Building floor slab and composite floor system

A floor and building technology, which is applied in the field of building floors and composite floors, can solve the problems of slow construction progress, large amount of wet work, waste of temporary construction measures, etc., and achieve the effect of good structural strength and improved boundary connection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

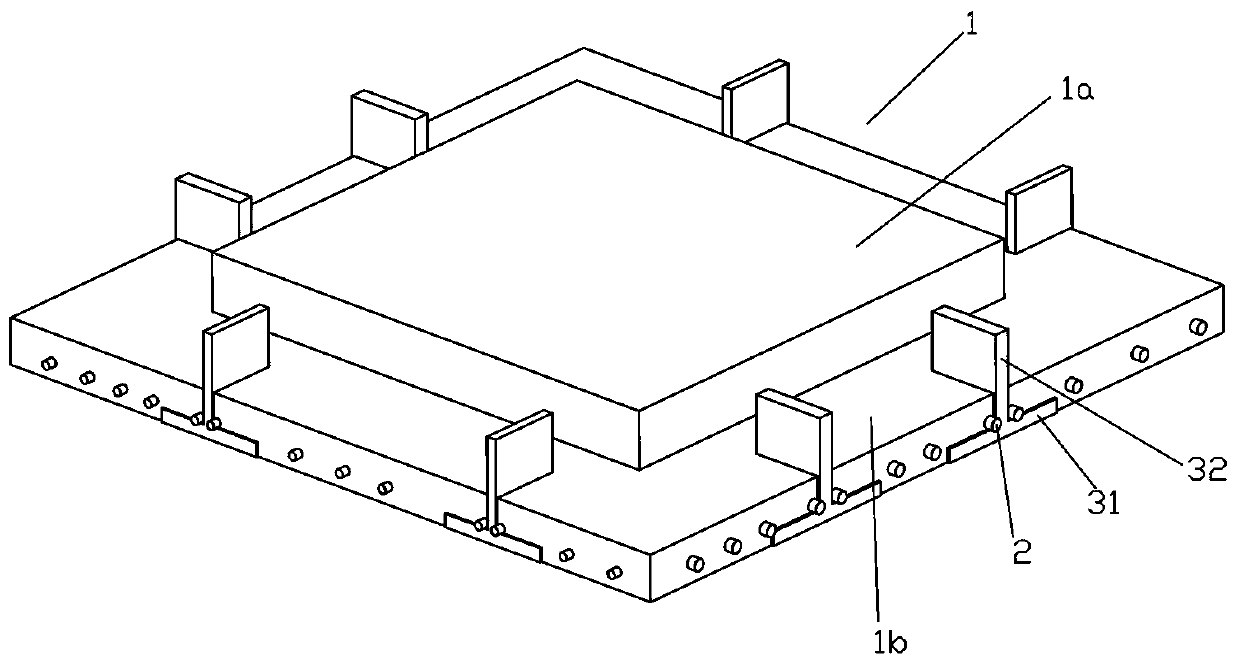

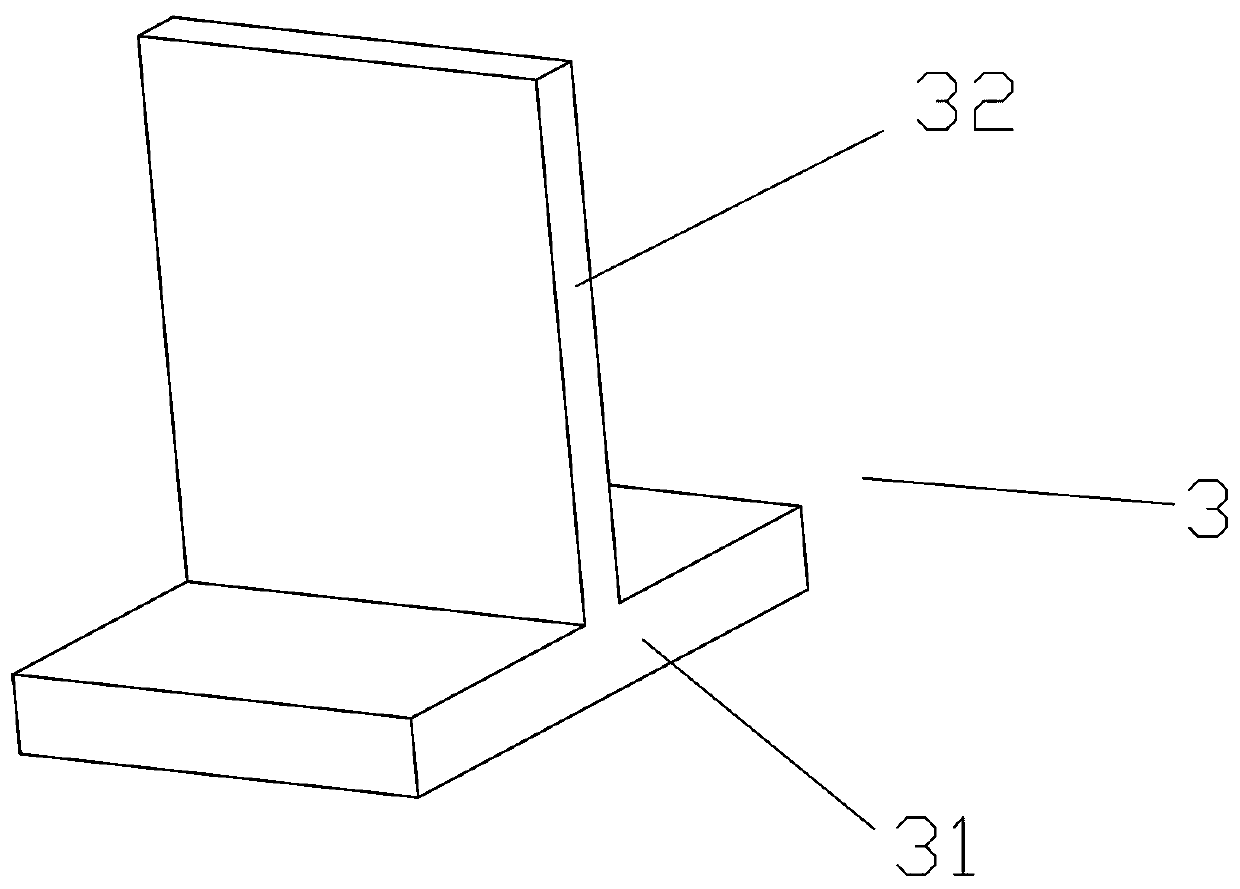

[0025] Example 1, such as figure 1 , 2 As shown, a building floor includes prefabricated concrete slab 1. This kind of prefabricated slab is widely used now. It is a concrete prefabricated part produced and processed in a prefabricated field, which is directly transported to the construction site for installation, so it is called a prefabricated slab. The prefabricated concrete slab 1 here is the prefabricated slab. In addition to the same as the prior art, the present application is formed by pouring concrete, and the steel bars will also be originally arranged during pouring. Therefore, the precast concrete slab 1 is also the basic structure of concrete and steel bars. For example, the above-mentioned The bottom of the precast concrete slab 1 is pre-embedded with bottom steel bars 2. However, the improvement of the present application is that the precast concrete slab 1 is also pre-embedded with several steel bars 2 fixed to the bottom and located at the edge of the precast ...

Embodiment 2

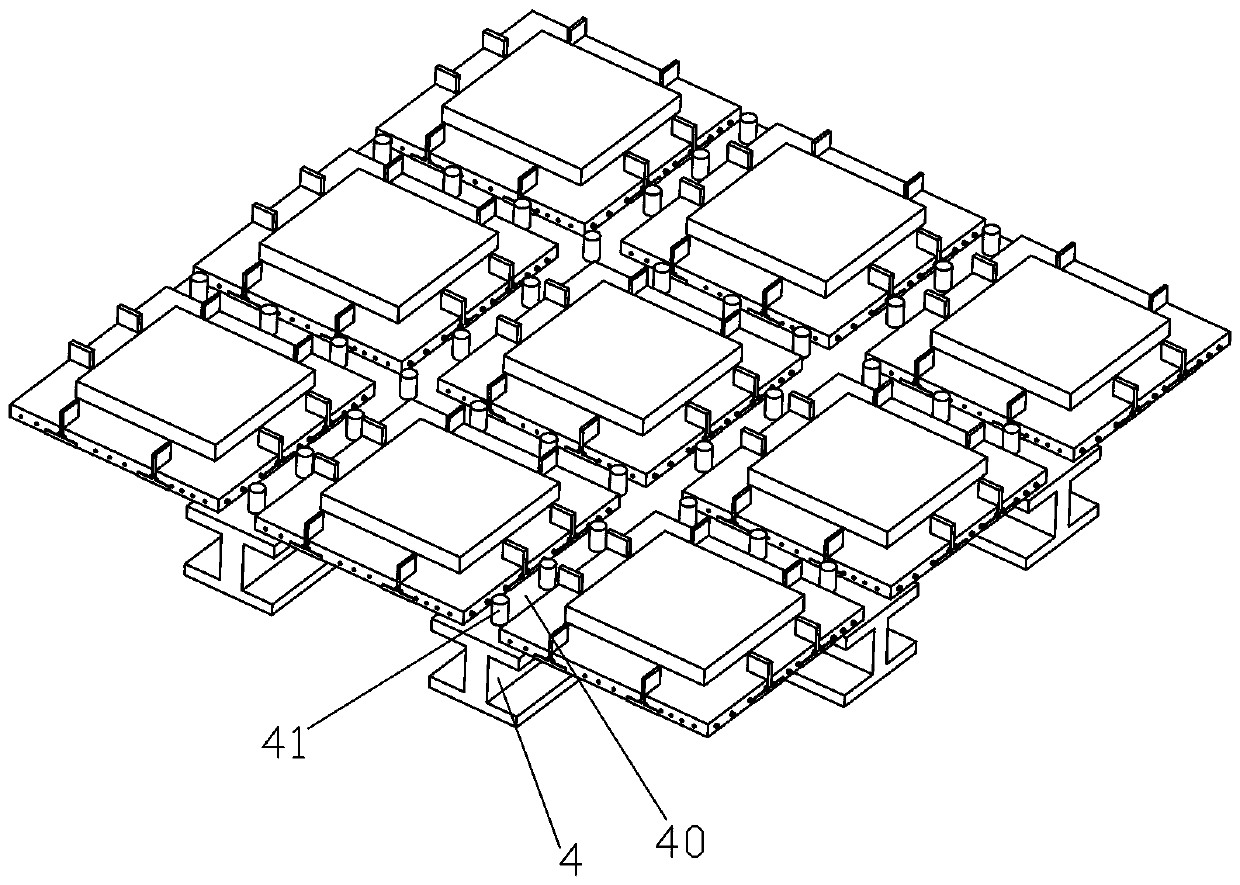

[0031] Example 2, such as image 3 , 4 , 5 and 6, a combined floor, the floor of this embodiment will be applied to the building floor in embodiment 1, this floor includes steel beam 4, and steel beam 4 can adopt existing cross steel Beam structure, the steel beam 4 is laid with a number of building floors in Embodiment 1, which can be further preferably arranged in a rectangular array, and adjacent building floors are arranged at intervals and space 40 is left, and the space between 40 is located above the beam body of the cross steel beam 4, and cast-in-place concrete c that can fill the respective low-level drop grooves 1c and the space 40 is poured between adjacent building floors, and the cast-in-place concrete c connects the adjacent building floors The interval space 40 between them has been connected and filled with the low-level drop groove 1c on the respective building floors, and the top surface of the cast-in-place concrete c should be equal to the height of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com