Full-automatic installation equipment for oil blades of compressor pump body

A technology of compressor pump and installation equipment, applied in metal processing equipment, metal processing, manufacturing tools and other directions, can solve the problems of low production efficiency of compressor pump body assembly, difficulty in meeting mass production, low degree of automation, etc. The effect of mass production, high production efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

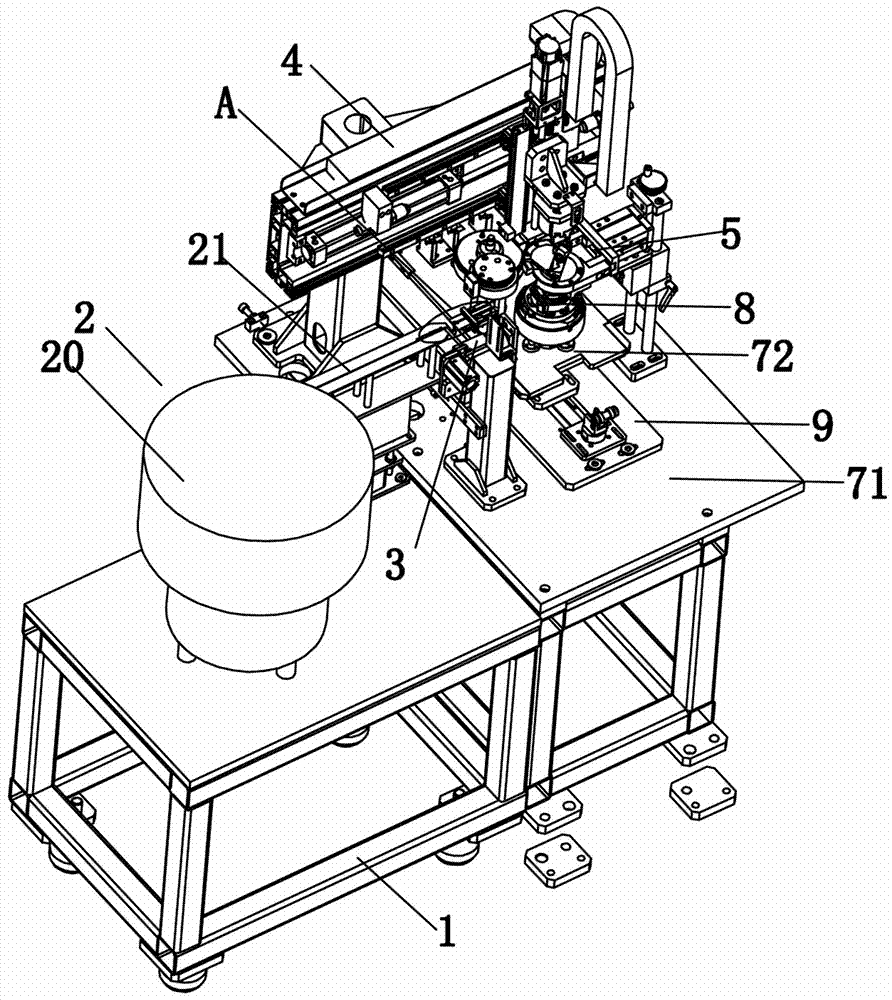

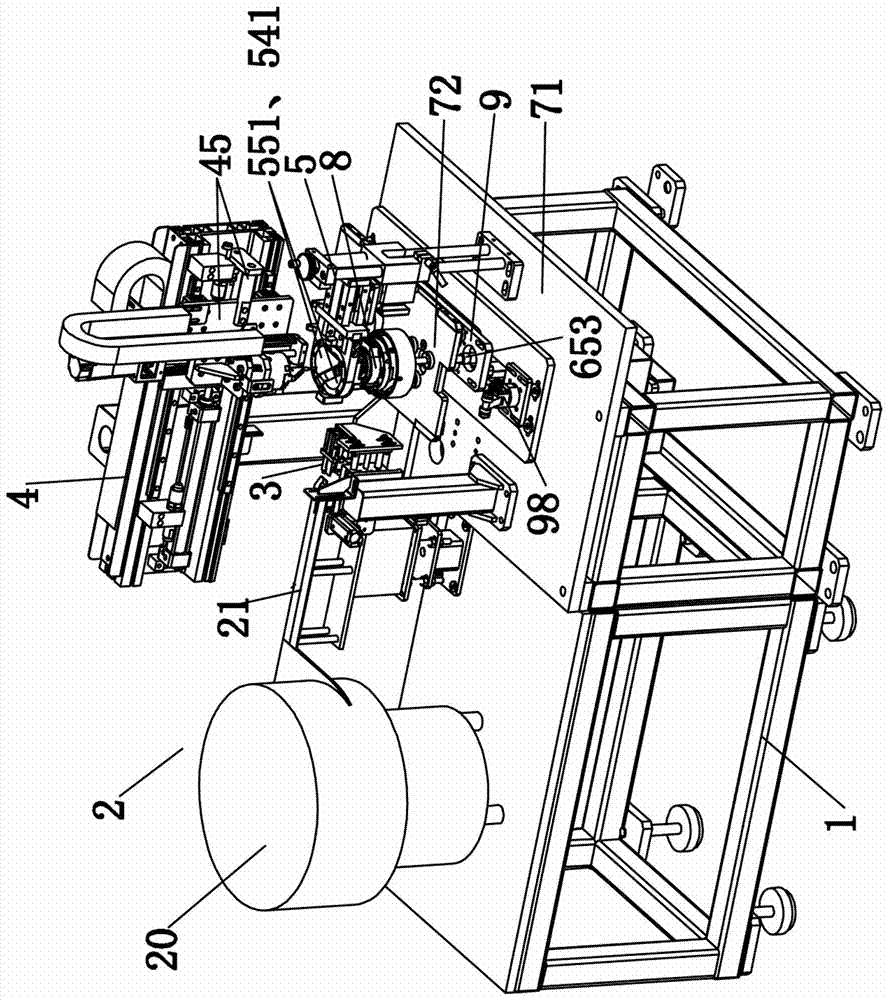

[0058] Embodiment one, such as Figure 1 to Figure 19 As shown, a fully automatic oil blade installation equipment for a compressor pump body 8 includes a frame 1, a vibrating feeding mechanism 2, an oil blade distribution mechanism 3, an oil blade conveying manipulator 4, an oil blade guide mechanism 5, and a tooling plate positioning Jacking mechanism 9, crankshaft alignment mechanism 6.

[0059] The vibrating feeding mechanism 2 is arranged on the frame 1, and is used for vibrating and screening the oil vanes 7, and transporting the oil vanes 7 to the oil vane distributing mechanism 3.

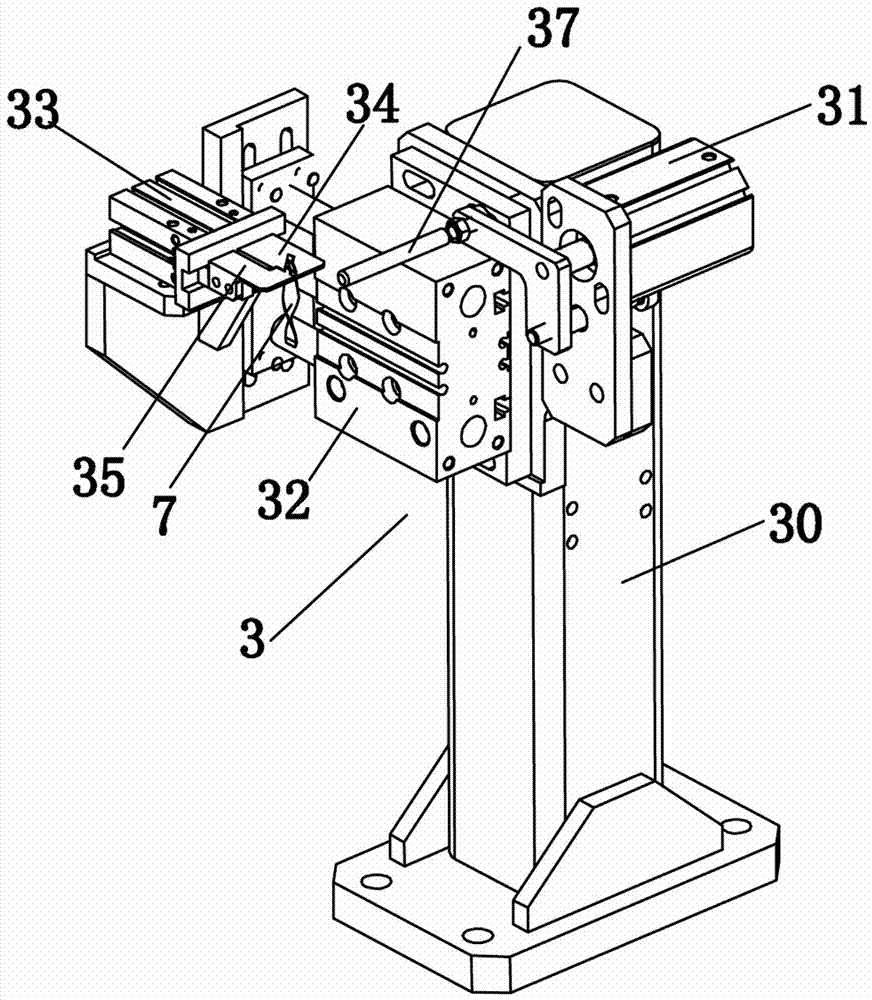

[0060] The oil vane distributing mechanism 3 is arranged on the frame 1, and is used to sort out the oil vanes 7 transported by the vibrating feeding mechanism 2 one by one, and deliver them to the oil vane conveying manipulator 4 for gripping.

[0061] Described oil vane conveying manipulator 4 is arranged on frame 1, and is used for clamping the oil vane 7 on the oil vane distribution me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com