Horizontal tail connection device for helicopter

A connecting device and helicopter technology, which is applied in the field of helicopter horizontal tail, can solve problems such as easy safety, adverse effects on flight safety, time-consuming and labor-intensive problems, and achieve the effects of accurate installation and positioning, convenient maintenance of horizontal tail, and simple connection form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below.

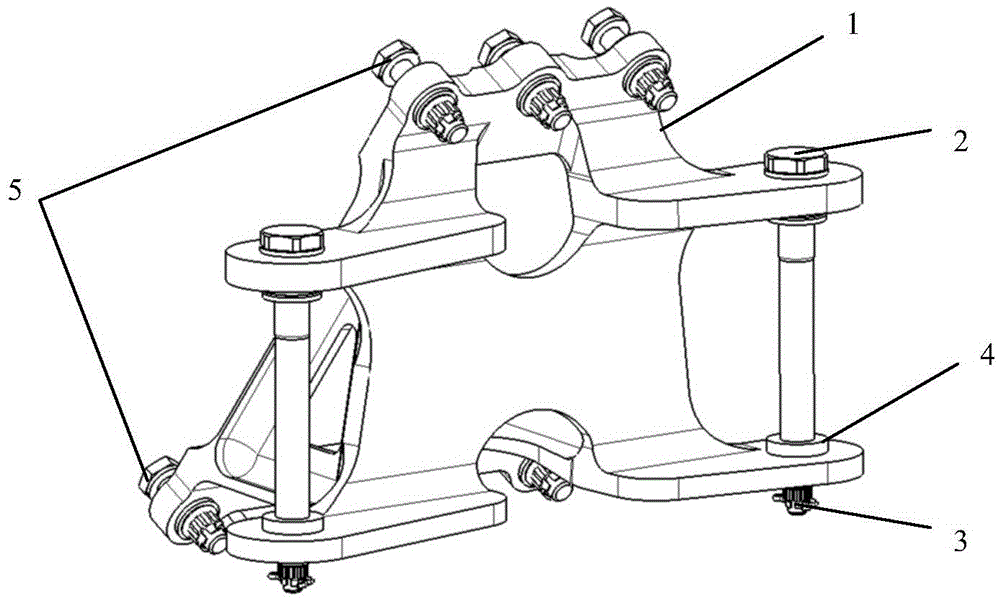

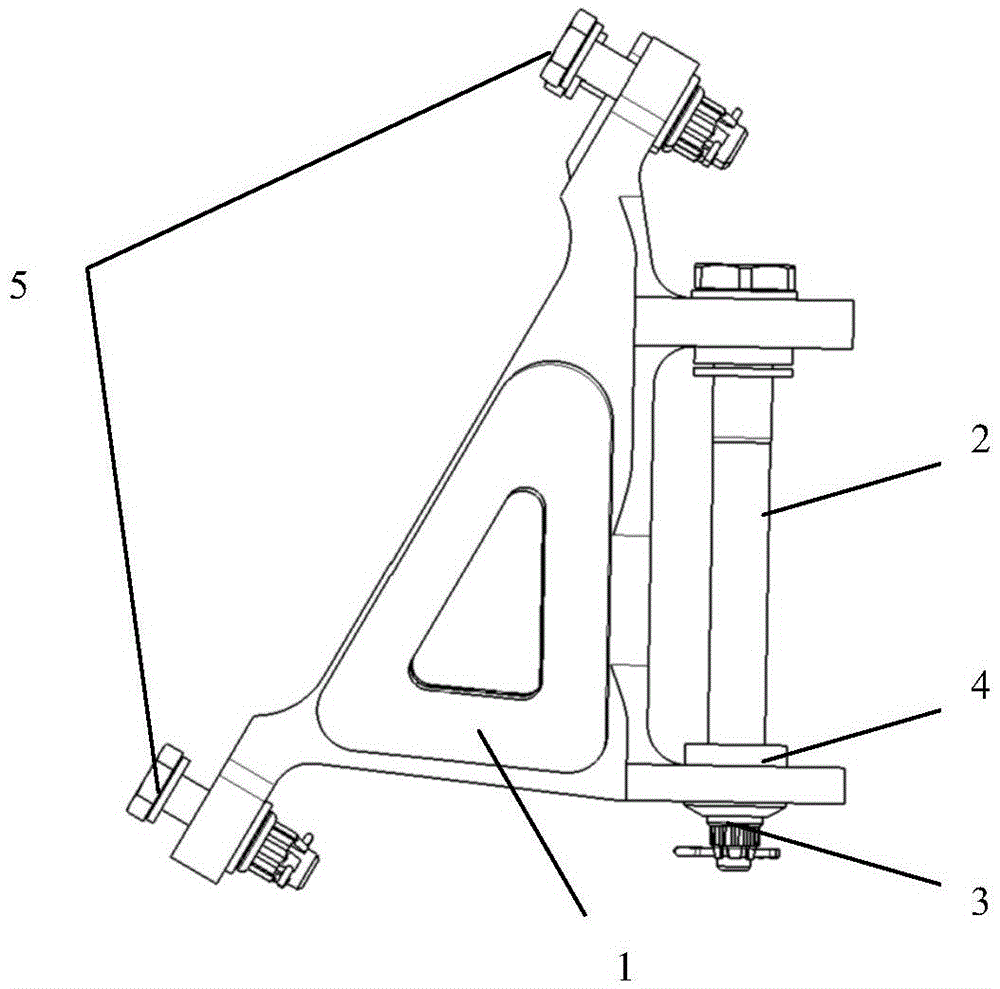

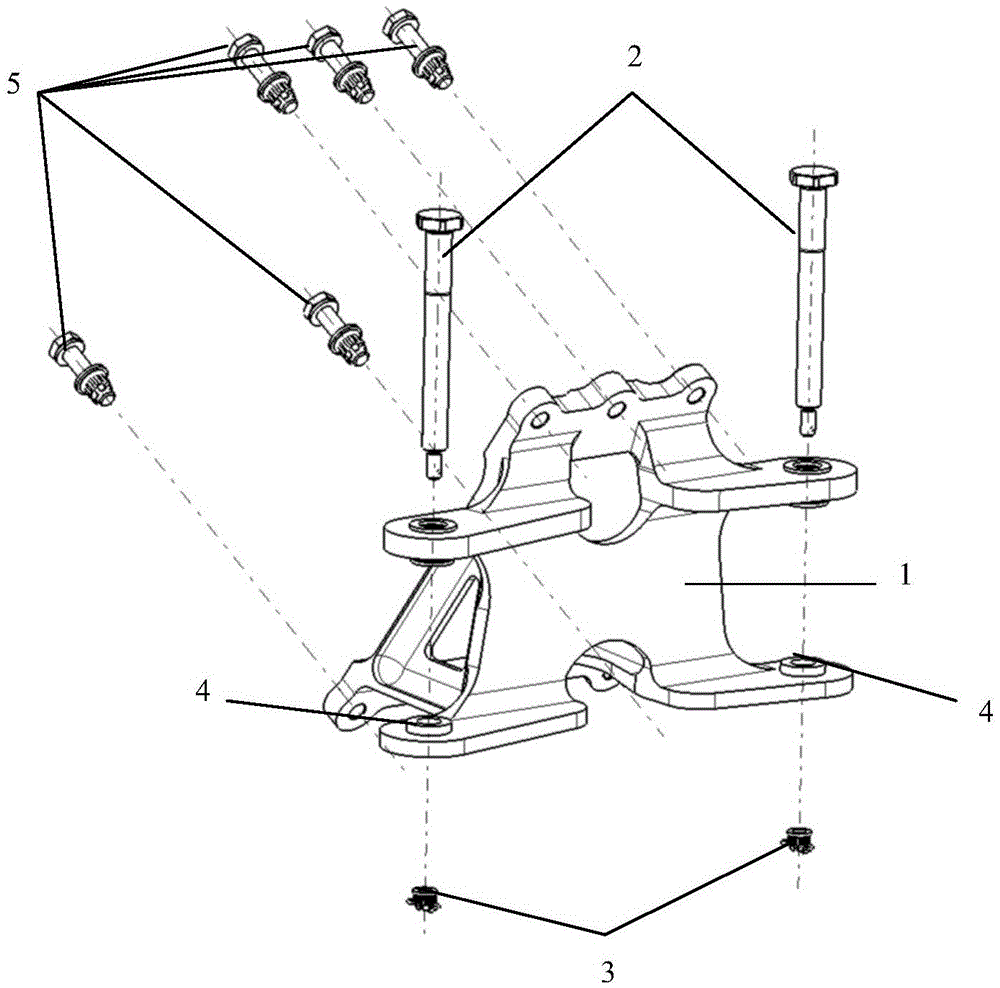

[0017] see figure 1 , the connecting device of the helicopter horizontal tail of the present invention has a fuselage connecting joint 1, one side of the fuselage connecting joint 1 is connected on the rear fuselage structure using a bolt combination 5, and the top of the other side is provided with double fork lugs for connecting with the horizontal tail , the double fork lug is connected with the mounting hole reserved on the main beam of the flat tail with the connecting bolt 2, the connecting nut 3, and the adjusting gasket 4. In this way, the plug and play of the flat tail can be realized, errors caused by complex assembly can be avoided, the installation and positioning are accurate, and the connection form is simple.

[0018] A triangular support structure is formed between the roots of the double-fork lugs of the fuselage connection joint to maximize the strength.

[0019] The triangular suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com