Cable core neatening device

A cable management device and cable technology, applied in circuits, electrical components, circuit/collector parts, etc., can solve the problems of cluttered work site, affect work efficiency, and large workload, and achieve easy wiring, bundling, The effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

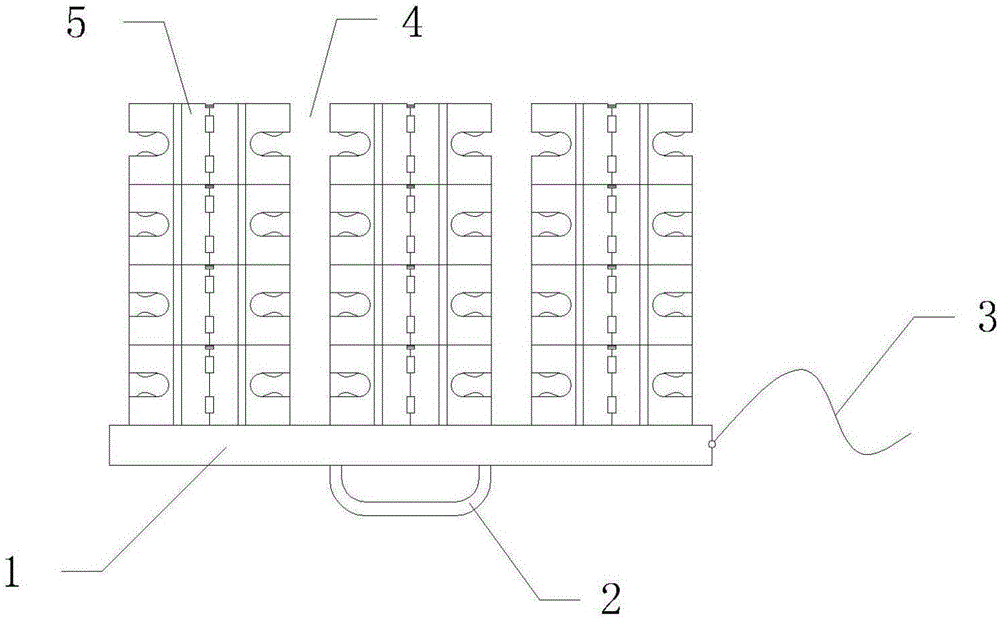

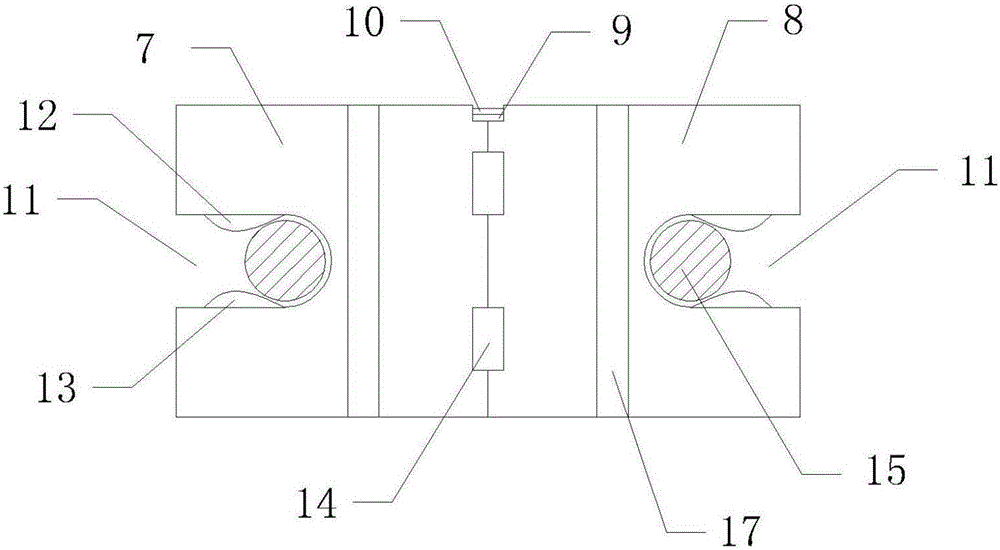

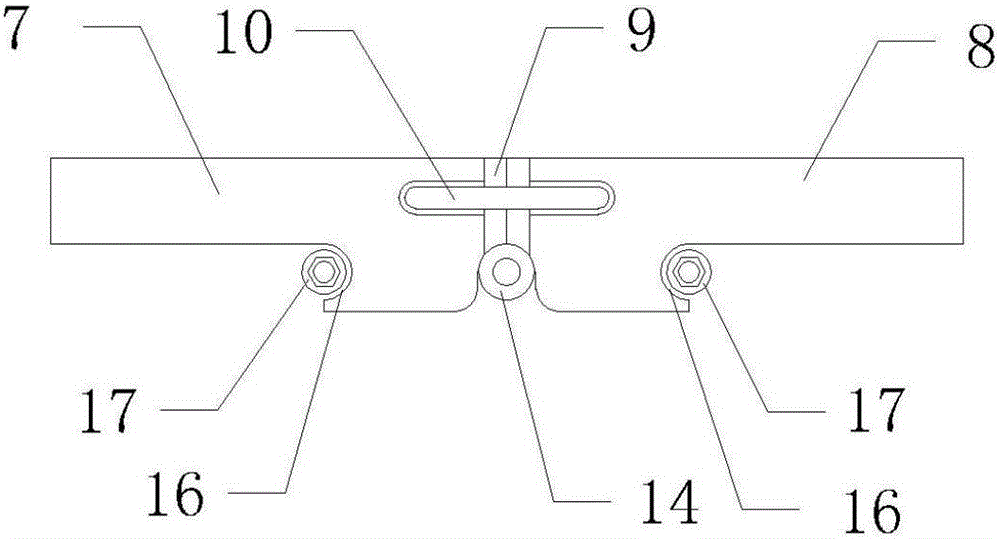

[0027] like Figures 1 to 7 As shown, the cable core wire management device includes a base plate 1 and several wire management boards 5, and the wire management board 5 includes a first movable board 7 and a second movable board 8, and the first movable board 7 and the second movable board The plate 8 is hinged, and the ends of the first movable plate 7 and the second movable plate 8 are provided with a draw-in groove 16, and a fixed rod 17 is arranged in the described draw-in groove 16, and a screw rod 19 is provided at the lower end of the fixed rod 17. The upper end of the fixed rod 17 is provided with a second threaded hole 18 and a wrench groove 20, the base plate 1 is provided with some first threaded holes 6, and a connecting pin is arranged between the first movable plate 7 and the second movable plate 8, The first movable plate 7 and the second movable plate 8 are provided with threading grooves 11 , and wire core fixing devices are arranged in the threading grooves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com