Patents

Literature

335results about How to "Accurate installation and positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

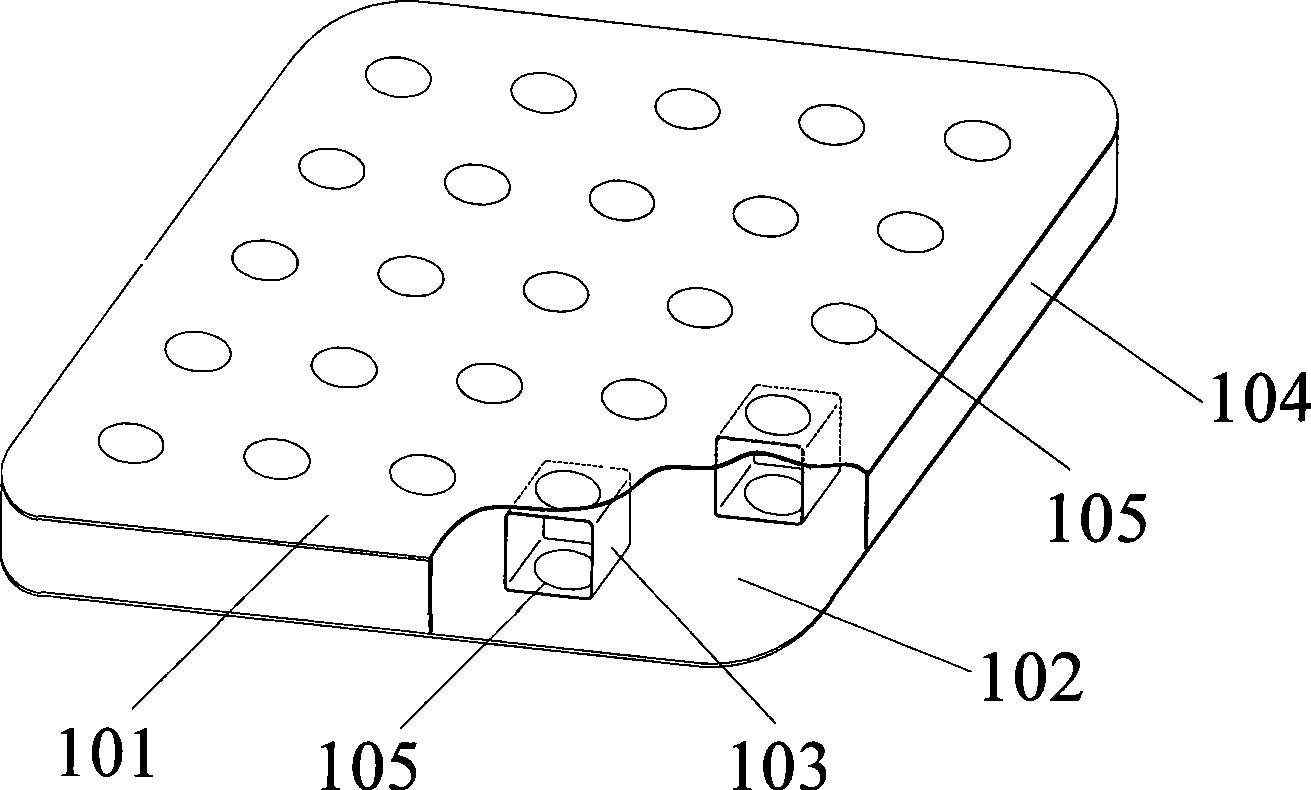

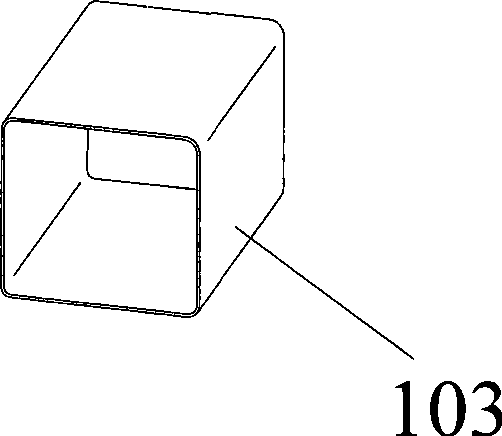

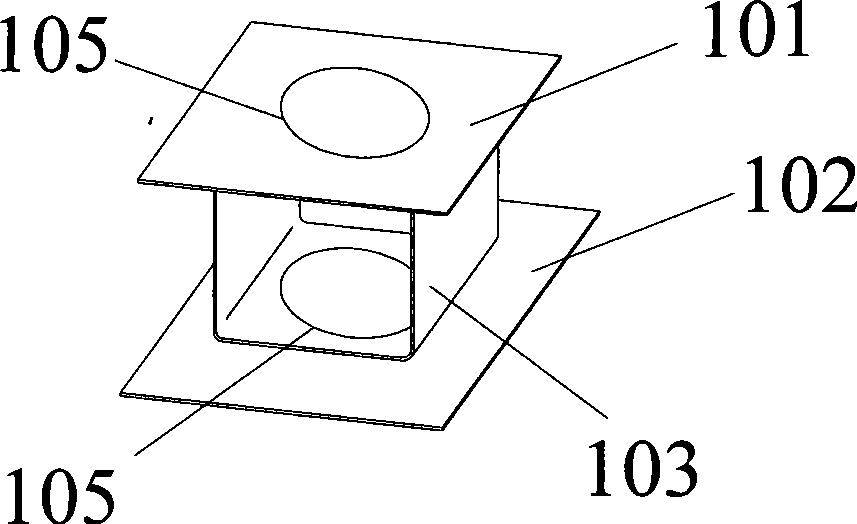

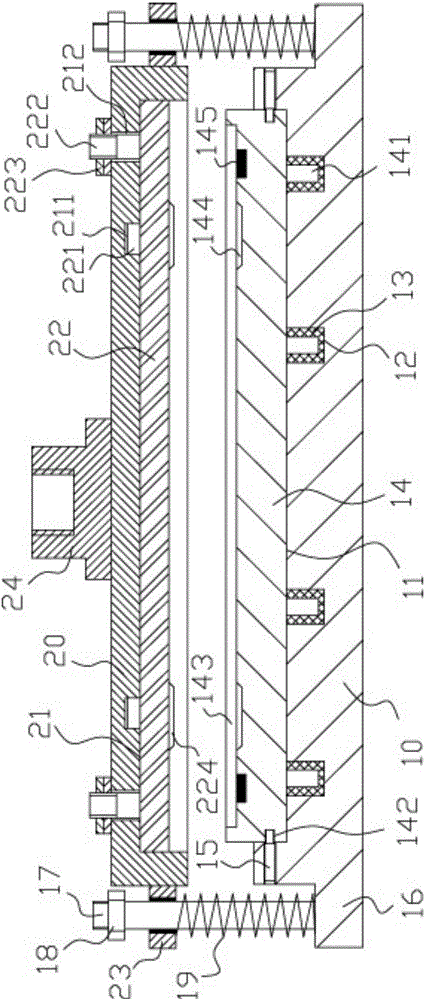

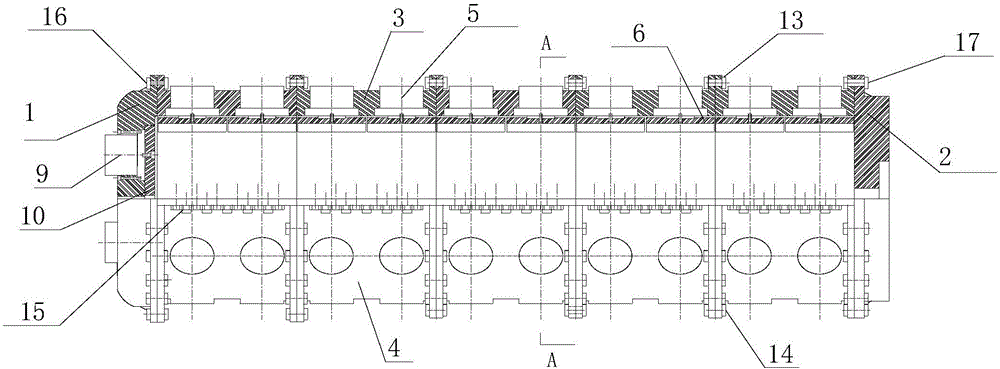

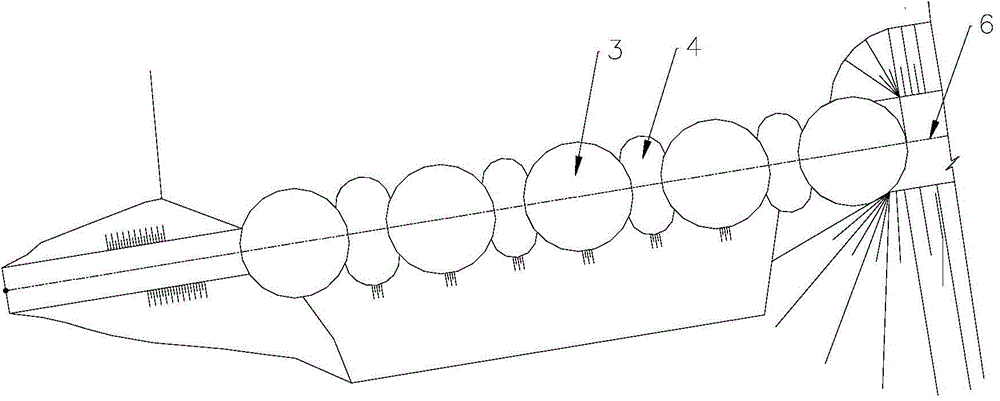

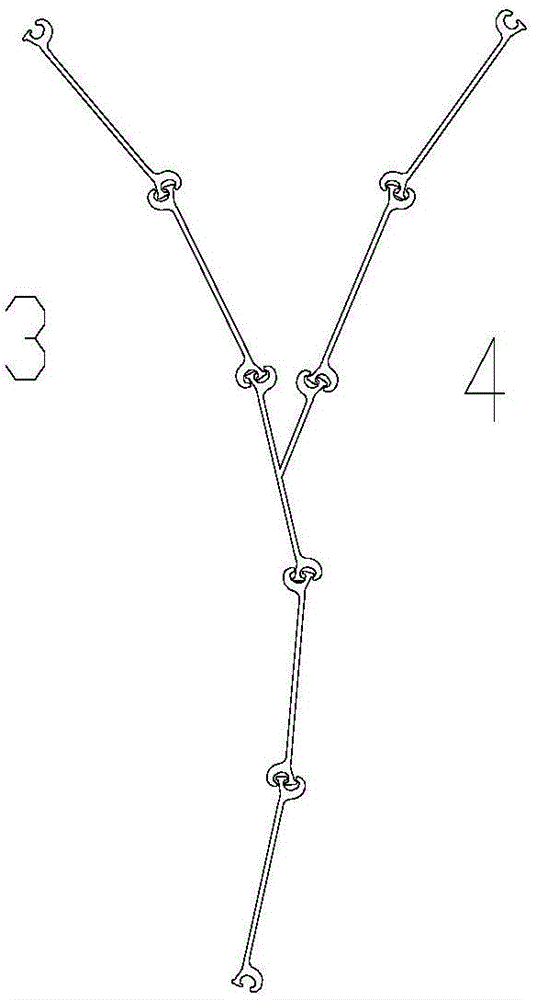

Fusion splicing technological process and equipment for hollow drawstring of air bed body

InactiveCN101439583AEasy to operateShort processing timeFluid mattressesDomestic articlesEngineeringFusion splicing

The invention discloses a heat-sealing technique for an airbed hole drawstring, comprising the following steps: (A) a plurality of hole drawstrings are positioned between the upper piece and the lower piece of a bed body in a certain position and in a certain arrangement mode; (B) lower heat transmission moulds are positioned at the bottom surface of the lower piece of the bed body and corresponding to hole drawstrings; upper heat transmission moulds are positioned at the superface of the upper piece of the bed body and corresponding to the hole drawstrings; the upper heat transmission moulds and the lower transmission moulds are clamped so that the upper piece and the lower piece of the bed body are tightly against each other; (C) a power supply is started to heat the upper heat transmission moulds and the lower heat transmission moulds; the upper heat transmission moulds heat-seal the upper piece and the hole drawstrings on the superface and the lower heat transmission moulds heat-seal the lower piece and the hole drawstring from the bottom surface; (D) the upper heat transmission moulds and the lower heat transmission moulds are separated and the bed body is taken out. The invention heat-seals the bed body and the hole drawstrings outside the bed body, thereby having the advantages of clear weld mark decorative patterns on the finished products, steady heat-sealing quality and fixed hole drawstring intervals. Meanwhile, the invention discloses heat-sealing equipment for the airbed hole drawstrings with high production efficiency.

Owner:ZHONGSHAN ZHANXIN PLASTIC PROD

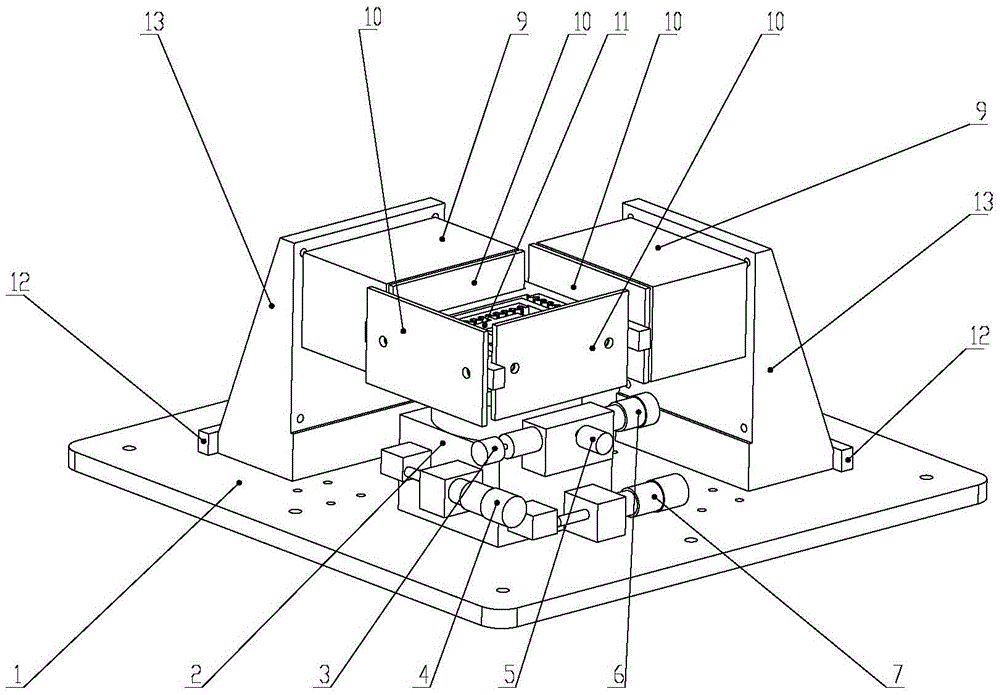

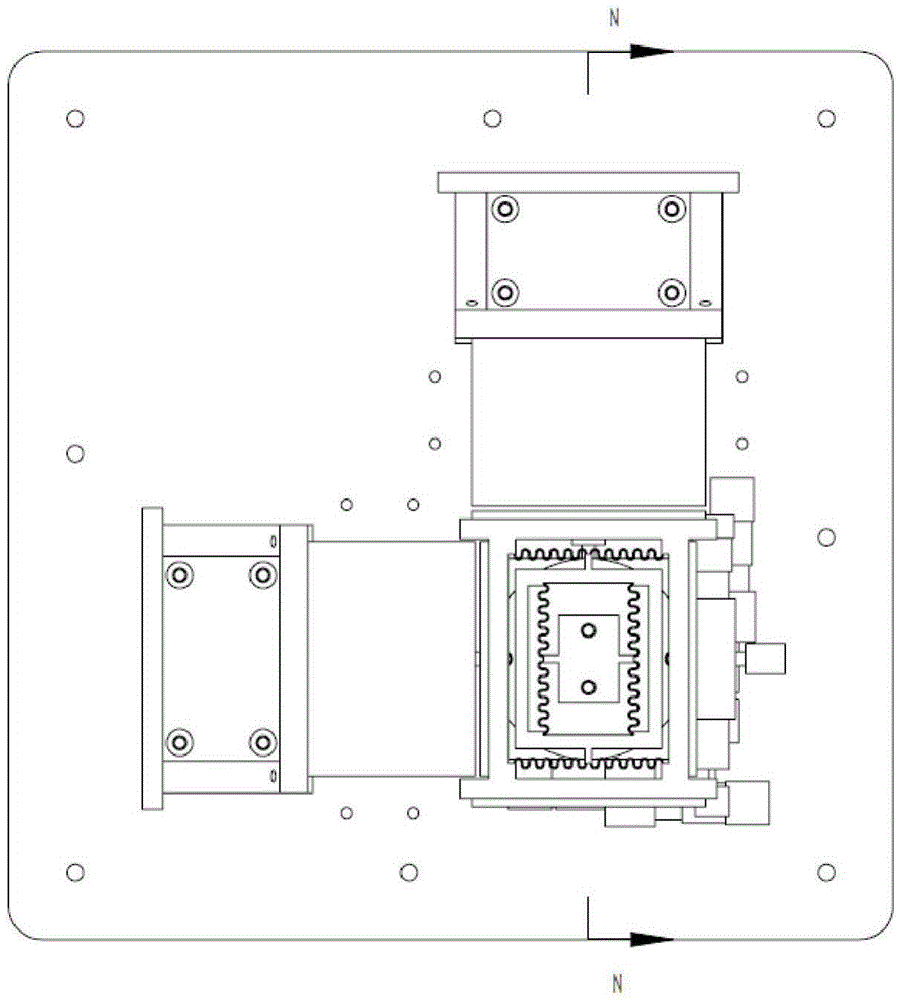

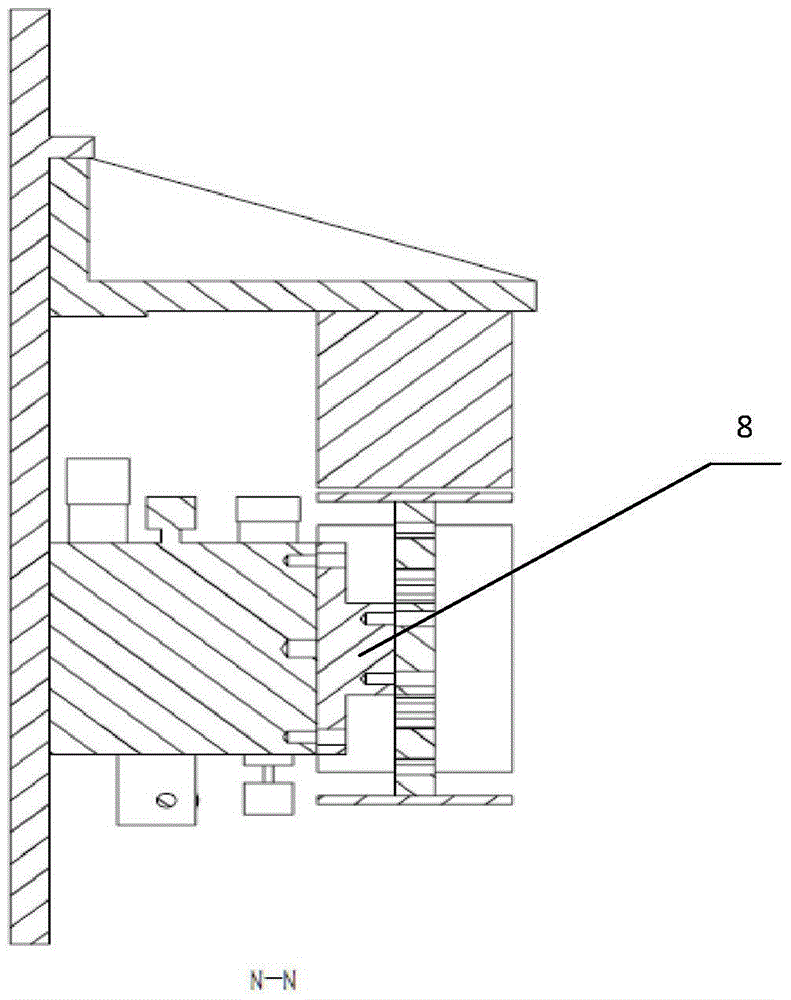

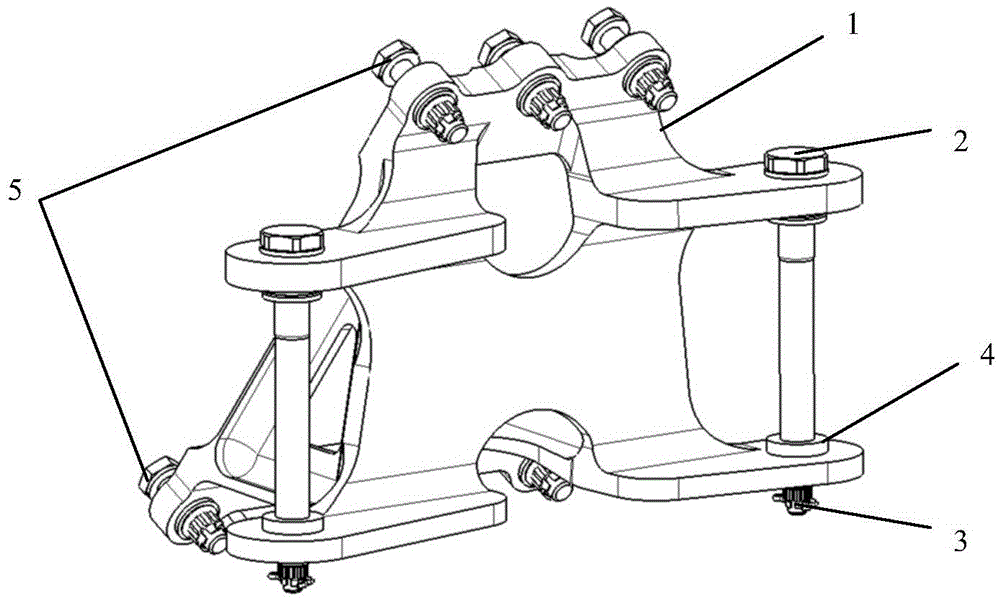

Displacement-adjustable precision locating platform

The invention discloses a displacement-adjustable precision locating platform. The displacement-adjustable precision locating platform comprises a base, a manual adjustable frame sliding table platform, a platform cushion block, a compliant hinge precision locating platform body, four electromagnetic armatures, two Z-axis right-angle junction plates and electromagnetic drivers. The manual adjustable frame sliding table platform can achieve three-freedom-degree precision locating adjustment through a cross rotating guide rail. The platform cushion block is arranged on a sliding table through four evenly-distributed threaded holes. The middle of the compliant hinge precision locating platform body is fixed to the platform cushion block through two threaded holes, and therefore the platform can achieve displacement in the X-axis direction and Y-axis direction along with the manual adjustable frame sliding table platform. The four electromagnetic armatures are fixed in the four directions of the compliant hinge precision locating platform body in a threaded connection manner. The two Z-axis right-angle junction plates are in threaded connection with the base of the platform. The electromagnetic drivers serve as drive equipment of the platform and are in threaded connection with the Z-axis right-angle junction plates to be connected with the base of the platform. The displacement-adjustable precision locating platform is simple in structure, small in overall size, low in cost and convenient to operate, and the high-precision locating requirement can be met.

Owner:SOUTH CHINA UNIV OF TECH +1

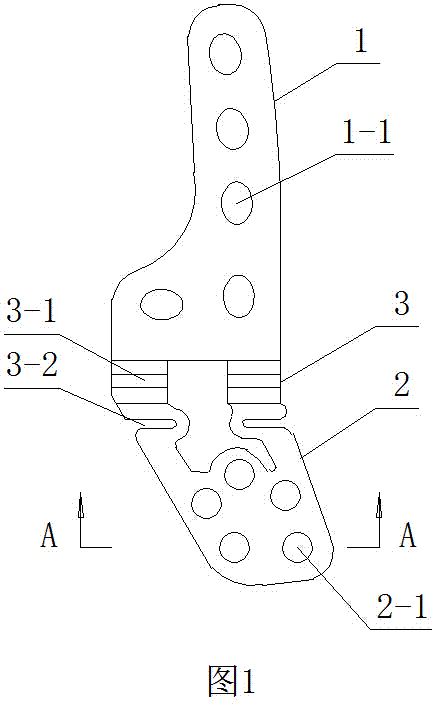

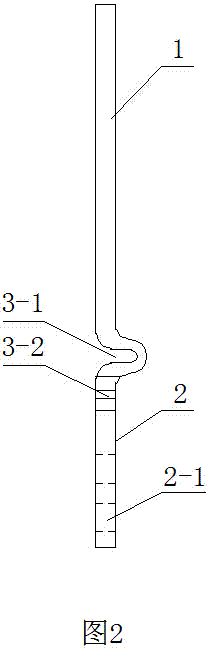

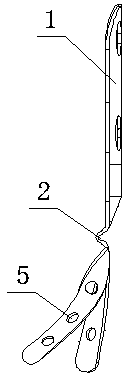

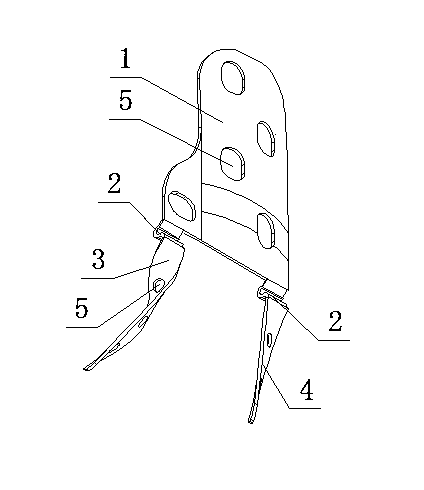

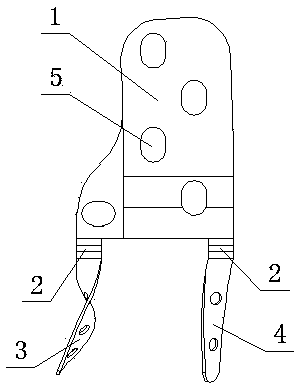

Flexible fixing plate for acromioclavicular joint

ActiveCN104116553AFixed firmlyEasy installation and positioningBone platesSteel platesSacroiliac joint

The invention relates to a flexible fixing plate for the acromioclavicular joint and belongs to the technical field of implantation materials in human bodies. The flexible fixing plate for the acromioclavicular joint is composed of an arc-shaped upper main board, an arc-shaped lower main board and an elastic deformation structure. The arc-shaped upper main board and the arc-shaped lower main board are connected and fixed through the two ends of the elastic deformation structure, and an upper main board fixing hole and a lower main board fixing hole are manufactured in the arc-shaped upper main board and the arc-shaped lower main board. Through the elastic deformation structure and the two arc-shaped main boards, the acromioclavicular joint can be elastically fixed, the original anatomical correspondence of the acromioclavicular joint can be restored to the maximum extent, the flexible fixing plate is firm and reliable in fixation, easy, convenient and accurate to install and position and good in treatment and healing effect, and postoperative restoration loss can be avoided. The flexible fixing plate for the acromioclavicular joint solves the problems that because the compressive stress of an existing hook steel plate structure on the acromion and the clavicle is too large, pain, the pressure swelling feeling, hook disengagement and fear of movement can be caused to a patient easily; the common problems that surgical restoration is not ideal, subacromial tissue is injured, and the treatment effect is seriously affected because an elastic micro movement fixing plate for the acromioclavicular joint is not high enough in elasticity are solved.

Owner:BIODA DIAGNOSTICS WUHAN

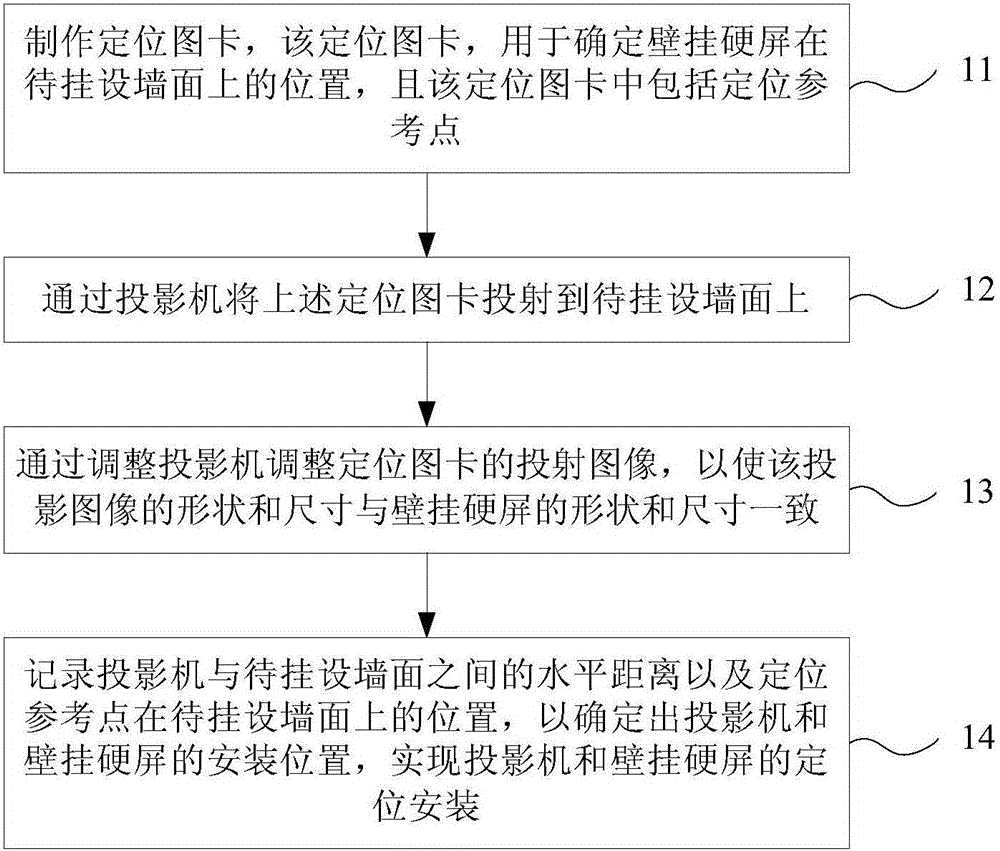

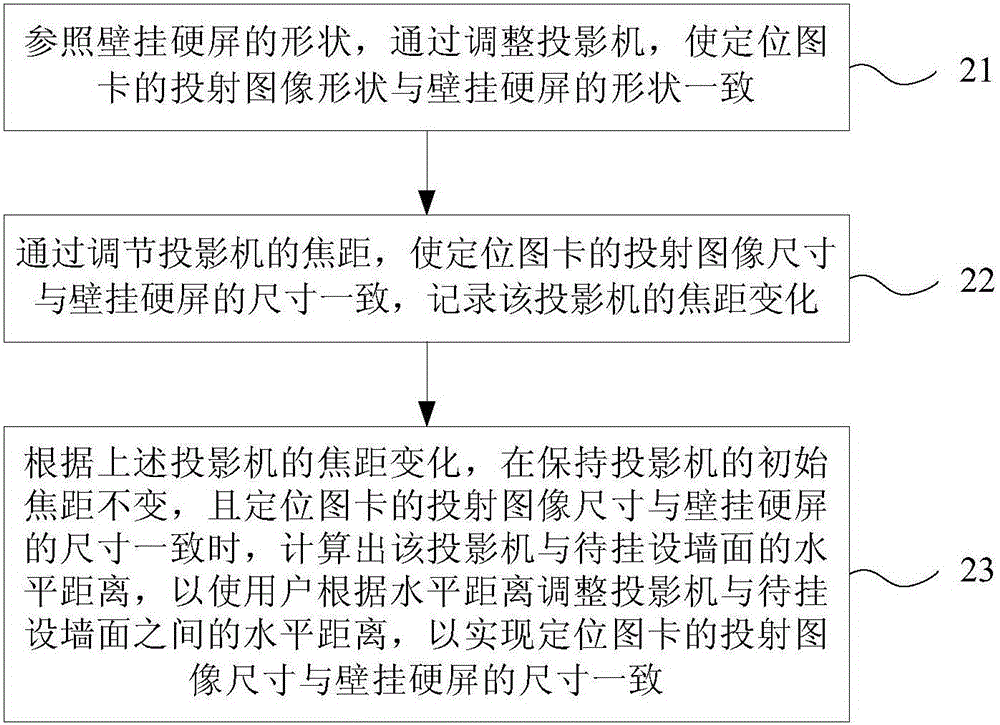

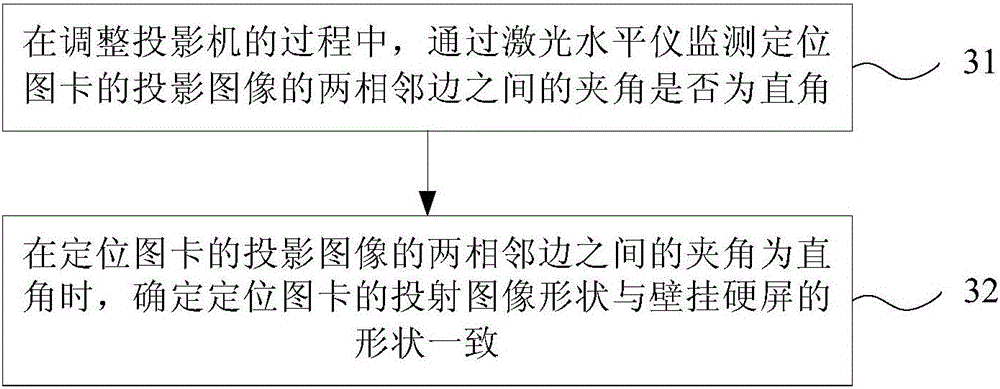

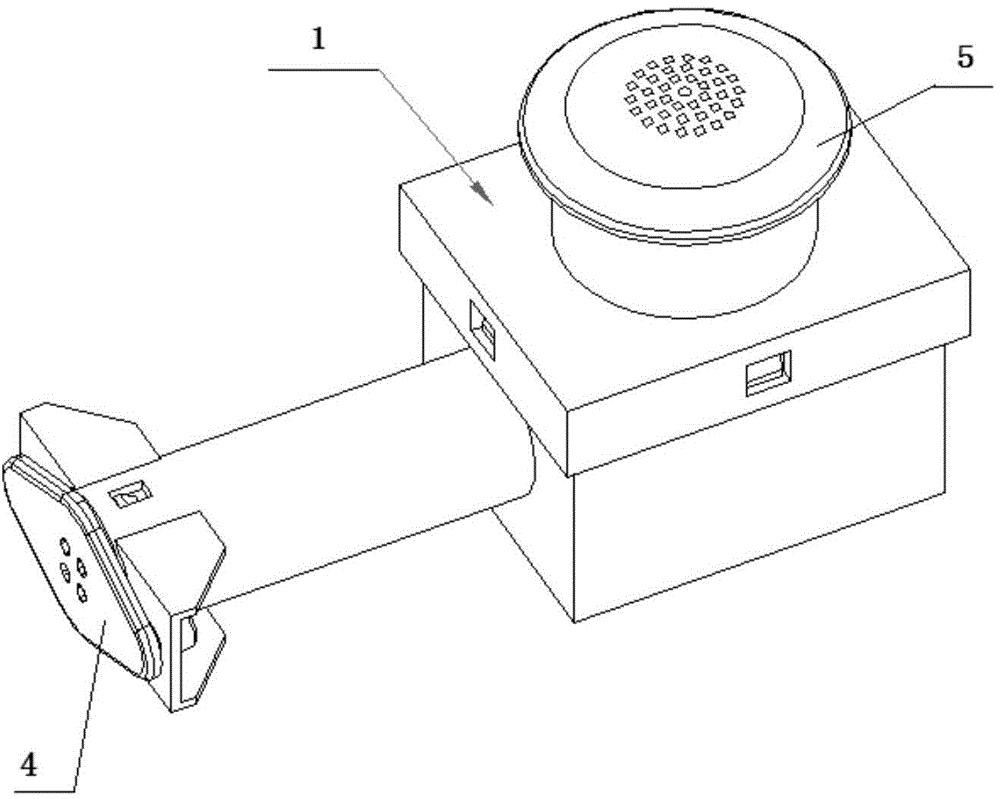

Projector positioning and installing method and device

ActiveCN105807544ASolve difficultySolving Installation ComplexityProjectorsComputer scienceProjector

The invention provides a projector positioning and installing method and device which is suitable for positioning and installation of a projector system. The projector system comprises a projector and a hard wall-hung screen matched with the projector. The projector positioning and installing method comprises the steps that a positioning image card for determining the position for the hard wall-hung screen to be hung on the wall face is made and is projected to the wall face for hanging through the projector, a projected image of the positioning image card is adjusted by adjusting the projector to make the shape and size of the projected image to be consistent with the shape and size of the hard wall-hung screen, a horizontal distance between the projector and the wall face for hanging and the position of a positioning reference point on the positioning image card on the wall face for hanging are recorded, accordingly the installing positions of the projector and the hard wall-hung screen are determined, and projector positioning and installation is achieved. By the adoption of the technical scheme, positioning and installation are rapid and accurate and are not affected by the internal accumulated tolerance of the projector, the installation complexity I reduced, and the efficiency is high.

Owner:HISENSE

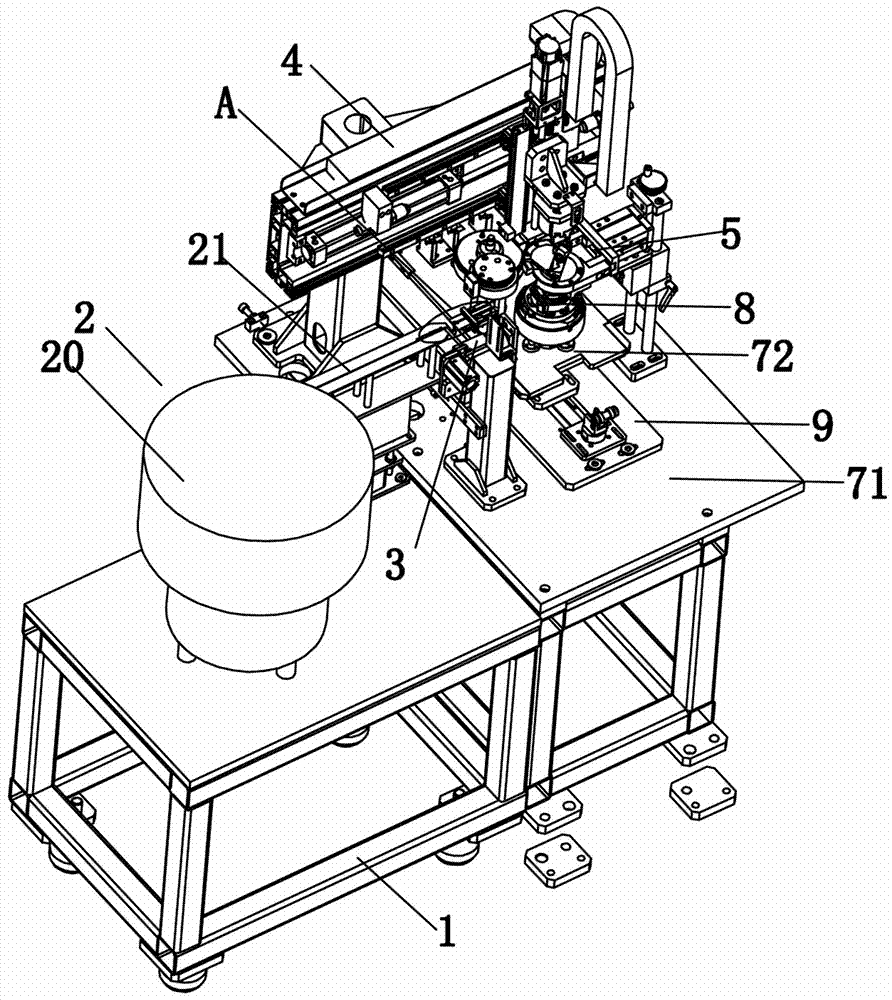

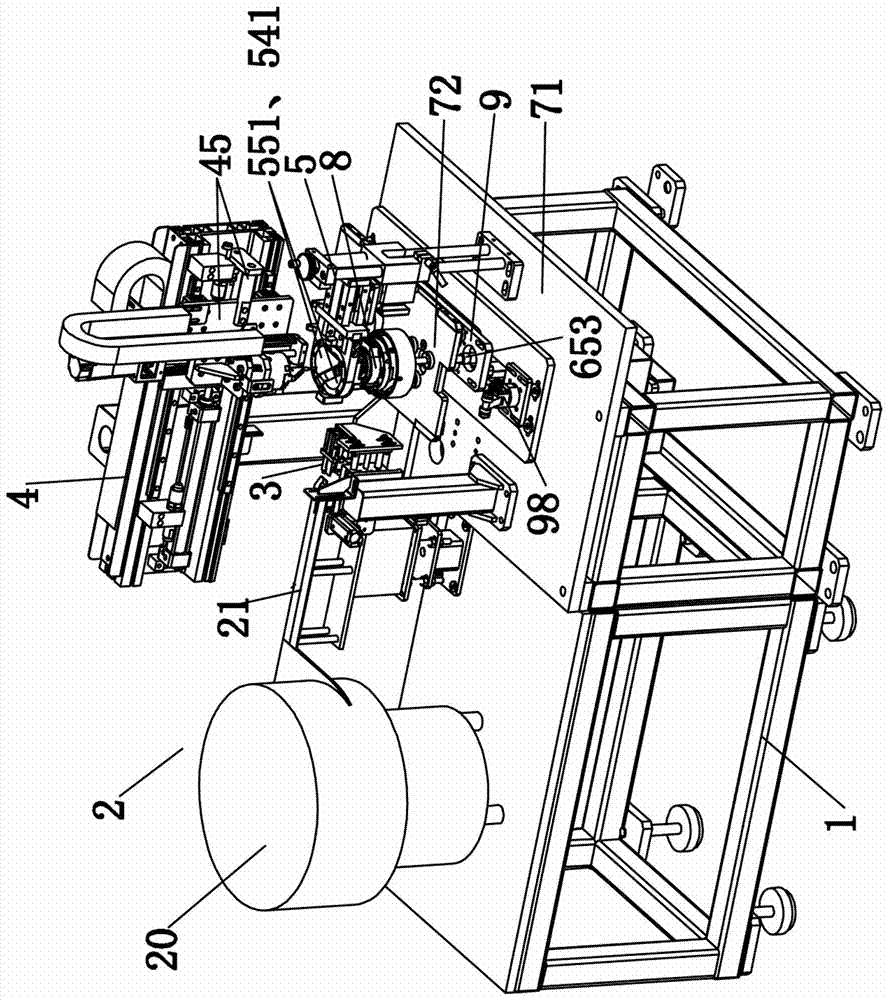

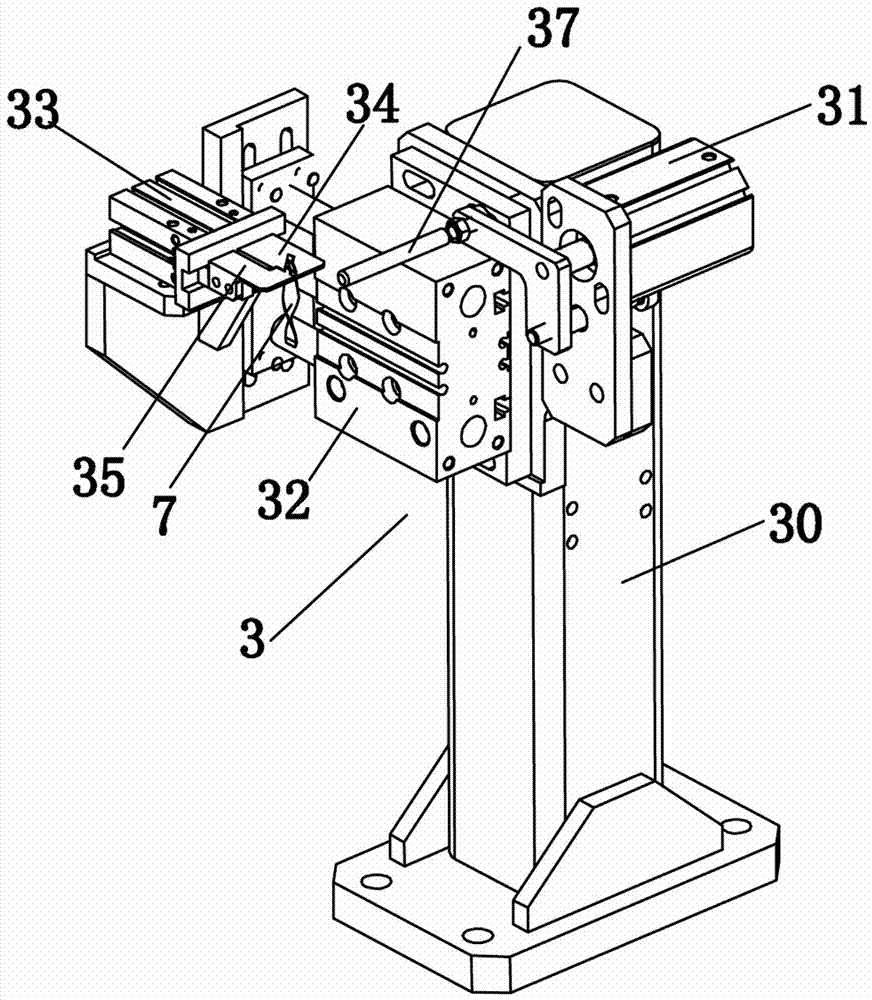

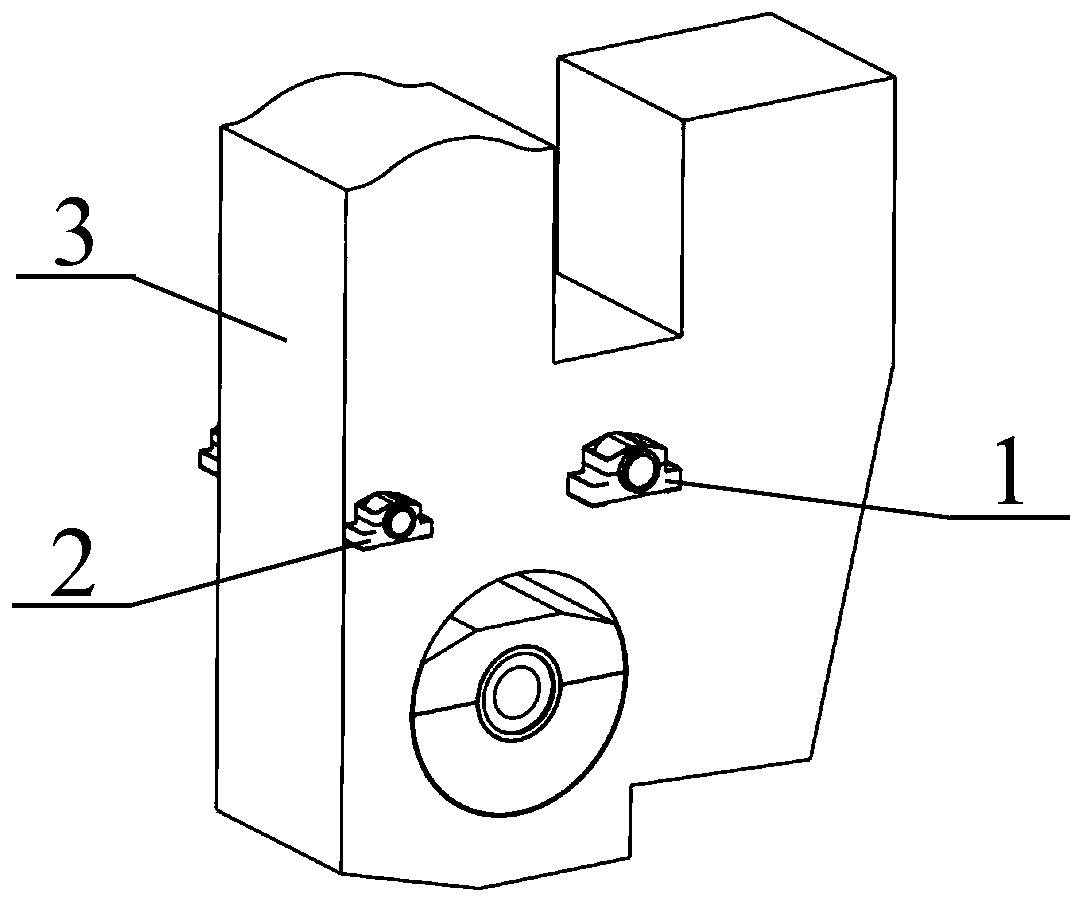

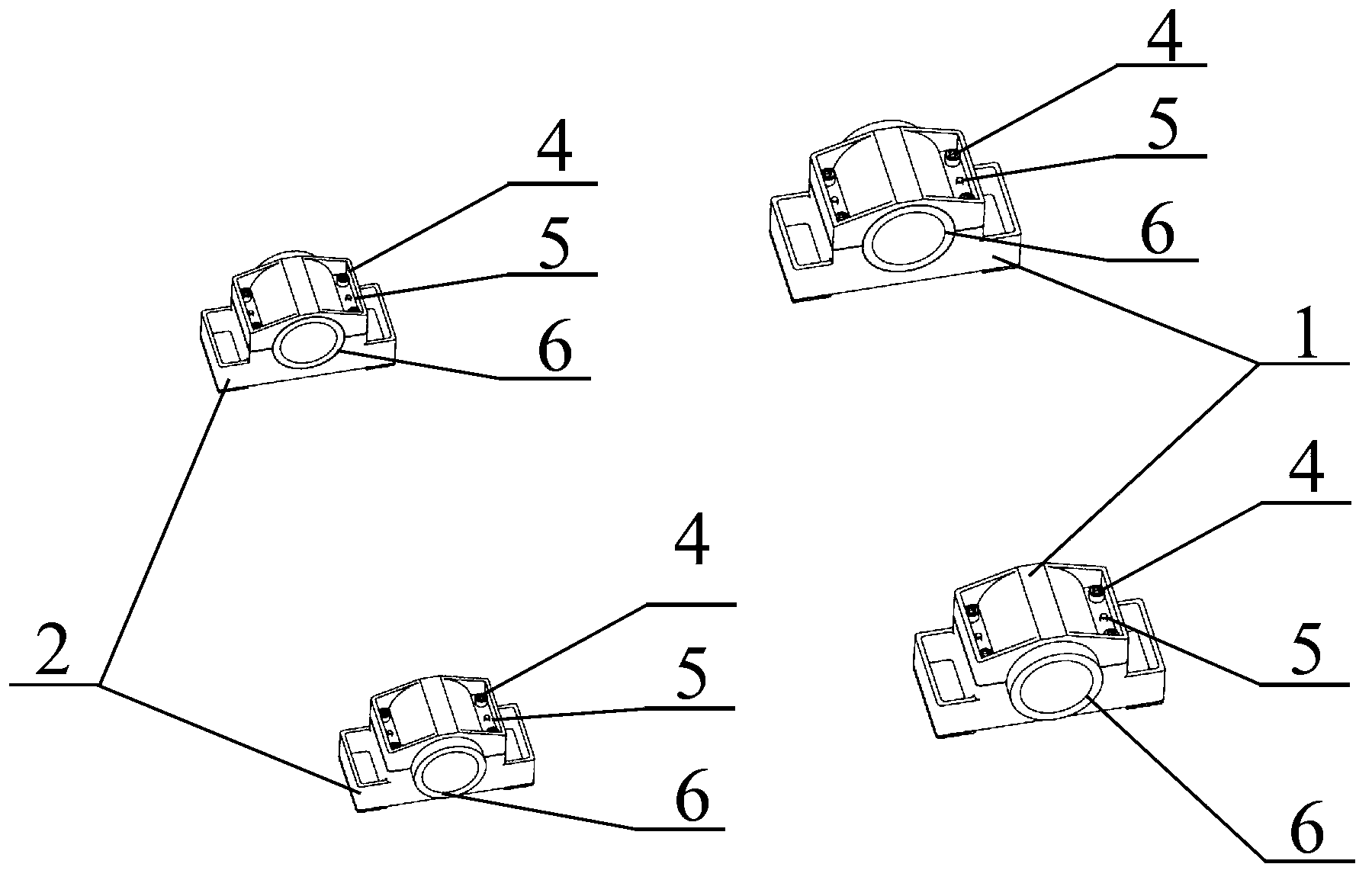

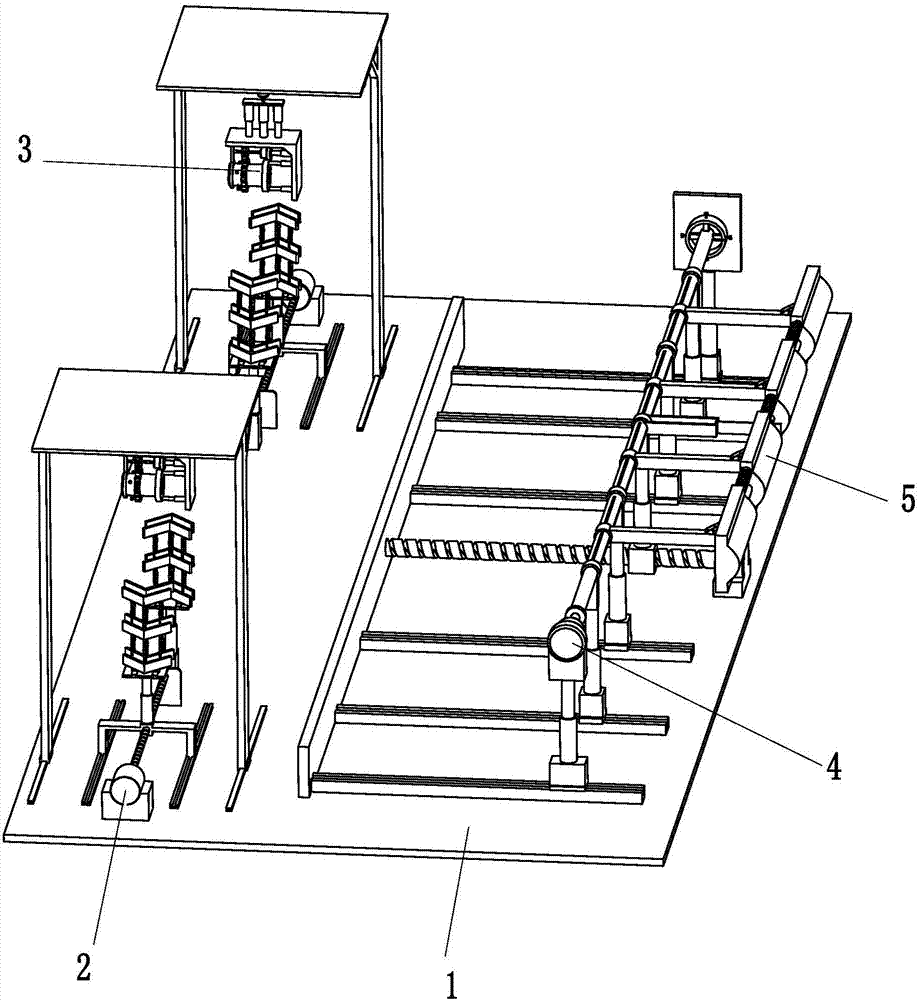

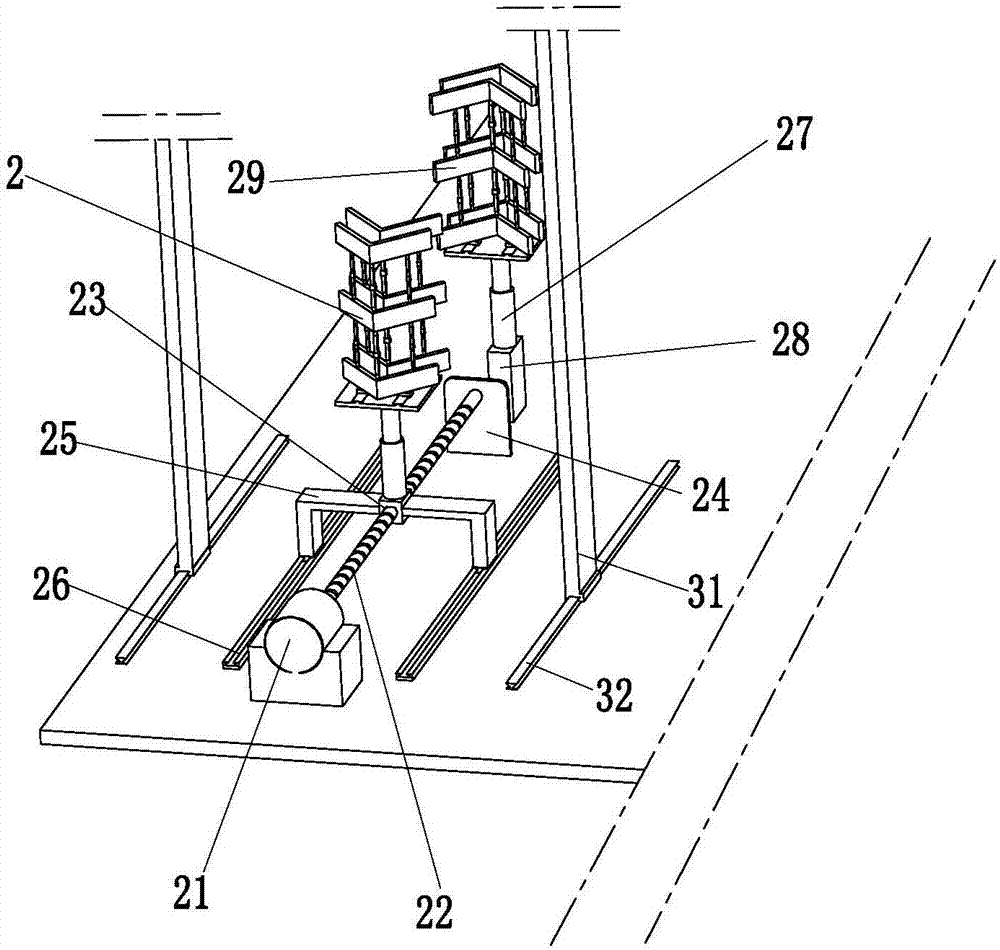

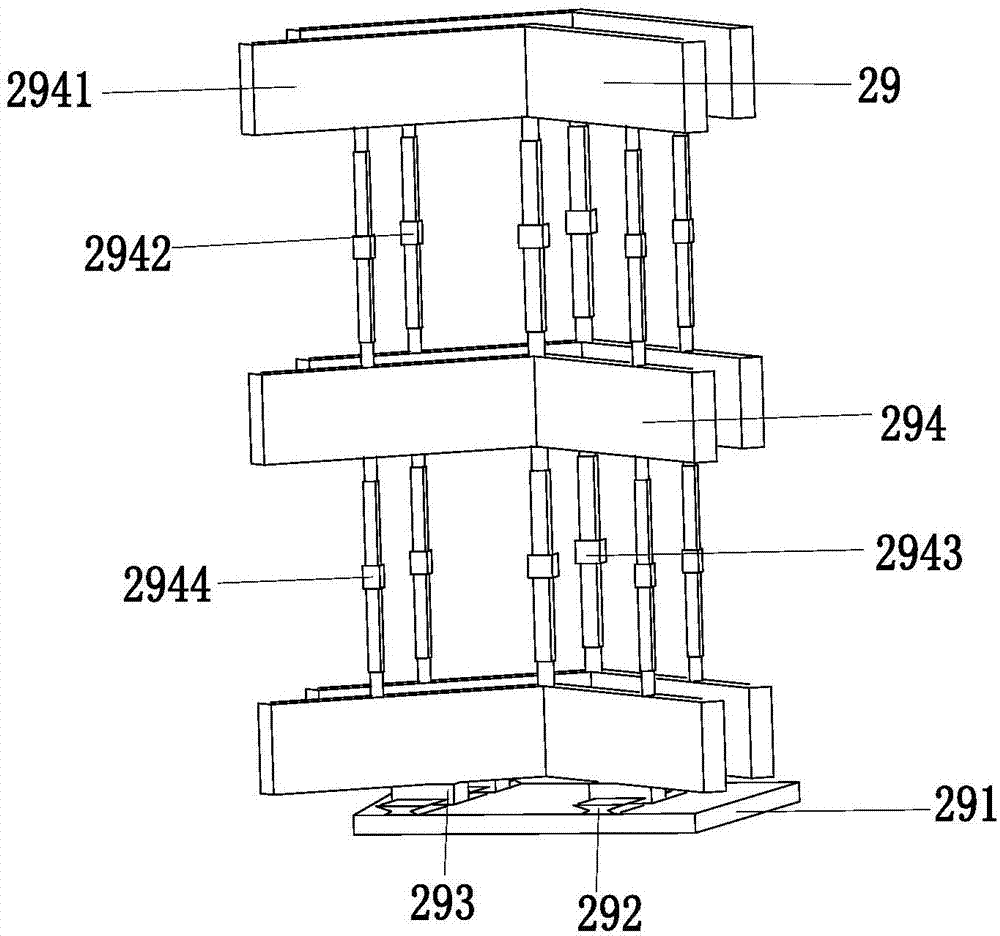

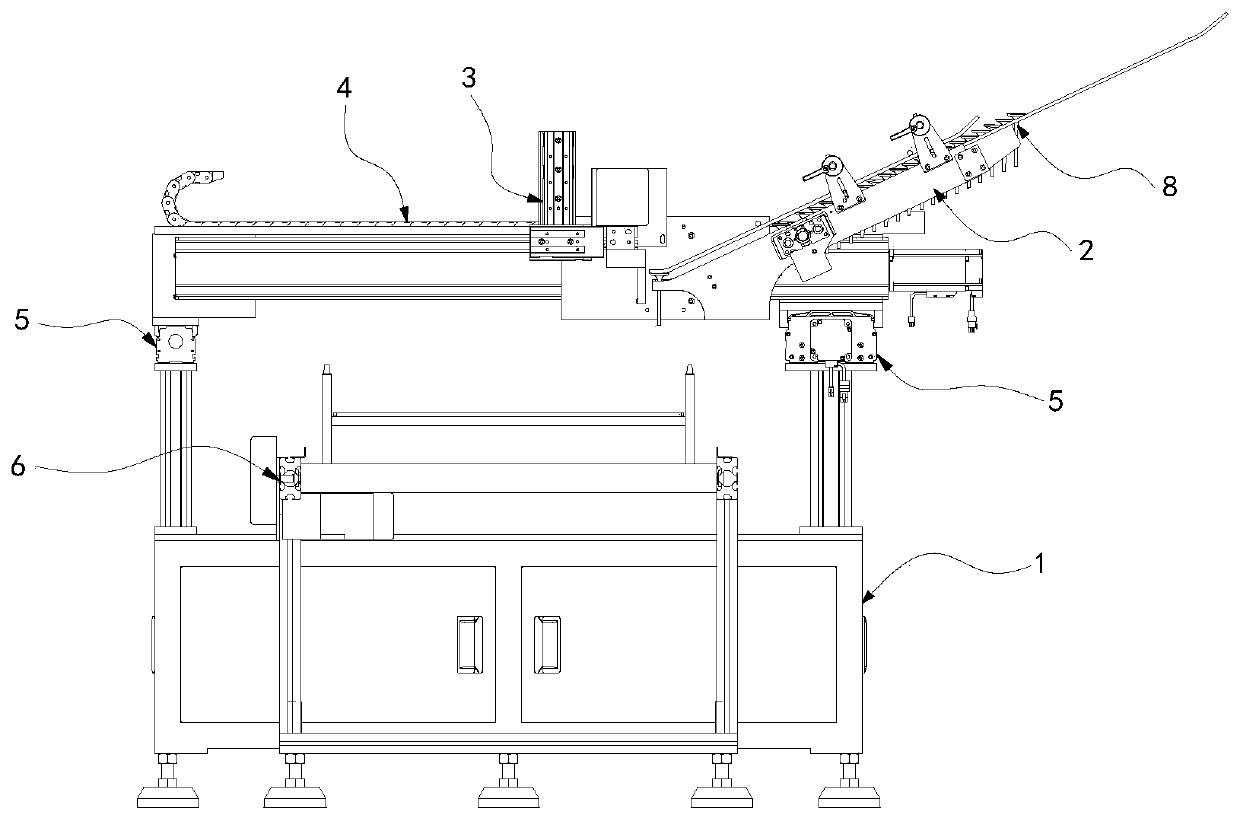

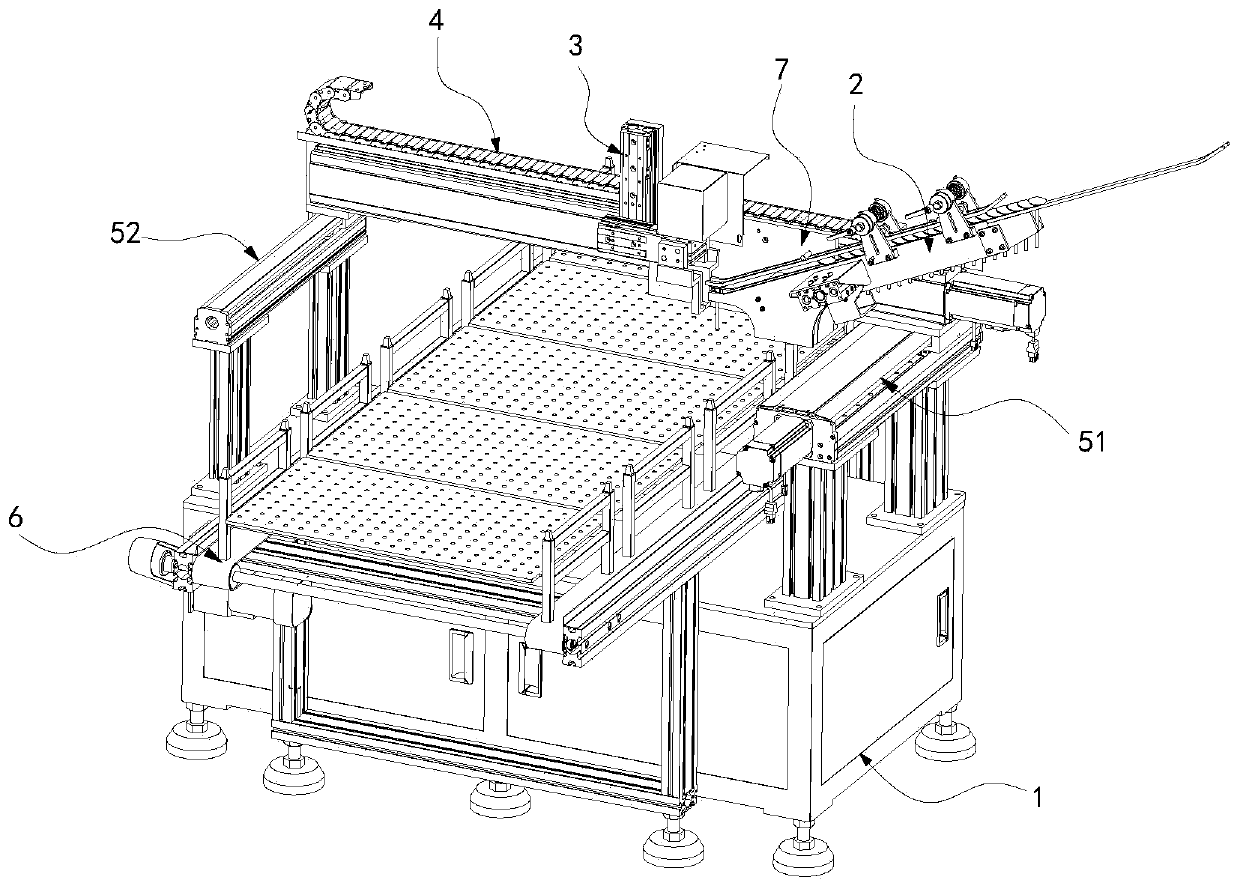

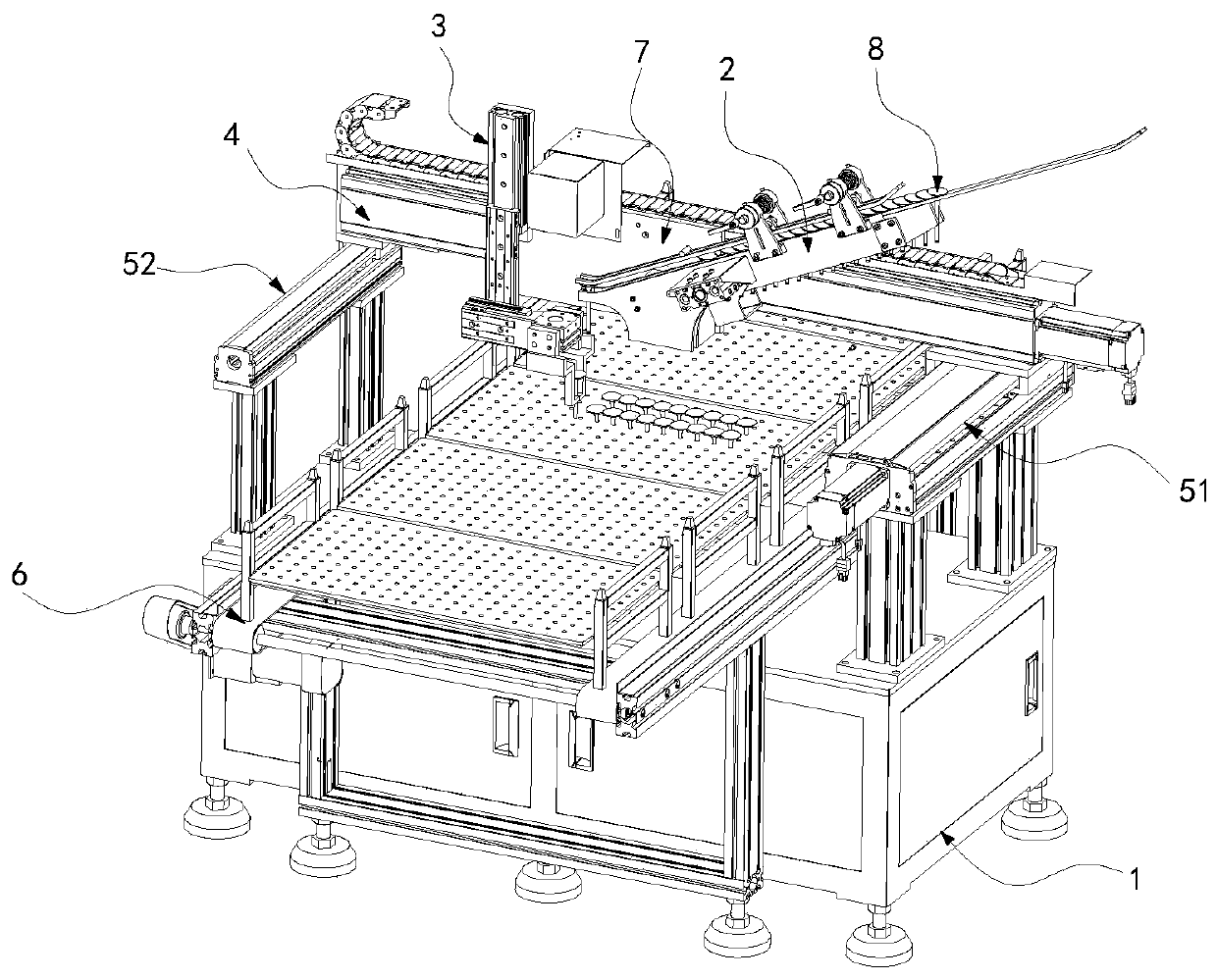

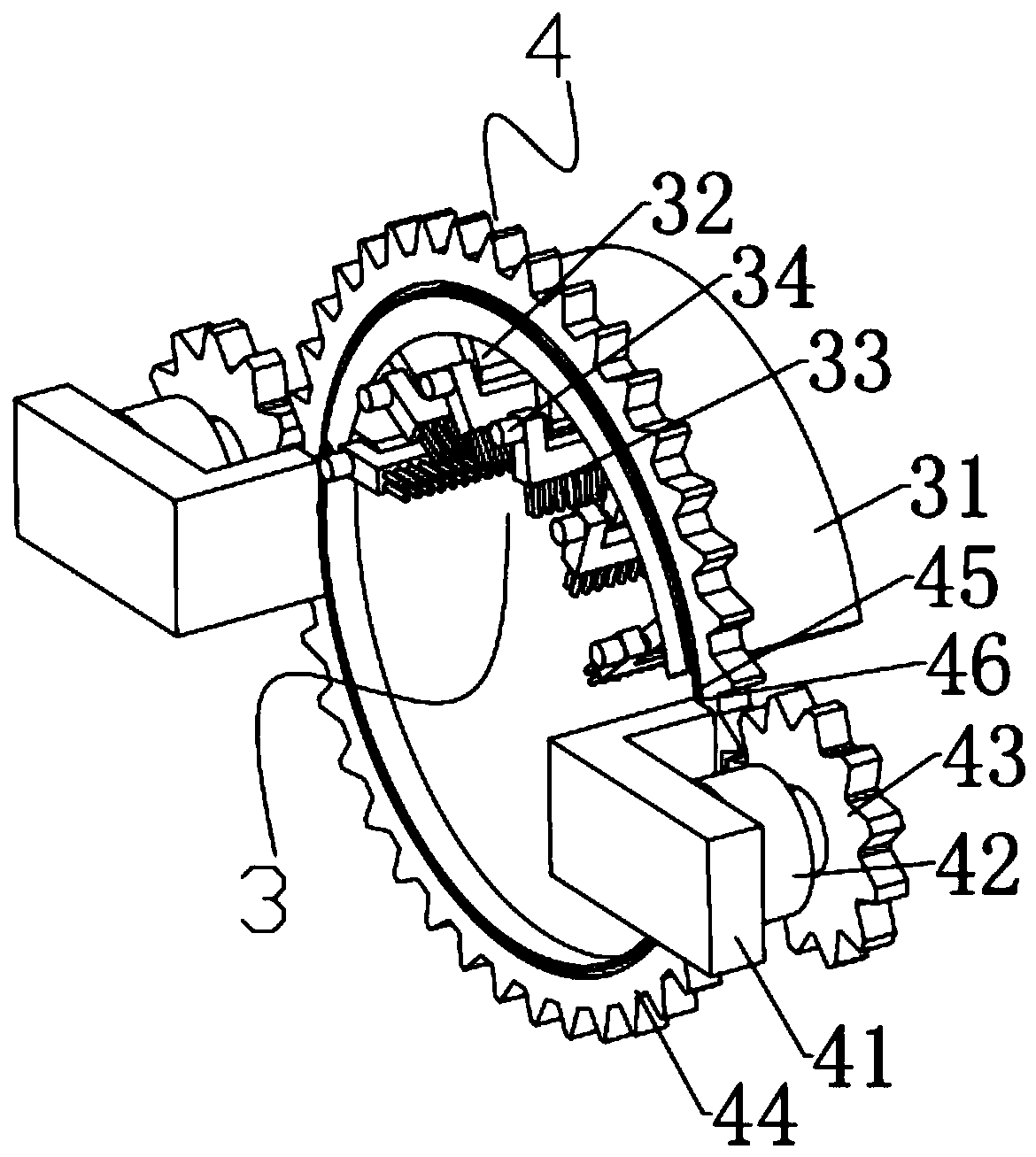

Full-automatic installation equipment for oil blades of compressor pump body

ActiveCN107378461AIncrease productivityHigh degree of automationWind energy generationMetal working apparatusRobot handControl engineering

The invention relates to the technical field of assembling of a compressor pump body, in particular to full-automatic installation equipment for oil blades of the compressor pump body. The full-automatic installation equipment comprises a rack, a vibration feeding mechanism, an oil blade distributing mechanism, an oil blade conveying mechanical arm, an oil blade guiding mechanism, a tool disk positioning and jacking mechanism and a crankshaft aligning mechanism. The full-automatic installation equipment for the oil blades of the compressor pump body is in an online installation manner and can be combined to a compressor pump body assembly line to achieve automatic butt connection of the whole line. According to the full-automatic installation equipment, by means of the vibration feeding mechanism, the oil blade distributing mechanism, the oil blade conveying mechanical arm, the oil blade guiding mechanism, the tool disk positioning and jacking mechanism and the crankshaft aligning mechanism, directional discharging, distributing, feeding, charging and other actions of the oil blades are achieved correspondingly, and therefore the full-automatic installation equipment is high in production efficiency and automation degree, discharging and charging are efficient and accurate, the online installation takt can be improved well, and the requirement for large batch production can be met.

Owner:GUANGDONG SHUNDE SANHE IND AUTOMATION EQUIP CO LTD

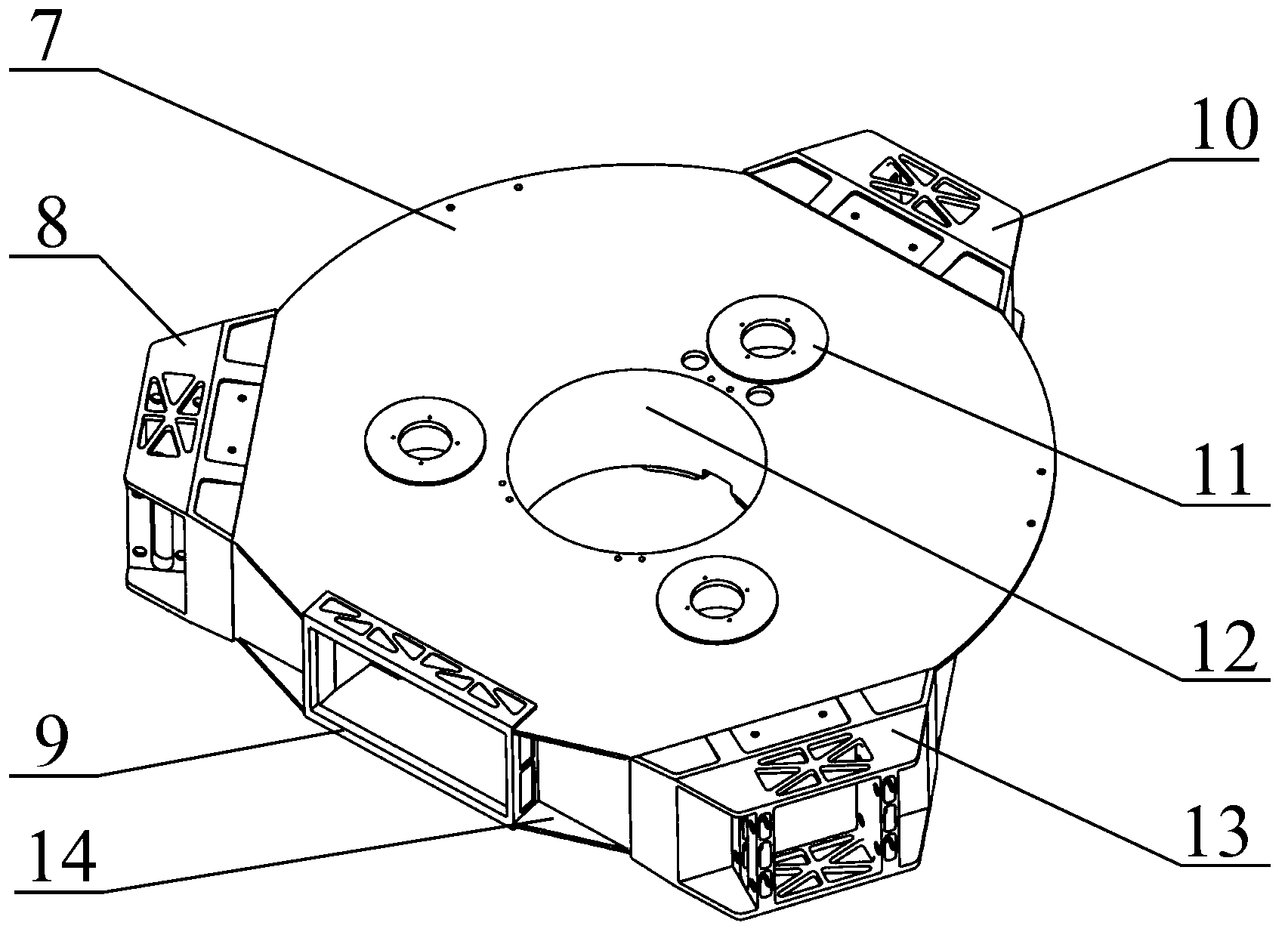

Space optical remote sensor main bearing plate structure adopting embedded part

ActiveCN102798960AImprove structural rigidityImprove structural strengthMountingsEmbedded systemMain bearing

The invention discloses a space optical remote sensor main bearing plate structure adopting an embedded part, and belongs to the technical field of space optical remote sensing, and relates to a main bearing plate structure of the embedded part. The technical problem to be solves is to provide a space optical remote sensor main bearing plate structure adopting an embedded part. The technical scheme is as follows: the structure comprises a main bearing plate front panel, a first truss embedded block, a second truss embedded block, a third truss embedded block, a three-mirror embedded block, a main mirror embedded block, a main bearing plate central hole, a main bearing plate back panel, a folded mirror embedded block, a bias current embedded block, a main mirror embedded block socket, a longitudinal bar groove, a transverse bar groove, a transverse bar and a longitudinal bar. By virtue of the embedded blocks on the main bearing plate, the corresponding mirror assemblies and the other supporting structure assemblies are mounted and located to form a main structure of the space optical remote sensor. The transverse bar and the longitudinal bar are arranged on a contact surface between each embedded block and the bearing plate, so that the effective contact area with a carbon fiber composite material is enhanced; the structure rigidity is reinforced; and the structure reliability is improved.

Owner:CHANGGUANG SATELLITE TECH CO LTD

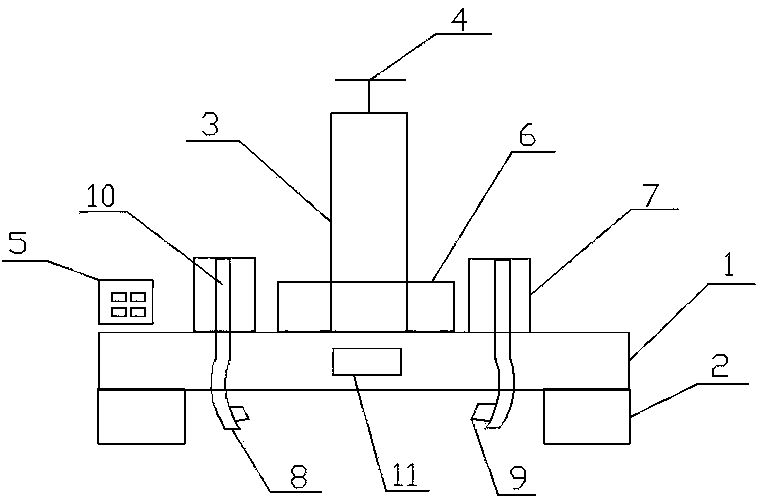

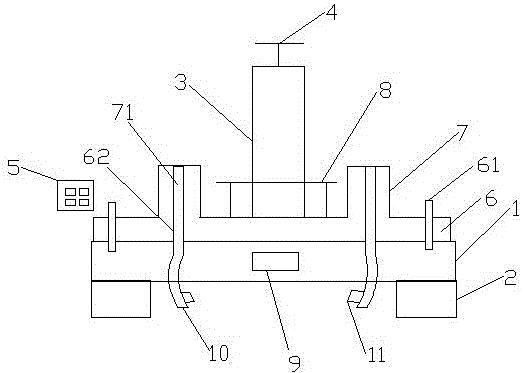

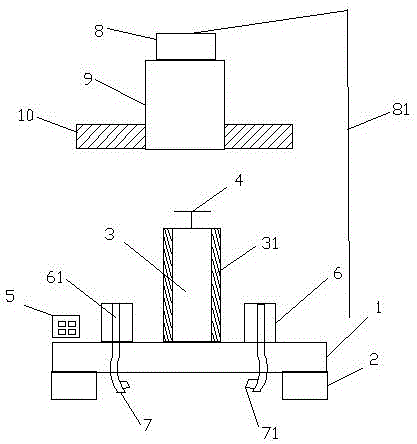

Casting tooling fixture capable of automatically clamping in place

ActiveCN104260014AHigh degree of automationIncrease productivityMeasurement/indication equipmentsWork holdersProgrammable logic controllerEngineering

The invention discloses a casting tooling fixture capable of automatically clamping in place. The casting tooling fixture comprises a bottom plate and a corner oil cylinder. A sleeve capable of lifting to different heights sleeves the periphery of the bottom of the corner oil cylinder, the periphery of the sleeve is uniformly provided with a plurality of positioning blocks, every positioning block is internally provided with an axial through hole connected to an air pipe, every air pipe is provided with a pressure sensor connected to a PLC (Programmable Logic Controller), the top of the corner oil cylinder is provided with an automatic locking handle connected with the PLC, and the height of the sleeve is smaller than that of the positioning block. Therefore, the pressure sensor can detect whether a casting tooling is installed and clamped in place or not, if not, the sleeve lifts to jack the casting tooling and then moves downwards to enable the casting tooling to be automatically matched with and installed to the positioning block until the pressure sensor detects that the requirement are met. The whole process of detection and adjustment are completed automatically without manual operations, the installation and the positioning are accurate, and the production efficiency is high.

Owner:盐城天源电力设备有限公司

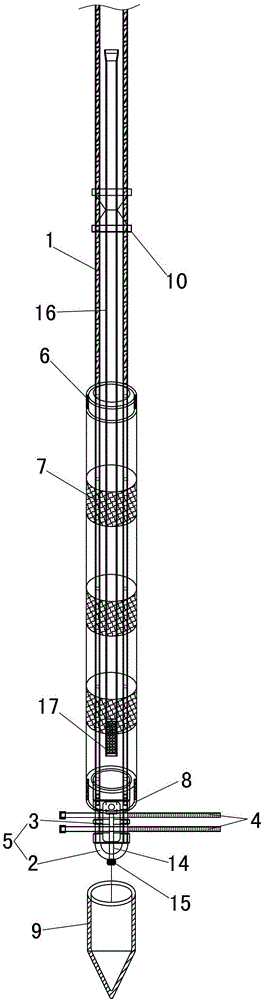

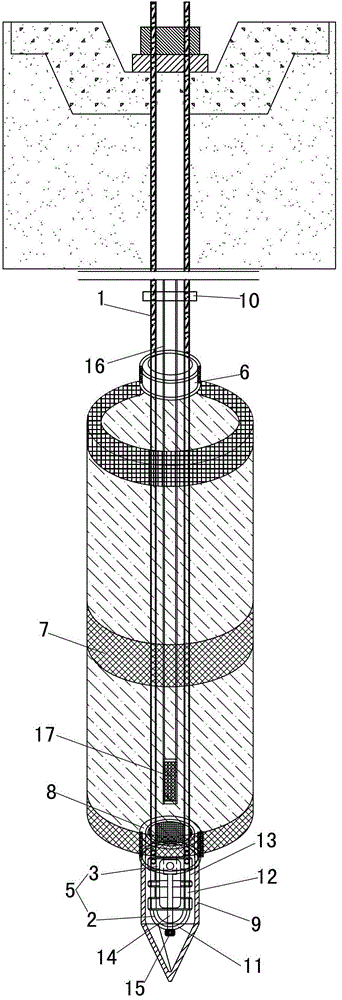

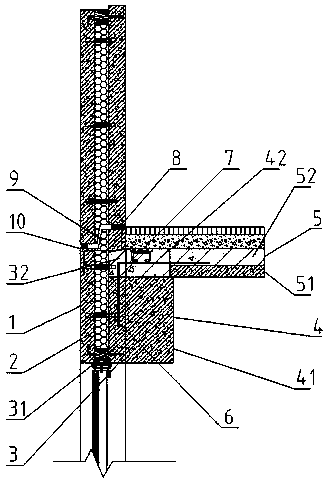

Insertion combination type recyclable expanding body anchor rod of high-bearing inner cabin and construction method

ActiveCN102943474APrecise positioningEasy to installBulkheads/pilesStructural engineeringHigh intensity

The invention relates to an insertion combination type recyclable expanding body anchor rod of a high-bearing inner cabin and a construction method and belongs to the technical field of civil engineering. An unbonded steel strand is rewound through a smooth arc-shaped top bearing anchor end to form a double number of steel strands, and after forming through a specially-made steel strand locking device, the steel strands, a locking body and a binding lacing strip are commonly locked to form an insertion locking assembly, and the assembly is connected with a cabin type assembly composed of a bottom fixed pedestal and the like and is fastened through a locking screw and a nut. After the insertion combination type recyclable expanding body anchor rod of the high-bearing inner cabin is sent into a stratum, the high-pressure grouting cabin is unfolded in an expanded mode, a large-diameter high-strength anchor body is formed, and after a supporting function with high anchoring safety is finished, the unbonded steel strand can be recycled efficiently and rapidly and is simple to construct and simple in structure.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Special automatic mounting equipment for putting up expressway stainless steel guardrails

InactiveCN107127565AImplement automatic installationRealize the function of automatic installationMetal working apparatusEngineeringUltimate tensile strength

The invention relates to a special automatic installation equipment for highway stainless steel guardrail construction, including a bottom plate, two automatic clamping devices, an automatic nut loading device, a wave plate turning device and a wave plate suction device. The bottom plate is a cuboid structure, two Two automatic clamping devices are symmetrically installed on the left side of the bottom plate, and an automatic nut-loading device is installed on the upper end of each automatic clamping device, the wave plate turning device is installed on the right side of the bottom plate, and the wave plate suction device is installed on the wave plate turning device; The invention can solve the problems of low work efficiency, high labor intensity, difficulty in installing the anti-blocking block, manual handling of the corrugated plate and inability to accurately position and install the existing manual installation of the anti-blocking block and the corrugated plate on the expressway. , realizes the function of automatic installation of corrugated plate and anti-blocking block, has the advantages of high work efficiency, fully mechanized operation, automatic installation of anti-blocking block, mechanized handling of corrugated plate and precise positioning and installation.

Owner:安庆米锐智能科技有限公司

Die device for stamping molding of steel plate

InactiveCN105855397AAccurate installation and positioningSimple structureShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a die device for stamping molding of a steel plate. The die device comprises a lower die connection block and a connection plate, wherein a lower die fixing groove is formed in the middle of the top surface of the lower die connection block; a plurality of positioning inserting holes are formed in the bottom surface of the lower die fixing groove; strong magnet sleeves are inserted into the positioning inserting holes in a sleeving manner; outer side walls of the strong magnet sleeves are fixed on inner side walls of the positioning inserting holes; a lower die is inserted into a lower die fixing groove in the sleeving manner; a plurality of inserting rods are arranged on the bottom surface of the lower die; the inserting rods are inserted into the strong magnet sleeves in the sleeving manner and are adsorbed in the strong magnet sleeves; screw jointing through holes formed in the inner side wall of the lower die fixing groove are internally connected with a plurality of positioning studs in a screw jointing manner; the end parts of the positioning studs are inserted into side wall concave holes formed in the outer side wall of the lower die in the sleeving manner; an upper die mounting groove is formed in the middle of the bottom surface of a connection plate; and an upper die is inserted into an upper die mounting groove in the sleeving manner and is fixed on the top surface of the upper die mounting groove, and the upper die is located just above the lower die. The die device is simple in structure and small in size, the lower die is convenient to mount and detach, and the steel plate is accurately mounted and positioned so that the manufacturing effect is greatly improved.

Owner:青岛鑫精诚精密科技有限公司

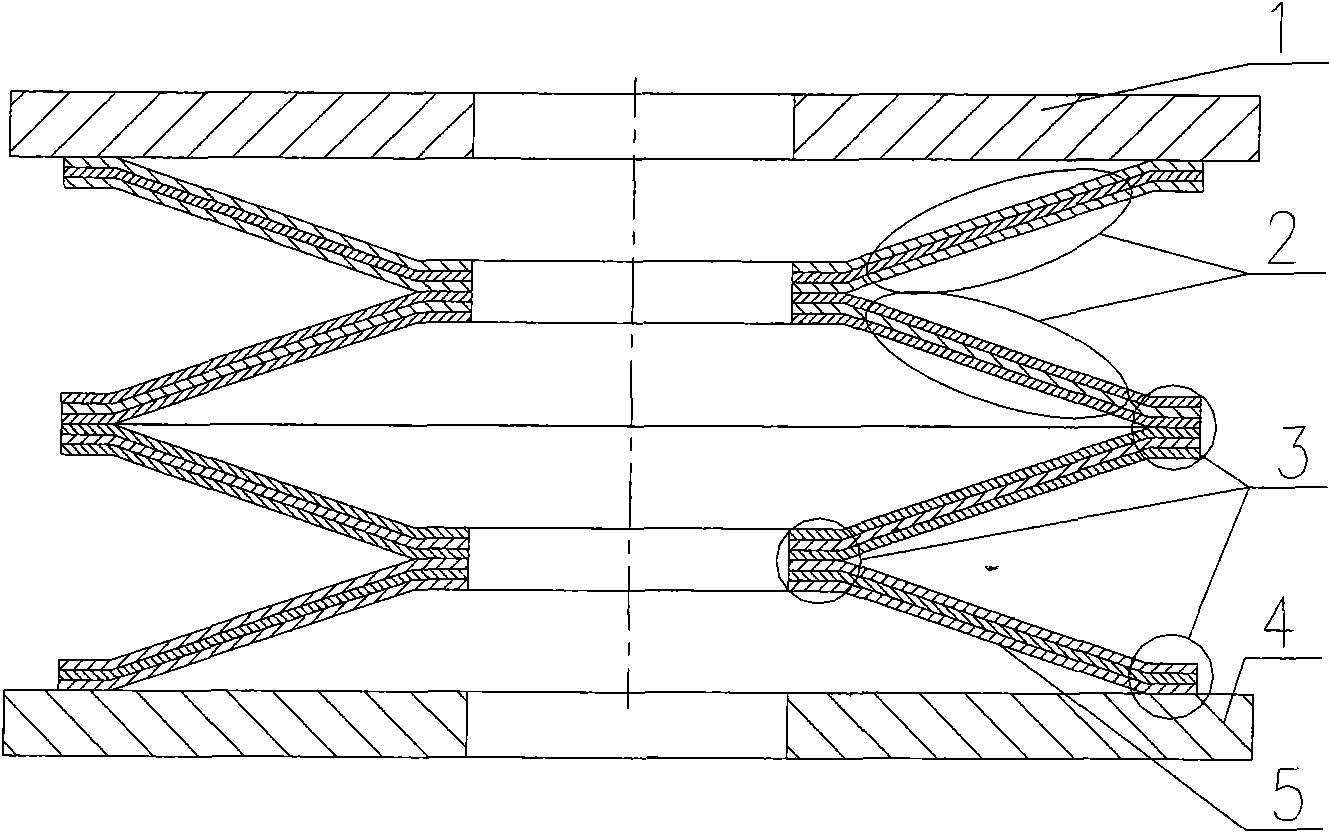

Diffusion welding multilayer structure diaphragm capsule

The invention is a diffusion welding multilayer structure diaphragm capsule, belonging to the field of diaphragm capsule manufacturing. By adopting the methods of diffusion welding, machining and shaping, the manufacturing of diaphragm capsule in the invention can be realized. The main procedures include thin wall blank preparation, surface cleaning, surface modified treatment, welding-stopping treatment, diffusion welding, machining, shaping and the like. Compared with the multilayer structure diaphragm capsule manufactured by other methods, the multilayer structure diaphragm capsule manufactured by the invention has the advantages of fine fatigue property (above 1 million times), strong pressurization performance, adjustable rigidity, high compression ratio (higher than 80%), capability of micromation of inner holes, high precision of geometric dimensions, strong destabilization resistance, precise and controllable weldingline profile, adjustable width of weldingline and the like. By using the invention, the diaphragm capsule in the shape of circle, square and other shapes can be manufactured, and can serve as a compensation element of displacement and angle in hydraulic, barometric, transferring pipeline installation, an elastic compensation element and a pore damping element as well as a measuring element for a manometer and an altimeter; besides, the diaphragm capsule can be also used as a heat transferring finned tube for air conditioning, refrigeration and other devices as well as a metal capsule of separating gas or liquid for an accumulator and a storage box. The invention can provide multilayer structure diaphragm capsule products with fine performance for related industries.

Owner:北京智创联合科技股份有限公司

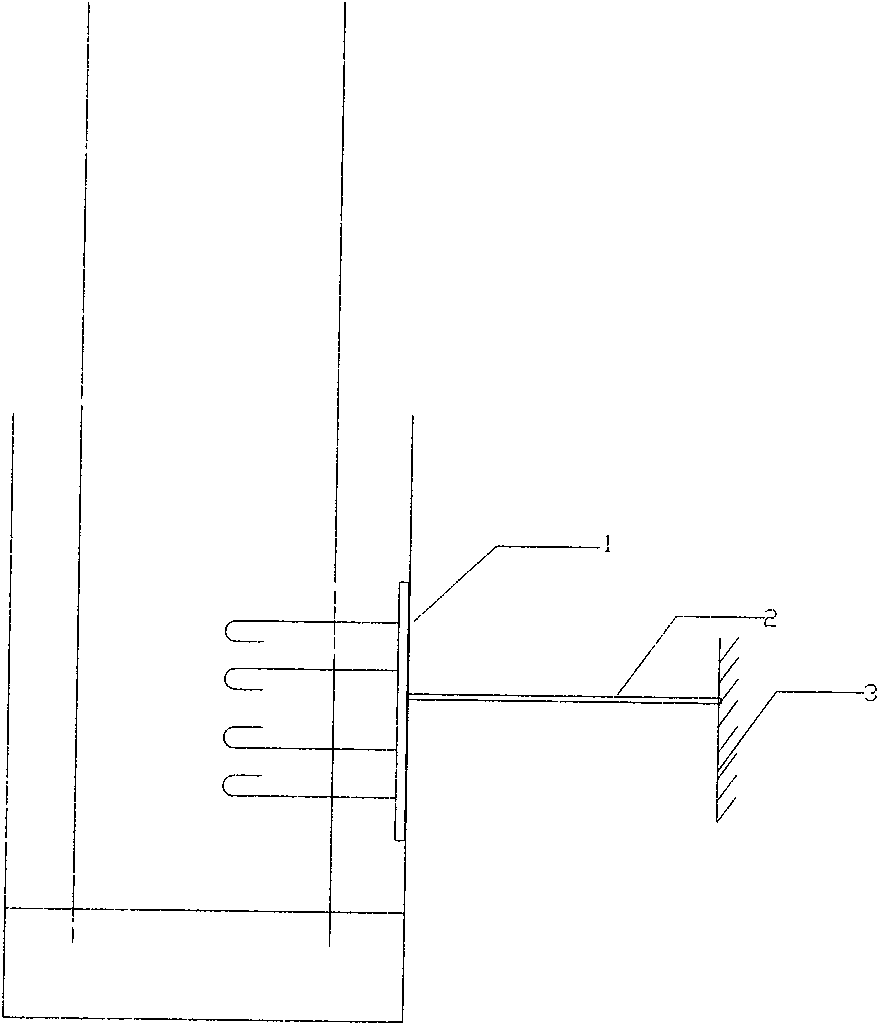

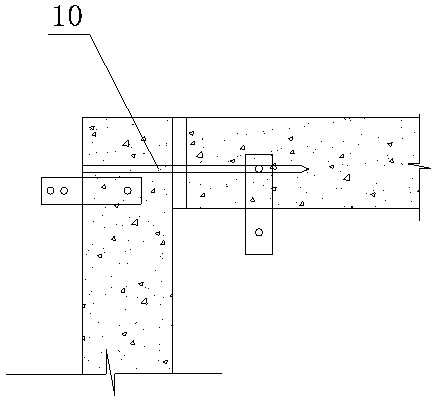

Fixation and installation method of embedded iron parts

InactiveCN101538899AAccurate positioning and installationLow costBuilding material handlingSteel tubeCost savings

The invention relates to a fixation and installation method of embedded iron parts. The method comprises the following steps: (1) welding a steel tube or a reinforced bar on a front surface of the embedded iron parts as a connecting rod, and fixing the embedded iron parts by connecting the connecting rod and an external firmware; and (2) tying the reinforced bars, molding or pouring concrete by taking the embedded iron parts as a formwork around the embedded iron parts, demolding and cutting off the connecting rod after the concrete reaches the strength. Compared with the existing installation method of the embedded iron parts, the method is not affected by concrete vibrating function and can help accurately position and install the embedded iron parts without deviation and displacement, and especially for large-tonnage embedded iron parts, the method does need a steel frame for fixing the iron parts to be installed in a member, thus saving cost. The method is characterized by rational design, convenient use and cost saving and especially suitable for high-precision installation of large-tonnage embedded iron parts.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

Construction method for light sand autoclaved aerated concrete (AAC) plates

The invention discloses a construction method for an autoclaved lightweight sand aerated concrete (AAC) plate, comprising: (1) determining the installation positioning line; (2) installing the plate in place; (3) installing a special connector; (4) Adjust the verticality and flatness of the board; (5) seam treatment; (6) fix the bottom of the board; (7) clean up; (8) check and accept. The construction method of an autoclaved lightweight sand aerated concrete (AAC) slab of the present invention has precise positioning and installation, good verticality and flatness, can control the construction quality, can improve work efficiency, and has good popularization and application value.

Owner:QINGDAO NO 1 CONSTR GRP

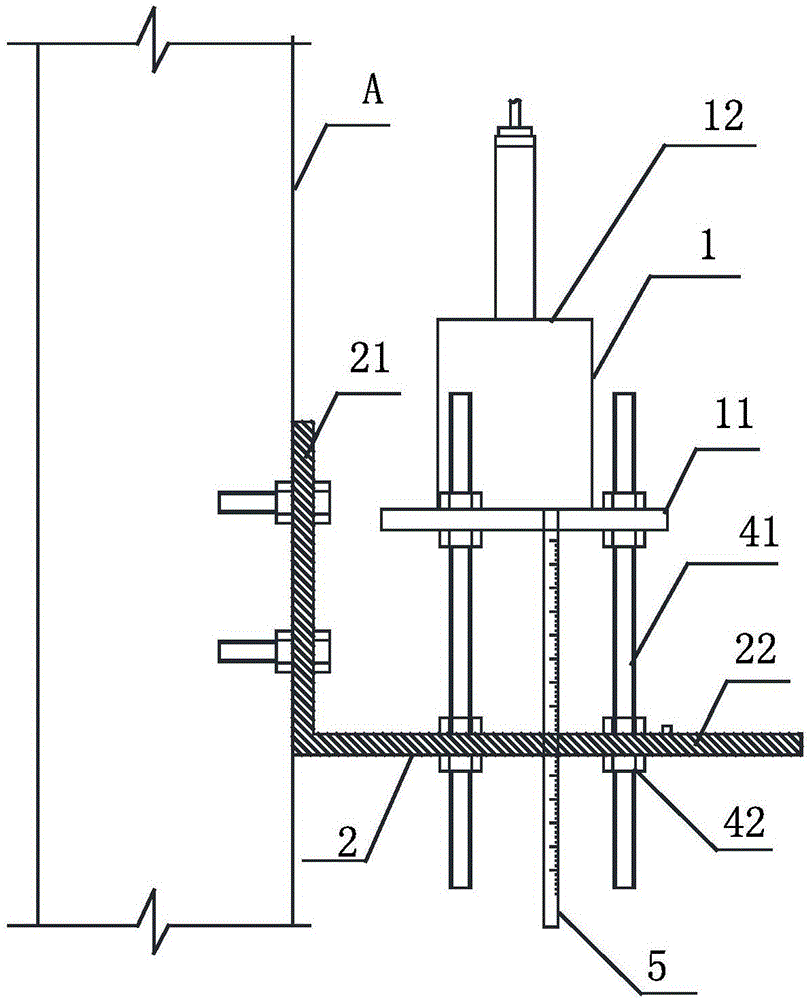

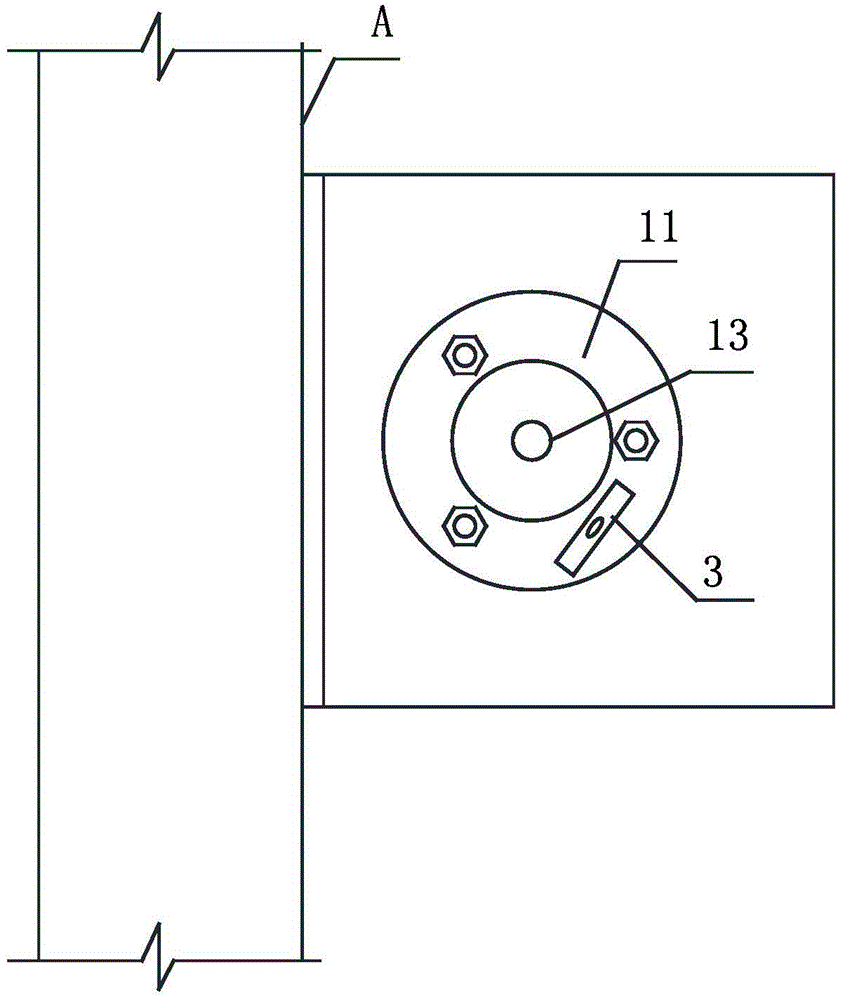

Wall-hanging hydrostatic level mounting device and wall-hanging hydrostatic level mounting method

InactiveCN104535045ASave installation timeSave time on levelingHydrostatic levellingEngineeringThreaded rod

Owner:SHANGHAI CONSTRUCTION GROUP

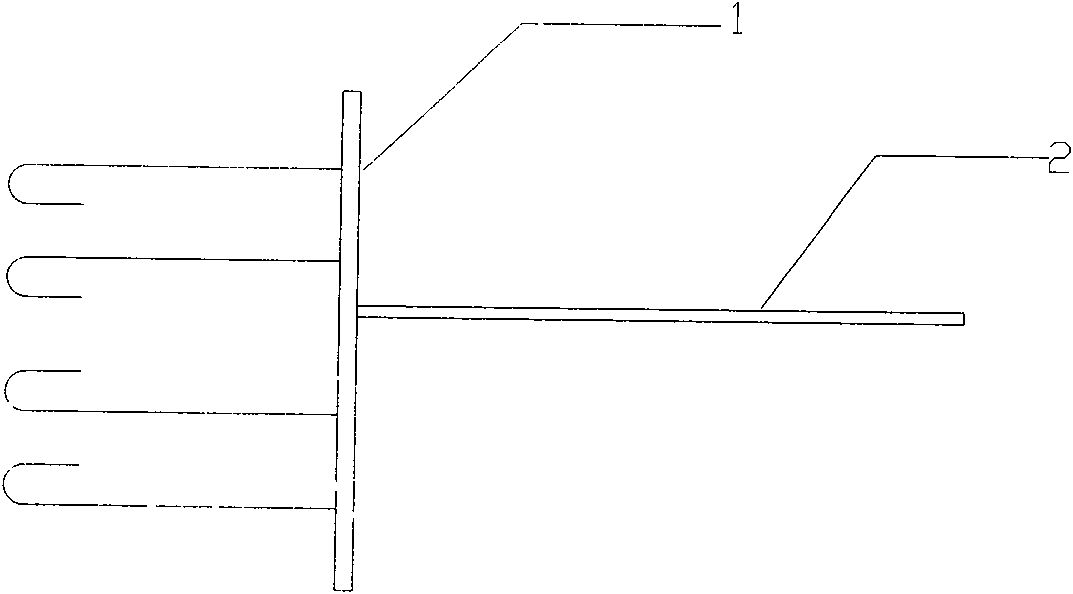

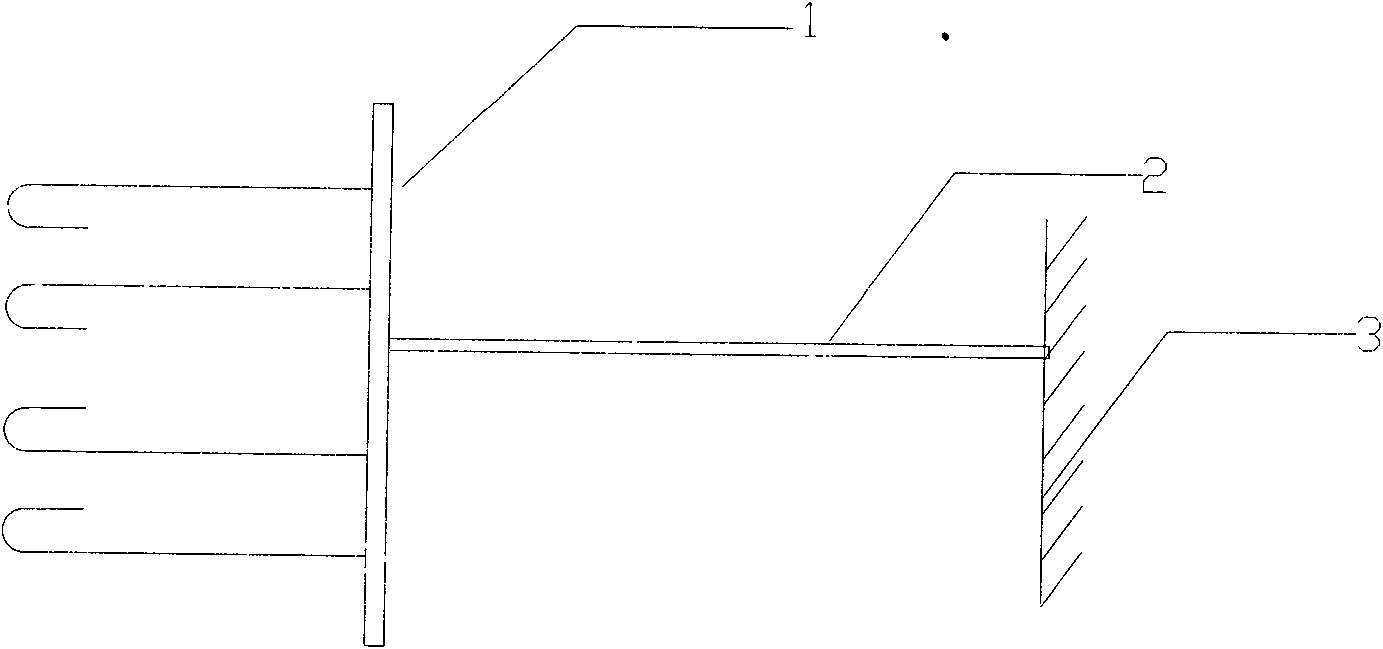

Acromioclavicular joint elastic micro-motion fixing plate

The invention relates to an acromioclavicular joint elastic micro-motion fixing plate and belongs to the technical field of human body implants. The acromioclavicular joint elastic micro-motion fixing plate is composed of a micro-arc-shaped main plate, two U-shaped structures, a left twisting plate and a right twisting plate. The left twisting plate and the right twisting plate are symmetrically manufactured at one end of the micro-arc-shaped main plate, the left twisting plate and the right twisting plate are connected with the micro-arc-shaped main plate through the U-shaped structures, and the U-shaped structures can conduct flexible adjustment in the horizontal plane and the vertical plane. The micro-arc-shaped main plate, the left twisting plate and the right twisting plate are provided with fixing holes respectively. The micro-arc-shaped main plate, the two U-shaped structures, the left twisting plate and the right twisting plate fixedly support the three ends of a shoulder blade, control the gap size and the moving range of an acromioclavicular joint, and are suitable for micro motion of the acromioclavicular joint in each direction, firm in fixing, and easy, convenient and accurate to install and position. The problems that an existing hook steel plate structure makes pressure stress of an acromion and the clavicle too large and cannot control the gap size and the moving range of the acromioclavicular joint, operation restoration is prone to being unsatisfactory, a hook slides down from the acromion, and the treatment effect is seriously impacted are solved.

Owner:BIODA DIAGNOSTICS WUHAN

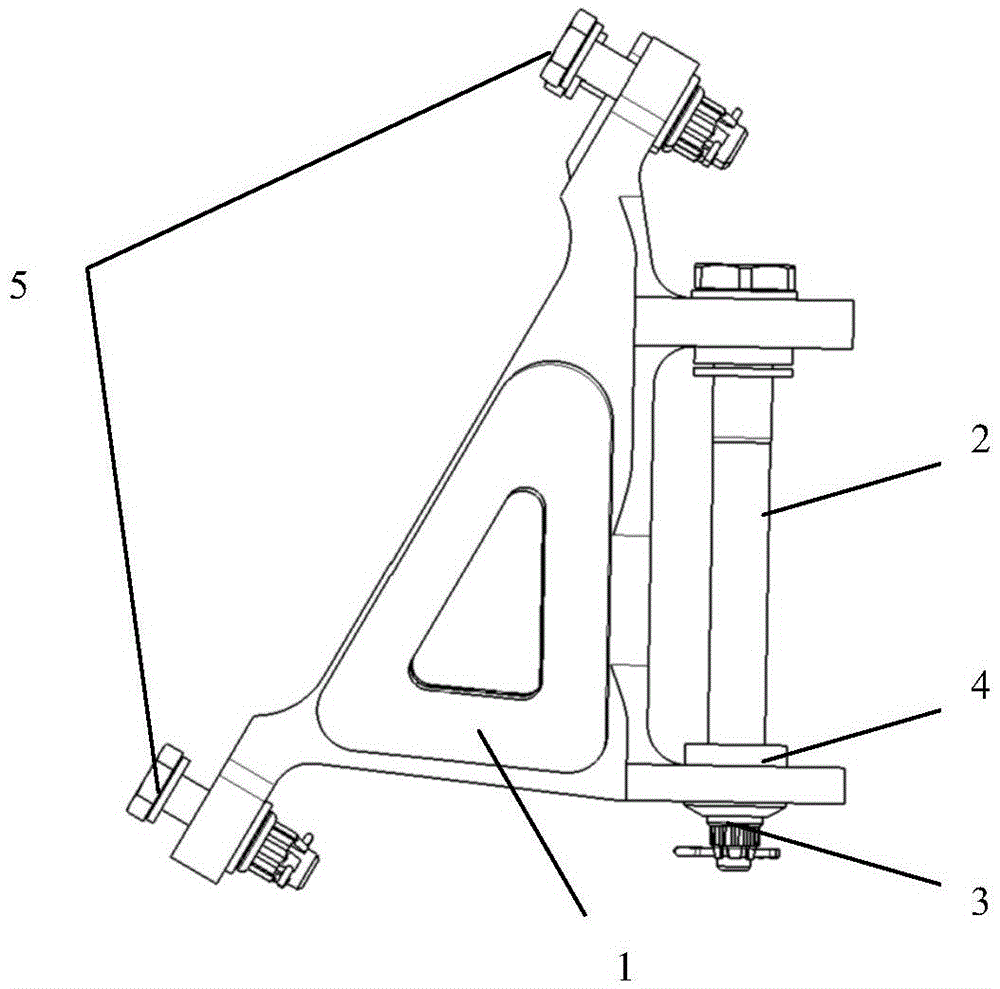

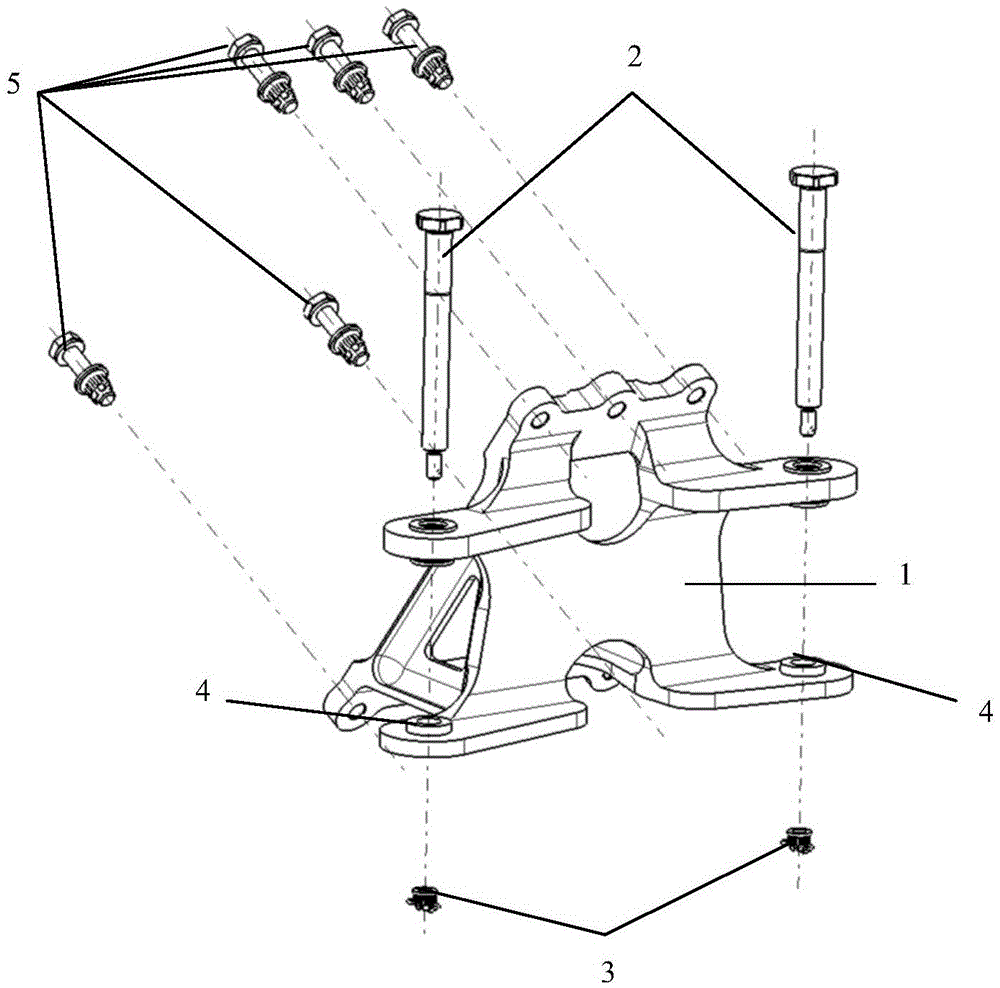

Horizontal tail connection device for helicopter

InactiveCN105109670AAvoid errorsAccurate installation and positioningAircraft stabilisationAircraft assemblyFuselagePetroleum engineering

The invention belongs to the technology of a horizontal tail of a helicopter, in particular to a horizontal tail connection device for the helicopter. The horizontal tail connection device is provided with a fuselage connection joint, one side of the fuselage connection joint is combined and connected to a rear fuselage structure through a bolt, and double fork ears used for being connected with the horizontal tail are arranged at the top of the other side of the fuselage connection joint. The double fork ears are connected with mounting holes preformed in a girder of the horizontal tail through connecting bolts, connecting nuts and adjusting gaskets. The connection device capable of quickly dismounting and mounting the horizontal tail of the helicopter can dismount the horizontal tail only by manually dismounting the bolts without a large tool and is convenient to maintain the horizontal tail of the helicopter.

Owner:HARBIN

Visual-system-based equipment for placing valves into trays automatically

PendingCN110587362AGet the job done efficientlyRegularly stacked and neatly placedMetal working apparatusEngineeringAssembly line

The invention relates to the field of automatic production equipment, in particular to visual-system-based equipment for placing valves into trays automatically. The visual-system-based equipment comprises an electric control cabinet, a material feeding mechanism, a material insert mechanism, a module horizontal traveling mechanism, a module longitudinal traveling mechanism and a material tray transmission mechanism, wherein the module longitudinal traveling mechanism comprises a driving guide rail set and a driven guide rail set which are parallelly arranged on the electric control cabinet, the material tray transmission mechanism is arranged above the electric control cabinet in an erected manner in the traveling direction of the module longitudinal traveling mechanism, the module horizontal traveling mechanism is arranged on the driving guide rail set and the driven guide rail set in an erected manner, the material feeding mechanism and the material insert mechanism are movably installed on the module horizontal traveling mechanism through a sliding plate, and the material feeding direction of the material feeding mechanism is inclined to the horizontal traveling direction of the material insert mechanism. The visual-system-based equipment for placing the valves into the trays automatically has the beneficial effects that the more accurate function of placing the valves intothe trays is realized in combination with a visual system, different from valve material tray positioning installation in the prior art and in combination with an assembly line type transmission method, the purpose of placing the valves into the trays is achieved more efficiently under an equipment continuous running state, operations are more flexible, and the work intensity is lowered more.

Owner:CHONGQING ELECTROMECHANICAL VOCATIONAL INST

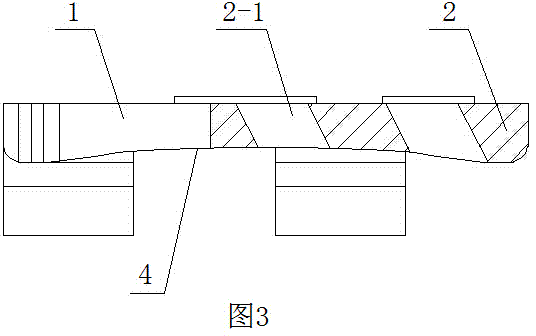

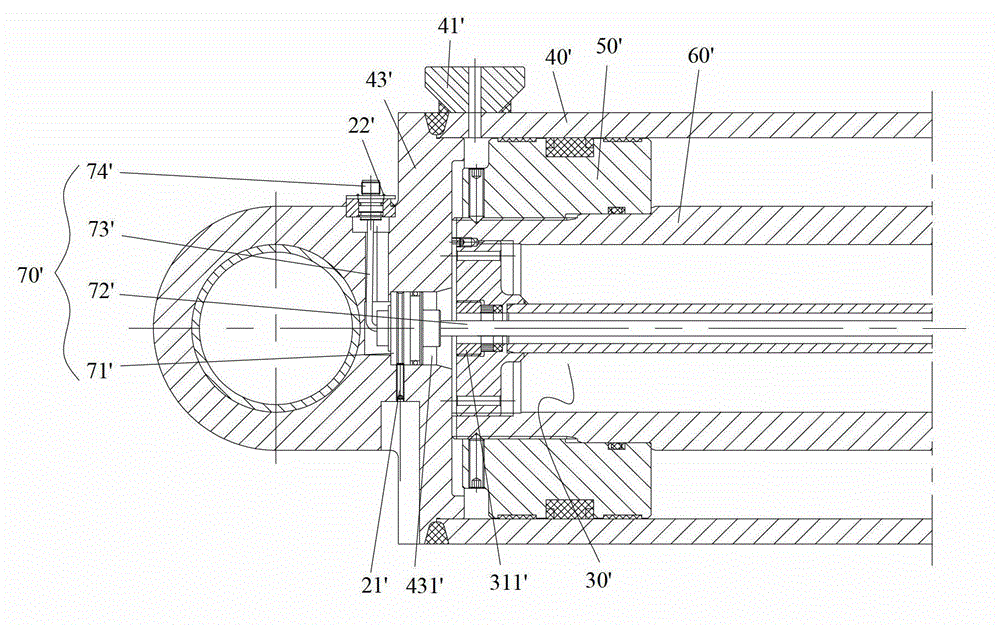

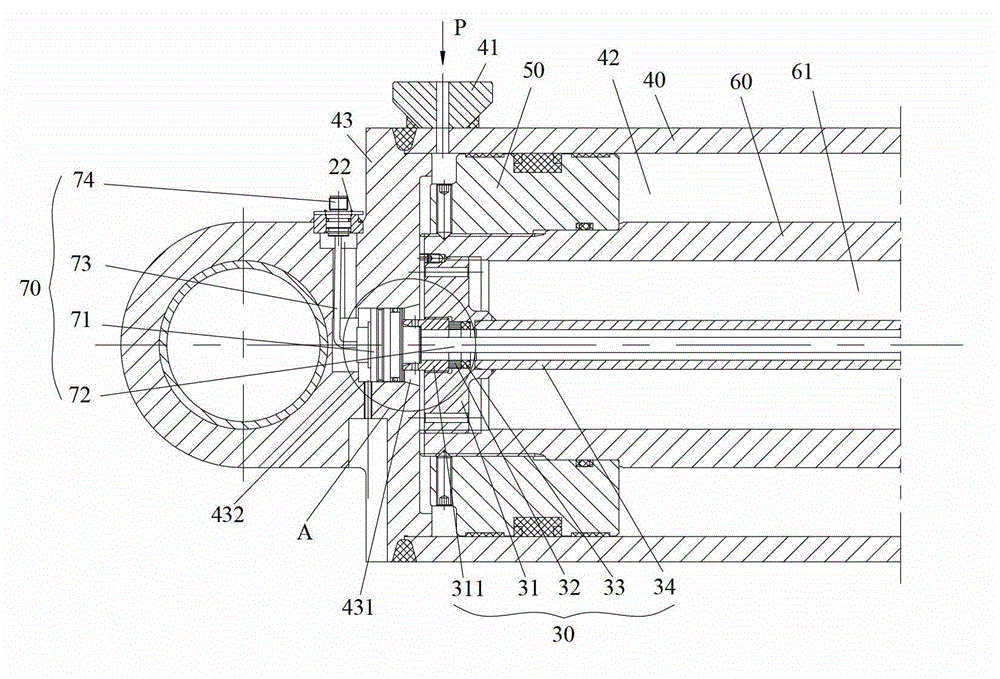

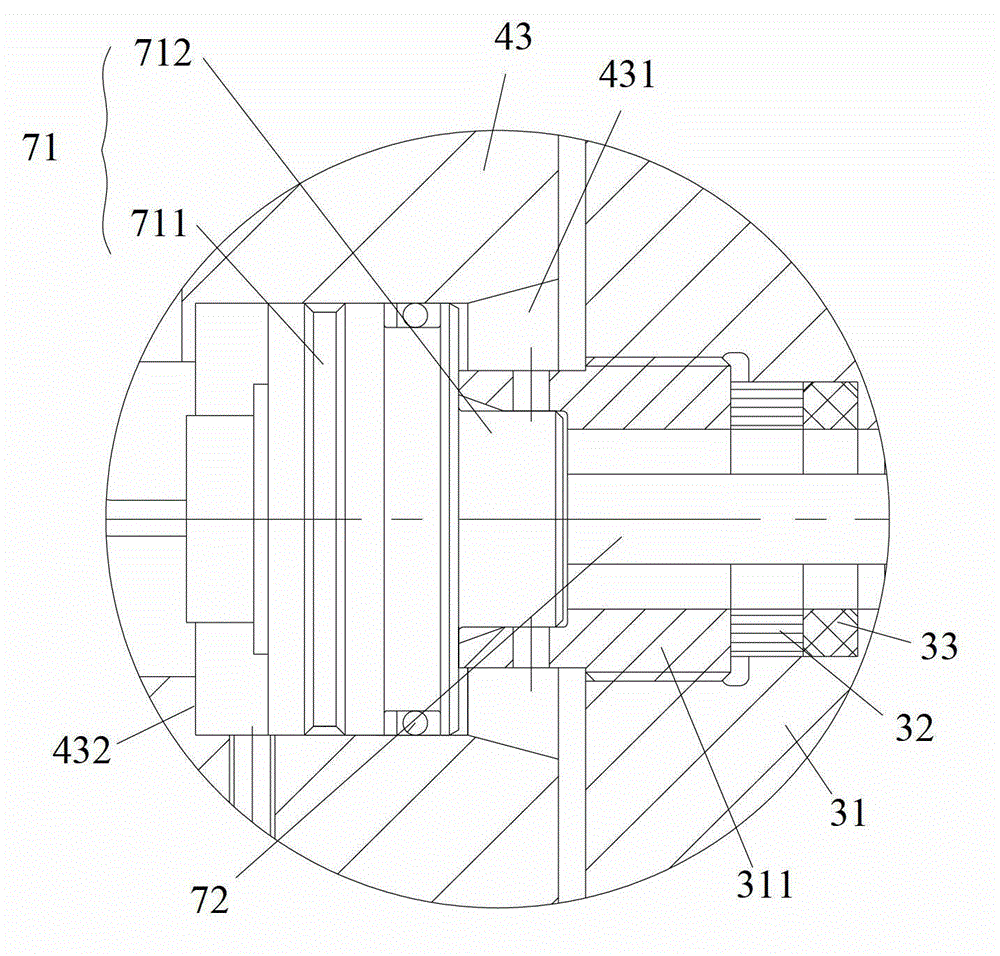

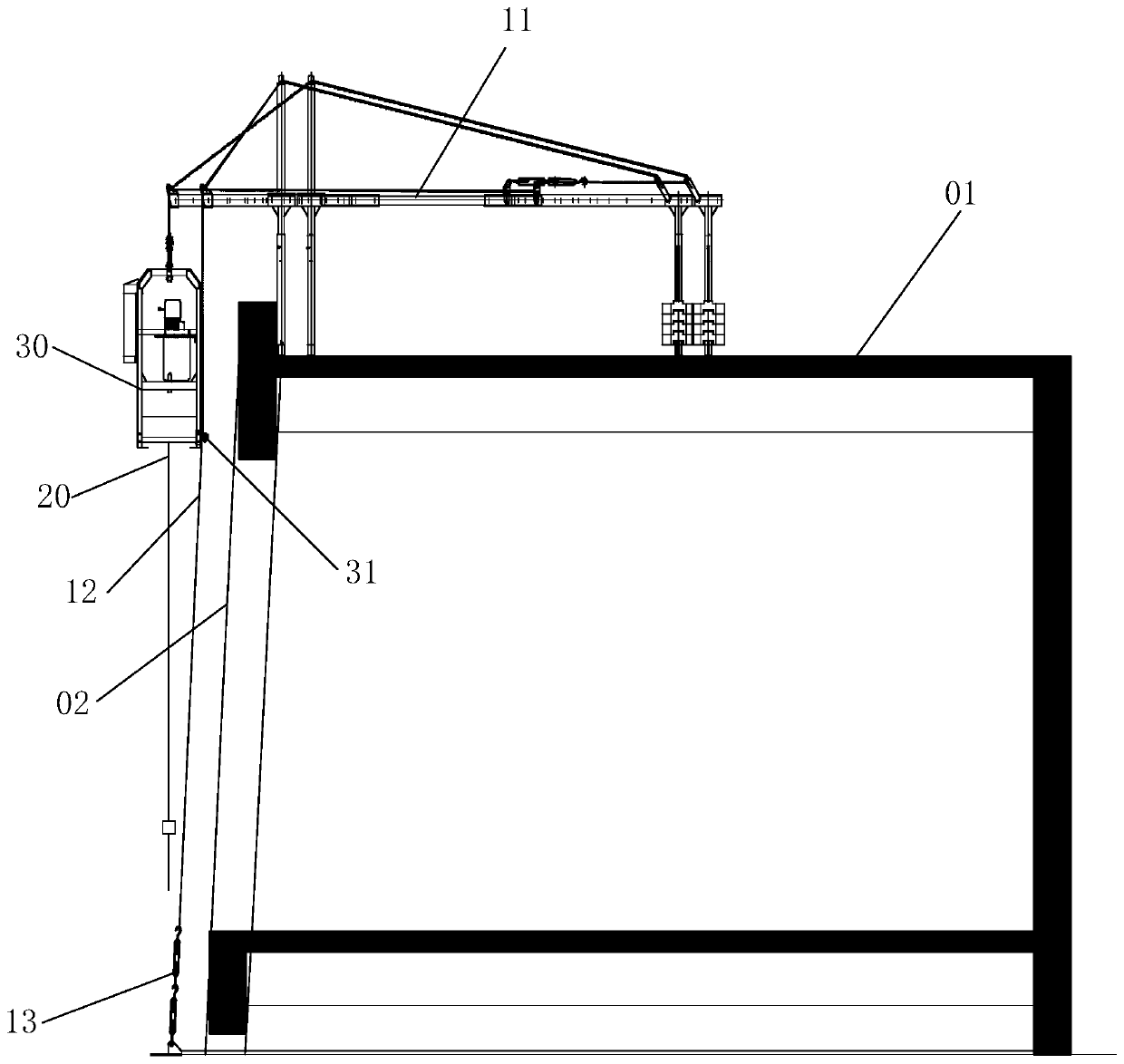

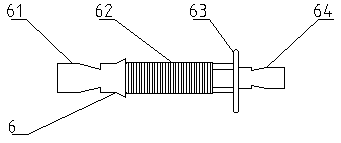

Piston cylinder and installation method thereof

ActiveCN102943785AAccurate installation and positioningAvoid damageFluid-pressure actuatorsBiochemical engineeringPiston cylinder

The invention provides a piston cylinder and an installation method thereof. The piston cylinder comprises a cylinder barrel (40), a piston rod (60) and an installation base assembly (30). The cylinder barrel (40) is provided with an end cover (43), the end cover (43) is provided with a first inner hole (431) arranged along the axial direction of the end cover (43), the piston rod (60) is provided with a second inner hole (61) which is coaxial with the first inner hole (431), the installation base assembly (30) is fixed in the second inner hole (61), the installation base assembly (30) is provided with a third inner hole, the third inner hole and the first inner hole (431) are arranged coaxially, the third inner hole penetrates through a sensor (70), the third inner hole comprises a first inner hole section (3112), and the first inner hole section (3112) adapts to a sensor head (71) of the sensor (70) so as to clamp the sensor head (71) and achieve radial positioning. The piston cylinder facilitates installation of the sensor.

Owner:HUNAN TELI HYDRAULIC

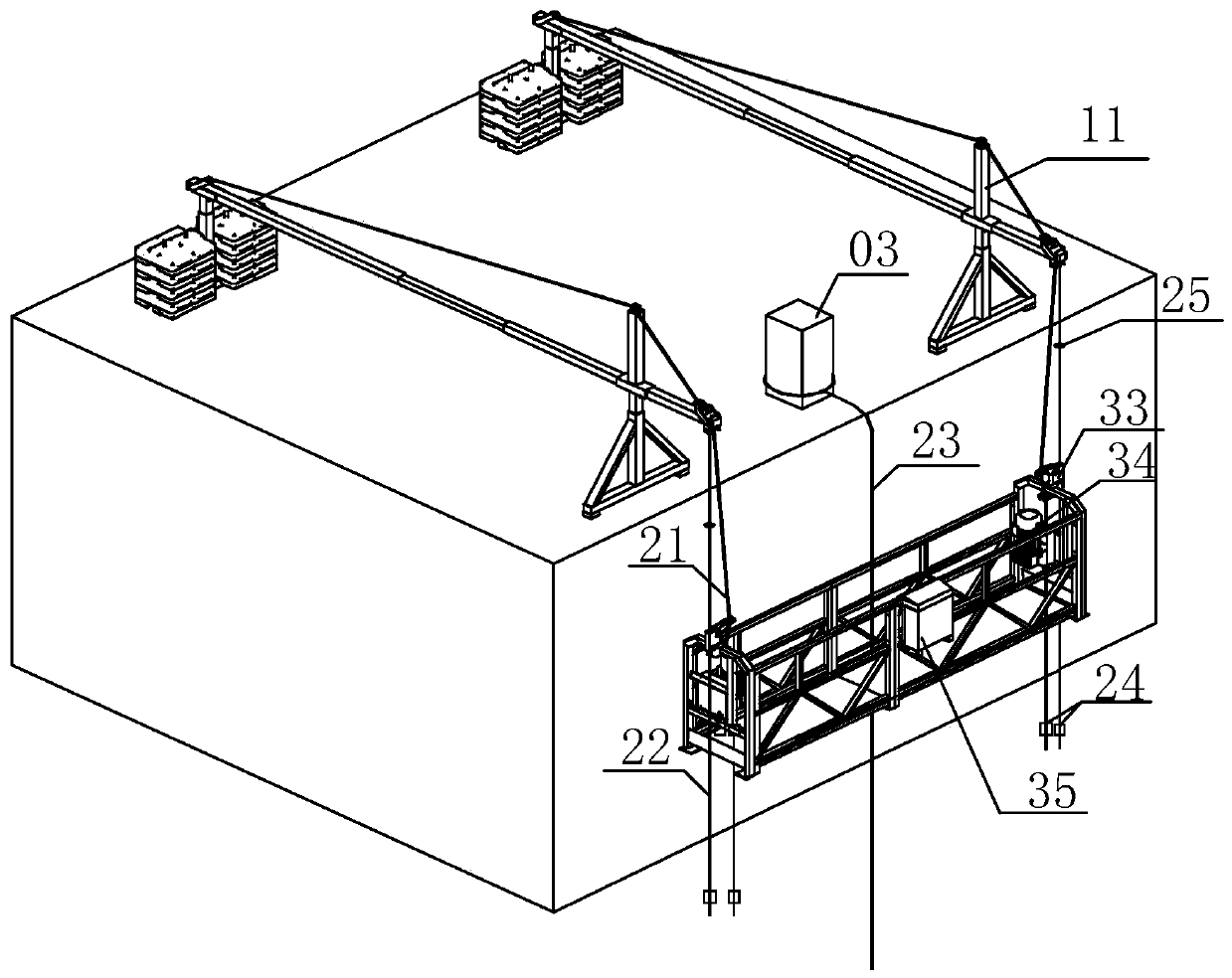

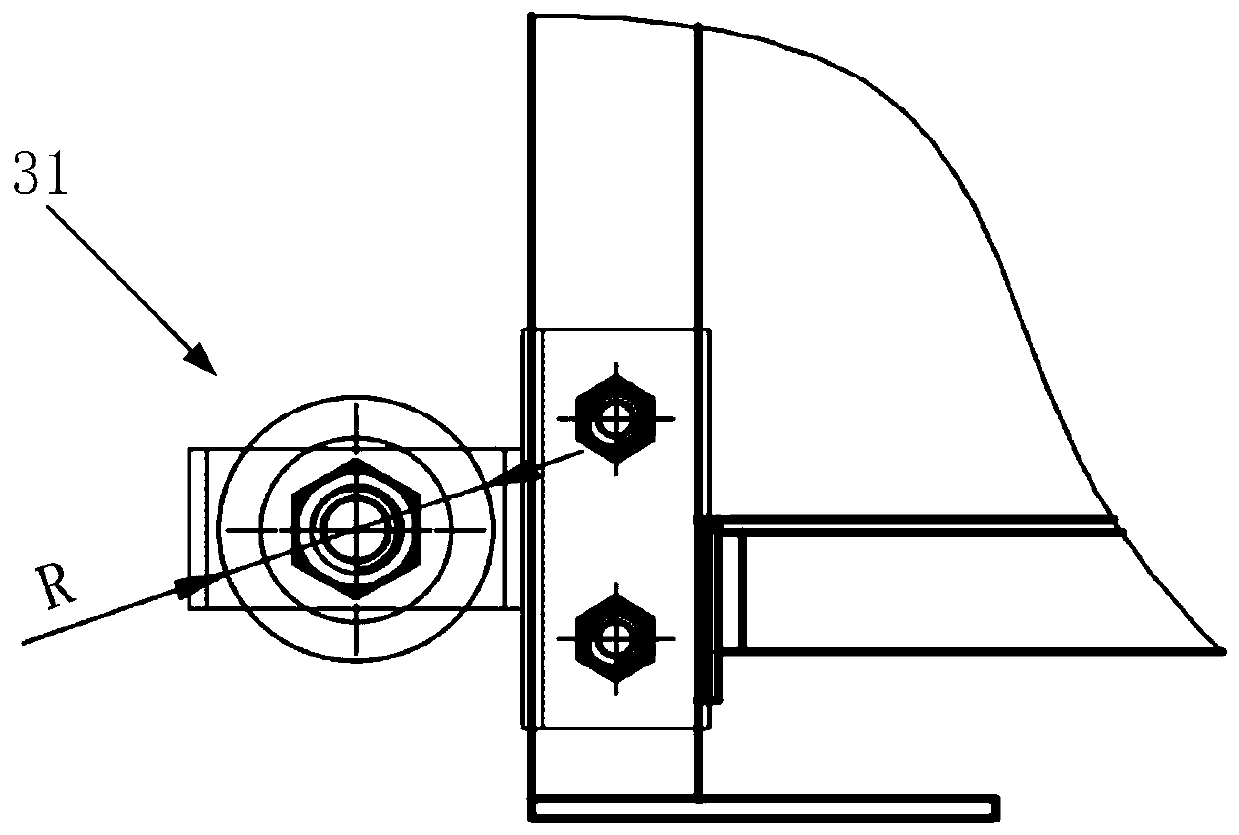

Hanging basket applied to curved surface and construction method thereof

PendingCN111021705AAppropriate distanceMeet construction requirementsBuilding support scaffoldsClassical mechanicsHanging basket

The invention relates to a hanging basket applied to a curved surface and a construction method thereof. The hanging basket comprises a guide mechanism, a suspension mechanism and a working platform,the guide mechanism comprises a support and a first steel wire rope, the support is fixed to the top of a building, one end of the first steel wire rope is fixed to the support, the other end of the first steel wire rope is fixed to the ground, and the first steel wire rope has pre-tightening force; the suspension mechanism comprises at least two second steel wire ropes, one end of each second steel wire rope is fixed to the support, and the other end of each second steel wire rope is a free end; the second steel wire ropes are adjustably hoisted on the working platform through a safety lock;a guide wheel device is arranged at the bottom of the side, close to the wall, of the working platform, and the first steel wire rope is arranged in a rail of the guide wheel device so that the working platform can slide along the first steel wire rope. According to the hanging basket, the guide mechanism independent of the suspension mechanism is matched with the guide wheel device on the workingplatform to guide the movement of the working platform, so that a proper distance is kept between the working platform and a construction wall surface, and the construction requirement is met.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

Automatic adjusting and positioning method for casting fixture

InactiveCN105058103AAccurate installation and positioningHigh degree of automationMeasurement/indication equipmentsPositioning apparatusEngineeringAutomatic testing

The invention discloses an automatic adjusting and positioning method for a casting fixture. The method comprises the following steps: mounting the casting fixture; primarily clamping a casting; detecting the primary clamping in place of the casting; jacking the casting; rotating a reference positioning block: enabling a turning and reversing motor to reverse to drive a reference rotating disk and the reference positioning block on the reference rotating disk to rotate; clamping the casting again; detecting the second clamping in place of the casting. According to the method, a pressure sensor can detect whether the casting is clamped in place or not; if not, a PLC automatically locks a handle and unlocks an automatic locking pin according to instructions. The turning and reversing motor turns, a jacking circular table can jack a casting to be accurately positioned; then, the turning and reversing motor reverses, the reference rotating disk is driven to rotate for a certain angle; then the turning and reversing motor continues to turn, and the jacking circular table declines, so that the casting and the reference positioning block are positioned again.

Owner:WUXI LEHUA AUTOMATION TECH

Casting tool fixture

InactiveCN105058119AHigh degree of automationIncrease productivityMeasurement/indication equipmentsPositioning apparatusProgrammable logic controllerEngineering

The invention discloses a casting tool fixture which comprises a PLC (Programmable Logic Controller), air pipes, a bottom plate, and a corner oil cylinder that is arranged in the center of the bottom plate, wherein a plurality of reference locating blocks are uniformly arranged on the bottom plate positioned at the periphery of the corner oil cylinder; each reference locating block is internally provided with an axial through hole connected with one air pipe; a pressure sensor connected with the PLC is arranged on each air pipe; an automatic locking handle connected with the PLC is arranged at the top of the corner oil cylinder; a hollow motor shaft with the height capable of being adjusted is coaxially arranged over the corner oil cylinder; the inner diameter of the hollow motor shaft is greater than the outer diameter of the corner oil cylinder; an annular electromagnet is mounted on the outer periphery of the bottom of the hollow motor shaft in a sleeving manner; the hollow motor shaft can rotate to drive the annular electromagnet to rotate; and the corner oil cylinder is coated with a non-magnetic layer. With the adoption of the structure, whole feeding, detection and adjustment processes are accomplished automatically, the mounting and location are precise, and the automation degree and the production efficiency are high.

Owner:WUXI LEHUA AUTOMATION TECH

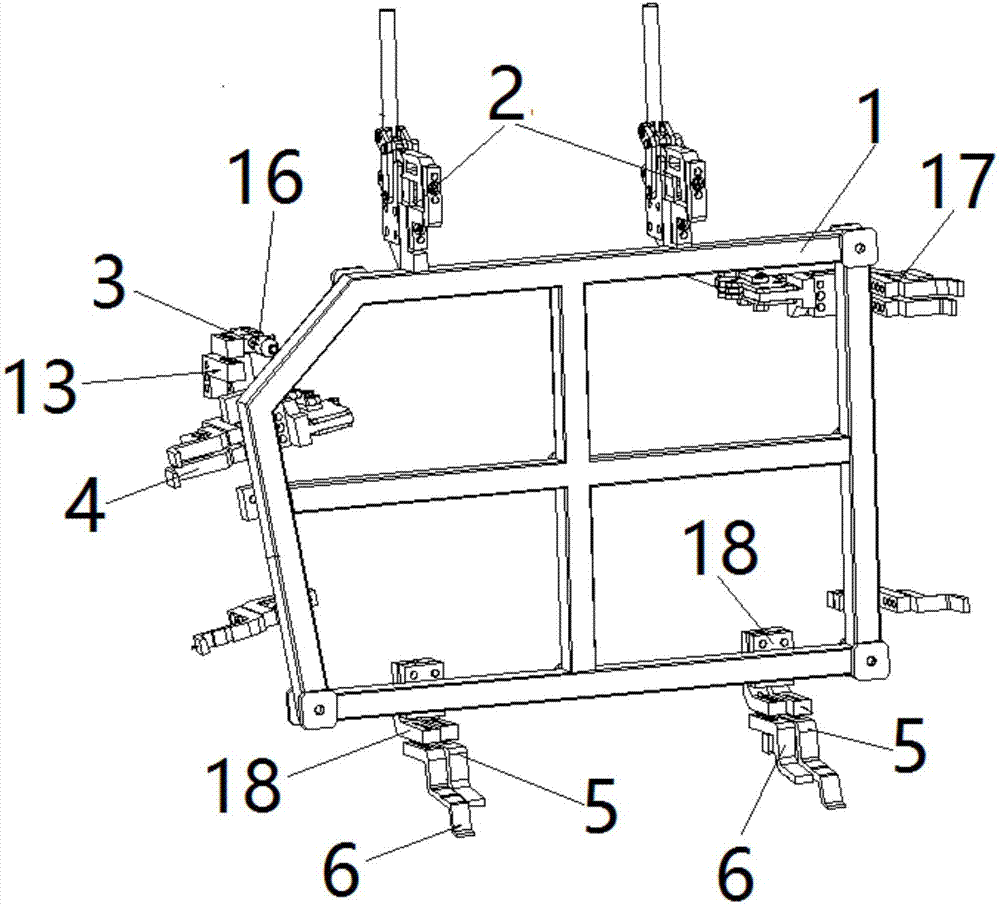

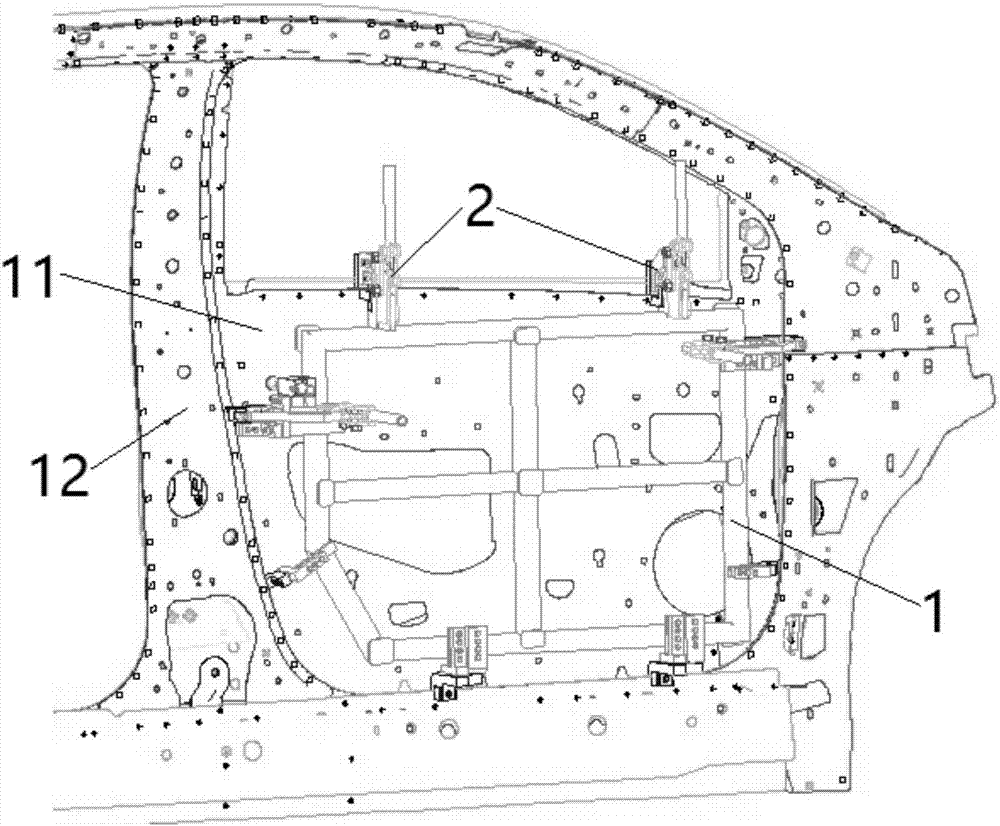

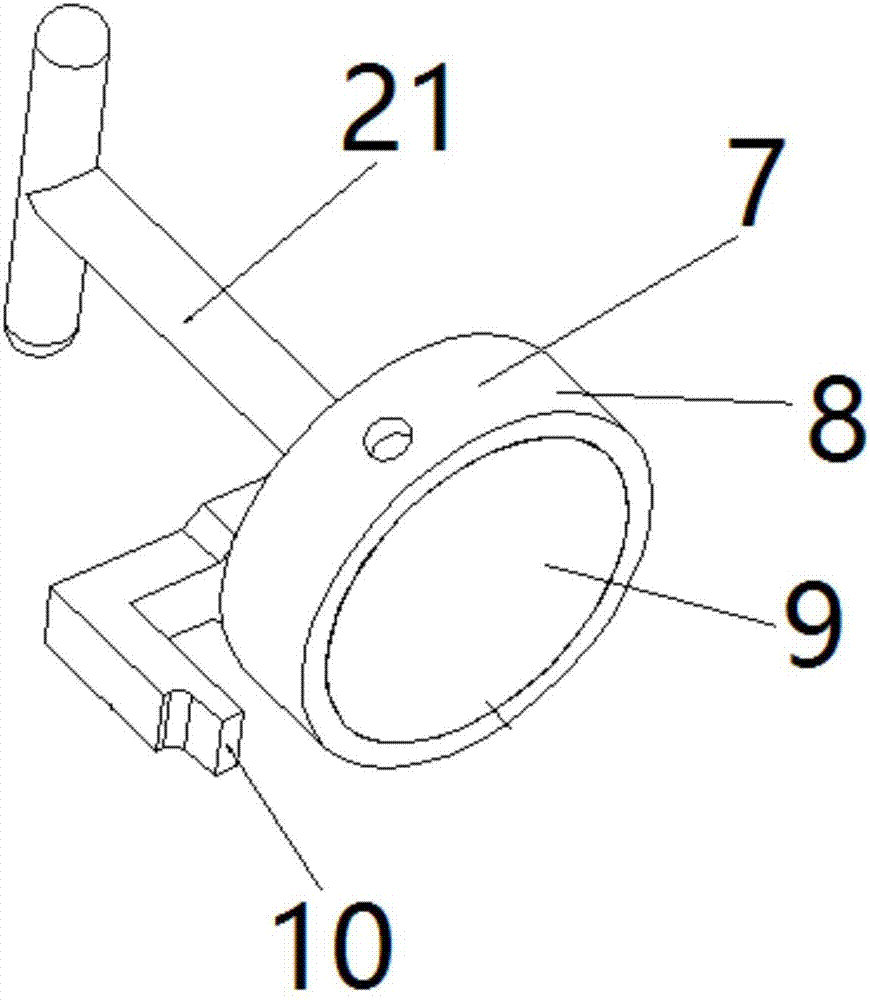

Automobile door positioning installation device

Owner:ANHUI RUIXIANG IND

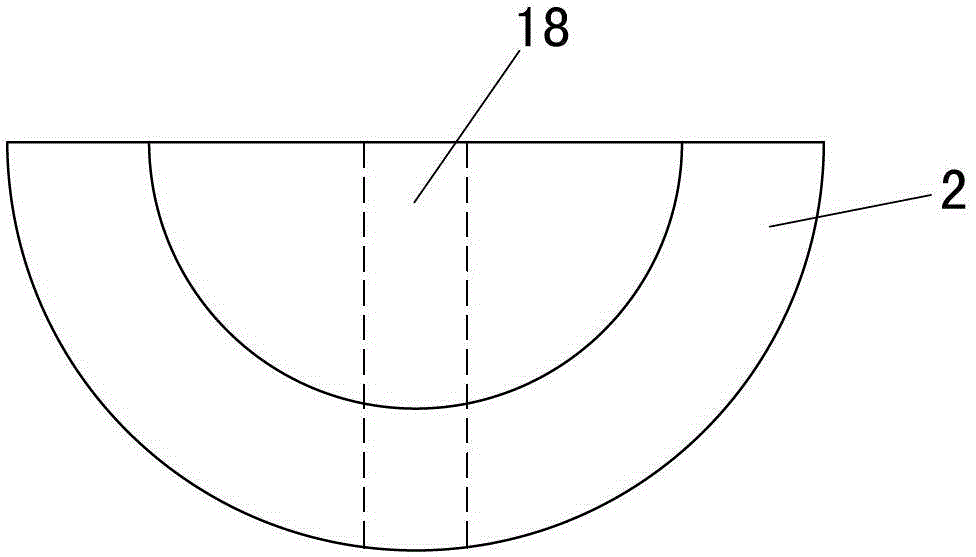

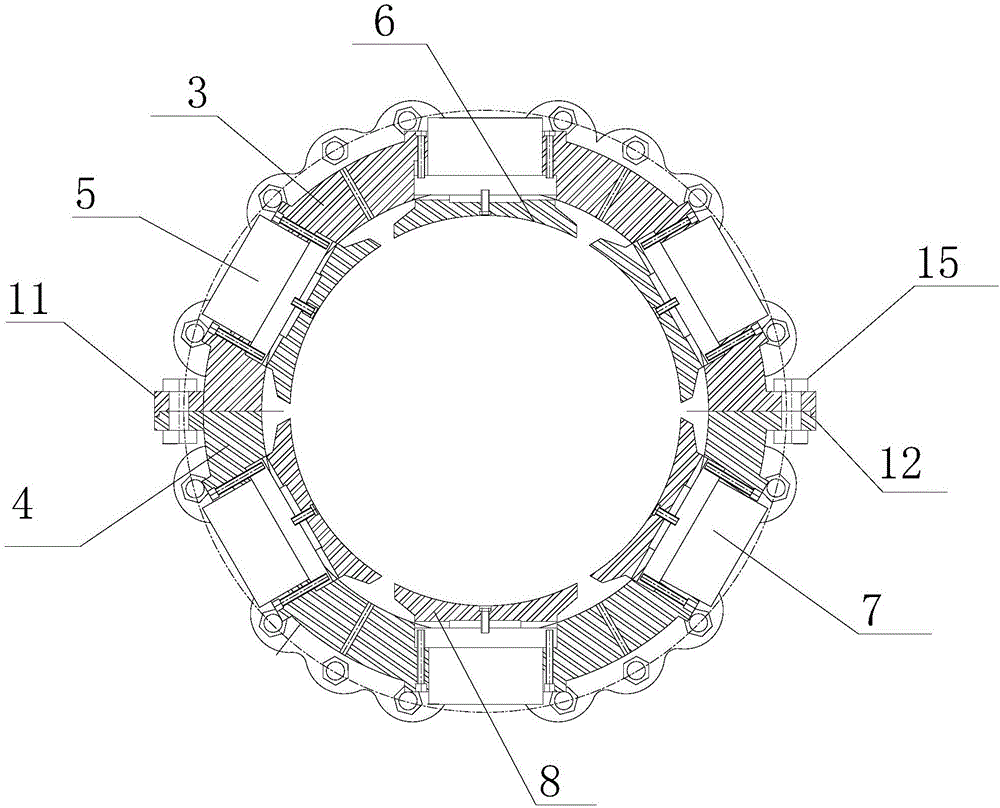

Cylindrical horizontal physical simulation test device for coal mine sinking and driving engineering

InactiveCN106289991AImprove integrityIncrease stiffnessMaterial strength using tensile/compressive forcesEducational modelsEngineering physicsCoal

The invention provides a cylindrical horizontal physical simulation test device for coal mine sinking and driving engineering. Each confining pressure loading unit is of a half structure and is formed by connecting and assembling an upper half-round arc plate and a lower half-round arc plate which are completely symmetric through longitudinal flanges and high-strength bolts, the whole device comprises five confining pressure loading units of the half structures in total, and the adjacent half structures are connected through circumferential flanges and high-strength bolts. A loading end cover and a constraining end cover are designed at the two ends of the device and are connected with a cylinder formed by the half structures through high-strength bolts. Radial loading oil cylinders are arranged at equal intervals in the radial direction along the circumference of a confining pressure loading mechanism, wherein two circles of radial loading oil cylinders with the total number of twelve are evenly arranged on each half structure unit, in other words, sixty radial loading oil cylinders are arranged on the five half structures in total. Four axial oil cylinders are arranged on the loading end cover. The integrity and rigidity of the confining pressure structures are improved; besides, the confining pressure loading units of the half structures can carry out independent loading and individual control on test models, and the requirement for tests with different sizes of models with different functions is met.

Owner:ANHUI PROVINCE COAL SCI RES INST

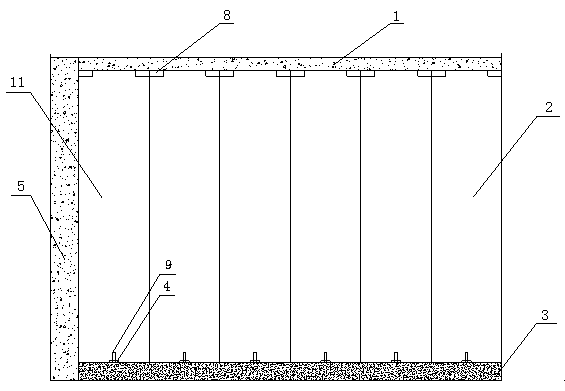

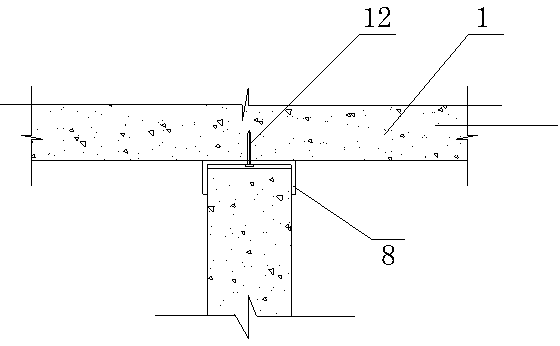

Precast sandwich external wall panel and structural system thereof as well as construction method

PendingCN107642194AEasy to installImprove structural strengthBuilding componentsWater-setting substance layered productThermal insulationUltimate tensile strength

The invention discloses a precast sandwich external wall panel and a structural system thereof as well as a construction method. The precast sandwich external wall panel comprises an outer shale plate, a thermal insulation layer and an inner shale plate, wherein the thermal insulation layer is arranged between the outer shale plate and the inner shale plate; in addition, the thermal insulation layer penetrates through the precast sandwich external wall panel; the outer shale plate, the inner shale plate and the thermal insulation layer are connected by anchored connecting members. The precastsandwich external wall panel and the structural system thereof provided by the invention have the characteristics of simple structure, convenience in mounting and high structural strength; by using the construction method provided by the invention, an external wall board can be quickly and conveniently mounted to be in place; besides, the construction method has the advantages of high mounting strength, accurate mounting and positioning and low possibility of deviation.

Owner:NINGXIANG YUANDA RESIDENTIAL IND CO LTD

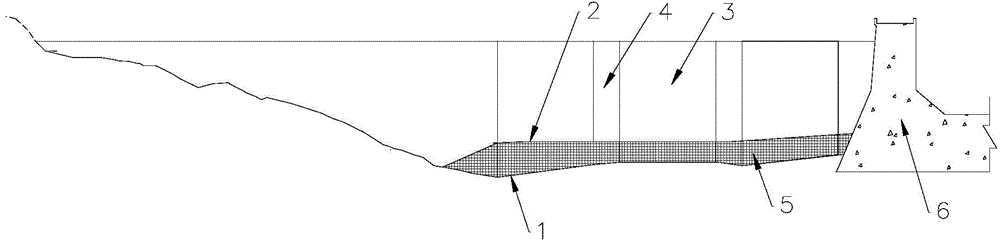

Construction method for steel sheet pile cofferdam on underwater exposed bedrock

ActiveCN104947698APrecise positioningAccurate installation and positioningBulkheads/pilesBedrockUnderwater

The invention discloses a construction method for steel sheet pile cofferdam on an underwater exposed bedrock. According to the method, steel sheet pile cofferdam can be constructed without grooving the exposed bedrock on an underwater plane. A covering layer is formed through sand filling, a construction environment that the covering layer is formed underwater is built, then a conventional steel sheet pile cofferdam construction technique is adopted directly, and steel sheet pile cofferdam construction is finished. The work of formation of a mounting groove through drilling on the water surface is omitted, the construction cost is effectively reduced, the construction cycle of a project is shortened, and the work efficiency is improved; a basic covering layer for steel sheet pile positioning is formed through sand throwing and filling, the construction environment that a covering layer is formed on the exposed bedrock underwater is built, steel sheet piles are subjected to insertion and closure construction, and then steel sheet pile cofferdam construction is completed. The method does not require underwater construction of mounting grooves, the steel sheet piles are accurately positioned, the difficulty of the construction technique is small, requirements for equipment are reduced, and high-efficiency and high-quality cofferdam construction is realized.

Owner:SINOHYDRO BUREAU 7 CO LTD

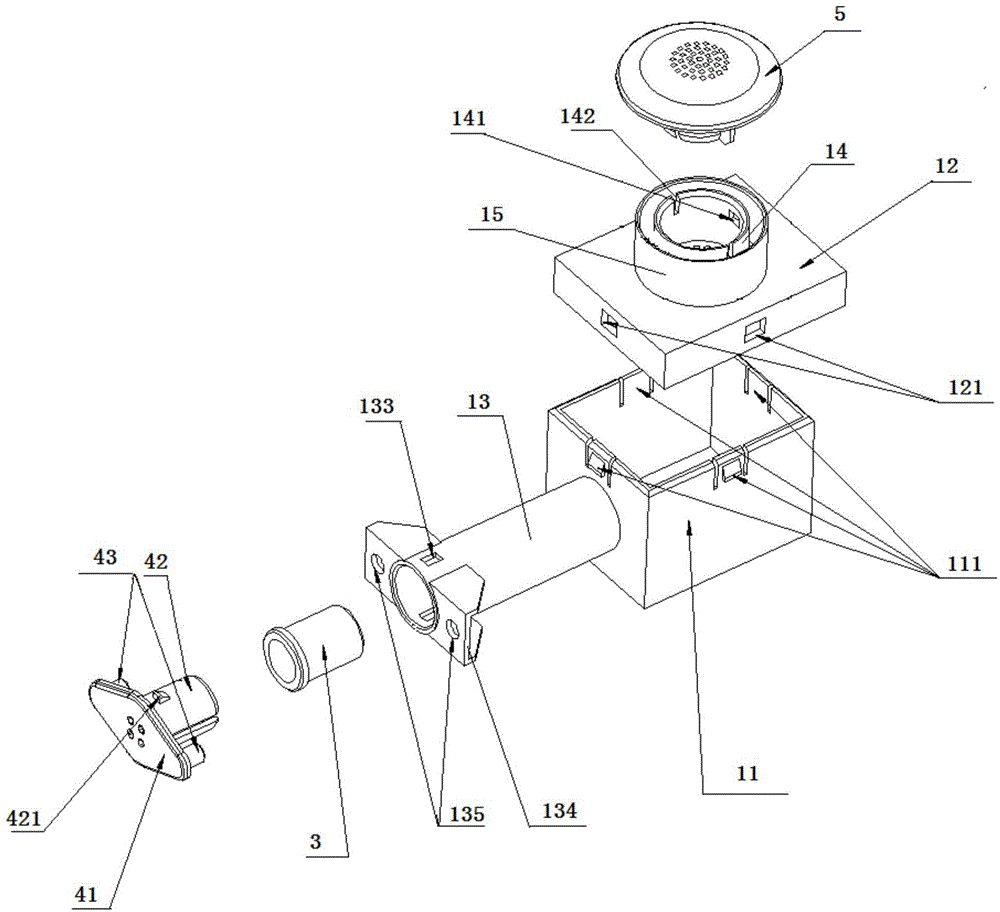

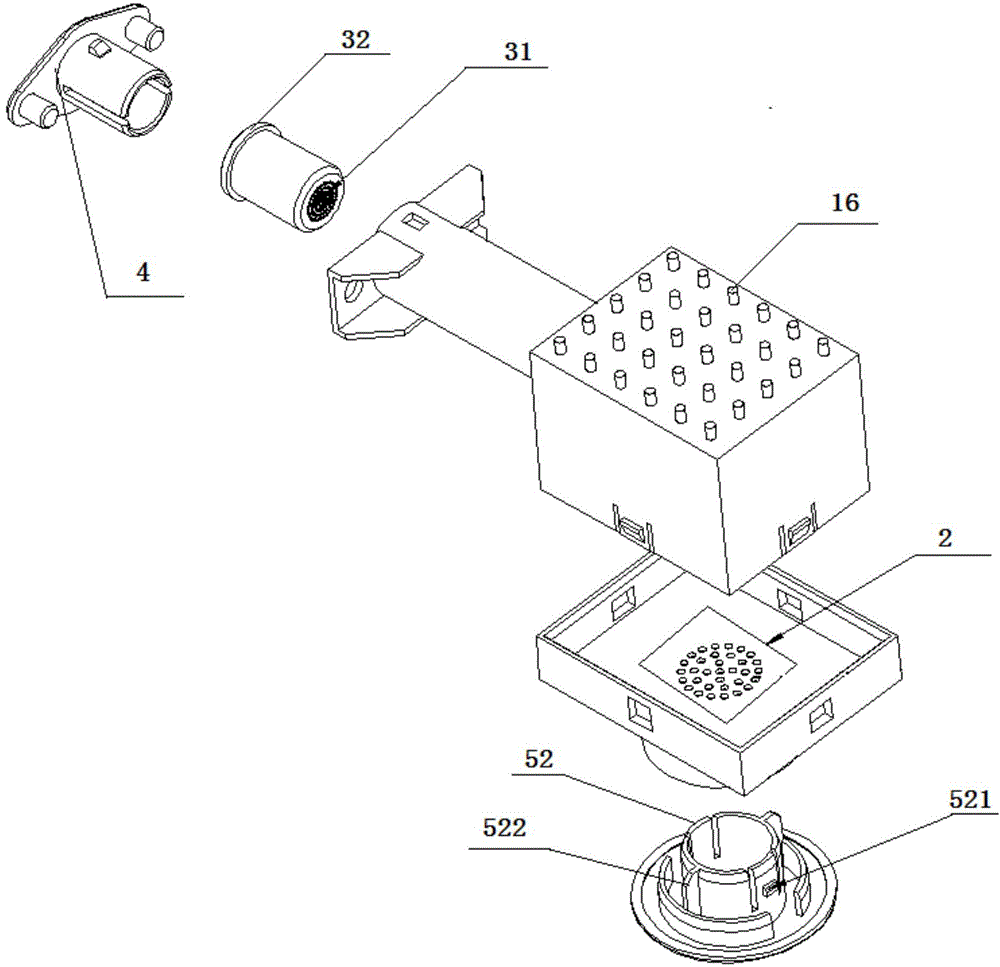

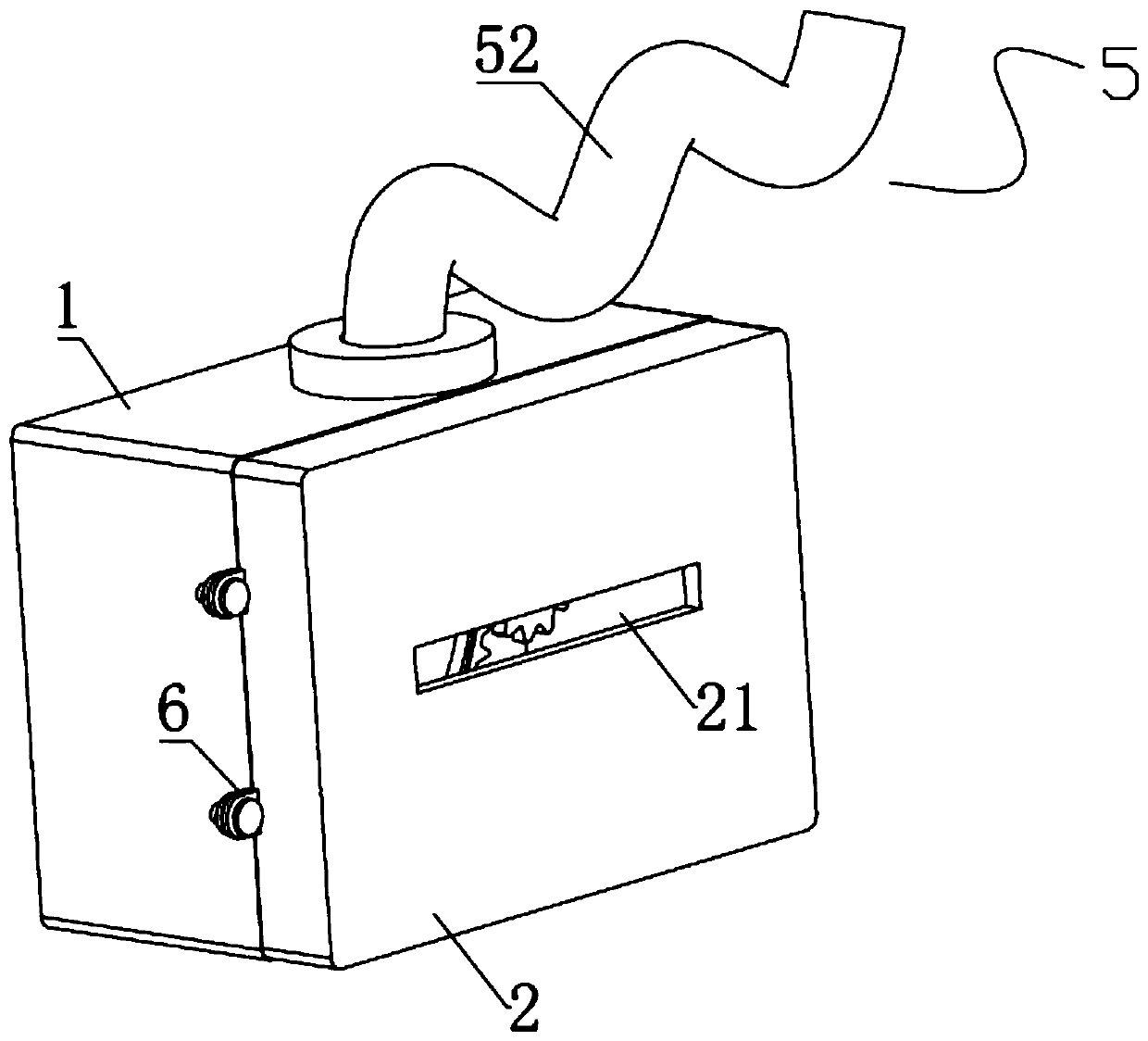

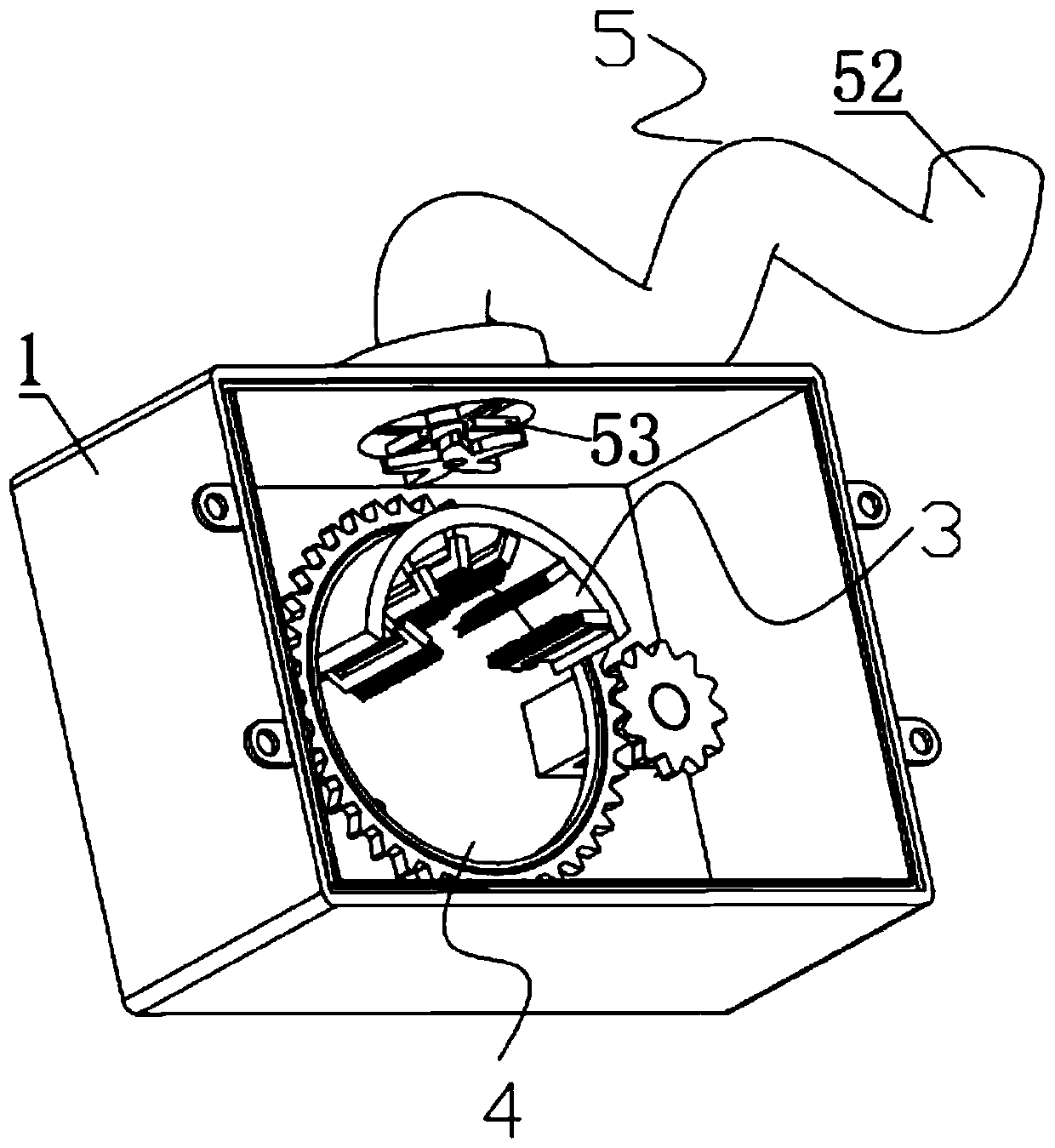

Ventilated defrosting device arranged on refrigerator door body and refrigerator

ActiveCN104949435AThe solution is not easy to openSolve the problem of energy consumptionLighting and heating apparatusDefrostingRefrigerator carRefrigerated temperature

The invention relates to a ventilated defrosting device arranged on a refrigerator door body and a refrigerator. The refrigerator door body comprises a shell and an inner container. The ventilated defrosting device comprises a molecular sieve box located between the shell and the inner container and enabling the interior and the exterior of the refrigerator to be communicated. According to the ventilated defrosting device arranged on the refrigerator door body and the refrigerator, the molecular sieve box is adopted to connect the inner side and the outer side of a refrigerator body, and the ventilated defrosting device is simple in mounting structure, easy to operate and free of other hoses in connection; the overall structure is suitable for production of different foaming clamps used in the rotating die combination and up-down die combination processes of the refrigerator door body, and the problems that it is difficult to open a door due to negative pressure in the refrigerator, and energy consumption is high due to frosting are solved effectively.

Owner:HEFEI HUALING CO LTD +1

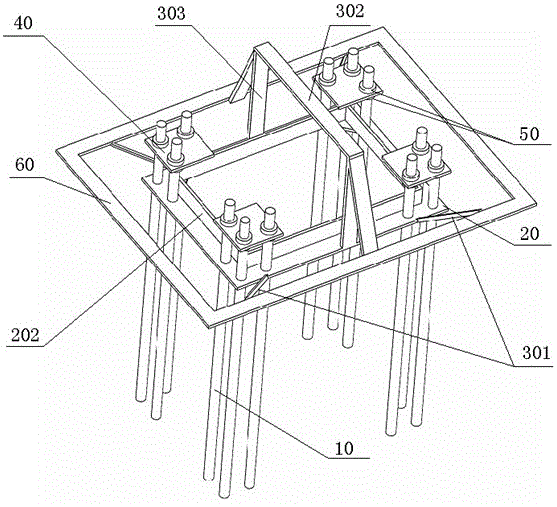

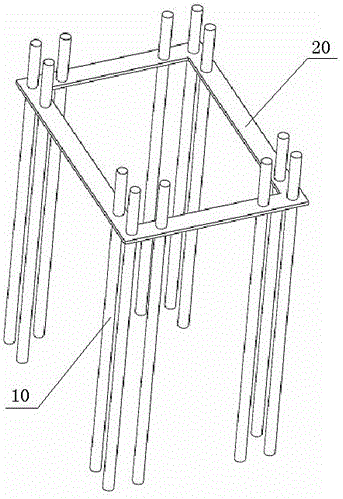

Construction method of foundation bolts of railway contact net and mounting bracket

ActiveCN105804110AAccurate installation and positioningReduce construction difficultyFoundation engineeringBridge erection/assemblyEngineeringAnchor bolt

The invention discloses a construction method of foundation bolts of a railway contact net and a mounting bracket. The mounting bracket comprises multiple vertical positioning support rods, a fixed limiting bracket, a space positioning bracket and multiple split limiting plates; the split limiting plates coat one set of foundation bolts with near positions, and are relatively fixed with the foundation bolts through upper and lower anchor nuts; the lower ends of the vertical positioning support rods are fixed according to the corresponding mounting positions of the foundation bolts, and the upper ends are inserted through the fixed limiting bracket; the foundation bolts coat the vertical positioning support rods; and the fixed limiting bracket is relatively fixed with a bridge pier body template through the space positioning bracket. The construction method of the foundation bolts of the railway contact net and the mounting bracket, provided by the invention, can realize precise positioning and mounting of the foundation bolts, prevent repeated measurement and adjustment, reduce the construction difficulty, accelerate the construction speed, and improve the pass percent of mounting inspection and acceptance of the foundation bolts of the contact net.

Owner:SINOHYDRO ENG BUREAU 4

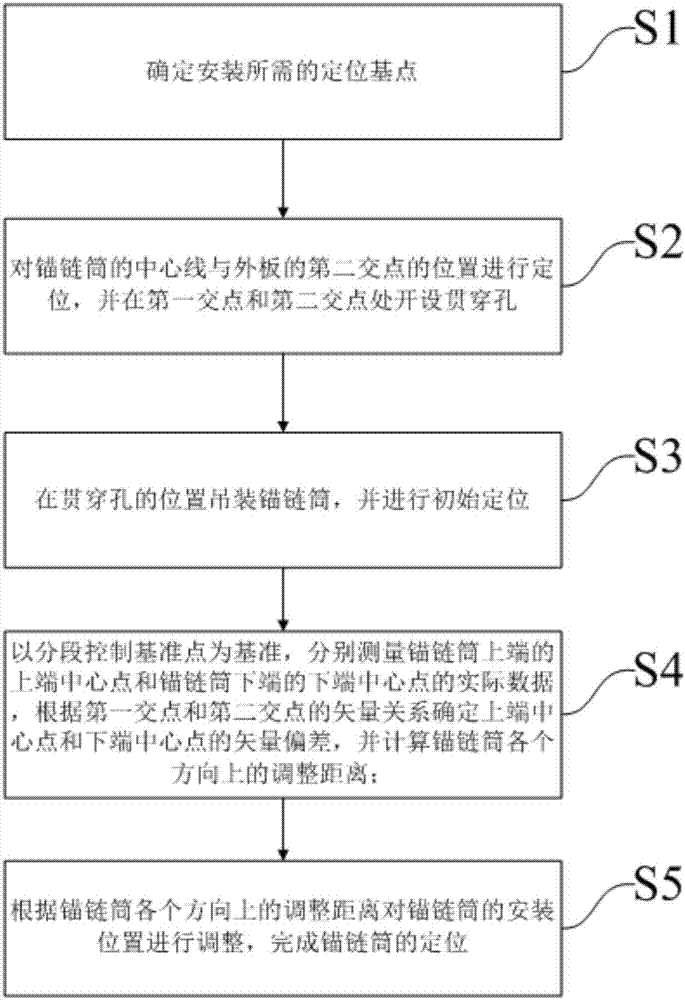

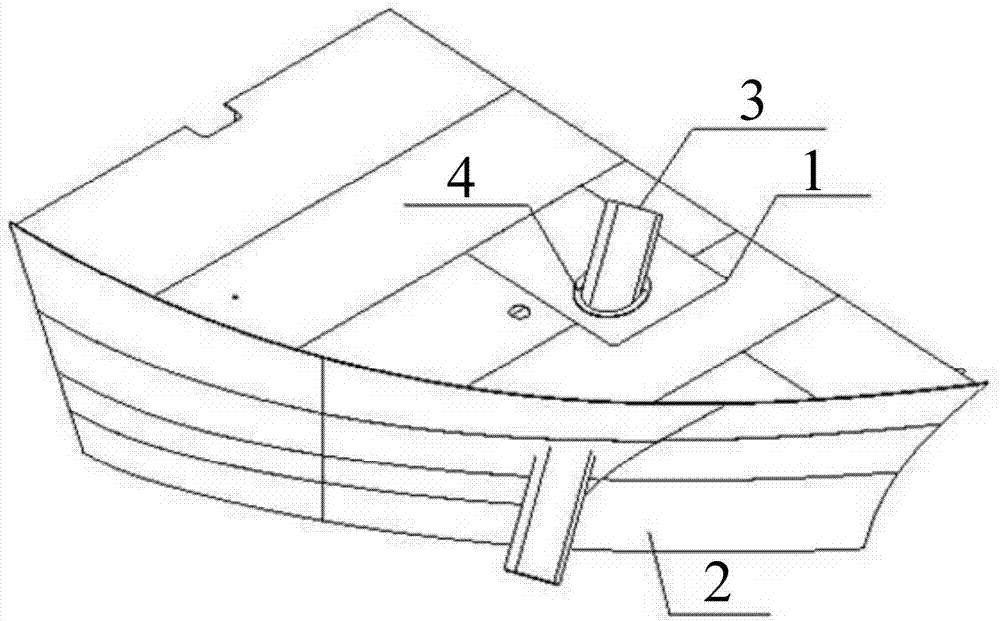

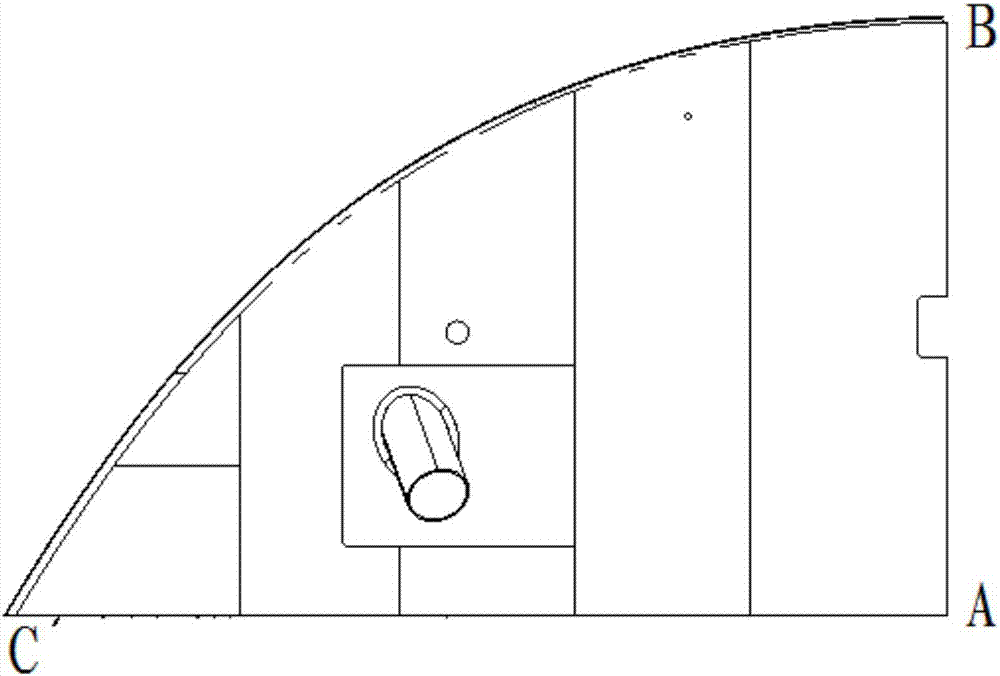

Mounting positioning method for ship hawse pipe

ActiveCN107458540AAccurate installation and positioningChange adjustabilityVessel designingEngineering

The invention provides a mounting positioning method for a ship hawse pipe. The mounting positioning method for the ship hawse pipe is used for the mounting the hawse pipe between decks and external plates and comprises the following steps that S1, a positioning base point required by mounting is determined; S2, positioning is conducted on the position of a second intersection point of the center line of the hawse pipe and the external plates, and penetrating holes are formed in a first intersection point and the second intersection point; S3, the hawse pipe is hoisted to the penetrating holes and initial positioning is conducted; S4, subsection control datum points serve as datum, real data of upper end center point of the upper end of the hawse pipe and lower end center point of the lower end of the hawse pipe are measured correspondingly, vector error of the upper end center point and the lower end point is determined according to vector relation of the first intersection point and the second intersection point, and adjusting distances of the hawse pipe in all directions are calculated; and S5, a mounting position of the hawse pipe is adjusted according to the adjusting distances of the hawse pipe in all directions, and positioning of the hawse pipe is finished. Precise and quick mounting positioning of the hawse pipe is achieved, and mounting efficiency of the hawse pipe is improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Dust removal device for PCB

InactiveCN110961392ARealize no dead angle cleaningAccurate installation and positioningDirt cleaningCleaning using toolsPhysicsEngineering

The invention discloses a dust removal device for a PCB, which relates to the technical field of PCB manufacturing. The device comprises a rear shell, a front shell, a dust removal mechanism, a driving mechanism and a dust collection mechanism, wherein the rear shell is connected with the front shell through screws; a feeding hole is formed in the front surface of the front shell; the dust removalmechanism is rotationally connected into the rear shell; the driving mechanism drives the dust removal mechanism to rotate; and the dust collection mechanism is arranged at the top end of the rear shell. The dust removal mechanism is arranged to clean the PCB, the driving mechanism is arranged to drive the dust removal mechanism to rotate around the PCB, dead-corner-free cleaning of the PCB is realized, the dust collection mechanism is used for sucking away dust generated by sweeping, the step in which drying is needed when an ultrasonic cleaning device is used for cleaning and other steps are not needed, large generated cost is not needed, and the side surfaces of the rear shell and the front shell are provided with connecting pieces and are connected through screws, so that the rear shell and the front shell are accurately mounted and positioned, and are more quickly mounted and dismounted, and therefore, the dust removal efficiency is high, the cost is reduced, and the dust removaldevice is suitable for small and medium-sized enterprises.

Owner:ANHUI TIANBING ELECTRONICS TECH

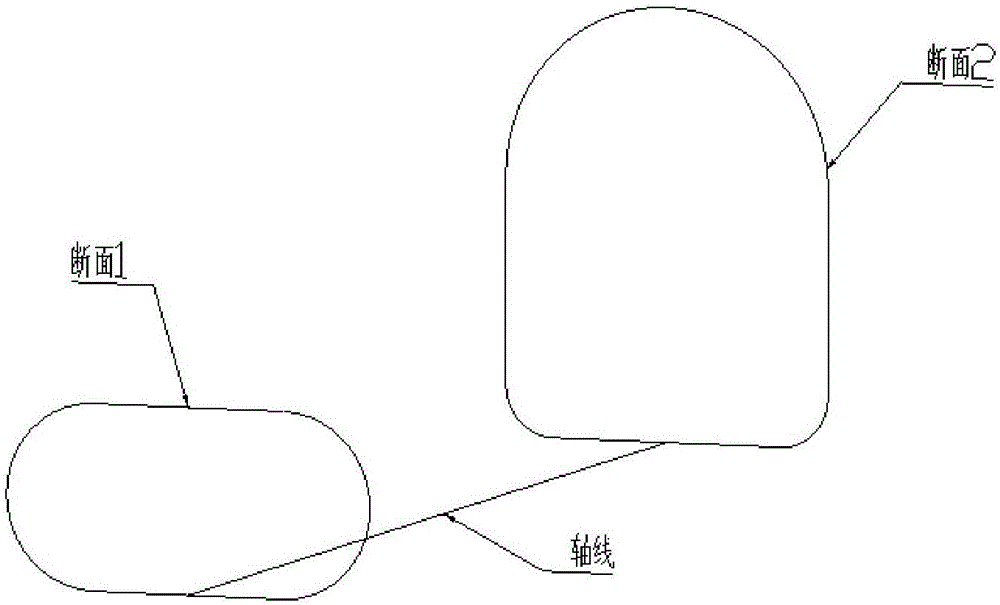

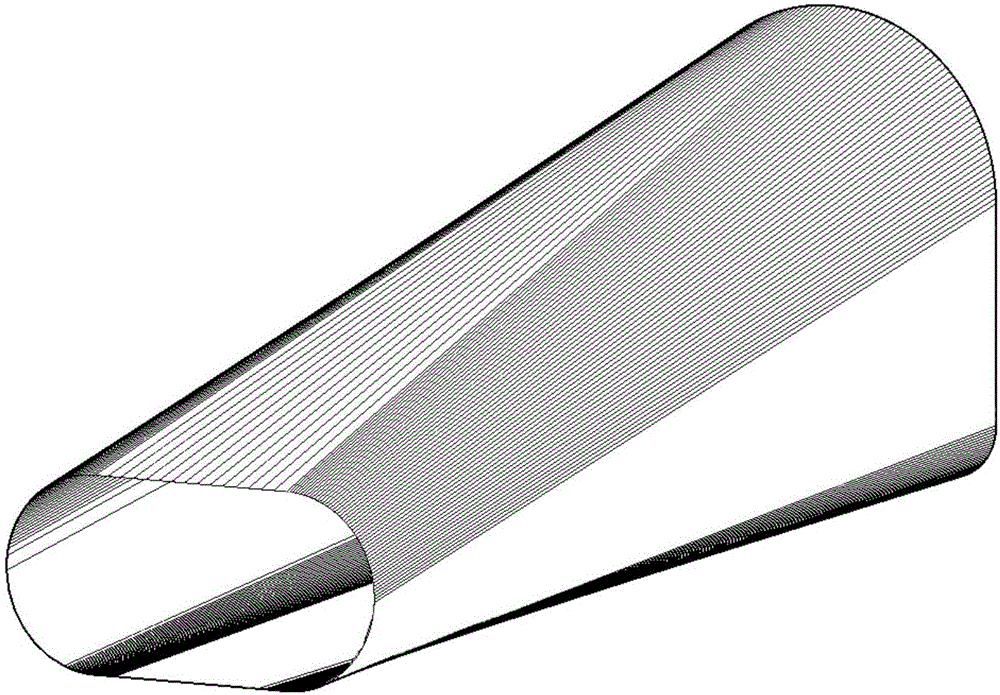

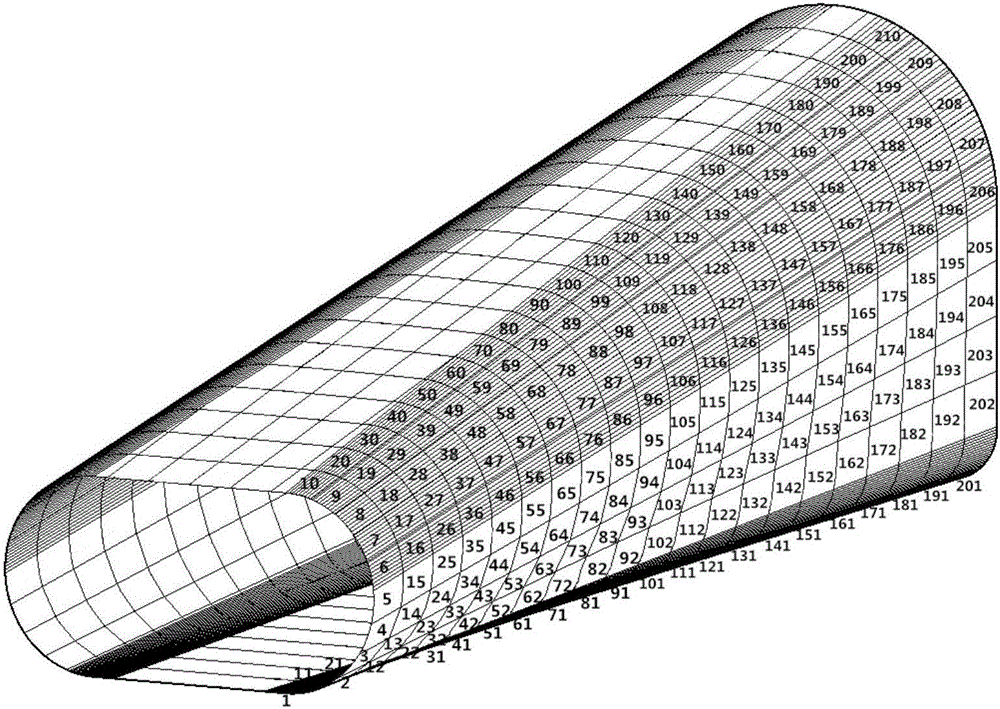

Method for designing and installing auxiliary special-shaped template of three-dimensional model

InactiveCN106245906AImprove design efficiencyShorten the timeForms/shuttering/falseworksTemplate designDimensional modeling

The invention discloses a method for designing and installing an auxiliary special-shaped template of a three-dimensional model. On the basis of establishing a special-shaped concrete formwork panel three-dimensional curve surface model, a body sectioning and measuring method is adopted to precisely design the special-shaped template, an accurate basis is provided for installing and lofting, and by means of the template specification number and the visualization character of the three-dimensional model, the special-shaped template is quickly installed. By means of the method, accurate data of size of each template can be provided for large special-shaped concrete structures, the template design time is saved, the template installation efficiency is accelerated, and the project quality is improved.

Owner:CHINA GEZHOUBA GRP THREE GORGES CONSTR ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com