Method for designing and installing auxiliary special-shaped template of three-dimensional model

A technology of three-dimensional model and formwork, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve the problems of insufficient precision of formwork design, huge building size, cumbersome estimation process, etc., and achieve the goal of formwork The effect of high design precision, strict patchwork and precise installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A three-dimensional model-assisted special-shaped formwork design and installation method proposed by the present invention will be further described in detail below in conjunction with specific implementation cases.

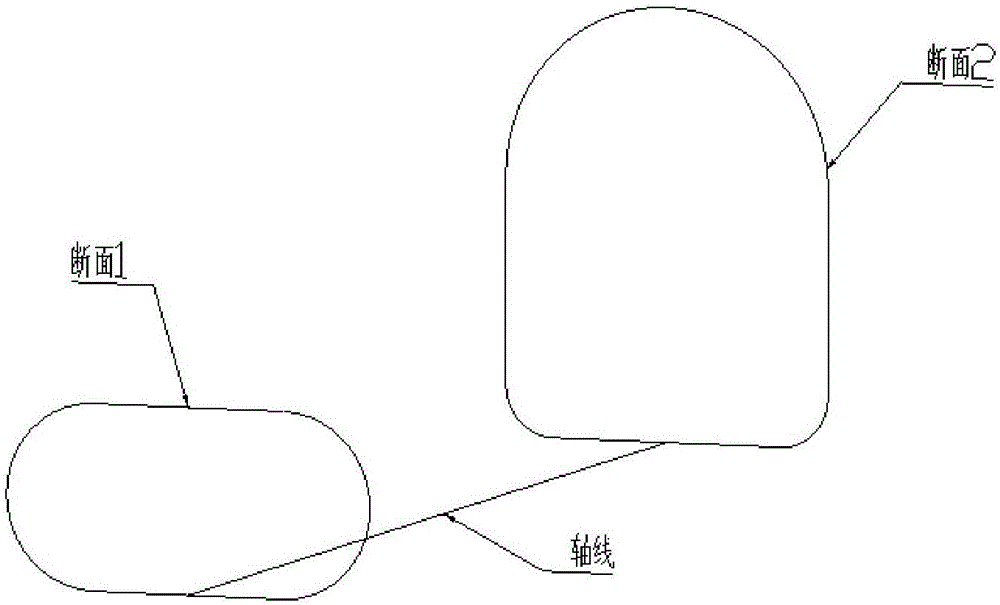

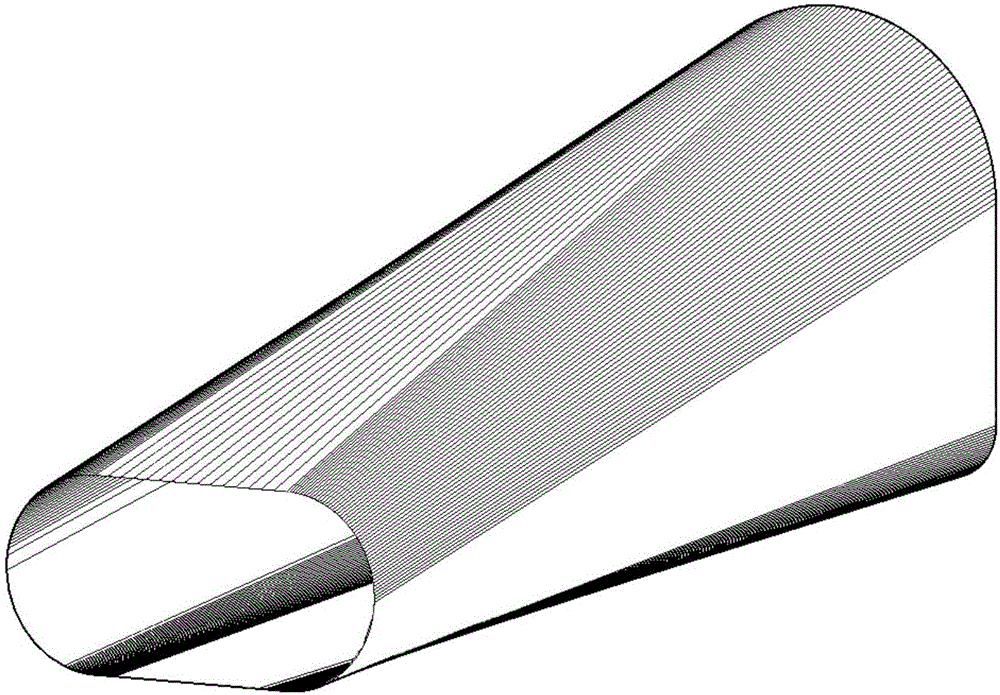

[0024] The concrete lining type of the tail water diffusion section of the underground powerhouse of a certain hydropower station is a gate-shaped hole with rounded bottom and rounded corners. The net size of the section changes gradually along the axis direction, and the curve changes complexly. Each template is unique, with different shapes and sizes. However, in civil engineering, the design unit usually only provides the detailed dimensions of the front and rear sections of the gradual tunnel. In this implementation case, the method of using a three-dimensional model to assist the design and installation of special-shaped formwork is as follows:

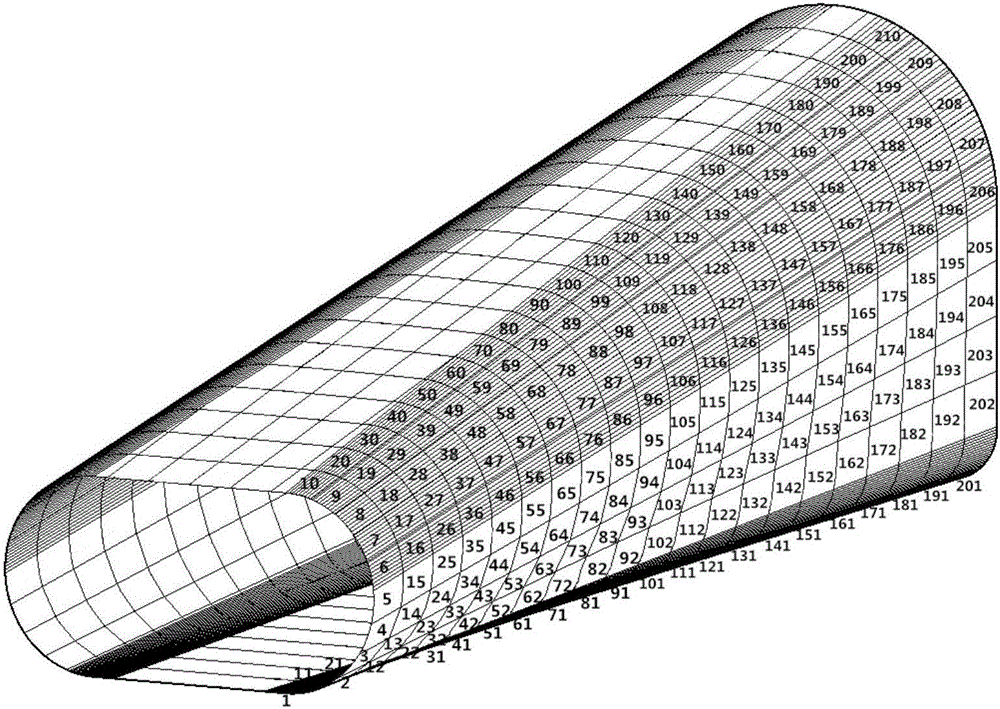

[0025] 1. Establish a three-dimensional model of the overall surface of the concrete lining formwork pan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com