Patents

Literature

76results about How to "Construction site clean and tidy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

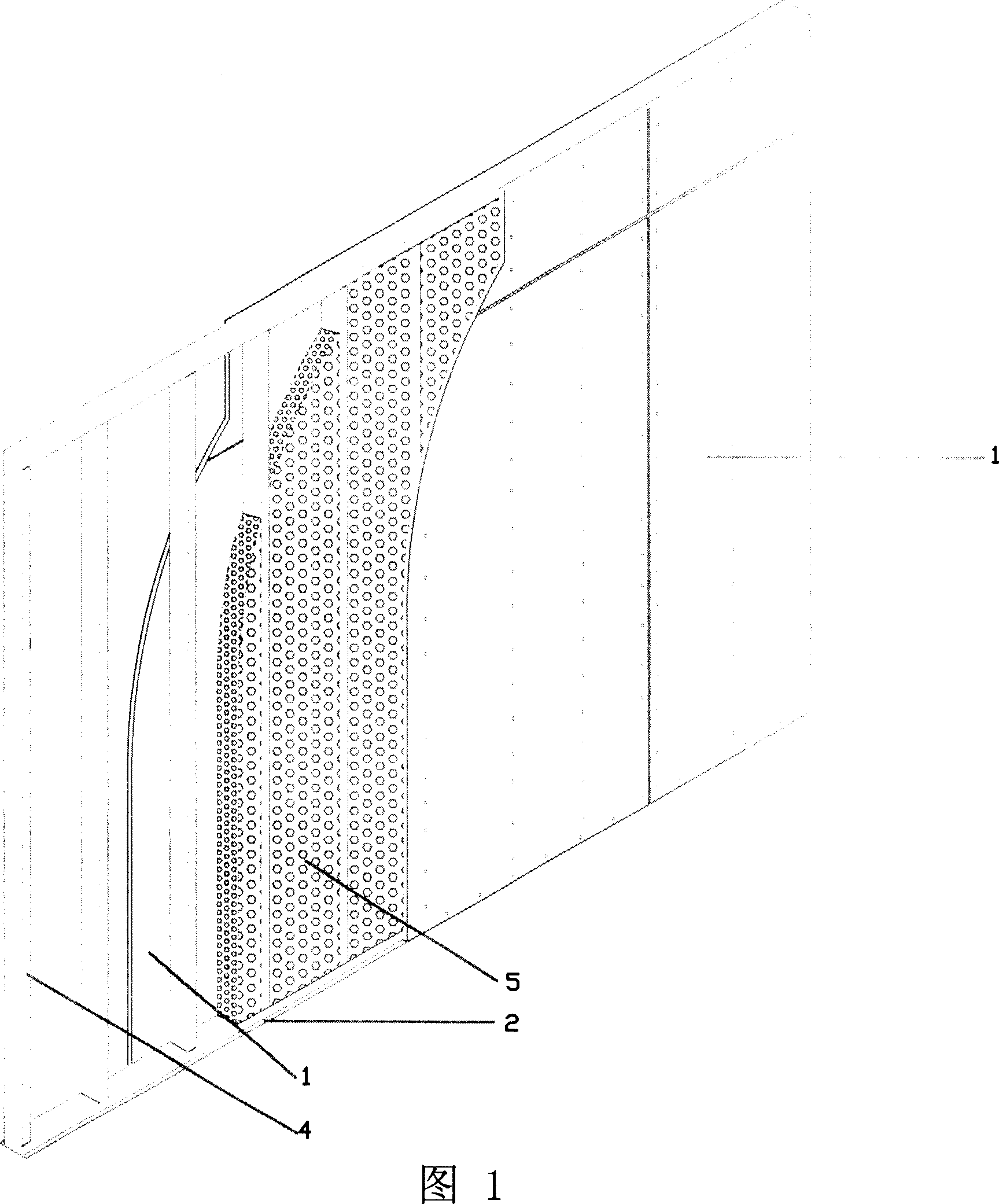

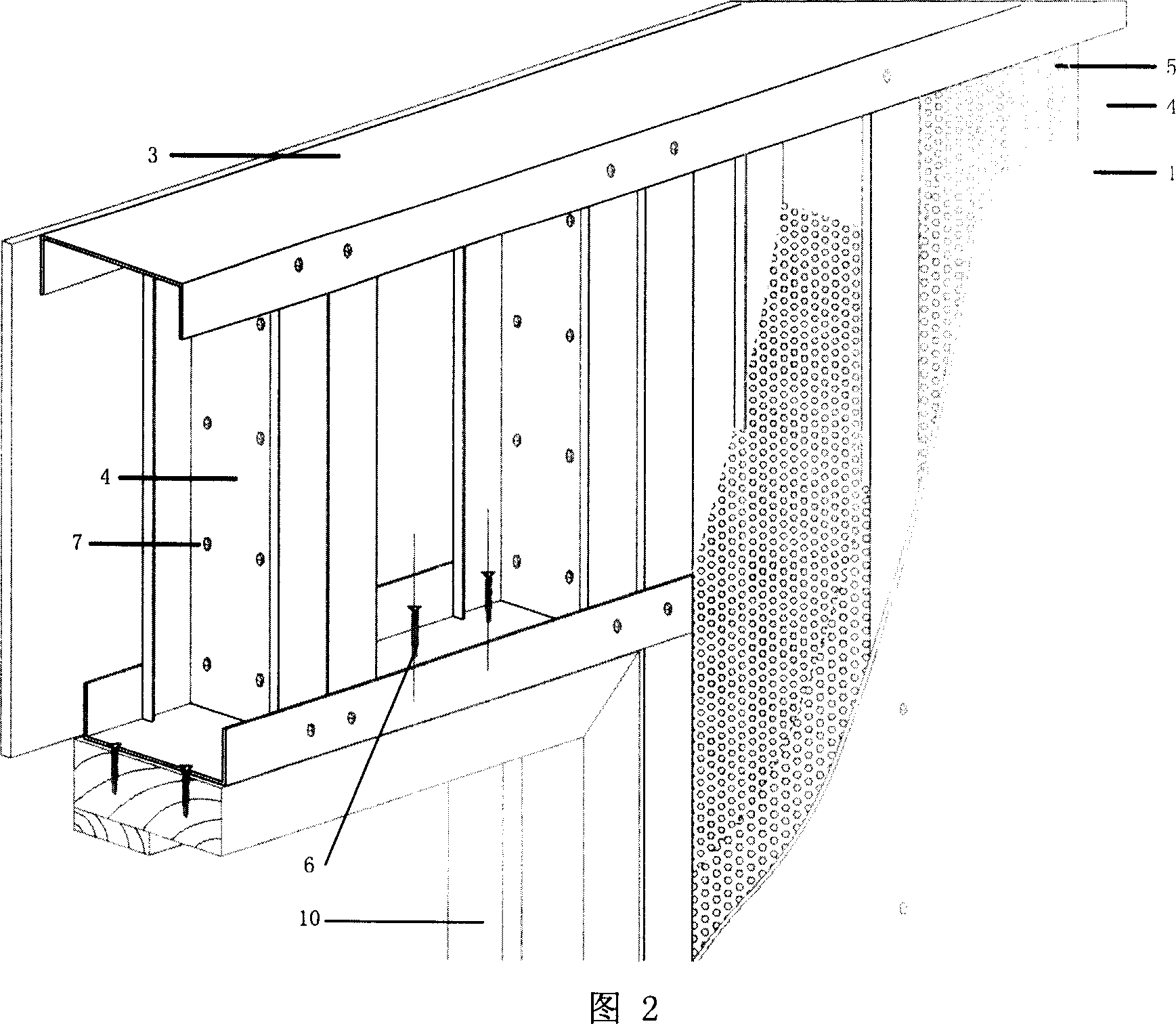

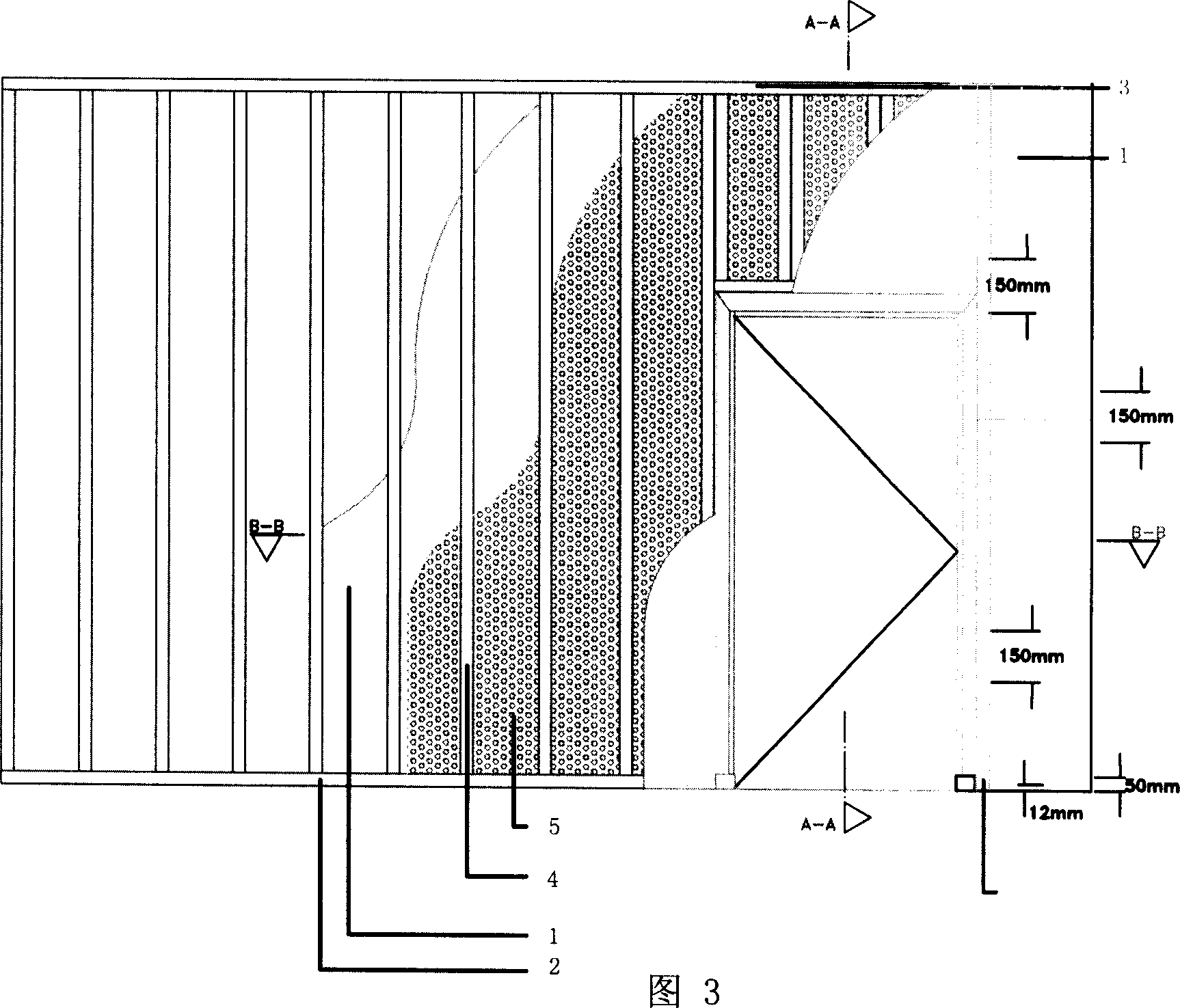

Fiver cement board grouting wall and construction method therefor

The invention discloses a lightweight nonbearing grouting wall and its construction method for inner walls of buildings, comprising a lightgage steel joist or C-shaped steel as a framework, two fiber cements covered on two sides, a hollow space within lightweight grouting materials by special equipment, and a skin layer decorated and dealt directly. The wall has a simple structure for easy construction and a light weight thereby reducing the cost of entire structure and improving the fireproof property up to 2.5 hours or more and the sound insulation property as 40dB, therefore the invention is an inner wall construction with higher utility and economic profit.

Owner:杨建平

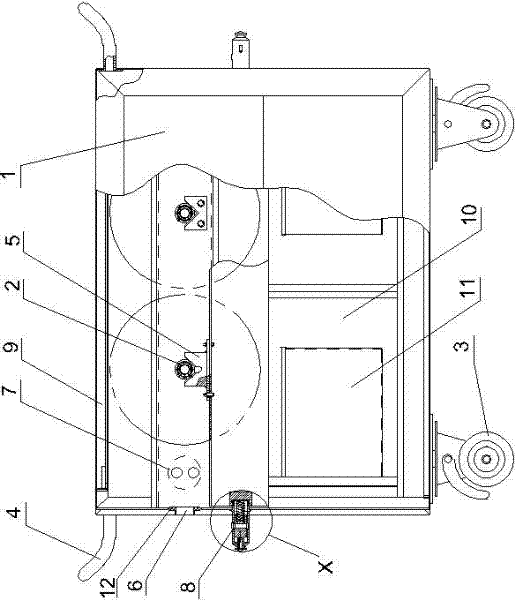

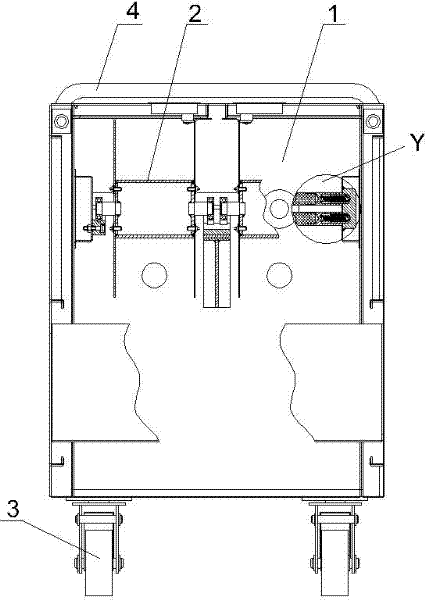

Outgoing line managing device for power construction

ActiveCN102398795ANo wasteEasy to replaceFilament handlingApparatus for removing/armouring cablesBobbinLocking mechanism

The invention provides an outgoing line managing device for power construction. The outgoing line managing device comprises a box body and bobbins, wherein braking wheels are arranged on four corners at the lower end of the box body; the front and back ends of the upper part of the box body are provided with push handles respectively; two rows and two lines of bobbins, i.e., four bobbins in total are arranged in the box body; bearings at the two ends of the bobbins are supported on a rapid assembling bearing base; the front and back wall plates of the box body are provided with outlet holes; a cable guiding mechanism is arranged between each outlet hole and each bobbin; the front and back wall plates of the box body are provided with line end locking mechanisms below the outlet holes; the upper end of the box body is provided with a top cover through a hinge; a tool room is formed below the bobbins in the box body; and the left and right wall plates of the box body are correspondingly provided with tool doors. Due to the adoption of the technical scheme of the invention, standardized and ordered management of the line outlet operation in a power construction site is realized, the line outgoing is convenient, labor is saved, the waste of cables is avoided, conductor cores on the bobbins are easier to replace, and the production efficiency is increased.

Owner:STATE GRID CHONGQING ELECTRIC POWER COMPANY SKILLTRAINING CENT +1

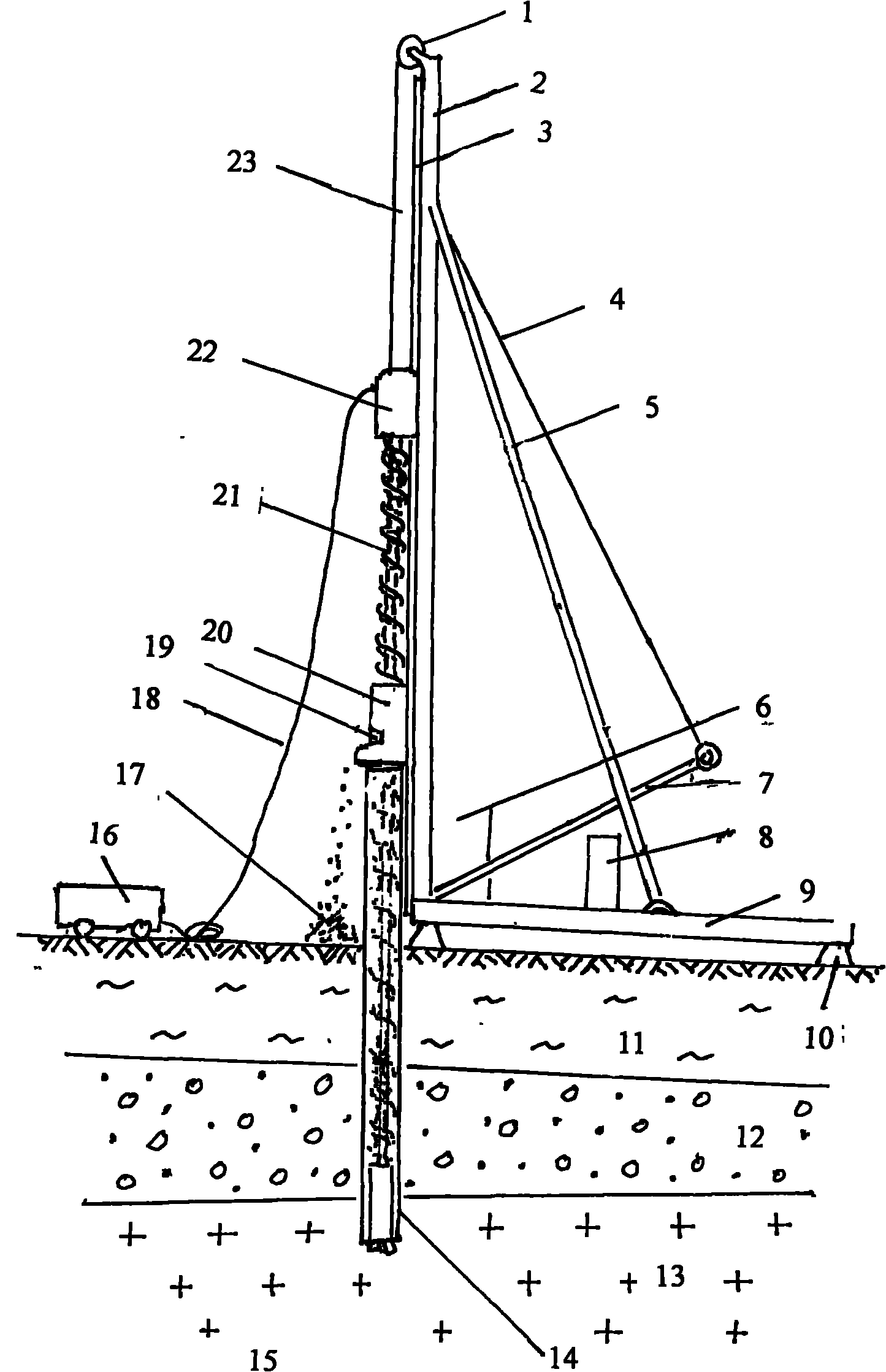

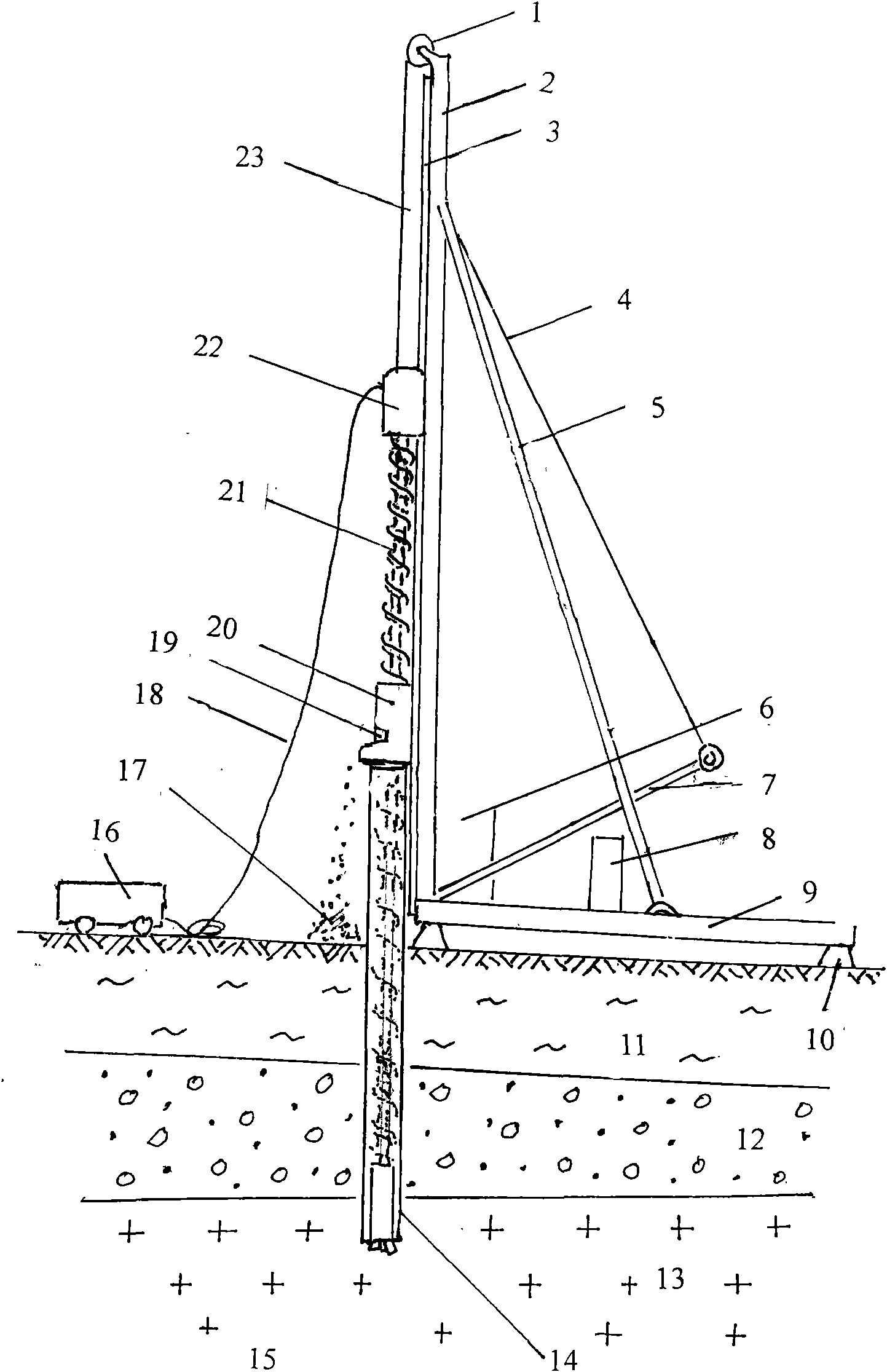

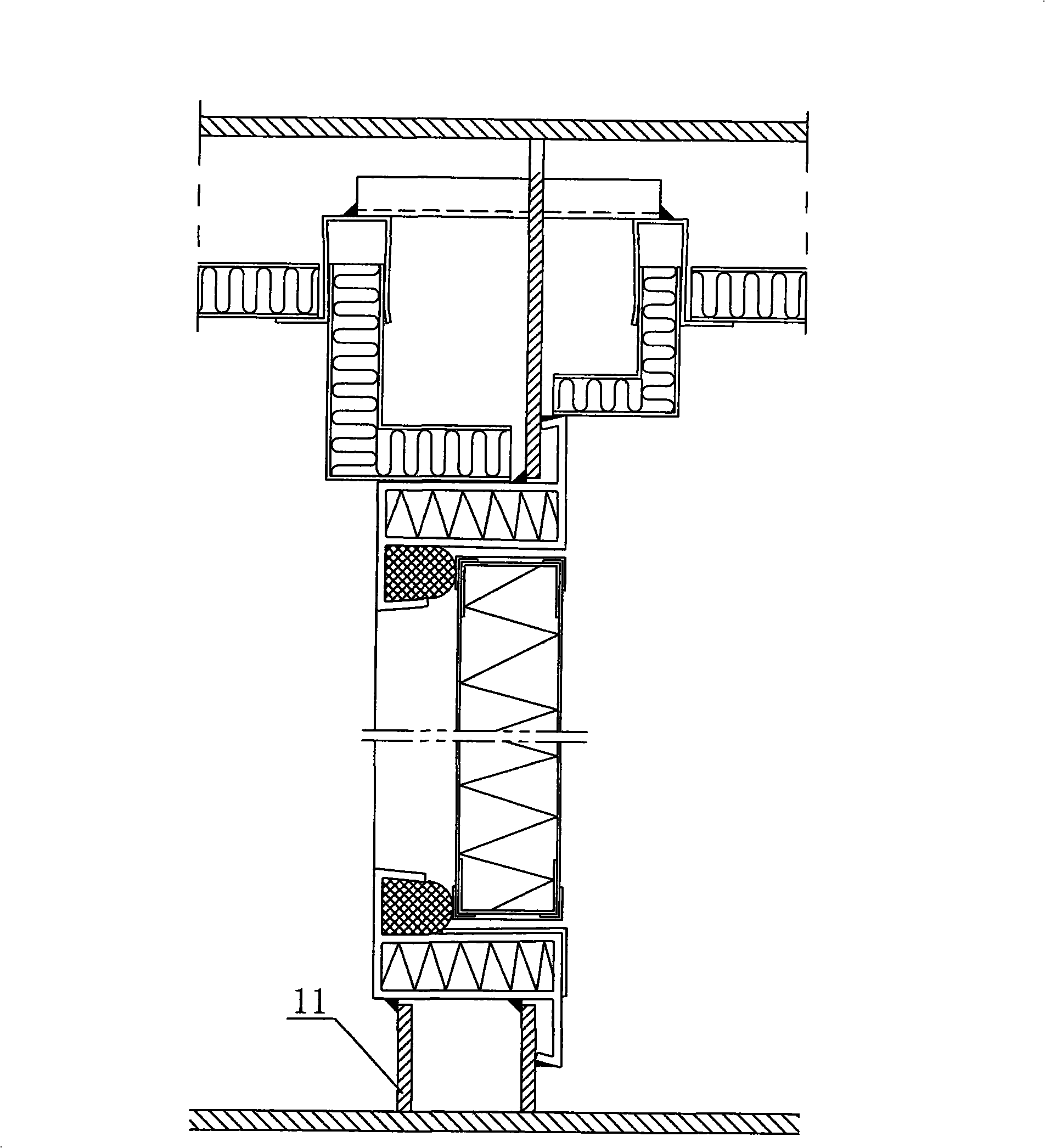

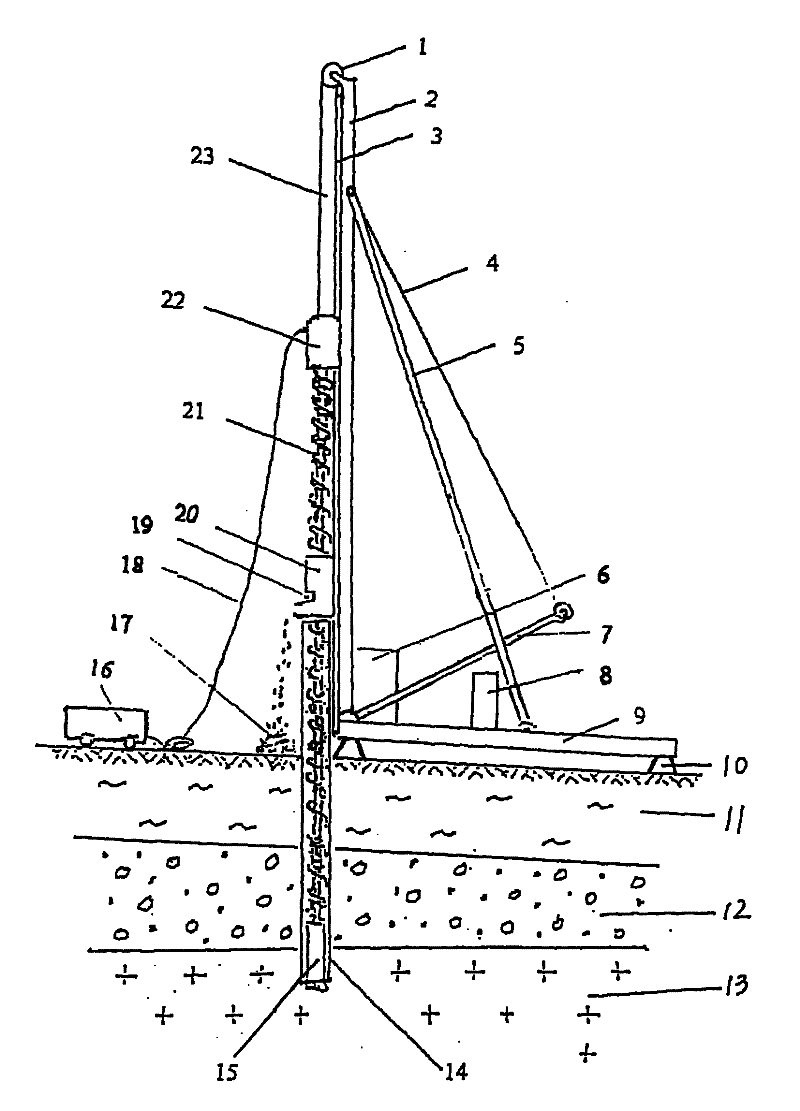

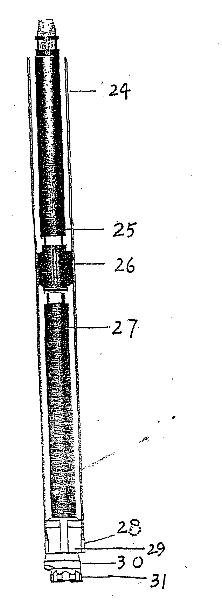

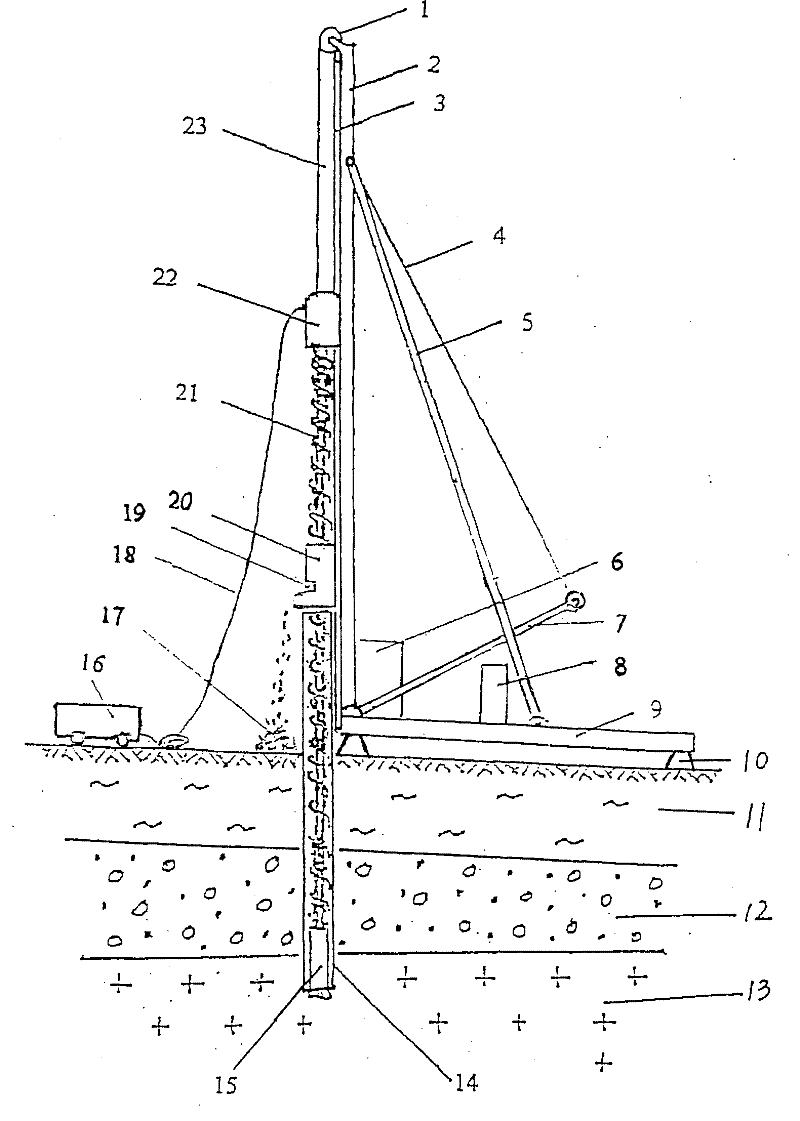

Dry type pneumatic rock drilling pile-driving machine and working method thereof

InactiveCN101831906ANo pollution in the processIncrease drilling speedBulkheads/pilesDrilling machines and methodsSlagHelical blade

The invention relates to a dry type pneumatic rock drilling pile-driving machine and a working method thereof. The pile-driving machine is characterized in that the pile-driving machine consists of a pile frame, an upper power head, a screw drill rod, a lower power head, a steel pile casing, a pneumatic down-the-hole hammer, a 30-60 m<3> air compressor and a high-pressure gas transmission pipe. The working method is characterized by comprising the steps of: firstly, installing equipment; secondly, crushing the rock by the pneumatic down-the-hole hammer, and discharging the crushed soil mass and rock ballast out of a pile hole from a slag outlet by using a helical blade; and thirdly, protecting the walls of a construction soil layer, a sand layer and a cobble and gravel layer by using the steel pile casing. Compared with the prior art, the invention has the advantages of high rock drilling speed, dry type and environment-protection construction, clean construction site, and no mud pollution in rock drilling and pile pouring construction.

Owner:温州长城基础工程有限公司

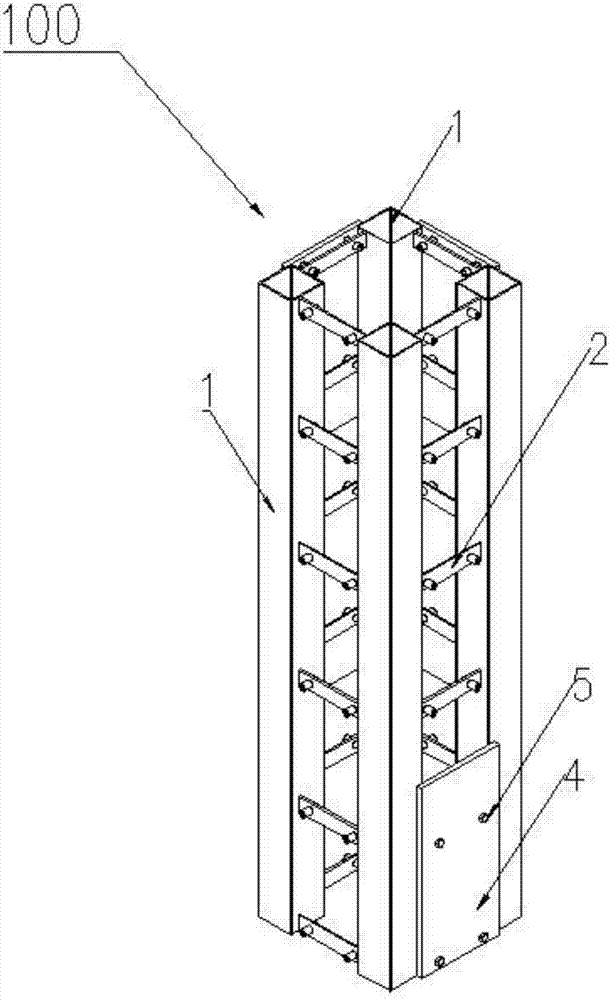

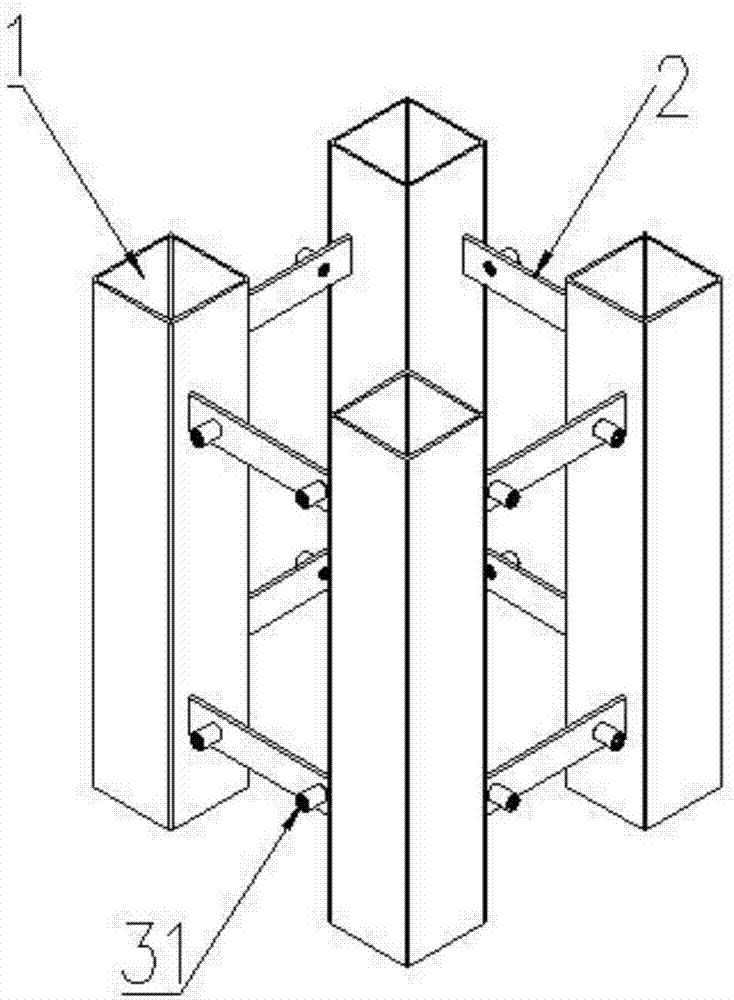

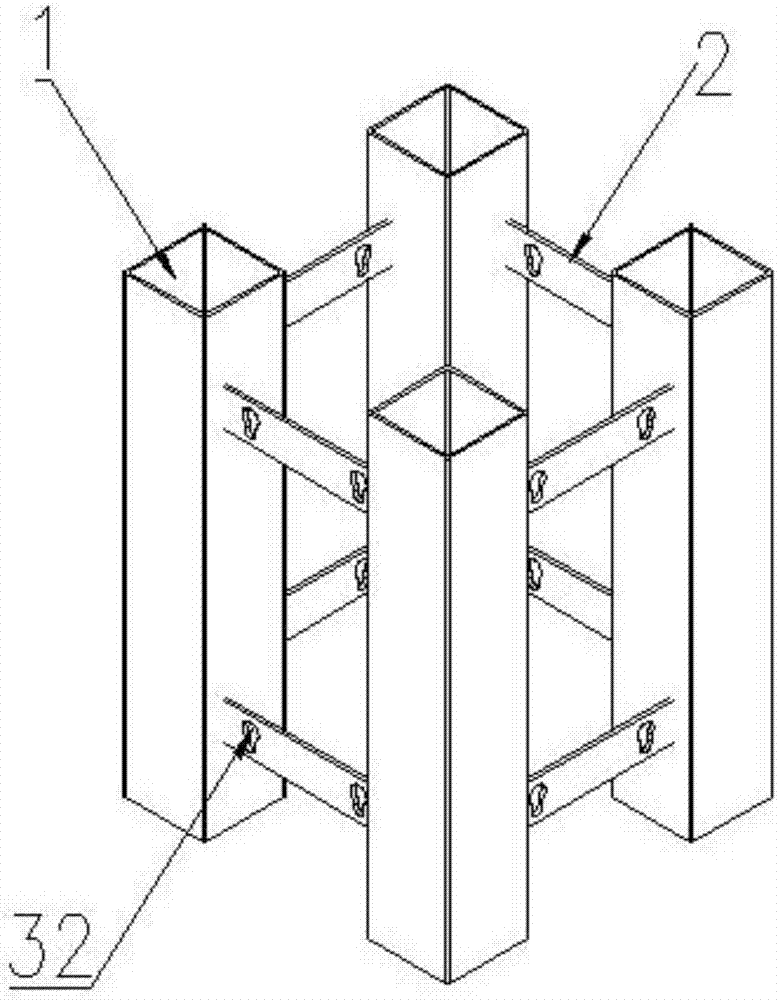

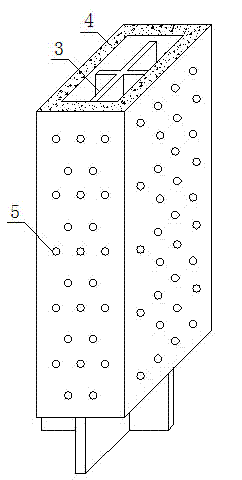

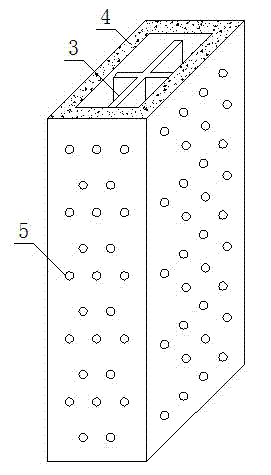

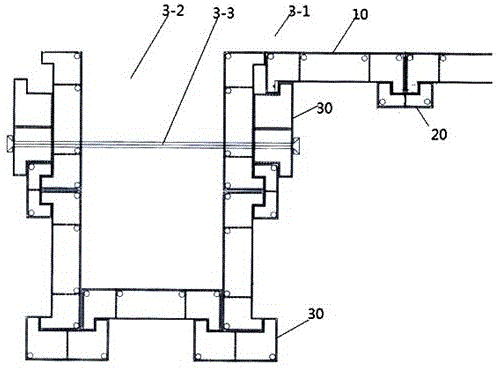

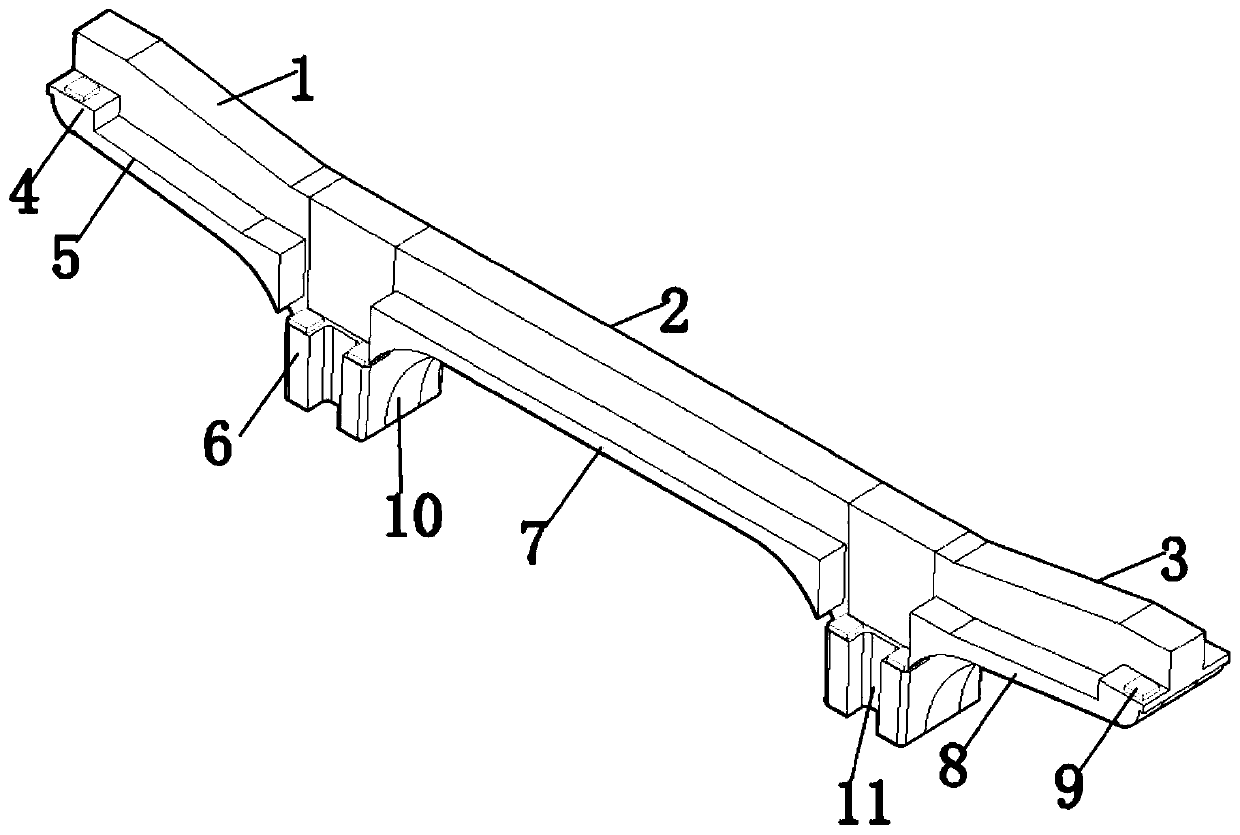

Steel pipe-batten plate combined building column and construction technology thereof

PendingCN107227822AReduce steel consumptionImprove economyStrutsBridge structural detailsReinforced concrete columnArchitectural engineering

The invention provides a steel pipe-batten plate combined building column and a construction technology thereof. The steel pipe-batten plate combined building column comprises a column skeleton and formworks detachably mounted outside the column skeleton, wherein the column skeleton comprises square steel pipes arranged at corners of the column skeleton and batten plates arranged between adjacent square steel pipes; the batten plates are arranged in the vertical directions of the square steel pipes according to certain intervals. The square steel pipes and the batten plates are combined to form the column skeleton, the steel pipe is arranged at each corner of the whole column skeleton, the formworks are arranged among the steel pipes, and then concrete is cast in place to form the steel-concrete combined column; the steel pipes are arranged at the corners of the column skeleton, while only batten plates are arranged at the middle positions of the column skeleton, so that when a beam is connected with an independent column, steel bars can freely extend into the column body and thus a fighting phenomenon of steel bars in the conventional reinforced concrete column is avoided; after the concrete is poured, a whole is formed, so that the rigidity in a node area is better.

Owner:SHANGHAI OPEN STEEL JOIST

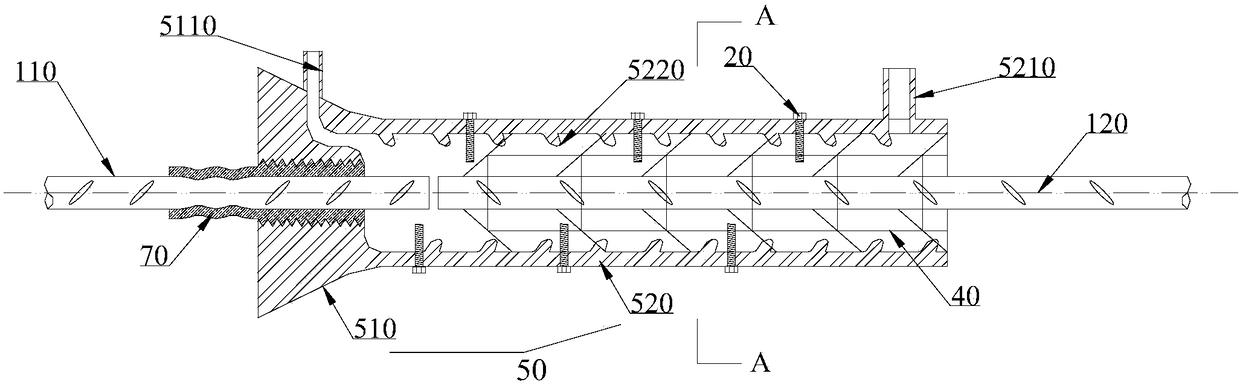

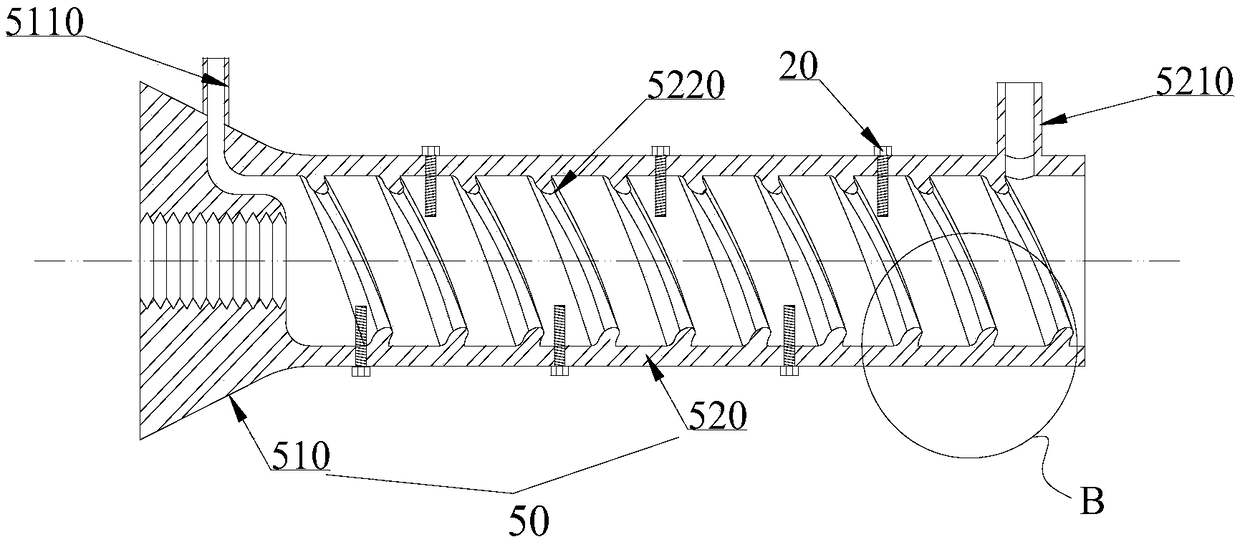

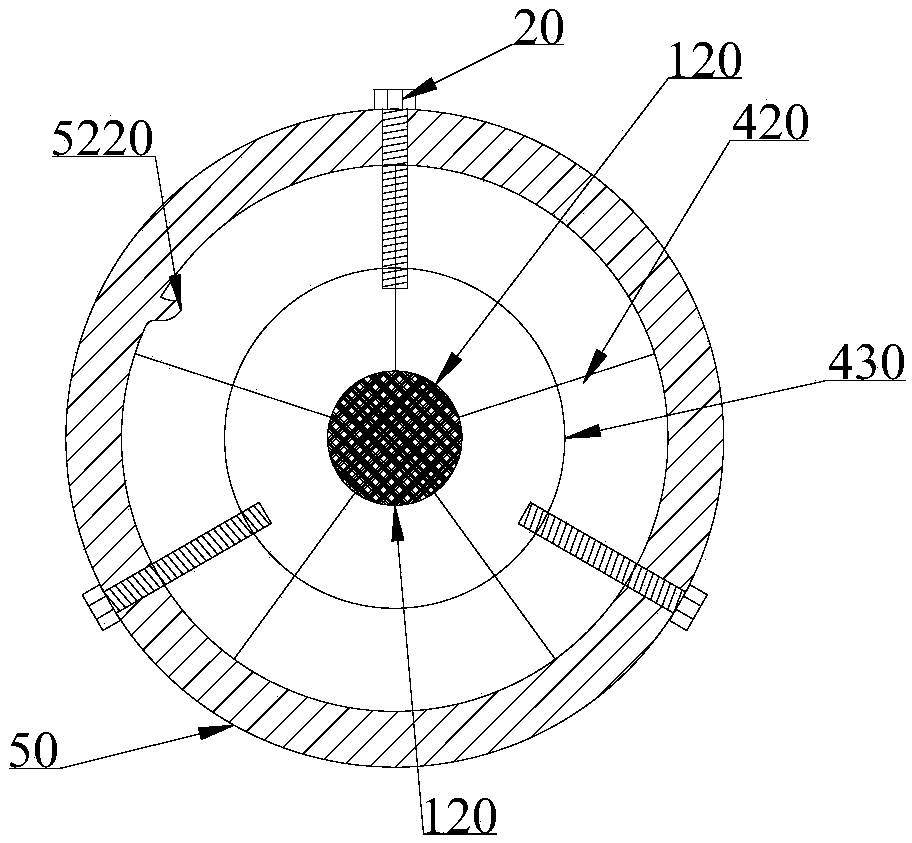

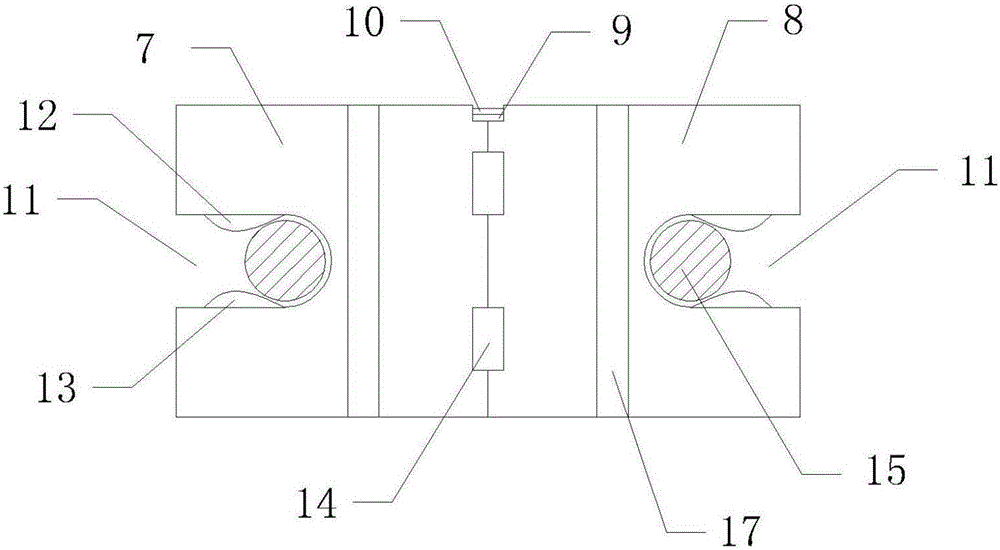

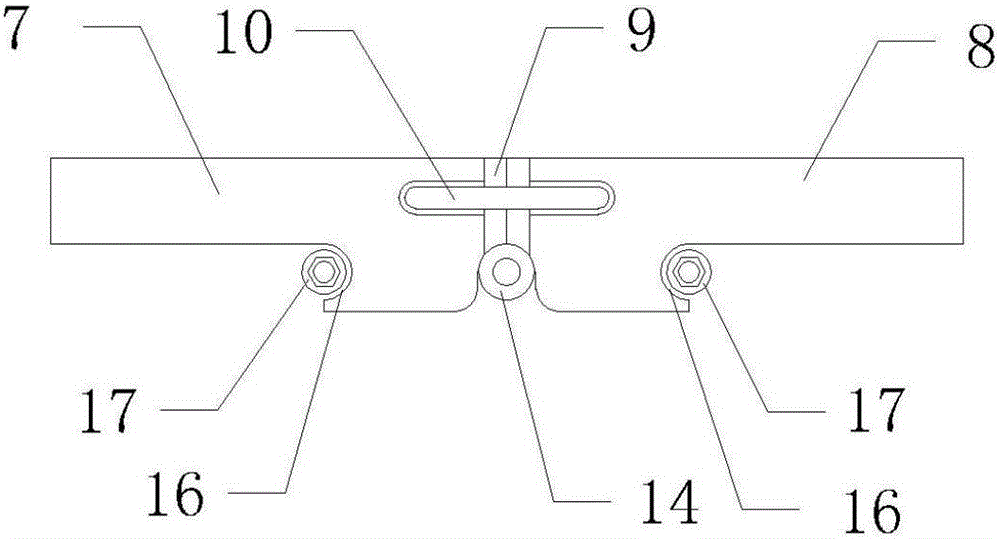

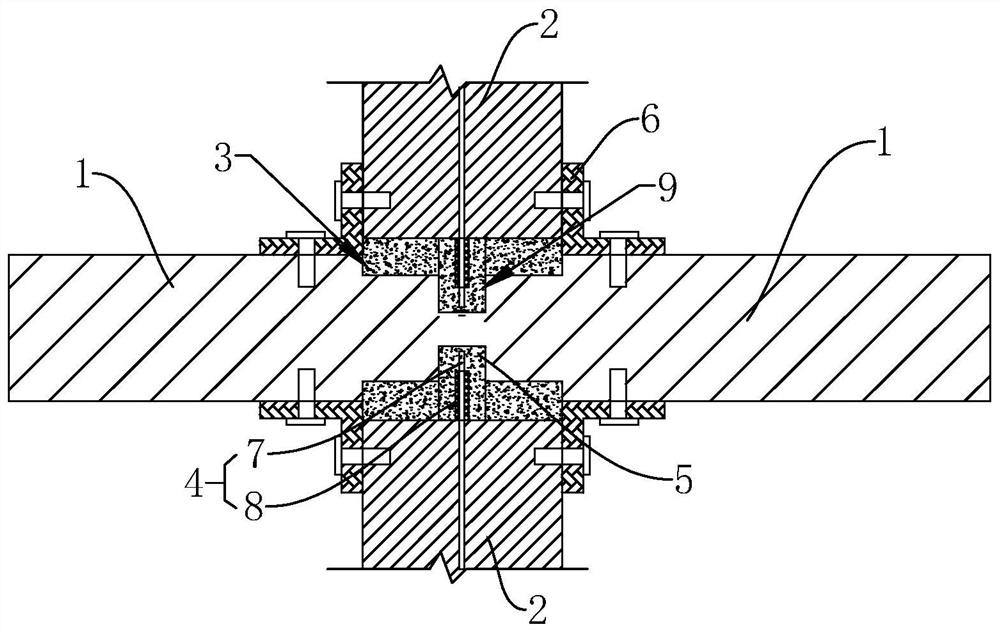

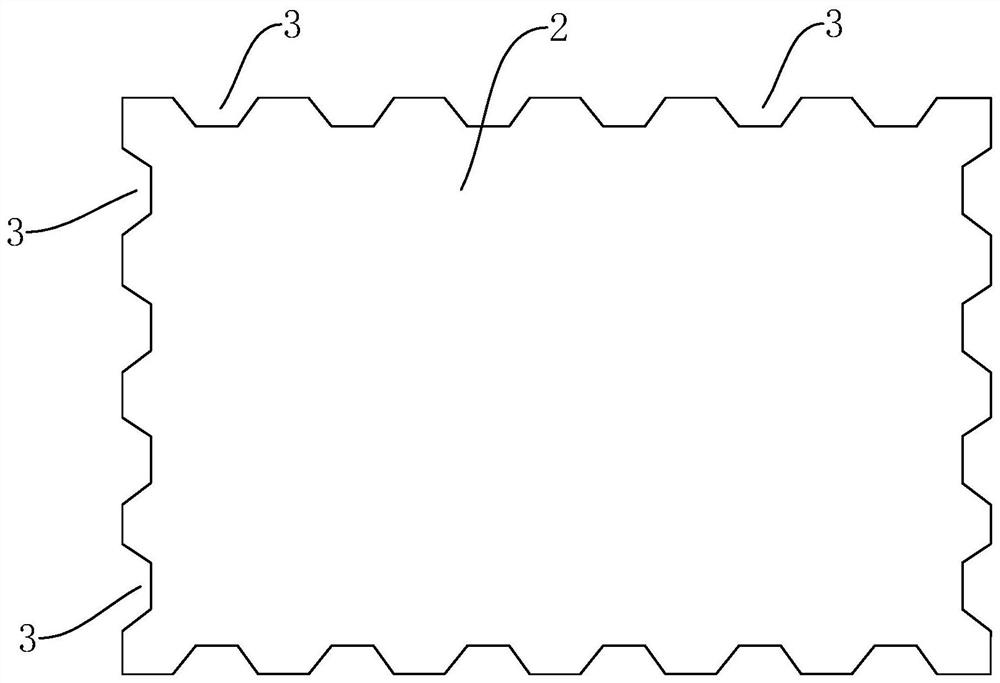

Assembly structure of assembly-type concrete member

The invention provides an assembly structure of an assembly-type concrete member. A sleeve comprises a non-grouting connection section and a grouting connection section. A steel skeleton comprises inner barbs and outer barbs, the diameter of a passage defined by the multiple inner barbs is smaller than that of a second to-be-connected steel bar, and the outline diameter defined by the outer barbsis larger than the diameter of an inner cavity of the grouting connection section. An alignment device comprises lower supports and upper supports which are both electromagnets, the same magnetic poles of the upper supports and the lower supports are opposite, and the upper supports and the lower supports are connected in the same circuit in series. All parts of the grouting sleeve are machined and manufactured correspondingly and then assembled, mass production is achieved, and the quality of all the parts is easy to control; connection of the grouting sleeve and a steel pipe transition section is operated by machines in a factory, the threaded connection quality is easy to control, the self-locking type steel skeleton is adopted, thus the purpose of pulling preventing is achieved, and shock resistance is improved; through the principle of magnetic levitation, fast and accurate centering of the steel bars of upper and lower concrete member bodies is achieved, so that the time and labor are saved; and through the series-connection circuit, the same magnetic forces of a plurality of supporting mechanisms can be achieved, and stable supporting is guaranteed.

Owner:HEFEI CONSTR ENG GRP

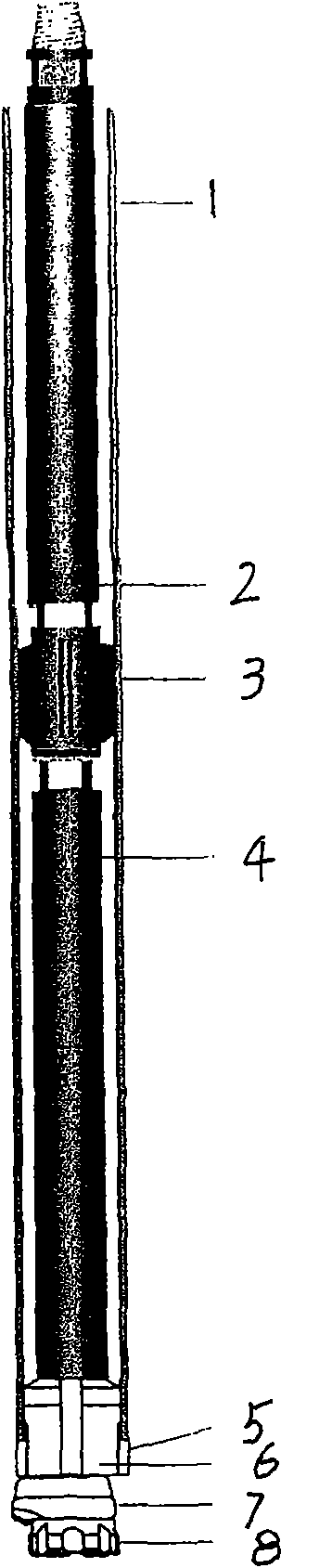

Energy dissipation, shock absorption and anti-liquefaction rigid and flexible slide-resistant pile and construction method

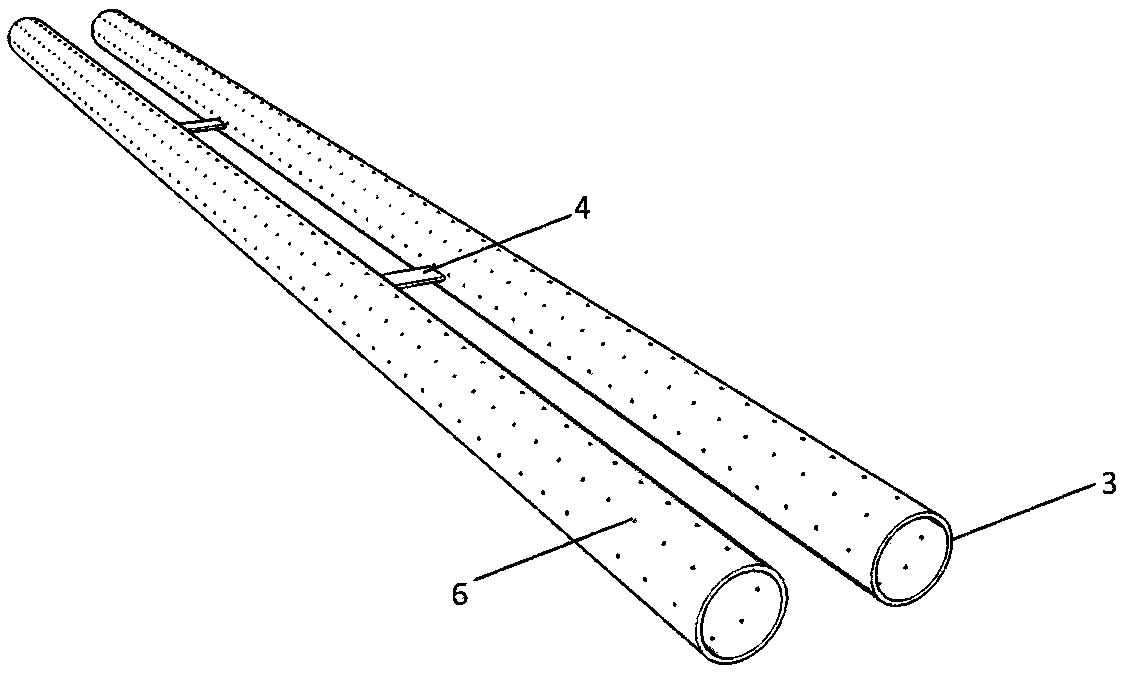

ActiveCN104762980AImprove ductilityImprove the bending capacityProtective foundationExcavationsRebarReinforced concrete

An energy dissipation, shock absorption and anti-liquefaction rigid and flexible slide-resistant pile and a construction method belong to the slope supporting technology field. The energy dissipation, shock absorption and anti-liquefaction rigid and flexible slide-resistant pile is composed of a hollow tubular pile, broken stones, anchor cables and air cushions, wherein the hollow tubular pile comprises first-type hollow tubular piles and second-type hollow tubular piles, which are all prefabricated with reinforcement concrete; crossed plates are embedded in an external barrel; water permeating holes are formed in the external barrel in a plum blossom shape; anchor cables penetrate through the hollow tubular piles and the air cushions are covered at the outer side; one first-type hollow tubular pile and many second-type hollow tubular piles are arranged in sequence in the pile holes of a slope body; the tops and the bottoms of the hollow tubular piles are embedded with one another; the hollow tubular pile is filled with the broken stones and a cover plate is arranged on the top; the anchor cables are anchored on the bottom plate and the cover plate through an anchorage device and the air cushions are full of gas. The slide-resistant pile is prefabricated, assembled and formed to be a rigid and flexible body, has high load-bearing capacity, plays a role in well dissipating energy under earthquake condition, has good drainage capacity and prevents soil around the pile from being liquefied; the construction method is simple and quick and the engineering cost is low.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

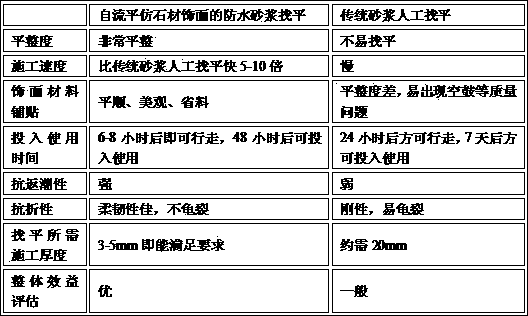

Self-leveling waterproof mortar of imitated stone facing and construction process of waterproof mortar

InactiveCN103936370AFast constructionRapid deployment for high construction speedFlooringCelluloseFiber

The invention discloses a self-leveling waterproof mortar of an imitated stone facing and a construction process of the waterproof mortar. The self-leveling cement mortar is composed of the following components in parts by weight: 250-300 parts of cement, 50-80 parts of ground calcium carbonate, 900-1000 parts of natural color sand, 2-8 parts of cellulose ether, 3-8 parts of wood fibers, 1-3 parts of PP (Poly Propene) fibers, 18-25 parts of latex powder and 2-8 parts of special natural rock slices for really stone paint; a water-to-material ratio is 4.2L-4.5l / 25kg. The construction process of the waterproof mortar comprises the steps of base surface treatment, interface treatment, material stirring and material construction. The self-leveling waterproof mortar is a dry-blending type powdery material composed of a plurality of active ingredients, and can be mixed with water in field to be use. The self-leveling waterproof mortar is slightly spread by using a scraper knife and then a high-level base surface can be obtained. The self-leveling waterproof mortar is hardened quickly, and after 4-8 hours, people can walk on the hardened mortar or subsequent work can be carried out on the hardened mortar; the self-leveling waterproof mortar is quick, simple and convenient in construction and can be applied to industrial factory buildings, workshops, commercial stores and the like.

Owner:南通苏宝建筑节能科技有限公司

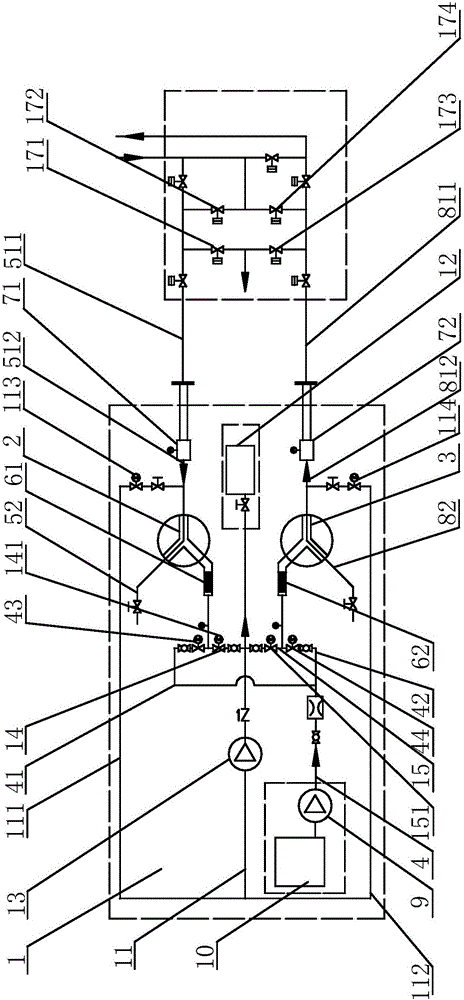

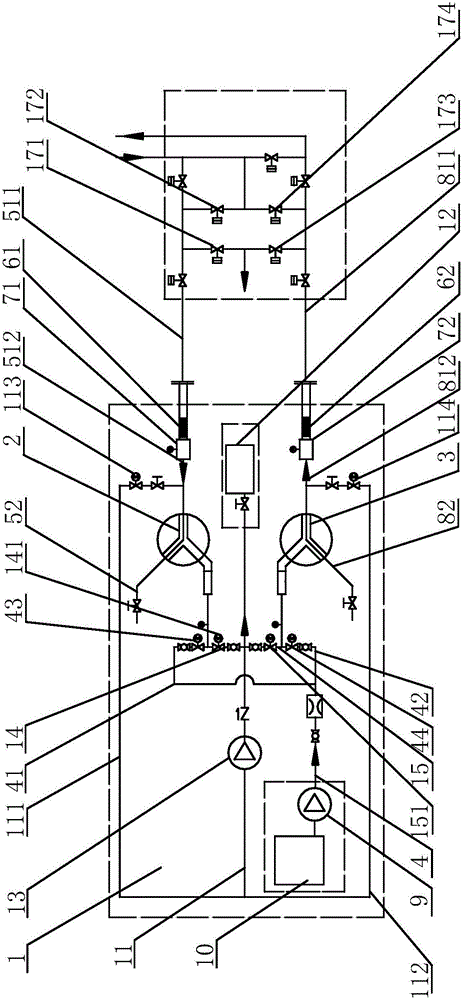

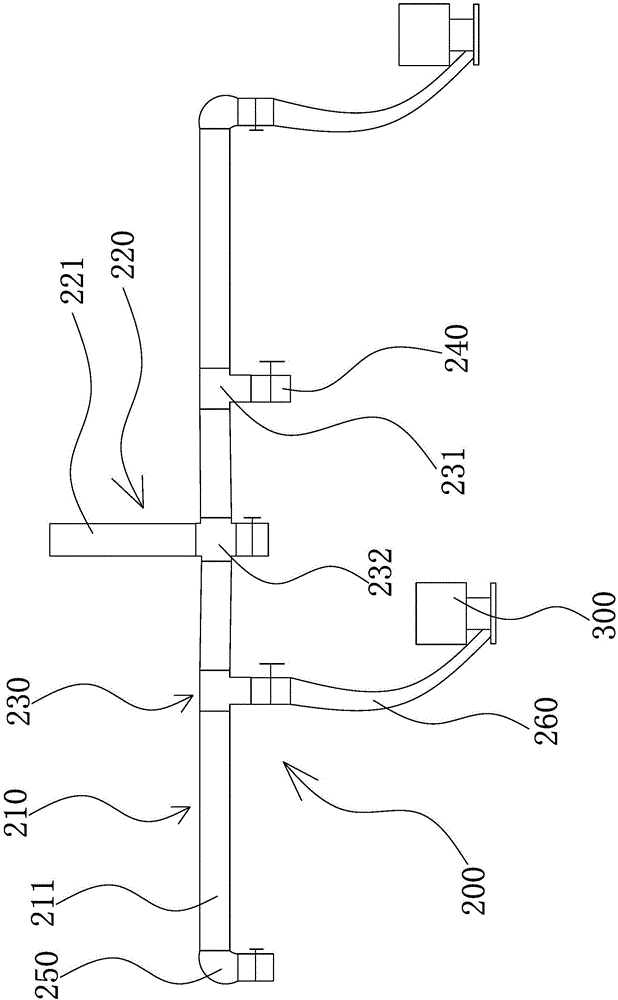

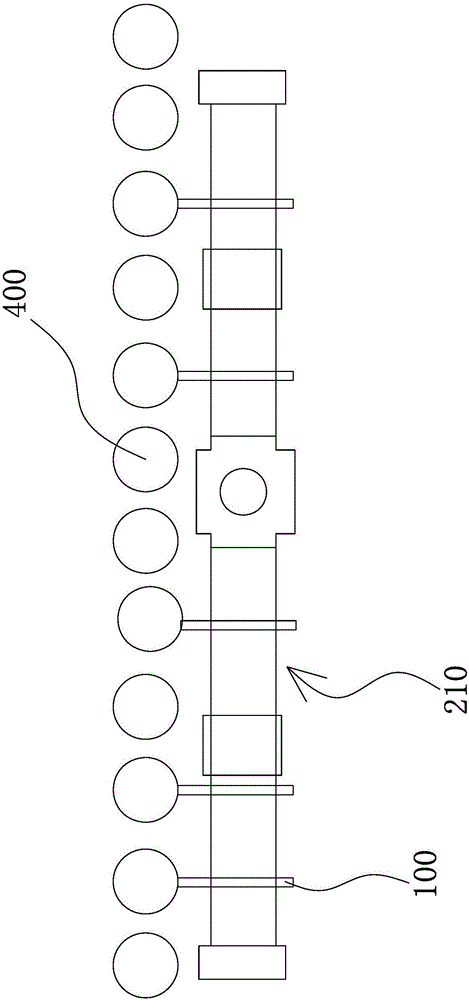

Cleaning type muddy water pipe extending device based on three-way valve

ActiveCN105782565AAvoid rankingMeet the requirements of repeated usePlug valvesPipe laying and repairEngineeringShield tunneling

The invention relates to a cleaning type muddy water pipe extending device based on a three-way valve. The cleaning type muddy water pipe extending device comprises a pipe connector trolley, the three-way reversing valve is arranged on the pipe connector trolley, a joint of the three-way reversing valve is communicated with a water supply pipe, a first muddy water pipe segment of a shield tunneling machine and a second muddy water pipe segment of the shield tunneling machine; the first muddy water pipe segment comprises a muddy water pipe fixing pipe segment and a muddy water pipe walking pipe segment which walks along with the pipe connector trolley, and the muddy water pipe fixing pipe segment and the muddy water pipe walking pipe segment are connected; the muddy water pipe walking pipe segment is connected with the joint of the three-way reversing valve, and a cleaning moving plug is arranged in a pipe cavity of the water supply pipe; under the water pressure effect, the cleaning moving plug enters the muddy water pipe fixing pipe segment through the three-way reversing valve; and a plug passing indicator which is used for reminding whether the cleaning moving plug passes through and enters the muddy water pipe fixing pipe segment or not is arranged on the first muddy water pipe segment. According to the device, the phenomenon that during pipe connecting of the shield tunneling machine, muddy water in a muddy water pipe is directly drained to the construction site can be avoided, the influence of muddy water on construction inside a tunnel is reduced, the clean and environment-friendly use effect is achieved, and the device is simple in structure, and pipe-connecting use is convenient.

Owner:HEFEI GENERAL MACHINERY RES INST

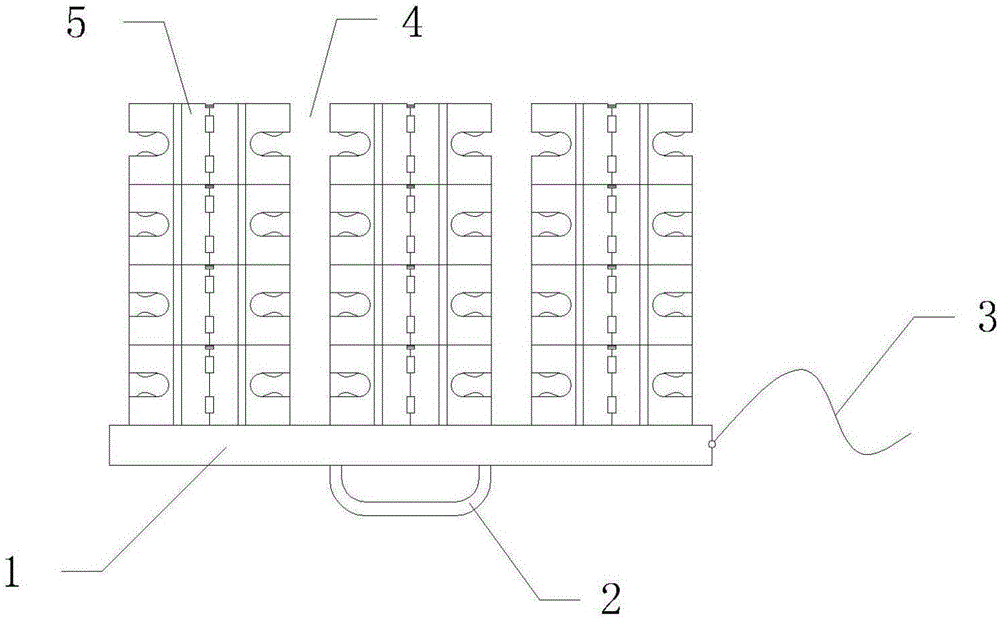

Fabricated building construction method based on 3D printing

InactiveCN107246150AImprove accuracyMeet needsBuilding material handlingArchitectural engineeringPre embedding

The invention discloses a fabricated building construction method based on 3D printing. By using the fabricated building construction method based on 3D printing, the building quality is high; the industrialized production of fabricated buildings renders building components more standardized, all components can be processed into integral wall boards, beams, columns, building floors and the like according to construction demands, and water pipes, wires, windows and the like can be pre-embedded inside a structural building, so that the workload of on-site construction operation is reduced, the construction sites are much tidier, pollution of noise and dust and generation of construction waste are decreased, energy consumption and emission of carbon dioxide are extremely low, the comfort degree of living is high, and the development of environment-friendly buildings is effectively facilitated.

Owner:浙江之江工程项目管理有限公司 +1

Method for carrying out cast-in-situ bored pile construction by means of travel revolution borer

InactiveCN101586336AConvenient and accurate positioningIncrease drilling speedBulkheads/pilesTerrainSlurry

The invention relates to a method for carrying out cast-in-situ bored pile construction by means of a travel revolution borer. The prior cast-in-situ bored pile normal / reverse circulation borer needs to be adjusted continuously in all directions during cast-in-situ bored pile construction; therefore, the stable boring speed completely depends on the construction experience of a driver; moreover, stable boring often takes longer time or is difficult to be adjusted in place under the condition of complex terrain; meanwhile, the construction method has difficulties in meeting the requirements of large pile diameter and long pile body, the positioning deviation is large and the pile position is inaccurate caused by difficult stable boring positioning. The method radically solves the problems and comprises the following steps: burying a protective barrel; preparing high-quality slurry; carrying out boring by the travel revolution borer; filling concrete; and finally, filling the prepared spare slurry in a hole bored by the borer. The method is used to solve the problem that the prior construction method is difficult to realize stable boring positioning.

Owner:LONGJIAN ROAD & BRIDGE

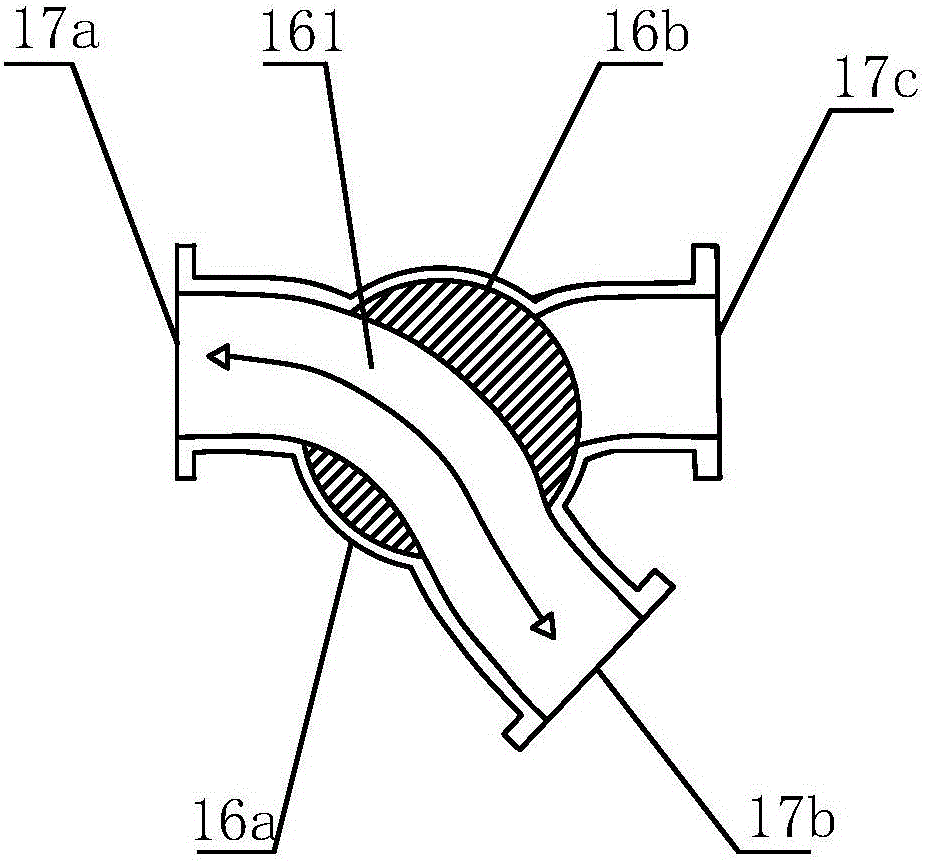

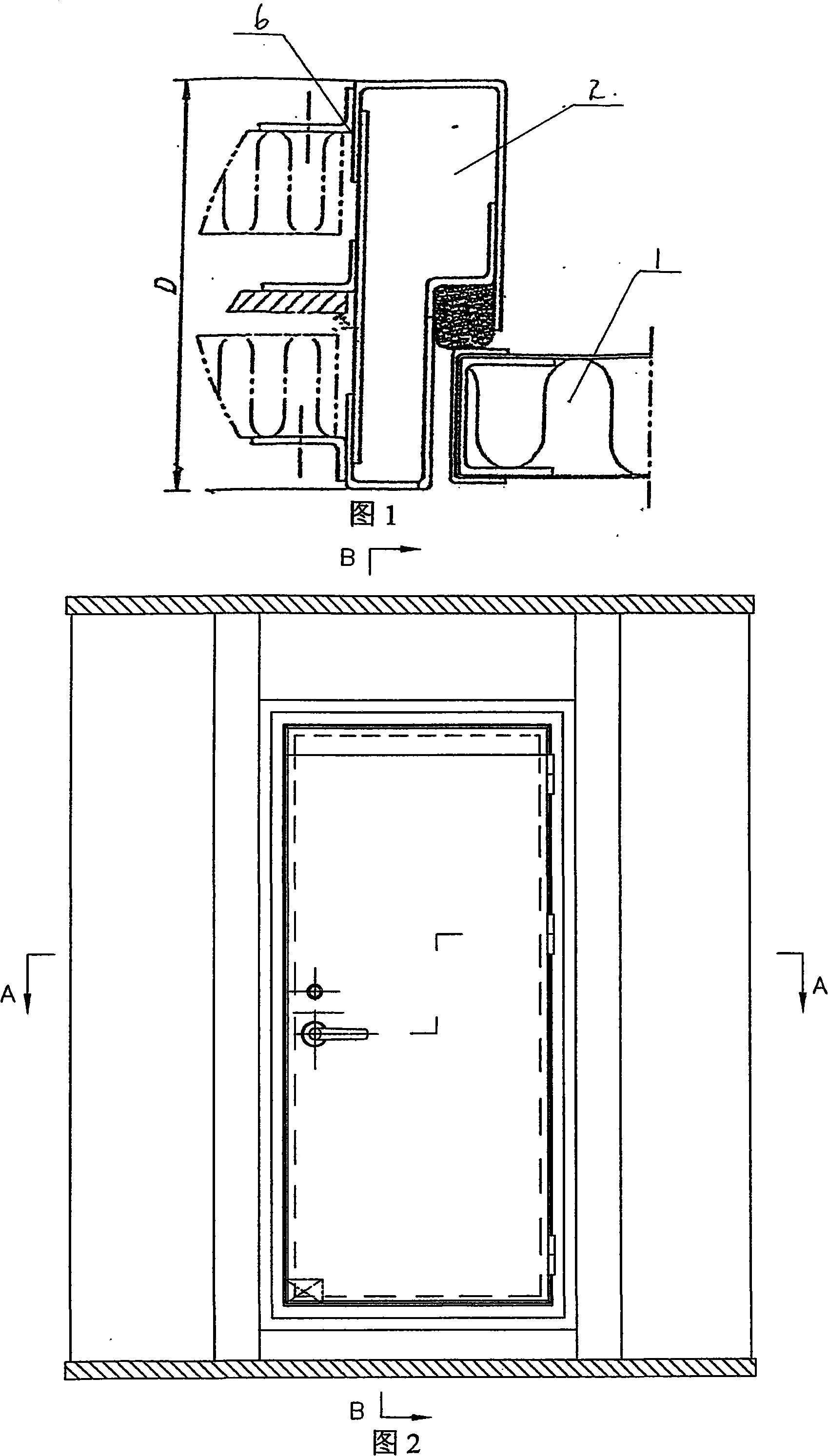

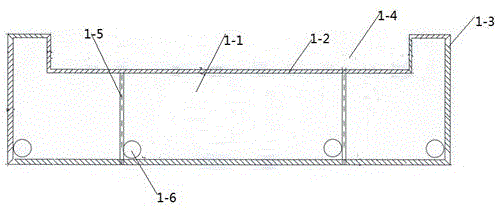

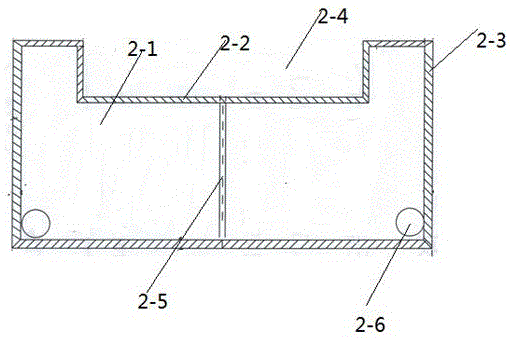

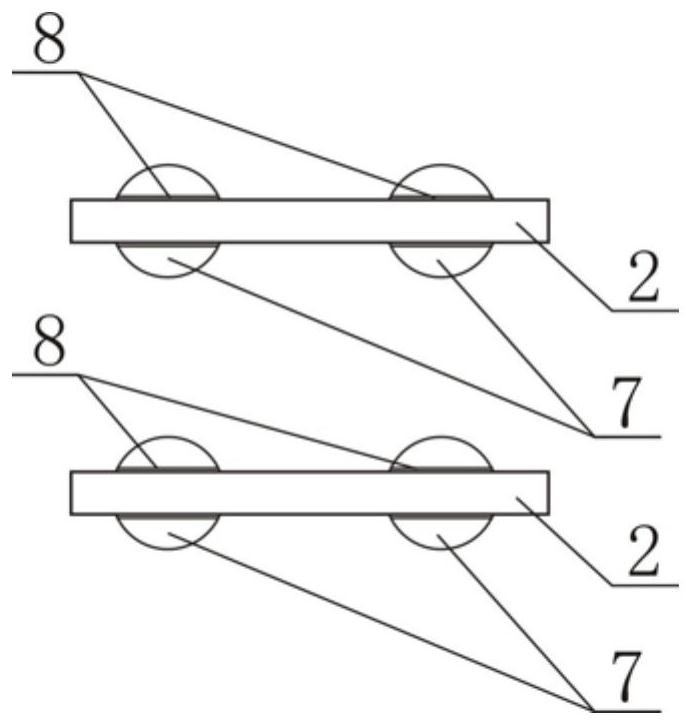

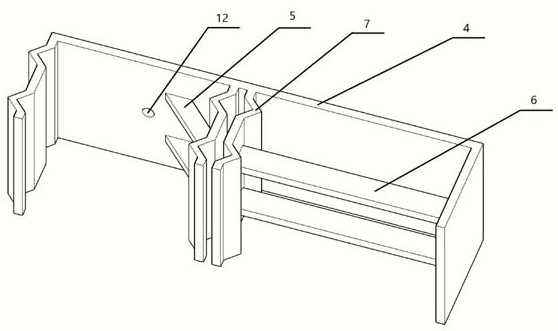

Novel jointing construction between door or frame and wall panel of cabin

ActiveCN101332860ASmall footprintShort preparation timeHull interior subdivisionHull bulkheadsEngineeringJamb

The invention relates to a novel connection structure of a door, a frame and a bulkhead plate which is mainly used for the decoration, fireproof and living areas separation of various ships. The connection structure includes a door leaf (2), a bulkhead plate (10) and a doorframe (1). The connection structure is characterized in that the bulkhead plate (10) includes a surrounding wall (8), an indoor side decoration rotation plate (9) and an outdoor side decoration rotation plate (7); the transverse section of the indoor side decoration rotation plate (9) is a 'reversed L'-shaped structure and is arranged in the inner side of the surrounding wall (8); the transverse section of the outdoor side decoration rotation plate (7) is an 'L'-shaped structure and is arranged in the outer side of the surrounding wall (8); the doorframe (1) is manufactured into a standard size; the transverse section of the doorframe (1) is similar to a zigzag structure and consists of a middle 'I' frame (1.1), an outdoor frame (1.2) and an indoor frame (1.3); one side of the door leaf (2) is hinged with the middle 'I' frame(1.1) of the doorframe (1) by a gemel (5). The novel connection structure of a door, a frame and a bulkhead plate meets the wood thickness t2 by adjusting the thickness t1 of the indoor side decoration rotation plate and the thickness of the outdoor side decoration rotation plate, thereby realizing the size standardization of the thickness of the doorframe.

Owner:JIANGSU HAILU TECH

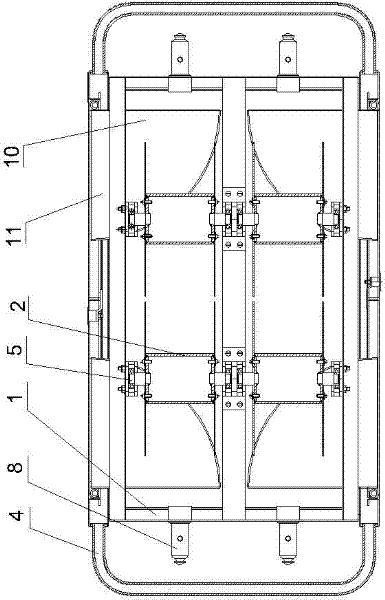

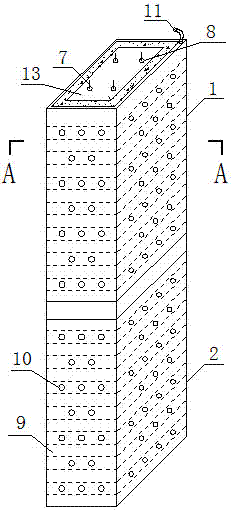

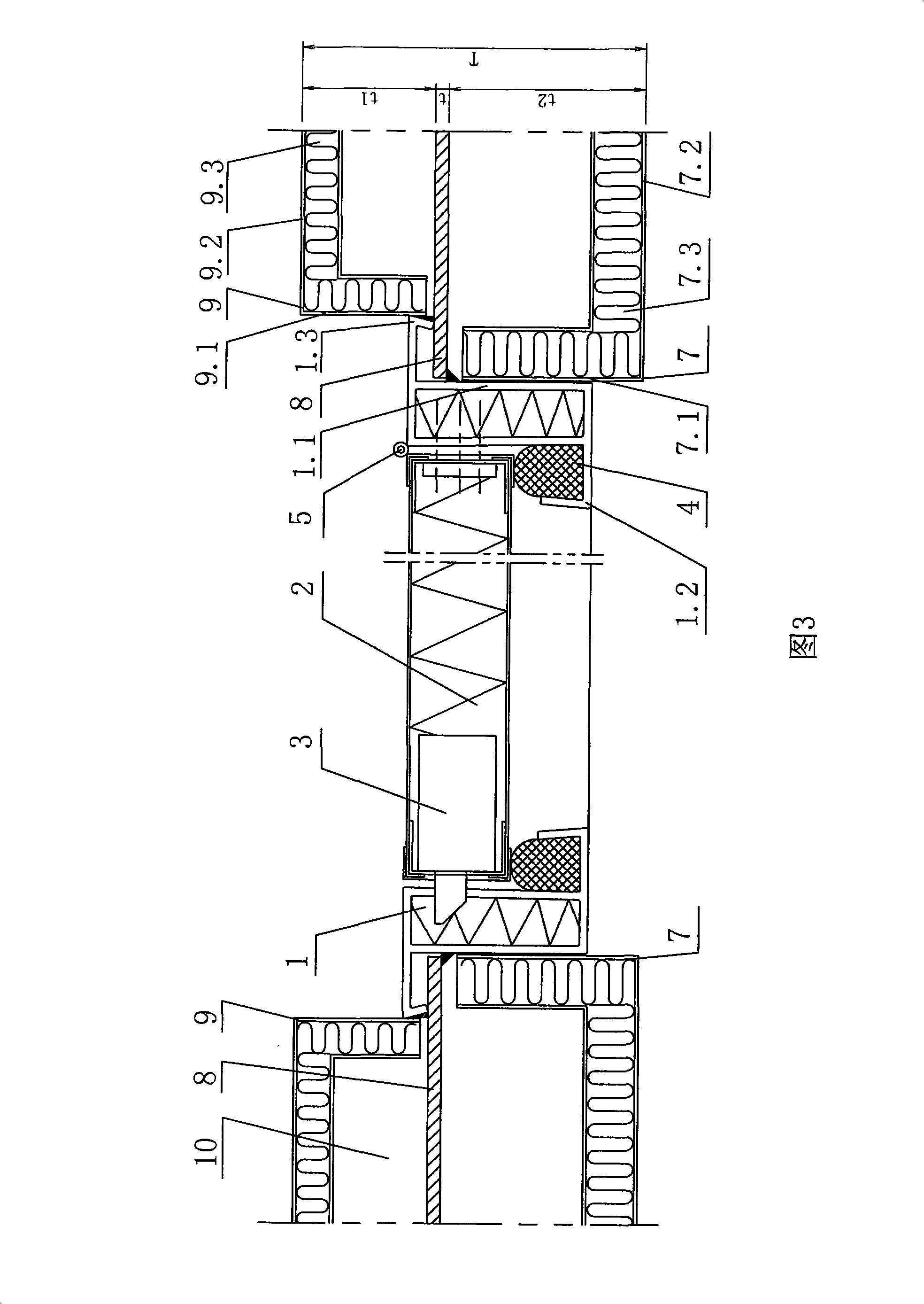

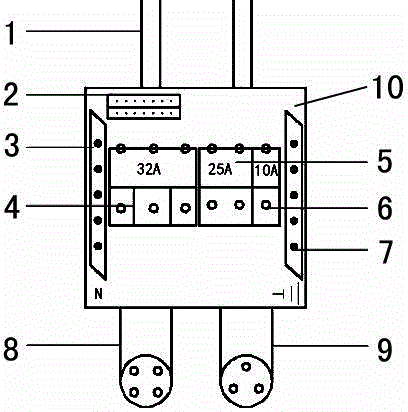

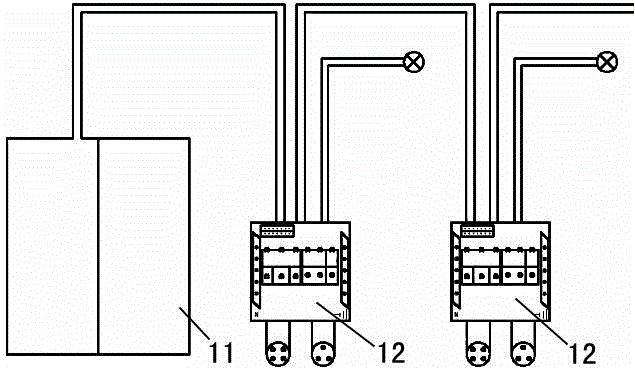

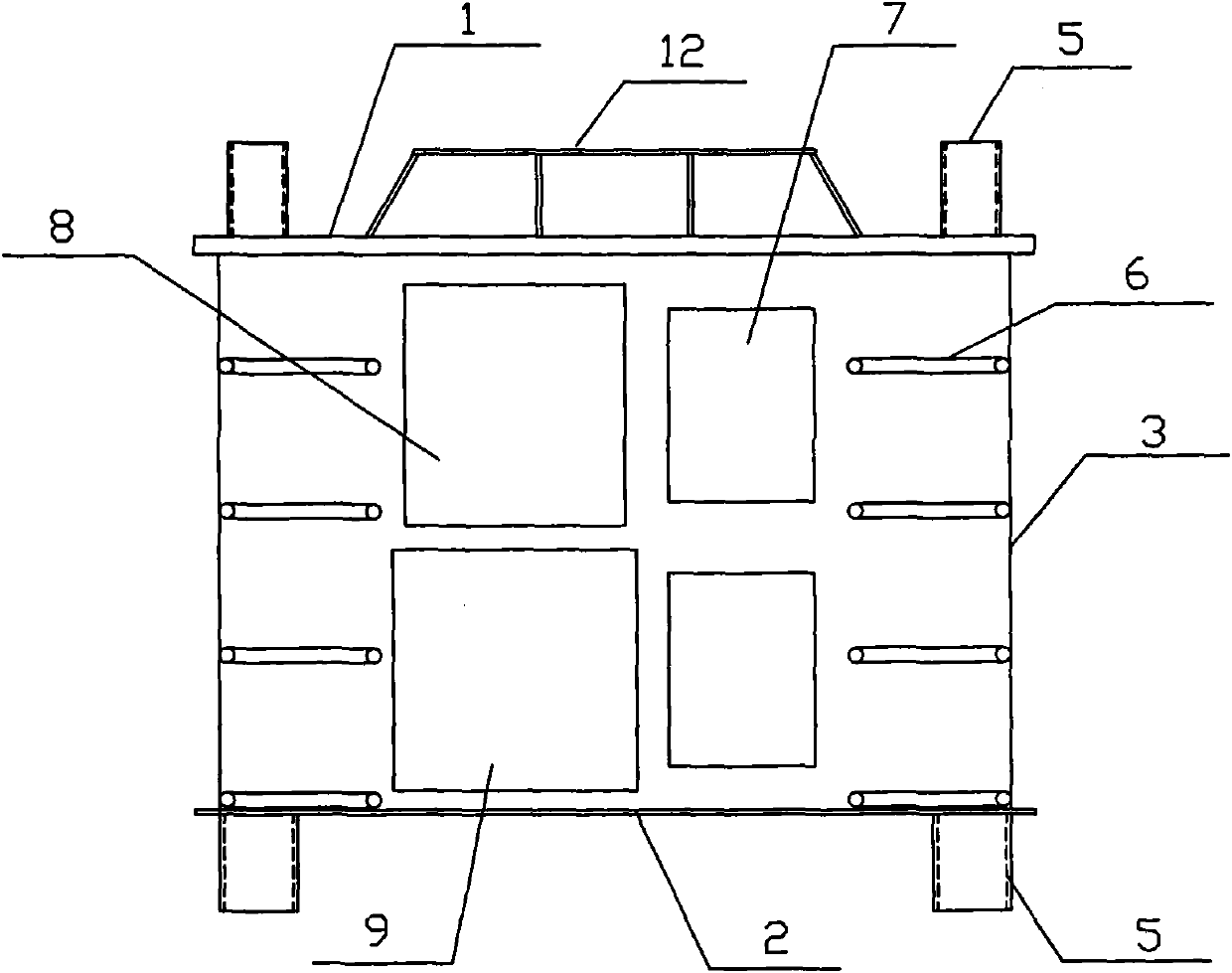

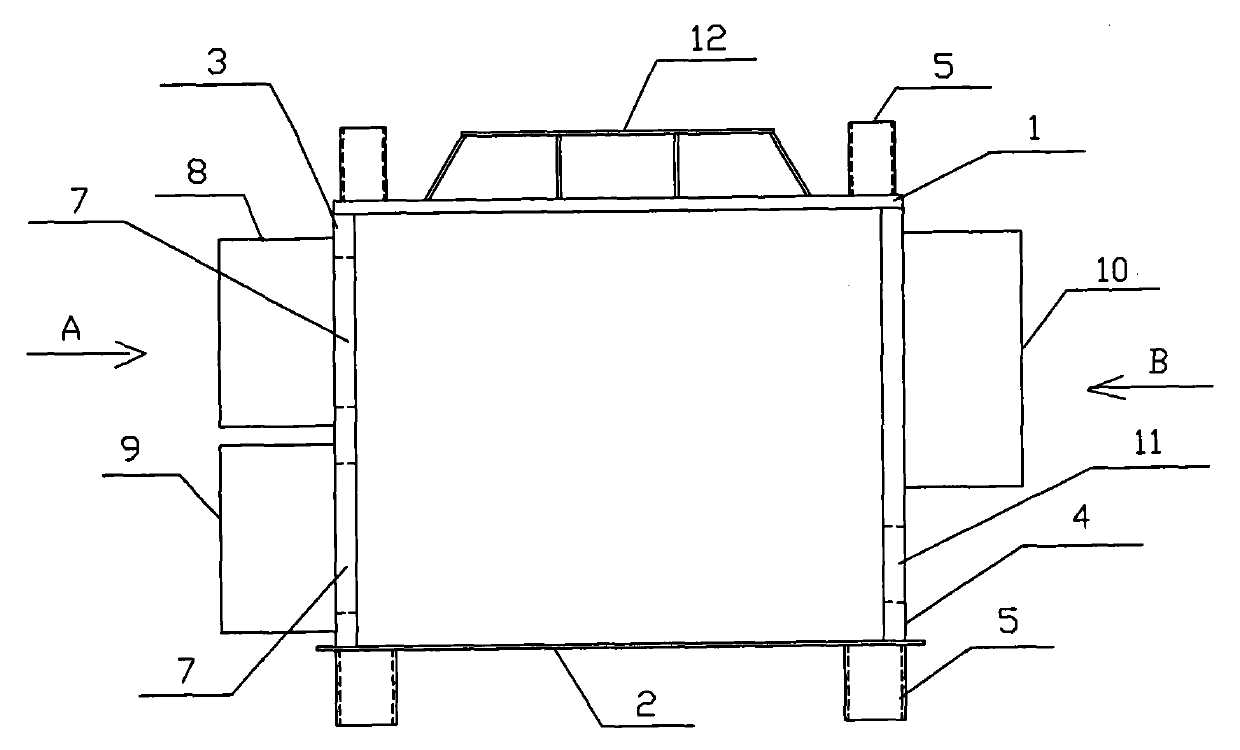

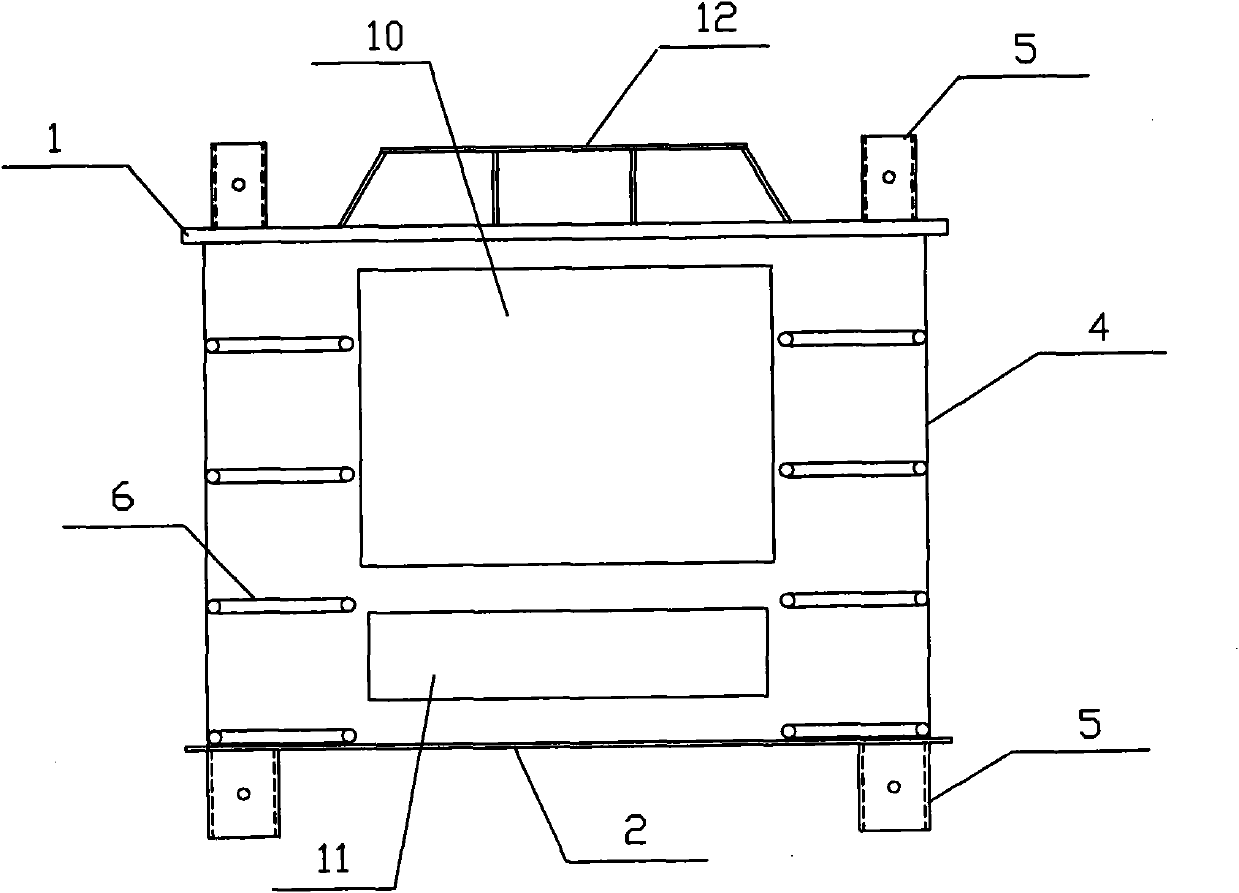

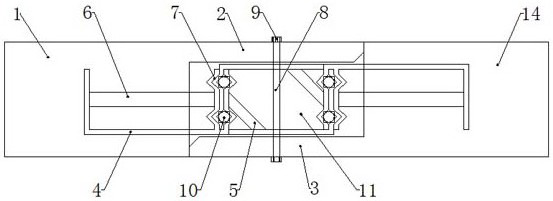

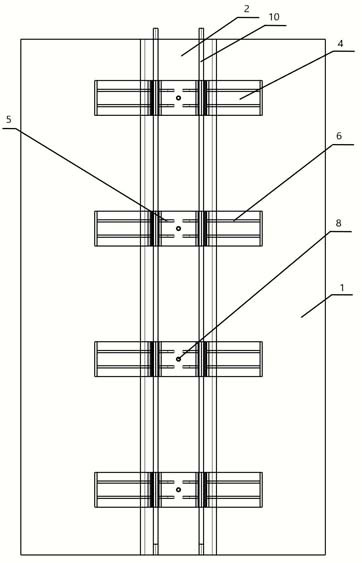

Distribution type two-stage distribution box

The invention discloses a distribution type two-stage distribution box comprising one two-stage distribution box (11) and multiple distribution box sub-units (12). The first distribution box sub-unit (12) is connected with the two-stage distribution box (11) via a cable, and the second distribution box sub-unit (12) is connected with the first distribution box sub-unit (12) via the cable. Similarly, other multiple distribution box sub-units (12) are connected to form a string. Each distribution box sub-unit (12) comprises a lighting box (10) which is respectively provided with a wiring terminal (2), a zero row (3), a 32A 3P air switch (4), a 25A 2P electric leakage protector (5), a 10A single-P air switch (6), a ground row (7), a 380V aviation socket (8) and a 220V aviation socket (9). According to the distribution type two-stage distribution box, temporary electricity utilization of a construction site is reasonable in arrangement and safe in application so that the construction site is more standard and neater.

Owner:GOLD MANTIS CONSTR DECORATION

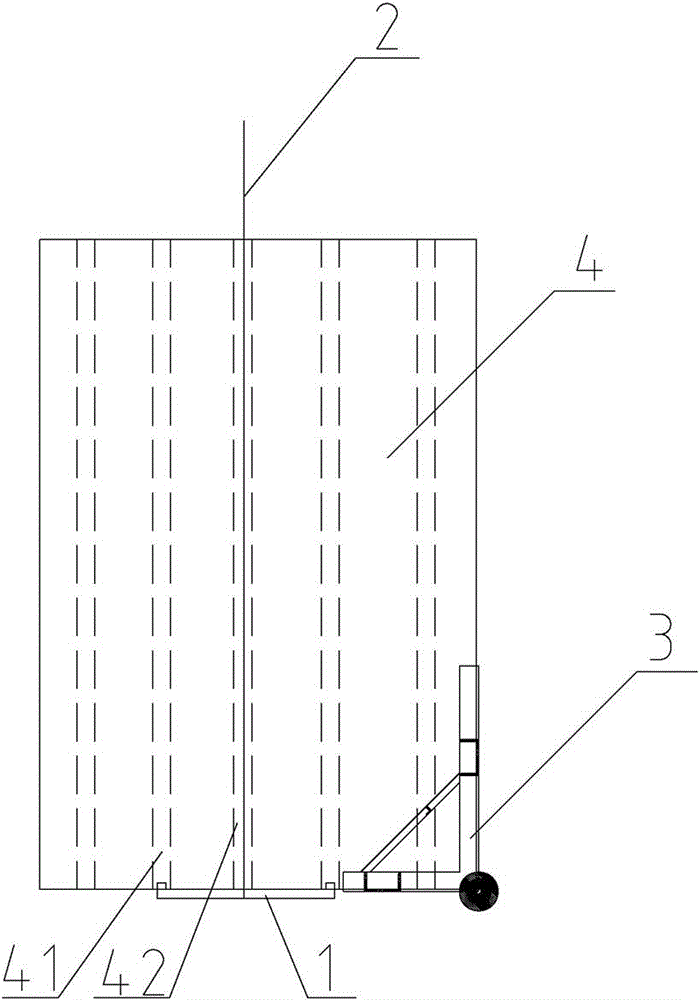

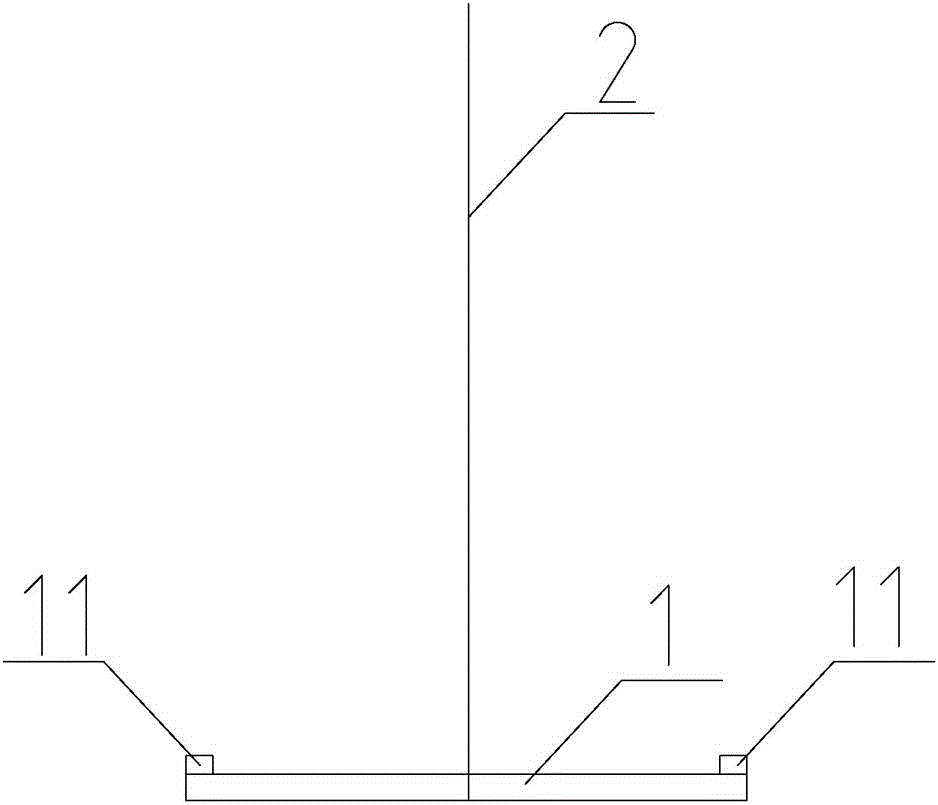

Mounting method of lightweight partition wallboard

ActiveCN105672536AImprove integrityImprove liftingWallsBuilding material handlingEngineeringPre embedding

The invention relates to a mounting method of a lightweight partition wallboard. The mounting method comprises the following steps: surveying and setting out, embedding a pre-embedded part, preparing the lightweight wallboard, lifting, mounting and performing anti-corrosion and anti-rust treatment. According to the mounting method of the lightweight partition wallboard, the integrity of the lightweight partition wallboard can be effectively protected, and particularly, a hollow board corner and a mouth part are significantly protected; the lifting and mounting speed of materials is improved.

Owner:临沂新科置业有限公司

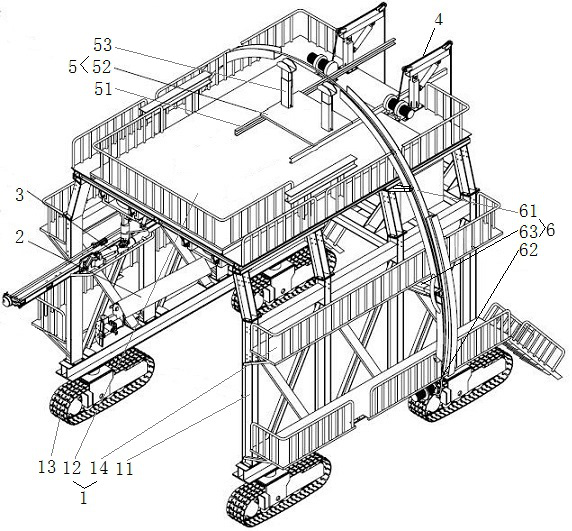

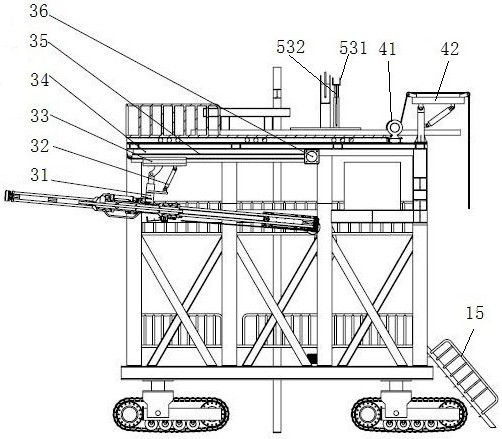

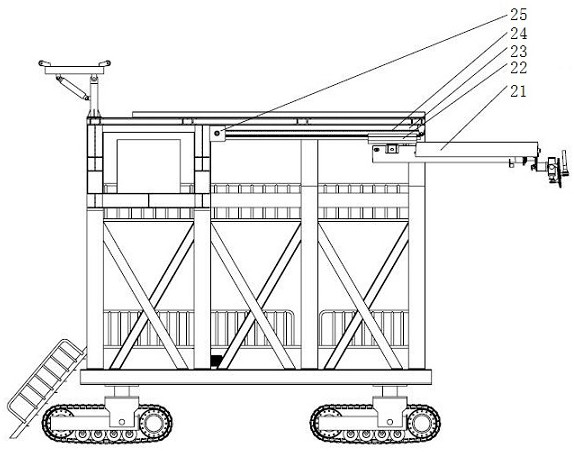

Multifunctional operation rack suitable for tunnel construction

ActiveCN113074001AQuality improvementLow failure rateUnderground chambersTunnel liningArchitectural engineeringRock bolt

The invention provides a multifunctional operation rack suitable for tunnel construction. The multifunctional operation rack comprises a movable portal, and a concrete guniting device, a jumbolter device and a steel arch splicing device are arranged on the movable portal. The steel arch splicing device is arranged on the movable portal, so that the splicing process of the steel arch is mechanized, the jumbolter device and the guniting device are integrated, the system integration degree is high, cooperative and efficient operation can be achieved, the working efficiency is improved, the arch is timely supported, the supporting efficiency is high, the quality is more stable, and the safety of tunnel construction is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Suspended type foundation pit drainage system and using method thereof

ActiveCN106638637AQuick releaseEfficient exclusionSewerage structuresFoundation engineeringEngineeringEarth surface

The invention provides a suspended type foundation pit drainage system and a using method thereof. The suspended type foundation pit drainage system comprises a fixed supporting frame, a drainage assembly and a water pump, wherein the fixed supporting frame is arranged on the side wall of a foundation pit; the drainage assembly arranged on the fixed supporting frame, one end of the drainage assembly extends into water in the foundation pit, and the other end of the drainage assembly is connected to an earth surface drainage trench; and the water pump is connected with the drainage assembly, and by means of the water pump, the water in the foundation pit is drained into the earth surface drainage trench through the drainage assembly. According to the suspended type foundation pit drainage system, the drainage assembly of which one end extends into the water in the foundation pit can touch the bottom of the foundation pit as much as possible, so that the water in the foundation pit can be rapidly and effectively drained out of the foundation pit, and accordingly the safety of the side wall of the foundation pit is improved.

Owner:浙江二十冶建设有限公司 +1

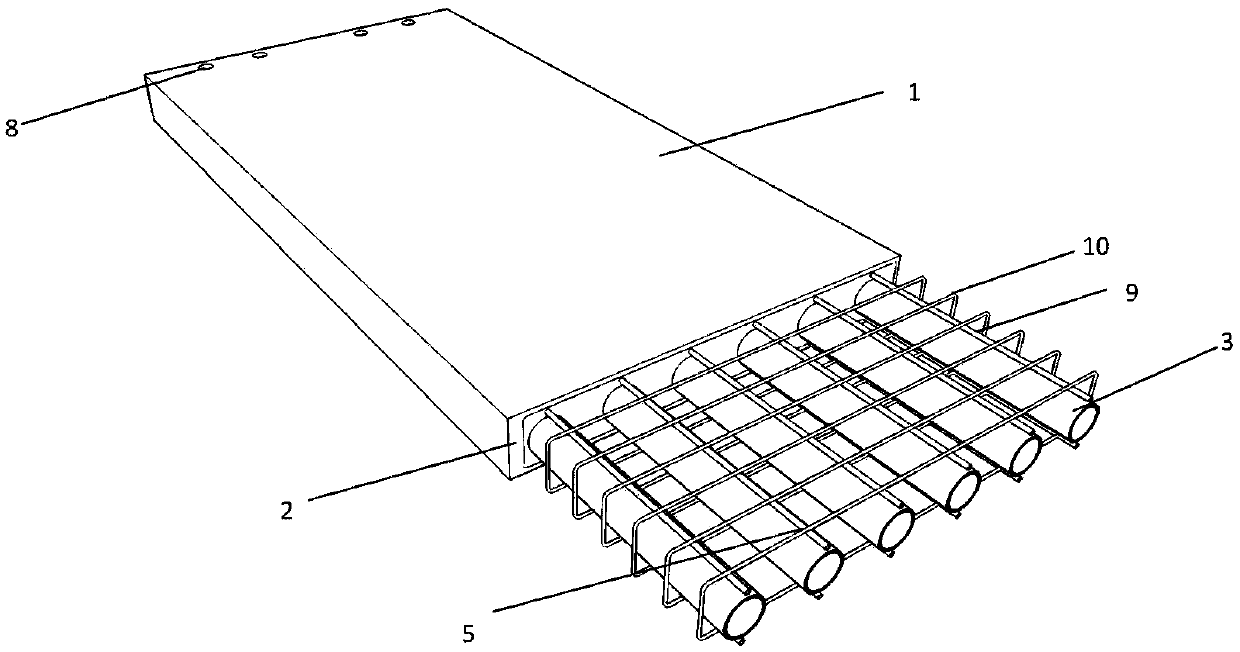

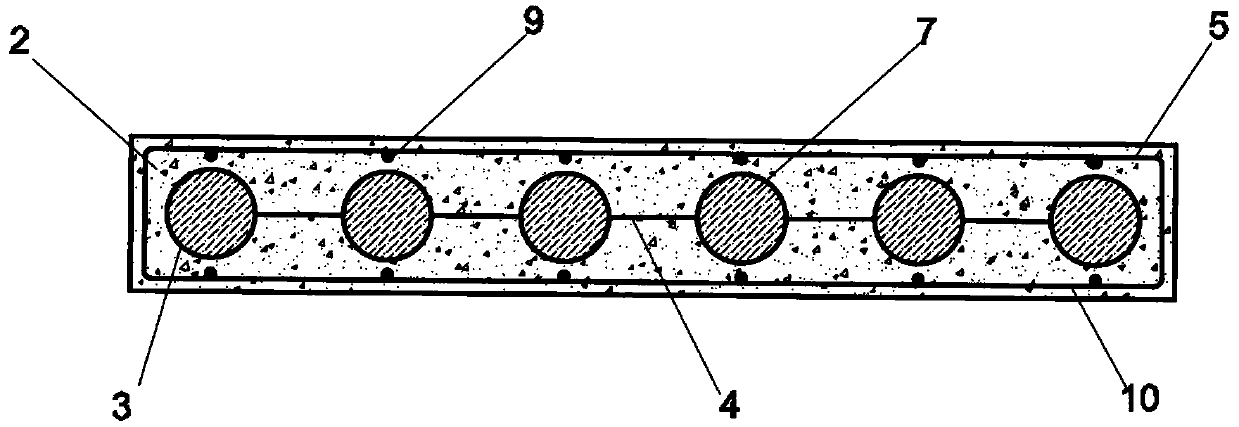

Prefabricated assembly type lightweight floor and manufacturing method thereof

The invention discloses a prefabricated assembly type lightweight floor and a manufacturing method thereof, and belongs to the technical field of building materials. The invention provides the prefabricated assembly type lightweight floor composed of a concrete matrix, a hollow steel tube, a batten plate, a reinforcing mesh frame, a hollow steel tube hole, a lightweight filling material and a toggle pin hole and the manufacturing method thereof, not only is the problem of large self-weight of a traditional cast-in-place floor solved, but also the problem of the lower intensity of lightweight concrete is solved, and the practical significance and engineering application value are significant.

Owner:JIANGNAN UNIV

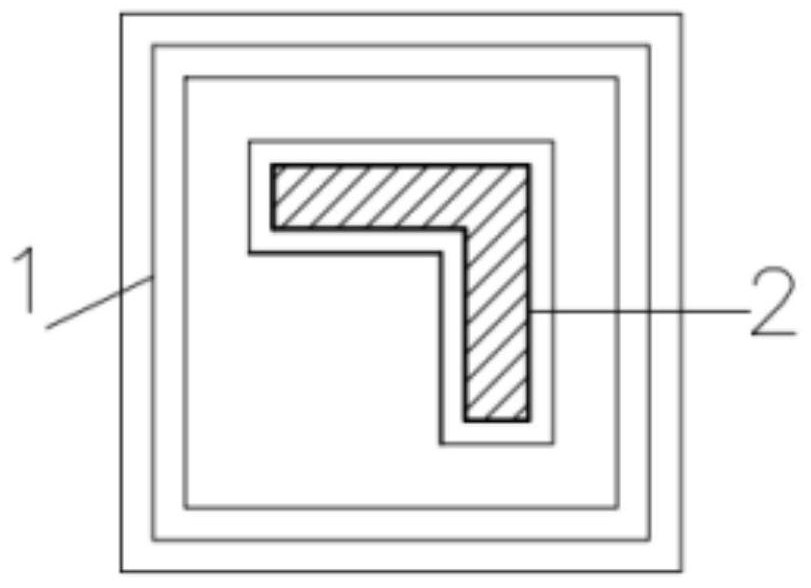

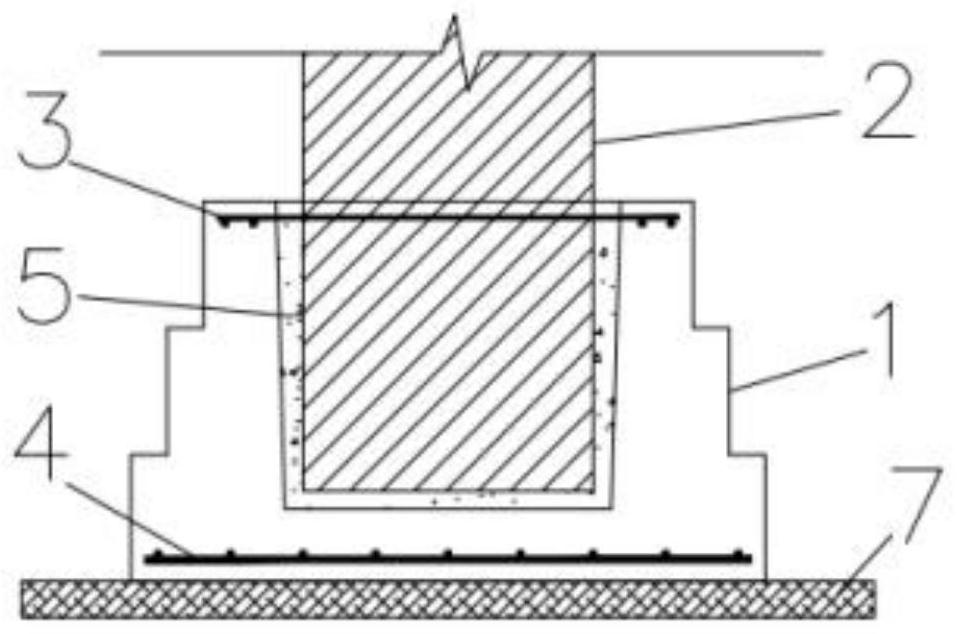

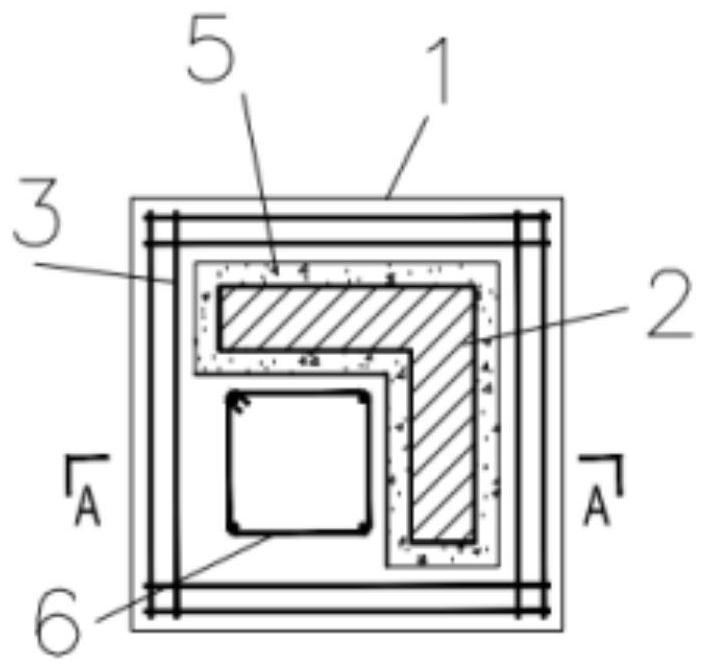

Prefabricated concrete L-shaped column cup opening foundation

PendingCN112695794AReasonable designHigh degree of industrializationFoundation engineeringSocial benefitsArchitectural engineering

The invention discloses a prefabricated concrete L-shaped column cup opening foundation. The prefabricated concrete L-shaped column cup opening foundation comprises a prefabricated concrete cup opening foundation body, a prefabricated concrete L-shaped column, a foundation top welding reinforcing mesh, foundation bottom bidirectional reinforcing steel bars, fine aggregate concrete filler, local reinforcing embedded columns and a foundation cushion layer, wherein the prefabricated concrete cup opening foundation body, the foundation top welding reinforcing mesh, the foundation bottom bidirectional reinforcing steel bars and the local reinforcing embedded columns form a main body structure of the prefabricated concrete L-shaped column cup opening foundation body; and the prefabricated concrete L-shaped column cup opening foundation body is in a three-step shape in the vertical direction, and the overall plane is square. The prefabricated concrete L-shaped column cup opening foundation is an important component for achieving a middle- and low-riser full-assembly type concrete building system, direct socket connection of prefabricated vertical components is achieved, and a grouting sleeve connecting manner with the quality difficult to control is replaced. A foundation assembly can be machined in a factory and transported to the site to be hoisted and installed, the industrialization degree is high, and on-site installation is convenient; and the construction site is clean and tidy, the construction period is short, good economic benefits and social benefits are achieved, and the prefabricated concrete L-shaped column cup opening foundation is suitable for usage and popularization.

Owner:CHINA RAILWAY CONSTR GROUP

Aluminum alloy formwork for buildings and method for applying aluminum alloy formwork

ActiveCN105155836ASolid structureGood stabilityForming/stuttering elementsAluminium alloyUltimate tensile strength

The invention discloses an aluminum alloy formwork for buildings and a method for applying the aluminum alloy formwork. The aluminum alloy formwork comprises universal planar aluminum plates and reinforcement clip aluminum plates. The universal planar aluminum plates and the reinforcement clip aluminum plates are respectively of 'concave' hollow structures and comprise hollow cavities and frames, the frames comprise convex edges and grooves, the heights of the convex edges of the universal planar aluminum plates are equal to those of the grooves of the reinforcement clip aluminum plates, and the sum of the widths of the two convex edges of each universal planar aluminum plate is equal to the widths of the grooves of each reinforcement clip aluminum plate, so that the grooves of each reinforcement clip aluminum plates can be exactly connected with the convex edges of the two corresponding universal planar aluminum plates in a clamped manner when the convex edges of the universal planar aluminum plates are connected and parallelly arranged and spliced with one another pairwise. The aluminum alloy formwork can be applied to constructing concrete structures of walls, columns, beams, plates, balconies, bay windows, exterior decoration lines and the like. The aluminum alloy formwork and the method have the advantages that the aluminum alloy formwork is high in strength and free of rusting, is light, can be poured at one step after being completely spliced and has obvious merits in the aspect of construction periods and prices as compared with aluminum formworks for identical floors; seams are fine, formed walls are attractive, and decoration at late periods can be facilitated.

Owner:ZHEJIANG EHOME CURTAIN WALL TECH

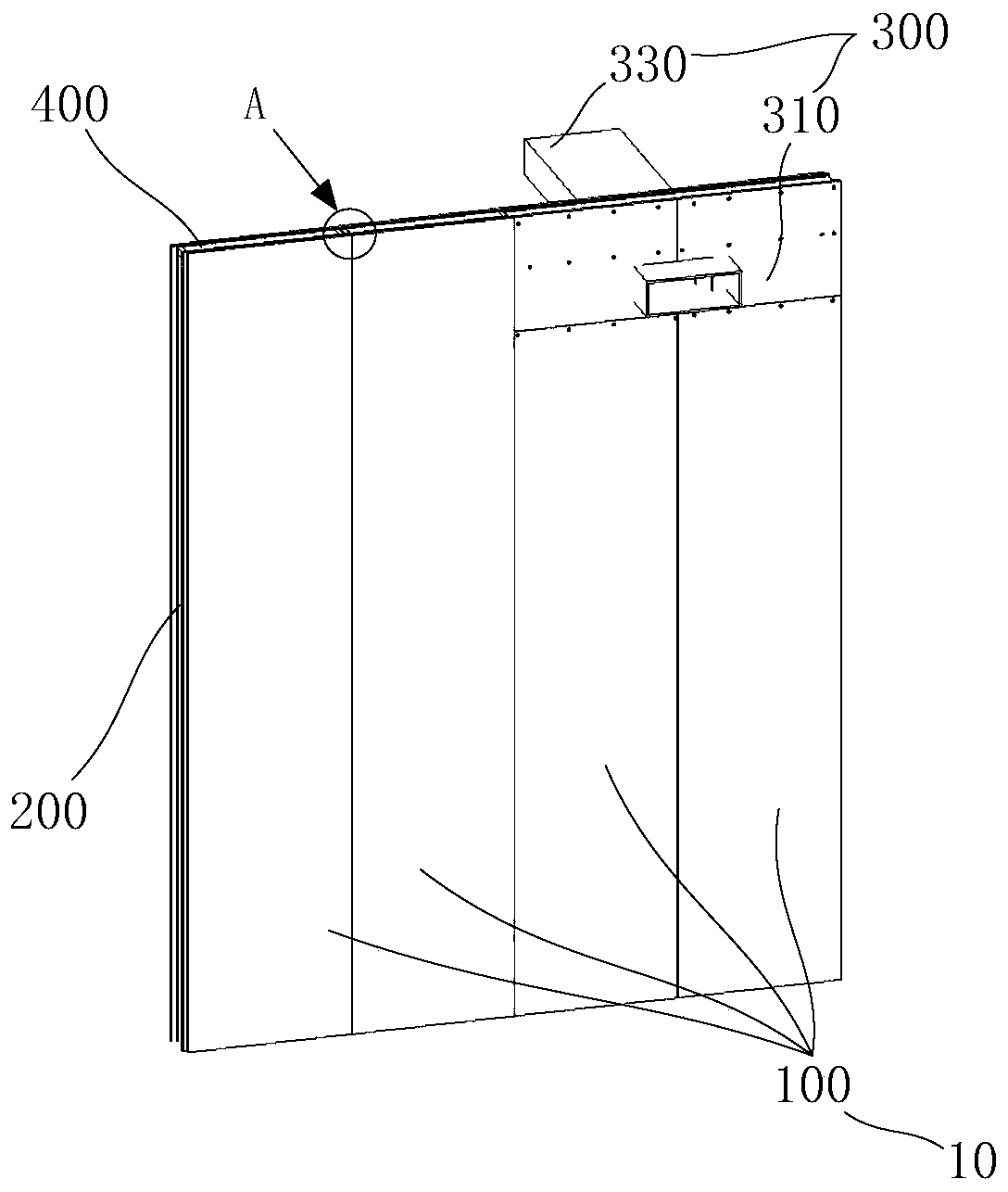

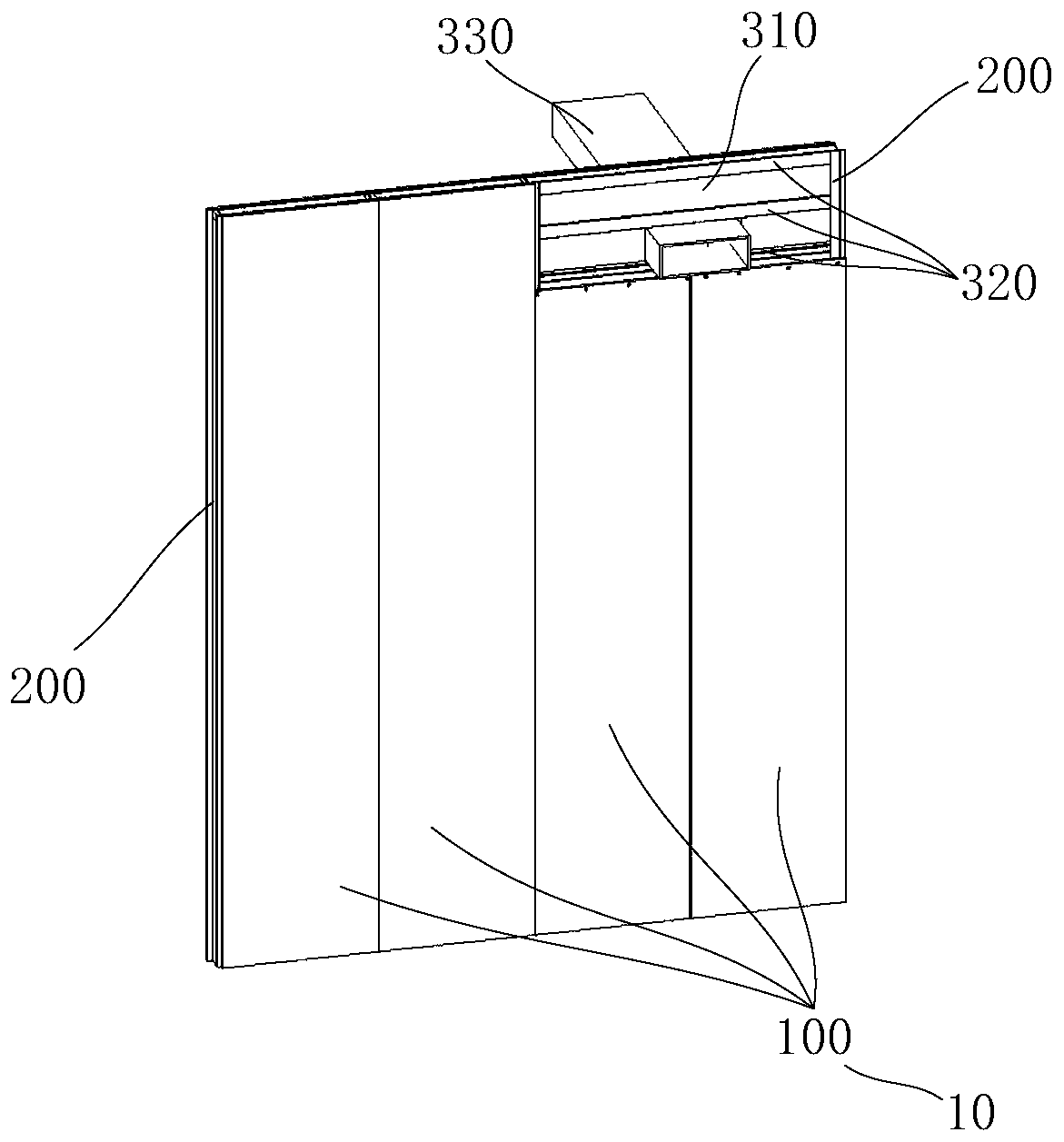

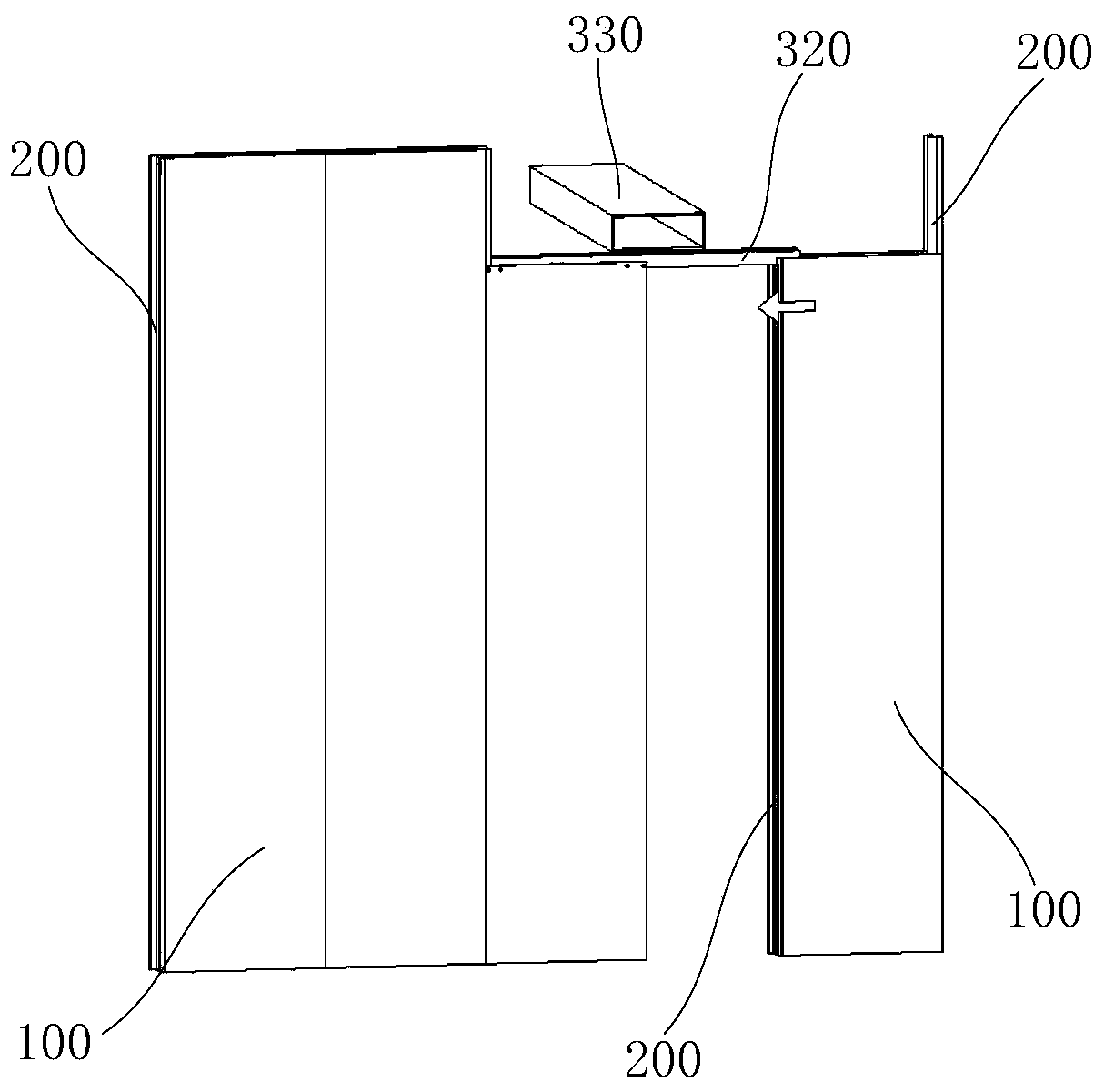

Fabricated wall crossed by air duct and mounting method of fabricated wall

PendingCN111576675AHigh impact strengthAvoid problems that cannot meet the requirements of the actual construction siteConstruction materialWallsEngineeringStructural engineering

The invention discloses a fabricated wall crossed by an air duct and a mounting method of the fabricated wall, and relates to the technical field of buildings. The problem that the position of a preformed ventilation opening of a wall module cannot meet the actual construction site requirement is avoided, and the building process is simple, convenient and rapid. The fabricated wall crossed by theair duct comprises a main wall body and a lower wall body which are lapped by a plurality of wall modules, and the heights of lapping profiles and a first wall panel of the main wall body are equal tothe distance between a building top plate and a building bottom plate; the heights of lapping profiles at the edge of the lower wall body are larger than the heights of lapping profiles in the middleof the lower wall body and equal to the heights of the lapping profiles of the main wall body, and the height of a first wall panel of the lower wall body is equal to the heights of the lapping profiles in the middle of the lower wall body; an air duct wall body comprises a second wall panel and supporting profiles, and the supporting profiles are connected with the lapping profiles at the edge of the lower wall body in a clamped mode; and a ventilation opening is formed in the second wall panel and located in the extending direction of the one or more lapping profiles in the middle of the lower wall body. The fabricated wall crossed by the air duct and the mounting method of the fabricated wall are used for construction walls.

Owner:BEIJING NEW BUILDING MATERIALS PLC

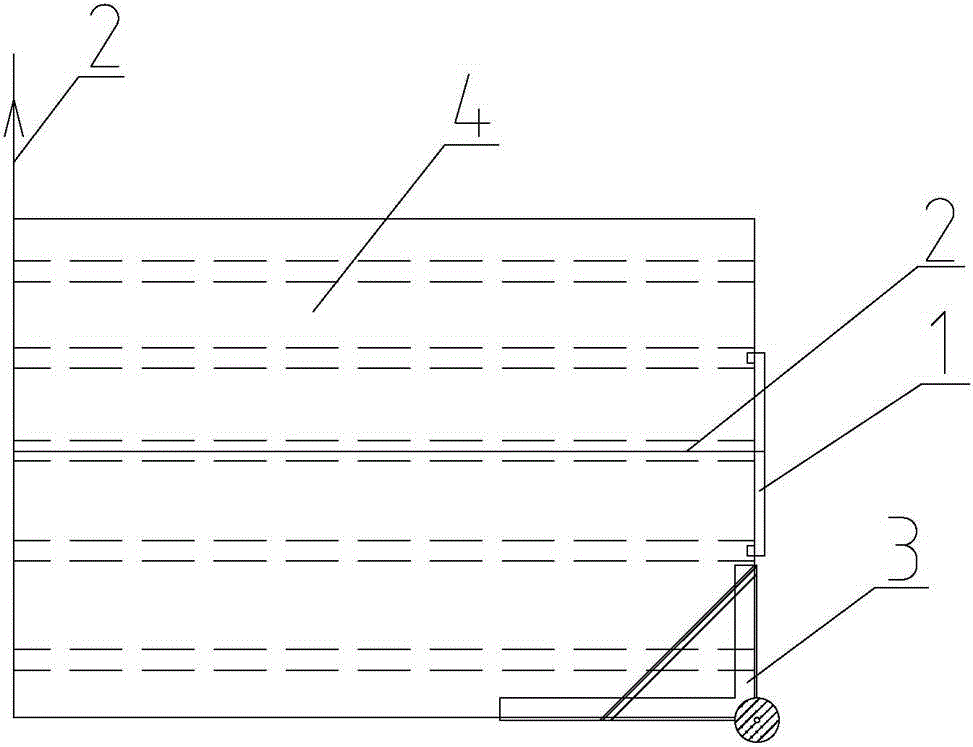

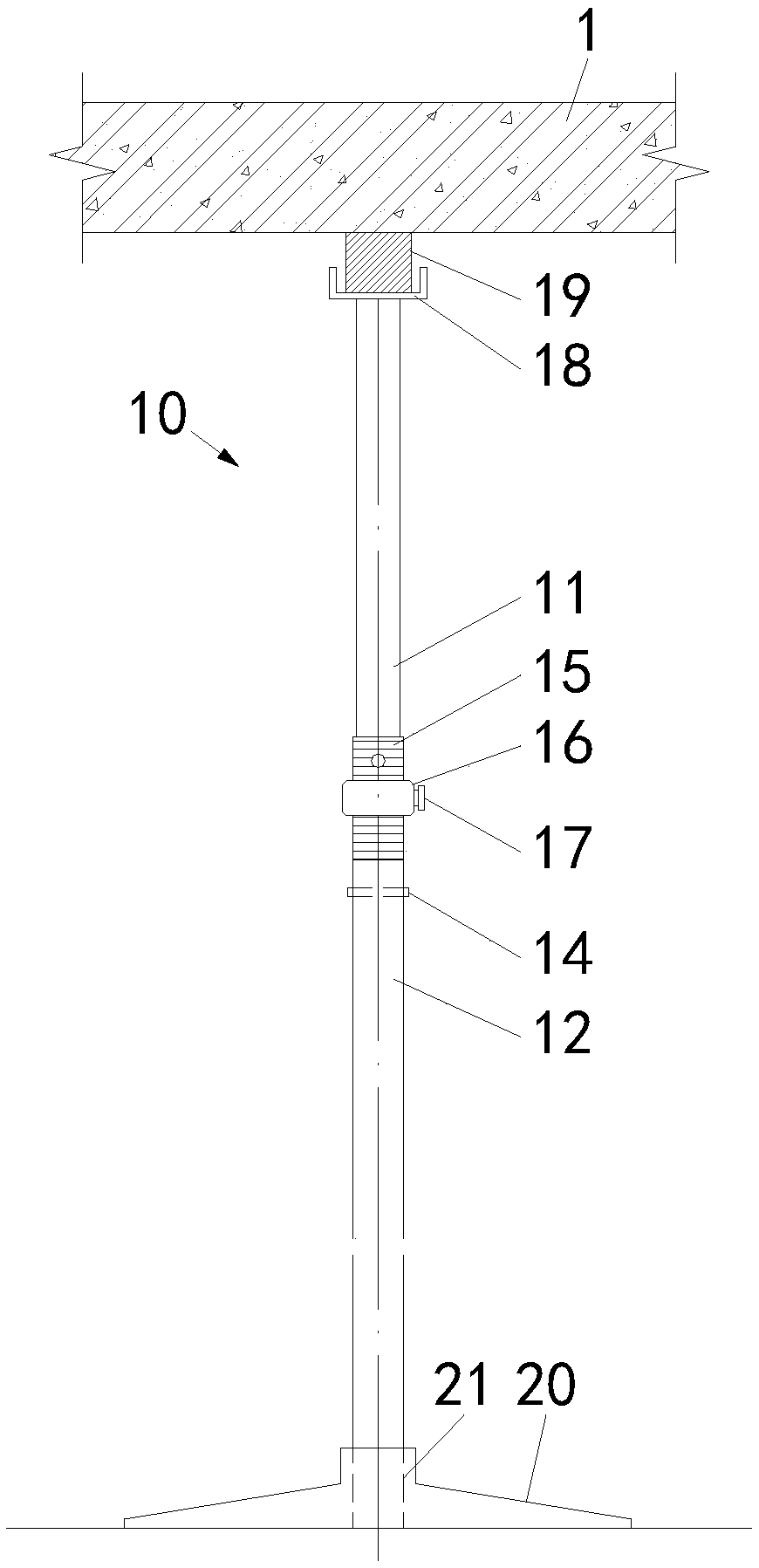

Adjustable supporting device and using method thereof

PendingCN109098437AImprove bearing capacitySimple structureForms/shuttering/falseworksShoresWork periodArchitectural engineering

The invention relates to an adjustable supporting device and a using method thereof, and relates to the technical field of assembly type building supporting. The invention aims to solve the problems that a working period is long during assembling and disassembling of an existing fastener type steel tube support, and the construction efficiency is low. The adjustable supporting device is verticallyarranged on the bottom of an assembly type prefabricated component, and comprises a steel stand column and a base connected to the bottom of the steel stand column; the steel stand column comprises an inner tube and an outer tube which are arranged in the up-down direction and are arranged in a sleeving manner; a plurality of corresponding positioning pin holes are formed in the side walls of theinner tube and the outer tube in the length directions of the inner tube and the outer tube; the inner tube and the outer tube are fixed and are coarsely adjusted through positioning latches which penetrate through the positioning pin holes; the base is provided with a rectangular or circular cross section; a through hole is formed in the center of the base; and the bottom of the steel stand column perpendicularly penetrates through the through hole and is fastened.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

Cable core neatening device

Owner:国网山东省电力公司高密市供电公司 +2

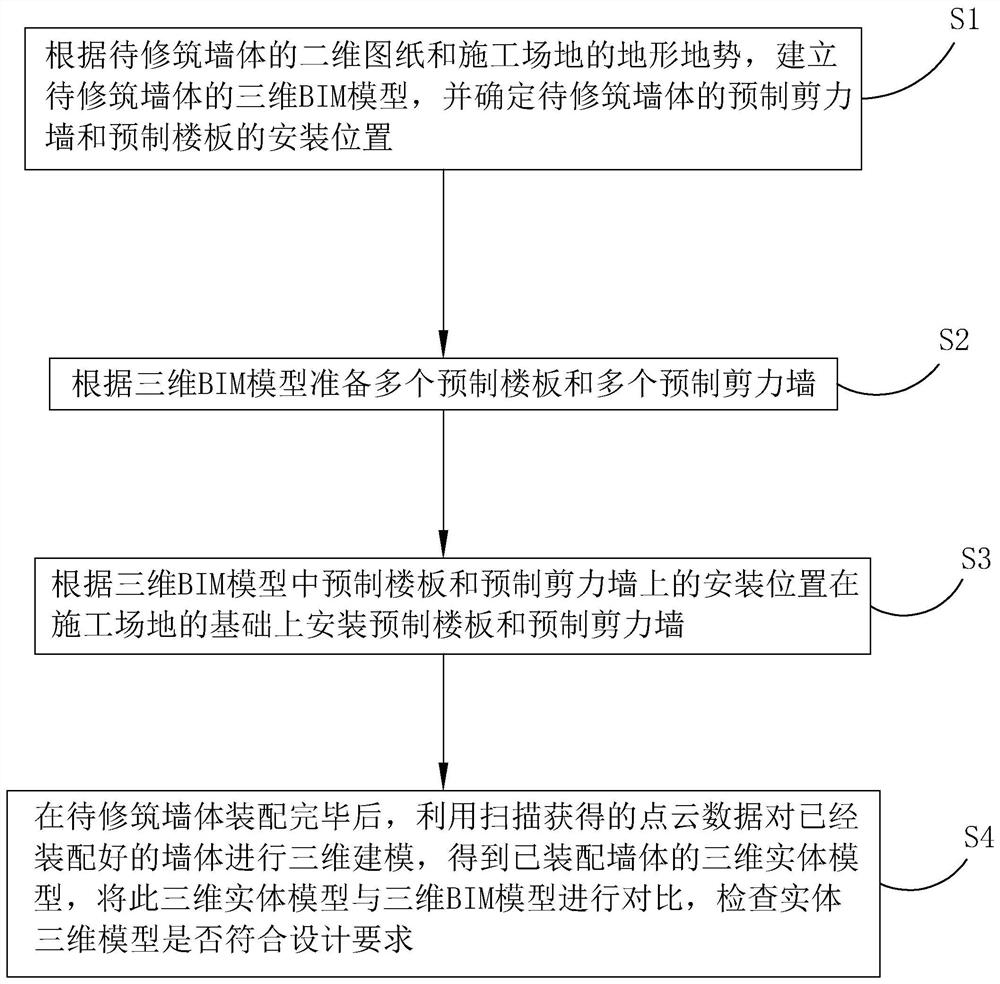

Wall green construction method based on BIM technology

InactiveCN112814146AEasy to understandEasy constructionGeometric CADBuilding reinforcementsPoint cloudFloor slab

The invention relates to a wall green construction method based on a BIM technology, and relates to the technical field of building walls. The method comprises the steps that according to a two-dimensional drawing of a to-be-built wall and the terrain of a construction site, a three-dimensional BIM model of the to-be-built wall is built, and the mounting positions of a prefabricated shear wall and a prefabricated floor slab of the to-be-built wall are determined; a plurality of prefabricated floor slabs and a plurality of prefabricated shear walls are prepared according to the three-dimensional BIM model; the prefabricated floor slabs and the prefabricated shear walls are installed on the basis of the construction site according to the installation positions of the prefabricated floor slabs and the prefabricated shear walls in the three-dimensional BIM model; and after the to-be-built wall is assembled, three-dimensional modeling is carried out on the assembled wall body by utilizing the point cloud data obtained by scanning to obtain a three-dimensional entity model of the assembled wall body, compared the three-dimensional entity model with the three-dimensional BIM model, and whether the entity three-dimensional model meets design requirements or not is checked. The construction method is low in energy consumption, short in construction period, energy-saving and environment-friendly.

Owner:湖北创威建筑装饰工程有限公司

Dry type pneumatic rock drilling pile-driving machine and working method thereof

InactiveCN101831906BNo pollution in the processIncrease drilling speedDrilling drivesBulkheads/pilesSlagHelical blade

Owner:温州长城基础工程有限公司

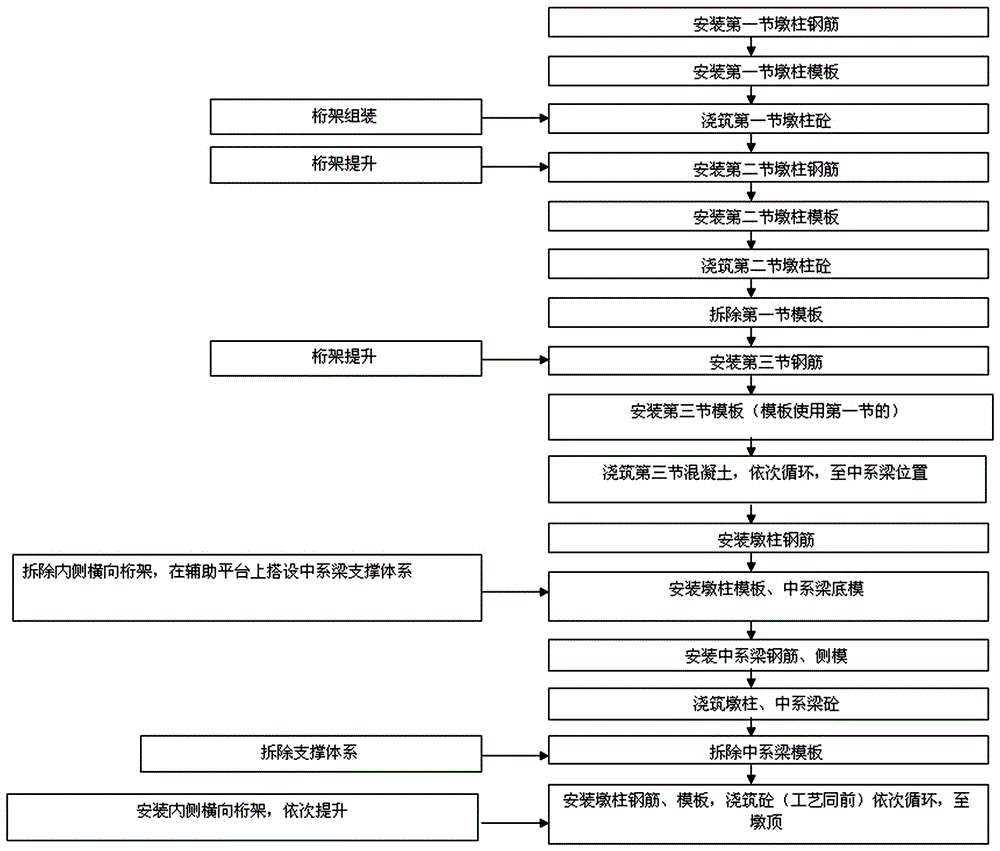

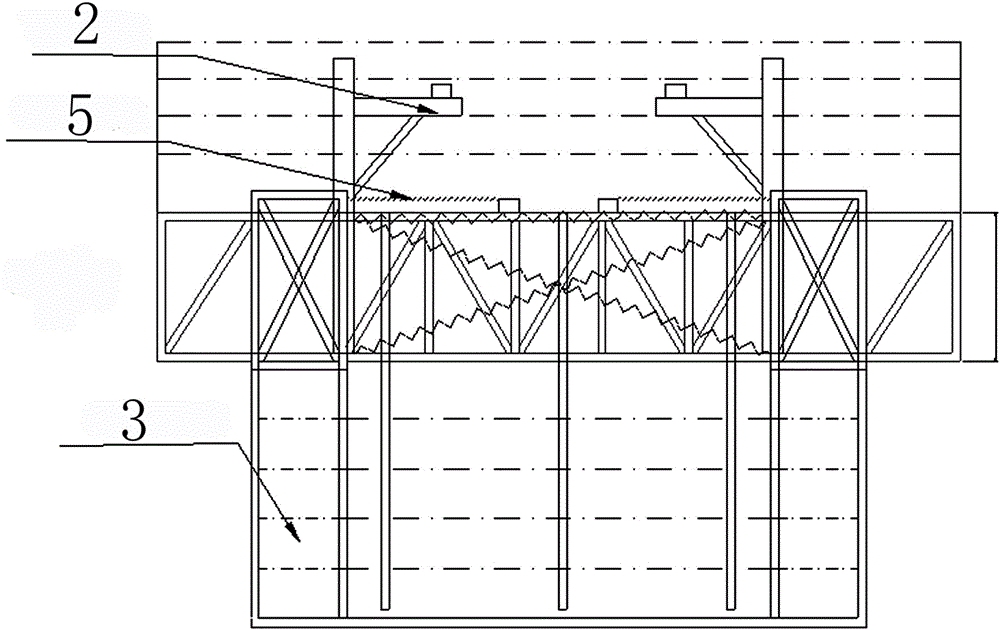

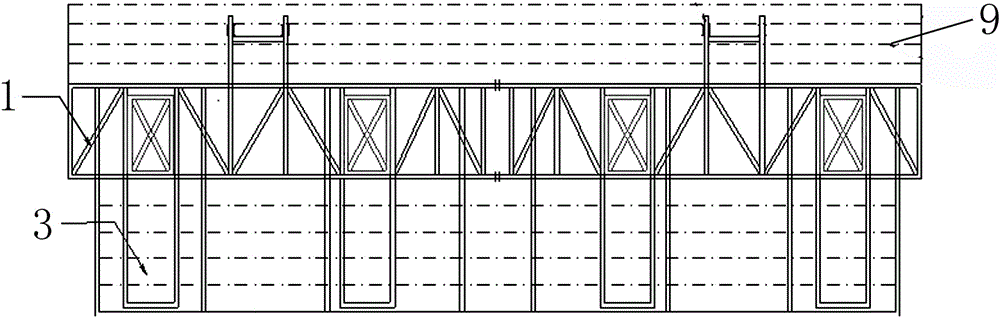

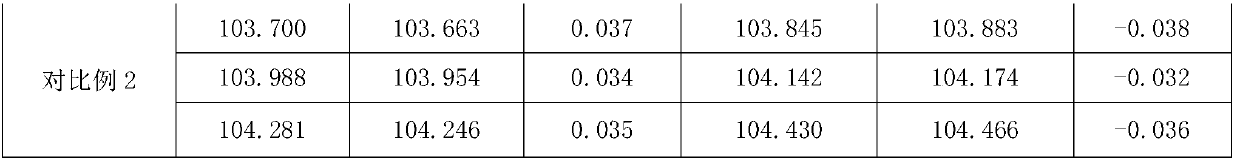

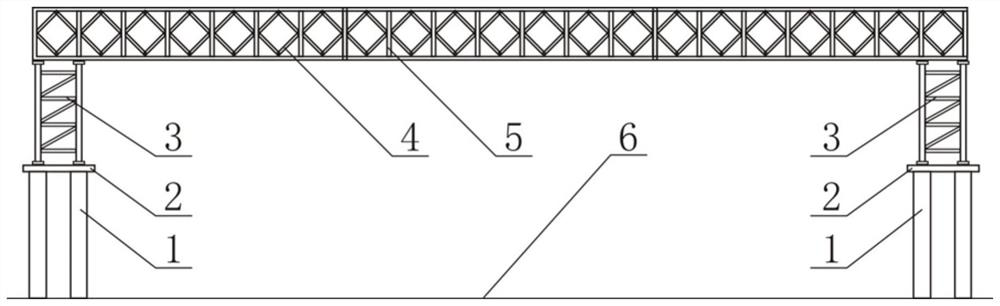

Two-column pier and middle tie beam construction method employing integral movement of trusses

ActiveCN106592438AQuality assuranceSpeed up the progress of the projectBridge erection/assemblySocial benefitsEconomic benefits

The invention belongs to the technical field of bridge construction and provides a two-column pier and middle tie beam construction method employing integral movement of trusses. By means of the construction method, the problems that traditional turnover form construction and climbing form construction are slow in construction progress of high bridge piers, and slip form construction affects the surface quality of pier bodies and damages inherent quality of concrete are solved. A truss platform, lifting frames, an auxiliary platform, supporting rods, a hydraulic system and formwork systems are included. The truss platform comprises transverse trusses and longitudinal trusses. The transverse trusses on the inner side are detachably connected with the truss platform. An upper opening and a lower opening of the truss platform are provided with two layers of jackscrews. An upper main rib and a lower main rib of each truss are provided with jackscrew fixing devices. The lower portion of the truss platform is connected with the auxiliary platform. The lifting frames and the truss platform are connected into a whole. Each lifting frame is supported on the corresponding supporting rod through a jack installed on a cross beam of the lifting frame. The lower ends of the supporting rods are embedded in concrete. The upper ends of the supporting rods penetrate through through holes of the hydraulic jacks. A bridge pier and a middle tie beam are constructed synchronously and quickly, the construction period is shortened, cost is reduced, operability is high, the method is economical and reasonable, and good economic benefits and social benefits are achieved.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

Combined welding machine tool box

InactiveCN101920419ASave spaceConstruction site clean and tidyWelding/cutting auxillary devicesAuxillary welding devicesWork periodEngineering

The invention discloses a combined welding machine tool box which comprises a top plate and a bottom plate, wherein a left side plate and a right side plate are vertically arranged between the top plate and the bottom plate, the top plate, the bottom plate and the two side plates form a space frame, both the upper surface and the lower surface of the space frame are connected with a plurality of supporting feet, the supporting feet are uniformly arranged at four end points of the space frame, both ends of the outer walls of the left side plate and the right side plate are connected with a plurality of vertical ladders, the outer wall of the left side plate is provided with two first shutters, a distributor box and a first terminal circuit box, the outer wall of the right side plate is provided with a second terminal circuit box and a second shutter, the second terminal circuit box and the second shutter are arranged among the vertical ladders on both ends of the outer wall of the right side plate, and the second terminal circuit box is arranged above the second shutter. The tool box has the advantages of reducing the occupied area, improving the production efficiency and shortening the work period.

Owner:NANTONG ZHONGLIAN S&T SERVICE

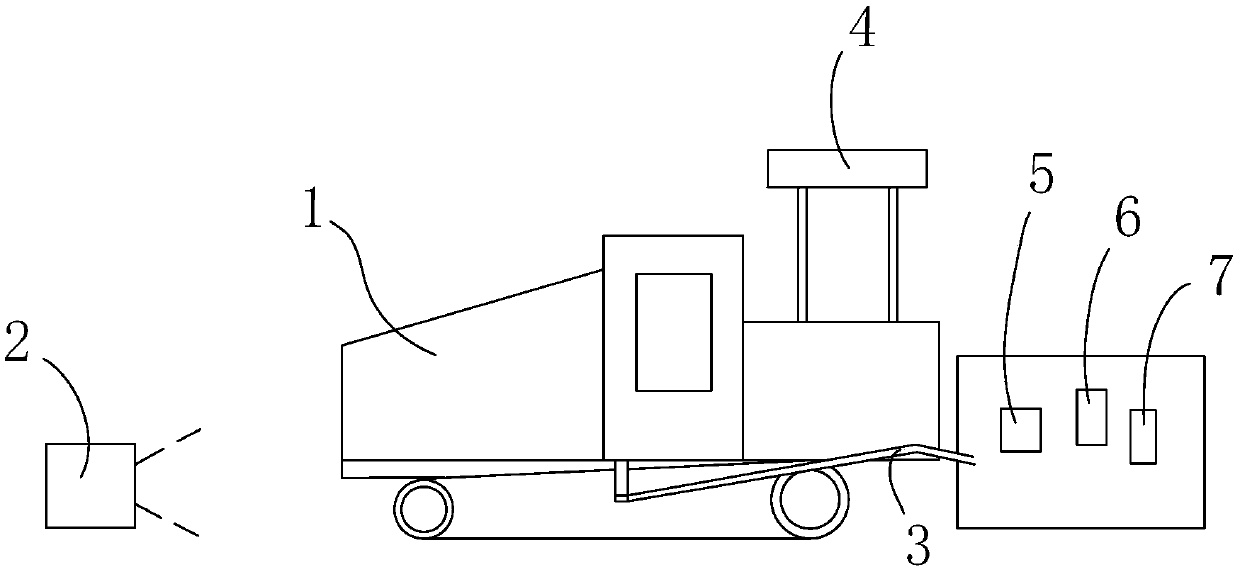

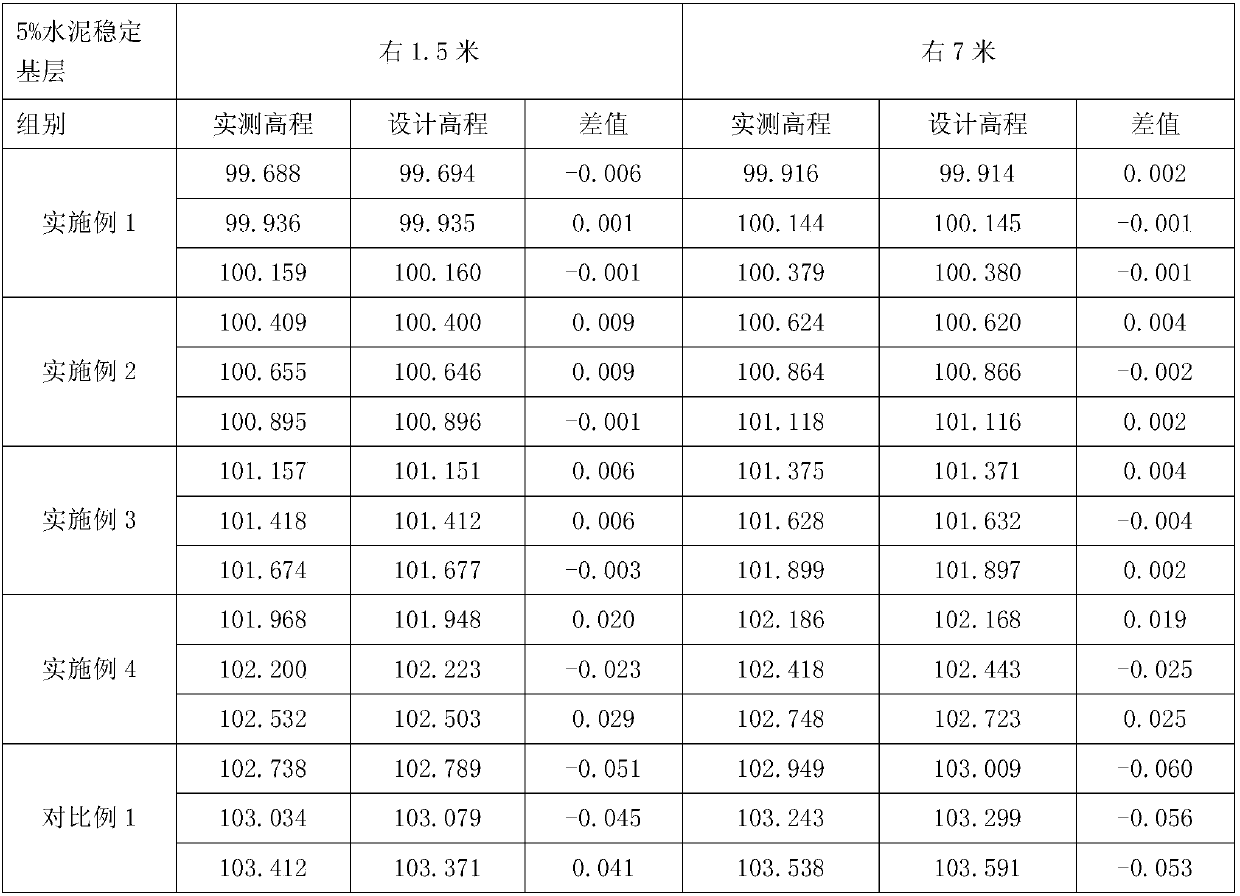

3D paving construction technology applicable to asphalt pavement

ActiveCN109554994ANot subject to lightNot affected by the weatherIn situ pavingsClimate change adaptationAutomatic controlControl system

The invention discloses a 3D paving construction technology applicable to an asphalt pavement, belonging to the technical field of road construction. A paver equipped with a 3D paving automatic control system is used to carry out construction without complicated and heavy operations such as setting out, piling and hanging lines, which can not only remarkably reduce labor intensity, but also greatly speed up the construction speed. The 3D paving automatic control system is used for paving construction by combining a warm agent, so that not only the quality of paver construction can be guaranteed, but also the emission of harmful smoke generated by asphalt paving can be reduced.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

Support for cast-in-place box girder and construction method thereof

PendingCN112813791ASolve the problem that the local stress is too large and does not meet the requirementsEnsure and improve support effectBridge erection/assemblyStress pointArchitectural engineering

The invention discloses a support for a cast-in-place box girder and a construction method thereof. The support for the cast-in-place box girder is characterized by comprising a pile foundation, a cross beam, a supporting frame and a bailey frame, wherein the bailey frame is supported on the supporting frame, a supporting point is located at a web member of the bailey frame, the supporting frame is arranged on the cross beam, the cross beam is arranged at the upper end of the pile foundation, and the lower end of the pile foundation extends into the ground. The construction method comprises the steps of building of the supporting frames, construction of the pile foundations, installation of the cross beams, hoisting of the supporting frames, installation of the adjacent pile foundations and hoisting of the bailey frame. According to the support, the supporting stress point of the bailey frame can be accurately located at the position of the web member through adjustment of the pile top cross beam, and therefore the supporting effect can be achieved; compared with traditional on-site support installation and welding, installation time is saved, and the support can be disassembled for multiple times to be recycled and is more economical and reasonable; in addition, due to overall installation, welding of the supporting frame at high altitude can be avoided, and higher safety guarantee is achieved.

Owner:THE GUANGDONG NO 3 WATER CONSERVANCY & HYDRO ELECTRIC ENG BOARD CO LTD

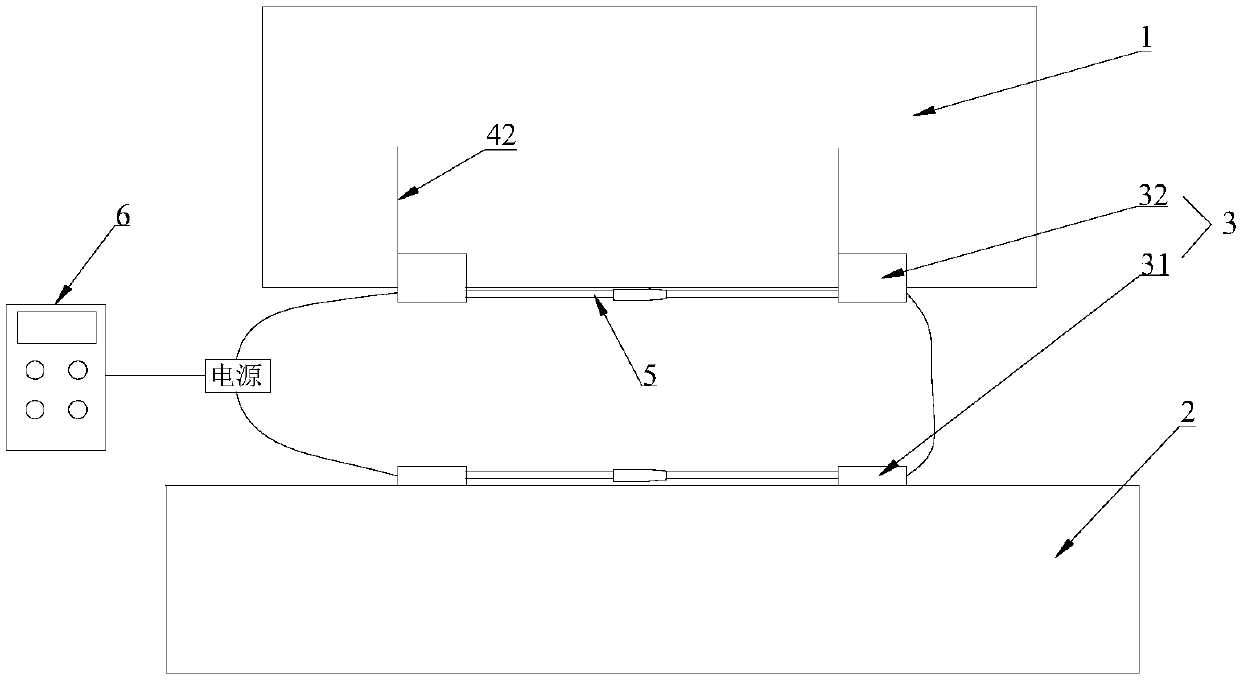

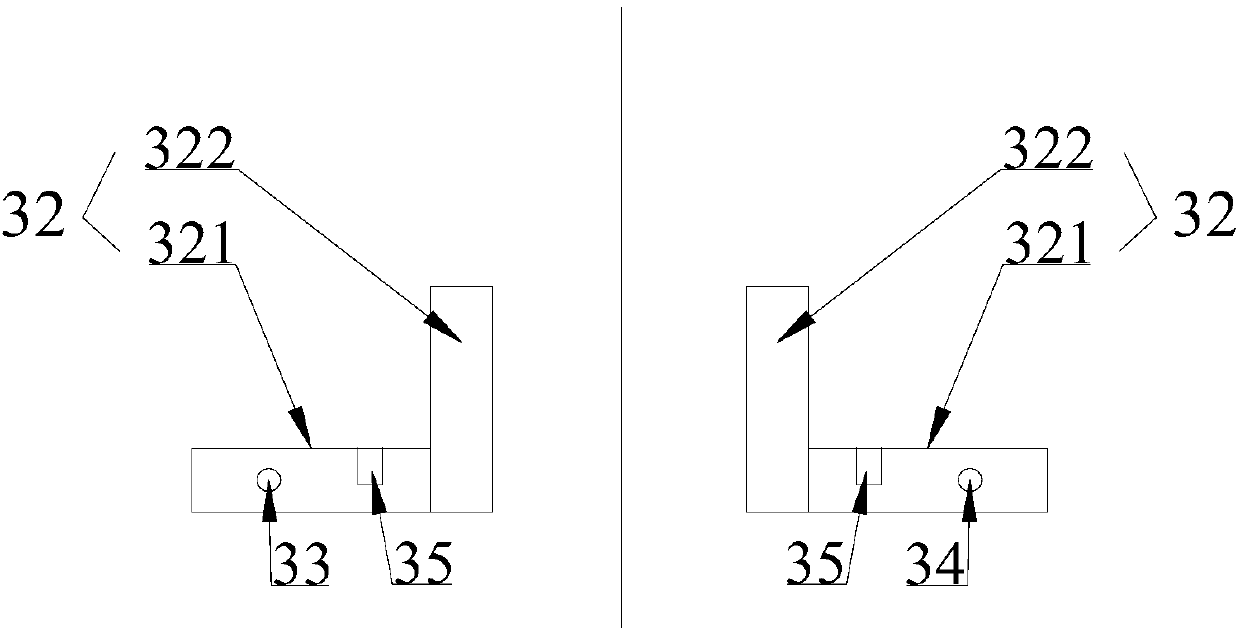

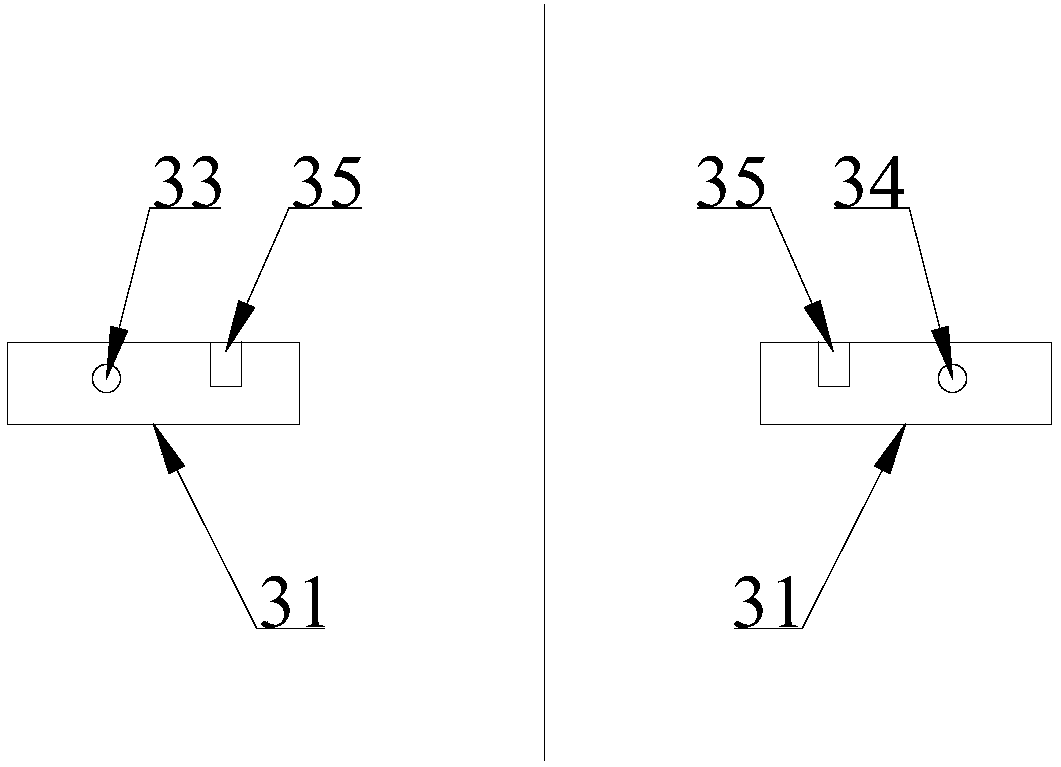

Assembled concrete component reinforcement magnetic suspension connecting and positioning device

The invention provides an assembled concrete component reinforcement magnetic suspension connecting and positioning device which is used for positioning an upper concrete component and a lower concrete component, so that upper and lower reinforcements to be connected are in coaxial butt joint. The device comprises a control mechanism, at least two groups of support mechanisms, a positioning mechanism and a support mechanism, the supporting mechanism comprises a lower support and an upper support, the upper support comprises a support plate and a limit plate, both the support plate and the lower support are electromagnets, like magnetic poles of the support plate and the lower support are oppositely placed, the positioning mechanism comprises a first mark and a second mark which are arranged at corresponding positions of assembly surfaces of the upper concrete component and the lower concrete component, the lower support is placed at the first mark, the upper support is placed at the second mark, coils in the support plate and the lower support are serially connected onto the same circuit, the support mechanisms can be the same in magnetic force, support stability is ensured, and the control mechanism is used for controlling the magnetic force of the electromagnets. By the aid of the principle of magnetic suspension, the reinforcements of the upper concrete component and the lower concrete component are rapidly and accurately centered.

Owner:HEFEI CONSTR ENG GRP

Precast concrete n-shaped beam for fabricated concrete canopy of railway station

PendingCN111502119AHigh degree of industrializationEasy to install on siteSpecial buildingGirdersSocial benefitsShaped beam

The invention discloses a precast concrete n-shaped beam for a fabricated concrete canopy of a railway station. The precast concrete n-shaped beam comprises a left side beam, a middle beam, a right side beam, an edge beam bracket support, a left bracket beam, a middle beam bracket support, a middle bracket beam, a right bracket beam, a support cushion block, a left side beam column pier and a right side beam column pier. A main structure of the concrete n-shaped beam is formed by the left side beam, the middle beam, the right side beam, the left side beam column pier and the right side beam column pier. The precast concrete n-shaped beams are symmetrically arranged along the longitudinal axis and the transverse axis. The precast concrete n-shaped beam can be machined in a factory and transported to the site to be hoisted and mounted, the industrialization degree is high, and field mounting is convenient; and the construction field is clean and tidy, the construction period is short, good economic benefits and social benefits are achieved, and the precast concrete n-shaped beam is suitable for popularization and use.

Owner:CHINA RAILWAY CONSTR GROUP

Formwork-free fabricated shear wall structure and connecting method

ActiveCN112942626AReduce pollutionEasy to operateWallsBuilding reinforcementsButt jointWorking environment

The invention discloses a formwork -free fabricated shear wall structure and a connecting method. The formwork-free fabricated shear wall structure comprises a plurality of shear wall units which are in butt joint with one another, wherein a plurality of rows of pre-embedded tensile connecting pieces are arranged in each shear wall unit in the height direction, and every two pre-embedded tensile connecting pieces matched with one another in every two adjacent shear walls are connected in an inserted mode at the butt joint position of the shear wall units; special-shaped steel bars are arranged at the inserting positions, the axes of the special-shaped steel bars are parallel to the height direction of the shear walls, and post-pouring concrete is arranged in the inserting areas of the adjacent pre-embedded tensile connecting pieces. According to the connecting method, the mode that shear wall components are prefabricated in a factory and assembled and connected on site is adopted, and formwork erecting is not needed in the on-site horizontal connection process of the prefabricated components, so that the working efficiency of a construction site is improved to the maximum degree, and the working environment is improved.

Owner:SHANDONG JIANZHU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com