Patents

Literature

127 results about "Toggle pin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Toggle Hitch Pin is a pin that utilizes a safety clip free securing mechanism (Toggle). The Toggle securing device is attached to the pin by high tensile steel chain to prevent loss and to ensure the Toggle is always readily available. The Toggle Pin comes with a large handle for ease of removal, and heavy duty washer welded to it.

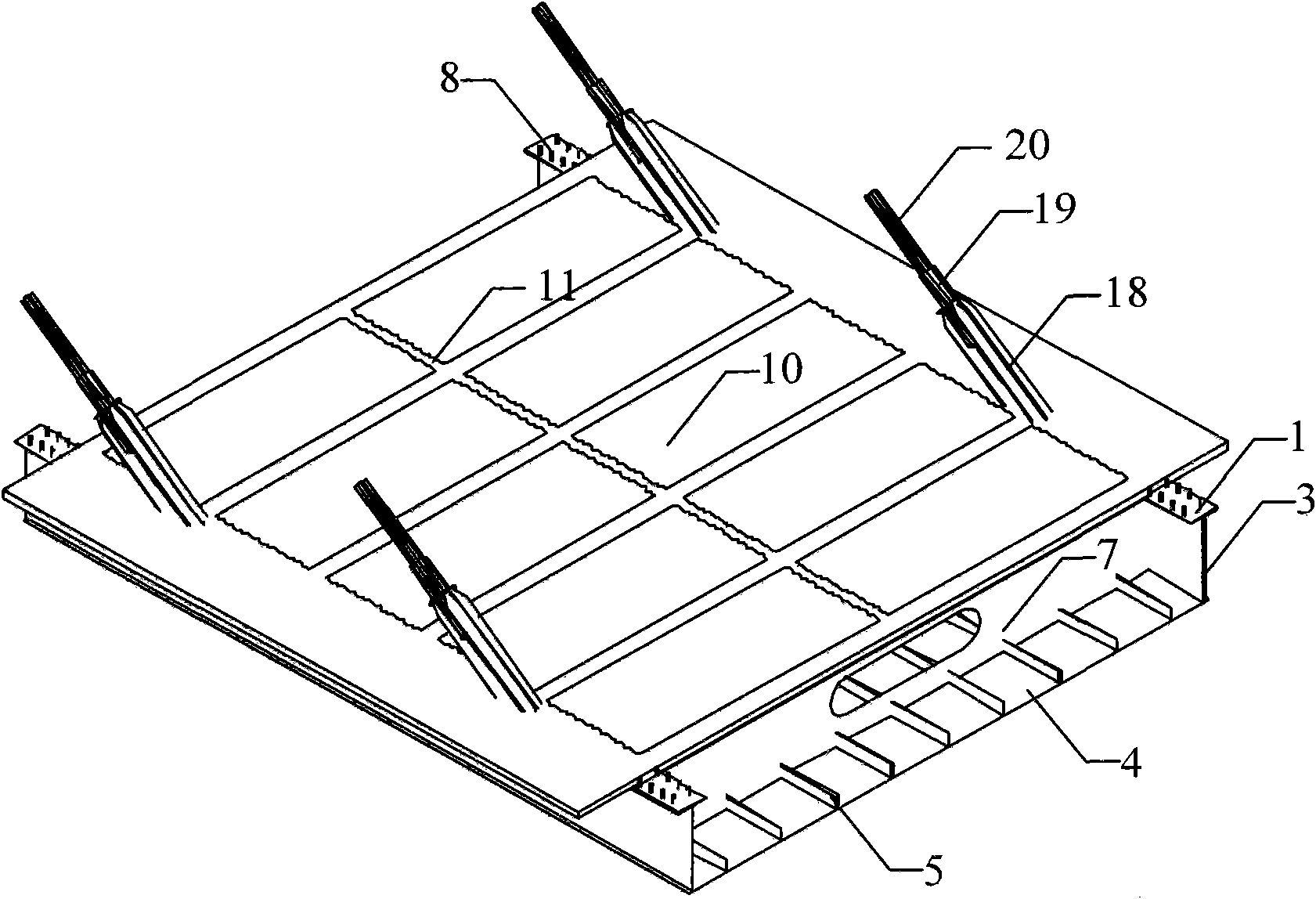

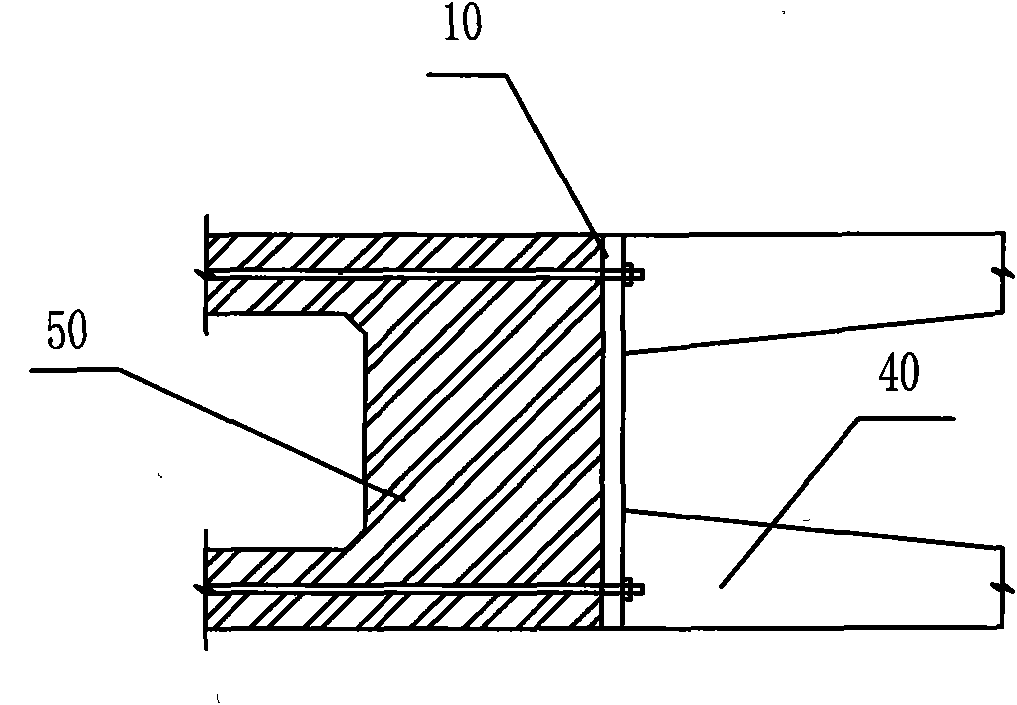

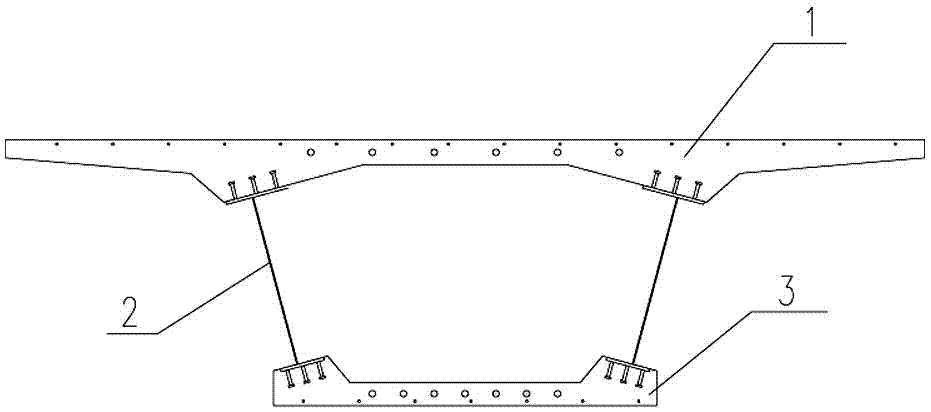

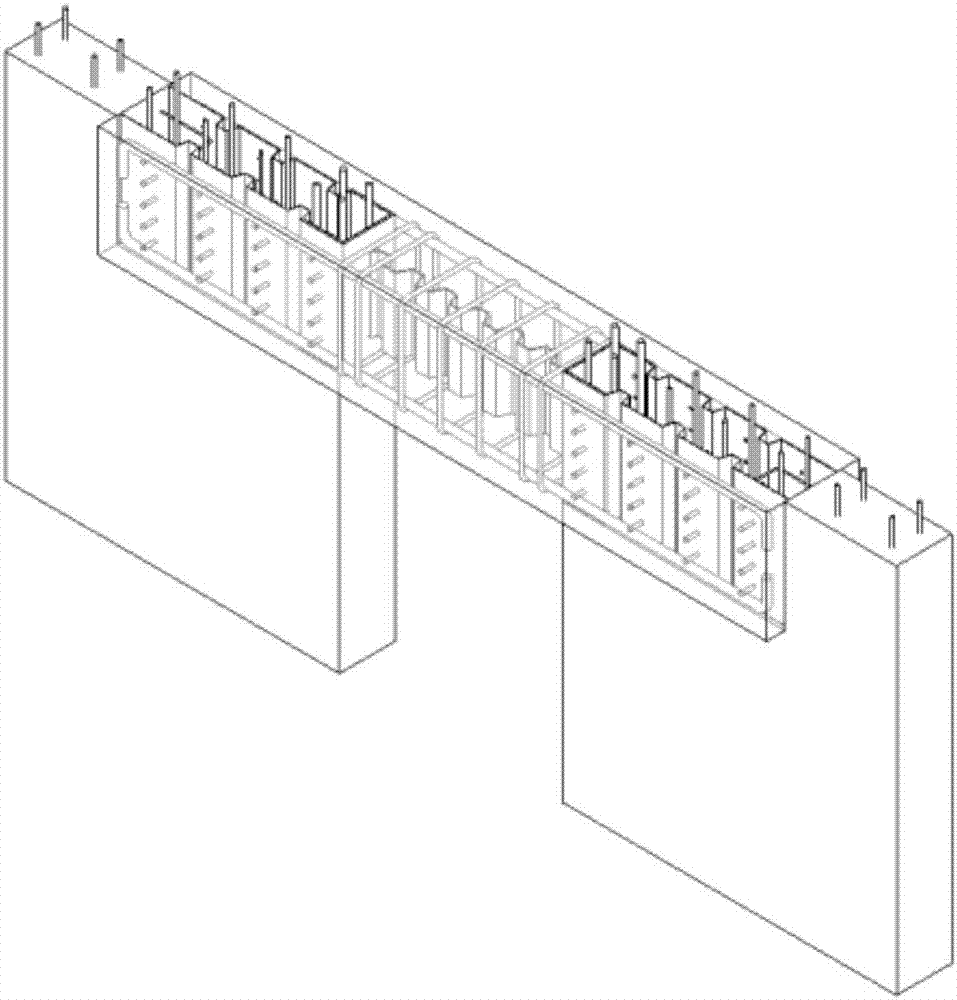

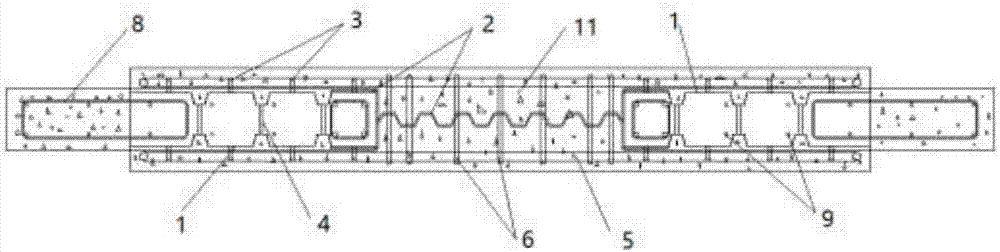

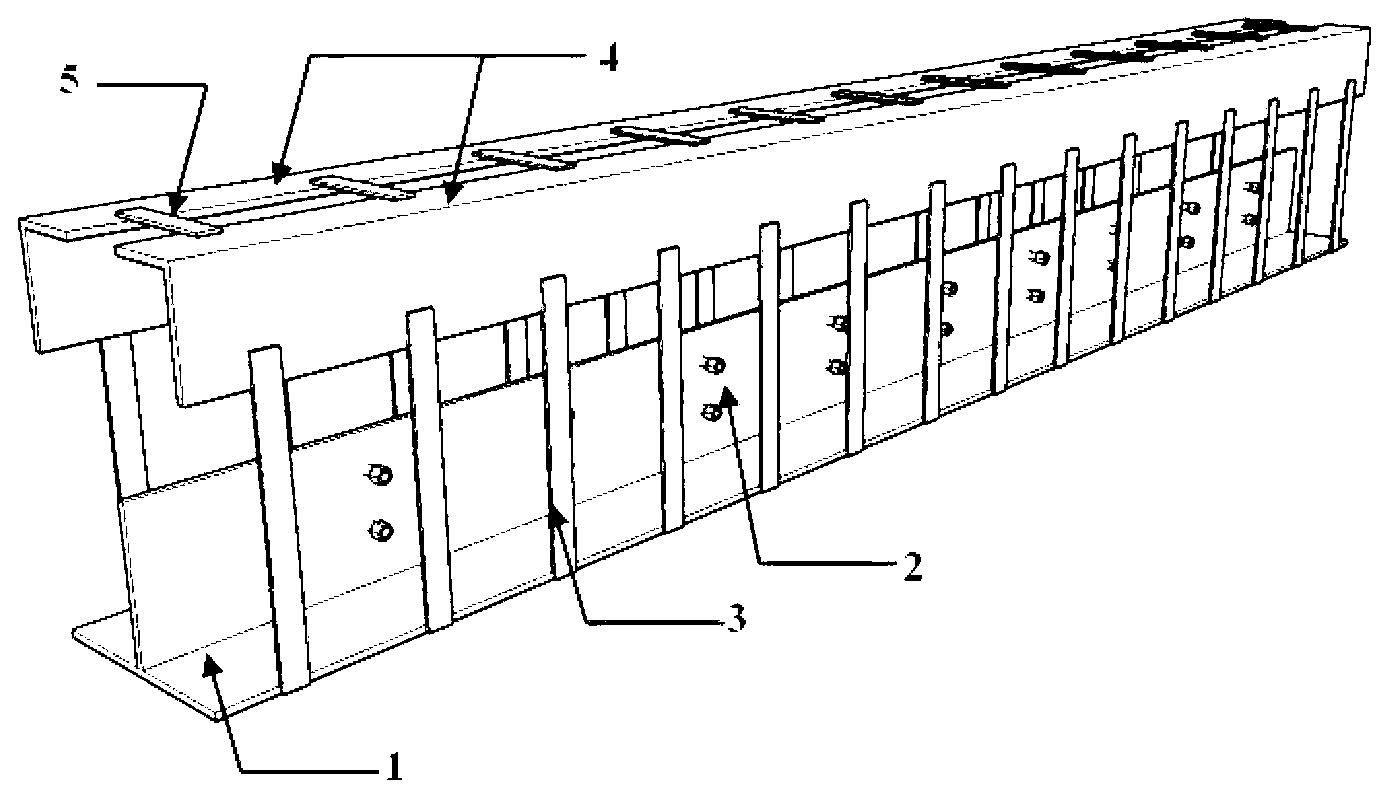

Corrugated steel webplate combined box girder floor system for cable-stayed bridge and construction method thereof

InactiveCN101864729AAvoid on-site molding processReduce wet work workloadCable-stayed bridgeBridge structural detailsCrack resistanceEngineering

The invention relates to a corrugated steel webplate combined box girder floor system for a cable-stayed bridge and a construction method thereof, and belongs to the technical field of bridge structures. The corrugated steel webplate combined box girder floor system comprises a precast concrete plank and a cast-in-place concrete seam, wherein the precast concrete plank is positioned on a steel box girder and is integrated with the steel box girder into a whole; the steel box girder is formed by welding a top flange steel plate, a corrugated steel webplate and a steel plate at the bottom of the box girder; a box girder baseplate stiffening rib and a diaphragm plate are welded in the steel box girder; the diaphragm plate comprises a top flange steel plate of the diaphragm plate and a steel webplate of the diaphragm plate; a toggle pin connecting piece is welded on the top flange steel plate and the top flange steel plate of the diaphragm plate; and a steel anchor pulling plate and a steel sleeve are welded on the top flange steel plate. The corrugated steel webplate combined box girder floor system simplifies the manufacturing process for the precast concrete plank, gives full play to the superior mechanical property of the corrugated steel webplate and the release action of the corrugated steel webplate on the creep effect of concrete shrinkage, improves the bearing capacity, stiffness and crack resistance of the structure, and improves the durability of the structure.

Owner:TSINGHUA UNIV

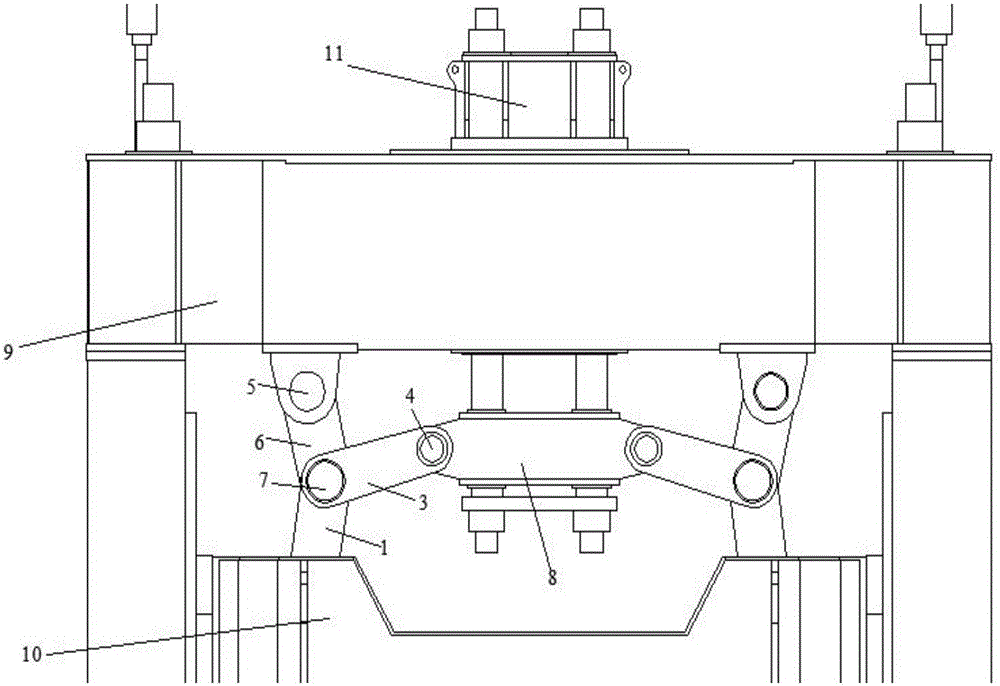

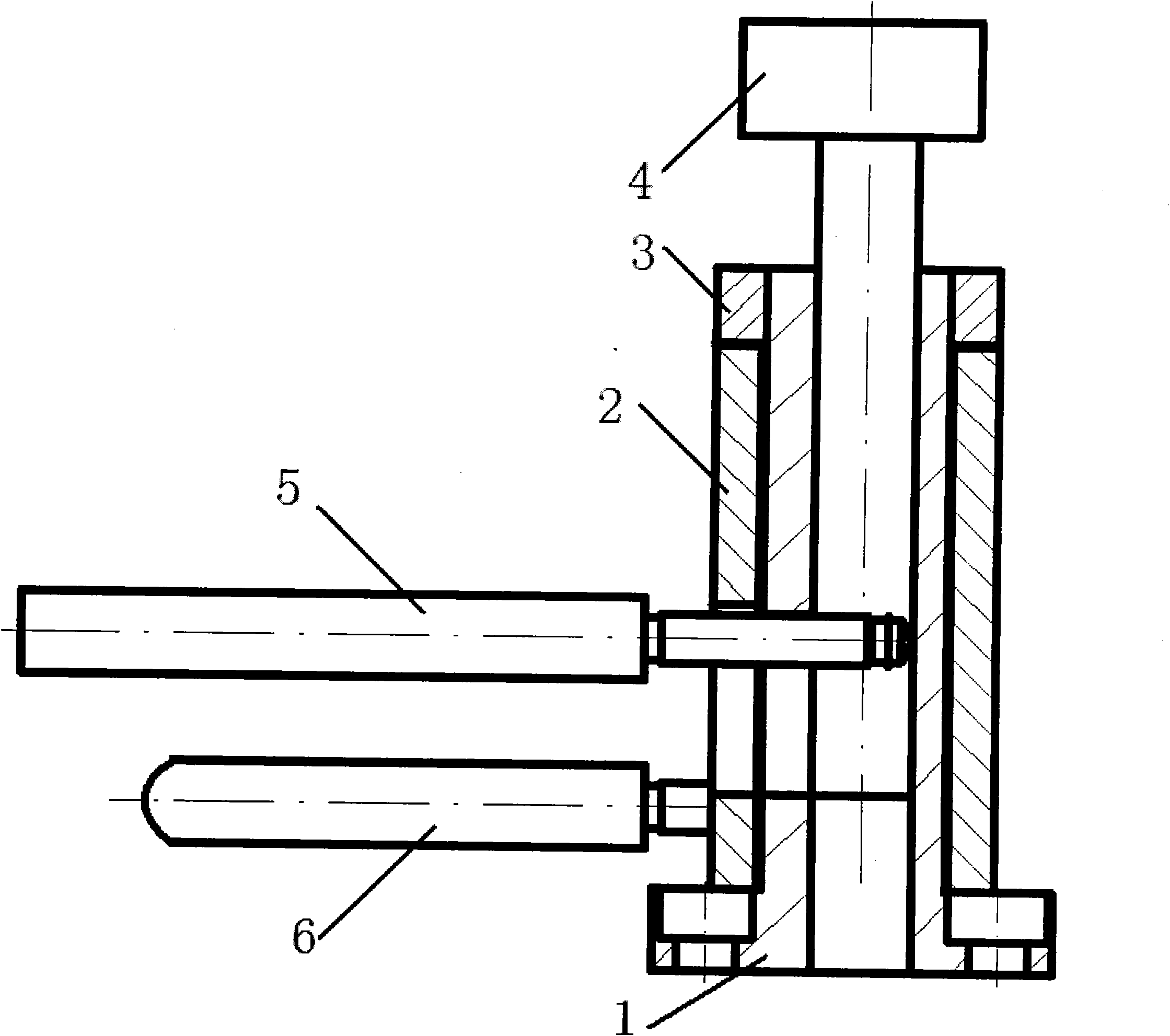

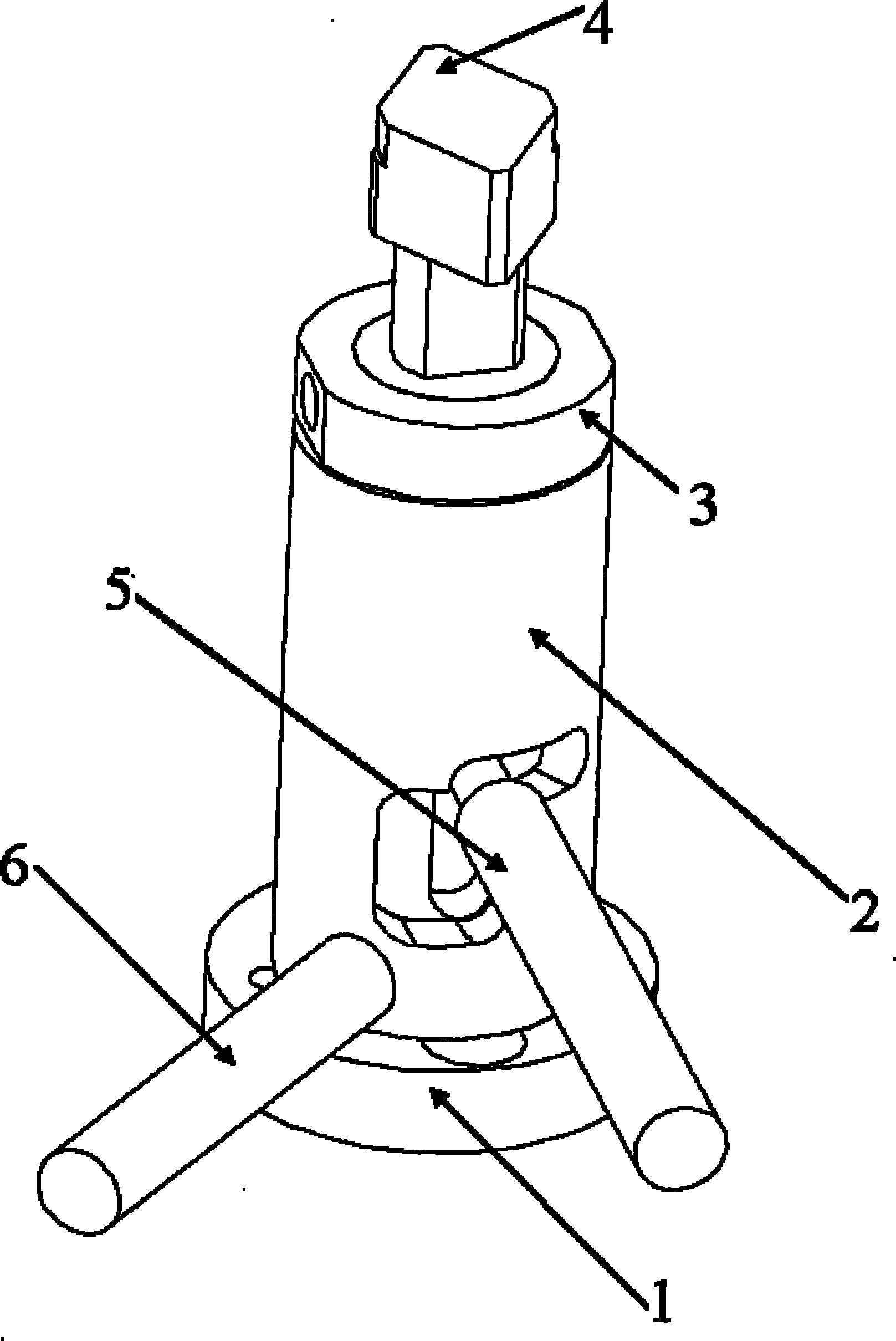

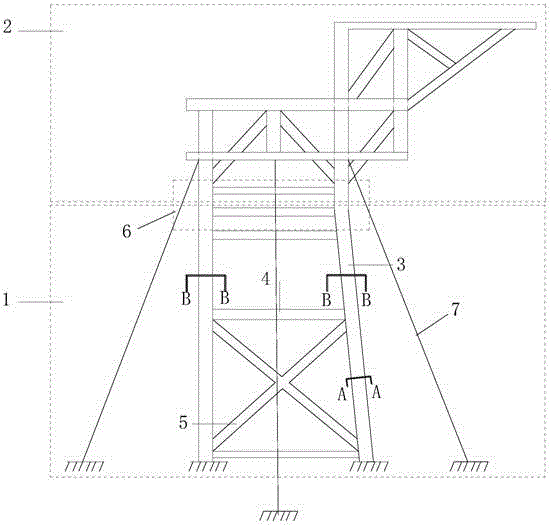

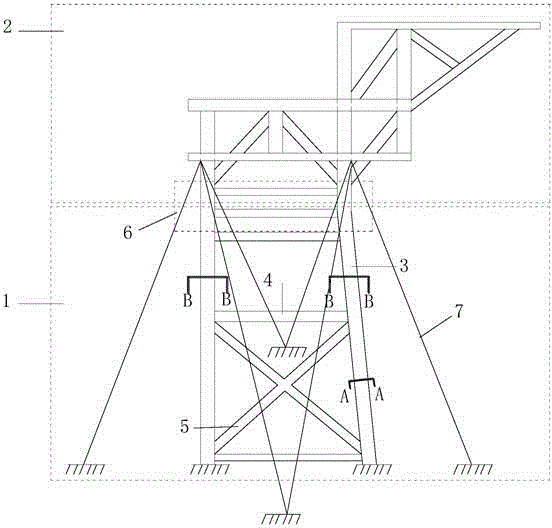

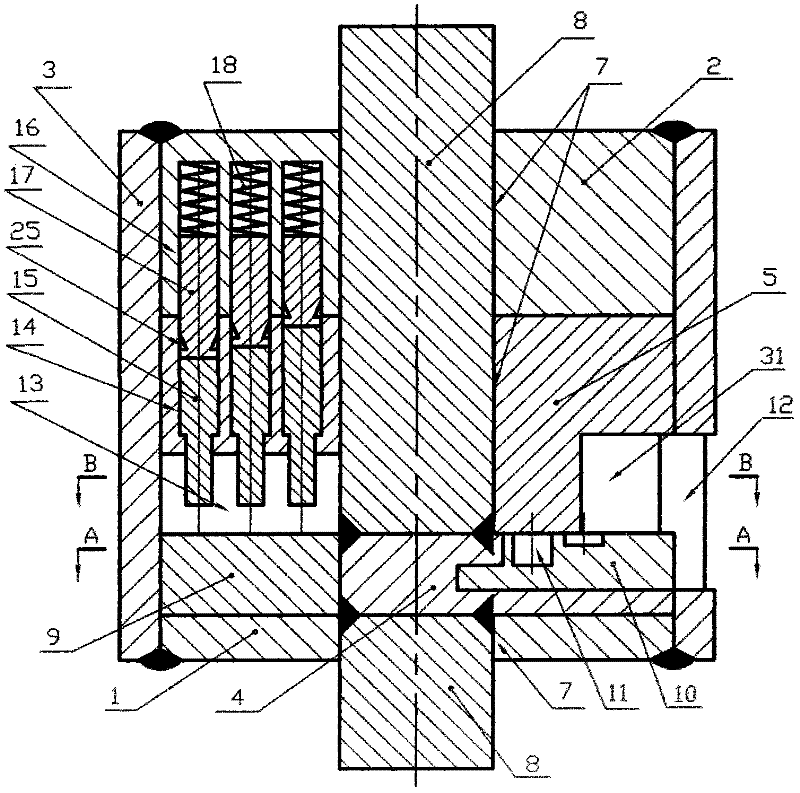

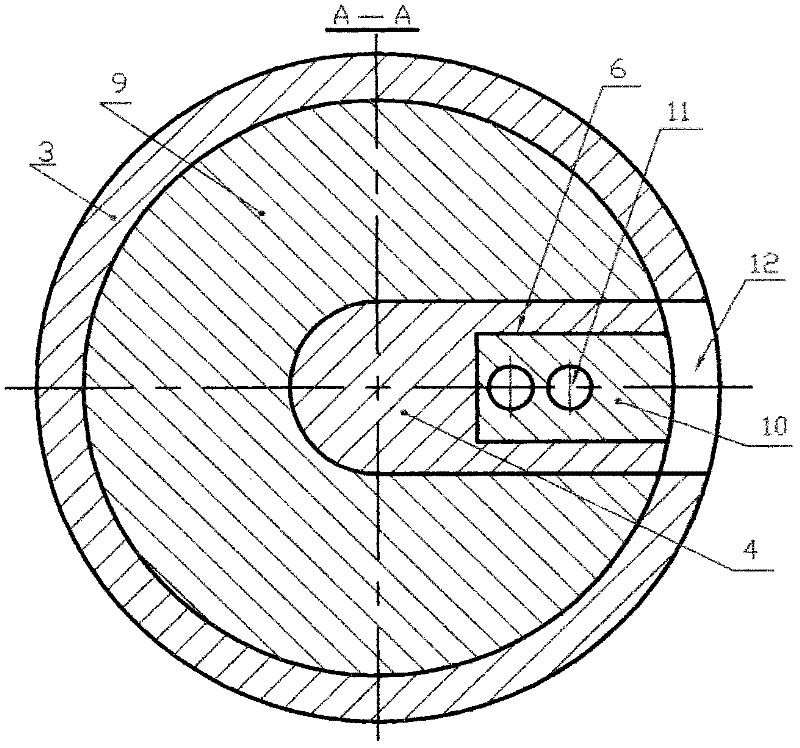

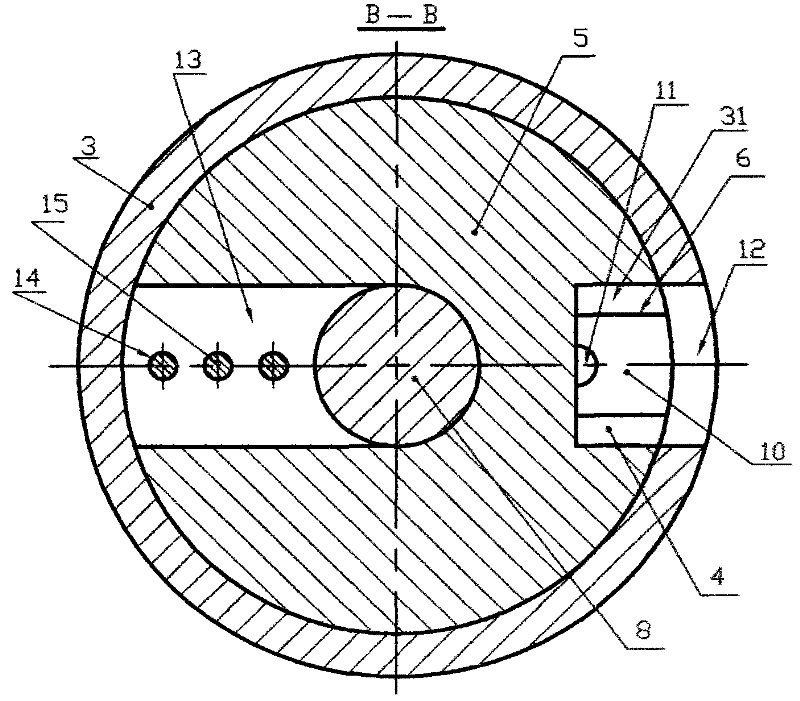

Oil cylinder and connecting rod drive system for compounded transmission hydraulic machine

An oil cylinder and connecting rod drive system for a compounded transmission hydraulic machine comprises a symmetric connecting rod force amplifier and a hydraulic machine oil cylinder. The symmetric connecting rod force amplifier is composed of four connecting rod mechanisms in two symmetric groups on the left side and the right side. Each connecting rod mechanism is composed of a toggle rod, a toggle pin, a force exerting rod, a force exerting pin, a drive rod, a drive pin and a hinge pin, wherein the toggle rod is connected with an upper cross beam of the hydraulic machine through the toggle pin, the drive rod is connected with a small slide rest of the hydraulic machine through the drive pin, the force exerting rod is connected with a slide block of the hydraulic machine through the force exerting pin, the toggle rod, the drive rod and the force exerting rod are connected through the hinge pin, the slide block of the hydraulic machine is driven by the hydraulic machine oil cylinder, and reciprocating movement of the hydraulic machine is achieved. The oil cylinder and connecting rod drive system for the compounded transmission hydraulic machine has the advantages that the drive system is compact in structure and high in efficiency, the radial component force is balanced by adoption of the symmetric connecting rod mechanisms and connecting rod small slide rest guide pillars, an eccentric load in the operating process of the hydraulic machine can be effectively overcome, the high precision of the slide block is maintained, and the installed capacity is decreased.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

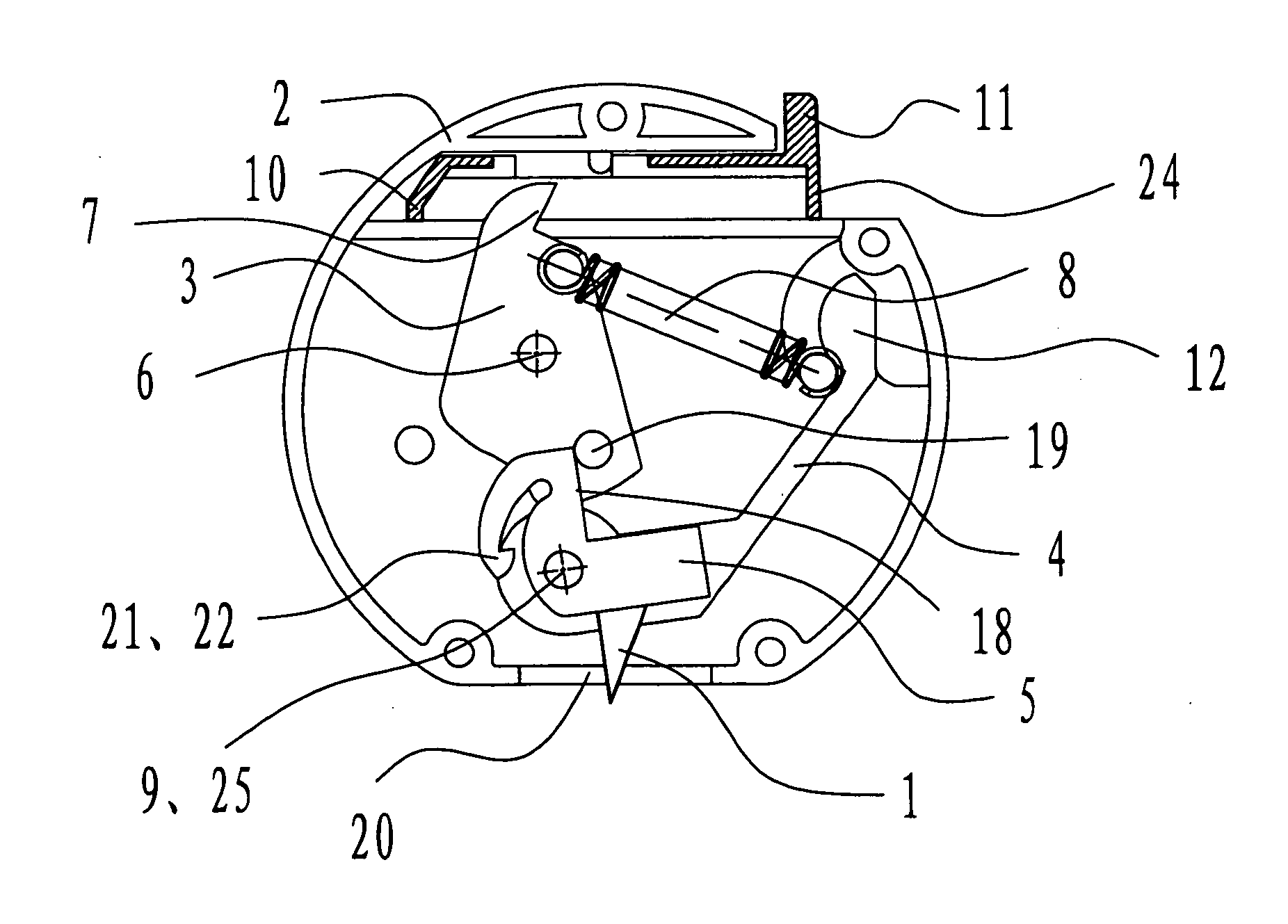

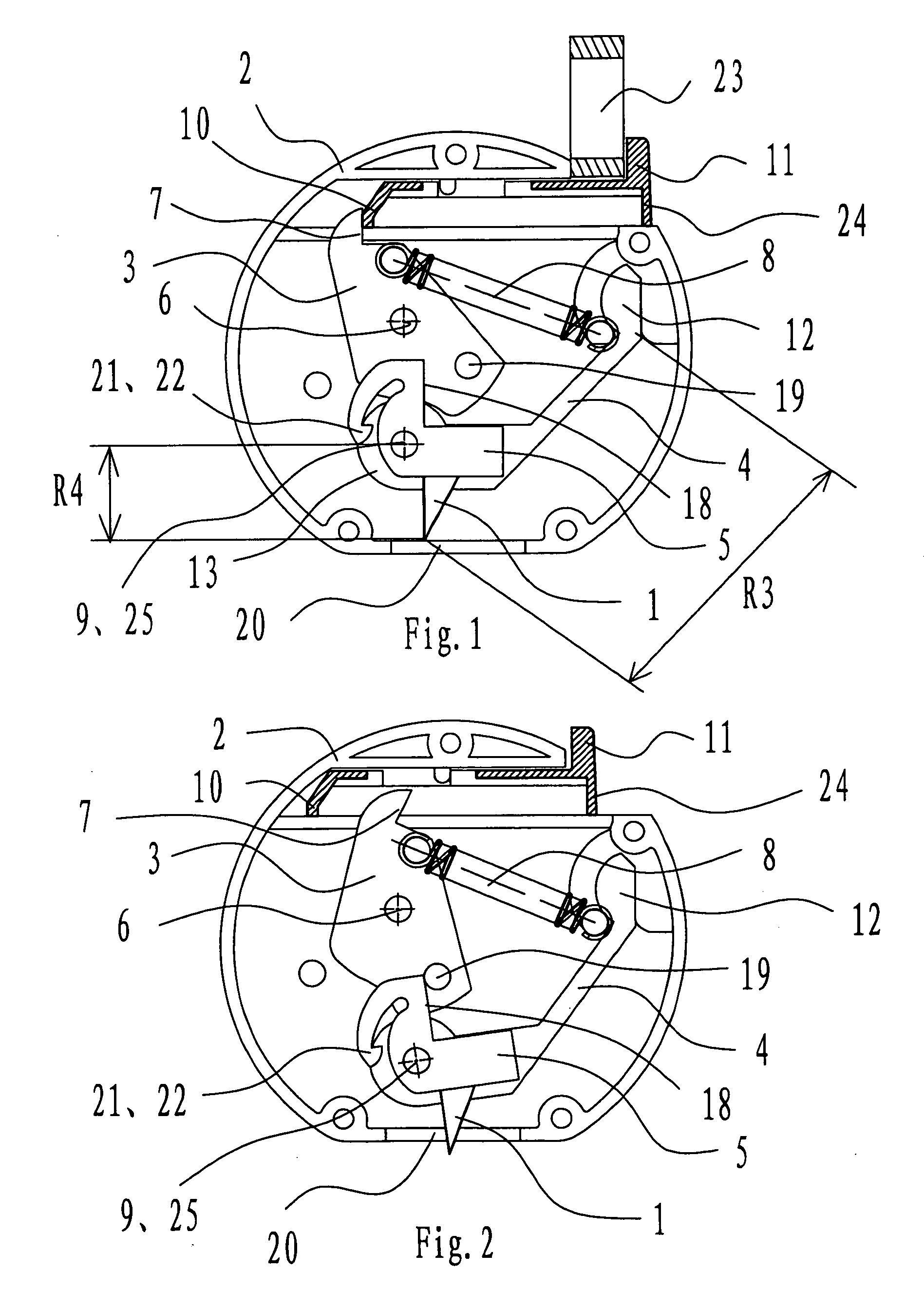

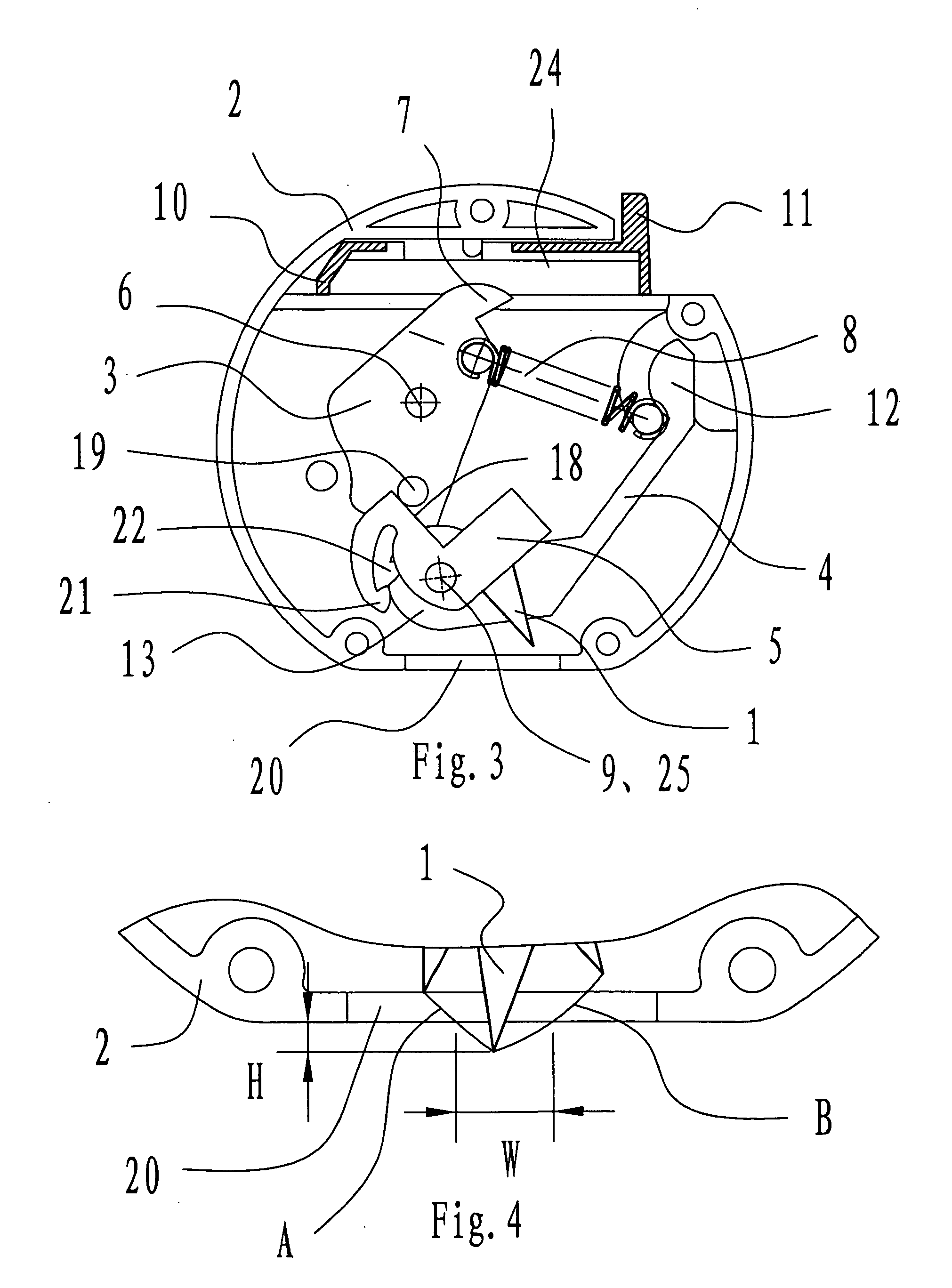

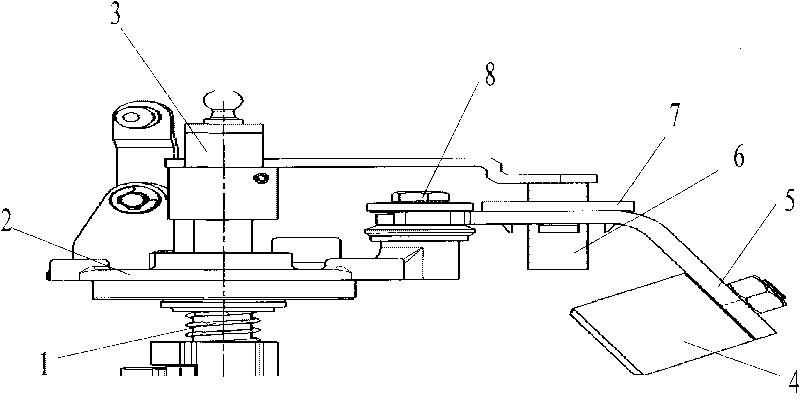

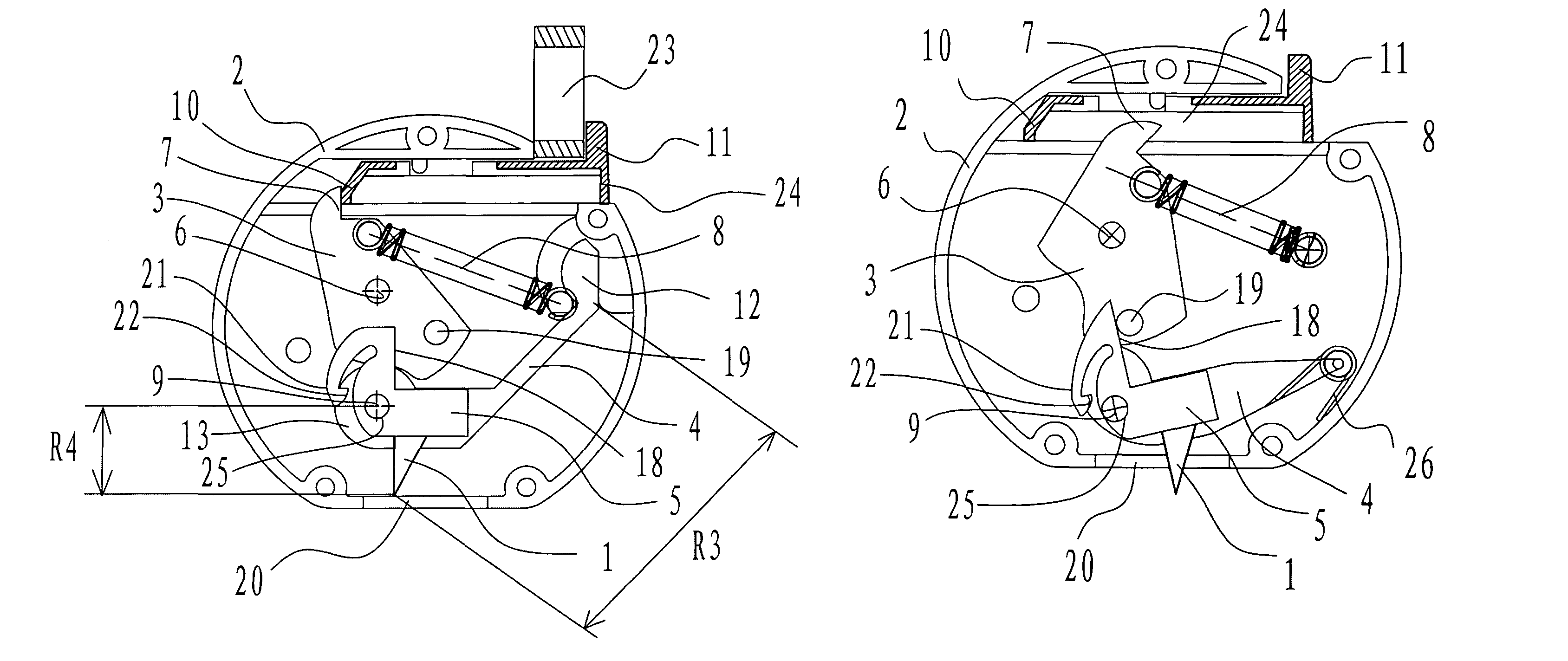

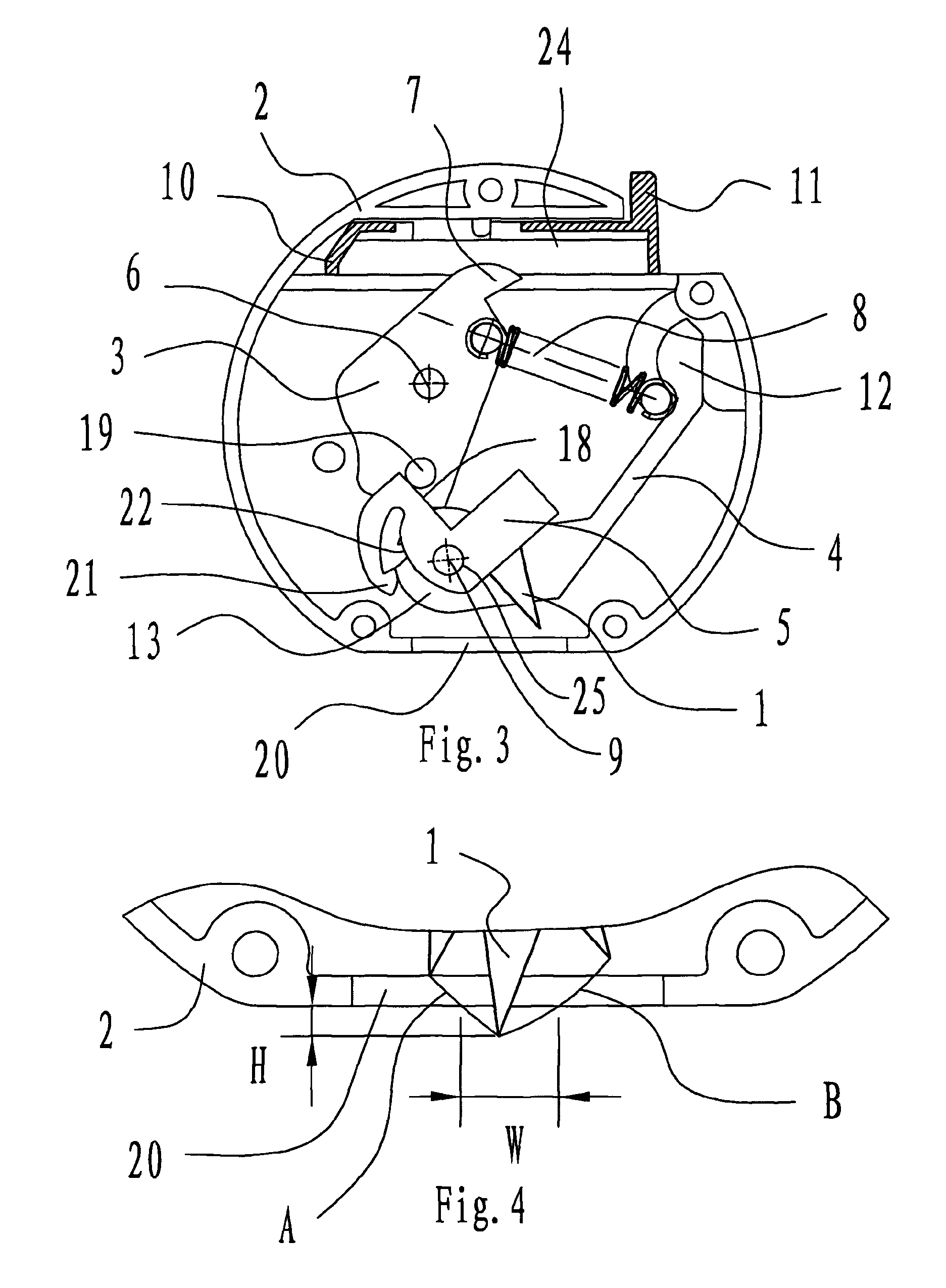

Disposable incision safety lancet

A disposable incision safety lancet is provided, including a casing (2) and a trigger. It is characterized in that the casing (2) is provided inside with an incision blood-taking mechanism composed of a cam (3), a main swing arm (4), a secondary swing arm (5), a blade (1) and a spring (8). The present invention combines the two arc-shaped tracks obtained from the two swing mechanisms, the main swing arm and the secondary swing arm, via the cam and a toggle pin provided on the cam effectively and interlockingly, thus making the point of the blade incise along a V-formed path composed of two arcs of different shape connected with each other. Compared with the prior art single-swing-arm structure of the incision blood-taking mechanism, such a double-swing-arm structure can move with higher accuracy and controllability. An incision of different blood-taking depth and blood-taking width can be designed by means of changing the difference of change of the radius of curvature of the flange of cam (3) as well as changing the swing radius of the main swing arm (4) and the secondary swing arm (5), which is especially suitable for taking blood from infants' heel.

Owner:SHI GUOPING

Toggle bolt assembly

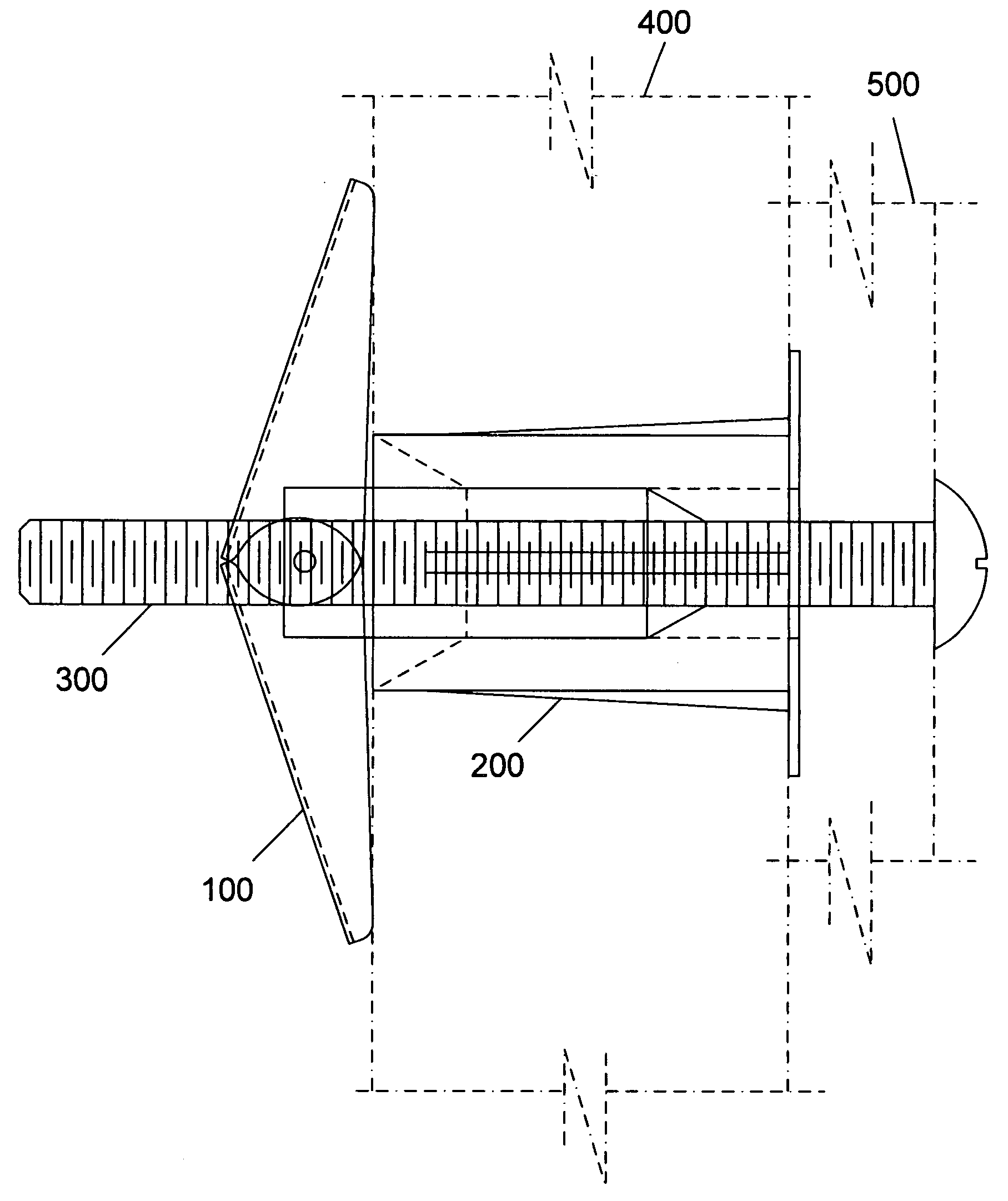

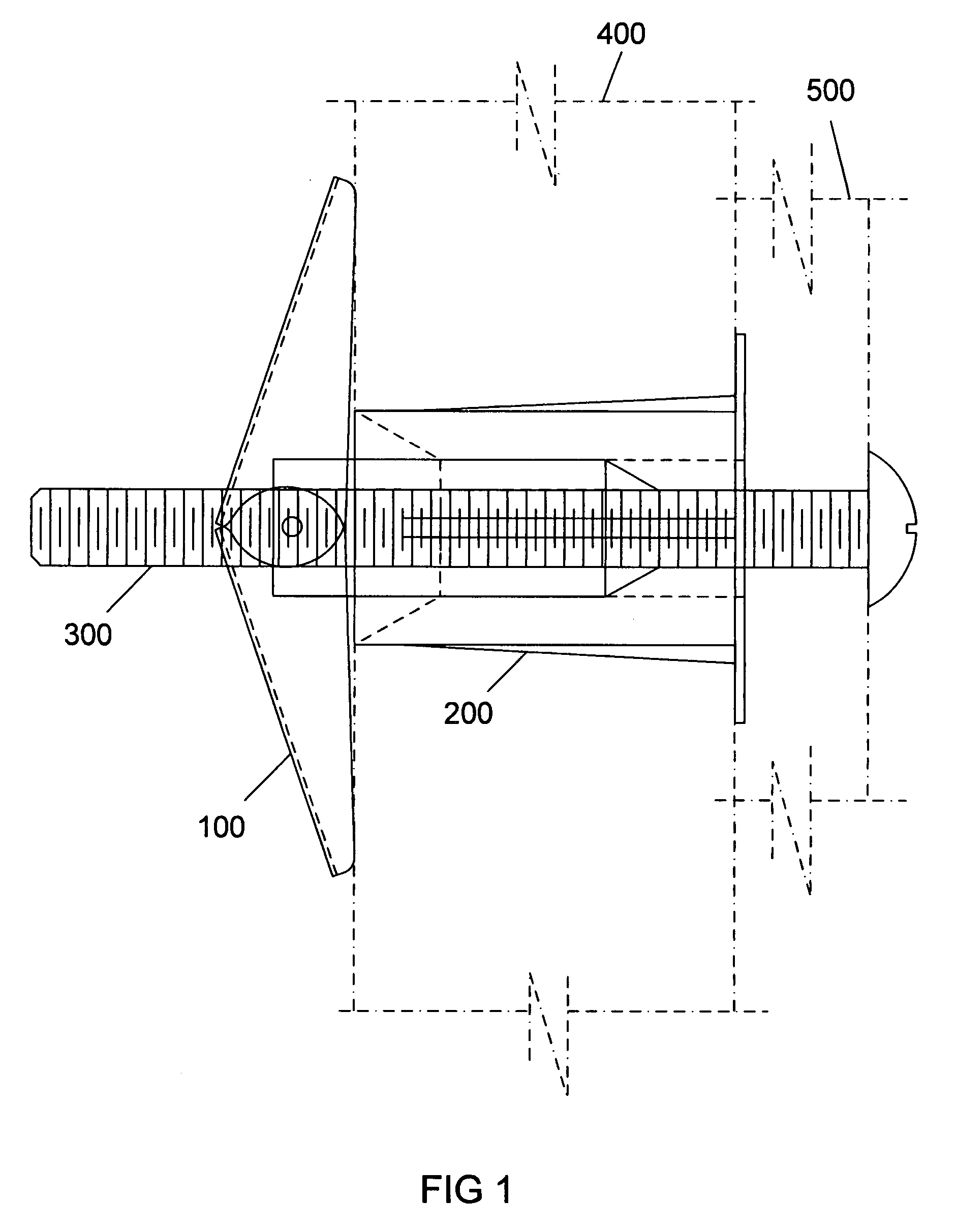

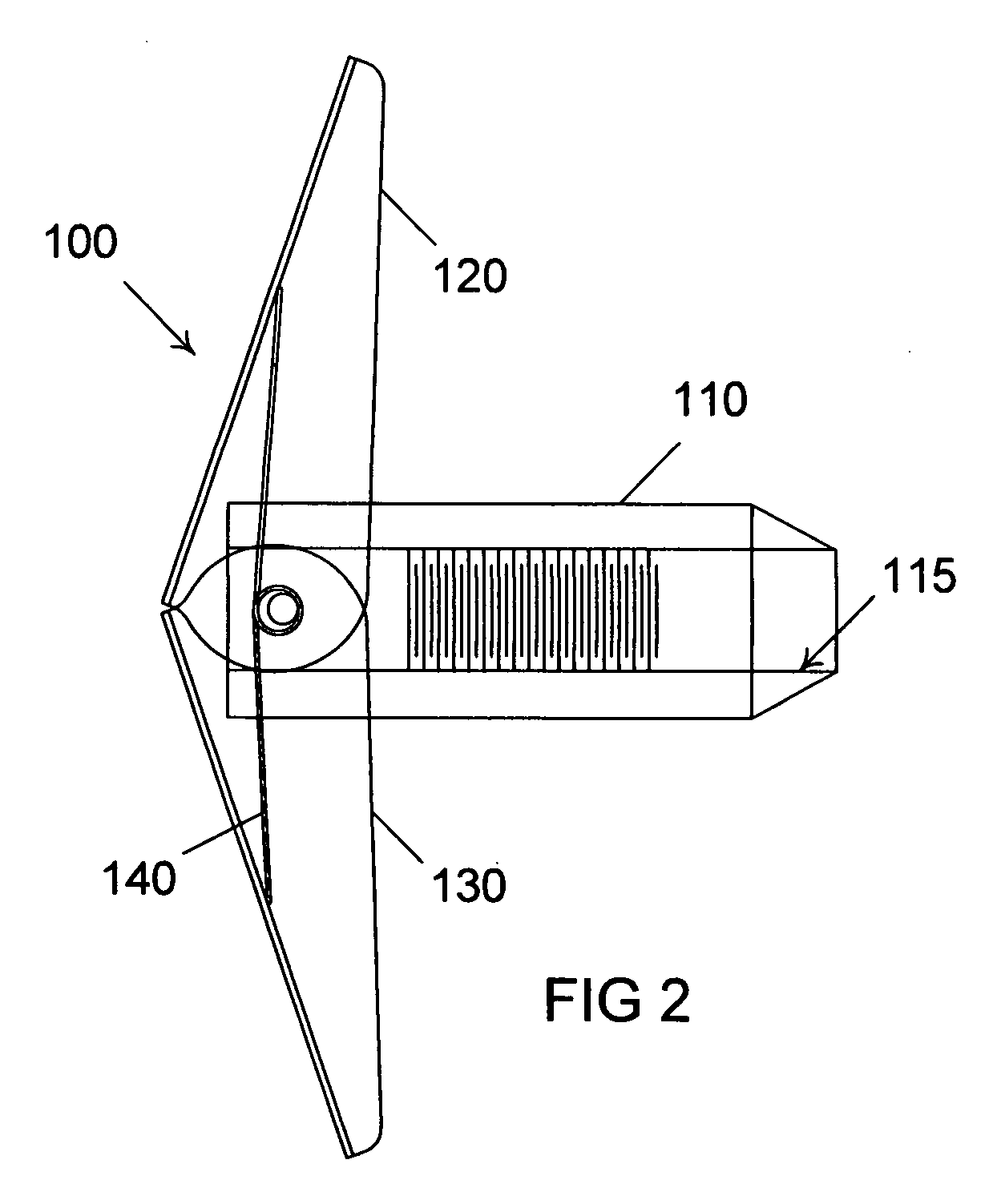

An improved toggle bolt assembly consisting of a toggle nut 100, collar 200, and screw 300, wherein the toggle nut 100 consists of an internally threaded cylindrical sleeve 110, a first winged member 120, and a second winged member 130. The cylindrical sleeve 110 of the toggle nut 100 engages with a collar 200, acting to center the assembly, hold the toggle nut 100 and collar 200 in place without engagement of the screw 300, and eliminate the need to apply tension to the screw 300 during installation.

Owner:FUCITO DOMINICK JOSEPH

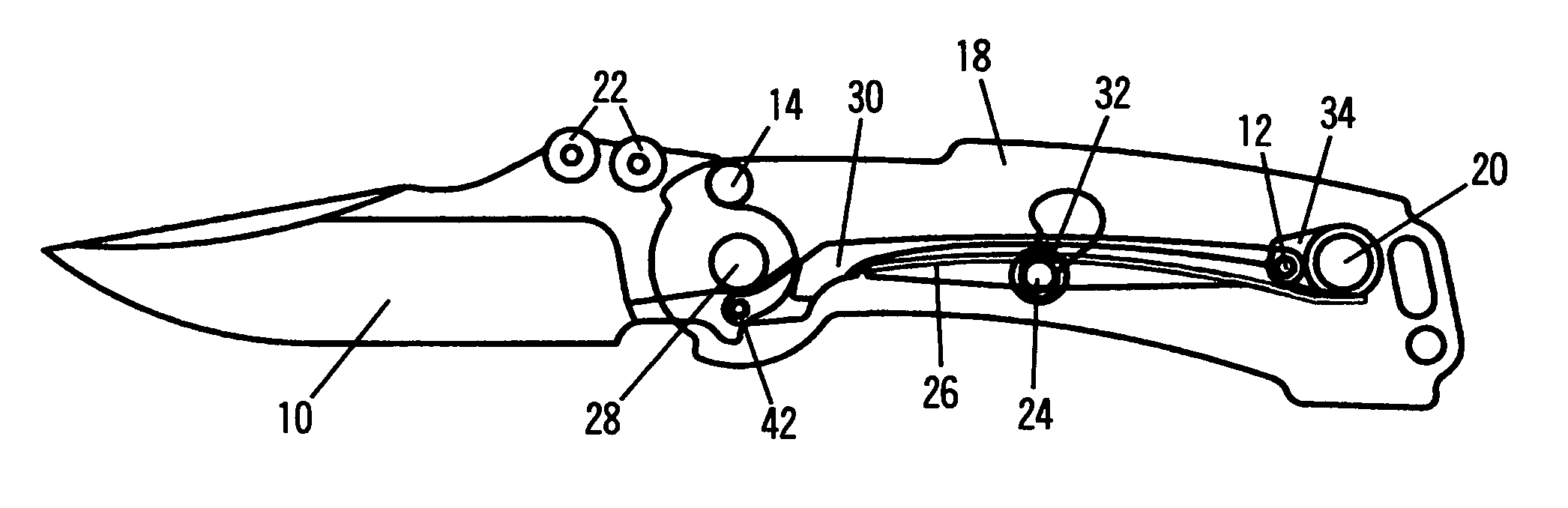

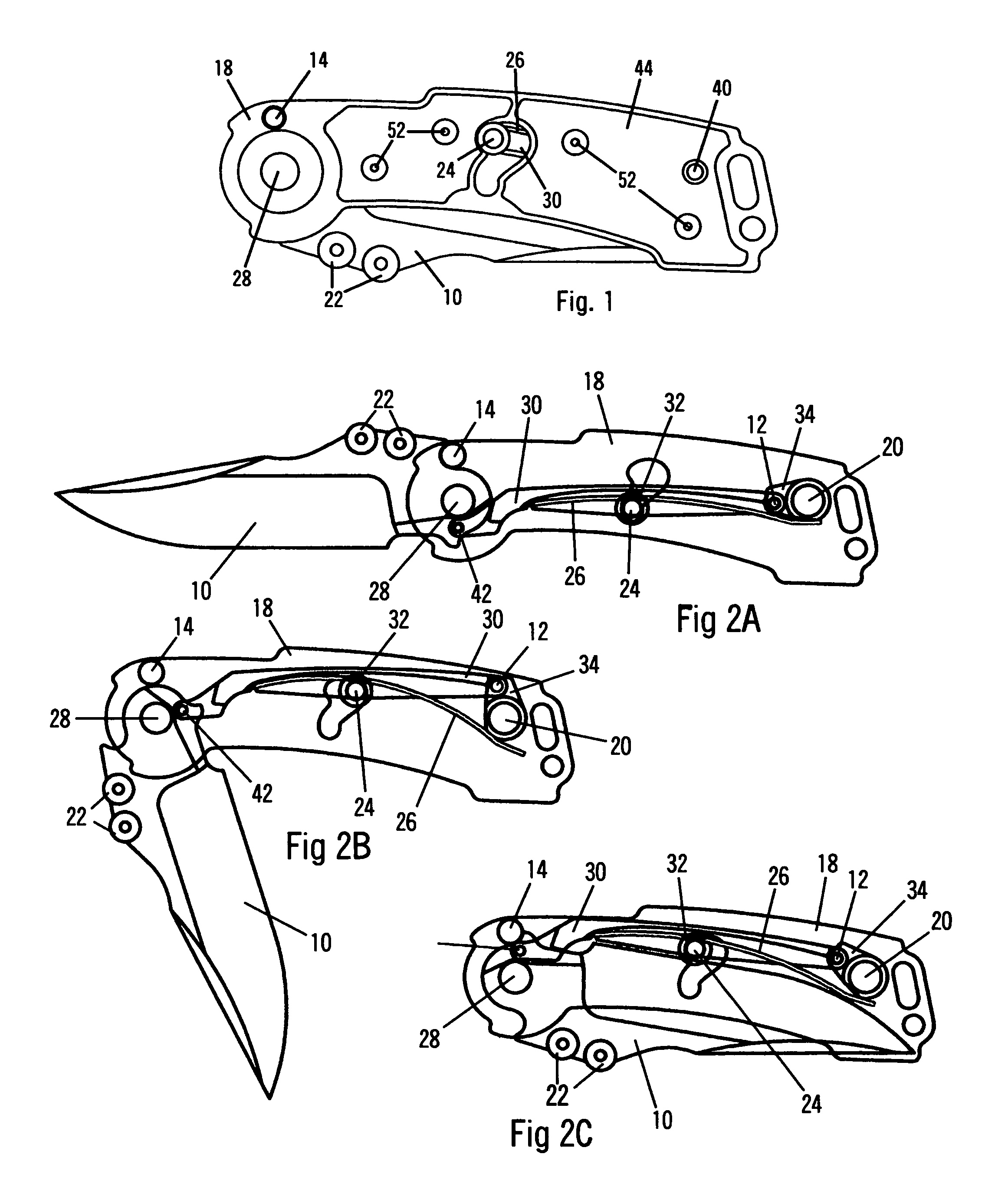

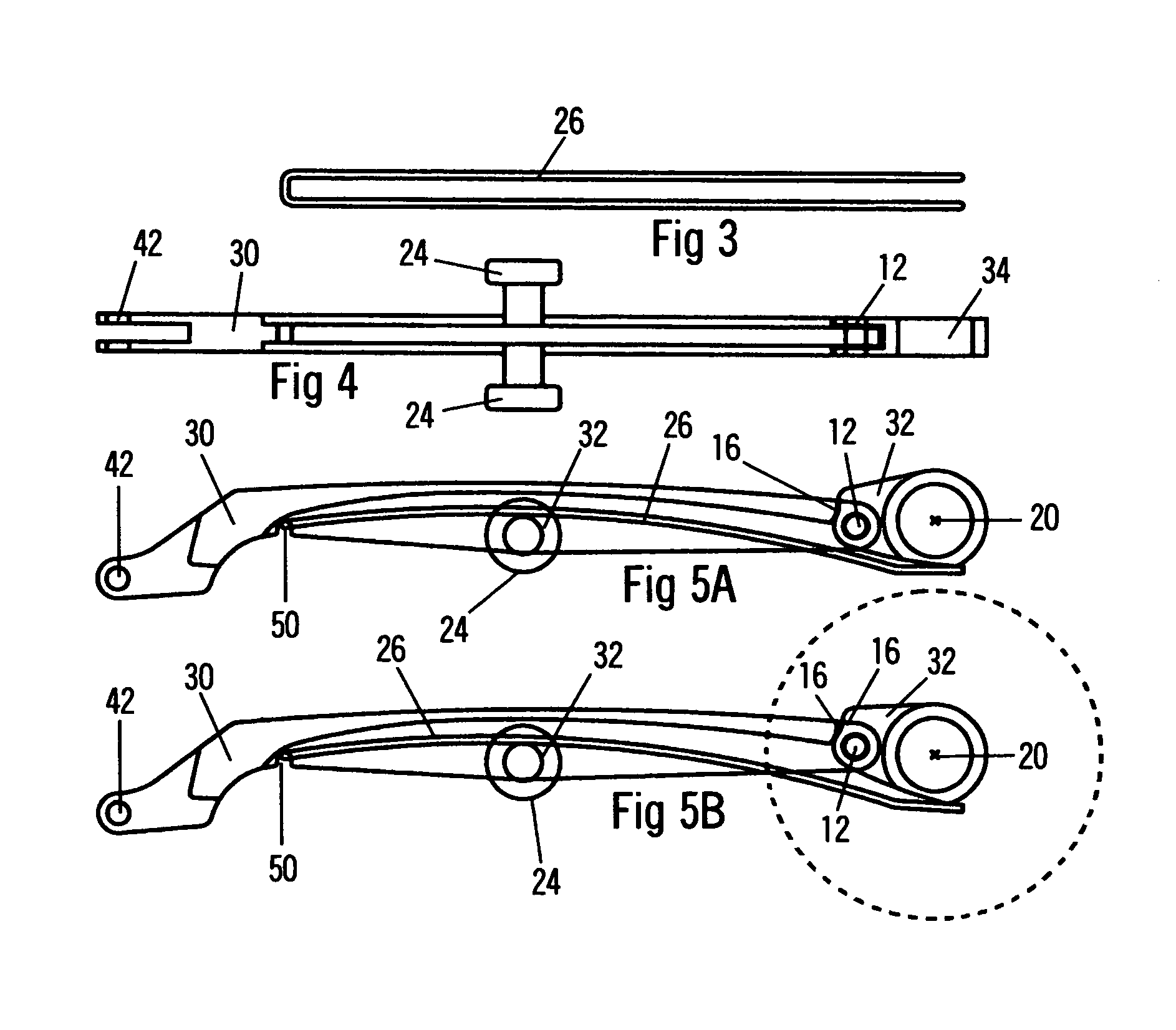

Spring powered toggle joint lock for a folding knife

A “spring powered toggle joint lock” for a folding knife; comprising a blade lock of three primary elements. A rotating toggle link at the rear of the knife handle connected by a pivoting knee joint to a traveling toggle, which is in turn pivotally joined to the tang of the opening and closing blade. A spring configured so as to constantly urge the pivot points of the rotating toggle and traveling toggle into a straight line, generating an over-center action. The effect of the spring and toggle combination is to propel the opening blade towards open and the closing blade towards closed. Control pins attached to the traveling toggle and protruding to the surface of the handle, on both sides of the handle, provides the means to collapse the toggle lockup by thumb pressure, thereby allowing ambidextrous, one handed manipulation of a toggle locking folding knife.

Owner:HAWK GRANT WOODROW

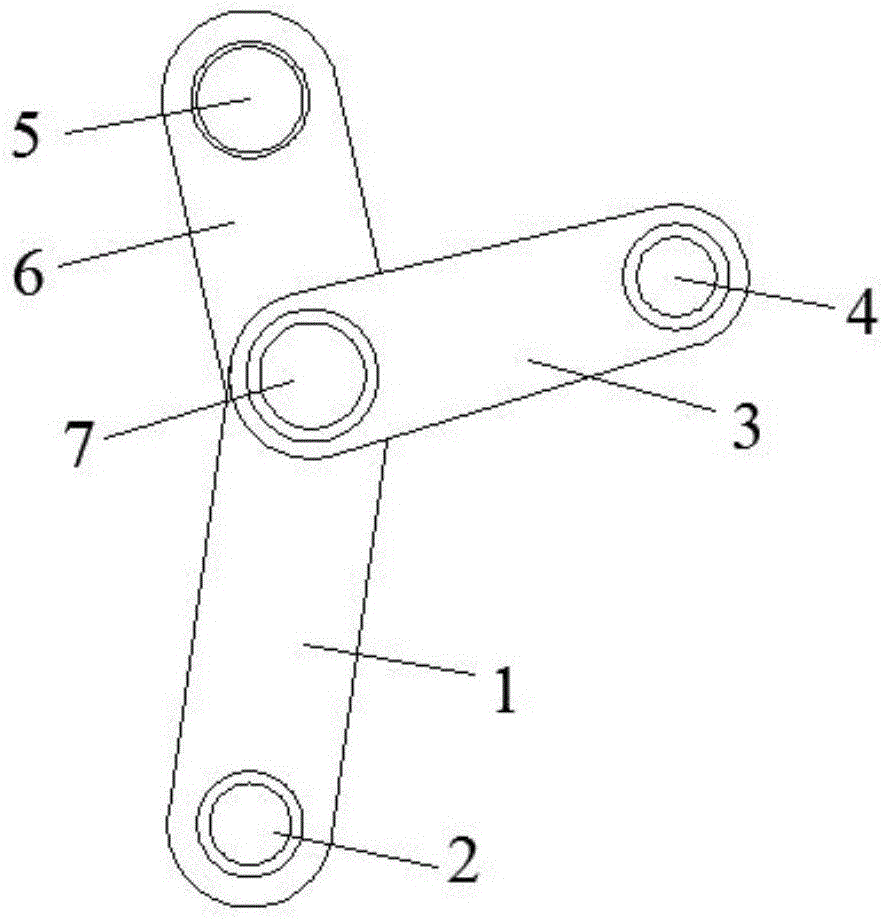

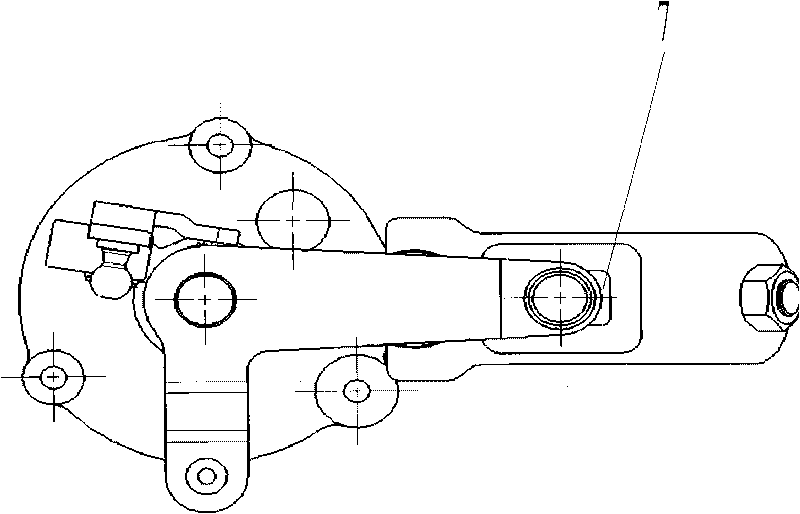

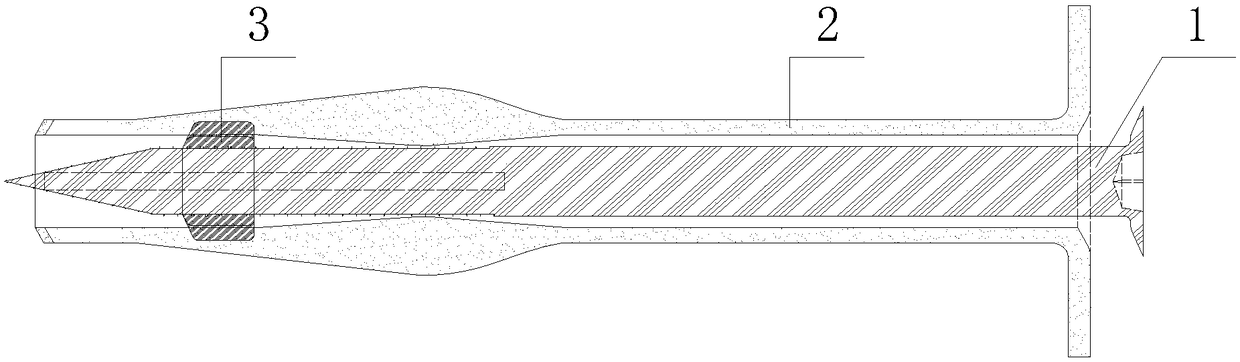

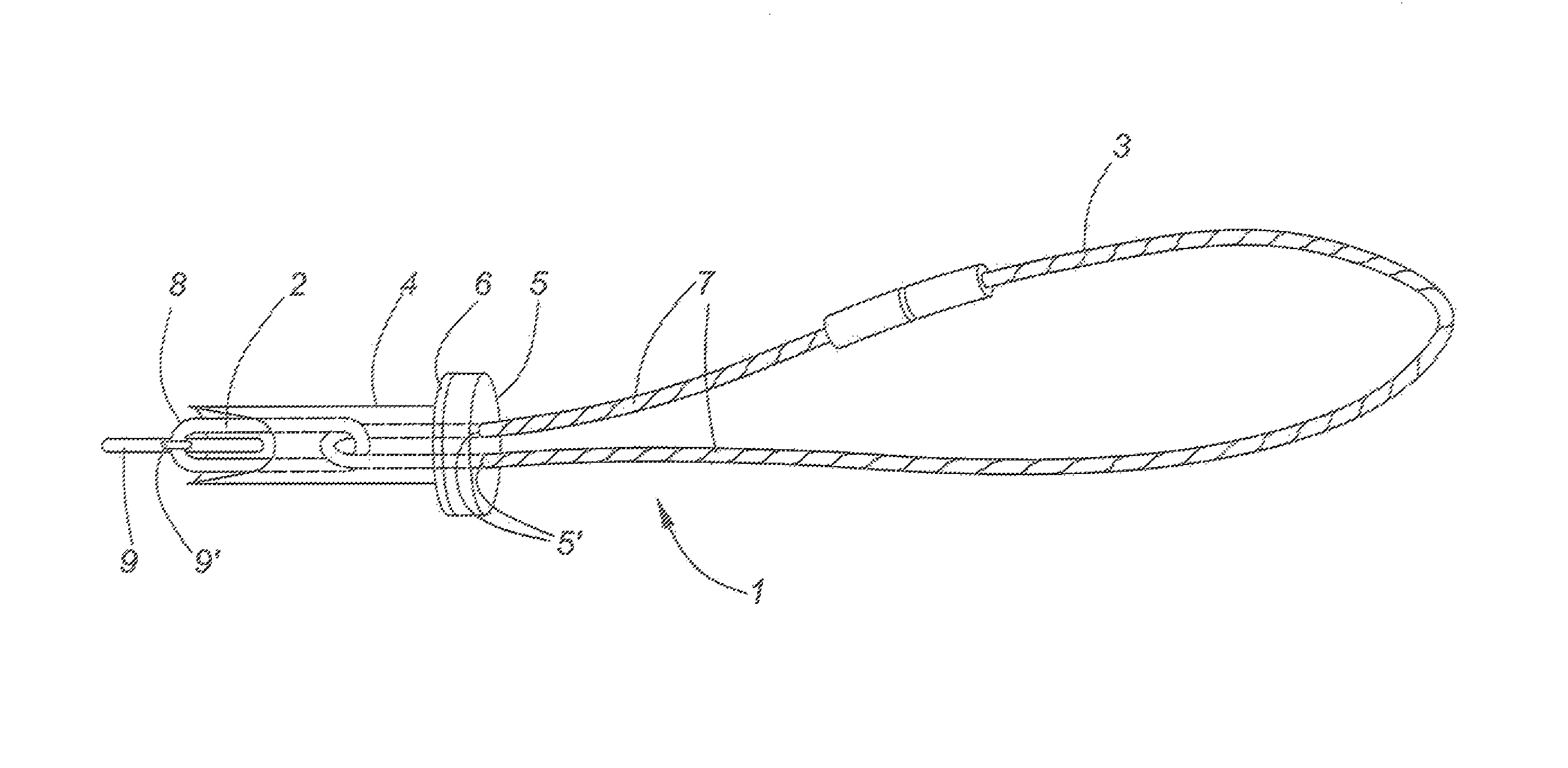

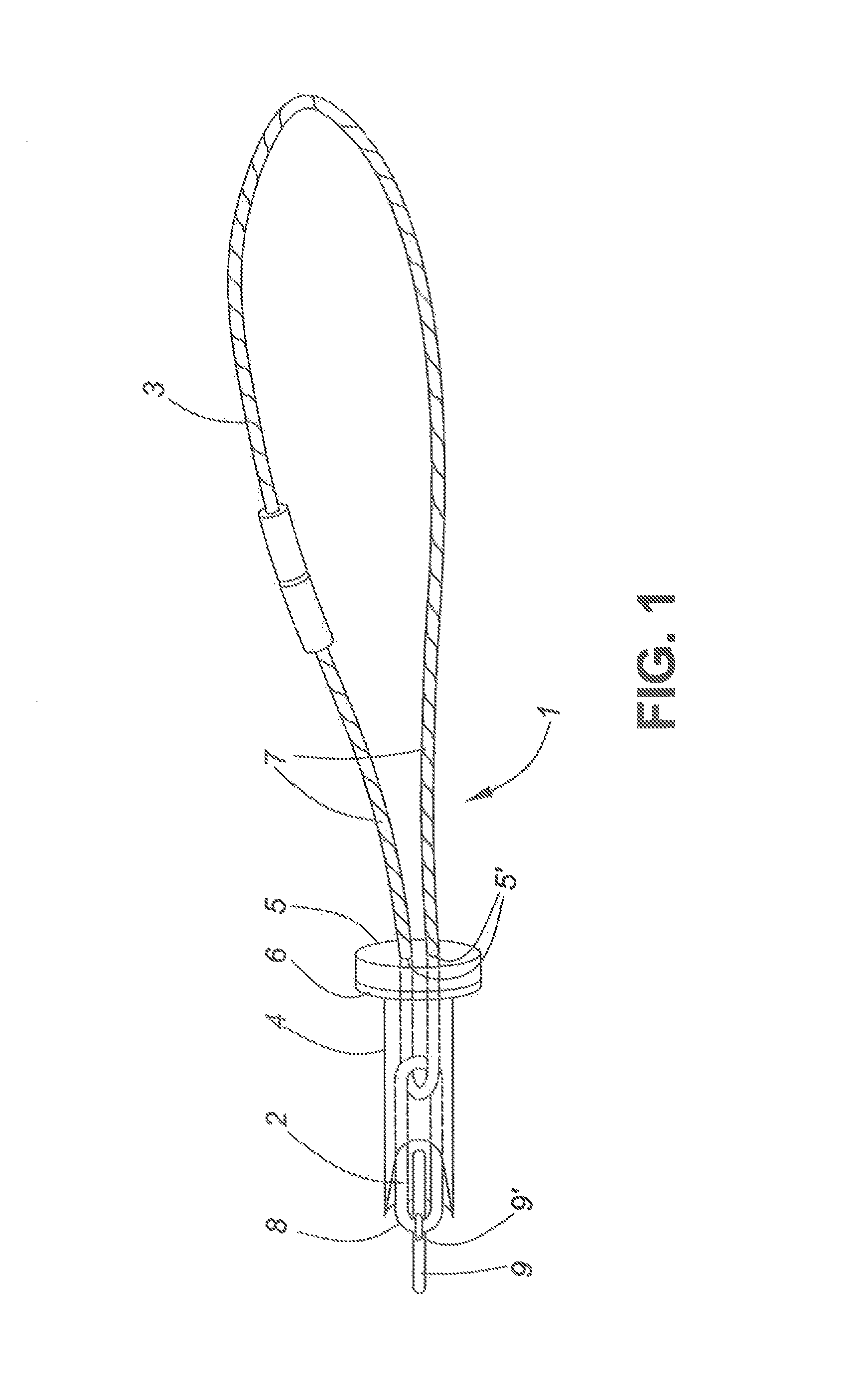

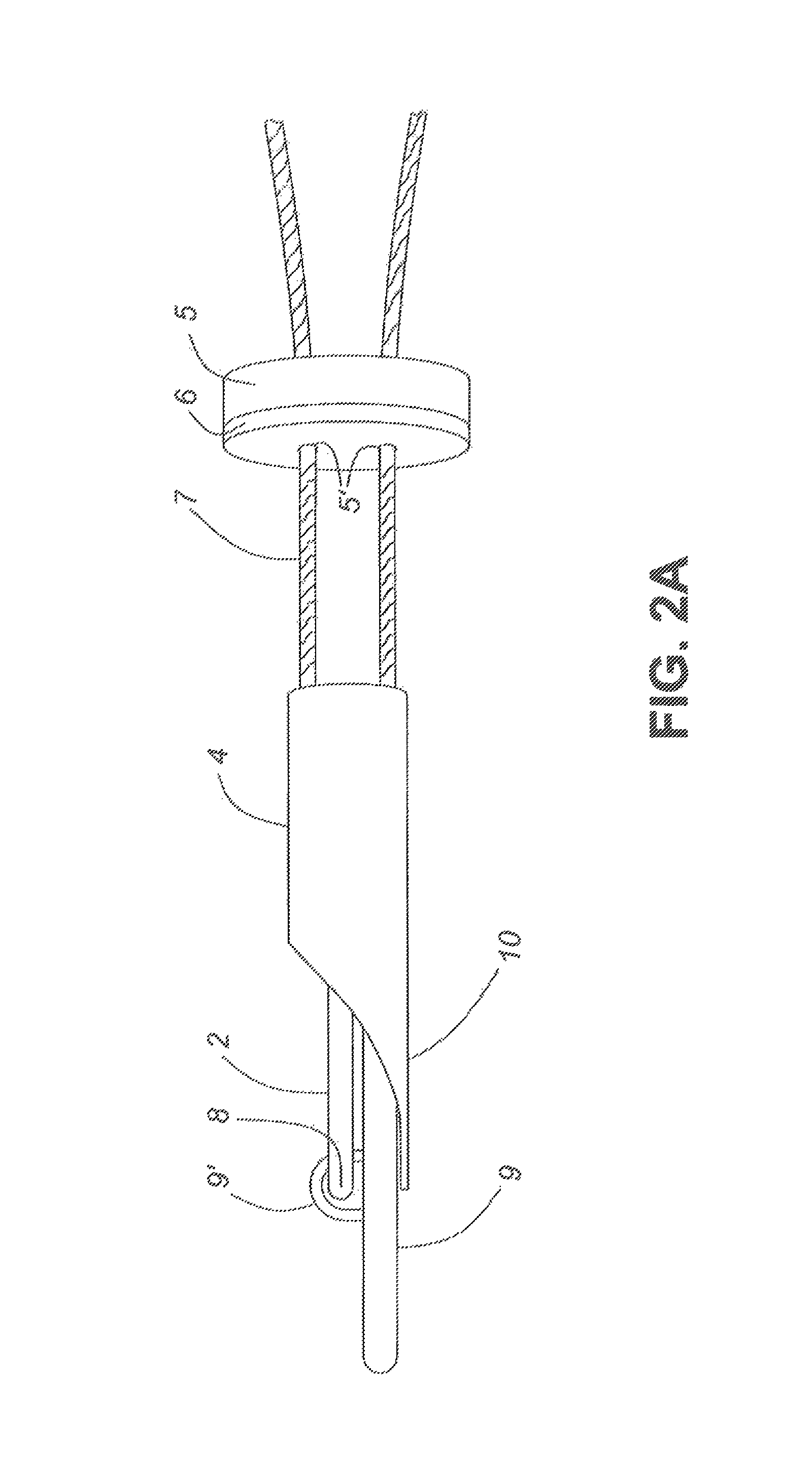

Toggle pin

InactiveUS20090249738A1Overcome disadvantagesSimple attachmentRopes and cables for vehicles/pulleyBuilding repairsEngineeringToggle pin

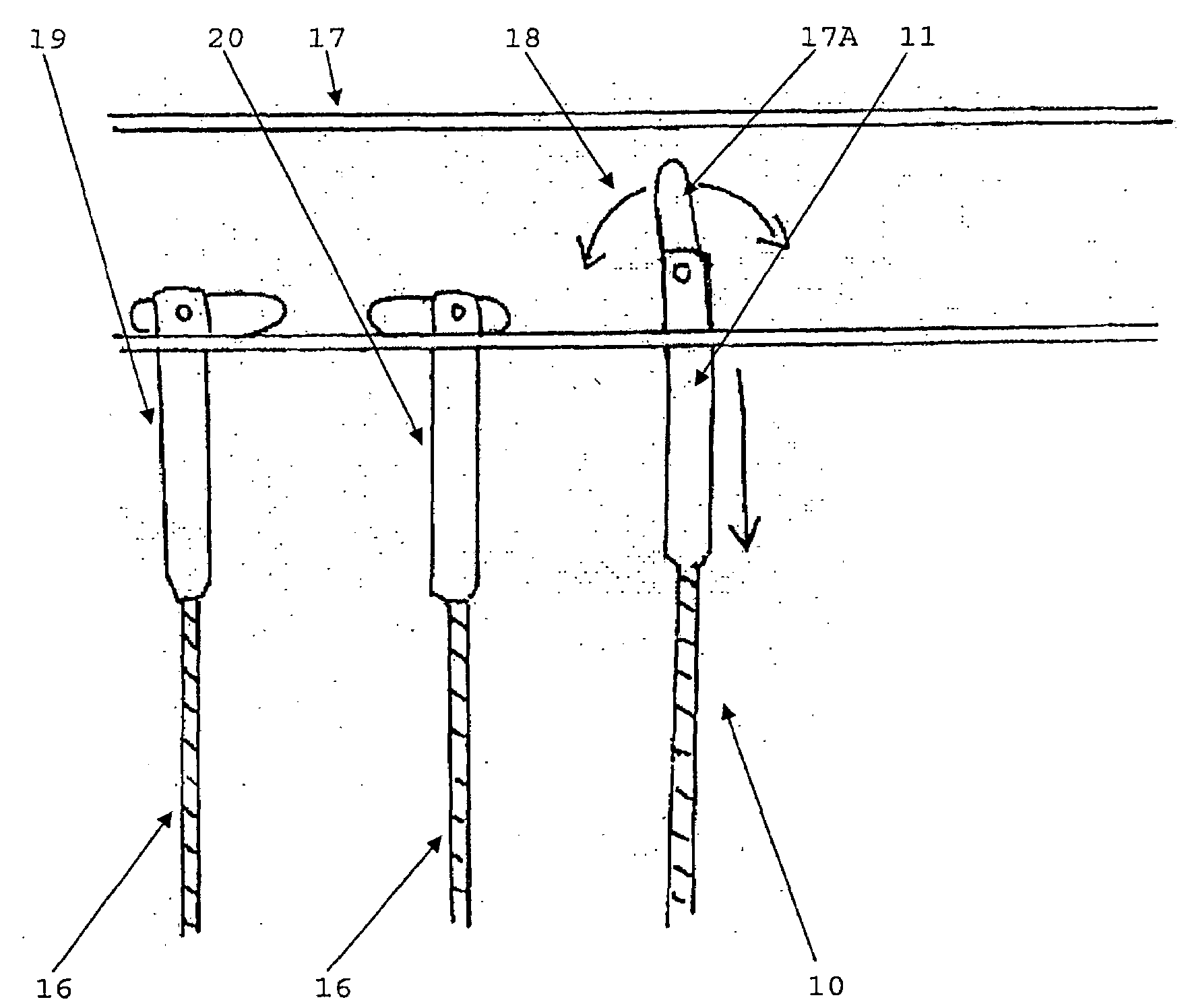

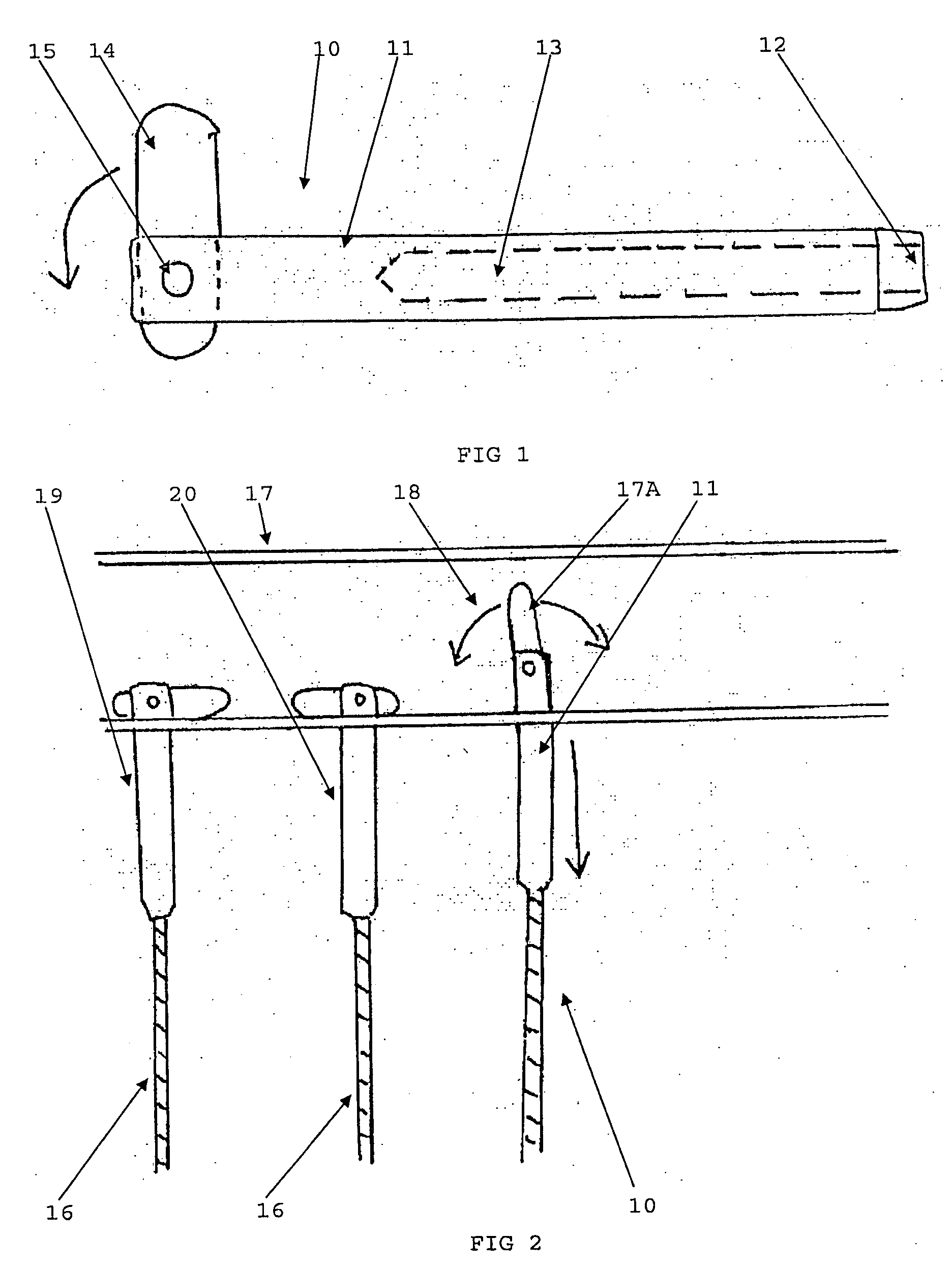

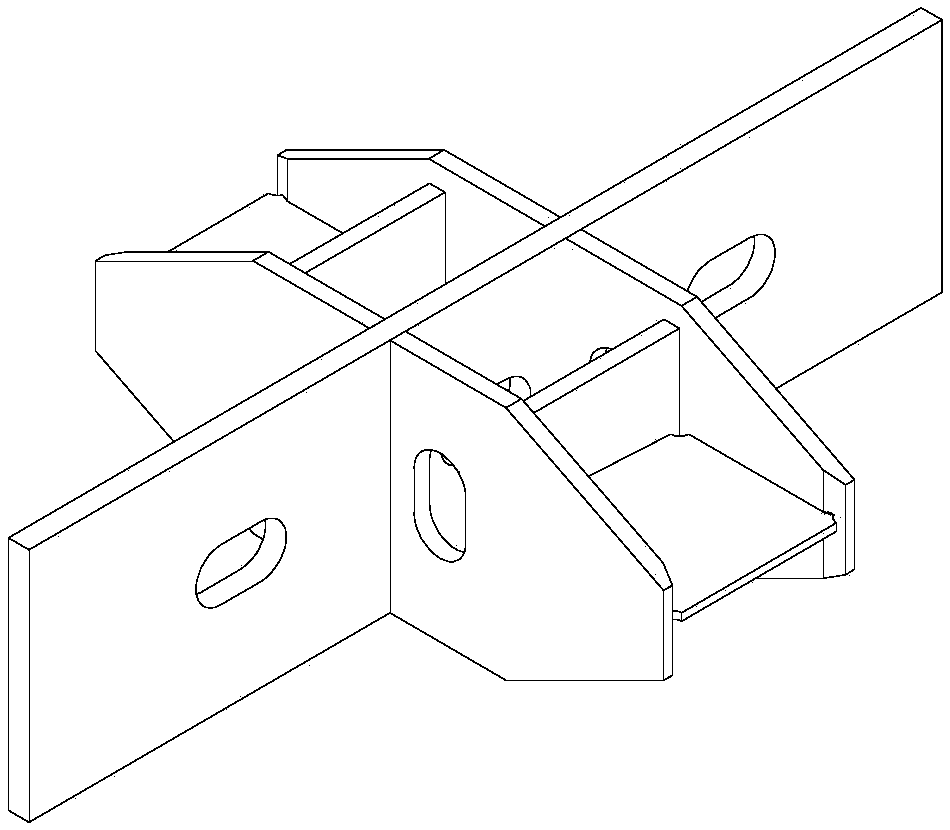

A toggle pin comprising an elongate main body portion having two ends, one end being provided with a passageway that extends at least partially through the main body portion and which is open at the one end such that a line member can pass into the passageway and be connected to the toggle pin, the other end being provided with a toggle plate, the toggle plate being pivoted to the main body portion in such a manner that the toggle plate can move between an unlocking position where the toggle plate is substantially in line with the main body portion, and a locking position where the toggle plate is substantially at right angles to the main body portion.

Owner:CABLESTRADE HLDG

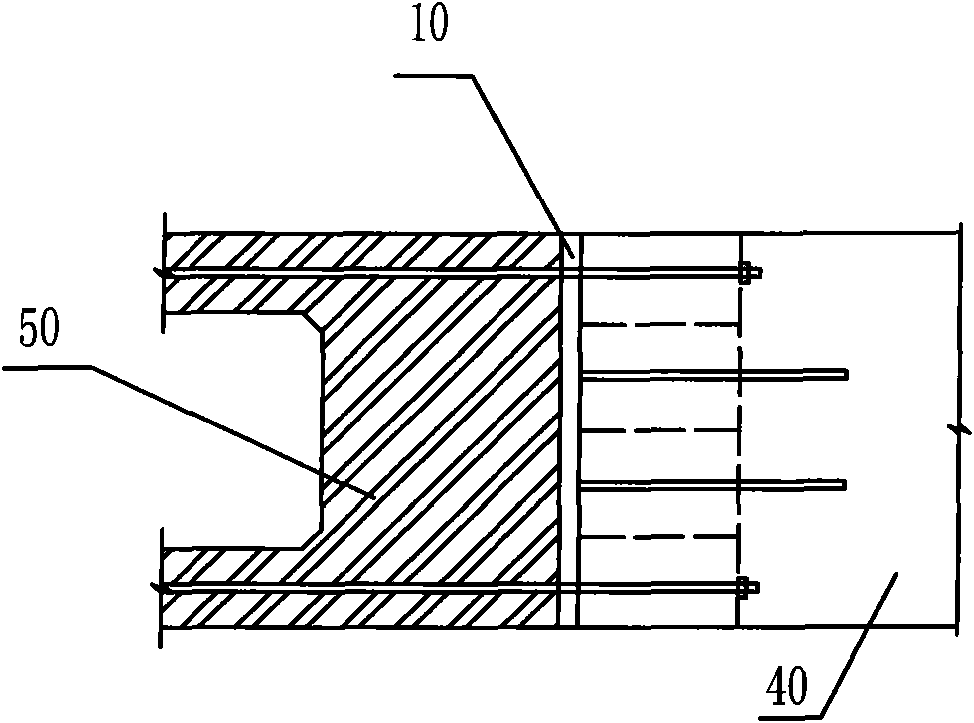

Steel-concrete joint section structure of beams

ActiveCN101831866AClear forceThe force is clear and reasonableBridge structural detailsSheet steelConcrete beams

The invention discloses a steel-concrete joint section structure of beams, which comprises a steel beam, a concrete beam and a bearing plate, wherein the steel beam is sheathed outside the concrete beam, thereby forming a transition section from the concrete beam to the steel beam; the steel beam web in the transition section is inserted into the concrete beam web to form a steel-concrete composite section; an upper and lower closed compartments are arranged in the transition section; the bearing plate is a steel plate of which the cross section being exactly matched with that of the steel beam; each contact site of the steel beam and the concrete beam in the transition section is provided with a shearing force toggle pin; the steel beam top plate and the steel beam bottom plate are respectively provided with a U-shaped ribbed stiffener; each U-shaped ribbed stiffener is welded with an pi-shaped ribbed stiffener; and the height of the pi-shaped ribbed stiffeners gradually increases from the steel beam side to the concrete beam side. The steel-concrete joint section of beams can be widely used in various composite beam bridges, such as continuous bridges, stayed-cable bridges, suspension bridges and arch bridges, and can solve the problems of complex process and manufacture, difficult construction operation and low fatigue resistance at the steel-concrete joint section.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

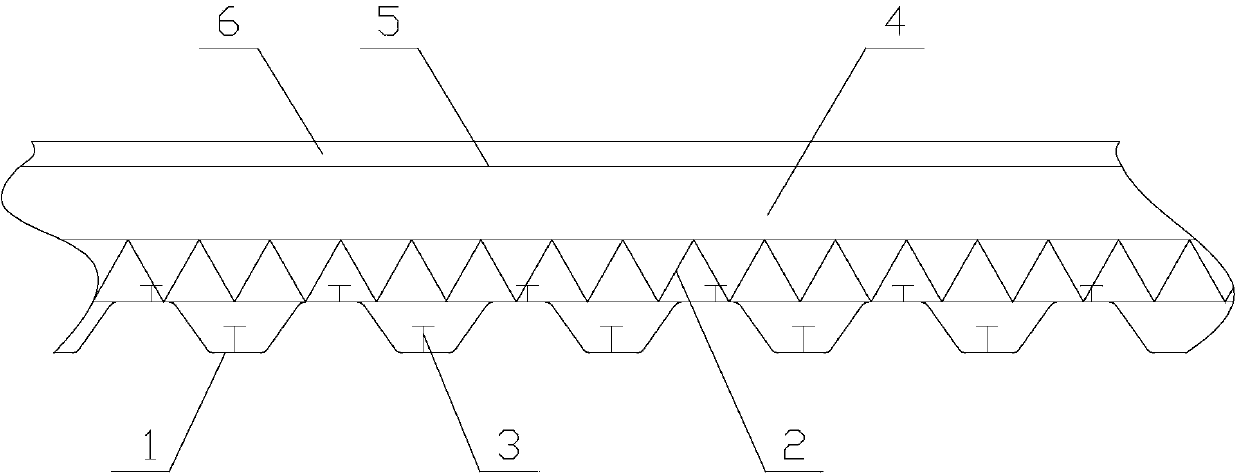

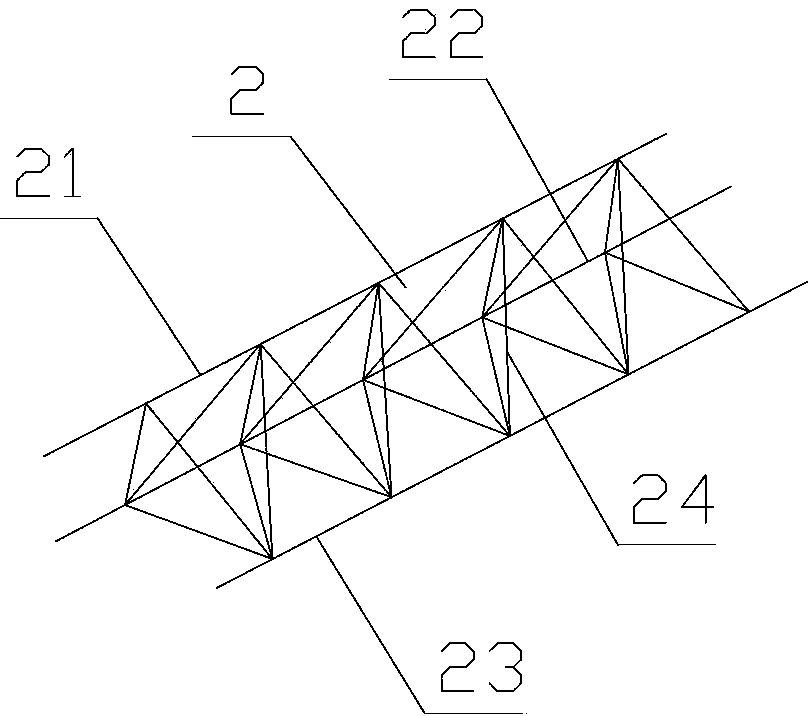

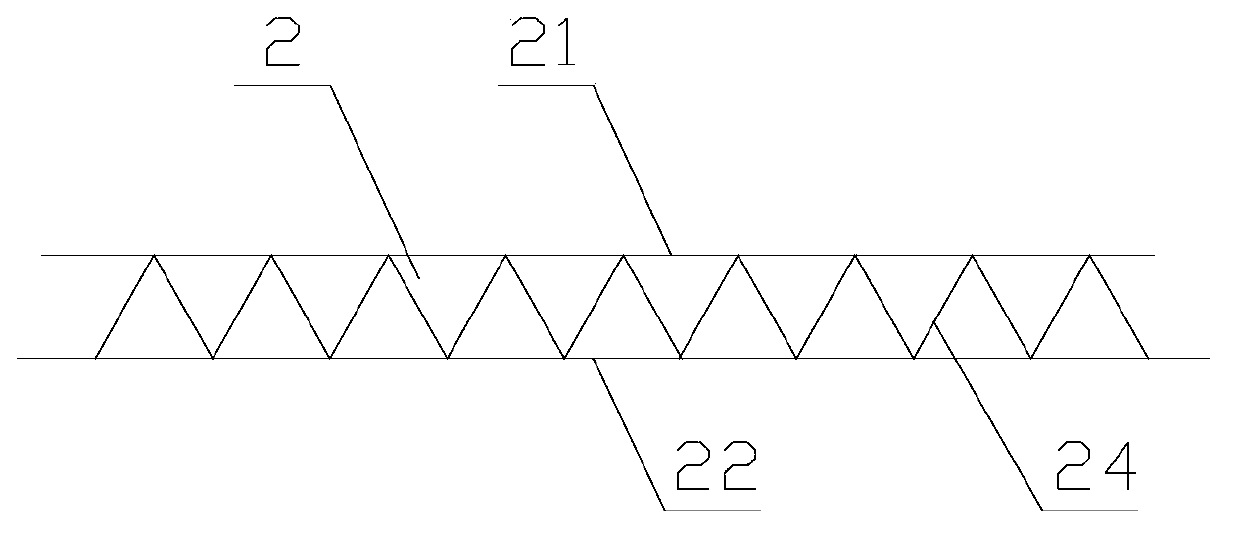

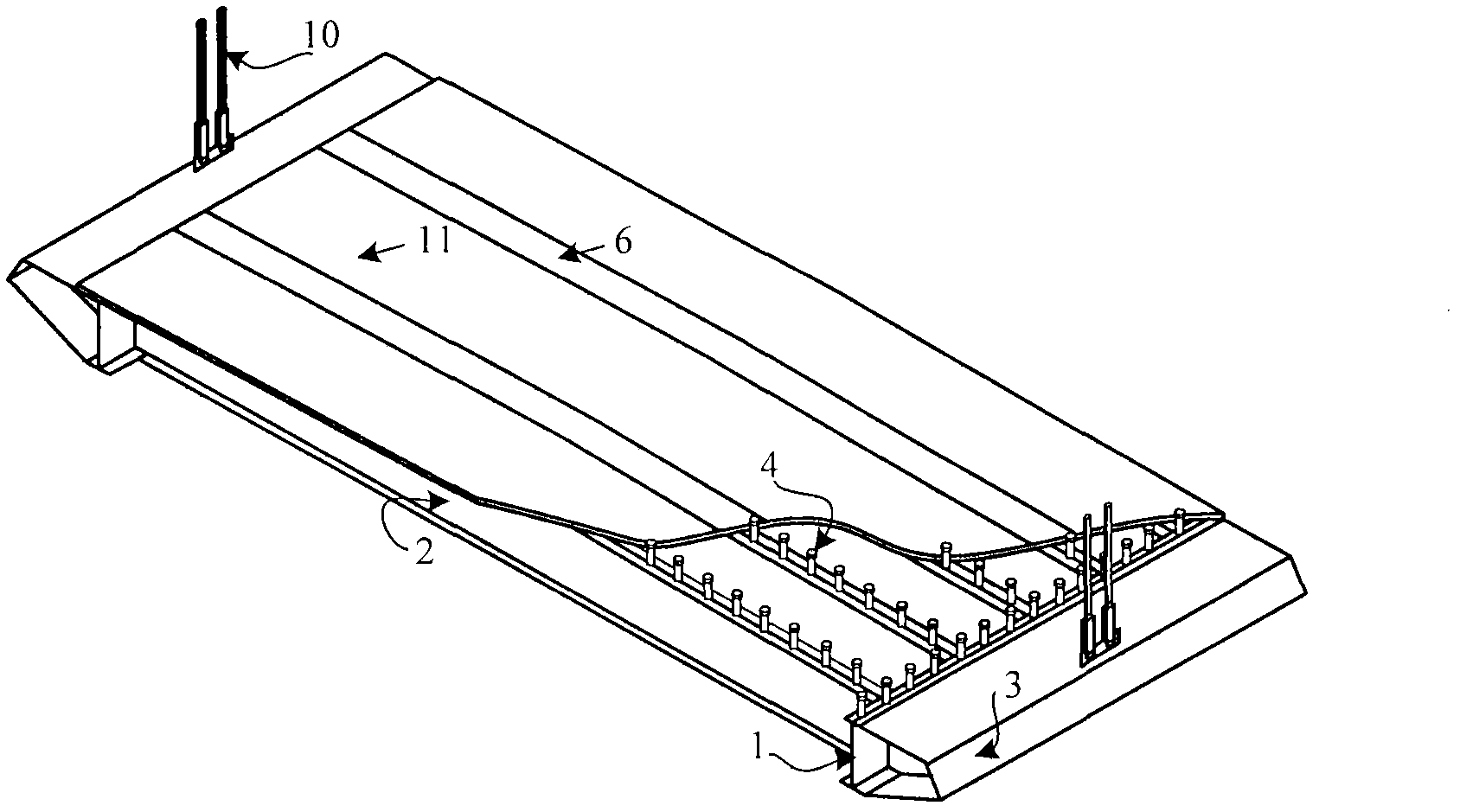

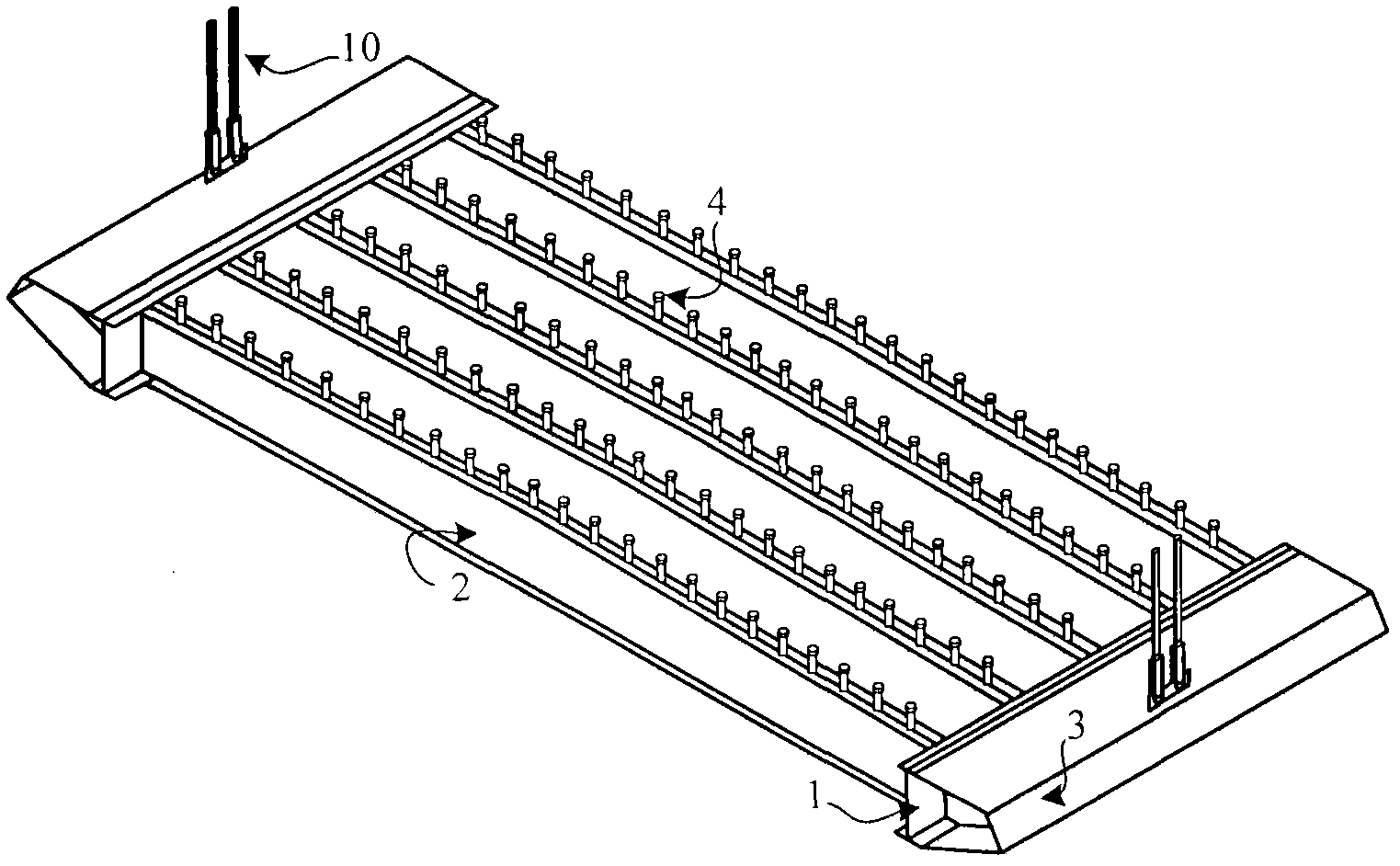

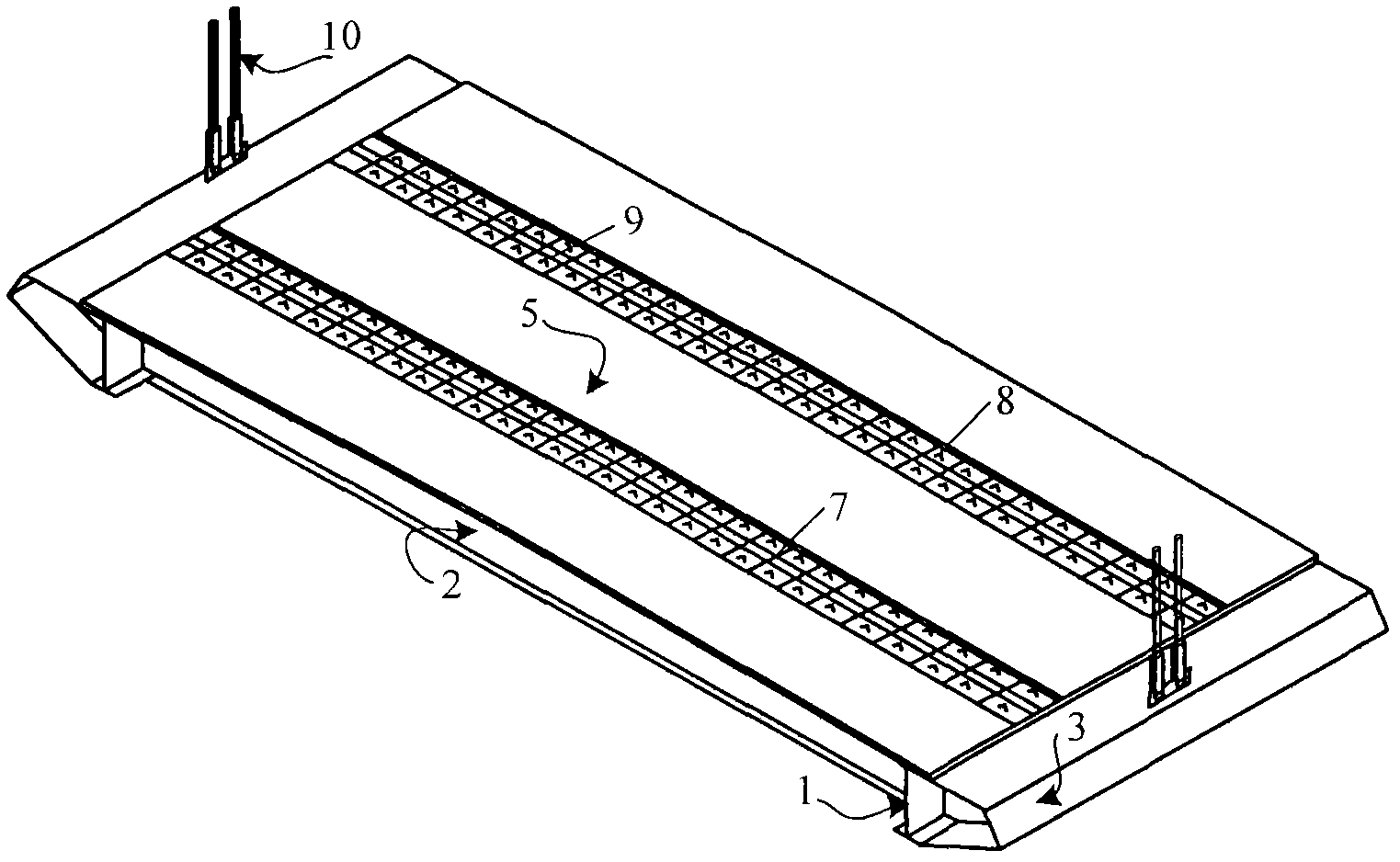

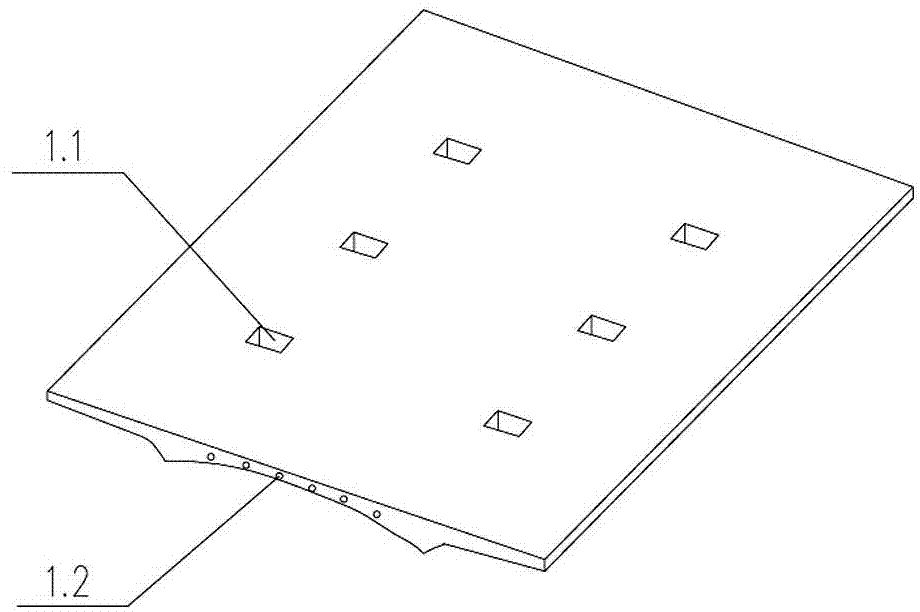

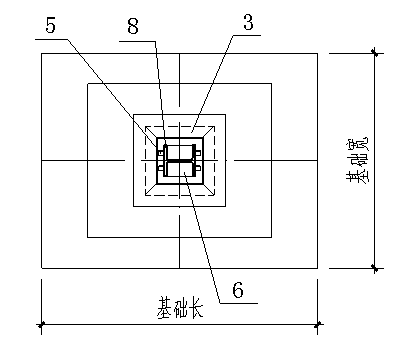

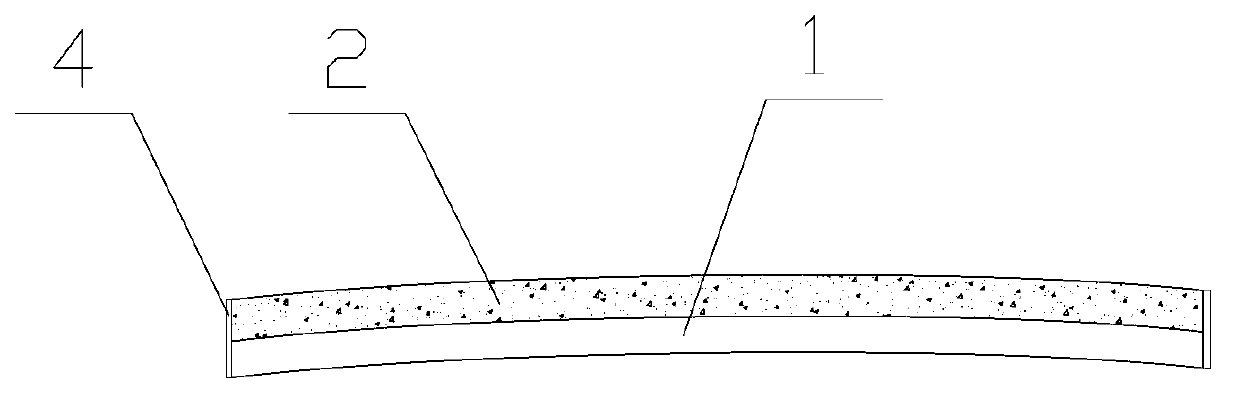

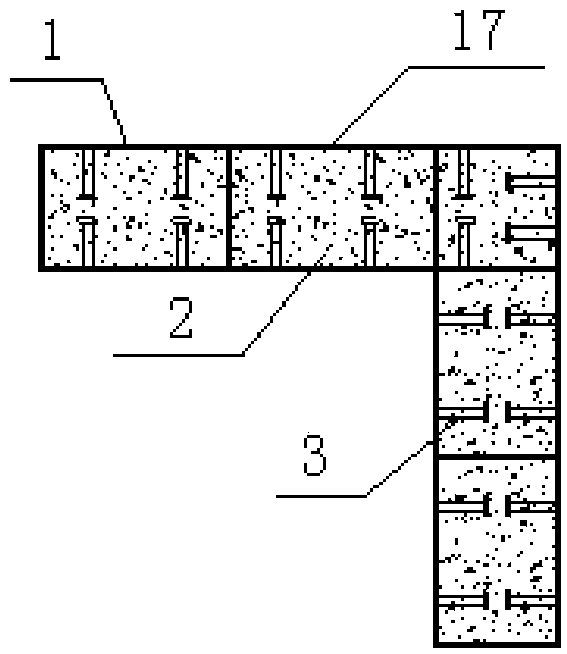

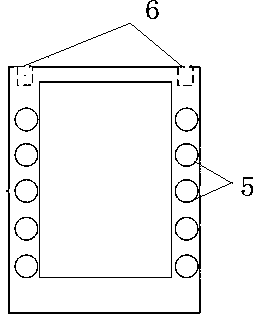

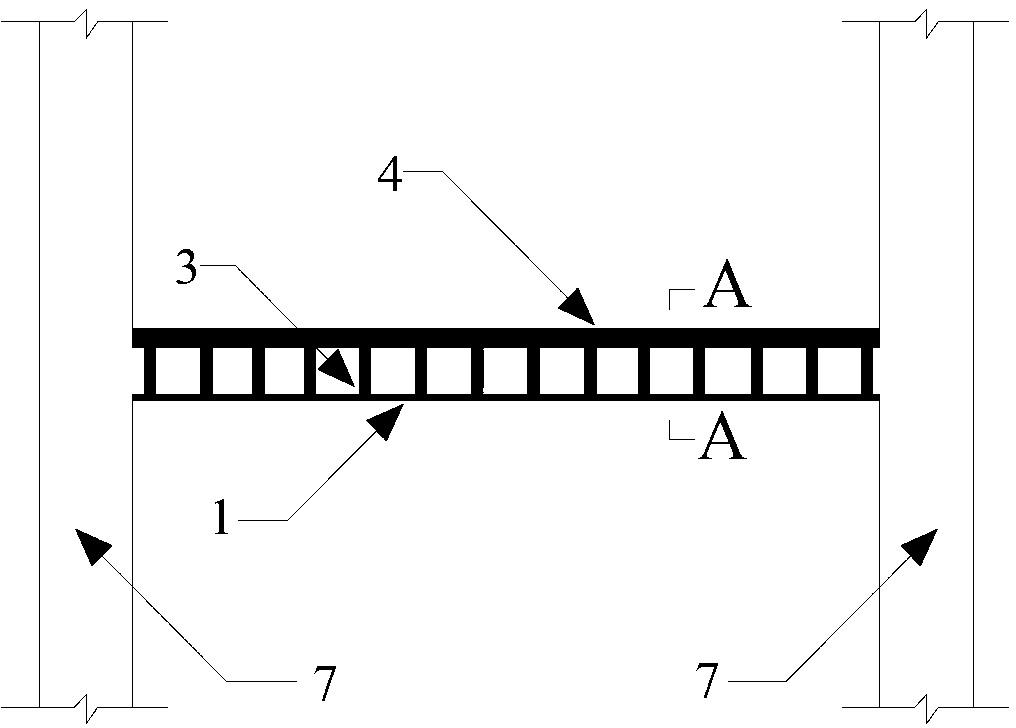

Corrugated sheet steel composite structure bridge deck system

The invention relates to bridges in civil engineering, and discloses a corrugated sheet steel composite structure bridge deck system. The corrugated sheet steel composite structure bridge deck system comprises corrugated sheet steel (1). A rebar framework (2) and toggle pins (4) are arranged on the corrugated sheet steel (1) and poured into concrete. The corrugated sheet steel serves as not only a bottom plate stress component but also a formwork in use and has the advantages of being low in maintenance cost in the later period, small in the number of potential safety hazards in use of a bridge, fast and convenient to construct, good in overall economical efficiency and the like, meanwhile wave troughs of the corrugated sheet steel play a role of stiffening ribs, so good diffusion of bridge deck loads is facilitated.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

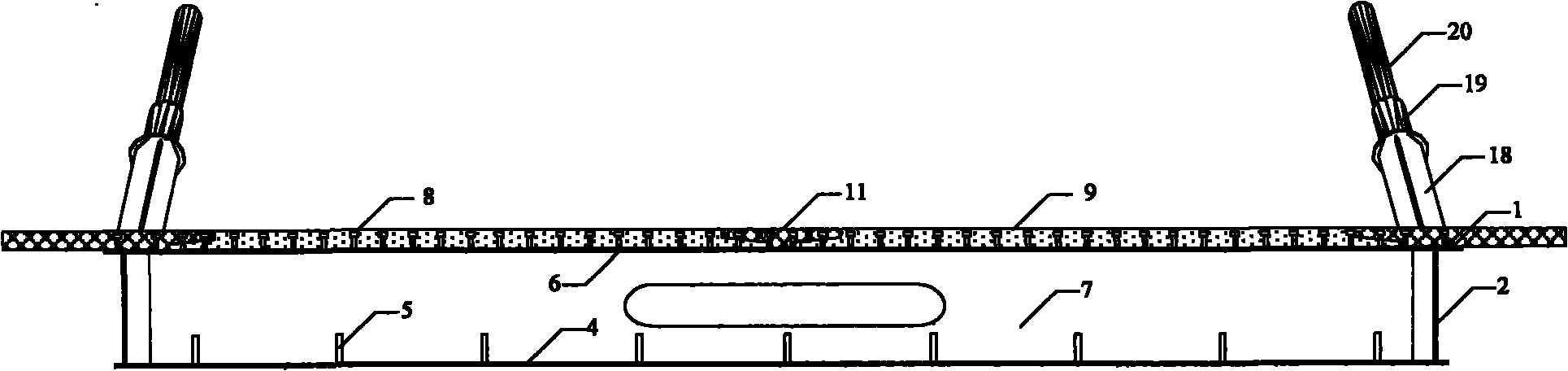

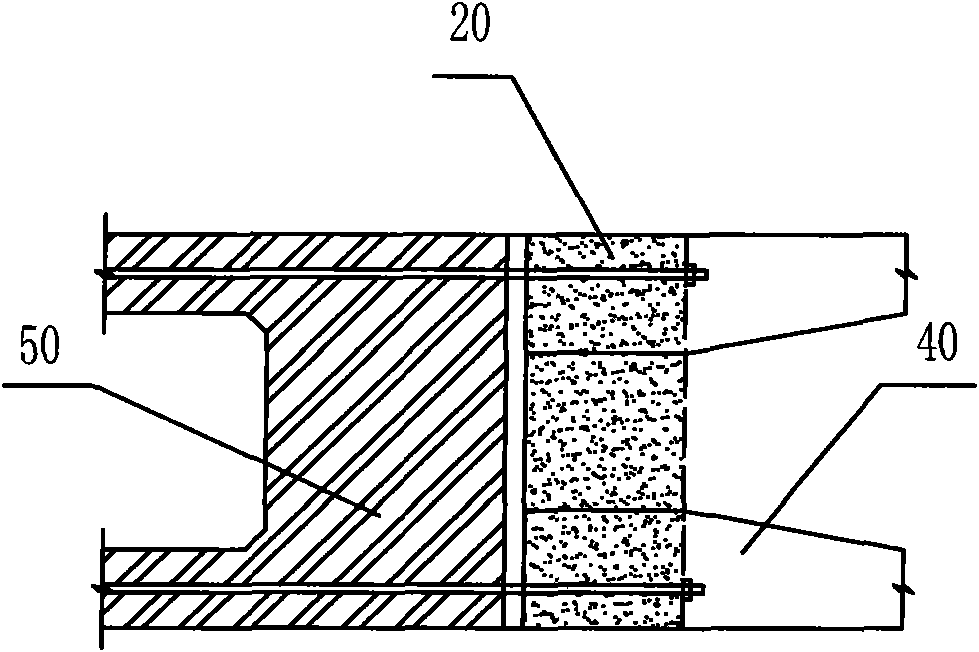

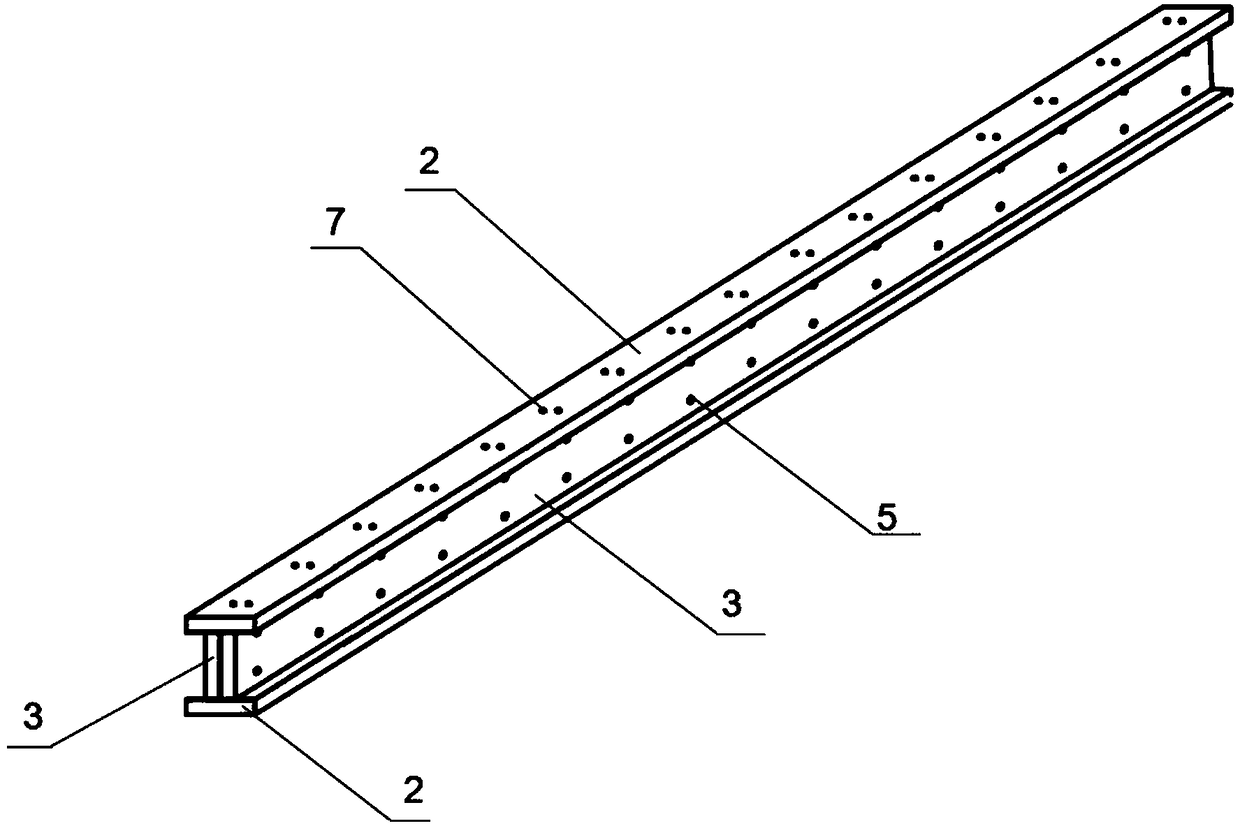

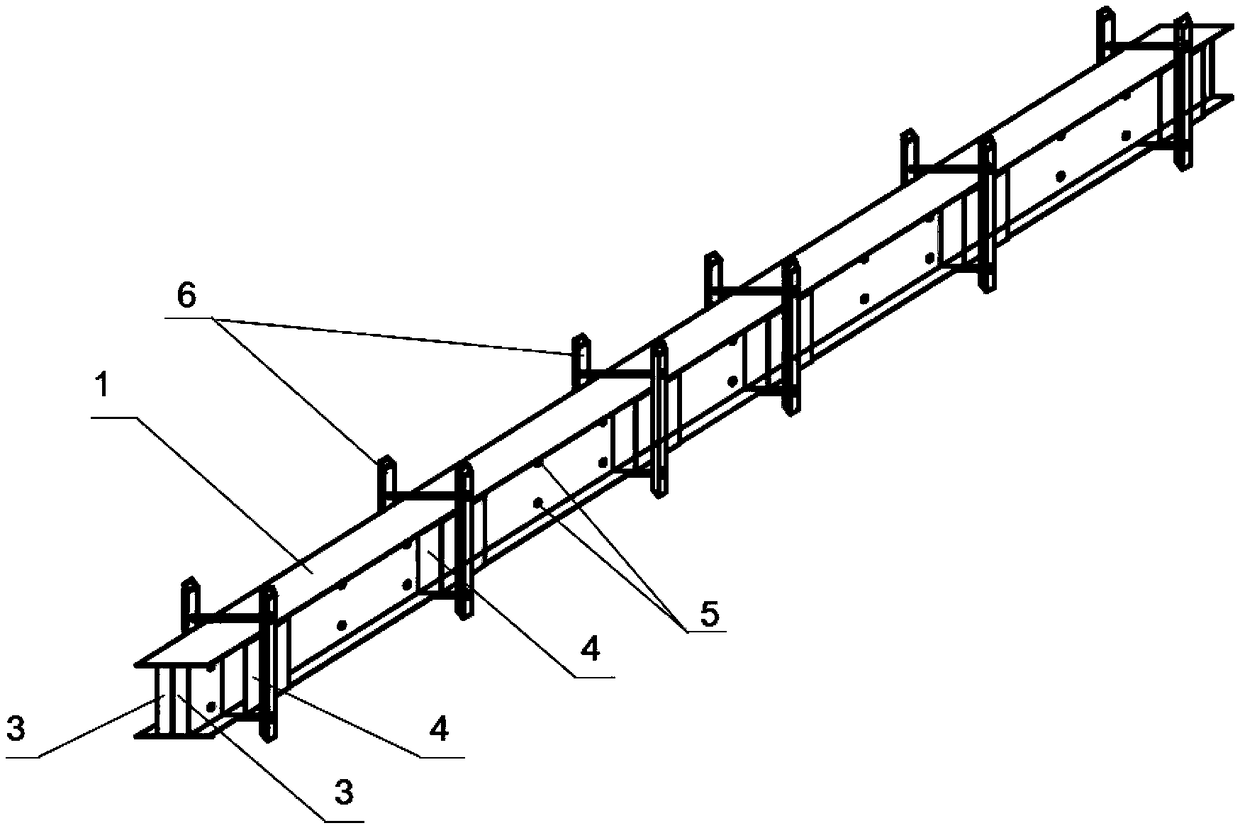

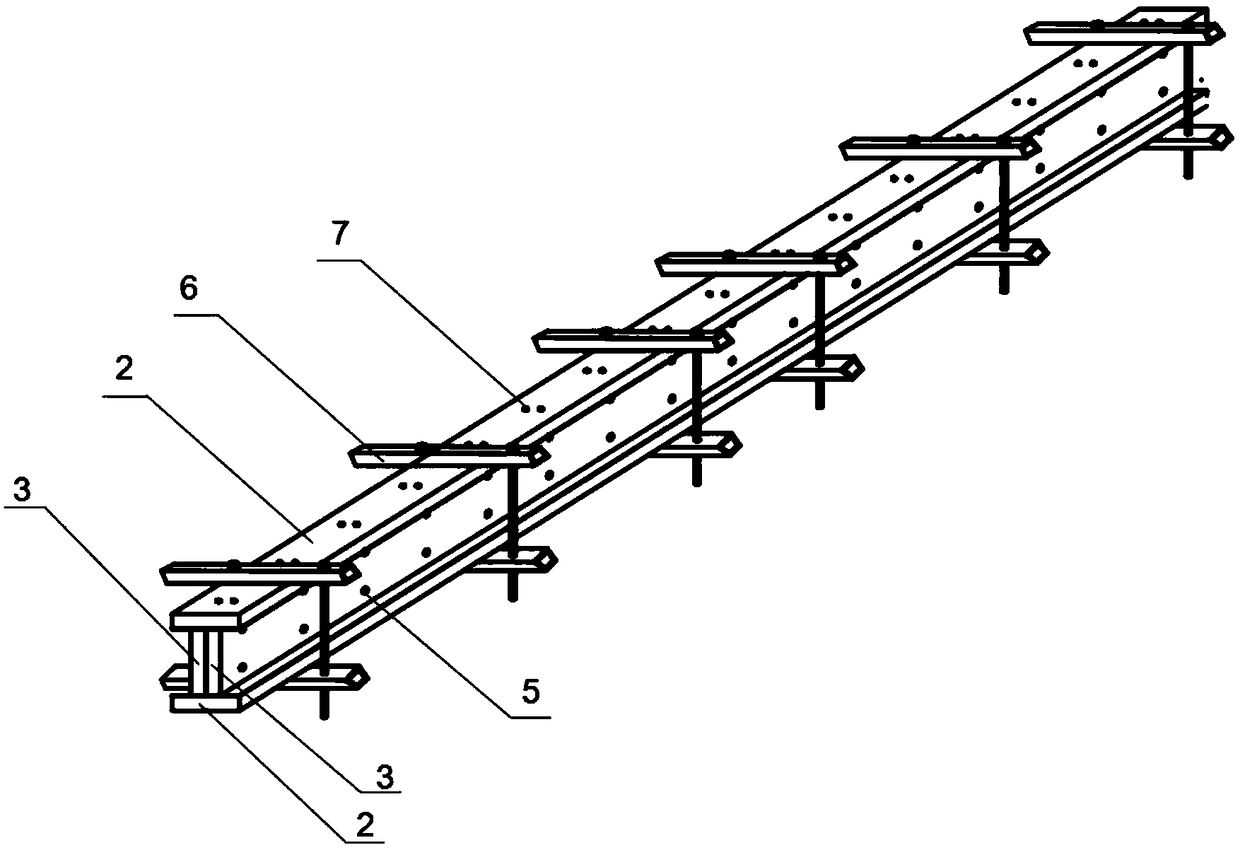

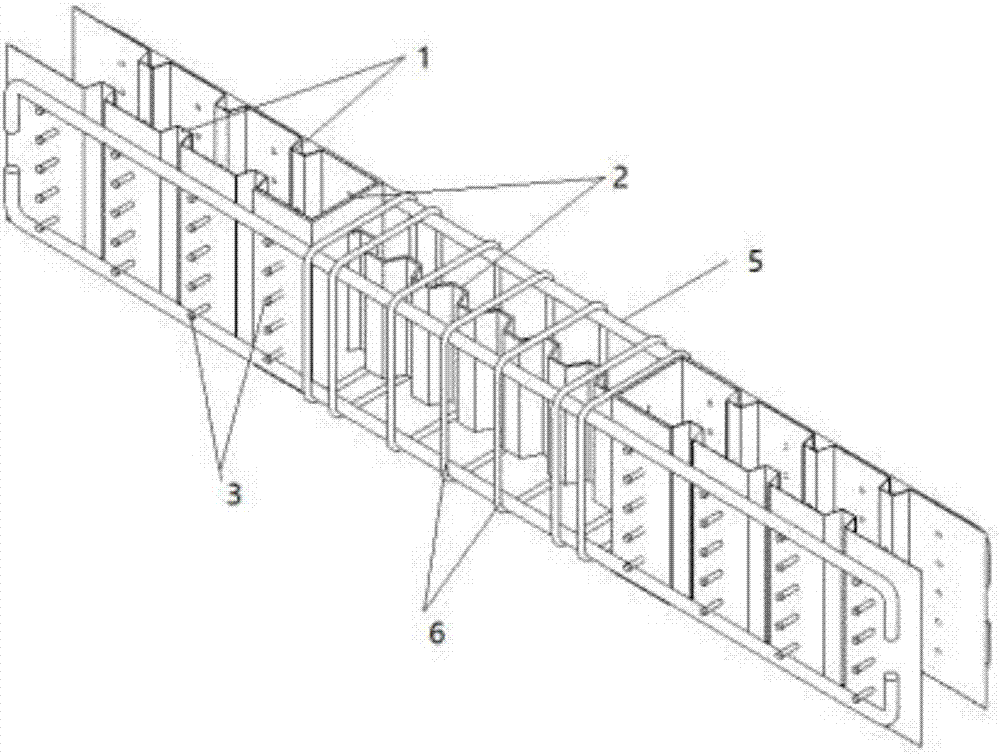

Locally uncombined suspension bridge steel-concrete combined bridge deck system and construction method of combined bridge deck system

ActiveCN102146658AReduce stress concentrationReduced risk of crackingSuspension bridgeBridge structural detailsCrack resistanceBridge deck

The invention discloses a locally uncombined suspension bridge steel-concrete combined bridge deck system and a construction method of the combined bridge deck system, and belongs to the technical field of bridge structures. The bridge deck system consists of concrete slabs, longitudinal steel beams, cross steel beams, air nozzles and toggle pin connectors; and a suspension bridge section steel-concrete combined bridge deck system is prefabricated in a factory. The prefabricated concrete slabs and section steel main beams form a whole through concrete wet joints and the toggle pin connectors. The prefabricated concrete slabs and cast-in-place concrete joints are only connected with the cross steel beams to form a whole through the toggle pin connectors, the longitudinal steel beams are not provided with the toggle pin connectors, and meanwhile, the toggle pin connectors are not arranged in a certain area of the ends of the cross steel beams at hoisting points. The problems of cracking, complex structures of toothed grooves at the slab ends of the prefabricated concrete slabs and the like due to the factors of temperature, contraction, creep and the like of the concrete slabs of the traditional suspension bridge combined bridge deck system are solved by adopting a locally uncombined technology on the premise of keeping the consumption of steel, the manufacturing process of the prefabricated slabs is simplified, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved.

Owner:TSINGHUA UNIV

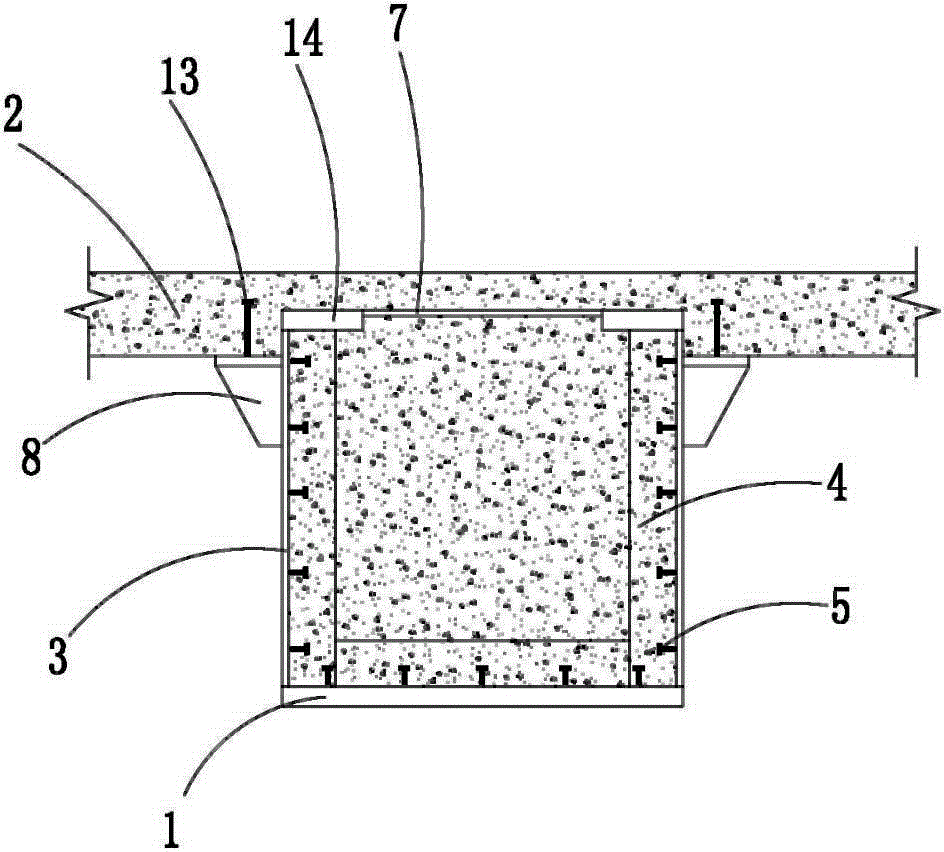

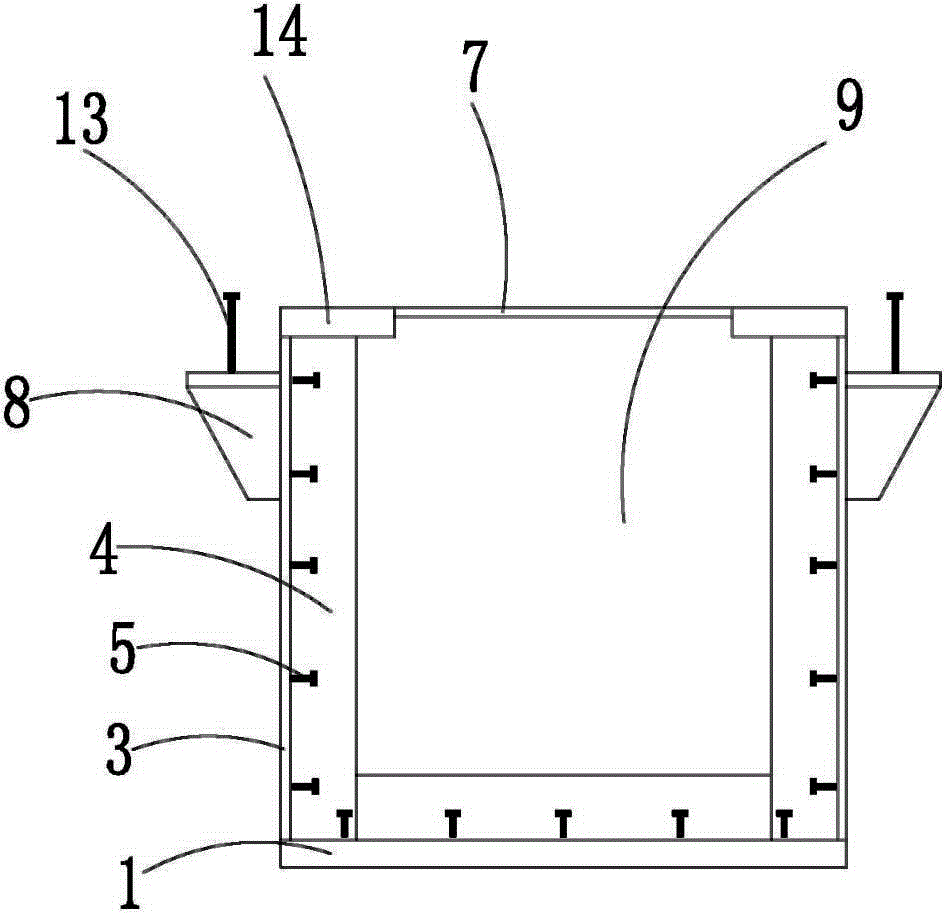

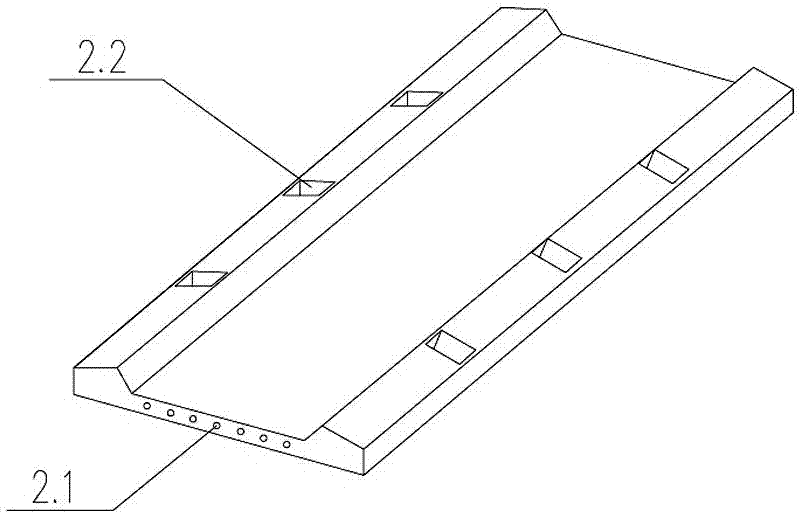

U-shaped steel-concrete composite section beam and construction method of section beam

ActiveCN104060761ACompact structureGuarantee processing qualityLoad-supporting elementsConcrete beamsConcrete composites

The invention relates to a section beam and in particular relates to a U-shaped steel-concrete composite section beam and a construction method of the section beam. The U-shaped steel-concrete composite section beam is used in the field of steel structure housing construction engineering. Web plates are respectively arranged at two side ends of the upper part of a base plate, wherein transverse stiffening plates and anti-shearing toggle pins are uniformly distributed and respectively arranged at the inner walls of the web plates and the upper part of the base plate; support section slotting top plates are arranged at the left ends and the right ends of the upper parts of the web plates; vertical battening plates are uniformly distributed between the two support section slotting top plates; support brackets are arranged on the outer walls of the web plates; the upper ends of the web plates, the support section slotting top plates and the vertical battening plates are inserted into a concrete beam; a grouting cavity is formed by the base plate, the web plates, the support section slotting top plates and the vertical battening plates; concrete is added into the grouting cavity. The construction method of the section beam comprises the following steps: manufacturing and processing the section beam in a factory, mounting and constructing the section beam in a field. According to the U-shaped steel-concrete composite section beam and the construction method of the section beam, the U-shaped steel-concrete composite section beam is compact in structure, capable of forming a complete set of industrial, assembling and mechanical processing, guaranteeing the processing quality and accelerating the construction period, easy and convenient in field construction and high in assembly degree.

Owner:浙江东南网架股份有限公司

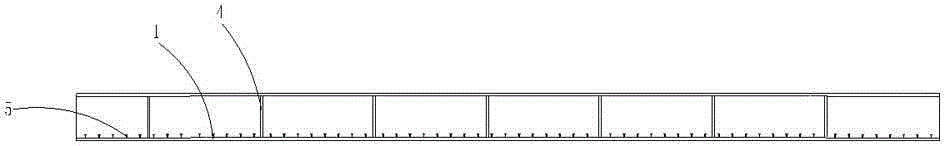

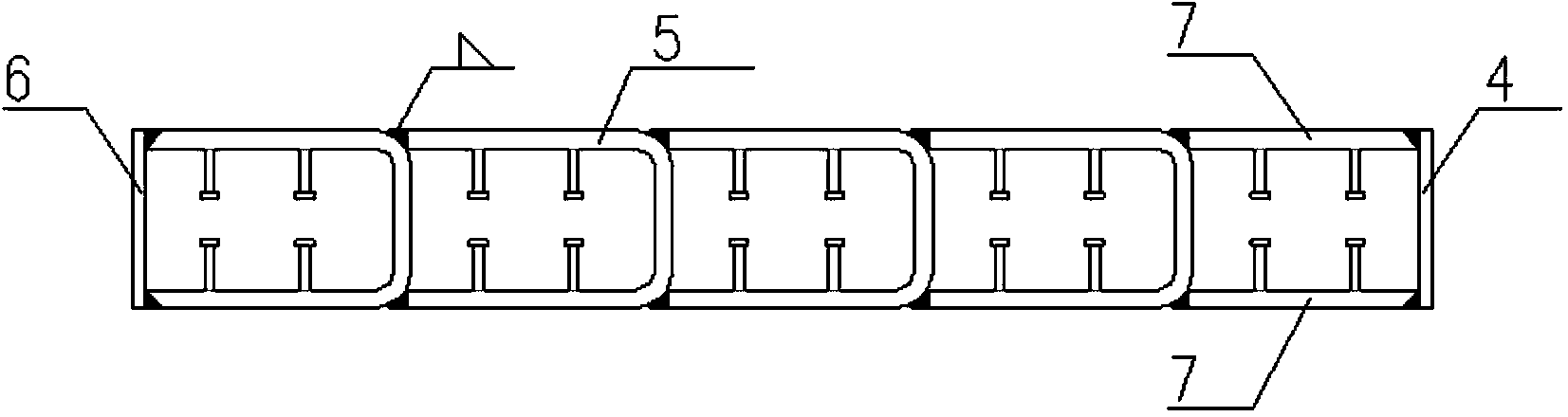

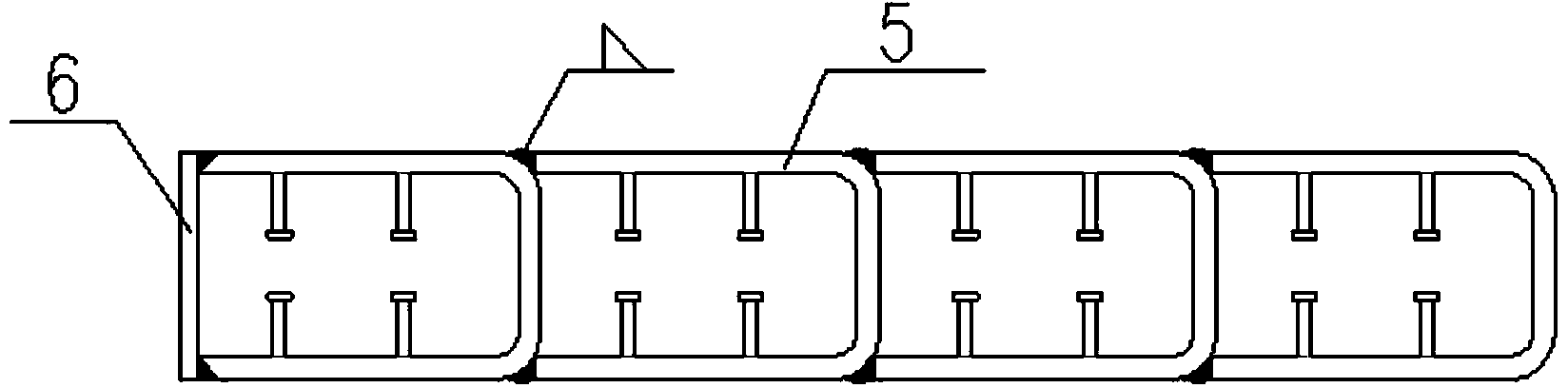

Construction method of fabricated pre-tensioned pre-stressing corrugated steel web composite box beam

ActiveCN106894326ASmall sunshine areaReduce volumeBridge erection/assemblyBridge materialsPre stressPre stressing

The invention discloses a construction method of a fabricated pre-tensioned pre-stressing corrugated steel web composite box beam. The fabricated pre-tensioned pre-stressing corrugated steel web composite box beam comprises a composite beam body formed by longitudinally connecting a plurality of prefabricated beam body units, and each prefabricated beam body unit comprises a concrete top plate, a pre-stressing concrete bottom plate and a corrugated steel web which are singly prefabricated and is of an inverted trapezoidal structure that the width of the concrete top plate is larger than that of the pre-stressing concrete bottom plate, and the corrugated steel web is obliquely arranged. Each concrete top plate is internally provided with a longitudinal connecting rebar and a pre-stressing hole canal, and a plurality of upper toggle pin notches are formed in the two sides of each concrete top plate in a spaced mode in the longitudinal direction; each pre-stressing concrete bottom plate is internally provided with a longitudinal connecting rebar and a pre-tensioned pre-stressing steel cable, and a plurality of lower toggle pin notches are formed in the two sides of each pre-stressing concrete bottom plate in a spaced mode in the longitudinal direction; and the upper end and the lower end of each corrugated steel web are separately provided with frange plates with toggle pin groups in a welded mode. According to the construction method of the fabricated pre-tensioned pre-stressing corrugated steel web composite box beam, beam erection is conducted by adopting the structural mode of blocking prefabricating assembly, the sizes and weights of all parts are small, transporting is stable, hoisting is safe, and construction is facilitated.

Owner:河南中鼎智建科技有限公司 +1

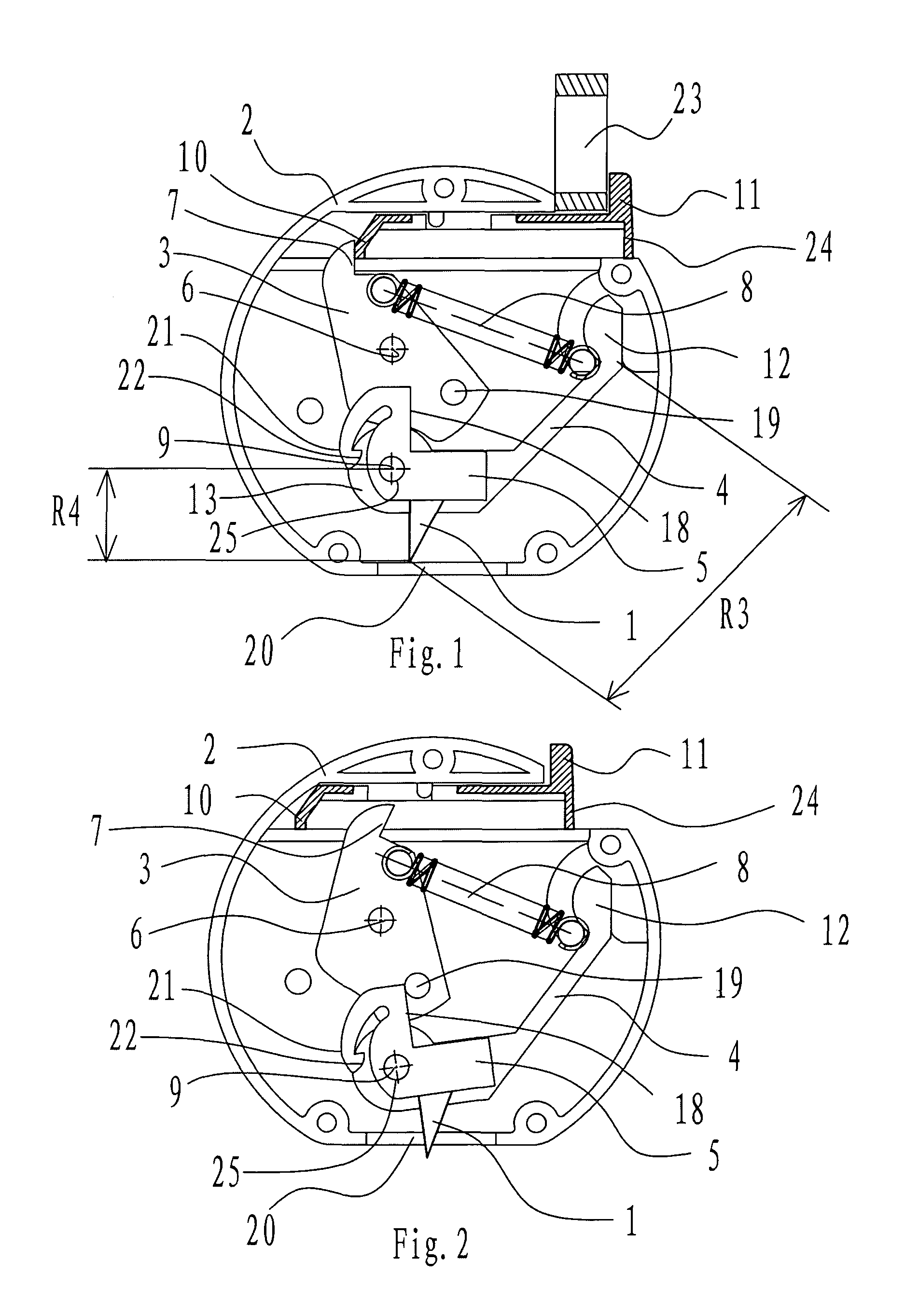

Gear-shifting mechanism for manual transmission

The invention embodiment discloses a gear-shifting mechanism for a manual transmission, which comprises a gear-shifting shaft, a gear-shifting box, a gear-shifting rotating arm, a weight block, a weight block connecting plate and a manual gear-shifting lever, wherein the gear-shifting shaft is arranged in the middle of the gear-shifting mechanism and assembled on the gear-shifting box capable of rotating freely and moving along the axial direction, the gear-shifting shaft is provided with the gear-shifting rotating arm which is connected together with the gear-shifting shaft, the gear-shifting rotating arm is connected with the manual gear-shifting lever in a moving state, a weight block shift pin is rigidly connected with the gear-shifting rotating arm and can drive the weight block connecting plate and the weight block to rotate around a rotating supporting bolt; and the weight block is rotationally connected on the rotating supporting bolt on the gear-shifting box through the weight block connecting plate. As the weight block is not directly connected with the gear-shifting rotating arm, and the gear-shifting shaft has no relation with the weight block except for the gear-shifting process, the vibration of the weight block is effectively prevented from transferring to a gear-shifting handle.

Owner:CHONGQING TSINGSHAN IND

Disposable incision safety lancet

ActiveUS7998161B2Novel structureClever in conceptCatheterDiagnostic recording/measuringMedicineEngineering

Owner:SHI GUOPING

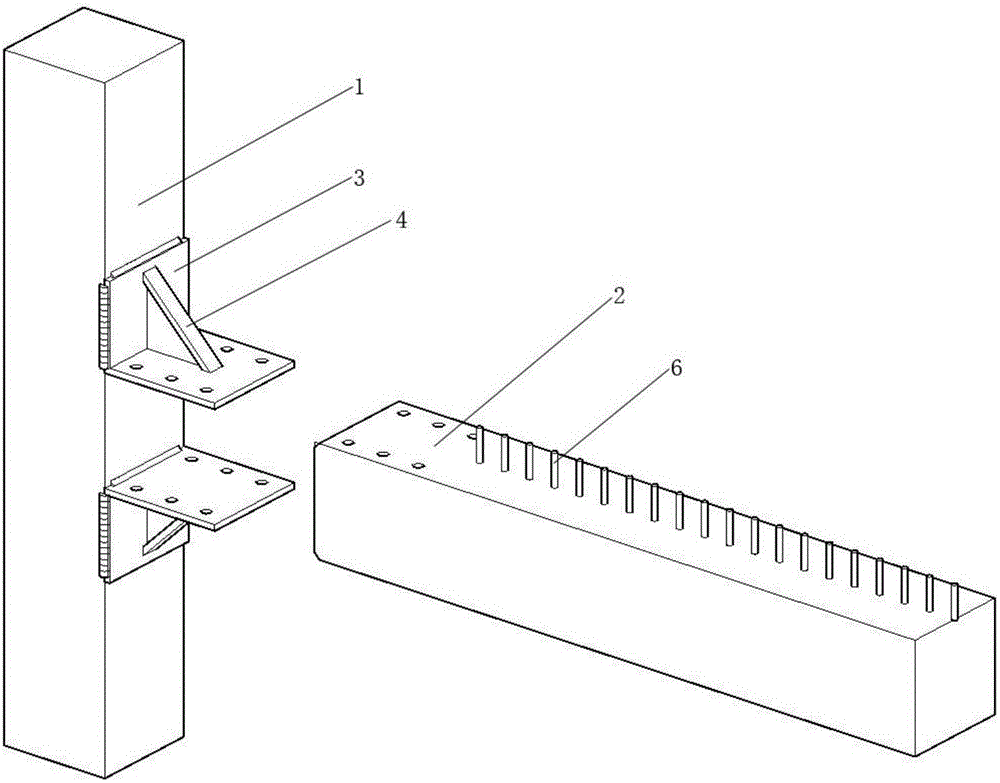

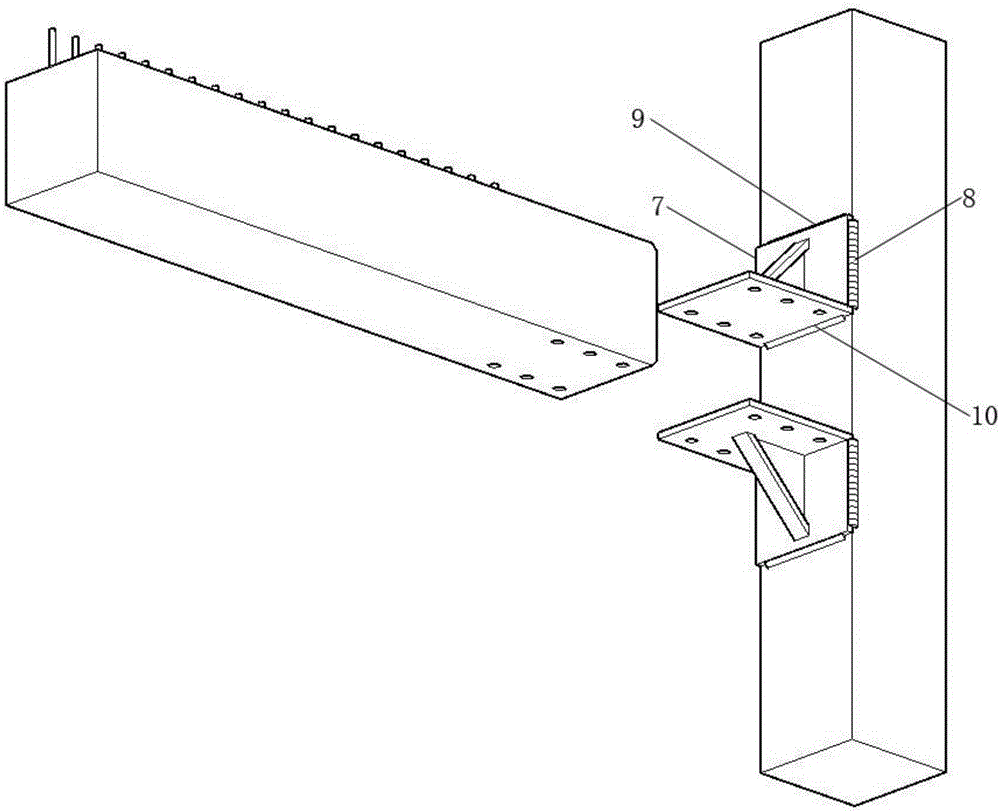

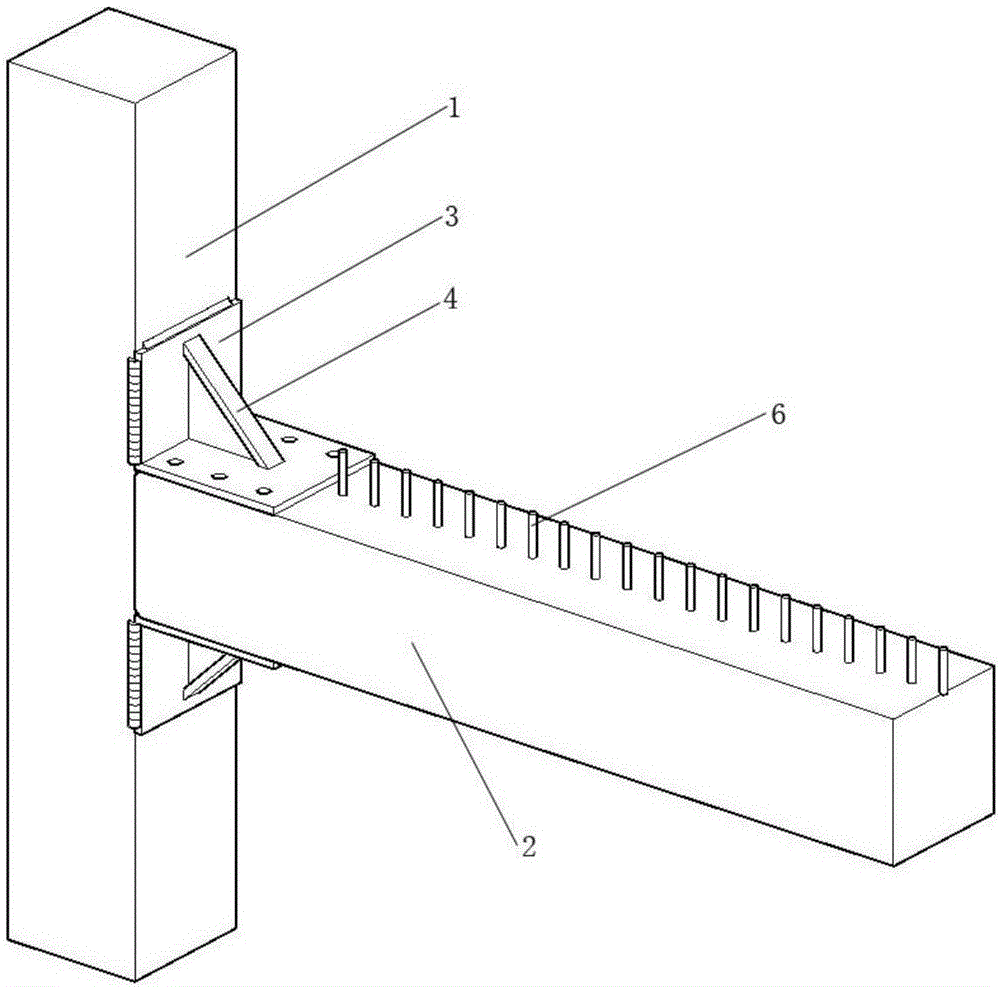

Connection node construction of concrete-filled square steel tube column and rectangular section steel beam

InactiveCN106703184ANode structure is simpleFlexible layoutBuilding constructionsLocal failureArchitectural engineering

The invention discloses a connection node construction of a concrete-filled square steel tube column and a rectangular section steel beam. The connection node construction is formed by the concrete-filled square steel tube column, the rectangular section steel beam, a right-angle connecting plate, a T-shaped triangle rib plate, a high-strength bolt, and a toggle pin on the top face of the steel beam. The connection node construction is simple, and the stress is clear. The amount of the steel for the connection node construction is less, and the connection node construction is only installed at one side of the column provided with the beam, so the composite cost is lower. The design of the beam column connection node is the ductile failure mode that the beam end is damaged by the tension, the obvious symptom and the duration time are existent before the damage, and the whole structure cannot be collapsed by the local failure. The connection of the steel beam and the concrete-filled steel tube column is firm, the integrality is good, the node rigidity is large, the assembly is simple and the construction period is short. New building rubbishes are not generated, and the requirements of housing industrialization and environmental protection are satisfied. The connection node construction is a novel node connection mode suitable for the connection of the current lower-layer and multi-layer light steel frame housing construction beam columns.

Owner:BEIJING UNIV OF TECH

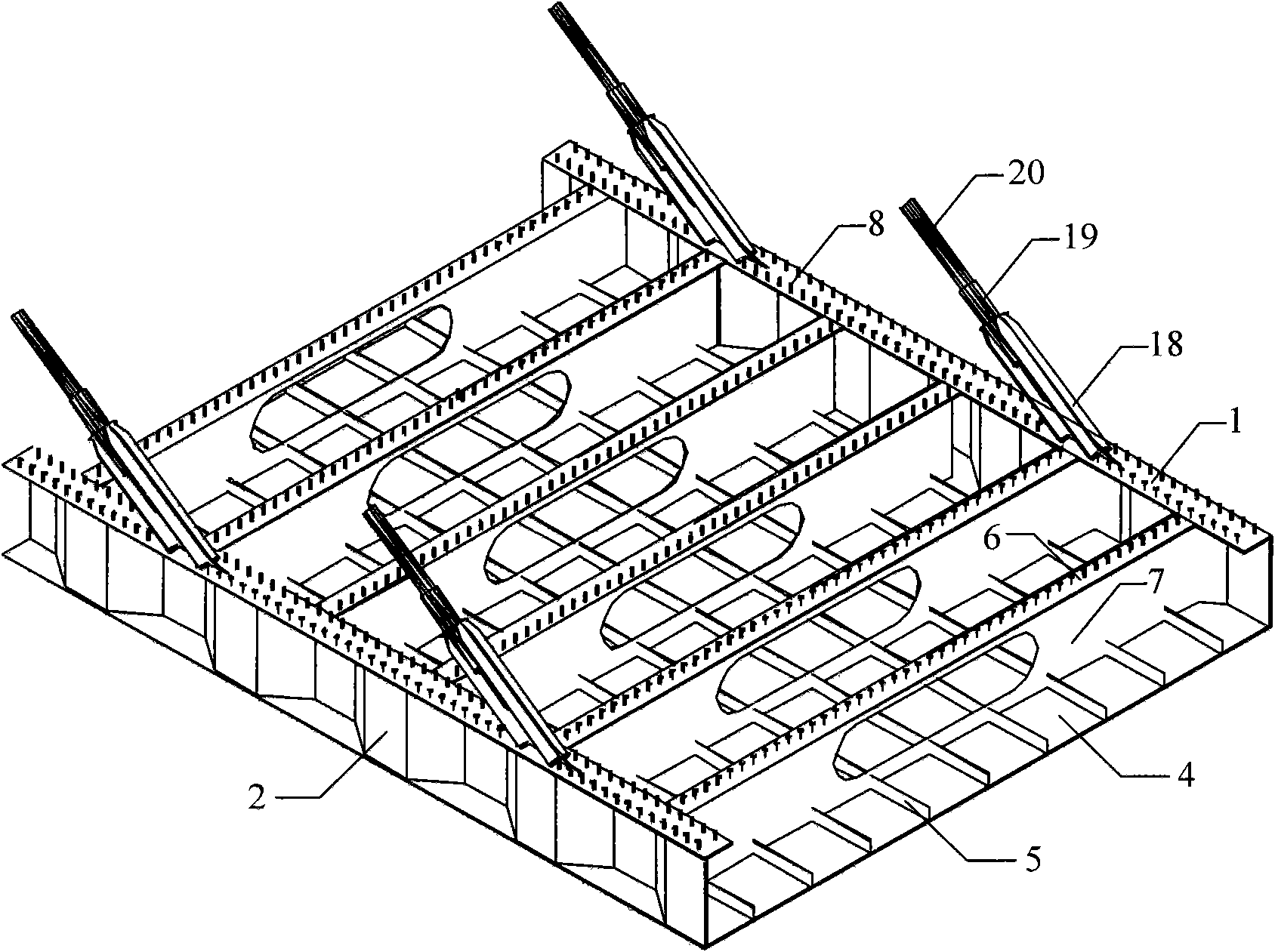

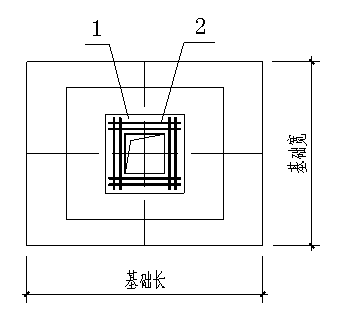

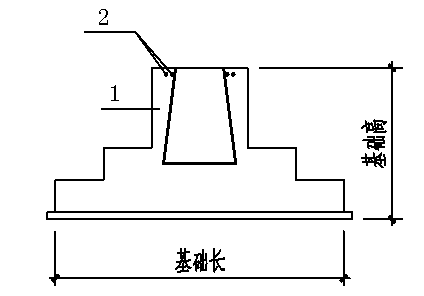

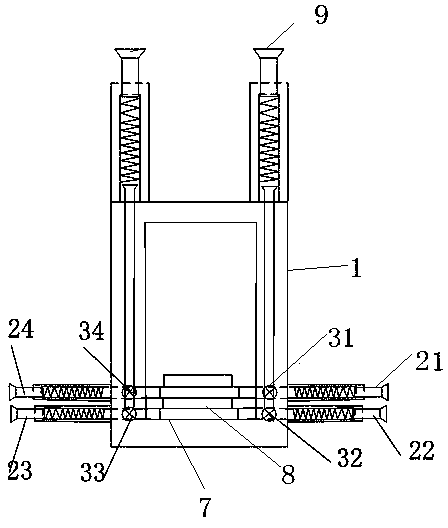

Anti-pulling embedded-type gate-type steel frame steel-joint column foot and construction method thereof

InactiveCN103161223ASmall sizeEasy to installFoundation engineeringBuilding material handlingSteel frameSteel columns

The invention discloses an anti-pulling embedded-type gate-type steel frame steel-joint column foot and a construction method thereof. The anti-pulling embedded-type gate-type steel frame steel-joint column foot is characterized in that a basic short column (1) is composed of injecting concrete, wherein a local-pressure-proof rebar net chip (2) is arranged on the top of the basic short column (1), a basic reverse cup-shaped hole (3) is formed inside the basic short column (1), the lower section of a steel column (8) is inserted into the basic reverse cup-shaped hole (3), a steel column base plate (4) is welded on the bottom of the steel column (8), a steel column toggle pin (5) is welded in the range of the height of the lower section of the steel column (8), a horizontal stiffening plate (6) is welded on the lower section, at the position of 100mm below the top of the basic short column (1), of the steel column (8), and the basic short column (1) is combined with the steel column (8) by the fact that cement mortars are injected in the basic reverse cup-shaped hole (3). According to the structure of the anti-pulling embedded-type gate-type steel frame steel-joint column foot, foundation bolts do not need to be arranged, the dimensions of the basic short column are small, structure is simple, steel materials are saved, and using is safe and reliable.

Owner:GUIYANG AL-MG DESIGN & RES INST

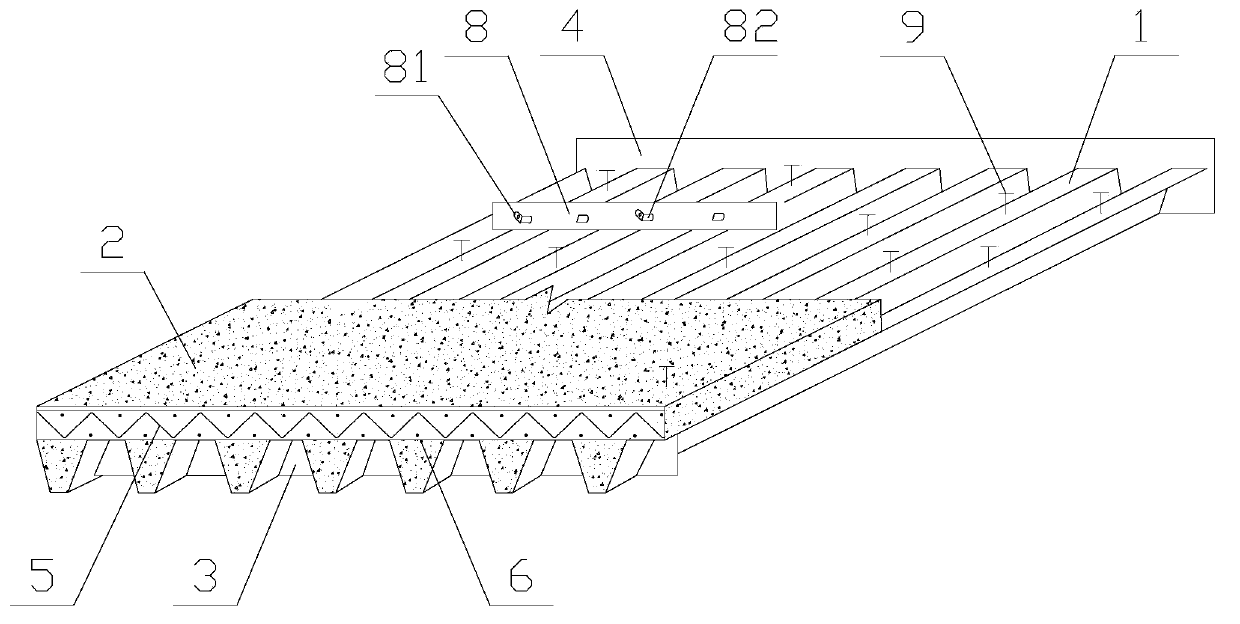

Corrugated plate steel mold integrated composite structure bridge deck system and construction technology thereof

ActiveCN103422435ASolve the phenomenon of poor combinationStrong bending resistanceBridge structural detailsSheet steelBridge deck

The invention relates to a corrugated sheet steel bridge deck system, and discloses a corrugated plate steel mold integrated composite structure bridge deck system and a construction technology thereof. The bridge deck system comprises corrugated sheet steel (1), a bent rebar (5), a straight rebar (6) and concrete (2). The bent rebar (5) is connected with the straight rebar (6) which is connected with the corrugated sheet steel (1), and the concrete (2) is poured to the upper portion of the corrugated sheet steel (1). The construction technology comprises the steps of assembling the corrugated sheet steel (1) on scene, welding the rebar or toggle pins, pouring the concrete (2) and welding steel stiffening ribs (3) on the lower side of the corrugated sheet steel (1). The corrugated sheet steel is adopted to serve as not only a bridge deck steel concrete combination structural part but also a bridge deck concrete formwork, meanwhile wave troughs of the corrugated sheet steel form multiple rib beams, so the system has good resistance to bending, especially bent force transferring rebars are configured on the corrugated sheet steel, and the phenomenon of poor combination of the bridge deck system is eliminated.

Owner:ZHEJIANG CTB WAVEFORM STEEL WEB

Manufacturing method of internally arranged thin-wall H-shaped steel and wood composite beam

InactiveCN108824698AImprove bearing capacityMake full use ofMaterial gluingLoad-supporting elementsEpoxyEngineering

The invention discloses a manufacturing method of an internally arranged thin-wall H-shaped steel and wood composite beam. The manufacturing method comprises the steps that epoxy resin adhesives are brushed on the two sides of a thin-wall H-shaped steel web and the inner sides of web wood plates, the thin-wall H-shaped steel web and the web wood plates are bonded and connected through web connecting bolts, and then thin-wall H-shaped steel and webs on the two sides are closely pasted through pre-tightening opposite-pulling devices; epoxy resin adhesives are brushed on the surfaces of thin-wallH-shaped steel flanges and the inner sides of flange wood plates, the thin-wall H-shaped steel flanges and the flange wood plates are bonded and connected through flange shear-resistant connecting toggle pins, and then the thin-wall H-shaped steel and the flange wood plates are closely pasted through the pre-tightening opposite-pulling devices; and finally, the internally arranged thin-wall H-shaped steel and wood composite beam is formed. According to the manufacturing method of the internally arranged thin-wall H-shaped steel and wood composite beam, efficient steel and wood compositing canbe achieved, the steel and wood composite beam with more excellent properties of bearing capacity, rigidity, durability and the like is formed, and industrial production and standardized constructionof the steel and wood composite beam in a steel and wood composite structure are facilitated.

Owner:SOUTHWEAT UNIV OF SCI & TECH

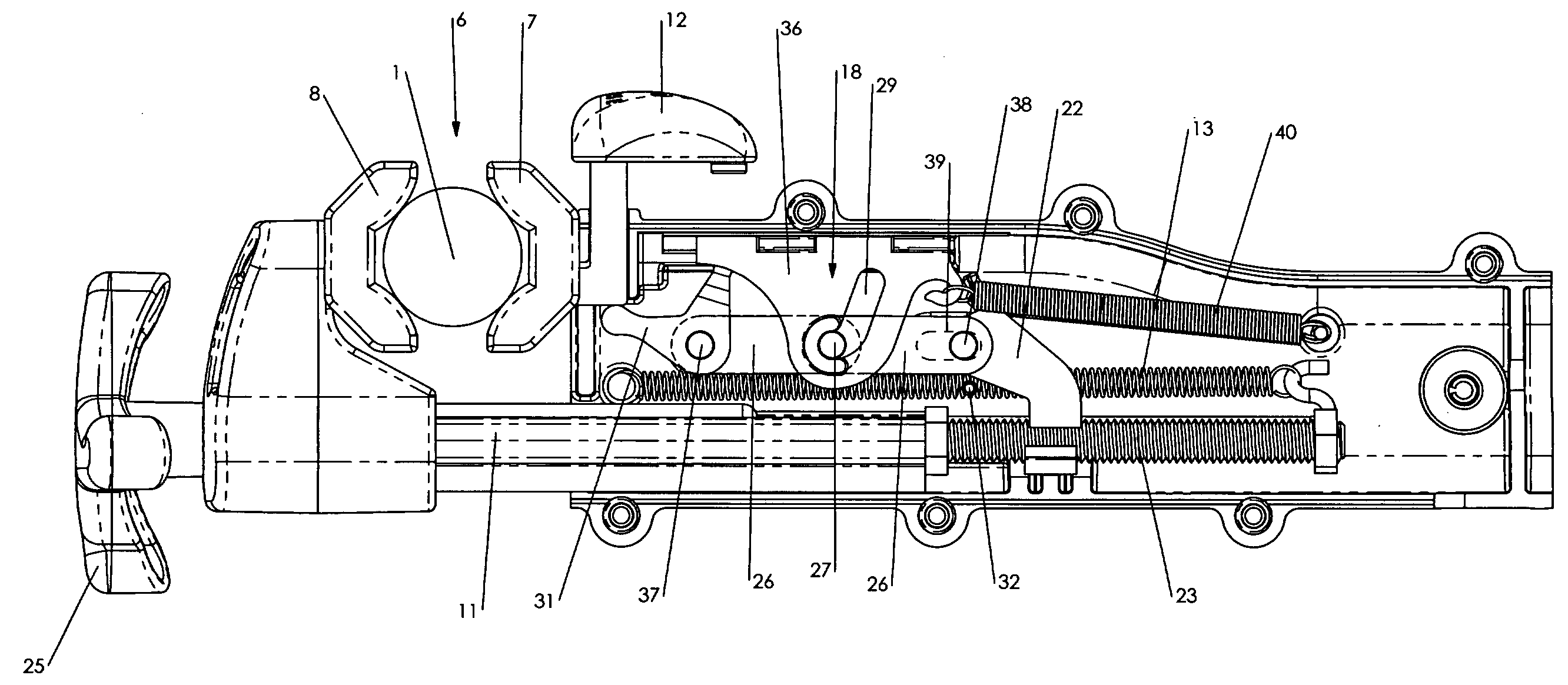

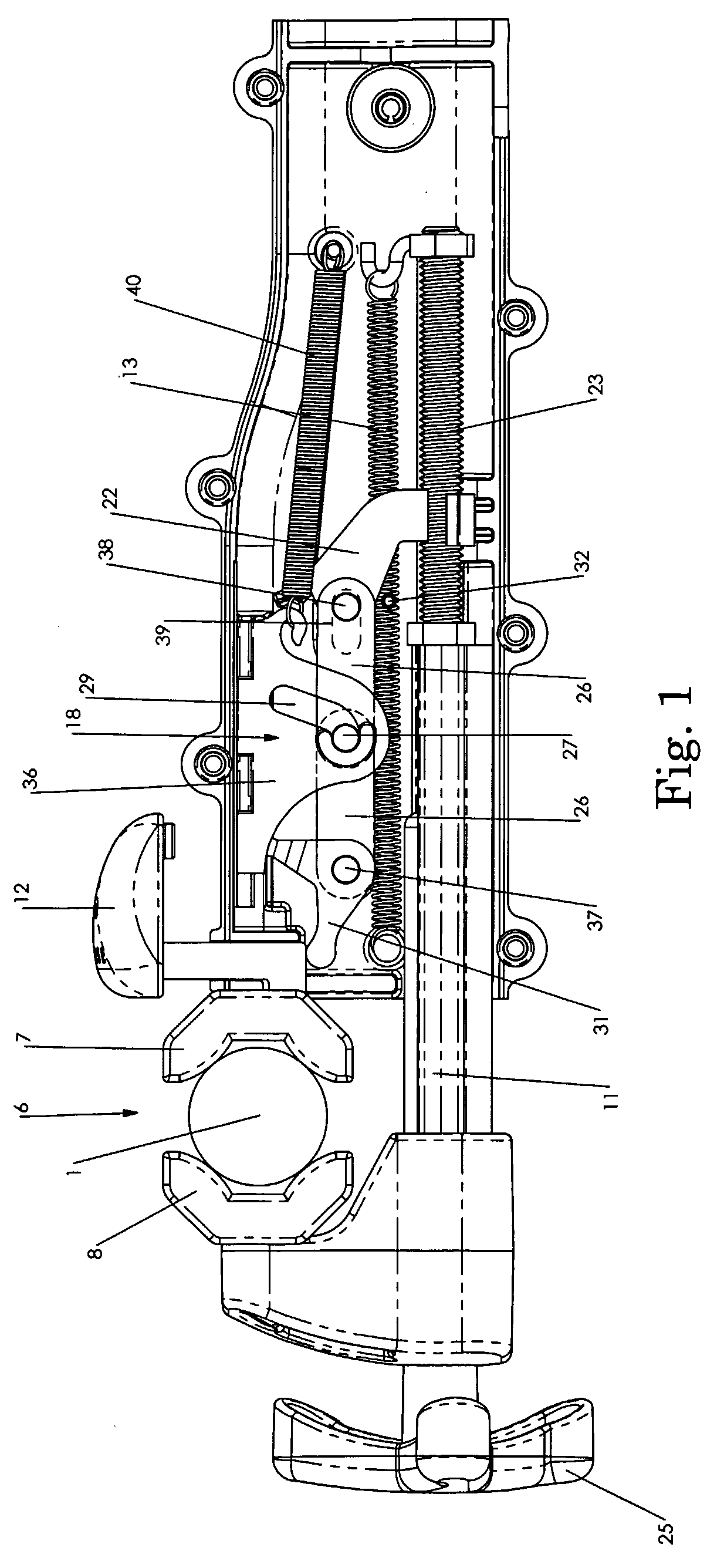

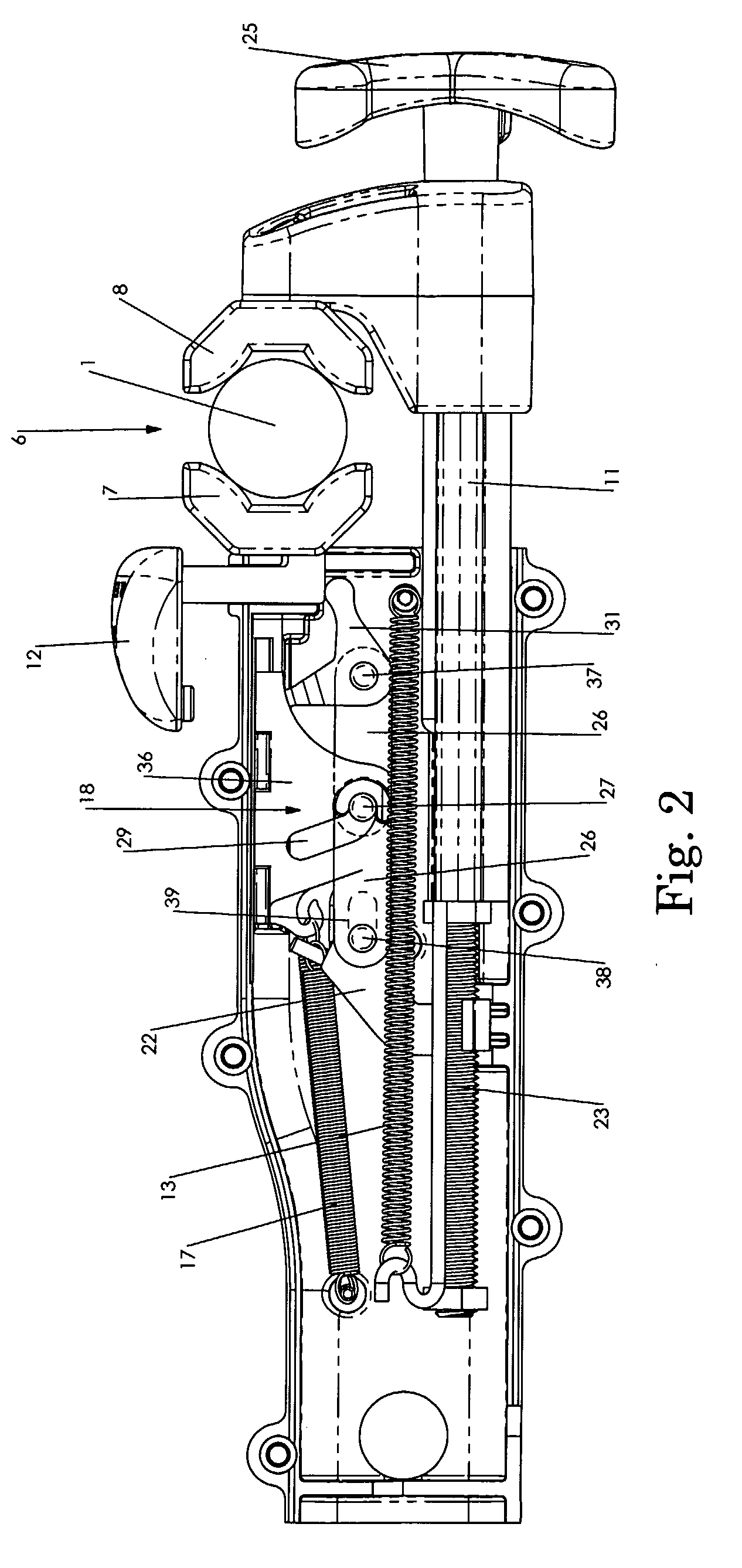

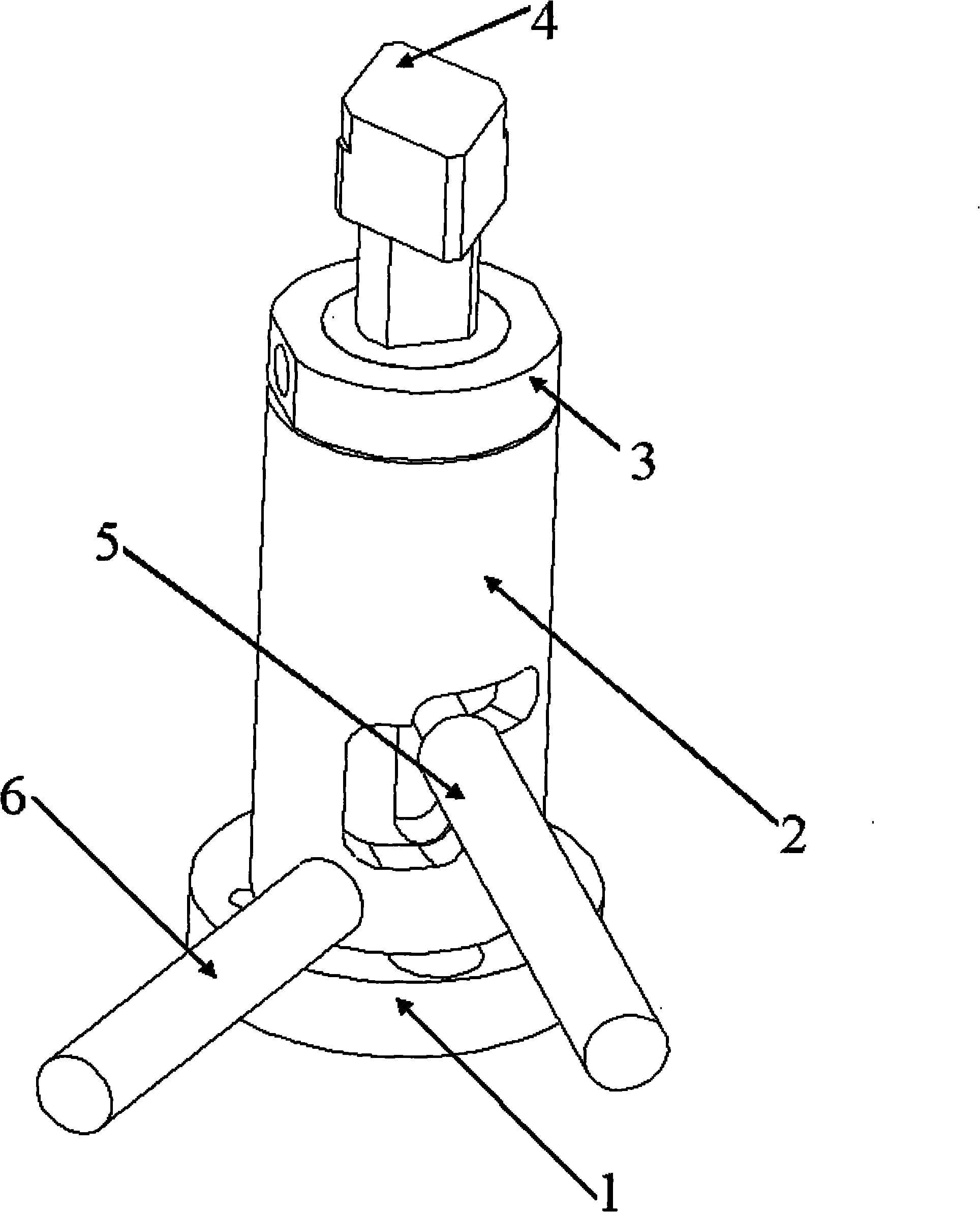

Secure, Quick Attachment and Release Bicycle Support Systems

ActiveUS20080203255A1Stable removalEasy to useCycle standsFurniture partsSupporting systemEngineering

A device and method of clamping bicycles in a mouth (6) having a moveable jaw (8) and a stationary jaw (7) to which a high load potential may be utilized within a toggle joint (18) and ratchet mechanism (14) and a release (12) may be triggered to open a mouth in a quick movement(s). In embodiments, a multisized object securement grip (9) may be located on a contact surface of a moveable jaw and stationary jaw to allow for universal gripping of various sized objects.

Owner:FEEDBACK SPORTS

D shape guide pin top and bottom positioning structure of hole position check tool

ActiveCN101858718AImprove convenienceMechanical measuring arrangementsPosition checkArchitectural engineering

The invention relates to a D shape guide pin top and bottom positioning structure of hole position check tool, comprising a detection pin, a rotating sleeve and a D shape guide pin sliding support; wherein the D shape guide pin sliding support is sheathed at the outer side of the detection pin, the lower end face thereof is provided with a larger-diameter step face with a bolt hole; the rotating sleeve is sheathed at the outer side of the D shape guide pin sliding support, the upper side of the rotating sleeve is provided with a limit press cake; the outer side of the rotating sleeve is fixed with a rotating handle pin, the wall of the rotating sleeve is provided with an inversed 'L' shape first through hole, the wall of the D shape guide pin sliding support is provided with a vertical second through hole, one end of an up-down shifting pin is respectively fixed on the detection pin by virtue of the through holes on the rotating sleeve and the D shape guide pin sliding support. In the invention, the rotating sleeve is sheathed at the outer side of the D shape guide pin sliding support, so that the previous detection pin which only can move up and down and can not be fixed at certain position can be fixed at one specific position, thus improving convenience of operation.

Owner:ROYAL GAUGE IND

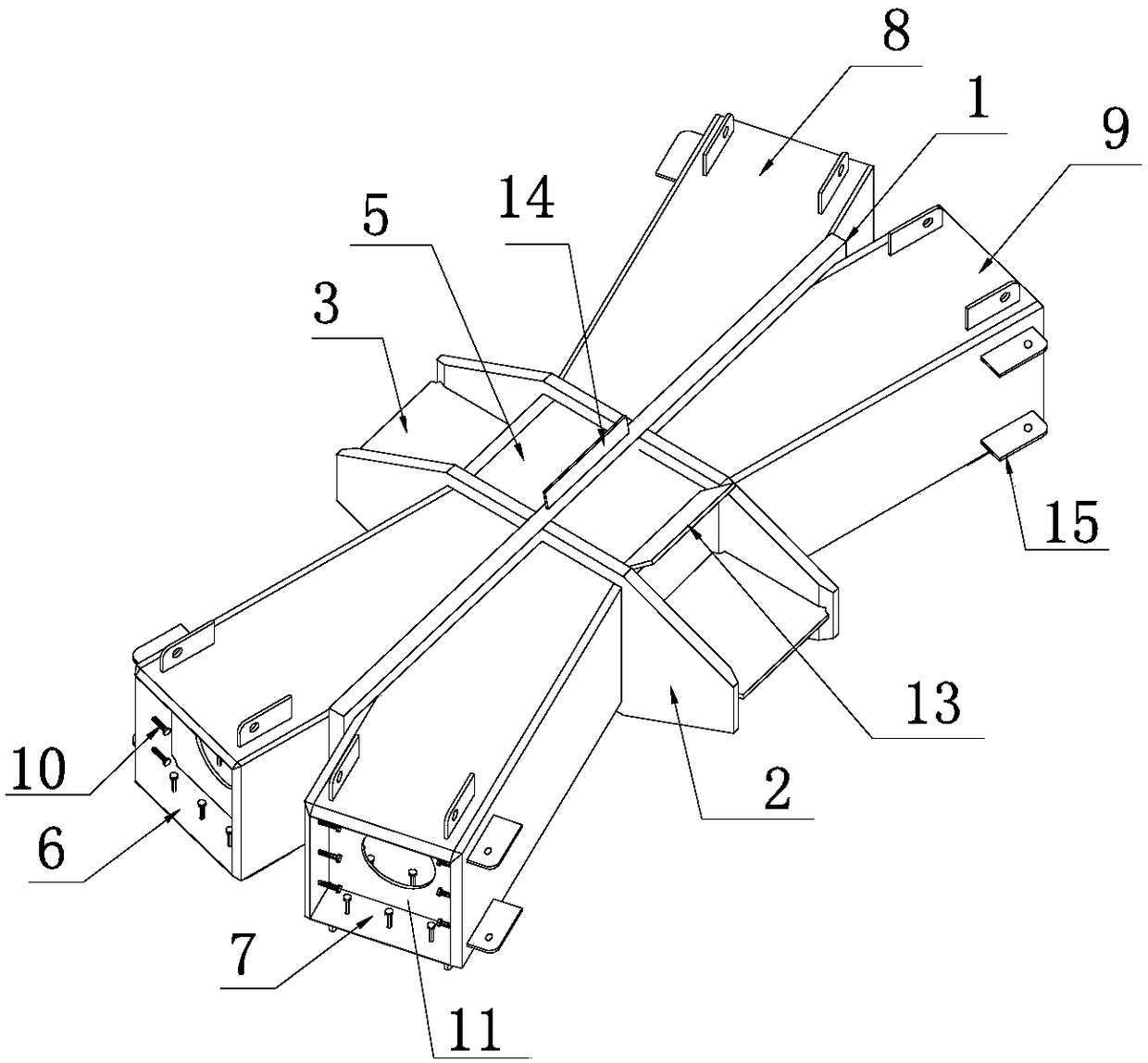

Method for manufacturing overlap changeover connection node shaped like Chinese character 'mi'

InactiveCN108517960AGuarantee welding qualityGuaranteed manufacturing accuracyBuilding constructionsChinese charactersEngineering

The invention relates to a complex overlap changeover connection node shaped like a Chinese character 'mi'. Two H-shaped brackets are symmetrically arranged at the two sides of a middle pulling plate,four box type brackets are symmetrically arranged at the two sides of the middle pulling plate in pairs, two box type brackets arranged at one side of the middle pulling plate are symmetrically arranged at the two sides of the same-side H-shaped brackets, the inner sides of the H-shaped brackets are provided with stiffening plates, the stiffening plates are perpendicular to bracket wing plates, the stiffening plates are packaged in the node through H-shaped bracket sealing plates, toggle pins are arranged at the inner sides of the box type brackets, end portion partition plates are arranged in the two box type brackets symmetrical with the middle pulling plate, the other two box type brackets are provided with end portion blanking plates, one of the H-shaped brackets is provided with a connecting plate, the middle pulling plate is perpendicularly provided with a pulling plate connecting plate, and the outer sides of the end portions of the four H-shaped brackets are provided with lifting lugs used for hoisting. According to the complex node, a special manufacture scheme is made, certain experience is provided for the component manufacturing with similar difficulty, and the promotion and use are easy.

Owner:CHINA CONSTR STEEL STRUCTURE JIANGSU CO LTD

L-shaped steel pipe bundle composite structure

InactiveCN103850367AEasy to pourCombination is reliableConstruction materialWallsCarrying capacityMetallurgy

The invention discloses an L-shaped steel pipe bundle composite structure which comprises an L-shaped steel pipe bundle assembly; the L-shaped steel pipe bundle assembly is formed by a plurality of steel pipe units which are sequentially connected; each steel pipe unit is provided with a cavity; concrete is poured into the cavities; the side wall of each cavity is provided with a toggle pin; a clapboard arranged between every two adjacent steel pipe units is provided with a through hole. According to a steel pipe bundle composite structure element, a steel pipe bundle is manufactured in an industrialized way, field assembly construction is realized, and the concrete poured into the element is a whole, so that pouring is convenient, and a formwork is not needed; the steel pipe bundle and the concrete can work in a cooperative way by the toggle pins, so that the combination function is reliable, and the bending capacity, compression resistance, the shearing resistance and the carrying capacity are high; all working procedures for producing the steel pipe bundle composite structure element adopt industrial equipment, so that the production speed is rapid, the product quality is reliable, and a great deal of manpower can be saved.

Owner:HANGXIAO STEEL STRUCTURE

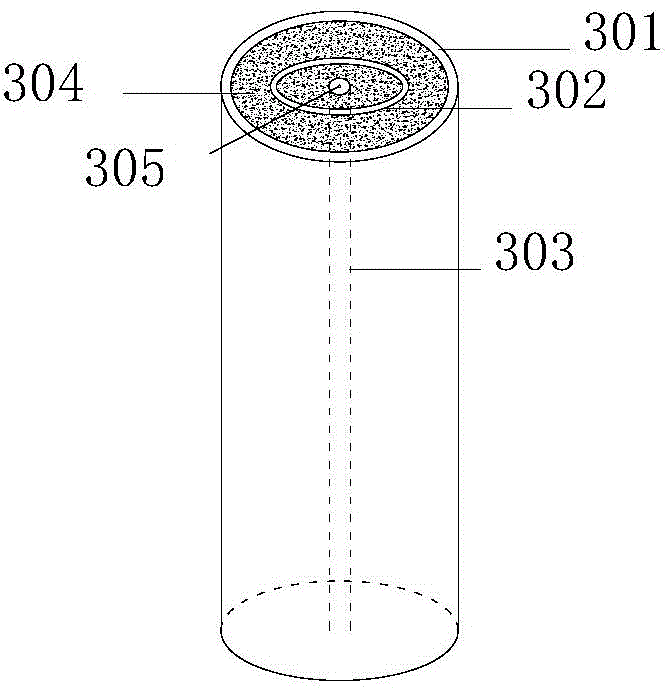

Self-returning offshore jacket platform and manufacturing method thereof

ActiveCN104912047AImprove vibration reductionImprove sexual functionArtificial islandsUnderwater structuresEngineeringUltimate tensile strength

The invention belongs to the field of structural engineering in civil engineering and provides a self-returning offshore jacket platform and a manufacturing method thereof. The self-returning offshore jacket platform solves the problem that an original offshore platform is poor in anti-seismic property and is large in rigidity, high in strength, convenient to construct, good in anti-seismic property and high in durability. The self-returning offshore jacket platform is formed by a platform frame and a platform body, the platform body is arranged on the platform frame, and a plurality of horizontal platform struts and inclined platform struts are arranged among platform pipes. External steel tubes, internal steel tubes and corrugated tubes of the platform pipes are coaxially arranged from outside to inside in a sleeving mode, interlayer concrete is arranged between the external steel tubes and the internal steel tubes and between the internal steel tubes and the corrugated tubes, locating toggle pins are arranged on the external steel tubes and are movably connected with the internal steel tubes, built-in prestressed steel pull rods are arranged in the corrugated tubes, reinforcing ribs are fixedly connected to the outer sides of the external steel tubes, flange plates are fixedly arranged at the top ends of the platform pipes, and the upper ends of the flange plates are connected with the platform body or spliced with platform pipes.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

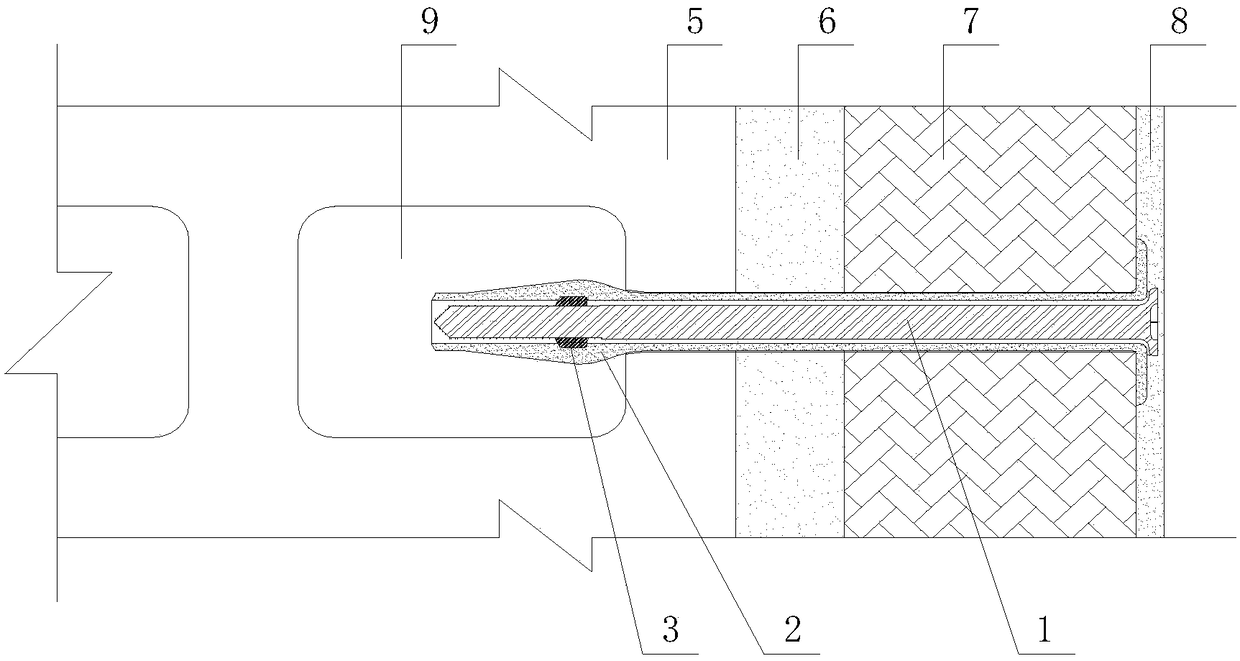

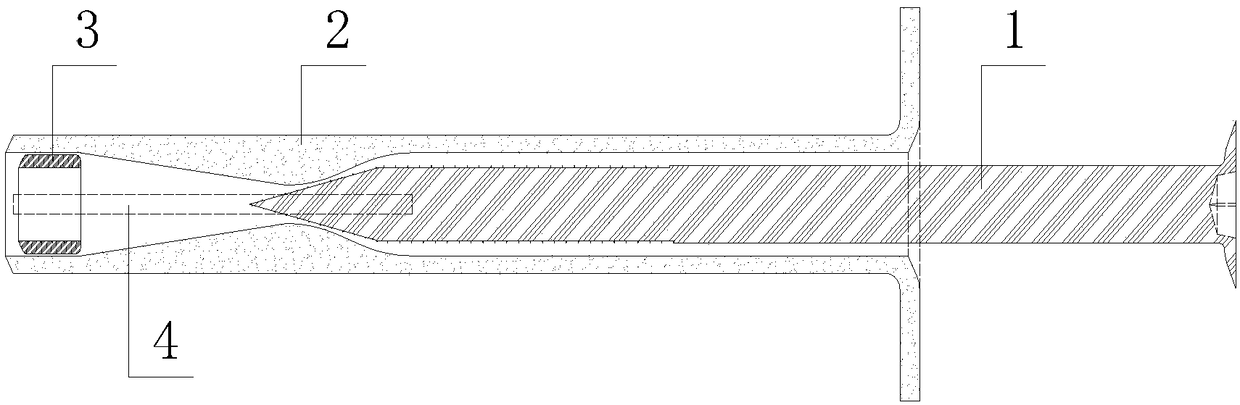

Pulling-resistant toggle pin for anchoring heat insulation plate on hollow brick wall

InactiveCN108591214ASolve the problem of insufficient effective anchorage lengthHeat proofingDowelsCircular discBrick

The invention relates to a pulling-resistant toggle pin for anchoring a heat insulation plate on a hollow brick wall. The pulling-resistant toggle pin for anchoring the heat insulation plate on the hollow brick wall comprises an expanding pipe with a circular disc on the tail part and a bulge section on the front middle section, wherein an expanding plug capable of being clamped to an inner wall of a cavity of a hollow brick is arranged at the front end of the expand pipe; sliding chutes for the expanding plug to slide front and back are formed in two sides of the bulge section; an inner-threaded circular hole is formed in the middle of the expanding plug; raised strips are arranged on two sides of the expanding plug and are matched with the sliding chutes in two sides of the expanding pipe; a metal screw rod is screwed into the expanding pipe; the tail part of the metal screw rod presses the circular disc of the expanding pipe; and the front end of the metal screw rod is screwed intothe expanding plug. The pulling-resistant toggle pin for anchoring the heat insulation plate on the hollow brick wall provided by the invention solves the problem that when the outer wall heat insulation plate is arranged on the hollow brick wall, the effective anchoring length of an outer wall insulation toggle pin is insufficient, so that the aim of anchoring the heat insulation plate on the hollow brick wall body is achieved.

Owner:MCC TIANGONG GROUP

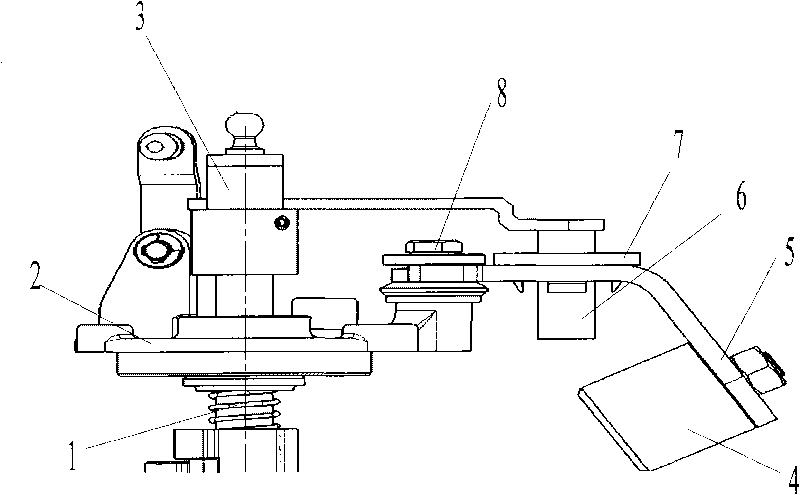

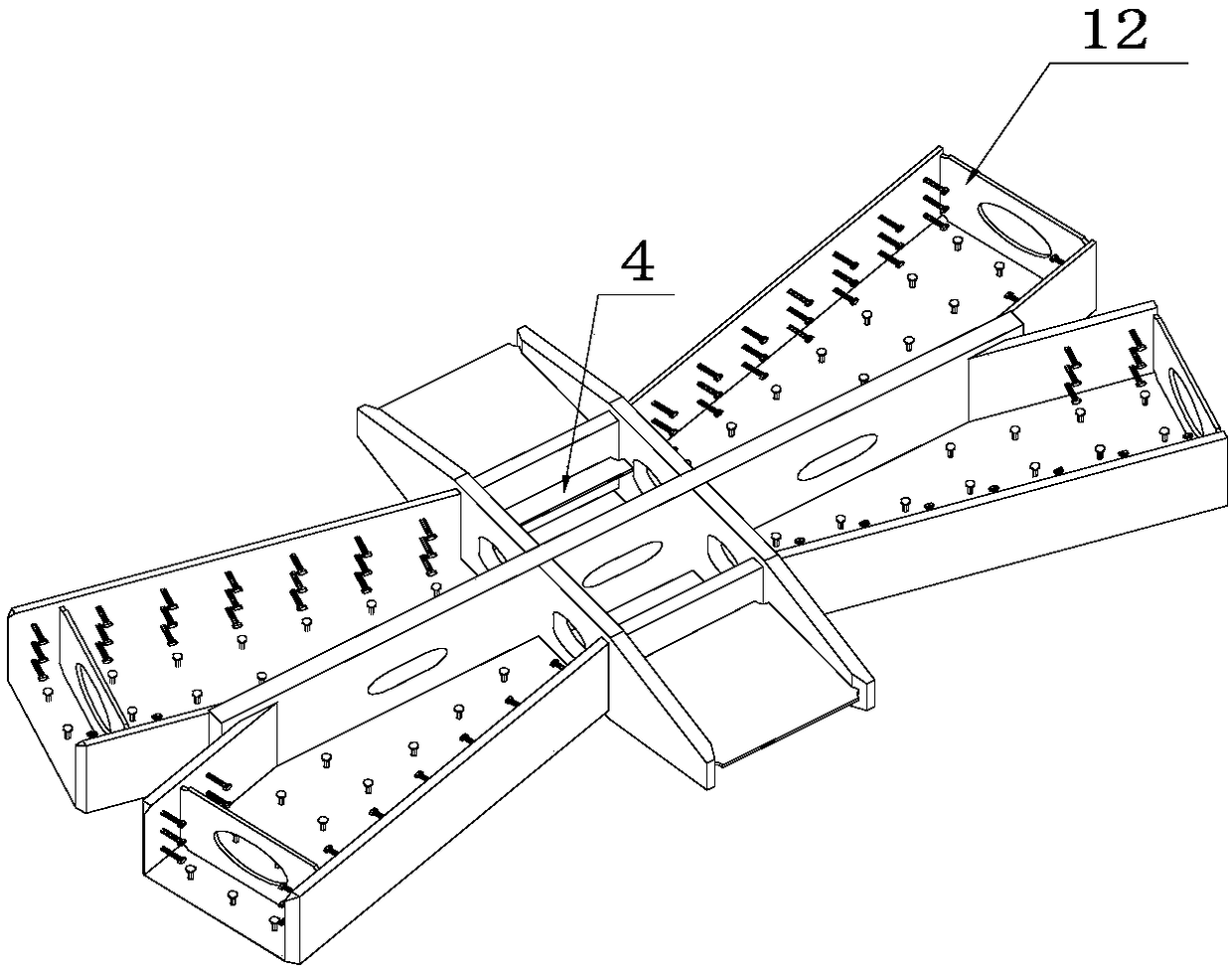

Fixture for packaging stack array of semiconductor laser

ActiveCN104934851APrecise positioningReduce mistakesLaser detailsSemiconductor lasersSemiconductor packageEngineering

The invention provides a fixture for packaging a stack array of a semiconductor laser. The fixture comprises two guide rails fixed on a fixed plate, and at least two toggle pins used for fixing transition heat sinks placed in the middles of the two guide rails, wherein the toggle pins are mounted on tracks of the two guide rails in a one-to-one correspondence manner, and comprise tube bodies; movable screws and ejector pins are mounted at the two ends of the tube bodies respectively; the ejector pins move forward by screwing the screws; and the ejector pins of the two toggle pins in the one-to-one correspondence manner face towards the middles of the two guide rails. The fixture can realize positioning and fixing of the transition heat sinks in a packaging process, and can avoid displacement of the transition heat sinks and chips due to movement in the packaging process.

Owner:ZHENGZHOU UNIV

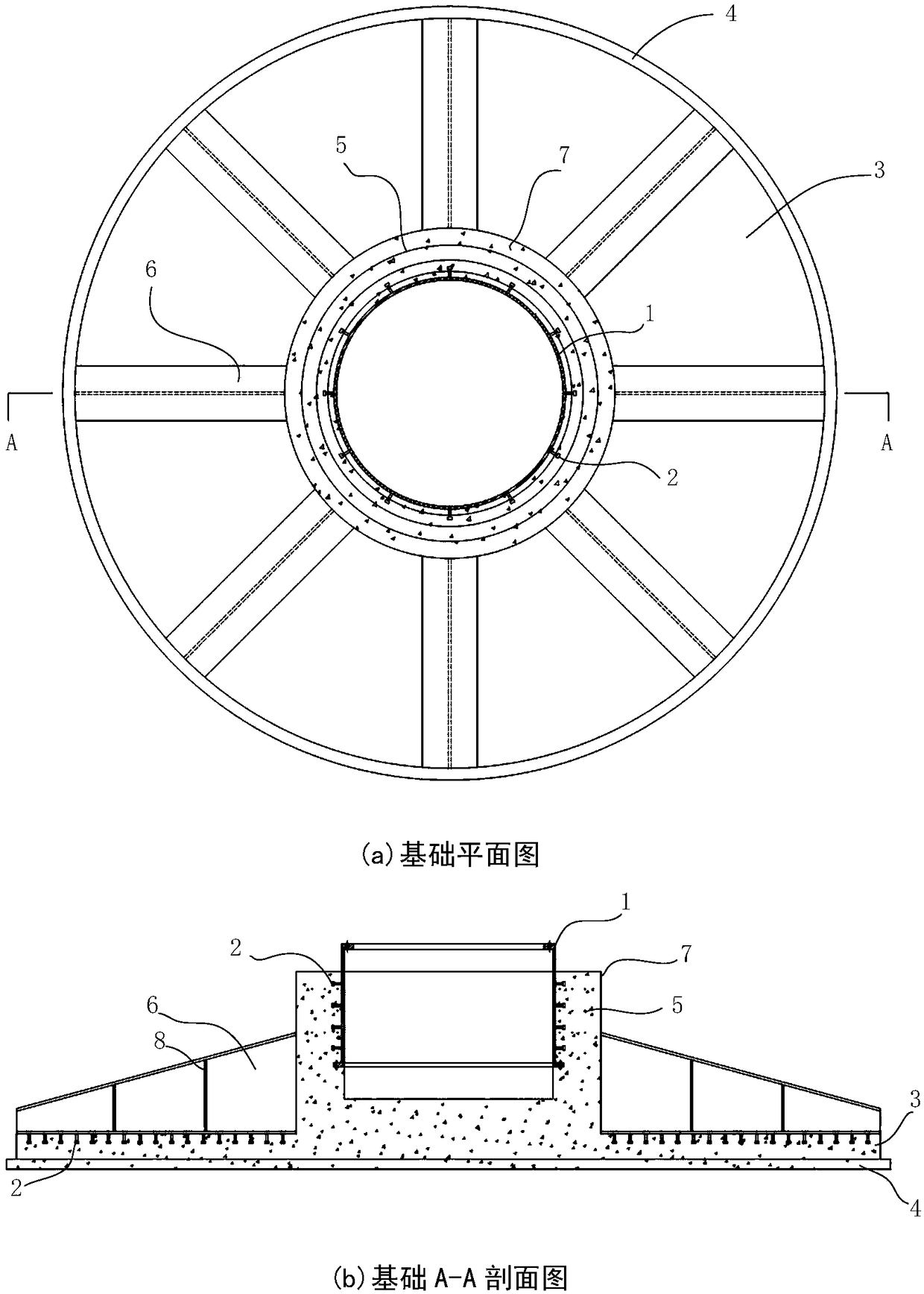

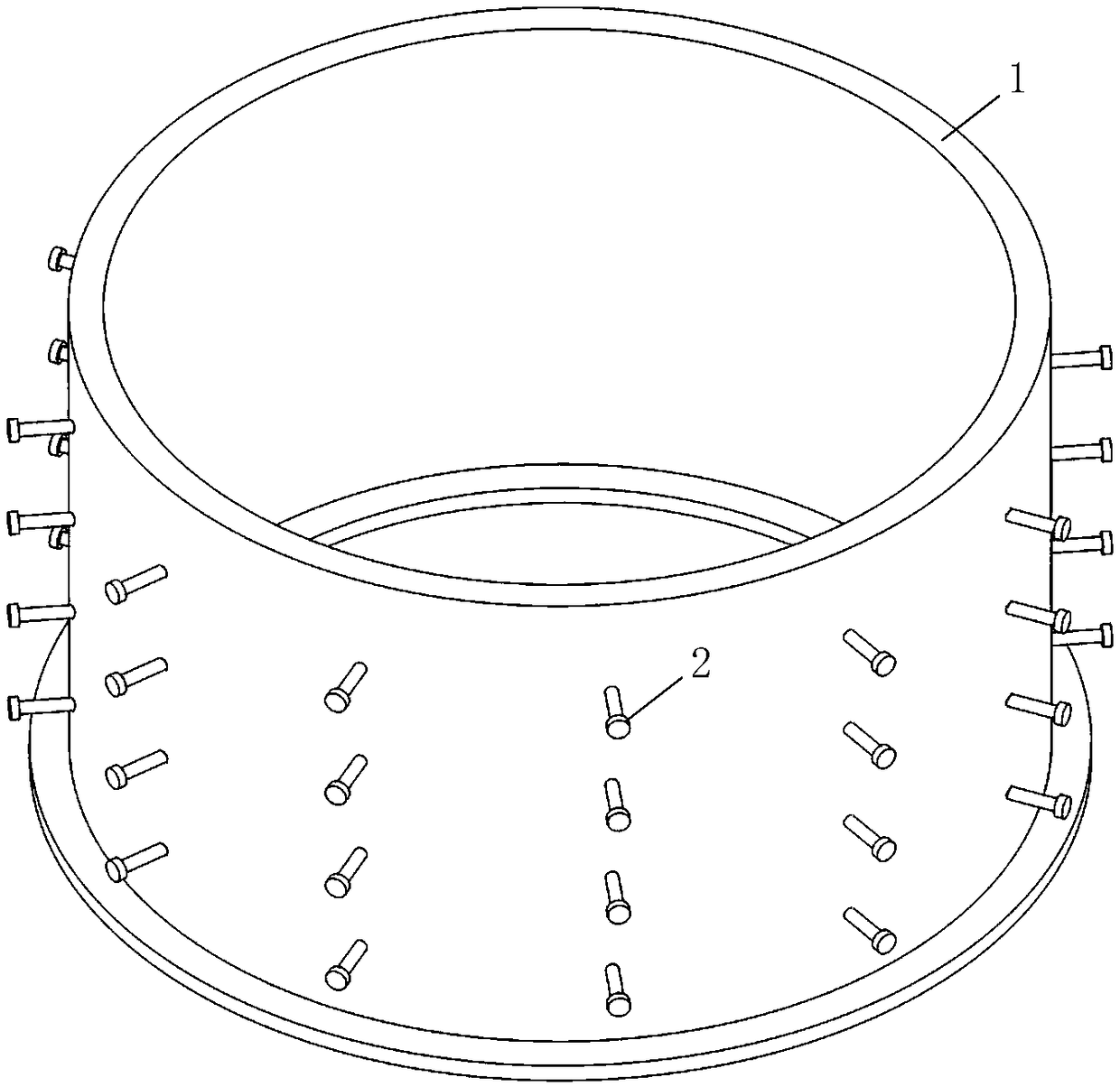

Wind power tower drum foundation ring ribbed beam type foundation based on combined structure

The invention discloses a wind power tower drum foundation ring ribbed beam type foundation based on a combined structure, and relates to the technical field of onshore wind power generation. The system comprises a foundation ring, a circular concrete floor, a variable-cross-section H-shaped steel rib beam, a hollow concrete pillar, a toggle pin and a square steel shear connector. The foundation ring is connected with a wind power tower drum on the upper part, and a perforation reinforcing steel bar required by a traditional basic ring is removed and replaced with the prefabricated welding toggle pin, so that the basic ring and a foundation concrete form effective connection by utilizing favorable shearing resistance and pulling resistance of the toggle pin, and the construction difficultyin reinforcing steel bar perforating on site is remarkably reduced. The variable-cross-section H-shaped steel rib beam is connected with a foundation slab and the pillar through the shear connector so as to form a combined structure stress system, so that the mechanical characteristics of two materials are fully played, and larger internal force produced by the upper load can be resisted. The foundation system can be applied to a circular bearing platform of a circular spread foundation or a pile foundation, and is high in on-site construction efficiency and material-saving so as to have a good engineering application prospect.

Owner:CHONGQING UNIV

Toggle link deck to building connector

A device for connecting an exterior deck structure to a contiguous building via a bore-hole through the deck ledger and building header retains the deck in place in the event of earthquake or similar stresses. A pair of tension members comprising interlocked tensile links, are encapsulated in a generally cylindrical plastic plug to maintain ½ to 2 inches separation, to provide a thermal barrier. A pivoting toggle pin on the end of one link pivots between a first position aligned with the axis of the link and a second position transverse to the axis. The plastic plug may have an extending lip supporting the pivot pin in axially alignment. The second link may be rigid or flexible, has a sealing member adapted to slide thereon to seal the bore-hole. The second link is adapted to be fastened securely to a joist or other appropriate member of the deck.

Owner:GRK CANADA

Assembled coupling beam with built-in profiled steel sheet groove structure

ActiveCN107217787AIncrease widthImprove the problem of insufficient shear pressure ratioGirdersJoistsHoopingSheet steel

The invention discloses an assembled coupling beam with a built-in profiled steel sheet groove structure and belongs to the technical field of an assembled concrete structure. The assembled coupling beam consists of coupling beam longitudinal bars, coupling beam hooping bars, coupling beam concrete, corrugated steel plates, profiled steel sheets, profiled steel sheet connecting rods and toggle pins. Groove structures are formed at the two ends of a prefabricated coupling beam by arranging the profiled steel sheets with the toggle pins serving as inner formwork at the two ends of an assembled concrete prefabricated coupling beam component, a beam nest and the parts enclosed by grooves are cast in situ, and a detachable splicing system which is more simple and easy to construct is formed at a beam end, so that work quantity of field templates can be reduced, and construction difficulty is reduced. Cooperative work between the profiled steel sheets and the concrete can be ensured by the toggle pins arranged on the profiled steel sheet, strong connection between the coupling beam and a shear wall slab is realized through the profiled steel sheets and connecting components of the profiled steel sheets, wide coupling beam advantage is exerted, depth-span ratio is reduced while bending rigidity of the coupling beam is ensured, and the integrality and energy consumption ability of the structure are further improved.

Owner:杭萧钢构(于都)有限公司

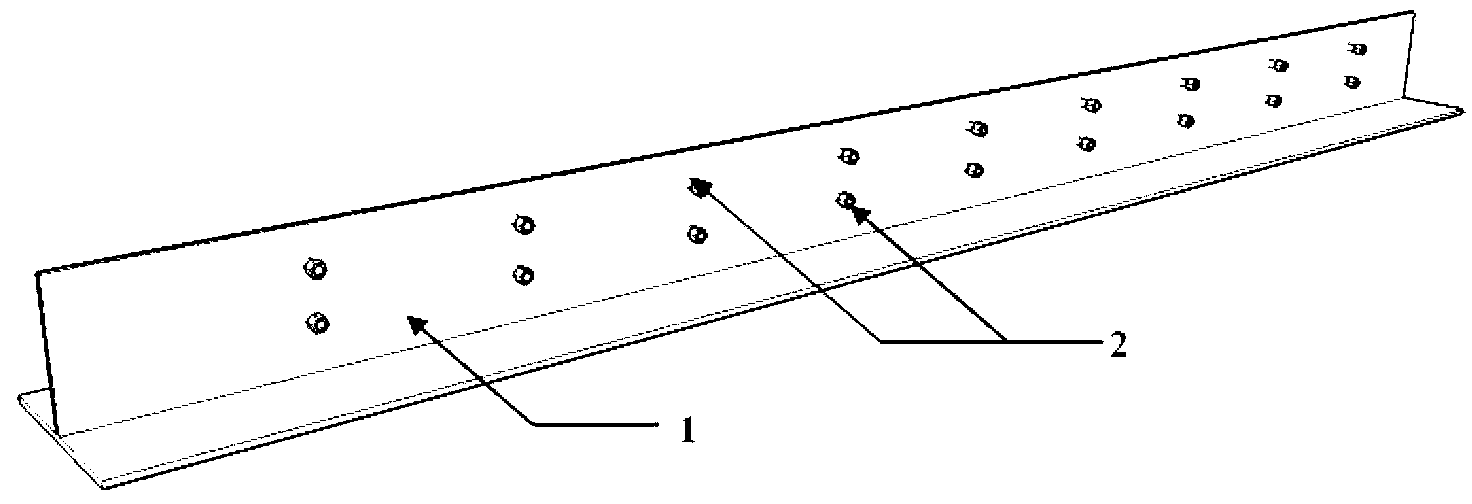

Embedded steel-encased high-intensity concrete combined beam with toggle pins

InactiveCN103015627AAvoid crackingEffective bondingLoad-supporting elementsFully developedHigh intensity

The invention discloses an embedded steel-encased high-intensity concrete combined beam with toggle pins. High-intensity concrete is filled in a steel framework; the steel framework consists of reversed T-shaped steel straight strips, reversed L-shaped angle steel and connection steel lacing bars; a transverse plate consisting of the reversed T-shaped steel straight strips is arranged at the bottom of the steel framework; the toggle pins are arranged on a vertical plate consisting of the reversed T-shaped steel straight strips; the reversed L-shaped angle steel is respectively positioned above the reversed T-shaped steel straight strips and is connected through the transverse lacing bars; and the reversed T-shaped steel straight strips are connected with the reversed L-shaped angle steel through the vertical lacing bars. By the combined beam, a phenomenon that a crack is produced too early because of fragileness of concrete is avoided; the dynamic advantages of two materials, namely the concrete and the steel, are fully developed; by the toggle pins, effective adhesion between the toggle pins and the concrete is improved, and anti-shear bearing capacity is realized; use of templates during construction can be reduced; the working procedures of supporting the templates are reduced; the construction progress is improved; and mechanical construction is facilitated.

Owner:GUANGXI UNIV

Pin lock cylinder or anti-theft locking device

The invention relates to a pin lock core or an anti-theft locking device which can prevent the pin pin from being unlocked by a universal key. In order to prevent the tumbler from being pulled, the transmission key mechanism transmits the key to the state of being isolated from the outside of the tumbler lock cylinder or anti-theft locking device for key inspection; in order to prevent the pintle from producing frictional resistance on the key, the transmission key rotating part rotates and transmits the key to the key inspection When the lower pin of the mechanism is at the position, the lower pin is not in contact with the rotating part of the transmission key and the key, so there is no frictional resistance caused by the lower pin, which completely solves the problem of unlocking the lock with the anti-pick pin and the frictional resistance of the pin against the key .

Owner:金学镐

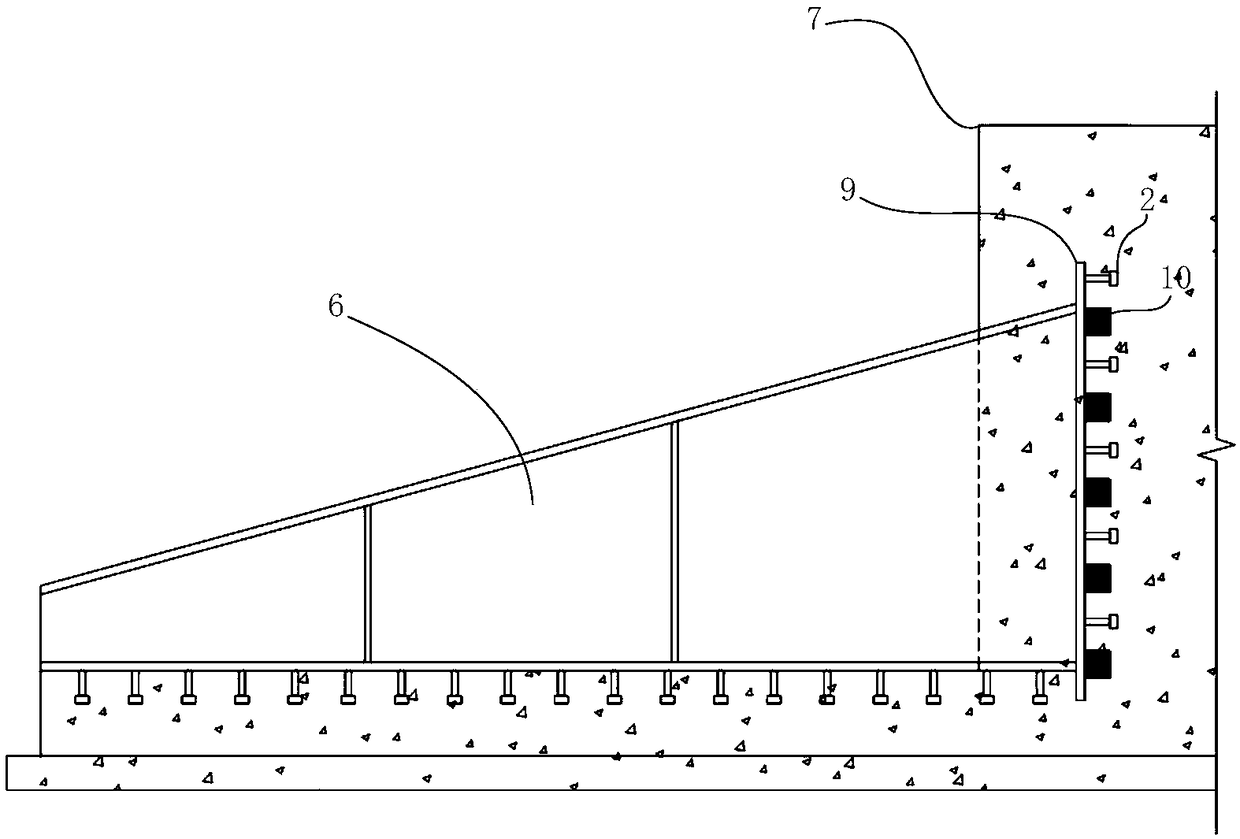

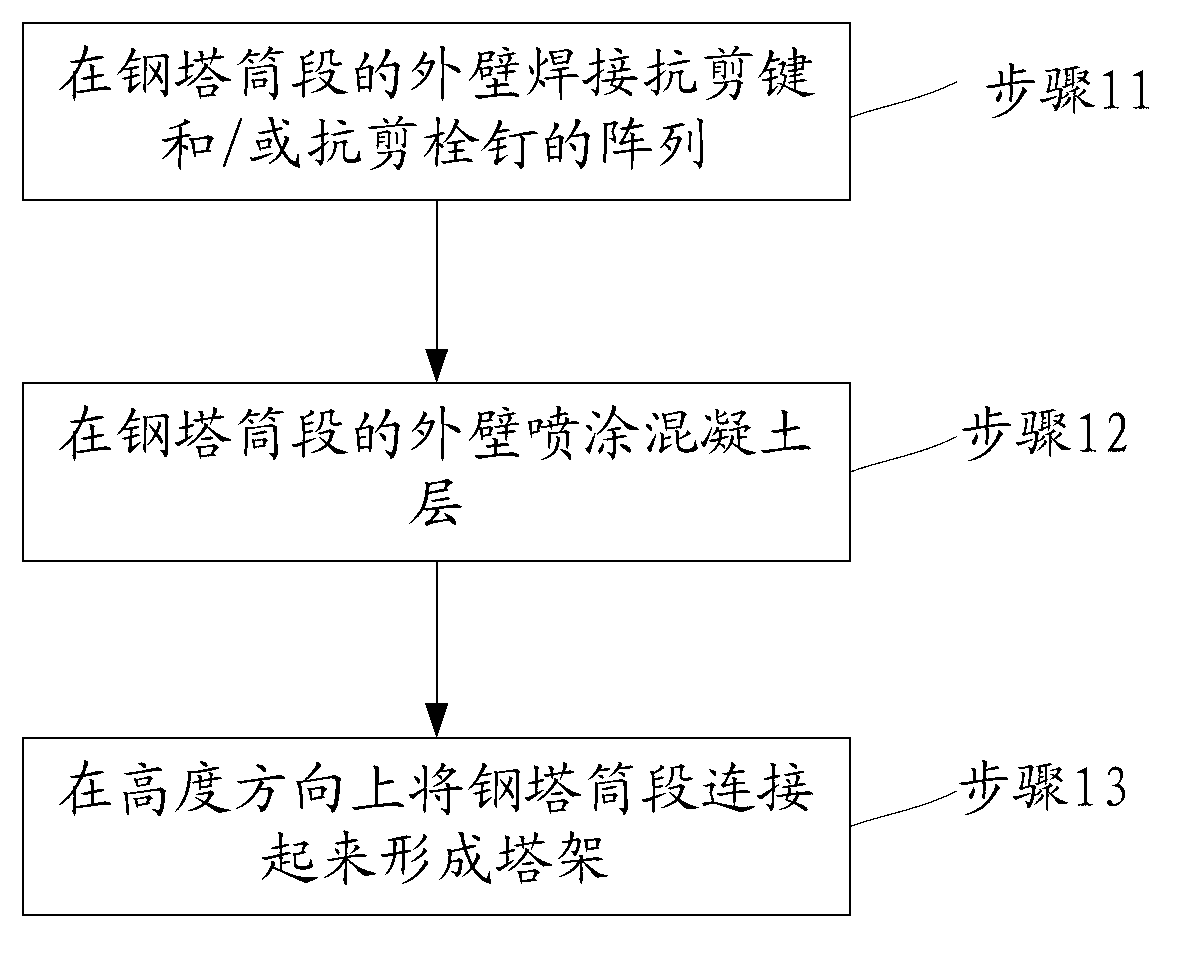

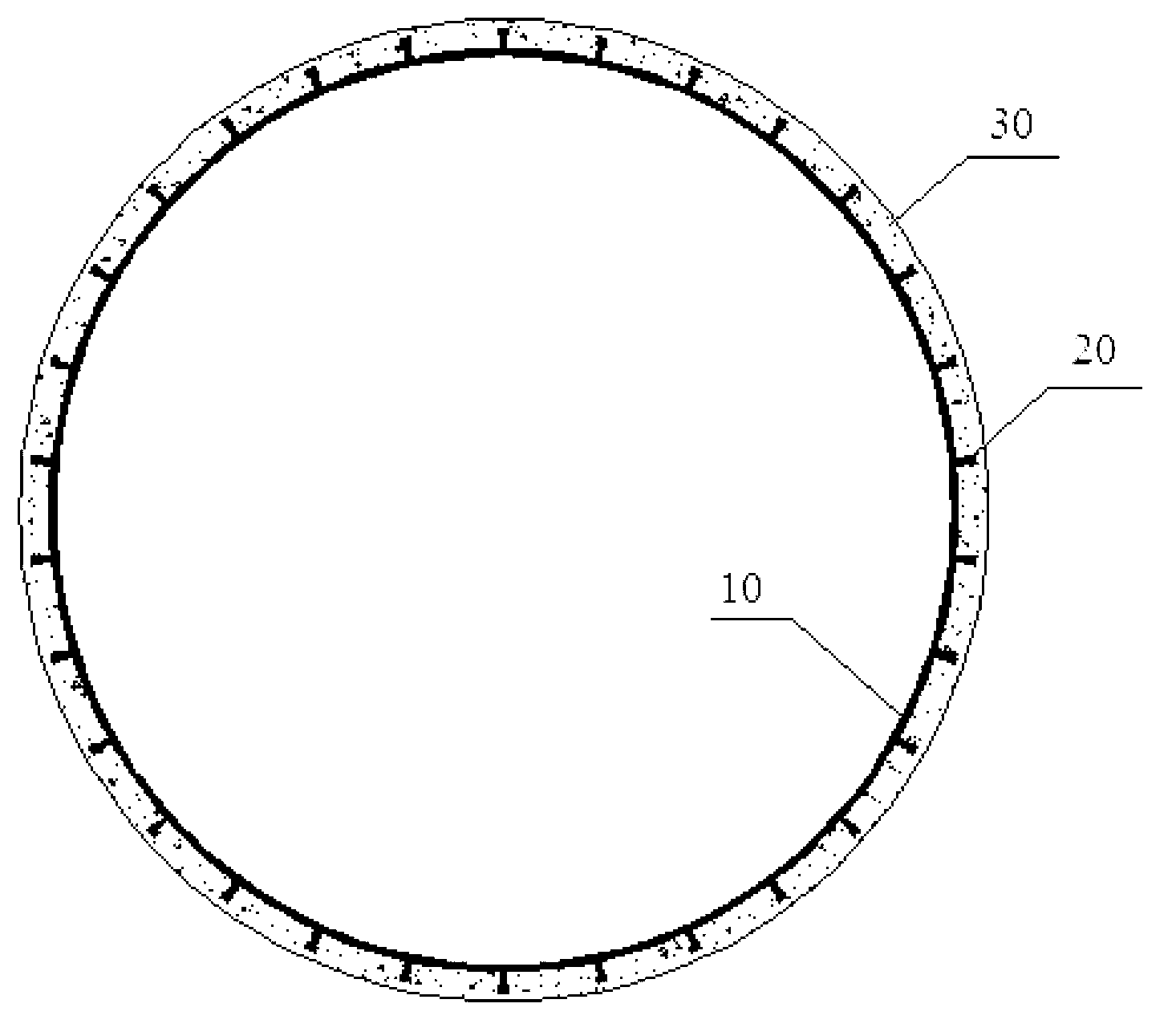

Constructing method of wind power generator set tower frame and wind power generator set tower frame

ActiveCN103015787AIncrease wall thicknessIncrease the outer diameterTowersWind energy generationEngineeringTower

The invention discloses a constructing method of a wind power generator set tower frame and the wind power generator set tower frame, relates to the wind power generation technology and is invented by reaching the goal of improving the rigidity of the tower frame on the basis without increasing the cost of the steel tower frame. The constructing method of the wind power generator set tower frame comprises the steps that anti-shearing keys and / or anti-shearing toggle pin arrays are welded at the outer wall of a steel tower tube section; a concrete layer is sprayed and coated at the outer wall of the steel tower tube section; and the steel tower tube sections are connected to form the tower frame in the height direction. The wind power generator set tower frame comprises a steel tower tube and the concrete layer sprayed and coated at the outer wall of the steel tower tube, wherein the anti-shearing keys and / or the anti-shearing toggle pin arrays are welded at the outer wall of the steel tower tube, and the anti-shearing keys and / or the anti-shearing toggle pin arrays are covered by the concrete layer. The constructing method and the wind power generator set tower frame are used for wind power generation.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com