Patents

Literature

32results about How to "Reliable carrying capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

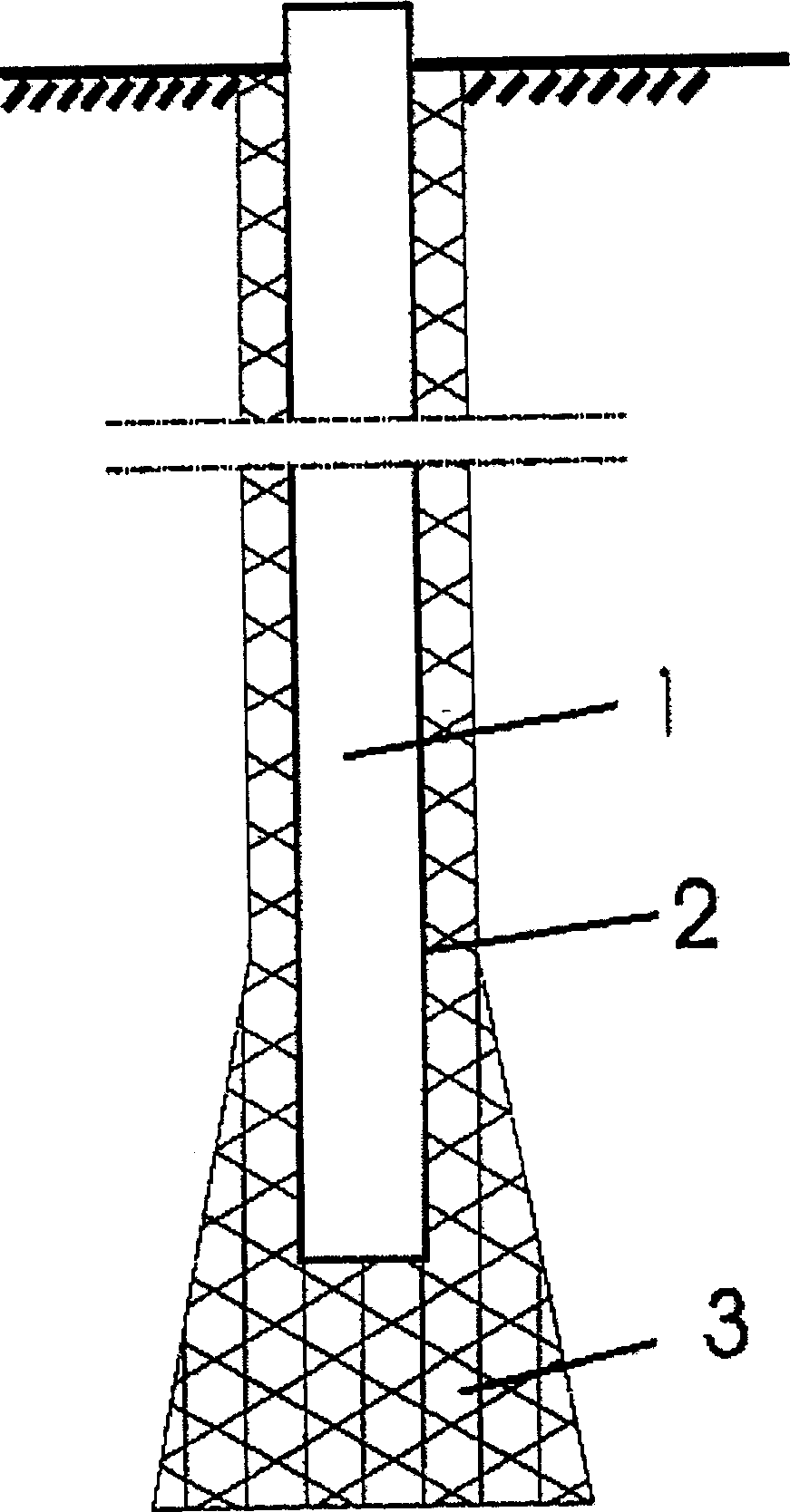

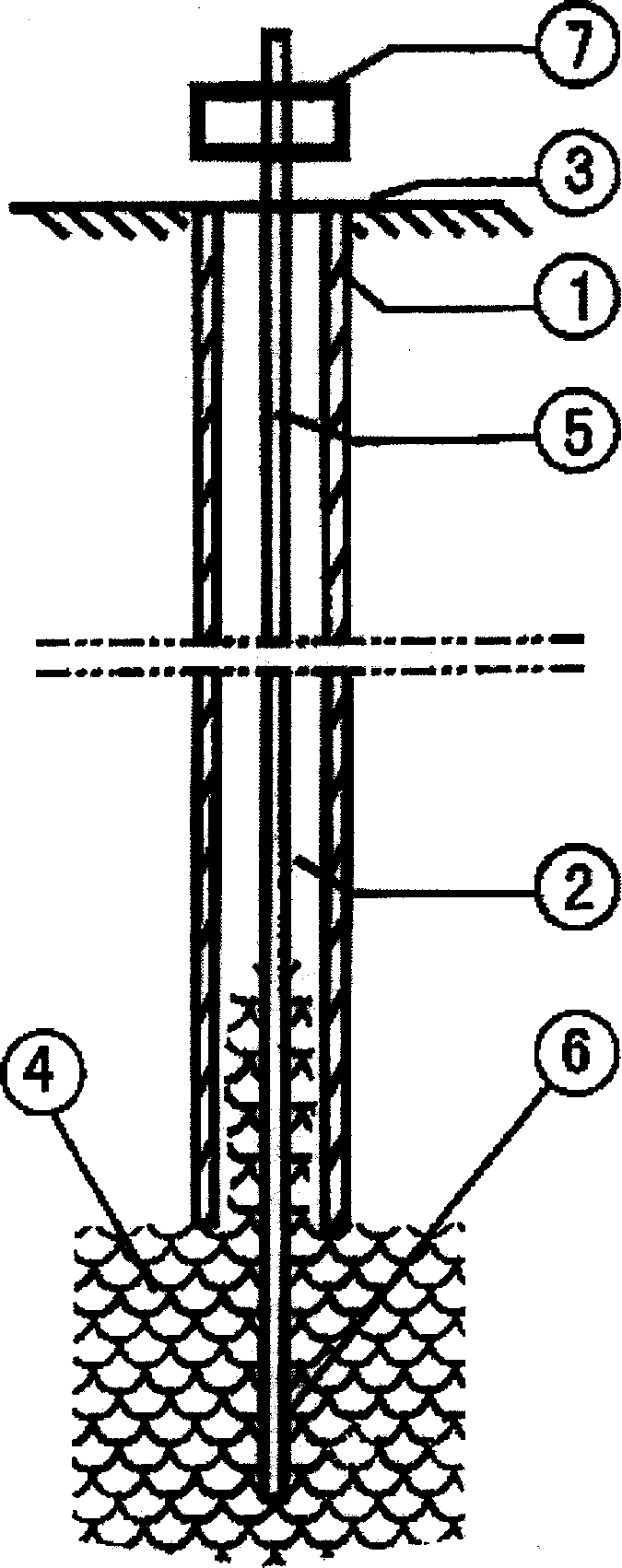

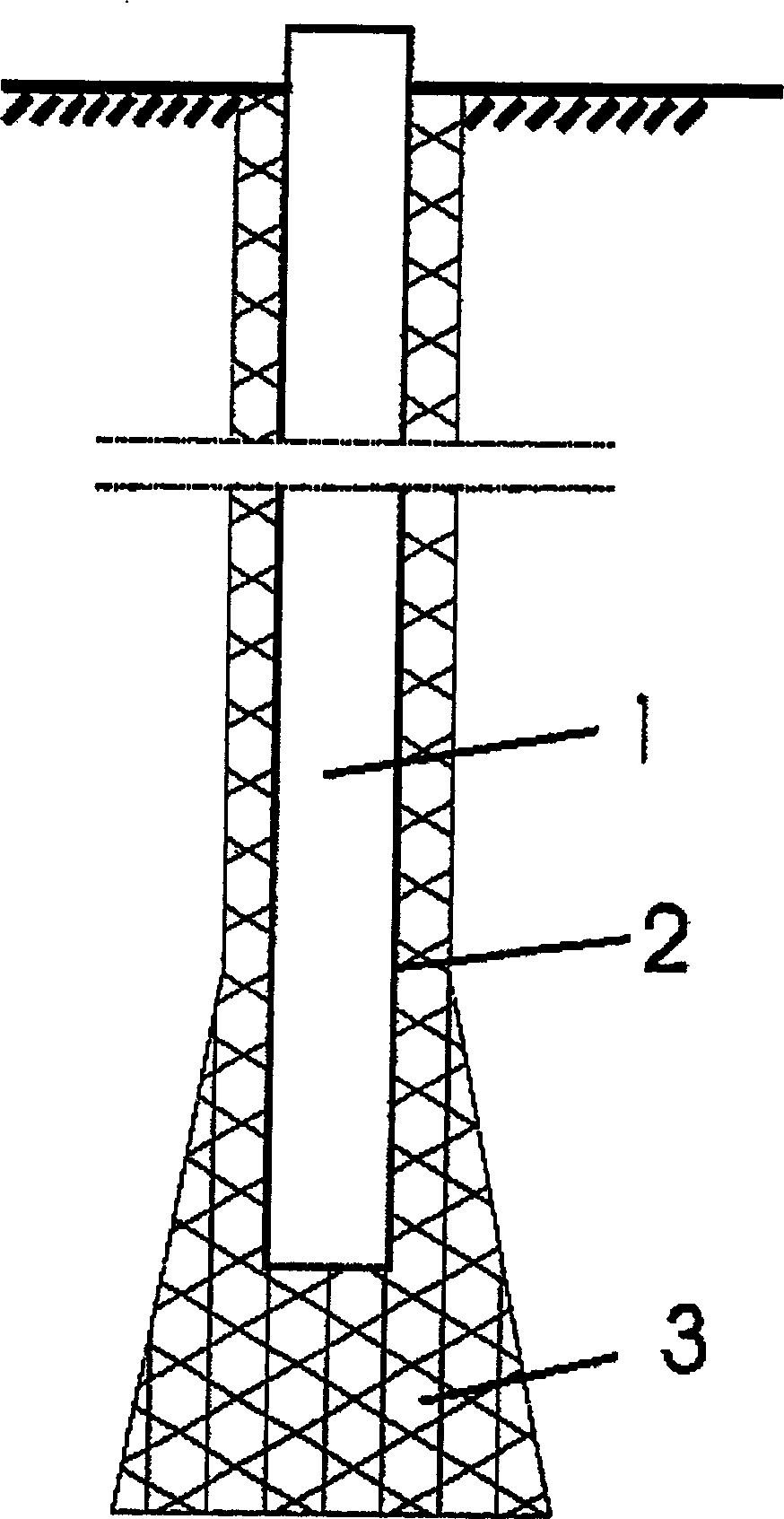

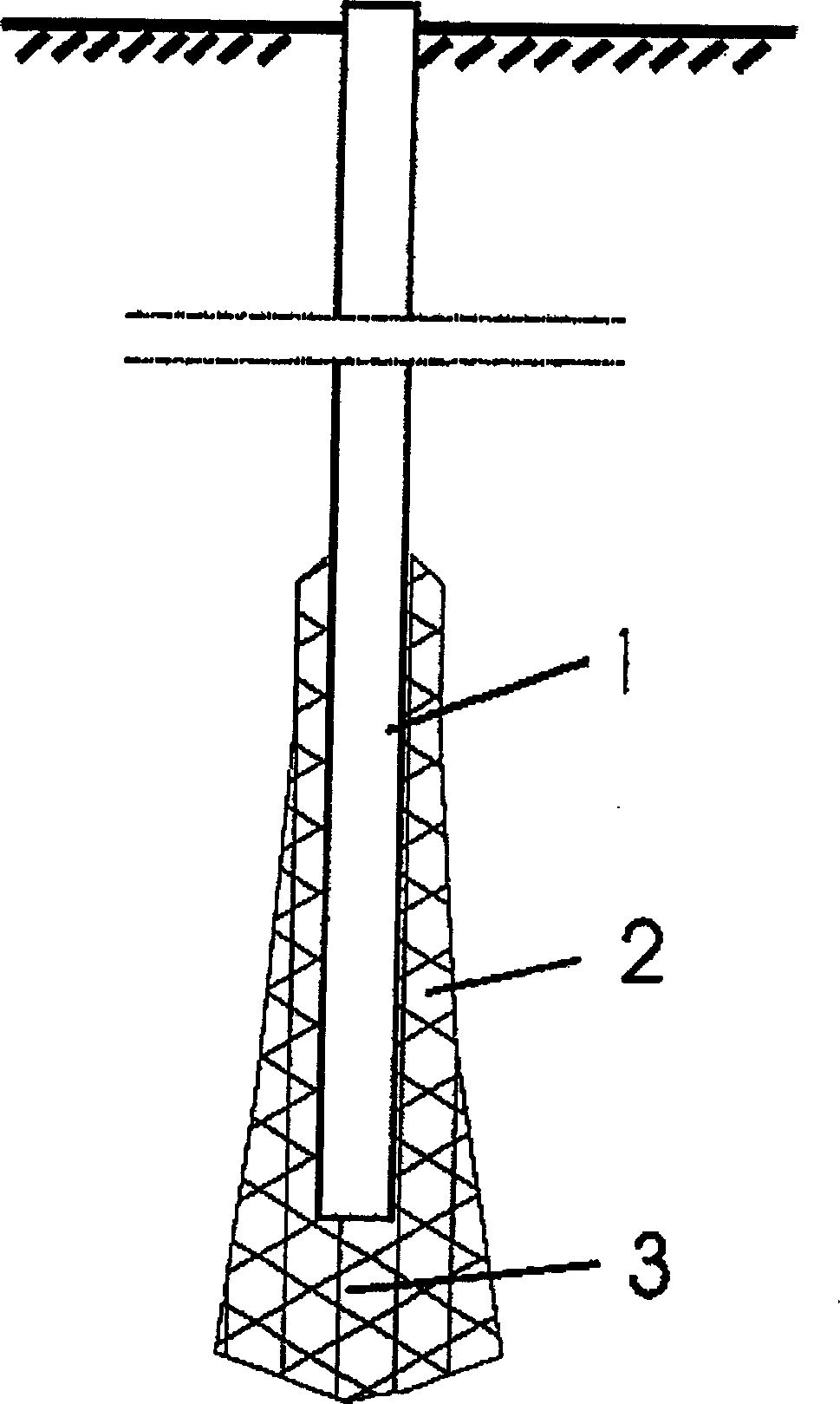

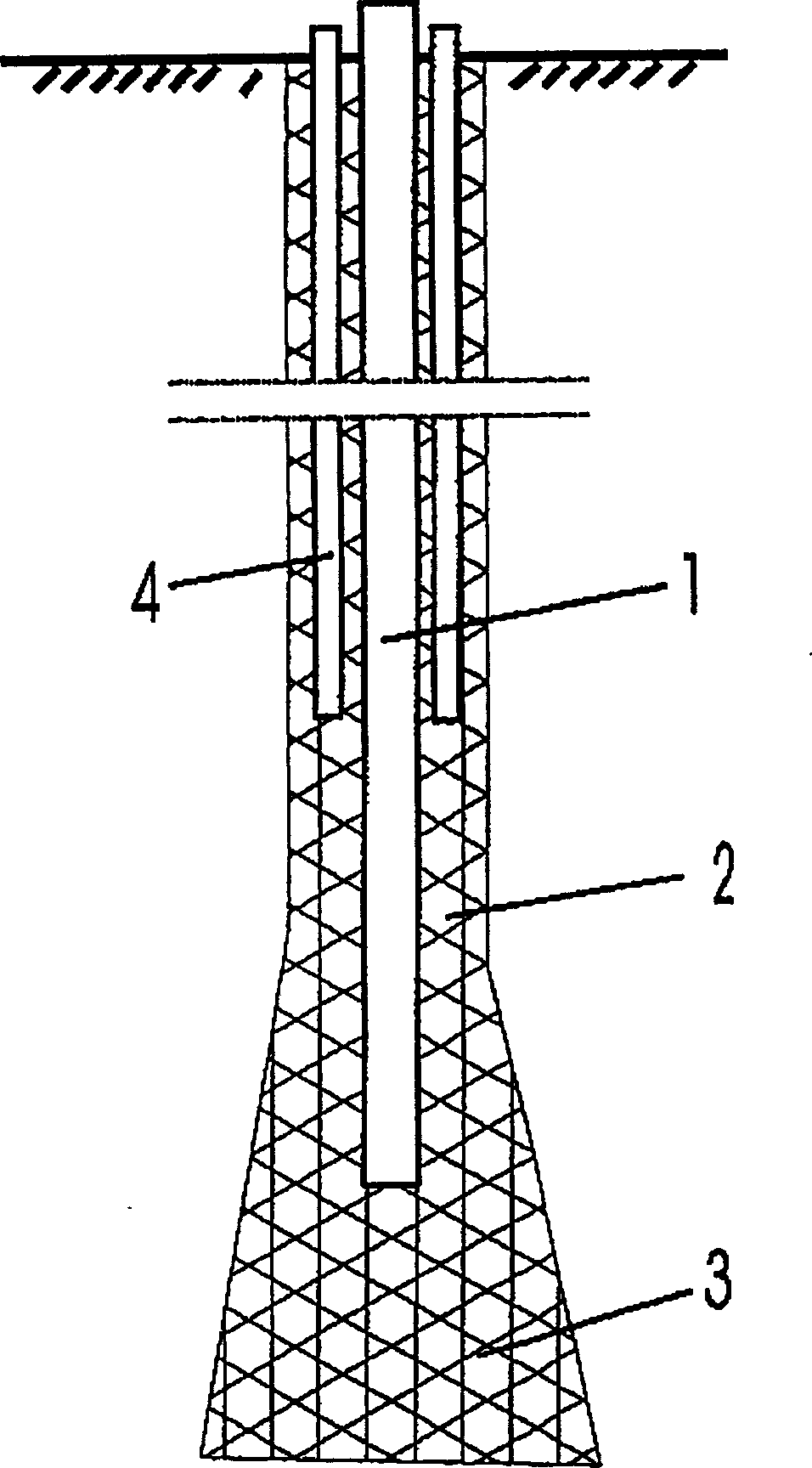

High-pressure rotary spraying and core inserting process to form pedestal pile

InactiveCN1441124AHigh strengthIncrease loading capacityBulkheads/pilesBridge engineeringReinforced concrete

The present invention relates to high-pressure rotary spraying and core inserting process to form pedestal pipe. The pedestal pile consists of core pile, column and pile depestal. The cylindrical or turned frustum-shaped core pile may be prefabricated reinforced concrete pile, in-situ deposited pile or other pile in different cross section shapes. The pile pedestal below the core pile has diameter greater than that of the core pile. The column has circular, semi-circular of fan-shaped cross section. There may be several auxiliary core piles around the main solid or hollow core pile and several rings in relatively great diameter around the column. The present invention has reasonable design, compact structure, high friction resistance, and wide application in building engineering, bridge engineering, civil engineering, water engineering, etc.

Owner:雷玉华

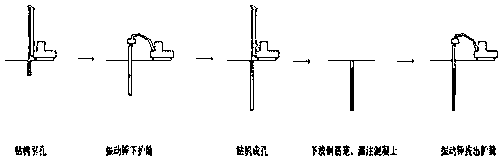

Construction method for cast-in-situ bored pile

InactiveCN110387880ANo pollution in the processDoes not affect workBulkheads/pilesGroundwaterPollution

The invention discloses a construction method for a cast-in-situ bored pile. The construction method comprises the following steps: S1, carrying out digging by a drilling machine: processing the surface of a basic layer of a drilling site, and trepanning the basic layer after rechecking a pile position; S2, laying down pile casings by a vibratory hammer: connecting the pile casings by using high strength bolts and nuts; S3, drilling a hole by the drilling machine: after the pile casings arrive a preset depth, carrying out drilling to a designed pile bottom elevation for first time hole cleaning; S4, laying down a reinforcement cage and pouring concrete, carrying out pouring continuously, and overpouring concrete for 1-2 m; and S5, pulling out the pile casings by the vibratory hammer: pulling out the pile casings from pile holes after pouring the concrete, and recycling the pile casings. The method is free of pollution to underground water and tidy in construction site, does not affectthe ambient environment, and meets the high environmental-friendly demand. Compared with a conventional process, the construction speed of the method is over doubled, so that the construction efficiency is high.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +1

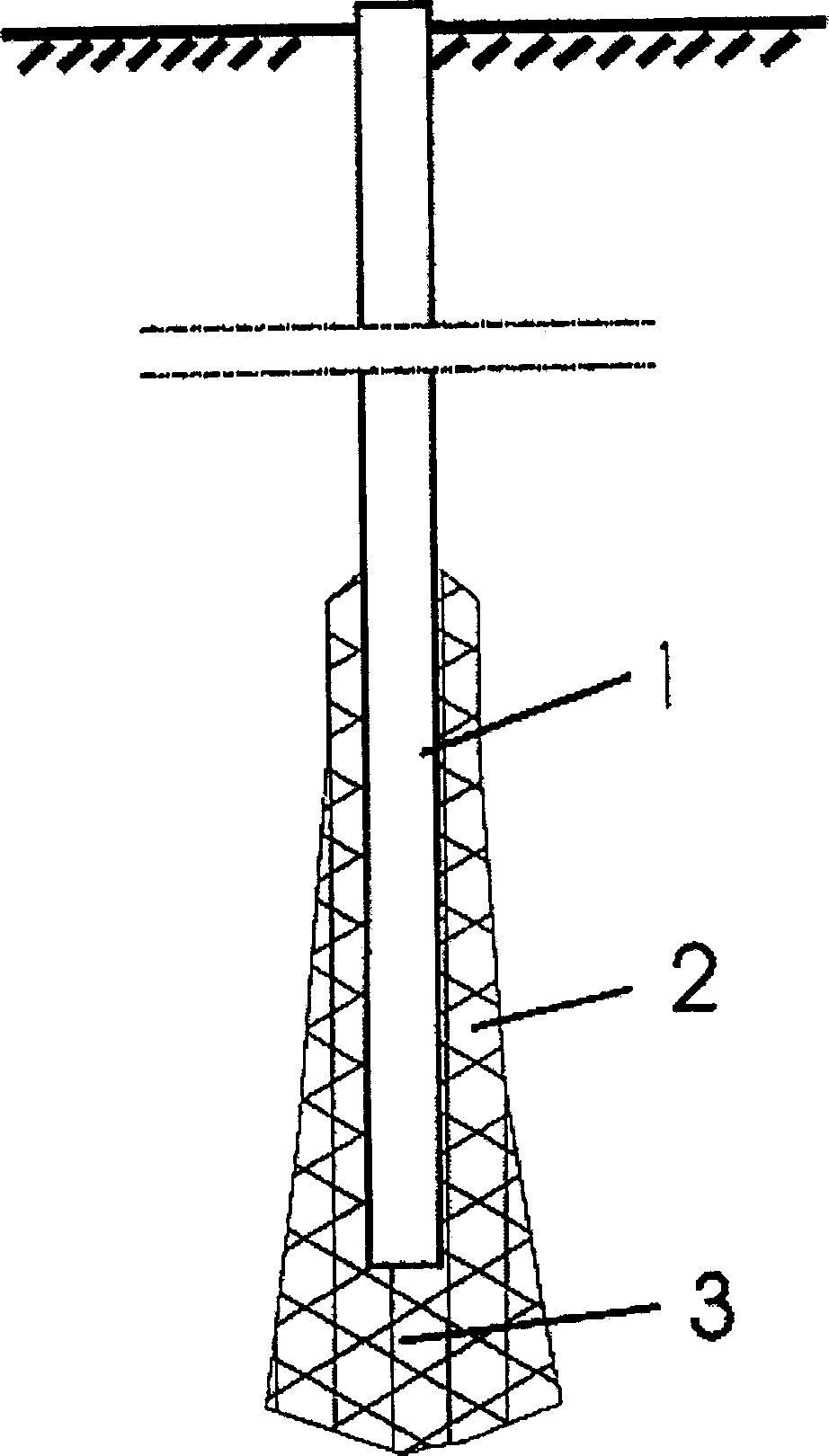

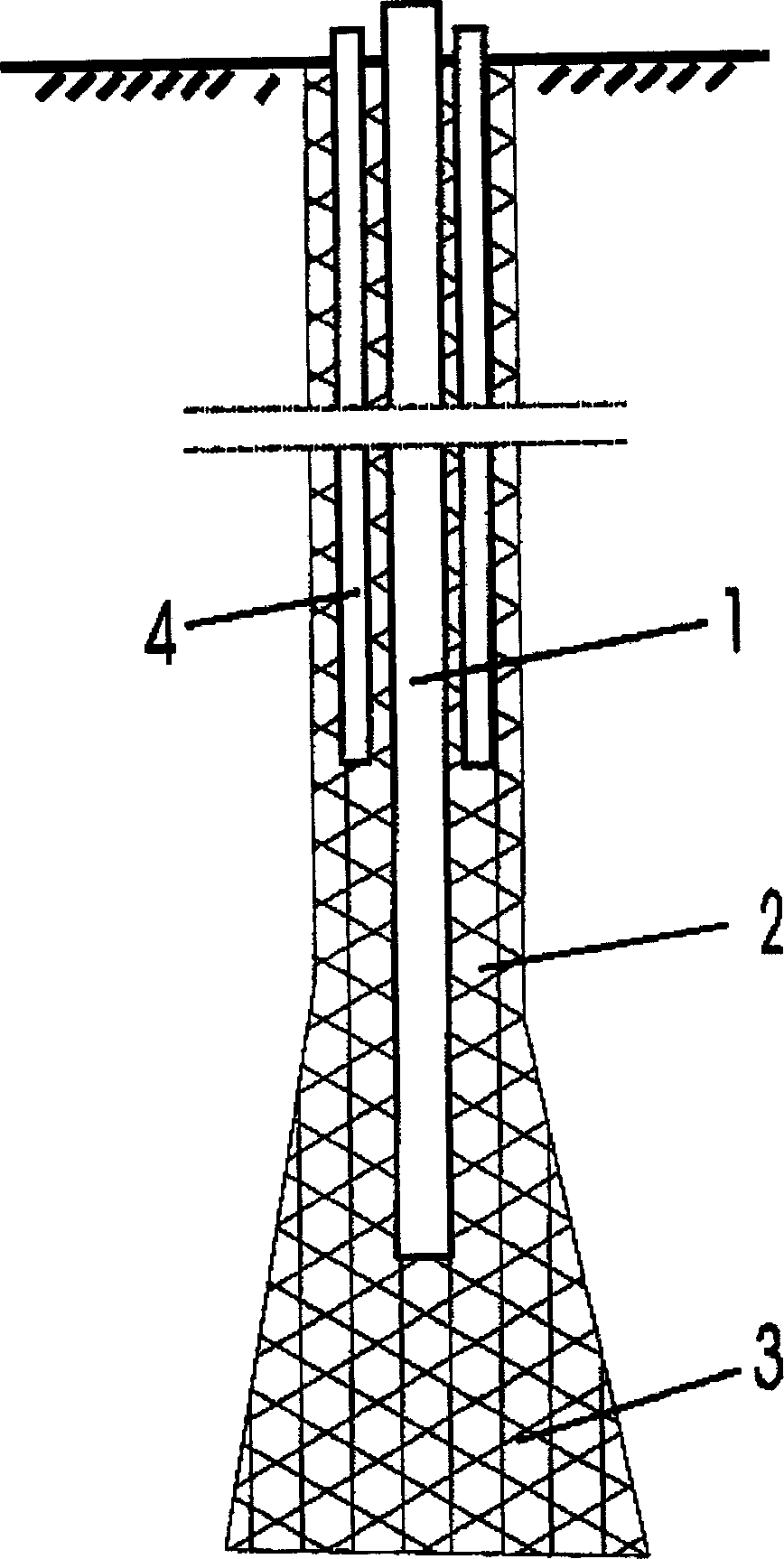

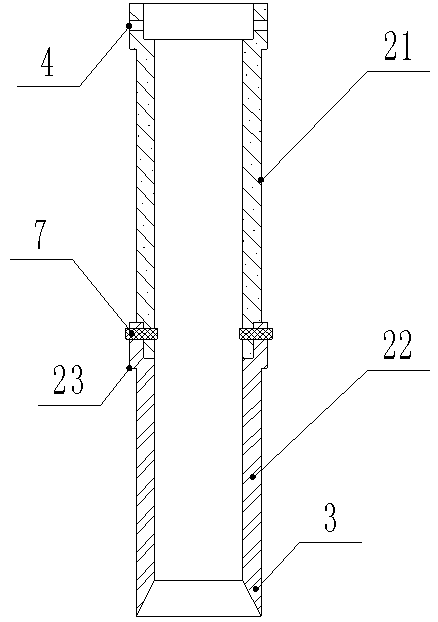

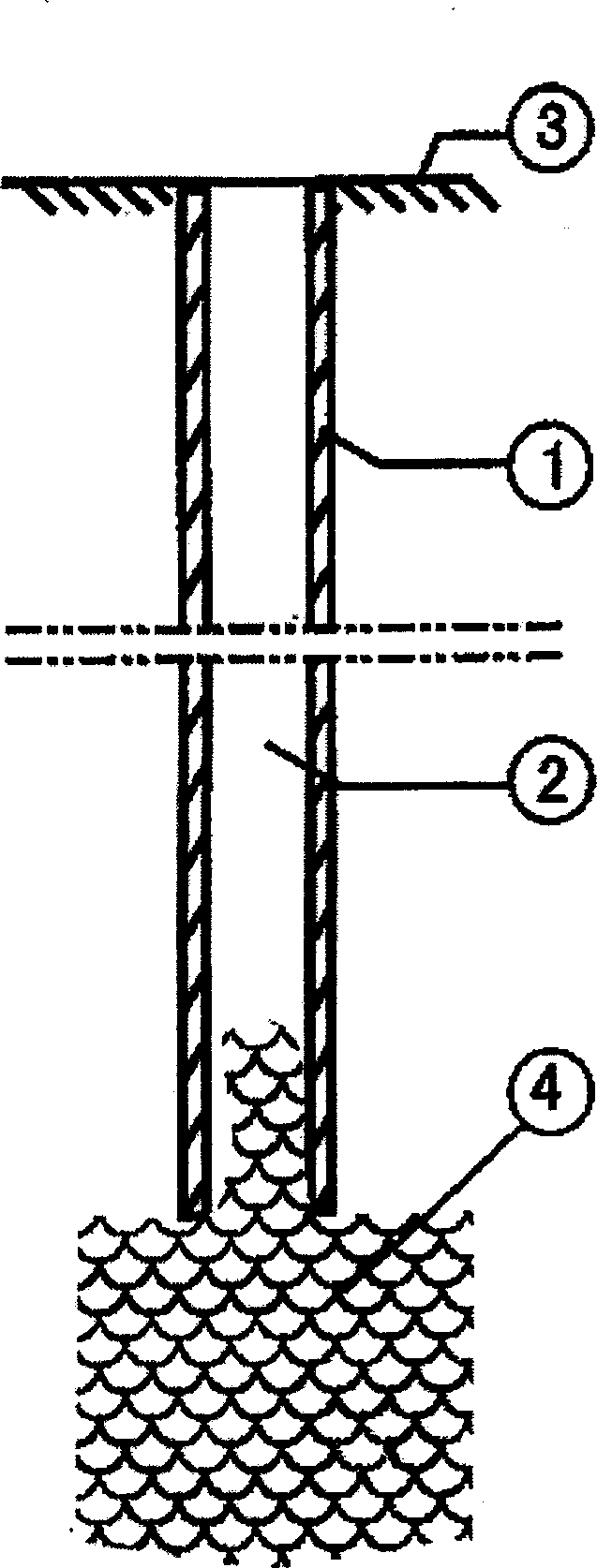

Prefabricated sleeve pipe pile capable of eliminating friction force of swelling-shrinking soil layer, and construction method thereof

The invention discloses a prefabricated sleeve pipe pile capable of eliminating the friction force of a swelling-shrinking soil layer, and a construction method thereof, belongs to the field of civilconstruction engineering, and aims at solving the technical problems of small pile diameter, high construction difficulty, low bearing capacity, limited application range and the like in an existing sleeve pipe pile. The prefabricated sleeve pipe pile capable of eliminating the friction force of the swelling-shrinking soil layer comprises an outer sleeve pipe, an annular supporting plate and a steel ball, wherein a prefabricated upper pile body is arranged in the outer sleeve pipe, the steel ball is filled into the upper part of the prefabricated upper pile body, and the lower end of the steelball is supported by the annular supporting plate; and the outer sleeve pipe and the prefabricated upper pile body are located in the swelling-shrinking soil layer, a prefabricated lower pile body isarranged at the lower end of the prefabricated upper pile body, and the prefabricated lower pile body is arranged in a stabilized soil layer. According to the prefabricated sleeve pipe pile capable of eliminating the friction force of the swelling-shrinking soil layer, and the construction method thereof, the side friction force of the upper section of the prefabricated pile is isolated by the outer sleeve pipe, and an outer sleeve pipe shell is capable of moving along with the swelling-shrinking soil layer, so that the harmful deformation caused by the changed side friction resistance is dissipated; and the lower section is located in the stabilized soil layer, and the friction force and the end-bearing force of the stabilized soil layer can be adequately utilized, so that the needed bearing capacity is provided for an upper structure.

Owner:LANZHOU ENG & RES INST OF NONFERROUS METALLURGY

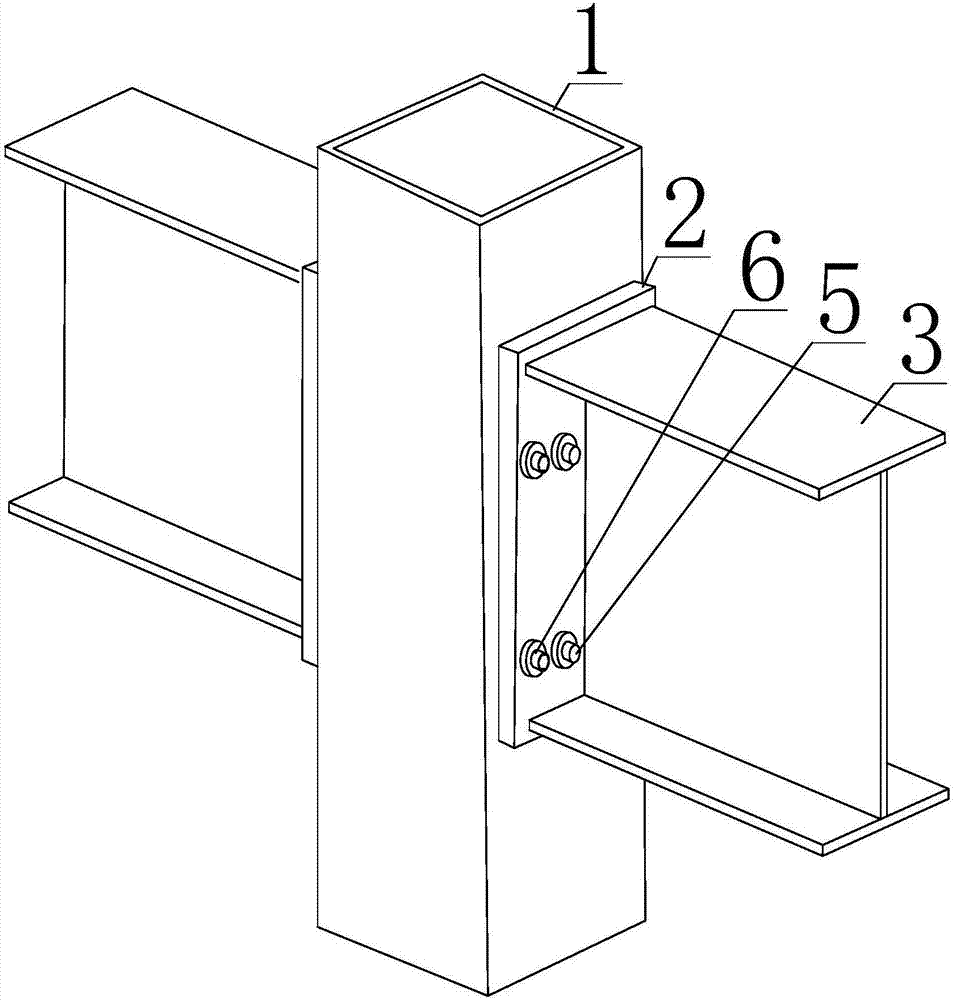

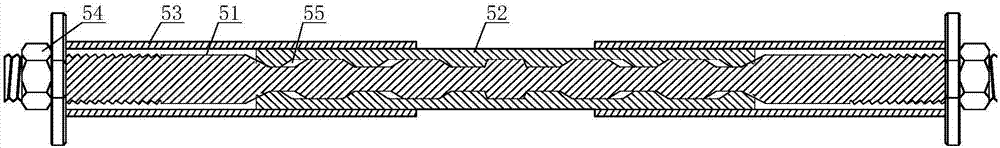

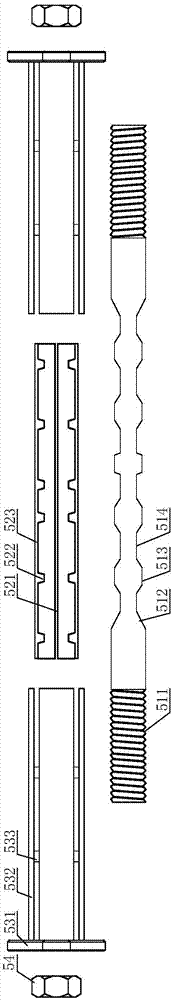

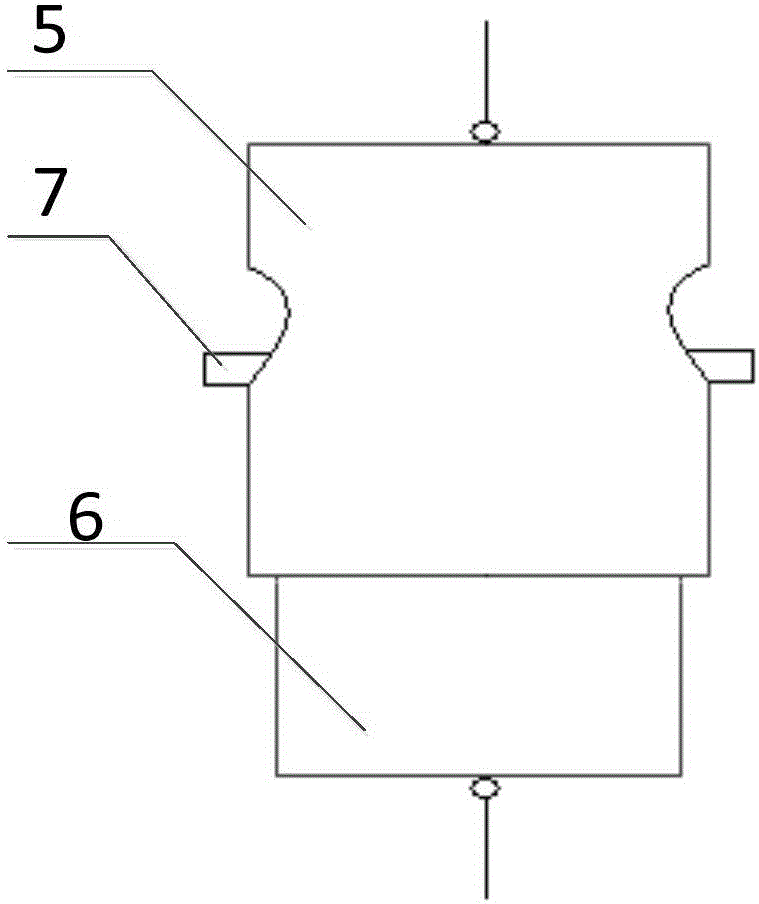

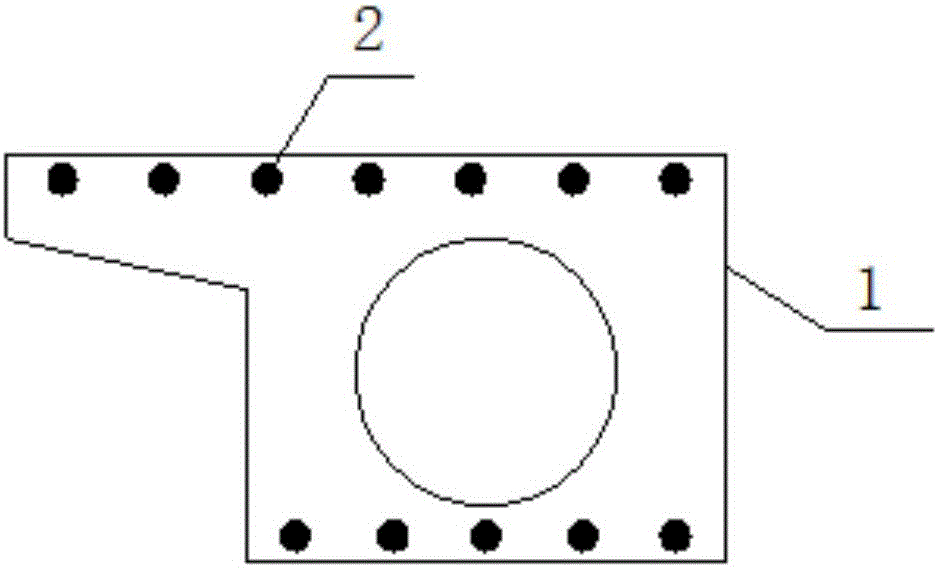

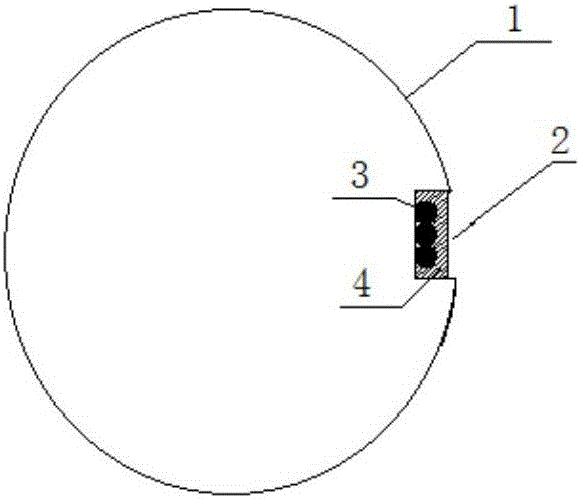

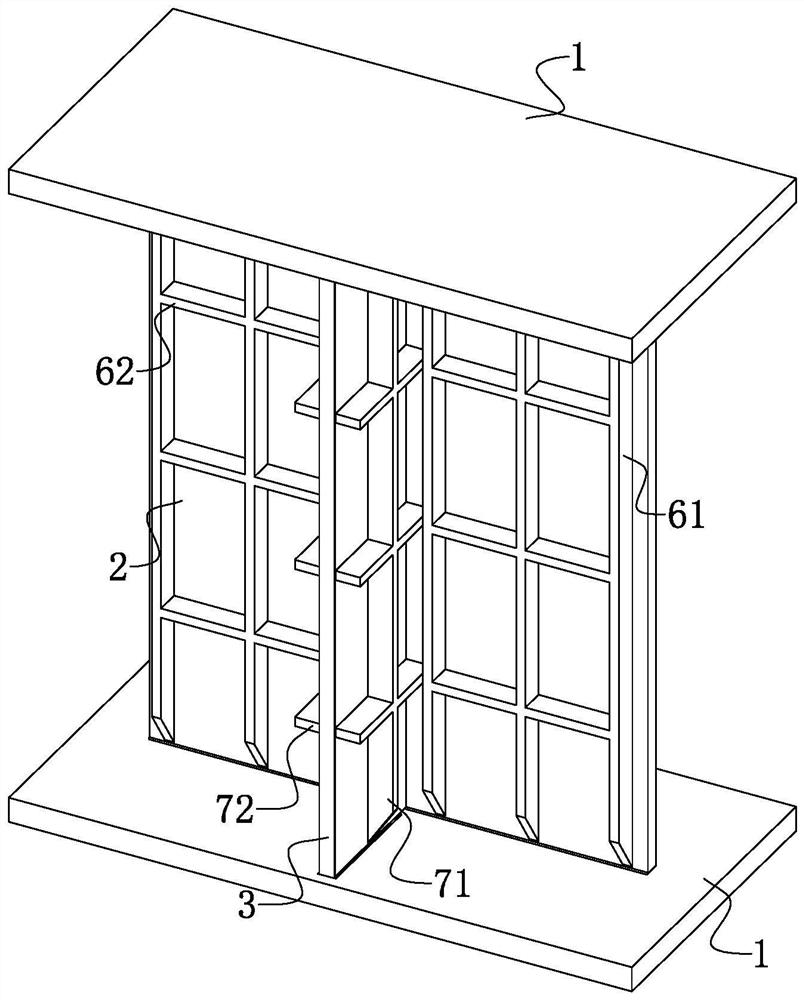

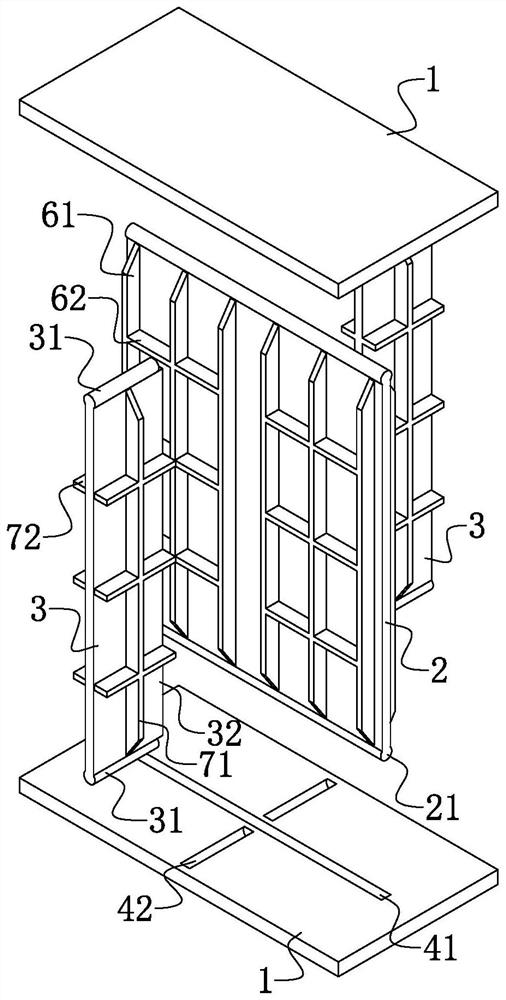

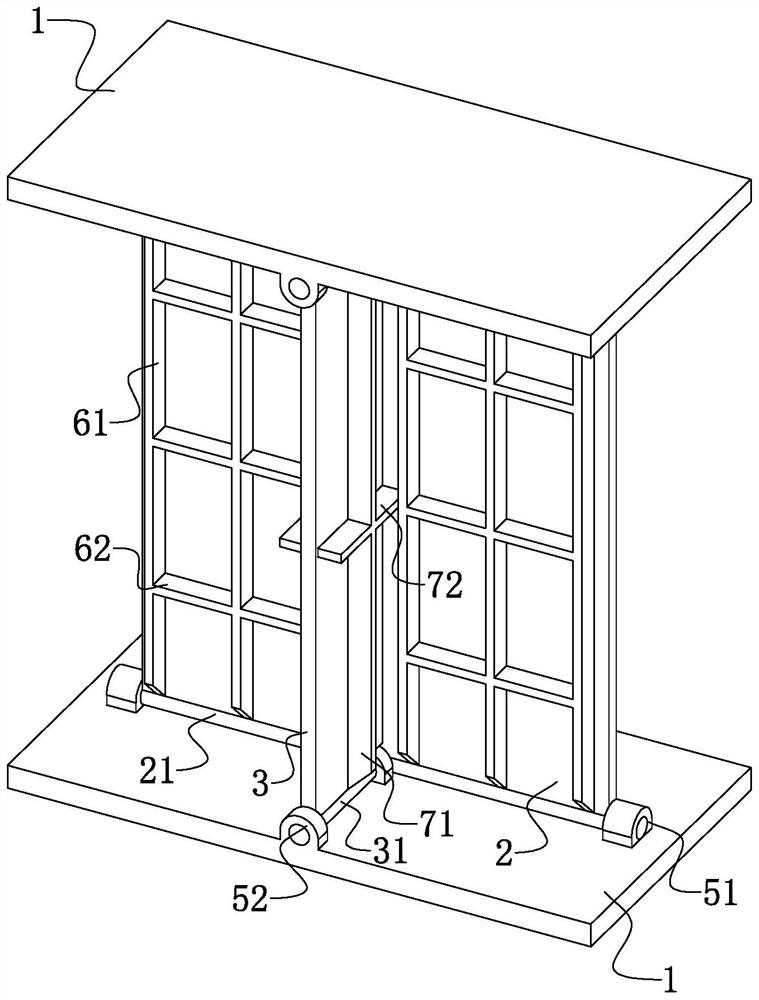

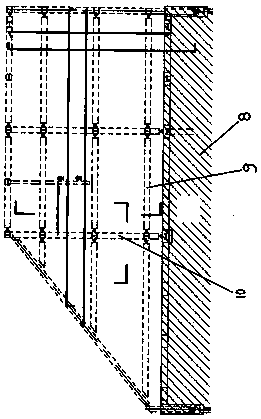

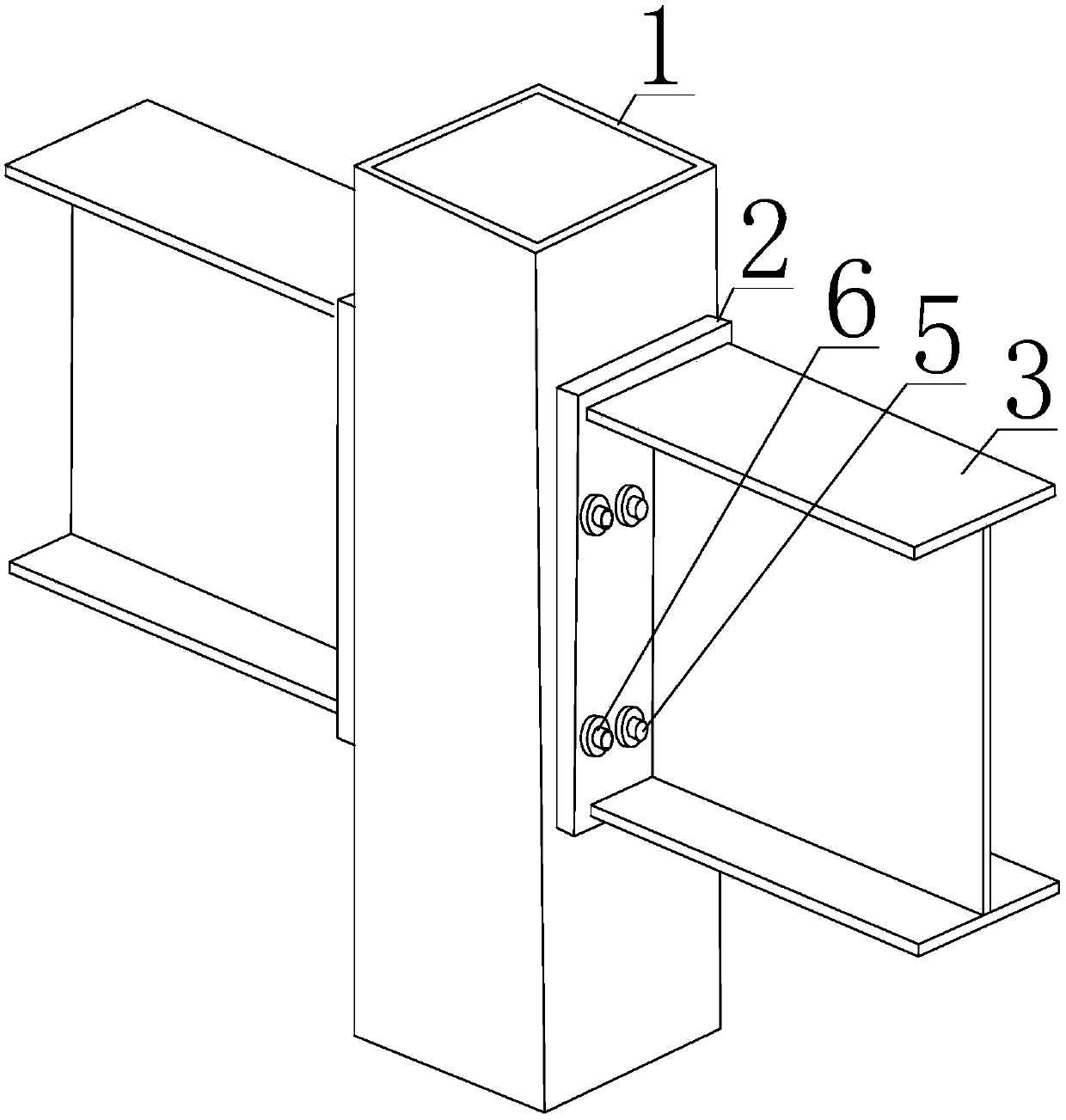

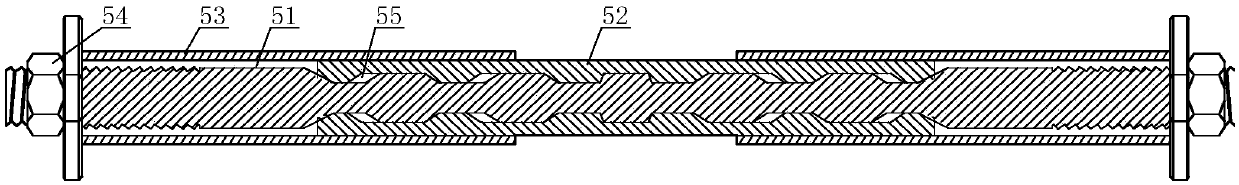

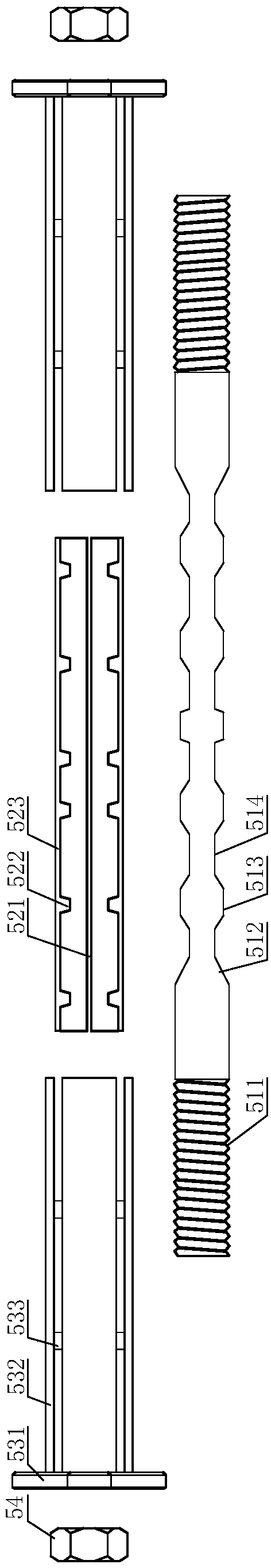

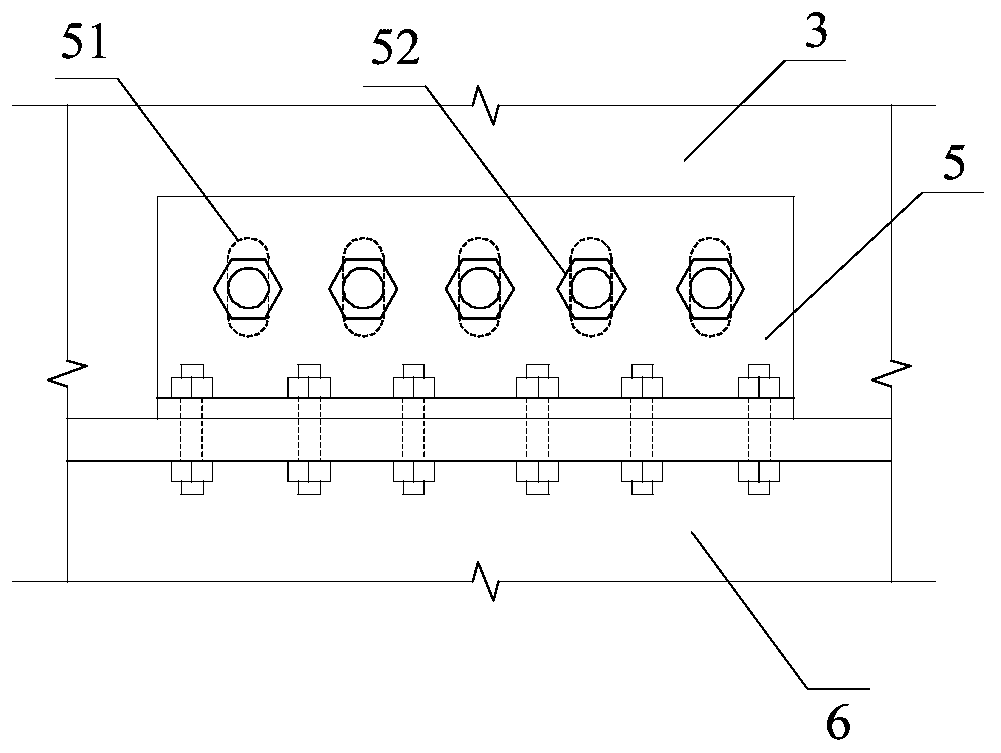

Combined type damping bolted connection joint

ActiveCN107165275AReduce distortionReliable carrying capacityProtective buildings/sheltersShock proofingBolt connectionSteel tube

The invention discloses a combined type damping bolted connection joint. The combined type damping bolted connection joint comprises a square steel tube, two connection end plates, two steel beams, a low-yield positioning piece and an unilateral bolt, wherein the two connection end plates are in contact with the outer side walls of the two opposite sides of the square steel tube. The steel beams are in an I shape or an H shape, one end of each steel beam is vertically and fixedly connected to the side wall of another side, opposite to the side in contact with the square steel tube, of the corresponding connection end plate, the two steel beams are connected with the two connection end plates in a one-to-one corresponding mode, and flange plates of the steel beams are perpendicular to the axis direction of the square steel tube. The low-yield positioning piece penetrates through the square steel tube and the two connection end plates, the unilateral bolt penetrates through one connection end plate and the side wall, in contact with the connection end plate, of the square steel tube, and is inlaid in the square steel tube. The distance between the low-yield positioning piece and a web of each steel beam is shorter than the distance between the unilateral bolt and the web of each steel beam. The combined type damping bolted connection joint is simple in the whole structure, convenient to achieve, and low in cost, and has good ductility, earthquake dissipating capability and bearing capability when being applied.

Owner:SICHUAN UNIV

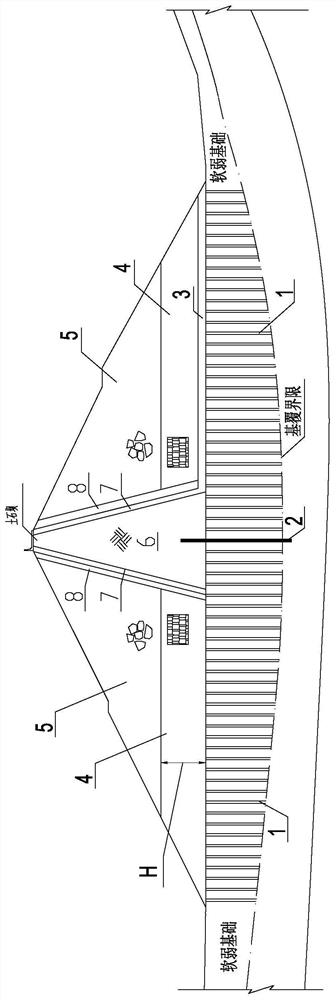

Vibro-replacement stone pile and rockfill reinforced earth and rockfill dam soft foundation treatment structure and construction method

InactiveCN112195910AHigh strengthImprove bearing capacityEarth-fill damsRock-fill damsCrushed stoneStructural engineering

The invention provides a vibro-replacement stone pile and rockfill reinforced earth and rockfill dam soft foundation treatment structure and a construction method. The construction method comprises the steps that a vibro-replacement stone pile group is arranged on a soft covering layer to reinforce a deep soft foundation of a dam foundation; the bottom of the stone pile is located on a covering layer compact layer or weathered bed rock; an earth and rockfill dam anti-seepage system is composed of a covering layer foundation anti-seepage wall and a dam body anti-seepage body; a foundation inverted filter cushion layer is arranged at the top of the stone pile on the downstream side of the anti-seepage wall; and a dam shell rockfill body reinforced area is filled at the upper part of an upstream side stone pile and the upper part of a downstream side foundation inverted filter cushion layer of the anti-seepage wall, so that the deformation modulus of a dam material at the lower part of adam shell is improved, the settlement deformation of a dam body caused by a weak foundation is homogenized, and dam body cracking caused by differential settlement is avoided. For deep and thick weakfoundation conditions, through reasonable treatment measures and methods combining weak foundation reinforcement and dam body structure reinforcement, foundation strength, bearing capacity and deformation control meet the dam building requirement, and the important significance is achieved for an earth and rockfill dam engineering damming technology under complex conditions.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

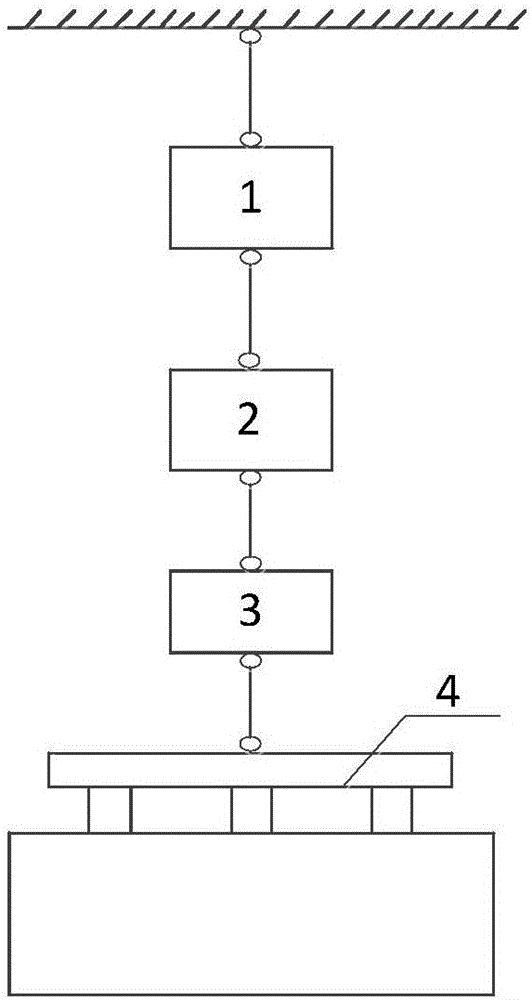

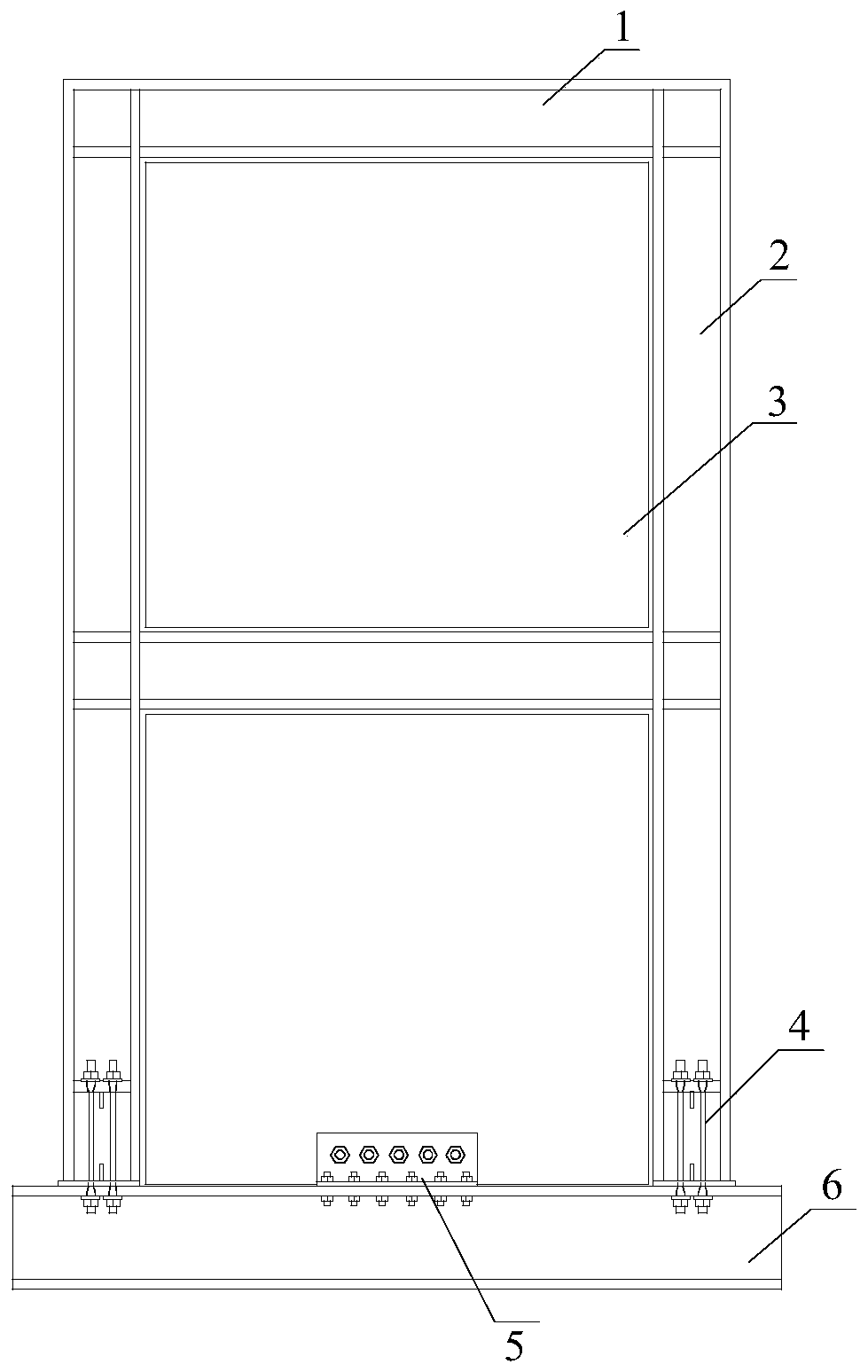

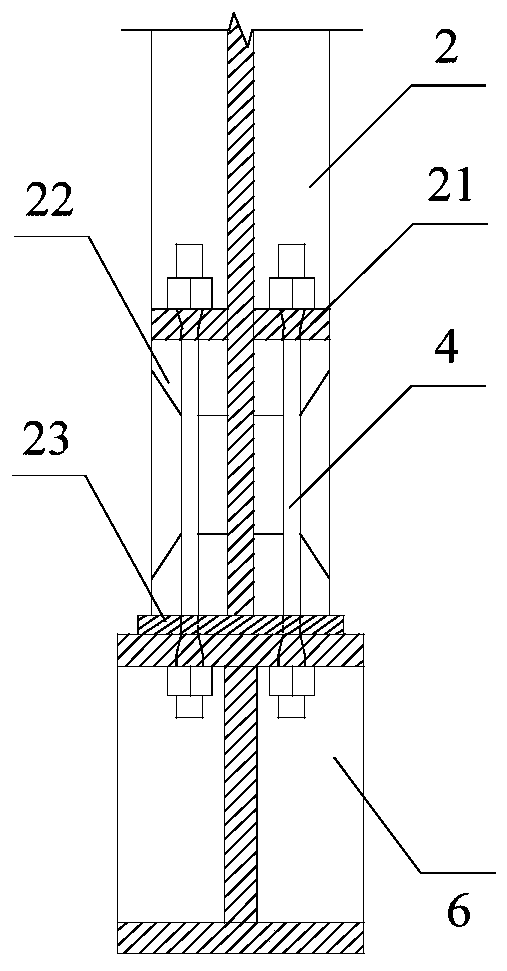

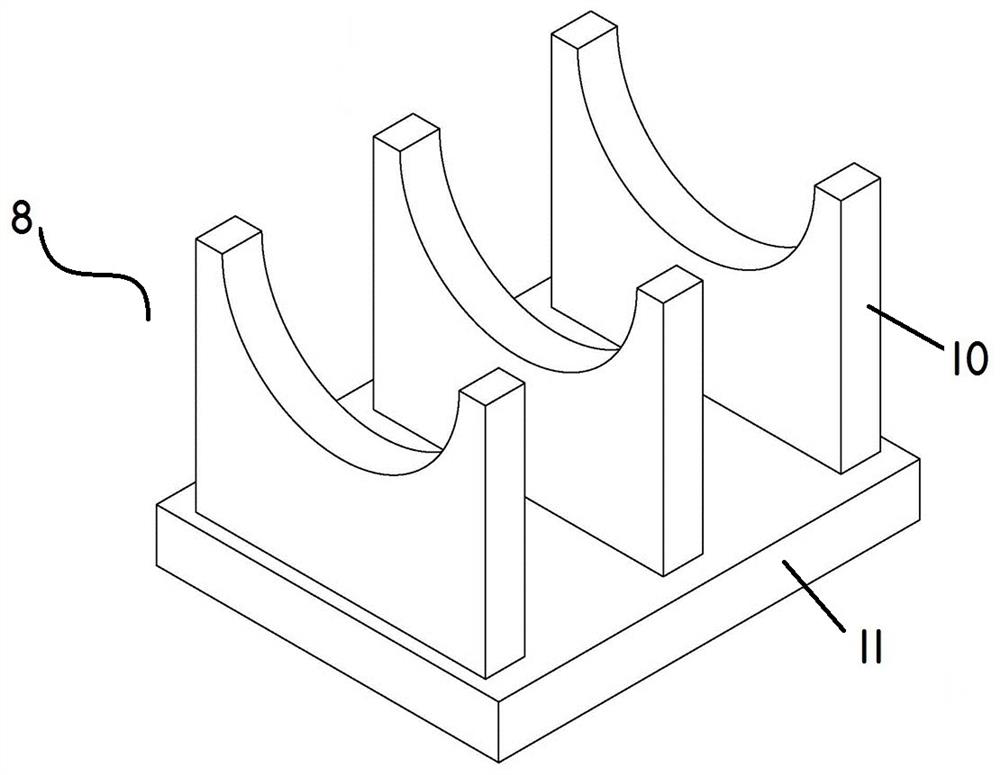

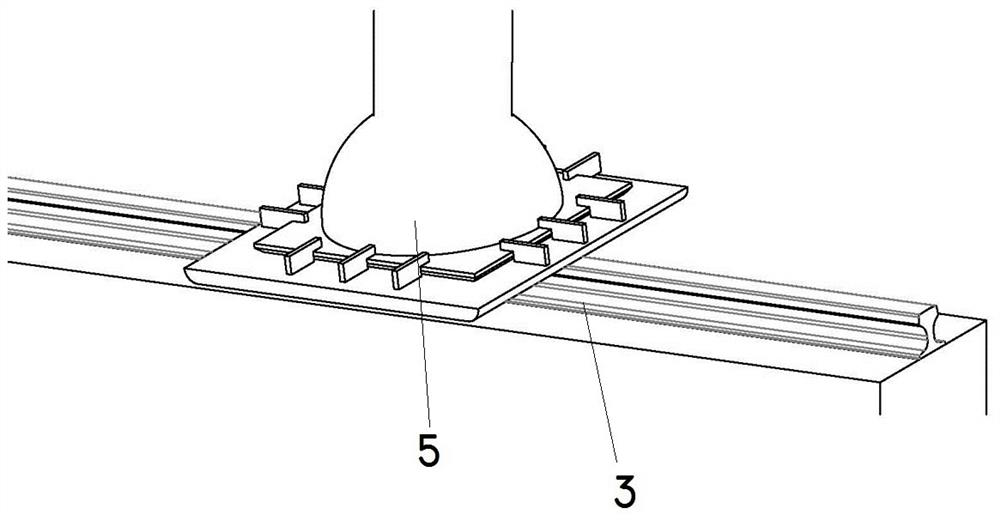

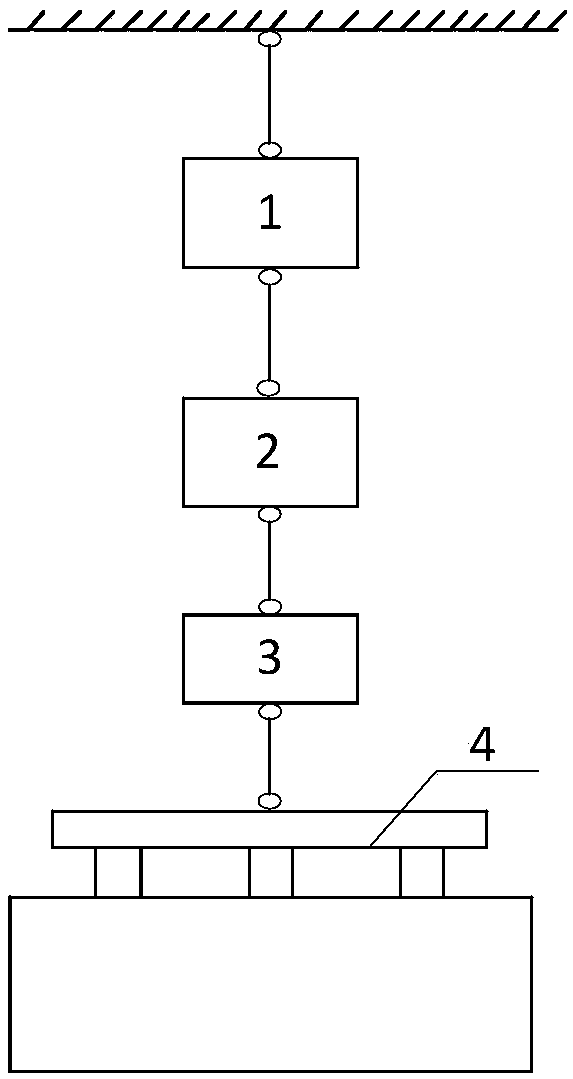

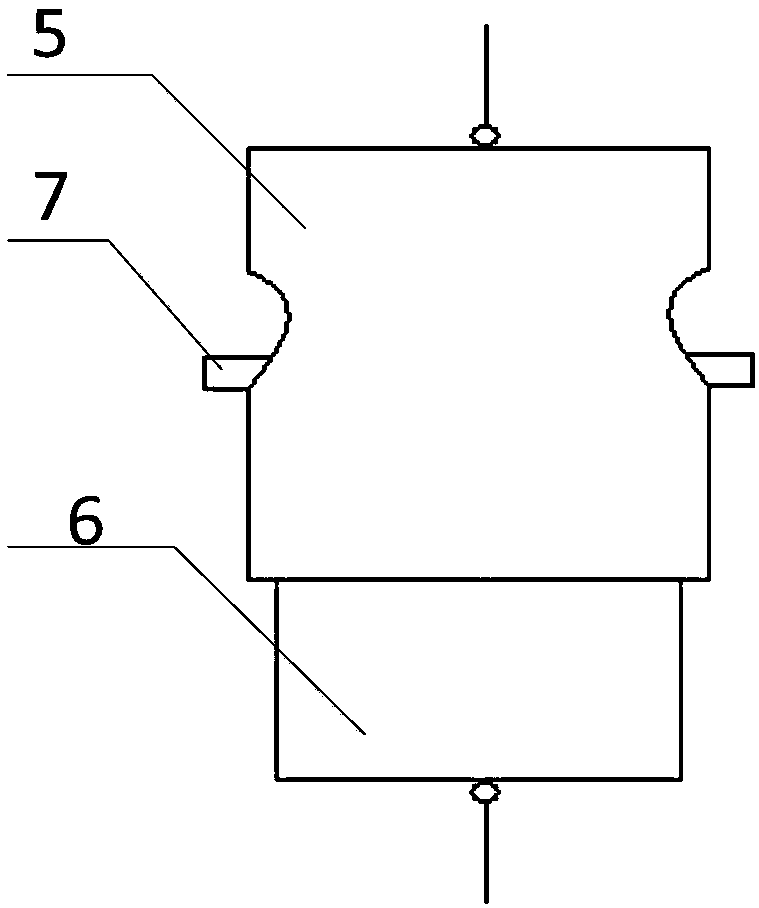

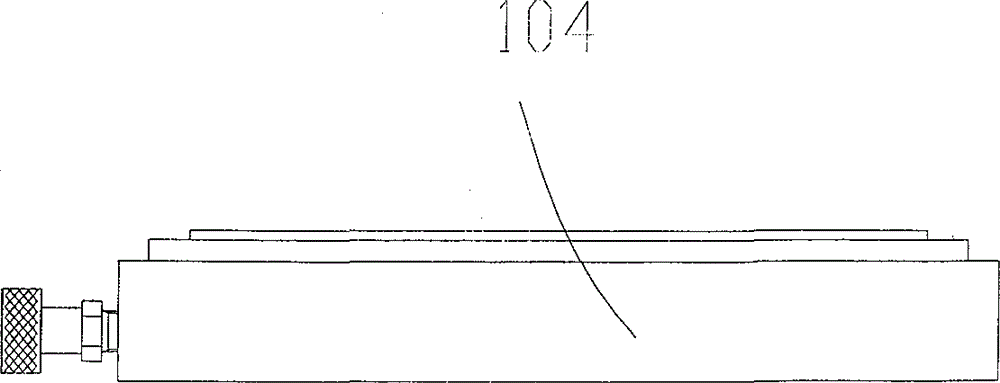

Suddenly applied load testing device

ActiveCN106404518AReliable carrying capacityRealize automatic controlStrength propertiesEngineeringCompressive strength

The invention discloses a suddenly applied load testing device. The suddenly applied load testing device comprises a support, a tension sensor, a cable force adjusting device, a cable breaking device, a gravity loading device and a controller, wherein the upper end of the cable force adjusting device is connected with the top of the support; an output end of the cable force adjusting device is connected with the upper end of the tension sensor through a rope; the lower end of the tension sensor is connected with the upper end of the cable breaking device; the lower end of the cable breaking device is connected with the upper end of the gravity loading device; the lower end surface of the gravity loading device is in contact with the upper surface of a test piece; an output end of the tension sensor is connected with an input end of the controller; and an output end of the controller is connected with a control end of the cable force adjusting device. By the device, instant compression strength of the test piece can be quantitatively analyzed.

Owner:西安华清科教产业(集团)有限公司

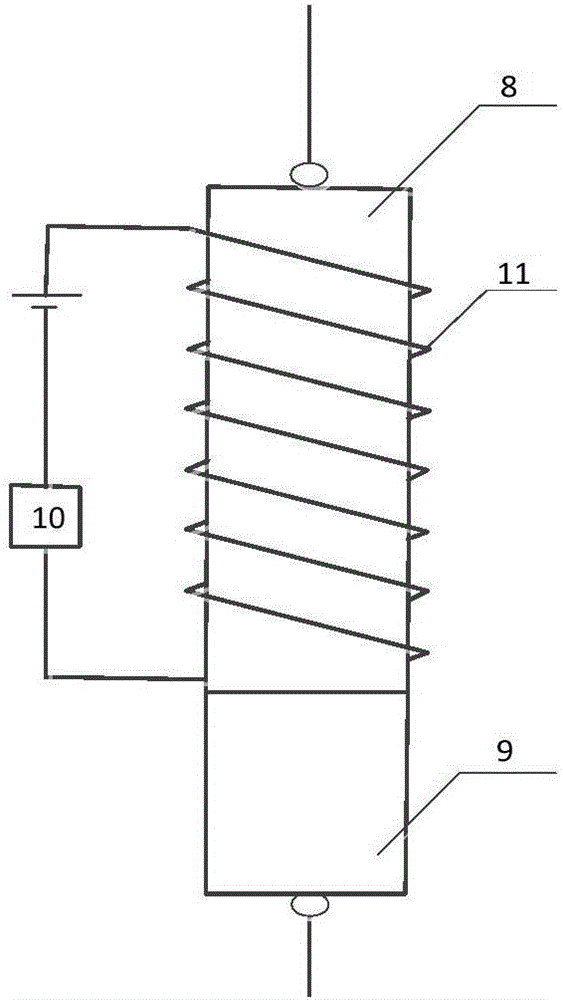

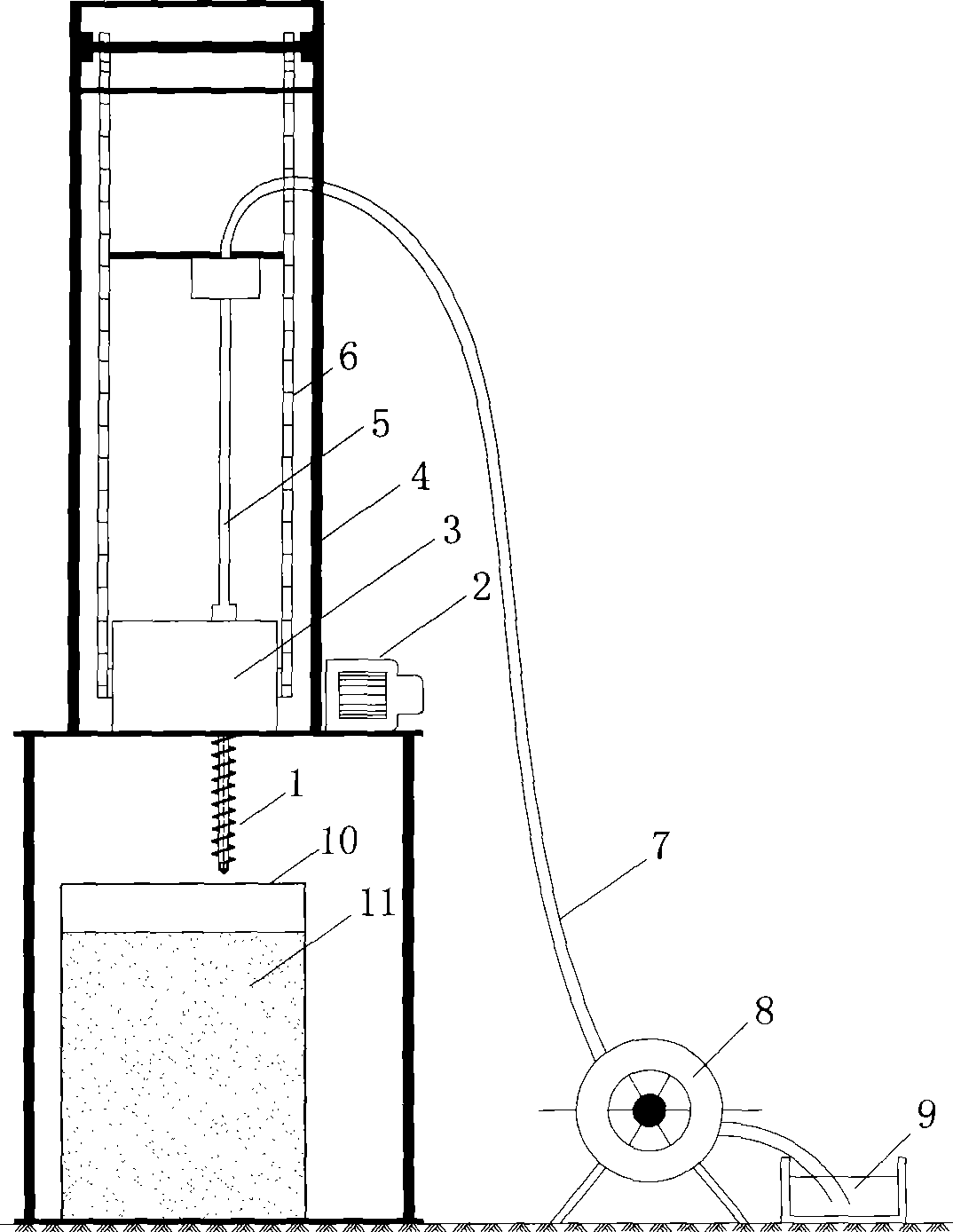

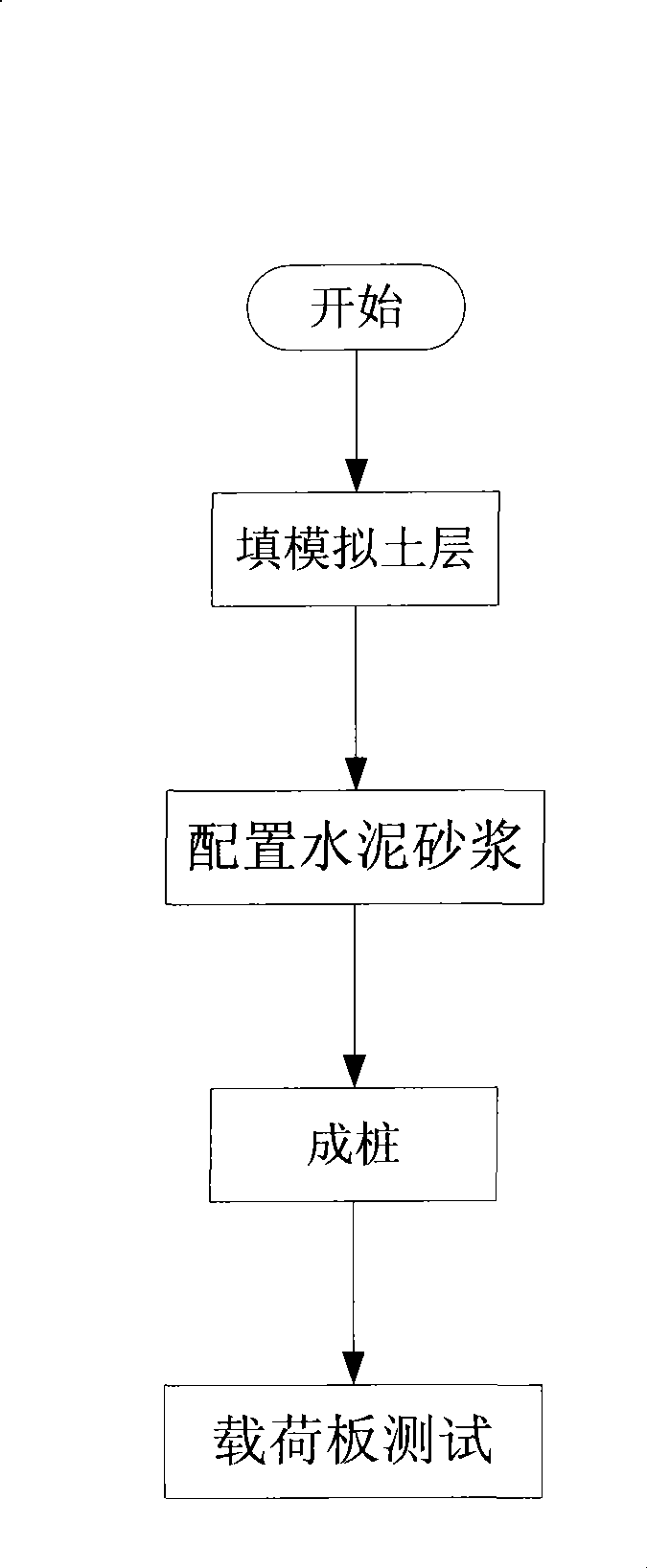

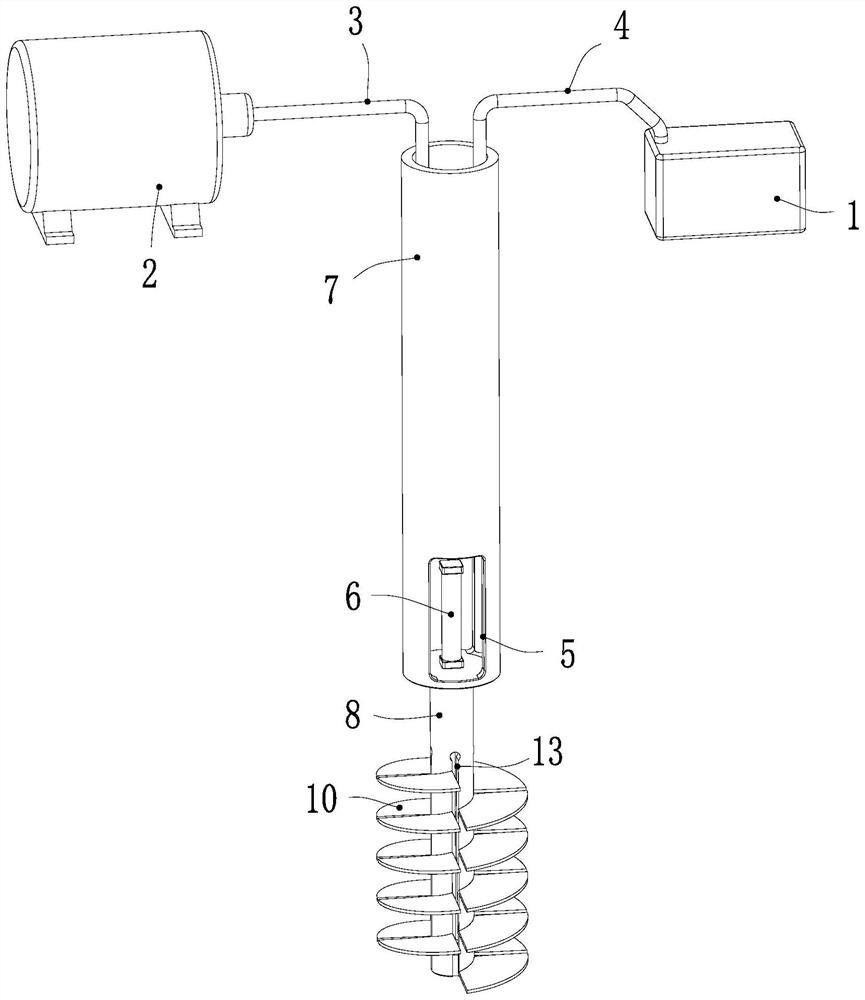

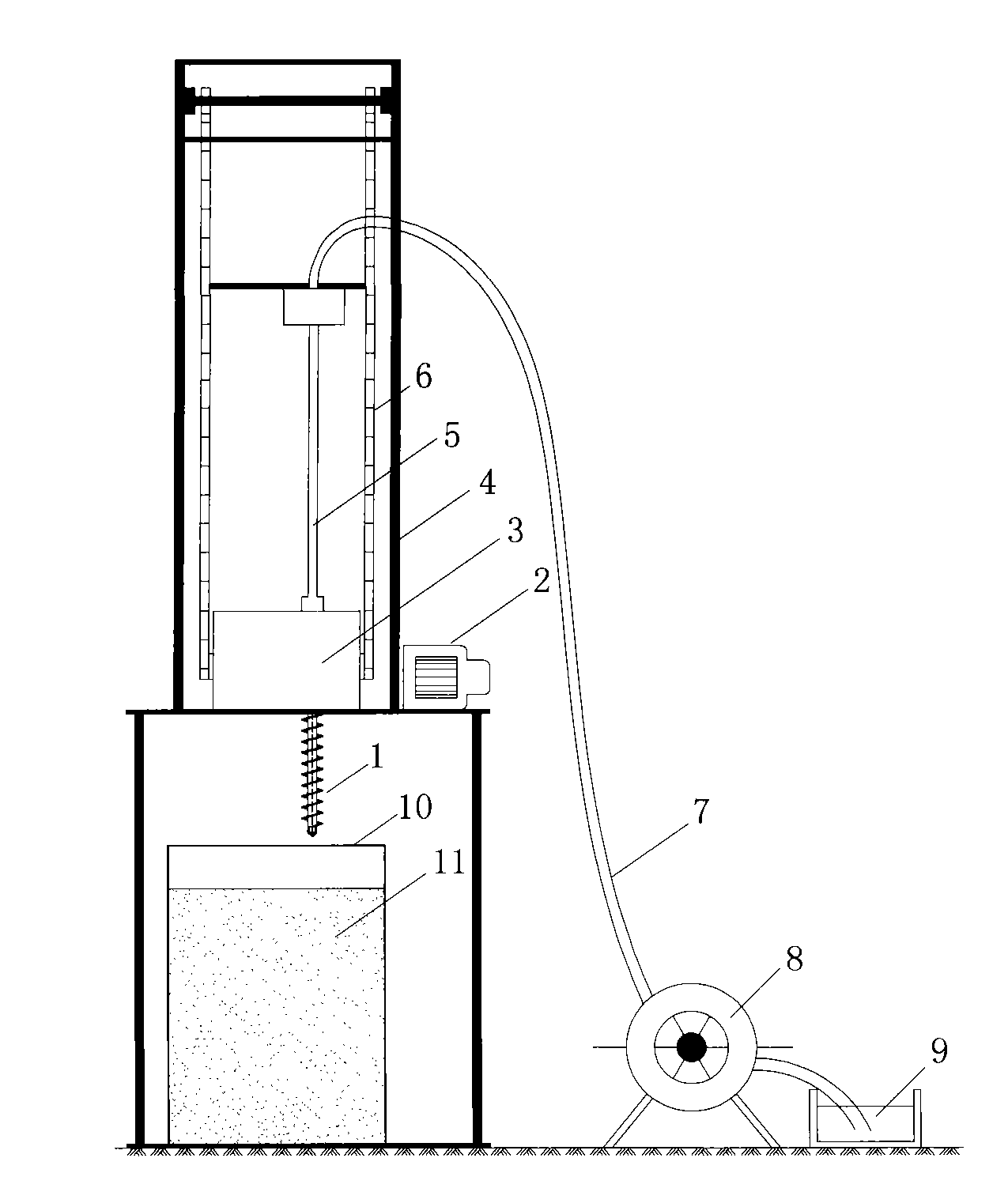

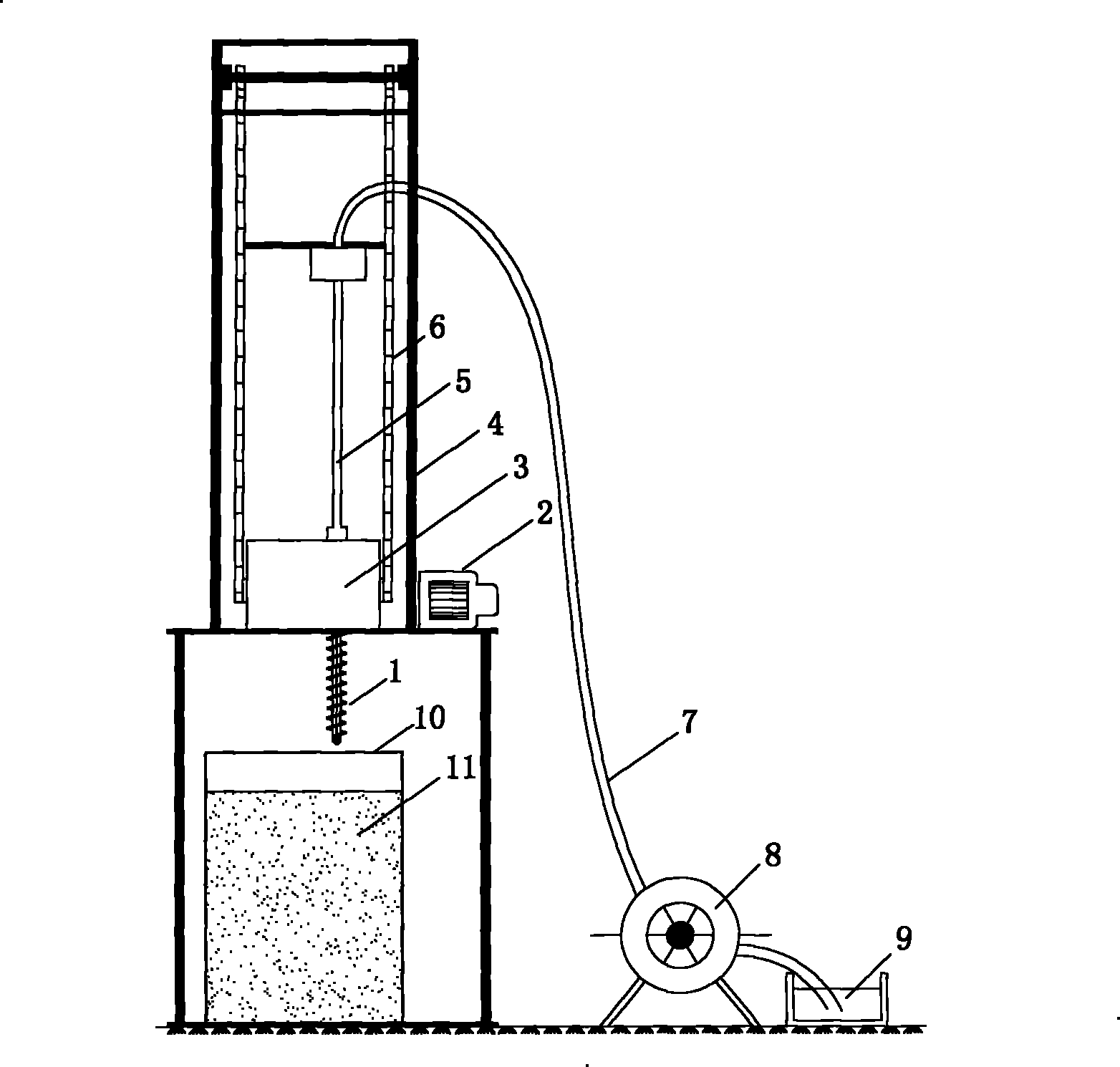

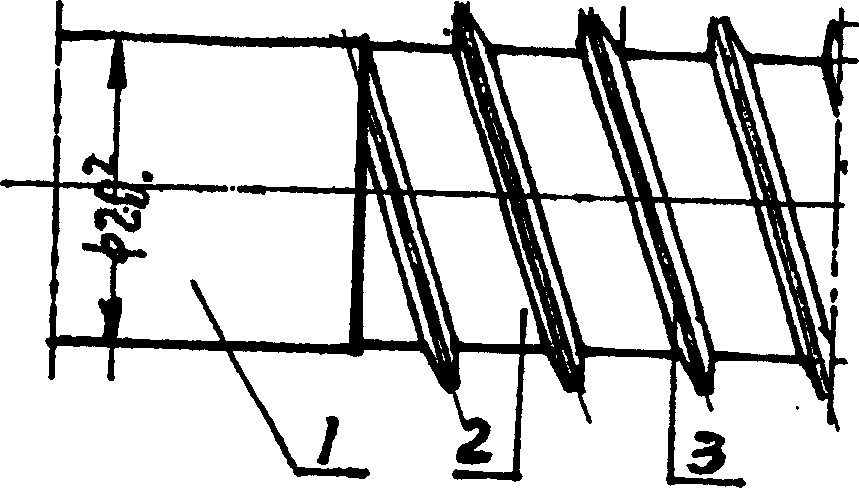

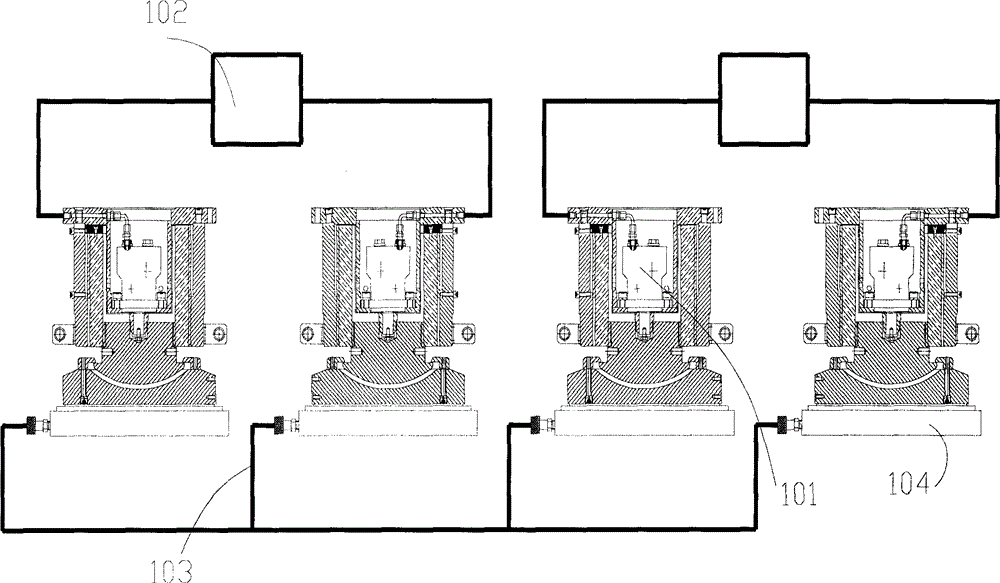

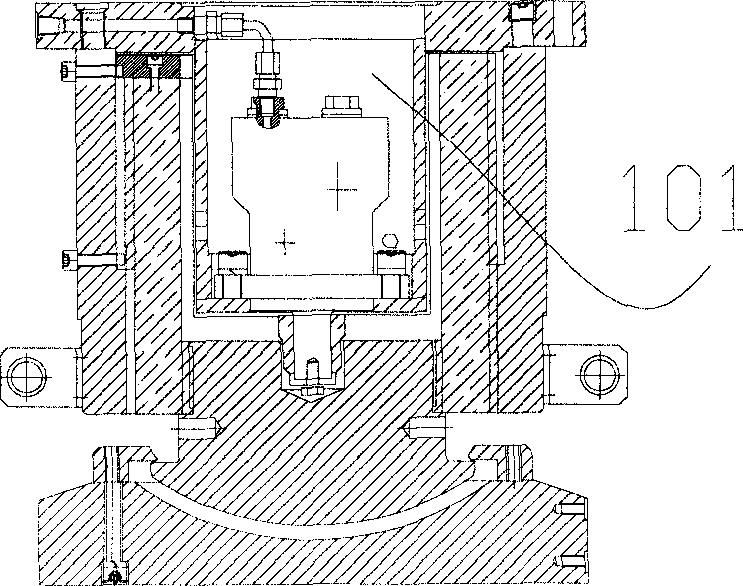

Pile-forming equipment and method of control modulus pile

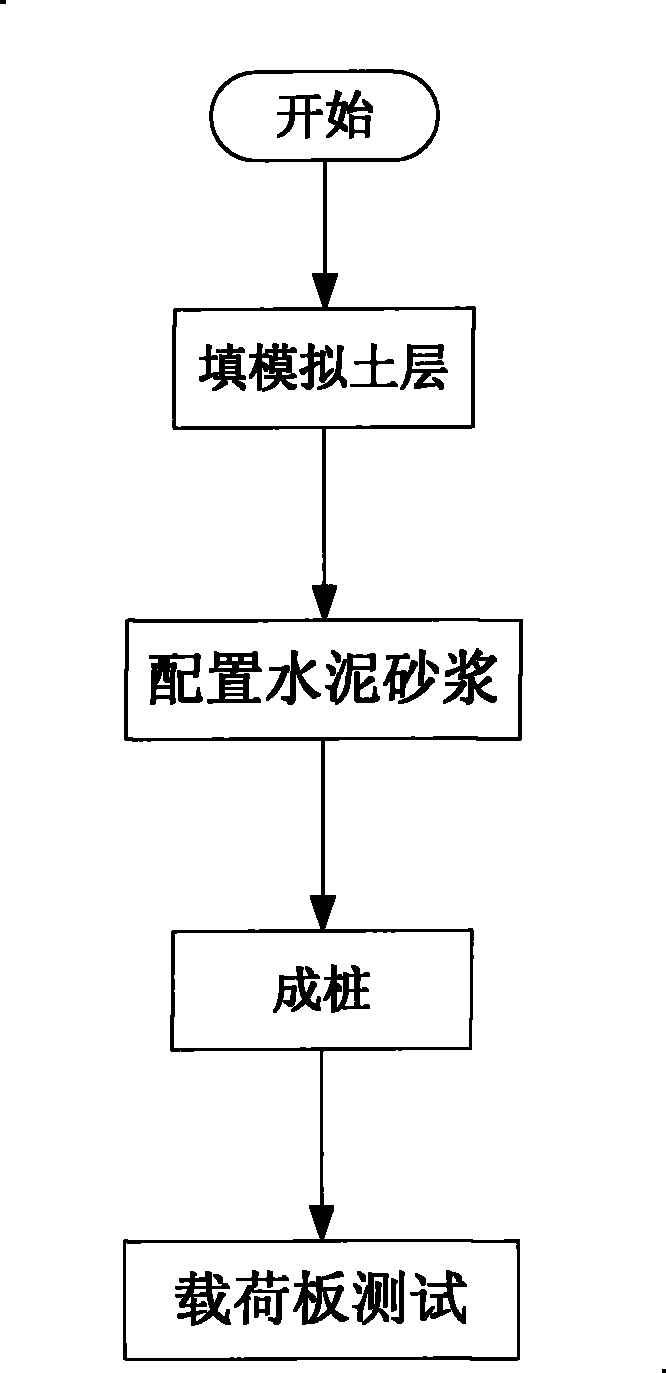

InactiveCN101435209AReliable carrying capacityRealize quantitative designFoundation testingStress ratioSlurry transport

The invention discloses a pile-forming device and pile-forming method for control modulus pile, belonging to the field of bearing characteristic testing of composite foundation of geotechnical engineering. The device of the invention is composed of a drill bit, a motor, a control platform, a drill frame, a drilling rod, a driving chain, a slurry transporting pipe, a pressure pump, and a model box. The method of the invention includes the steps of filling simulation soil layer, preparing cement slurry, and forming pile. The invention realizes the quantitative design of control deform and control bearing force of the composite foundation, and fully mobilizes the function of the soil among piles by adjusting the stress ratio of the pile soil.

Owner:SOUTHEAST UNIV

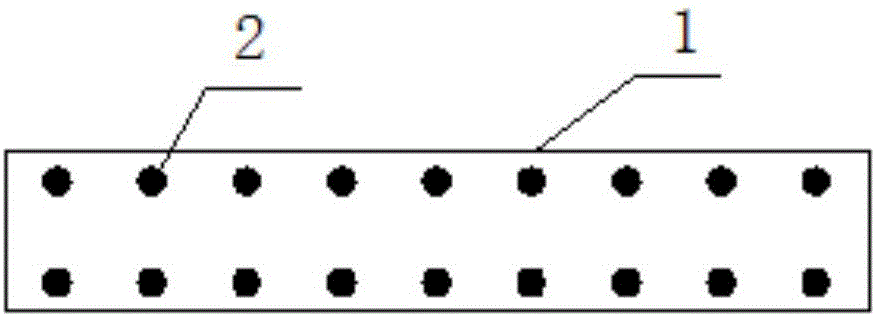

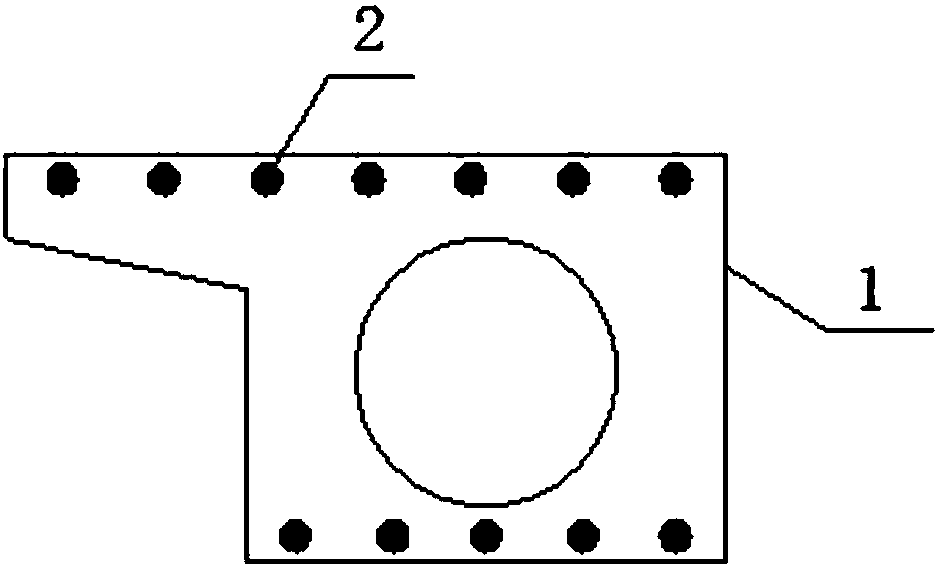

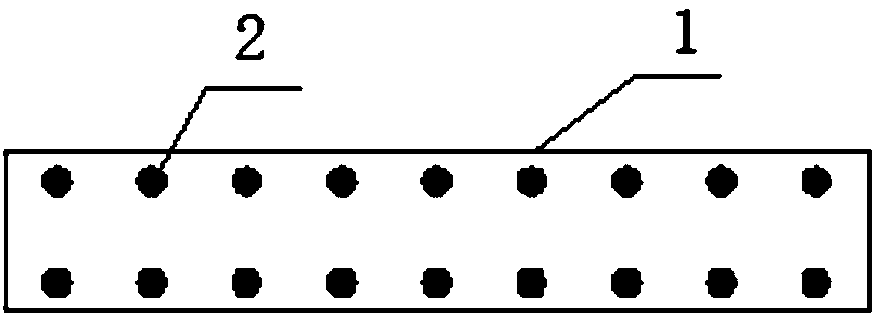

Intelligent aluminum alloy bar concrete structure, and manufacturing and construction method thereof

ActiveCN106498843AIncreased durabilitySave reinforcement and maintenance costsBridge structural detailsBridge erection/assemblyGratingProtection layer

The invention discloses an intelligent aluminum alloy bar concrete structure, and a manufacturing and construction method thereof. A skeleton of the concrete structure consists of aluminum alloy bars, and the aluminum alloy bars contain intelligent aluminum alloy bars. Each aluminum alloy bar is formed as follows: a groove is formed in aluminum alloy, a fiber grating sensor is placed in the groove, and the inner wall of the groove and the fiber grating sensor are coated with protective layers. The intelligent aluminum alloy bar concrete structure provided by the invention is lightweight, high-strength and corrosion-resistant, improves the durability of the concrete structure, can monitor the stress and safety health of the concrete structure in real time and perform early warning, and has high strain measuring precision and is low in cost.

Owner:GUANGXI UNIV

Intelligent aluminum alloy reinforced concrete structure and its fabrication and construction method

ActiveCN106498843BIncreased durabilitySave reinforcement and maintenance costsBridge structural detailsBridge erection/assemblyReinforced concreteFiber gratings

Owner:GUANGXI UNIV

Piston diameter changeable air spring

PendingCN108412935AExtended service lifeEnhance friction strengthSpringsGas based dampersAir springEngineering

The invention discloses a piston diameter changeable air spring. The piston diameter changeable air spring comprises a cover plate, a rubber air bag and a piston assembly. The rubber air bag is pressed and assembled to a lower port of the cover plate, and a lower port of the rubber air bag is pressed and assembled to the piston assembly. The piston assembly comprises a hollow columnar piston framework, a piston ejector rod arranged at the bottom of the piston framework in a sliding fit manner, and a plurality of piston sections evenly and movably hinged to the circumferential wall of the piston framework in the circumferential direction. The piston ejector rod and the middle portion of each piston section are movably hinged through a connecting rod, and a plurality of slider-crank mechanisms are formed. According to the piston diameter changeable air spring, an actuating mechanism can be used for changing the position of the piston ejector rod in the piston assembly to expand the piston sections, accordingly, the diameter of the piston and the effective diameter of the air spring are adjusted, and through combined action with a car body height adjusting mechanism, the bearing rigidity of the air spring can be changed under the situation that the bearing weight is not changed.

Owner:SOUTH CHINA UNIV OF TECH

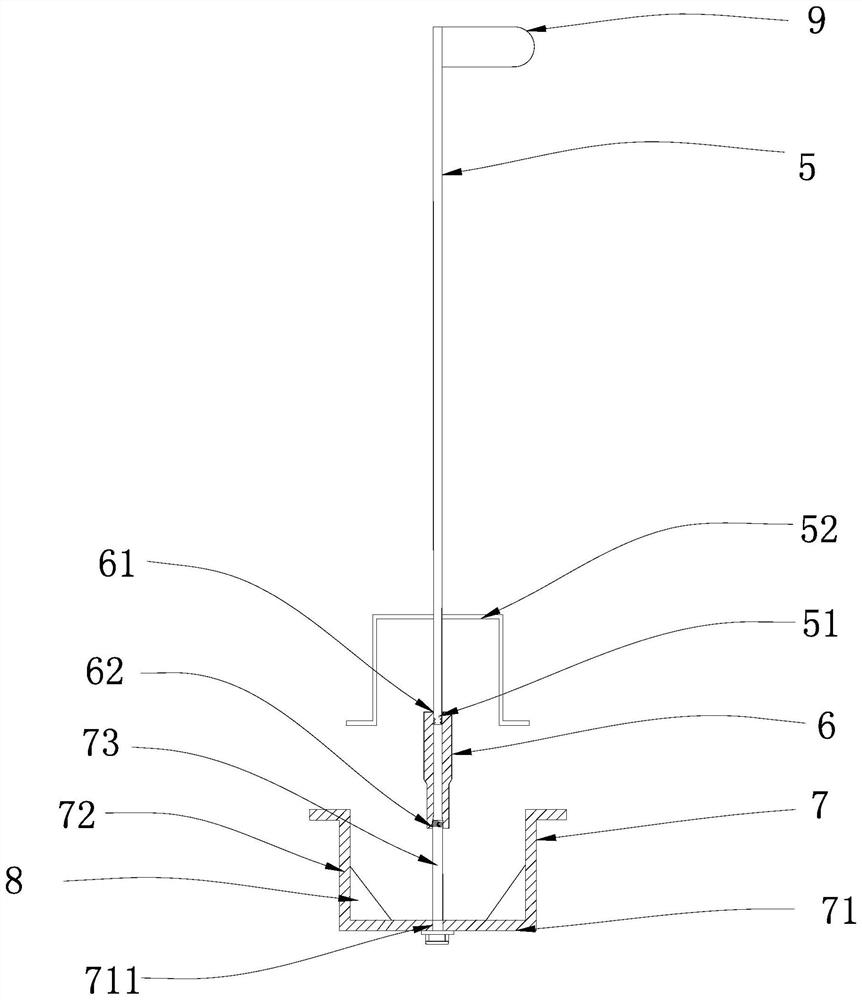

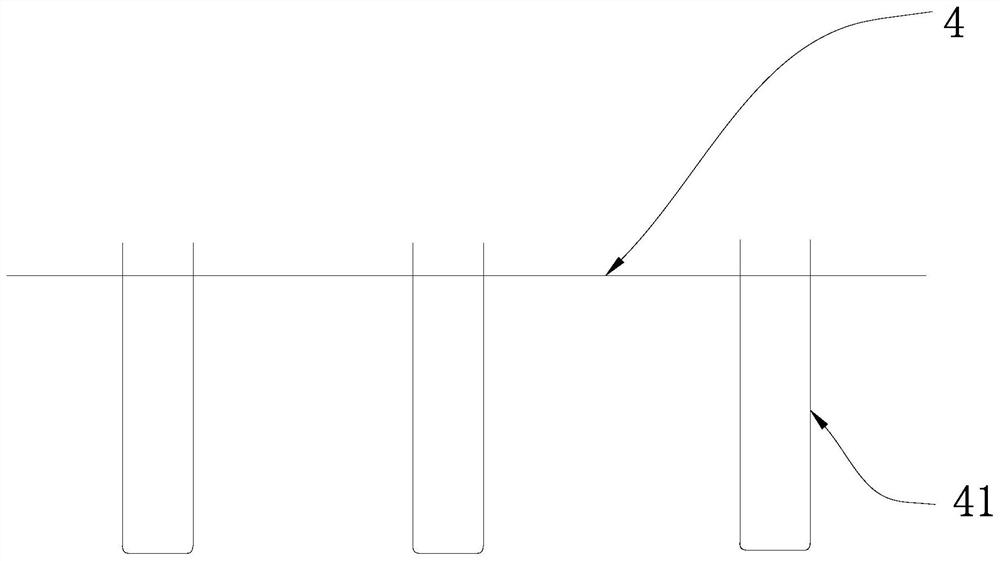

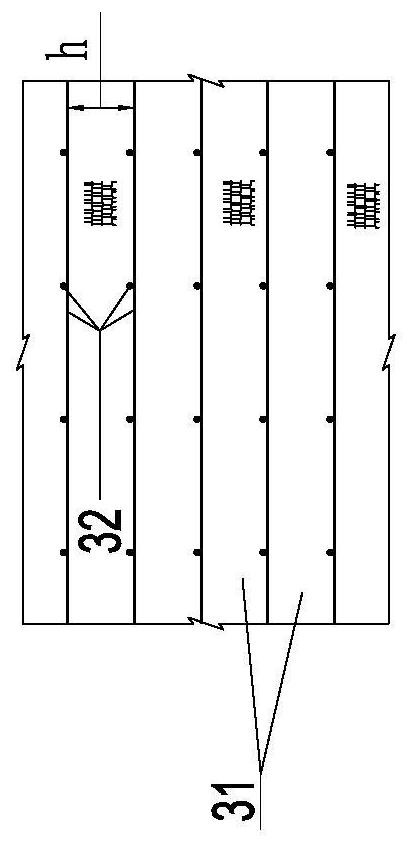

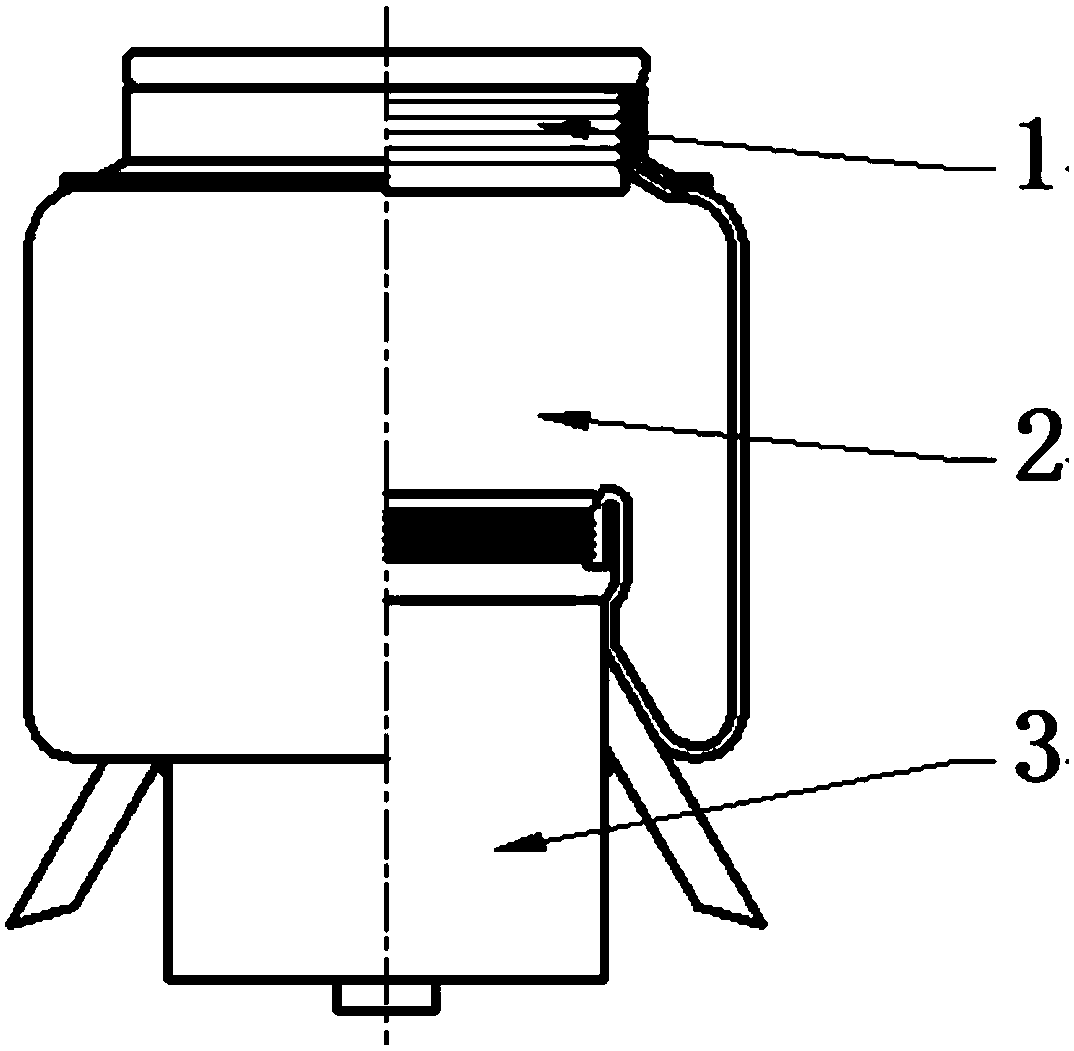

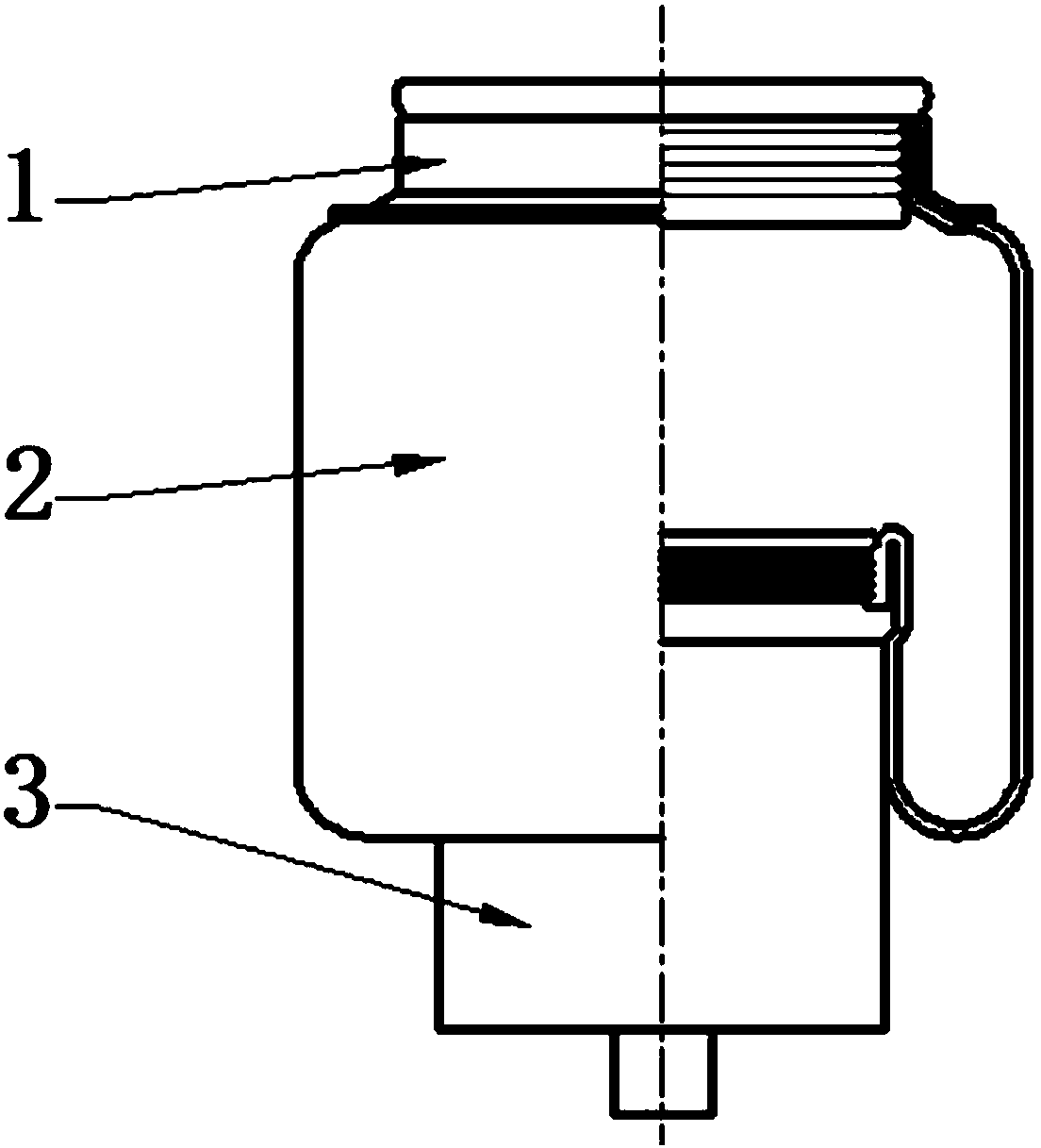

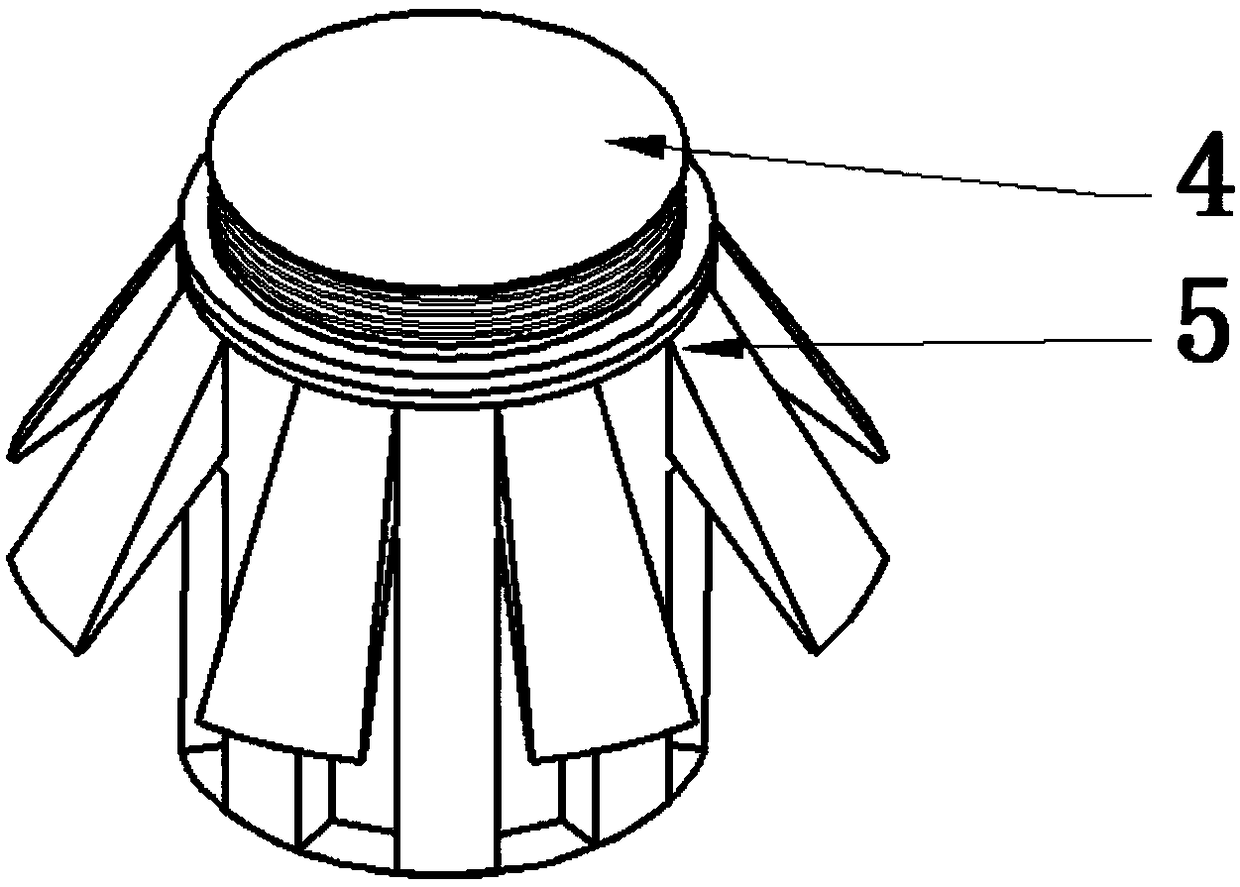

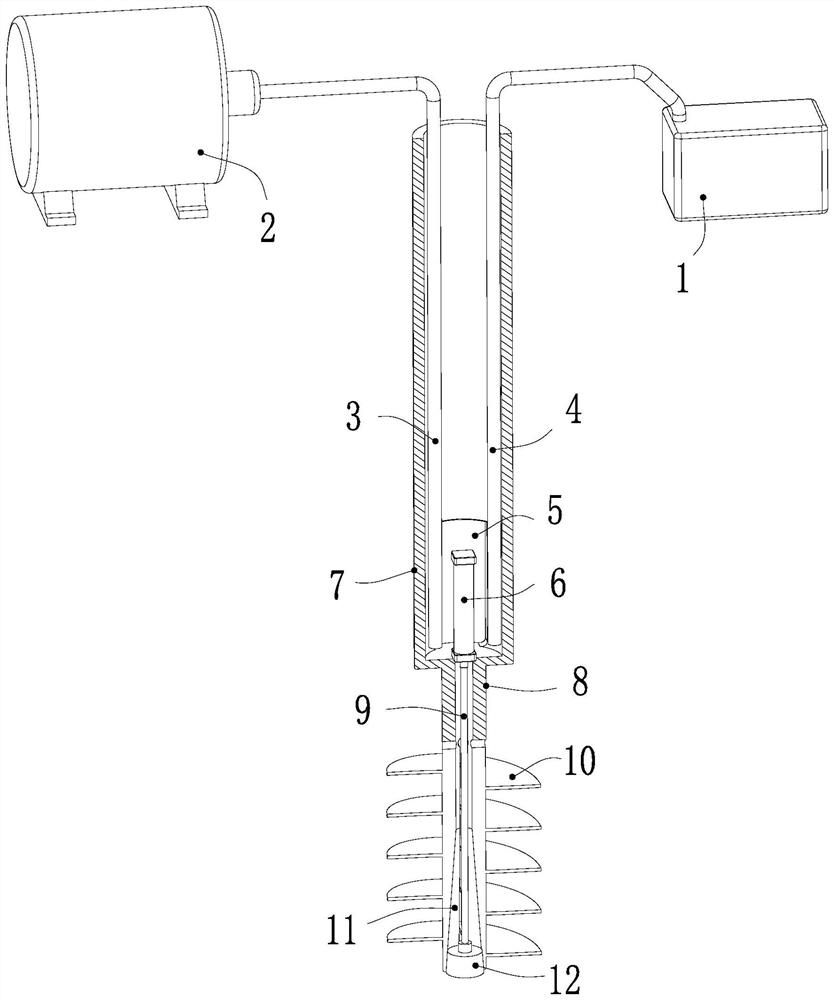

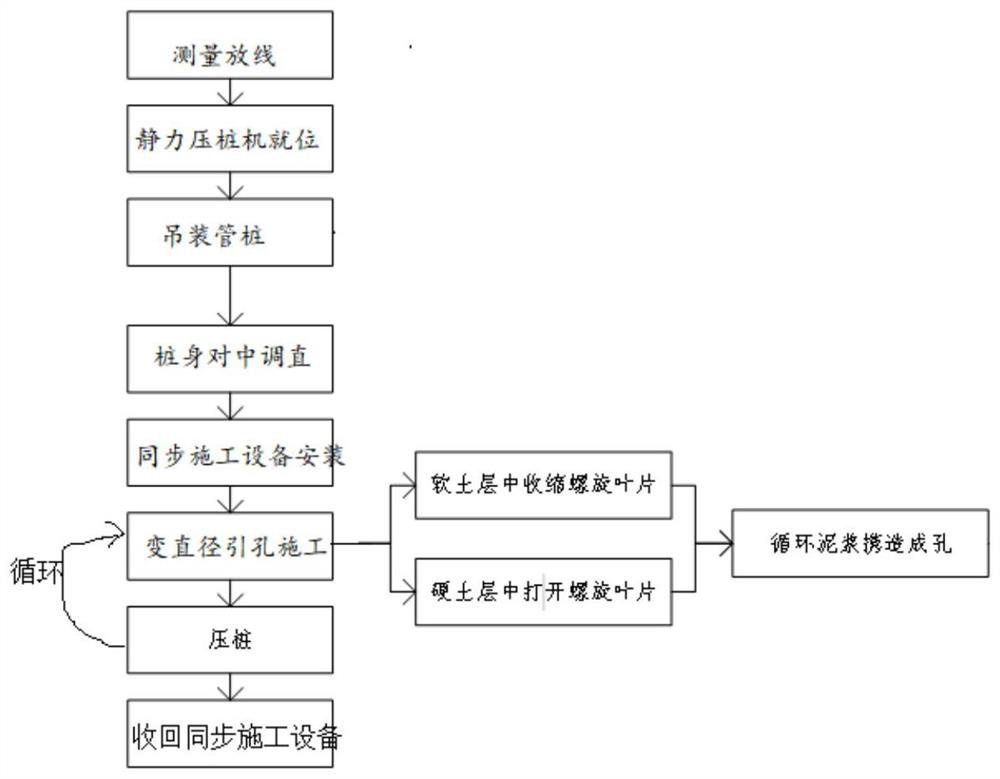

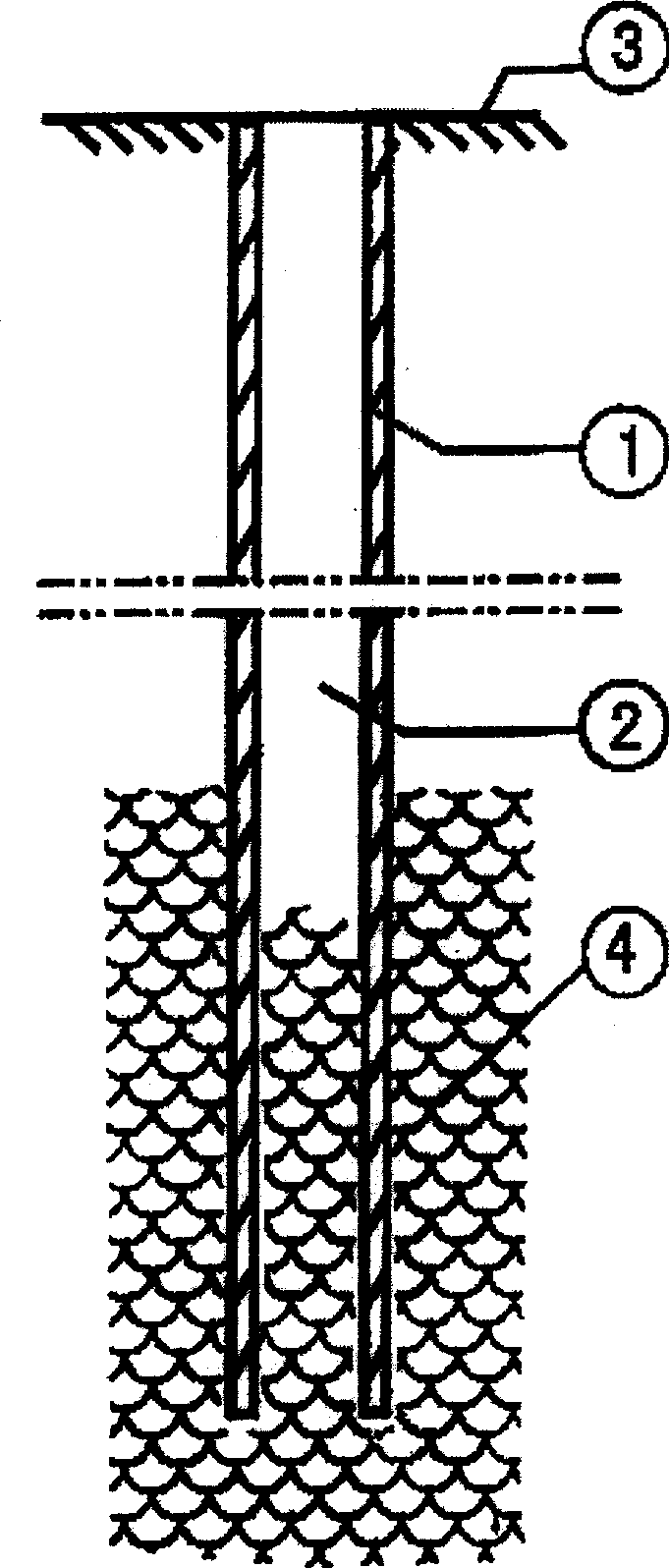

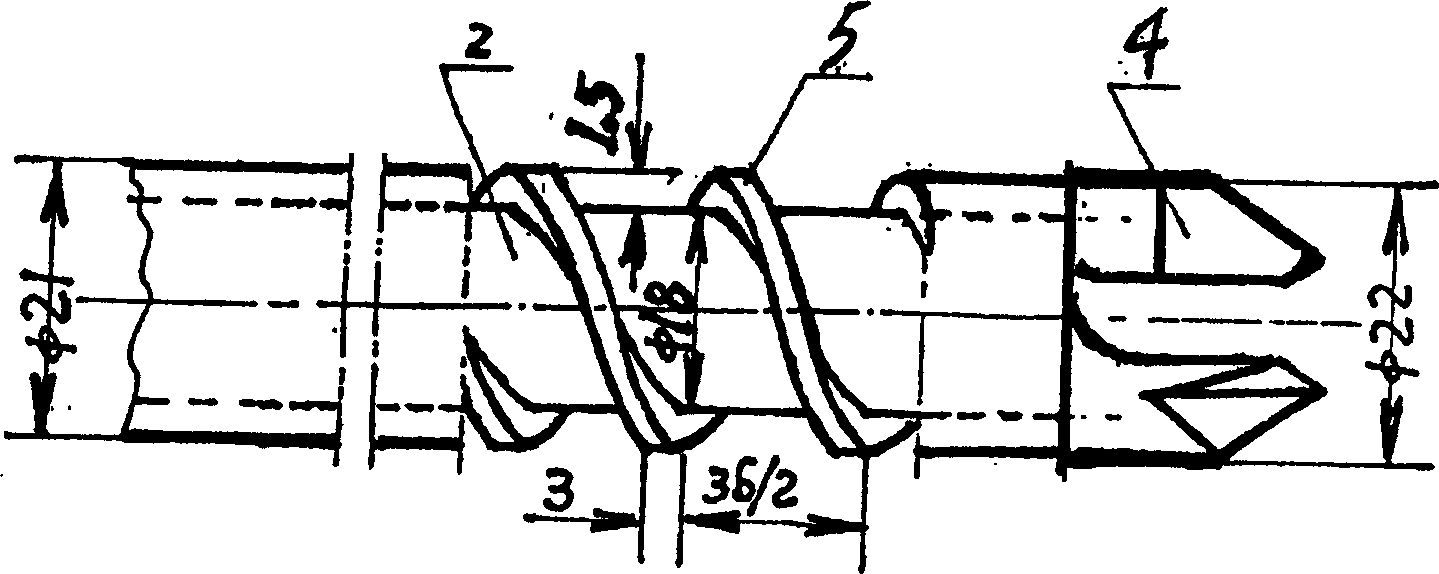

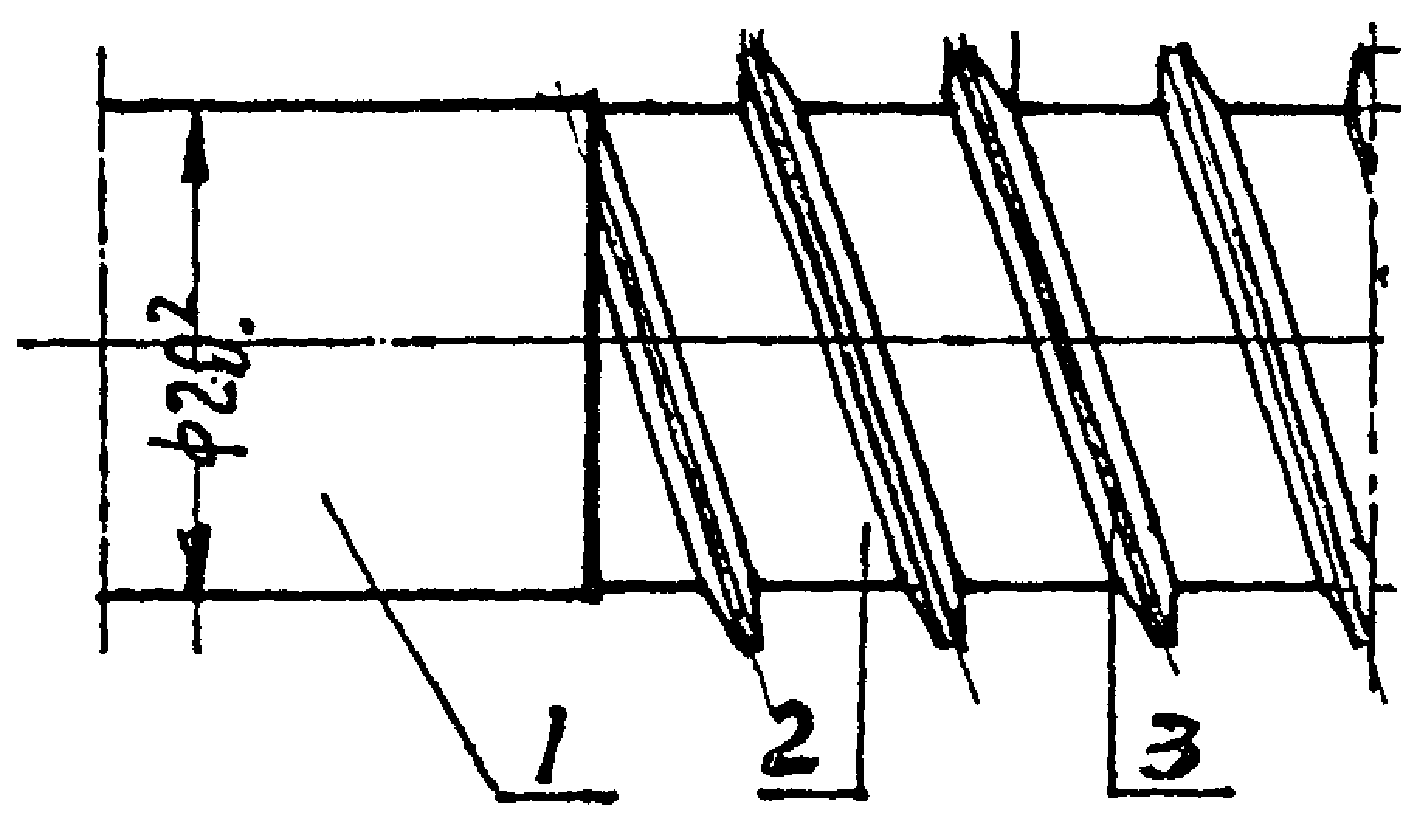

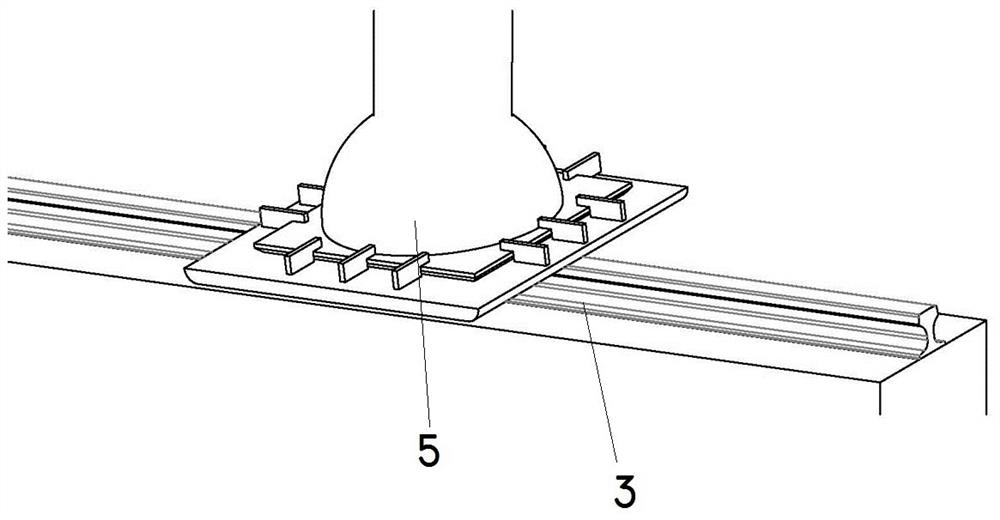

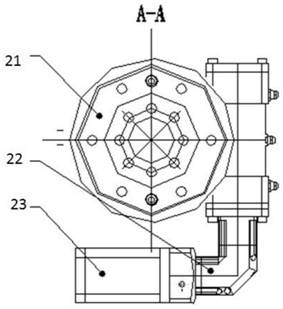

Pipe pile variable-diameter hole guiding and pile pressing synchronous construction equipment and method thereof

ActiveCN113774911ACrowding effect is controllableReliable carrying capacityFlushingRotary drillingDrill holeEngineering

The invention discloses pipe pile variable-diameter hole guiding and pile pressing synchronous construction equipment in the technical field of building construction. The pipe pile variable-diameter hole guiding and pile pressing synchronous construction equipment comprises a drill rod driven by an external power device to rotate, wherein the lower end of the drill rod is coaxially and fixedly connected with a mounting rod; the lower end of the mounting rod is provided with a spiral blade; the spiral blade is driven by a driving unit to radially stretch out and draw back along the mounting rod, so that the adjustment of the hole diameter of a drilling hole is realized; a through groove communicated with the interior of the drill rod is formed in the outer wall of the lower end of the drill rod; a water filling unit and a slurry discharging unit are arranged in the drill rod; the water filling unit is used for filling water into the drill hole; and the slurry discharging unit is used for discharging slurry in the drill hole. The pipe pile variable-diameter hole guiding and pile pressing synchronous construction equipment and method thereof provided by the invention have the beneficial effects that hole guiding and pile pressing can be synchronously carried out, the soil squeezing effect of the pipe pile is controllable, the characteristics of reliable bearing capacity after pile forming and the like are achieved, static pressure of soft soil layers, hard soil layers and soft and hard interbedding areas or construction of variable-diameter hole guiding needed by hammering the pipe pile can be completed, and compared with a traditional construction method, the method has the characteristics that the construction efficiency is high, the soil squeezing effect of the pipe pile is controllable, and the bearing capacity is reliable after pile forming.

Owner:SHANDONG JIANZHU UNIV

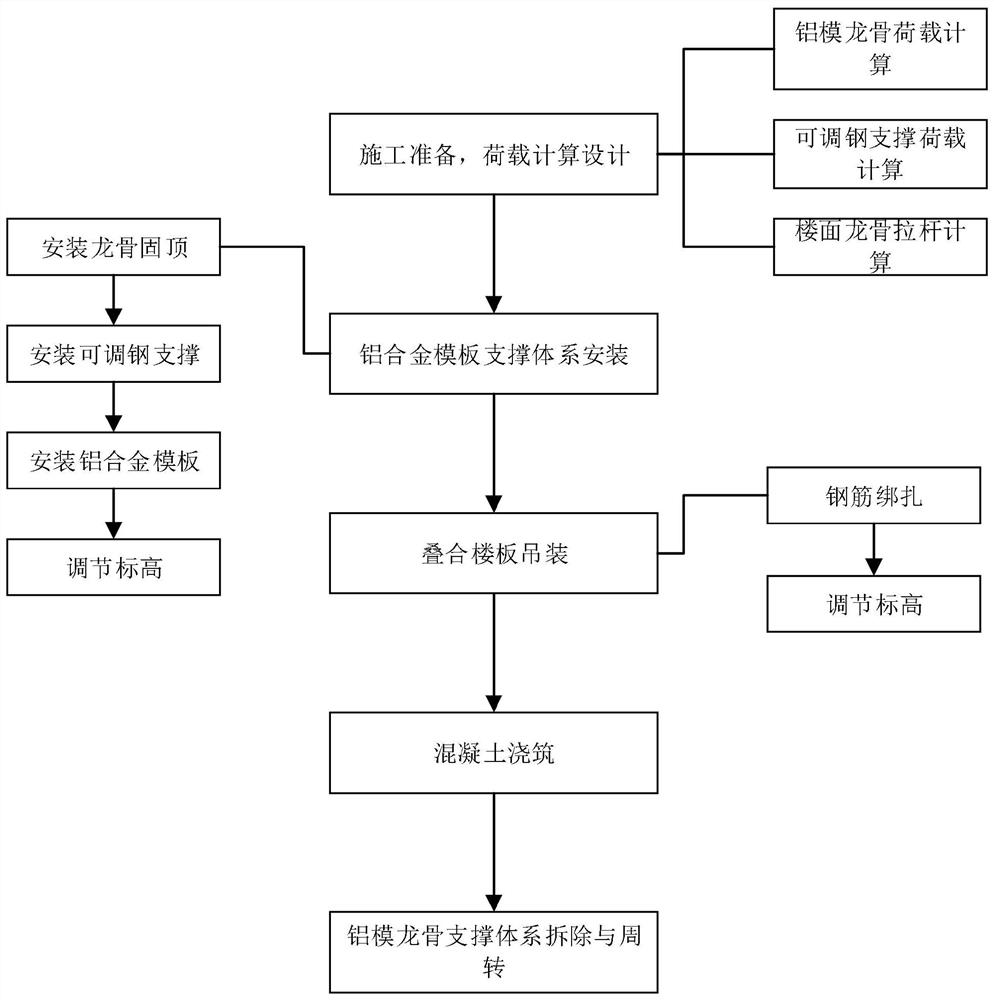

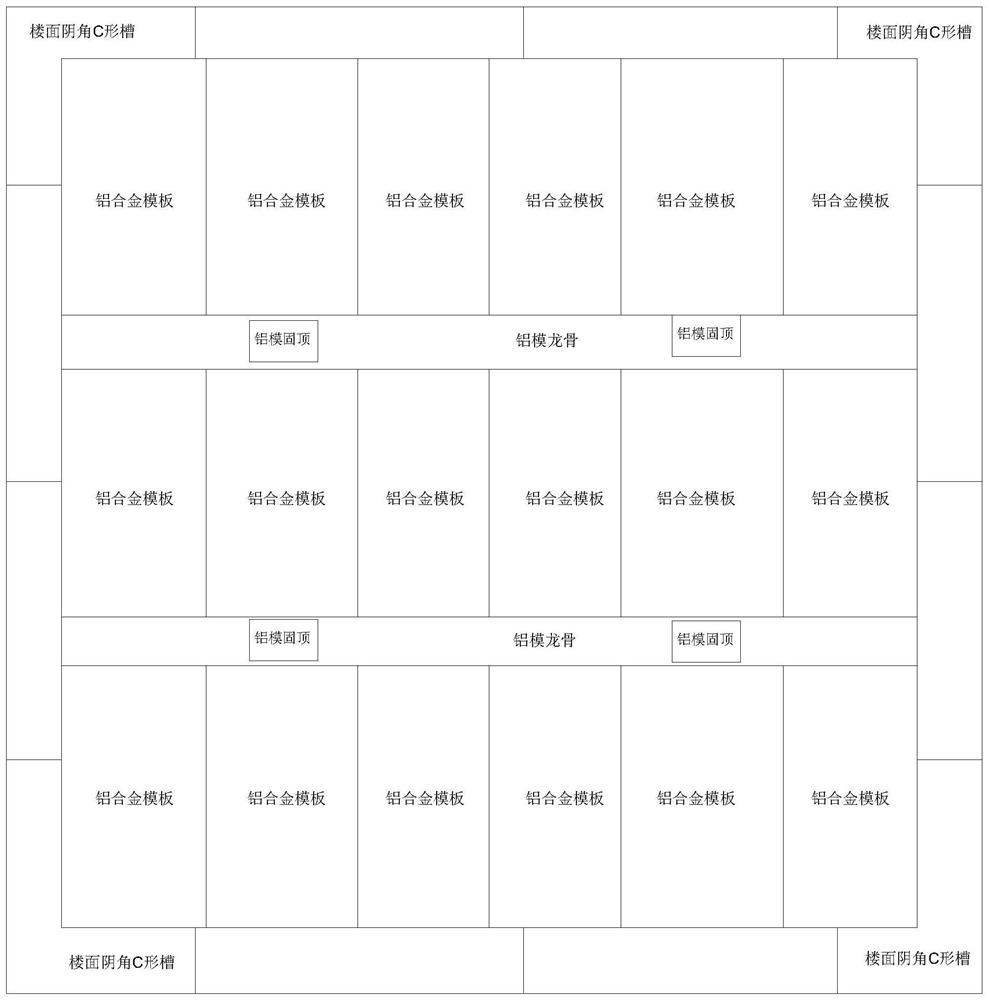

Composite floor slab construction method based on aluminum alloy formwork support

PendingCN113719116AHigh strengthEasy dismantling and turnoverFloorsForms/shuttering/falseworksRebarFloor slab

The invention discloses a composite floor slab construction method based on aluminum alloy formwork support. The composite floor slab construction method comprises the following construction steps that S1, construction preparation is achieved: formwork matching design of an aluminum alloy formwork support system is completed; S2, the aluminum alloy formwork support system is installed; S3, composite floor slabs are hoisted, specifically, the composite floor slabs are arranged at the top of the aluminum alloy formwork support system in a hoisting mode and supported by aluminum alloy formworks and keel fixed tops, and the composite floor slabs are connected through reserved steel bars on the composite floor slabs bonded by steel bars; S4, concrete pouring is conducted, specifically, concrete is poured to the position above a composite floor slab; and S5, an aluminum formwork keel support system is dismantled and turned over, specifically, after concrete curing is achieved, an aluminum alloy formwork support system structure except aluminum formwork fixed tops is dismantled, and turning over is conducted. According to the composite floor slab construction method based on the aluminum alloy formwork support, the composite floor slab is supported through aluminum formwork keels and the aluminum formwork fixed tops, when a plurality of aluminum formwork fixed tops exist, all the aluminum formwork keels are connected through the aluminum alloy formworks, horizontal stability is guaranteed, and overturning is prevented in the hoisting process.

Owner:CHINA HUASHI ENTERPRISES

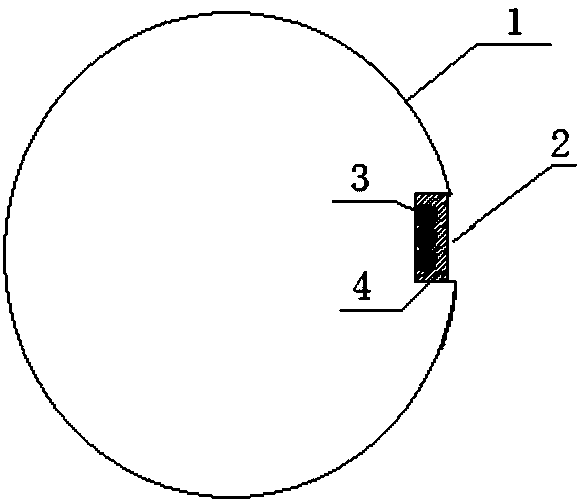

A kind of anti-wind ball bearing

ActiveCN106522083BIncreased durabilityExtended service lifeBridge structural detailsBall bearingWind power

A wind-resistance spherical supporting seat comprises a convex spherical steel lining plate and a concave spherical steel lining plate. A middle subplate, the convex spherical steel lining plate and the concave spherical steel lining plate are arranged in a pelvic cavity of a supporting seat base plate in sequence; the plane side of the convex spherical steel lining plate is matched with the middle subplate in a sliding mode, the convex spherical surface of the convex spherical steel lining plate is matched with the convex spherical surface of the concave spherical steel lining plate in a sliding mode, the plane side of the concave spherical steel lining plate is matched with a supporting seat top plate in a sliding mode; a rotary mechanism of the supporting seat is formed by the convex spherical steel lining plate and the concave spherical steel lining plate, the functions of bridge horizontal load and rotation of the supporting seat are achieved; and an interval is left between the middle subplate and a supporting seat bottom plate, butterfly-shaped springs are arranged in the interval, and thus an elastic supporting mechanism is formed. The wind-resistance spherical supporting seat can freely and flexibly rotate in all directions, has a buffering impact on waggle, caused by bridge horizontal wind power or earthquake force, of a bridge girder, and normal sliding and rotation of a girder body in the vertical direction or the vertical bridge direction are guaranteed; and the demands of the large bearing capacity and large angle rotation of the girder body are met, the durability of the supporting seat is good, and the service life is long.

Owner:柳州东方工程橡胶制品有限公司

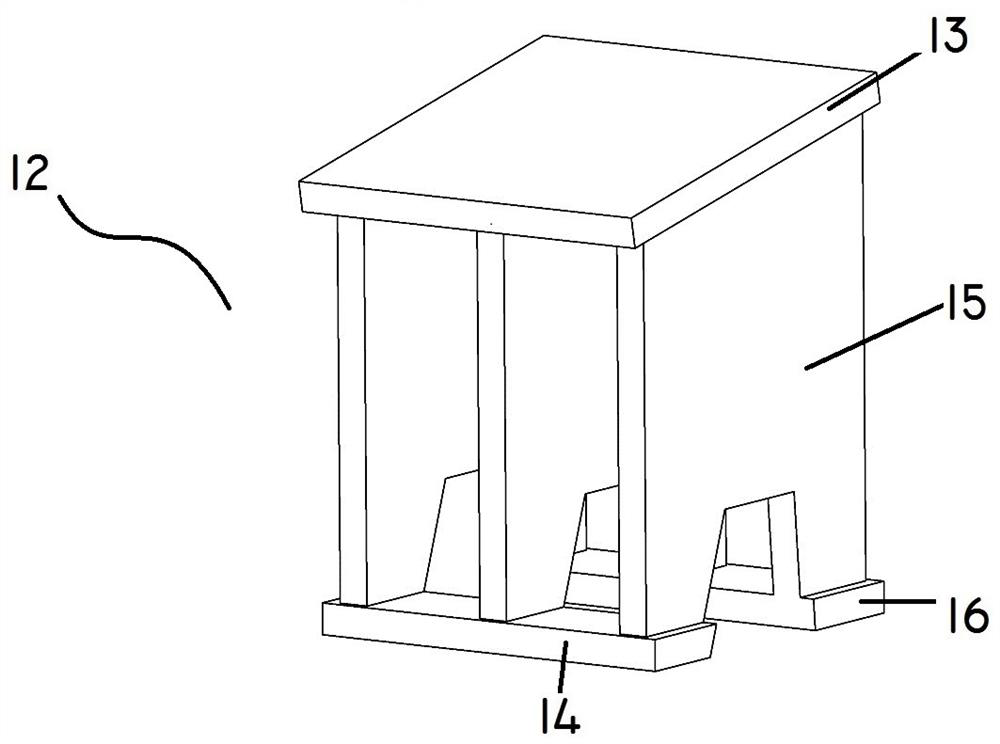

Bidirectional shearing metal damper

PendingCN113404364AReliable carrying capacityExtended service lifeProtective buildings/sheltersShock proofingPhysicsBidirectional coupling

The invention discloses a bidirectional shearing metal damper. The bidirectional shearing metal damper comprises two end plates which are oppositely arranged up and down, wherein a transverse energy consumption plate and a longitudinal energy consumption plate which are perpendicular to each other are connected between the two end plates, one side of the longitudinal energy consumption plate is in contact with the side wall of the transverse energy consumption plate, the upper ends and the lower ends of the transverse energy consumption plate and the longitudinal energy consumption plate are rotationally connected with the corresponding end plates, the transverse energy consumption plate can rotate back and forth in the direction of the longitudinal energy consumption plate, and the longitudinal energy consumption plate can rotate back and forth in the direction of the transverse energy consumption plate. According to the bidirectional shearing metal damper, bidirectional separate energy consumption can be realized, bidirectional coupling deformation can be effectively adapted, and stable and reliable bearing capacity, rigidity and energy consumption capacity can be provided under the bidirectional coupling deformation.

Owner:KUNMING UNIV OF SCI & TECH +1

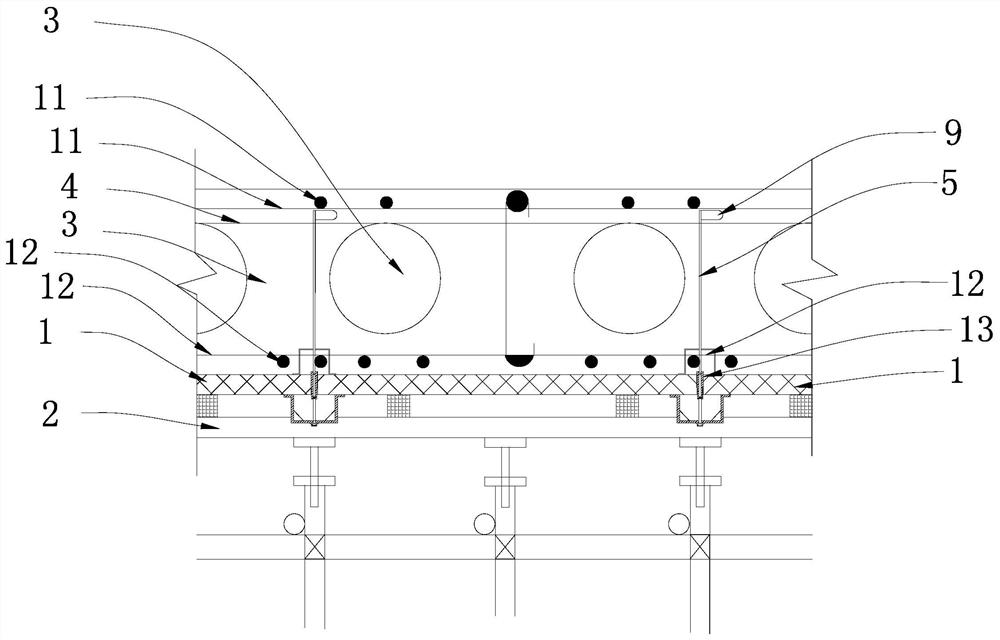

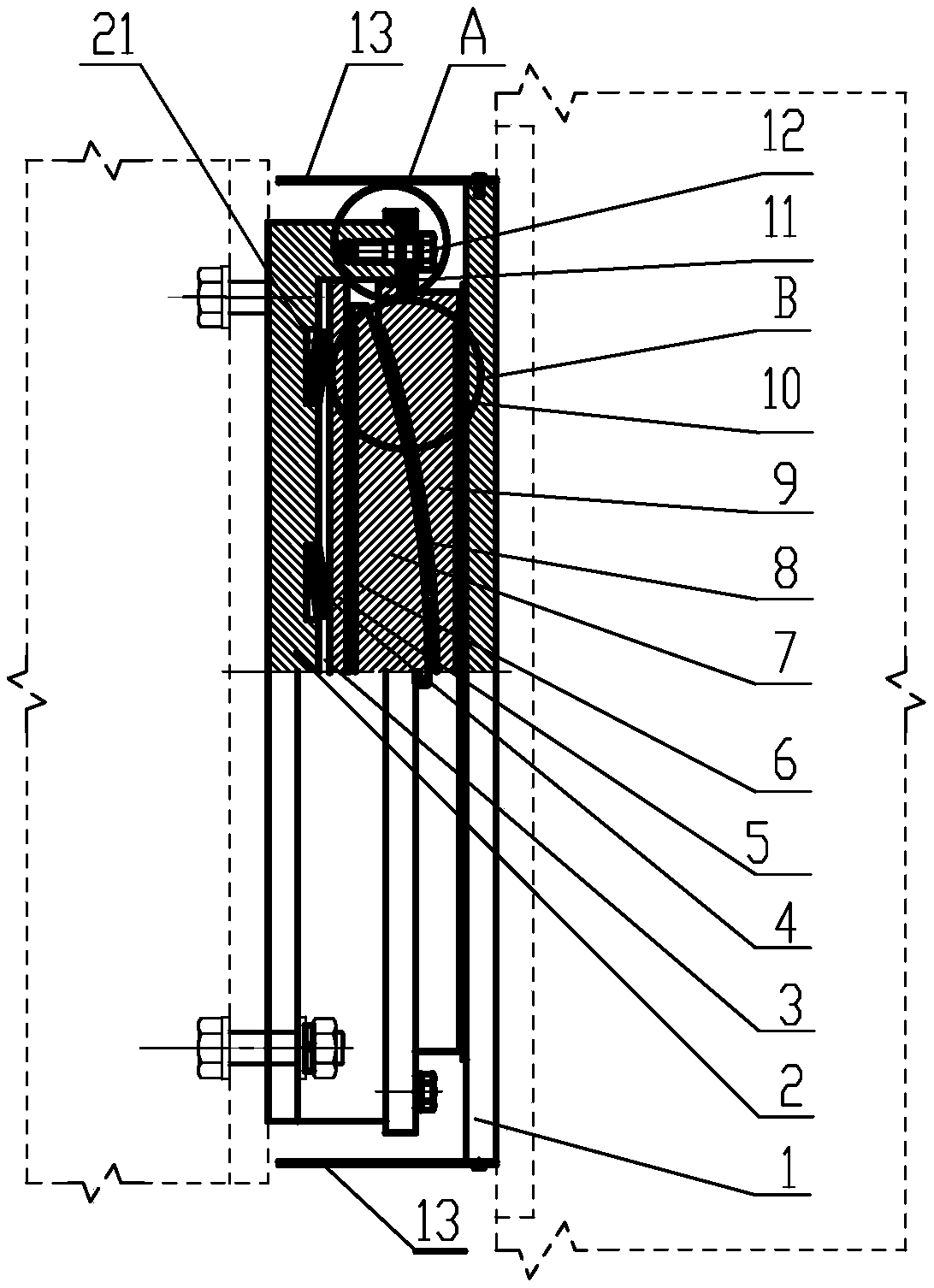

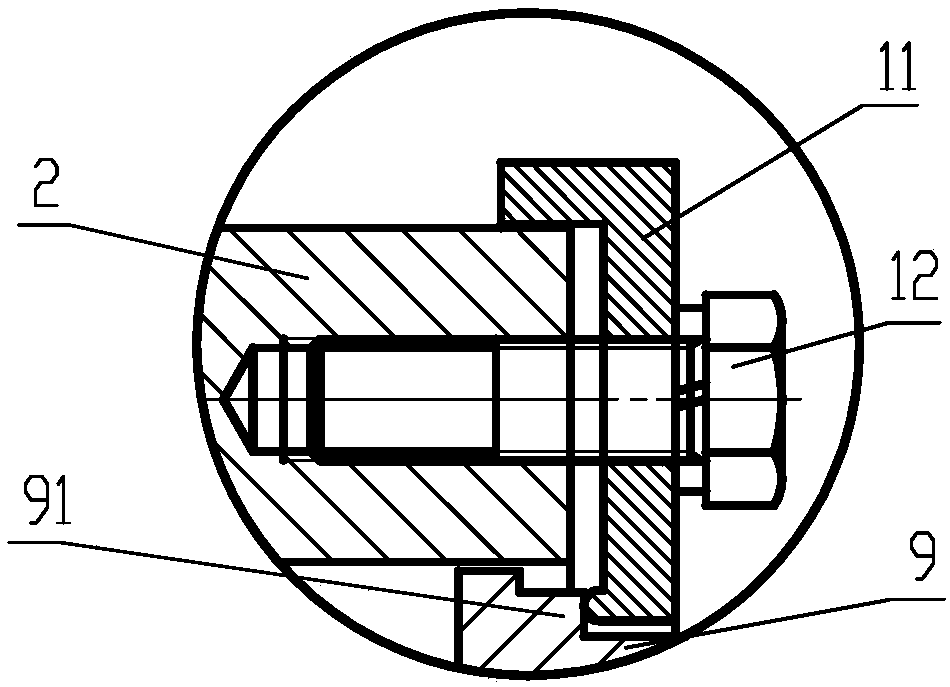

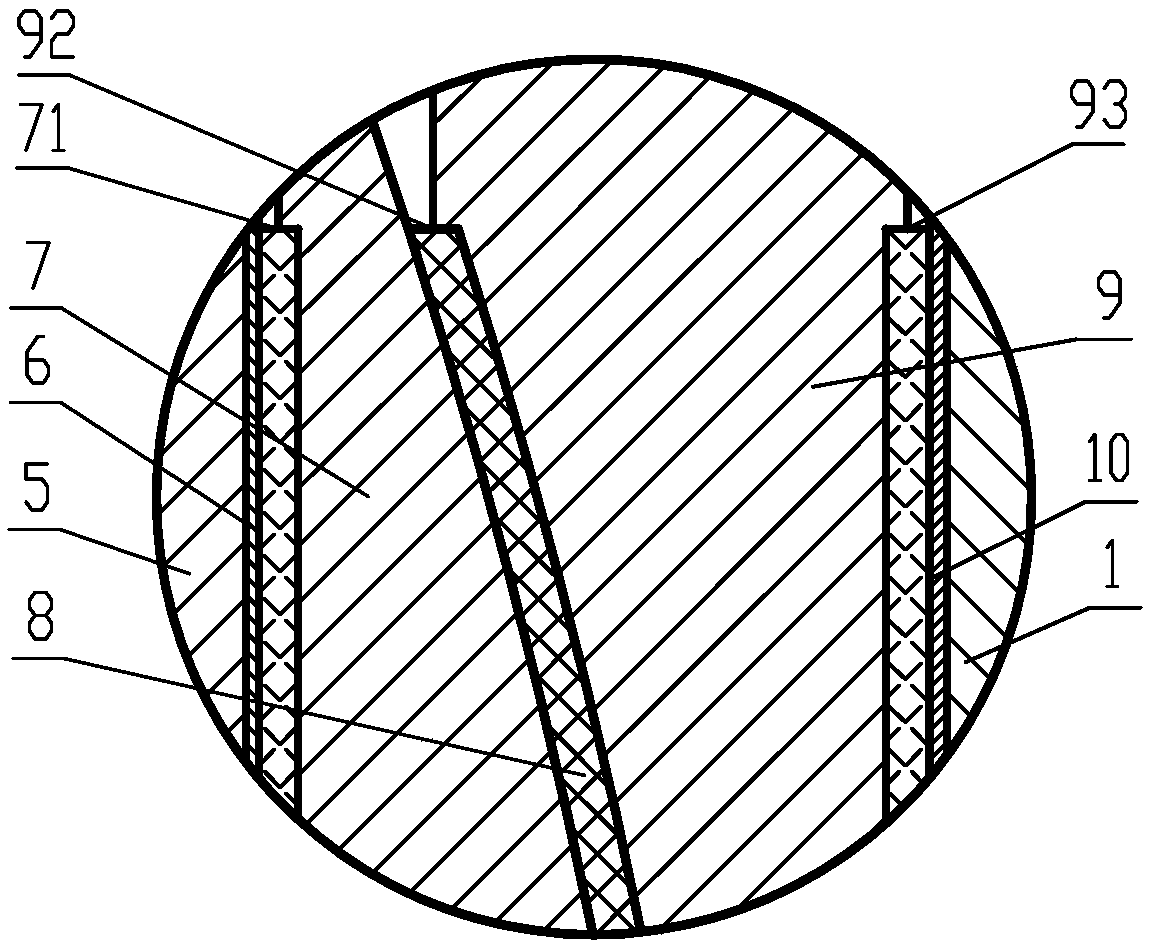

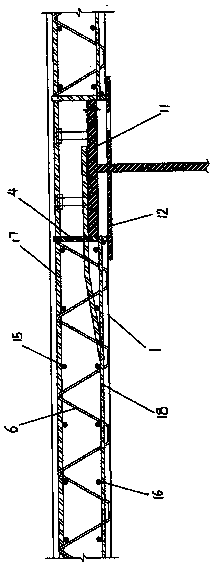

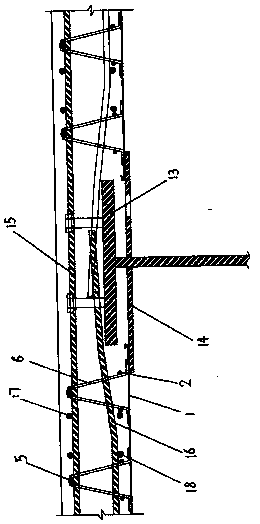

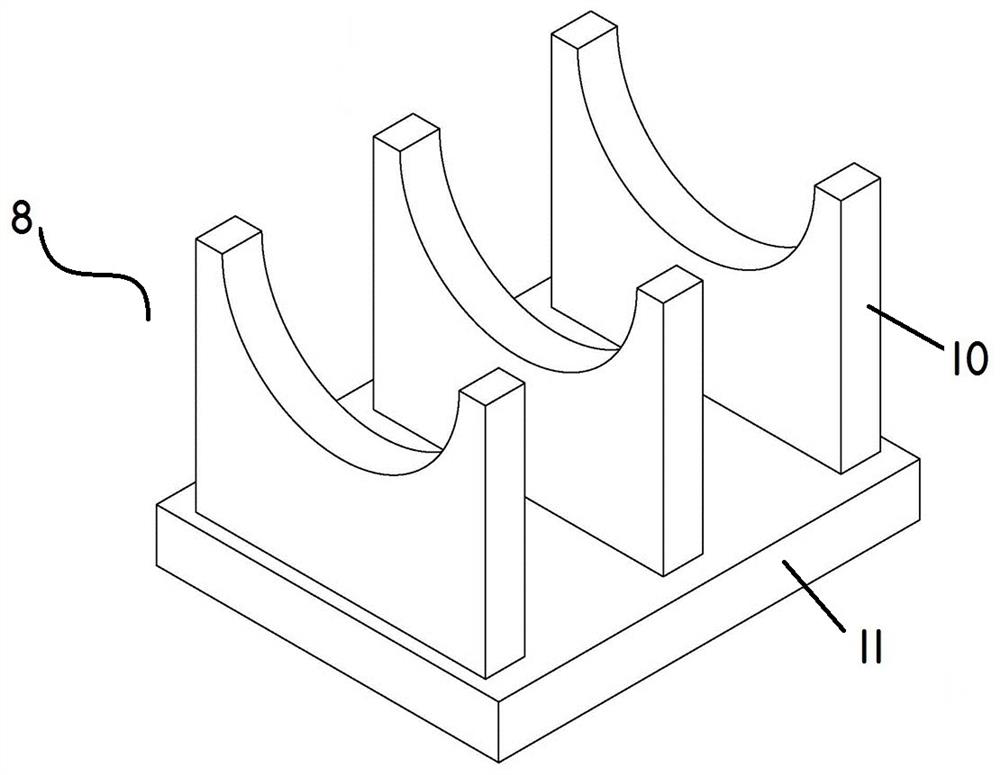

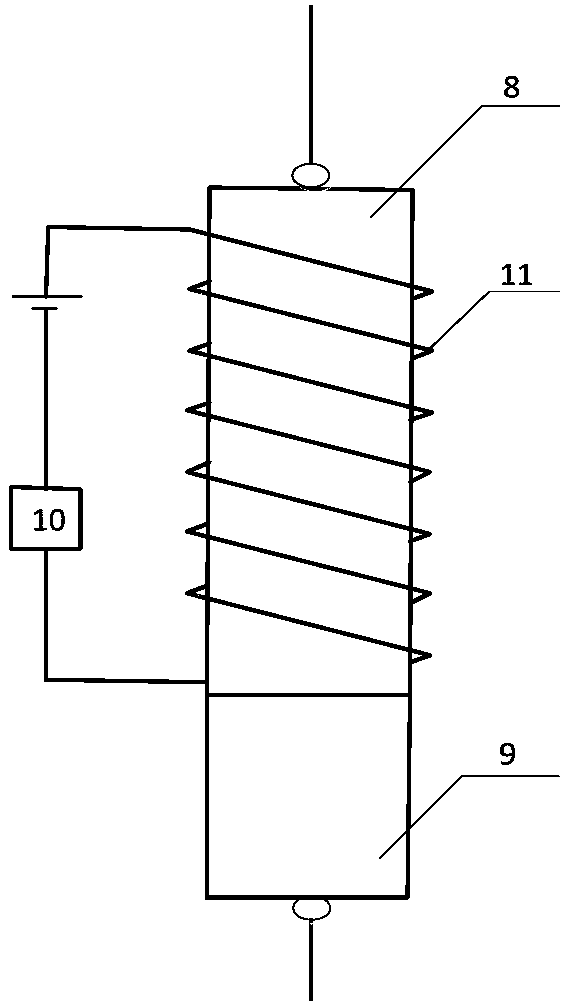

Cantilevered floor slab rebar structure adopting steel bar truss formworks and bar reinforcing method

PendingCN110952651AReliable carrying capacityImprove bearing capacityFloorsForms/shuttering/falseworksRebarSteel plates

The invention discloses a cantilevered floor slab rebar structure adopting steel bar truss formworks and a bar reinforcing method. The problem that support formworks of a cast-in-place cantilevered reinforced concrete floor slab of an existing high-altitude cantilever floor have support difficulties and are long in construction period and high in construction price is solved. A main building structure (8) is included, a steel beam cantilever frame composed of steel beams (9) parallel to the main building direction and steel beams (10) perpendicular to the main building direction is arranged onthe outer side of the main building structure (8) in an overhang manner, steel beam panels (11) parallel to the main building direction are arranged on the steel beams (9) parallel to the main building direction, and steel beam panels (13) perpendicular to the main building direction are arranged on the steel beams (10) perpendicular to the main building direction, the steel bar truss formworks are fixedly welded to the steel beam cantilever frame and are composed of rectangular bottom mold steel plates (1) and steel bar framed bents fixedly arranged in the left-right direction at intervals,and the steel bar framed bents are fixedly arranged on the rectangular bottom mold steel plates in the left-right direction. The on-site reinforcement lashing workload can be reduced by 60% to 70%.

Owner:北京建工集团山西建设有限公司

A Combined Anti-seismic Bolt Connection Node

ActiveCN107165275BReduce distortionReliable carrying capacityProtective buildings/sheltersShock proofingEngineeringBolt connection

The invention discloses a combined anti-seismic bolt connection node, comprising a square steel pipe, a connecting end plate, a steel beam, a low-yield positioning piece and a single-sided bolt, wherein the number of connecting end plates is two, and the two connecting end plates are respectively In contact with the outer sidewalls on opposite sides of the square steel pipe. The steel beam is I-shaped or H-shaped, and the number of steel beams is two. One end of the steel beam is vertically fixedly connected to the side wall on the other side of the connecting end plate opposite to the side that contacts the square steel pipe. The two steel beams are connected to the two The end plates are connected one by one, and the flange plate of the steel beam is perpendicular to the axial direction of the square steel pipe. The low-yield positioning piece passes through the square steel pipe and two connecting end plates, and the unilateral bolt passes through a connecting end plate and the side wall of the square steel pipe in contact with the connecting end plate and is embedded in the square steel pipe. The distance between the low-yielding positioning piece and the steel beam The distance between the webs is smaller than the distance between the unilateral bolts and the web of the steel beam. The overall structure of the invention is simple, easy to realize, low in cost, and has good ductility, dissipative earthquake capacity and bearing capacity in application.

Owner:SICHUAN UNIV

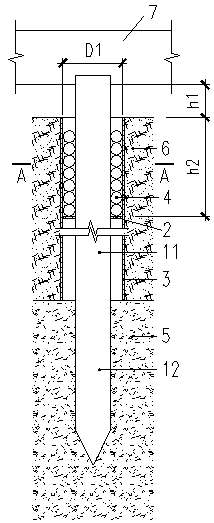

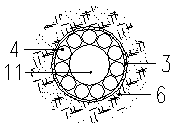

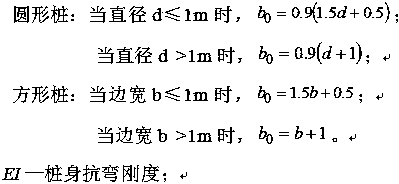

High-pressure rotary-jetting hollow bottom-expanding pile and making method thereof

InactiveCN1252358CSmall discreteImprove bearing capacityBulkheads/pilesBridge engineeringPrice ratio

The invention is a kind of high pressure rotary-spraying hollow pedestal pile and the manufacturing method. The invention sets pile along the ground vertically, in the middle part of the pile, hollow holes are set parallel to the pile, the hollow holes is all through the pile, there sets a pedestal pile feet on the subjacent part of pile in the ground, the section of the pile is circular, rectangular or polygon. The invention is reasonable, the structure is compact, and the constructing is convenient, easy to be controlled. It saves material, labor, time, energy and investment. It upgrades the bearing ability of the pile, the bearing and price ratio of single pile is higher than current pile. It can applied to pile base of building foundation, constructing material, device base or soft soil base in constructing engineering, bridge engineering, municipal works and hydraulic engineering. The invention accords to the standards (building pile base technology standards) JGJ94-94 and (building ground process technology standards)JGJ79-91.

Owner:雷玉华

Pile-forming equipment and method of control modulus pile

InactiveCN101435209BReliable carrying capacityRealize quantitative designFoundation testingStress ratioSlurry transport

The invention discloses a pile-forming device and pile-forming method for control modulus pile, belonging to the field of bearing characteristic testing of composite foundation of geotechnical engineering. The device of the invention is composed of a drill bit, a motor, a control platform, a drill frame, a drilling rod, a driving chain, a slurry transporting pipe, a pressure pump, and a model box. The method of the invention includes the steps of filling simulation soil layer, preparing cement slurry, and forming pile. The invention realizes the quantitative design of control deform and control bearing force of the composite foundation, and fully mobilizes the function of the soil among piles by adjusting the stress ratio of the pile soil.

Owner:SOUTHEAST UNIV

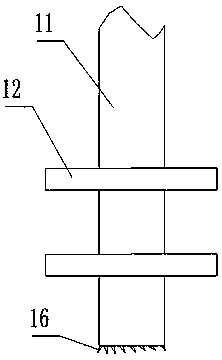

A self-resetting steel plate shear wall based on a superelastic shape memory alloy screw

ActiveCN106592822BAchieving hyperelasticityPlay the role of dissipating earthquake energyWallsShape-memory alloySteel plate shear wall

The invention relates to a self-resetting steel plate shear wall based on a hyperelastic shape memory alloy screw, and the shear wall comprises a boundary beam, boundary columns, an embedded steel plate, a shear-resistant element, and a foundation beam. The foundation beam is disposed at a lowermost part, and the number of boundary columns is two, wherein the two boundary columns are arranged to be parallel. The boundary columns and the foundation beam are connected through the hyperelastic shape memory alloy screw arranged at the lowermost part. The boundary beam is connected with the upper ends of the two boundary columns, and the embedded steel plate is disposed between the two boundary columns. The shear-resistant element is disposed between the bottom of the embedded steel plate and the foundation beam. According to the invention, the hyperelastic shape memory alloy screw plays a role in consuming energy and providing a self-resetting effect, and also achieves the self-resetting effect. Compared with the prior art, the shear wall is simple in structure, is flexible in design, and is convenient to construct. The self-resetting capability can effectively reduce the cost of post-earthquake repair or reinforcement of the structure, and improves the recovery capability of post-earthquake use of the overall structure.

Owner:TONGJI UNIV

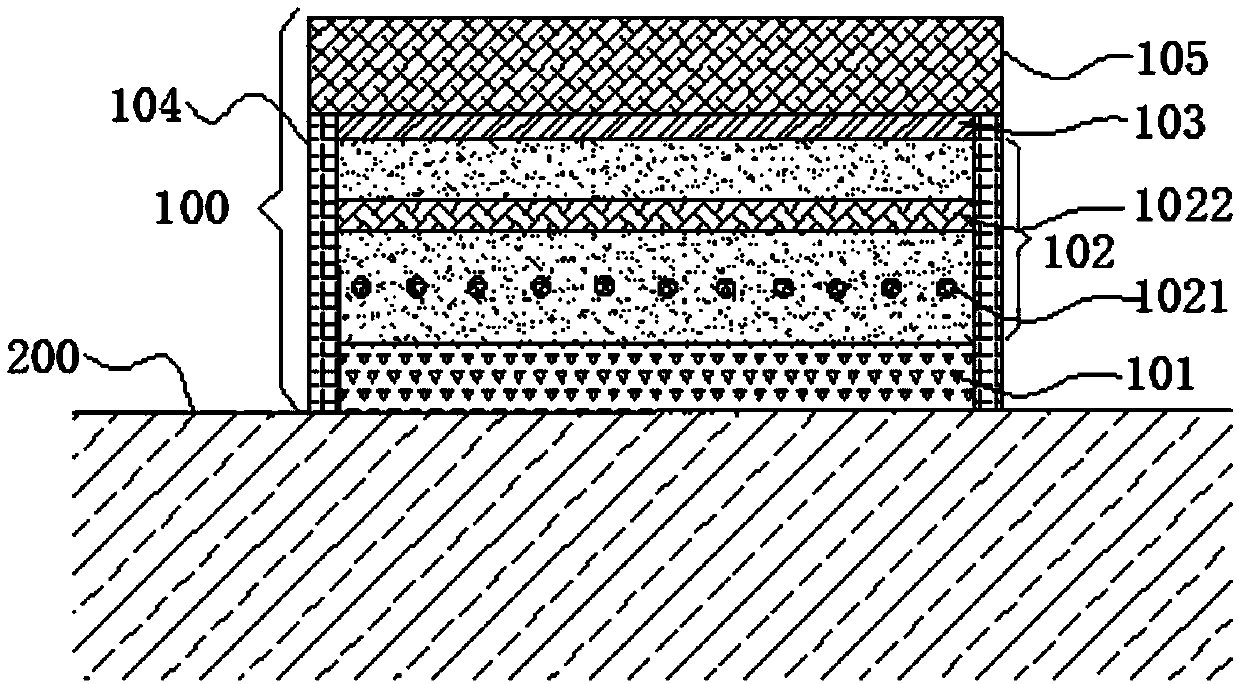

Construction method of municipal soft soil subgrade

InactiveCN106592363BReasonable structureReliable carrying capacityRoadwaysHydration reactionUltimate tensile strength

The invention discloses a construction method for a municipal soft soil roadbed. The roadbed comprises a cement stabilization layer, a cushion layer, a reinforcing layer, a top sealing layer and a retaining wall; the structure is reasonable, the bearing capacity of the roadbed can be enhanced by the adoption of the retaining wall, in the cement stabilization layer, a curing agent promotes cement and soil to be subjected to a hydrolysis hydration reaction, gel is formed, finally a stable whole structure is formed, so that the overall strength of a soil body is improved, and the use bearing capacity of the roadbed is further improved. The cushion layer is laid for three times to be constructed and leveled and compacted layer by layer, the compactness is improved, and therefore the stability of the roadbed is improved. Longitudinal reinforcing ribs are arranged between the laid layer at the first time and the laid layer at the second time, transverse reinforcing ribs are arranged between the laid layer at the second time and the laid layer at the third time, the supporting force of the roadbed is enhanced, and the bearing capacity of the roadbed is further improved. Therefore, the construction method has the beneficial effects of being high in feasibility and efficiency, and the roadbed has the beneficial effects of being high in bearing capacity, unlikely to settle and collapse and the like.

Owner:滨州京鲁交通工程有限公司

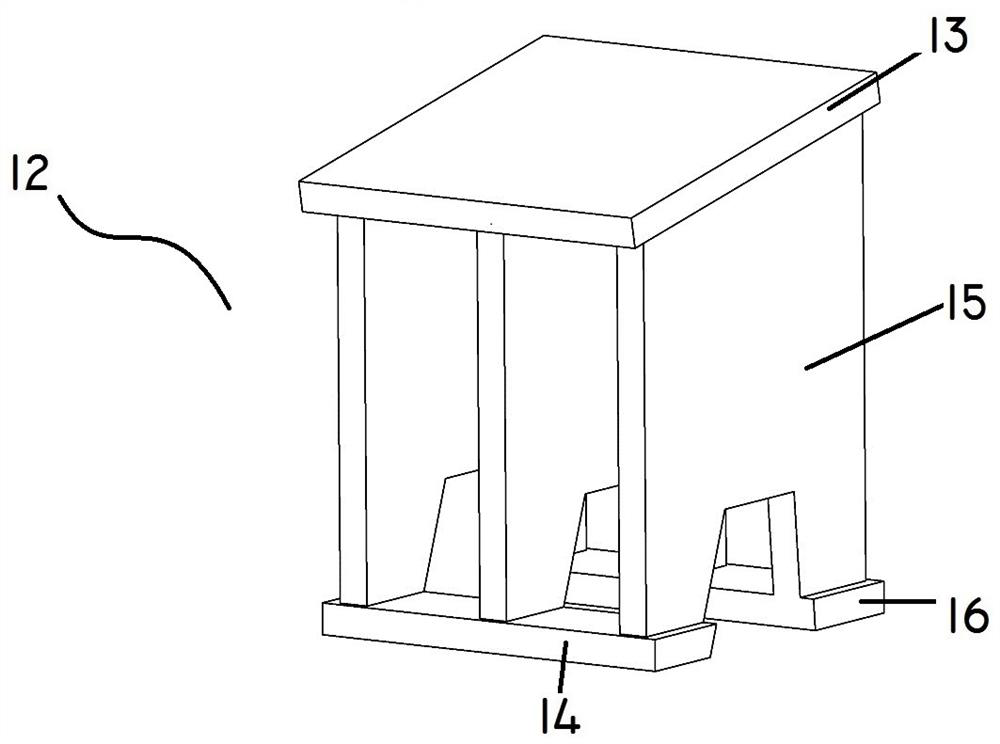

Steel truss support unloading structure and construction method for unloading tracks by using same

ActiveCN111794527ASatisfy uninstall useSimple structureBuilding material handlingJackscrewSteel columns

The invention discloses a steel truss support unloading structure and an unloading construction method. The steel truss support unloading structure comprises at least three steel trusses, connecting pipes symmetrically arranged in the middles of the two sides of each steel truss, and trucks symmetrically arranged at the bottom of each steel coupling beam; the dismounting structure comprises steelcolumn limbs, hemispheres arranged at the bottoms of the steel column limbs, sliding shoes connected with the tracks in a clamped mode, pressing plates used for fixing the sliding shoes and the hemispheres and supporting assemblies symmetrically arranged on the two sides of each steel column limb; each supporting assembly comprises a pipe support, a jack and a jack base; and the jack bases are arranged on the tracks, the lower ends of the connecting pipes are erected on the pipe supports, and each jack is arranged between the bottom of the corresponding pipe support and the corresponding jackbase. The equipment is simple in structure, convenient to machine, flexible in arrangement, reliable in bearing capacity, safe, stable and capable of meeting unloading use of all support point positions; meanwhile, the tool can completely detach the sliding trucks so that the trucks can be used in different projects in a turnover mode; and the popularization value is quite high.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

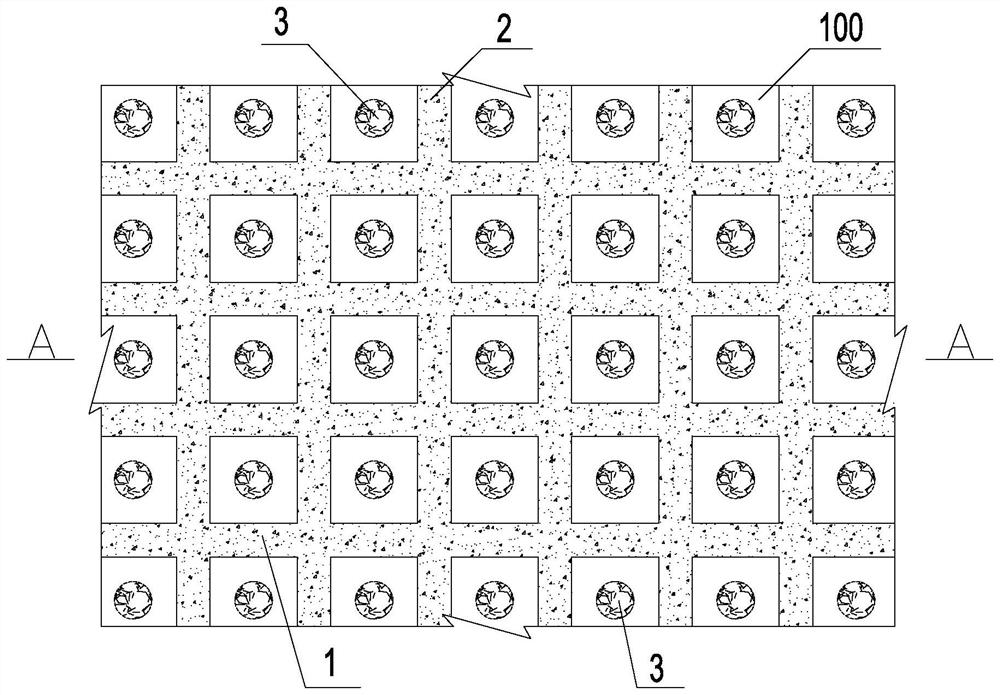

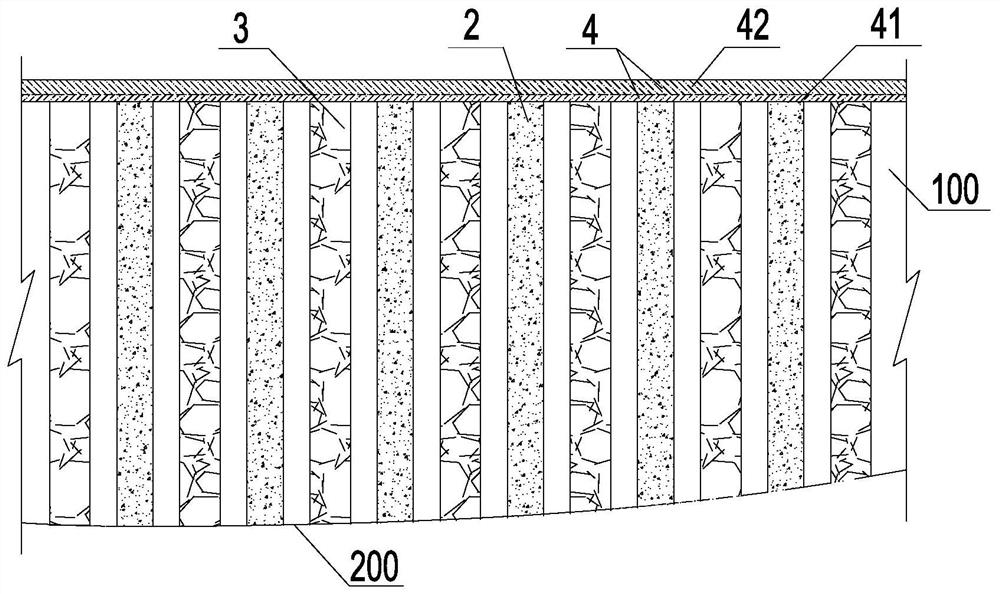

Concrete lattice wall and discrete material pile combined deep soft soil foundation reinforcement treatment structure and construction method

PendingCN114045808AHigh strengthImprove bearing capacitySoil preservationSoil scienceReinforced concrete

The invention provides a concrete lattice wall and discrete material pile combined deep soft soil foundation reinforcement treatment structure and a construction method. A reinforced concrete lattice wall which is orthogonal in the transverse direction and the longitudinal direction is arranged on a deep soft soil foundation; discrete material piles such as gravel piles or sand piles are arranged in the center of the concrete lattice wall frame; the bottoms of the concrete lattice wall and the discrete material piles are located on a soft foundation bottom dense layer or weathered bed rock; and the horizontal permeable cushion layer is arranged at the tops of the concrete lattice wall and the discrete material piles. According to the deep soft soil foundation condition, the rigid reinforcing structure and the flexible reinforcing body are reasonably utilized to jointly reinforce the soft soil foundation, and meanwhile, the reinforcing treatment measure and method create conditions for accelerating drainage consolidation of foundation soft soil and improving the strength of the foundation soft soil, the strength, the bearing capacity and the deformation modulus of the soft soil foundation meet the requirements of an upper structure and a building. And the method is of great significance to a deep soft soil foundation treatment technology under complex conditions.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +2

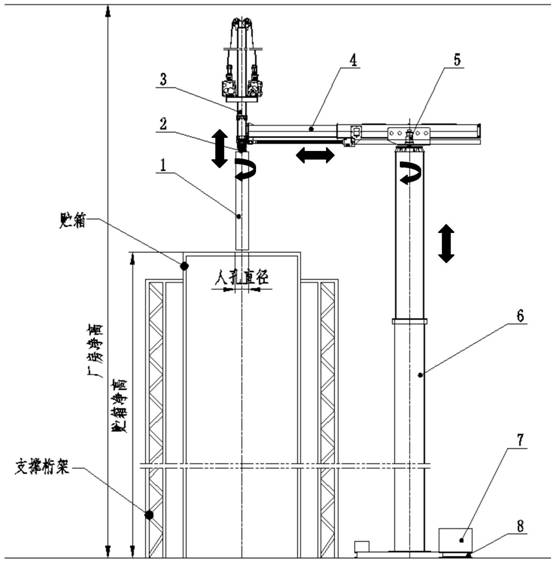

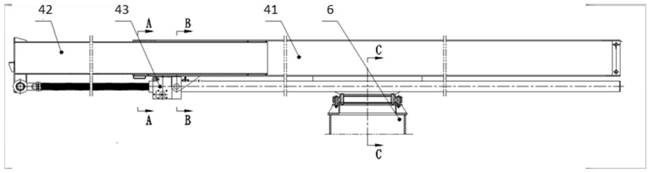

A kind of automatic cleaning equipment with tank structure

ActiveCN107377550BCleaningfull heightRealize spatial positioningHollow article cleaningReciprocating motionEngineering

The invention relates to an automatic cleaning facility for a rocket storage tank structure, and belongs to cleaning and washing of long and thin tank structures in the field of mechanical engineering. The automatic cleaning facility comprises a cleaning head, an autorotation mechanism, a feeding mechanism, a horizontal telescoping mechanism, a rotating mechanism, a vertical telescoping mechanism and a base frame. The vertical telescoping mechanism is fixedly arranged on the top of the base frame, and the rotating mechanism is fixedly arranged at the telescoping end of the vertical telescoping mechanism. The horizontal telescoping mechanism is fixedly arranged at the top end of the rotating mechanism, and the rotating mechanism is used for driving the horizontal telescoping mechanism to conduct 360-degree rotation on the horizontal plane. The telescoping end of the horizontal telescoping mechanism is connected with the feeding mechanism. The telescoping end of the feeding mechanism is connected with the autorotation mechanism, and the feeding mechanism is used for driving the autorotation mechanism to conduct reciprocating movement in the vertical direction. The bottom end of the autorotation mechanism is connected with the cleaning head, and the autorotation mechanism is used for driving the cleaning head to rotate. The automatic cleaning facility can achieve all-height all-around cleaning of the inner wall, and is particularly suitable for high-efficiency and high-quality cleaning of redundant objects in a rocket storage tank.

Owner:HARBIN INST OF TECH

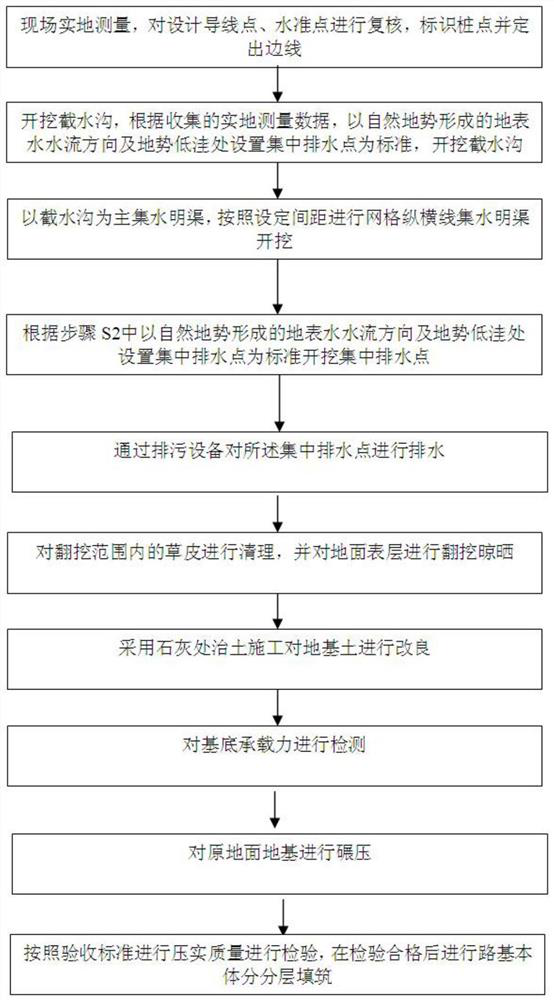

Soft soil layer drainage improvement construction method

PendingCN114395946AAchieve the drain effectReliable carrying capacityRailway tracksSoil preservationSoil scienceDitch

The invention discloses a soft soil layer drainage improvement construction method which comprises the steps that S1, field measurement is conducted on site, rechecking is conducted on designed traverse points and benchmarks, pile points are marked, and side lines are determined; s2, an intercepting ditch is excavated, and a water retaining dam is built; s3, taking the intercepting ditch as a main water collection open channel, and excavating grid longitudinal and transverse line water collection open channels according to a set interval; s4, a centralized drainage point is excavated; s5, drainage is conducted on the centralized drainage point through a pollution discharge device; s6, the turf within the digging range is cleaned, and the surface layer of the ground is dug and aired; s7, the foundation soil is improved through lime treatment soil construction; s8, detecting the bearing capacity of the base; s9, the original ground foundation is rolled; and S10, the compaction quality is inspected according to the acceptance standard. According to the method, the construction speed can be fully increased, the draining effect of the foundation is rapidly achieved, the bearing capacity of the foundation meets the design requirement rapidly, the construction cost is greatly saved, and the construction period is shortened.

Owner:中铁五局集团第二工程有限责任公司

Unloading structure of steel truss support and construction method of track unloading using this structure

ActiveCN111794527BSatisfy uninstall useSimple structureBuilding material handlingJackscrewSteel columns

The invention discloses a steel truss support unloading structure and an unloading method. The steel truss support unloading structure includes at least three steel trusses, connecting pipes symmetrically arranged in the middle of both sides of the steel trusses, and rails symmetrically arranged at the bottom of the steel connecting beams. The dismantling structure includes a steel column limb, a hemisphere arranged at the bottom of the steel column limb, a sliding shoe clamped on the track, a pressure plate for fixing the sliding shoe and the hemisphere, and support components symmetrically arranged on both sides of the steel column limb. The support assembly includes a pipe support, a jack and a jack base, the jack base is arranged on the track, the lower end of the connecting pipe is set on the pipe support, and the jack is arranged between the bottom of the pipe support and the jack base. The equipment has simple structure, convenient processing, flexible layout, reliable bearing capacity, safety and stability, and can meet the unloading requirements of all support points. At the same time, the tooling can completely remove the sliding track, so that the track can be used in different projects. It has high promotional value.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

A sudden load test device

InactiveCN106404518BReliable carrying capacityRealize automatic controlStrength propertiesEngineeringCompressive strength

The invention discloses a suddenly applied load testing device. The suddenly applied load testing device comprises a support, a tension sensor, a cable force adjusting device, a cable breaking device, a gravity loading device and a controller, wherein the upper end of the cable force adjusting device is connected with the top of the support; an output end of the cable force adjusting device is connected with the upper end of the tension sensor through a rope; the lower end of the tension sensor is connected with the upper end of the cable breaking device; the lower end of the cable breaking device is connected with the upper end of the gravity loading device; the lower end surface of the gravity loading device is in contact with the upper surface of a test piece; an output end of the tension sensor is connected with an input end of the controller; and an output end of the controller is connected with a control end of the cable force adjusting device. By the device, instant compression strength of the test piece can be quantitatively analyzed.

Owner:西安华清科教产业(集团)有限公司

High-pressure rotary spraying and core inserting process to form pedestal pile

InactiveCN1219945CHigh strengthIncrease loading capacityBulkheads/pilesBridge engineeringReinforced concrete

The present invention relates to high-pressure rotary spraying and core inserting process to form pedestal pipe. The pedestal pile consists of core pile, column and pile depestal. The cylindrical or turned frustum-shaped core pile may be prefabricated reinforced concrete pile, in-situ deposited pile or other pile in different cross section shapes. The pile pedestal below the core pile has diameter greater than that of the core pile. The column has circular, semi-circular of fan-shaped cross section. There may be several auxiliary core piles around the main solid or hollow core pile and several rings in relatively great diameter around the column. The present invention has reasonable design, compact structure, high friction resistance, and wide application in building engineering, bridge engineering, civil engineering, water engineering, etc.

Owner:雷玉华

Follow-up supporting device and method

InactiveCN102180426BReliable carrying capacityReliable synchronizationLifting devicesSupporting systemHydraulic pump

The invention provides a follow-up supporting system which comprises a plurality of follow-up jacks, a hydraulic pump station, an oil pipe and balancing oil cylinders. The follow-up jacks adopt hydraulic drive, and internally adopt mechanical threads to bear upper part loads; and the system presses part of hydraulic oil to the balancing oil cylinder with smaller load from the balancing oil cylinder with larger load through the balancing oil cylinders and hydraulic oil lines till the loads borne by follow-up devices corresponding to the balancing oil cylinders at all points are basically uniform. The follow-up supporting system has the benefits that the follow-up supporting system has reliable bearing force, synchronicity and integral carrying capability, can overcome uniform loads caused by a mechanical machining error of the follow-up jacks, and ensures that the loads of the follow-up jacks in the same group is uniform.

Owner:SHANGHAI URBAN CONSTR GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com