Automatic adjusting and positioning method for casting fixture

A tooling fixture and automatic adjustment technology, applied to positioning devices, manufacturing tools, clamping, etc., can solve problems such as high scrap rate, low efficiency, and equipment stagnation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

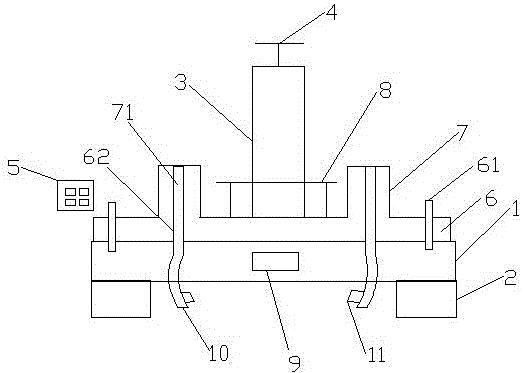

[0032] Such as figure 1 As shown, a casting fixture capable of automatically adjusting and positioning includes a PLC 5 , an air pipe 10 , a bottom plate 1 and a corner oil cylinder 3 arranged at the center of the bottom plate 1 .

[0033] The top of the corner oil cylinder 3 is provided with an automatic locking handle 4 connected with the PLC5.

[0034] The bottom periphery of the corner oil cylinder 3 is coaxially sleeved with a reference rotating disk 6 through a bearing, and the reference rotating disk 6 is fixedly connected with the base plate 1 through several automatic locking pins 61, and each automatic locking pin 61 is connected with the PLC5.

[0035] The above-mentioned reference rotary disk 6 is uniformly provided with several reference positioning blocks 7 and several first axial through holes 62 along the ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com