Die device for stamping molding of steel plate

A stamping forming and steel plate technology, which is applied in the direction of forming tools, storage devices, feeding devices, etc., can solve the problems of troublesome installation of positioning mechanisms, many parts, troublesome installation and disassembly, etc., to improve the production effect, accurate installation and positioning, installation and disassembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

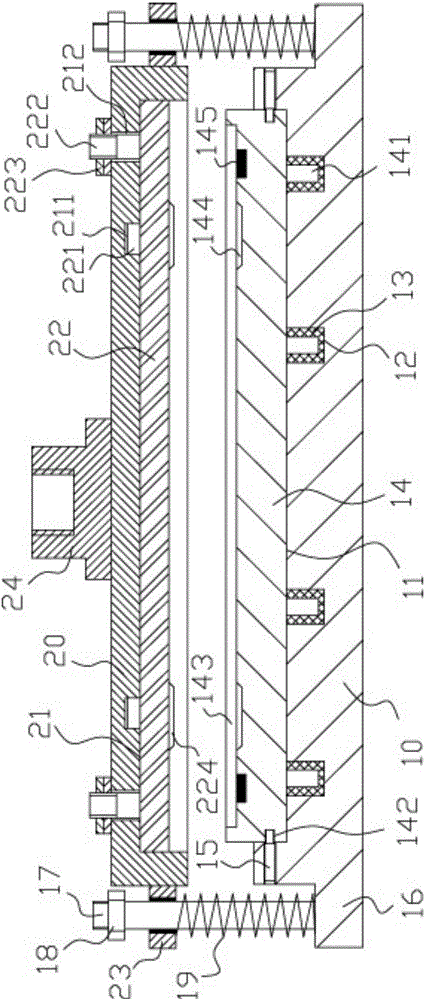

[0014] Example: see figure 1 As shown, a mold device for stamping and forming of a steel plate comprises a lower die connecting block 10 and a connecting plate 20, the middle part of the top surface of the lower die connecting block 10 has a lower die fixing groove 11, and the bottom surface of the lower die fixing groove 11 There are a plurality of positioning jacks 12, a strong magnet sleeve 13 is inserted into the positioning jack 12, the outer wall of the strong magnet sleeve 13 is fixed on the inner wall of the positioning jack 12, and the lower mold 14 is inserted into the lower mold fixing groove 11 Among them, the bottom surface of the lower mold 14 has a plurality of inserting rods 141, the inserting rods 141 are inserted into the strong magnet sleeve 13 and adsorbed in the strong magnet sleeve 13, and the screw holes on the inner side wall of the lower mold fixing groove 11 The middle screw is connected with a plurality of positioning studs 15, and the ends of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com