Casting tool fixture

A technology of fixtures and castings, which is applied in the field of casting production auxiliary tools, can solve problems such as low efficiency, high scrap rate, and long adjustment time, and achieve the effects of accurate installation and positioning, high production efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

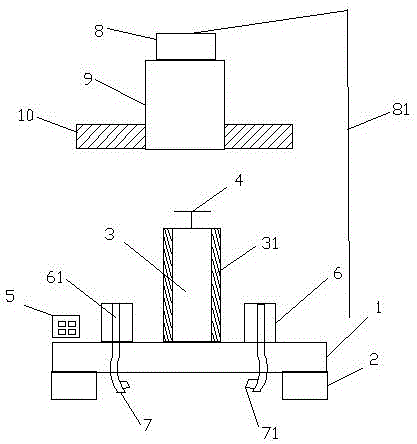

[0027] Such as figure 1 As shown, a casting fixture includes a PLC 5 , an air pipe 7 , a base plate 1 , a corner oil cylinder 3 arranged in the center of the base plate 1 , a motor 8 , a hollow motor shaft 9 and an annular electromagnet 10 .

[0028] The bottom of the bottom plate 1 is provided with a plurality of legs 2 , and a plurality of reference positioning blocks 6 are evenly arranged on the bottom plate 1 located on the outer periphery of the corner oil cylinder 3 .

[0029] The outer periphery of the corner oil cylinder 3 is covered with a non-magnetic layer 31 , and the top of the corner oil cylinder 3 is provided with an automatic locking handle 4 connected to the PLC 5 .

[0030] Each reference positioning block 6 is provided with an axial through hole 61 connected with the air pipe 7 , and each air pipe 7 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com