Precast sandwich external wall panel and structural system thereof as well as construction method

An external wall panel and sandwich technology, applied in chemical instruments and methods, building components, building structures, etc., can solve the difference between the total height of the external wall panel and the height of the floor, which affects the cleanliness of the external wall panel facade, and the section of the external wall panel Unevenness and other problems, to achieve the effect of high installation strength, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

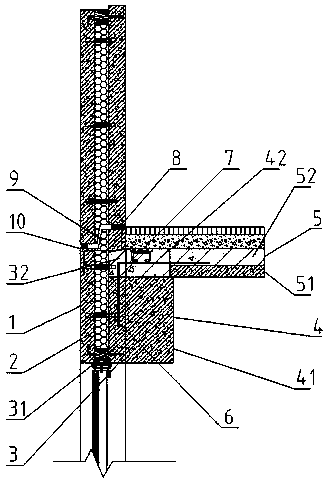

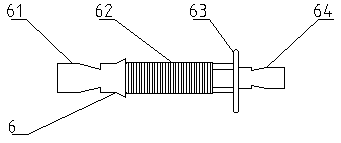

[0025] Referring to the accompanying drawings: a prefabricated sandwich external wall panel, comprising an outer panel 1, an insulation layer 2 and an inner panel 3, the insulation layer 2 is arranged between the outer panel 1 and the inner panel 3, and the The thermal insulation layer 2 runs through the prefabricated sandwich external wall panels, and the outer panel 1 , the inner panel 3 and the thermal insulation layer 2 are connected by anchor connectors 6 .

[0026] Further, the end of the prefabricated sandwich external wall panel is provided with a waterproof groove 9, and the upper side and lower side of the outer panel 1 are lower than the upper side and lower side of the inner panel 3 respectively.

[0027] In the above scheme, by setting the insulation layer 2 that exposes the external wall panels, and the upper and lower ends of the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com