A self-resetting steel plate shear wall based on a superelastic shape memory alloy screw

A steel plate shear wall and memory alloy technology, applied in the direction of walls, buildings, building components, etc., can solve the problems of large residual deformation of the structure, self-damage, repair difficulties, etc., to meet the design requirements, wide application range, and flexible design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

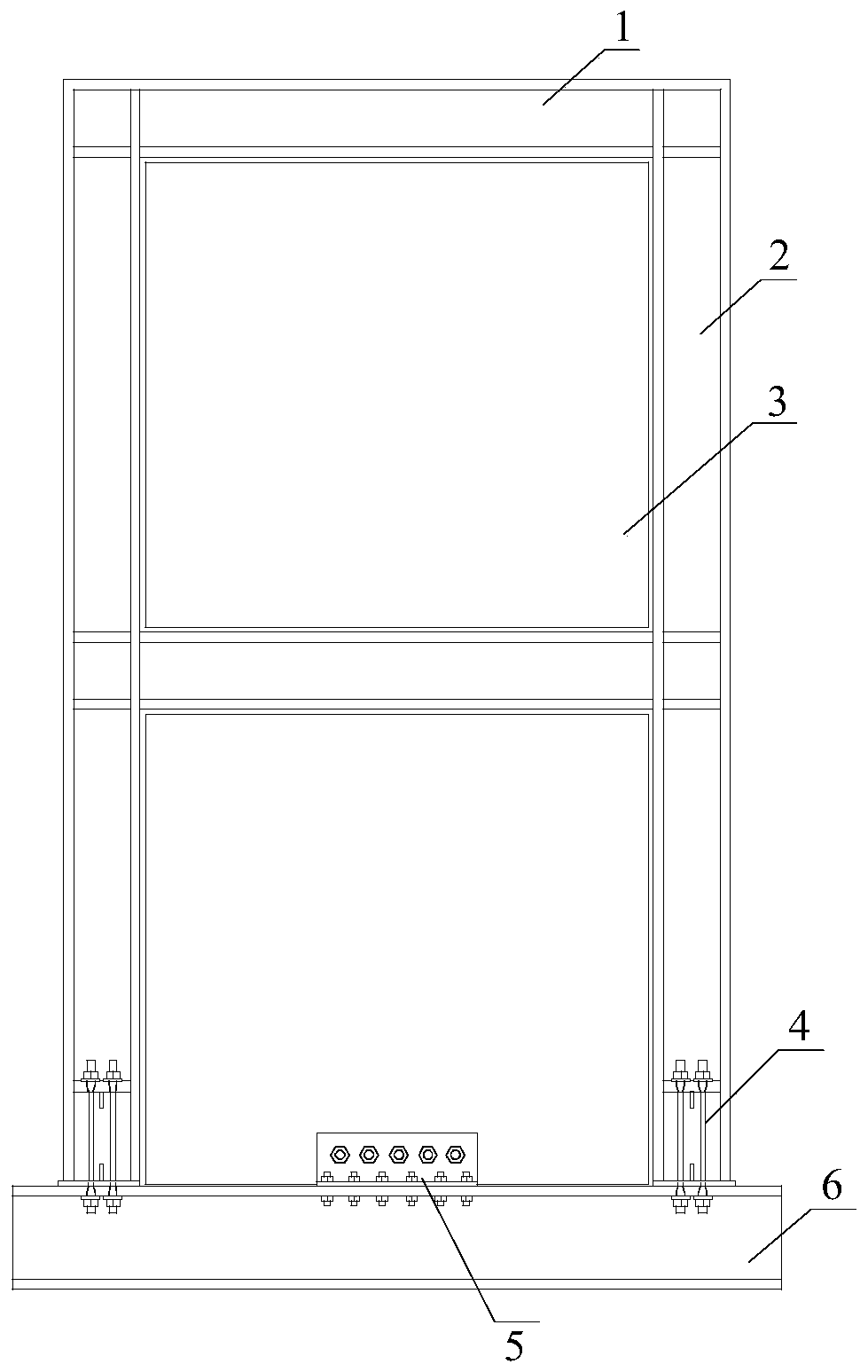

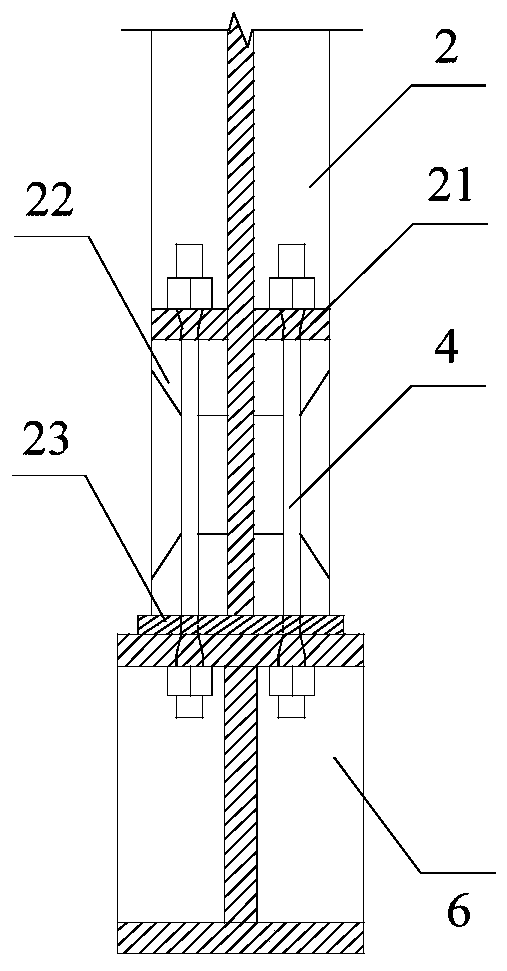

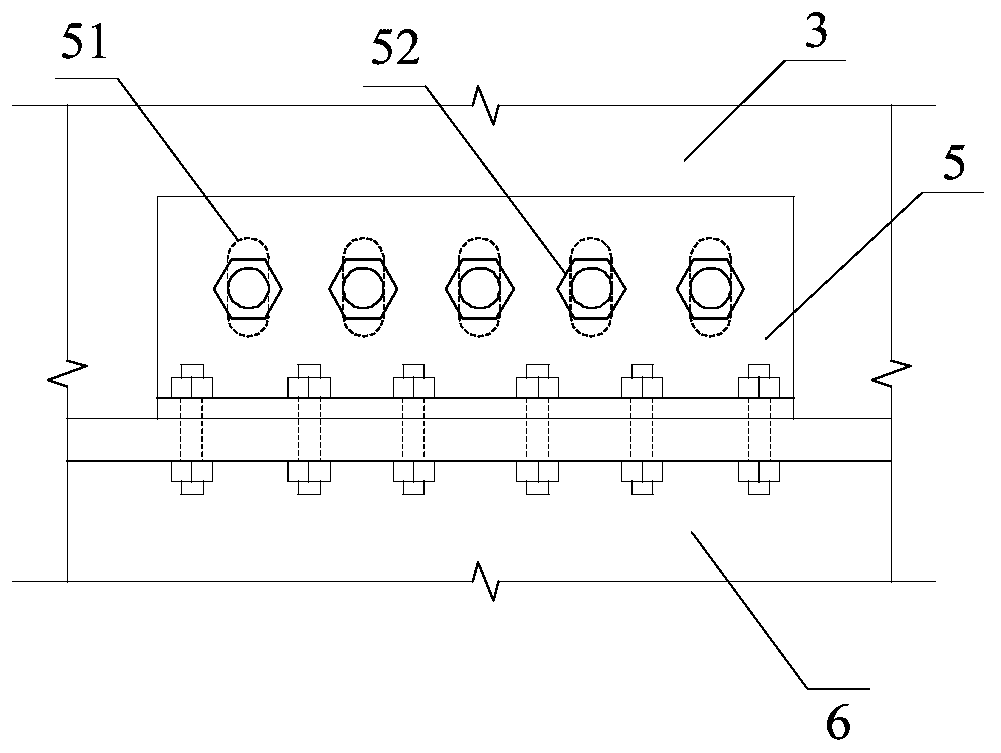

[0034] Such as figure 1 As shown, a self-resetting steel plate shear wall based on superelastic shape memory alloy screw, including boundary beam 1, boundary column 2, embedded steel plate 3, superelastic shape memory alloy screw 4, shear element 5 and foundation beam 6 , the foundation beam 6 is set at the bottom, and there are two boundary columns 2 arranged in parallel. The boundary column 2 and the foundation beam 6 are connected by a superelastic shape memory alloy screw 4 arranged at the bottom of the column. At the upper end of two boundary columns 2, the embedded steel plate 3 is arranged between the two boundary columns 2, and the shear element 5 is arranged between the bottom of the embedded steel plate 3 and the foundation beam 6. A certain pre-strain is applied to the superelastic shape memory alloy screw 4 so that it is in a tensioned state during the whole working stage, and the shear element 5 only resists the horizontal force without restricting the vertical ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com