Cantilevered floor slab rebar structure adopting steel bar truss formworks and bar reinforcing method

A steel truss and steel bar technology is applied in the field of concrete pouring formwork, which can solve the problems of long construction period, difficulty in supporting formwork and high cost, and achieve the effects of improving efficiency, reducing the workload of reinforcing steel bar binding, and shortening the construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

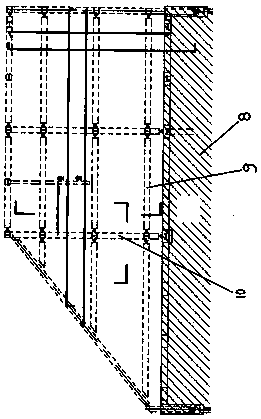

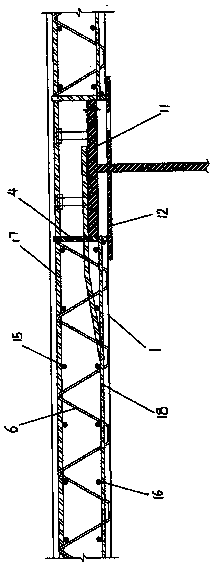

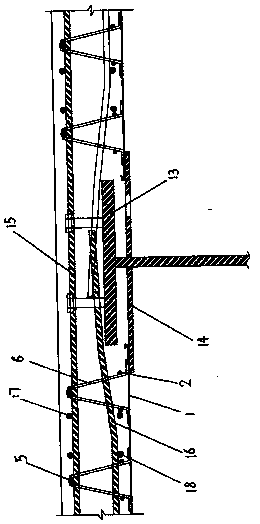

[0012] The present invention is described in detail below in conjunction with accompanying drawing:

[0013] A reinforced structure of cast-in-place cantilevered floor slabs using steel truss formwork, including a main building structure 8, and a steel beam suspension composed of steel beams 9 parallel to the direction of the main building and steel beams 10 perpendicular to the direction of the main building cantilevered on the outside of the main building structure 8 On the pick frame, the steel beam 9 parallel to the main building direction is provided with a steel beam panel 11 parallel to the main building direction, and the steel girder steel supporting plate 12 parallel to the main building direction is arranged on the I-steel vertical plate below the steel beam panel 11 parallel to the main building direction. The steel girder 10 perpendicular to the direction of the main building is provided with a steel beam panel 13 perpendicular to the direction of the main building...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com