Patents

Literature

62results about How to "Improve pull resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

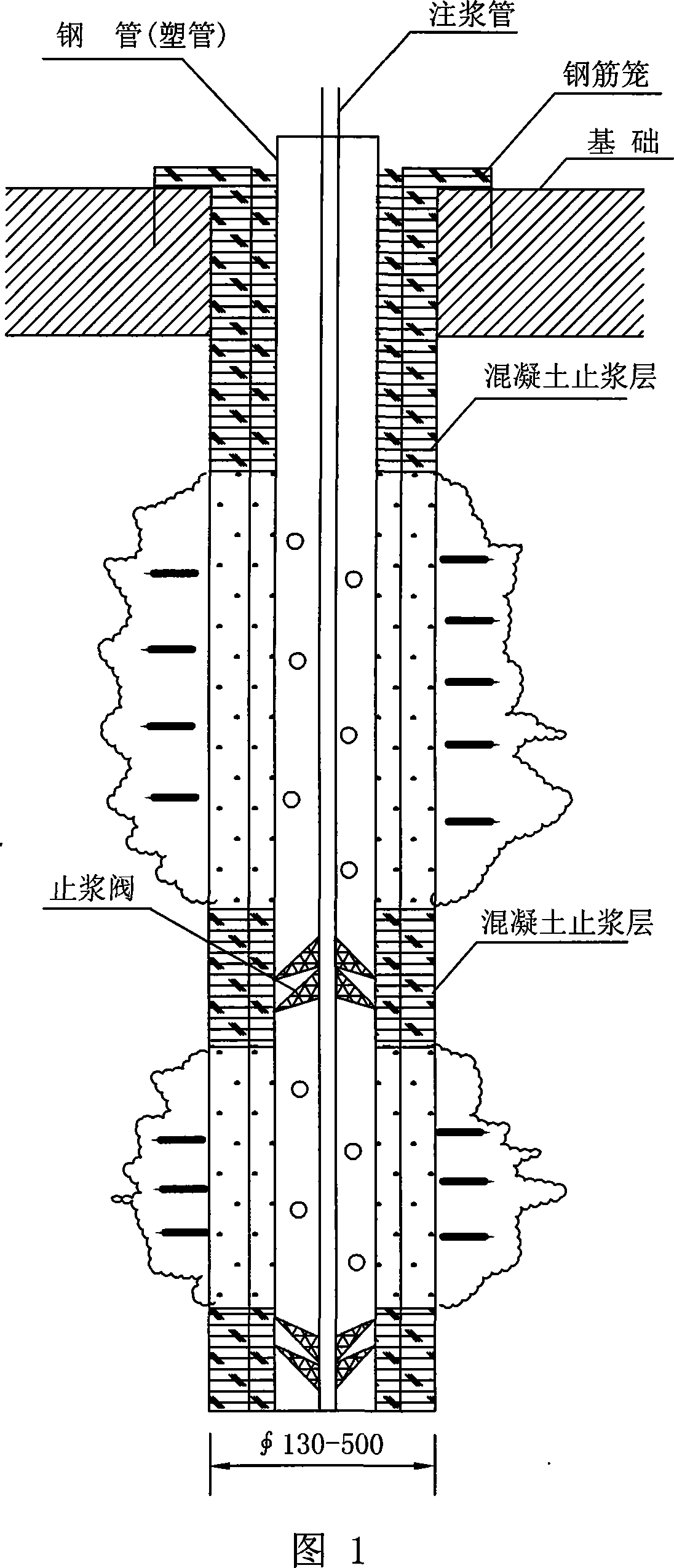

Construction method for pulling-resistant and pressure-resistant slip casting pipe pile

InactiveCN101058979ASolve the problem of insufficient pullout resistance of pullout pilesImprove pull resistanceBulkheads/pilesCrushed stoneWater table

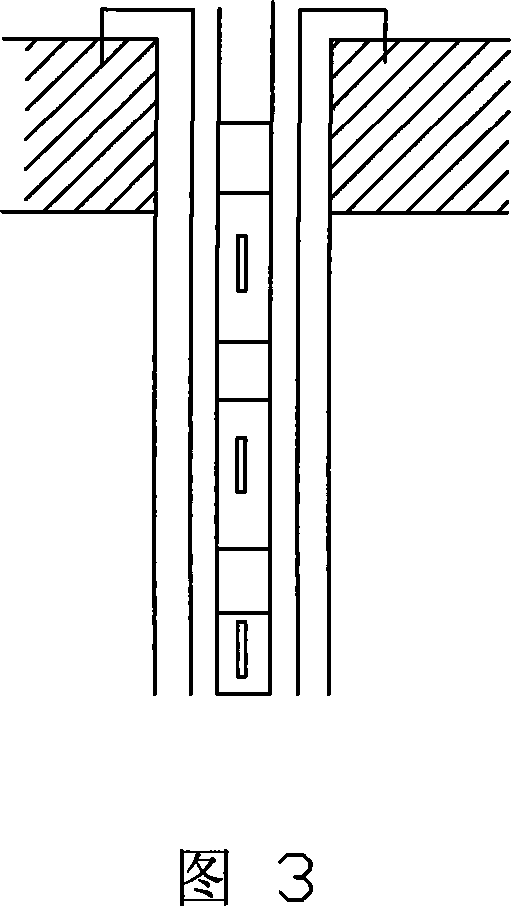

A construction method of casting pipe pile plucking with resistance to plucking and pressing, The invention relates to a construction method of pipe pile. The purpose of the invention is: solving the insufficient problems of resistance to plucking and pressing happened in the buildings which are built under complex geological conditions or under higher groundwater level geological strata and the problems are generated by bottom board percolating water due to buildings bottom board plucking resistance is insufficient, declination due to excessive eccentricity when design buildings and when design the resistance to plucking of new buildings. The invention drills hole downward on the buildings basic layer according the design height mark and bore diameter of pipe pile, lifts downward steel pipes or plastic pipes with slip casting hole after the drilled hole is completed, lifts downward reinforcement bar or reinforcement cage in the hole out the steel pipes or plastic pipes, lifts downward sands and broken stone between the outer wall of the steel pipes or plastic pipes and the hole wall. The invention has extremely distinctive action in buildings plucking-resistance and reinforcement, buildings declination correction and the foundation reinforcement project of house floors addition and reconstruction. The pile type in the invention is suitable for various geological strata, it can be used for the plucking-resistance, reinforcement and foundation reinforcement of prior buildings and the resistance-plucking pile construction of new buildings.

Owner:何新东

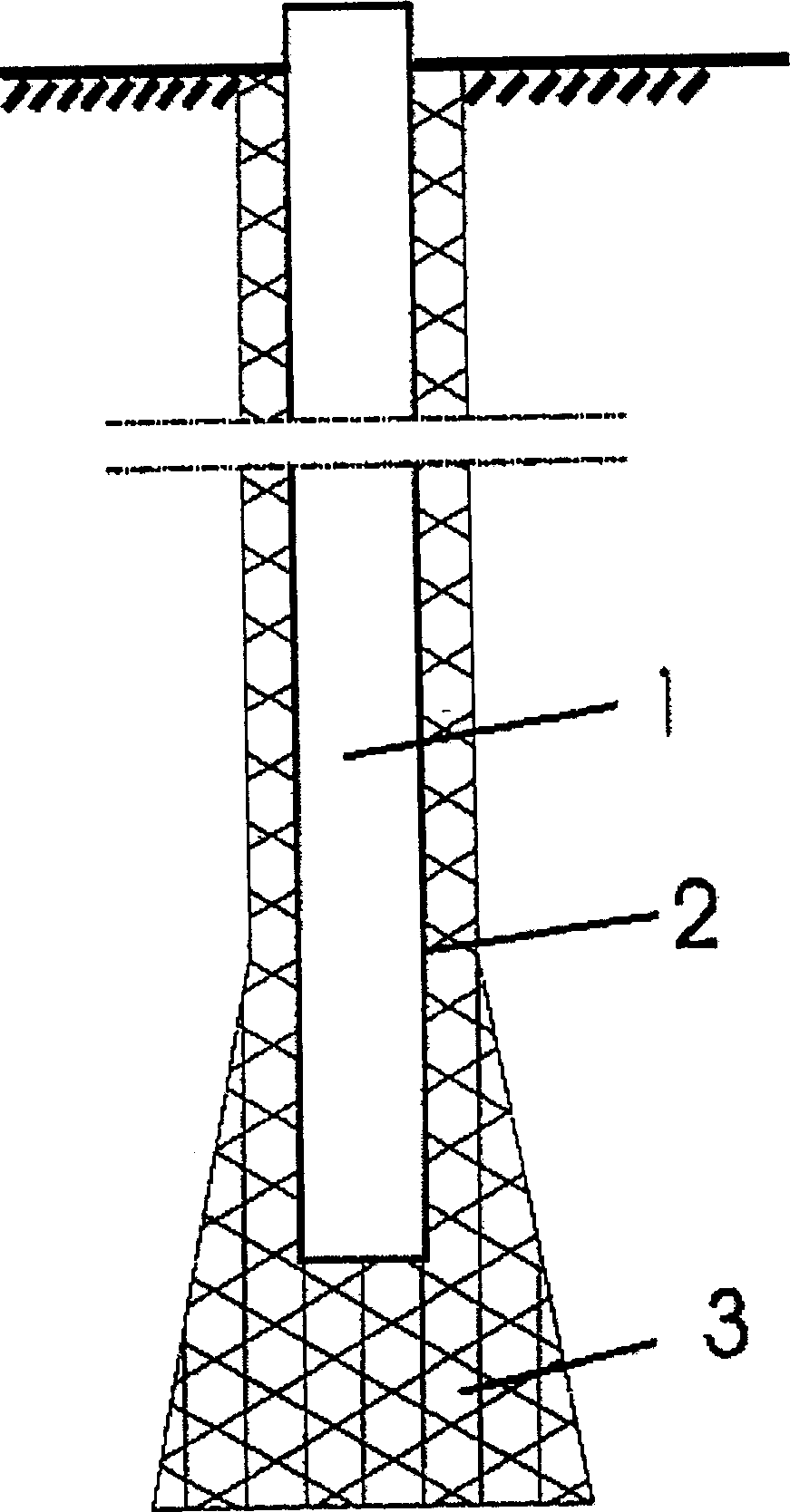

High-pressure rotary spraying and core inserting process to form pedestal pile

InactiveCN1441124AHigh strengthIncrease loading capacityBulkheads/pilesBridge engineeringReinforced concrete

The present invention relates to high-pressure rotary spraying and core inserting process to form pedestal pipe. The pedestal pile consists of core pile, column and pile depestal. The cylindrical or turned frustum-shaped core pile may be prefabricated reinforced concrete pile, in-situ deposited pile or other pile in different cross section shapes. The pile pedestal below the core pile has diameter greater than that of the core pile. The column has circular, semi-circular of fan-shaped cross section. There may be several auxiliary core piles around the main solid or hollow core pile and several rings in relatively great diameter around the column. The present invention has reasonable design, compact structure, high friction resistance, and wide application in building engineering, bridge engineering, civil engineering, water engineering, etc.

Owner:雷玉华

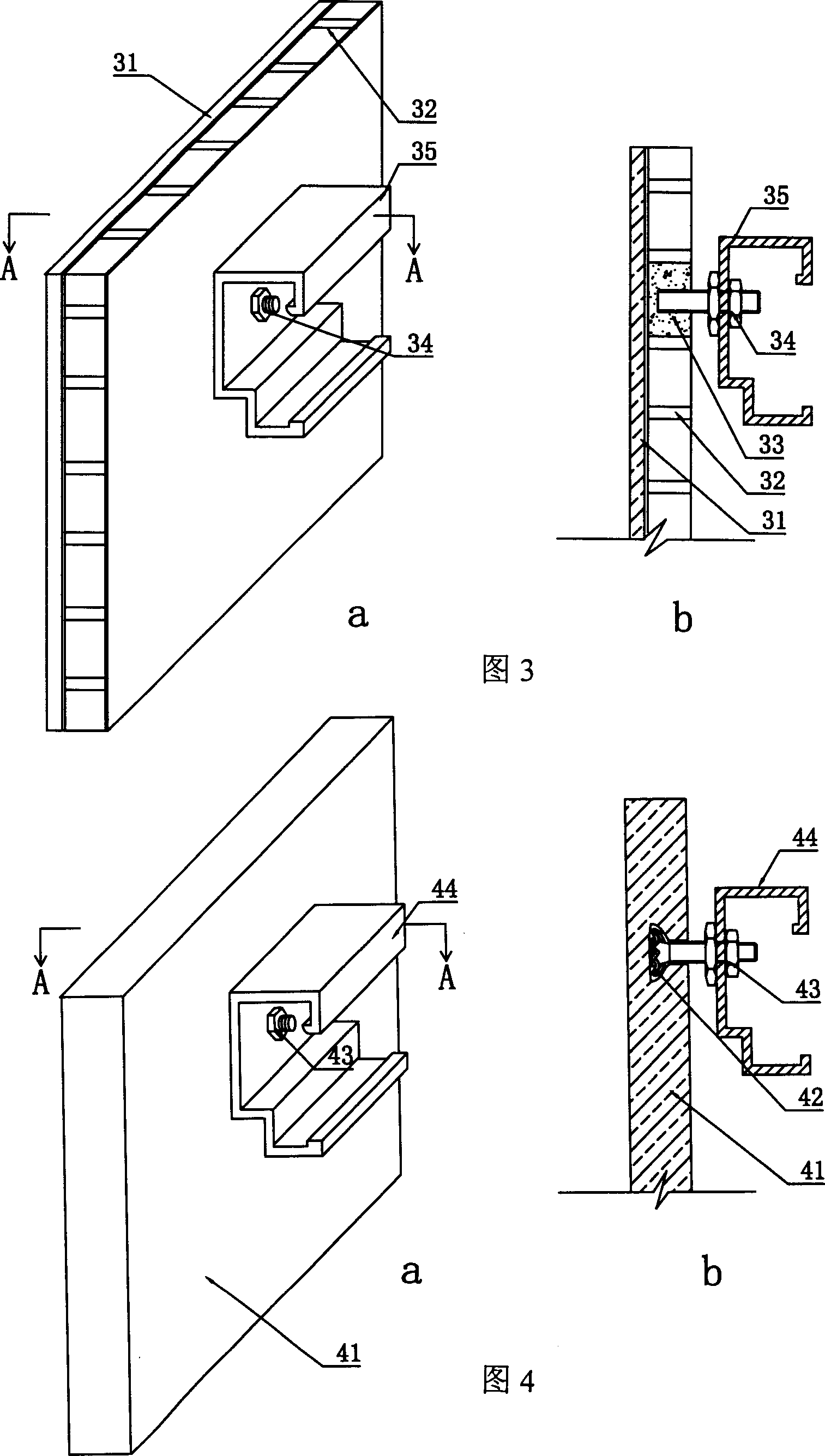

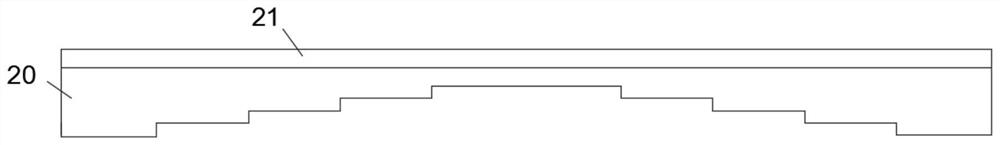

Hanger embedded decorative panel of stone material and its making method

An embedded hanger type decorative stone slab is composed of surfacial stone layer, embedded hangers in the slot on the back of said surficial stone layer, and insulating layer on the back of said surficial layer. It is possible to attach a reinforcing layer to it. Its advantages are less consumption of stone, low cost, and high stress performance.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV +1

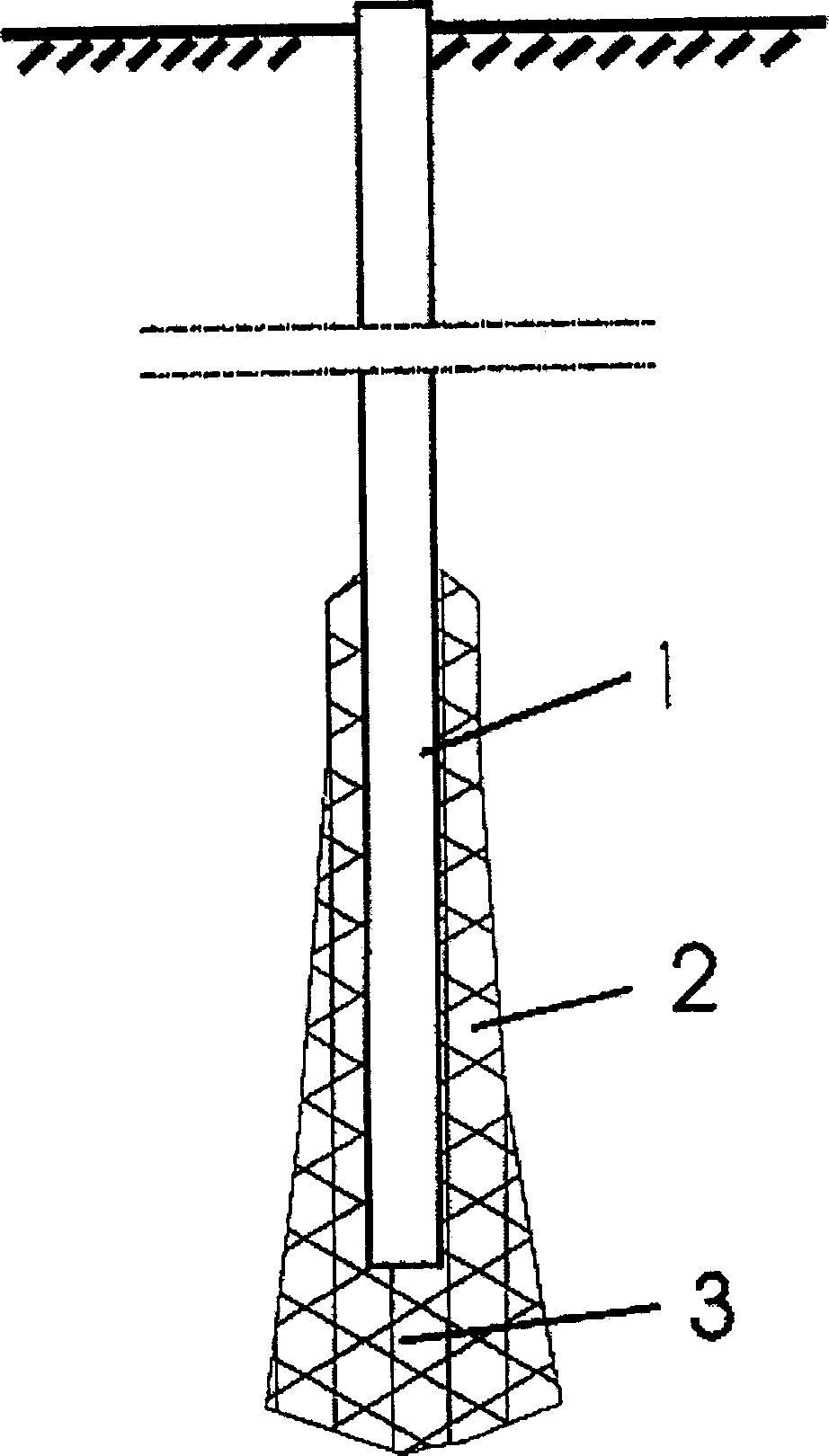

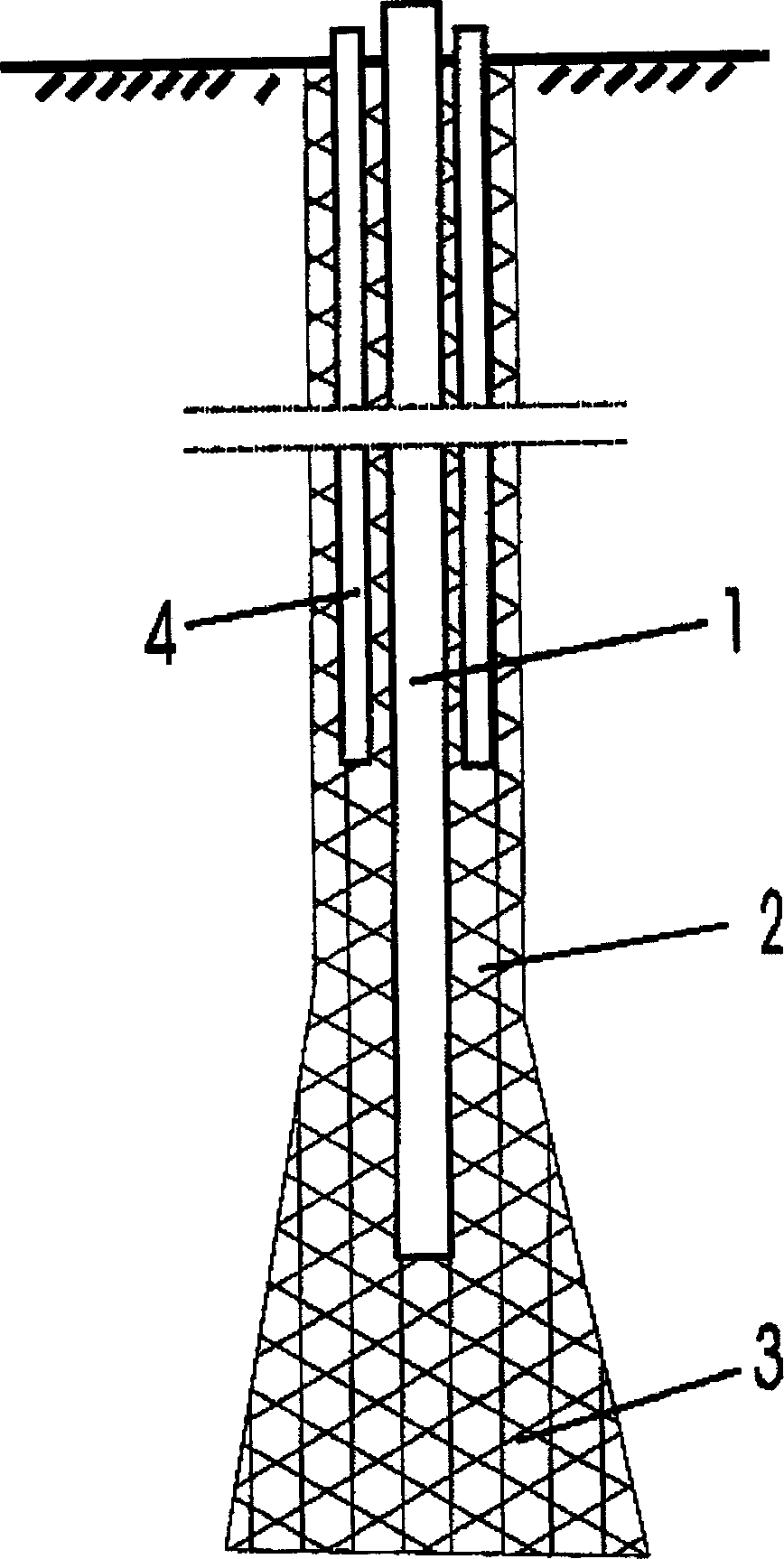

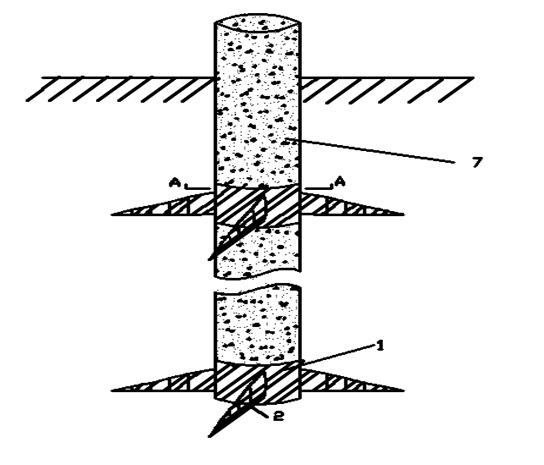

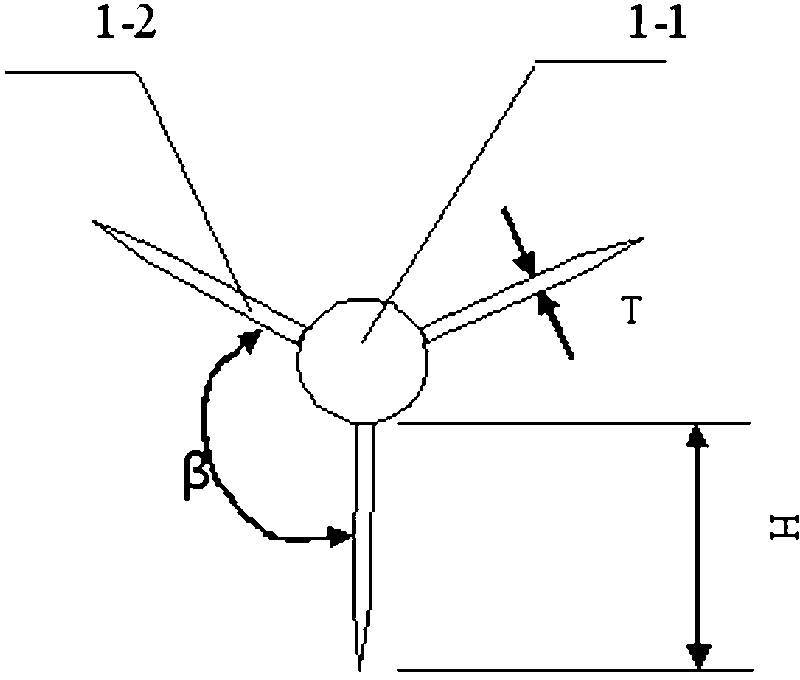

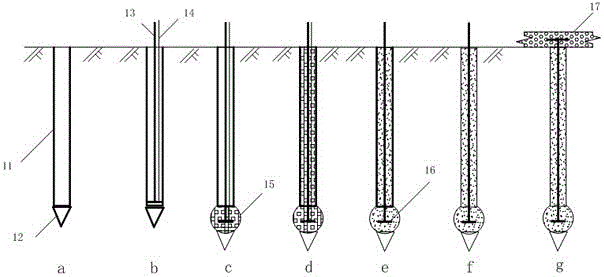

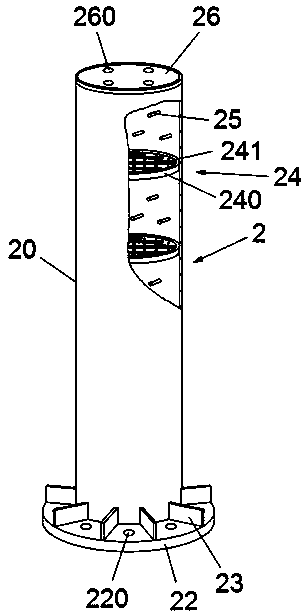

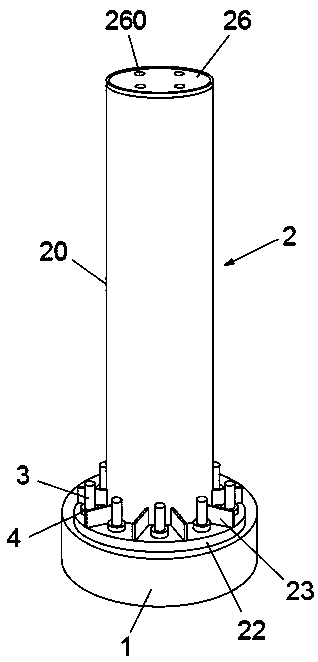

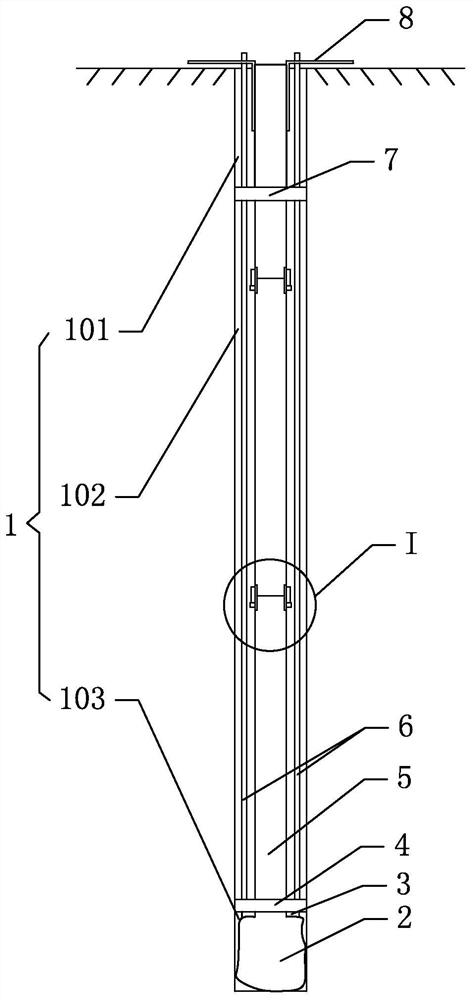

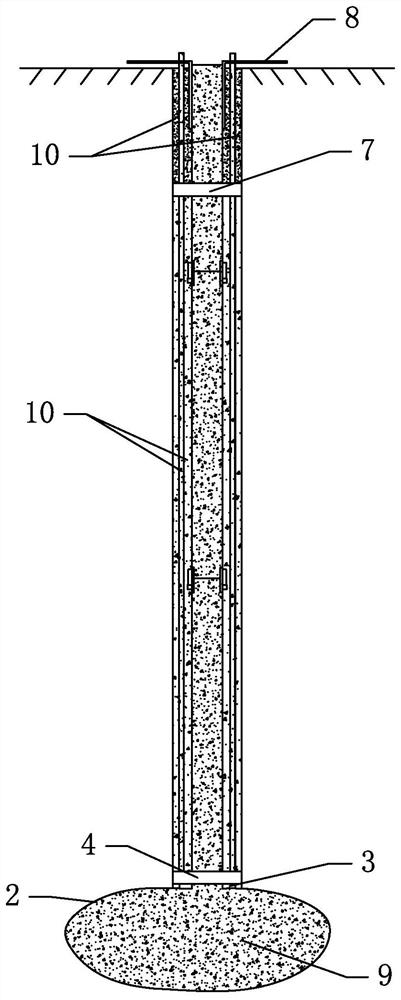

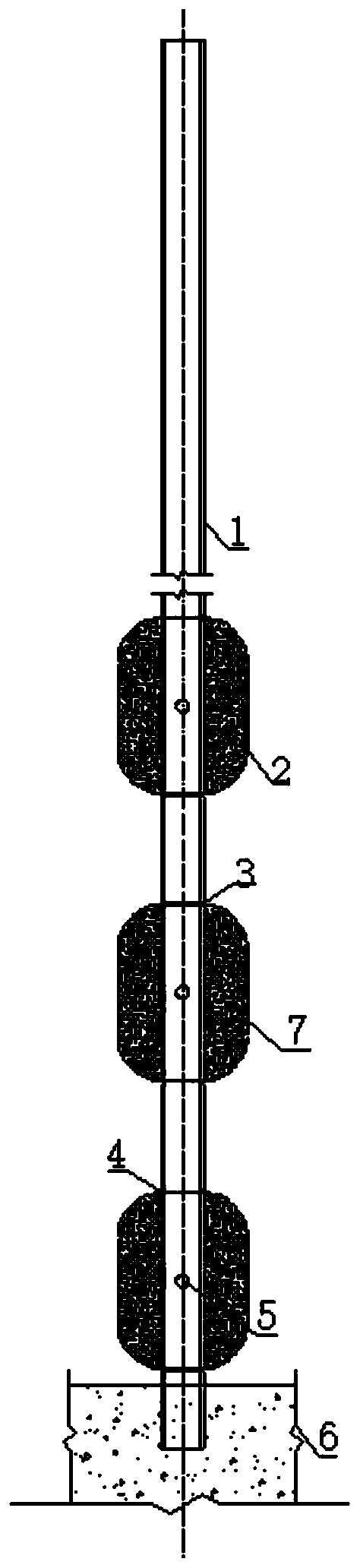

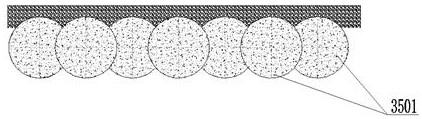

Novel tree root structure pile and construction process thereof

InactiveCN102051876AReasonable structural designImprove bearing capacityBulkheads/pilesTree rootFilling materials

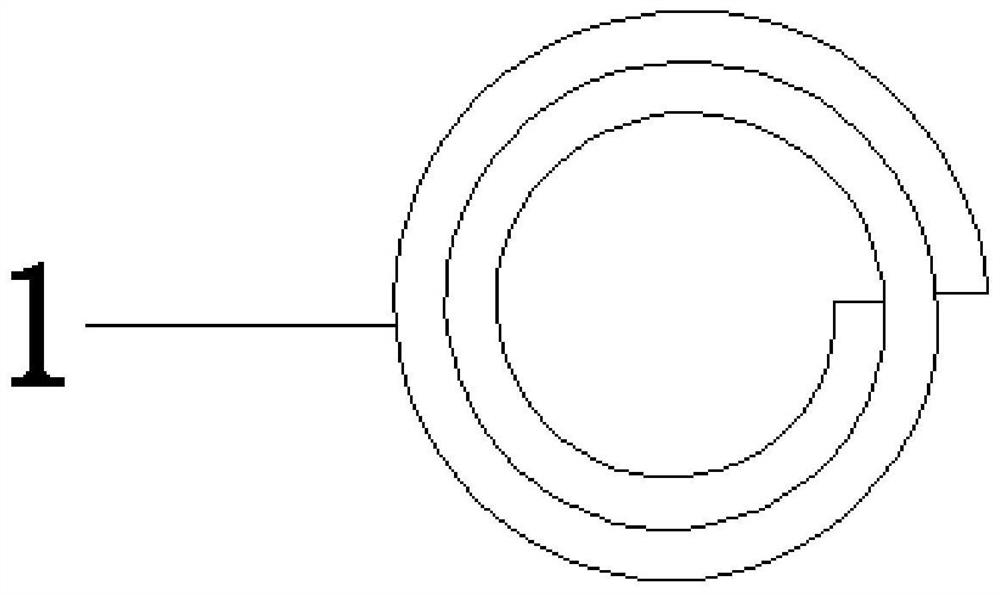

The invention discloses a novel tree root structure pile. The tree root structure pile is characterized by comprising a hollow column (1), wherein the upper end of the hollow column (1) is provided with a top cap (4), the lower end of the hollow column (1) is provided with a base (6), the side wall of the hollow column (1) is provided with a telescopic joint (2) communicated with the interior of the hollow column (1), and an expanding agent is filled in the hollow column (1). According to a construction process for the tree root structure pile, the telescopic joint extends outwards as tree roots in the construction process; and after the outward extension of the telescopic joint is completed, a filling material such as concrete and the like is poured so that the pile has higher strength and is completely stuck with the surrounding soil body. The pile of the type has reasonable structural design and wide application range; and on the premise that the length and the section area of the pile are not changed, the contact area between a pile foundation and a surrounding soil layer is obviously enlarged, so bearing capacity, friction resistance and stability of the pile are increased. Moreover, pulling resistance and sliding resistance of the pile are remarkably improved.

Owner:HOHAI UNIV

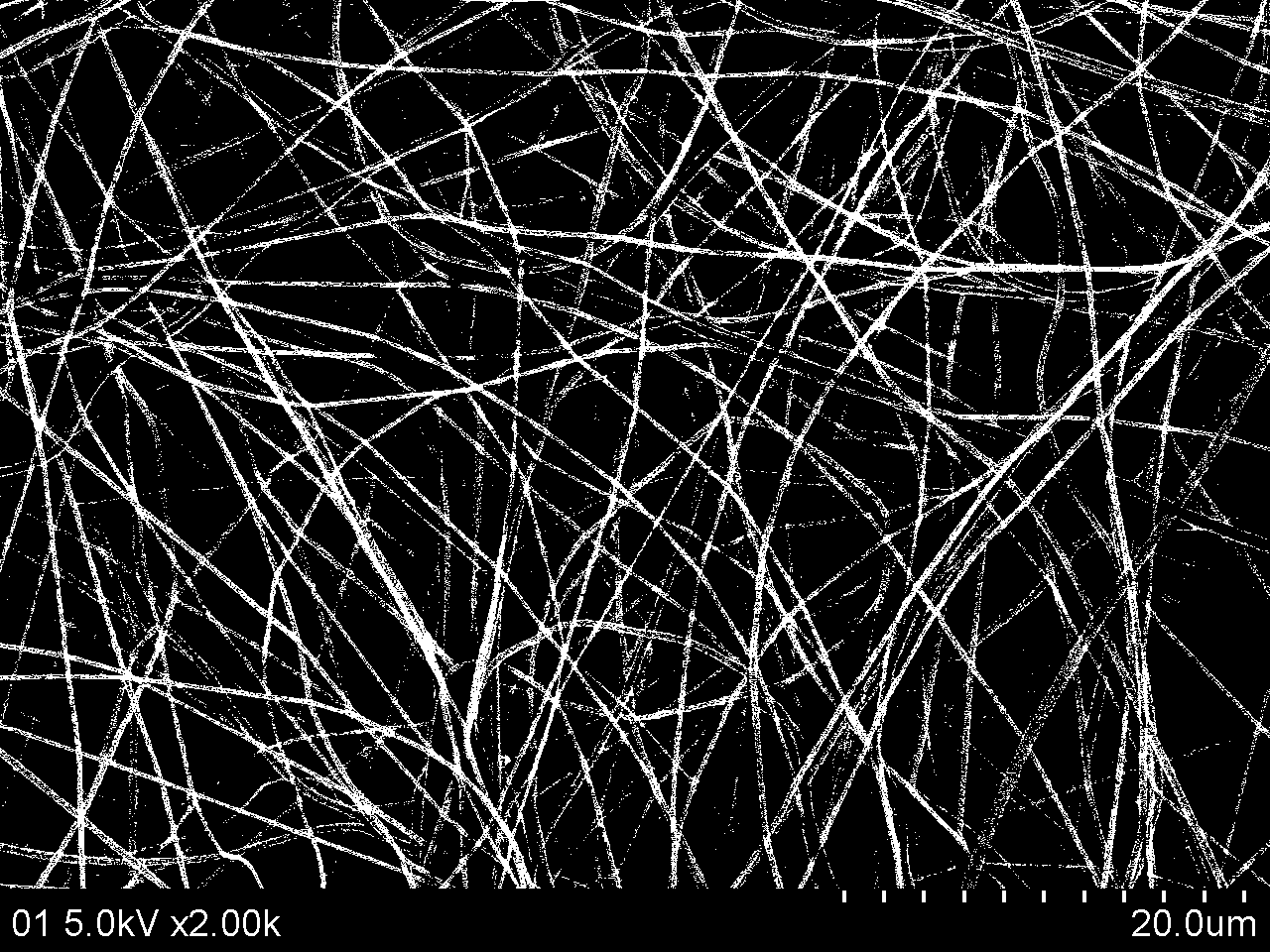

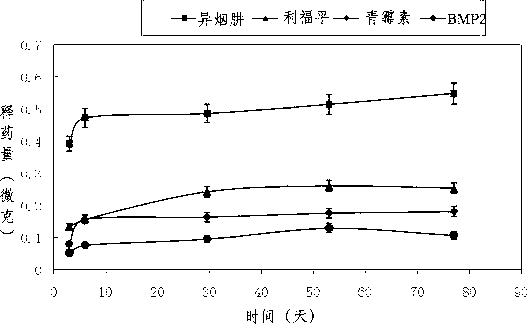

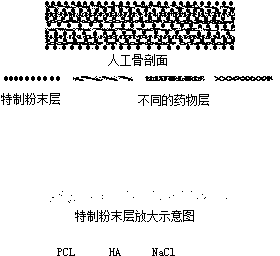

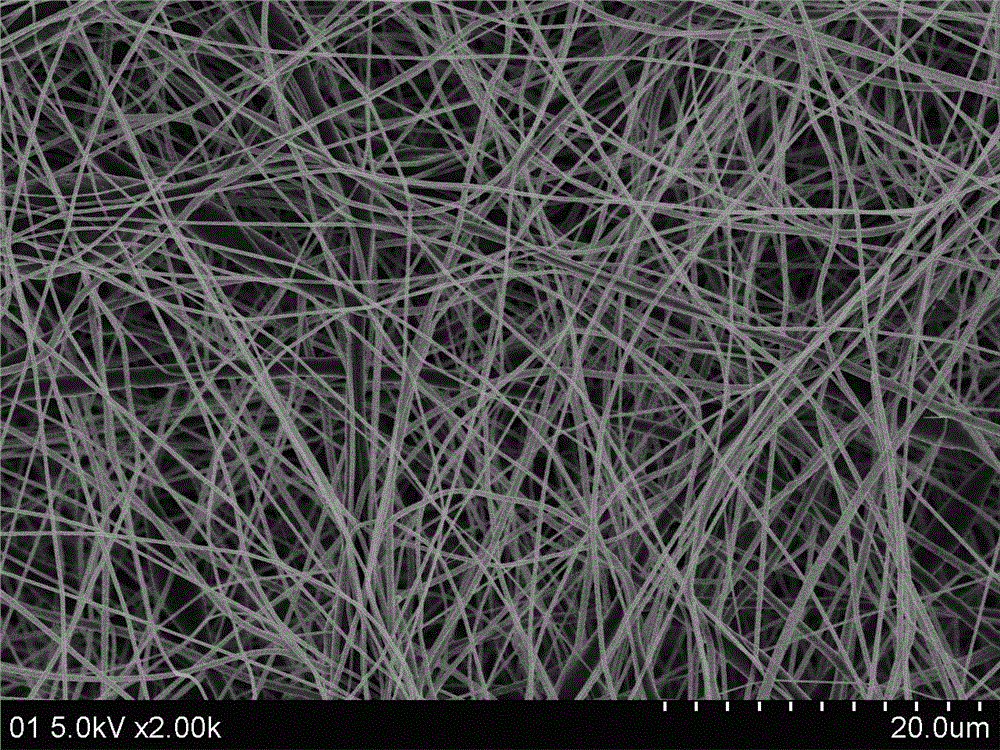

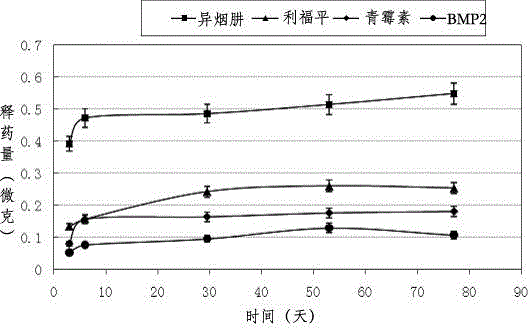

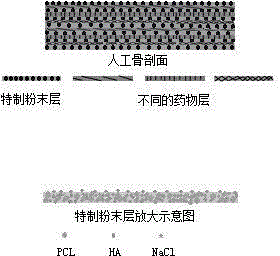

Method for preparing spliced artificial bone-filled sustained-release material with treatment effect

InactiveCN103251983APromote regenerationIncreased risk of infectionProsthesisControl releaseElectrospinning

The invention belongs to the field of nanobiomedicine, and particularly relates to a method for preparing a spliced artificial bone-filled sustained-release material with a treatment effect. The method comprises the steps of by taking biodegradable nano-materials with biocompatibility as carrier attachments, spinning a film from mixing solution in which a medicine is loaded by an electrospinning technique; and alternatively pressing and forming the film and special powder at an interval, so as to obtain an artificial bone filler which has long-term sustained-release property and treatment effect, and can be mutually spliced. The artificial bone-filled sustained-release material disclosed by the invention has good biocompatibility and biodegradability, can achieve the treatment effect by controlled release of the loaded medicine; the artificial bone can be mutually spliced, and can be conveniently clinically spliced into different shapes according to difference of bone defects; and the stress intensity and the traction resistance of the artificial bone can be strengthened in difference directions according to different splicing methods.

Owner:TONGJI UNIV

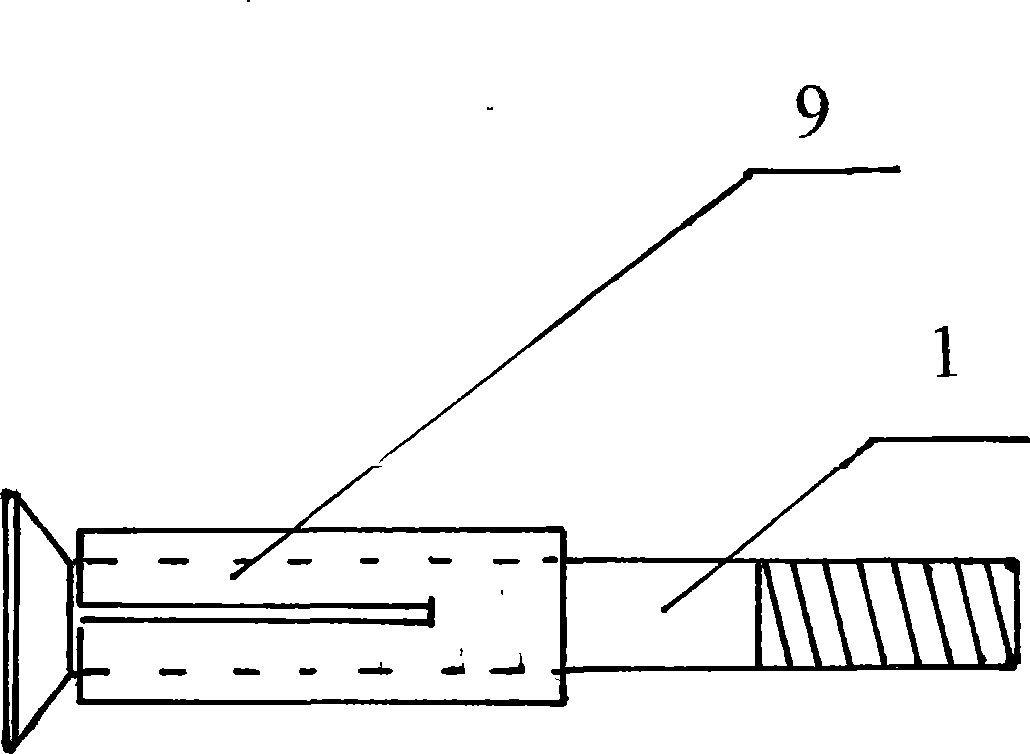

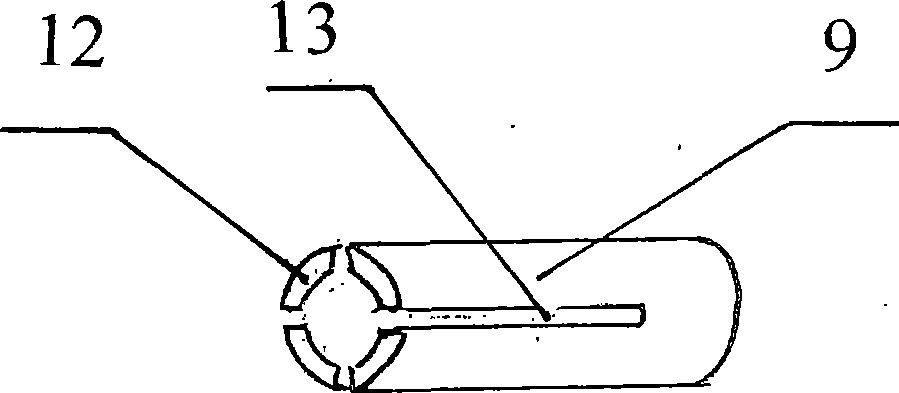

Extending-bulging type glue fixing nail and use method

The invention relates to an expansion adhesive fastening nail and a use method thereof, wherein the expansion adhesive fastening nail consists of a big-end tube expansion nail, an expansion sleeve, a hanging piece head and adhesive; the big-end tube expansion nail (1) is matched with the expansion sleeve (9) and is fixed with a wall body; an expansion plate (12) expands to exceed the nail head of the big-end tube expansion nail (1) and splits into the shape of petals; the nail head of the big-end tube expansion nail (1) is clamped at a petaloid bottom to increase pulling resistant and shear resistant; therefore, the nail is particularly suitable to install various equipment and veneers on floppier wall bodies such as an autoclaved aerated concrete wall body, thereby ensuring the longtime safety and steadiness of a project; moreover, the member saves raw material and reduces cost along with a reasonable and convenient use method. Obviously, the nail and the method have high use value and enormous social benefits and economic benefits.

Owner:郭祥山

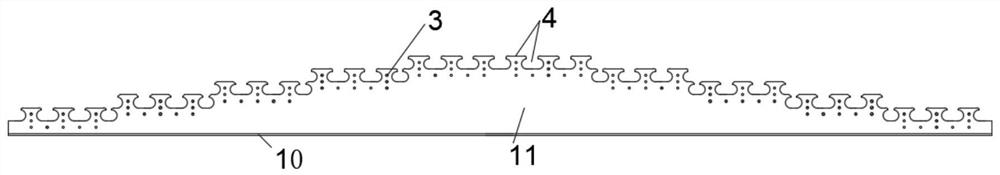

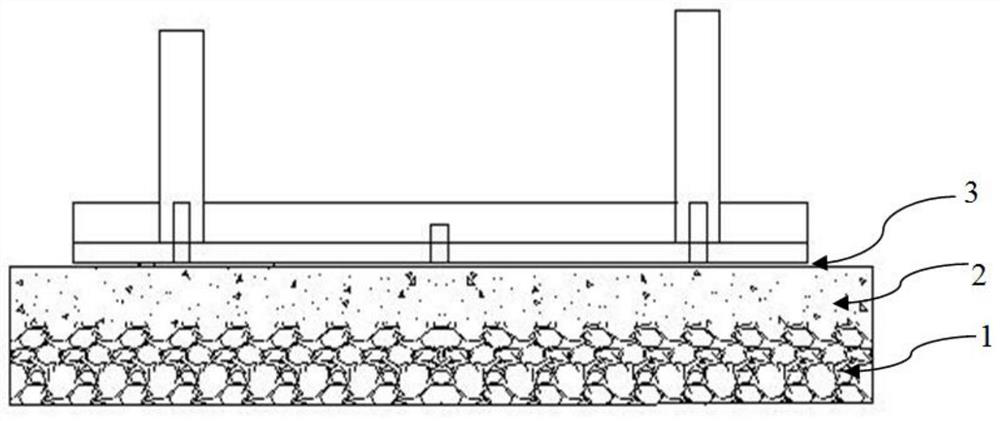

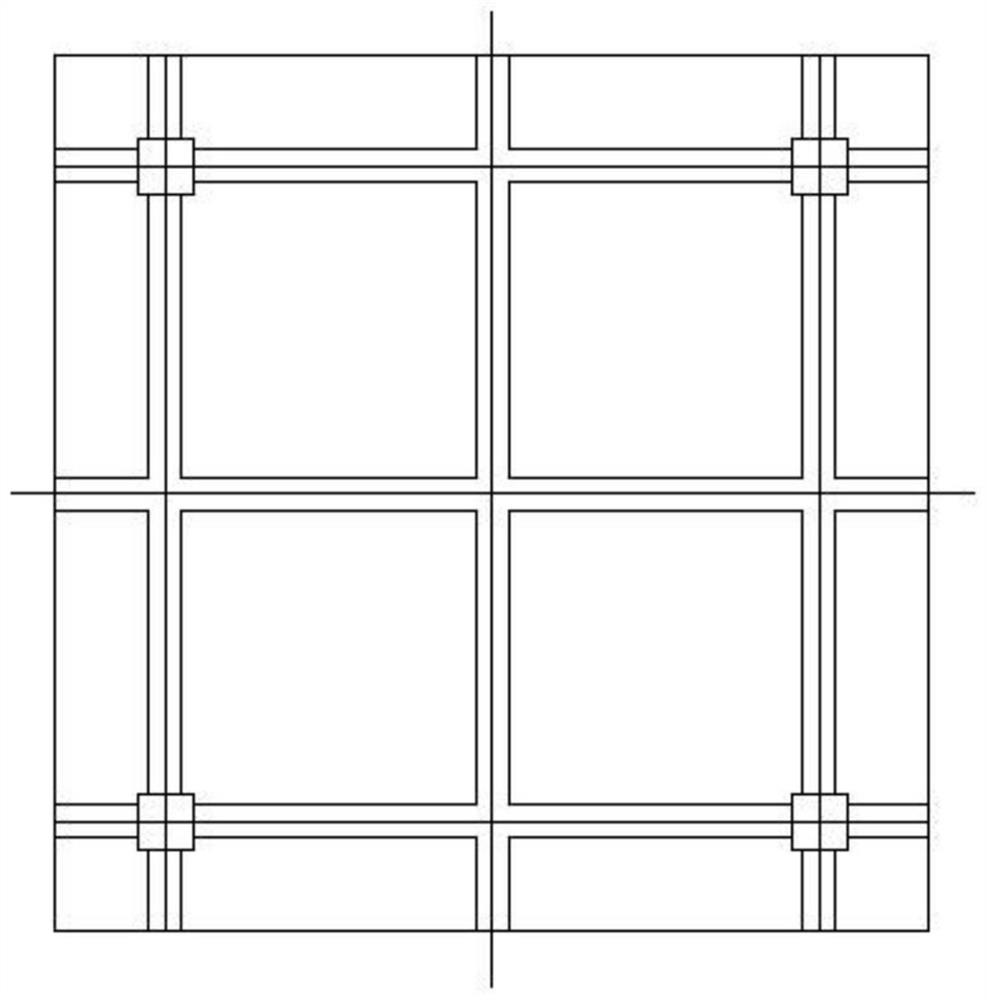

Hybrid fiber concrete prefabricated laminated slab and preparation method thereof

InactiveCN111268969AIncreased durabilityGood compatibilityFloorsSurface layering apparatusPolyvinyl alcoholRebar

The invention discloses a hybrid fiber concrete prefabricated laminated slab and a preparation method thereof. The hybrid fiber concrete prefabricated laminated slab comprises a bottom plate fiber concrete layer, and a post-pouring layer is arranged on the bottom plate fiber concrete layer; the bottom fiber concrete layer comprises cement, fly ash, silica fume, sand, a water reducing agent, steelfibers, polyvinyl alcohol fibers and water; the post-pouring layer is formed by pouring common reinforced concrete; the hybrid concrete slab is arranged in the lower tension area, the advantages of high tensile strength and good ductility of the hybrid concrete are effectively played, the upper part is pressed by adopting the common reinforced concrete, and the characteristics of the two types ofconcrete are fully played; the steel fibers are doped into the hybrid fiber concrete so that the later strength and toughness of the concrete are effectively enhanced; the thickness of the laminated slab is reduced, the self-weight is reduced and the cost is saved, the manufacturing process is simple, and application and popularization are facilitated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

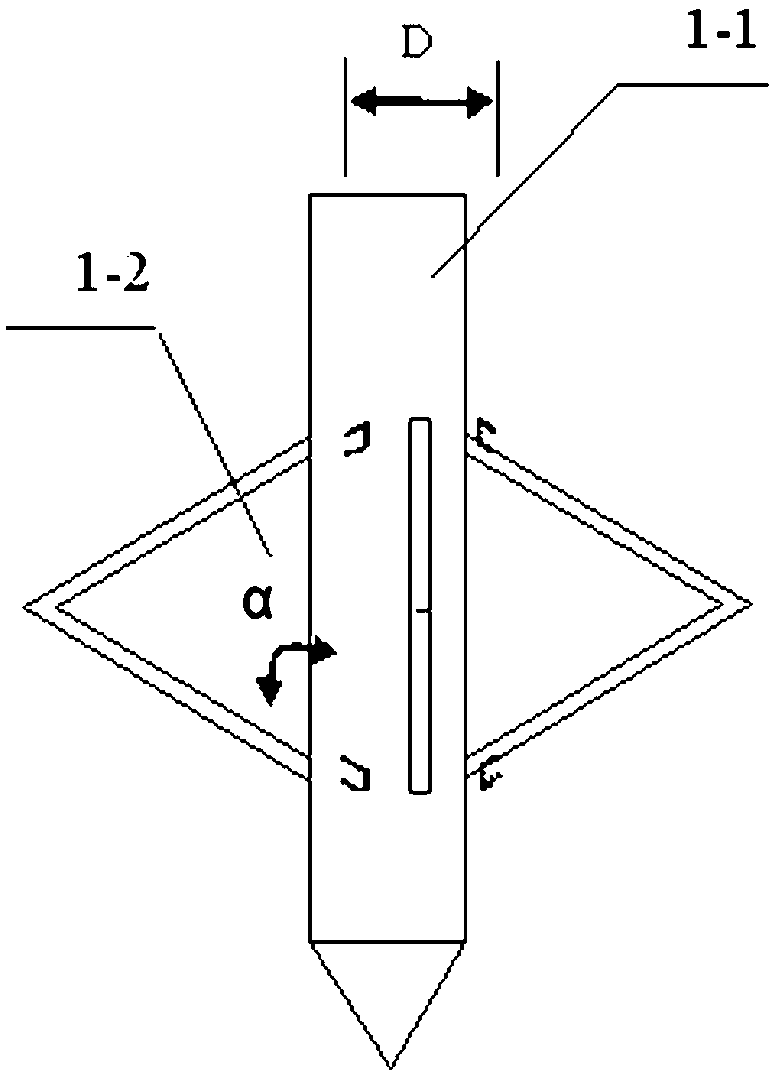

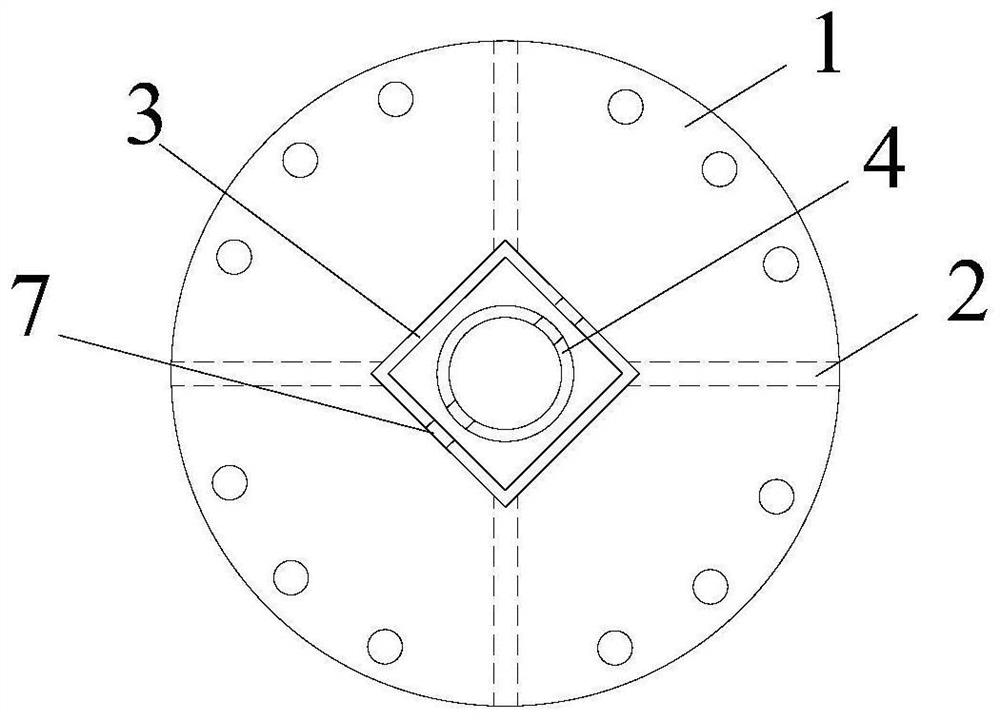

Polymer multi-edge pile grouting method

ActiveCN103233473AImprove tensile propertiesQuick buildBulkheads/pilesSocial benefitsChemical reaction

Owner:SAFEKEY ENG TECHZHENGZHOU

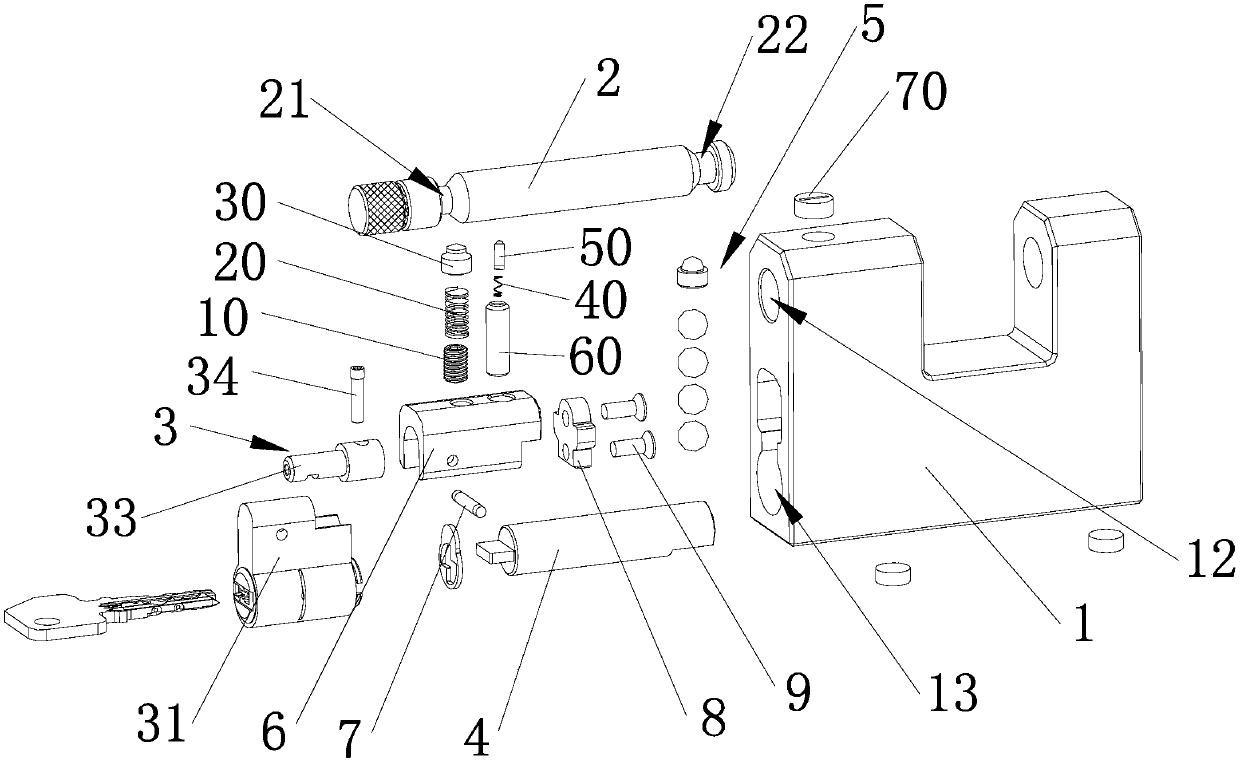

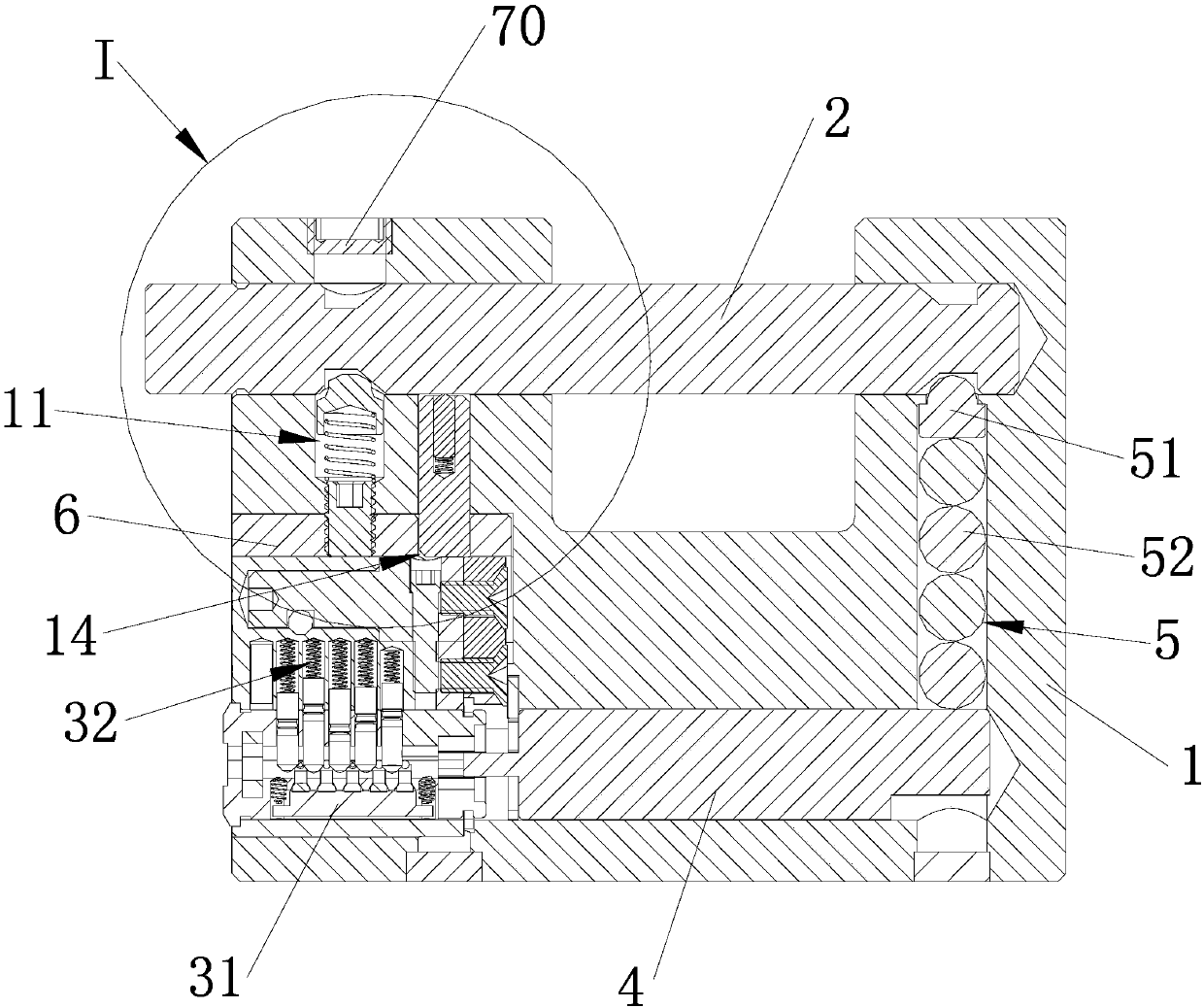

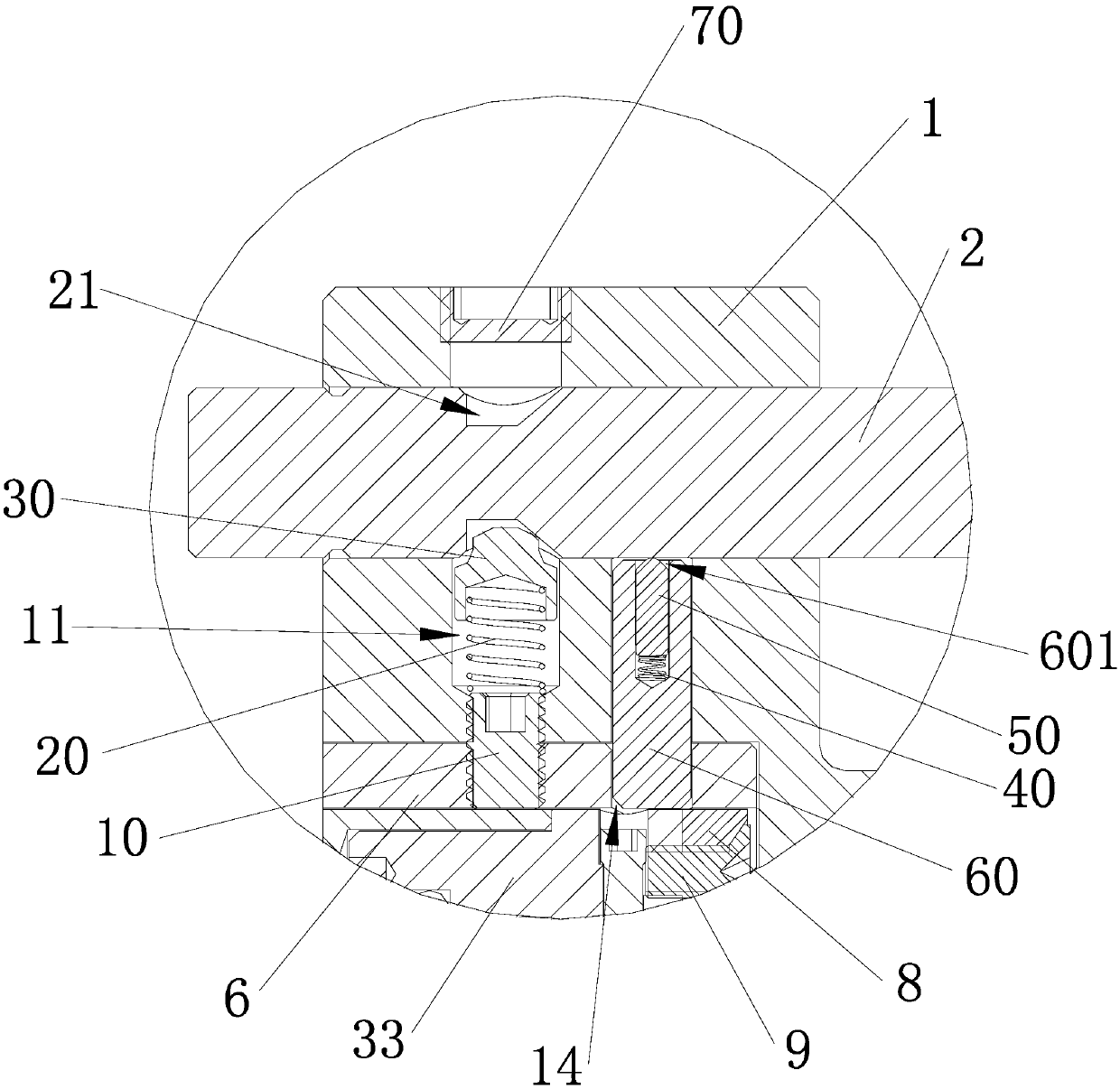

Novel anti-pull-cut padlock capable of replacing lock cylinder structure

The invention discloses an anti-pull-cut padlock capable of replacing a lock cylinder structure. Dual fixing of a protective cover fastening lock nail and a protective cover lock pin is adopted in thevertical direction, a lock cylinder main body is dually fixed through a lock cylinder fastening piece and lock cylinder fastening screws in the transverse direction, fixing is conducted through a lock cylinder lock pin in the longitudinal direction, thus a lock cylinder can be prevented from falling off in the three directions, and the anti-pull performance of the lock cylinder is greatly enhanced accordingly. In addition, in an opening state of the padlock, a lock hook is pulled out from a lock hook hole in a lock body, after a positioning bead and a positioning spring are taken out, the protective cover fastening lock nail can be unscrewed, then the entire lock cylinder structure is taken out, finally the lock cylinder lock pins and the lock cylinder fastening screws in the longitudinaldirection and the transverse direction of the lock cylinder structure are taken out to replace the lock cylinder, and the rest of parts of the padlock can still continue being used so that the cost of lock cylinder replacing can be greatly saved; and therefore, the structure is more reasonable, pull-cut prevention and lock cylinder replacing can be both achieved, and the cost of lock cylinder replacing is low.

Owner:ZHONGSHAN CITY JIXIN CORE LOCK CO LTD

Construction method for expansion head anti-pressing and anti-pulling pile

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

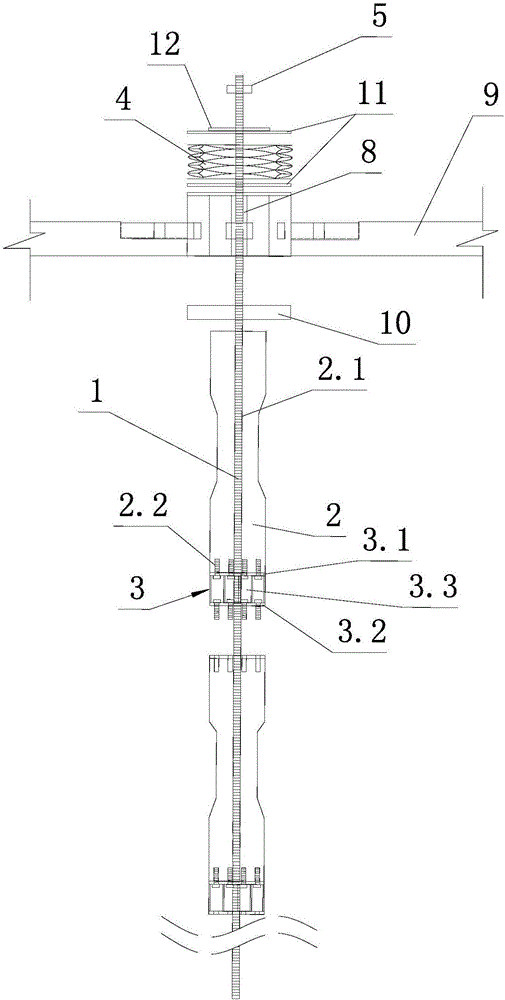

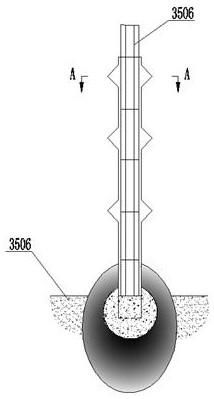

Static pressure type rear support spiral pile based on bionics and construction method thereof

The invention discloses a static pressure type rear support screw pile based on bionics, which comprises a pile tip, an outer sleeve, a flange and an empennage, the empennage is arranged at the upperend of the outer sleeve, the flange is arranged at the top ends of the empennage and the outer sleeve, an outer support blade is arranged at the lower part of the outer sleeve, and when the outer support blade is pressed at the top of the outer sleeve, the outer supporting blades are unfolded outwards. A built-in steel pipe or a flexible anchor rod is arranged in the outer sleeve, and the pile tipis fixedly connected with the built-in steel pipe or the flexible anchor rod. By optimally designing the pile body, the side resistance is small during static pressure pile sinking penetration, the outer supporting blades are unfolded through secondary sinking of the outer sleeve, the vertical uplift and compression resistance bearing capacity of the outer supporting blades is improved, the horizontal bearing capacity of the outer supporting blades is improved through the arrangement of the empennage, and the uplift bearing capacity of the pile side and the blades is improved by utilizing thecharacteristics of compression shrinkage and tension expansion of negative poisson ratio materials. The method has the advantages of small soil disturbance, low construction noise and environmental friendliness.

Owner:HOHAI UNIV +3

Method for preparing spliced artificial bone-filled sustained-release material with treatment effect

The invention belongs to the field of nanobiomedicine, and particularly relates to a method for preparing a spliced artificial bone-filled sustained-release material with a treatment effect. The method comprises the steps of by taking biodegradable nano-materials with biocompatibility as carrier attachments, spinning a film from mixing solution in which a medicine is loaded by an electrospinning technique; and alternatively pressing and forming the film and special powder at an interval, so as to obtain an artificial bone filler which has long-term sustained-release property and treatment effect, and can be mutually spliced. The artificial bone-filled sustained-release material disclosed by the invention has good biocompatibility and biodegradability, can achieve the treatment effect by controlled release of the loaded medicine; the artificial bone can be mutually spliced, and can be conveniently clinically spliced into different shapes according to difference of bone defects; and the stress intensity and the traction resistance of the artificial bone can be strengthened in difference directions according to different splicing methods.

Owner:TONGJI UNIV

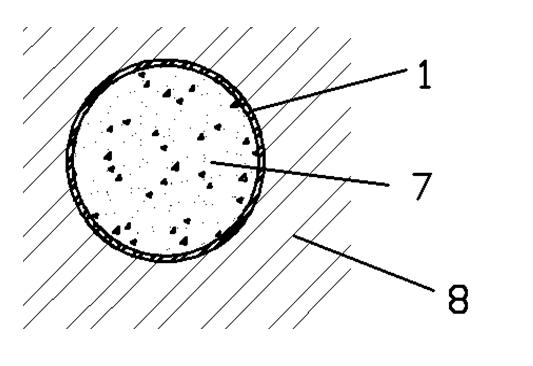

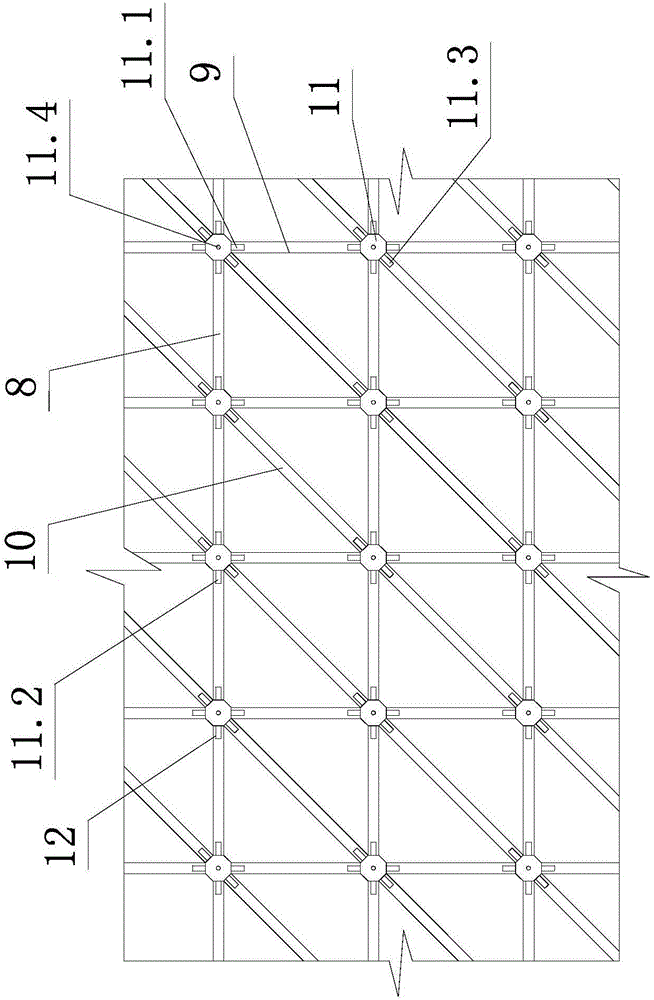

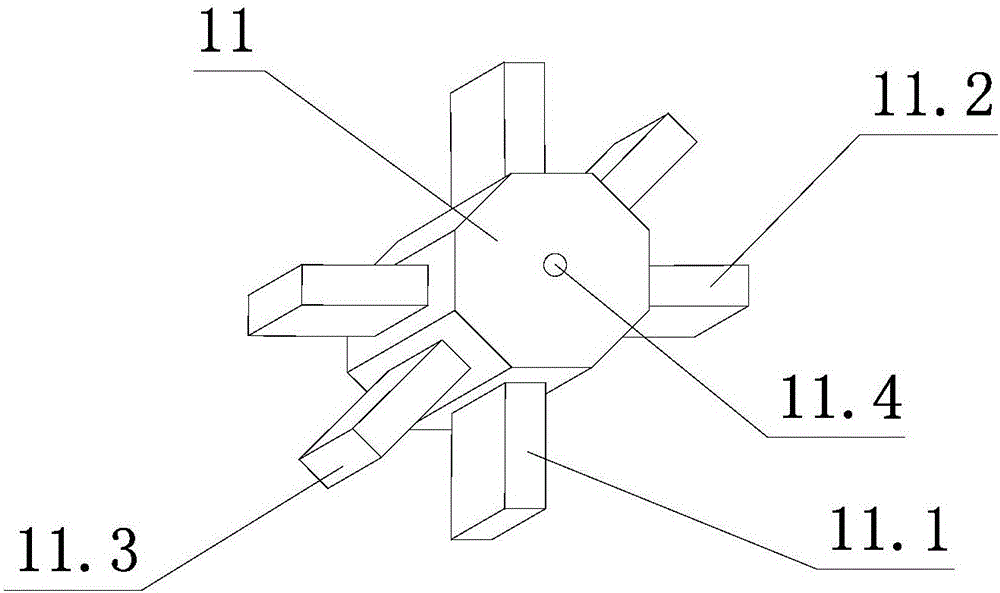

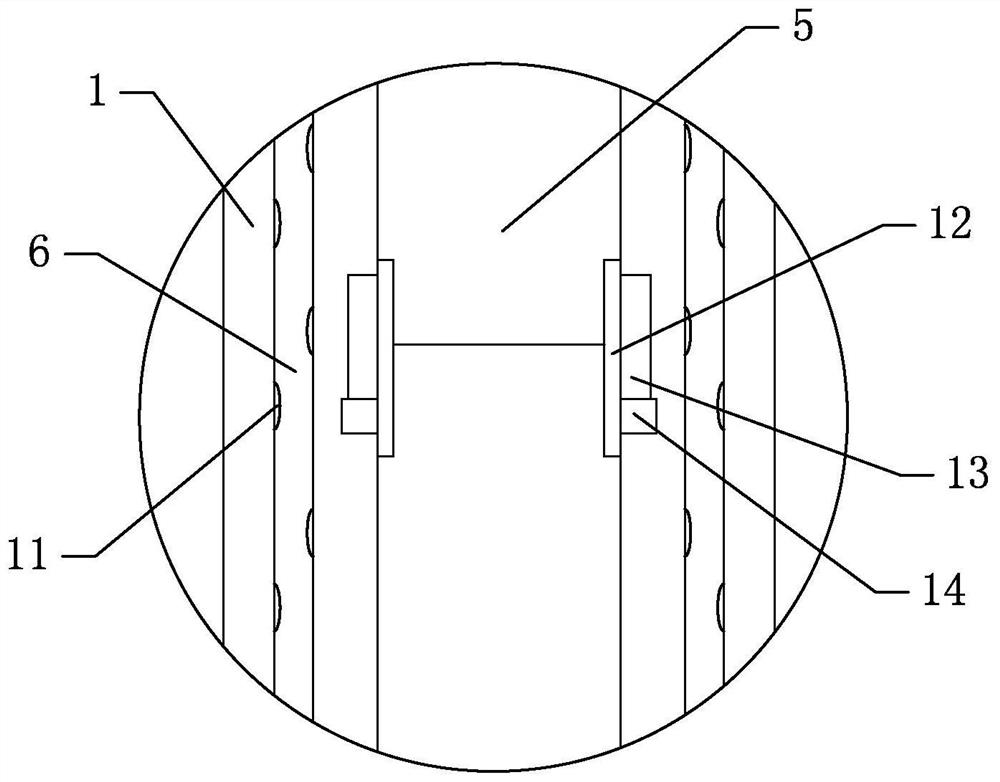

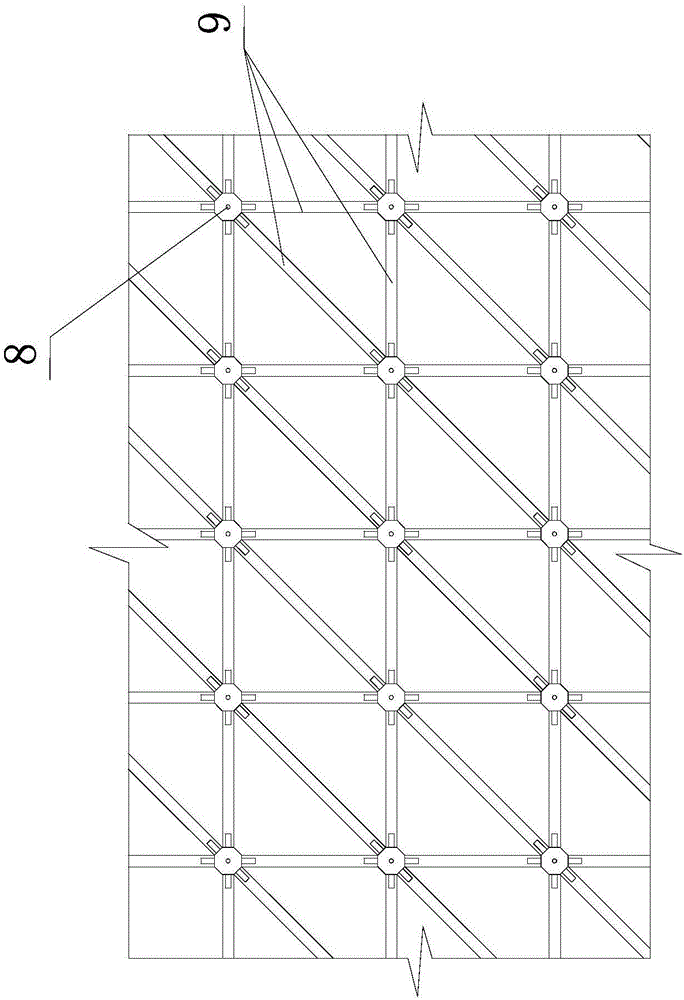

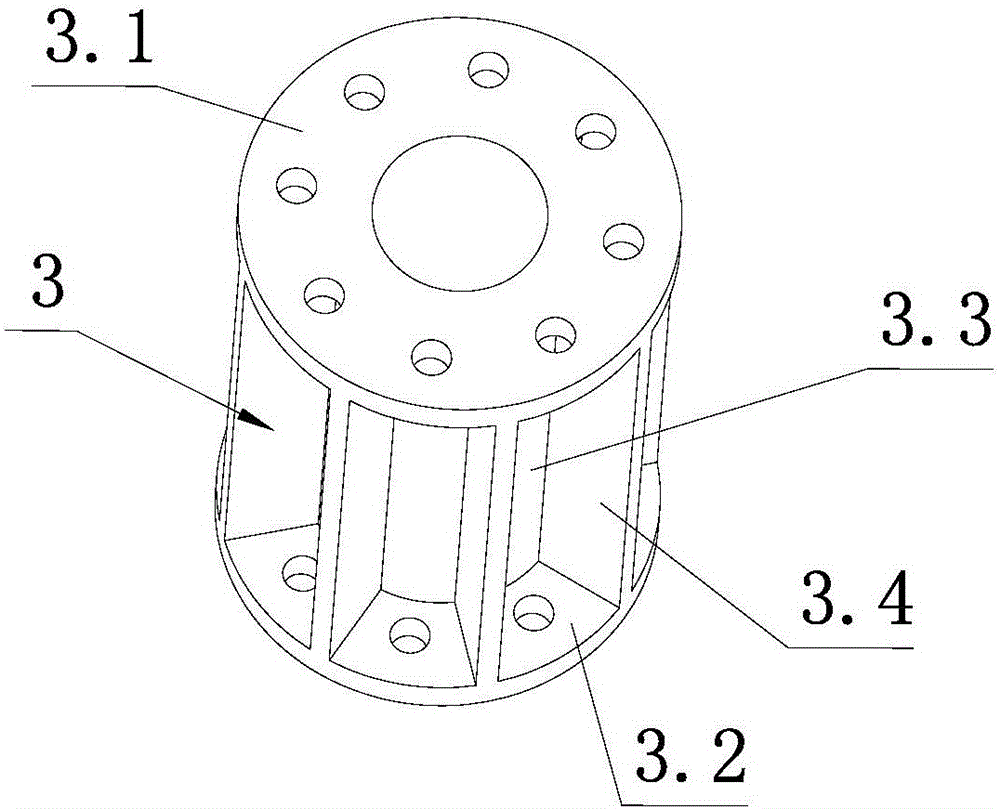

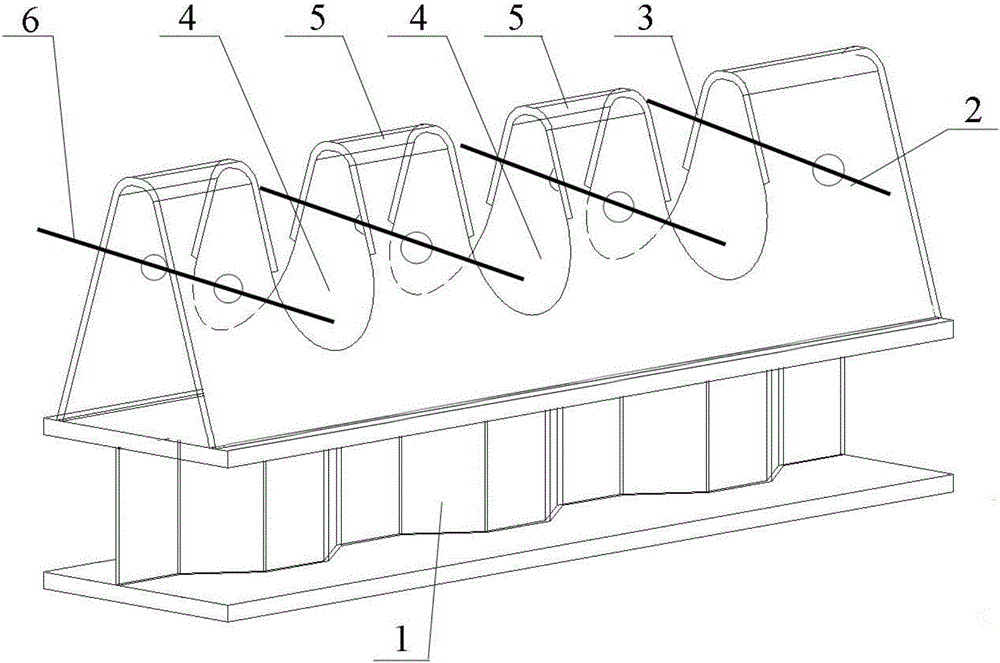

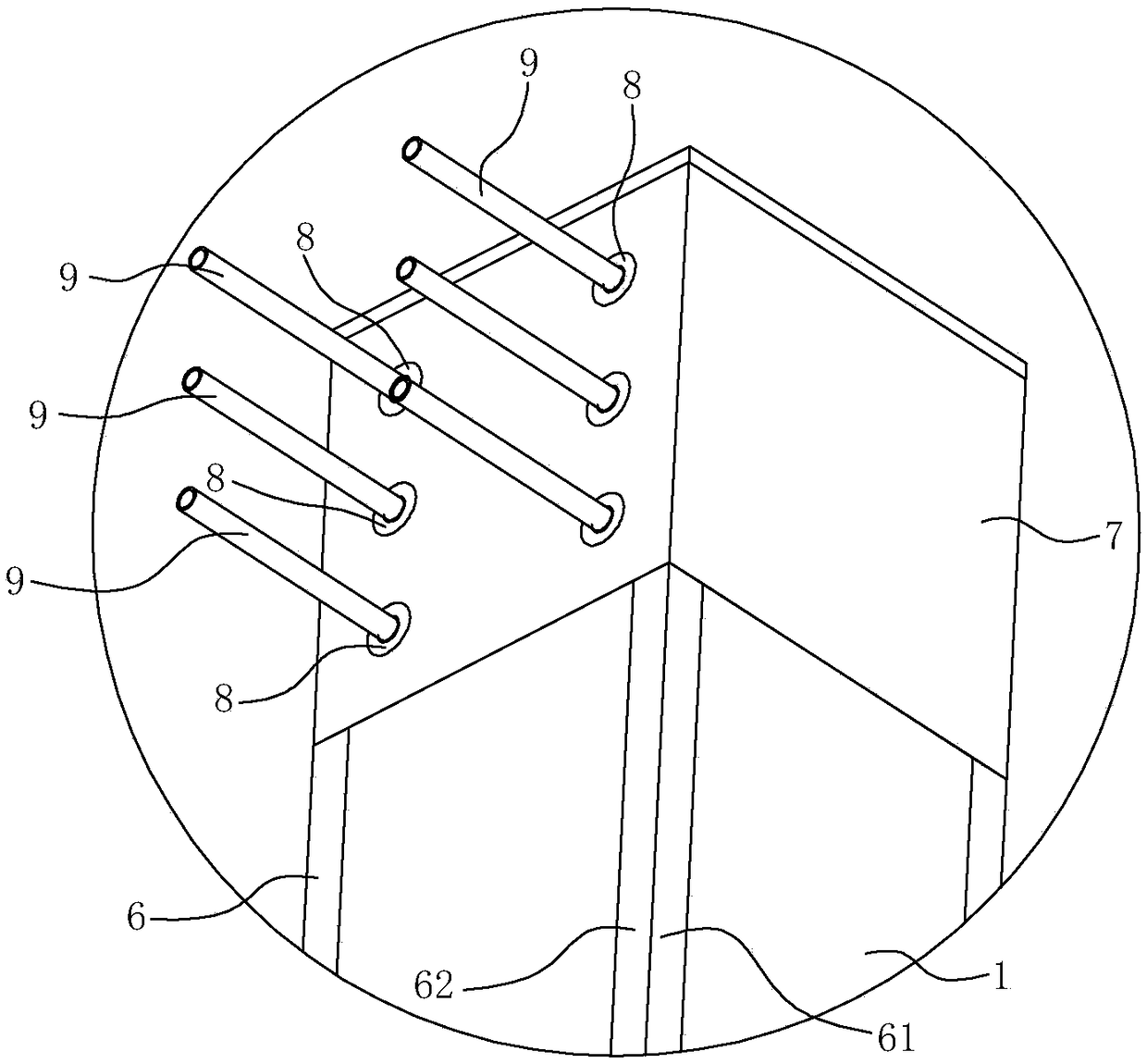

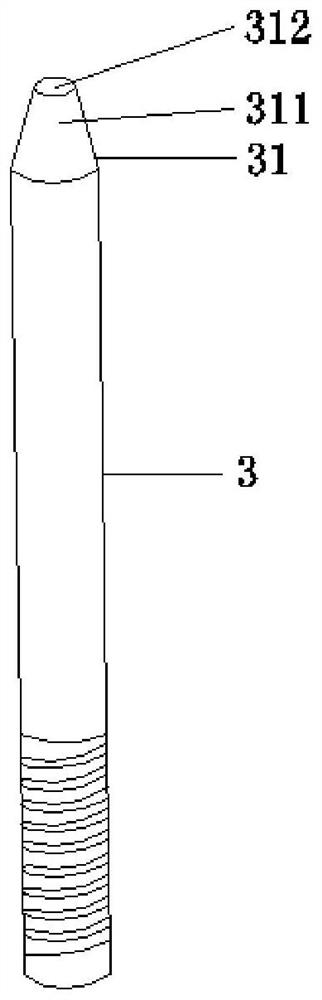

Prestressing anchor body assembly type frame hoop slope protection device and construction method

InactiveCN105862871AReduce the amount of groutReduce labor intensityExcavationsBulkheads/pilesBuilding construction

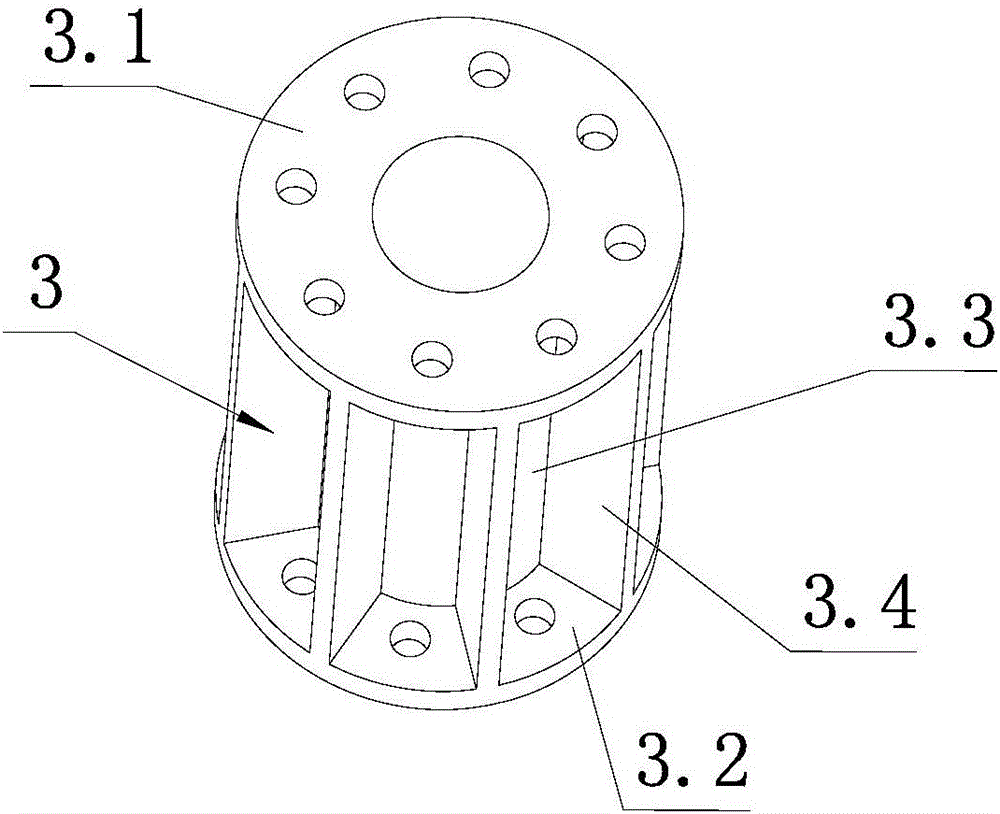

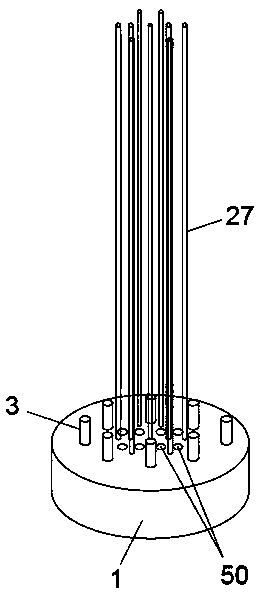

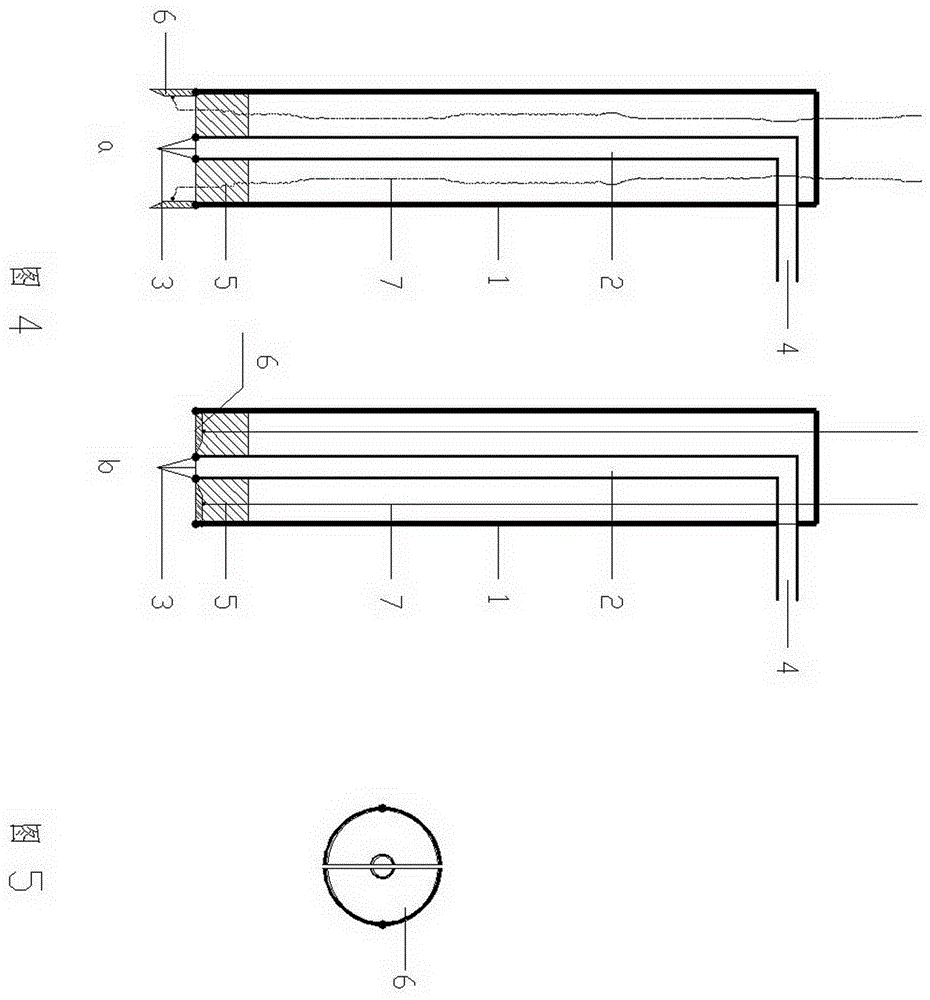

The invention discloses a prestressing anchor body assembly type frame hoop slope protection device and a construction method. The prestressing anchor body assembly type frame hoop slope protection device comprises a frame hoop used for restraining a slope surface and an anchor structure used for tightly pressing the frame hoop. An integrated anchor body (6) is formed by concrete bamboo joint blocks (2), connecting discs (3) and a screw (1), wherein the concrete bamboo joint blocks (2) and the connecting discs (3) are arranged and distributed alternately. An anchor hole (7) is formed in the slope surface of a soil body. The anchor body (6) is placed in the anchor hole (7), and the gap between the anchor body (6) and the anchor hole (7) is filled with concrete mortar. The construction method comprises the key steps that the integrated anchor body (6) is formed by all the concrete bamboo joint blocks (2), all the connecting discs (3) and the screw (1); and the anchor body (6) is placed in the anchor hole (7), and the concrete motor is poured into the gap between the anchor hole (7) and the anchor body (6). By the adoption of the structure and method, the construction speed can be increased, the construction period can be shortened, field construction is convenient and fast, the anti-drawing strength and the shearing strength are both ideal, the restraining effect on the soil body is good, the tightness degree can be adjusted along with the expansion and contraction of the soil body conveniently, and the slope protection area of the frame loop can be changed freely.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

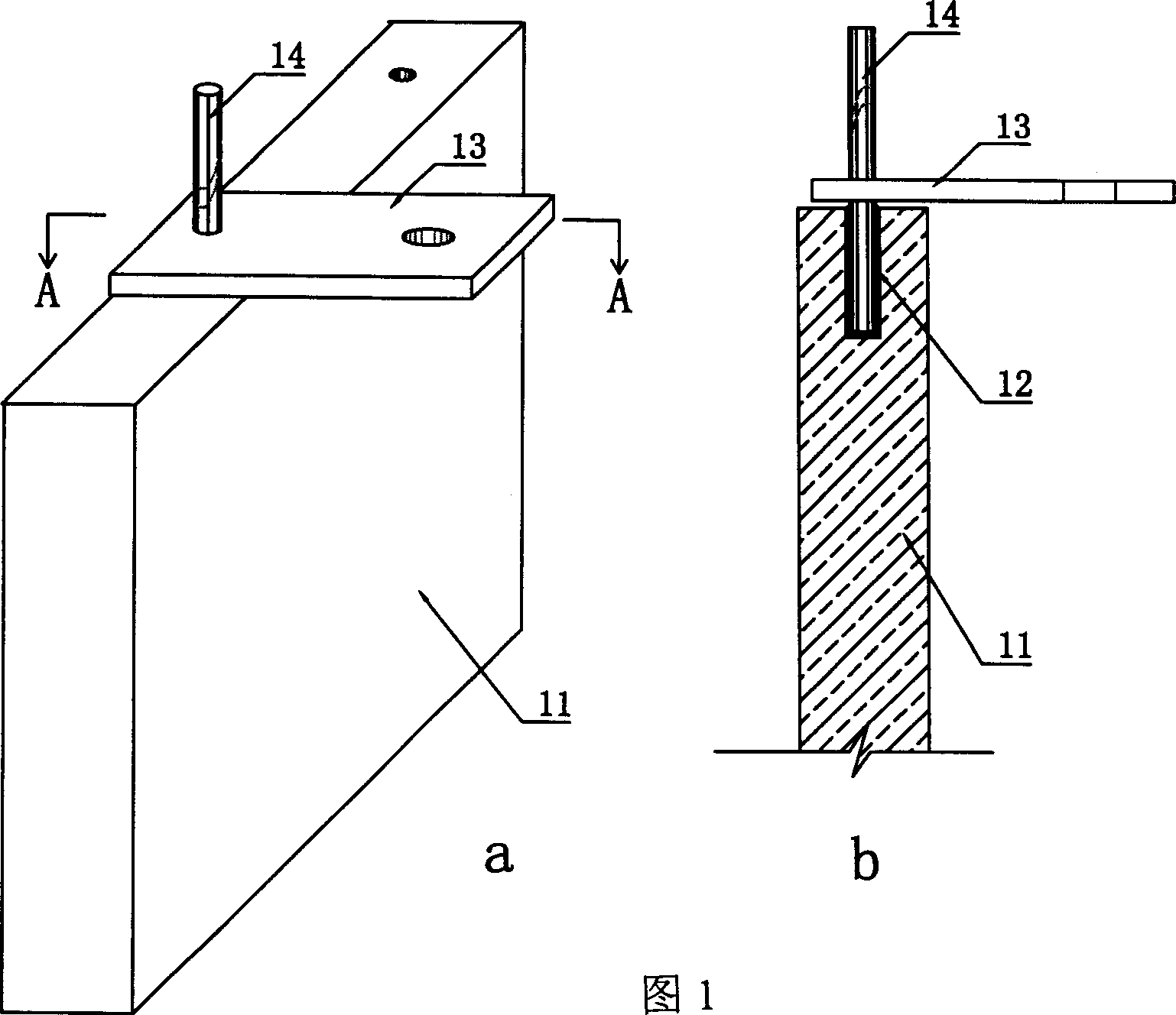

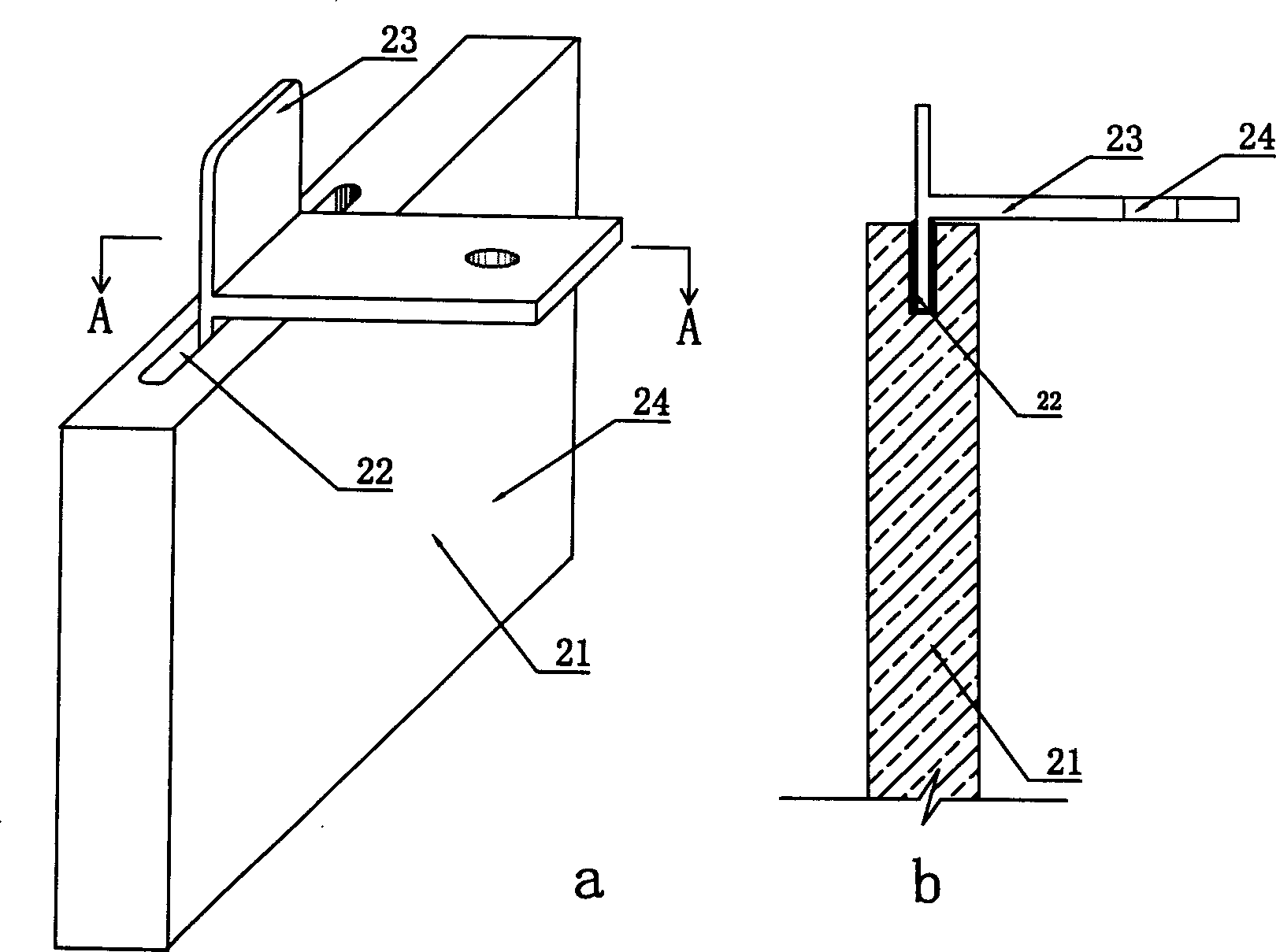

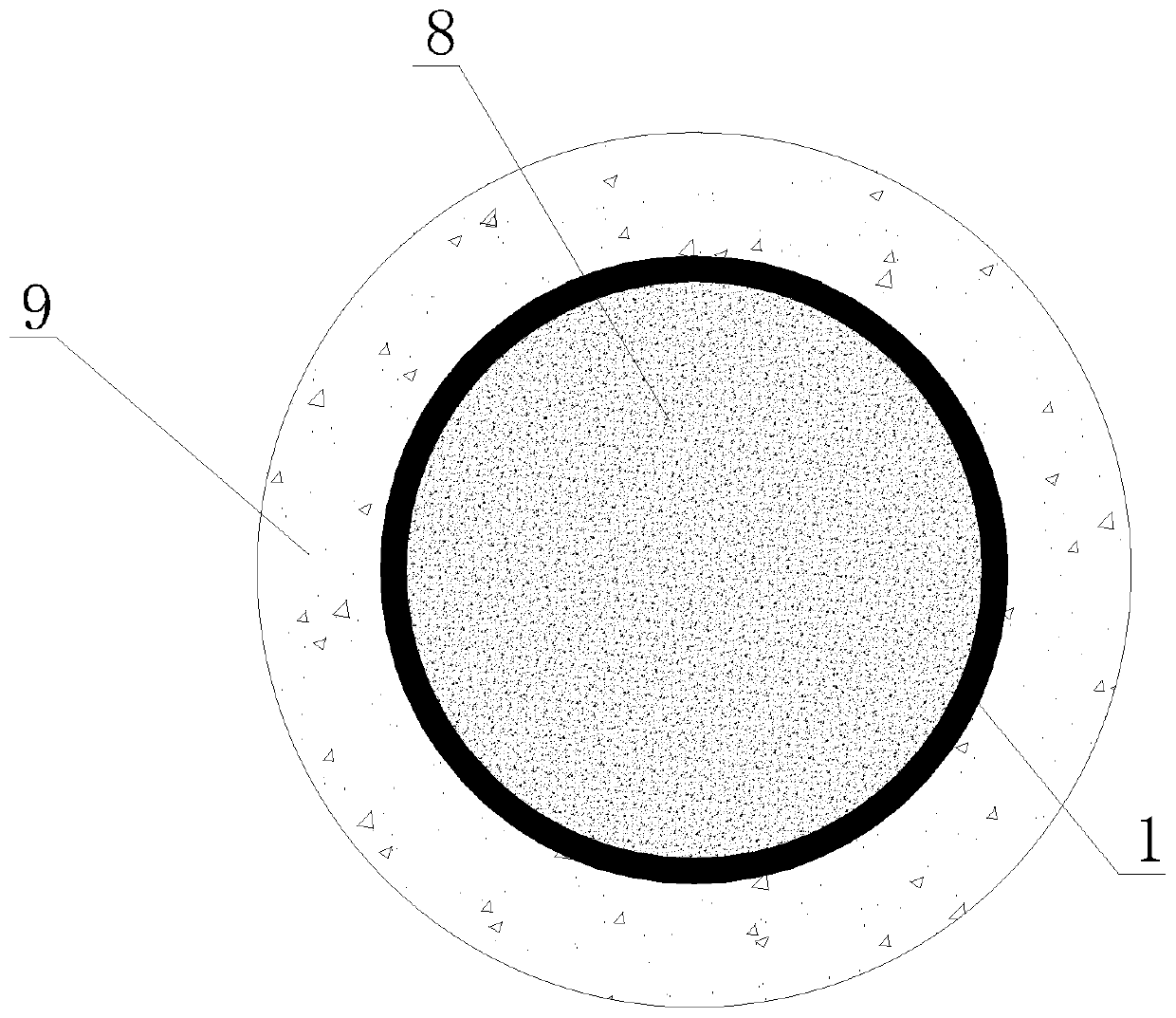

Composite connection type concrete filled steel tube bridge pier and construction method thereof

PendingCN109577176AStrong shearImprove seismic performanceBridge structural detailsBridge erection/assemblyConnection typeWhole body

The invention relates to a composite connection type concrete filled steel tube bridge pier. The composite connection type concrete filled steel tube bridge pier comprises a load-bearing foundation and steel tube concrete; the steel tube concrete comprises a steel tube, a bottom plate and bridge pier column concrete cast in the steel tube in situ; multiple fixing holes used for fixing anchor boltsare formed in the bottom plate; the anchor bolts penetrate through the fixing holes from bottom to top and are in close fit with nuts to lock the bottom plate on the load-bearing foundation; multipleU-shaped stabilizing tubes are embedded and fixed at the upper end of the load-bearing foundation in the longitudinal direction; two openings of each U-shaped stabilizing tube both communicate with the cavity of the steel tube; and the bridge pier column is poured into the U-shaped stabilizing tubes from the openings to be solidified to form anti-pulling buckles. According to the composite connection type concrete filled steel tube bridge pier, through combination of a prefabricated construction method and a cast-in-situ construction method, the steel tube, the bridge pier column concrete andthe load-bearing foundation can be compositely connected to form a whole body; and the anti-pulling capacity, anti-shearing capacity and anti-seismic capacity of the constructed bridge pier are high.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

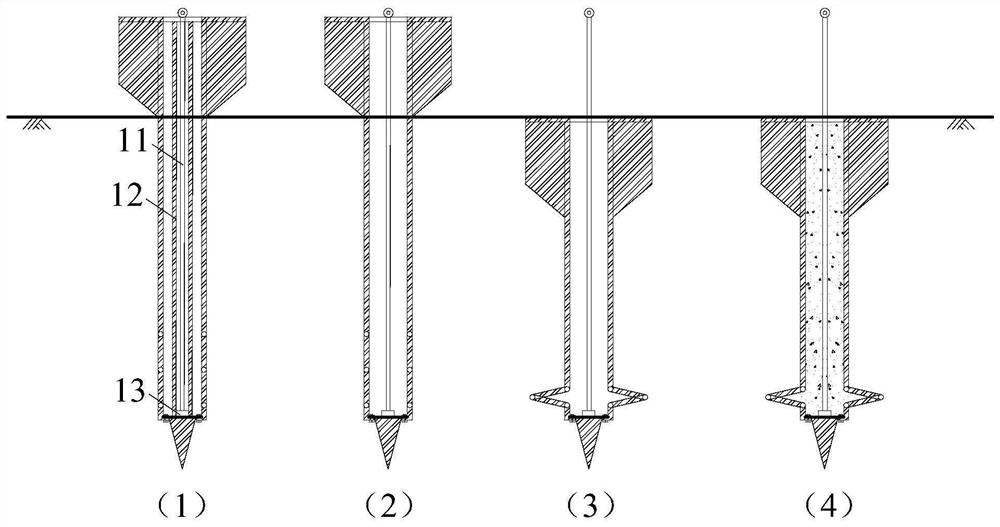

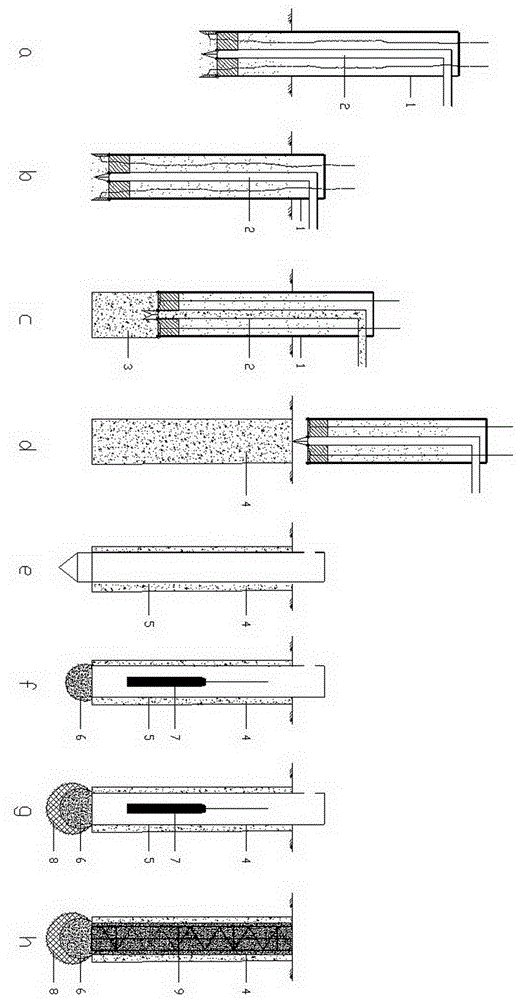

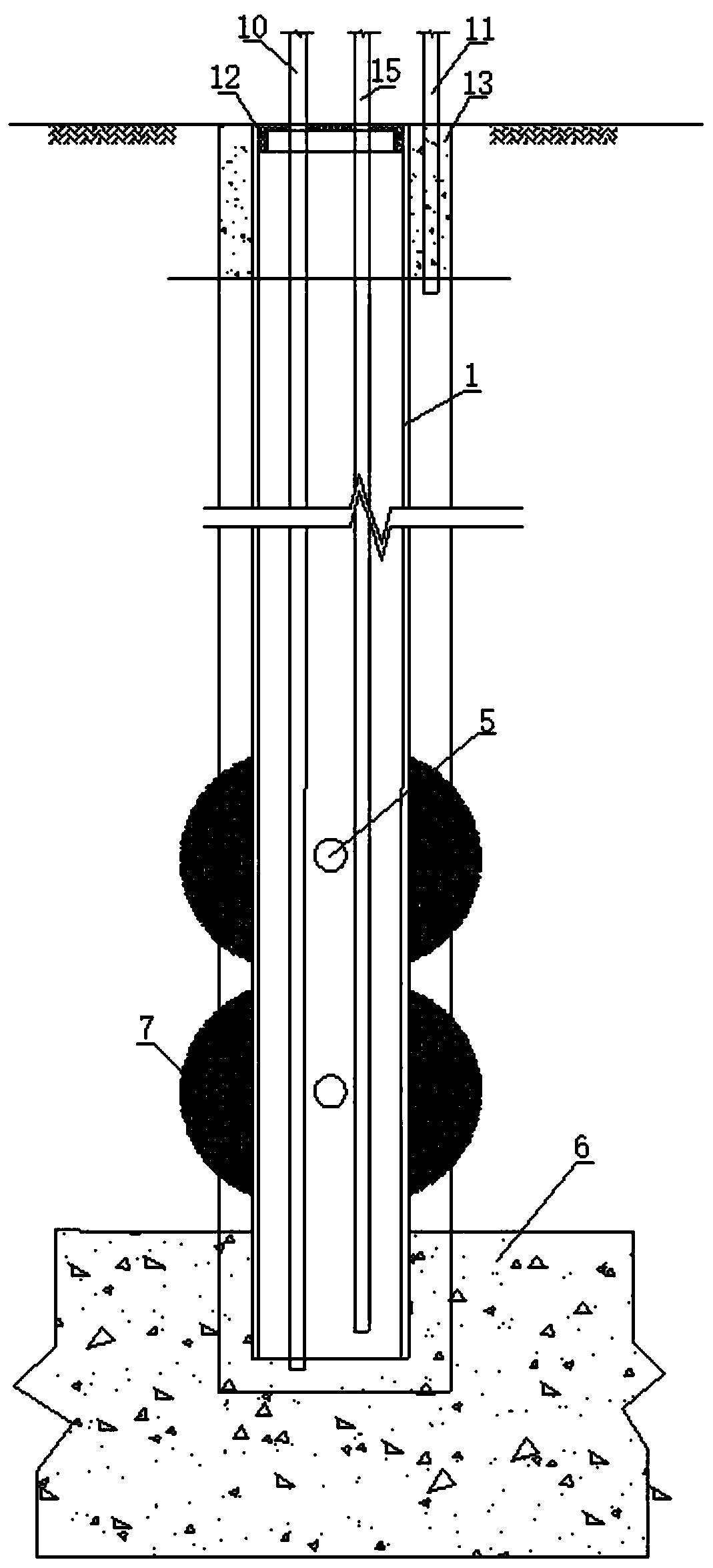

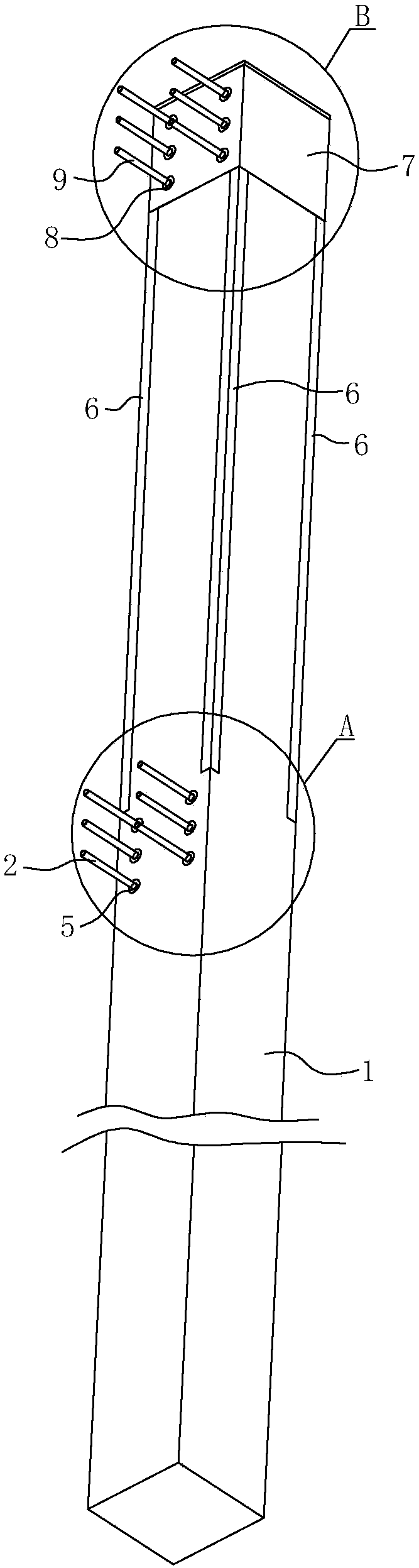

Reinforcing construction method for micro pile of soft soil foundation

ActiveCN113174927AImprove pull resistanceImprove stress resistanceClimate change adaptationBulkheads/pilesSlurryCement grout

The invention relates to a reinforcing construction method of a micro pile for a soft soil foundation, which belongs to the field of micro piles. The reinforcing construction method comprises the following steps that a, a hole is drilled in the foundation; b, a grouting film bag is connected with the bottom end of a main grouting pipe, meanwhile, a first blocking plate is vertically connected with the bottom end of the main grouting pipe, and the first blocking plate is located above the grouting film bag; c, the main grouting pipe with the bottom end connected with the grouting film bag is inserted into the drill hole, then at least two auxiliary grouting pipes are inserted into the drill hole on the outer side of the main grouting pipe, and grout leakage holes are formed in the outer walls of the auxiliary grouting pipes; d, cement grout is injected into the auxiliary grouting pipes, the drill holes in the outer sides of the main grouting pipes are filled with the cement grout, and the cement grout is waited to be solidified; and e, after the cement grout is solidified, cement mortar is injected into the main grouting pipe at high pressure, and the grouting film bag at the bottom is expanded through the cement mortar to form a bag body. The grouting direction can be easily controlled on the basis that the bearing capacity of the micro pile is enhanced, and the problem of waste of the grout amount caused by grout runout is solved.

Owner:山东高新岩土科技有限公司

Butt joint prefabricated combined beam and construction method

PendingCN112482187AReasonable forceEnhanced pullout and shear resistanceBridge structural detailsBridge materialsTransverse shearButt joint

The invention relates to a butt joint prefabricated combined beam and a construction method. The butt joint prefabricated combined beam comprises a steel main beam, and the steel main beam comprises asteel beam bottom plate and a steel beam web fixed to the steel beam bottom plate; a bottom-layer bridge deck slab is included and arranged at the top of the steel beam web, and the bottom-layer bridge deck slab comprises a concrete web and a concrete top plate; the steel beam web is in butt joint with the concrete web through transverse shear nails; and the height of the steel beam web and the height of the concrete web are changed in the longitudinal bridge direction. By adjusting the heights of the steel beam web and the concrete web, a structural stress is more reasonable, and the durability of the combined beam structure is enhanced while the shear resistance and the pulling resistance of the steel-concrete combined beam are enhanced.

Owner:CHINA MAJOR BRIDGE ENERGINEERING

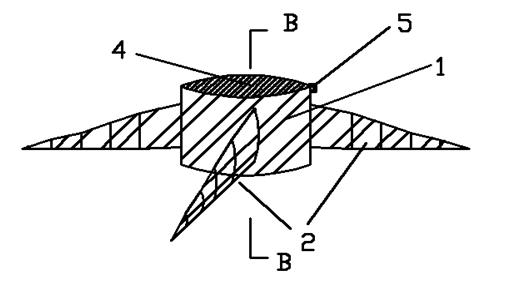

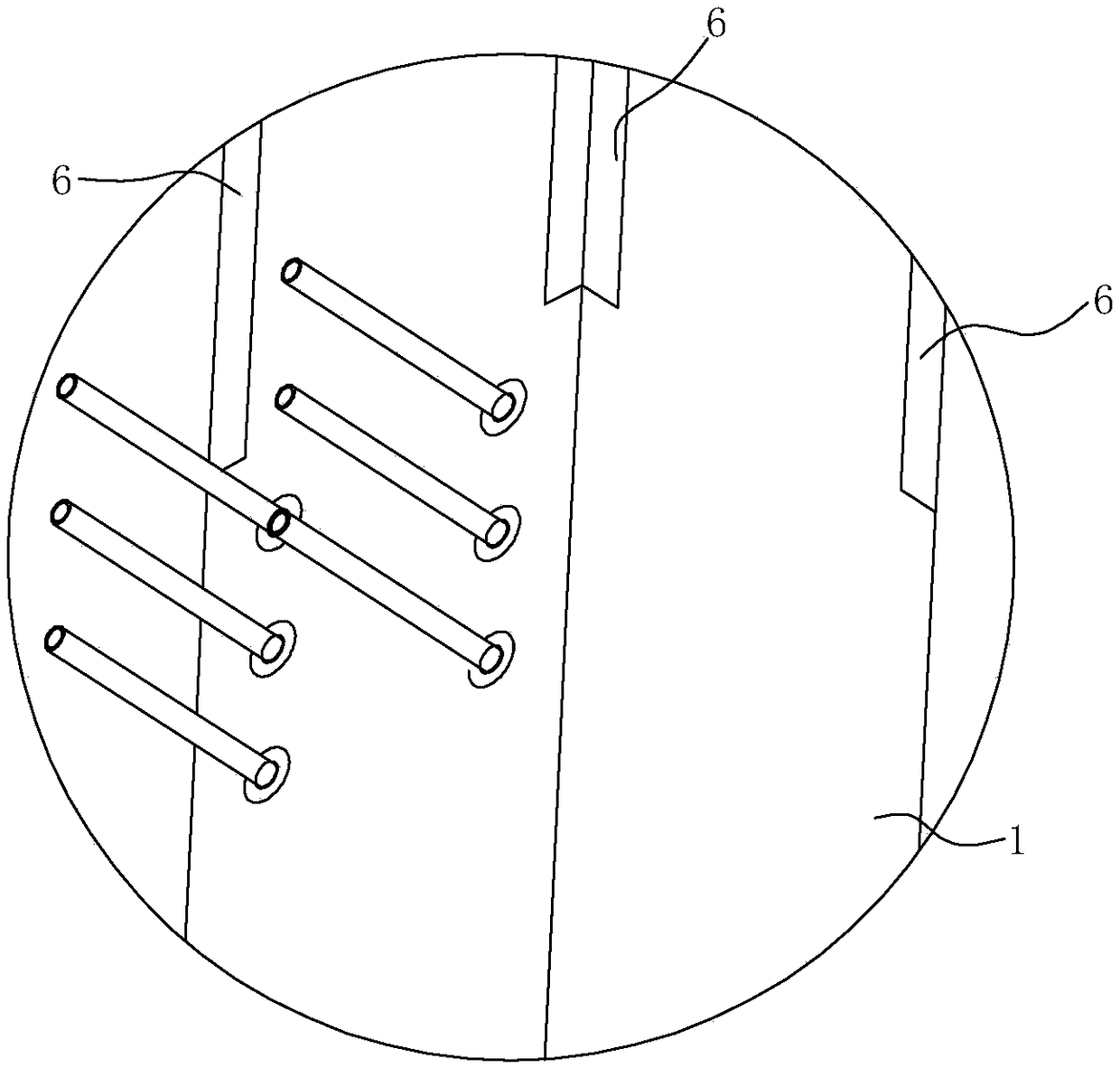

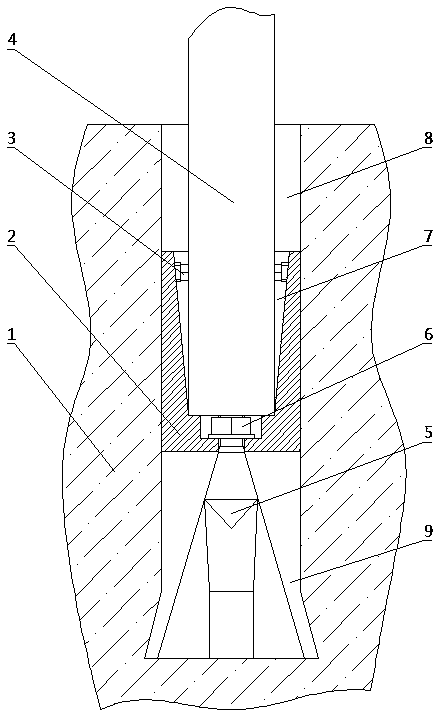

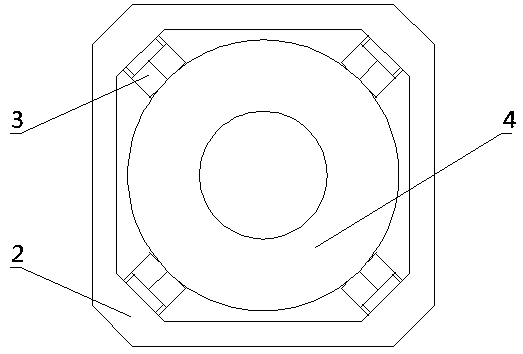

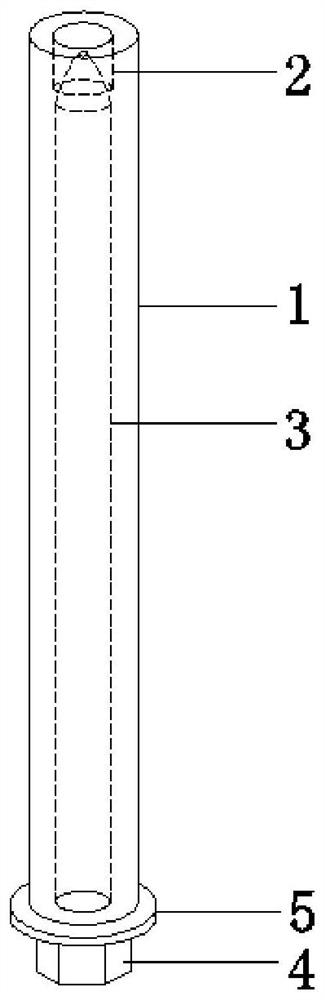

Pre-applied force anchoring system for slope protection device and construction method thereof

InactiveCN105804098AIncrease binding forceIncrease constraintsExcavationsEngineeringSystem construction

The invention discloses a pre-applied force anchoring system for a slope protection device and a construction method thereof. The pre-applied force anchoring system comprises a threaded rod (1), concrete bamboo joint blocks (2), connection discs (3), a spring (4) and a nut (5). The concrete bamboo joint blocks (2), the connection discs (3) and the threaded rod (1) form an integrated anchoring body (6), and the concrete bamboo joint blocks (2) and the connection discs (3) are arranged at intervals. The anchoring body (6) is placed into an anchor hole (7), and the gap between the anchoring body (6) and the anchor hole (7) is filled with concrete mortar. The nut (5) is screwed on the threaded rod (1) in a matched mode. The nut (5) tightly presses the slope protection structure and the concrete bamboo joint blocks (2) through the spring (4). The construction method is characterized in that all the concrete bamboo joint blocks (2), all the connection discs (3) and the threaded rod (1) form the integrated anchoring body (6), the anchoring body (6) is placed into the anchor hole (7), and the gap between the anchoring body (6) and the anchor hole (7) is filled with the concrete mortar. According to the pre-applied force anchoring system for the slope protection device and the construction method thereof, the construction speed can be increased, site construction is convenient and quick, the anti-drawing strength and the shearing strength are both ideal, and the constraint effect on soil bodies is good.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Bridge and shear resistant combined structure thereof

InactiveCN106436553AImprove integrityImprove the shear resistance of the structureBridge structural detailsReinforced concreteEngineering

The invention discloses a shear resistant combined structure of a bridge. The shear resistant combined structure comprises a supporting structure and a shear key arranged on the supporting structure, wherein the shear key comprises a first shear resistant plate, second shear resistant plates and shearing rods; the top end of the first shear resistant plate and the top ends of the second shear resistant plates are mutually connected, and the bottom end of the first shear resistant plate and the bottom ends of the second shear resistant plates are respectively connected with two side edges of the supporting structure; each shearing rod laterally penetrates through the first shear resistant plate and the second shear resistant plates; a plurality of through holes allowing reinforced concrete to be embedded are formed in the first shear resistant plate and the second shear resistant plates; the first shear resistant plate and the second shear resistant plates form the shape of a triangle or a trapezoid, so that the structural shear resistant performance is greatly improved; the reinforced concrete is embedded by the through holes for resisting upward pulling force generated because the left side and the right side of the bridge are stressed unevenly; the shearing rods can strengthen the completeness of the combining of the shear key and the reinforced concrete, so that pulling resistant capacity and collapsing resistant capacity are effectively improved; and during construction, the construction cost can be reduced, and the construction efficiency can be improved. The invention also discloses the bridge comprises the shear resistant combined structure, and the bridge has the above beneficial effects.

Owner:GUANGDONG UNIV OF TECH

Construction method of concrete pile by soil extraction and pressure filling

ActiveCN105970919AImprove construction efficiencyImprove the use effectBulkheads/pilesEngineeringBuilding construction

The invention aims at providing a construction method of a concrete pile by soil extraction and pressure filling. The construction method is characterized by comprising the following steps: 1, pressing a soil extraction device with a material conveying pipe into a soil body by one or several modes of vibration, hammering and static pressing, wherein the soil body rushes into an inner cavity of the soil extraction device in the sinking process; 2, pumping a cement mixture at the bottom of the soil extraction device through the material conveying pipe and lifting up the soil extraction device at the same time, keeping doing the operations until the soil extraction device reaches the surface of a foundation, to form a filling pile body; and 3, discharging the soil body in the soil extraction device, and carrying out subsequent construction on the filling pile body. According to the construction method, the construction procedures of hole forming by soil extraction and pile body filling can be completed at a time; the soil extraction and hole forming speeds are high, and the working efficiency is high; and meanwhile, the construction method is applicable to a pile foundation and a compound foundation, and is large in application range.

Owner:北京波森特岩土工程有限公司

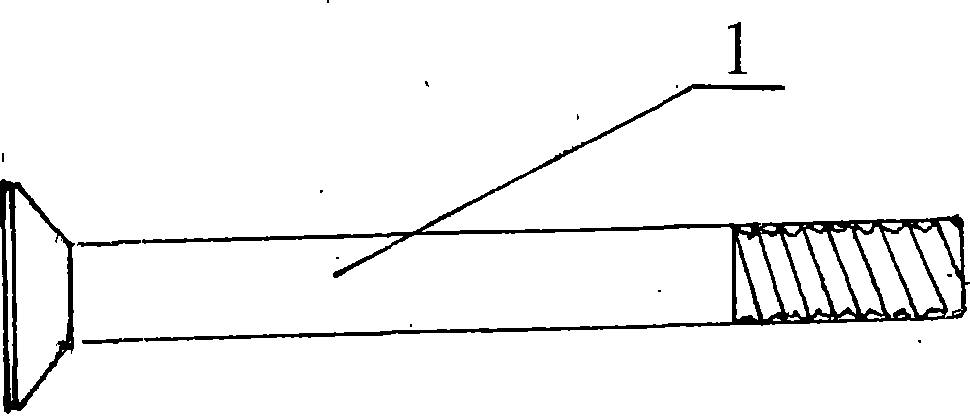

Steel tube miniature pile and construction method thereof

The invention provides a steel tube miniature pile. The steel tube miniature pile comprises a steel tube, an inner slurry layer located inside the steel tube and an outer slurry layer located outsidethe steel tube, and the steel tube comprises an ordinary steel tube segment, an anchoring segment and a fixed end which are connected successively from top to bottom; the anchoring segment is providedwith a grouting hole and a clamping throat for assembling a rubber film, the rubber film sleeves the outer wall of the grouting hole and is used for sealing the grouting hole, and the rubber film isfilled with cement slurry to form an convex structure; and the fixed end is arranged at the lowermost end of the steel tube and used for embedding into a stratum. The invention further provides a specific construction method of the steel tube miniature pile. According to the construction method of the steel tube miniature pile, the situation that grouting slurry in the steel tube does not flow outcan be guaranteed, the problem of slurry runout at the bottom of the pile is solved, the grouting amount is controllable, and the grouting cost is lowered; and meanwhile, friction resistance of the side wall of a pile body can be increased, and the overall compression resistant, anti-pull and axial load resistant capacity of the steel tube miniature pile is improved.

Owner:CENT SOUTH UNIV

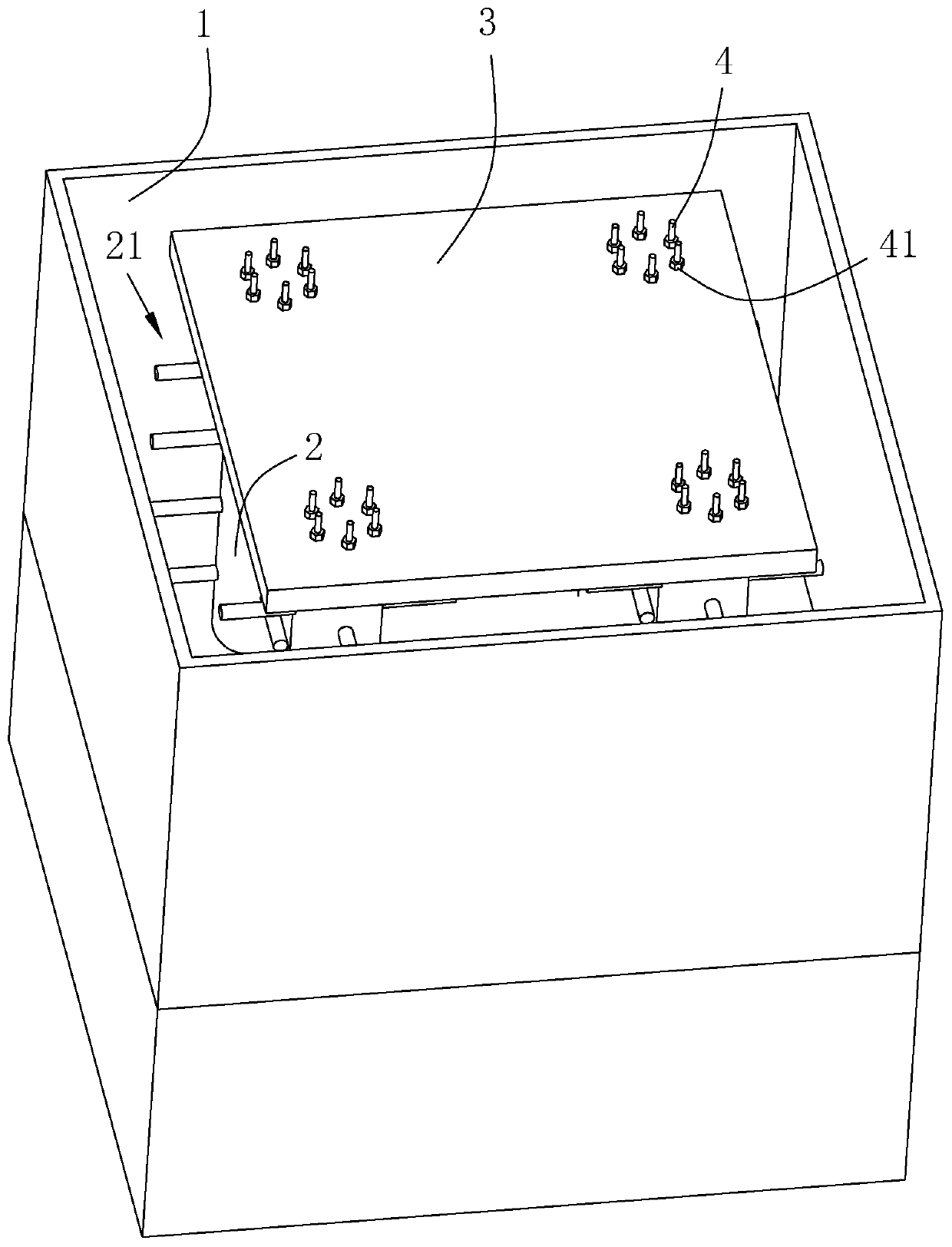

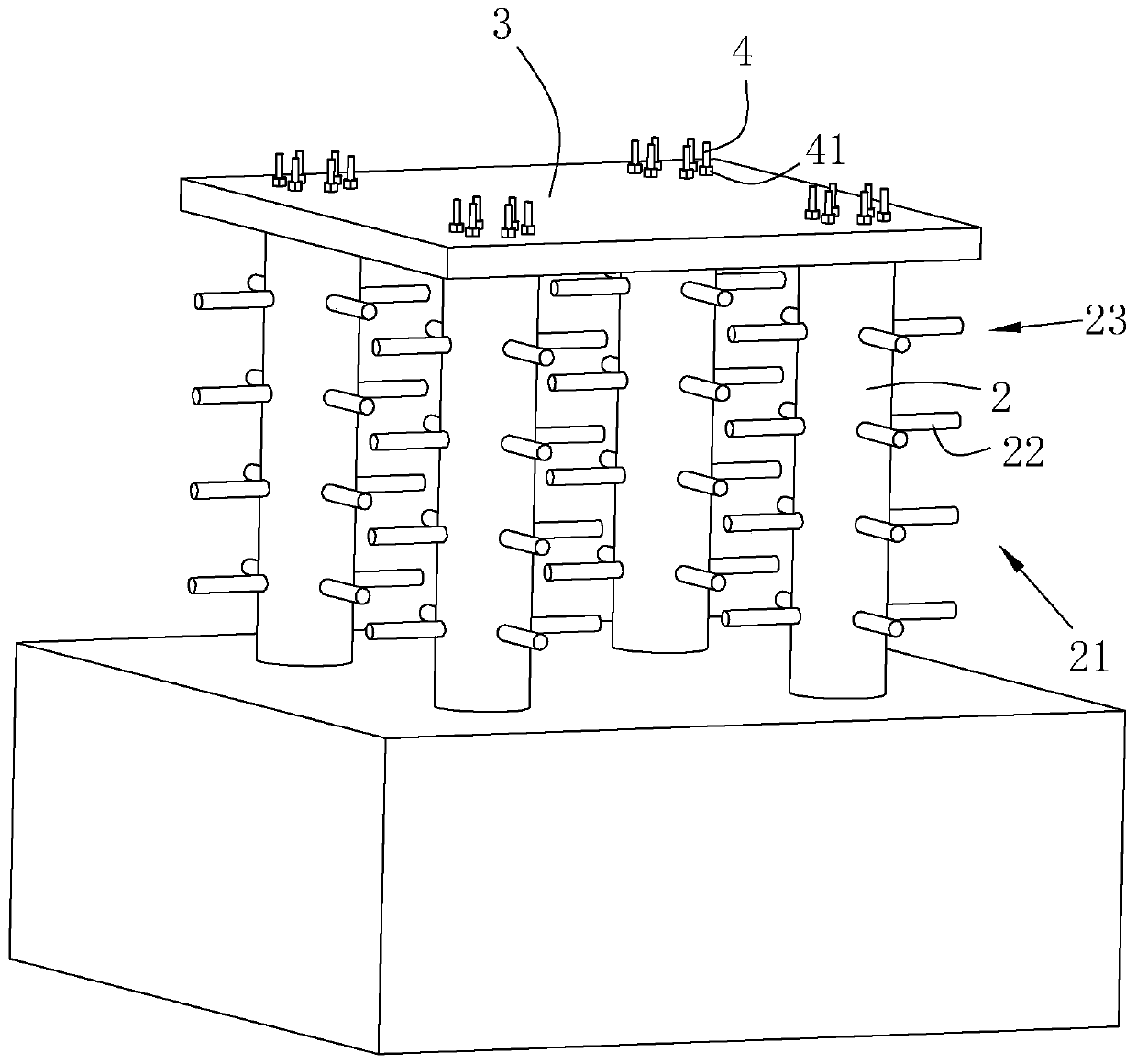

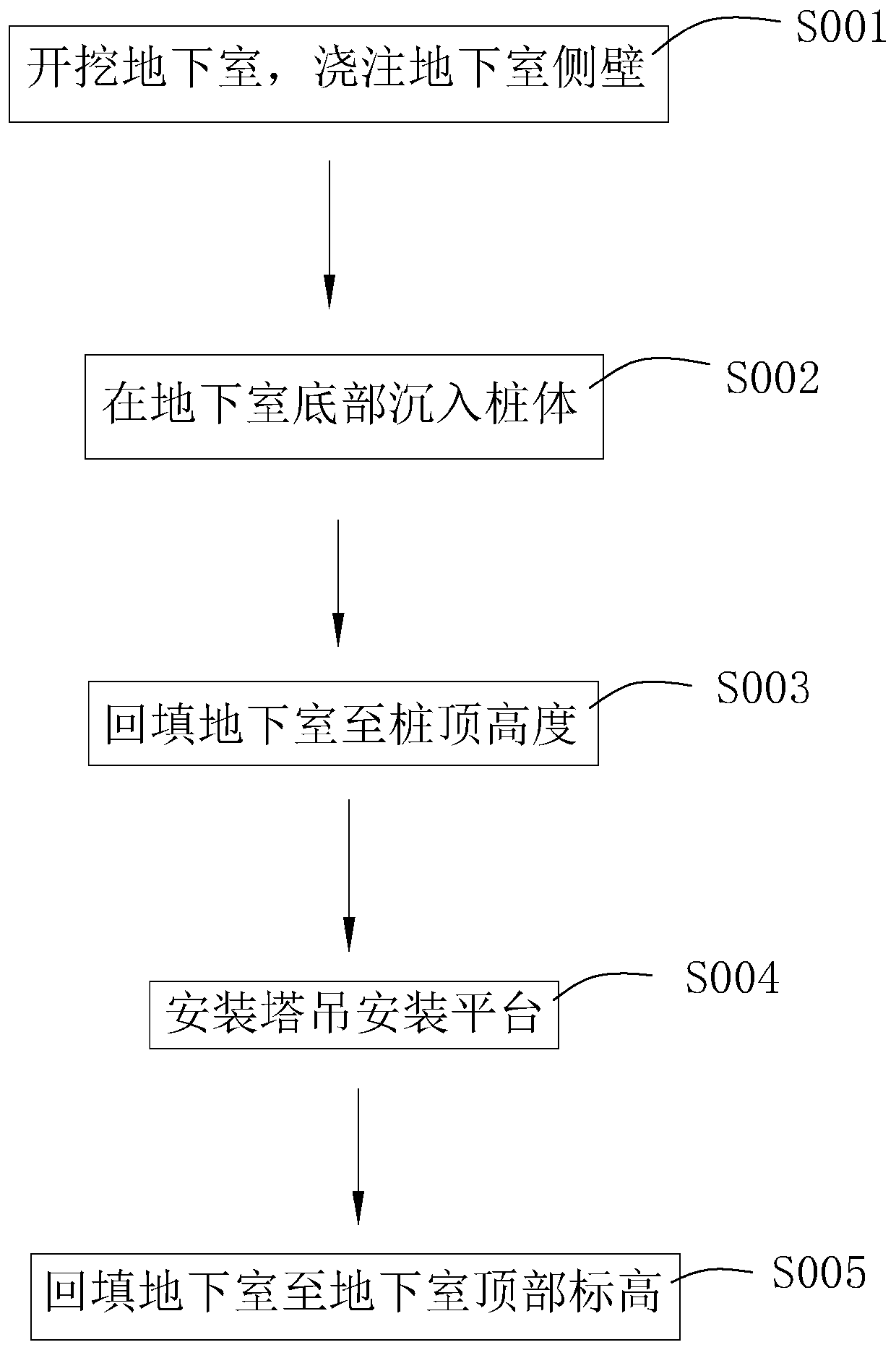

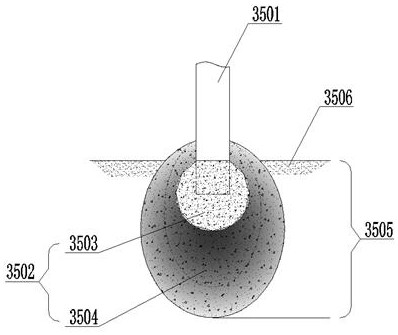

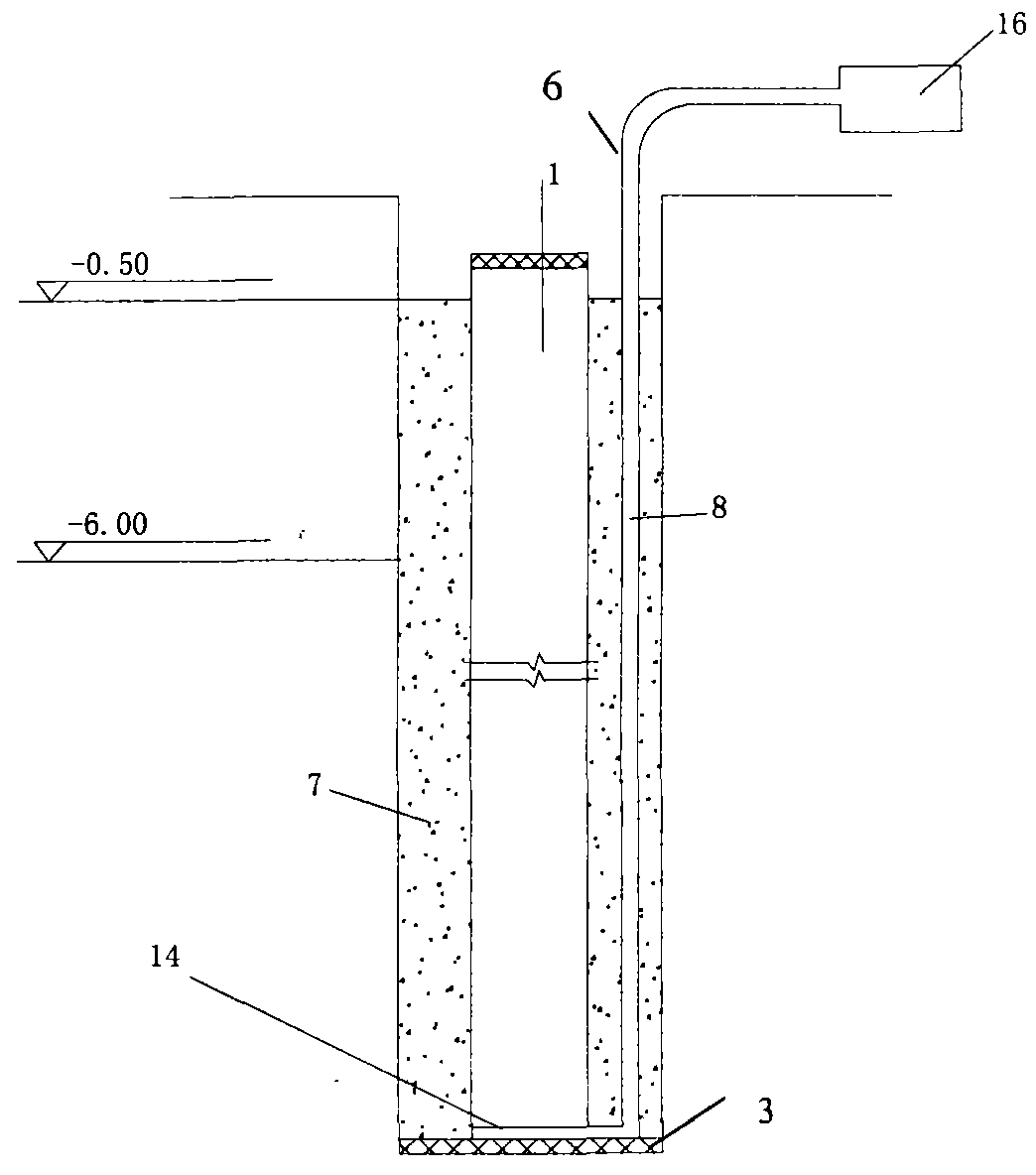

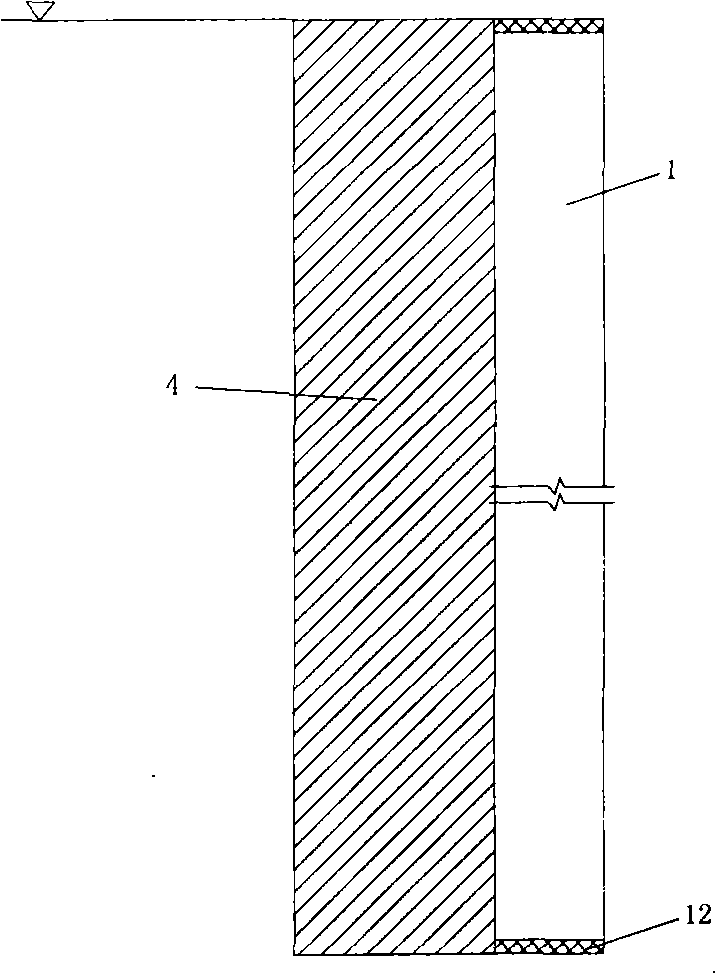

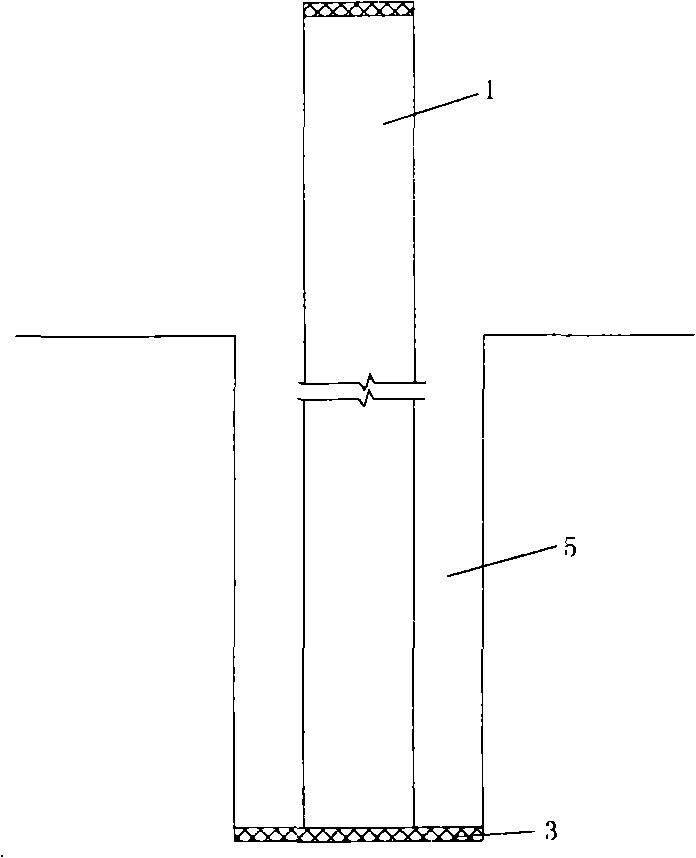

Tower crane foundation structure and its construction method

ActiveCN108222054BStrong pulloutImprove pull resistanceFoundation engineeringBasementStructural engineering

The invention relates to the technical field of buildings, and provides a tower crane base structure and a construction method thereof so as to solve the problem that an existing tower crane base structure can not be used repeatedly. The tower crane base structure can be disassembled wholly and used repeatedly. According to the technical scheme, the tower crane base structure comprises a pluralityof pile bodies and a tower crane mounting platform; the pile bodies sink into the bottom of a basement; the tower crane mounting platform is connected with the pile tops; and the basement is filled with a compact soil layer. The construction method of the tower crane base structure comprises the following steps that (1) the basement is excavated, and the basement side wall is poured; (2) the pilebodies sink into the bottom of the basement; (3) the basement is backfilled to the pile top height; (4) the tower crane mounting platform is mounted; and (5) the basement is backfilled to a basementtop elevation. The basement is filled with the compact soil layer, so that the pile bodies have higher pulling and pressure resistance and bending resistance; and by excavating the soil layer in the basement, the tower crane base structure can be dismounted wholly and be used repeatedly, the disassembly is facilitated, and project waste is reduced.

Owner:广州芳建工程建设集团有限公司

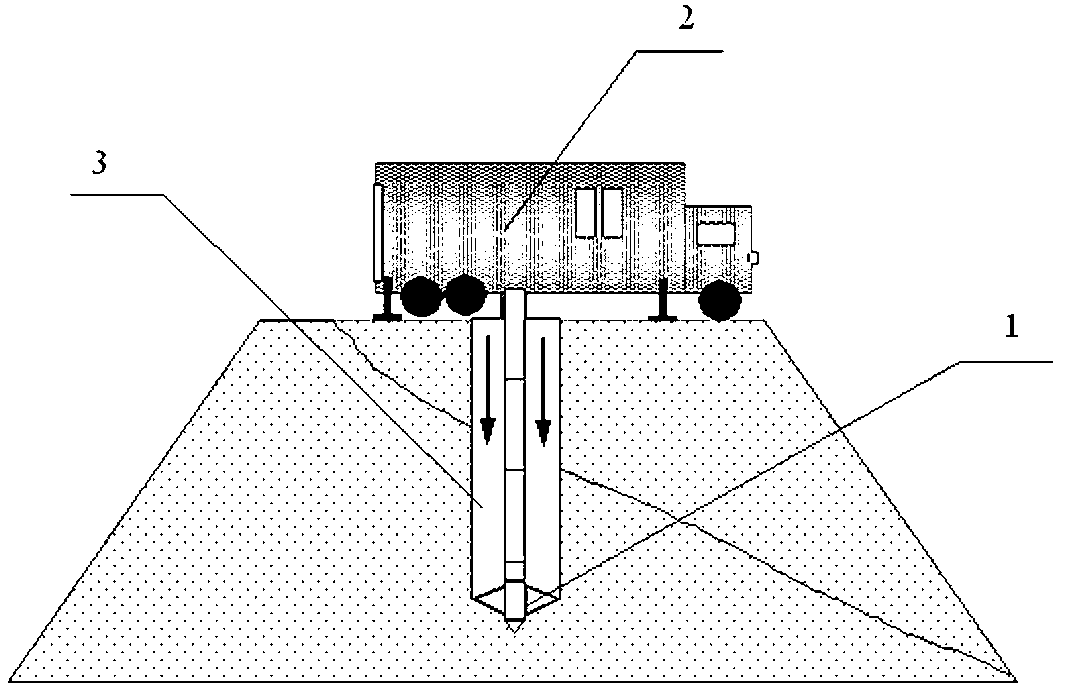

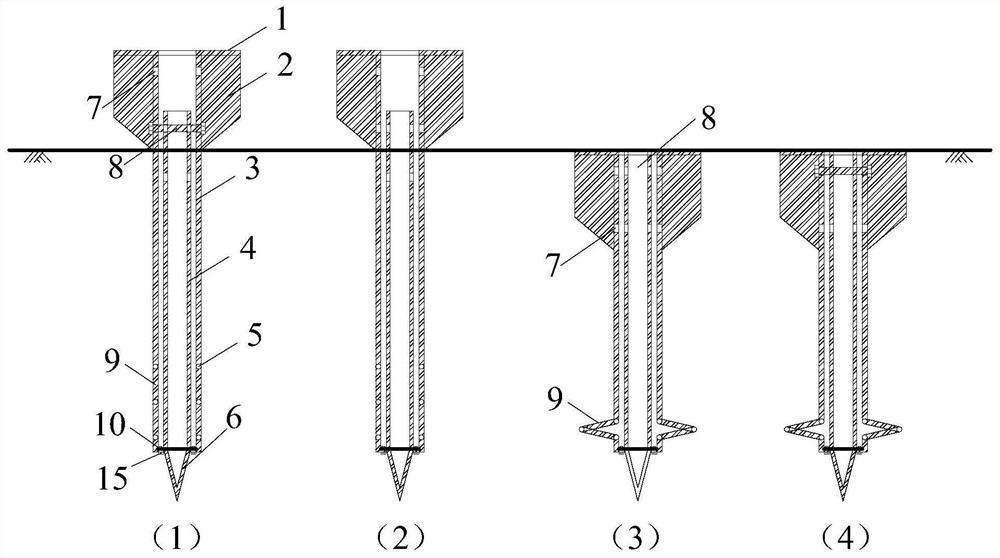

Novel BNT carrier pile and construction equipment construction method thereof

PendingCN112012199AEnsure safetyGuarantee the pile qualityBulkheads/pilesArchitectural engineeringDowel

The invention relates to the field of civil engineering, in particular to a novel BNT carrier pile and a construction equipment construction method of the novel BNT carrier pile. A pile hammer, a diesel hammer or a vibration hammer is used for replacing a shaking or rotary device as power, and a dowel bar and a replacement standard pile hammer are strongly combined with the BNT technology to achieve construction of the carrier pile. The high-quality potential of high bearing capacity of the carrier pile and the advantages of high pile forming quality and high applicability of the BNT technology are fully explored; some problems existing in the original carrier pile forming concept and construction are solved; through diversification of construction forms and equipment and by taking the three-strike penetration requirement as a criterion, the design and the construction are enabled to be based on the evidence; and complexity is replaced by simplicity, the process is simplified, and finally the BNT carrier pile with high bearing capacity, good effect, high speed, low cost and wider application range is realized to meet the increasingly high different requirements of engineering construction on pile foundations.

Owner:张掖市陇原地基基础工程有限公司

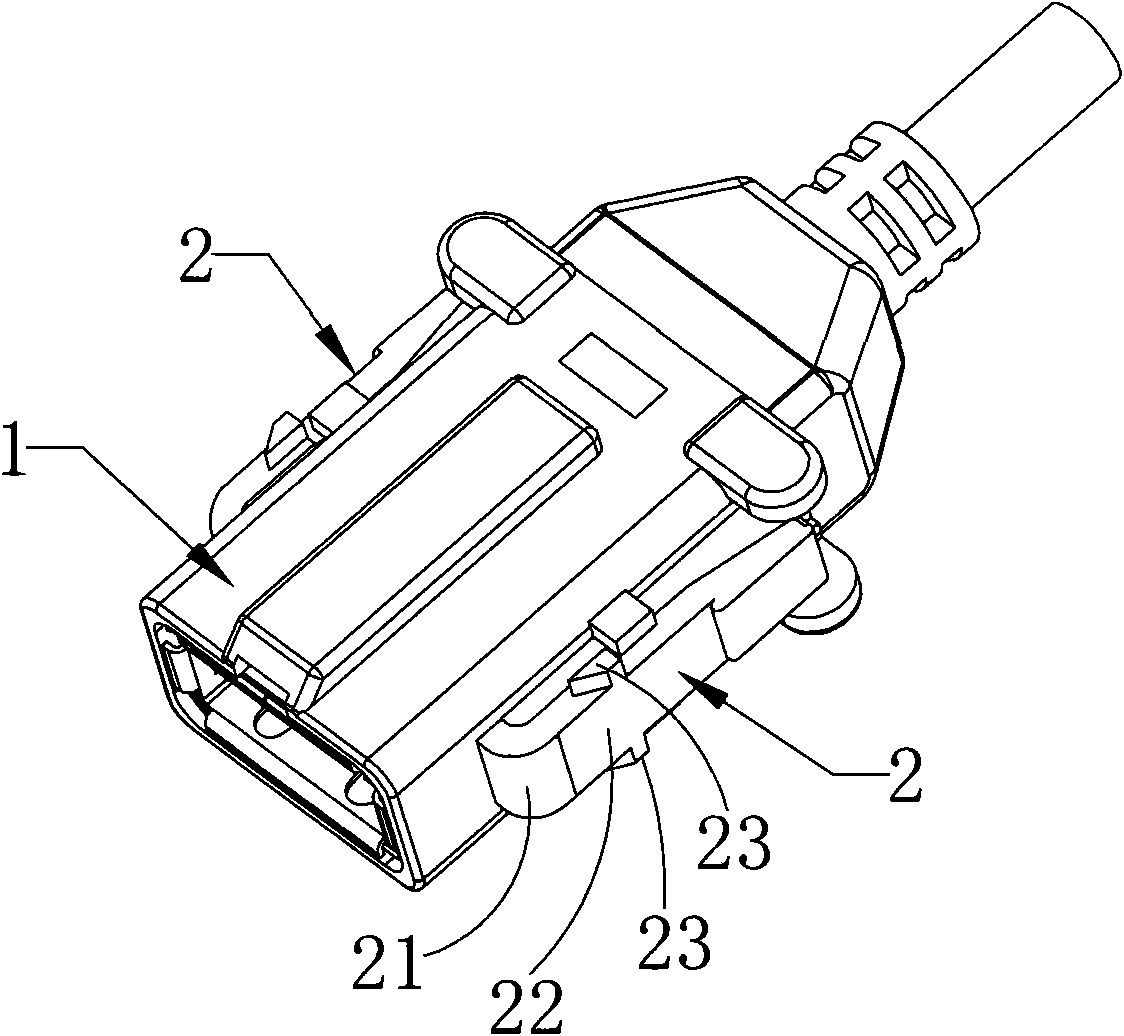

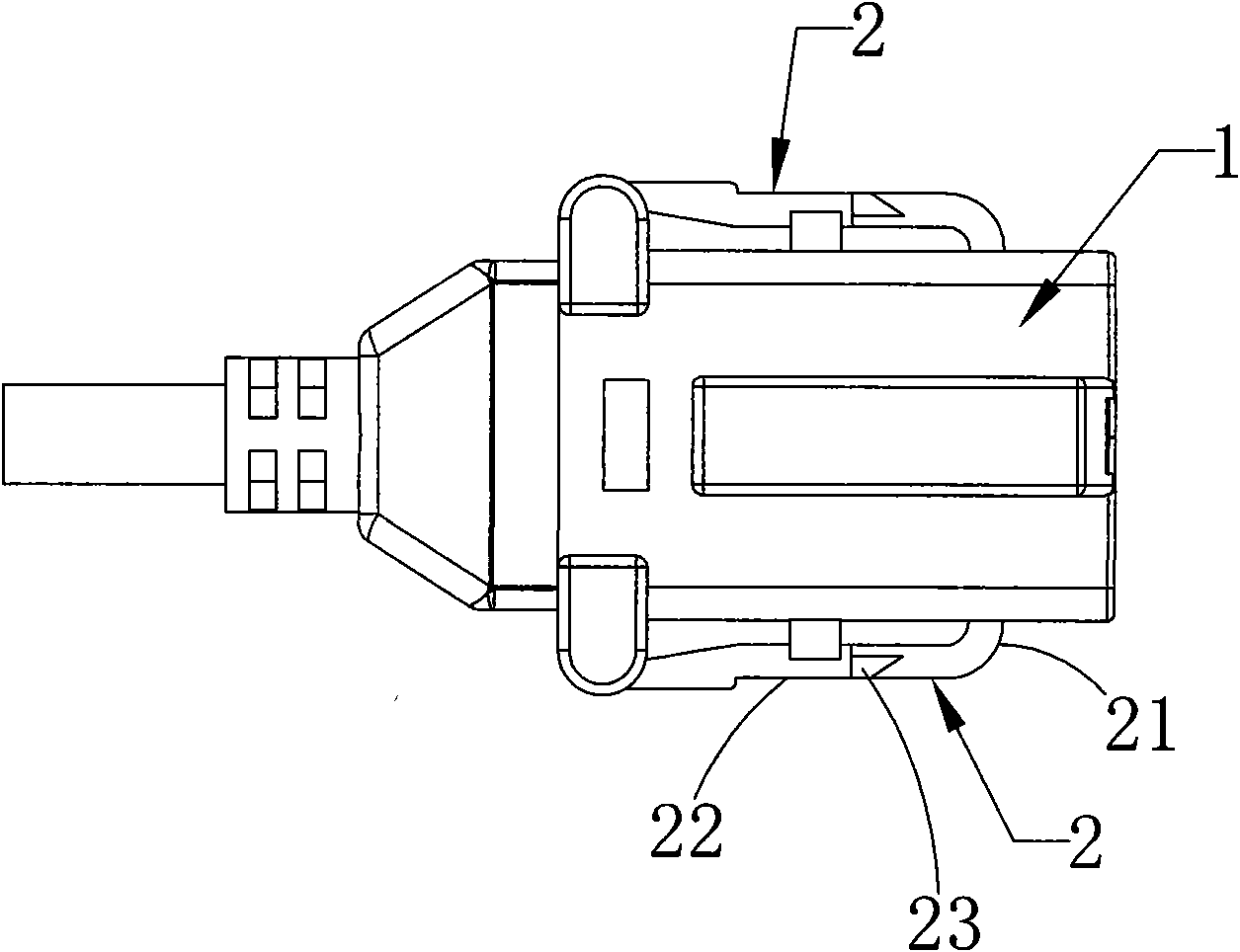

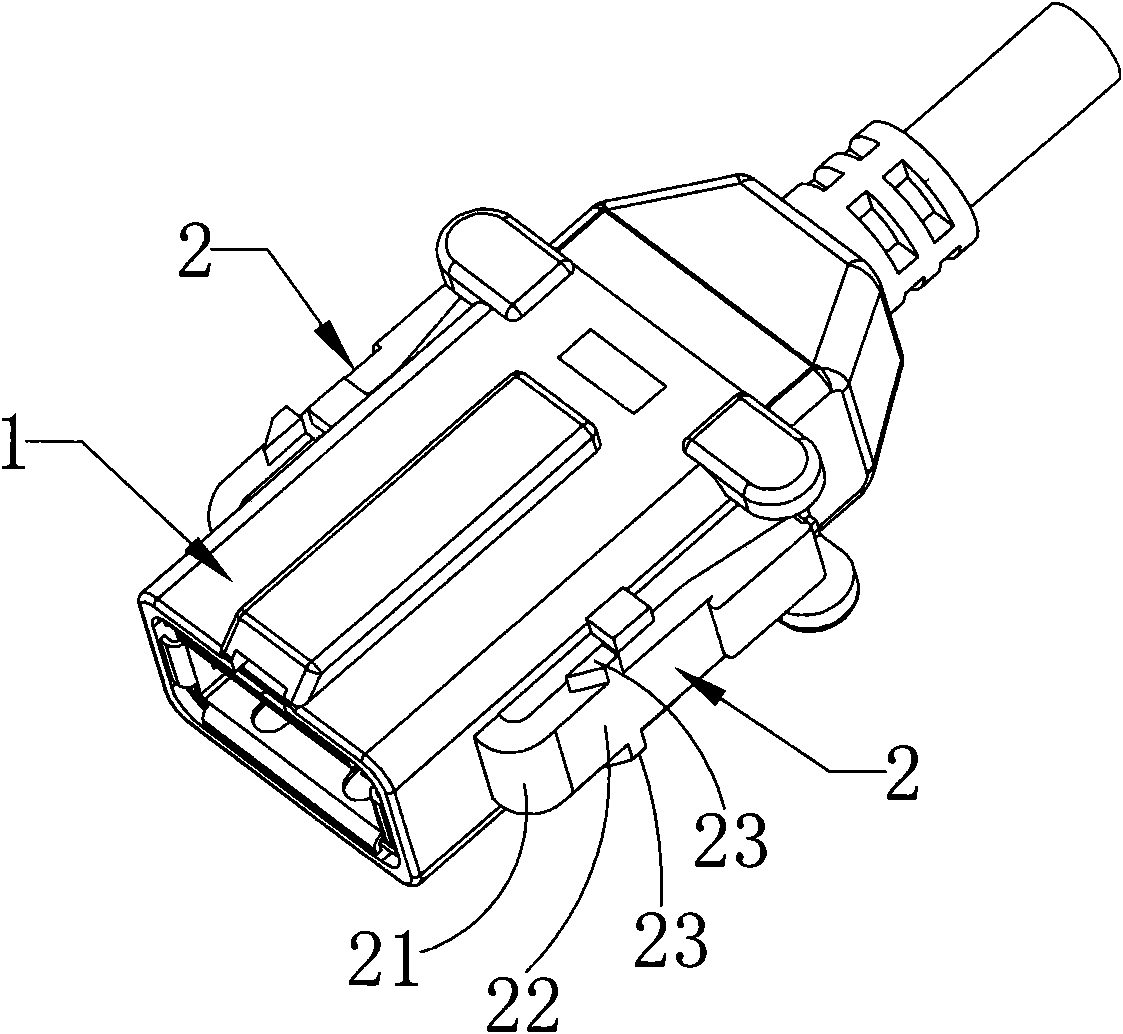

Structure improvement of connector plug end for vehicles

InactiveCN101924298AFast assemblyEasy to import automationCoupling device detailsLeft directionAutomation

The invention discloses a structure improvement of a connector plug end for vehicles. The connector plug end is provided with a plastic body, two wider symmetrical surfaces in the four surfaces of the plastic body are an upper surface and a lower surface, the other two symmetrical surfaces are a left side surface and a right side surface, and plastic elastic buttons are respectively and integrally connected to the outer surfaces of the left side surface and the right side surface, have elasticity in the left direction and the right direction, and can be buckled with the corresponding positions of accessories without external force so that the function of buckling can be realized without using stainless steel elastic sheets. The connector plug end can quicken the assembling sped and has the advantages of convenient introducing automation, reduction of manufacturing cost and enhancement of pulling resistance.

Owner:JIANGSU HUASHENG AUTOMOTIVE ELECTRONICS CO LTD

Polyethylene composition for drip irrigation pipe/belt

A polyethylene composition for drip irrigation pipes / belts belongs to the field of polymer materials. It is characterized in that it is made of the following components by weight: polyethylene resin A75~85 parts, polyethylene resin B15~25 parts, antioxidant 0.3~0.6 parts, carbon black masterbatch 4~5 parts, carbon black concentration 45%~50%; polyethylene resin A is a copolymer of ethylene and 1-hexene, with a density of 0.941~0.948g / cm 3 ; Melt mass flow rate is 10.7~13.8g / 10min, weight average molecular weight is 18.9×10 4 ~20.5×10 4 , molecular weight distribution 18.7 ~ 20.0; described polyethylene resin B is the copolymer of ethylene and 1-butene, density is 0.944 ~ 0.950g / cm 3 ;Melt mass flow rate is 51~56g / 10min, weight average molecular weight is 11.1×10 4 ~12.6×10 4 , molecular weight distribution 14.8~16.0. The polyethylene composition of the invention has excellent processability and ESCR, high mechanical strength and drawing resistance.

Owner:CHINA PETROLEUM & CHEM CORP

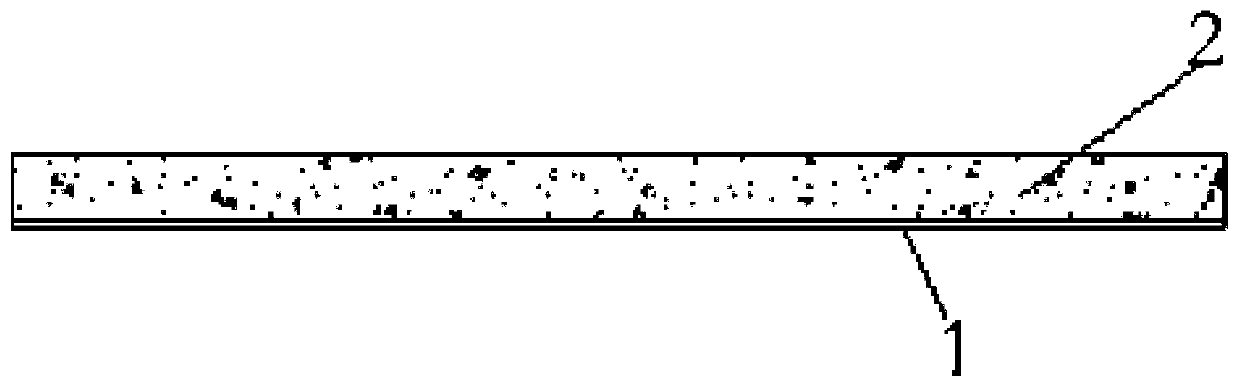

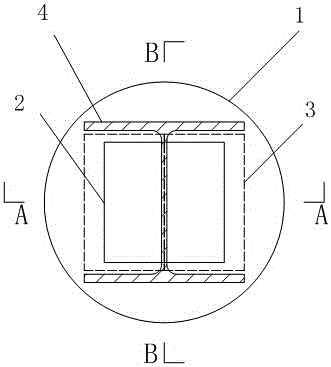

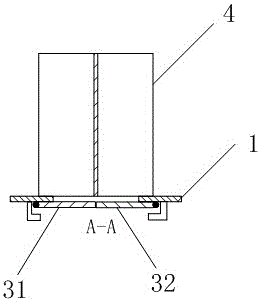

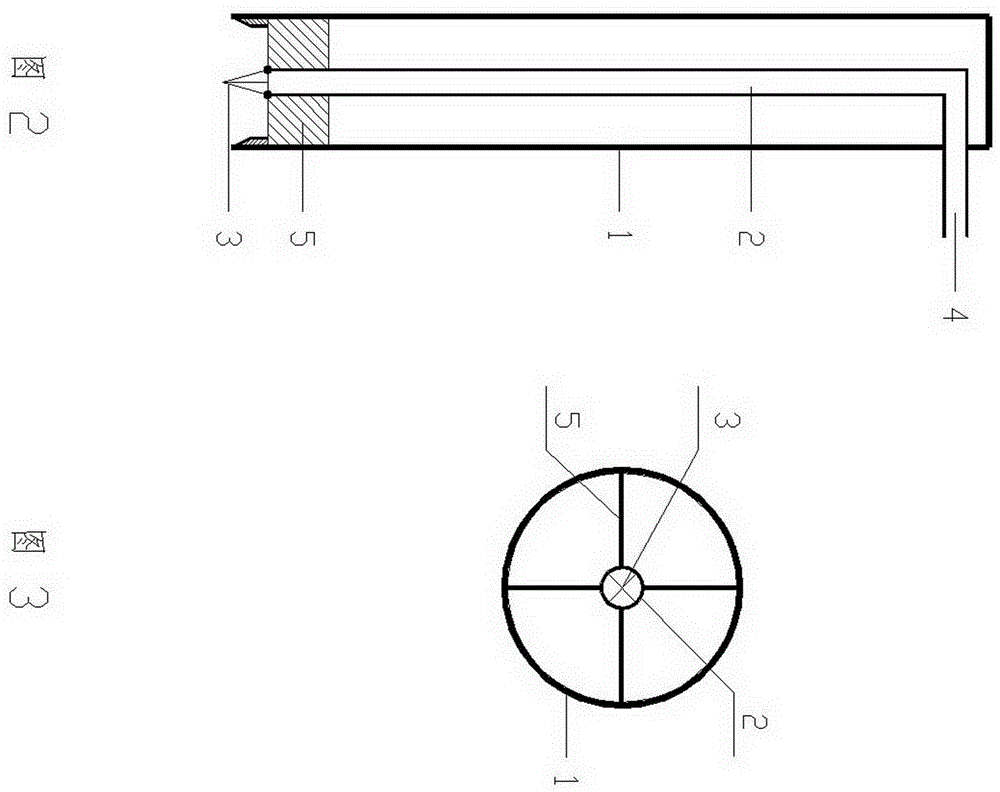

Rectangular concrete piles for building side walls of pipe gallery

ActiveCN106368211BFast constructionShort construction periodArtificial islandsUnderwater structuresRebarBuilding construction

The invention relates to rectangular concrete piles used for constructing a side wall of a pipe gallery. Each rectangular concrete pile comprises a pile body (1) with the rectangular cross section. The rectangular concrete piles are characterized in that a plurality of middle anchoring ribs (2) protruding out of the front end face of each pile body (1) are arranged in the middle of the pile body (1). The middle anchoring ribs protruding out of the front end faces of the pile bodies are arranged in the middles of the pile bodies, a reinforcement framework structure inside a pipe gallery bottom plate can be conveniently constructed between the middle portions of the concrete piles through the exposed anchoring ribs, and thus the pipe gallery bottom plate is constructed; meanwhile, after pouring is completed, a continuous wall and the bottom plate are connected through the exposed anchoring ribs, and the wall and the pipe gallery bottom plate can be connected more firmly; and the continuous wall manufactured from the rectangular concrete piles can be used as a foundation pit enclosure during pipe gallery construction and also can be used as the wall of the pipe gallery, and walls on the two sides of the pipe gallery do not need to be constructed additionally.

Owner:俞晓东

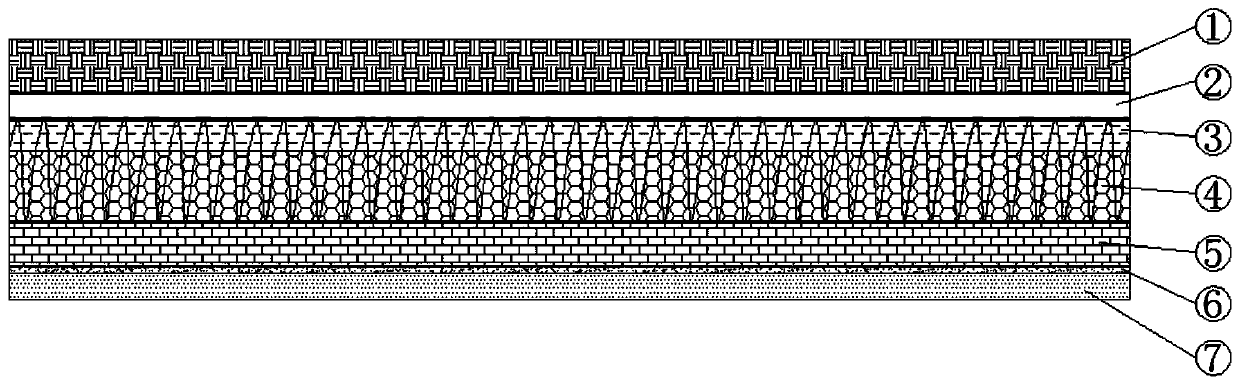

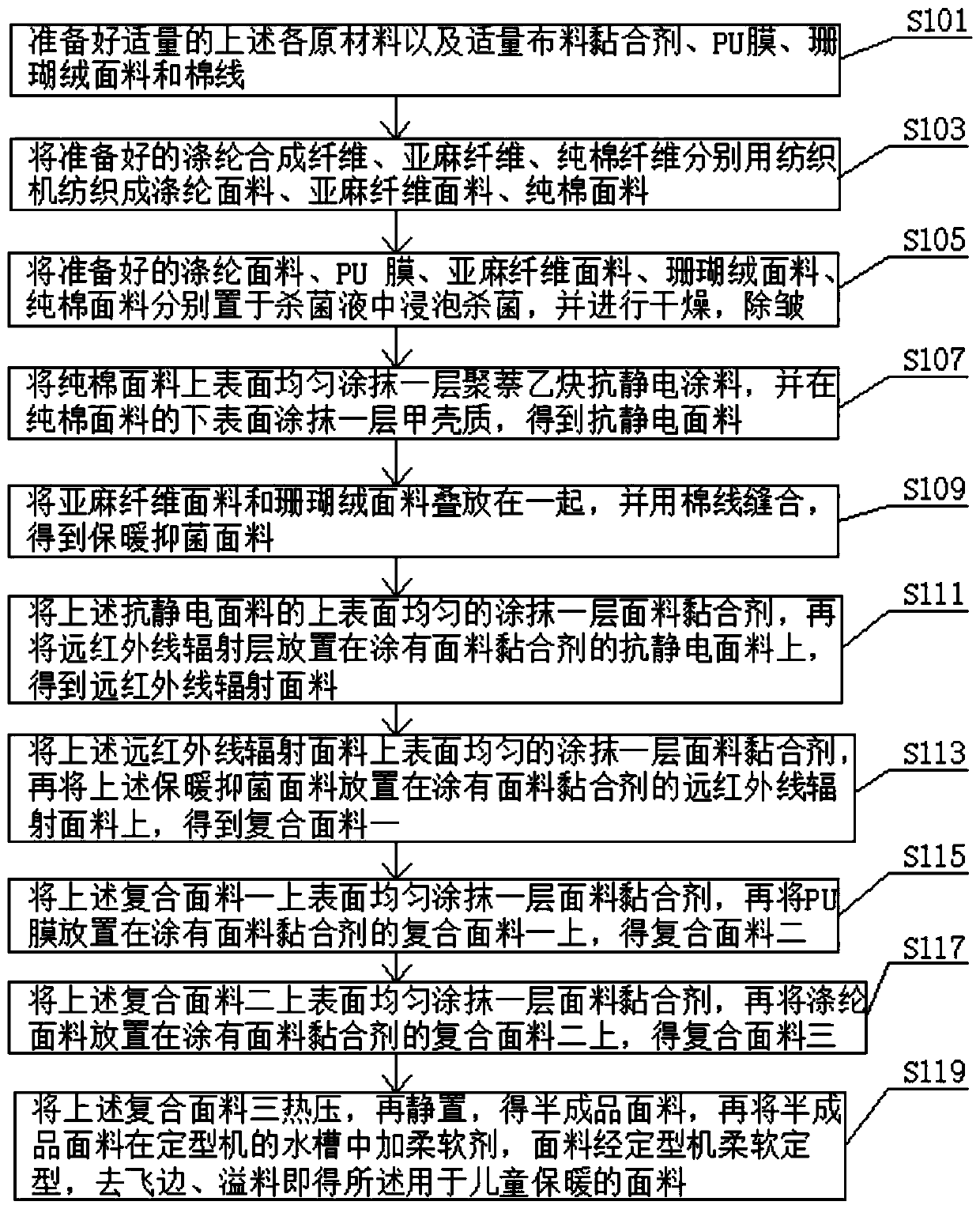

Fabric for children warmth and preparation method of fabric

InactiveCN110774679AImprove thermal effectGood thermal effectGarment special featuresLamination ancillary operationsFlax fiberHemp fiber

The invention discloses a fabric for children warmth and a preparation method of the fabric. The fabric comprises an outer layer, a PU (polyurethane) membrane layer, a flax fiber fabric layer, a coralfleece fabric layer, a far infrared radiation layer, an anti-static layer and an inner layer, wherein the PU membrane layer is arranged under the outer layer; the flax fiber fabric layer is arrangedunder the PU membrane layer; the coral fleece fabric layer is arranged under the flax fiber fabric layer; the far infrared radiation layer is arranged under the coral fleece fabric layer; the anti-static under layer is arranged under the far infrared radiation layer; and the inner layer is arranged under the anti-static layer. The fabric has the beneficial effects that far infrared rays of 4-14[mu] m which are mostly expected by human bodies can be radiated back, the far infrared rays have resonance with human cells to achieve a heat effect, the heat preservation effect can be realistically improved, the heat preservation effect is good, and meanwhile, the fabric has the advantages of being solid, durable to wearing, not easy to damage, and the like.

Owner:杭州乐发长科技有限公司

Wind-resistant and overturn-preventing external expansion pole foundation for electric power

InactiveCN111042186APay attention to reinforcementDoes not affect aestheticsFoundation engineeringTowersControl theoryElectric power

The invention provides a wind-resistant and overturn-preventing external expansion pole foundation for electric power. The pole foundation is arranged underground and used for supporting a pole, so that the pole has better wind-resistant, overturn-preventing and anti-pulling capacity; and the foundation can be reused during pole replacement or line transfer in the future, and investment is not wasted. The foundation is characterized in that the foundation is placed on the ground and directly driven or pressed underground after being straightened; a four-way expansion board is arranged at the lower part of the foundation and can be increased and decreased according to actual conditions, a nut is tightened to allow a two-way conical screw to rise, the expansion board expands in each direction, and the lower part of the expansion board is claw-shaped to strengthen the stability and anti-pulling capacity of the foundation; an inverted horn-shaped countersink is formed in the upper part ofthe foundation, and positioning bolts are arranged on the periphery of the upper part of the inverted horn-shaped countersink; and a heavy electric pole is placed in the inverted horn-shaped countersink, the lower end of the heavy electric pole is clamped at the bottom of the inverted horn-shaped countersink, the positioning bolts adjusts the vertical degree of the heavy electric pole, then, a wedge block is plugged in the inverted horn-shaped countersink to further fix the heavy electric pole, and finally, the countersink is filled with soil.

Owner:张若玮

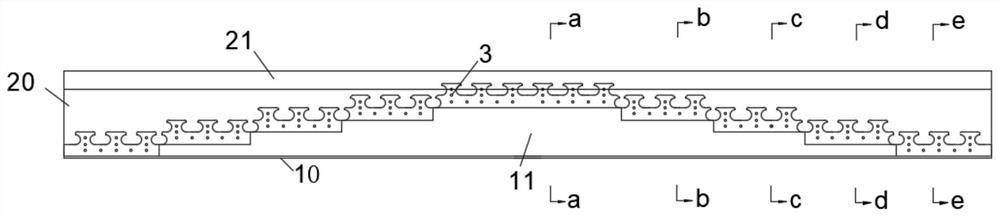

Method for manufacturing a PHC tubular pile in soft soil region through chambering and grouting

ActiveCN101545255BImprove stress resistanceImprove pull resistanceBulkheads/pilesSoil preservationHorizontal forceEconomic benefits

Owner:TIANJIN JIANCHENGJIYE GRP

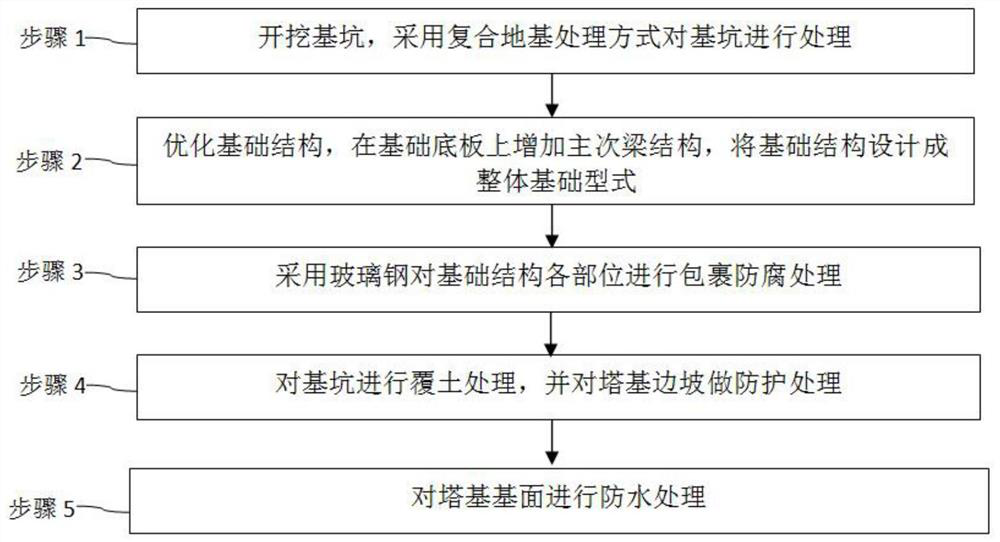

Salt lake area power transmission line iron tower foundation construction method

The invention belongs to the technical field of power transmission line iron tower foundation design, and particularly relates to a salt lake area power transmission line iron tower foundation construction method. The construction method comprises the following steps that S1, a foundation pit is excavated, and the foundation pit is treated in a composite foundation treatment mode; S2, a foundation structure is optimized, a primary beam structure and a secondary beam structure are added on a foundation bottom plate, and the foundation structure is designed into an integral foundation type; S3, glass fiber reinforced plastics are adopted for carrying out wrapping anti-corrosion treatment on all parts of the foundation structure; S4, soil covering treatment is conducted on the foundation pit, and protection treatment is conducted on a tower footing slope; and S5, waterproof treatment is conducted on the base face of the tower footing. The method systematically solves the problems of foundation instability and salinized soil corrosion of the power transmission line iron tower in the salt lake area, ensures safe and stable operation of the power transmission line, and has important significance for improving the economical efficiency and the safe stability of industrial production in a salt lake mining area and promoting sustainable and healthy development of the industrial production in the salt lake area.

Owner:QINGHAI ELECTRIC POWER DESIGN INST

Shear part of spiral spring bolt and construction method

PendingCN113389133AImprove pull resistanceImprove shear resistanceBridge structural detailsBridge erection/assemblyClassical mechanicsCoil spring

The invention discloses a shear part of a spiral spring bolt and a construction method. The shear part comprises an elastic sleeve, an elastic nut, a screw rod and a nut, the elastic sleeve is connected to the screw rod and the elastic nut in a sleeving mode, one end of the elastic nut abuts against the top of the elastic sleeve, the other end of the elastic nut abuts against one end of the screw rod, the other end of the screw rod is in threaded connection with the nut, the end, abutting against the elastic nut, of the screw rod is conical, the elastic sleeve comprises an elastic steel plate, and the elastic steel plate is wound around a rod body of the screw rod by at least three circles. The nut is tightened to apply pre-tightening force, the elastic sleeve can be extruded through the screw rod, due to the fact that the elastic sleeve has elasticity, when the elastic sleeve has an expansion effect, the elastic sleeve is not damaged, the screw rod interacts between the nut and the elastic nut, and the elastic sleeve and a concrete block can generate an anchoring effect, so that the friction force between the shear part and the steel-concrete interface is increased, and the friction force between a bridge deck and a steel beam is increased.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com