Construction method for cast-in-situ bored pile

A technology of bored piles and construction methods, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of drill pipe offset and affect the efficiency of construction, and achieve clean construction site, fast construction speed and smooth construction. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

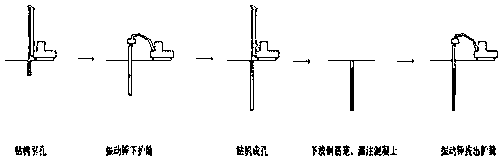

[0042] A construction method for bored piles, comprising the following steps:

[0043] Step 1. Drilling hole:

[0044] Treatment of the base surface of the drilling site: field leveling, removal of surface garbage and obstacles, and obstacles that cannot be drilled, excavated with excavators, backfilled with plain soil and compacted;

[0045] According to the requirements of pile location design drawings, measure and set the pile location and mark it well, draw a circle with a radius of 45cm with the pile location as the center, and check the pile location. The tip is aligned with the center of the pile position to open the pilot hole, the depth of the pilot hole is 7m, and the depth of the pilot hole is selected according to the situation of the grassroots on site. For the grassroots that is soft or easy to collapse, a deeper pilot hole depth is selected.

[0046] Pilot holes can overcome the influence of shallow obstacles. The engineering drilling rig can effectively overc...

Embodiment 2

[0072] A construction method for bored piles, comprising the following steps:

[0073] Step 1. Drilling hole:

[0074] Treatment of the base surface of the drilling site: field leveling, removal of surface garbage and obstacles, and obstacles that cannot be drilled, excavated with excavators, backfilled with plain soil and compacted;

[0075] According to the requirements of pile location design drawings, measure and set the pile location and mark it well, draw a circle with a radius of 45cm with the pile location as the center, and check the pile location. The tip is aligned with the center of the pile position to open a lead hole, and the depth of the lead hole is 6m.

[0076] Pilot holes can overcome the influence of shallow obstacles. The engineering drilling rig can effectively overcome the influence of obstacles, and the obstacles that cannot be drilled through should be dug out with an excavator to prevent damage to the curling of the casing;

[0077] The position of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com