Patents

Literature

85results about How to "Reduce wet work load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

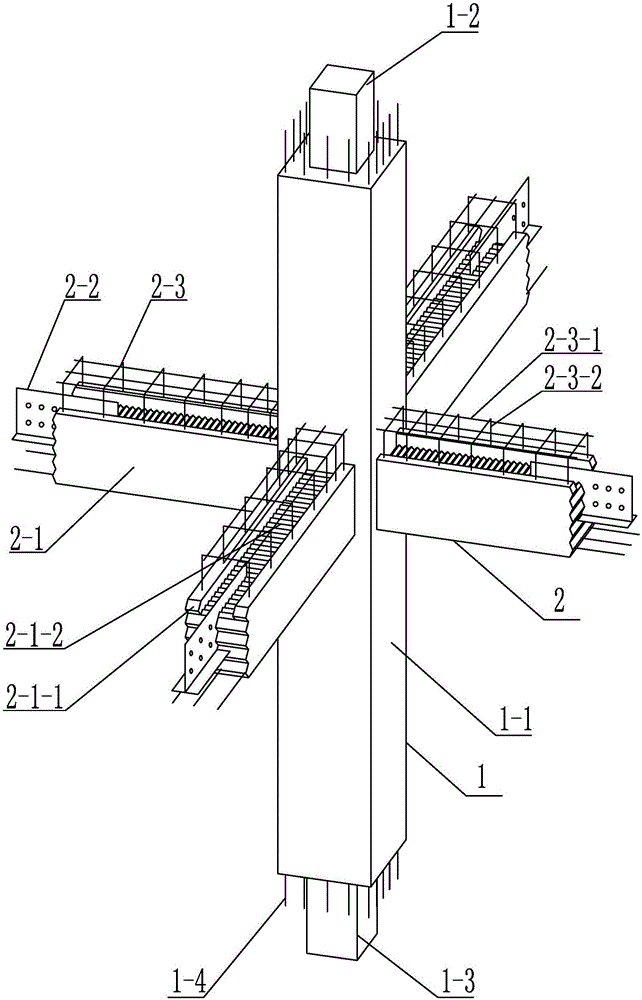

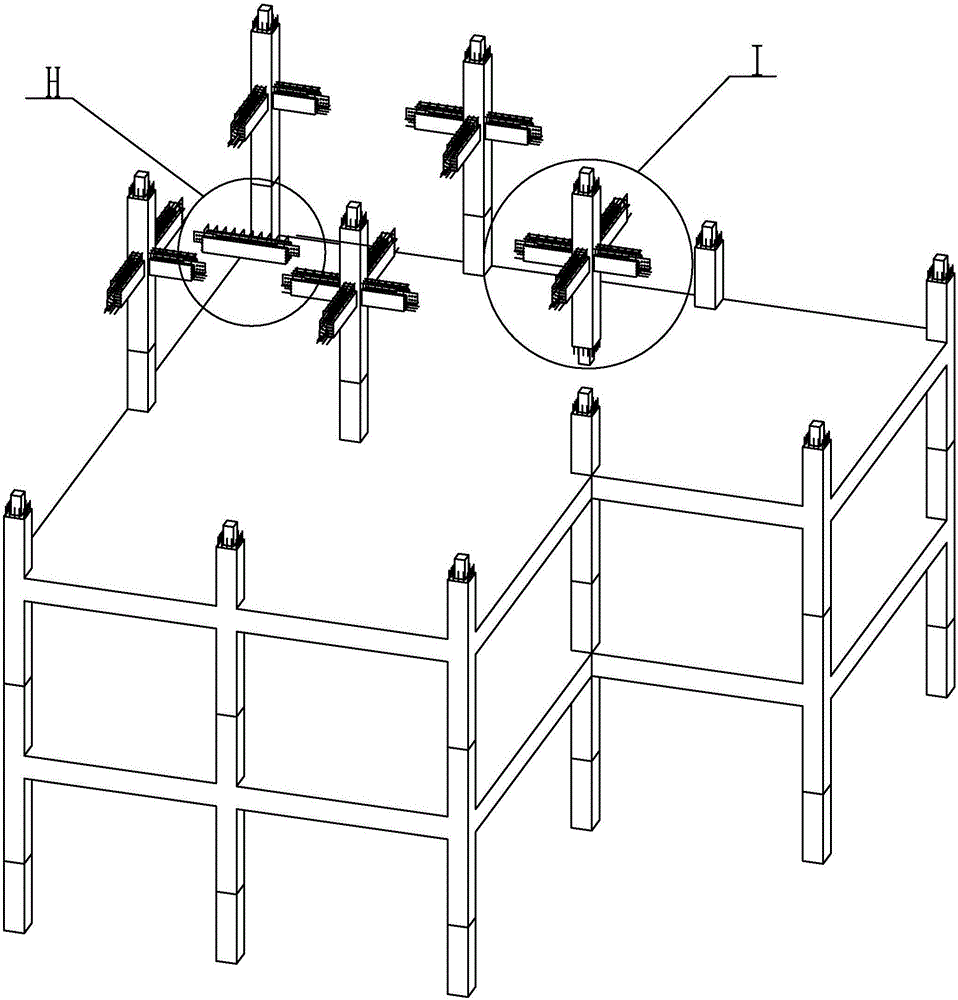

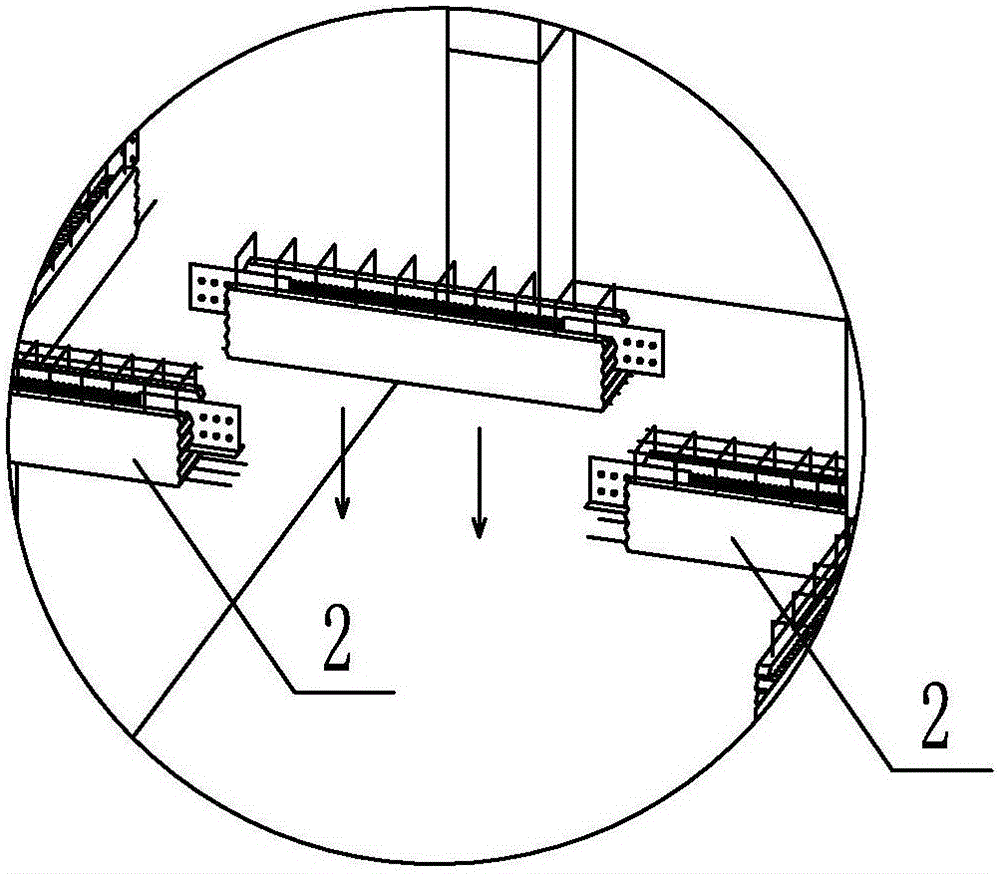

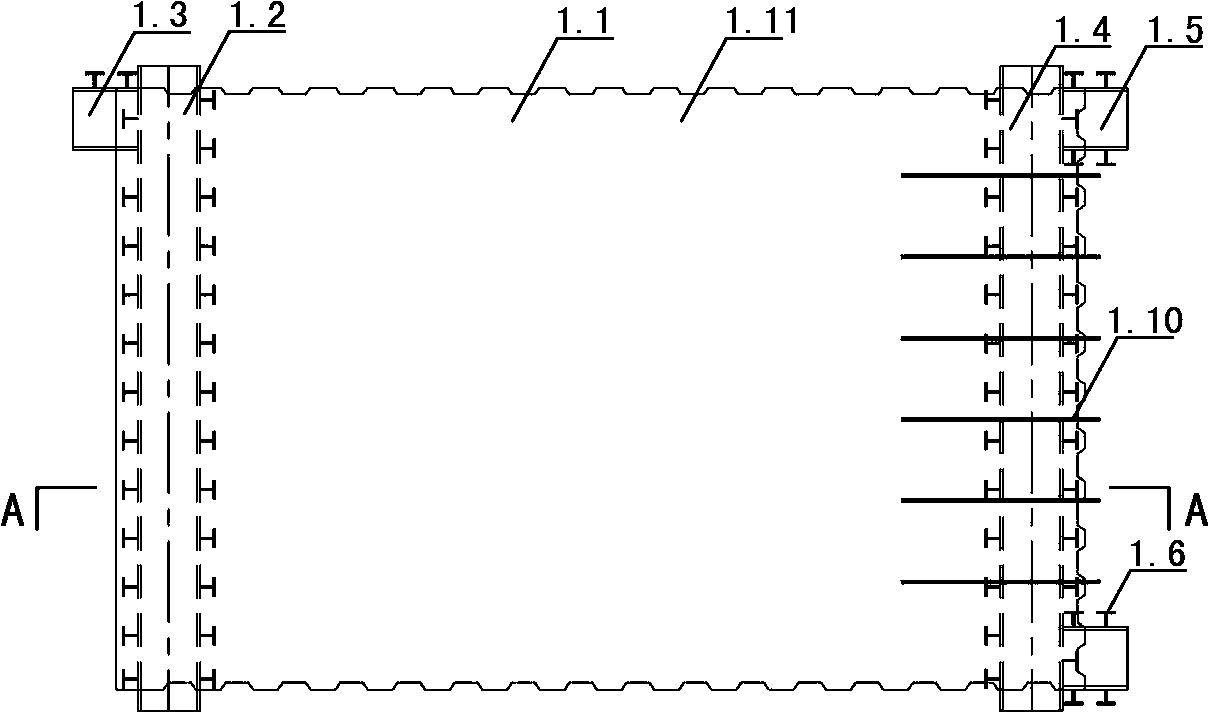

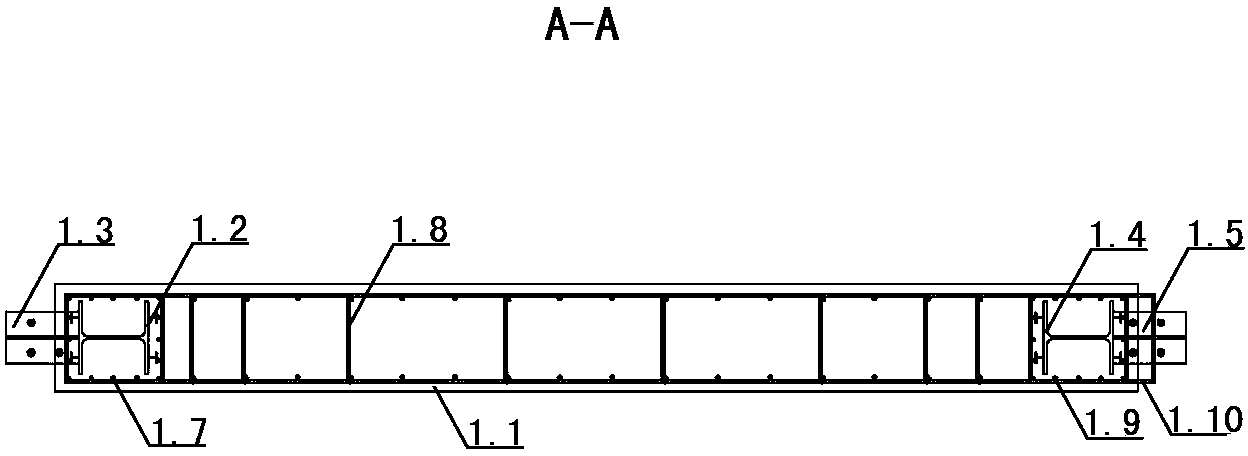

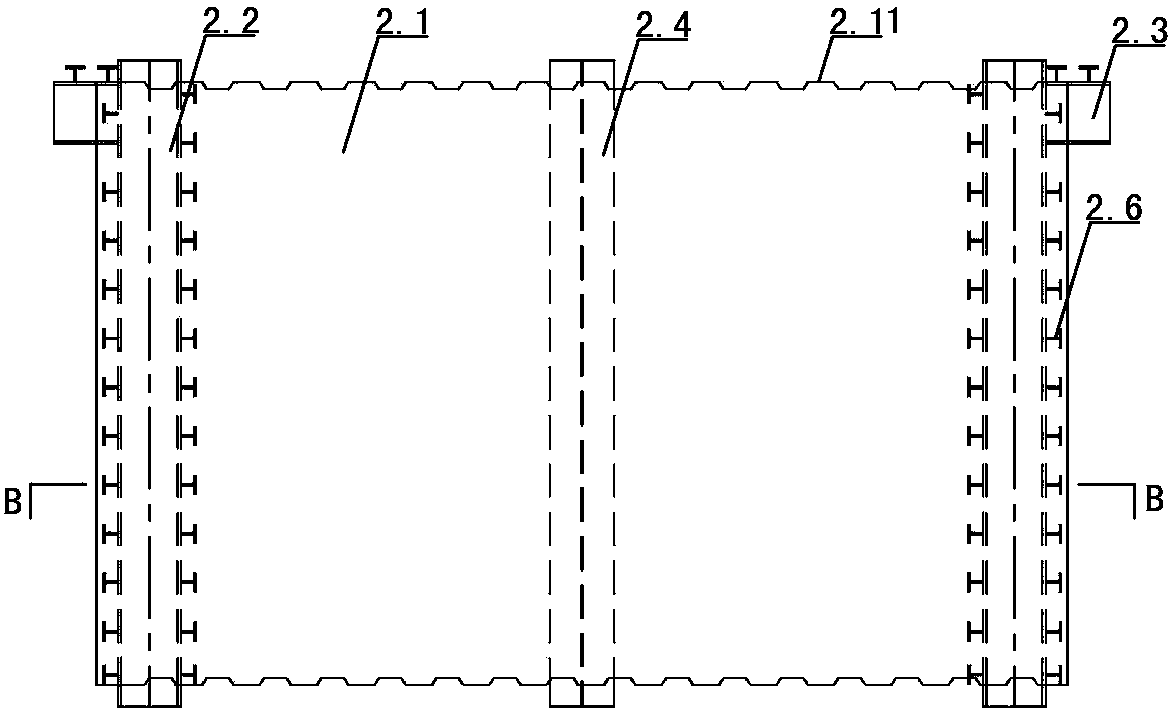

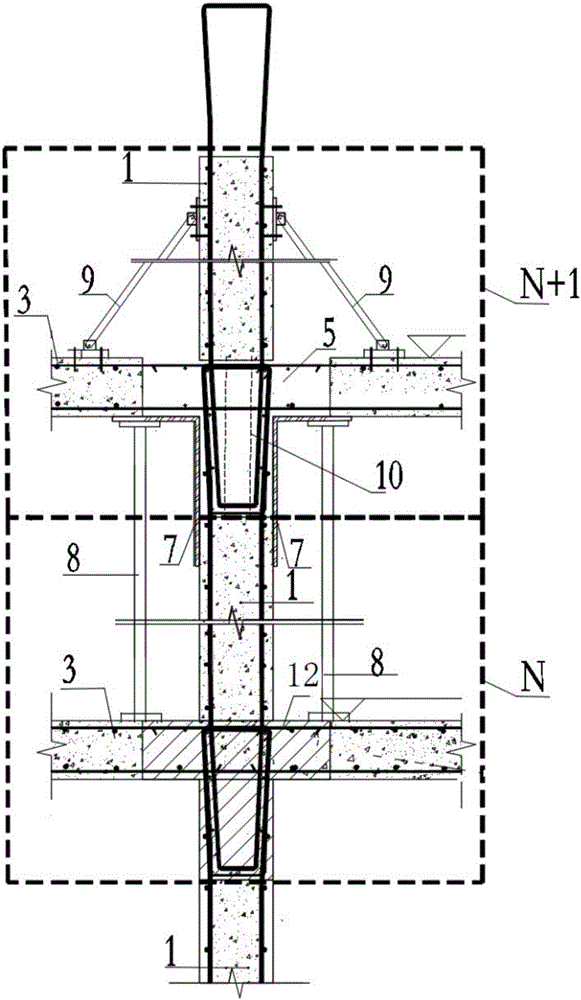

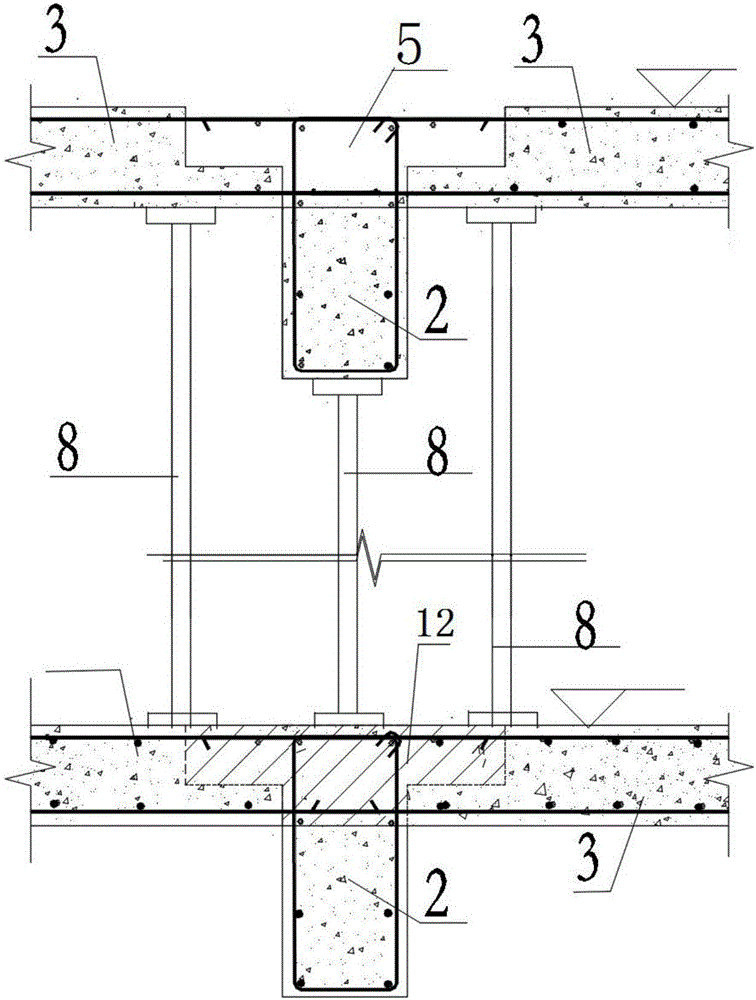

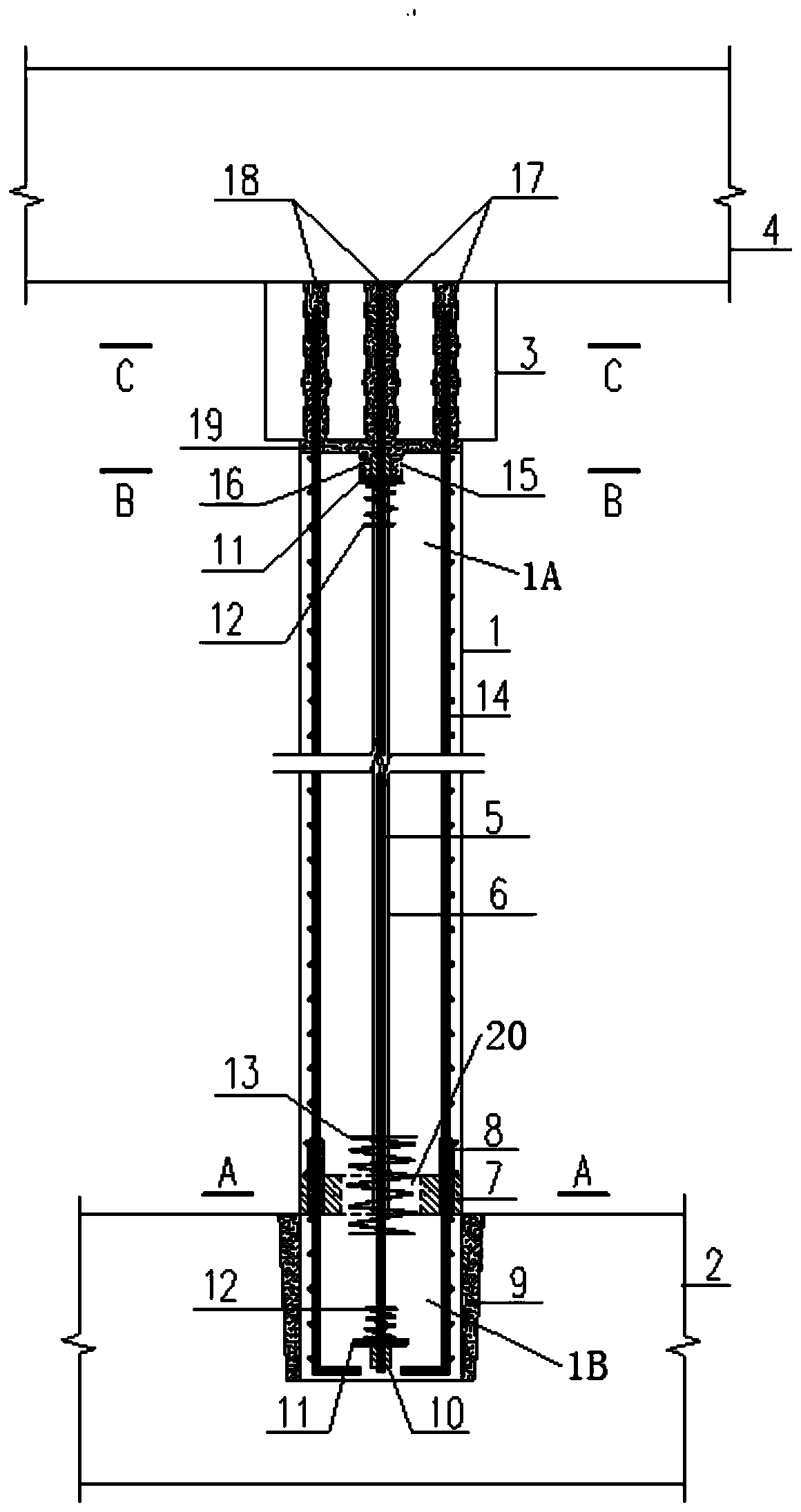

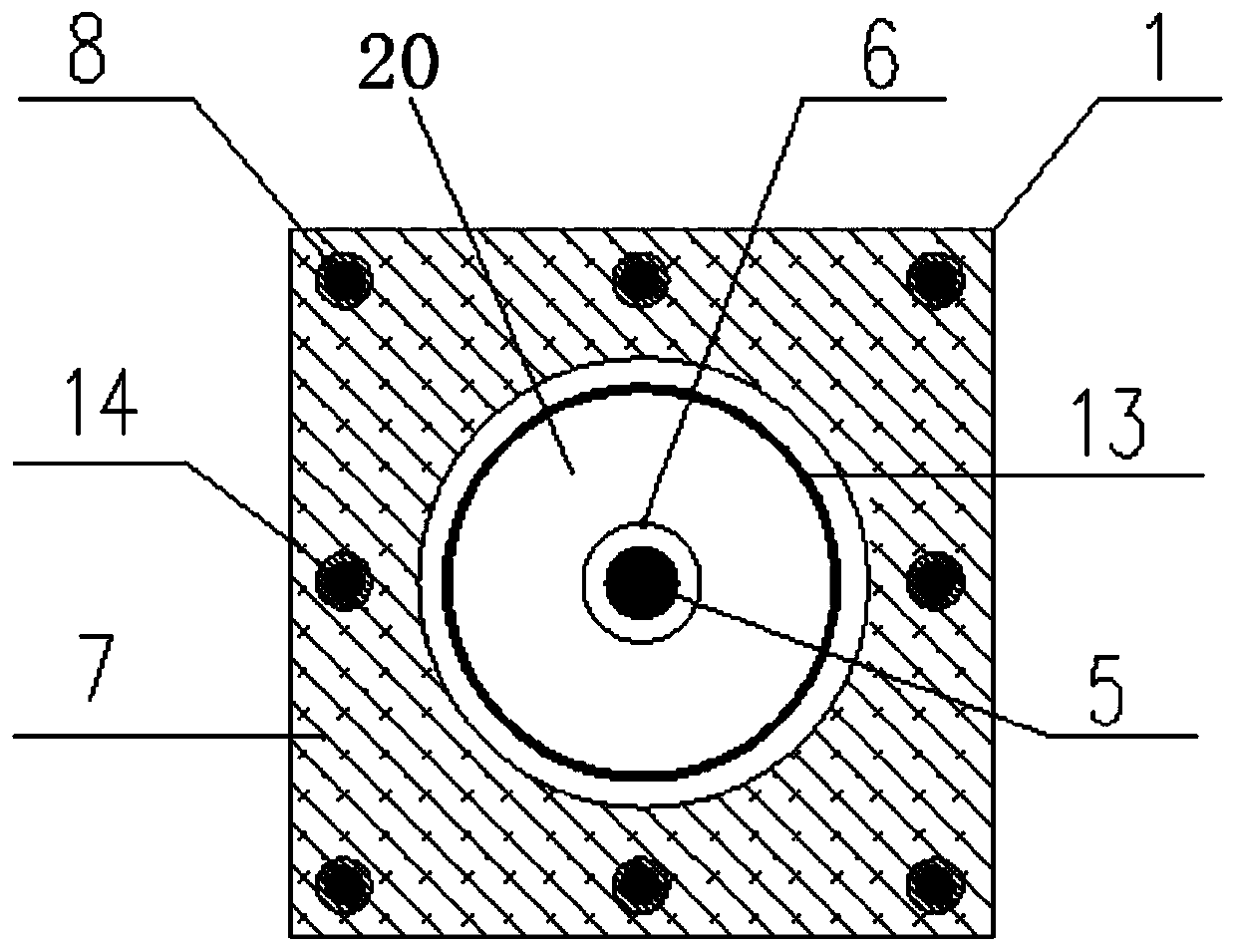

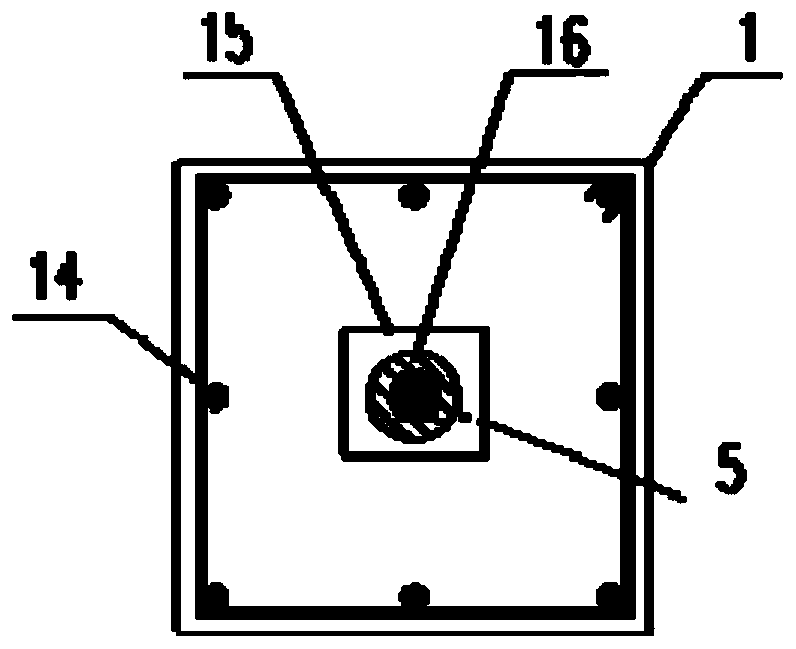

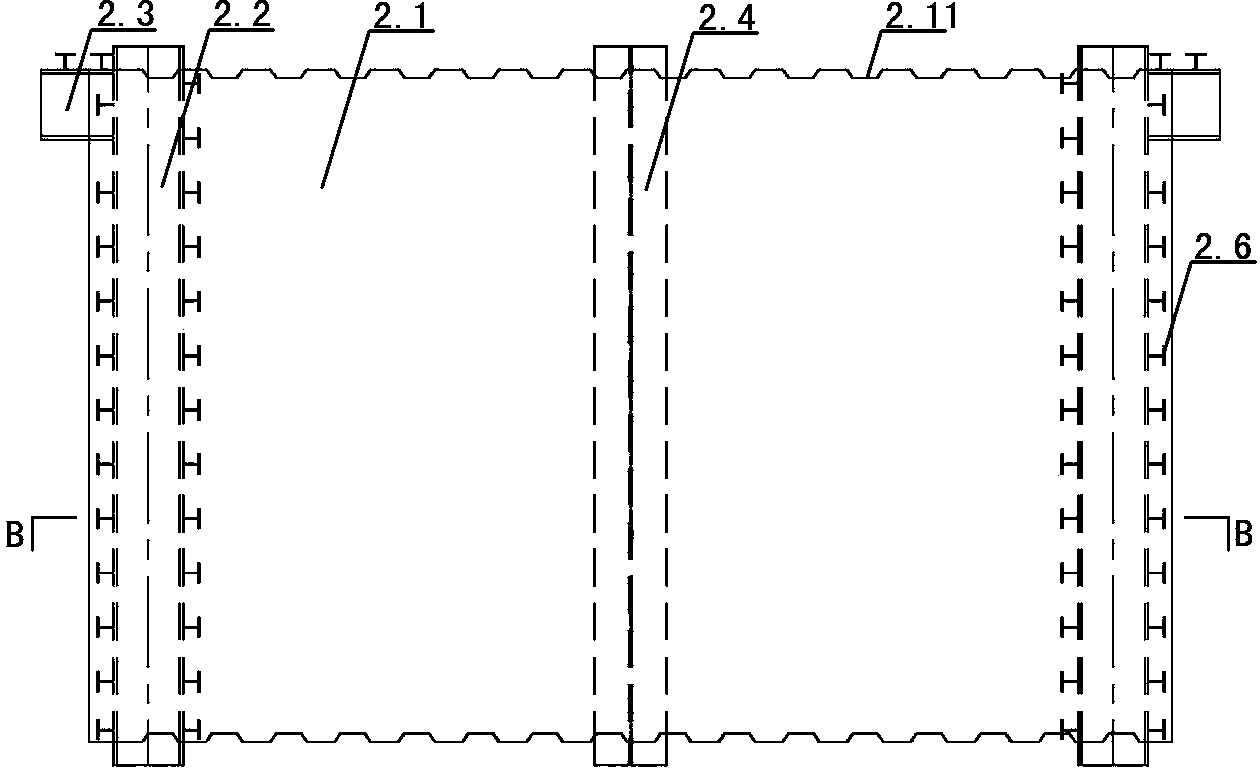

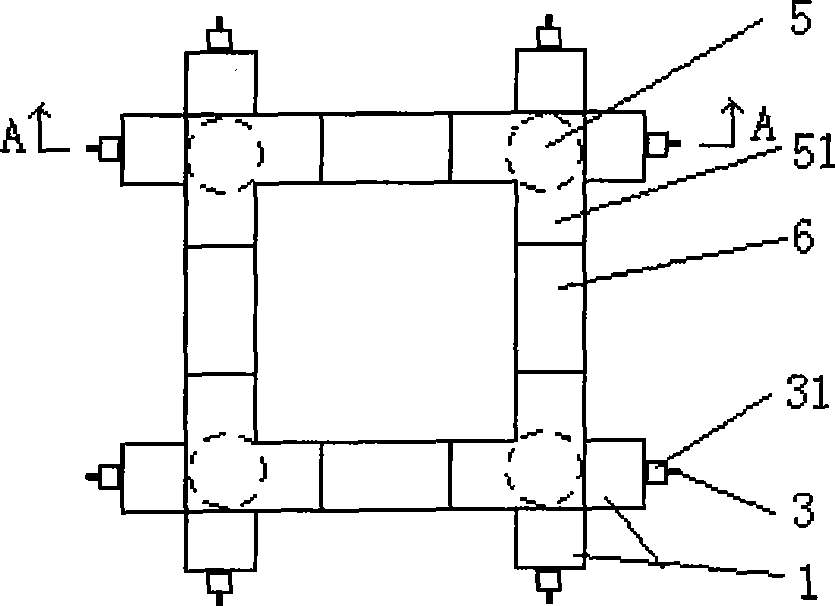

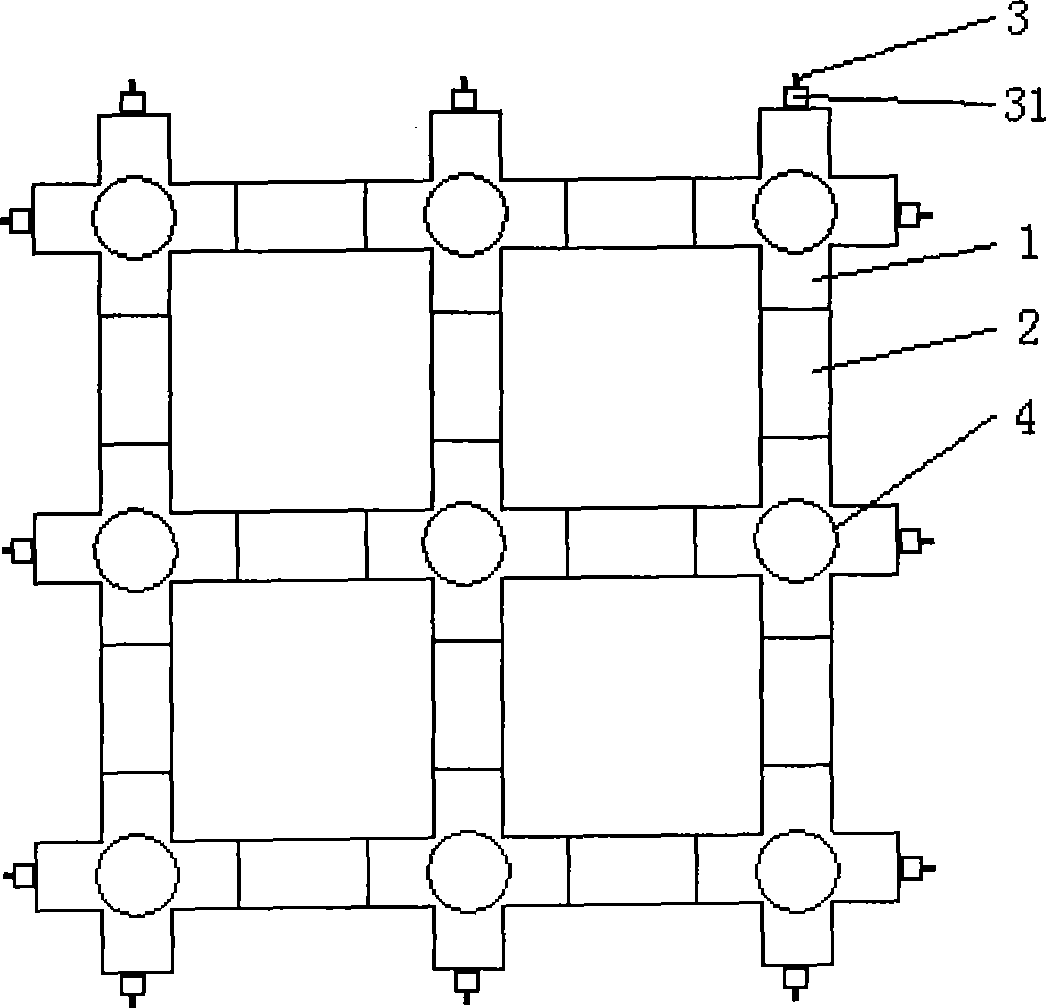

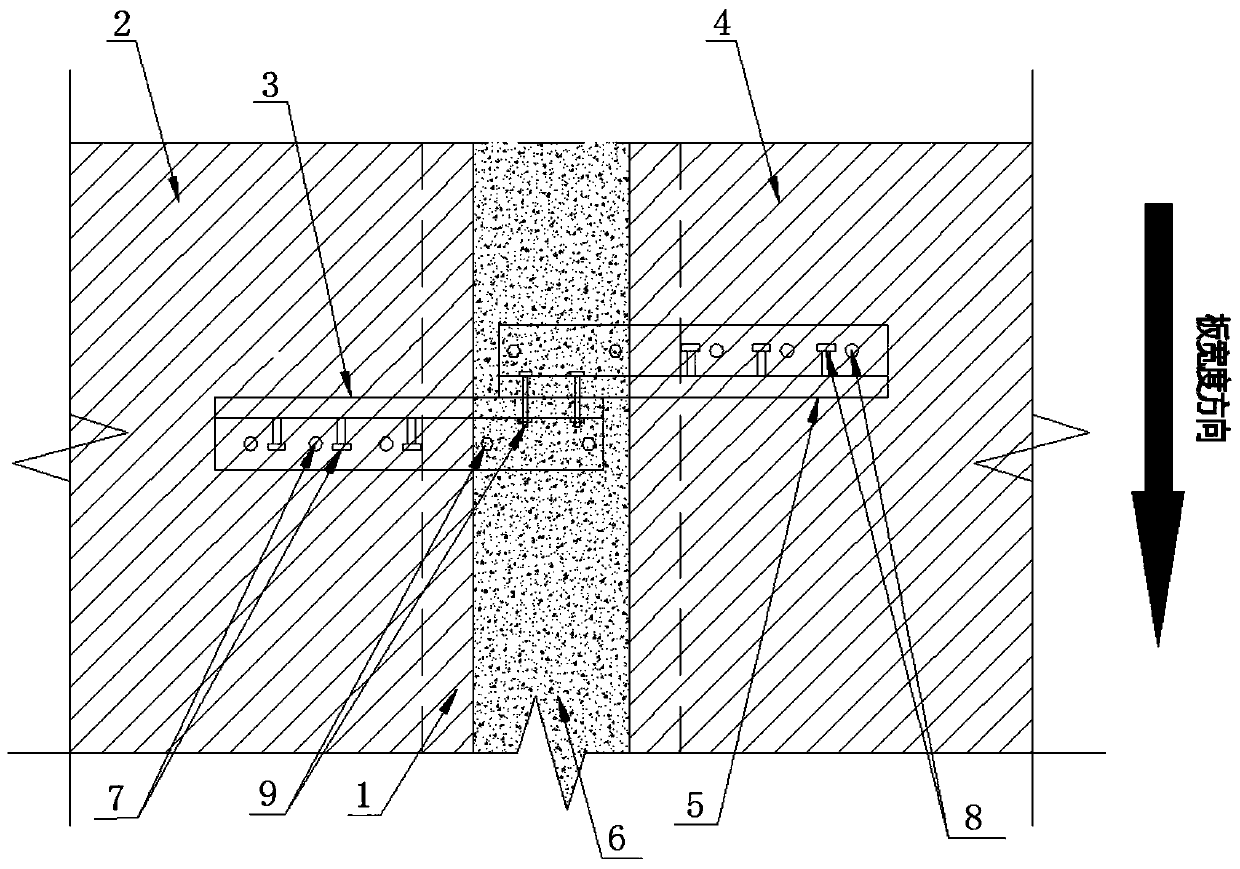

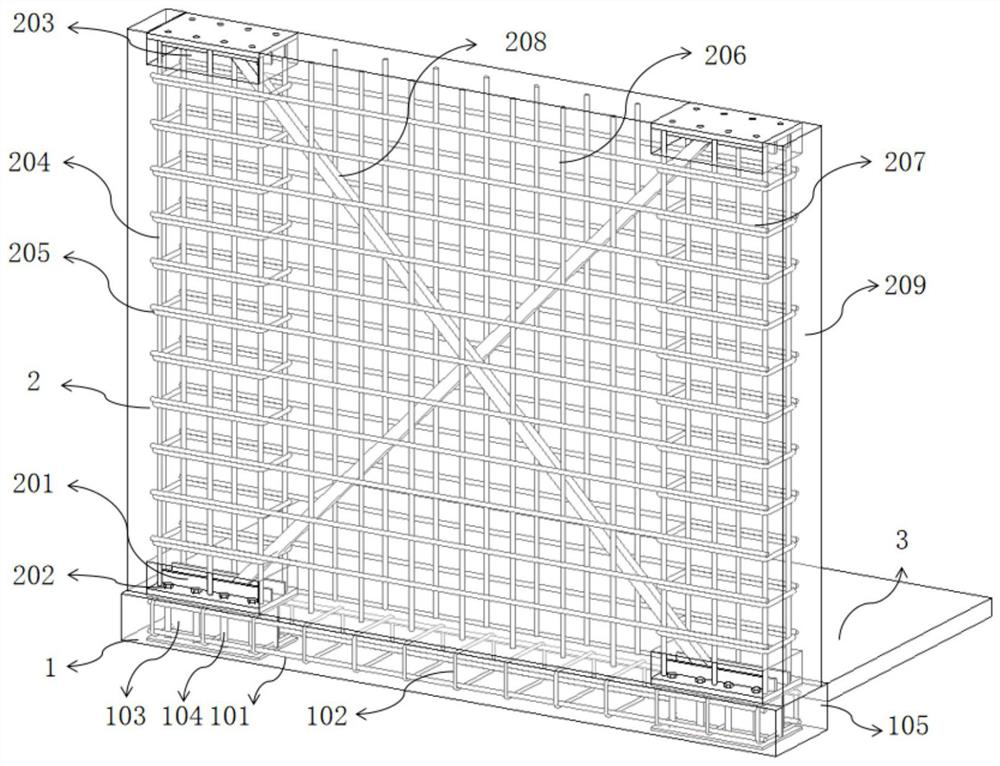

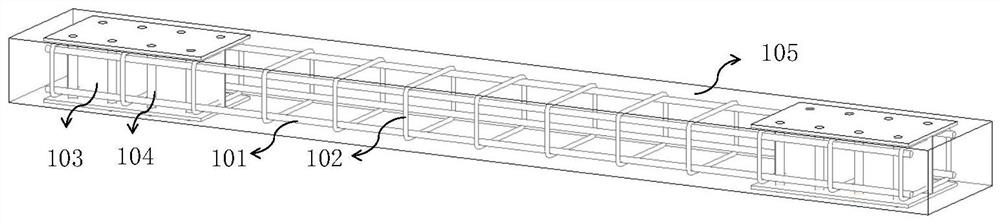

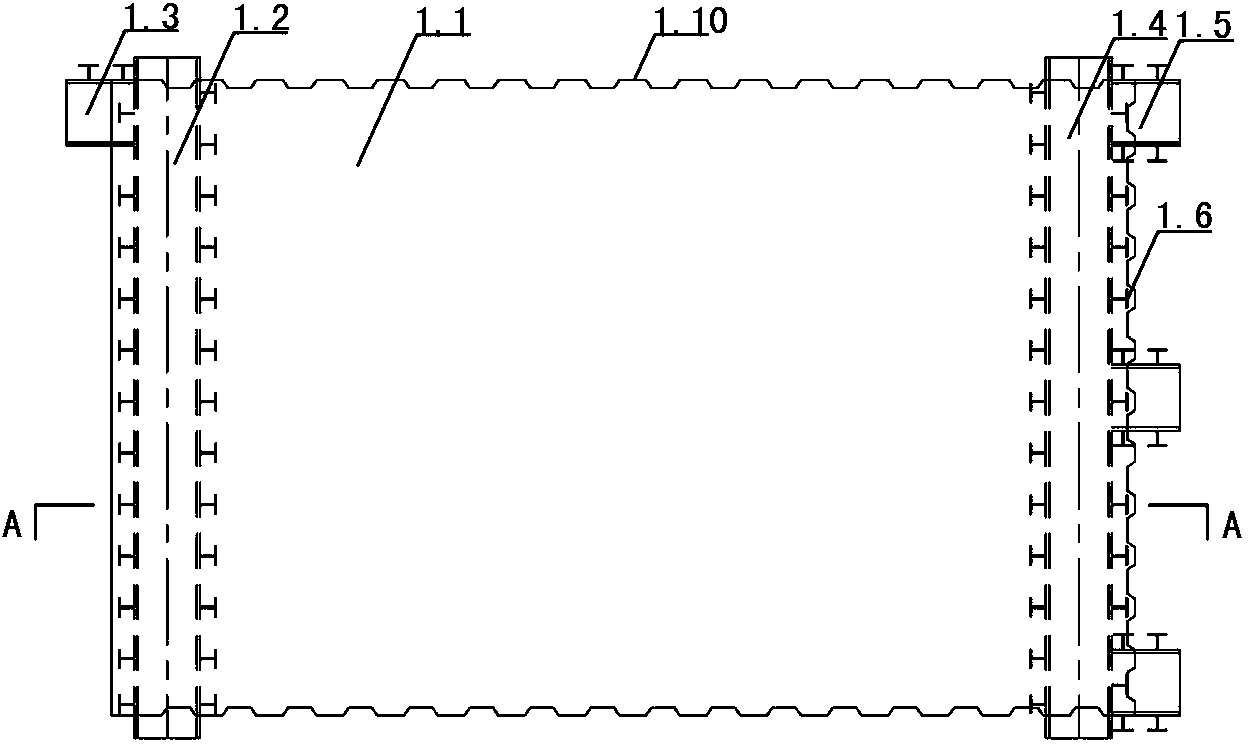

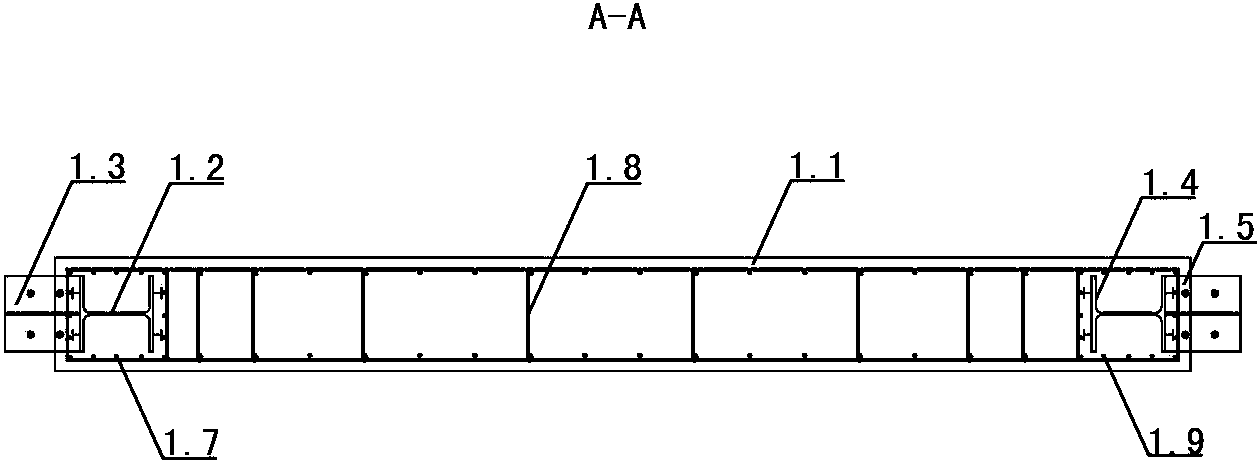

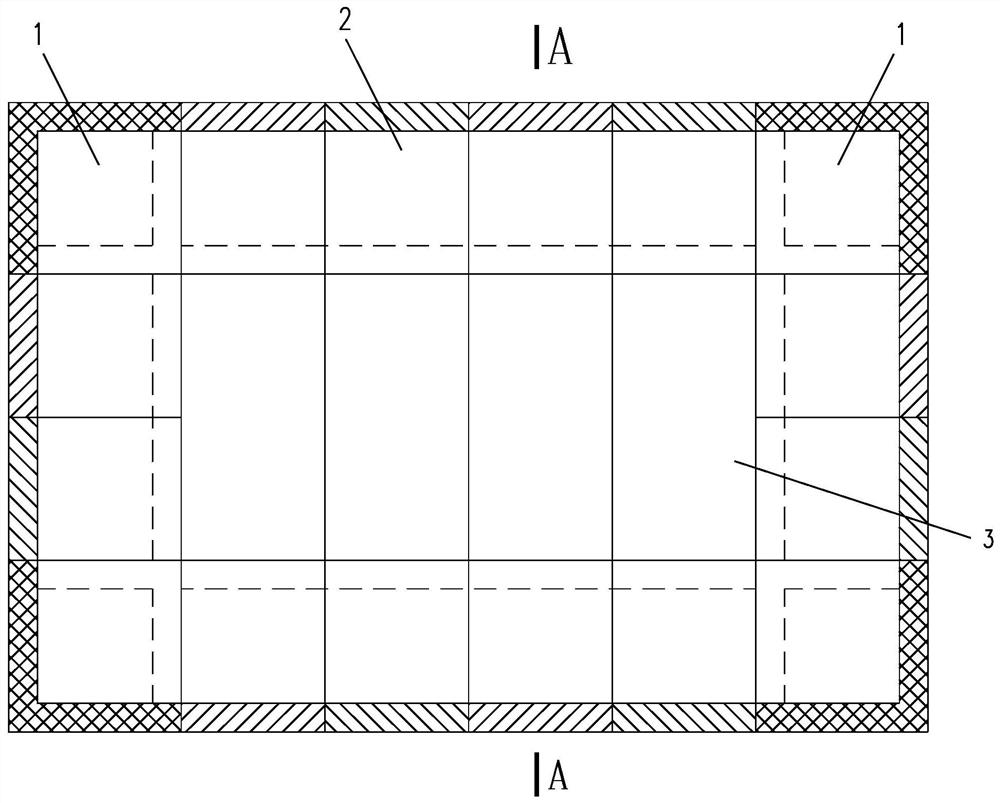

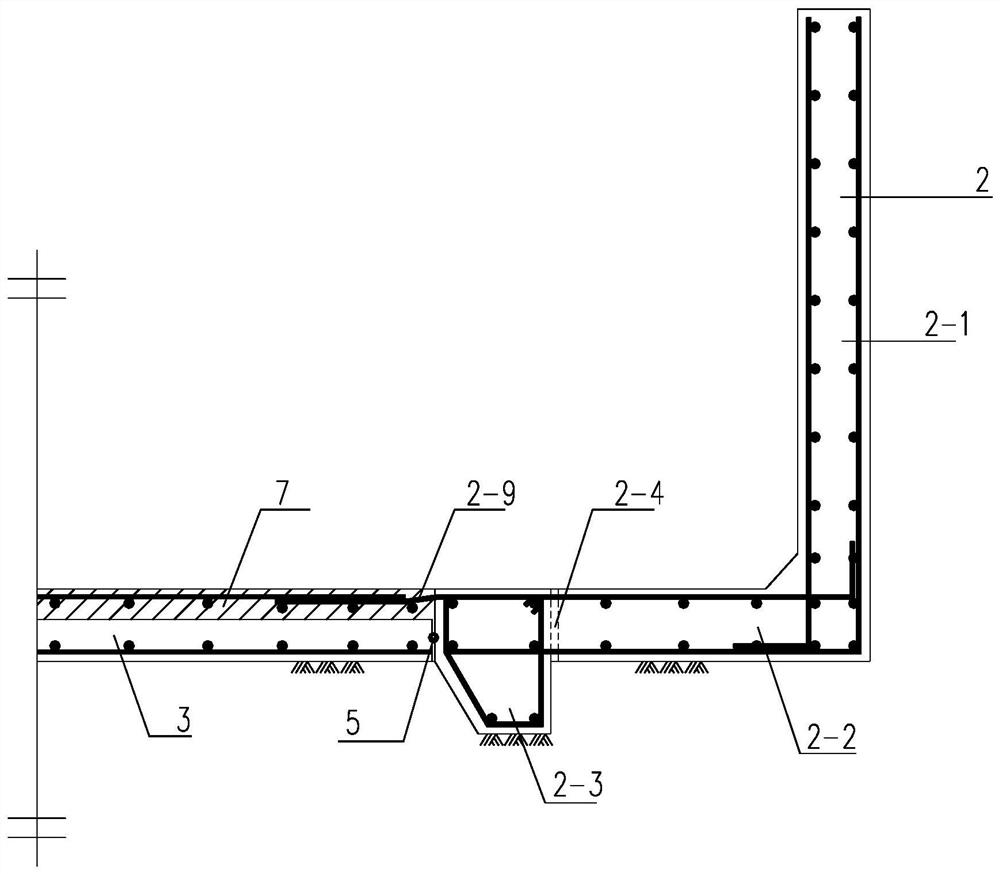

Single-layer prefabricated assembly type reinforced concrete beam-column joint

The invention relates to a prefabricated reinforced concrete beam-column joint, in particular to a single-layer prefabricated assembly type reinforced concrete beam-column joint. In order to solve the problem that the connection integrity of existing prefabricated beams and prefabricated columns is hard to guarantee, the prefabricated joint for one-piece casting manufacturing of a column section and part of beam sections is provided according to the concept of the point of inflection. The single-layer prefabricated assembly type reinforced concrete beam-column joint is formed by overall manufacturing of a vertical column section (1) and joint superposed beam sections (2) in a factory for prefabrication. A manufacturing method comprises the steps of beam-column longitudinal bar and stirrup binding, connector pre-burying, formwork erecting and concrete pouring and curing. The height of the vertical column section (1) of the joint is 1 / 2 of the storey height, and the length of each joint superposed beam section (2) is 1 / 3 of the span of adjacent columns. The vertical column section (1) comprises a pouring section (1-1), a concrete filled steel tube connector (1-2), a steel tube connector (1-3) and column section longitudinal bars (1-4). Each joint superposed beam section (2) comprises a groove-shaped pouring section (2-1), inverted-T-shaped structural steel connectors (2-2) and a reinforcement cage framework (2-3). The single-layer prefabricated assembly type reinforced concrete beam-column joint is applied to the construction industry.

Owner:HARBIN INST OF TECH

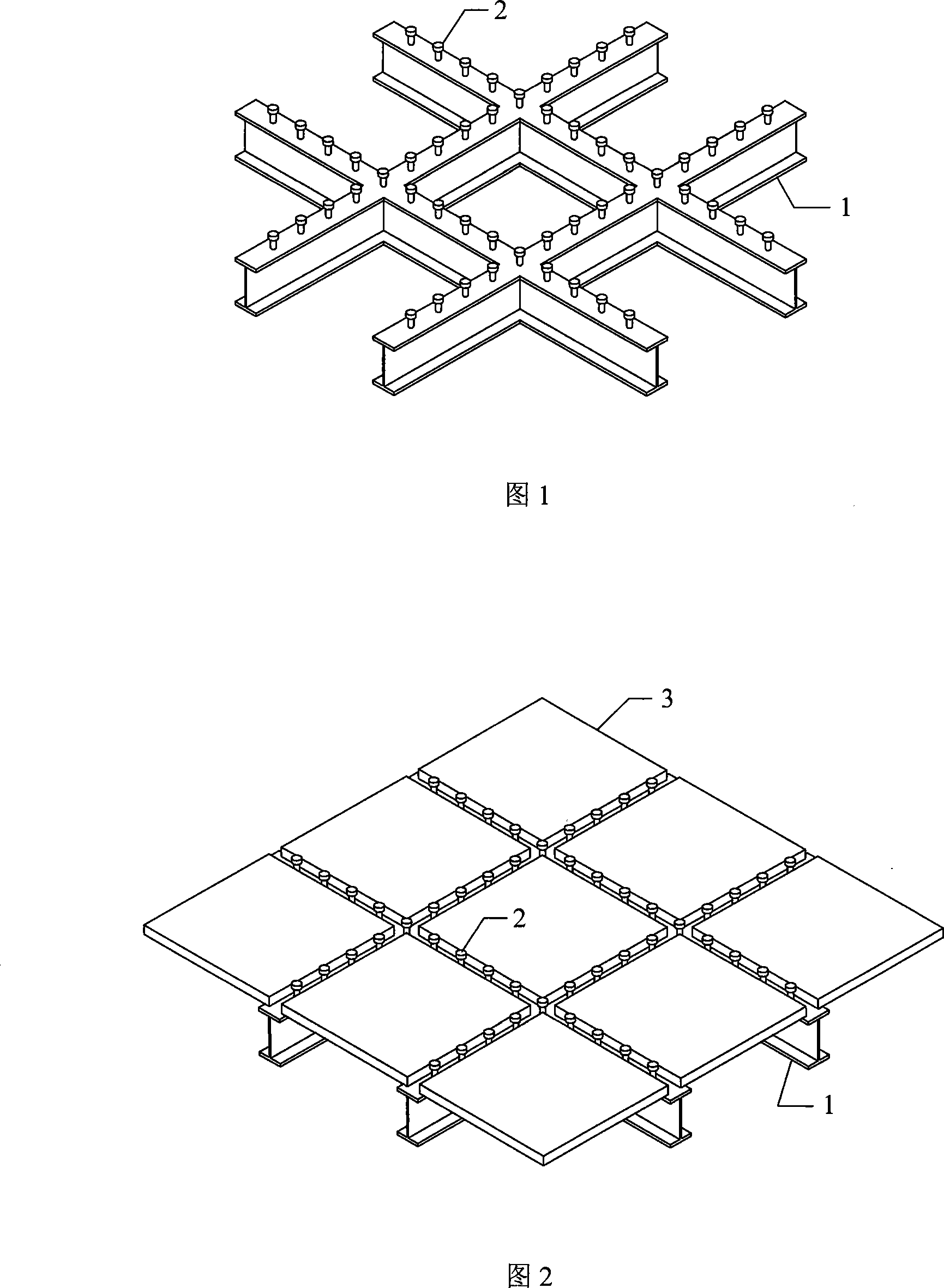

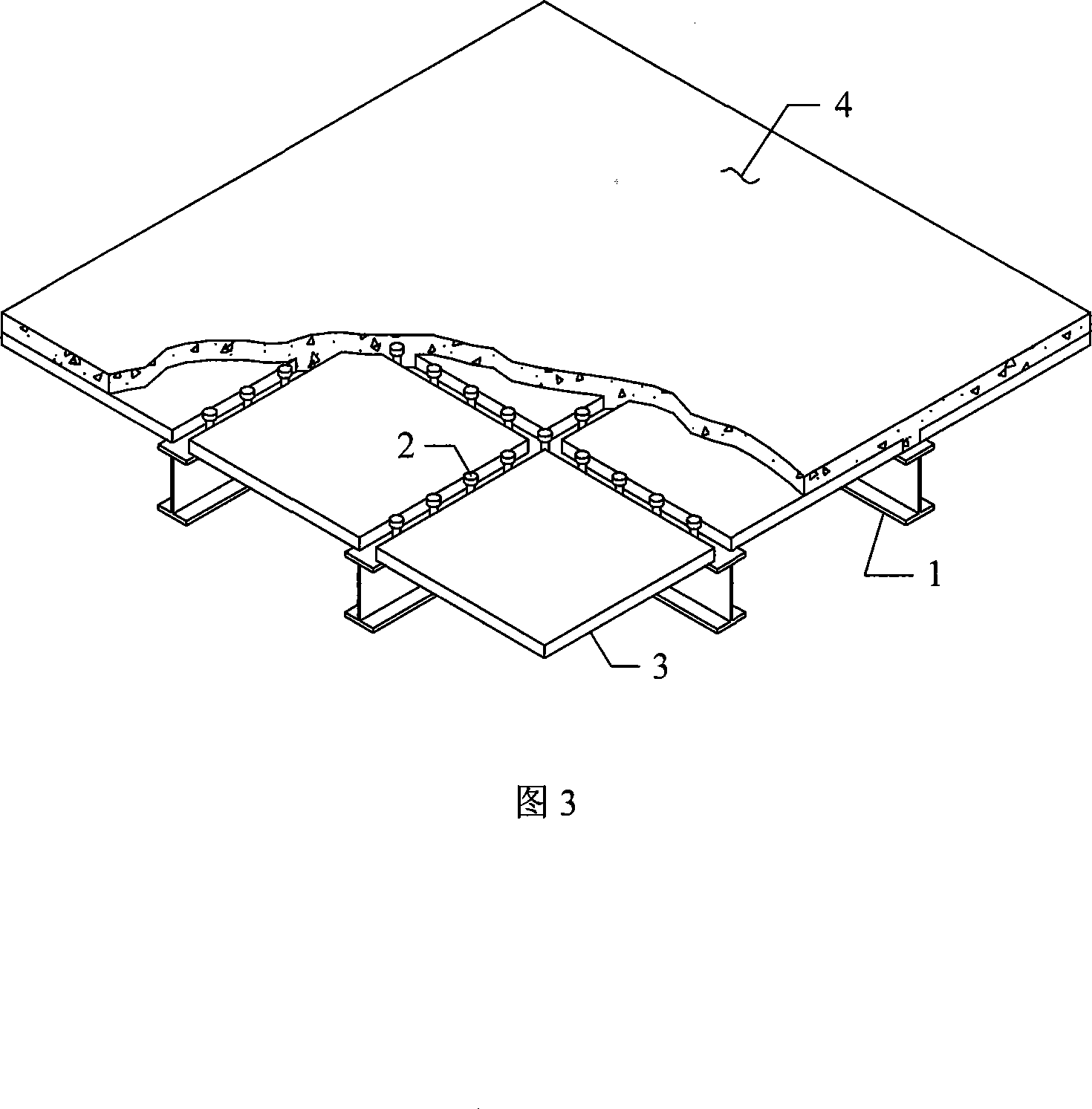

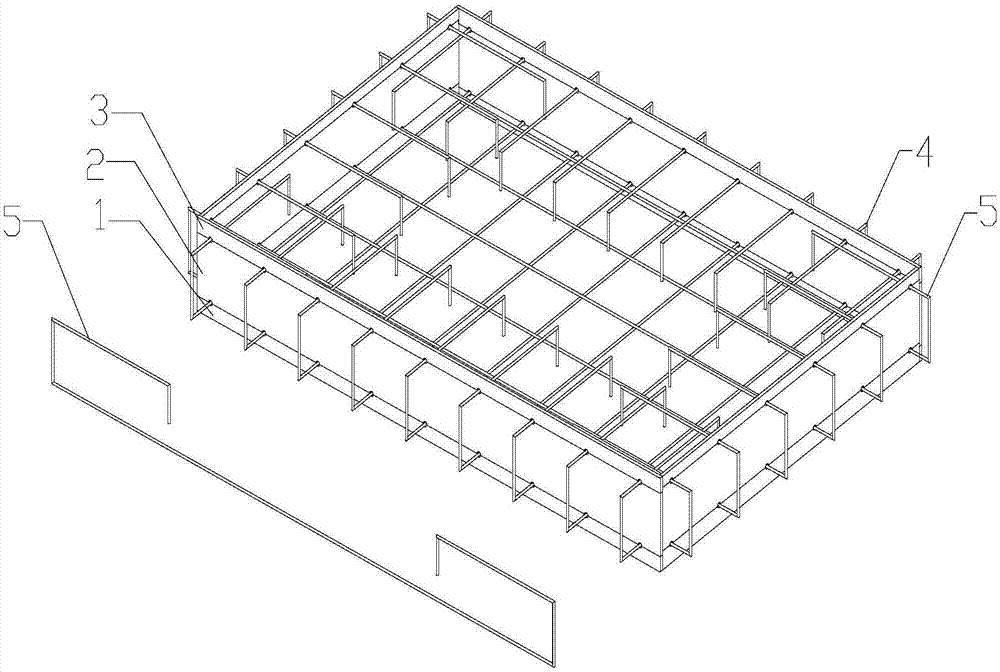

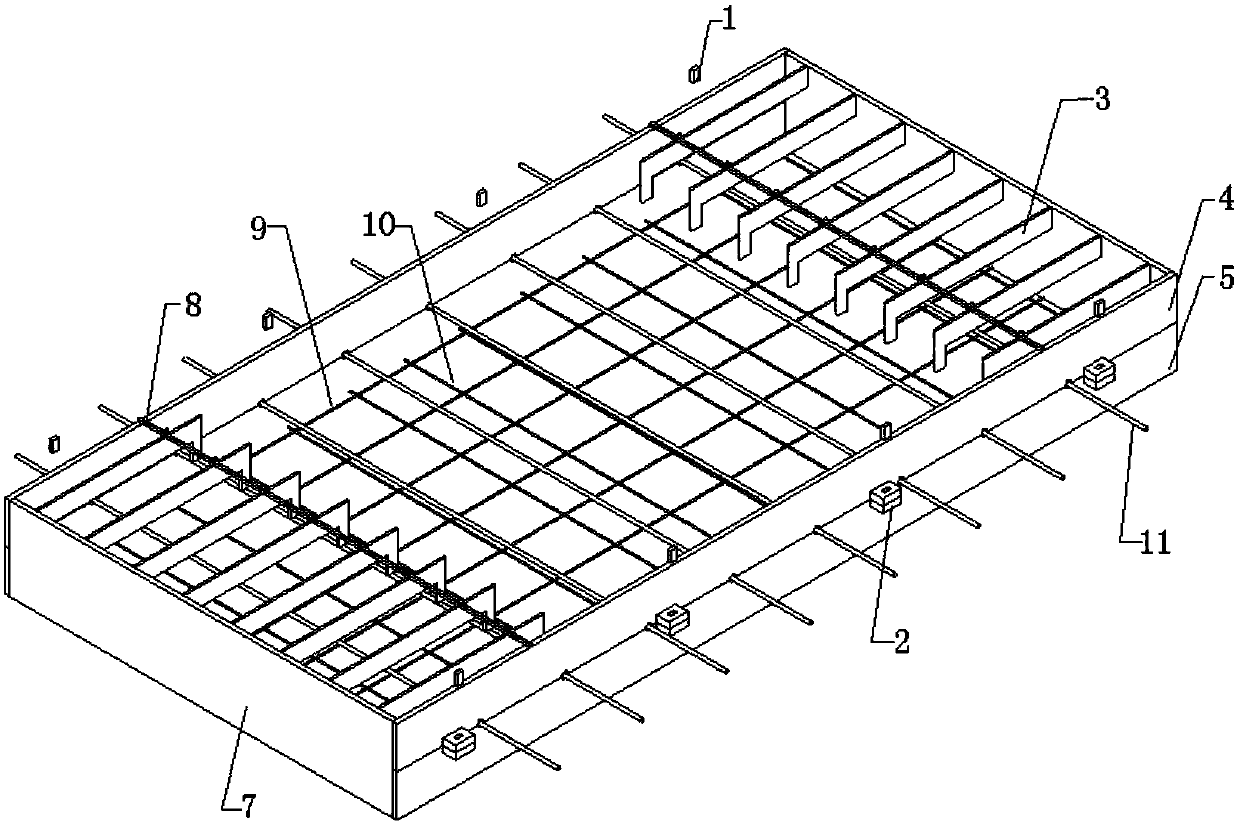

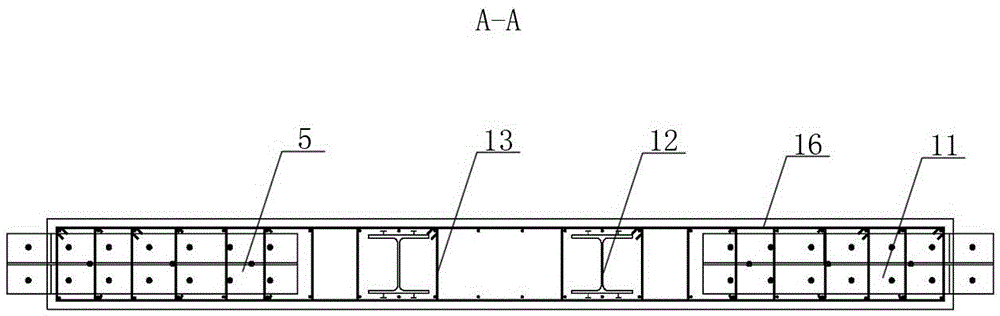

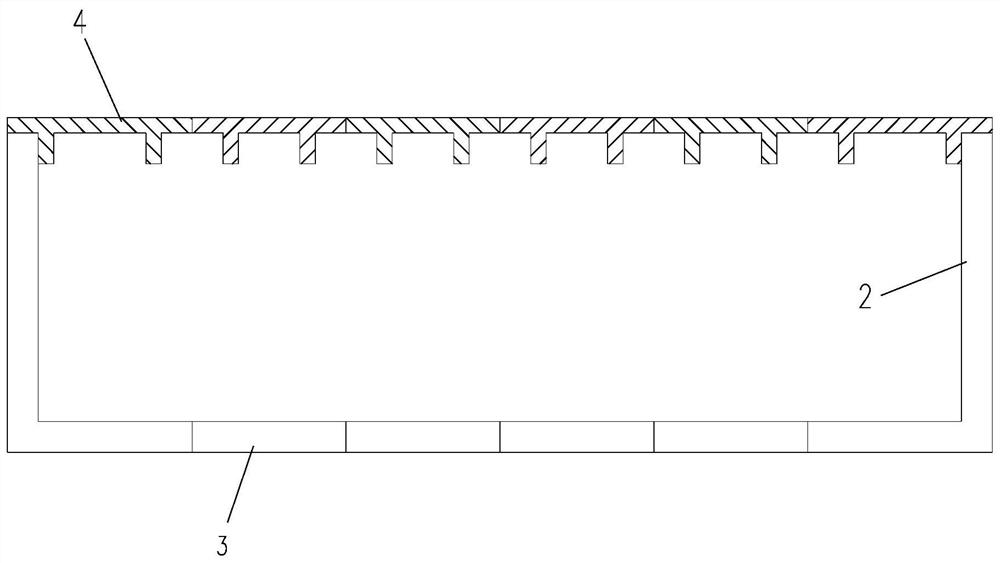

Bidirectional steel-stacked plate concrete composite building roof

The invention relates to a dual-way steel-laminated slab concrete composite floor, belonging to a new large span floor structure, comprising a cross steel beam, a prefabricated slab and a later pouring concrete layer, wherein the cross steel beam is an I shaped cross section or box section steel beam; the prefabricated slab, a common reinforced concrete slab or a prestressed concrete slab, is held on the cross steel beam and covered on the grids between the steel beams; the later pouring concrete layer is concrete poured on the prefabricated slab and the steel beam. The invention has the advantages of low structure height, high bearing capacity, stiffness, bilateral support effect, saved forming procedure and formwork, reduced the wet work amounts of site concrete, favorableness to the three-dimensional construction, and shortened construction period.

Owner:TSINGHUA UNIV

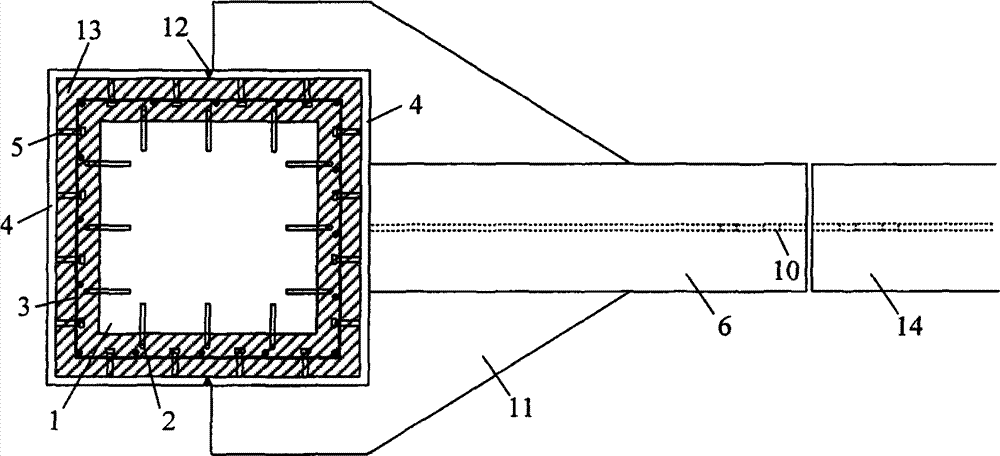

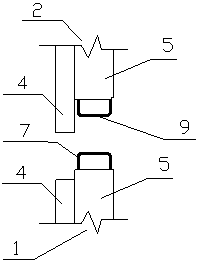

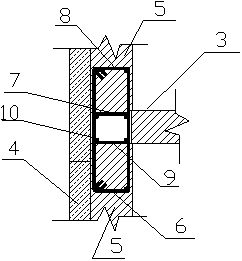

Connecting method of steel beam and existing reinforced concrete column

InactiveCN102966245AEasy to get materialsReduce wet work loadBuilding repairsReinforced concrete columnEngineering

The invention relates to a connecting method of a steel beam and an existing reinforced concrete column, which can be used for reinforced modification of an existing reinforced concrete structure, and belongs to the technical field of structural engineering. The method comprises the steps of: scabbling, planting bars and binding reinforced mesh pieces on the surface around with a node connection domain of the original reinforced concrete column; processing two pieces of channel steel and welding a stud connection piece inside; extending an extending bracket and external reinforcing plate on the channel steel connected to the steel beam; buckling the two pieces of channel steel and wrapping the original reinforced concrete column; welding in an abut manner; pouring node area concrete; and finally connecting the steel beam. The method overcomes the deficiencies of the conventional connection method, is simple in structure, quick and convenient to construct, good in stress performance of the connecting node, reliable in force transfer, and can efficiently prevent a node core area from cracking and being exposed. The core area concrete is wrapped by a steel plate so that the concrete is strongly constrained, and the quake-proof ductility of the node is good. The method has high practicality and wide application prospect.

Owner:TSINGHUA UNIV

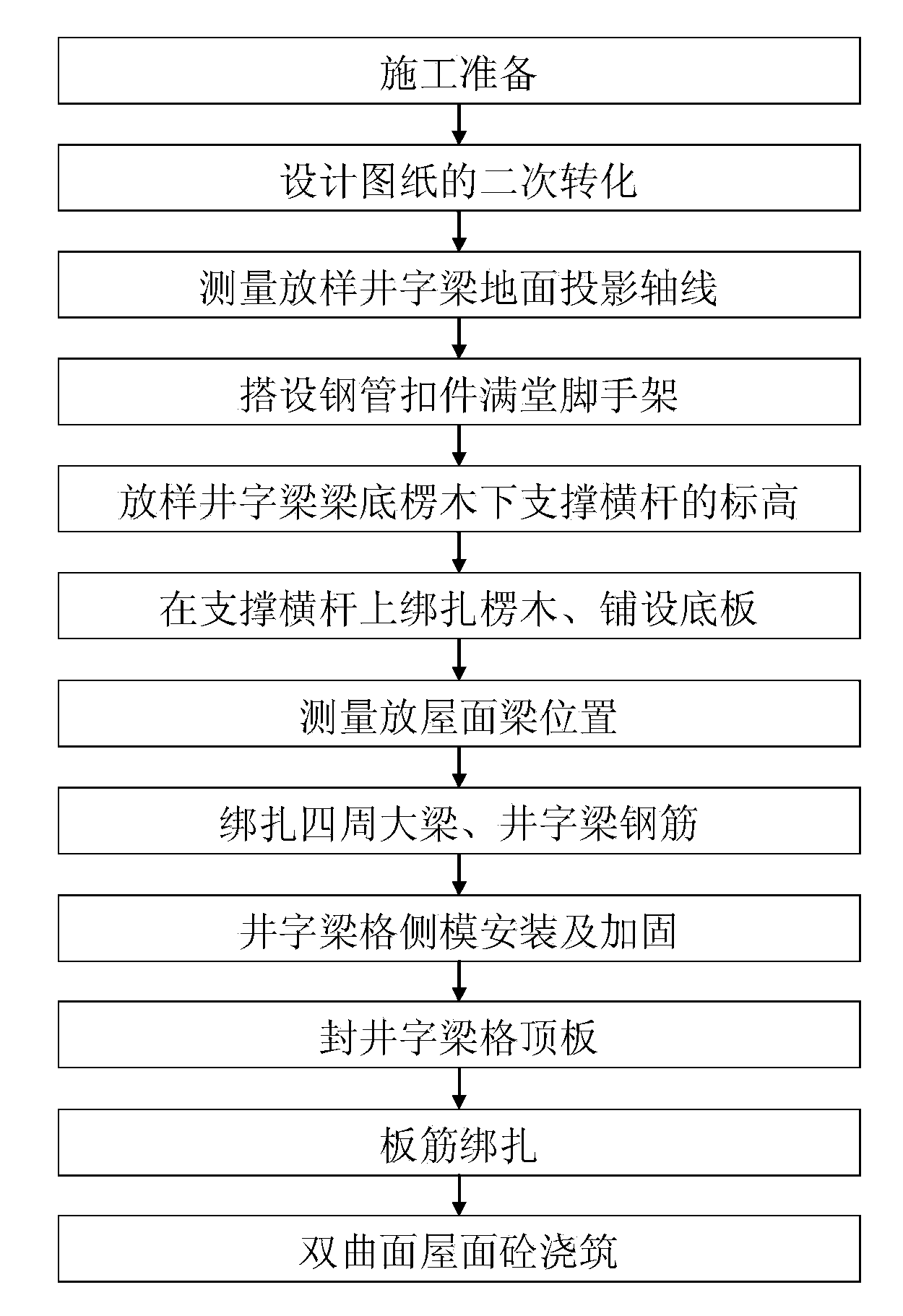

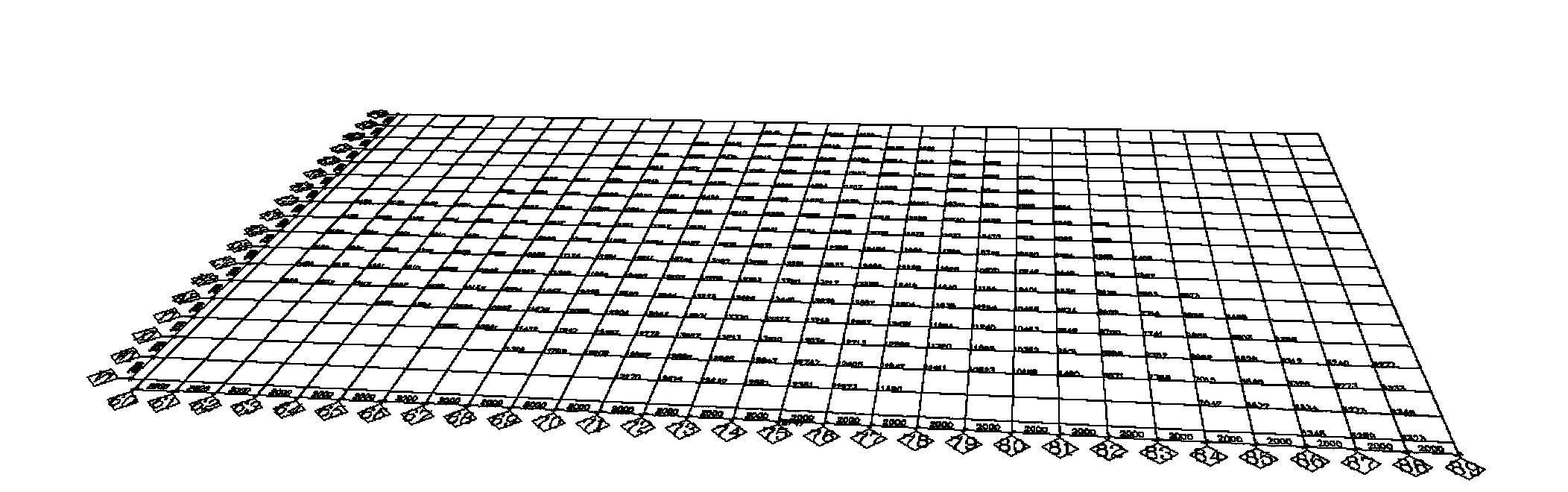

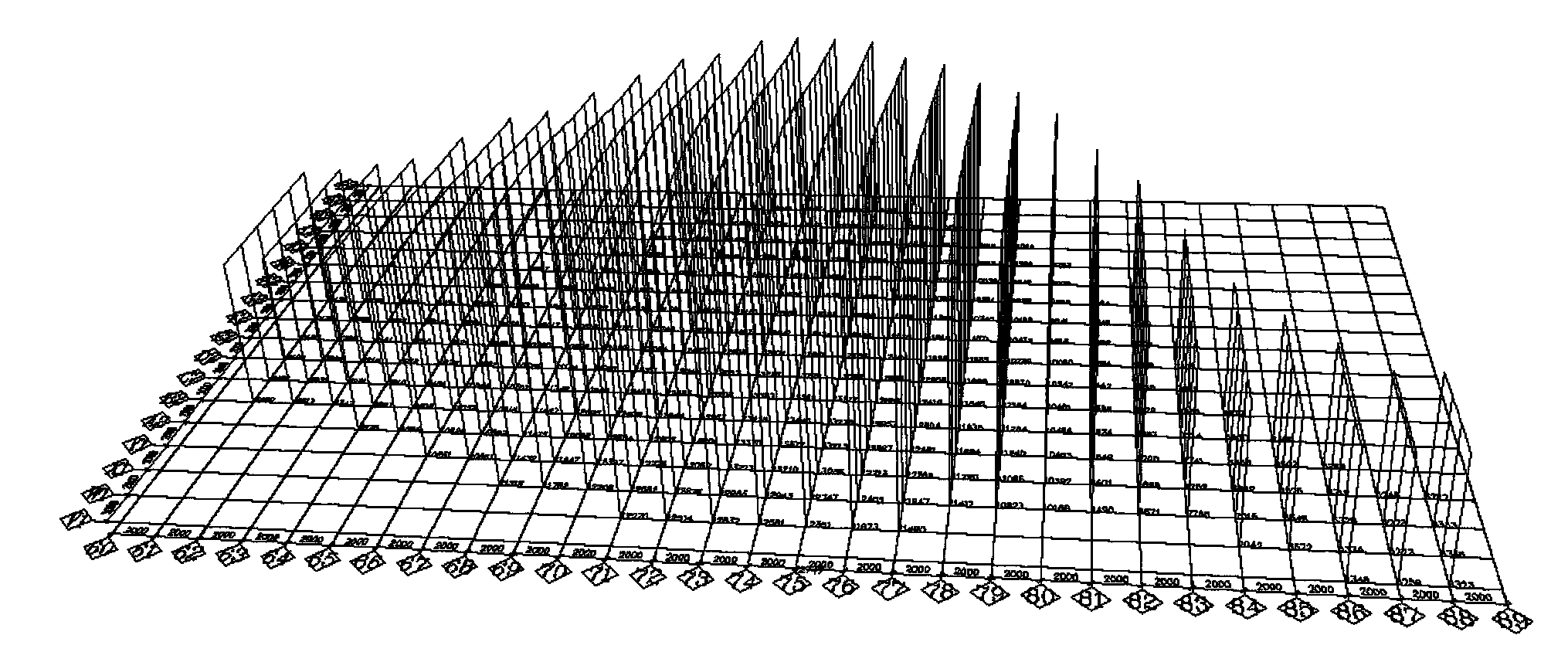

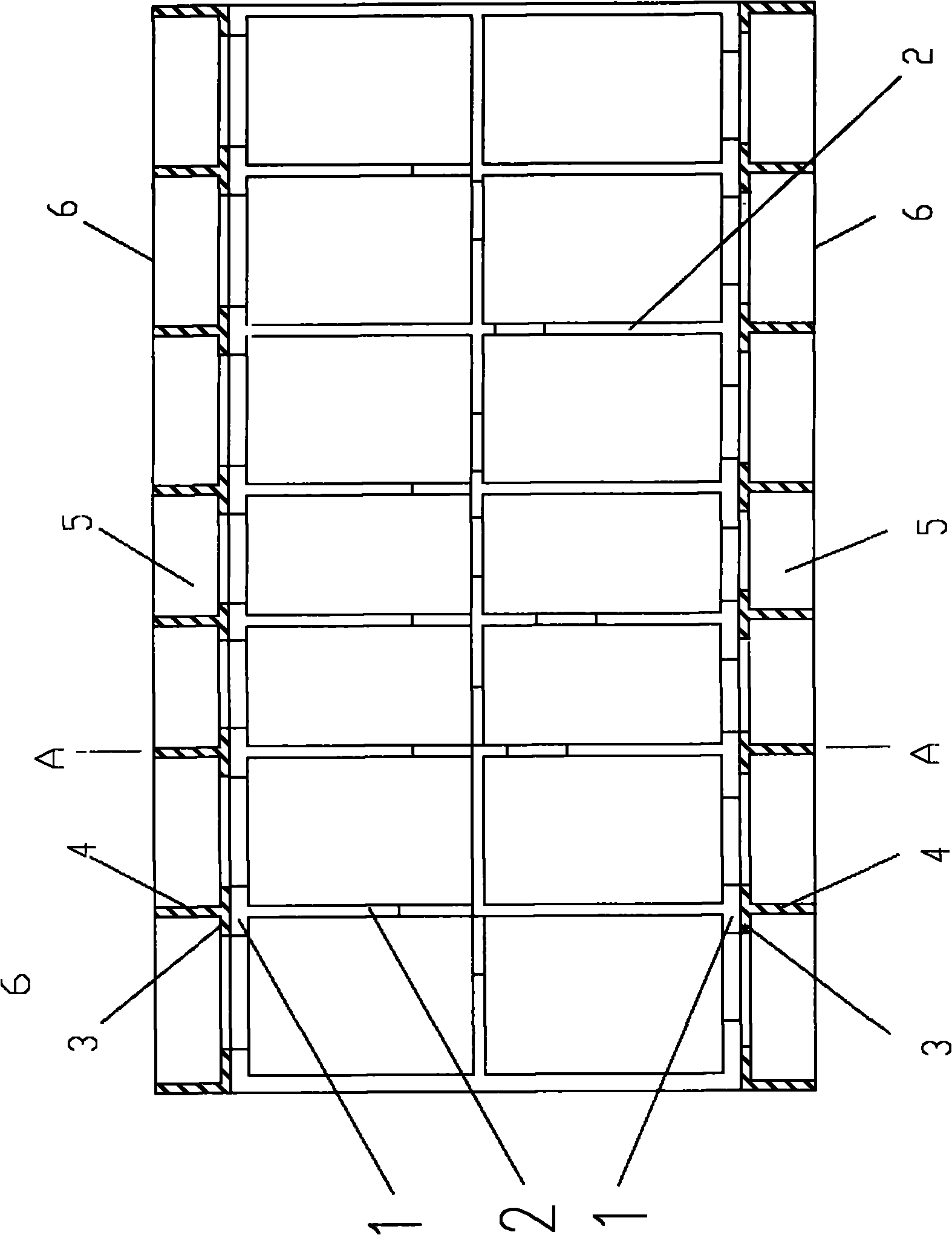

Irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method

ActiveCN103615110AImprove work efficiencyShorten the construction periodBuilding material handlingFalseworkSupporting system

An irregular oblique-crossing web-shaped grillage beam hyperbolic roof structure construction method comprises the steps of construction preparing, secondary conversion of design drawing, lofting grillage beam ground projection axis measuring, steel pipe buckling piece all-round scaffold supporting system erecting, grillage beam bottom wood ridge lower support horizontal rod elevation giving off, wood ridge binding and bottom plate paving on a supporting horizontal rod, given-off roof beam position measuring, bound grillage beam steel rib machining, grillage beam grillage side mould mounting and reinforcing, grillage beam top plate mounting and reinforcing, face plate steel rib binding and hyperbolic roof concrete pouring. Through a space three-dimensional technology, a reasonable supporting system and accurate location of a hyperbolic roof and a grillage beam, the concrete mixing proportion is optimized, the quality and the attractive degree of the hyperbolic roof can be improved, construction difficulty is lowered, and construction efficiency is improved.

Owner:广西建工第一建筑工程集团有限公司

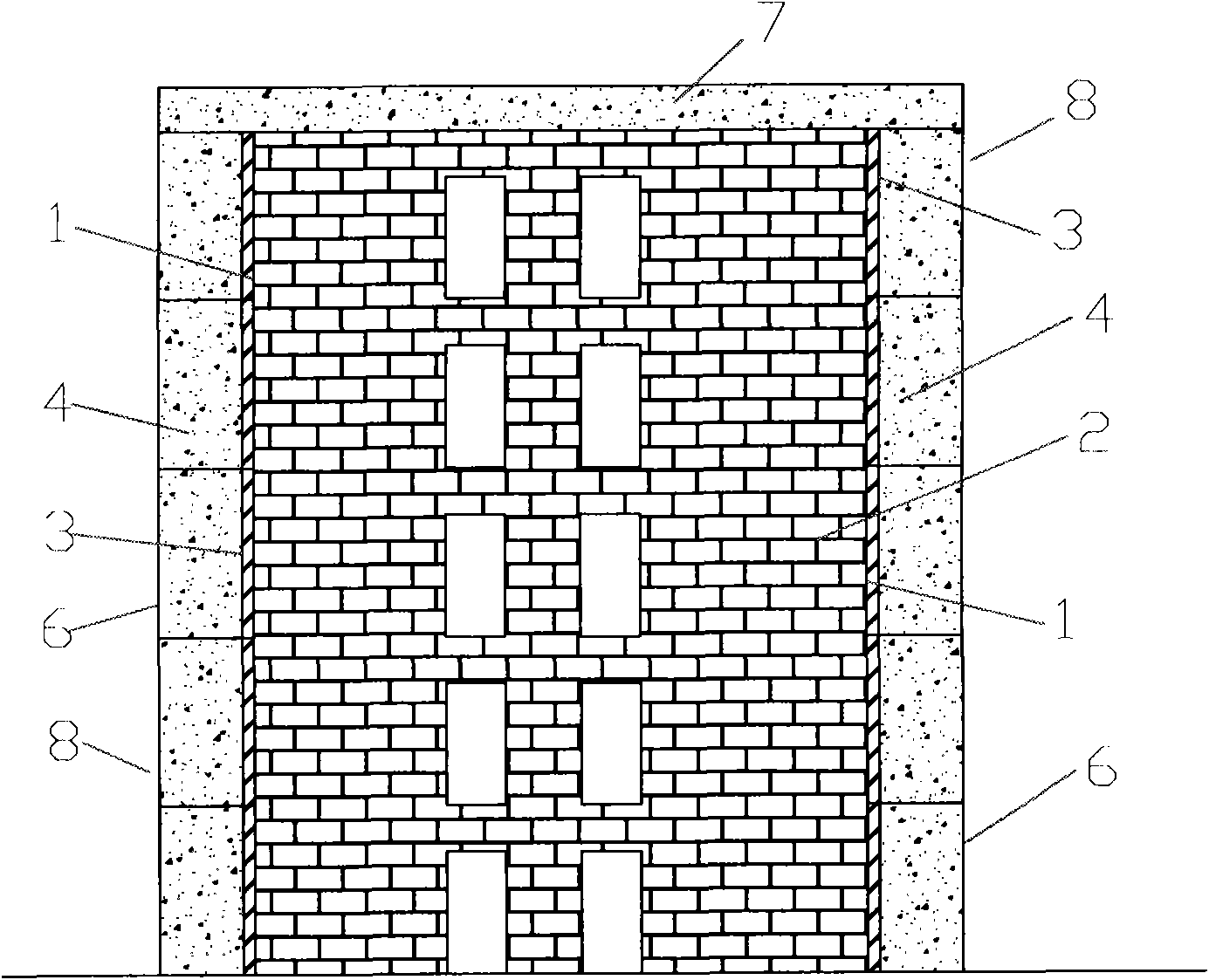

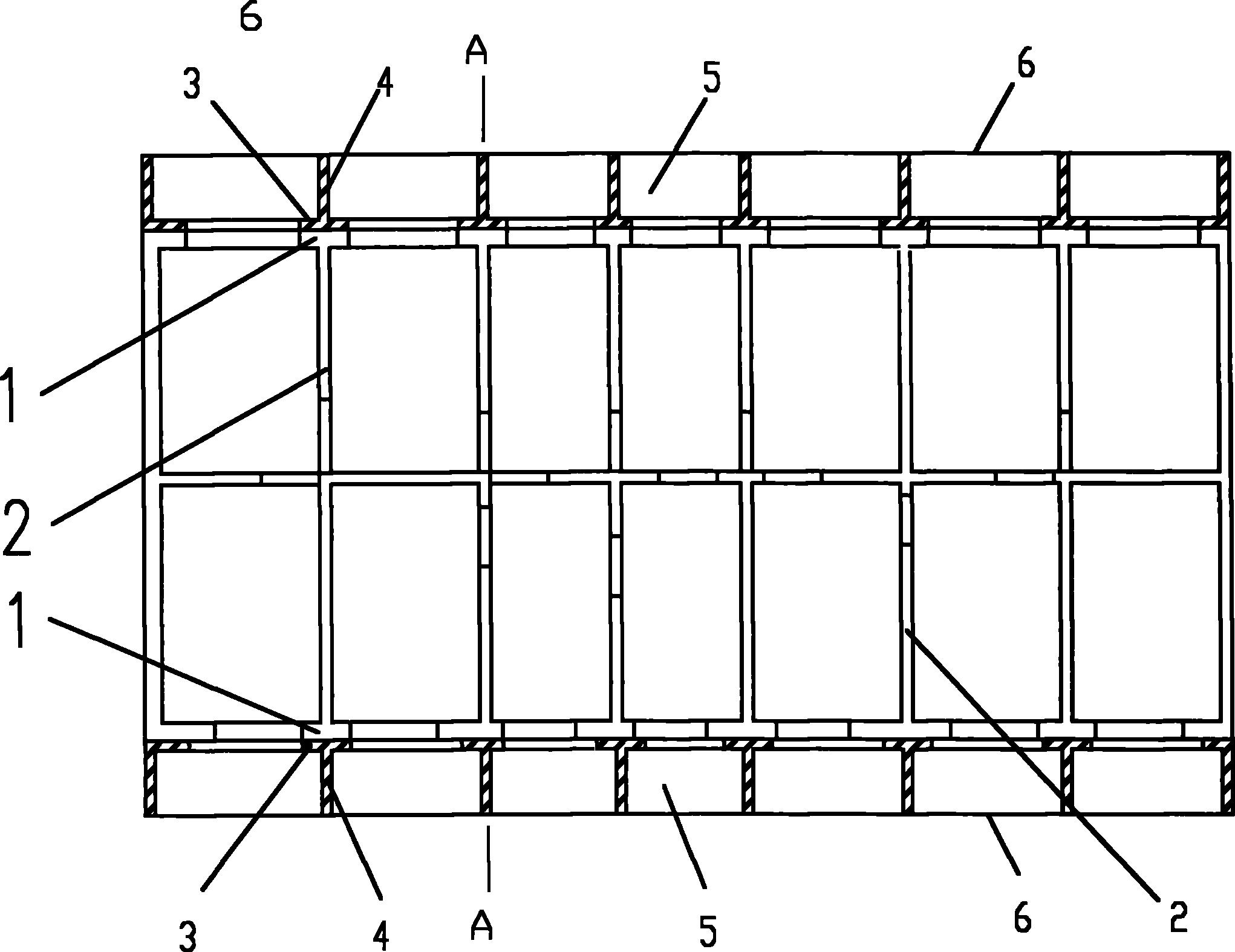

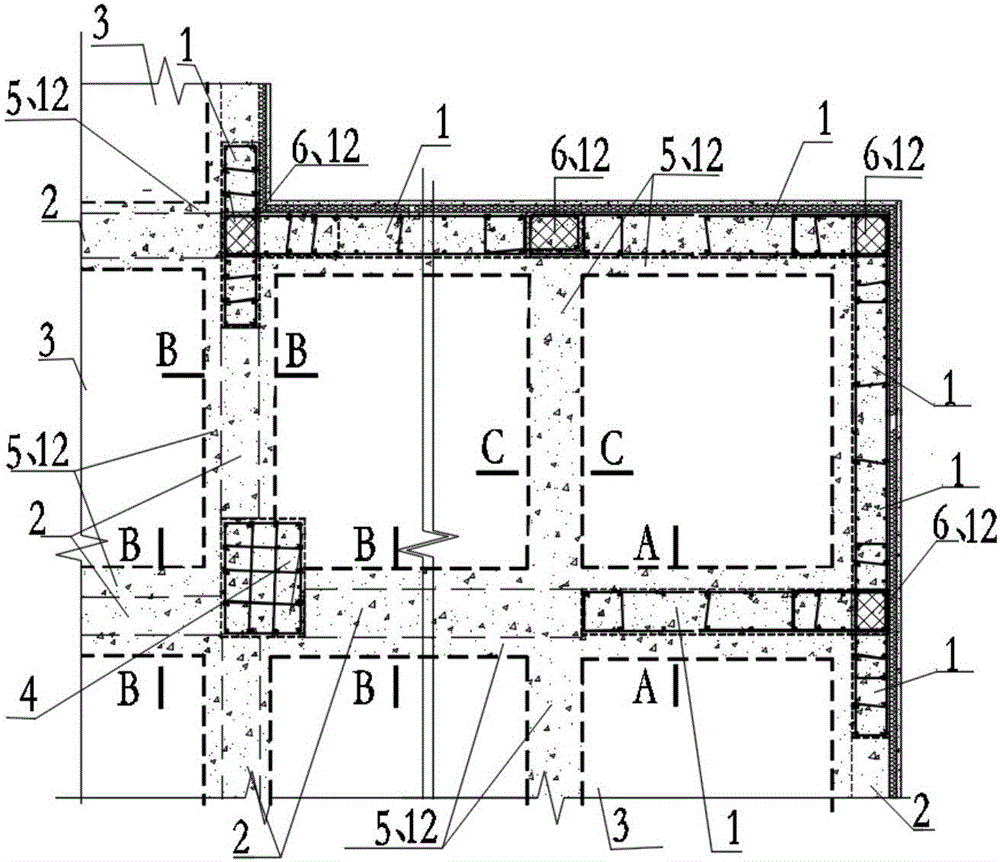

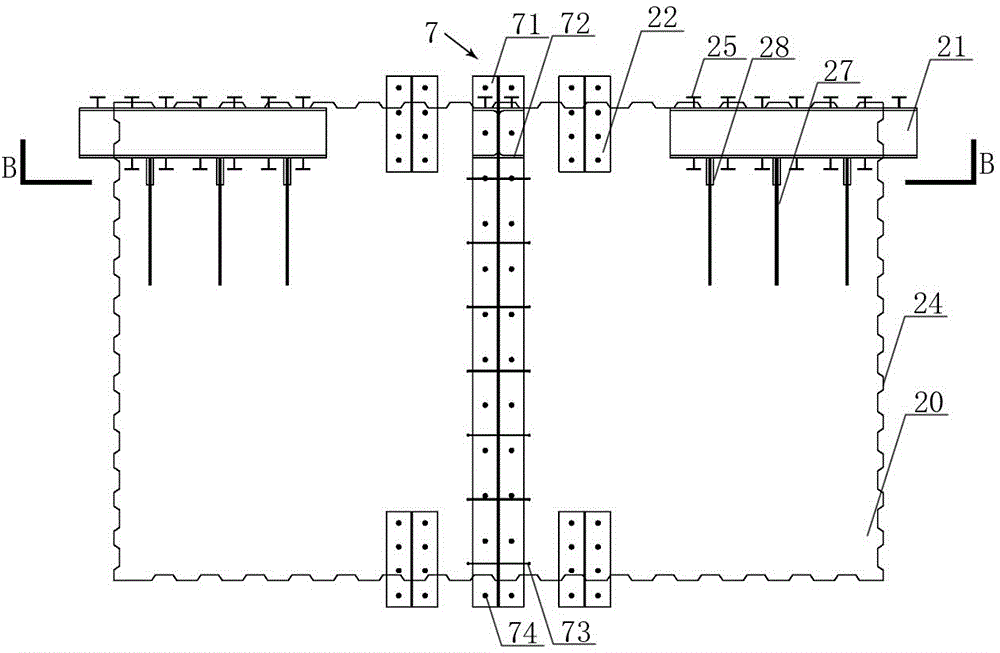

Anti-seismic reinforcing structure and method of old brickwork building

ActiveCN102003080AGood seismic reinforcement systemMeet planning requirementsBuilding repairsProtective buildings/sheltersFloor slabLife quality

The invention relates to an anti-seismic reinforcing structure and a method of an old brickwork building. Sheathed prefabricated structures are respectively arranged at two sides of the old brickwork building to anti-seismically reinforce the old brickwork building and the inner sides of the sheathed prefabricated structures are connected with the outer longitudinal wall of the old brickwork building; a roof straining beam is arranged on the roof and the sheathed prefabricated structures at the two sides are fixedly connected into a whole through the roof straining beam; the reinforcing structure consists of the sheathed prefabricated structures at the two sides and the roof straining beam; and the sheathed prefabricated structures respectively comprise a newly added longitudinal wallboard, a newly added transverse wallboard, a newly added floor and a roof straining beam. The anti-seismic reinforcing structure has reliable anti-seismic performance, and can ensure that the residents are unnecessary to move and the construction is carried out outdoor during the reinforcing construction; the constructional members are machined in a prefabrication way, therefore, the site construction time is short, the wet operation volume is small, the quantity of construction templates is less, and the work noise at the construction site is low; moreover, the anti-seismic reinforcing aim of the old building and the using condition improving aims are skillfully combined, thereby increasing the usable area and improving the life quality of the residents.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

Locally uncombined suspension bridge steel-concrete combined bridge deck system and construction method of combined bridge deck system

ActiveCN102146658AReduce stress concentrationReduced risk of crackingSuspension bridgeBridge structural detailsCrack resistanceBridge deck

The invention discloses a locally uncombined suspension bridge steel-concrete combined bridge deck system and a construction method of the combined bridge deck system, and belongs to the technical field of bridge structures. The bridge deck system consists of concrete slabs, longitudinal steel beams, cross steel beams, air nozzles and toggle pin connectors; and a suspension bridge section steel-concrete combined bridge deck system is prefabricated in a factory. The prefabricated concrete slabs and section steel main beams form a whole through concrete wet joints and the toggle pin connectors. The prefabricated concrete slabs and cast-in-place concrete joints are only connected with the cross steel beams to form a whole through the toggle pin connectors, the longitudinal steel beams are not provided with the toggle pin connectors, and meanwhile, the toggle pin connectors are not arranged in a certain area of the ends of the cross steel beams at hoisting points. The problems of cracking, complex structures of toothed grooves at the slab ends of the prefabricated concrete slabs and the like due to the factors of temperature, contraction, creep and the like of the concrete slabs of the traditional suspension bridge combined bridge deck system are solved by adopting a locally uncombined technology on the premise of keeping the consumption of steel, the manufacturing process of the prefabricated slabs is simplified, the bearing capacity, the rigidity and the cracking resistance of the structure are improved, and the durability of the structure is improved.

Owner:TSINGHUA UNIV

Connecting node of assembled whole thick prefabricated slab unit and slab unit thereof

The invention discloses a connecting node of an assembled whole thick prefabricated slab. Connecting steel bars are reserved on the connecting surface of a prefabricated slab unit in the mode, the exposed parts of the connecting steel bars are ' '-shaped, and the exposed parts and the connecting surface form a closed polygon. In the connecting mode for the prefabricated slab unit and a beam or a wall, the connecting steel bars of the prefabricated slab unit are inserted with steel bars configured for the beam or the wall together at the connecting positions in a penetrating mode. Viewing from the cross section of the whole connecting node, the connecting steel bars and the steel bars configured for the beam or the wall form a single closed stirrup or a composite stirrup, and longitudinal bolt steel bars penetrate into the inner corner position of the single closed stirrup or the composite stirrup. The connecting node of the whole thick prefabricated slab unit can achieve the equivalent performance as a prefabricated slab connecting nodes and a cast-in-place concrete structure while achieving higher prefabrication rate and assembly rate. The invention further provides the whole thick prefabricated slab unit for achieving the connecting mode.

Owner:刘祥锦

Assembly-type T-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type T-shaped mixed coupled wall and a construction method thereof. The assembly-type T-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form a T shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type T-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved, building operating requirements can be met conveniently, and assembly procedures can be simplified conveniently; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

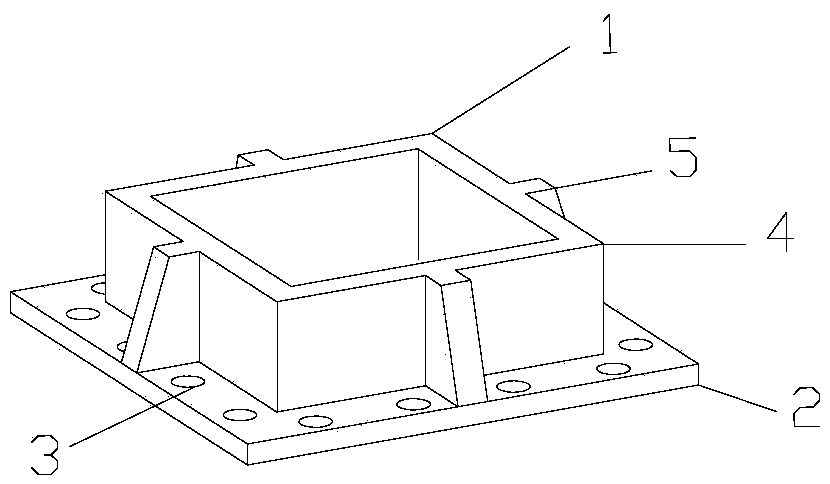

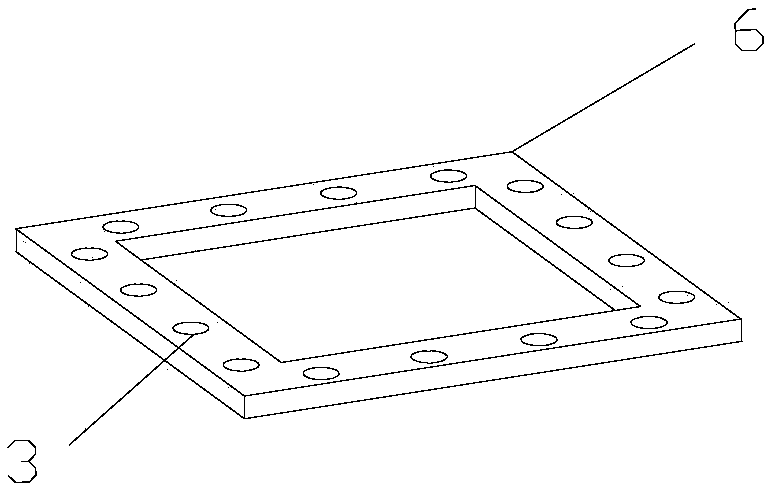

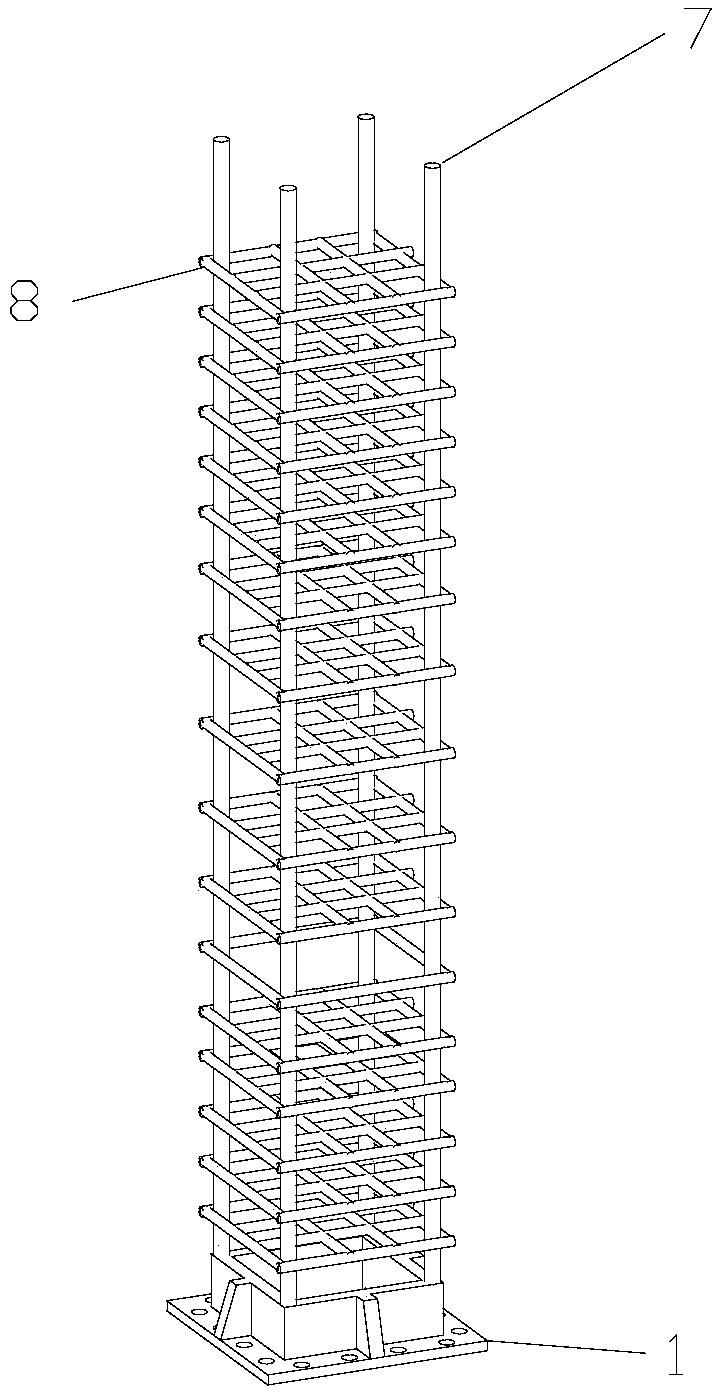

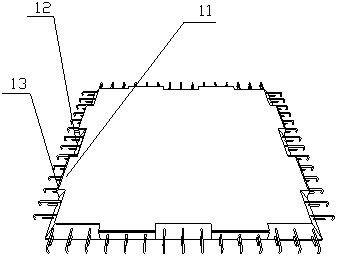

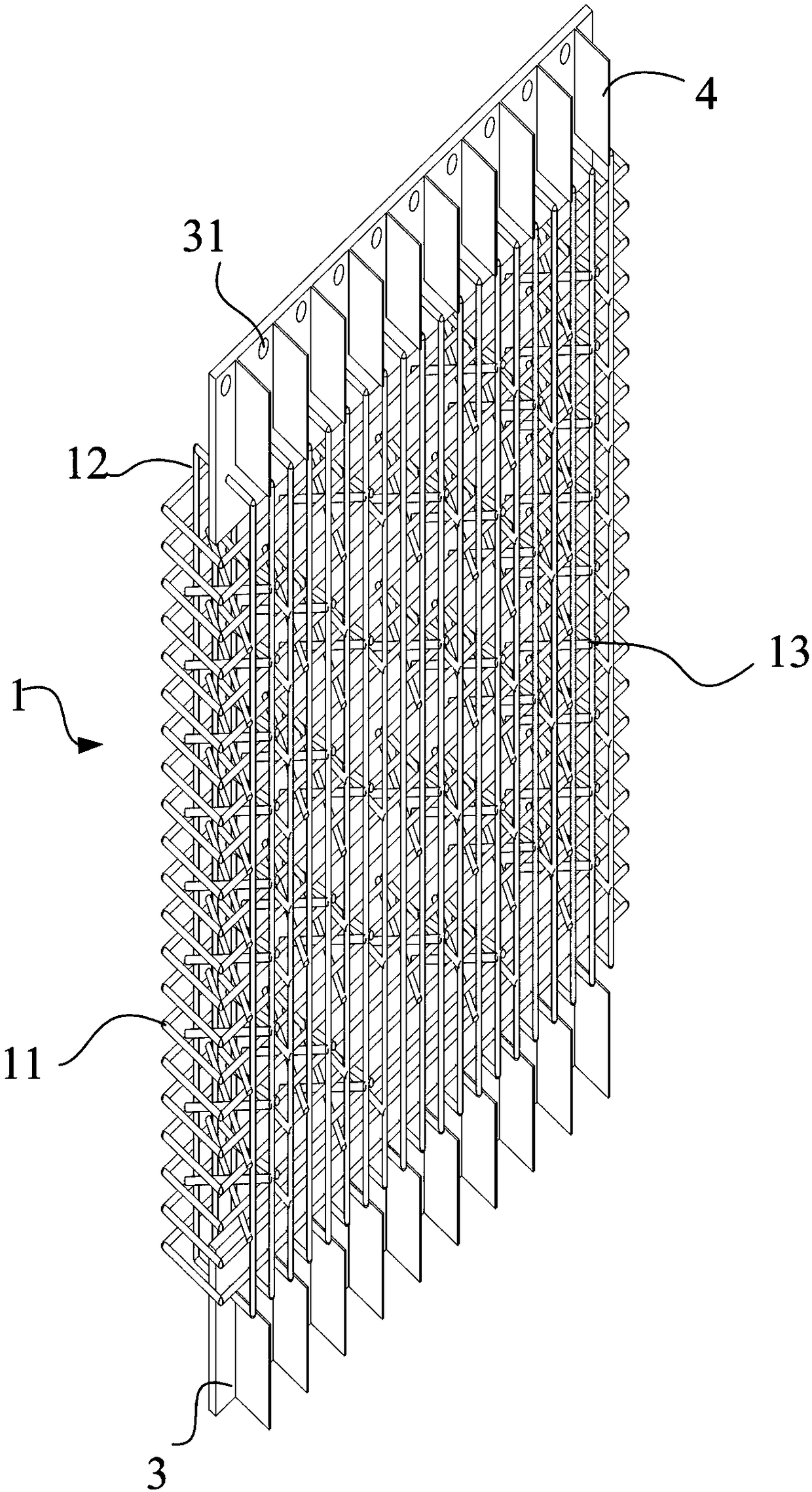

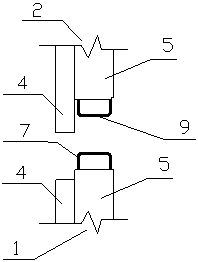

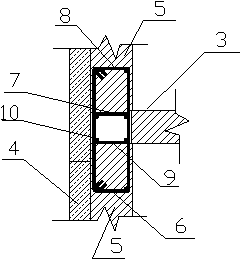

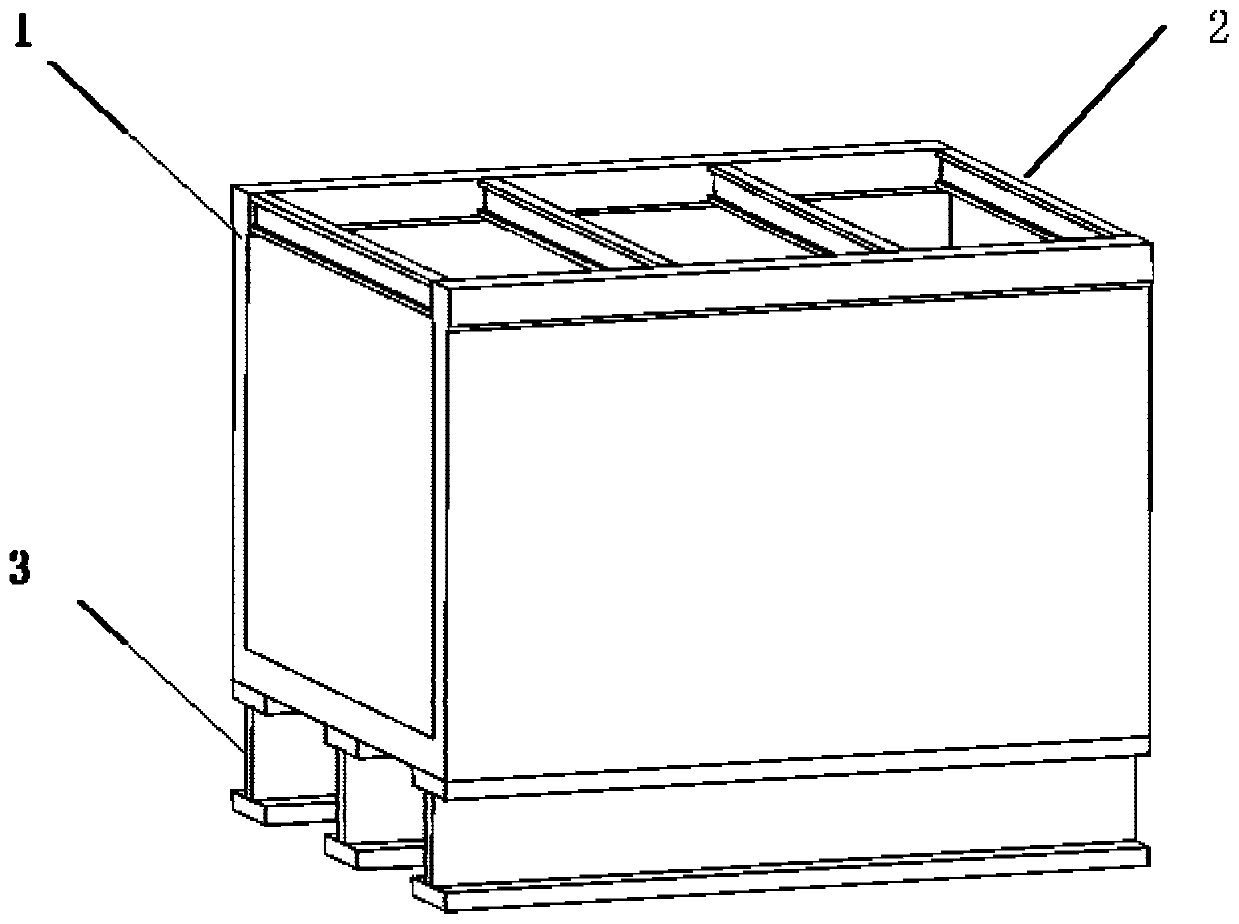

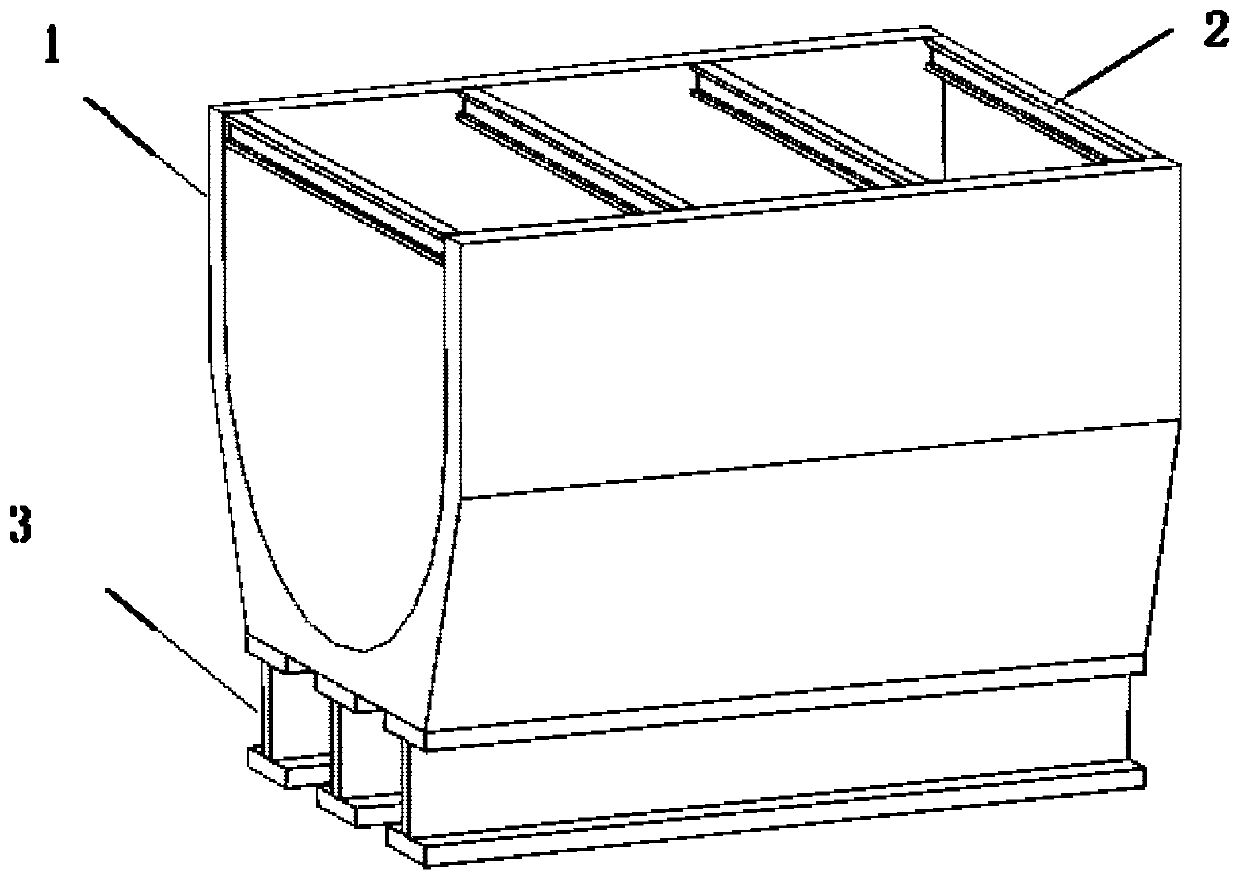

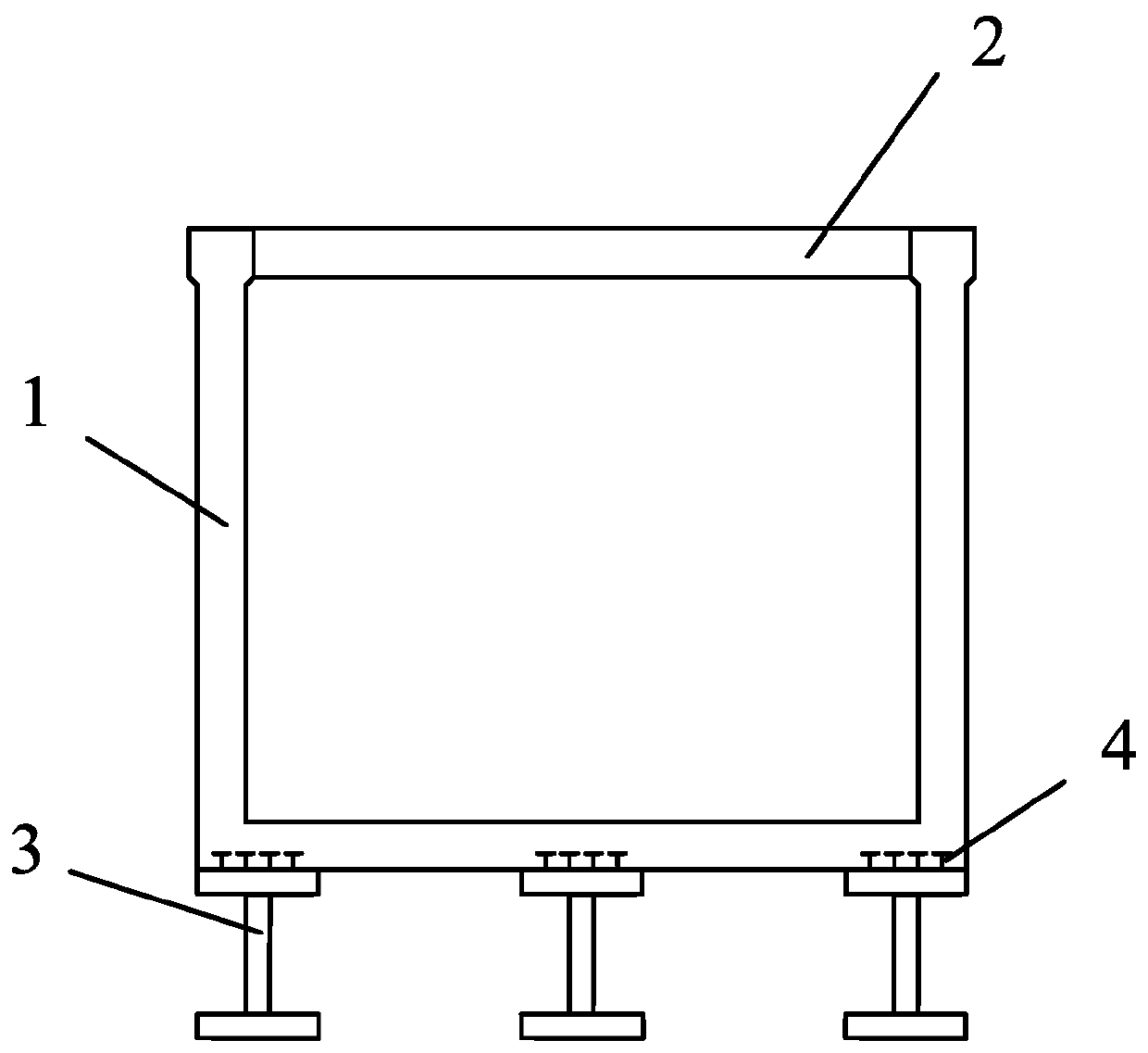

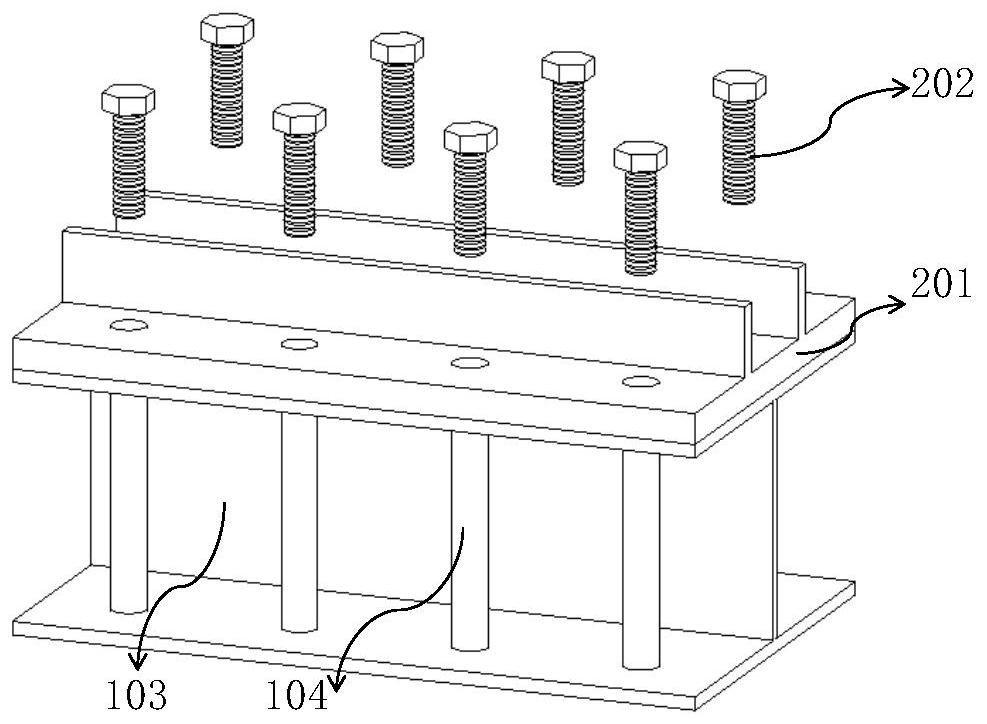

Assembly type concrete truncated pyramid type foundation and column steel connecting structure and assembling method

The invention relates to the field of prefabricated concrete structures, in particular to an assembly type concrete truncated pyramid type foundation and column steel connecting structure and an assembling method. A prefabricated column is composed of in-column longitudinally stressed rebars, column tie-bars, a prefabticated member under the columns and concrete, the in-column longitudinally stressed rebars vertically arranged in the shaped of a square are connected through the column tie-bars to form a frame structure, the bottom face of the frame structure is welded to the prefabticated member under the columns. Bolt bar assemblies in the truncated pyramid type foundation are arranged in the longitudinally stressed rebars in the truncated pyramid type foundation, and uniformly provided with long bolt bars through a long bolt bar constraint steel plate, prefabricated truncated pyramid type foundation framework is formed, concrete is poured around a prefabricated truncated pyramid typefoundation framework, and the prefabricated truncated pyramid type foundation is obtained. Accordingly, on the premise that prefabricated concrete members are connected, the workload of wet construction is reduced as much as possible, the construction speed is greatly increased, and construction quality is greatly improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Assembled concrete structure construction method

ActiveCN106193623AIncrease stiffnessReduce supportBuilding material handlingEngineeringStructure system

The invention discloses an assembled concrete structure construction method. According to the construction method, a reversed construction procedure is adopted for installation of a vertical component of a currently constructed floor, that is, before connection assembly of a horizontal component of the currently constructed floor, the vertical component connected to the upper portion of the horizontal component is hoisted firstly, and finally connection concrete is poured at a time to connect the horizontal component with the vertical component of the currently constructed floor into a whole. The construction method adopts the reversed construction procedure, so that construction links are reduced, and the construction period is shortened; the method is suitable for assembled concrete building construction for structure systems such as precast shear walls, composite wallboards and frameworks, and has the advantages of convenient construction, time saving, economy, environment friendliness and the like; and meanwhile, the requirement for identical performance as a cast-in-place structure is met.

Owner:刘祥锦

Partially bonded prestress assembly self-reset bridge pier column node and method

ActiveCN110359363ABuild fastImprove construction qualityBridge structural detailsBridge erection/assemblyPre stressEngineering

The invention relates to a partially bonded prestress assembly self-reset bridge pier column node and a method. The node comprises a pier column, wherein a main body of the pier column is fabricated by concrete; the lower end of the pier column is inserted into a foundation and fixedly connected with the foundation; the upper end of the pier column is fixedly connected with a capping beam; a prestressed reinforcement is arranged in the pier column; a central axis of the pier column is coincided with that of the prestressed reinforcement; the lower end of the prestressed reinforcement is inserted into the foundation along with the pier column; the middle of the prestressed reinforcement is arranged in the pier column; the upper end of the prestressed reinforcement penetrates out of the piercolumn and is inserted into the capping beam; the lower end of the prestressed reinforcement is bound and fixed to the pier column; the upper end of the prestressed reinforcement is bound and fixed to the capping beam; the middle of the prestressed reinforcement is arranged in a prestressed reinforcement duct of the pier column; the upper end of the prestressed reinforcement duct penetrates through the pier column; the lower end of the prestressed reinforcement duct is positioned in the pier column; and the lower end of the prestressed reinforcement is fixedly connected with the pier column through an anchor piece. The disadvantages of long construction cycle and high cost due to adoption of an external dissipative element and post tensioned application of prestress can be avoided, and the probability of brittle failure of the pier column is reduced.

Owner:SHANDONG JIANZHU UNIV

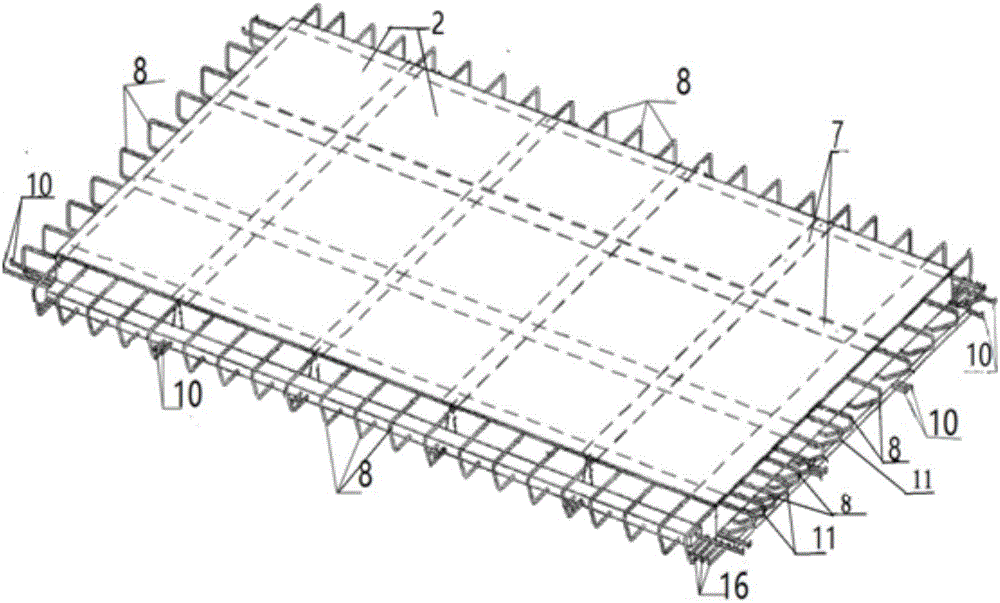

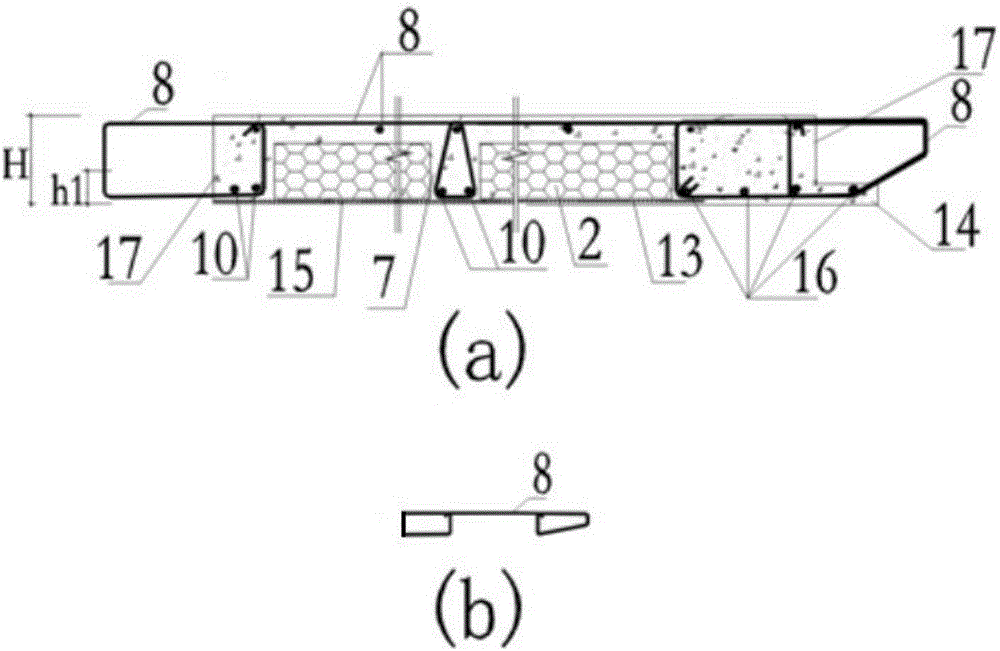

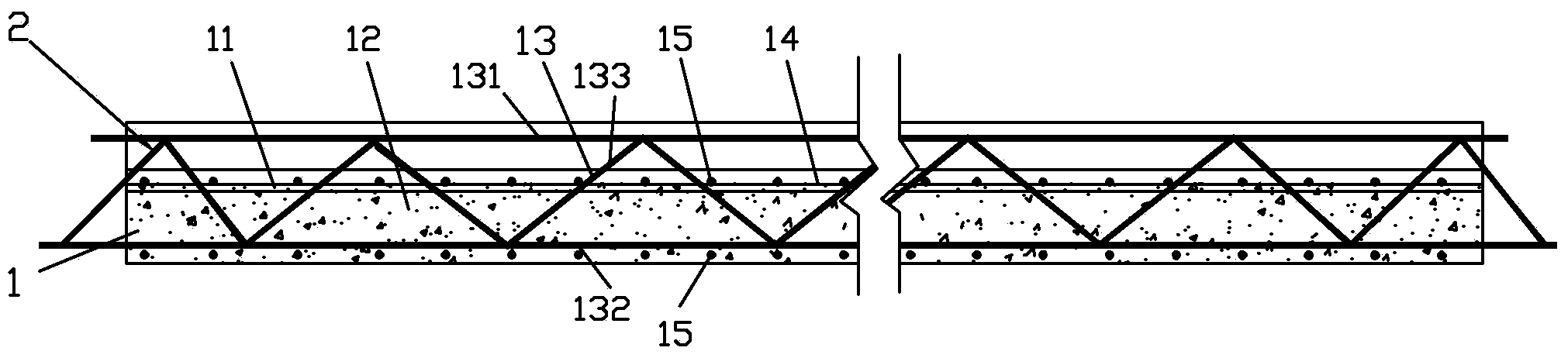

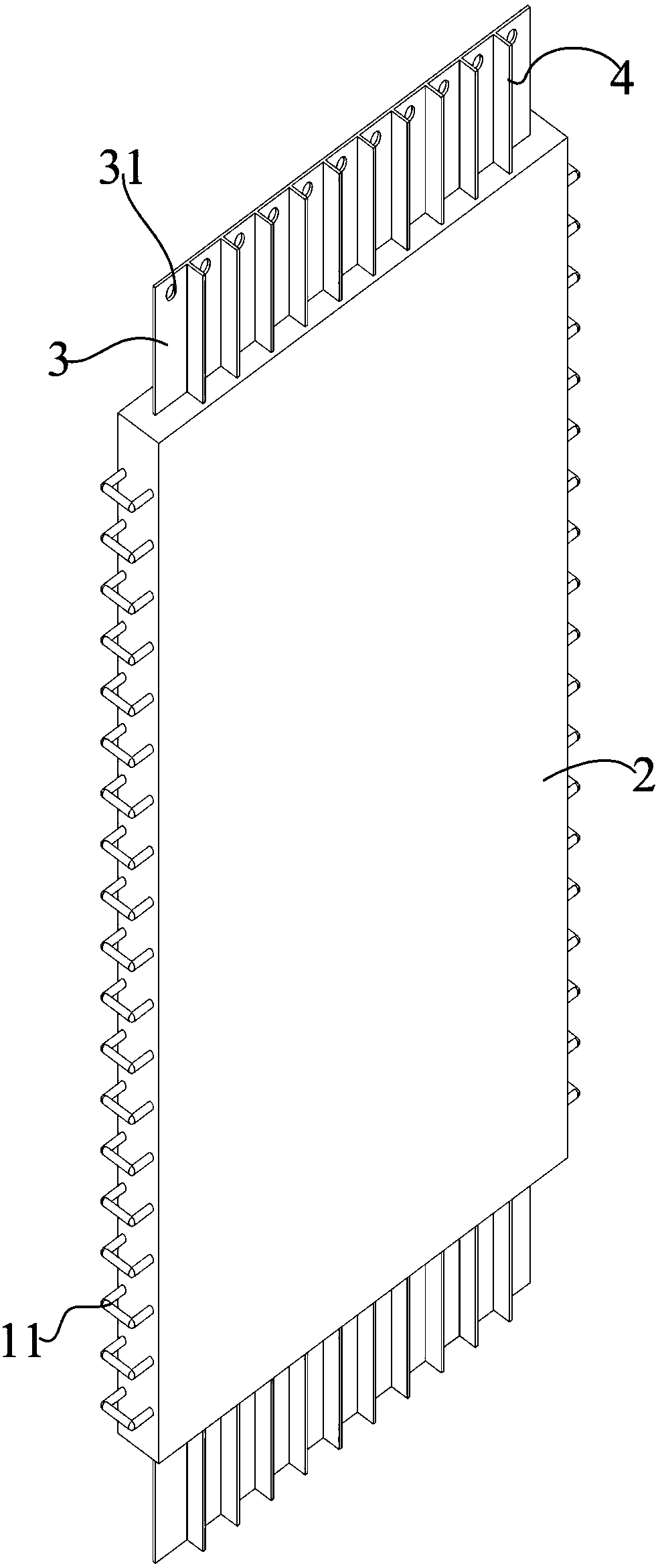

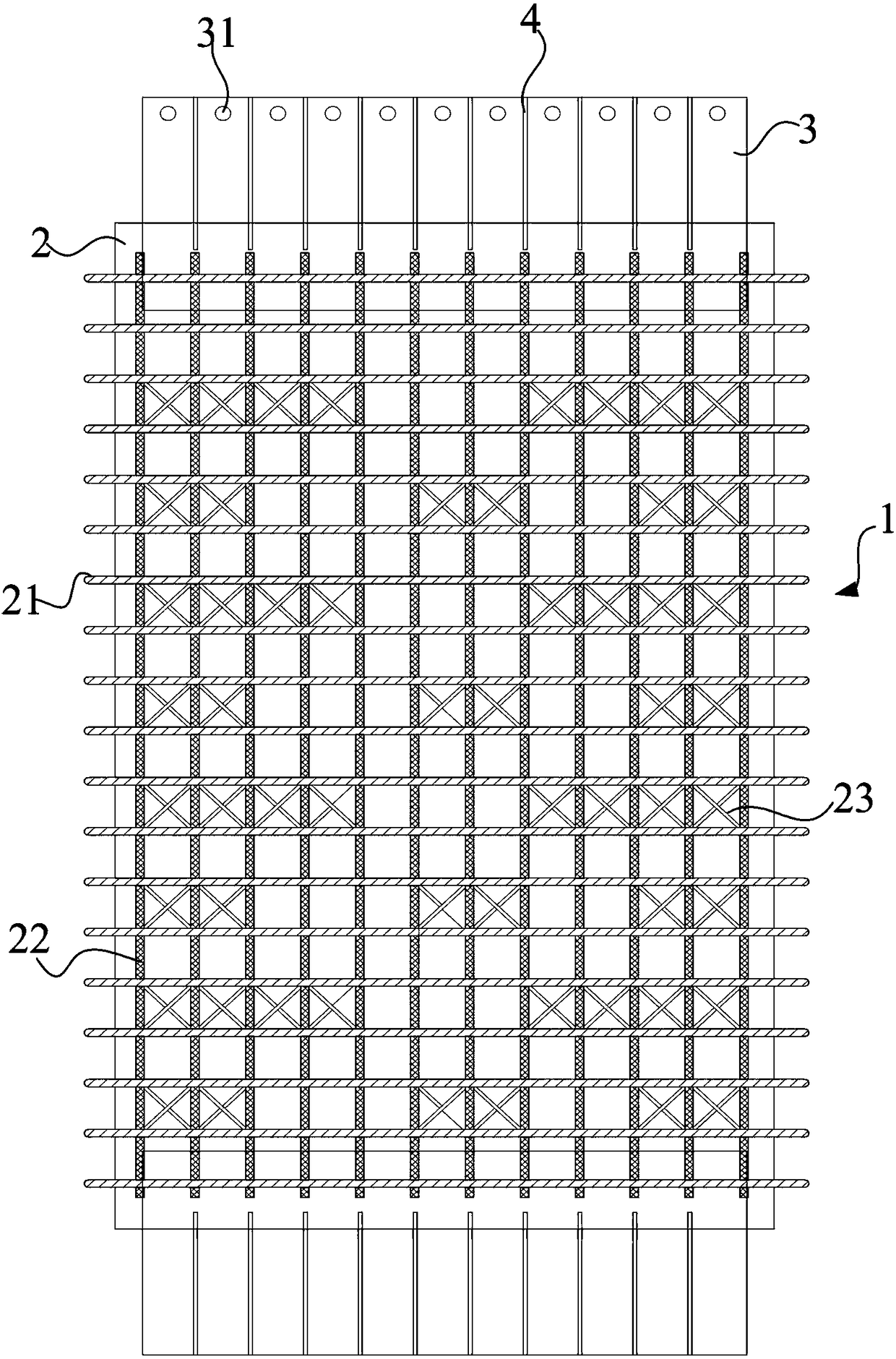

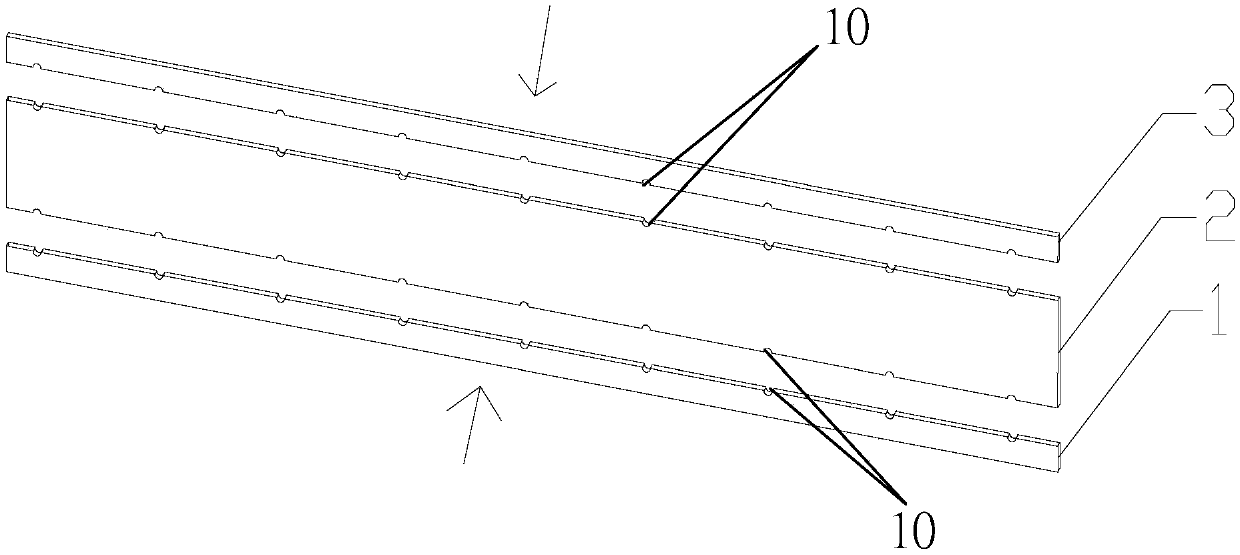

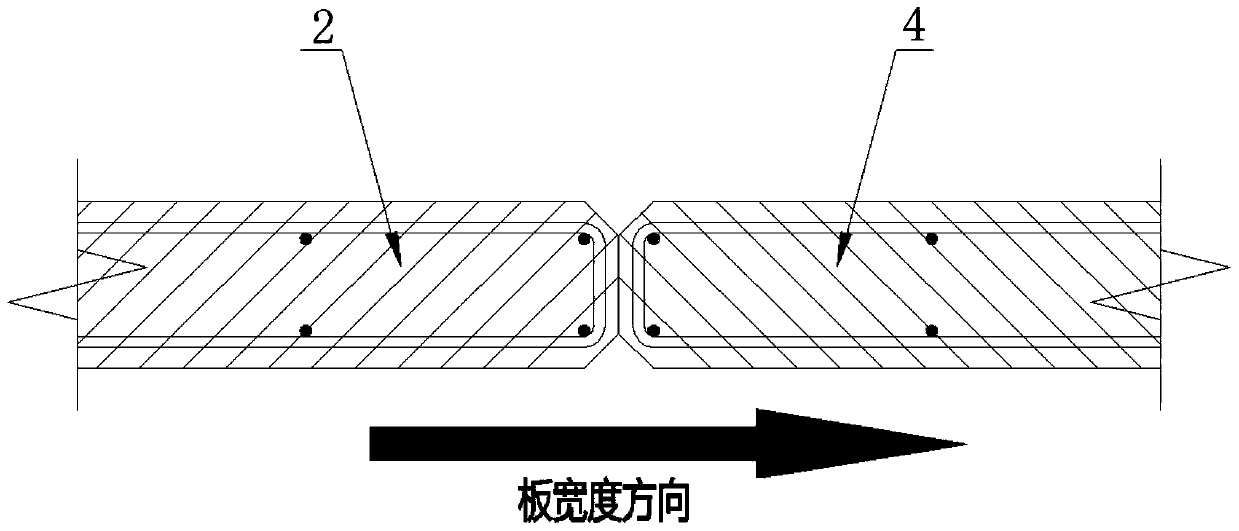

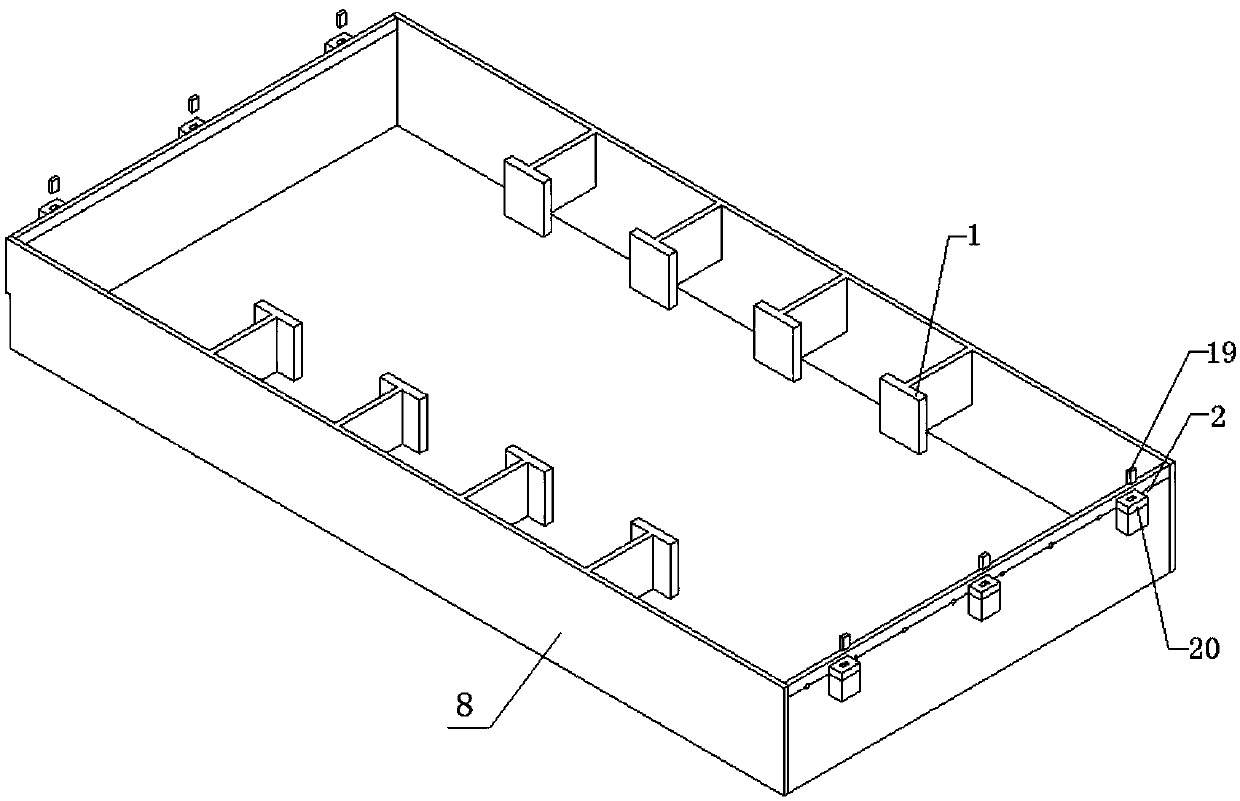

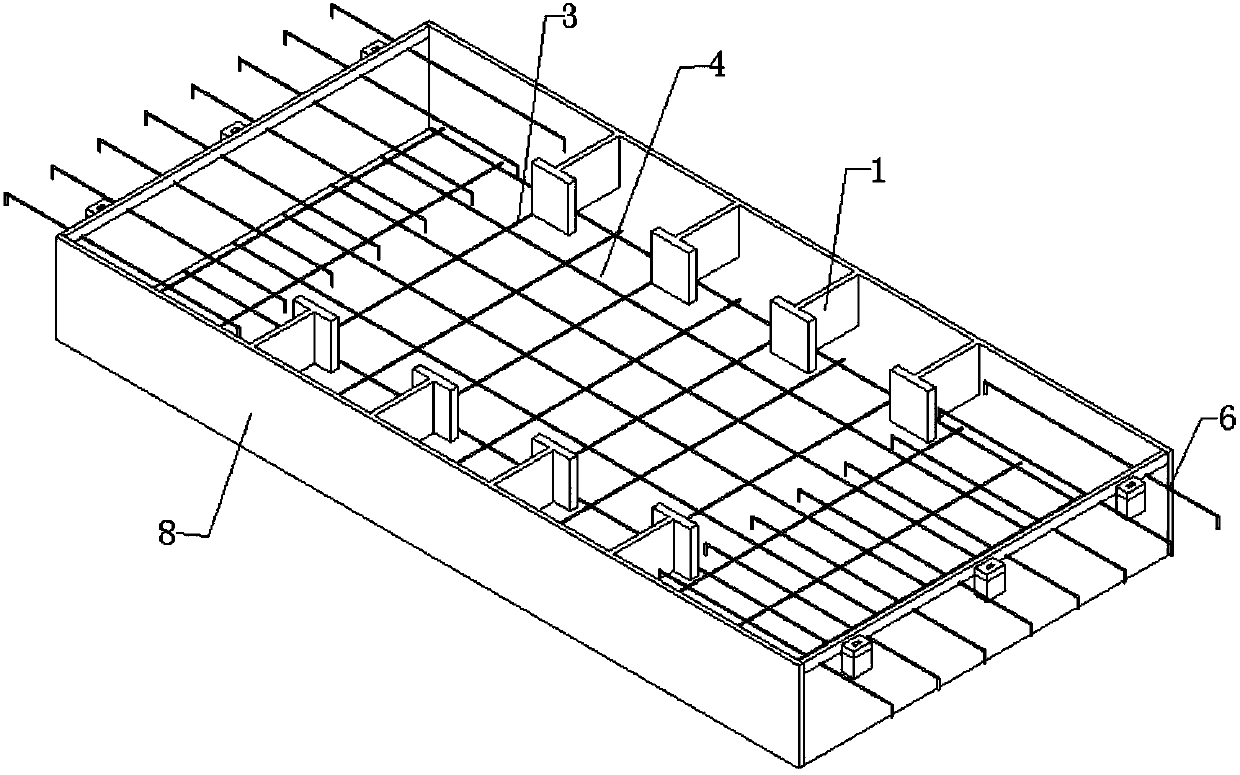

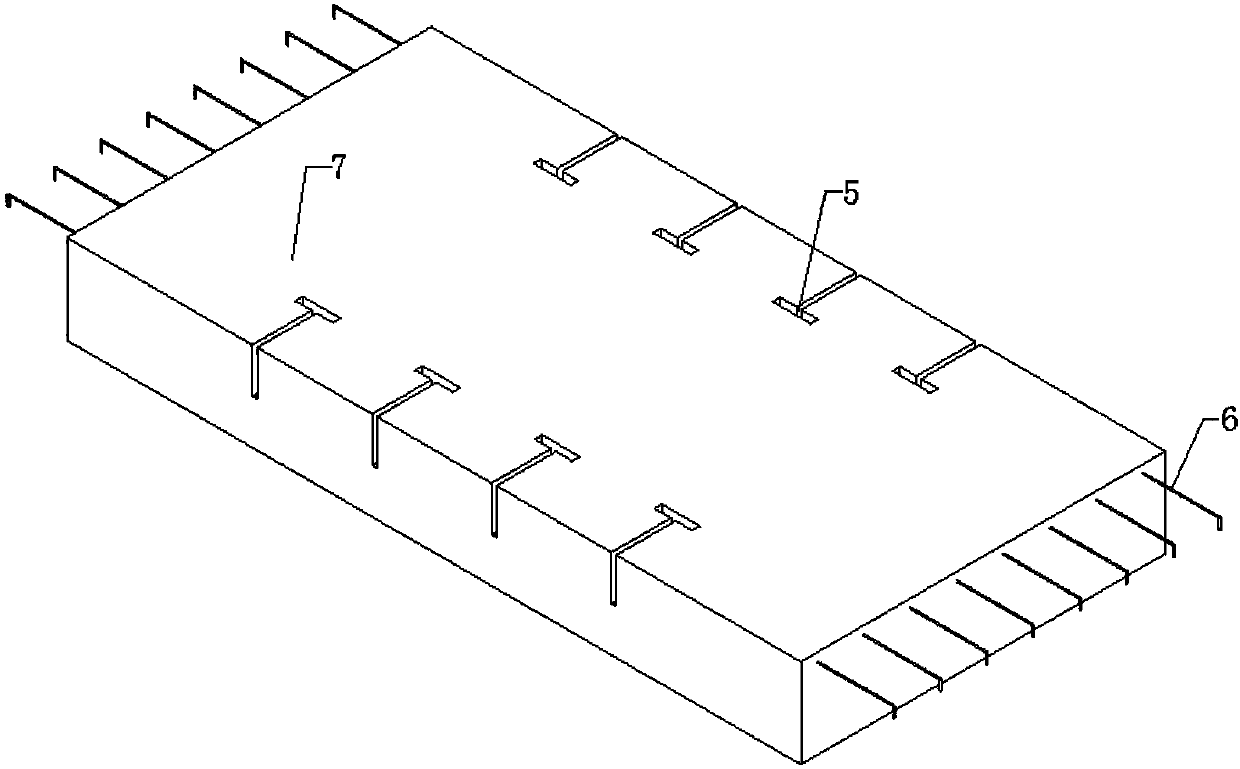

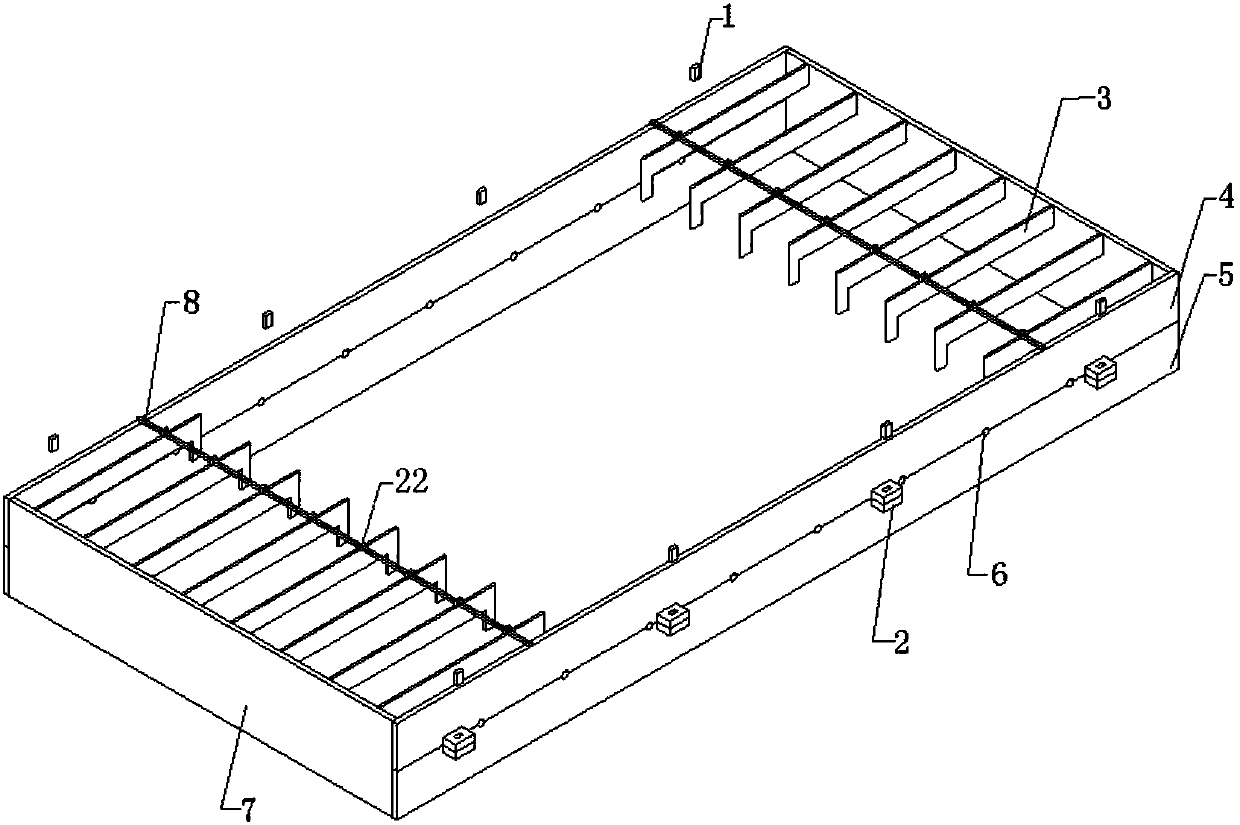

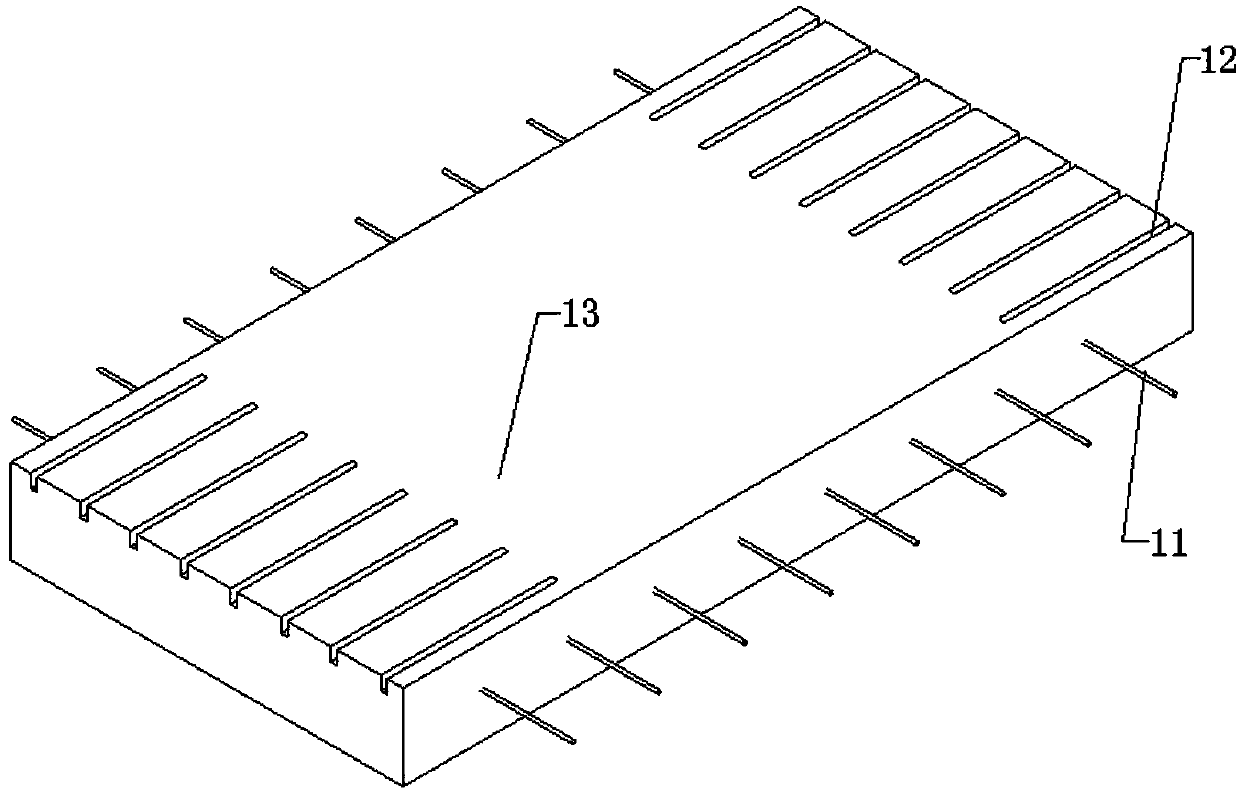

Concealed beam type connecting fully-prefabricated concrete plate structure and manufacturing and assembling methods

PendingCN107975185AReduce wet work loadEasy to assemble on siteConstruction materialCeramic shaping apparatusLap jointRebar

The invention relates to the field of prefabricated assembly type concrete structure buildings, in particular to a concealed beam type connecting fully-prefabricated concrete plate structure and manufacturing and assembling methods. Fully-prefabricated concrete plates are formed in the mode that concrete is poured into formwork structures; longitudinal steel bars and transverse steel bars are arranged in the fully-prefabricated concrete plates horizontally and are each of the structure with the two ends being bent on the inner side of the corresponding fully-prefabricated concrete plate; and vertical sections between the bottom edges of the longitudinal steel bars and the transverse steel bars and the bent sections of the longitudinal steel bars and the transverse steel bars are arranged on the outer sides of the fully-prefabricated concrete plates. According to the concealed beam type connecting fully-prefabricated concrete plate structure, concealed beam longitudinal steel bars penetrate through closed hoops formed by lap joint of the exposed steel bars of the two prefabricated concrete plates, then, concrete is poured, and thus the plates are connected; the concealed beam longitudinal steel bars penetrate through the closed hoops formed by lap joint of in-beam reserved connecting steel bars and the exposed steel bars of the prefabricated concrete plates, then, the concrete is poured, and thus fixing of the plates on beams is completed; and the requirement for plate and beam connection in actual engineering is completely met.

Owner:SHENYANG JIANZHU UNIVERSITY

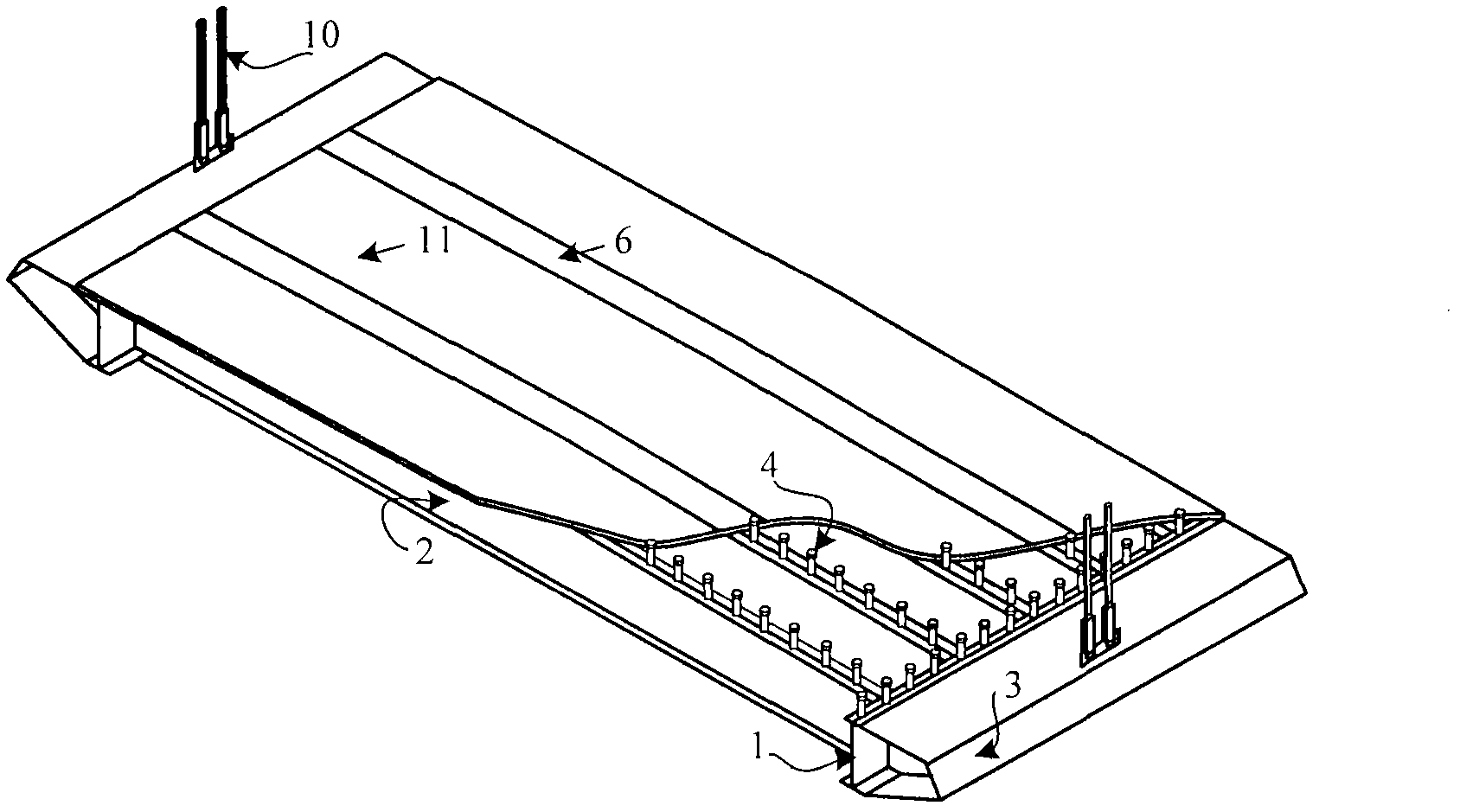

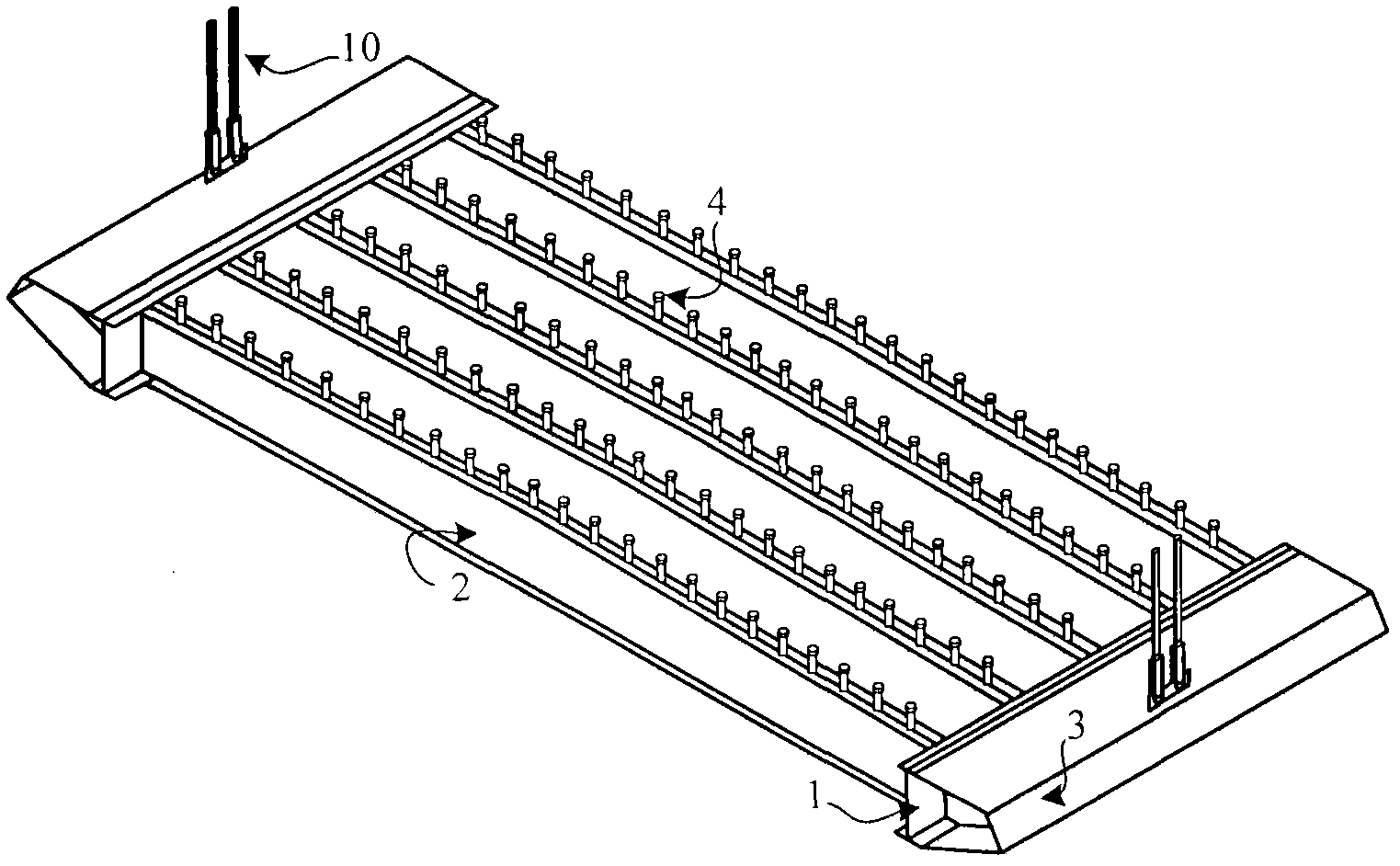

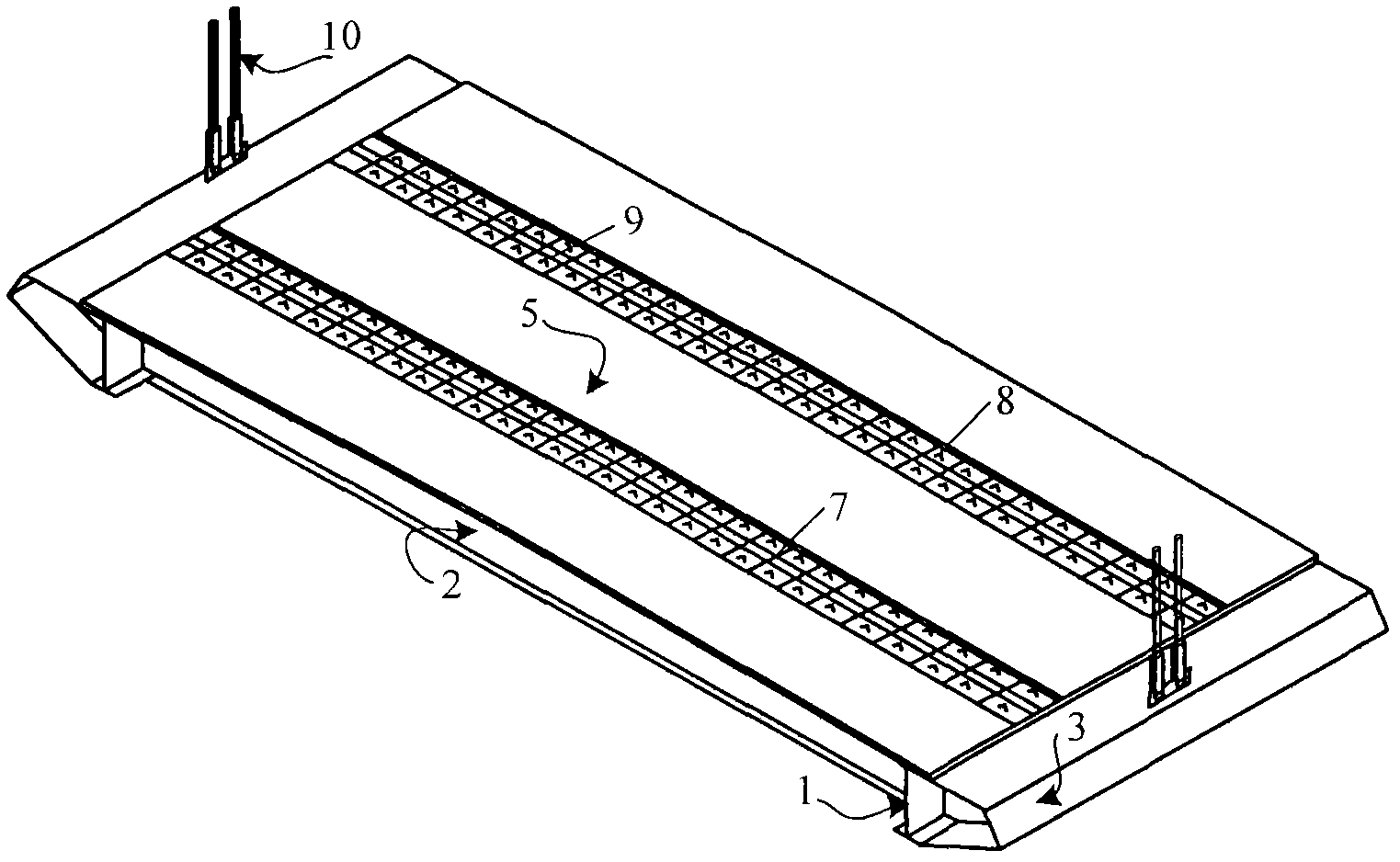

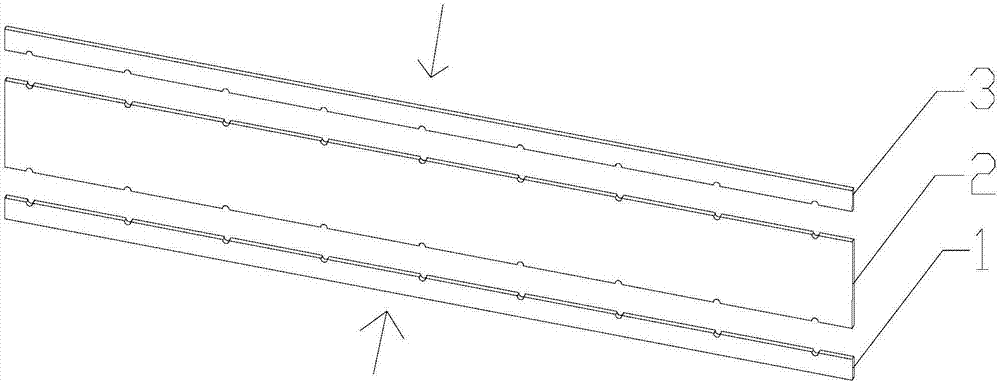

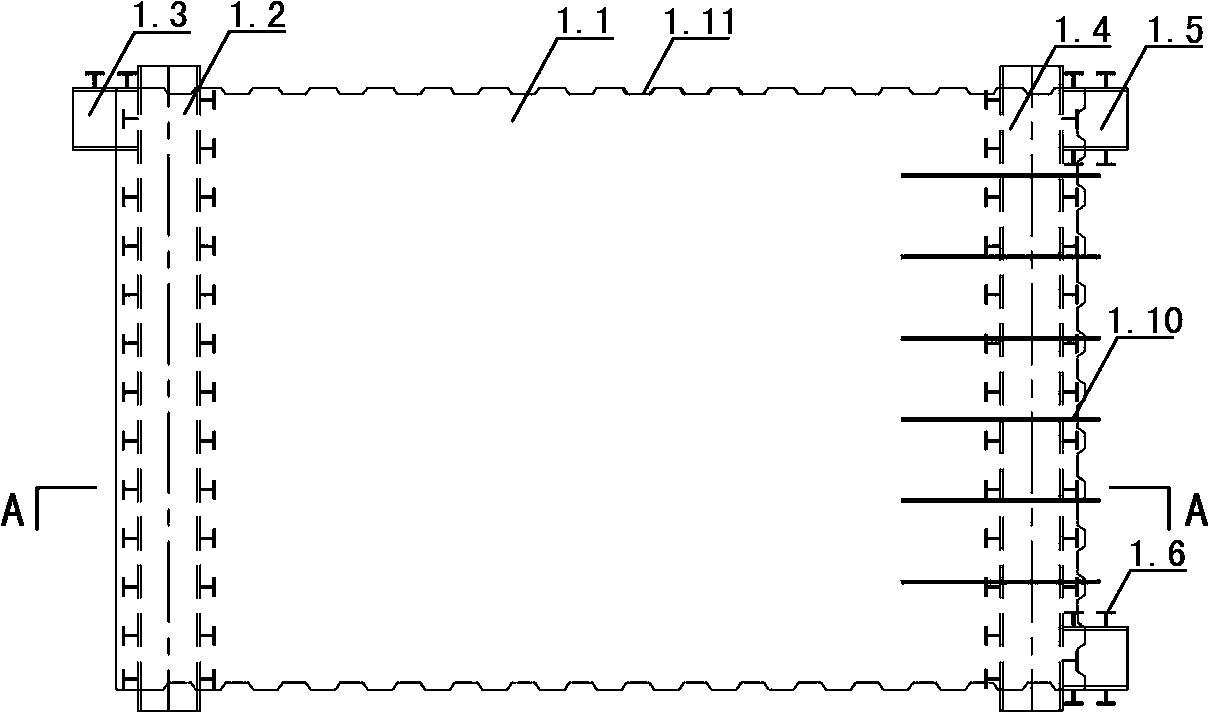

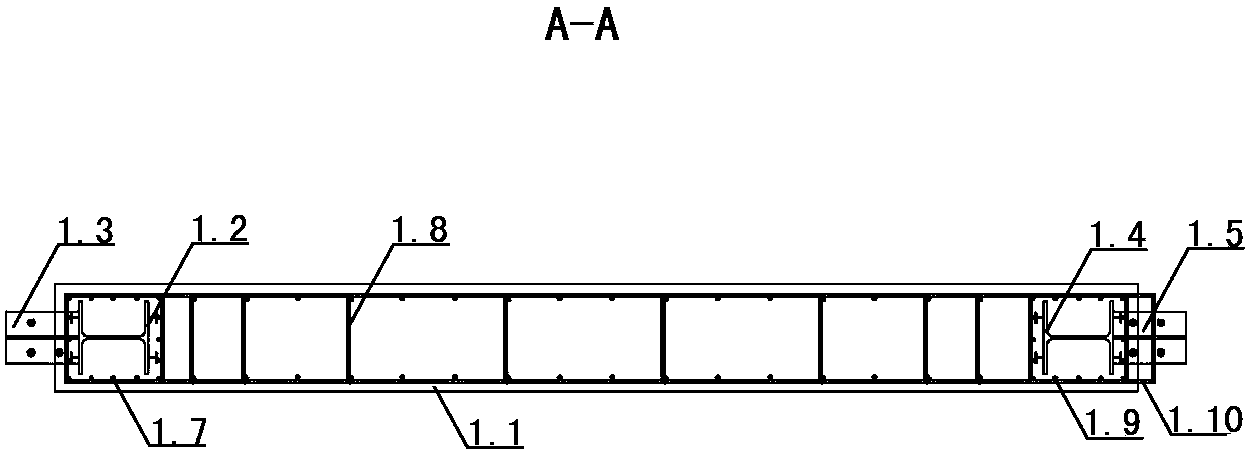

Truss concrete superposed beam

ActiveCN103711255ANo reduction in headroomSufficient shelving lengthLoad-supporting elementsFloor slabSteel bar

The invention discloses a truss concrete superposed beam comprising a prefabricated layer and a superposed layer, wherein the prefabricated layer comprises a truss reinforcing mesh and a concrete layer at the lower part of the truss reinforcing mesh; the truss reinforcing mesh comprises a truss, erection steel bars and stirrups; the truss comprises a lower chord member, an upper chord member and a web member for connecting the lower chord member and the upper chord member; the upper chord member of the truss is positioned above the concrete of the prefabricated layer; the superposed layer is a cast-in-place concrete layer positioned on the prefabricated layer. The truss concrete superposed beam disclosed by the invention has the advantages of convenience and quickness in construction without temporary shoring, capability of providing a relatively longer laying length for a floor slab, quality guarantee, good integrity and good economical efficiency.

Owner:SHANGHAI IRON & STEEL TECHN INST

Assembly-type cross-shaped mixed coupled wall and construction method thereof

InactiveCN104032855AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type cross-shaped mixed coupled wall and a construction method thereof. The assembly-type cross-shaped mixed coupled wall comprises first wall units and a second wall unit which are connected together perpendicularly and form a cross shape. The first wall units are symmetrically distributed on the two sides of the second wall unit, the first wall units and the second wall unit are all prefabricated parts, and the first wall units and the second wall unit are connected through joint post-pouring belts. According to the assembly-type cross-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Assembly method of upper and lower interior walls and floors

The invention provides an assembly method of upper and lower interior walls and floors, including the following steps: S1, prefabricating interior wall shear walls and floors; S2, hoisting and installing: a first interior wall shear wall is hoisted and positioned, a first floor and a second floor are respectively hoisted on the two end faces of the top side of the first interior wall shear wall, asecond interior wall shear wall is hoisted on the top side of the first interior wall shear wall, and the two ends of the bottom side of the second interior wall shear wall are respectively pressed on the supporting ribs on the top sides of the first floor and the second floor; a cavity is formed between the floors and the first and second interior wall shear walls, and longitudinal steel bars, lacing wires and anchoring parts are ingeniously arranged in different ways; and S3, casting connection: concrete is poured into the cavity to form a double-overlapping post-poured connecting beam or adouble-anchorage horizontal post-poured strip which connects the floors and the interior wall shear walls together. The on-site construction work for the connection joint is less. The construction cost is lowered, and the construction period is shortened. The integrality and seismic strength of the building are greatly improved.

Owner:绿建科技集团新型建材高技术有限公司

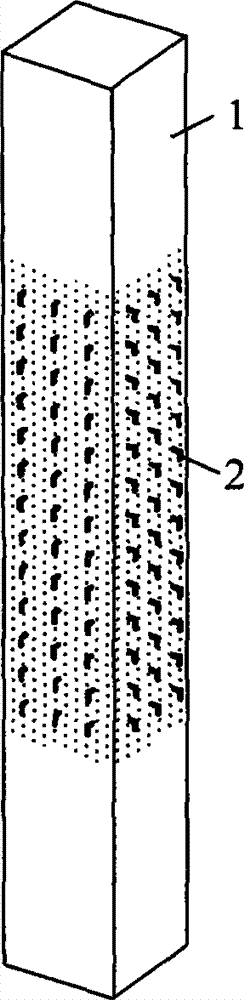

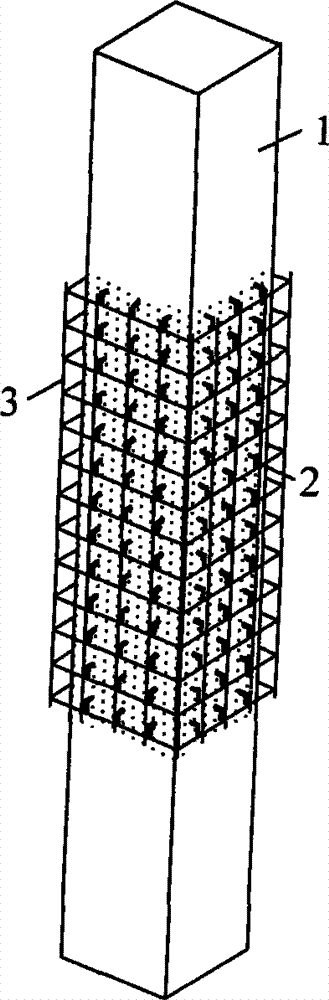

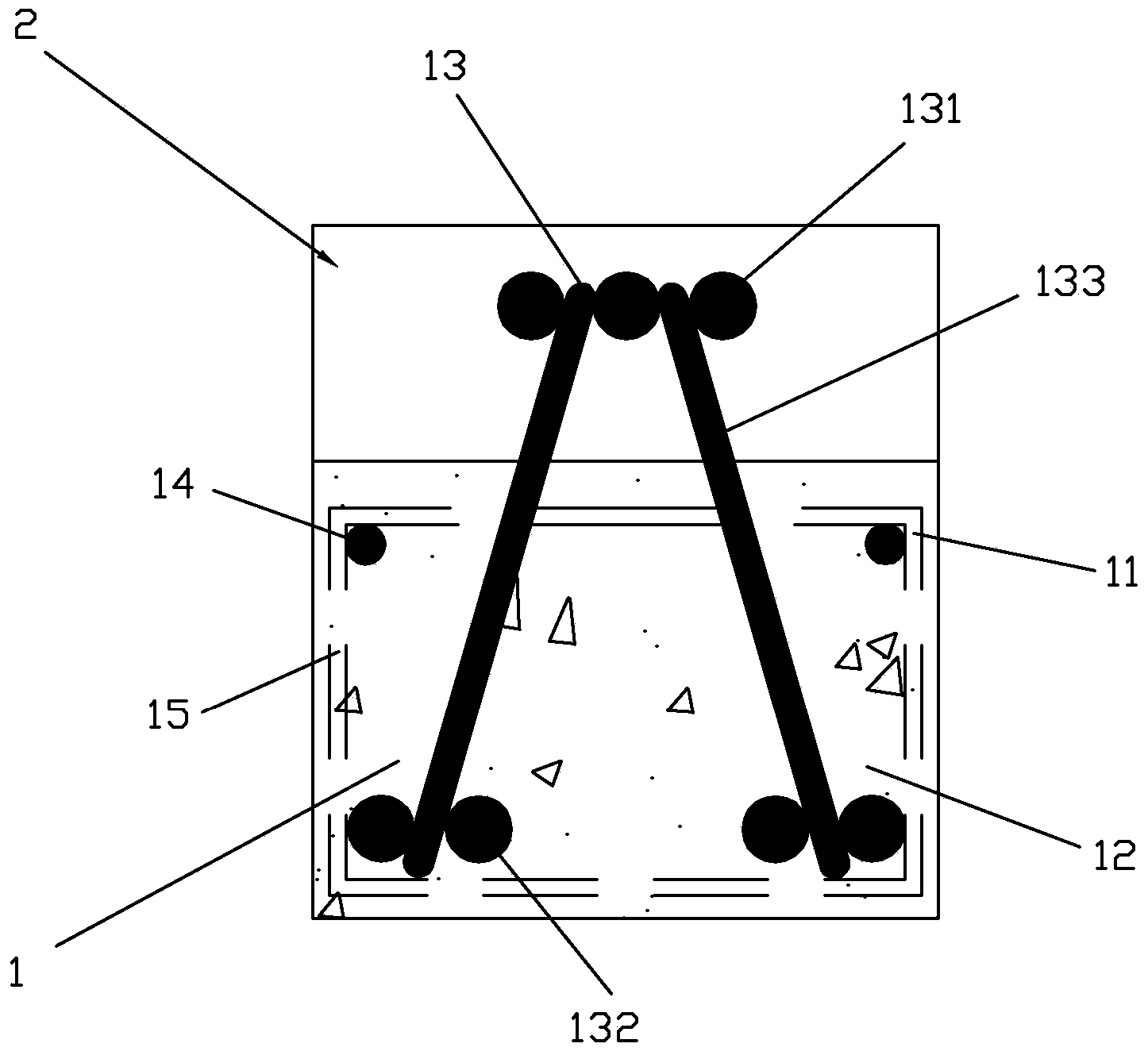

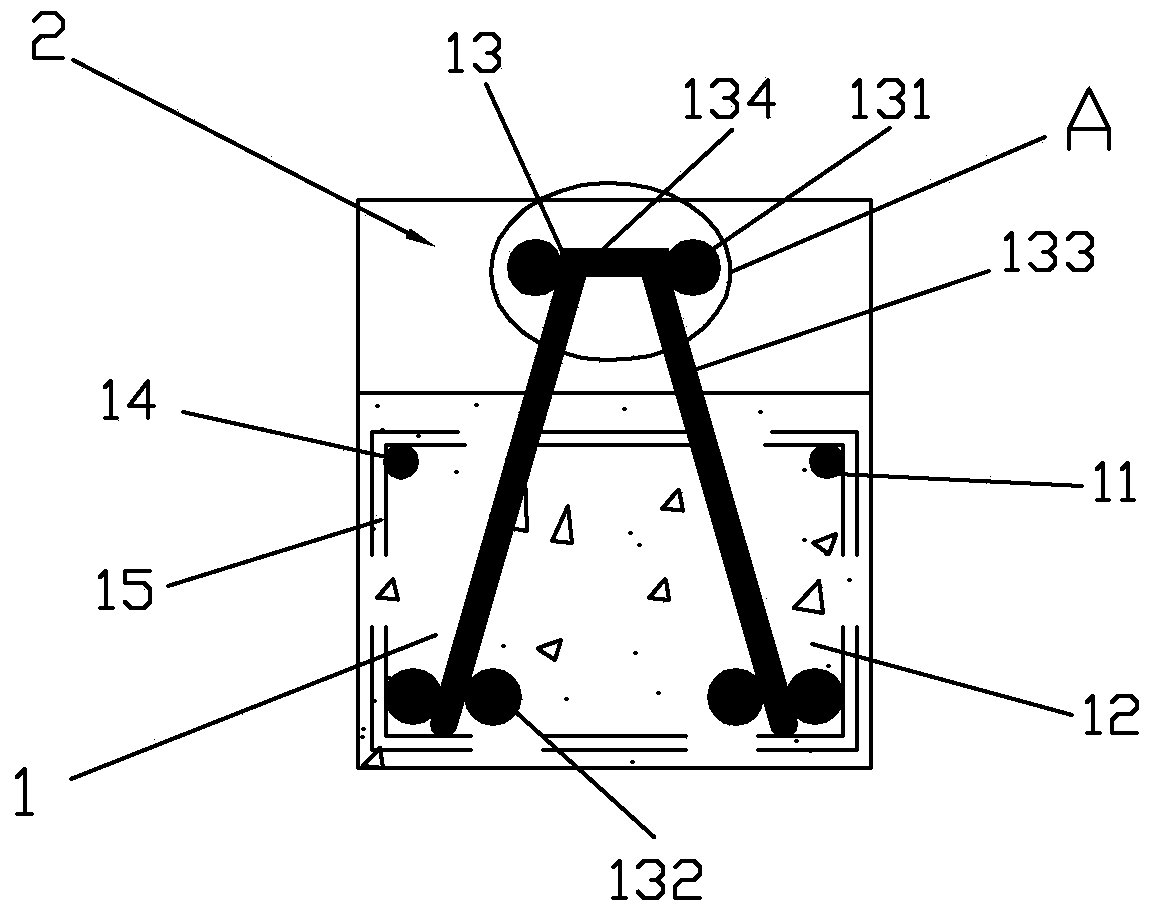

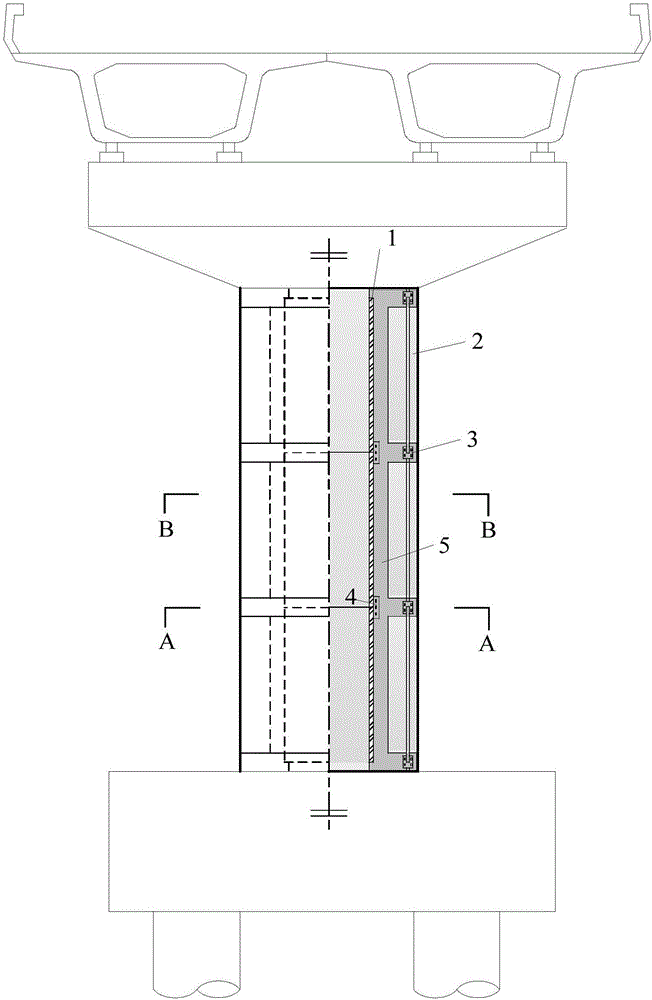

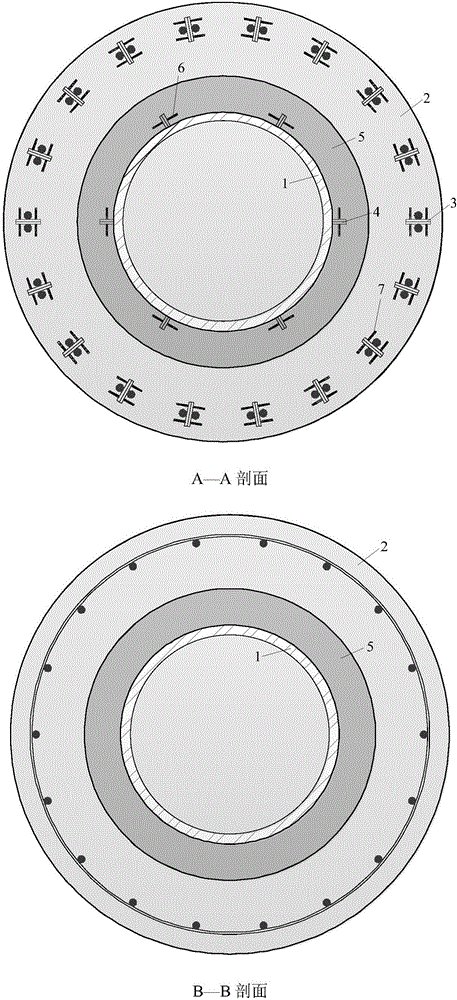

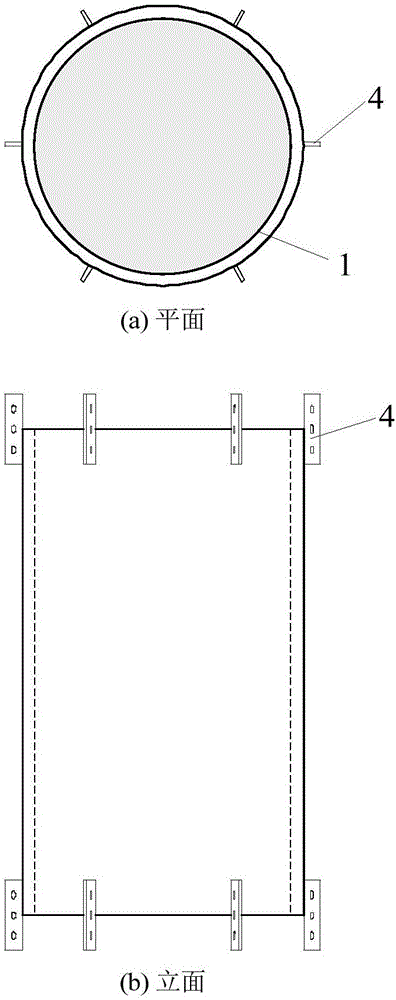

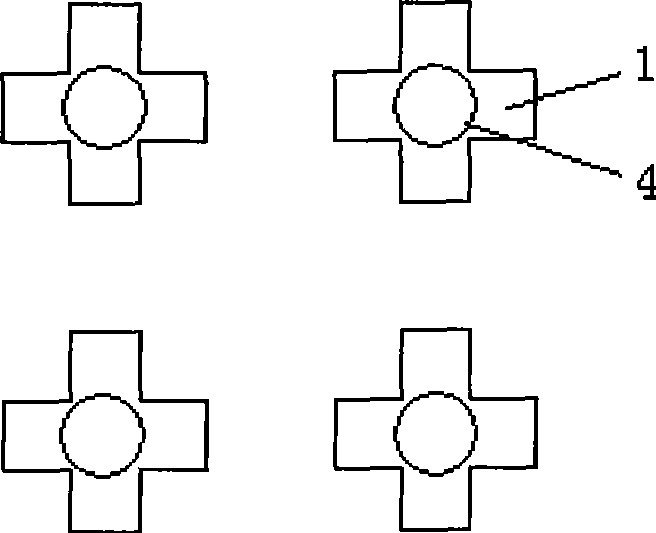

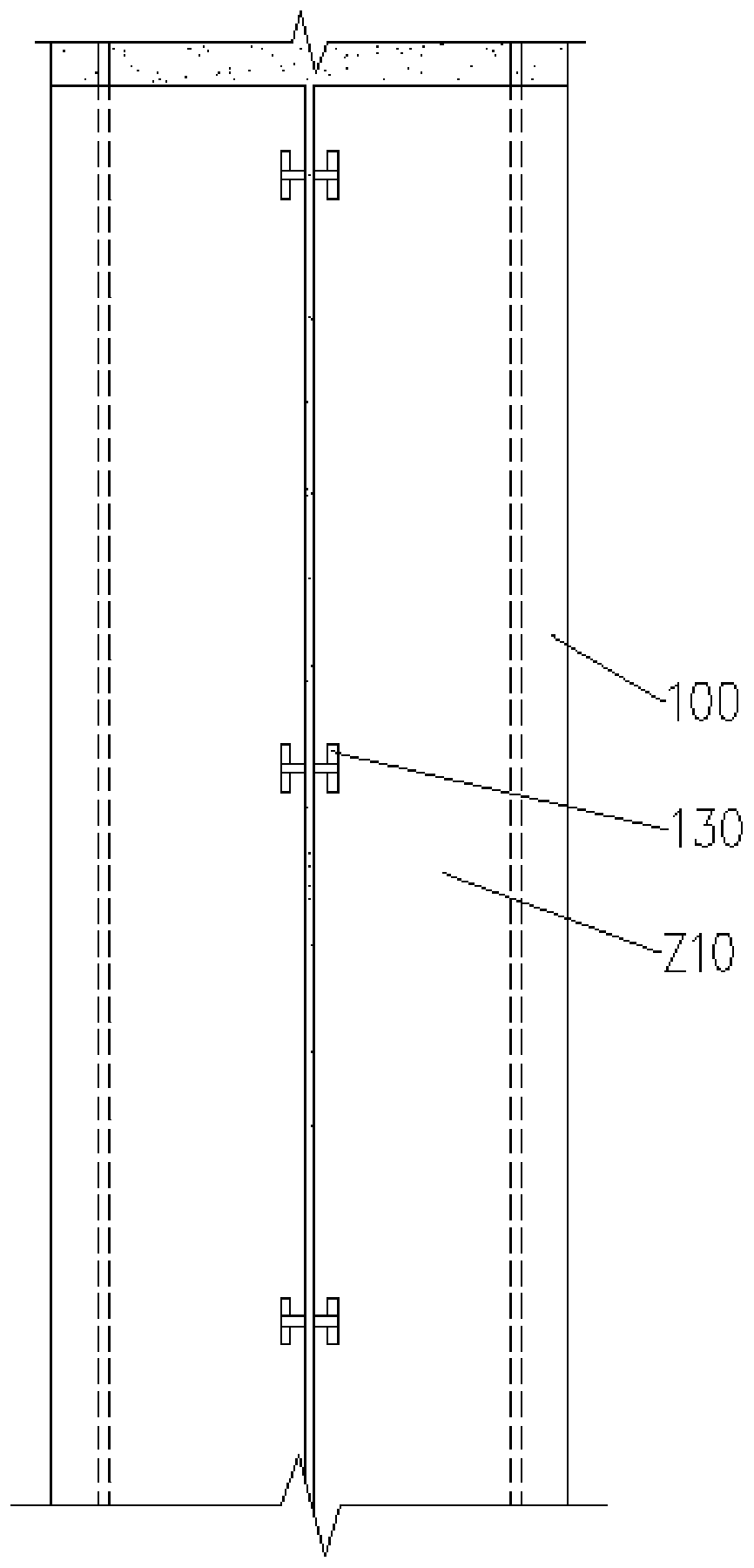

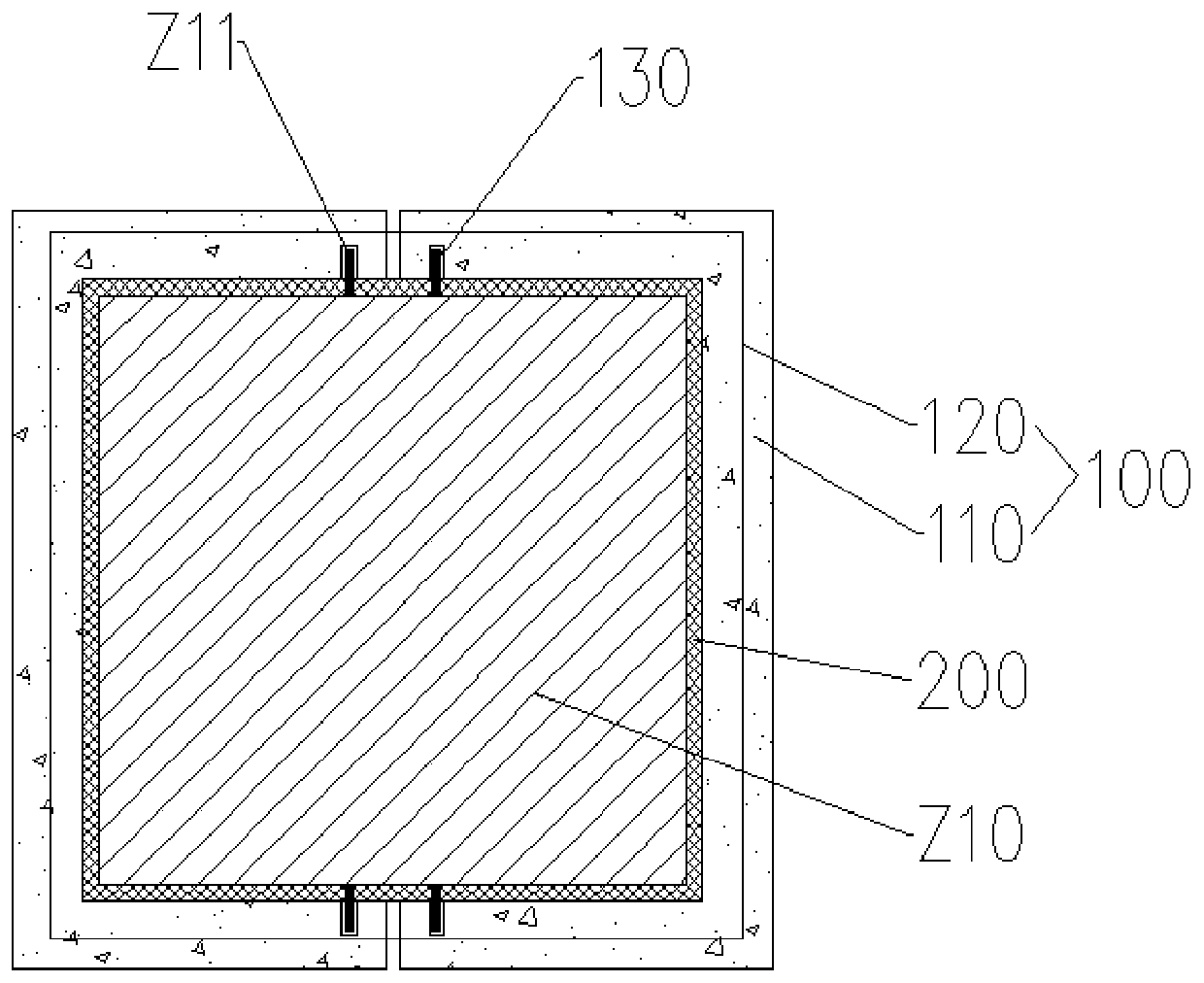

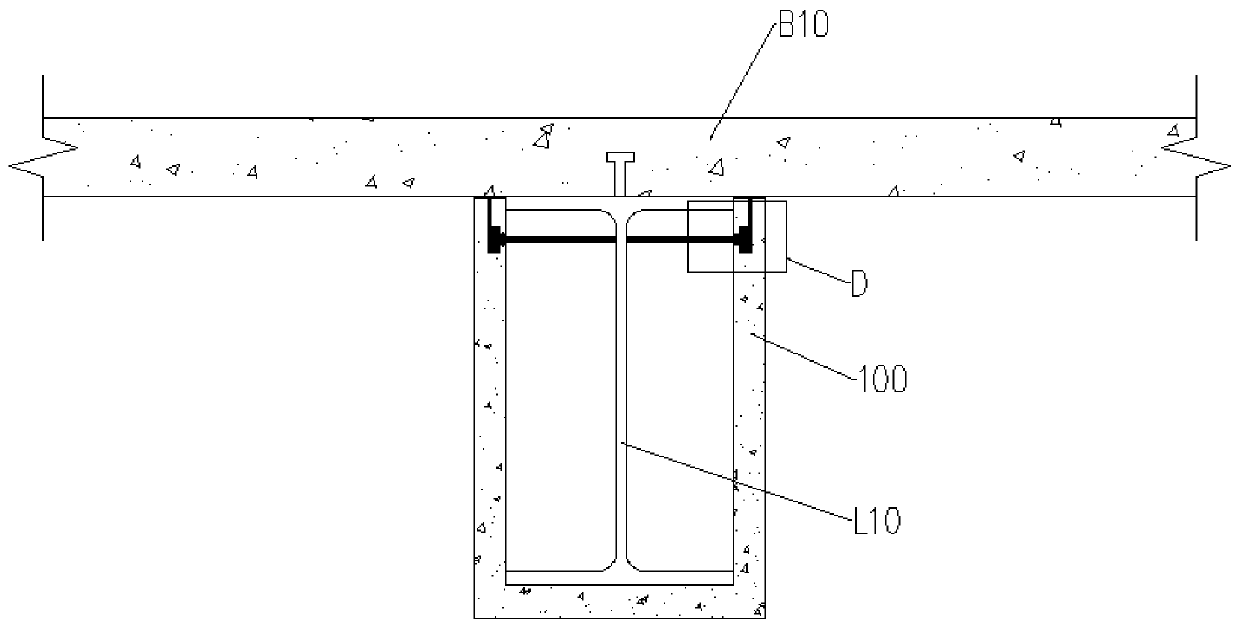

Prefabricated concrete-filled steel tube overlapped pier

InactiveCN106320165AImprove fire resistanceImprove corrosion resistanceBridge structural detailsBridge engineeringConstant load

The invention relates to a prefabricated concrete-filled steel tube overlapped pier and belongs to the technical field of bridge engineering. The prefabricated concrete-filled steel tube overlapped pier comprises a prefabricated concrete-filled steel tube column, a prefabricated concrete-filled steel tube sleeve, rebar connecting parts, steel tube connecting parts, a concrete post-cast strip, short rebars in the steel tube connecting parts, and short rebars in the rebar connecting parts. The prefabricated concrete-filled steel tube sleeve is installed outside the prefabricated concrete-filled steel tube column. The prefabricated concrete-filled steel tube column bears main constant loads of the upper structure after being connected. Self-compaction micro-expansion concrete is poured into the concrete post-cast strip. The prefabricated concrete-filled steel tube overlapped pier can be used for steel-concrete composite structure bridge systems of urban viaducts, expressway viaducts and high-speed railway viaducts, has the advantages of being high in bearing capacity and excellent in anticorrosion capacity, can improve the capacity of resisting rare occurrence earthquakes by a bridge and durability, is high in construction speed and low in influence on traffic, and has wide engineering application prospects.

Owner:CHONGQING UNIV

Building combined type foundation, collar beam and combined frame composed of foundation and collar beam

InactiveCN101498132AHighlight superiorityShort construction periodFoundation engineeringBuilding constructionsFloor slabArchitectural engineering

The invention discloses a combined type base of a building, a ring beam and a combined type shell frame formed by the bases and the ring beams. Each part is a concrete prefab standard element. When a house is built, the prefab standard elements only need to be carried to a jobsite and can be assembled into the shell frame according to the building requirements of the house. In the course of the assembly of the shell frame, the invention has no wet construction, and the labor intensity of an operator is low. More importantly, the construction period is greatly shortened. If a prefab lamella cast-in-situ superimposed hollow floor in a patent application submitted by the inventor previously is used, the wet construction in the course for building the house can be lowered to be the lowest, the construction period can be lowered to be the shortest, and especially when serious disasters and accidents happen, the house with the combined type shell frame structure has more outstanding advantages.

Owner:从卫民 +1

Spliced joint of prefabricated concrete shear walls and construction method thereof

InactiveCN108457401AReduce wet work loadImprove assembly rate and construction speedWallsSteel platesEngineering

The invention belongs to the field of prefabricated building structures, and particularly relates to a spliced joint of prefabricated concrete shear walls and a construction method thereof. The spliced joint comprises a prefabricated concrete wall body and a double-layer reinforcing mesh arranged in the prefabricated concrete wall body; and splicing steel plates used for connecting an upper prefabricated concrete shear wall and a lower prefabricated concrete shear wall are pre-buried in the upper end and the lower end of the prefabricated concrete wall body and extend out of the prefabricatedconcrete shear walls to be arranged. According to the spliced joint and the construction method thereof, the prefabricated concrete shear walls connected by adopting the steel plates are manufacturedin a workshop, the upper shear wall and the lower shear wall can be spliced on site just in a bolted connection mode or a welded mode, the advantage that steel structures are convenient to connect andthe advantage of the strength of concrete are well combined, and therefore the traditional site wet construction amount can be greatly decreased, the defect that site construction is difficult due tothe fact that the prefabricated concrete shear walls are connected by adopting a grouting sleeve can be overcome, the prefabrication rate and the construction speed can be increased, and the splicedjoint and the construction method thereof are particularly suitable for prefabricated buildings.

Owner:SHANDONG ZHONGTONG STEEL STRUCTURE ENG

Fabricating method of upper and lower self-insulation outer walls and floor slab

The invention provides a fabricating method of upper and lower self-insulation outer walls and a floor slab. The fabricating method comprises the following steps that S1, shear walls and the floor slab are prefabricated; S2, hoisting and installing are carried out, specifically, a first shear wall is hoisted and positioned, the floor slab is hoisted and is arranged at one end of the top side the first shear wall, a second shear wall is hoisted and is arranged on the top side of the first shear wall, the inner face of the bottom side of a heat preservation layer of the second shear wall is tightly attached to the upper wall of a load-bearing layer of the first shear wall, the bottom side of a load-bearing layer of the second shear wall is arranged on the top side of the floor slab, a cavityis formed by the floor slab, the load-bearing layer of the fist shear wall, the load-bearing layer of the second shear wall and the bottom side of the heat preservation layer of the second shear wall, and longitudinal steel bars, tie bars and anchoring parts are ingeniously arranged in different modes; and S3, pouring and connecting are carried out, specifically, concrete is poured in the cavityto form a self-insulation double-overlapping post-pouring connecting beam or a double-anchoring horizontal post-pouring strip, and the floor slab, the first shear wall and the second shear wall are connected into a whole. On-site construction quantity of the fabricated joint is little, the manufacturing cost is low, the construction period is saved, and integrality and anti-shock strength of a building are improved.

Owner:绿建科技集团新型建材高技术有限公司

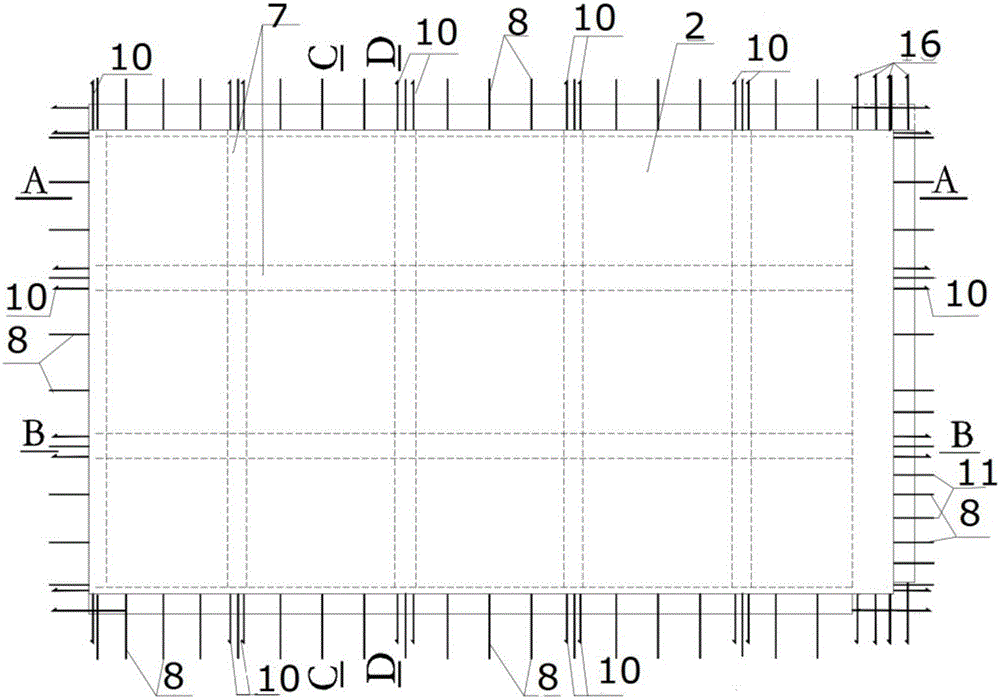

Improved hidden beam type connection full-prefabricated slab structure and manufacturing and assembling method

PendingCN109577533AReduce wet work loadEasy to assemble on siteFloorsCeramic shaping plantsFloor slabEngineering

Owner:SHENYANG JIANZHU UNIVERSITY

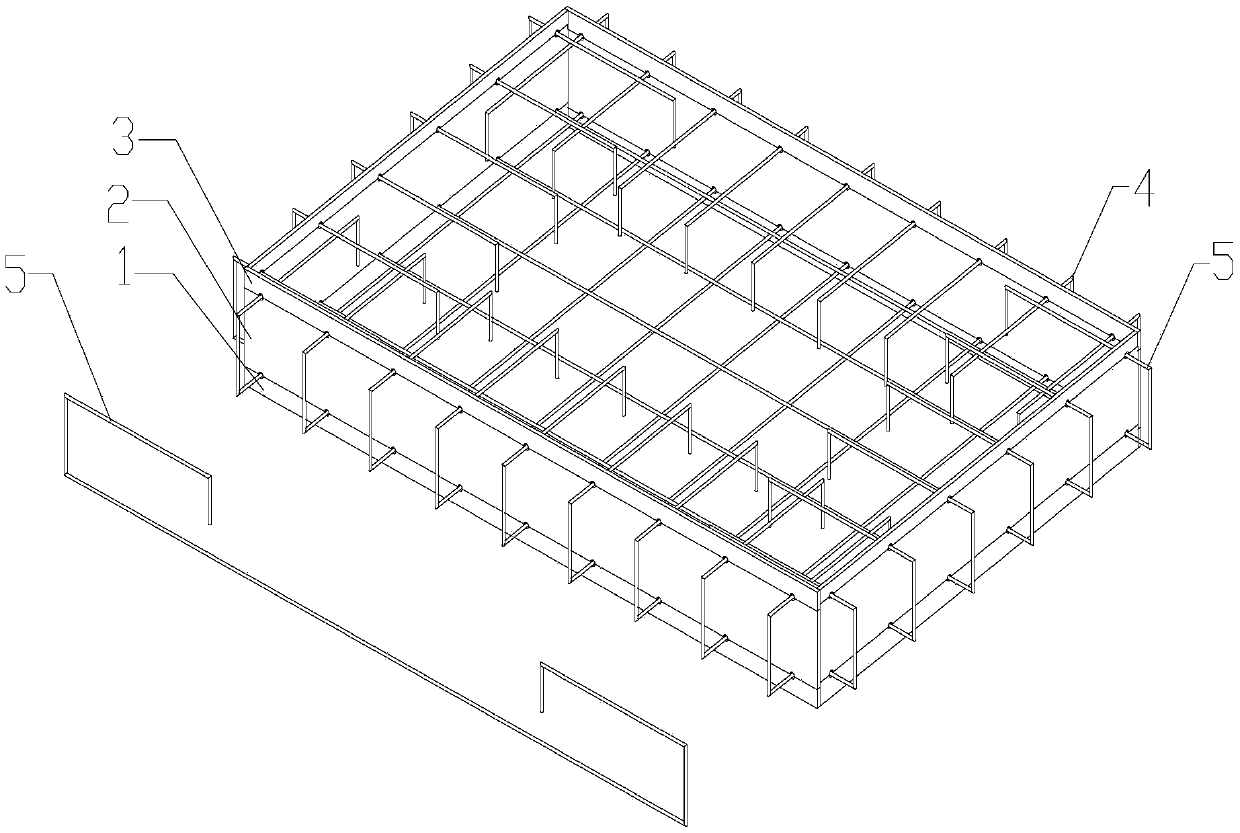

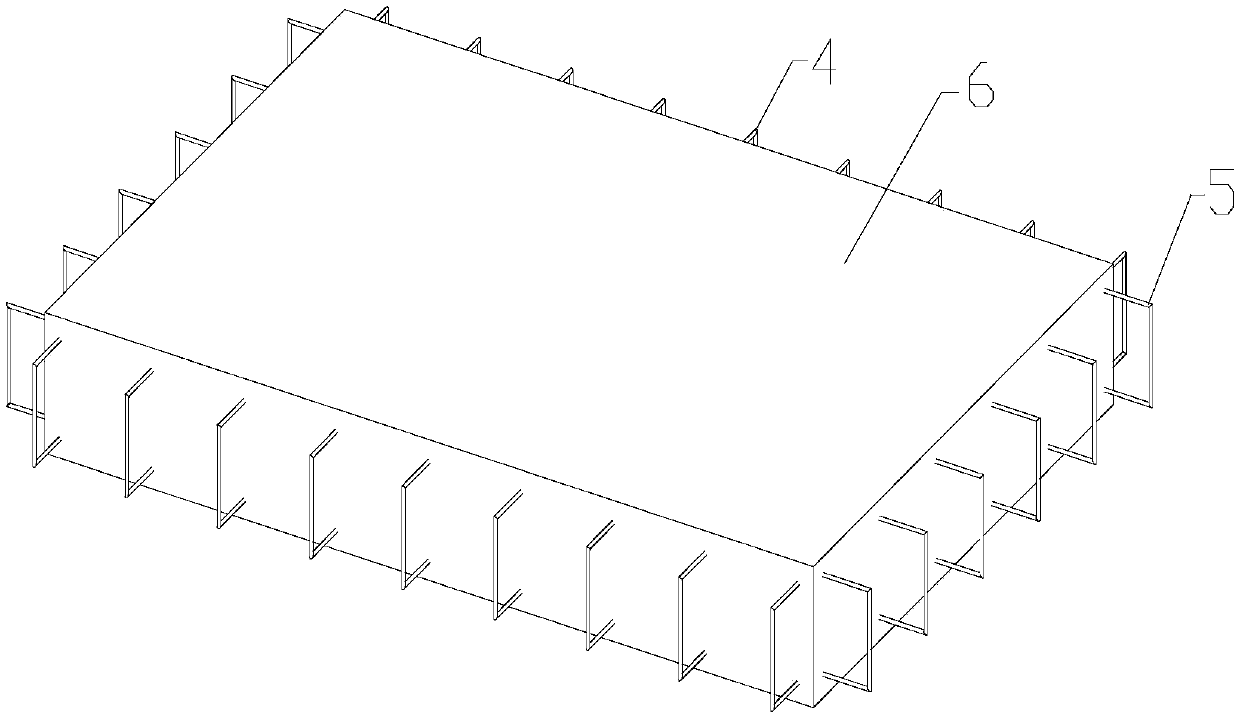

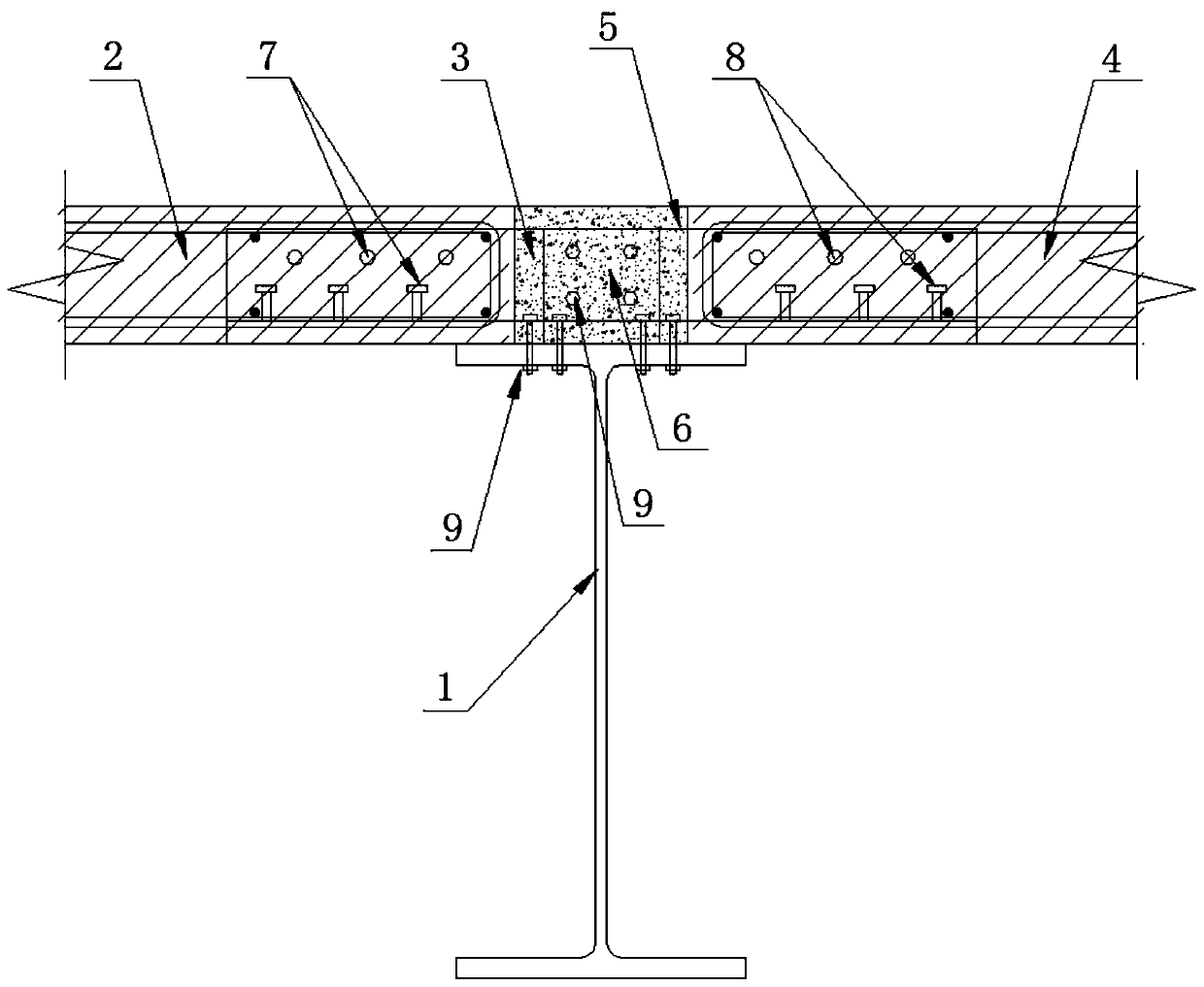

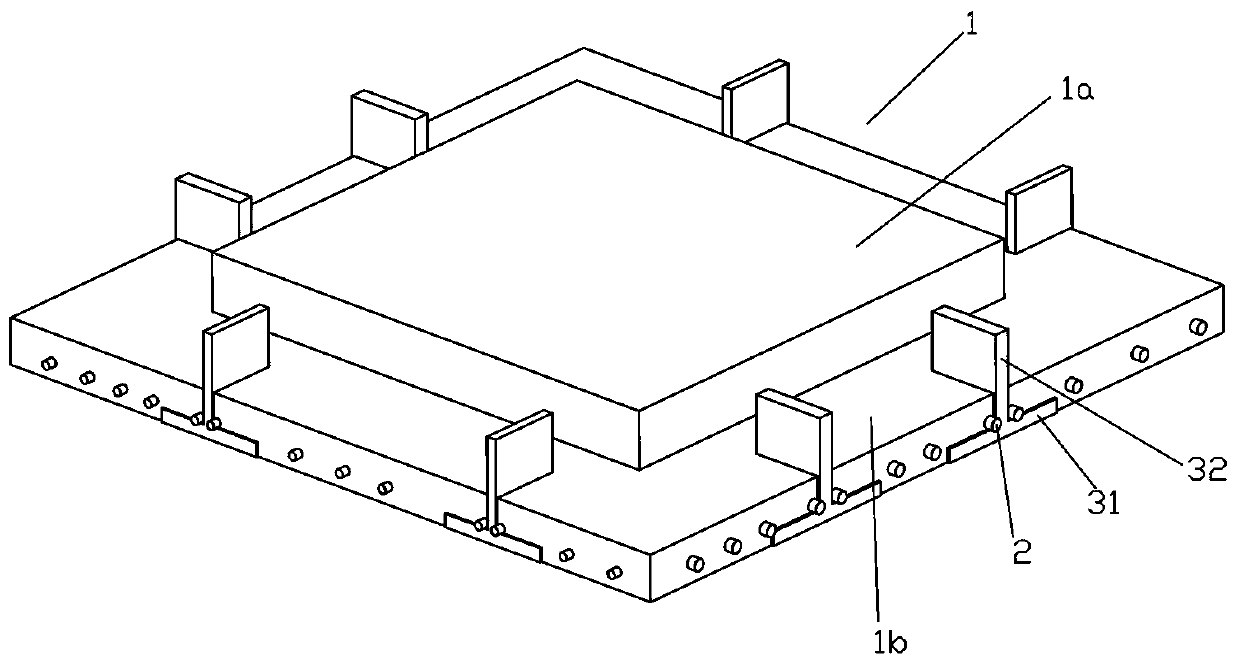

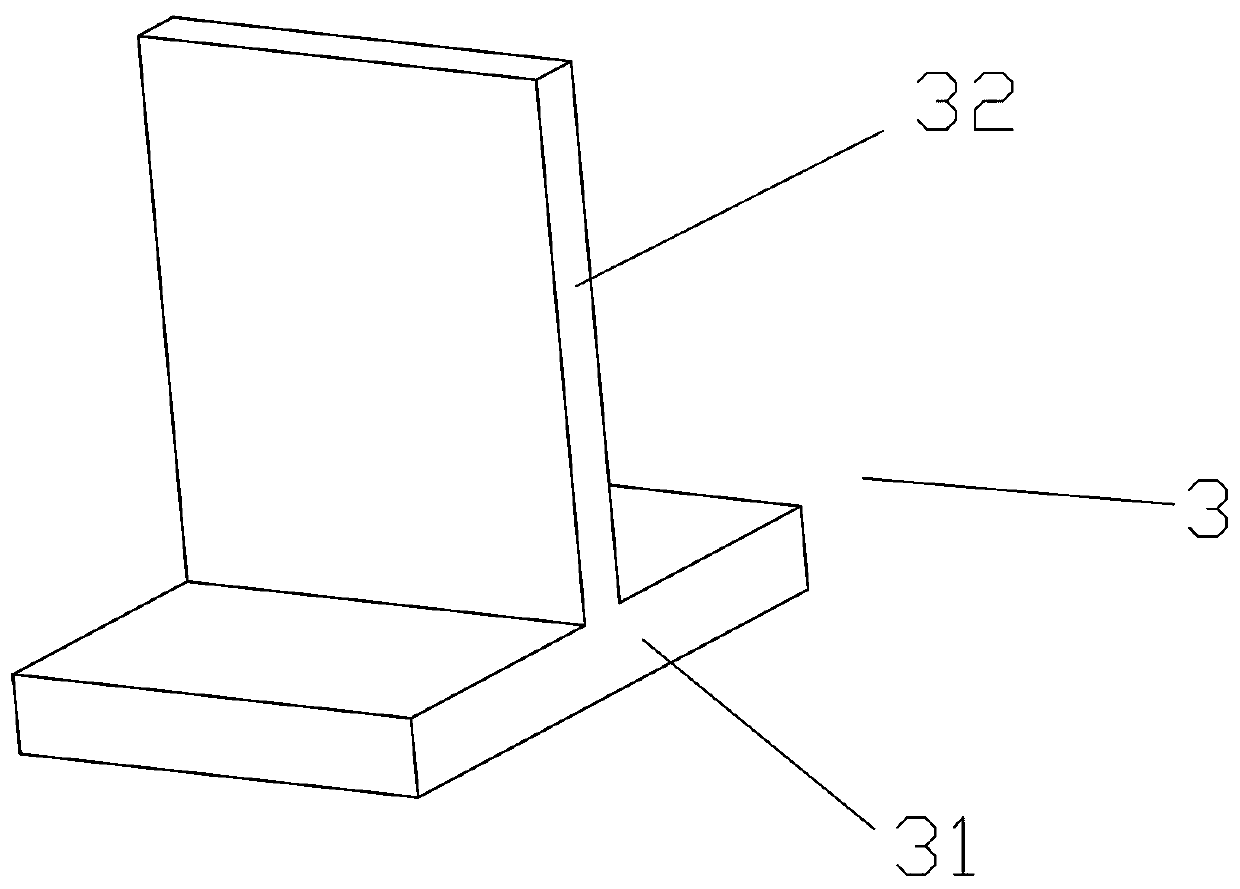

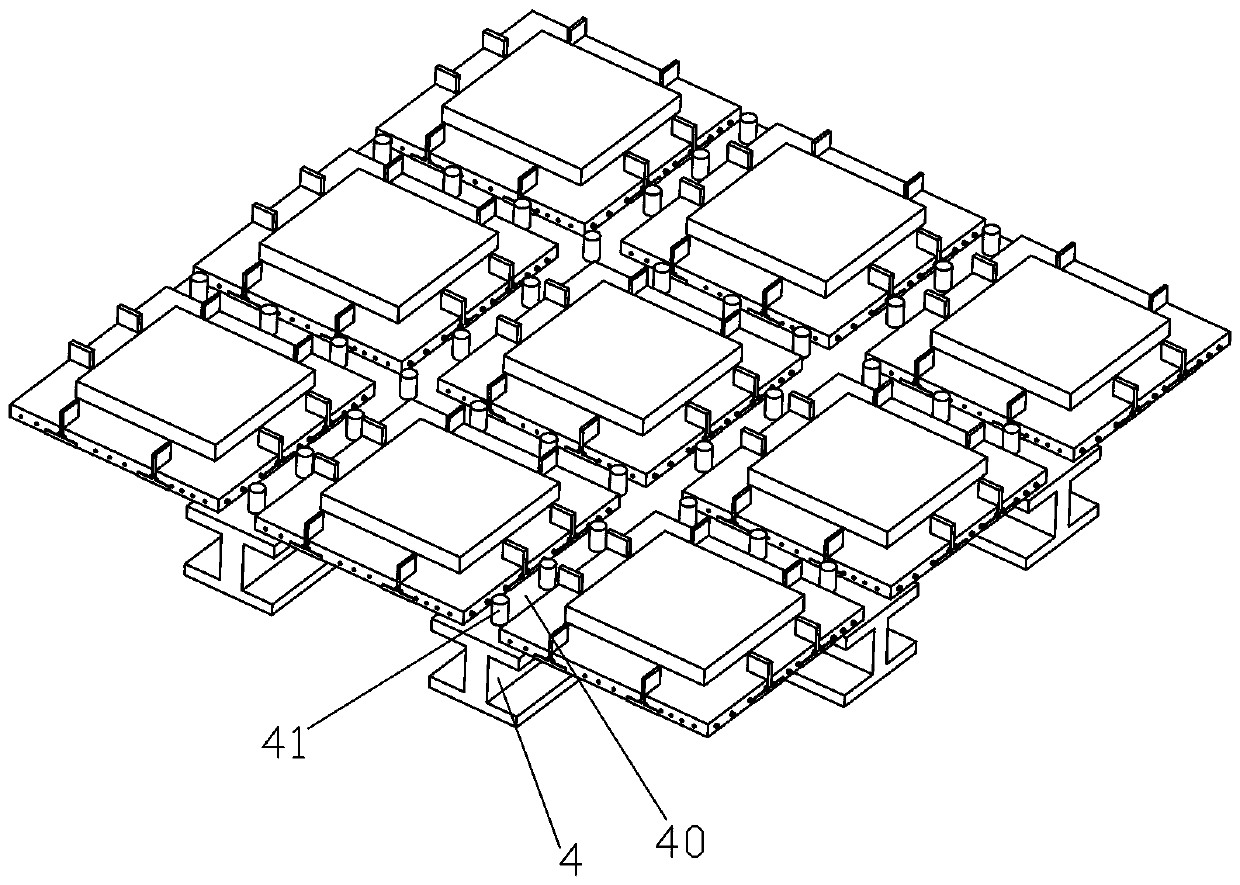

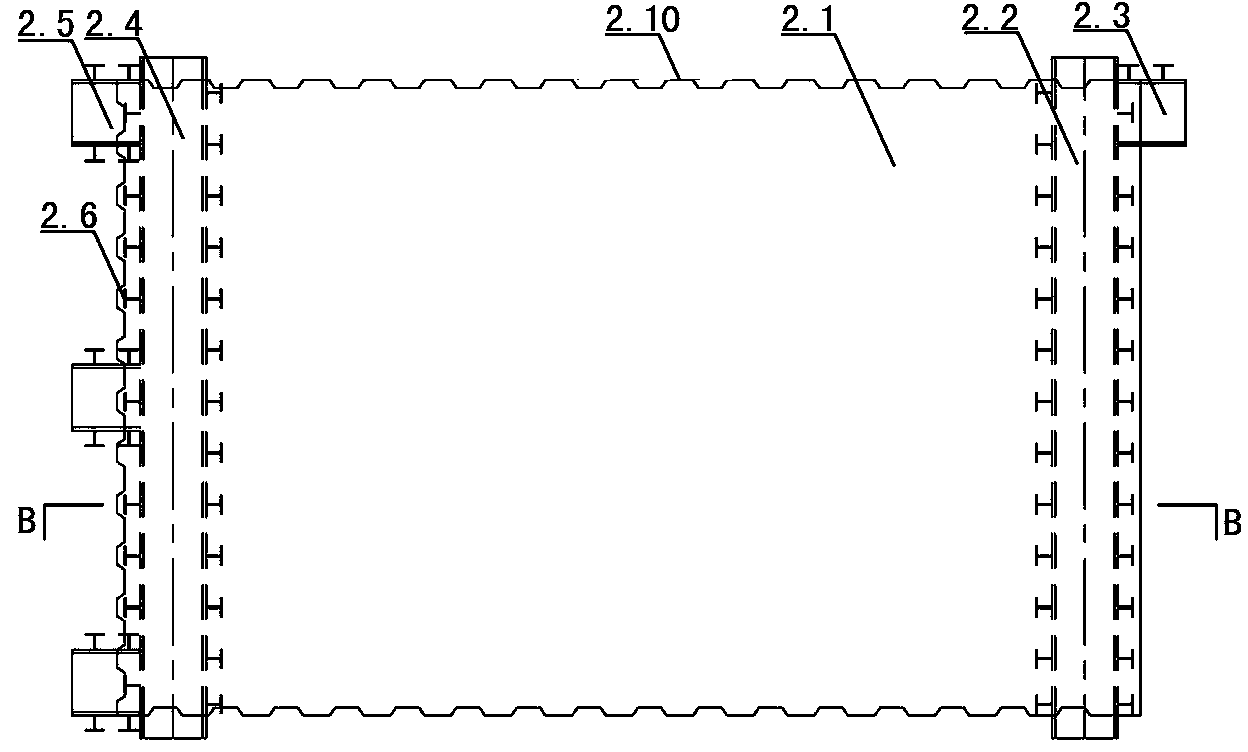

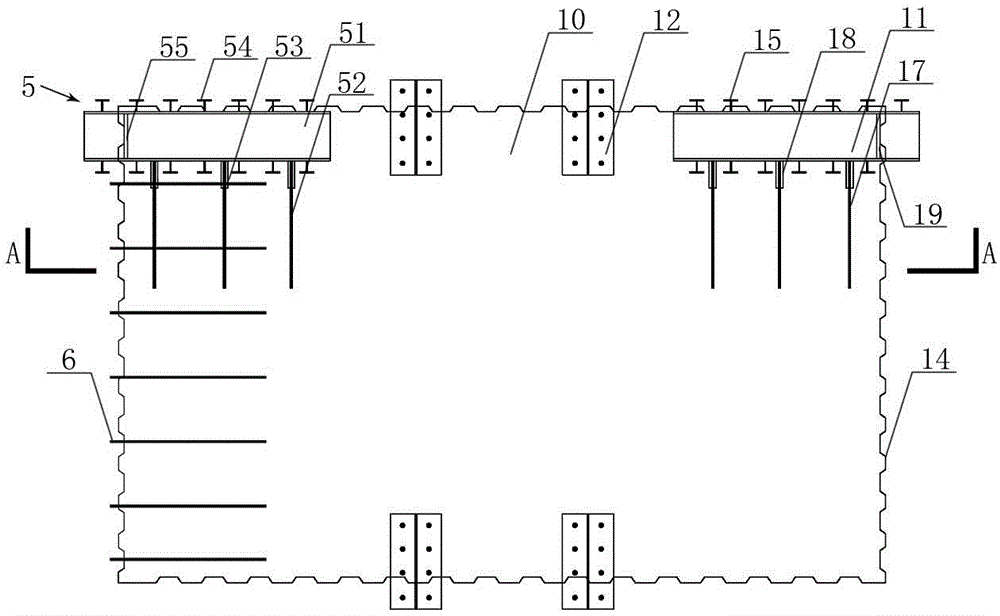

Steel structure support-free fully-prefabricated concrete floor slab connecting joint and connecting method

The invention discloses a steel structure support-free fully-prefabricated concrete floor slab connecting joint and a connecting method, and solves the technical problem that in the prior art, the overall construction progress is influenced by low construction efficiency caused by large wet construction amount during steel structure house floor slab construction. The connecting joint comprises a steel beam, a first span concrete prefabricated slab, a first connecting piece, a second span concrete prefabricated slab, a second connecting piece and a filling structure. The connecting method mainly comprises the steps that the angle steel is anchored to the ends of the concrete prefabricated slabs, the ends of the concrete prefabricated slabs are directly connected to the steel beam in a lap joint mode, the angle steel is connected through bolts, the angle steel is connected with the steel beam through bolts, and finally micro-expansion fine aggregate concrete is densely poured on an upperwing plate of the steel beam. The connecting joint is simple in structure, scientific and reasonable in design and convenient to use, and the fully-prefabricated floor slabs are stably connected in the steel structure, so that the wet work amount during steel structure house floor slab construction is reduced, the overall construction efficiency is improved, and the construction progress is guaranteed.

Owner:CHINA MCC5 GROUP CORP

Steel structure fireproof structure and building comprising same

PendingCN111173154AReduce weightReasonable forceBuilding insulationsFire proofingUltimate tensile strengthFire prevention

The invention provides a steel structure fireproof structure and a building comprising the same. The steel structure fireproof structure comprises a steel structure part and an anti-corrosion and fireproof protective shell; the anti-corrosion and fireproof protective shell is a prefabricated part made of mortar emulsion and a nanometer material additive, and a reinforcing framework used for enhancing the strength and rigidity of the anti-corrosion and fireproof protective shell and preventing the anti-corrosion and fireproof protective shell from cracking is arranged in the prefabricated part;and the anti-corrosion and fireproof protective shell wraps the steel structural part and is used for corrosion prevention and fire prevention of the steel structural part. The steel structure fireproof structure has the advantages of being high in standardization degree, high in construction efficiency, easy and convenient in connection, good in anti-corrosion and fireproof performance, high indurability, wide in application range, good in economical efficiency and the like, and has good application prospects in steel structure engineering.

Owner:SHENZHEN YJY BUILDING TECH +2

Structure of fully prefabricated one-way plate with splicing grooves and manufacturing and assembling method of structure of fully prefabricated one-way plate with splicing grooves

ActiveCN107905424AReduce wet work loadImprove assembly rateConstruction materialMouldsClassical mechanicsEngineering

Owner:深圳市正大建业建筑工程有限公司

Structure of steel-concrete combined structural aqueduct and construction method thereof

ActiveCN110725282AAvoid crackingTransverse tensile stress peak reductionArtificial water canalsSheet steelPre stress

The invention relates to a structure of a steel-concrete combined structural aqueduct and a construction method thereof, and belongs to the technical field of building structures. The steel-concrete combined structural aqueduct comprises an upper concrete groove body, a groove body top steel pull rod and a lower steel beam, wherein the upper concrete groove body adopts a rectangular or U-shaped cross section, and the lower steel beam is arranged along the longitudinal through length of the groove body, and is connected with the upper concrete groove body through a connecting piece to form a whole; the side wall of the groove body is reinforced through the mode that a variable cross section is adopted, an L-shaped thin steel plate is pasted on the inner side or prestressed reinforcements are arranged in the vertical direction; and the top of the side wall of the groove body is connected in a pulled mode through adopting the steel pull rod. According to the structure of the steel-concrete combined structural aqueduct, the stress state and the construction detail of a traditional concrete aqueduct are changed, so that the aqueduct does not need to rely on a large amount of prestressedtendons to control concrete cracking, the water conveying safety of the aqueduct is greatly improved, the structure is simple, the construction is convenient, and the economy and the practicability are achieved.

Owner:TSINGHUA UNIV +1

Fully-prefabricated floor and composite floor composite structure and manufacturing and assembly method

The invention relates to the field of prefabricated assembly type concrete structure buildings, in particular to a fully-prefabricated floor and composite floor composite structure and a manufacturingand assembly method. The fully-prefabricated floor and composite floor composite structure and the manufacturing and assembly method are only suitable for the working condition that a floor is a one-way slab. The composite structure is one of the following three structures of (1) a composite structure of the fully-prefabricated concrete one-way slabs and concrete composite floors, (2) a connection structure of the fully-prefabricated floor and composite floor composite structure and a side beam, and (3) a connection structure of the-fully prefabricated floor and composite floor composite structure and a middle beam. The structures all adopt prefabricated concrete one-way slabs which are formed by pouring concrete in template structures. By changing the structures of the fully-prefabricated slab and a composite slab, then the fully-prefabricated one-way slab and the composite slab are alternately composited and assembled together to form a floor, according to the floor, compared with the composite slab, the usage amount of cast-in-place concrete is greatly reduced, and compared with the fully prefabricated slab, the better integrity is achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

Reinforced concrete shear wall with profile steel connecting pieces and soft steel supports and construction method

ActiveCN113502948AQuality controllableGuaranteed compactnessWallsProtective buildings/sheltersReinforced concreteFloor slab

The invention discloses a reinforced concrete shear wall with profile steel connecting pieces and soft steel supports. The reinforced concrete shear wall is composed of a prefabricated frame beam, a prefabricated reinforced concrete shear wall body and a cast-in-place floor slab, profile steel is pre-buried at the two ends of the prefabricated frame beam, double-web profile steel connecting plates are arranged at the tops and the bottoms of edge embedded columns of the prefabricated reinforced concrete shear wall body, the double-web profile steel connecting plates are connected with flanges of the profile steel through high-strength bolts, a soft steel support is connected between the two diagonal double-web profile steel connecting plates, and the two soft steel supports form a cross structure. The invention further provides a construction method of the structure, based on the idea of partial prefabrication and partial cast-in-place, the novel profile steel connecting pieces and the soft steel supports are adopted, the structure has the advantages of being convenient to install and accurate in positioning, the on-site wet construction amount can be reduced, the construction period can be shortened, and the energy dissipation capacity of the shear wall can be enhanced.

Owner:中铁二十局集团市政工程有限公司 +1

Building floor slab and composite floor system

PendingCN110777998AImprove structural strengthBoundary connectivity enhancementsFloorsFloor slabArchitectural engineering

The invention relates to the technical field of building floor slabs, in particular to a building floor slab and a composite floor system. A precast concrete slab is included, bottom steel bars are embedded in the bottom of the precast concrete slab, a plurality of edge reinforcement pieces are embedded on the precast concrete slab, the edge reinforcement pieces and the bottom steel bars are fixed, the edge reinforcement pieces are located at the edge portions of the precast concrete slab, and the boundary connection strength is better.

Owner:ZHEJIANG DADONGWU CONSTR TECH CO LTD

Assembly-type steel beam joint linear mixed coupled wall and construction method thereof

InactiveCN104032858AImprove stabilityReduce wet work loadWallsBuilding material handlingButt weldingConcrete beams

Disclosed are an assembly-type steel beam joint linear mixed coupled wall and a construction method thereof. The assembly-type steel beam joint linear mixed coupled wall comprises a first wall unit and a second wall unit which are connected and are arranged in a linear mode. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type steel beam joint linear mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved and assembly procedures are simplified; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

T-shaped rigid seam coupled wall with pre-embedded seam beam segment, and construction method thereof

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

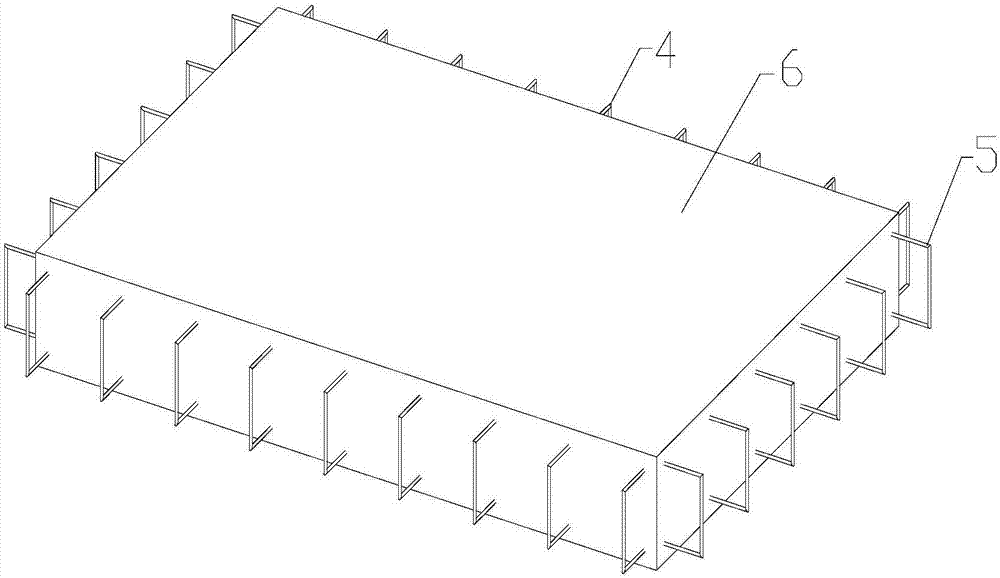

Fabricated integral type concrete pool

PendingCN112983089ASelf-stableResist overturningArtificial islandsProtective foundationArchitectural engineeringWall plate

The invention relates to a fabricated integral type concrete pool which is formed by splicing prefabricated corner wallboards and prefabricated wallboards; the prefabricated corner wallboards are arranged at corners respectively; the prefabricated wallboards are spliced between the adjacent prefabricated corner wallboards; each prefabricated wallboard comprises a vertical side wall plate A and a transverse bottom plate A; the lower side faces of the transverse bottom plates A are provided with anchoring flanges A corresponding to the vertical side wall plates A; each prefabricated corner wallboard comprises an L-shaped vertical side wall plate B and a transverse bottom plate B; the lower side faces of the transverse bottom plates B are provided with two anchoring flanges B; and the anchoring flanges B correspond to two vertical wall surfaces of the vertical side wall plates B respectively. The provided fabricated integral type concrete pool can be suitable for construction of overground pools and buried pools with large plane sizes. The fabricated integral type concrete pool has the advantages that Z-shaped prefabricated wallboards are adopted on the side faces of the pool, so that self-stability is achieved under the action of side face water pressure and soil pressure, and overturning and sliding caused by side pressure can be resisted.

Owner:FCEC PREFABRICATED BUILDING RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com