Large-corner high-friction shock-absorbing and shock-isolating support

A high-friction, shock-absorbing and isolation technology, applied in the direction of shockproof, bridge parts, bridges, etc., can solve the problems of large corner deformation capacity, high friction coefficient, etc., and achieve the effect of prolonging the cycle, ensuring quality, and reducing earthquake response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

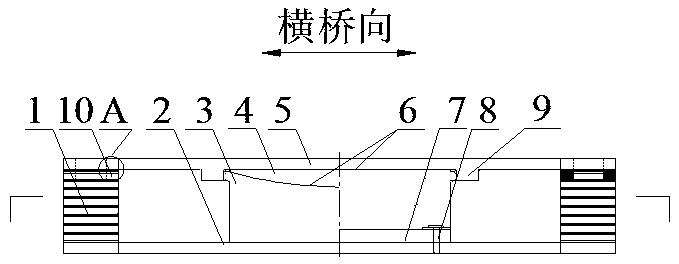

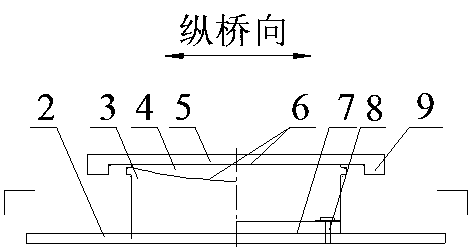

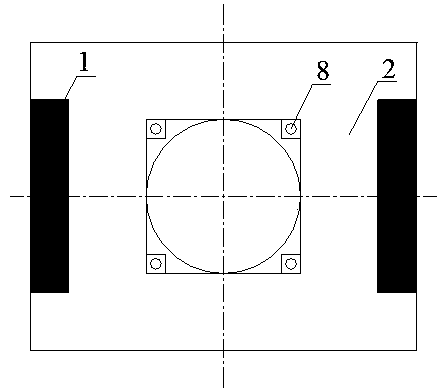

[0026] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0027] Embodiment The design parameters of the large-rotation-angle high-friction shock-absorbing and isolation bearing are shown in the table below.

[0028] Table 1 Design parameters of high-friction shock-absorbing and isolating bearings with large rotation angle

[0029] Support Design Parameters Large-angle high-friction shock-absorbing and isolation bearing Vertical bearing capacity N 4000kN Lateral horizontal bearing capacity under small earthquake action F 1 400kN corner θ 0.06rad Low coefficient of friction in normal use mu 1 0.02 Displacement requirements during normal use D 1 + / -0.1m High coefficient of friction under large earthquakes mu 2 0.08 Horizontal vibration isolation horizontal stiffness K 2 1000kN / m Horizontal seismic isolation displacement cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com