Locally uncombined suspension bridge steel-concrete combined bridge deck system and construction method of combined bridge deck system

A combined bridge deck and concrete technology, which is applied to suspension bridges, bridges, bridge parts, etc., can solve the problems affecting the mechanical performance of the new and old concrete joints, the difficulty of guaranteeing the quality of concrete pouring, the large amount of on-site work and the difficulty of construction, etc., to achieve The construction quality is easy to guarantee, the wet work load and construction difficulty are reduced, and the effect of reducing the risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, structure of the present invention, construction process are described further.

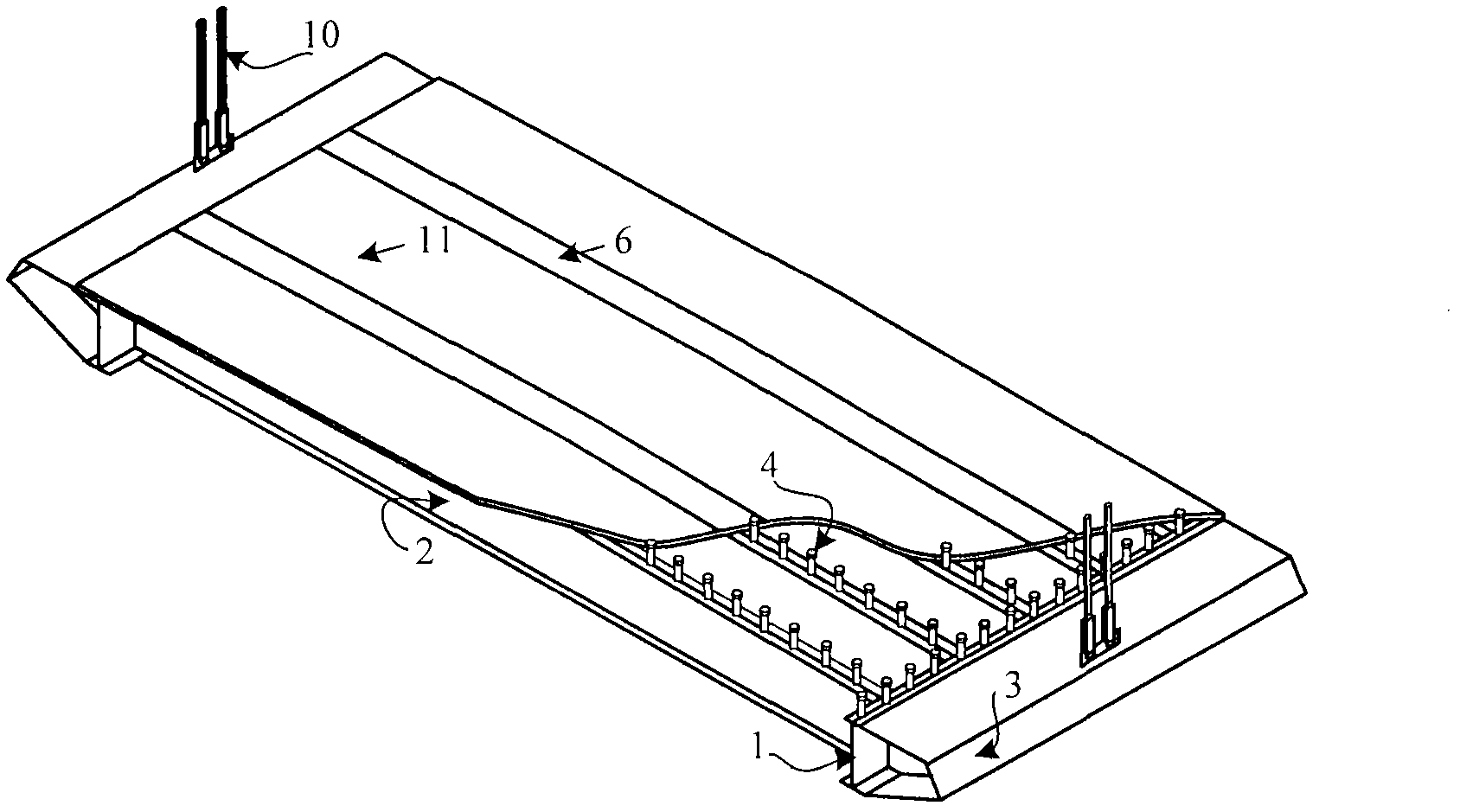

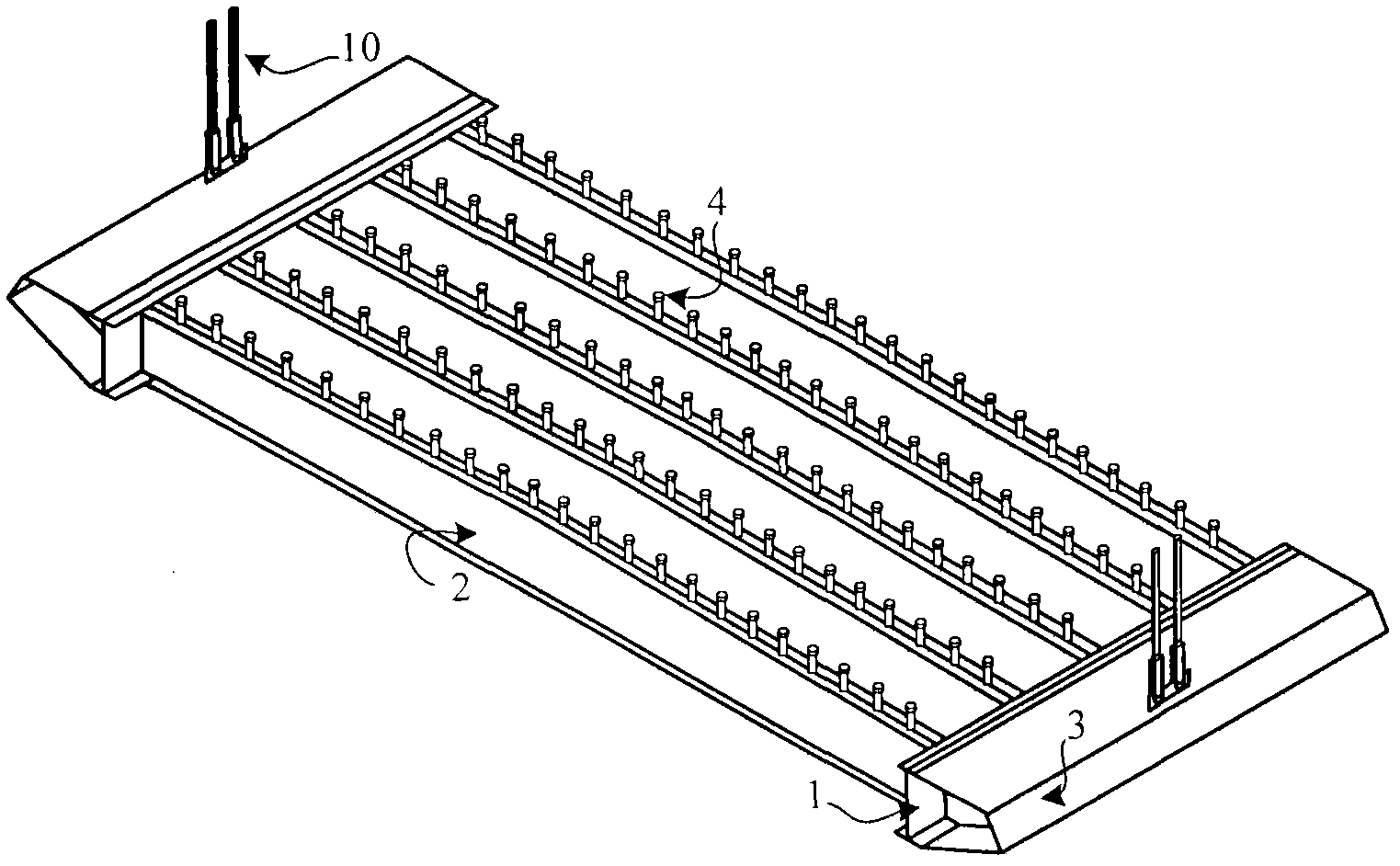

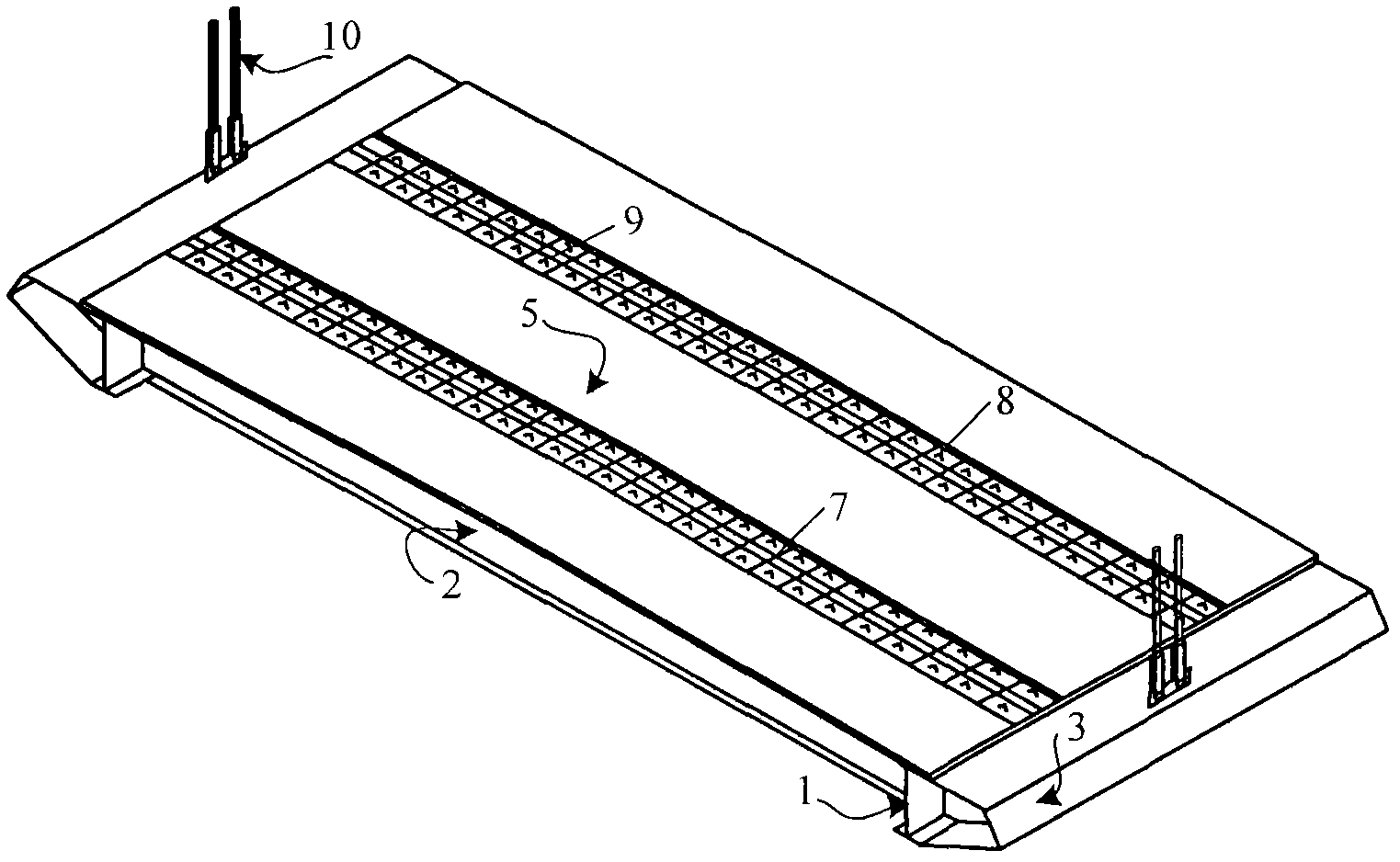

[0024] Compared with the traditional steel-concrete composite bridge deck system of the traditional suspension bridge, the present invention has less on-site workload and construction difficulty, easy guarantee of concrete pouring quality, higher structural bearing capacity, rigidity and crack resistance, and better economic performance. The steel-concrete composite deck system of partially uncombined suspension bridges. Such as Figure 2 to Figure 5 As shown, the structure consists of steel longitudinal beams 1, steel beams 2, air nozzles 3, stud connectors 4, prefabricated concrete panels 5 and cast-in-place concrete joints 6, and is suspended from the lower part of the main cable through slings 10. The steel longitudinal beam 1, the steel cross beam 2 and the tuyere 3 are connected into a segmental steel girder by welding; the prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com