Reinforced concrete shear wall with profile steel connecting pieces and soft steel supports and construction method

A reinforced concrete and shear wall technology, applied to walls, building types, building components, etc., can solve the problems of high labor costs, easy generation of large construction waste and dust, and long construction period, so as to achieve convenient construction and ensure structural coordination Work performance and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

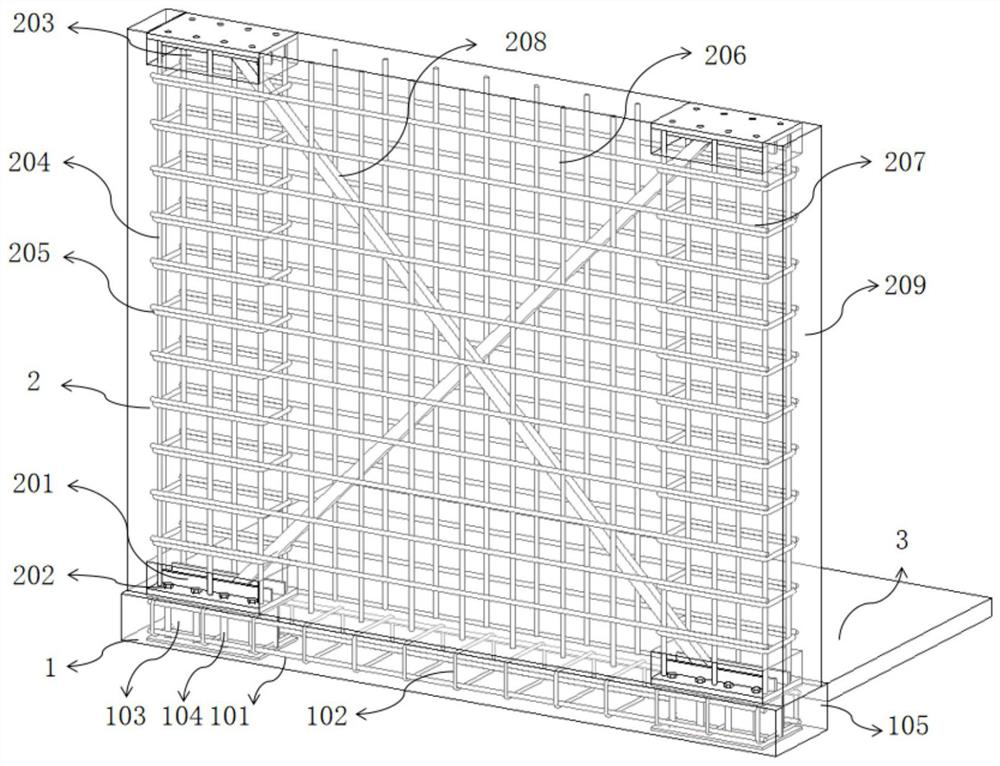

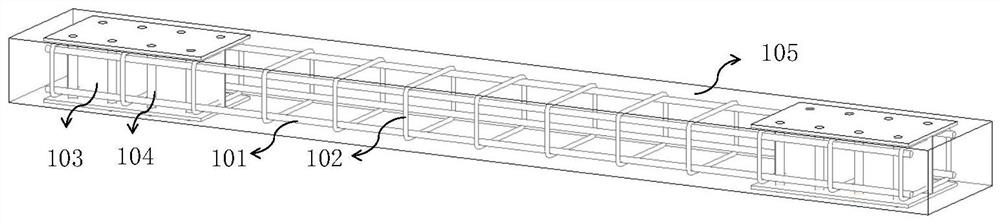

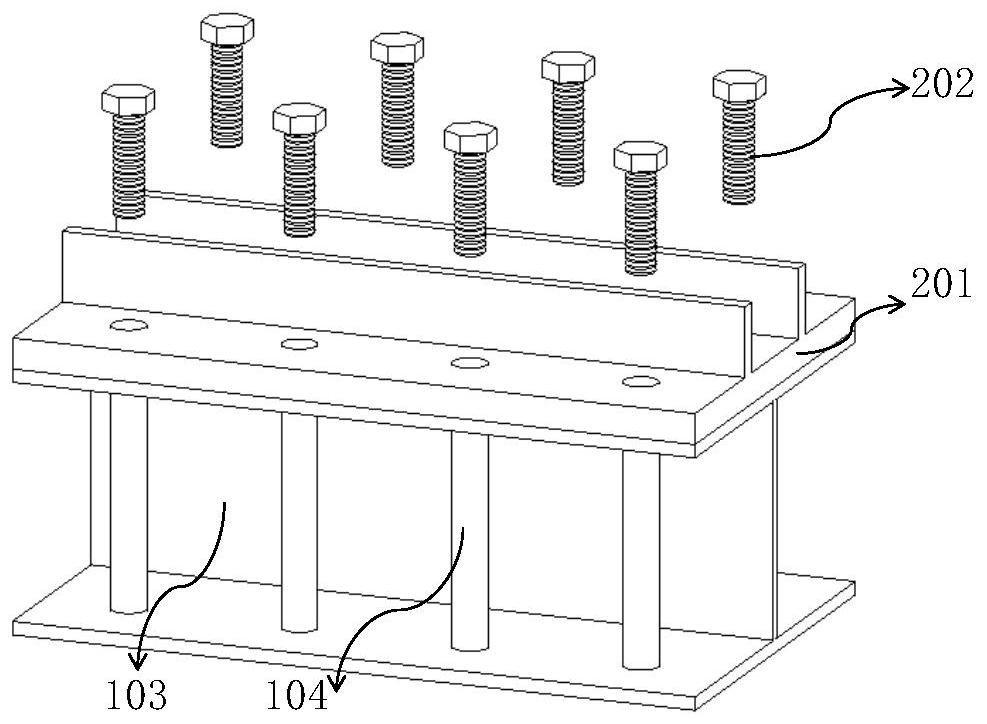

[0033] Such as figure 1 As shown, a reinforced concrete shear wall with steel connectors and soft steel supports is composed of three parts: prefabricated frame beam 1, prefabricated reinforced concrete shear wall 2 and cast-in-place floor 3. Prefabricated frame beam 1 and prefabricated reinforced concrete The shear wall 2 is a prefabricated part. Both ends of the prefabricated frame beam 1 are pre-embedded with section steel 103 , and the top and bottom of the edge concealed column of the prefabricated reinforced concrete shear wall 2 are provided with double-web section steel connecting plates 201 . The double-belly shaped steel connecting plate 201 is connected to the flange of the shaped steel 103 through high-strength bolts 202, and a mild steel support 208 is connected between the two diagonally double-belly shaped steel connecting plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com