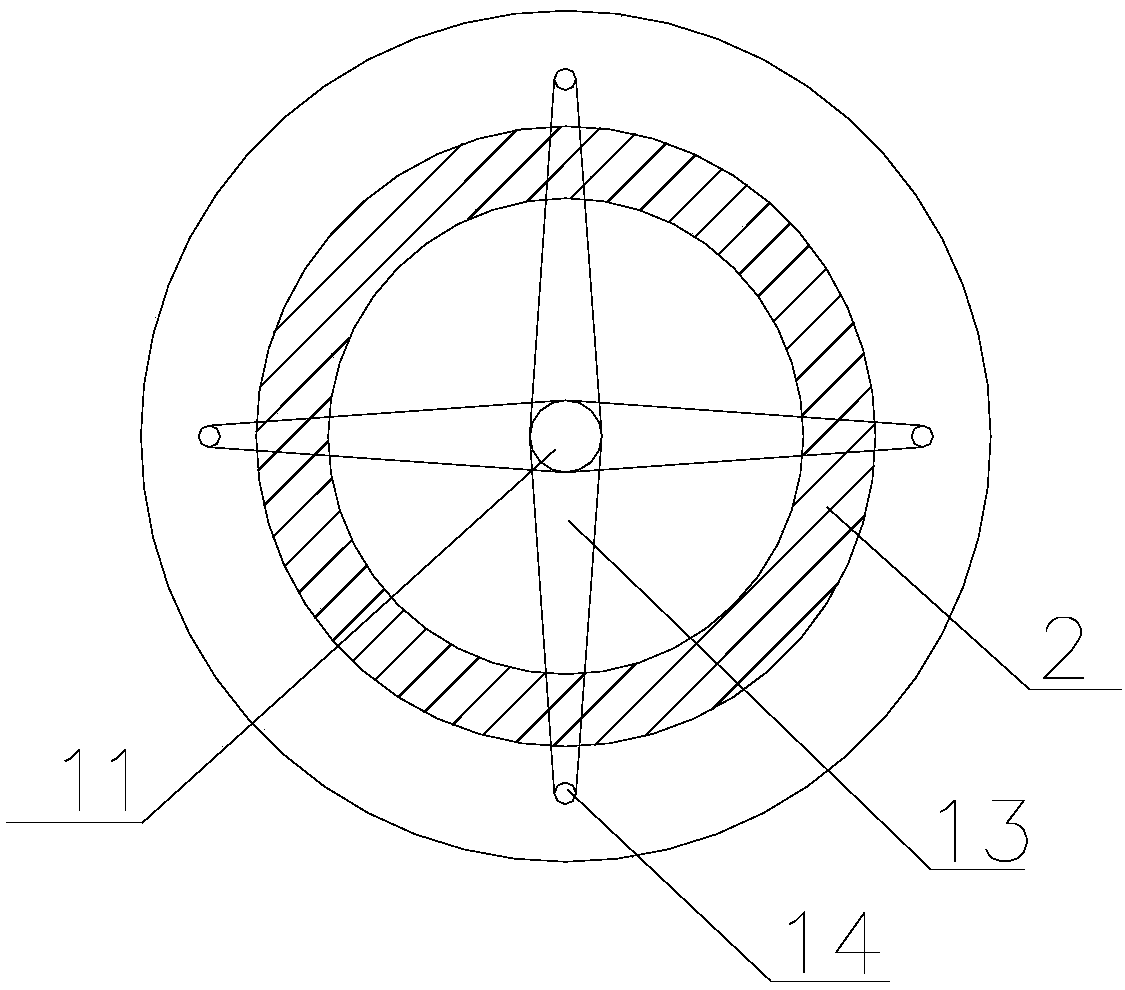

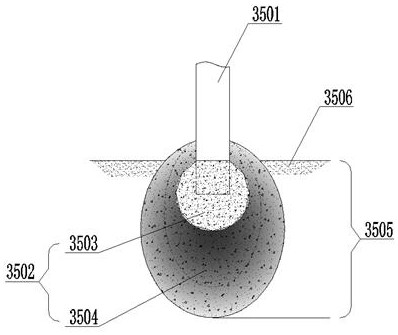

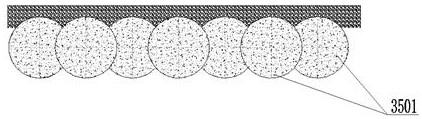

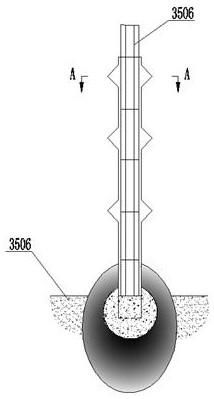

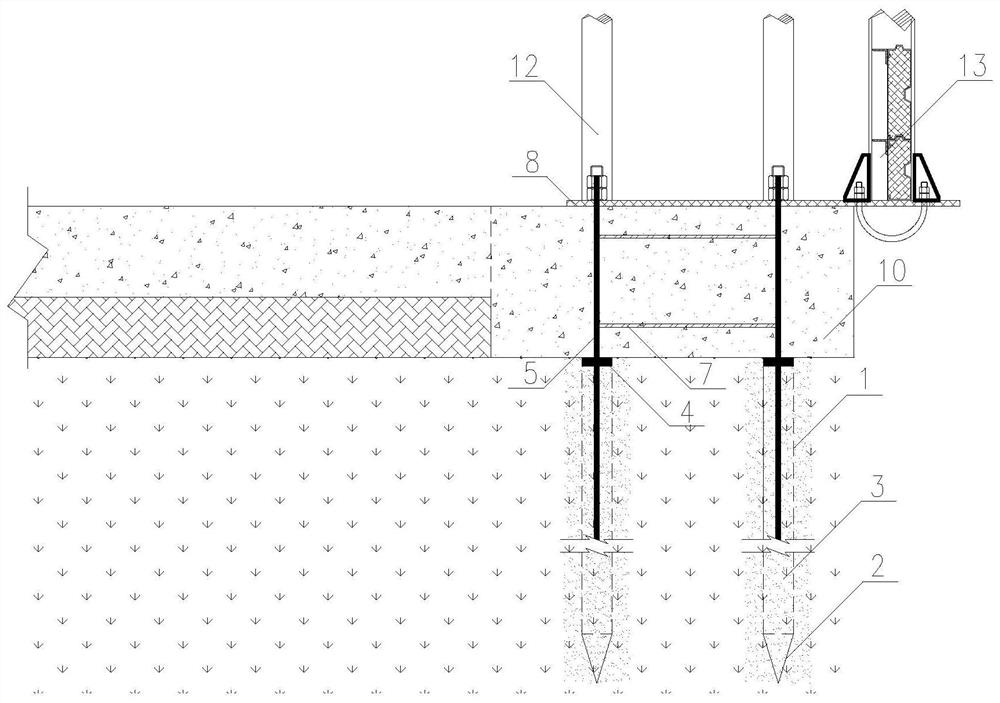

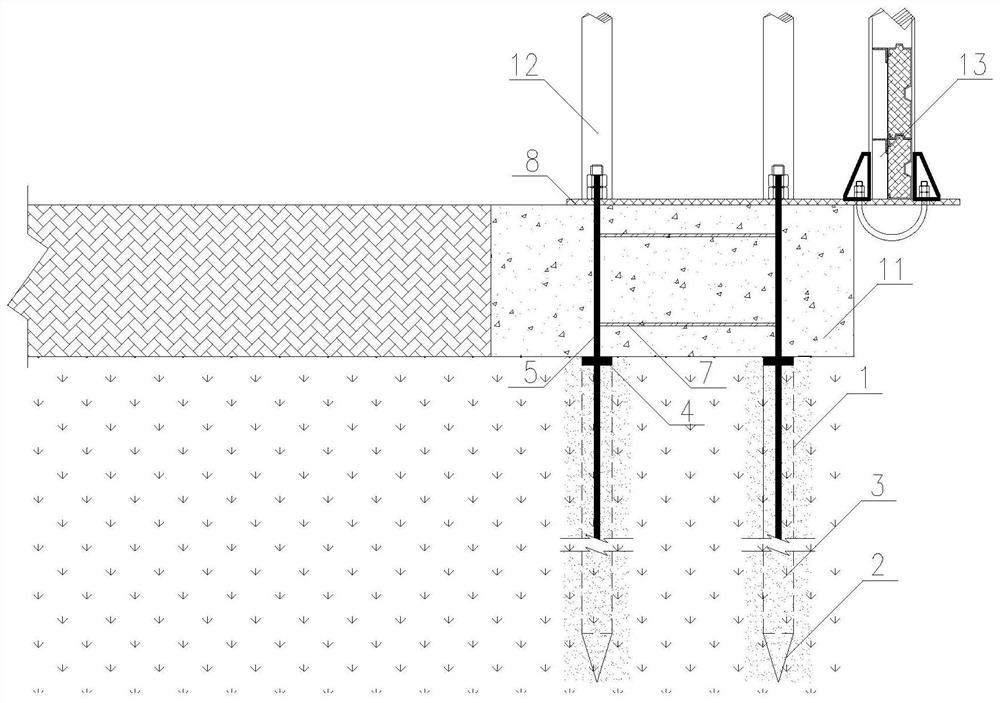

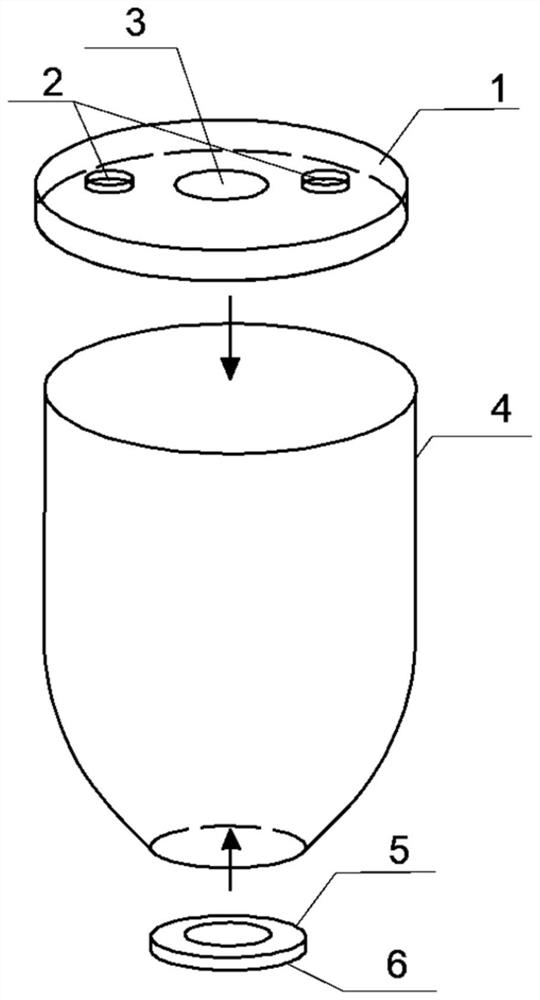

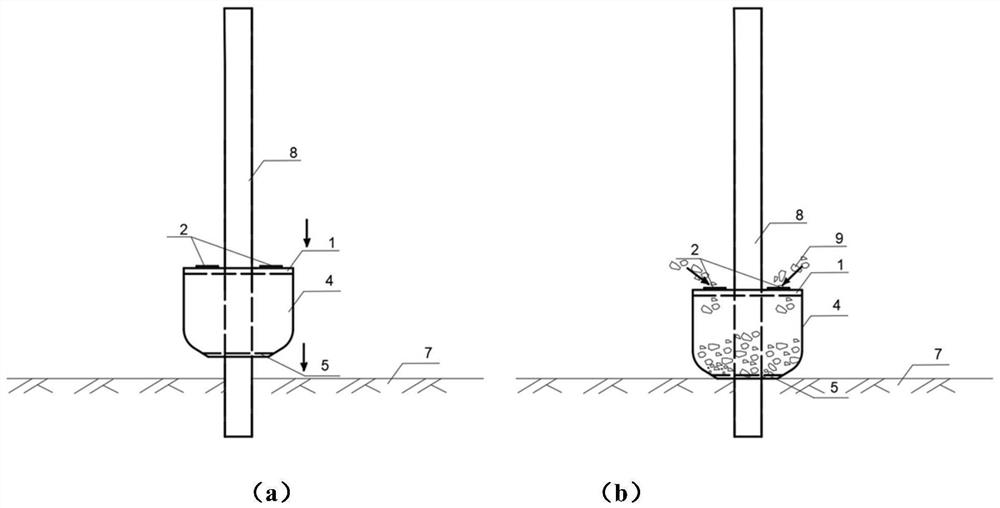

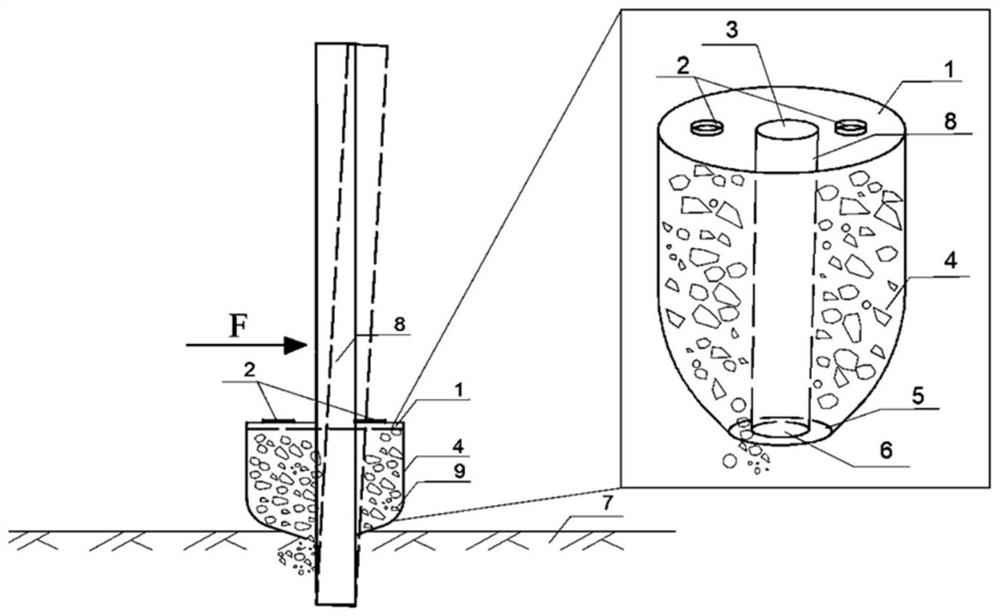

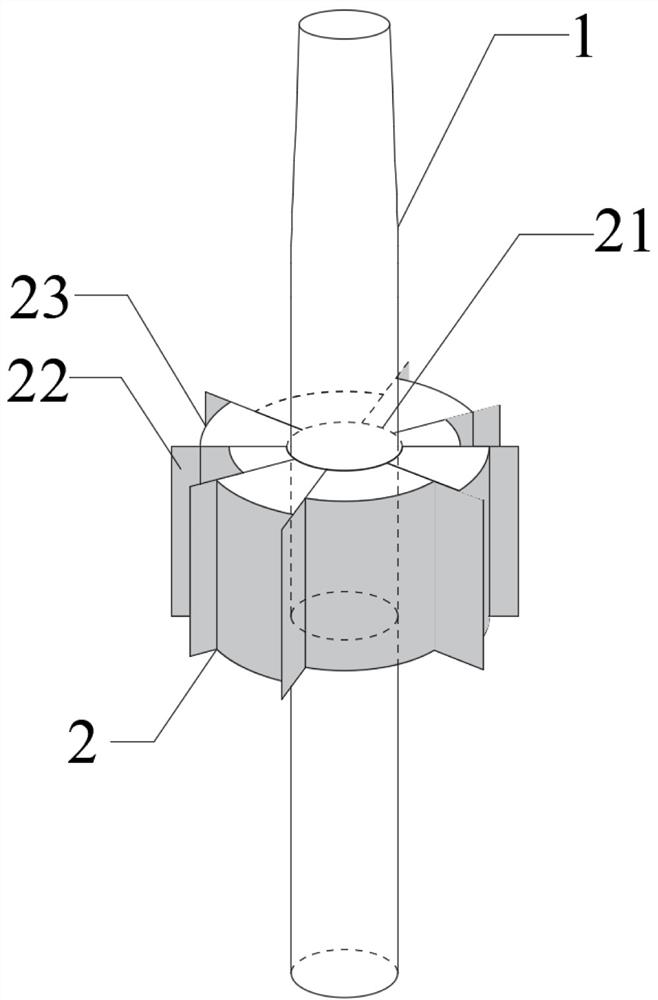

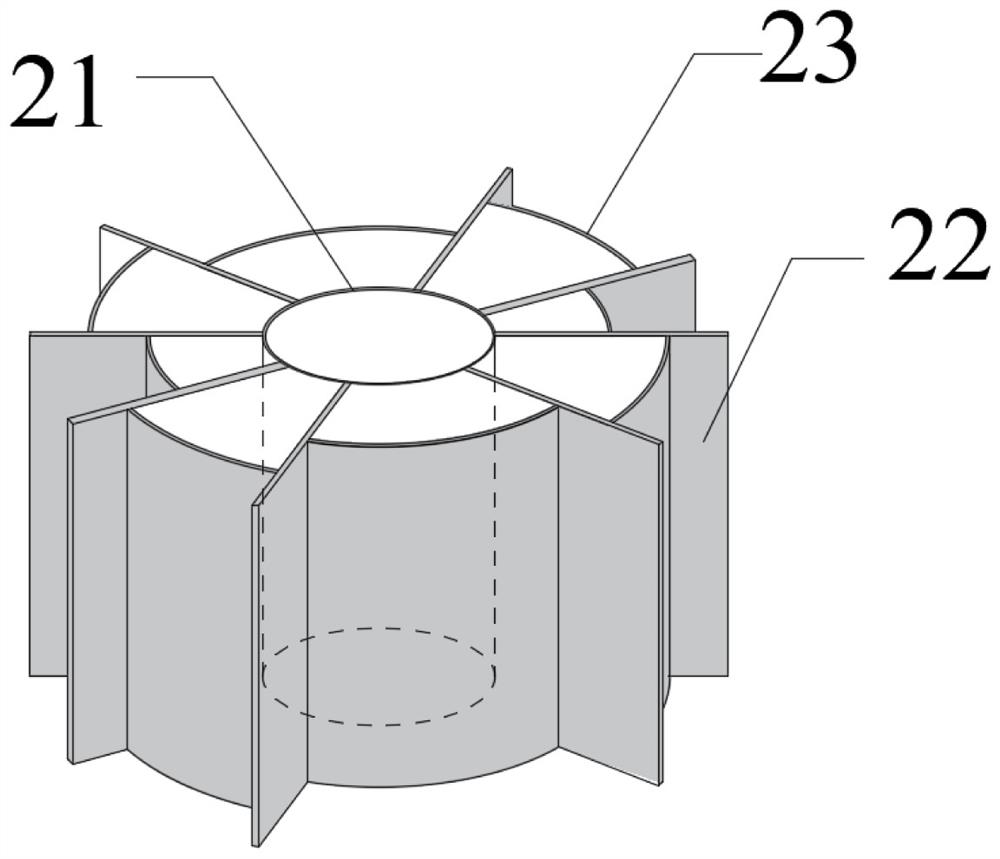

Offshore wind power single pile-friction cone composite foundation and construction method thereof

PendingCN110984213AImprove carrying capacityImprove bearing capacityFoundation engineeringCrushed stoneOffshore wind power

The invention discloses an offshore wind power single pile-friction cone composite foundation and a construction method thereof. The offshore wind power single pile-friction cone composite foundationcomprises a single pile and a friction cone, wherein a rock-fill body is arranged inside the friction cone, a cemented rock-fill body shell is arranged outside the friction cone, and the cemented rock-fill body shell is obtained by grouting and cementing the rock-fill body outside the friction cone. The construction method of the offshore wind power single pile-friction cone composite foundation comprises the following steps of 1, carrying out single pile construction by using pile sinking equipment; 2, stacking graded crushed stone materials on seabed around the single pile to form the friction cone; 3, placing a grouting device on the surface of the rock-fill body outside the friction cone; and 4, conveying underwater self-protection cementing materials through the grouting device, wherein the cementing materials fill gaps of the rock-fill body outside the friction cone to form a cemented rock-fill body. The offshore wind power single pile-friction cone composite foundation has the advantages of high horizontal bearing capacity, small pile body horizontal displacement, deformation and bending moment and the like, and has the characteristics of simple construction, high adaptability to geological conditions and the like.

Owner:CHINA THREE GORGES CORPORATION

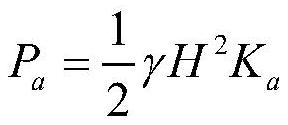

Method for supporting foundation pit

The invention discloses a method for supporting a foundation pit, and relates to the technical field of geotechnical engineering. The method includes steps of firstly, constructing a space enclosing structure, a pier pile supporting row and a pile base line at the design position simultaneously; then constructing a crown beam at the top part of the space enclosing structure, and then excavating earthwork in the foundation pit until the top part of the pier pile supporting row is exposed; constructing a strip-shaped supporting base at the top part of the pier pile supporting row; constructing apurlin on the space enclosing structure beneath the brown beam, and erecting a supporting arm between the strip-shaped supporting base and the purlin; then excavating the earthwork at the edge of thefoundation pit to the bottom part of the foundation pit by a reversed basin shaped excavation method; constructing a side span bottom plate at the top part of the pile base row, and then constructinga diagonal arm between the strip-shaped supporting base and the side span bottom plate so that the strip-shaped supporting base and the side span bottom plate are effectively connected. The method has the advantages of effectively reducing the main body construction difficulty, improving the construction efficiency, facilitating the earthwork excavation of the foundation pit, and effectively reducing the construction cost.

Owner:ANHUI URBAN CONSTR DESIGN & RES INST

Device for reducing negative friction resistance of pile foundation in soft soil area and construction method

InactiveCN110158585AReduce the impactNegative friction avoidanceBulkheads/pilesEconomic benefitsHearing perception

The invention discloses a device for reducing negative friction resistance of a pile foundation in a soft soil area and a construction method. The device for reducing negative friction resistance of the pile foundation in the soft soil area comprises an inner sleeve, a negative friction pipe and an outer sleeve; the negative friction pipe is connected with the inner sleeve through a rubber sealingring at the bottom and peripheral cushion blocks at a certain interval; the negative friction pipe is in an inverted cone shape; and a gap between the negative friction pipe and the inner sleeve is filled with pebbles and fine sands. According to the construction method, the vertical bearing capacity of the vertical load-hearing pile foundation can be improved by utilizing the inverted cone-shaped negative friction pipe, the pile diameter of the negative friction pipe is larger than the diameter of the pile foundation, and the horizontal bearing resistance of the pile foundation can also be increased; meanwhile, the combination device of the negative friction pipe and the inner sleeve is utilized, so that the pile foundation and the negative friction pipe slide relatively, the negative friction resistance caused by settlement of oversize soils around a pile is reduced, additional load and additional settlement of the pile foundation can be effectively reduced, and problem of the uneven settlement of the pile foundation in the soft soil area is solved. The construction method is wide in application range, and has the advantages of saving resources, improving social and economic benefits, being beneficial to traffic operation safety and building safety, and the like.

Owner:SOUTHEAST UNIV

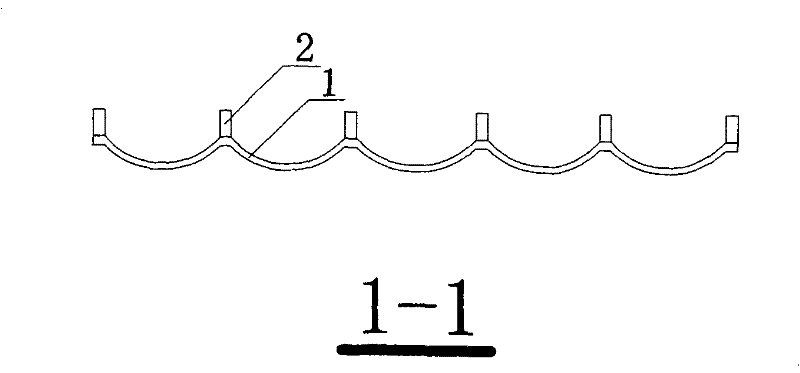

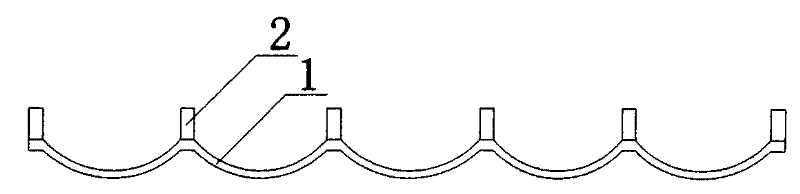

Arch bar base and construction method

The invention discloses an arch bar foundation the foundation plate of which comprises a plurality of arch bars with arch sections. As the arch bar shape of the arch bar foundation of the invention has better structural stiffness and better stability than the plate shape of the traditional foundation, capabilities of horizontal force resistance, slippage resistance, differential settlement reduction and the like of the foundation are improved. The invention also provides a construction method of the arch bar foundation, comprising the following steps: 1) leveling the land; 2) producing arch groves; 3) casting and pounding a cushion coat; 4) arranging an arch bar moulding board; 5) arranging a foundation beam moulding board; 6) binding the arch bar and foundation beam steel; 7) casting and pounding arch bar concrete; and 8) casting and pounding foundation beam concrete.

Owner:SINO RISING SUN CONSTR GRP

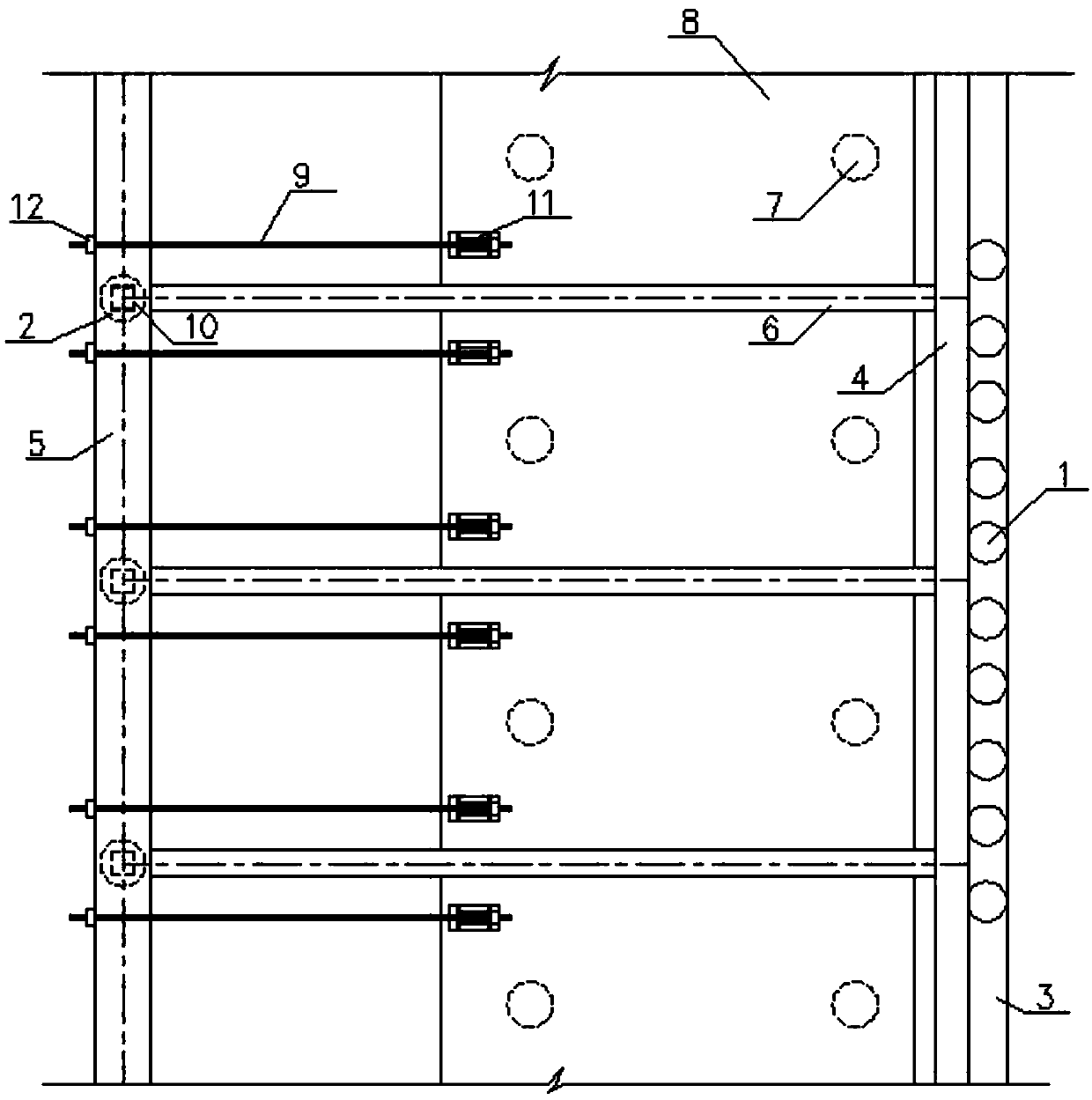

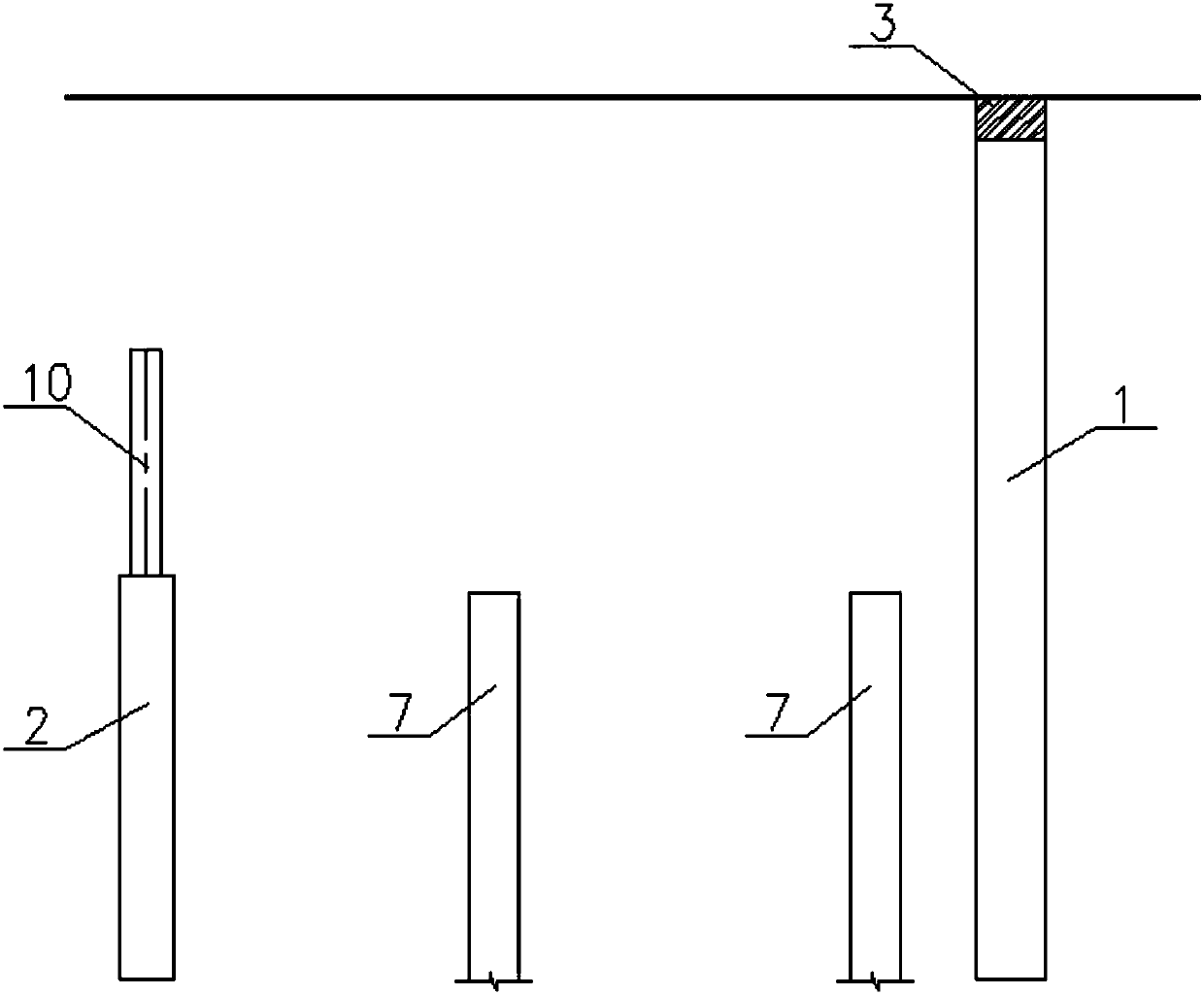

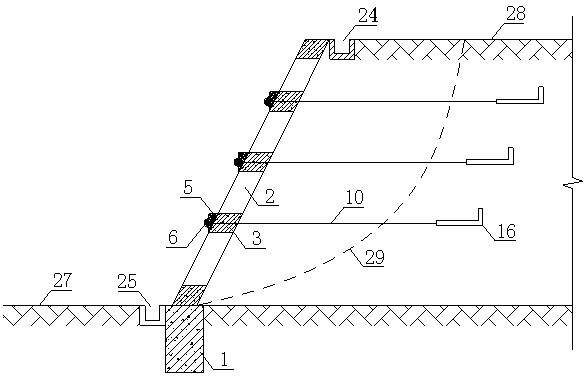

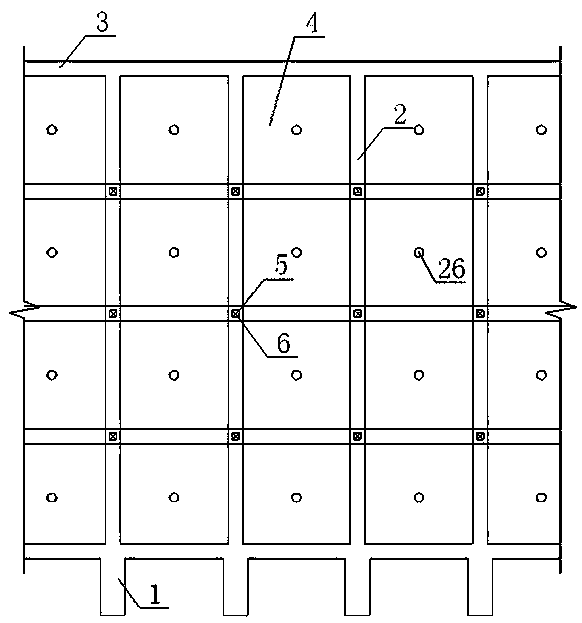

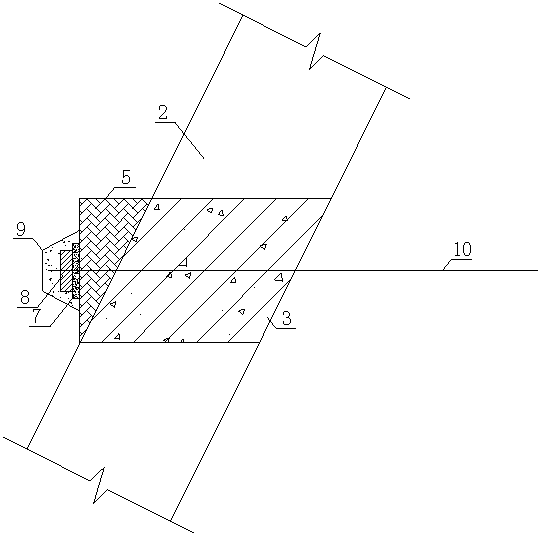

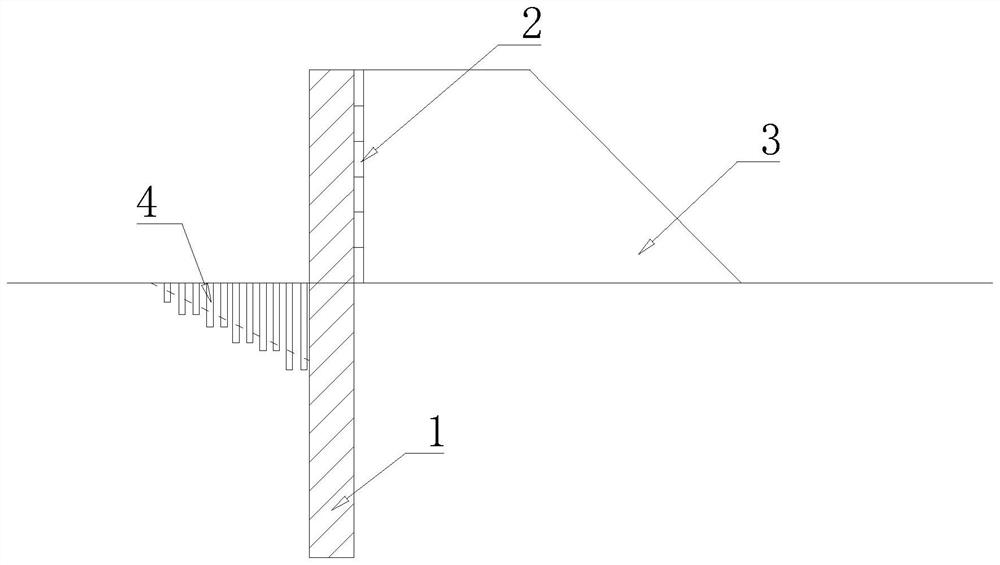

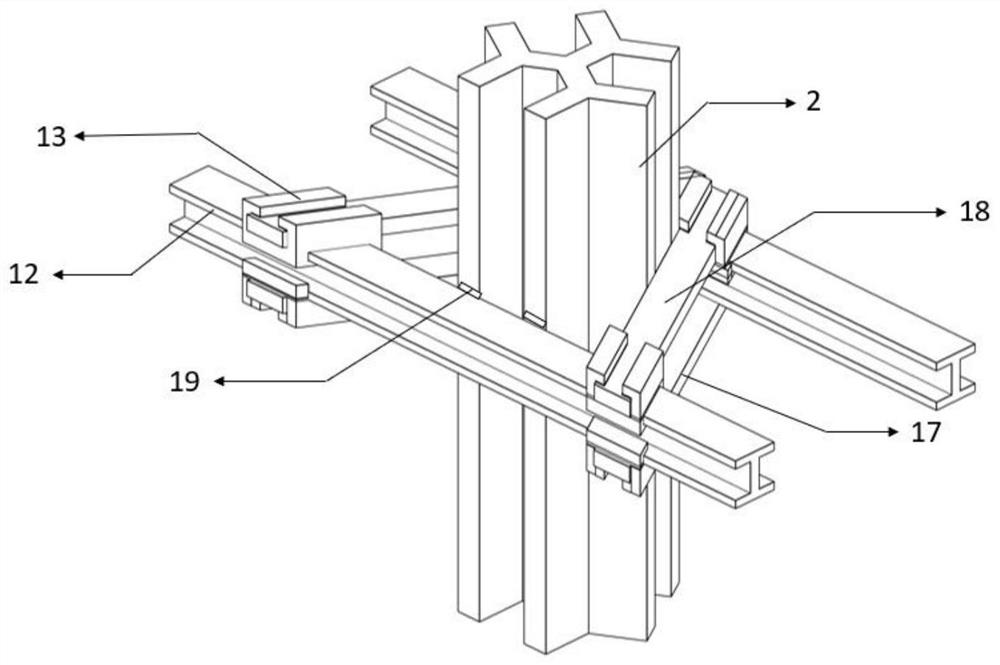

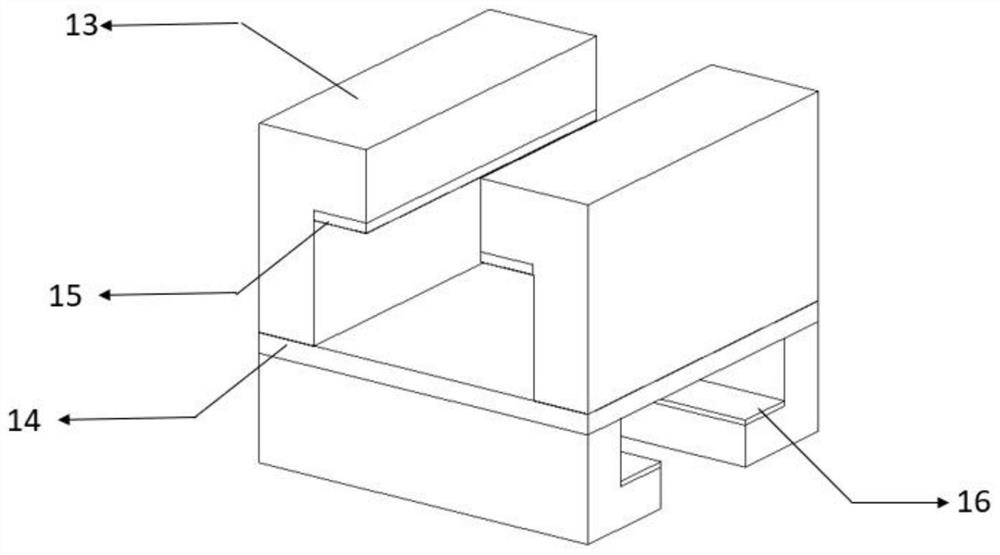

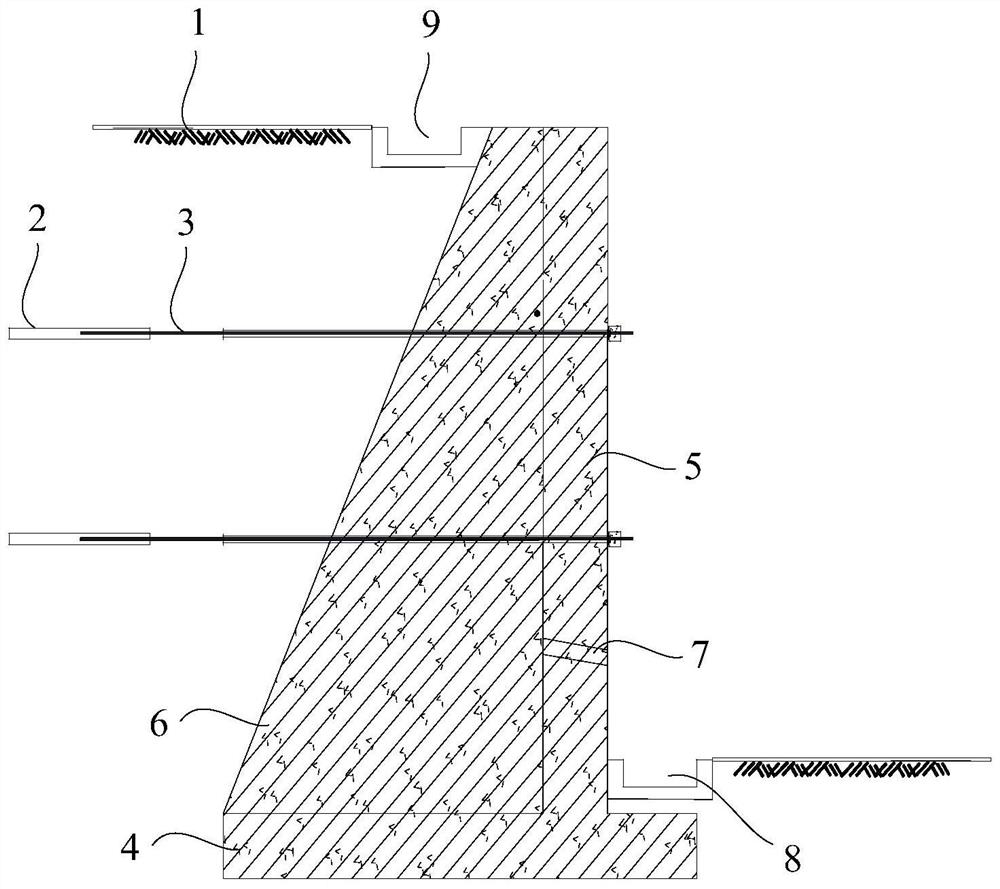

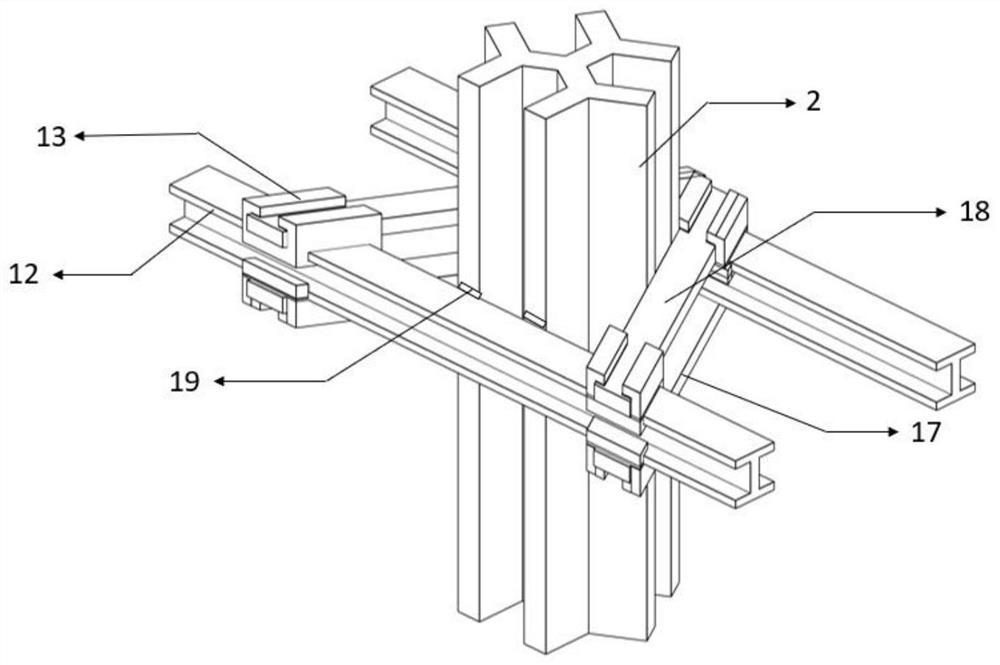

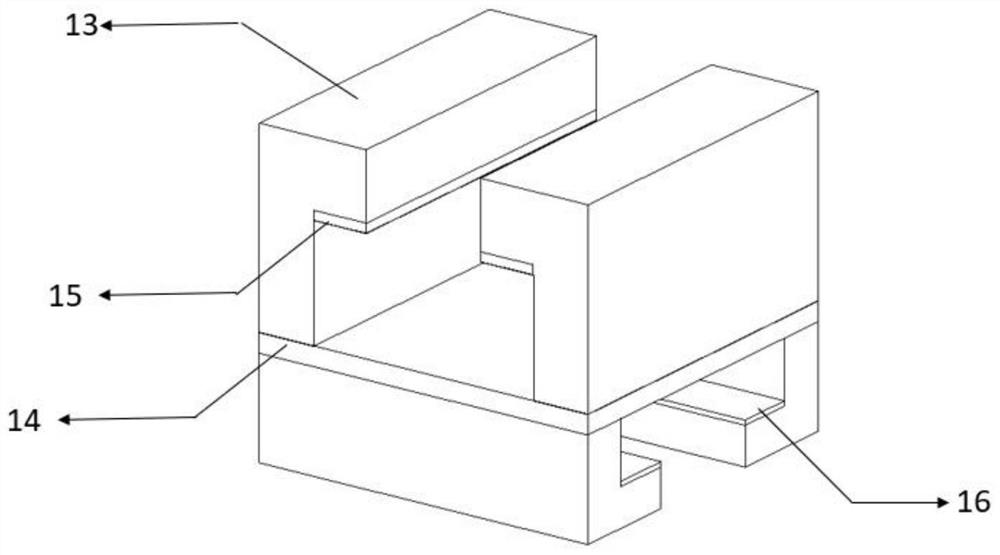

Fill slope frame micro-tensioning supporting anchor plate supporting structure and construction method thereof

PendingCN109750681ASimple structureReasonable forceExcavationsBulkheads/pilesEconomic benefitsLarge range

The invention relates to a fill slope frame micro-tensioning supporting anchor plate supporting structure and a construction method thereof. The supporting structure comprises a frame body arranged along a fill slope surface, a plurality of supporting anchor plates (16) arranged in a fill soil body and arranged in parallel in the height direction, and a plurality of steel strand inhaul cables (10)connecting the supporting anchor plates (16) and the frame body. The frame body comprises a soil retaining panel (4), cross beams (3) and stand columns (2) which are arranged on the soil retaining panel (4) in a staggered mode, foundation piles (1) which are arranged below natural ground (27) at the toe of the fill slope and connected with the bottom ends of the stand columns (2), and cast-in-place concrete which enables the foundation piles, the stand columns, the cross beams and the soil retaining panel to be cast in place into a whole. The supporting structure is simple in form, reasonablein stress and high in practicability, the related construction technology is simple and convenient, the cost is low, and the supporting structure has high engineering practical value and important social and economic benefits and is worthy of large-range application and popularization.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

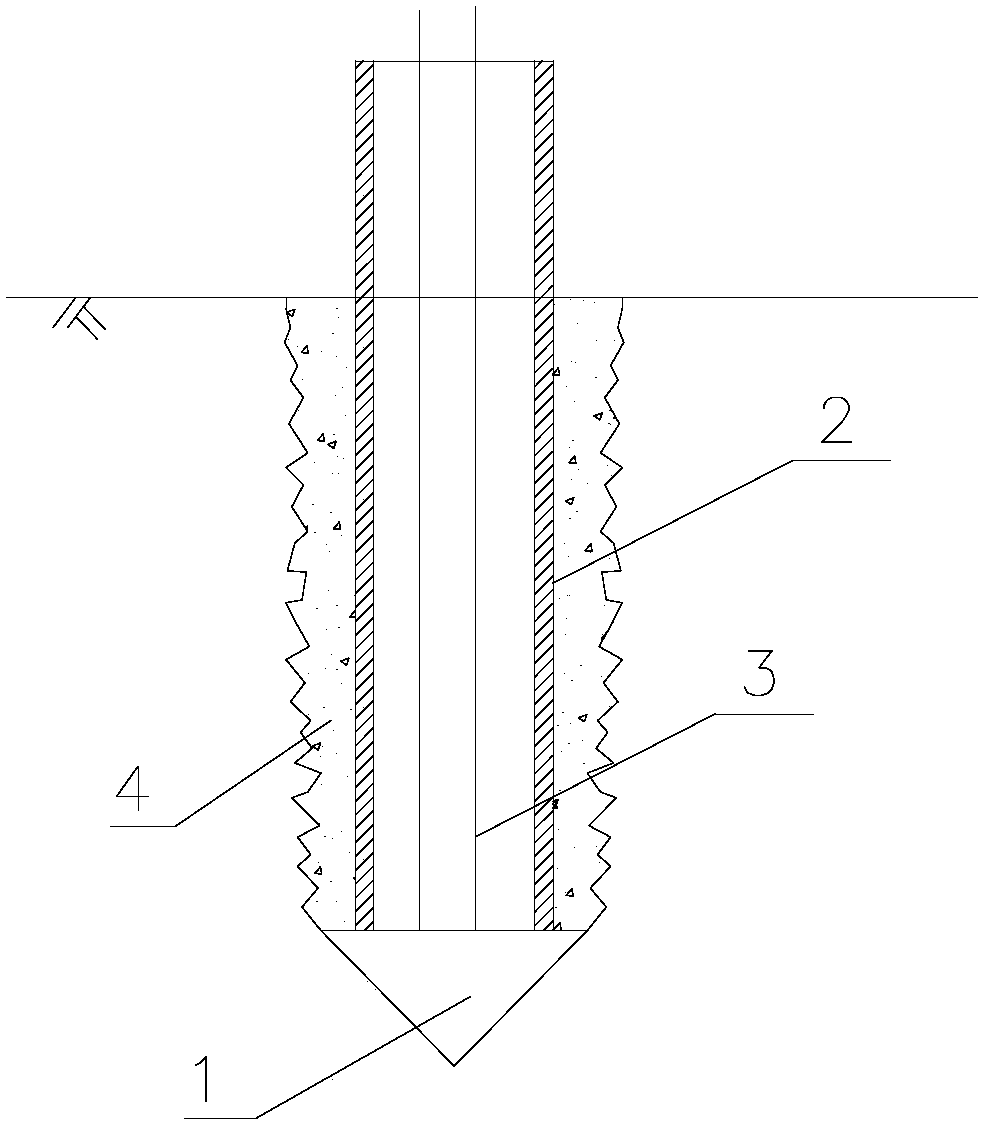

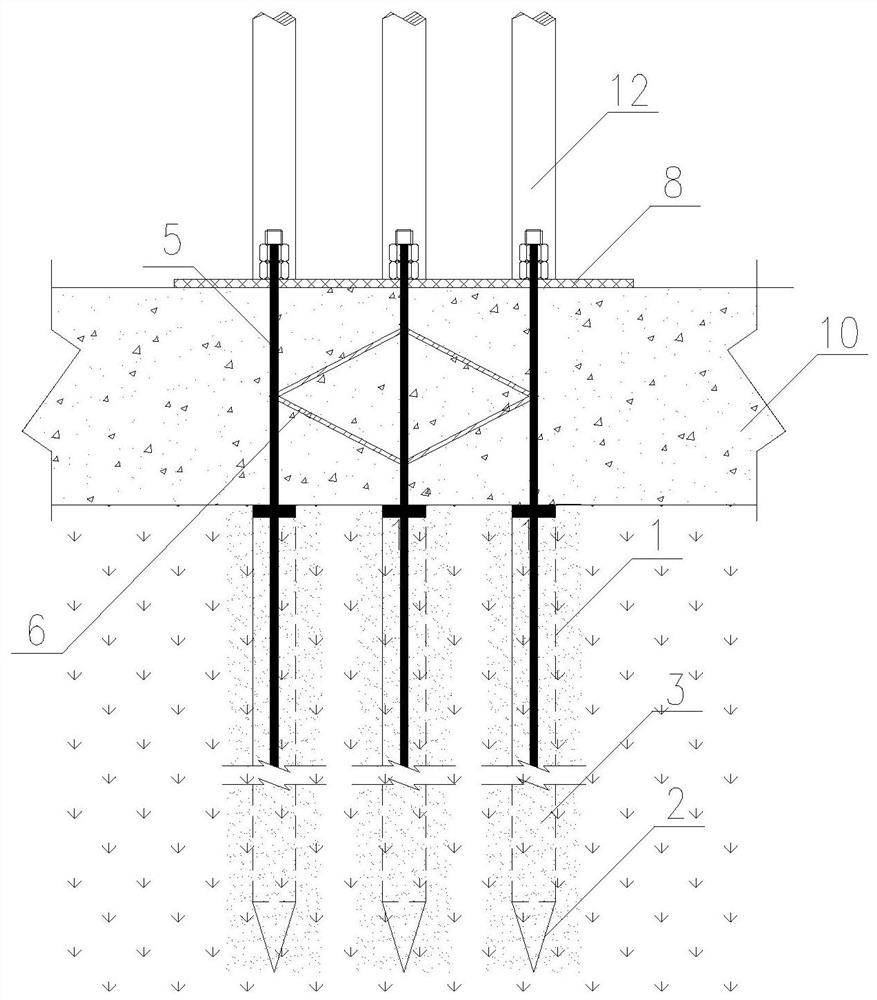

Synchronous-grouting pre-stressed pipe pile and construction method thereof

PendingCN108179743AReduced bearing capacity requirementsReduce the difficulty of pile pressingBulkheads/pilesPre stressPre stressing

The invention relates to a synchronous-grouting pre-stressed pipe pile. The synchronous-grouting pre-stressed pipe pile comprises a special pile shoe device, a prefabricated pipe pile, a grouting pipedevice and a grouting layer; the special pile shoe device comprises a main grouting pipe, branch pipe joints, branch pipes and grout discharging holes; the upper end of the main grouting pipe is connected with the grouting pipe device; the lower end of the main grouting pipe is connected with the branch pipes via the branch pipe joints; each branch pipe is connected with the corresponding grout discharging hole; the grout discharging holes are uniformly distributed at an equal interval in the outer side of a pipe pile juncture at the edge of a pile shoe; the grouting pipe device is arranged inside a cavity of the prefabricated pipe pile; and the grouting pipe device comprises a four-claw hook, an upper end interface, a grouting pipeline and a lower end interface. The synchronous-groutingpre-stressed pipe pile provided by the invention has the beneficial effects that the synchronous-grouting pre-stressed pipe pile is a novel pile foundation which is formed by adopting a pile jacking-in method and is additionally provided with a special pile shoe based on an original pre-stressed pipe pile; by synchronous grouting, the sidewall of the pipe pile can be lubricated by grouting liquid,so the difficulty of pile pressing is reduced, and the requirements on the bearing capacity of a place and the requirements on pile pressing equipment are reduced.

Owner:ZHEJIANG UNIV CITY COLLEGE

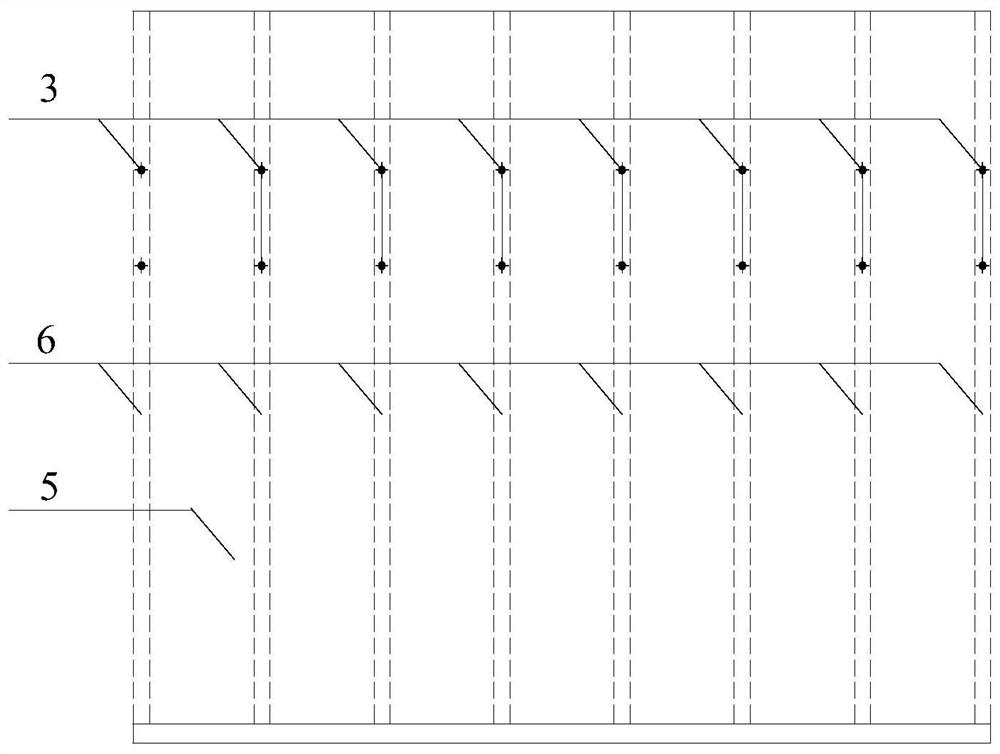

Integrated steel anchor pipe foundation structure of highway guardrail and sound barrier and a construction method thereof.

ActiveCN109736156AFast constructionEasy constructionRoadwaysBulkheads/pilesMaterials preparationSound barrier

The invention discloses an integrated steel anchor pipe foundation structure of a highway guardrail and a sound barrier and a construction method thereof. A steel anchor pipe has the advantages of rapid construction and low cost construction, and the key is that the superior anchoring performance of the steel anchor pipe, which is deeply anchored in the ground, can provide large horizontal resistance for the guardrail and the sound barrier and ensure long-term safe use of an upper structure; and at the same time, the reinforcement of steel anchor pipe can improve the stability of subgrade slope. The construction method comprises the following construction methods of material preparation and manufacture, measuring and placing of steel anchor pipe pile positions, driving holes into steel pipes, preparing grouting liquid and working procedures, first grouting, embedding vertical ribs and installing grout sealing sheets and the like. The technology is mature, the working procedures are reasonable, the construction is carried out simultaneously with subgrade and pavement construction, and the construction method has the characteristics of rapid construction. A wide application prospectfor a road equipped with the guardrails and the sound barrier is achieved.

Owner:CHINA FIRST HIGHWAY ENG +1

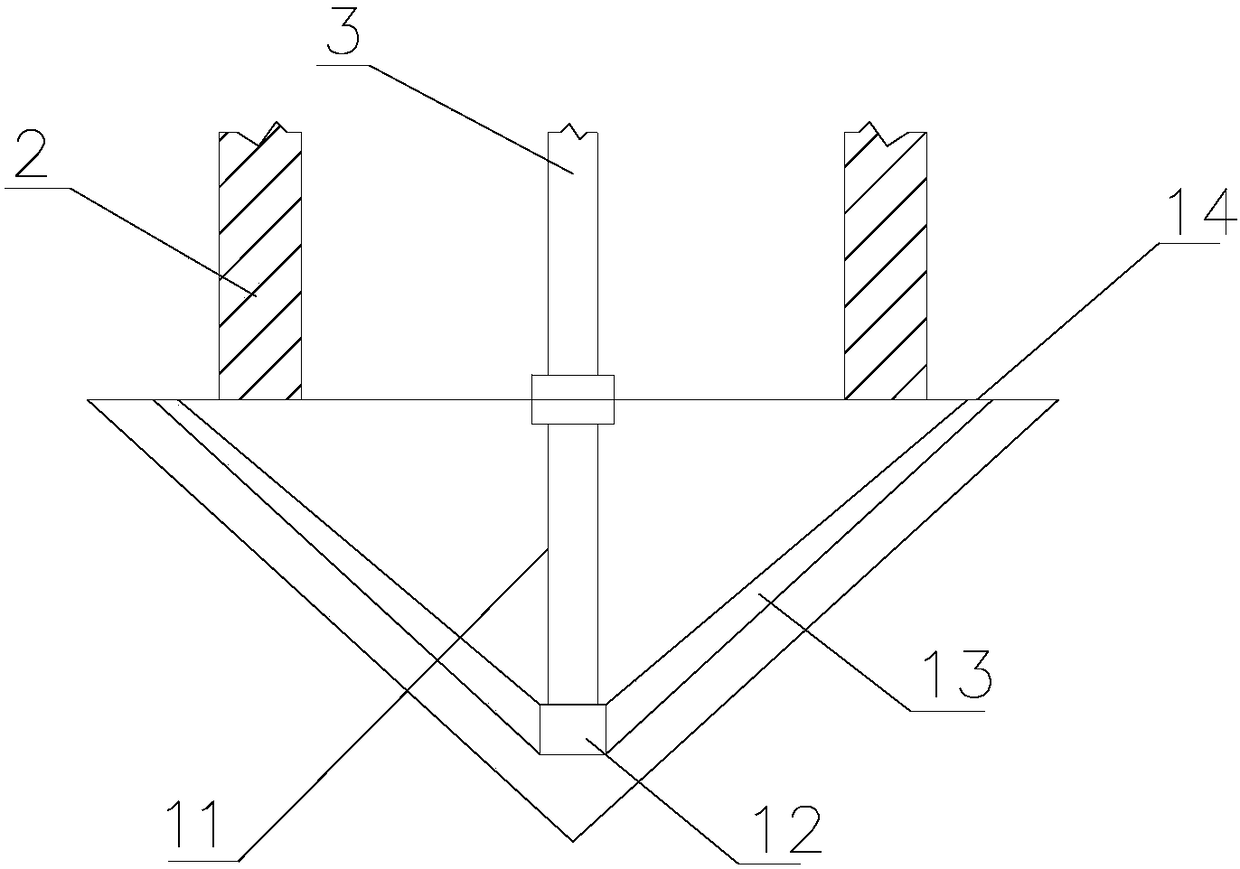

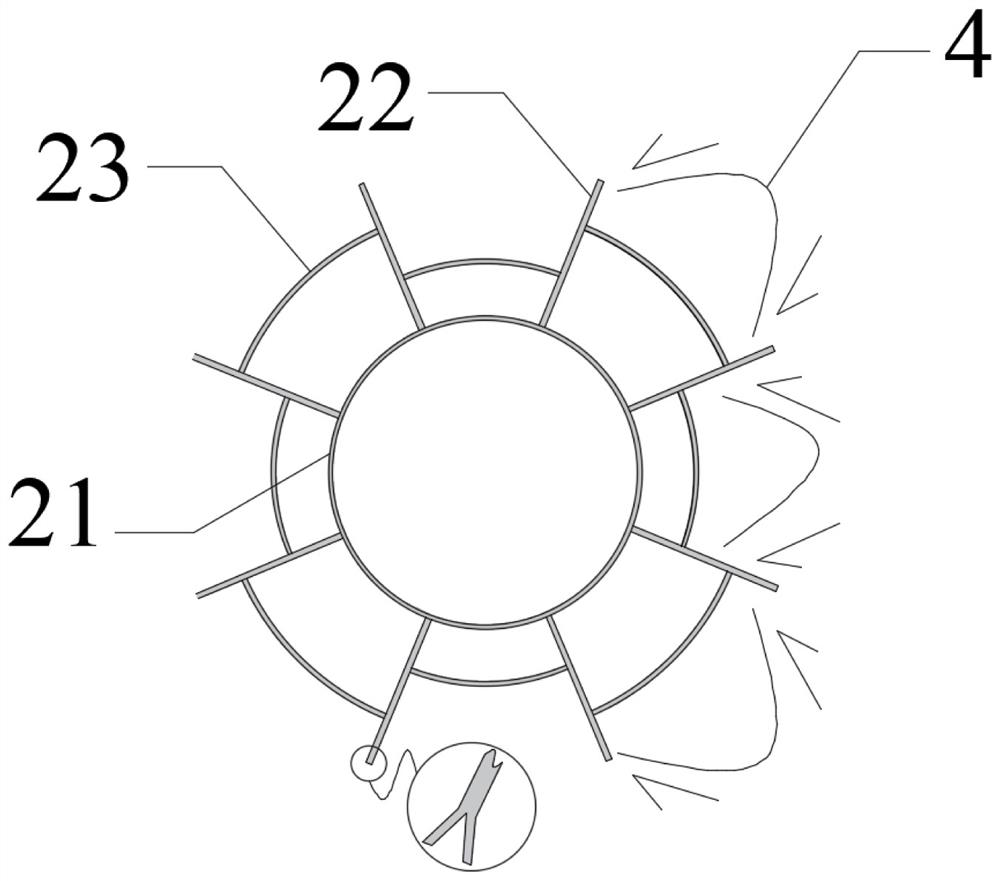

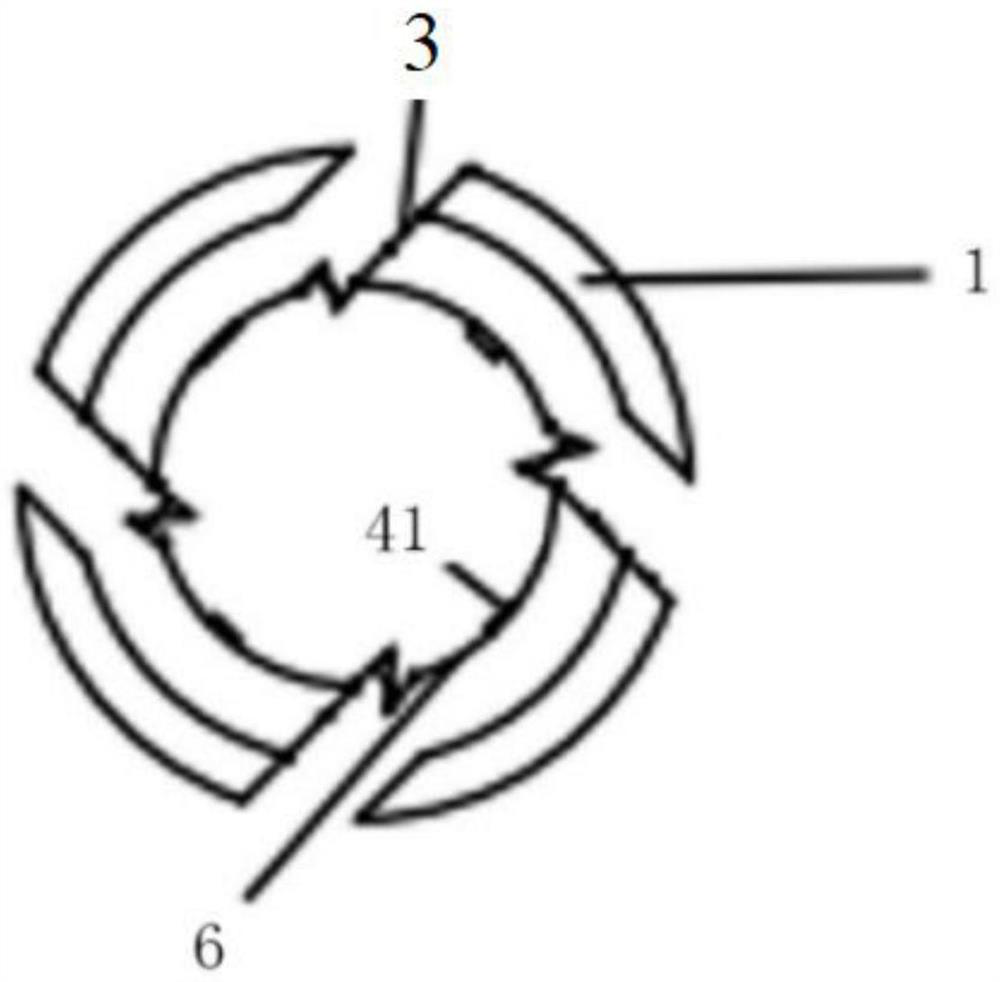

Offshore wind power single pile-friction wing composite foundation and construction method thereof

ActiveCN112942407AIncrease the interaction areaImprove carrying capacityWind motor supports/mountsWind energy generationSoil archingOffshore wind power

The invention discloses an offshore wind power single pile-friction wing composite foundation and a construction method thereof. The offshore wind power single pile-friction wing composite foundation comprises a single pile and a friction wing, wherein the friction wing is connected to the single pile through a force transmission pipe, a conical transition section of the single pile goes deep into a seabed bearing stratum, and the force transmission pipe of the friction wing located in the bearing stratum is in close contact with the conical transition section of the single pile; a side wing of the friction wing is connected to the outer wall of the force transmission pipe, and a ring wing is arranged in a side wing included angle. According to the offshore wind power single pile-friction wing composite foundation, the friction wing is of a through structure in the axial direction, so that the friction wing can conveniently penetrate through a seabed sludge layer to be embedded into the bearing stratum; the side wing, the ring wing and the force transmission pipe support each other, so that the structural stability of the friction wing is kept, a soil arching effect is generated between the side wing and the ring wings by a soil body, the resistance of the soil body is remarkably improved, the interaction area of the structure and the soil body is increased by the friction wing, and the bearing capacity of the single pile-friction wing composite foundation is improved.

Owner:CHINA THREE GORGES CORPORATION +1

Non-brace support device and construction method thereof

ActiveCN109056717AIncreased level of affordabilityPrevent horizontal displacementExcavationsBulkheads/pilesHorizontal forceBuilding construction

The invention discloses a non-brace support device which comprises support piles, anchor cables, support pillars and unbonded anchor cables. The invention provides a construction method of the non-brace support device. According to the device, by utilizing the functions of the anchor cables and the support pillars, the acting forces stressed on the support piles are transmitted into a soil body. According to the non-brace support device and the construction method thereof provided by the invention, the sufficient horizontal forces are provided through the unbonded anchor cables, and the horizontal pulling forces stressed on the unbonded anchor cables are transmitted to the bedrock positions on the pile bottoms through the support pillars. By adopting the vertically arranged anchor cables and the horizontally arranged unbonded anchor cables, the occurrence of the phenomenon that an existing anchor cable is slantways inserted into the soil body and occupies a large area so as to be limited by the neighboring building foundation is avoided, and the occupied area is reduced, so that the non-brace support device not only meets the engineering needs but also can be applicable to the places with the limited area. On the premise of ensuring the safety, the use of the anchor cables is reduced, the cost is saved, and the non-brace support device has the beneficial effects of simple structure, less occupied range, and low construction cost.

Owner:GUANGDONG UNIV OF TECH

Soil foundation road shoulder pile sheet wall reinforcing structure and design method

ActiveCN111636255AControl Horizontal DistortionDecrease the set depthRailway tracksBulkheads/pilesStructural engineeringGeotechnical engineering

The invention discloses a soil foundation road shoulder pile sheet wall reinforcing structure and a design method. The soil foundation road shoulder pile sheet wall reinforcing structure comprises reinforcing pieces, an embankment project and a pile sheet wall structure. The pile sheet wall structure comprises at least two reinforcing piles, the at least two reinforcing piles are arranged in a foundation at intervals in the longitudinal direction of a line, the reinforcing pieces are buried in the foundation on one sides of the reinforcing piles, and the foundation on the other sides of the reinforcing piles is filled with embankment project in a layered mode. The reinforcing pieces are arranged in front of the reinforcing piles, so that the foundation soil horizontal resistance in front of the reinforcing piles is increased; horizontal deformation of the reinforcing piles can be effectively controlled, and the setting depth of the reinforcing piles is reduced; the construction is simple and safe and the economy is good; the plane position and the depth range of a composite pile foundation are determined, the utilization efficiency of the composite pile foundation can be effectively improved, the setting depth of the composite pile foundation is the depth of a deformation influence area before the composite pile foundation is reinforced, it can be guaranteed that the deformation resistance of the reinforcing piles has enough safety reserves, and the method has the advantages of being simple in construction, safe and good in economical efficiency.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Novel BNT carrier pile and construction equipment construction method thereof

PendingCN112012199AEnsure safetyGuarantee the pile qualityBulkheads/pilesArchitectural engineeringDowel

The invention relates to the field of civil engineering, in particular to a novel BNT carrier pile and a construction equipment construction method of the novel BNT carrier pile. A pile hammer, a diesel hammer or a vibration hammer is used for replacing a shaking or rotary device as power, and a dowel bar and a replacement standard pile hammer are strongly combined with the BNT technology to achieve construction of the carrier pile. The high-quality potential of high bearing capacity of the carrier pile and the advantages of high pile forming quality and high applicability of the BNT technology are fully explored; some problems existing in the original carrier pile forming concept and construction are solved; through diversification of construction forms and equipment and by taking the three-strike penetration requirement as a criterion, the design and the construction are enabled to be based on the evidence; and complexity is replaced by simplicity, the process is simplified, and finally the BNT carrier pile with high bearing capacity, good effect, high speed, low cost and wider application range is realized to meet the increasingly high different requirements of engineering construction on pile foundations.

Owner:张掖市陇原地基基础工程有限公司

A composite driven snowflake pile system and construction method

The invention discloses a composite driven snowflake pile system and a construction method. The system comprises an outer core of a cement mixing pile, an inner core of a snowflake steel sheet pile, a guide component, a pile connecting device and a cement slurry state monitoring system; a snowflake steel plate A pile cap is installed on the top of the inner core of the pile, and the pile cap is connected with the bearing platform; when the outer core of the cement mixing pile exceeds the set length, the inner core of the snowflake-type steel sheet pile is driven into the pile through the pile connection device and the guide assembly by means of segment connection. The outer core of uninitialized cement mixing pile. The invention combines the bearing characteristics of the cement mixing pile and the snowflake steel sheet pile, makes up for the insufficient lateral friction resistance and insufficient structural stability caused by the relatively small volume of the high-strength steel sheet pile, and improves the bearing capacity of the pile body. The invention balances the construction cost, enhances the bearing capacity of the pile body, has a wide range of applications, is used to solve the problems of soft soil foundation reinforcement, foundation pit support and differential settlement of bridge heads, and has broad application prospects in the fields of bridges, foundation pits and roads. .

Owner:HOHAI UNIV

A highway guardrail and sound barrier share an integrated steel anchor pipe foundation structure and construction method

ActiveCN109736156BFast constructionEasy constructionRoadwaysBulkheads/pilesMaterials preparationSound barrier

The invention discloses a foundation structure and a construction method of an integrated steel anchor pipe shared by a highway guardrail and a sound barrier. The steel anchor pipe of the invention has the advantages of rapid construction and low-cost construction, and the key is to rely on its superior anchorage deep anchored in the ground The performance can provide greater horizontal resistance for guardrails and sound barriers, ensuring the long-term safe use of the upper structure; at the same time, the reinforcement treatment of steel anchor pipes can improve the stability of the embankment slope. The invention includes material preparation and production, steel anchor pipe pile position measurement, lead hole driving into steel pipe, grouting liquid preparation and process, first grouting, pre-embedded vertical reinforcement and grout sealing sheet installation and other construction methods with mature technology , the process is reasonable, and the subgrade and road surface construction are carried out at the same time, with the characteristics of rapid construction. It has wide application prospects for installing roads with guardrails and sound barriers.

Owner:CHINA FIRST HIGHWAY ENG +1

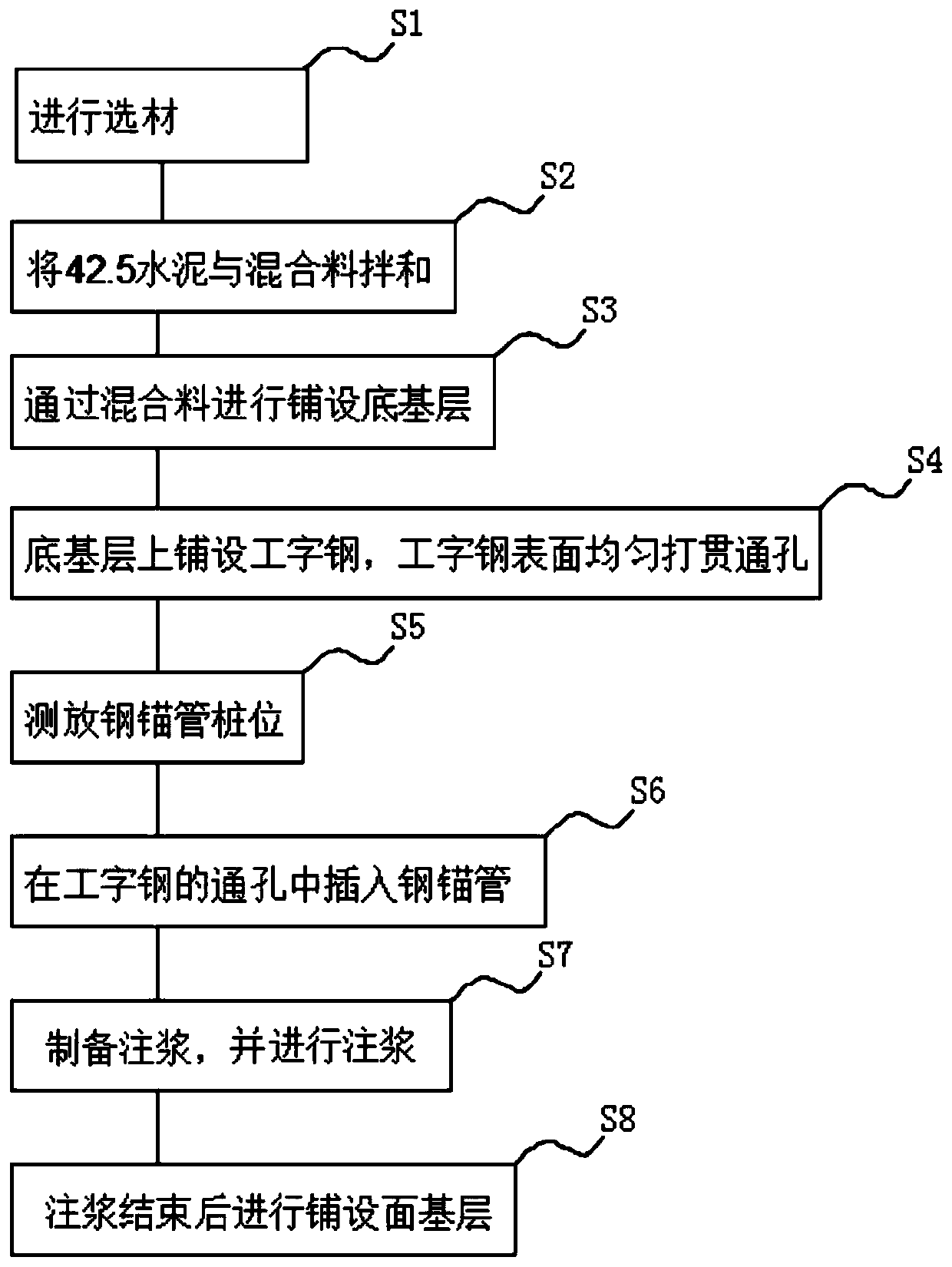

Construction process of bridge insertion-plate-type noise barrier

InactiveCN110656593AImprove stabilityImprove construction qualityNoise reduction constructionRoadway safety arrangementsNoise barrierArchitectural engineering

The invention discloses a construction process of a bridge insertion-plate-type noise barrier. The construction process comprises the steps of selecting materials to form a mixture, mixing 42.5 cementwith the mixture, allowing the amount of the cement to be 2.5-4.5% of the mixture, allowing the amount of water to be 4-6% of the mixture, laying a bottom base layer through the mixture, laying an I-beam on the bottom base layer, uniformly punching through holes in the surface of the I-beam, performing measurement and lofting of pile positions of steel anchor pipes, inserting the steel anchor pipes into the through holes of the I-beam, preparing and performing grouting, and paving a surface base layer after grouting. According to the construction process of the bridge insertion-plate-type noise barrier, the I-beam is pre-embedded between the bottom base layer and the surface base layer so that the stability of the I-beam can be improved and the noise barrier can be more stably connected to the I-beam in installation. The steel anchor pipes are inserted into the I-beam to provide larger horizontal resistance for guardrails and the noise barrier by virtue of the superior anchoring performance of the steel anchor pipes which are deeply anchored in the ground so as to ensure the long-term safe use of the upper structure, improve the construction quality of the base layers, prolong theservice lives of the base layers of the noise barrier, and improve the installation stability of the noise barrier.

Owner:安徽中源环保科技有限公司

Dividing wall anchoring type supporting structure and construction method thereof

InactiveCN112127375ASimple structureReasonable forceArtificial islandsExcavationsArchitectural engineeringEconomic benefits

The invention discloses a dividing wall anchoring type supporting structure and a construction method thereof. The supporting structure is used for supporting a fill slope body and comprises a cast-in-place anchor plate, anchor rods and a counterfort type retaining wall, the counterfort type retaining wall comprises a bottom plate, soil retaining vertical plates and a plurality of counterforts arranged in parallel, and the bottoms of the counterforts and the bottoms of the vertical plates are vertically poured on the bottom plate; one side face of each counterfort is tightly attached to one side face of the corresponding vertical plate, and the space between every two adjacent counterforts is filled with the fill slope body; and the cast-in-place anchor plate is arranged in the fill slopebody, the cast-in-place anchor plate is connected with one ends of the anchor rods, and the other ends of the anchor rod pass through the space between two adjacent counterforts, penetrate through thevertical plates and then are limited on the sides, away from the counterforts, of the vertical plates. The structure form is simple, stress is reasonable, practicability is high, the construction process is simple and convenient, cost is low, the stability of the fill slope is high, higher engineering practical value and important social and economic benefits are achieved, and the structure is worthy of large-scale application and popularization.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

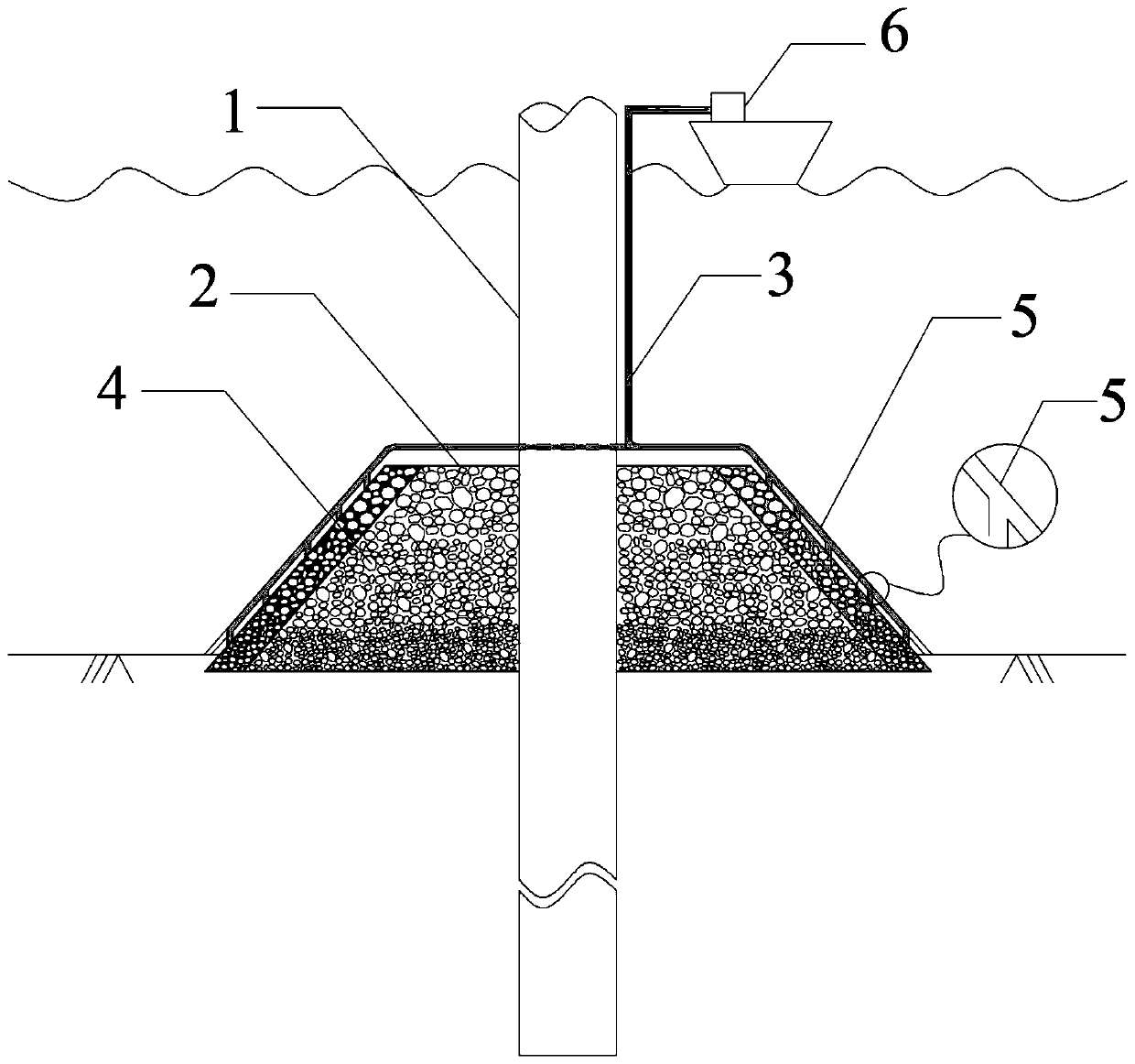

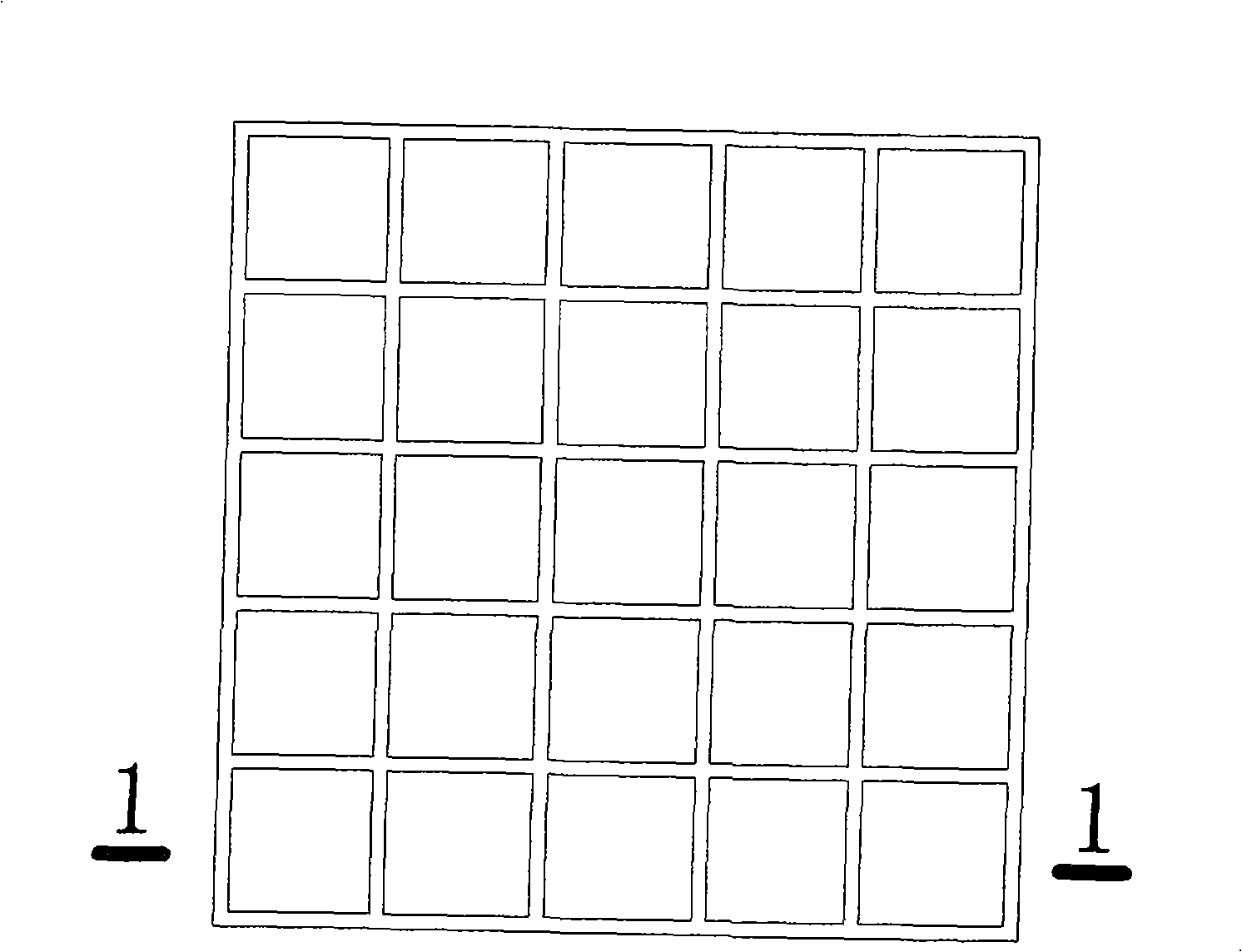

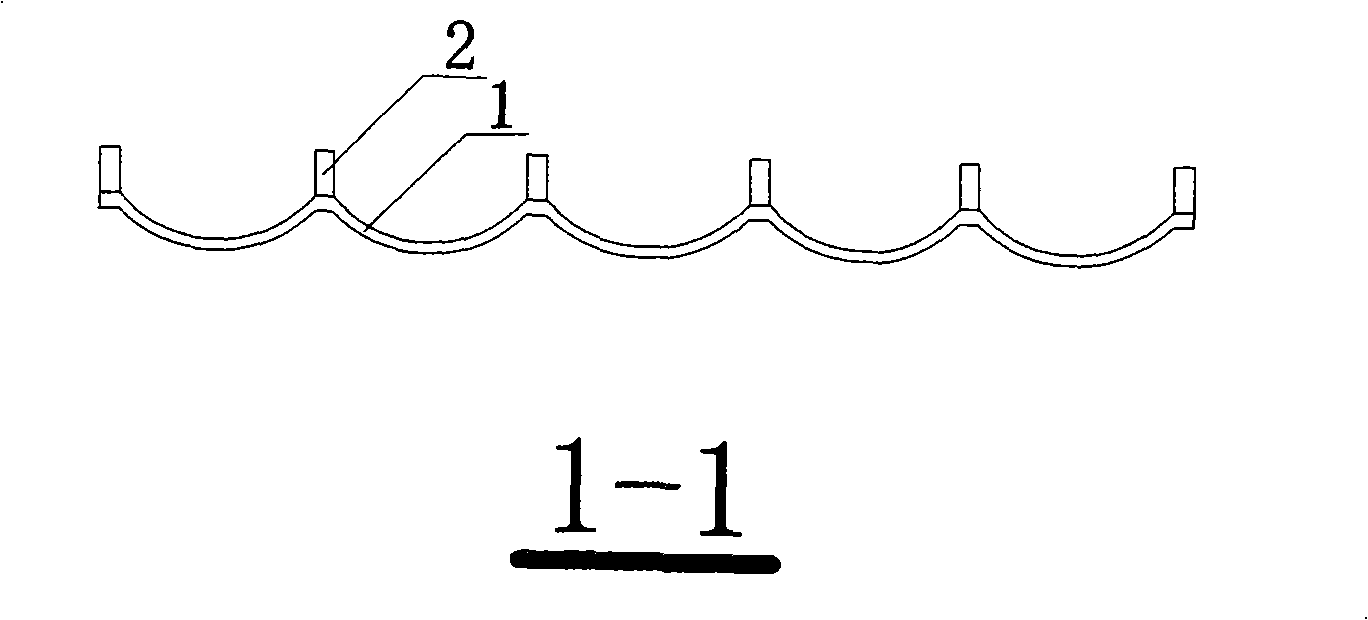

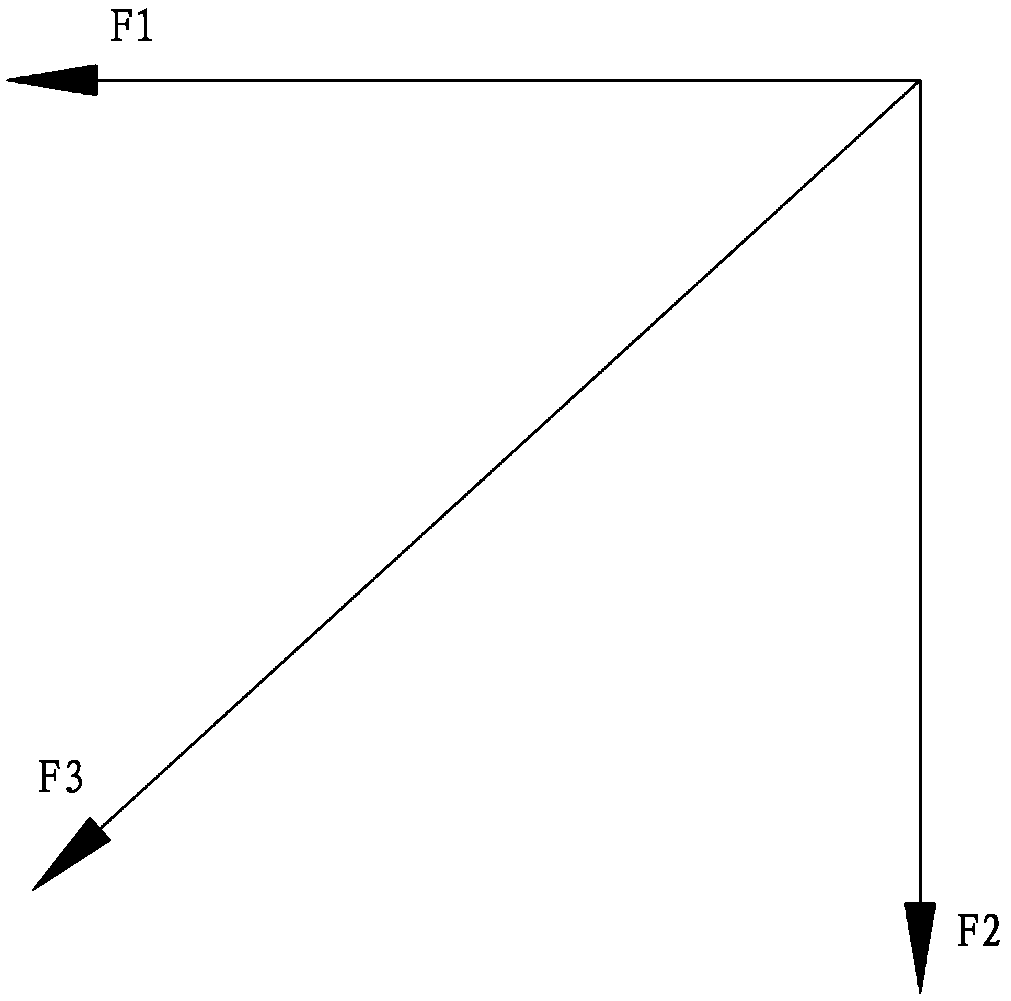

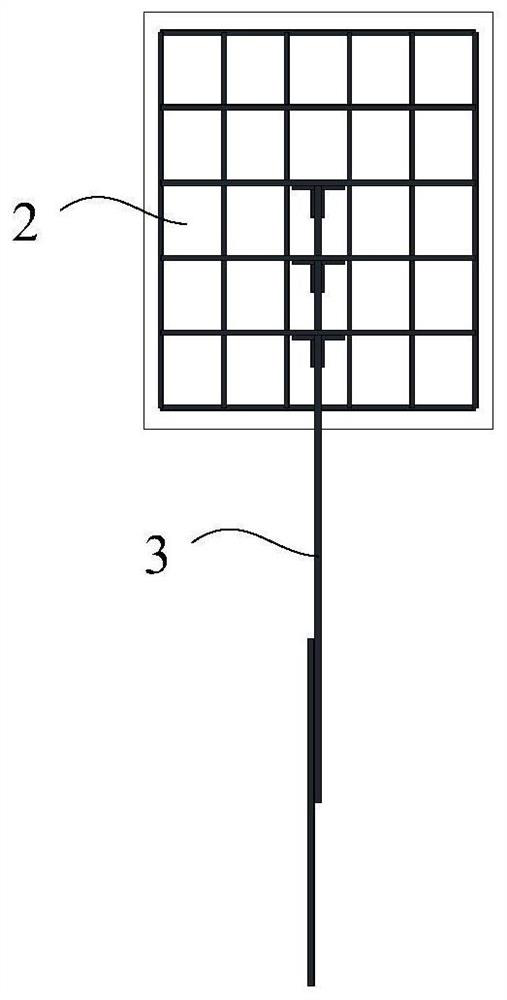

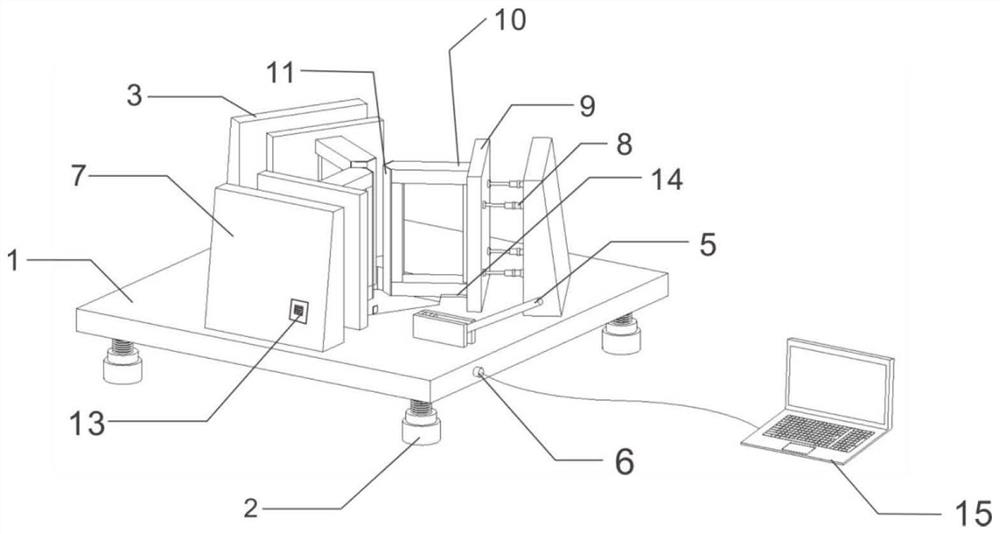

Method for increasing horizontal bearing capacity of pile foundation by using steel-gravel cylinder structure around pile

ActiveCN112523247AIncrease stiffnessIncrease horizontal resistanceSoil preservationVertical displacementBearing capacity

The invention discloses a method for increasing the horizontal bearing capacity of a pile foundation by using a steel-gravel cylinder structure around a pile. According to the method, the cylinder wall of the cylinder structure penetrates through a pile body and is installed on the top surface of foundation soil, gravel is filled in the cylinder wall, then horizontal external force is applied to the pile foundation so as to enable the pile body to move, and a soil layer below the inclined side of the pile body is compressed to deform at the moment, so that the part, which makes contact with acylinder bottom plate, of the pile body on the other side is separated so as to generate a gap, and the gravel filled in the cylindrical foundation can leak into the foundation soil from the gap. Similarly, loading is performed on the other sides of the pile body, so that soil bodies on the other sides are also subjected to the same effect. The steps are repeated in the piling process, so that shallow poor foundation soil can be replaced by gravel, and the horizontal resistance of the pile foundation is improved. The foundation form provided by the invention has the advantages that a single-pile foundation effectively controls vertical displacement and a cylindrical foundation effectively controls horizontal displacement, the horizontal bearing capacity and the bending bearing capacity ofthe foundation are increased, and the foundation form is particularly suitable for foundations of structures with complex stress such as offshore wind turbines and the like.

Owner:ZHEJIANG UNIV

Method for manufacturing a PHC tubular pile in soft soil region through chambering and grouting

ActiveCN101545255BImprove stress resistanceImprove pull resistanceBulkheads/pilesSoil preservationHorizontal forceEconomic benefits

Owner:TIANJIN JIANCHENGJIYE GRP

Composite driven snowflake type pile system and construction method

The invention discloses a composite driven snowflake type pile system and a construction method. The system comprises a cement mixing pile outer core, a snowflake type steel plate pile inner core, a guide assembly, a pile connecting device and a cement paste state monitoring system; a pile cap is installed on the top of the snowflake type steel plate pile inner core and connected with a bearing platform; and when the length of the cement mixing pile outer core exceeds the set length, the snowflake type steel plate pile inner core is driven into the cement mixing pile outer core which is not initially set in a segmented pile connecting manner through the pile connecting device and the guide assembly. According to the composite driven snowflake type pile system and the construction method, the bearing characteristics of a cement mixing pile and a snowflake type steel plate pile are combined, the situation that due to the fact that the size of a high-strength steel plate pile is relatively small, the side friction resistance and the structural stability are insufficient is made up for, and the bearing capacity of a pile body is improved. According to the composite driven snowflake type pile system and the construction method, the construction cost is balanced, the bearing capacity of the pile body is enhanced, the application range is wide, the composite driven snowflake type pile system and the construction method are used for solving the problems of soft soil foundation reinforcement, foundation pit supporting and differential settlement of a bridgehead, and wide application prospects are achieved in the fields of bridges, foundation pits and roads.

Owner:HOHAI UNIV

Building pile structure

InactiveCN104818708AImprove structural strengthIncrease frictionBulkheads/pilesHorizontal forceSurface mounting

The invention discloses a building pile structure. The building pile structure comprises a pile body, wherein the top of the pile body is connected with a pile fixed connecting piece; the pile fixed connecting piece and the pile body are integrally connected; a pile fixed connecting hole is formed in the pile fixed connecting piece; connecting anchor pipes are arranged on the pile body near the top; two connecting anchor pipes are provided, adopt arc structures, and are vertically arranged; a reinforcing column is arranged between the two connecting anchor pipes; the top and the bottom of the reinforcing column are connected with the connecting anchor pipes through connecting bolts; a protective strip is arranged at the bottom of the pile body, and is connected with the pile body through a fastening nail; and a spiral filling pile is mounted on the lower surface of the protective strip. The building pile structure is high in structure strength; the friction force, the horizontal force resistance and the cutting force of the pile are enhanced to a certain extent; the stability and the bearing intensity of the pile are effectively improved; the building pile structure is convenient to be disassembled for recycling; the construction cost is reduced to a certain extent; and the construction efficiency is greatly improved.

Owner:CHENGDU LYUDI TECH

Offshore wind power single pile-friction wing composite foundation and its construction method

ActiveCN112942407BIncrease the interaction areaImprove carrying capacityWind motor supports/mountsWind energy generationOffshore wind powerSoil resistance

An offshore wind power monopile-friction wing composite foundation and its construction method, which includes a single pile and a friction wing, the friction wing is connected to the single pile through a force transmission tube, and the conical transition section of the single pile goes deep into the bearing layer of the seabed and is located at The force transmission tube of the friction wing in the force-bearing layer is in close contact with the conical transition section of the single pile, the side wings of the friction wing are connected to the outer wall of the force transmission tube, and the ring wings are arranged inside the included angle of the side wings. The friction wing of the present invention is a penetrating structure in the axial direction, which is convenient to pass through the seabed silt layer and embed into the force-bearing layer; The soil arch effect is generated between the wings, which significantly improves the resistance of the soil. The friction wing increases the interaction area between the structure and the soil, and improves the bearing capacity of the single pile-friction wing composite foundation.

Owner:CHINA THREE GORGES CORPORATION +1

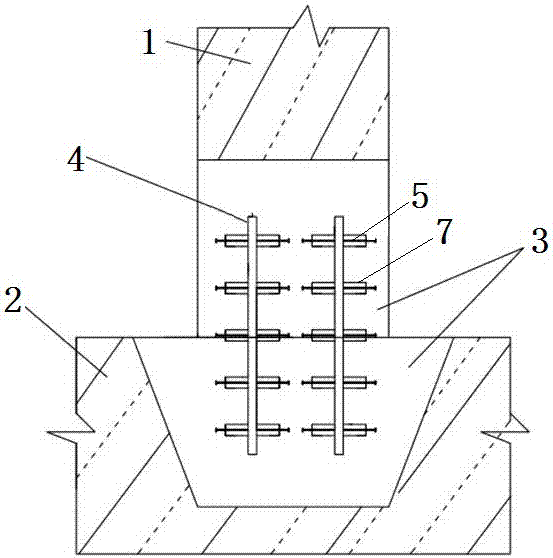

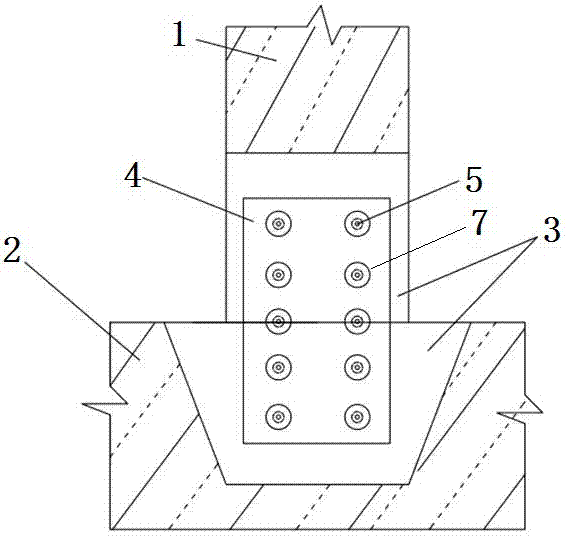

Composite column and foundation joint structure with horizontal seismic performance and its construction method

InactiveCN105863073BHigh strengthImprove carrying capacityProtective buildings/sheltersShock proofingEngineeringHouse building

The invention relates to a combined column and foundation node structure with horizontal seismic performance and a construction method thereof. The combined column and foundation node structure comprises a combined column and a foundation, wherein the connecting nodes of the combined column and the foundation are integrally connected through a poured concrete layer, at least two vertical steel plates are transversely buried inside the concrete layer, a plurality of studs are arranged on the surface of each vertical steel plate in a matrix manner, the studs vertically penetrate the surface of the vertical steel plate and are welded to the vertical steel plate, nuts are welded to two ends of the studs, and a sleeve which is manufactured through ultrahigh-performance concrete pouring and used for being integrally connected with the periphery of each stud is arranged on the periphery of the stud. The combined column and foundation node structure has the advantages that the structure is convenient in construction and applicable to house building and bridges to increase the horizontal seismic performance of houses and the bridges, and the strength and ductility of the combined column and the foundation nodes are increased.

Owner:FUZHOU UNIV

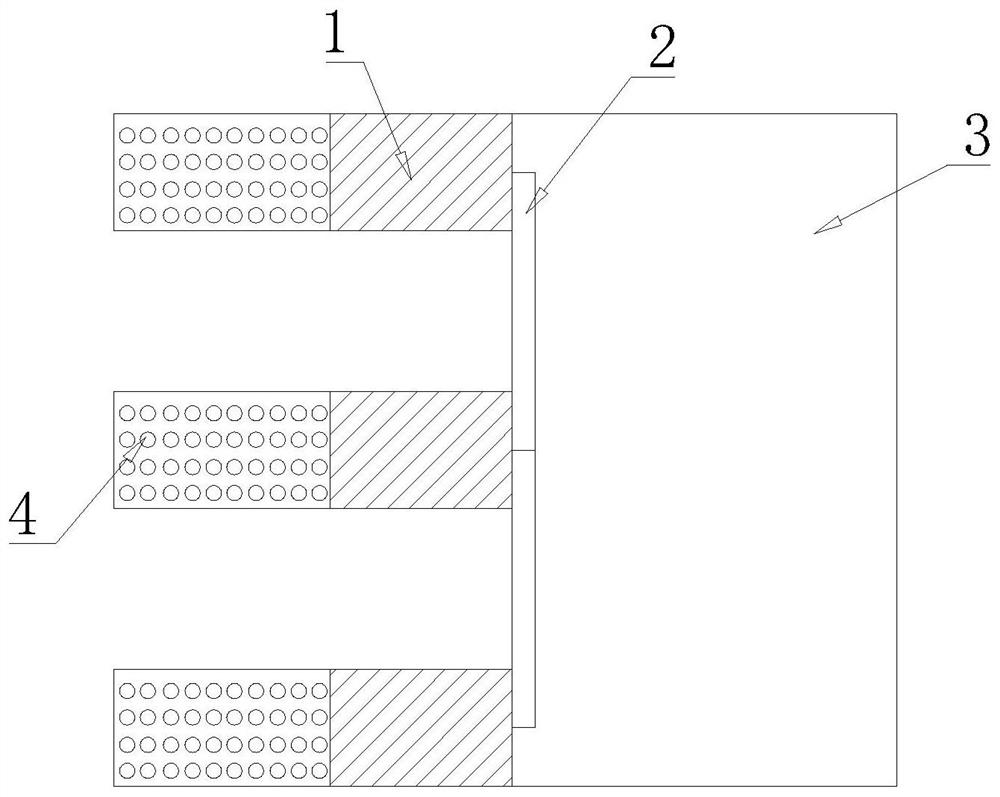

Vertical-to-transverse bidirectional constraint anchoring pile supporting structure and construction method thereof

PendingCN111962526AIncrease spacingReduce in quantityExcavationsBulkheads/pilesArchitectural engineeringSupport point

The invention discloses a vertical-to-transverse bidirectional constraint anchoring pile supporting structure. The structure comprises a plurality of anti-slide piles which are arranged in parallel and vertically or obliquely, top beams and brackets are arranged at the tops of the anti-slide piles; an inter-pile baffle is arranged between every two adjacent anti-slide piles; a first anchor cable is arranged at the top of the bracket; one end of the first anchor cable is connected with the top of the bracket through a first anchor head, an anchor cable steering device is arranged on the bracket, one end of the anchor cable steering device is fixedly connected with one end of the first anchor cable, the other end of the anchor cable steering device is fixedly connected with one end of the second anchor cable, and the other end of the second anchor cable is fixed to the front side of the anti-slide pile through a second anchor head. Vertical constraint and transverse constraint are simultaneously provided through an anchor cable of the anchor cable steering device; the supporting function of the anchoring piles is achieved, the supporting points of the first anchor cables and the steering devices act on bracket vertical loads, the anti-slide pile top anti-overturning bending moment is provided, pile top deformation can be strictly controlled, the supporting cost is reduced, the reliability of a supporting structure system is improved, and application and popularization are facilitated.

Owner:GUIZHOU UNIV

Pile body toughening and monitoring device based on assembly ribs

ActiveCN114215120AIncrease side frictionIncrease stiffnessFoundation testingApparatus for force/torque/work measurementArchitectural engineeringData acquisition

The invention belongs to the technical field of civil engineering, and relates to an assembly rib-based pile body toughening and displacement monitoring test device, which comprises an outer protective cylinder for fixing an assembly rib, a wedge-shaped assembly rib and a connecting rod for ensuring the perpendicularity of the assembly rib on the wedge-shaped assembly rib, the pressure sensors are arranged on the contact surfaces of the assembling ribs and the pile body; the stay wire displacement meters are arranged on the connecting rods; and an intelligent data acquisition device. The assembling ribs are selected, on one hand, the pulling resistance of the pile can be enhanced, meanwhile, the contact area between the pile side and soil is increased, and the pile side friction resistance is improved; meanwhile, the pile side assembling ribs can play a hoop role, the compression resistance and the horizontal displacement resistance of the pile body are enhanced, and the overall toughness of the pile body is improved; transportation is convenient, and certain engineering significance is achieved; and meanwhile, on-site installation can prevent the rib from being damaged or the sensor from being disturbed during pile pressing. And a scientific and feasible design method is provided for pile body sidesway monitoring.

Owner:SHENZHEN UNIV +1

Partially buoyant offshore platform for offshore wind power, bridges and marine structures and construction method

ActiveCN103362113BIncrease horizontal resistanceImprove stabilityArtificial islandsUnderwater structuresMarine architectureMulti platform

Owner:黄灿光 +1

Arch bar base and construction method

InactiveCN101492921BImprove structural rigidityImprove stabilityFoundation engineeringHorizontal forceRebar

Owner:SINO RISING SUN CONSTR GRP

Combined snowflake type pile foundation construction system and construction method

InactiveCN113266032AImprove pile performanceImprove bearing capacityBulkheads/pilesSoil preservationArchitectural engineeringStructural engineering

The invention discloses a combined snowflake type pile foundation construction system and a construction method. The pile foundation construction system comprises a combined snowflake type pile foundation and construction equipment, wherein the combined snowflake type pile foundation comprises a snowflake type concrete steel sheet pile and a powder spraying pile; the snowflake type concrete steel sheet pile is pressed into the powder spraying pile under the action of the construction equipment; the construction equipment comprises a base and an operation device; the operation device comprises a plurality of positioning locking devices, a manual operation system, a two-dimensional code remote operation system, a computer remote operation system and an operation system control center; the positioning locking devices are used for positioning the snowflake type concrete steel sheet pile; and the operation system control center is used for converting the manual operation system, the two-dimensional code remote operation system and the computer remote operation system so as to control the locking sizes of the positioning locking devices and the height of the construction equipment. According to the combined snowflake type pile foundation construction system and the construction method, the perpendicularity of a pile body is guaranteed when the snowflake type concrete steel sheet pile is sunk into the powder spraying pile, and the horizontal ultimate bearing capacity of the combined snowflake type pile foundation is improved.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com