Construction method for steel sheet pile cofferdam on underwater exposed bedrock

A technology of steel sheet pile cofferdam and construction method, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of high drilling position accuracy, long construction period for installation grooves, and difficult control, and reduces equipment requirements. , The effect of shortening the construction period and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is specifically described below through the examples, the examples are only used to further illustrate the present invention, and cannot be interpreted as limiting the protection scope of the present invention, some non-essential claims made by those skilled in the art based on the above-mentioned content of the present invention Improvements and adjustments also belong to the protection scope of the present invention.

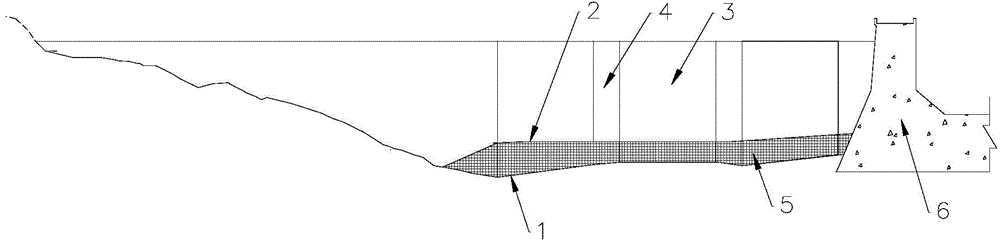

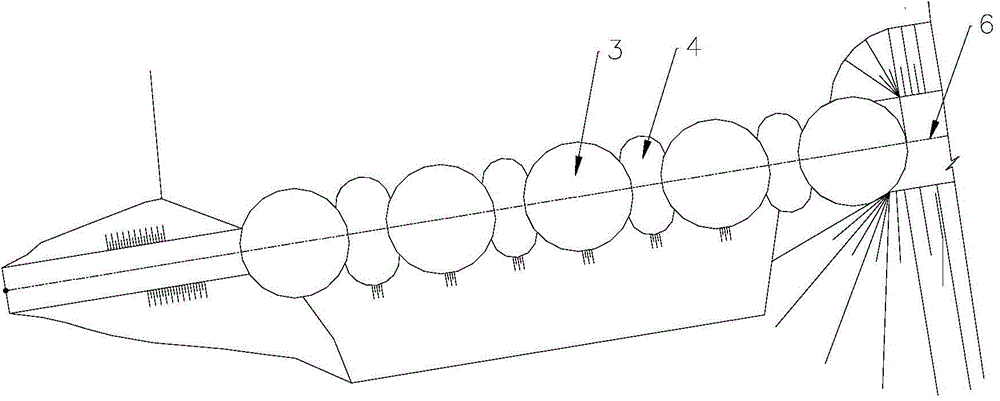

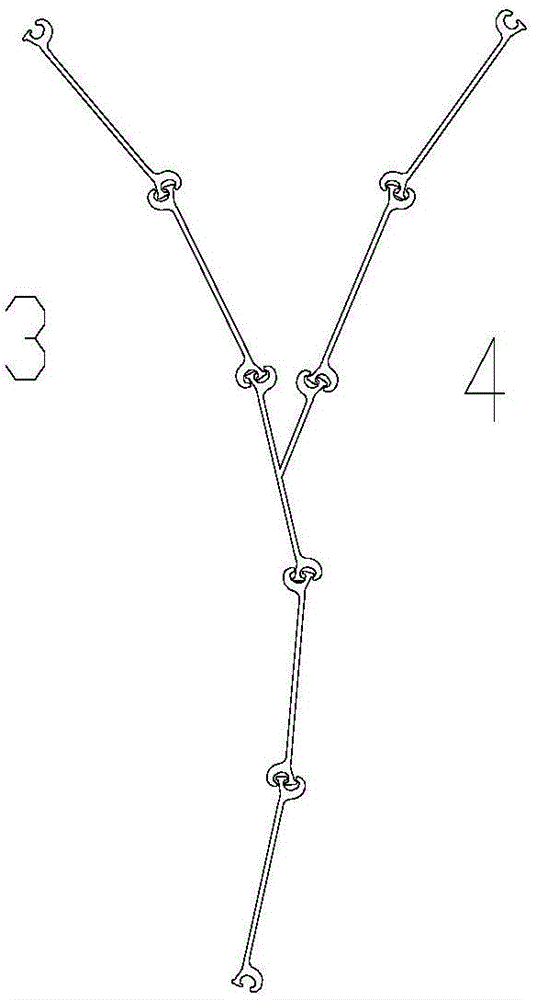

[0030] combine Figure 1 to Figure 5 .

[0031] As shown in the figure, the steel sheet pile cofferdam construction method without grooves on the exposed bedrock of the present invention is applicable to the riverbed being washed by water without a covering layer on the surface, and the surface is basically exposed bedrock, and the ground undulation is not large, which is relatively smooth. Flat places, suitable for underwater steel sheet piles of various shapes.

[0032] According to the designed cofferdam structure size and con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com