Elevator hoistway door system

A door system and elevator hall technology, applied in the field of elevators, can solve the problems of low space utilization of the well, complex linkage structure of wire ropes, inconvenient installation, etc., and achieve the effect of improving the utilization of the well, simple structure and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

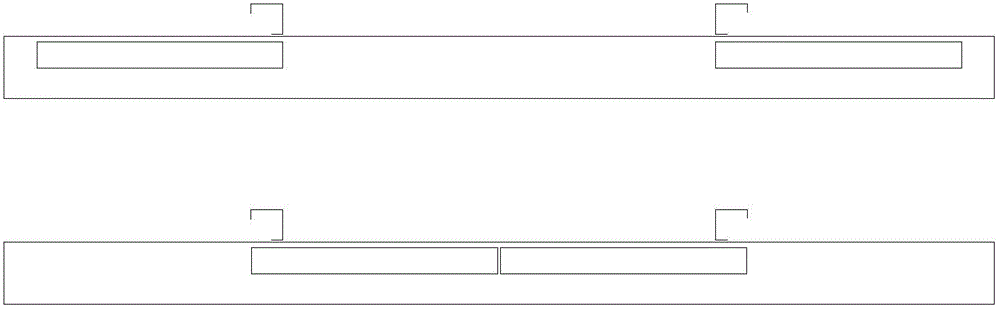

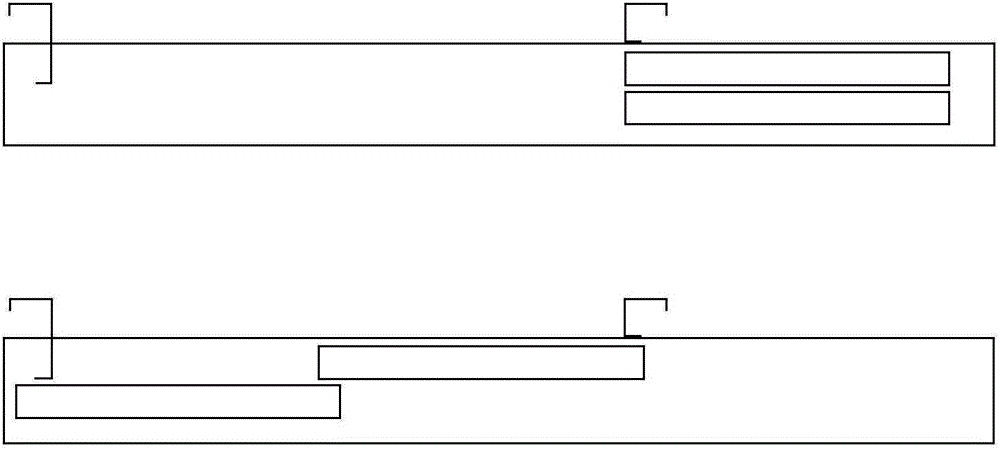

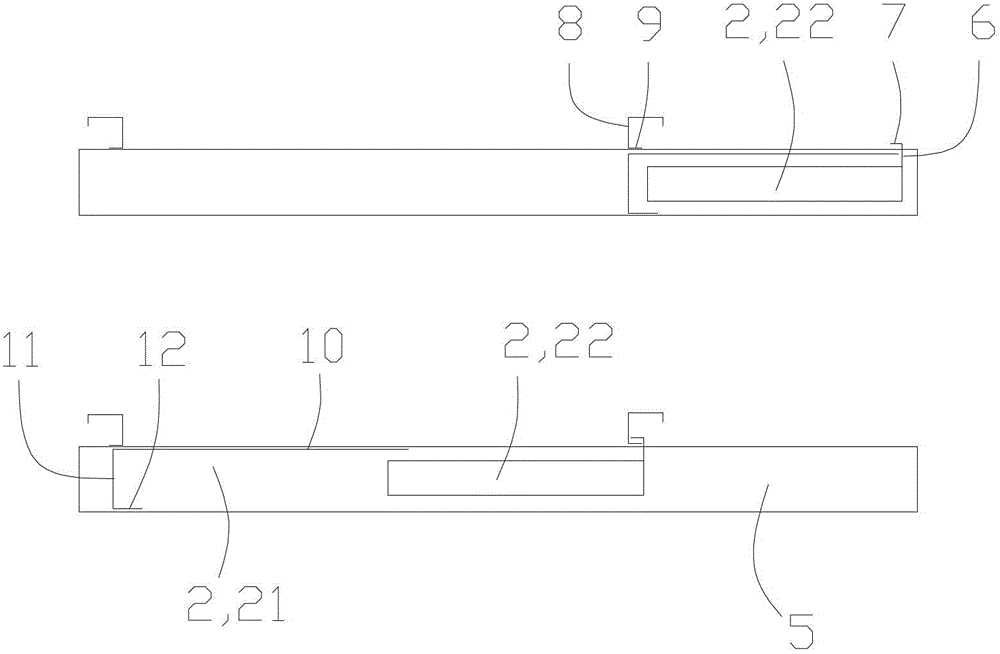

[0026] A kind of elevator hall door system in this embodiment, such as Figure 6 As shown, it includes an upper sill 6 with guide rails and two hall doors. The hall door of this embodiment is a side-opening form, and the two hall doors adopt an embedded structure. The two hall doors are the first hall door with a long opening and closing stroke and the second hall door with a short door opening and closing stroke. The first hall door is composed of a first door panel 21 and a first hanging plate 31 arranged on the top of the first door panel. The second hall door is composed of a first door panel 22 and a first hanging plate 32 arranged on the top of the first door panel, and two pulleys 4 are installed in parallel distribution at the upper edges of the first hanging plate and the second hanging plate. like Figure 8 As shown, the upper sill includes a body, which is bent along the length direction and has an L-shaped structure in cross-section. In this way, an upper flat pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com