Assembled concrete component reinforcement magnetic suspension connecting and positioning device

A positioning device and concrete technology, applied in building construction, construction, building materials processing and other directions, can solve the problem of difficult to ensure the coaxial butt joint of non-grouting connecting steel bars and grouting connecting steel bars, weakening the load transfer of the connecting parts of the components, and the sleeves. The connection strength decreases and other problems, to avoid relative horizontal displacement, facilitate disassembly and assembly, and ensure the safety of electricity use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

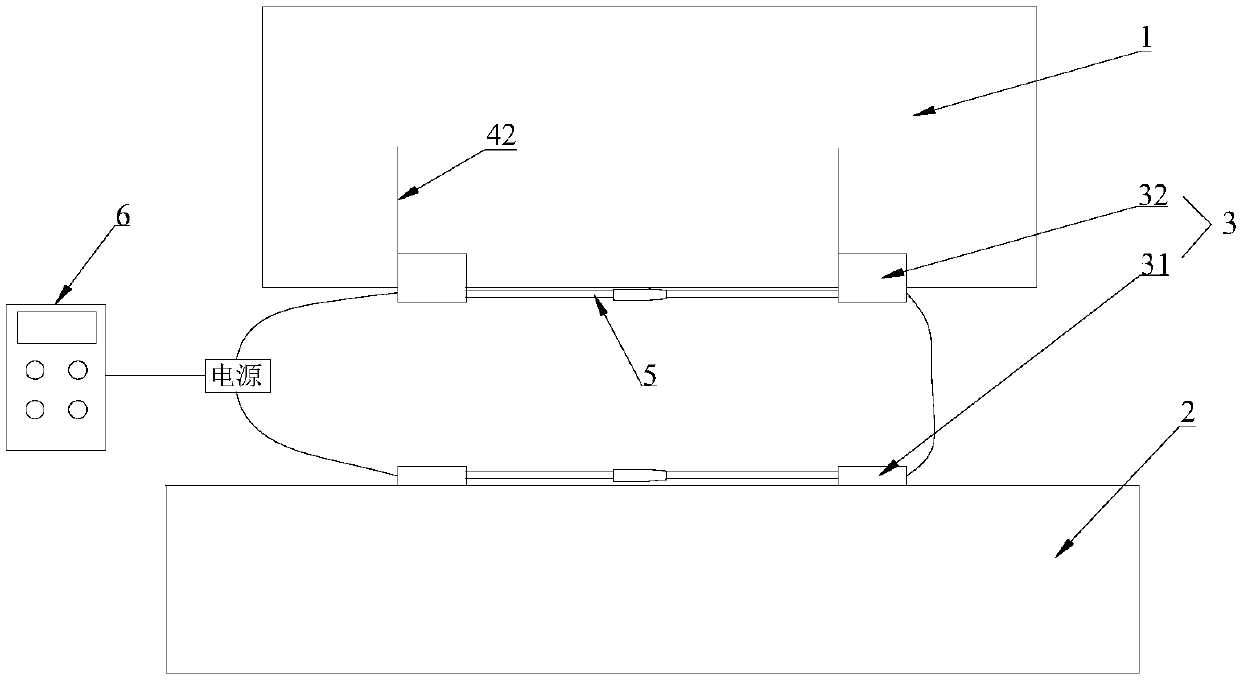

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a prefabricated concrete member steel bar magnetic levitation connection positioning device is used to position the upper concrete member 1 and the lower concrete member 2, so that the non-grouted connecting steel bars in the upper concrete member 1 and the grouted connecting steel bars in the lower concrete member 2 coaxial.

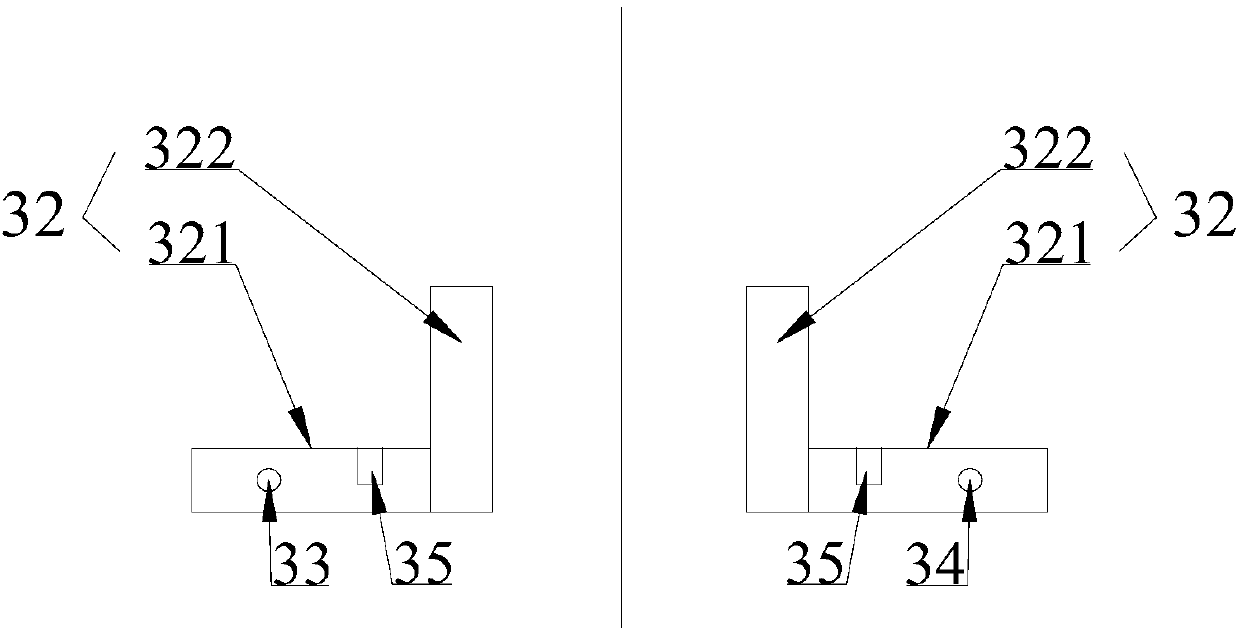

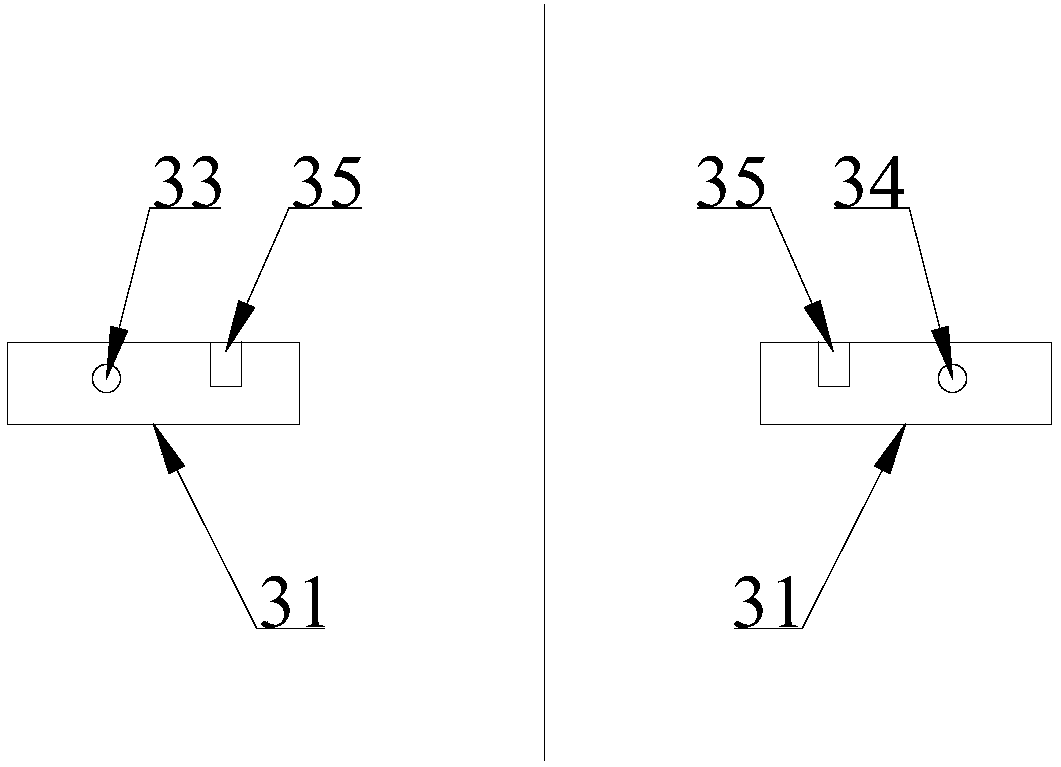

[0038] The positioning device includes a control mechanism 6, at least two groups of support mechanisms 3, and a positioning mechanism 4; the support mechanism 3 includes a lower support 31 and an upper support 32; the upper support 32 includes a supporting plate 321 and a limit plate 322; The plate 322 is vertically fixed on the end of the supporting plate 321, forming an L-shaped structure with the supporting plate 321; the supporting plate 321 and the lower support 31 are both electromagnets; the positioning mechanism 4 is included on the assembly surface of the uppe...

Embodiment 2

[0047] A prefabricated concrete member reinforcement magnetic levitation connection positioning method, comprising the following steps:

[0048] Step 1. Marking: setting at least two first marks on the assembly surface of the lower concrete member 2, and setting second marks corresponding to the number and position of the first marks on the side wall of the upper concrete member 1;

[0049] Step 2. Rough centering: first hoist the upper concrete member 1 to the set position, carry out rough centering of the upper and lower concrete members, and place the lower support 31 and the upper support 32 respectively at the first mark and the second mark , the supporting plate 321 and the lower supporting plate 31 on the upper supporting 32 are all electromagnets, and they are placed opposite to the magnetic poles, and the inner coils of the lower supporting 31 and the supporting plate 321 are connected in series on the same circuit; two adjacent upper supporting The support 32 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com