Construction method of fabricated pre-tensioned pre-stressing corrugated steel web composite box beam

A corrugated steel web and prestressing technology, applied in the field of bridge construction, can solve the problems of easy transportation, hoisting and post-maintenance, and achieve the effects of easy transportation and hoisting, reducing engineering volume, and avoiding poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The construction method of the pre-tensioned prestressed corrugated steel web composite box girder of the present invention mainly comprises the following steps:

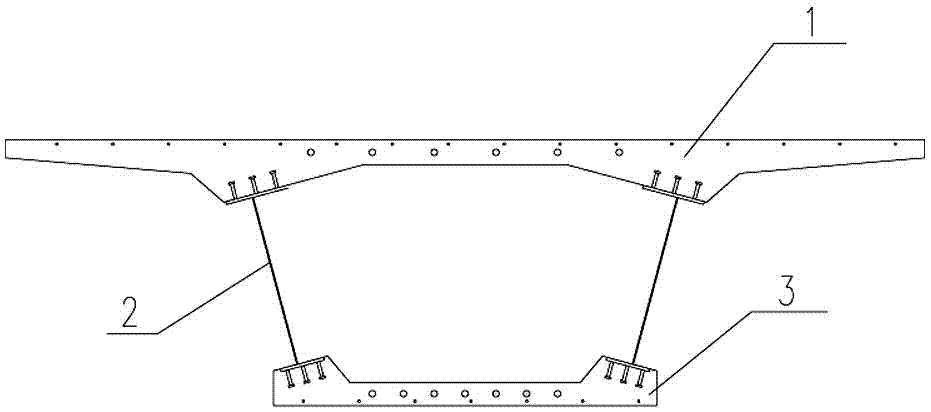

[0031] In the first step, according to the design requirements of the bridge, an inverted trapezoidal beam unit (such as figure 1 Shown) with precast concrete top slab, prestressed concrete bottom slab and corrugated steel web:

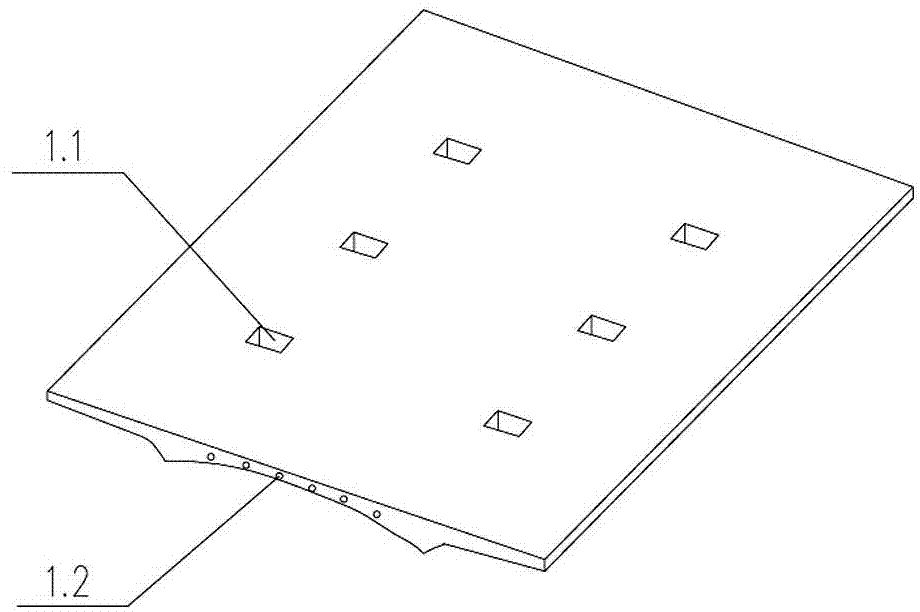

[0032] Specifically, prefabs such as figure 2 For the prefabricated concrete roof 1 shown, the roof reinforcement mesh with longitudinal connecting bars and stud notches 1.1 is first bound, and the stud notches 1.1 are arranged on both sides of the roof reinforcement mesh at longitudinal intervals, and then the top of the pier is loaded. The bending moment prestressed channel 1.2 is installed in the steel mesh of the roof, and then the limit formwork is installed, and the concrete is poured; after the concrete reaches the design strength, the limit formwork is removed.

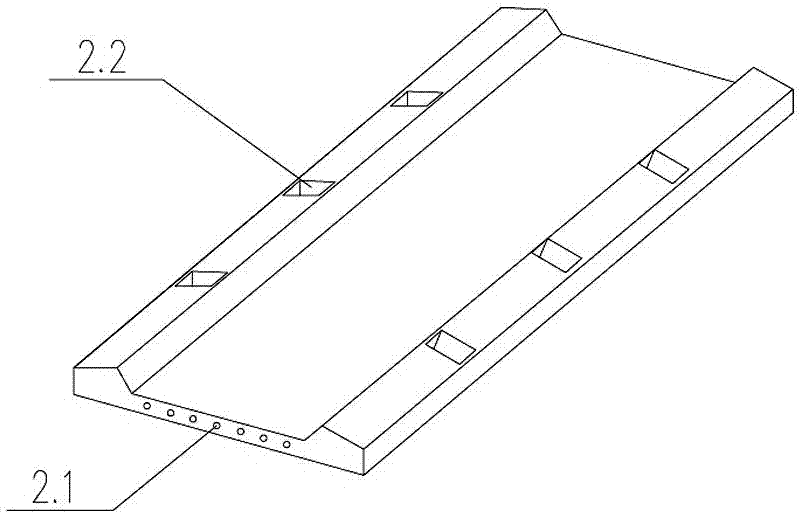

[0033] pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com