Patents

Literature

141results about How to "Less prone to deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

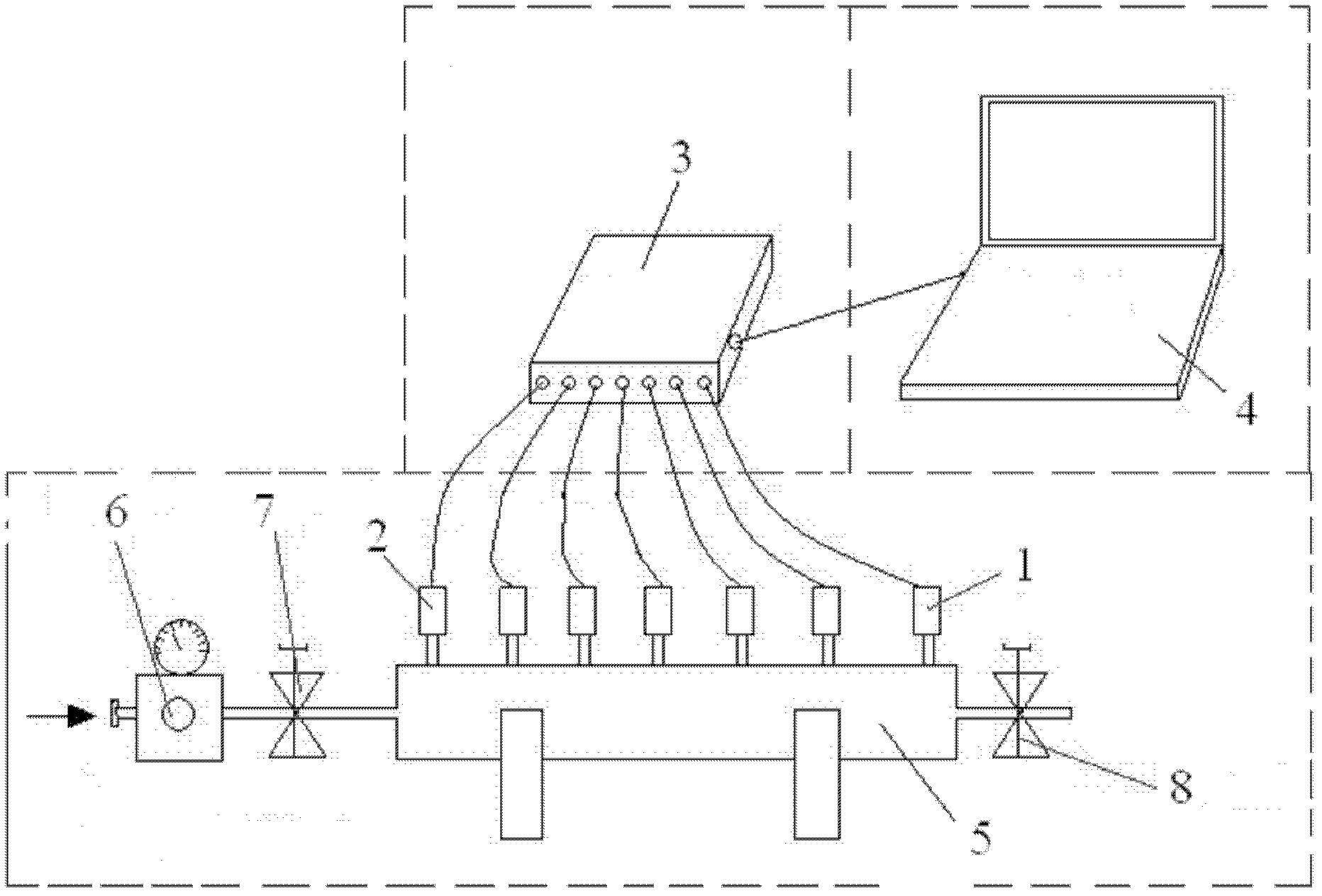

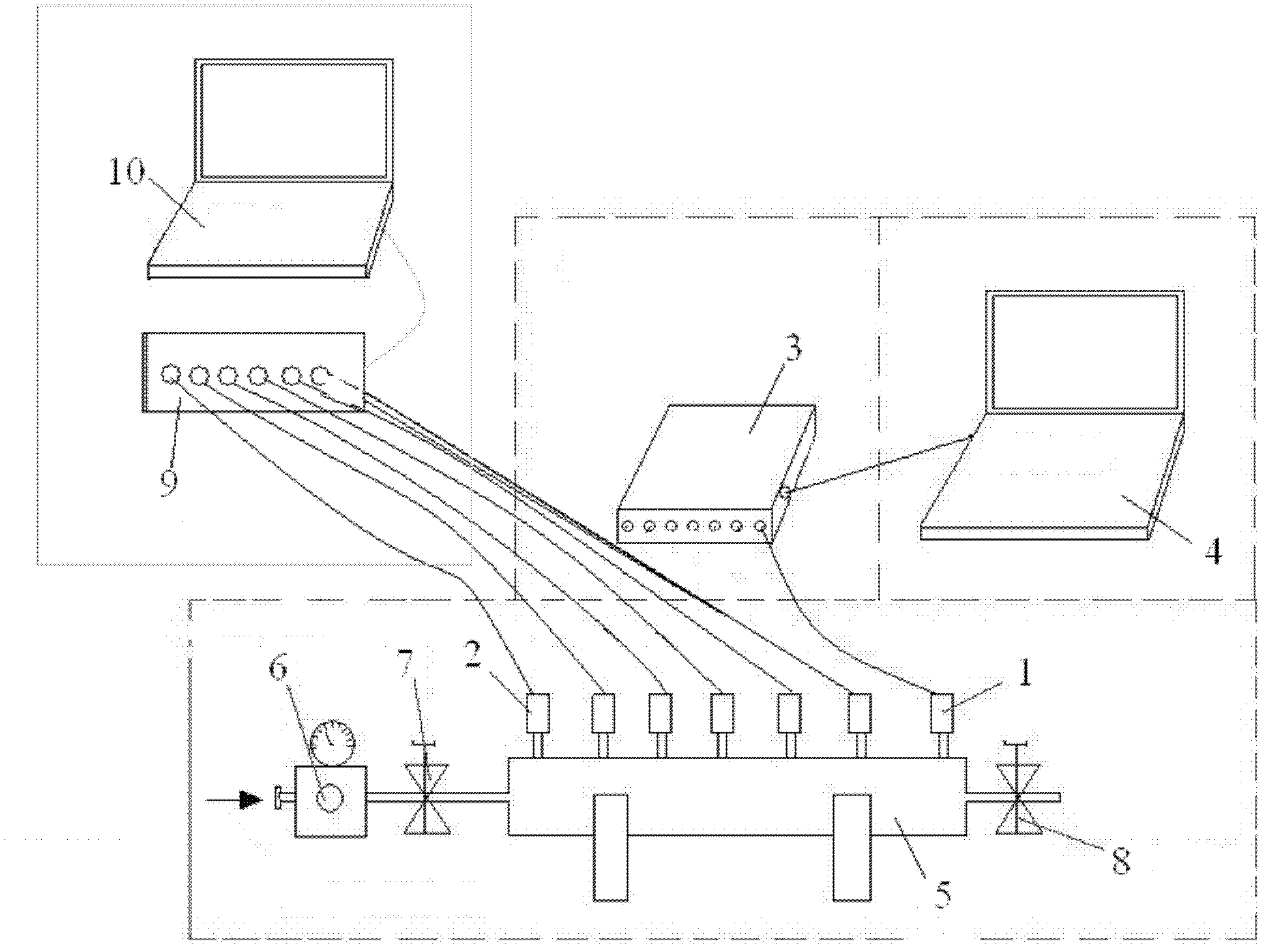

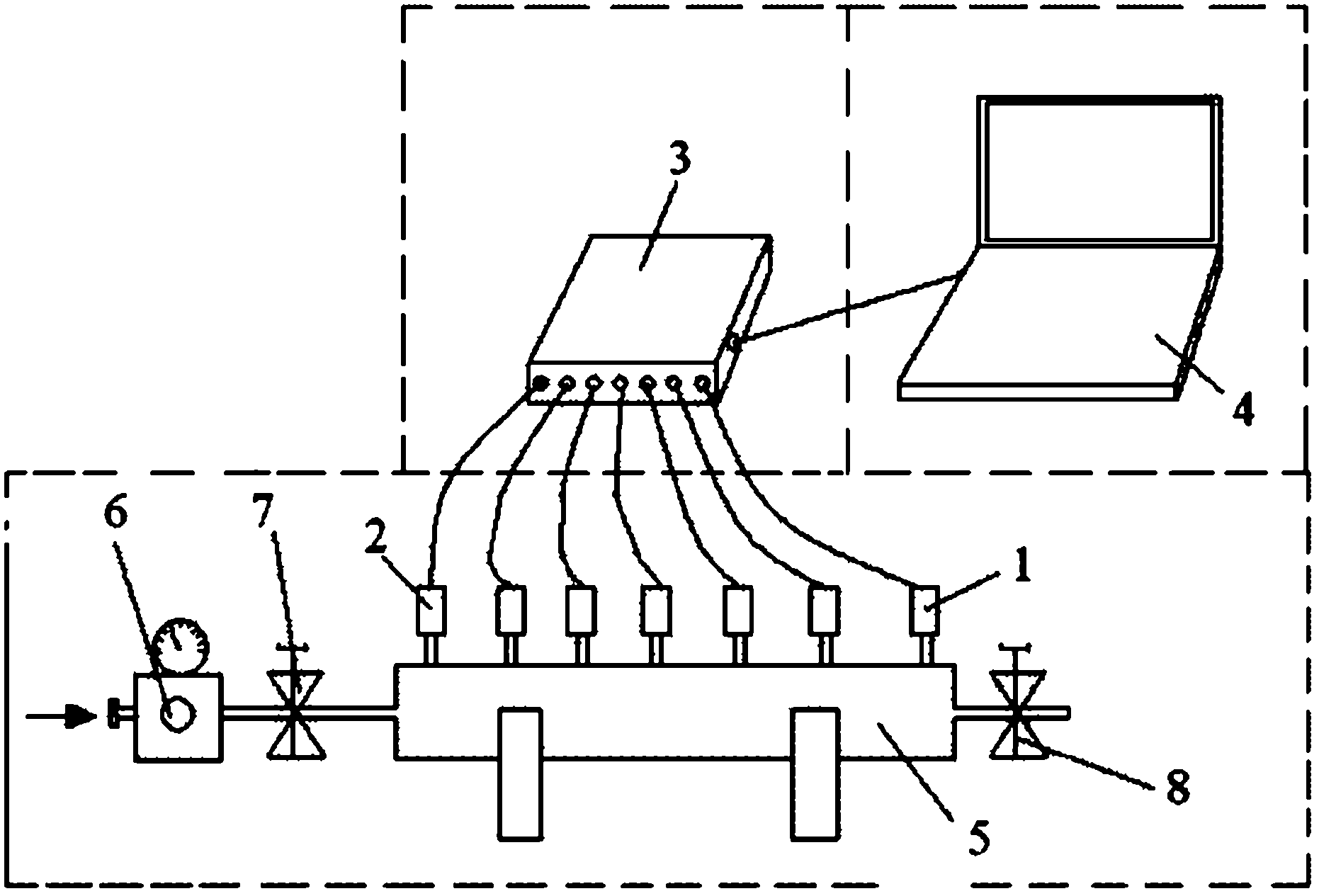

Pressure sensor calibration system

InactiveCN102494841ALess prone to deviationAccurate measurementFluid pressure measurementEngineeringData treatment

The invention relates to a pressure sensor technology field and discloses a pressure sensor calibration system. The system comprises a pressure source, a data acquisition unit, a data processing unit and a standard pressure sensor. The standard pressure sensor and pressure test ends of one or more tested pressure sensors are communicated with the pressure source. The standard pressure sensor and pressure signal output ends of the tested pressure sensors are connected with a pressure signal input end of the data acquisition unit. The data processing unit compares a detected pressure value of the tested pressure sensors with the detected pressure value of the standard pressure sensor and outputs a difference value of the two detected pressure values. By using the pressure sensor calibration system, the pressure value of the tested pressure sensors and the pressure value of the standard pressure sensor can be automatically collected; and the collected pressure value of the tested pressure sensors and the pressure value of the standard pressure sensor can be automatically compared and the difference value of the two detected pressure values can be output. A measuring result is accurate. By using the pressure sensor calibration system, a plurality of pressure sensors can be checked simultaneously. Working efficiency is high.

Owner:WEICHAI POWER CO LTD

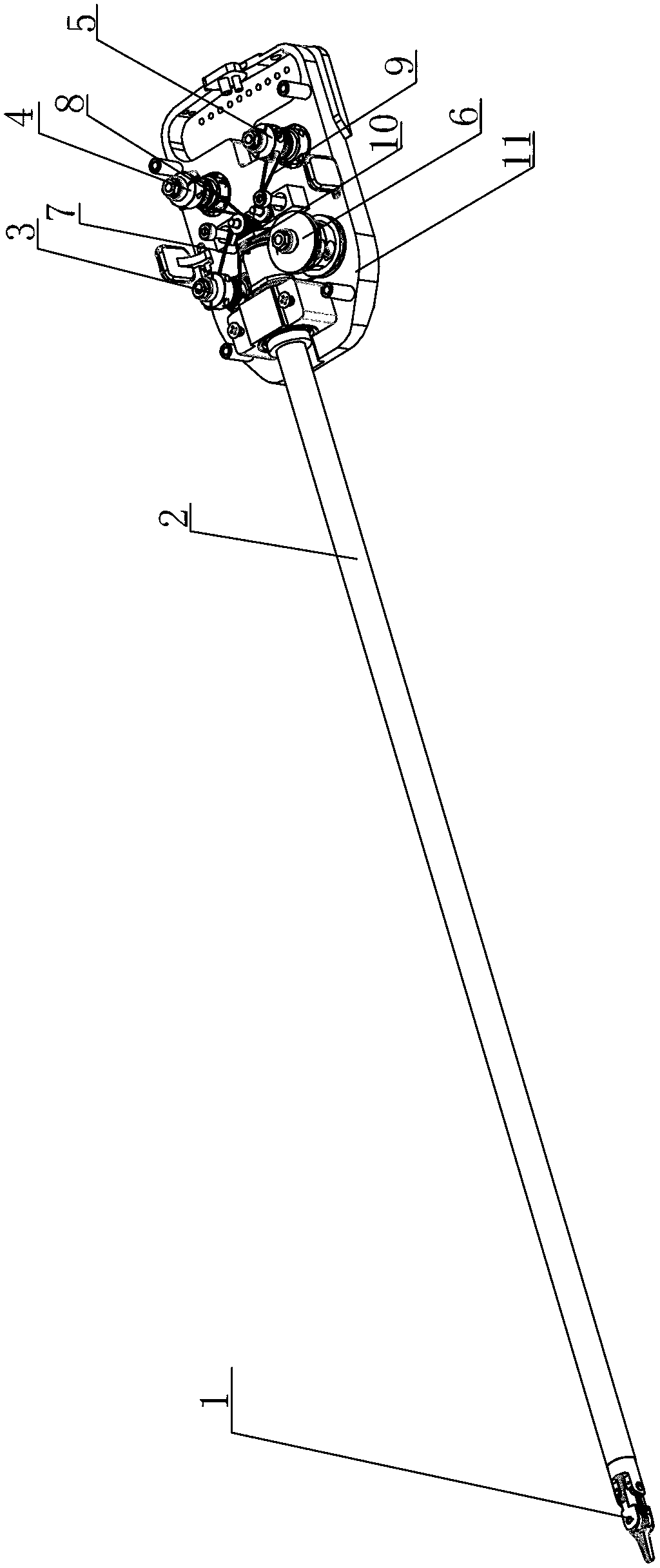

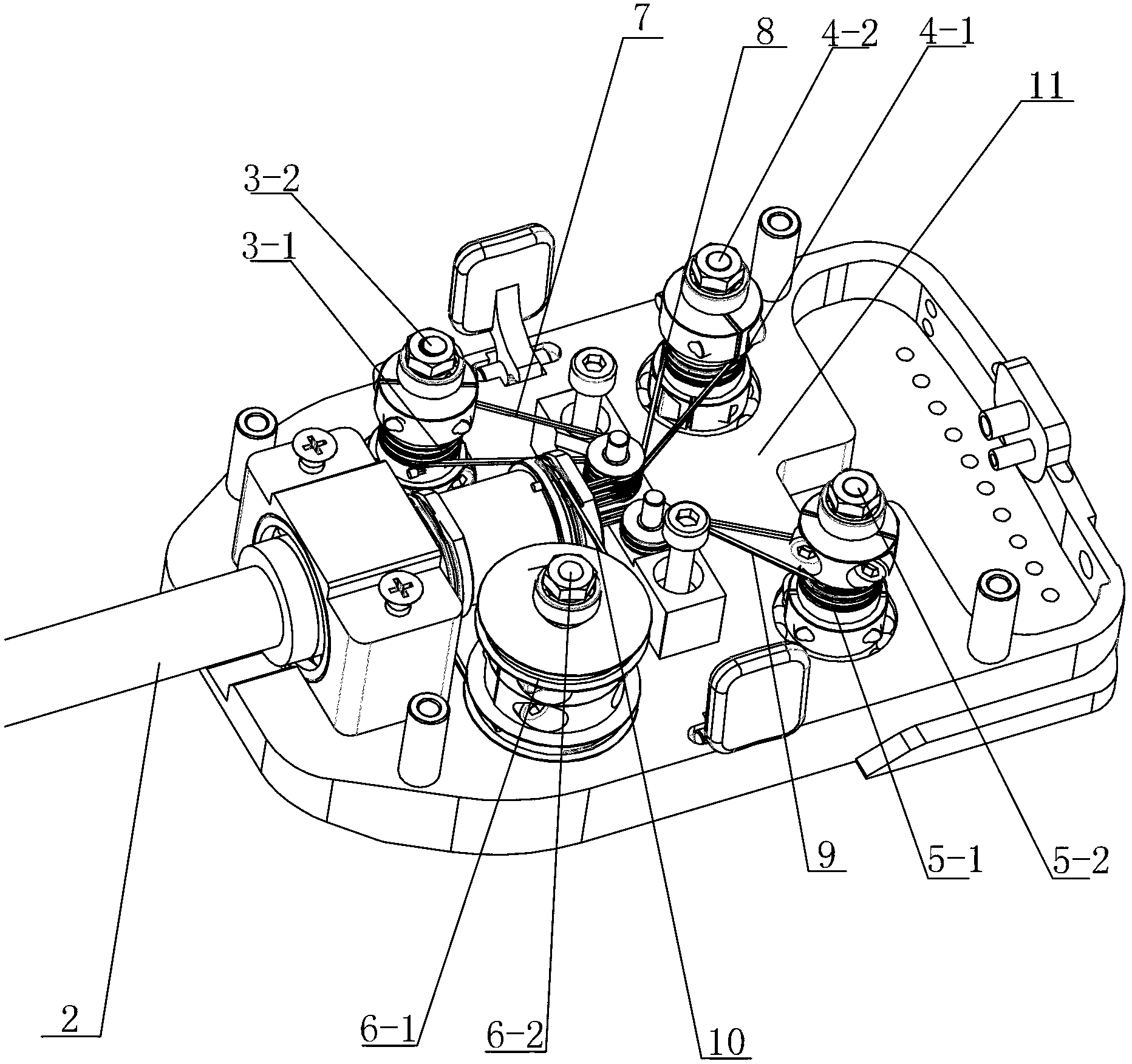

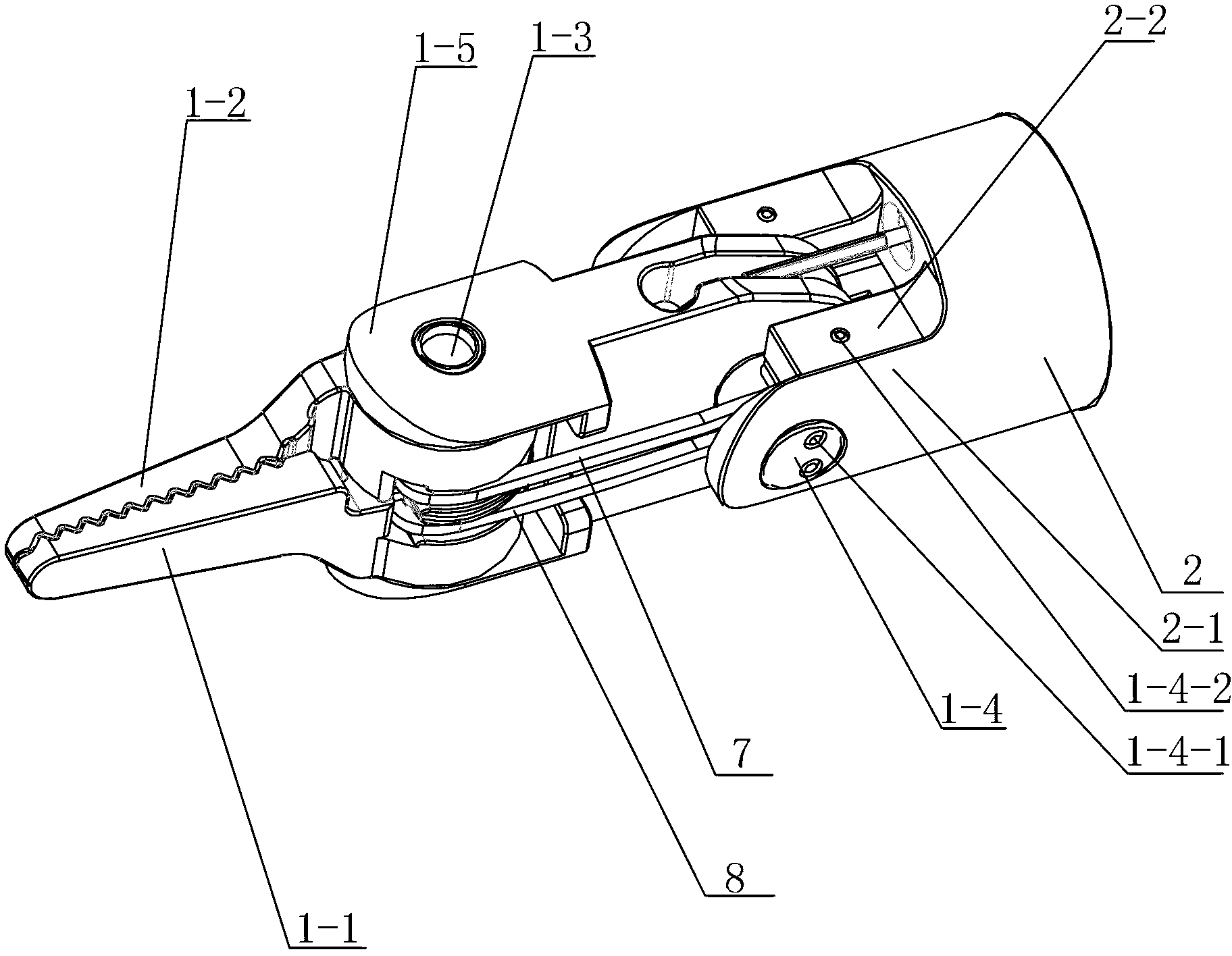

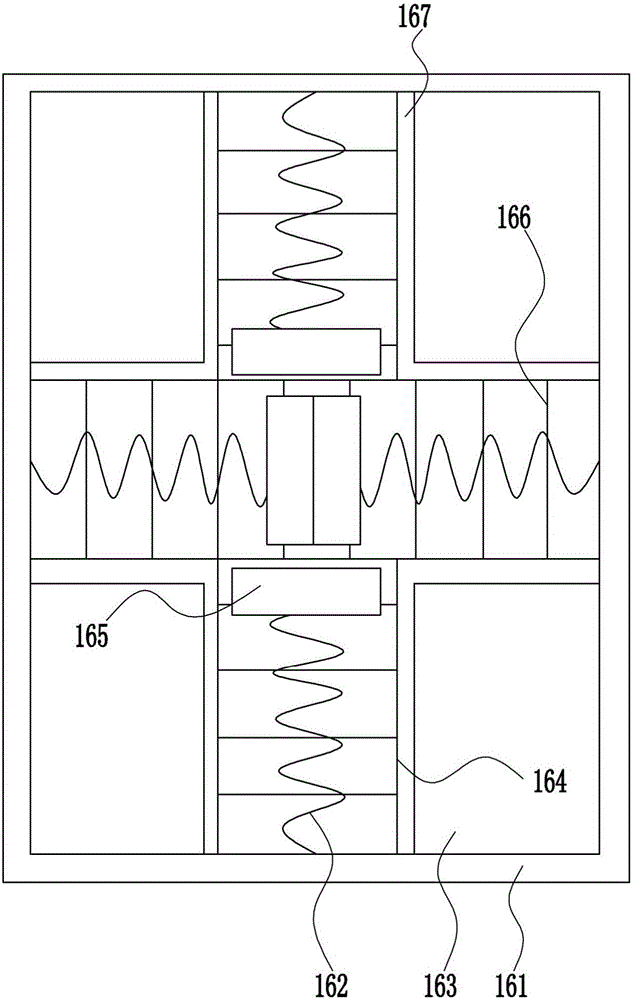

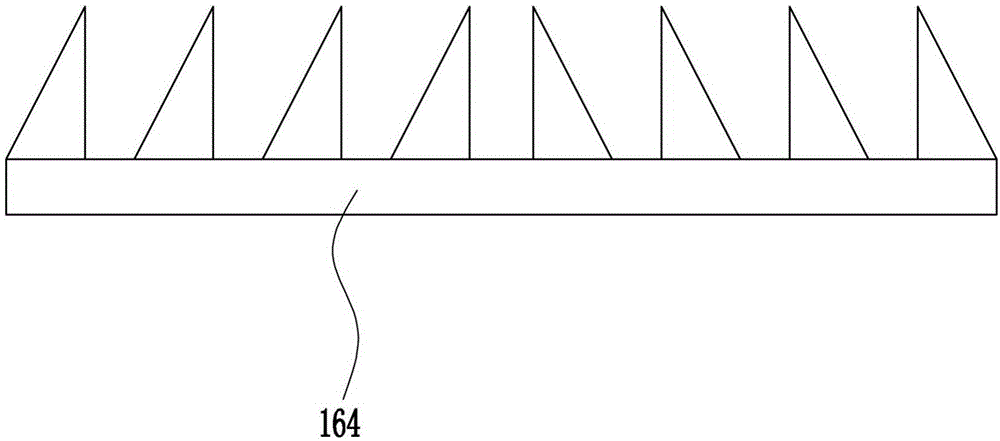

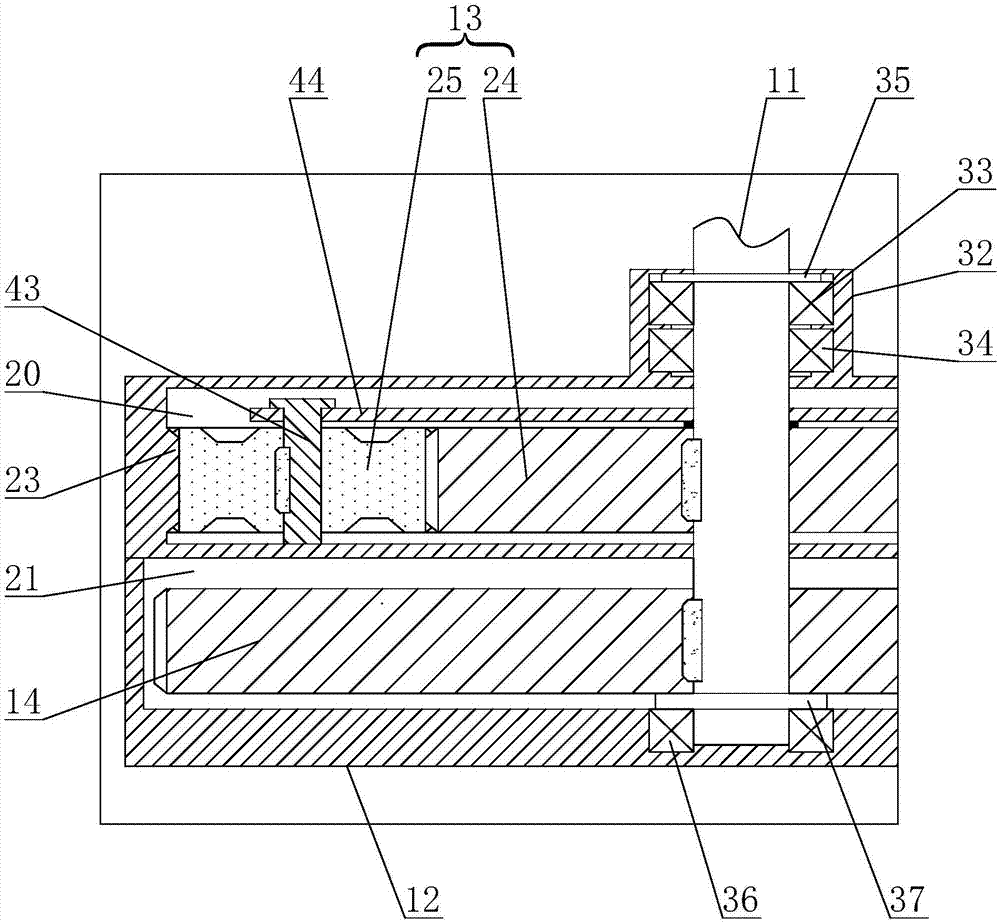

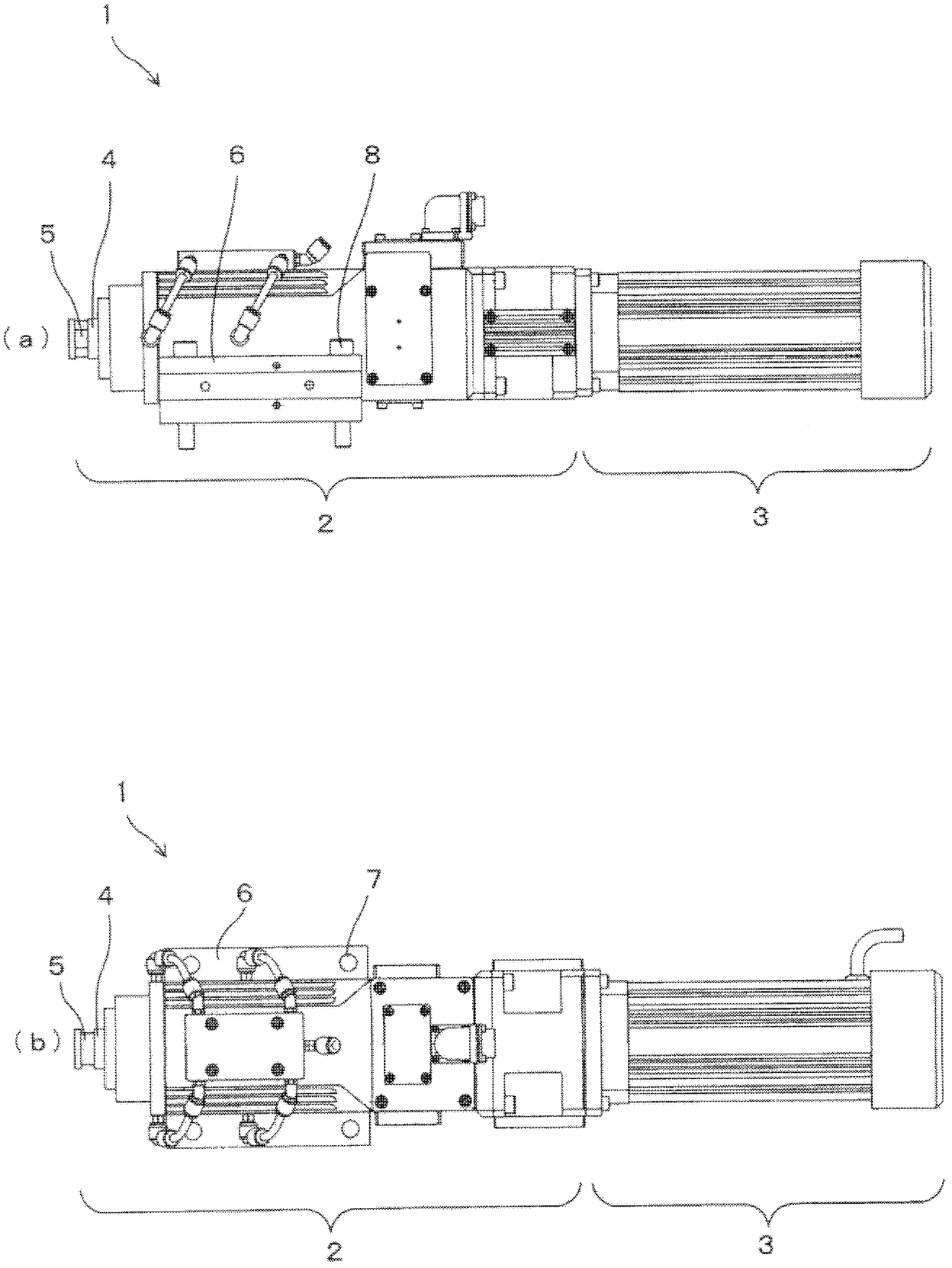

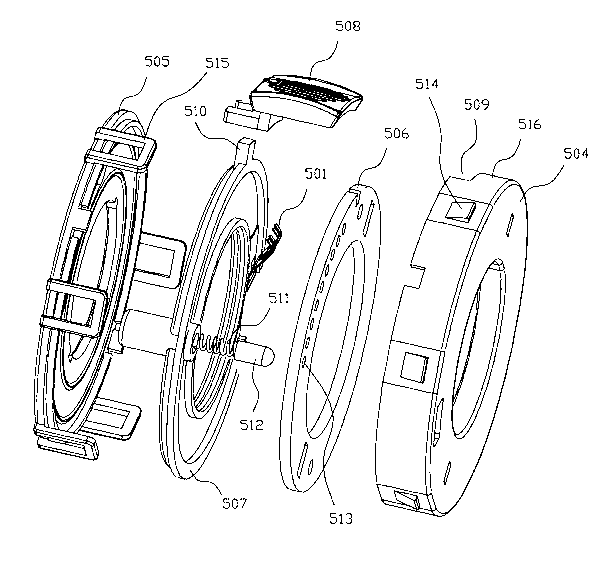

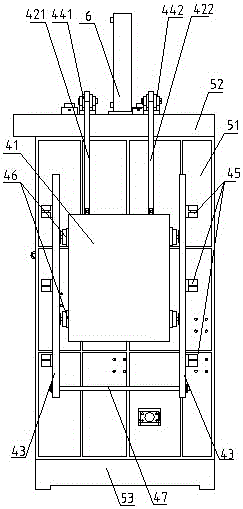

Decoupling type surgical device used for peritoneoscope minimally invasive surgery

InactiveCN103169542AReduce complexityImprove motor flexibilityDiagnosticsSurgeryLess invasive surgeryPERITONEOSCOPE

The invention relates to surgical devices used for peritoneoscope minimally invasive surgery, in particular to a decoupling type surgical device used for the peritoneoscope minimally invasive surgery, and aims at solving the problem that existing surgical instruments are not in a decoupling form, so that control of a system in a surgery process is quite inconvenient. The decoupling type surgical device used for the peritoneoscope minimally invasive surgery comprises a first rotating shaft mechanism, a second rotating shaft mechanism, a third rotating shaft mechanism and a fourth rotating shaft mechanism, wherein the first rotating shaft mechanism, the second rotating shaft mechanism, the third rotating shaft mechanism and the fourth rotating shaft mechanism are mounted in a control box in a matrix-shaped mode. The first rotating shaft mechanism is connected with a separating pliers mechanism through a first transmission rope and controls the separating pliers mechanism to be opened through the first transmission rope. The third rotating shaft mechanism is connected with the separating pliers mechanism through a third transmission rope and controls the pitching actions of the separating pliers mechanism through the third transmission rope. The fourth rotating shaft mechanism is connected with the other end of a rotary rod through a fourth transmission rope and controls the rotary motion of the rotary rod through the fourth transmission rope. The decoupling type surgical device used for the peritoneoscope minimally invasive surgery is used in the medical field.

Owner:苏州信诺泰克医疗科技有限公司

Adjustable mechanical-electrical integrated cutting knife

PendingCN107243936AReasonable structureFunctionalMetal working apparatusStructural engineeringManufacturing engineering

The invention discloses an adjustable mechanical-electrical integrated cutting knife which comprises a workbench, an operating floor, a cutting knife body and a base. The operating floor is arranged on the upper surface of the workbench. Sliding grooves are formed in the left end and the right end of the upper surface of the operating floor. Sliding blocks are arranged in the sliding grooves. A support is fixedly arranged at the upper ends of the sliding blocks. Pins are arranged in the lower end of the support. The upper ends of the pins penetrate through the surface of the outer side of the lower end of the support. The cutting knife body can be controlled by a rotary shaft to select any angle for cutting. The purpose of cutting at any angle can be achieved without changing the placing position of an object. Operation is easy, using is convenient, the cutting efficiency is improved, the position can be changed according to actual requirements, different portions of the object can be cut conveniently during cutting, the cutting efficiency is high for an object needing to be cut repeatedly, in addition, protecting grooves corresponding to the cutting knife body are formed in the upper surface of the operating floor, the cutting knife body is not prone to damaging the surface of the operating floor, and the cutting knife is suitable for popularization.

Owner:洪灵坪

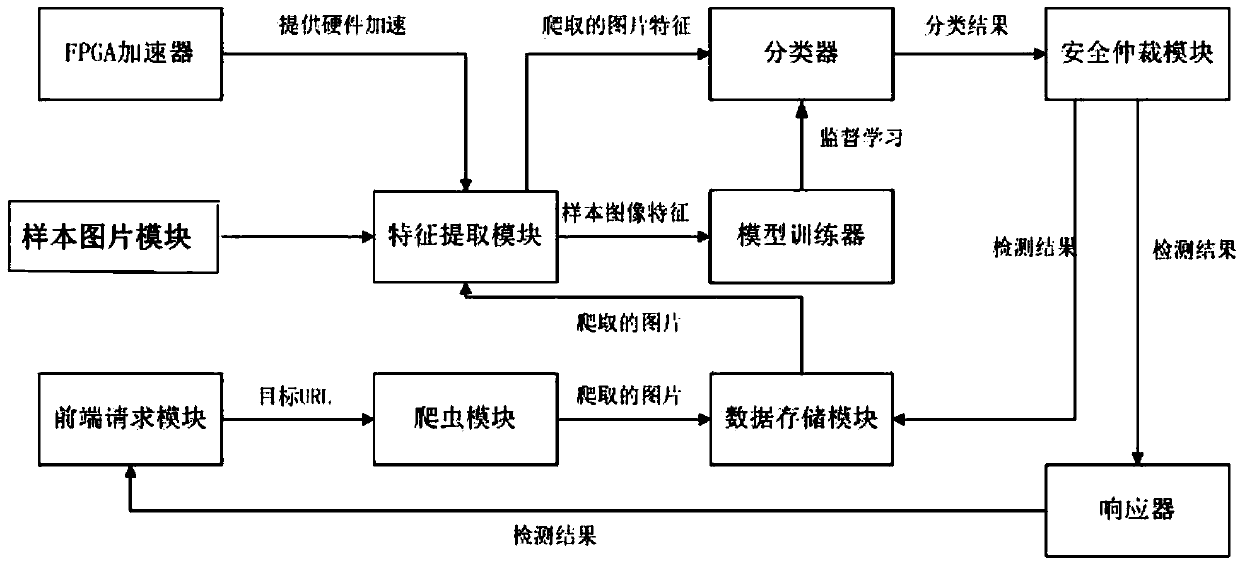

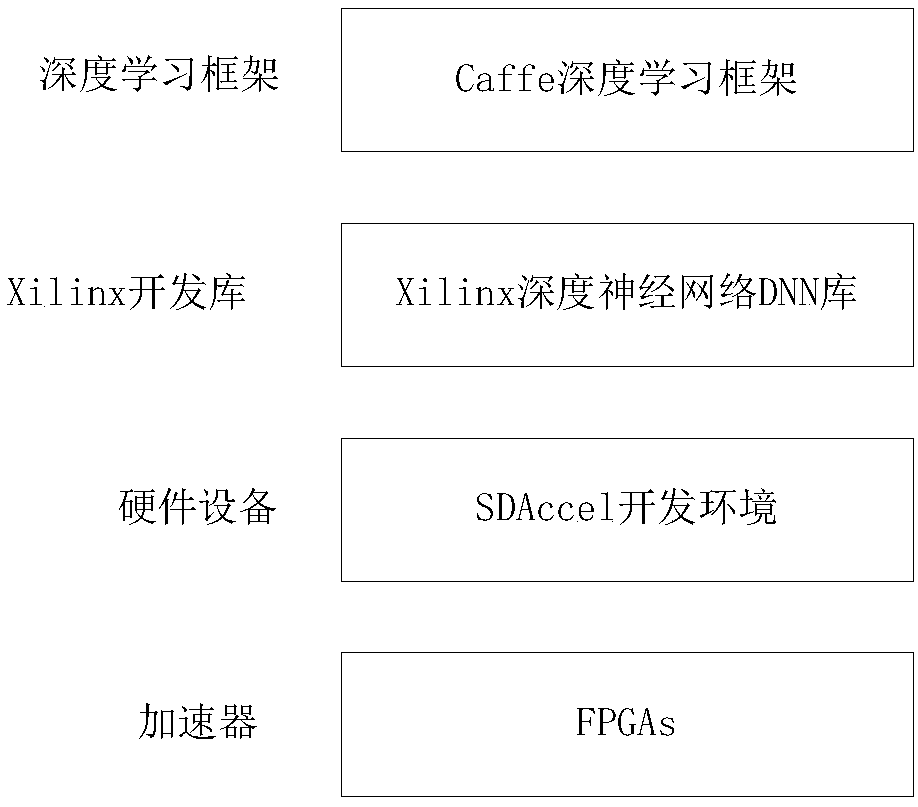

Website content safety testing system and method

InactiveCN107862050AFast security detectionEfficient and accurate safety detectionWeb data indexingWebsite content managementFeature vectorFeature extraction

The invention discloses a website content safety testing system and method. The system includes a front-end request module, a web spider module, a feature extraction module, a model training device, an FPGA hardware accelerator and a safety arbitration module; the front-end request module inputs to-be-tested URLs and submits a request to the web spider module; the web spider module crawls pictureinformation of a target URL; the feature extraction module extracts the picture information of the web spider module and the picture information of a sample picture module as feature vectors; the model training device utilizes the feature vectors of sample pictures to generate a classification device by means of a supervised learning mode; the FPGC hardware accelerator provides a hardware acceleration function for the feature extraction module; the safety arbitration module calculates the safety coefficient of the target URL according to a classification result obtained after the classification device classifies the features of the pictures. By means of the principle above, by inputting the features of the sample pictures into the model training device to obtain the classification device and using the FPGA hardware accelerator to accelerate an algorithm of the feature extraction module to increase the response speed of the system, the purpose of implementing a fast, efficient and accurate website content safety test is achieved.

Owner:INFORMATION & TELECOMM COMPANY SICHUAN ELECTRIC POWER

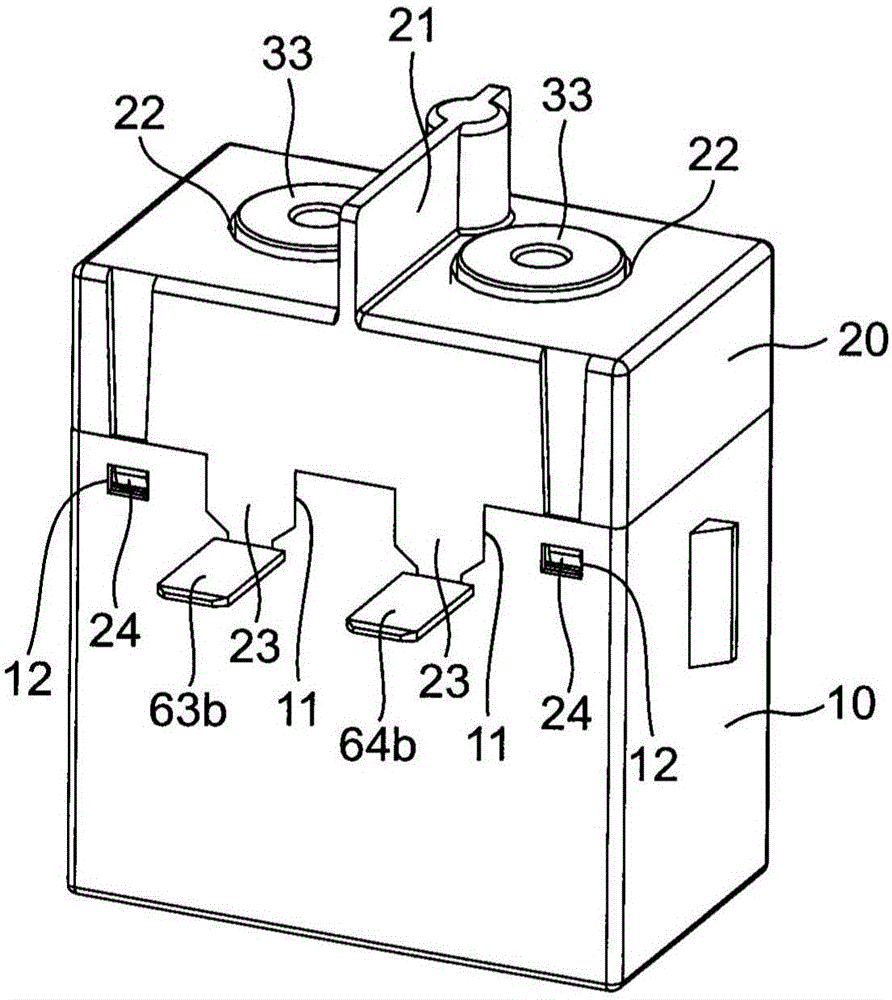

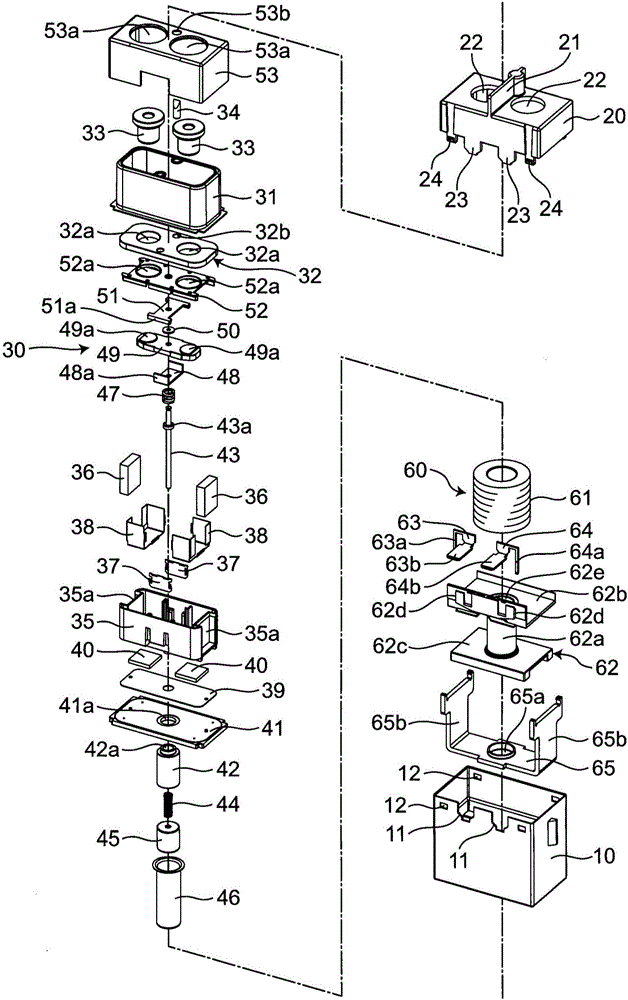

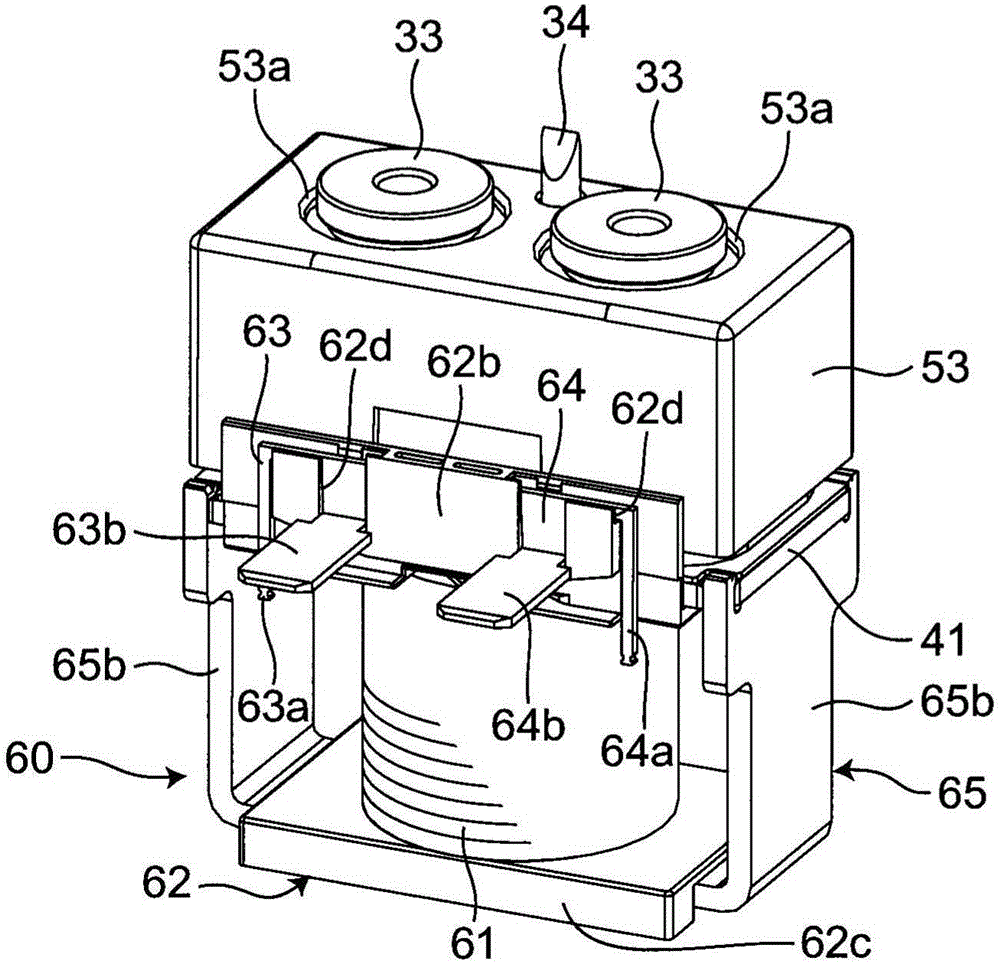

Contact switching device

ActiveCN106504948ASimplify assembly workIncrease productivityElectromagnetic relay detailsEngineeringPower flow

There is provided a contact switching device which has high productivity and in which operation characteristics hardly vary. The contact switching device includes an electromagnetic unit (60), a holder (35), a movable shaft (43), a movable yoke (48), a movable contact piece (49) having movable contacts (49a) at both ends, fixed contacts (33a), and a fixed yoke (51). At the time of excitation of the electromagnetic unit (60), the movable shaft (43) moves to the holder (35) side along a direction of an axis center. A magnetic circuit is formed of the fixed yoke (51) and the movable yoke (48) due to a magnetic field generated by a current that flows into the movable contact piece (49) as a result of the movable contacts (49a) coming into contact with the fixed contacts (33a). The movable yoke (48) is then attracted to the fixed yoke (51).

Owner:ORMON CORPORATION

Precision edge cutting device for thin film for capacitor

The invention discloses a precision edge cutting device for a thin film for a capacitor. The precision edge cutting device comprises a workbench, a first supporting frame, a second supporting frame, a cutting device and a positioning device. The two supporting frames are arranged. The cutting device and the positioning device are arranged on the upper surface of the workbench through the first supporting frame and the second supporting frame. The cutting device comprises a sliding shaft, an edge cutting table and a cutter. The bottom end of the edge cutting table is connected with a hydraulic rod, and one side of the edge cutting table is connected with an adjusting lead screw. The positioning device comprises a fixed shaft and two positioning rods, one ends of the two positioning rods and the fixed shaft are sleeved together through sliding sleeves, an infrared transmitter is arranged on the surface of the workbench, and infrared receivers are arranged on the two sides of the cutter. According to the device, the cutting device is used for cutting, meanwhile, the thin film is subjected to rapid cutting positioning through infrared rays, different positions can be rapidly positioned during edge cutting, deviation caused by edge cutting is avoided, the edge cutting precision is higher, and the device is worthy of popularization.

Owner:山东格新精工有限公司

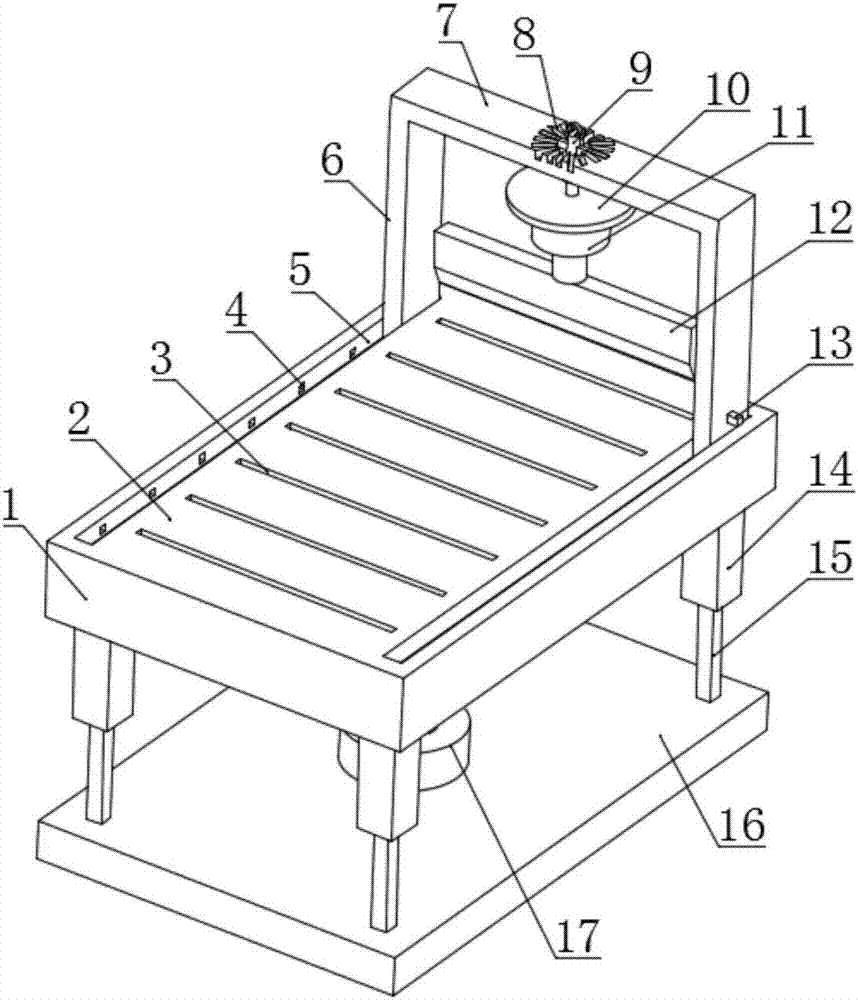

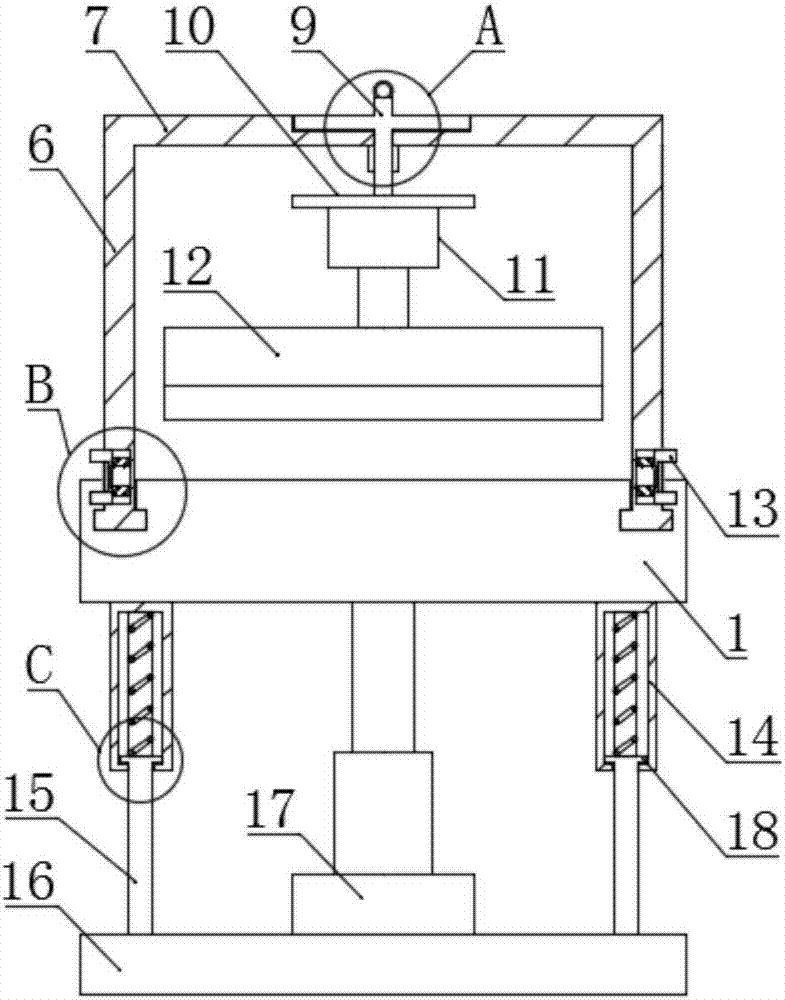

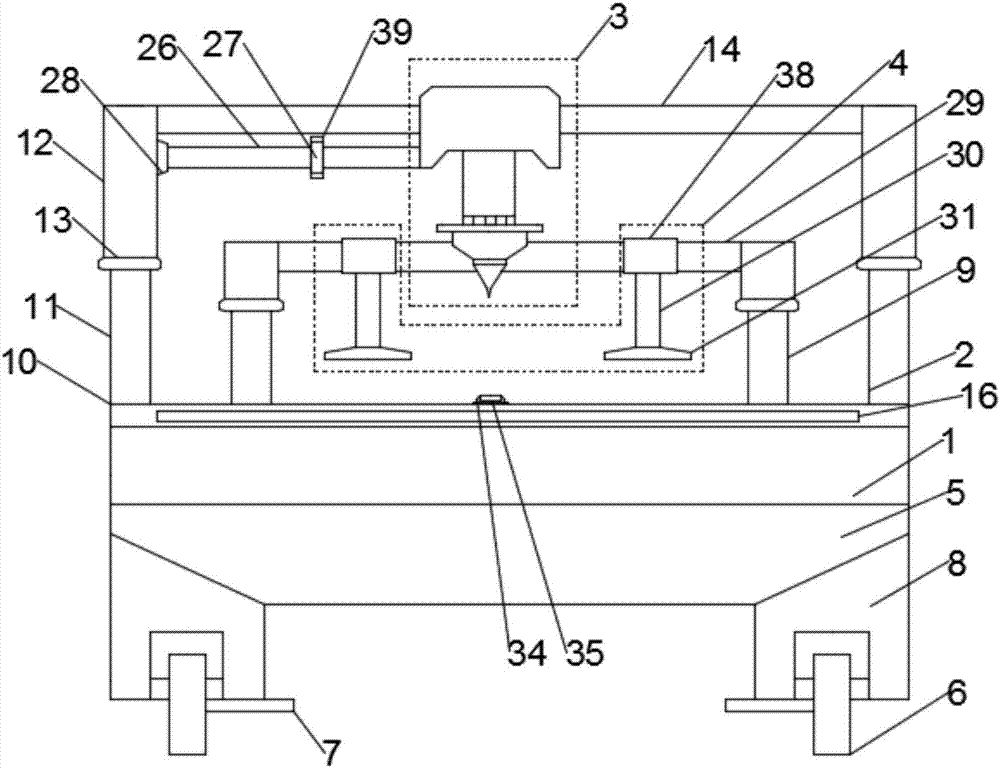

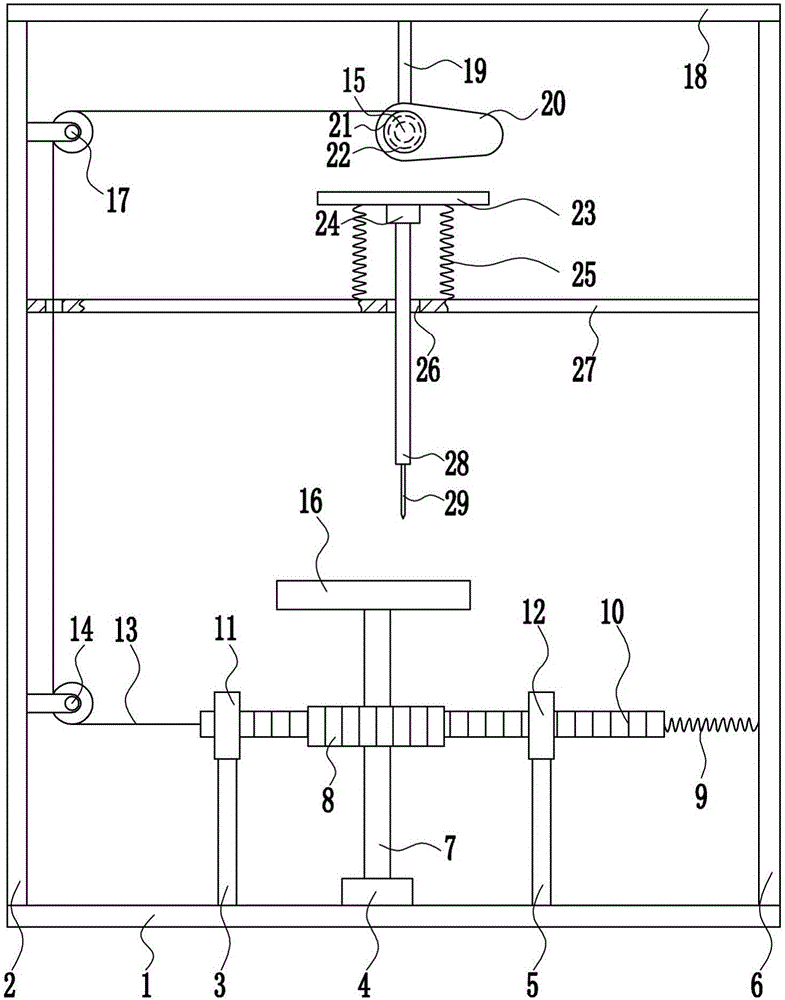

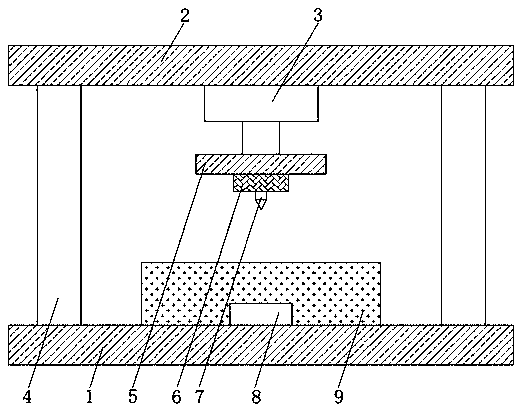

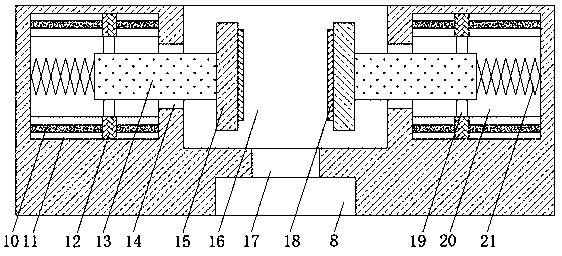

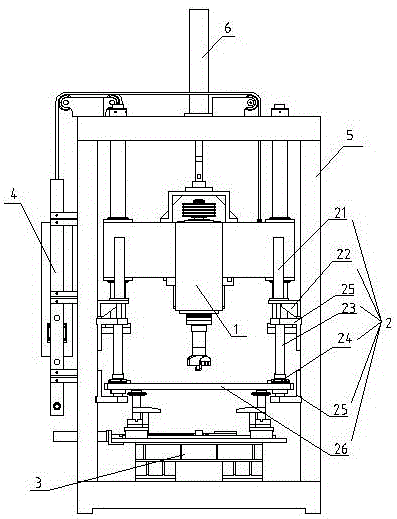

Drilling equipment of plastic suction die

InactiveCN106738035AUniform punching effectLess prone to deviationMetal working apparatusCamMechanical engineering

The invention relates to drilling equipment, in particular to drilling equipment of a plastic suction die, which aims at solving the technical problem to provide drilling equipment of a plastic suction die, with capability of uniform drilling on a gypsum die. To solve the technical problem, the drilling equipment of the plastic suction die comprises a bottom plate, a left frame, a first bracket, a bearing block, a second bracket, a right frame, a first rotary shaft, a gear, a first spring, a first gear rack, a first guide sleeve, a second guide sleeve and the like, wherein the left frame and the first bracket are welded at the left side of the top part of the bottom plate; the left frame is positioned at the left side of the first bracket; the second bracket and the right frame are welded at the right side of the top part of the bottom plate; the right frame is positioned at the right side of the second bracket. The drilling equipment has the advantages that the uniform drilling effect is realized by the uniform-speed rotation of a cam and a fixing device; by specially adding a slide rail and a slide block on the device, the descending of a twist drill is stabilized, so that the easiness in deviation of drilling is avoided.

Owner:东莞市杰出塑胶科技有限公司

System for real-time monitoring operating conditions for power supply station and its operating method

InactiveCN1937353AEasy to masterImprove business qualityCircuit arrangementsInformation technology support systemLine lossPower substation

The system for carrying out monitoring operation status of power substation in real time includes following parts: CPU, modules including safe operations, production run, marketing operations, professional operations, and synthesis operations. All the said modules are connected to CPU. The professional operation module includes voltage no-load operation module, module for running at voltage monitor point, operation module for power supply reliability target, operation module for scheduled outage, operation module for temporary outage, operation module for accident outage, and operation module of line loss. Comparing with prior art, the invention overcomes disadvantages: difficult to collect data, issuing result out of time, low efficiency for operating service, poor reliability of power service, deviation and mistake appearing easily, and even creating accident.

Owner:XIAN POLYTECHNIC COLLEGE

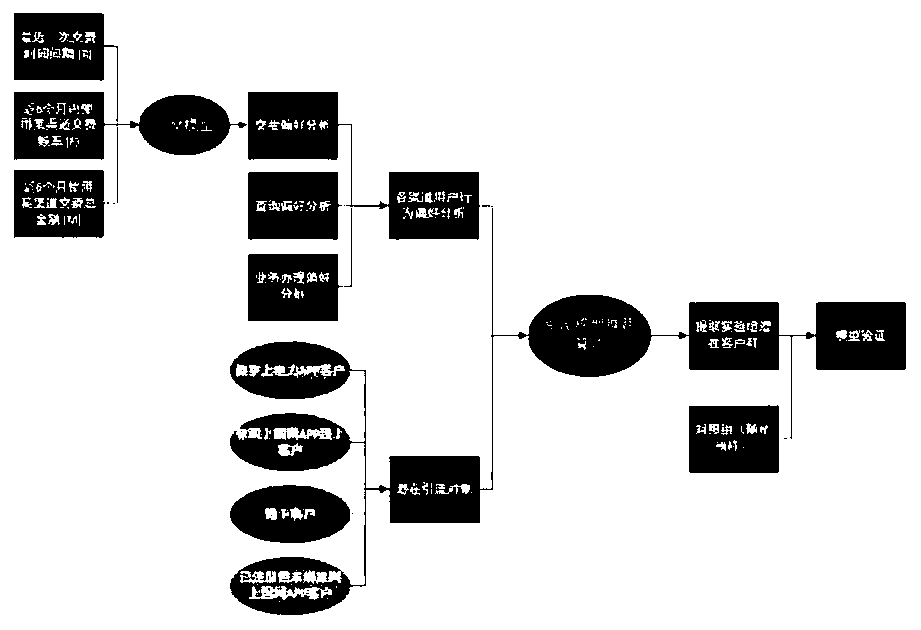

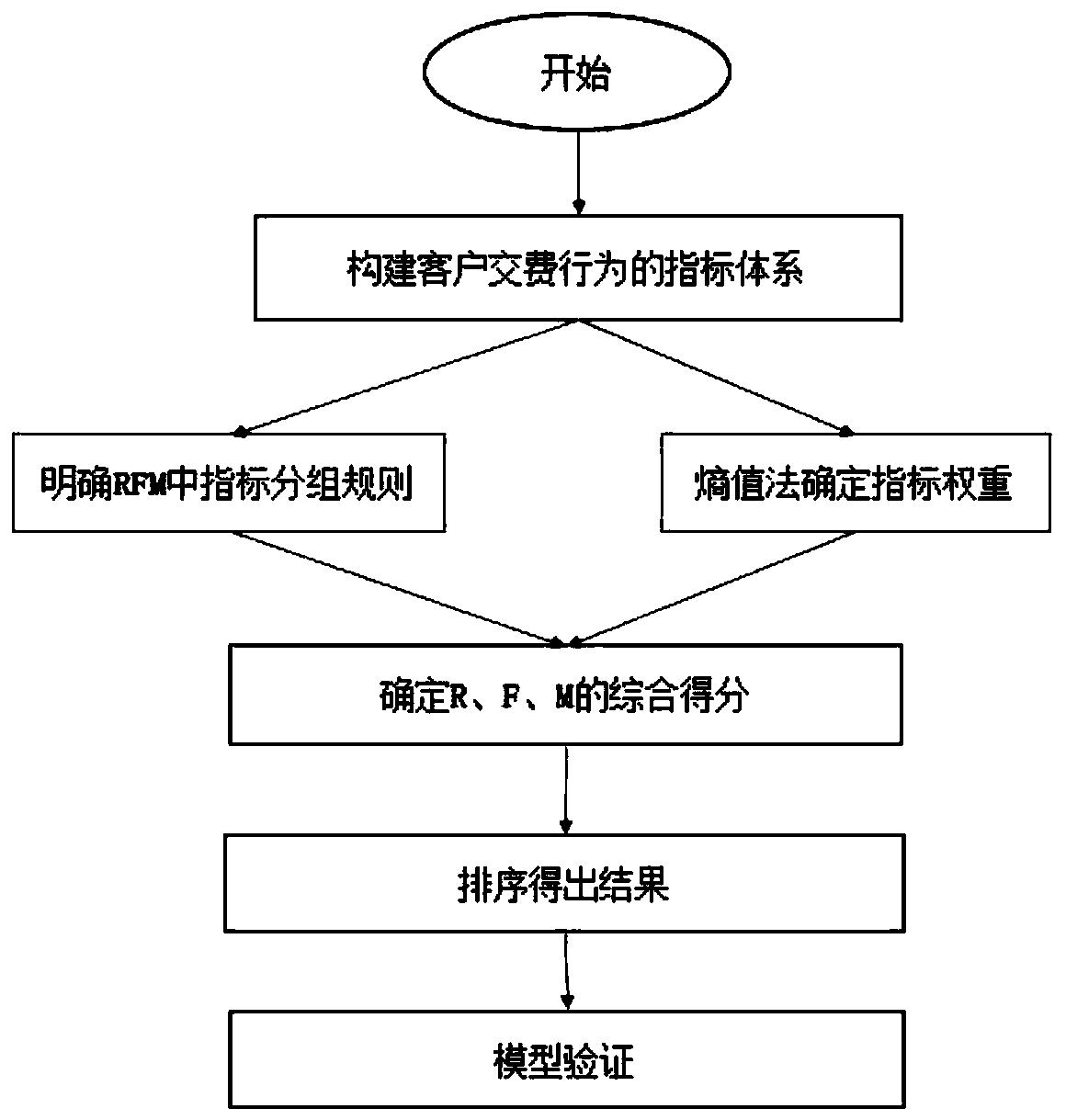

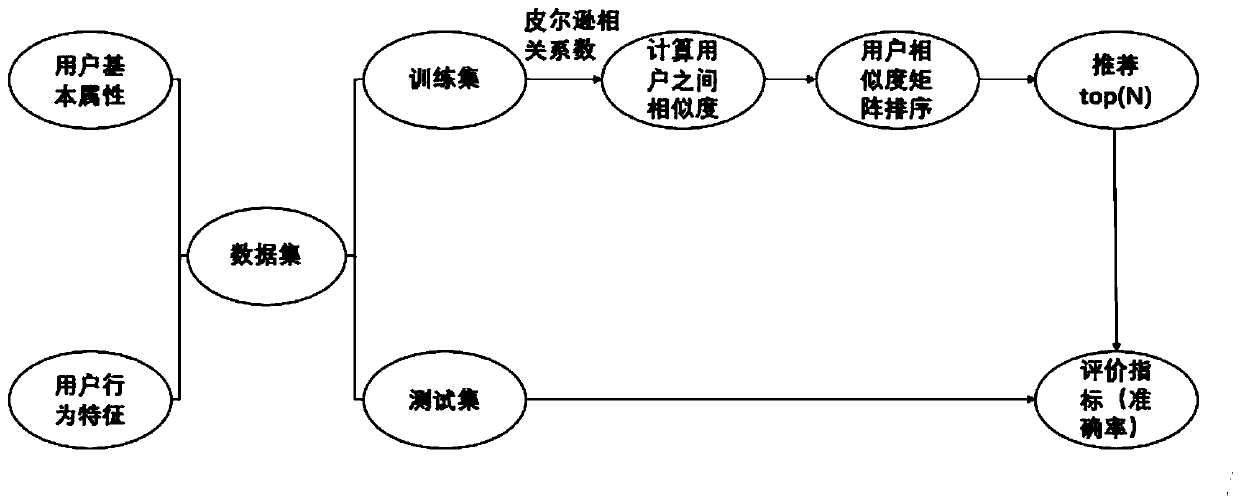

Client channel drainage method based on big data recommendation algorithm

PendingCN111127080AComprehensive drainage planRigorous drainage planAdvertisementsTerminal equipmentProduct demand

The invention discloses a client channel drainage method based on a big data recommendation algorithm, and belongs to the technical field of power operation. An existing channel drainage method mainlydepends on experience, cannot accurately screen target customers, and cannot mine customers with drainage potential. According to the invention, a client channel drainage model is established by taking a client as a center, and the tendency of the client to handle business by means of terminal equipment is analyzed from service and product requirements triggered by the client; meanwhile, the customer use information of each electronic channel is effectively fused, the customer group is subdivided, the internal characteristics and rules of using various electronic channels by customers are deeply explored, the purpose of using the electronic channels by the customers is more comprehensively understood, and guidance is provided for development and marketing of the electronic channels; and thus, the client channel can be guided. The drainage scheme is comprehensive, rigorous and scientific, and deviation is not prone to occurring.

Owner:HUANGYANG ELECTRIC POWER

Drilling sample plate with positioning and supplementing functions

The invention provides a drilling sample plate with positioning and supplementing functions, and belongs to the technical field of machining. The drilling sample plate with positioning and supplementing functions is characterized in that on a plane on which ribs are located, a top face and a side of a lateral edge strip of a part are used as a supplementing outer edge of a drilling sample plate, namely a positioning edge; corresponding parts of an edge of the drilling sample plate and the positioning edge of the part are adhered with each other; two edges are used as positioning references of the drilling sample plate and the part in two directions of height and width; when the drilling sample plate is used, the drilling sample plate is clamped on the part and is adhered to the ribs. When the sample plate is used in a manufacturing plant, positioning can be directly carried out, working steps of requiring measurement during numeric value positioning and sample placement can be reduced, the working time is shortened, and rapid positioning of the drilling sample plate is realized, so that convenience is provided for the manufacturing plant, and the working efficiency is improved. By adhesion of the drilling sample plate and the surface of the part, the deviation is difficult to produce during machining, and the accuracy of technological holes can be guaranteed relatively.

Owner:SHENYANG AIRCRAFT CORP

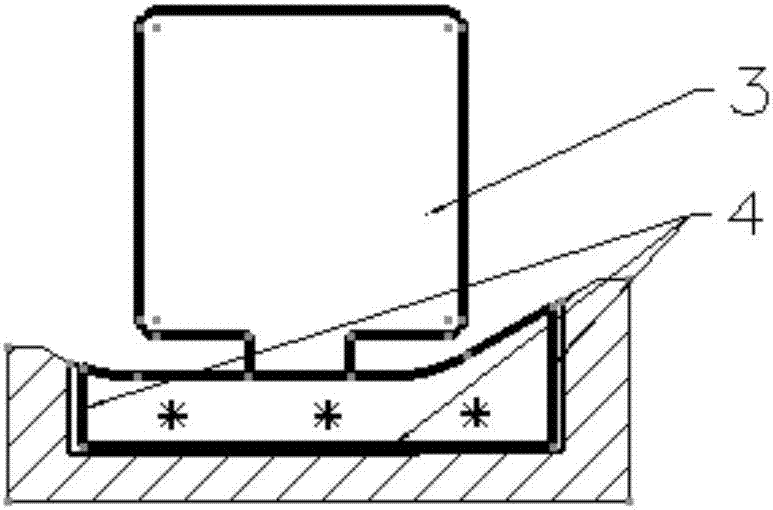

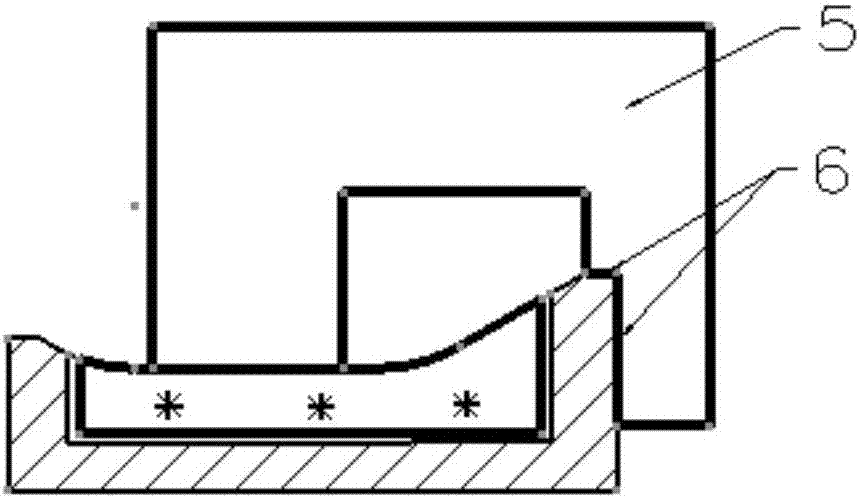

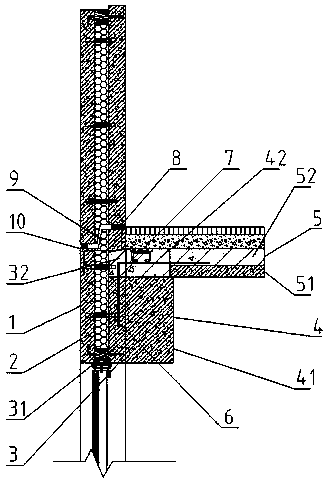

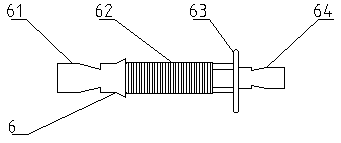

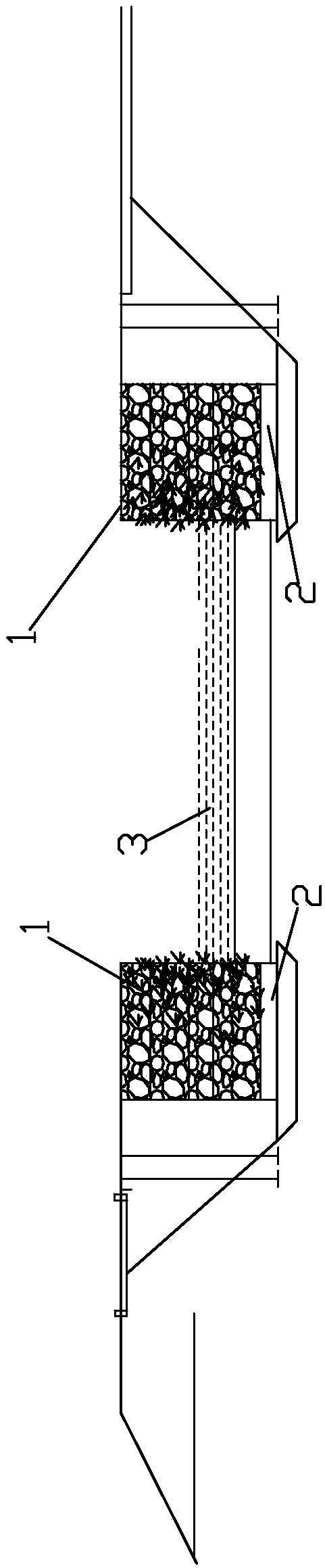

Precast sandwich external wall panel and structural system thereof as well as construction method

PendingCN107642194AEasy to installImprove structural strengthBuilding componentsWater-setting substance layered productThermal insulationUltimate tensile strength

The invention discloses a precast sandwich external wall panel and a structural system thereof as well as a construction method. The precast sandwich external wall panel comprises an outer shale plate, a thermal insulation layer and an inner shale plate, wherein the thermal insulation layer is arranged between the outer shale plate and the inner shale plate; in addition, the thermal insulation layer penetrates through the precast sandwich external wall panel; the outer shale plate, the inner shale plate and the thermal insulation layer are connected by anchored connecting members. The precastsandwich external wall panel and the structural system thereof provided by the invention have the characteristics of simple structure, convenience in mounting and high structural strength; by using the construction method provided by the invention, an external wall board can be quickly and conveniently mounted to be in place; besides, the construction method has the advantages of high mounting strength, accurate mounting and positioning and low possibility of deviation.

Owner:NINGXIANG YUANDA RESIDENTIAL IND CO LTD

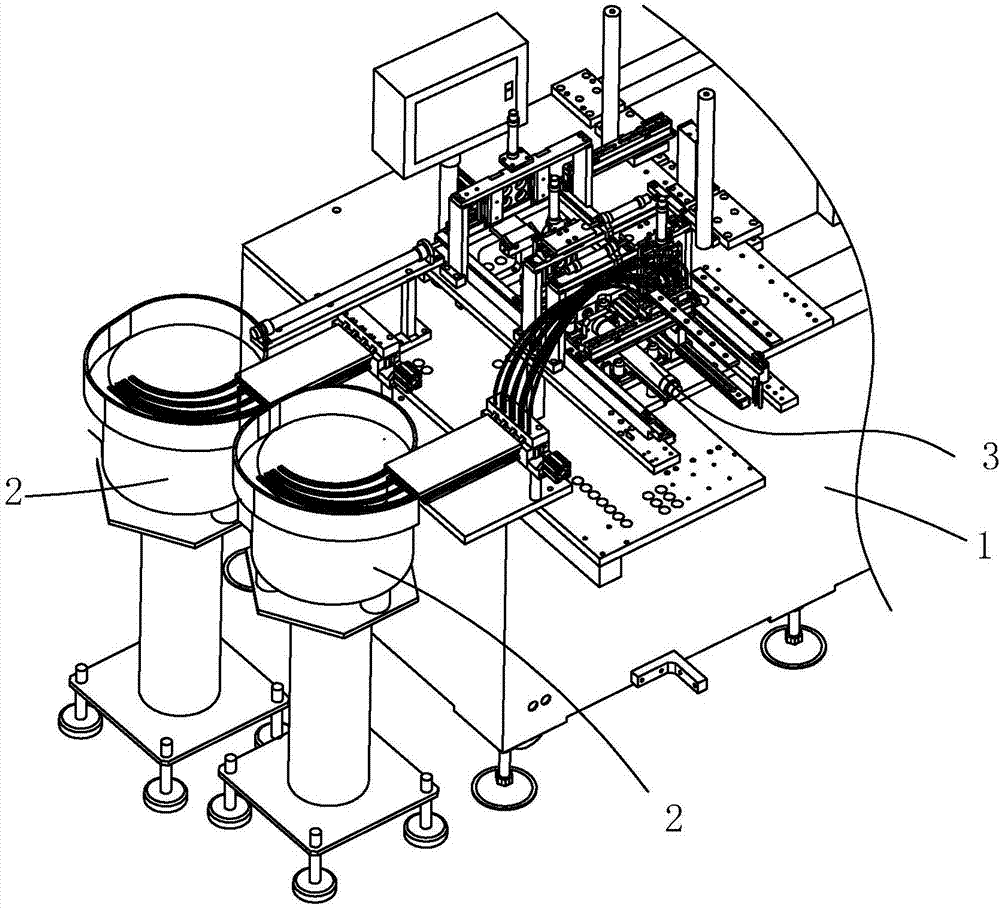

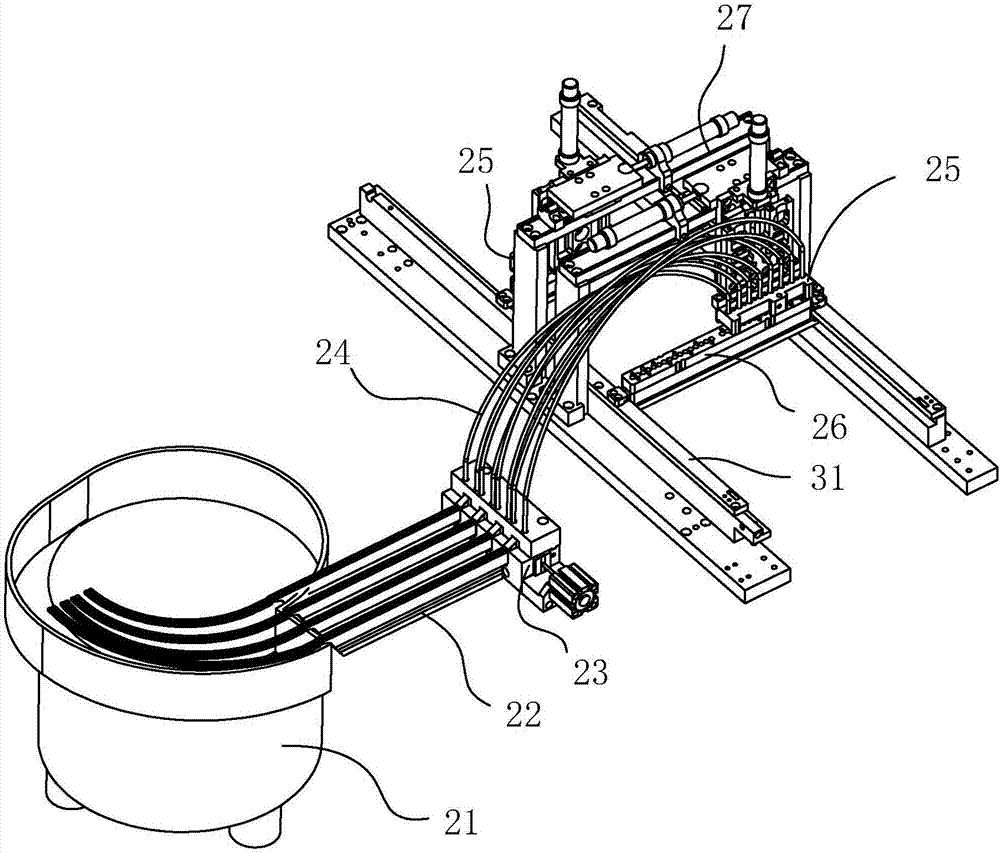

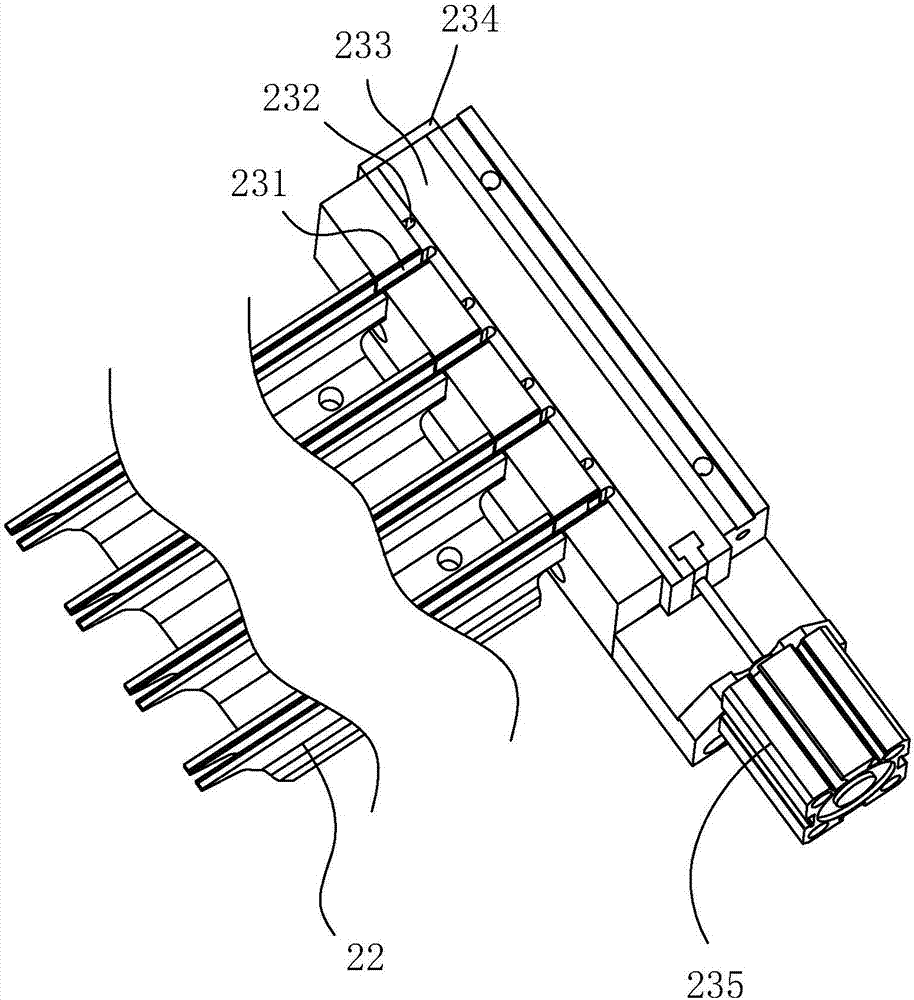

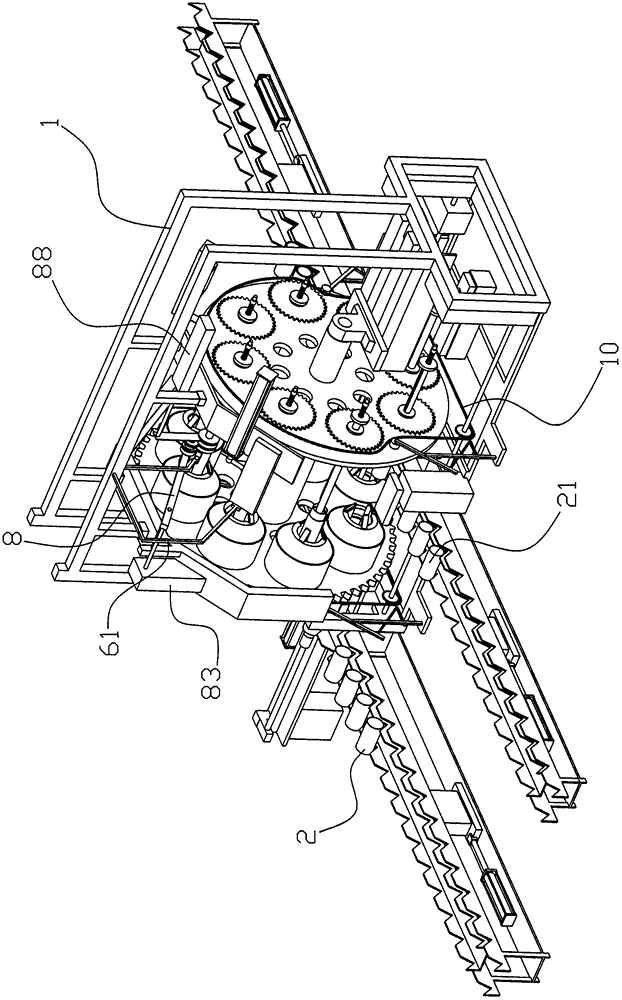

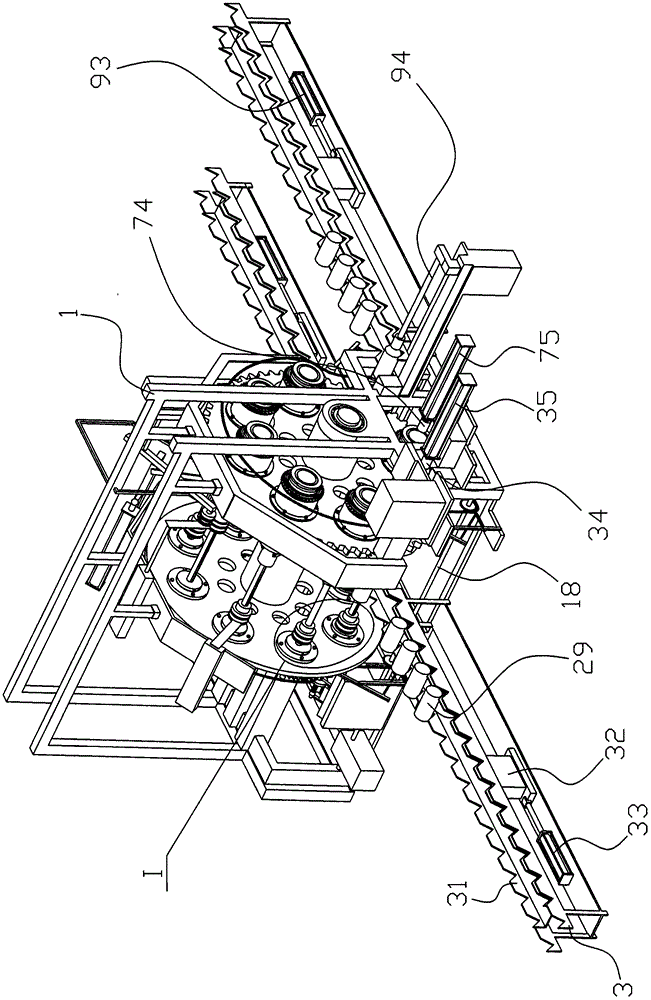

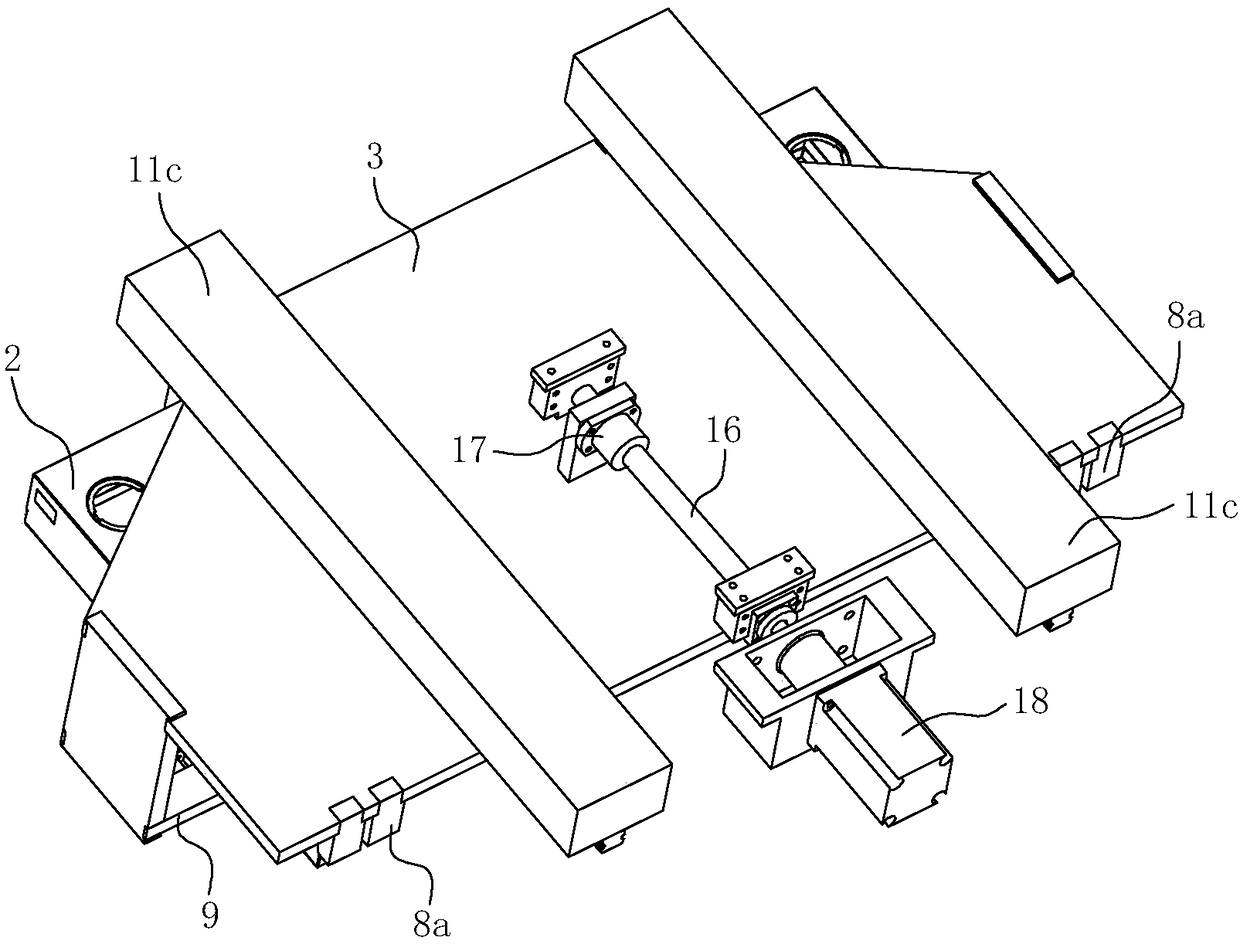

Efficient feeding mechanism and method for DC plug production line

ActiveCN107309625AEasy to processEasy to assembleMetal working apparatusProduction lineProcess engineering

The invention discloses an efficient feeding mechanism and method for a DC plug production line. The efficient feeding mechanism for the DC plug production line comprises a rack and is characterized by further comprising a vibrating disk, a plurality of material conveying guide rails, a plurality of conveying pipes, a material guide plate and a mold strip, wherein the vibrating disk, the material conveying guide rails, the conveying pipes, the material guide plate and the mold strip are connected with one another from the upper stream to the lower stream, the vibrating disk is used for screening and conveying parts, and the conveying pipes conduct conveying through the air pressure; the material guide plate is provided with a plurality of material guide holes, and each material guide hole is connected with the corresponding conveying pipe; the mold strip is provided with material receiving holes, and the number of the material receiving holes is twice of that of the material guide holes; and the rack is provided with a first pushing mechanism which pushes the material guide plate to move and aligns the material guide holes with the material receiving holes. The efficient feeding mechanism for the DC plug production line has the advantages of whole-process automatic operation and high intelligent degree; and in addition, one-time batch loading of the parts can be achieved so that batch machining or assembling can be conducted, and the production efficiency is greatly improved.

Owner:JOLLYKING ELECTRONICS

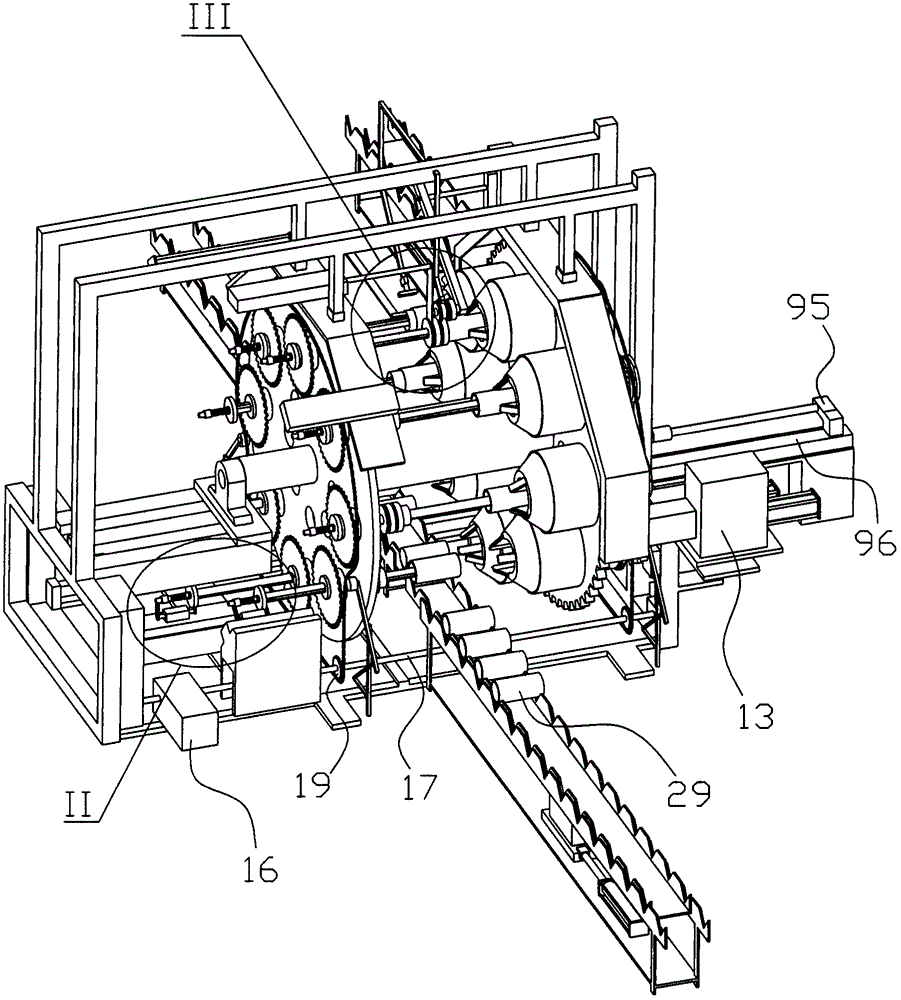

Full-automatic glass cup welder

PendingCN106830648ALess prone to deviationEvenly heatedGlass reforming apparatusGlass productionEngineeringMoving parts

The invention discloses a full-automatic glass cup welder, comprising a frame, an outer buckle arm, an inner buckle arm, a moving part and a welding part; a first rotating disk and a second rotating disk which can rotate in relative to the frame are concentrically arranged on the frame; the outer buckle arm is rotationally arranged on the first rotating disk, and the inner buckle arm is rotationally arranged on a corresponding position of the second rotating disk; the first rotating disk is connected with the first driving device capable of driving the first rotating disk to intermittently move; the outer buckle arm and the inner buckle arm are connected with the second driving device for driving the outer buckle arm and the inner buckle arm to rotate at the same speed, the upper part of the frame is provided with a thread manufacturing part, and a big glass cup conveying device is arranged on the frame at the outside of the first rotating disk; a big glass cup positioning device, a small glass cup positioning device and a small glass cup conveying device are arranged on the frame between the first rotating disk and the second rotating disk; the other side of the frame in opposite to the small glass cup conveying device is provided with a double-layered glass cup conveying device. The full-automatic glass cup welder has the advantages of being high in welding efficiency, uniform in welding, and good in effect.

Owner:NINGBO BEILUN HANXIN NEW ENERGY TECH

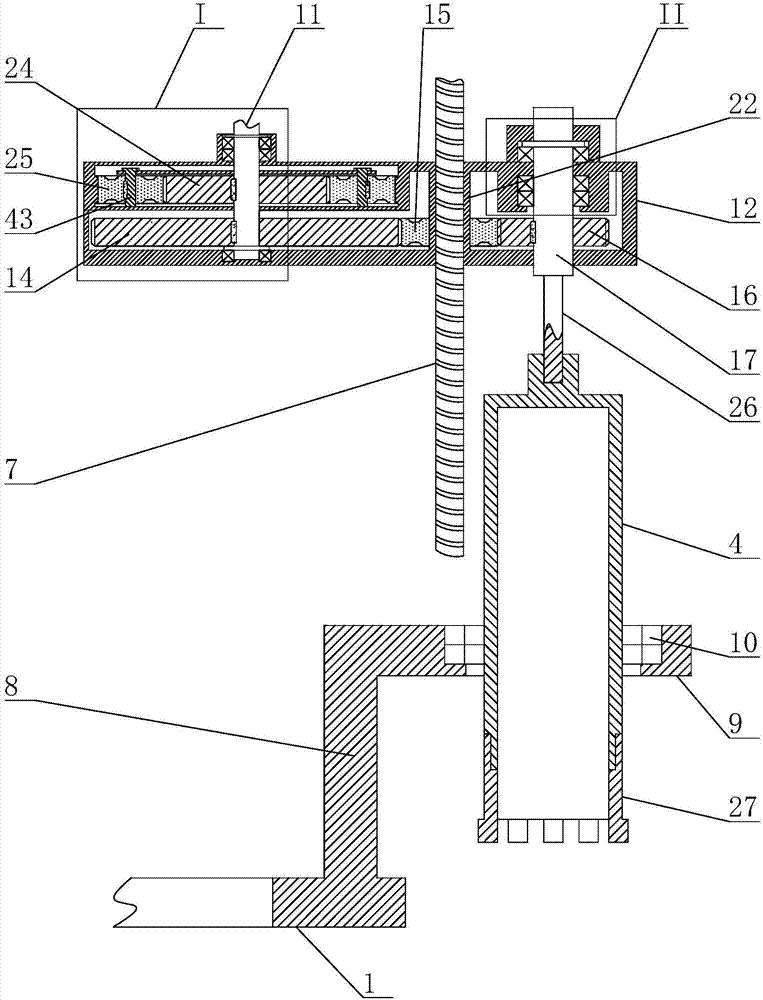

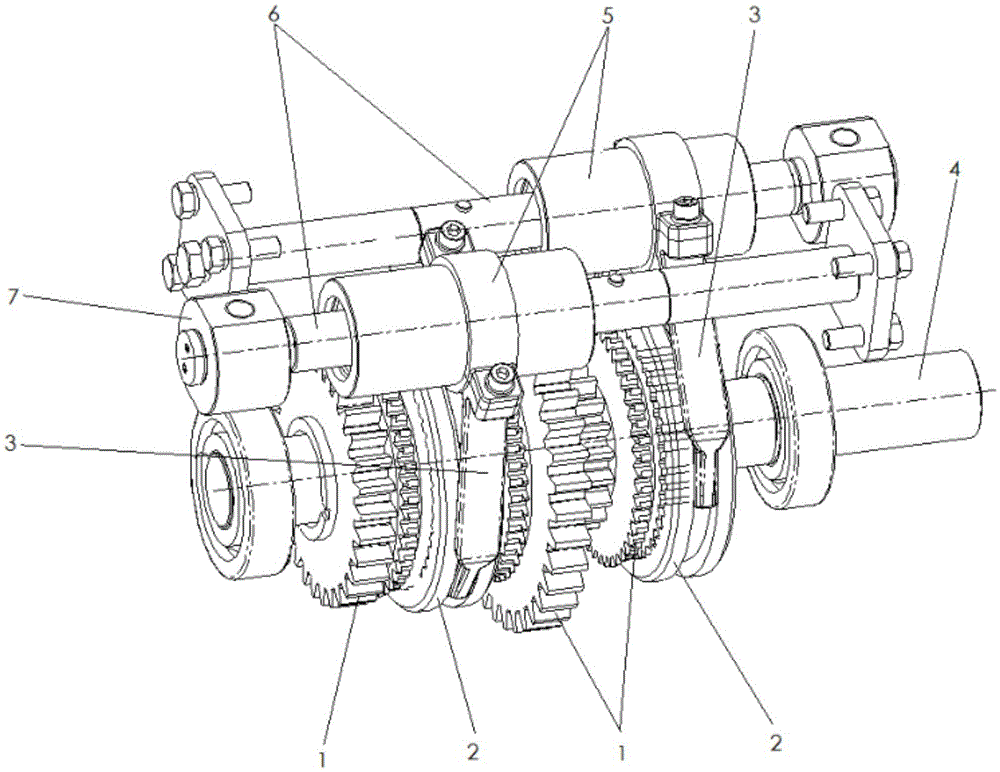

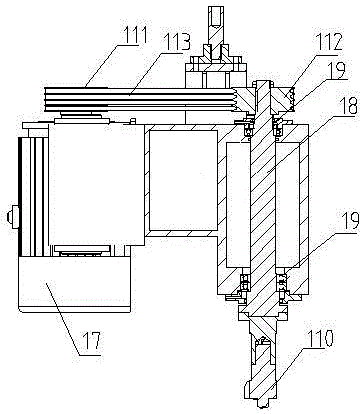

Precision core drilling machine

ActiveCN107191148ASmooth motionSmooth transmissionToothed gearingsCore removalDrive shaftEngineering

The invention discloses a precision core drilling machine. The machine includes a base, a threaded rod, an anti-deviation device, an actuator assembly, a vertical engine, a hollow drill, a top base, a rotating hand wheel and a leading screw, wherein the actuator assembly is composed of a driving shaft, an outer shell body, a planetary gear train, a big sun gear, a transition gear, a tail end gear and a driven shaft; the side wall of a planetary gear groove is provided with annular gears, and the planetary gear train includes a small sun gear and small planetary gears; the driving shaft is successively connected to the small sun gear and the big sun gear in a key joint mode; one end of the transition gear is meshed with the big sun gear, and the other end of the transition gear is meshed with the tail end gear; the leading screw is connected to the internal of a nut sleeve, the driven shaft is connected to the tail end gear in a key joint mode, and the bottom of the driven shaft is connected to the hollow drill. The precision core drilling machine has the advantages that a series of deficiencies in the adoption of belt transition are abandoned, and transmission is much stabler during drilling; the rotation of the hollow drill is much stabler, deviation does not occur easily, and obtained core samples are more precision and uniform.

Owner:杨婷

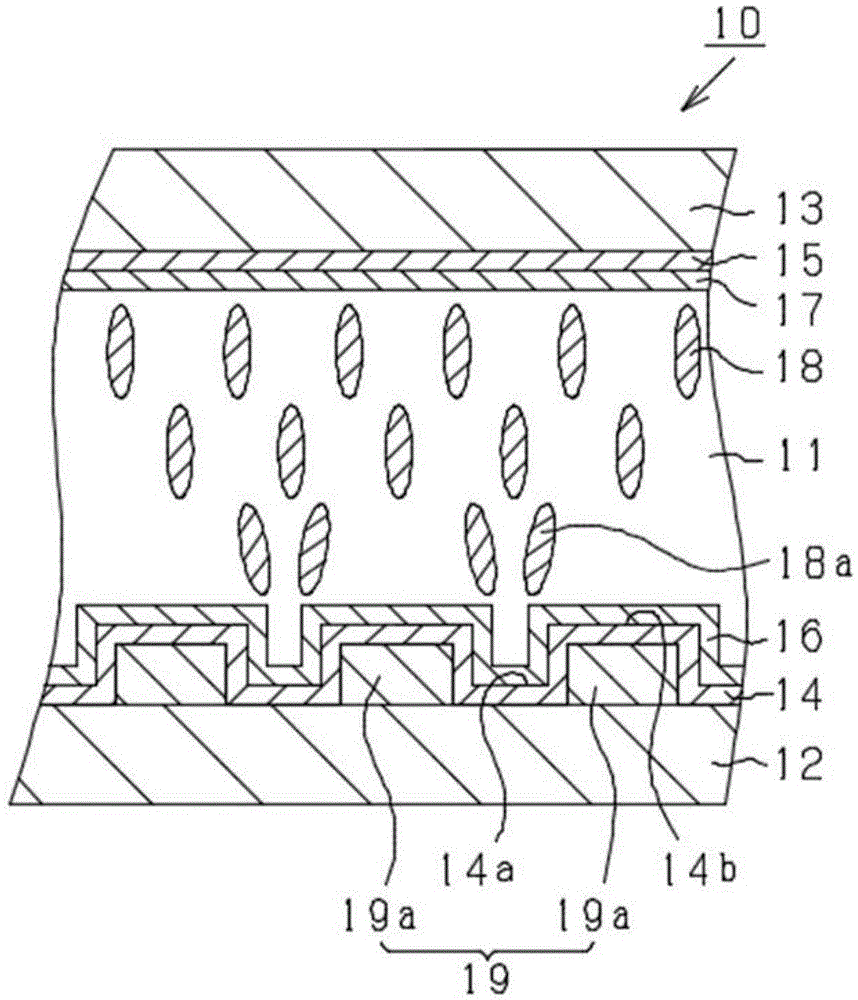

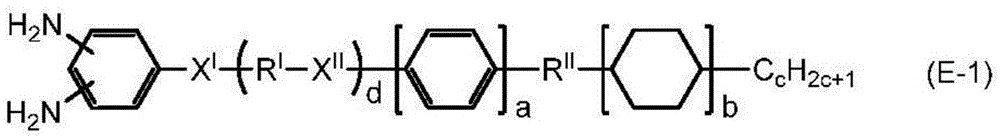

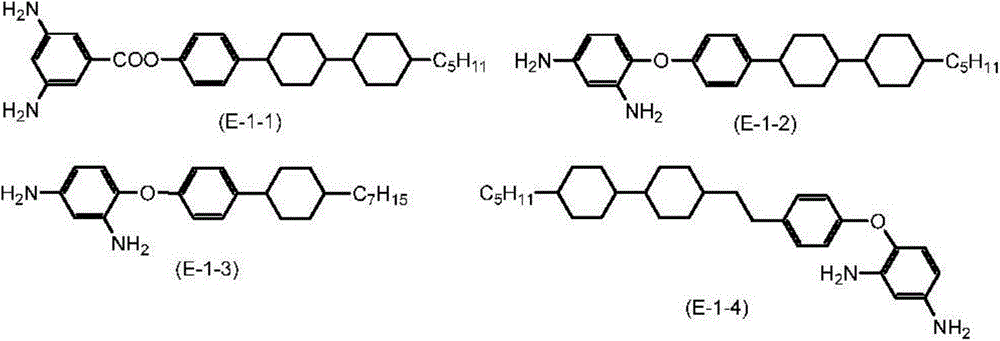

Liquid crystal display assembly, manufacturing method thereof, and liquid crystal aligning agent

InactiveCN105988252AUniform thicknessLess prone to deviationLiquid crystal compositionsNon-linear opticsConvex structureLiquid-crystal display

The invention provides a liquid crystal display assembly, a manufacturing method thereof, and a liquid crystal aligning agent. The liquid crystal display assembly comprises a liquid crystal layer, a pair of substrates including a first substrate and a second substrate which are configured oppositely in such a way of clamping the liquid crystal layer, a pixel electrode disposed on the liquid crystal layer side of the first substrate, an opposite electrode disposed on the liquid crystal layer side of the second substrate opposite to the pixel electrode, and liquid crystal aligning layers disposed on the respective liquid crystal layers of the pixel electrode and the opposite electrode. In the liquid crystal display assembly, at least one of the pixel electrode and the opposite electrode is provided with a concave-convex structure at the surface of the liquid crystal layer. In addition, the liquid crystal aligning layer disposed on the electrode with the concave-convex structure is formed by a liquid crystal aligning agent having a polymer [P] with weight average molecular weight over 30000. The liquid crystal aligning layer of the liquid crystal display assembly has small thickness deviation and good liquid crystal aligning performance.

Owner:JSR CORPORATIOON

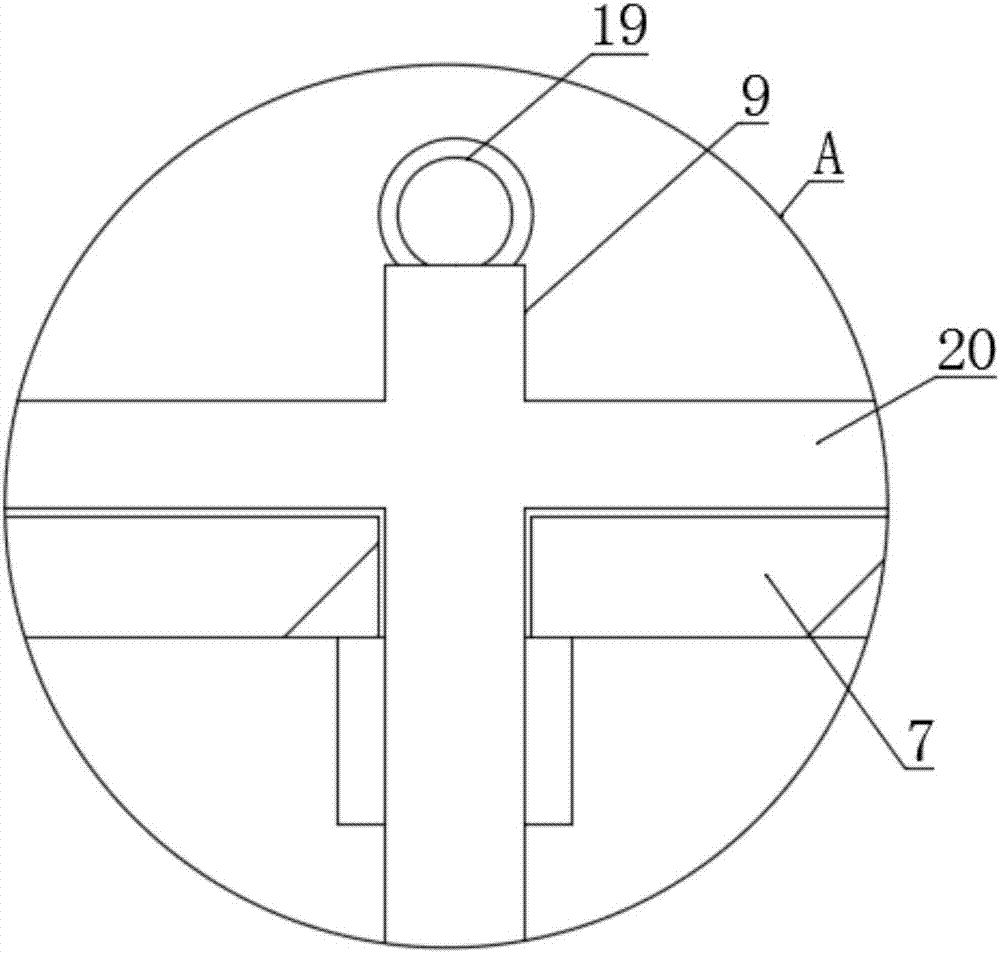

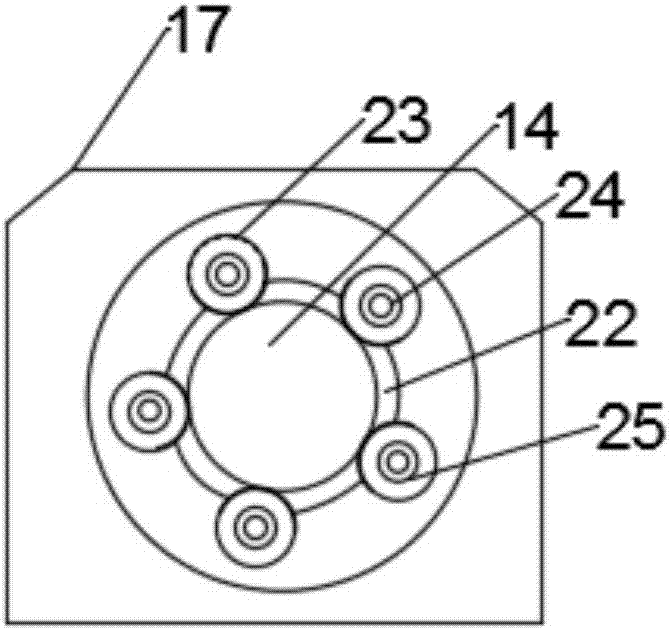

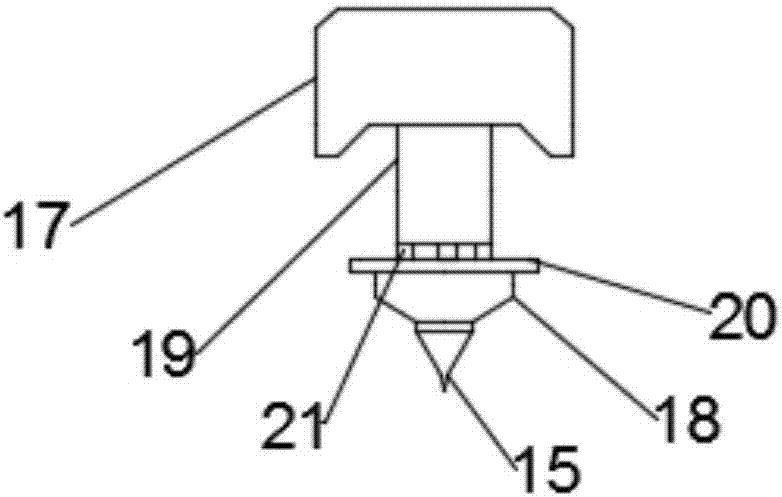

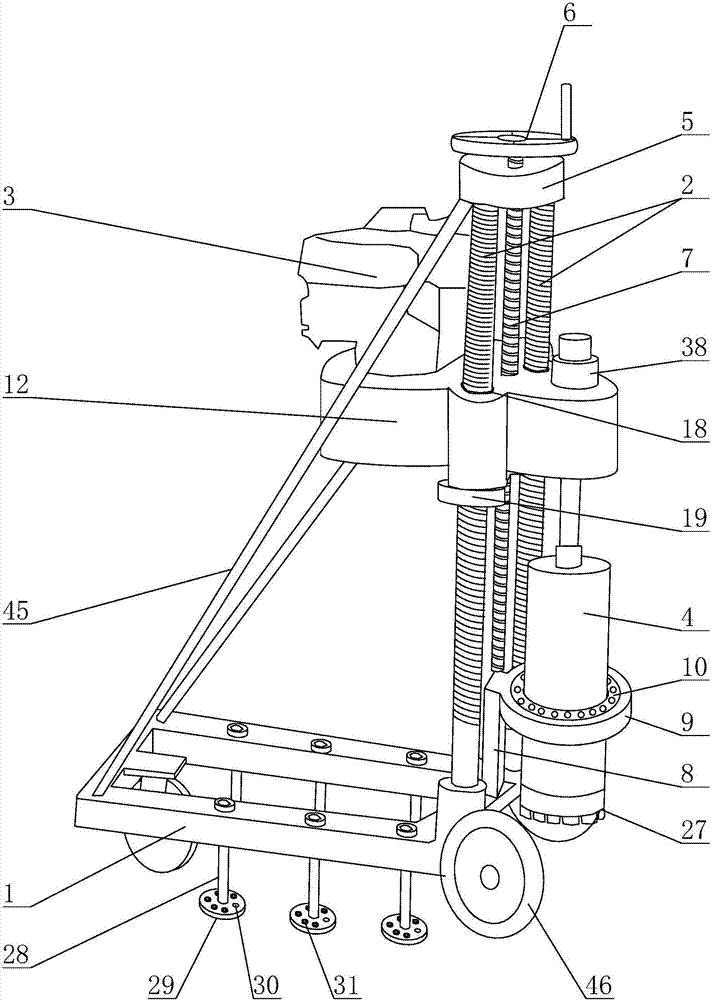

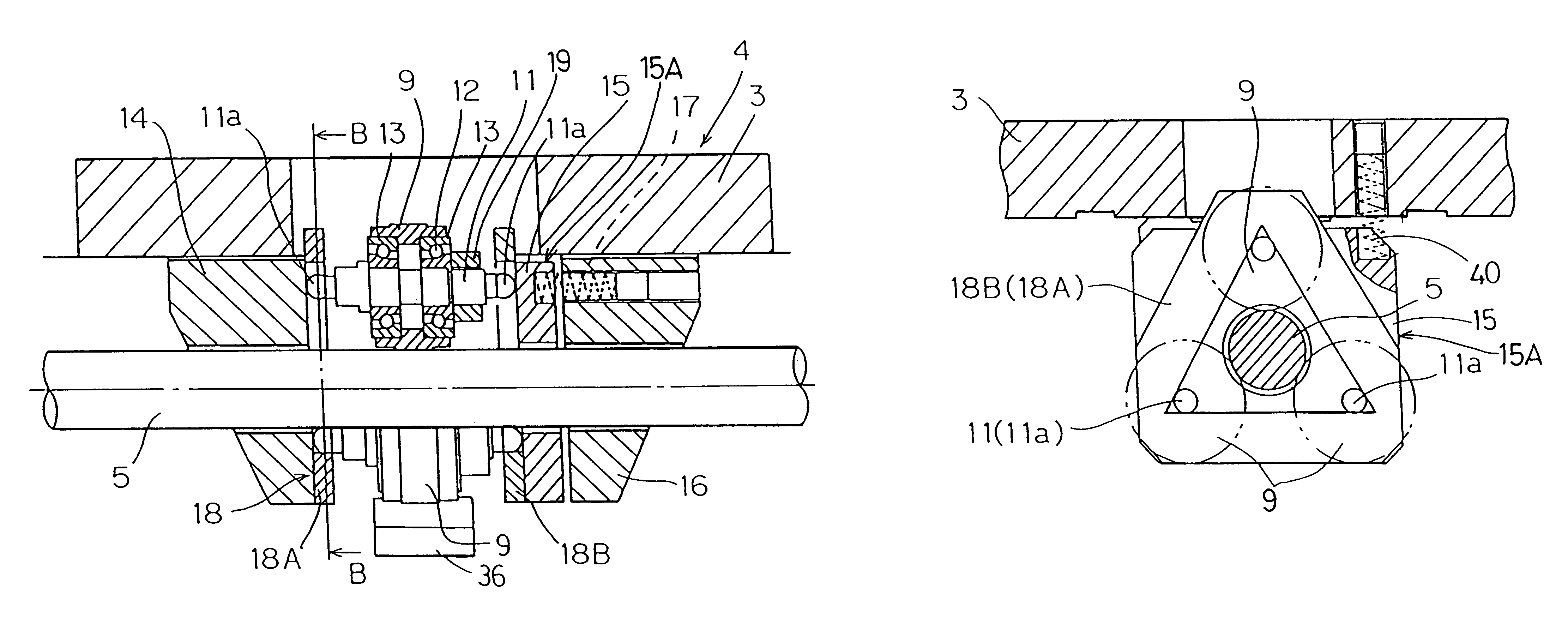

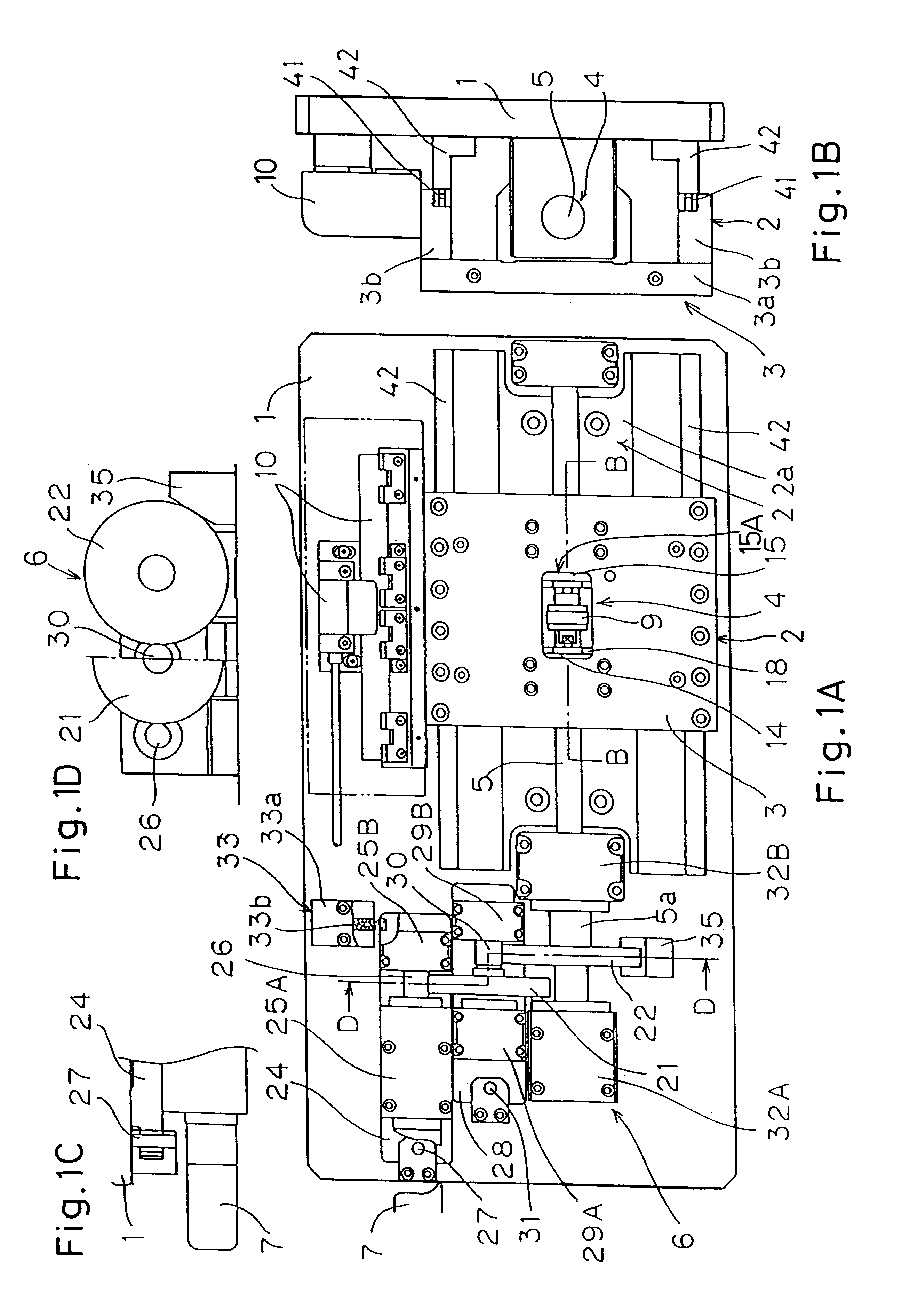

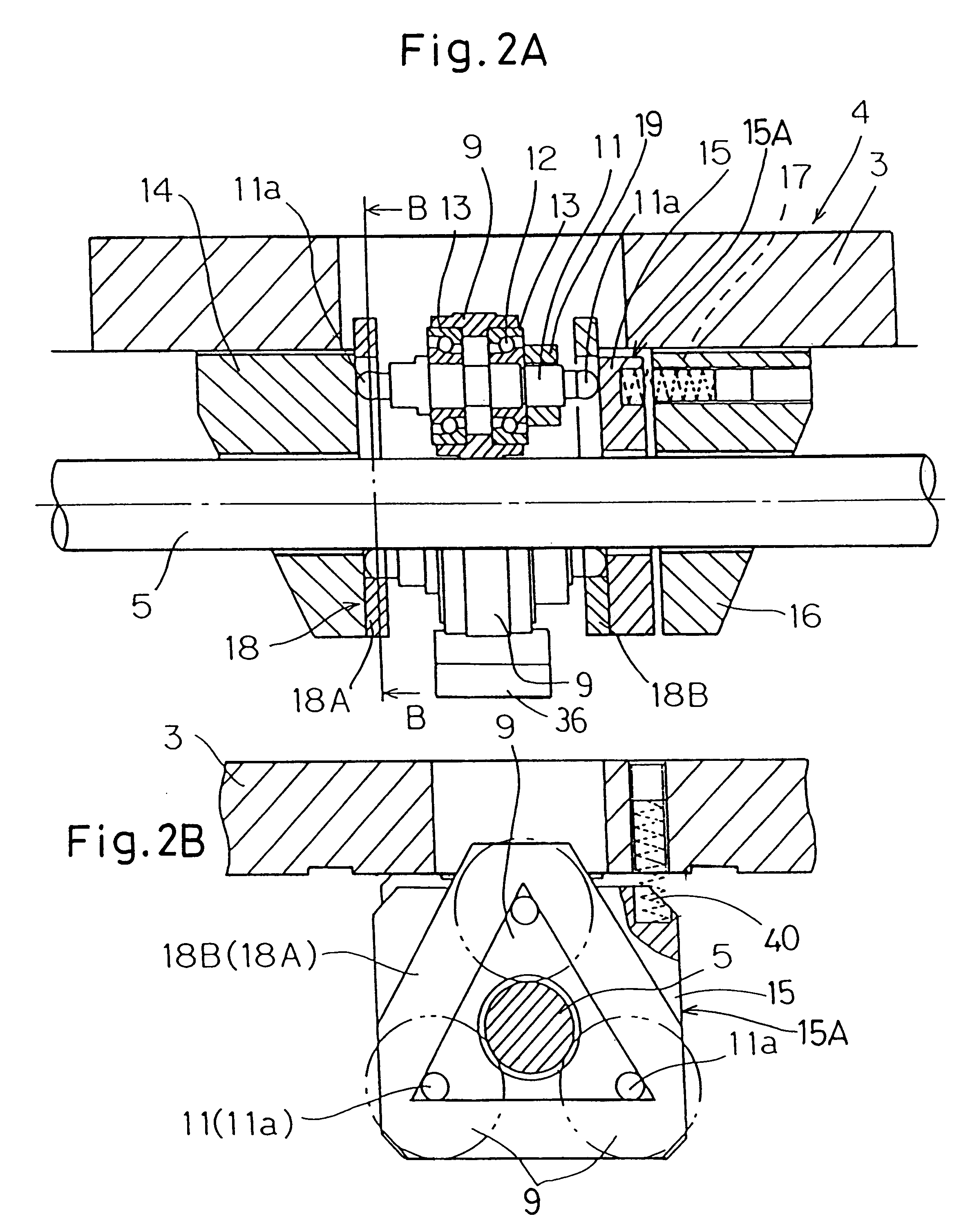

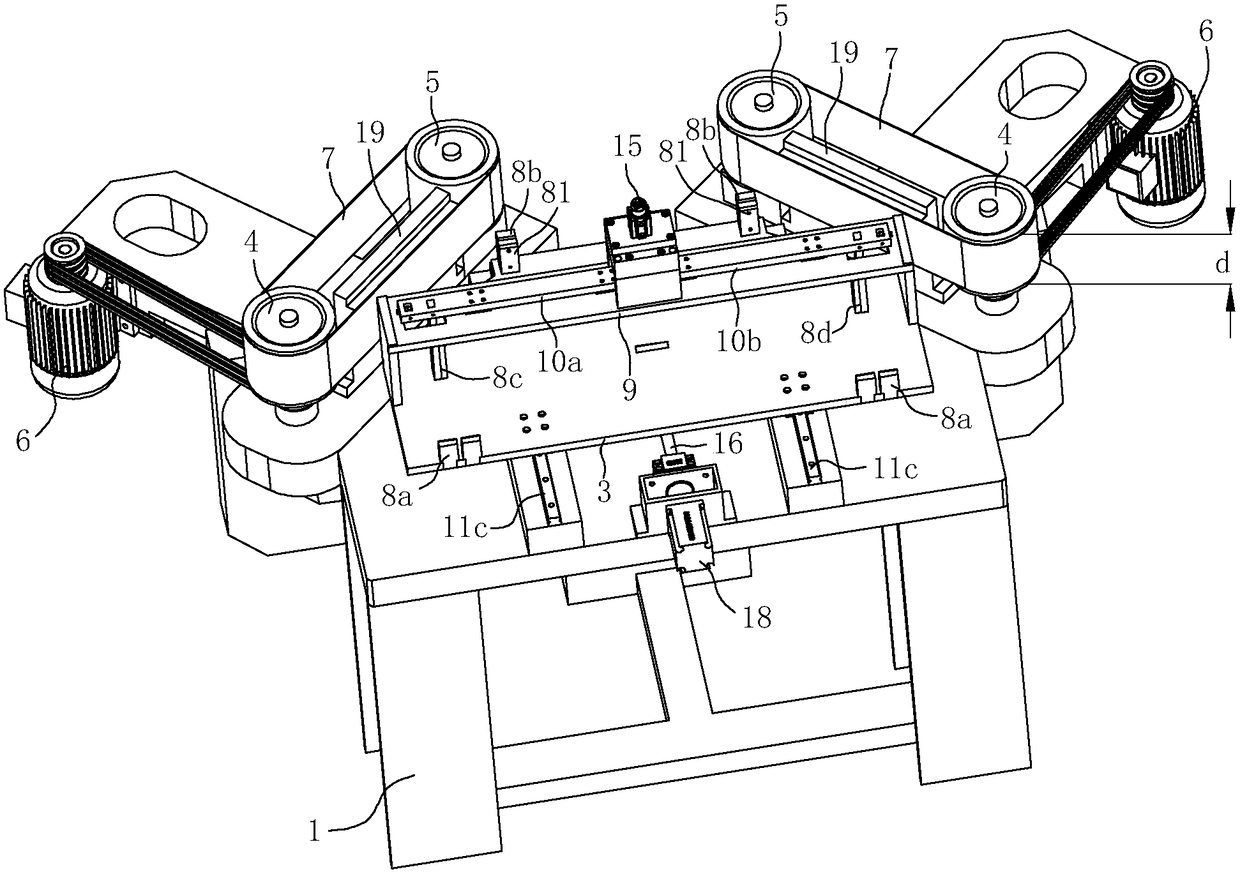

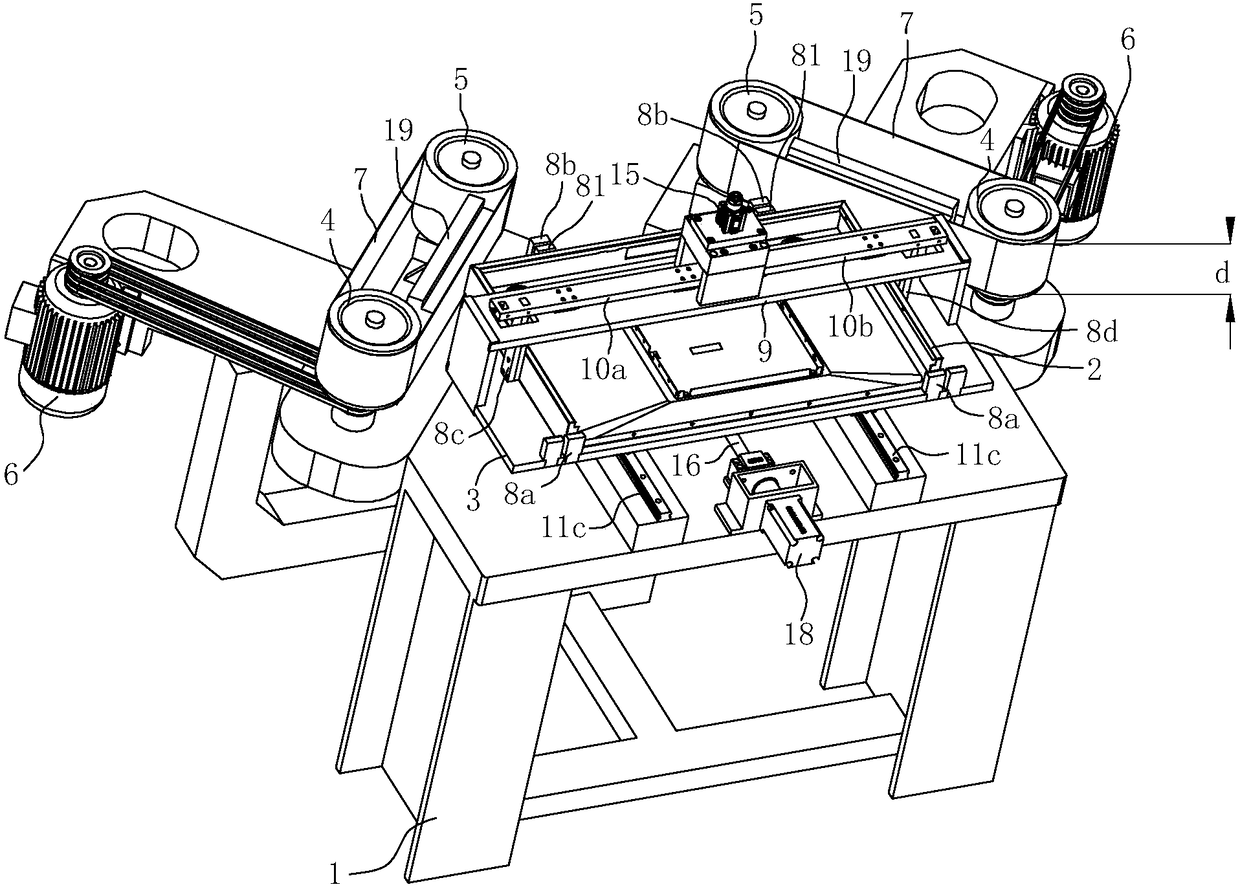

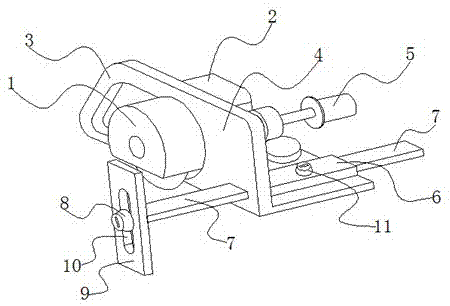

Positioning apparatus

InactiveUS6178836B1Less prone to deviationConvenient and accuratePortable liftingFeeding apparatusEngineeringCeramic

A positioning apparatus includes a machine bench 1, an external pressure linear bearing assembly 2 and a slide body 3 mounted on the machine bench 1 through the bearing assembly 2 for reciprocating movement relative to the machine bench. The positioning apparatus has a frictional reciprocating drive mechanism 4 for reciprocatingly driving the slide body 3 which is provided and includes a main shaft 5 adapted to be rotated, and a plurality of rollers 9 disposed around the main shaft 5 and inclined at a predetermined angle relative to the main shaft 5. Each roller 9 is pressed relative to the main shaft 5 by a pressing member 15. The slide 3 and a rail 20 are made of ceramics. Magnets 41 are provided on the slide body 3 for developing forces of magnetic attraction between magnetizable members 42, provided on the machine bench 1, and the slide body 3.

Owner:NTN CORP

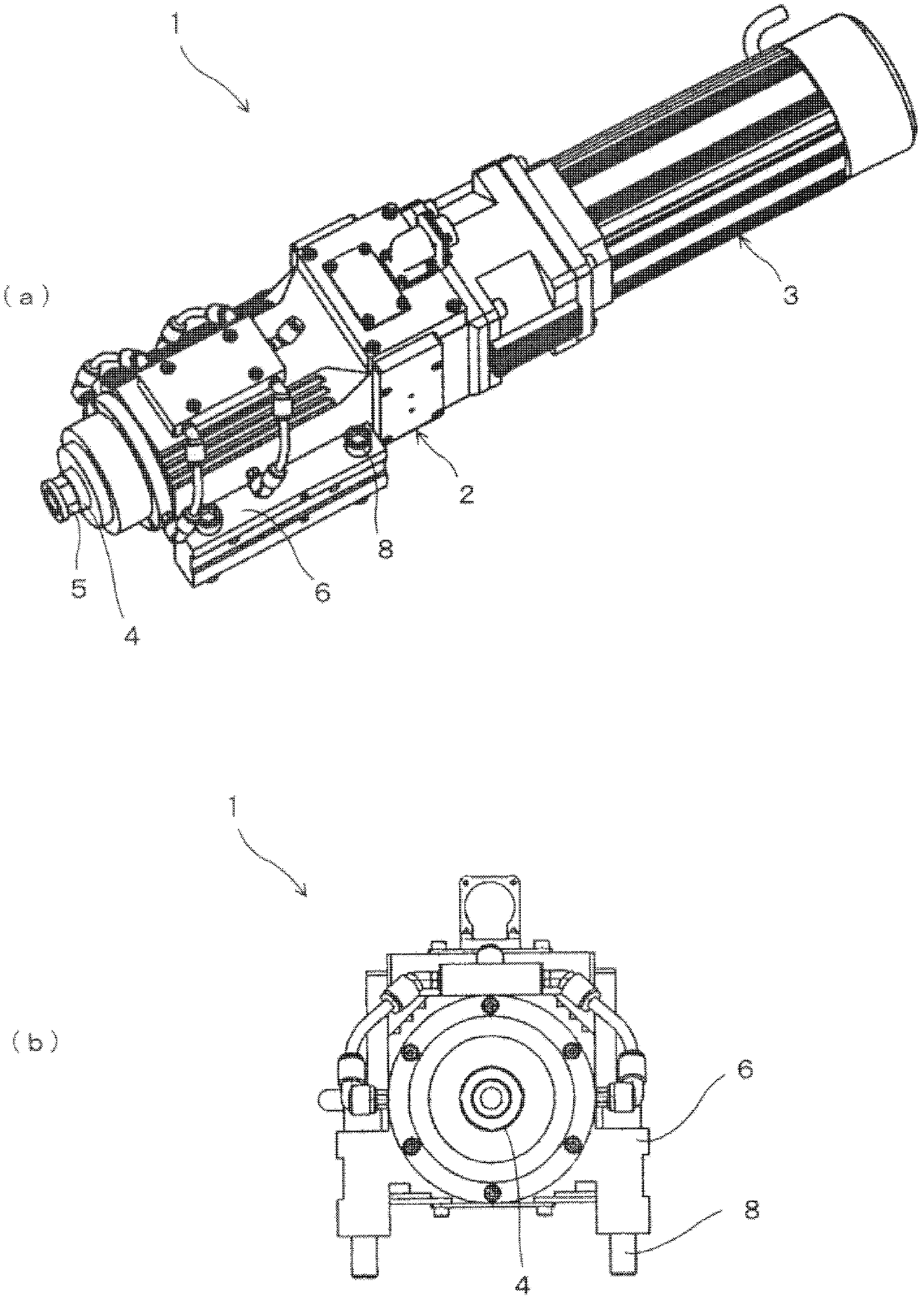

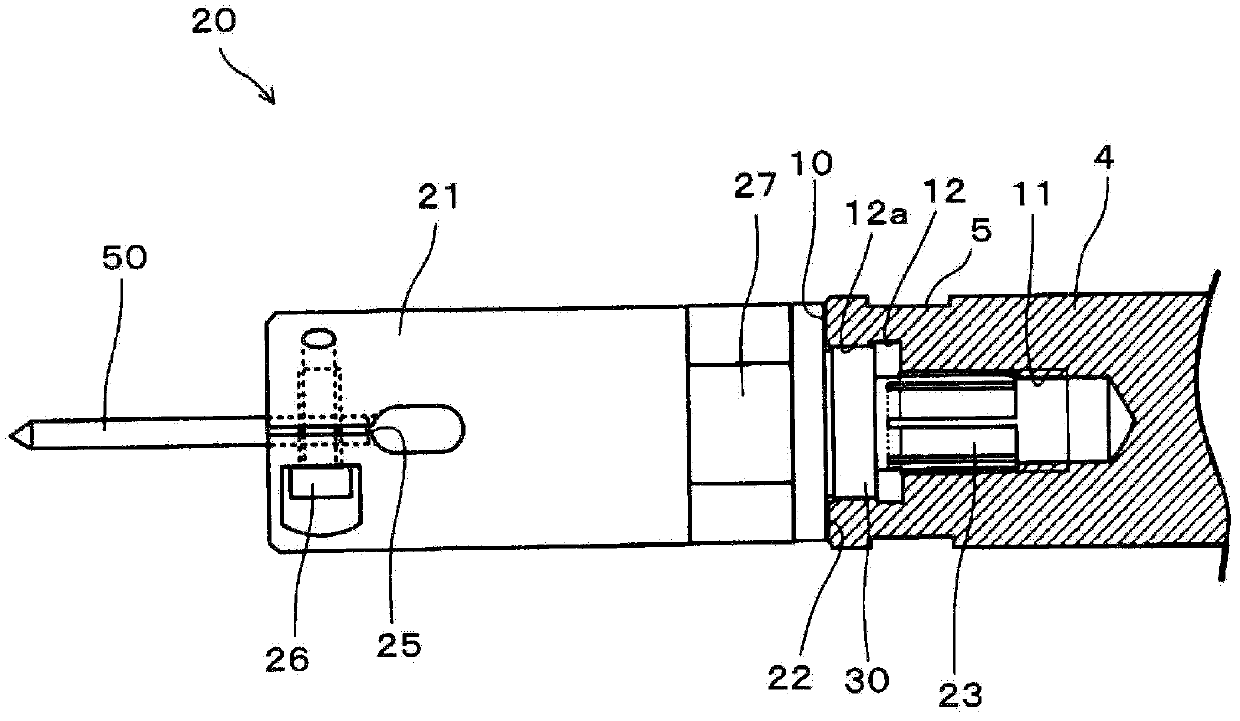

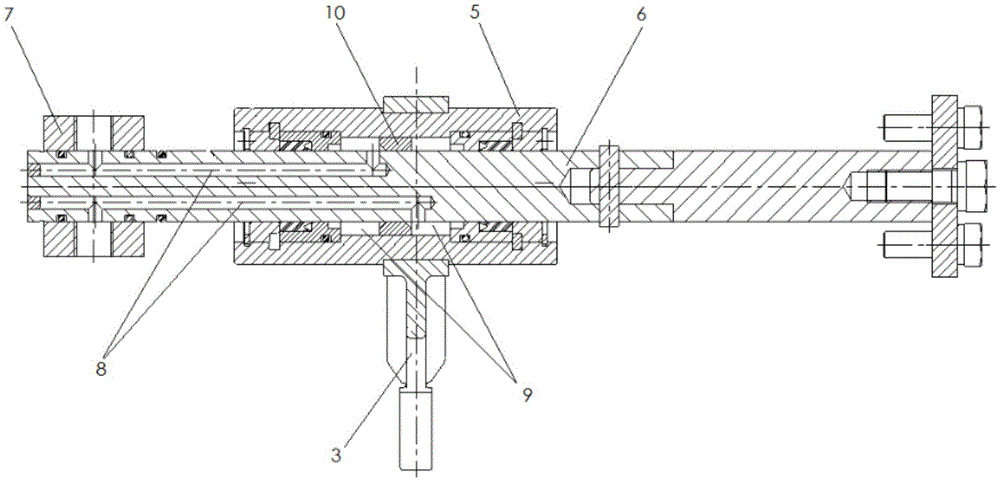

Cutter holder and main shaft device

The invention provides a cutter holder and a main shaft device, wherein the cutter holder (20) is mounted on a rotating shaft (4) of the main shaft device and holds the cutter (50), ensuring mounting and dismounting relative to the rotating shaft (4) and at least uneasily-generated deviation of the mounting angle relative to the rotating shaft (4). The constitution is that: a cutter fixing part (21) which fixes the cutter (50) is arranged on a top end side, a base end face (22) (a joint face at the cutter holder side) which joints with a top end face (10) of the rotating shaft (4) (a joint face at the rotating shaft side) is formed on a base end side, and in addition, a mounting shaft (23) which protrudes form a center of the base end face (22) towards an axial direction is also formed on the base end side, the periphery of the mounting shaft (23) is provided with a screw thread part (23) which is in screw joint with a screw thread hole (11) that is formed at a center of a top end of the rotating shaft (4), and the mounting shaft (23) is of an elastically deformable structure (a structure having gaps (29)).

Owner:欧立机电株式会社

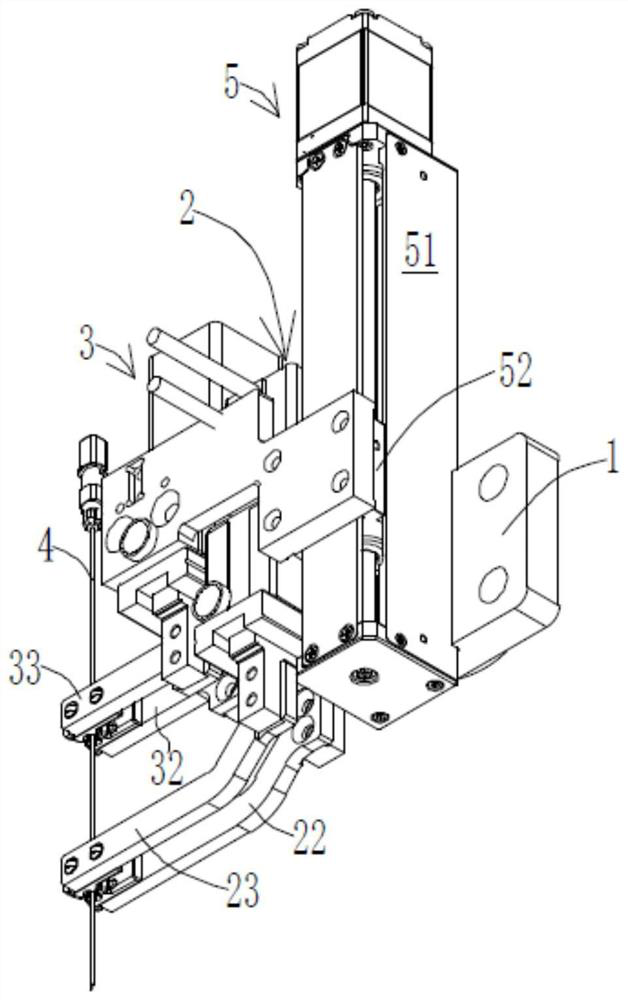

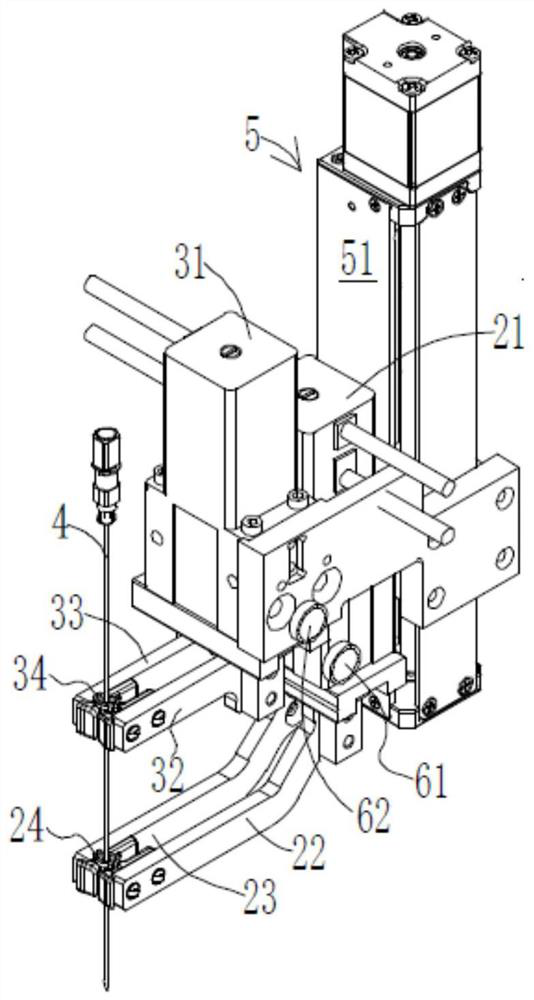

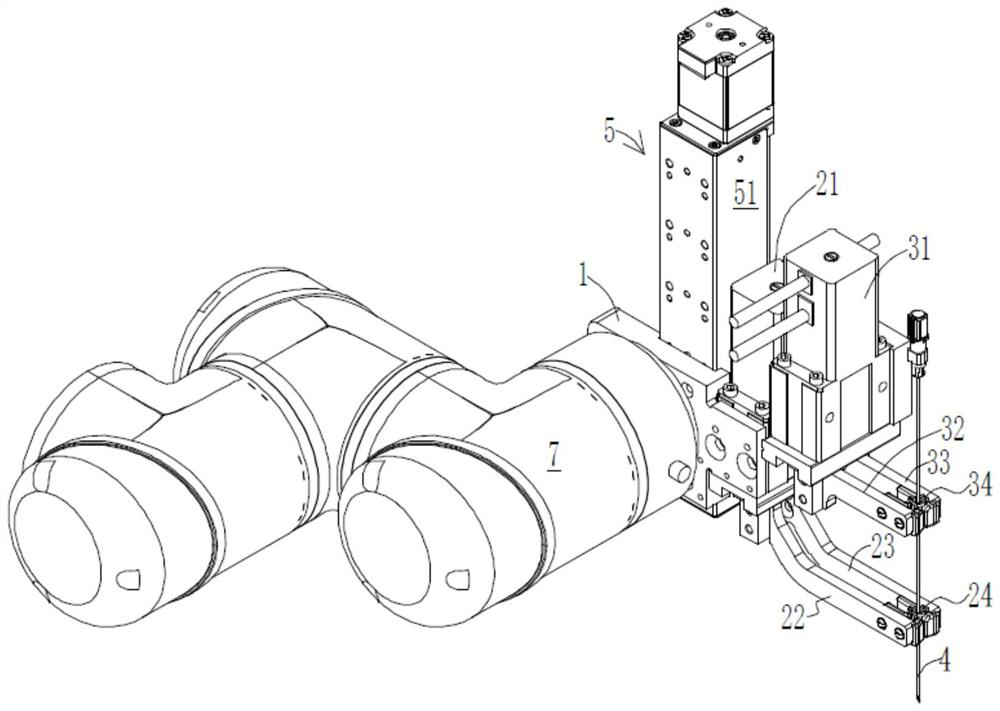

Puncture device and surgical robot

PendingCN113243978AAchieve positioningNo deformationSurgical needlesSurgical navigation systemsPhysical medicine and rehabilitationEngineering

The invention relates to the technical field of medical instruments, in particular to a puncture device and a surgical robot. The puncture device comprises a fixing frame, a first clamping assembly and a second clamping assembly, wherein both the first clamping assembly and the second clamping assembly are connected to the fixing frame; both the first clamping assembly and the second clamping assembly can clamp a puncture needle; and the puncture needle can be clamped and positioned by the first clamping assembly and the second clamping assembly at the same time. The surgical robot comprises an upper puncture device. The invention aims to provide the puncture device and the surgical robot, so that the technical problems that a puncture surgical robot easily affects the surgical quality and easily brings potential safety hazards to a patient in the prior art are solved.

Owner:磅客策(上海)智能医疗科技有限公司

Hydraulic shifting mechanism of gearbox

InactiveCN105465358ASliding stress equalizationReduce wearGearboxesGearing controlEngineeringMechanical engineering

The invention provides a hydraulic shifting mechanism of a gearbox. The hydraulic shifting mechanism comprises a shifting gear, a synchronizer, a shifting fork and a hydraulic oil cylinder that are mounted in a gearbox housing, wherein a shifting gear bearing is connected with an input shaft; the synchronizer is in spline fit with the input shaft; the shifting fork is connected with the synchronizer; a piston rod of the hydraulic oil cylinder is fixedly arranged in the gearbox housing; a cylinder barrel of the hydraulic oil cylinder is connected with the shifting fork; and the cylinder barrel can drive the synchronizer to slide on the input shaft through the shifting fork, so as to allow the synchronizer to be combined with or separated from the shifting gear. According to the hydraulic shifting mechanism of the gearbox, and the hydraulic oil cylinder driving the shifting fork to move is arranged in the gearbox housing, and the hydraulic oil cylinder and the gearbox are integrated, so that the assembling difficulty is reduced, the mounting is convenient, a space is saved, and no damage is caused easily. The cylinder barrel slides integrally to drive the shifting fork to move, and no deviation is produced in a moving process, so that the precision is high, the stability is good, the sliding stress of the synchronizer is balanced, the abrasion is little, the service life can be prolonged, and the shifting reliability can be improved.

Owner:天津萨克赛斯机械技术开发有限公司

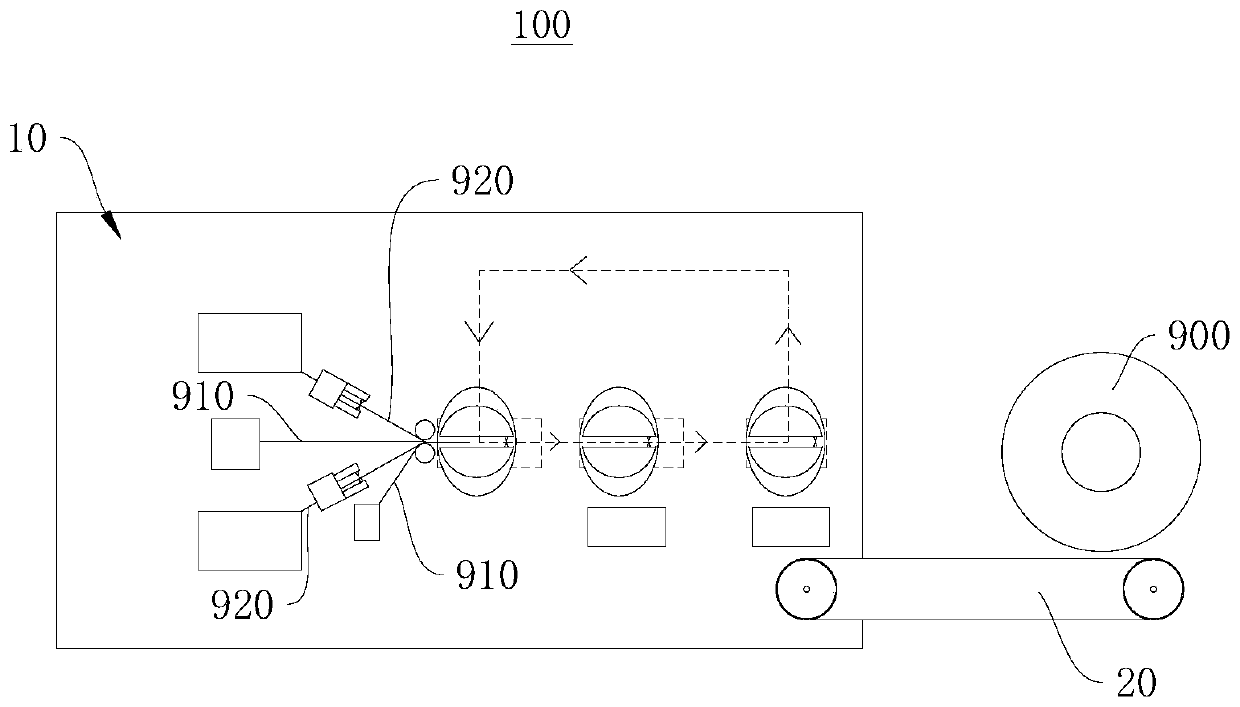

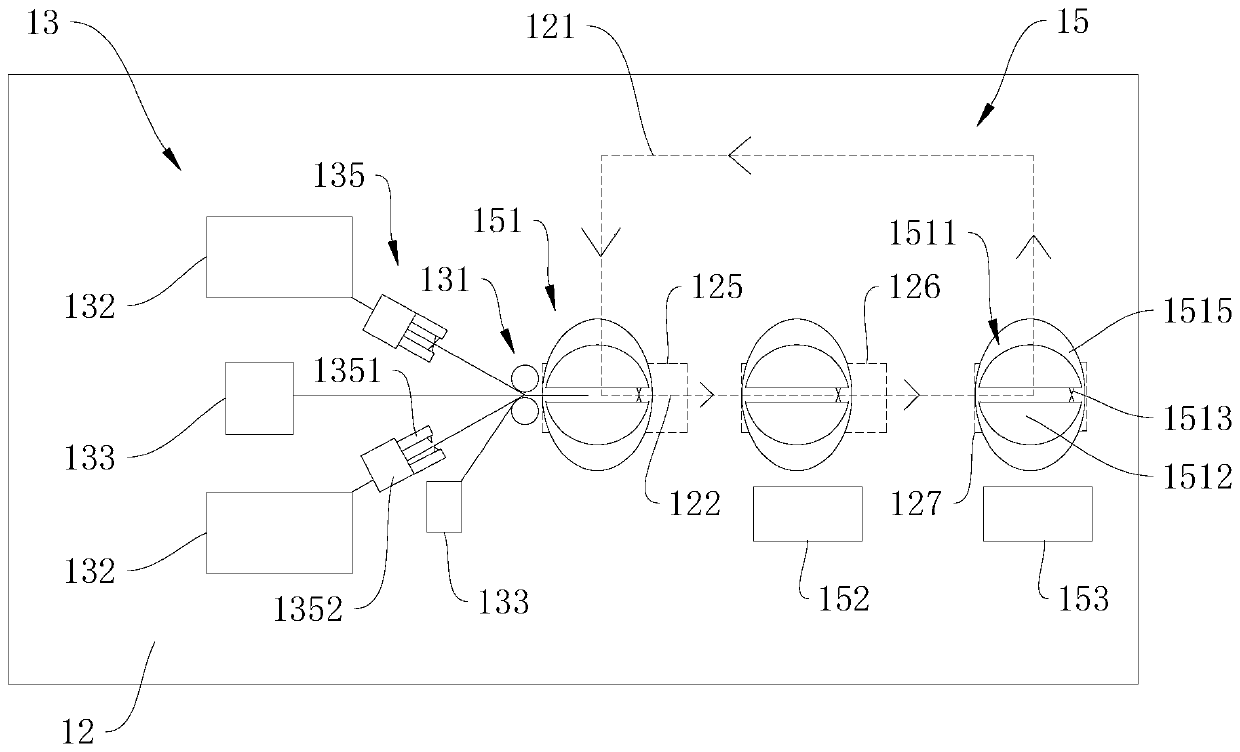

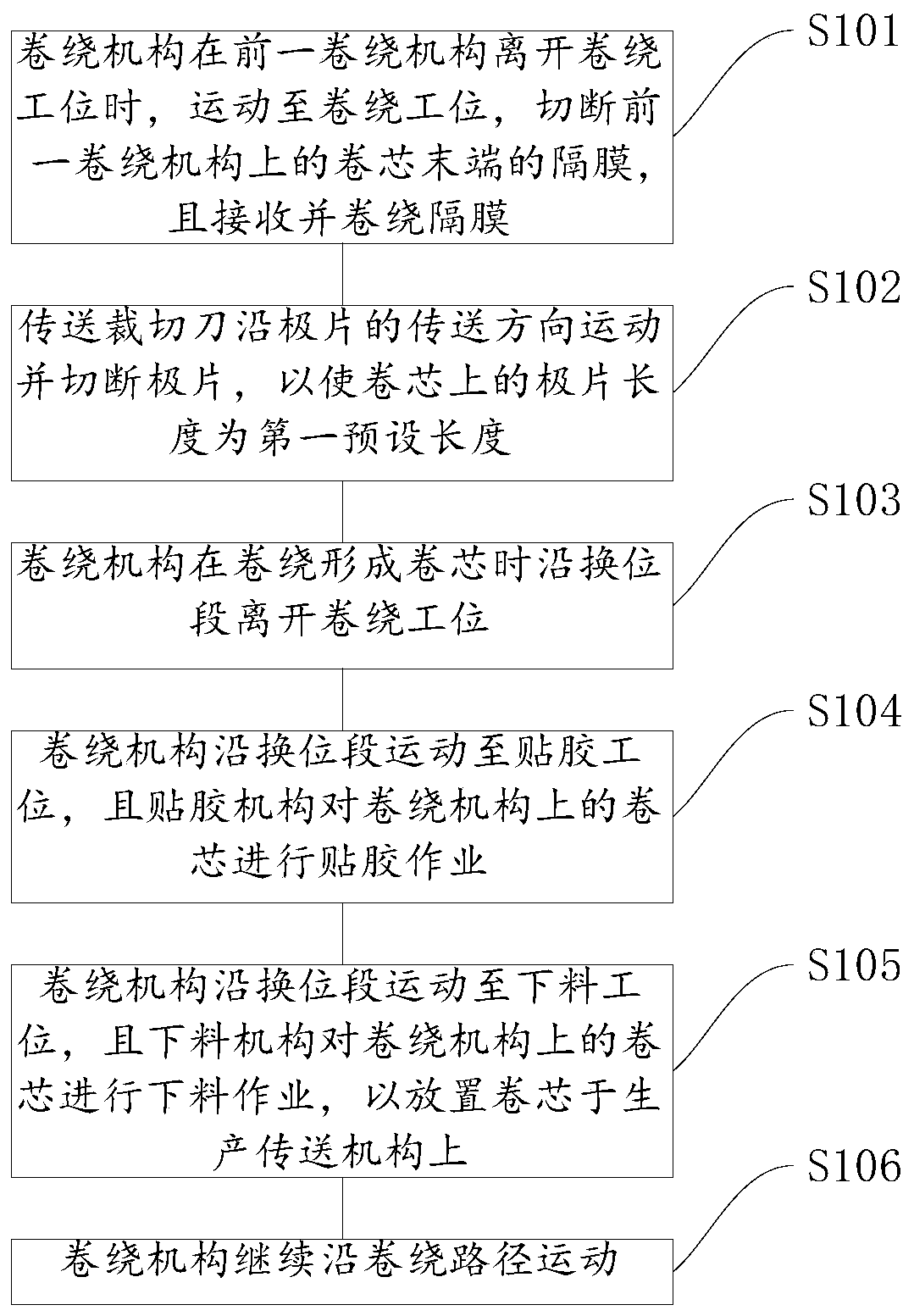

Battery cell winding device and method

PendingCN111146506ALess prone to deviationEasy for winding workAssembling battery machinesFinal product manufacturePole pieceControl theory

The invention discloses a battery cell winding device and method, and relates to the technical field of battery cell winding. The battery cell winding device comprises a mounting platform, a conveyingassembly and a plurality of winding mechanisms, wherein an annular winding path is arranged on the mounting platform; the winding path is provided with a transposition section which is arranged alonga straight line and provided with a winding station at one end; the conveying assembly is mounted on the mounting platform; a diaphragm conveying device is used for conveying diaphragms and pole pieces to a winding station; the conveying direction of the conveying assembly and the extending direction of the end, away from the winding station, of a transposition section are the same in direction and collinear. Multiple winding mechanisms are movably connected to the mounting platform and can move along the winding path, and the winding mechanisms can enter the winding station when the previouswinding mechanism leaves the winding station along the transposition section, the diaphragm is cut at the tail end of the winding core, the diaphragm is received and wound, and the formed winding core leaves the winding station along the transposition section when the winding core is formed. The battery cell winding device and the battery cell winding method have the characteristics that the diaphragm can be continuously conveyed, and the winding efficiency and the winding quality are higher.

Owner:GEESUN AUTOMATION TECH

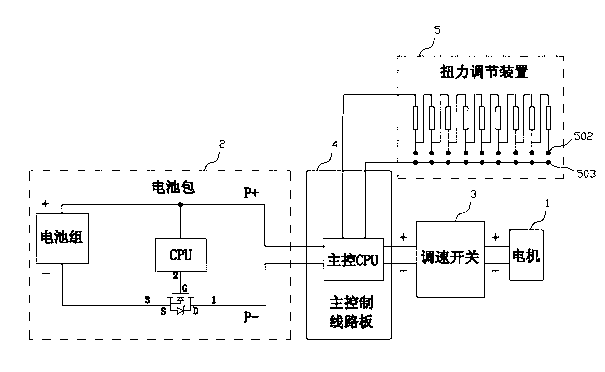

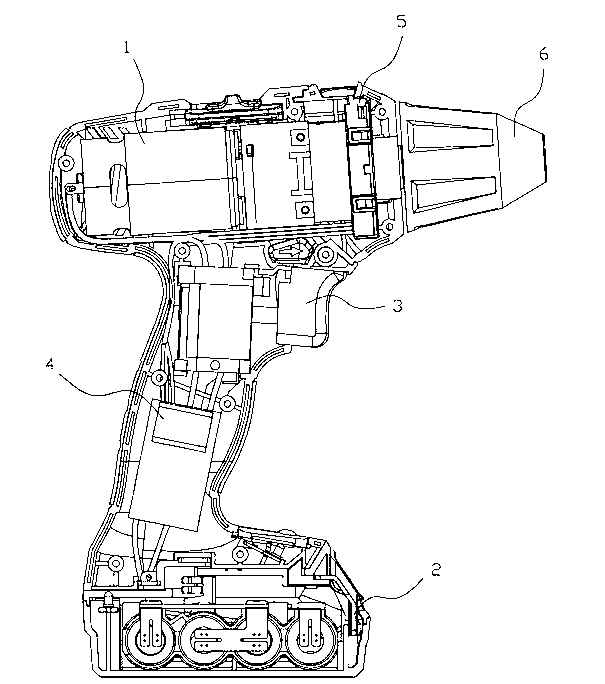

Electric drill

InactiveCN103121120ASimple structureSmall sizeMechanical power/torque controlPortable drilling machinesPower flowControl signal

The invention discloses an electric drill. The electric drill comprises a power source, a speed regulation switch (3) and a motor (1) and further comprises a main control circuit board (4) and a torsion regulating device (5) which can send a control signal to control output current of the main control circuit board (4), wherein the power source, the main control circuit board (4), the speed regulation switch (3) and the motor (1) are electrically connected in sequence. The electric drill can accurately control the maximum output torque of a drill chuck and is small in size.

Owner:NINGBO HAILIAN ELECTRIC APPLIANCE

Convenient-to-use drilling equipment for thermal insulation sheet processing

InactiveCN107791321AEasy to useEasy-to-use insulation panels are easy to processMetal working apparatusThermal insulationEngineering

The invention discloses an easy-to-use drilling device for processing heat-insulating boards, which includes a base, a top plate is placed directly above the base, and two symmetrical support columns are fixedly connected to the upper surface of the base, each support column The upper surface of the top plate is fixedly connected with the bottom surface of the top plate, the middle part of the bottom surface of the top plate is fixedly connected with an electric push rod, the telescopic end of the electric push rod is fixedly connected with a support plate, the bottom surface of the support plate is fixedly connected with a drilling equipment body, and The output end of the base is fixedly connected with a drill bit, the middle part of the upper surface of the base is fixedly connected with a fixed block, and the upper surface of the fixed block is provided with a groove. The easy-to-use drilling equipment for heat insulation board processing can make the heat insulation board processing more convenient, can collect debris, and can clamp and fix the heat insulation board by using the extrusion force of the strong spring. The performance is good, the deviation is not easy to occur when drilling, the use is more convenient, and the drilling efficiency of the heat insulation board is improved.

Owner:无锡龙博机械有限公司

Ecological gabion stone cage retaining wall construction method

ActiveCN107859054AProtect environmentReduce the impactArtificial islandsUnderwater structuresEngineeringSlurry

The invention discloses an ecological gabion stone cage retaining wall construction method. Specific to the defects in the prior art, the construction method comprises the steps that temporary bafflesare built coastwise firstly, specifically, the baffles can prevent slurry and mud from falling into a river, convenience is brought to workers for construction, and the construction safety is improved; then a foundation pit is excavated, gabions are assembled, a formwork is built in advance after the gabions are assembled, the mounting positions of the gabions are limited by aid of the formwork,the mounting positions of each gabion can be accurately marked, errors are not likely to occur, the mounting operation is achieved through one step, the working efficiency is remarkably improved, theconstruction period is shortened, during construction, the gabions are protected by the formwork and are quite stable, and construction faults are not likely to occur; and after the formwork is built,the gabions are accurately installed in the formwork and mutually fixed, and finally the formwork is removed.

Owner:NINGBO SHUNXING LANDSCAPE CONSTR CO LTD

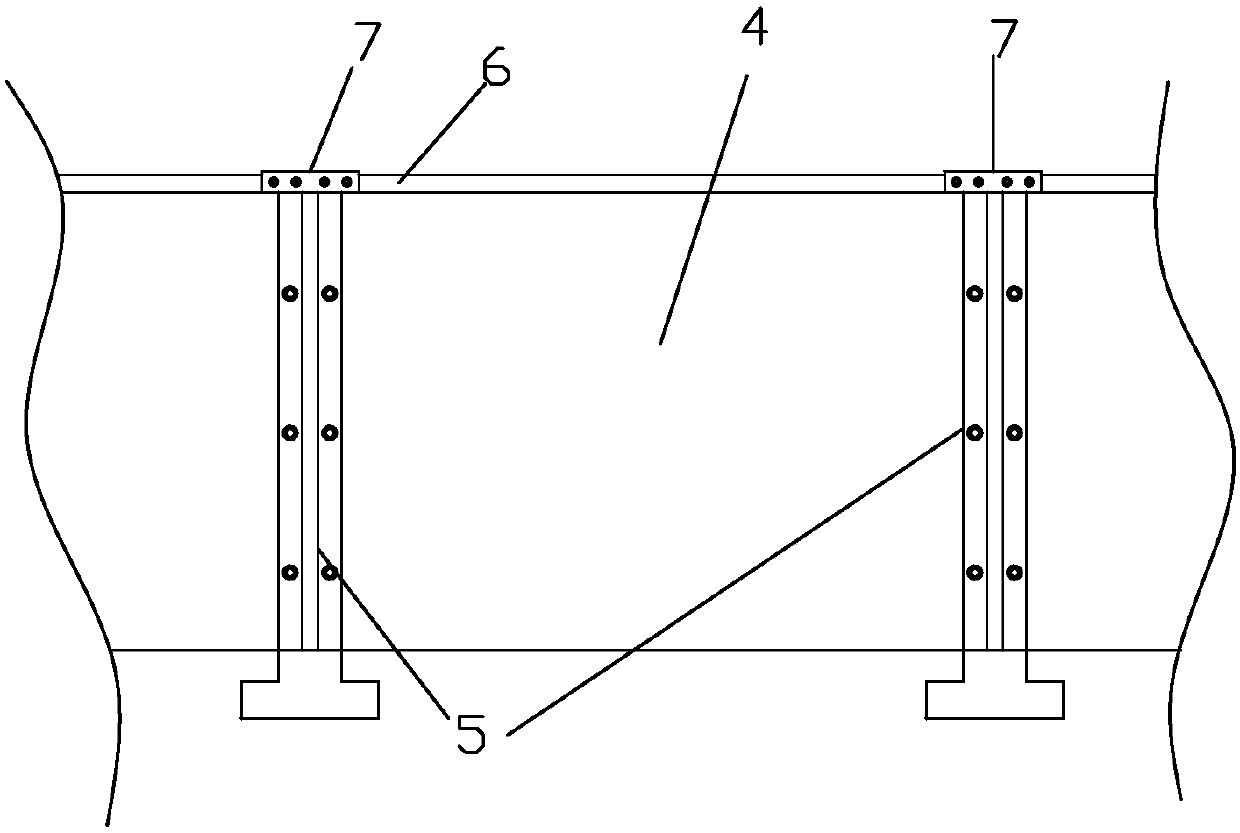

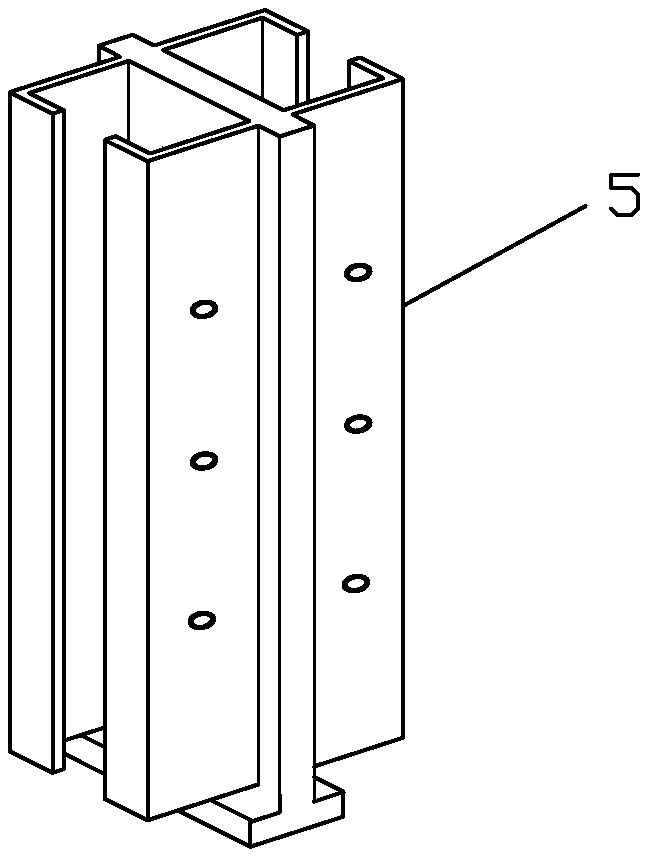

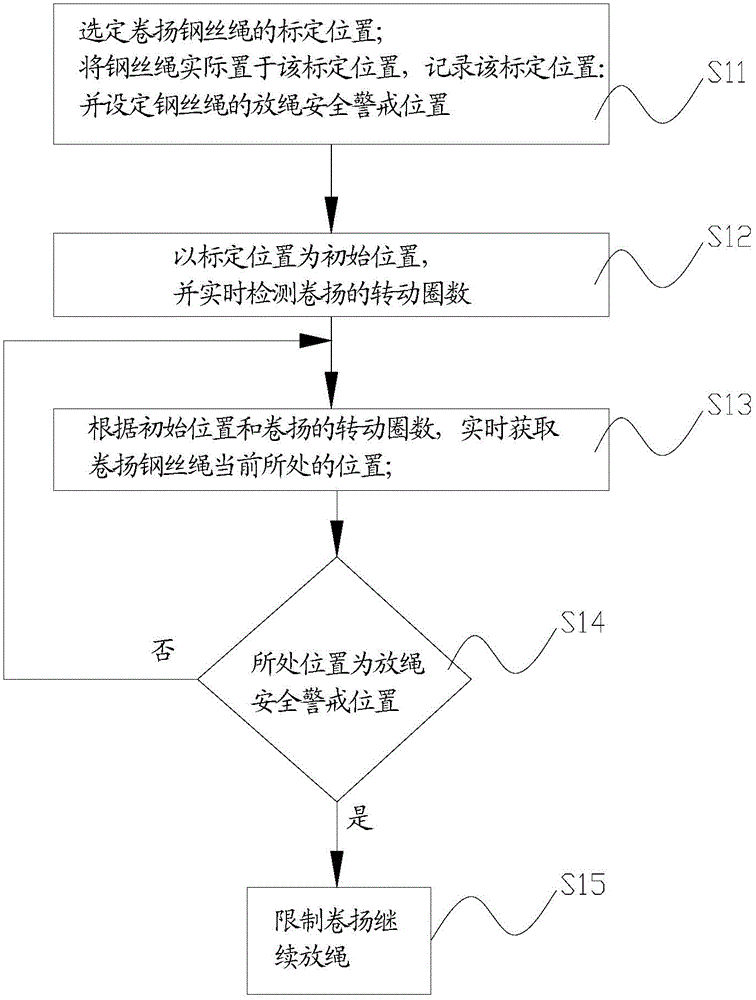

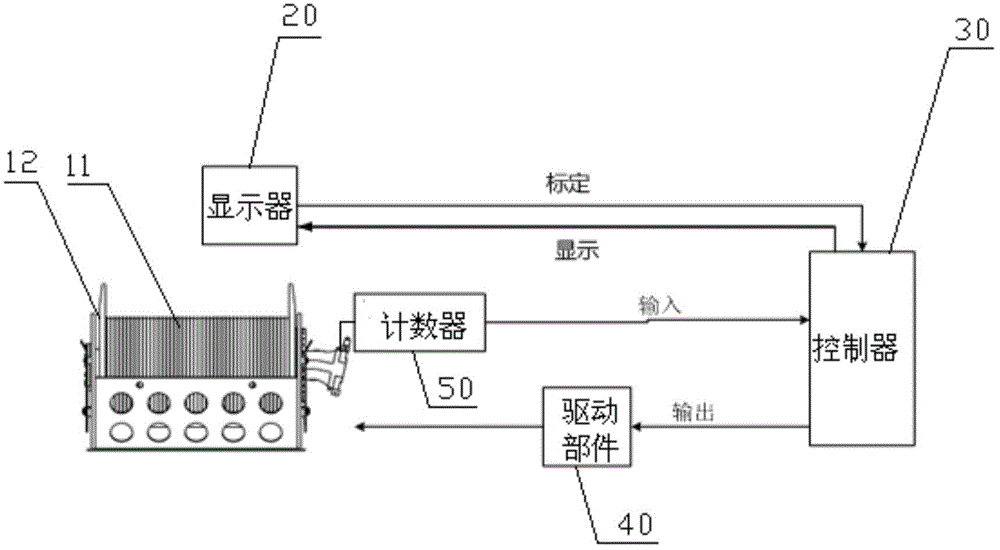

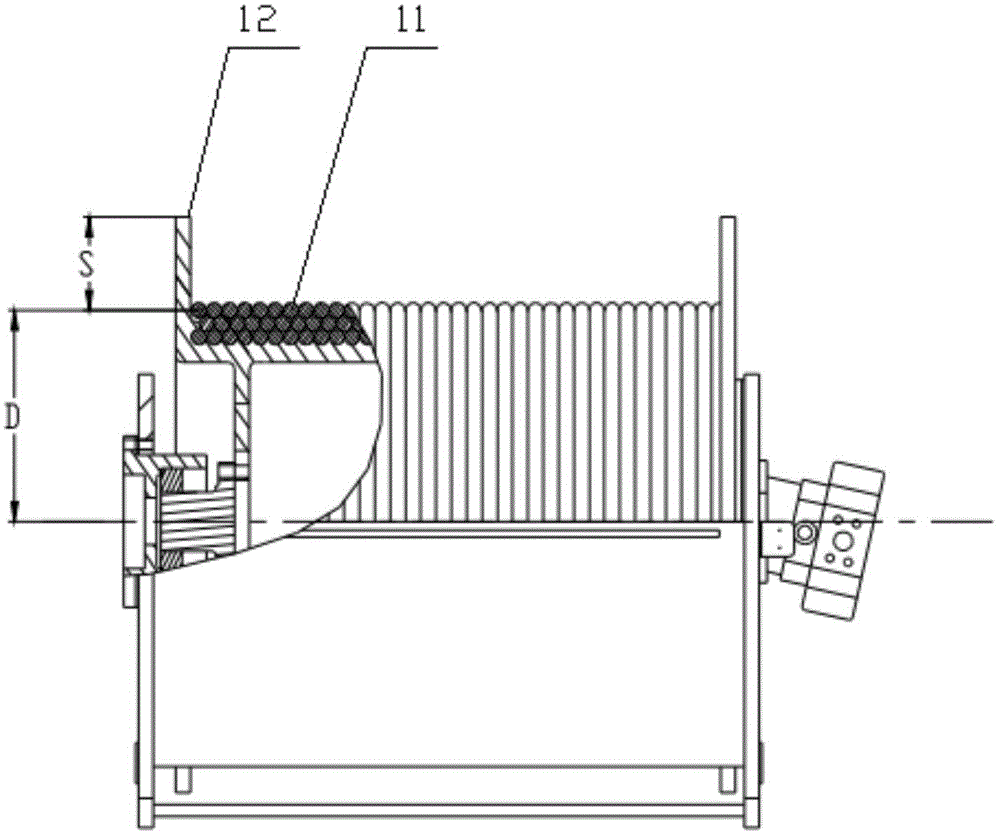

Control method and control system for safely releasing winding steel wire rope

ActiveCN103552946AReliable controlRelease the rope to limit in timeWinding mechanismsWinding machineControl system

The invention discloses a control method and a control system for safely releasing a winding steel wire rope. The control method comprises the following steps: selecting a marking position of the winding steel wire rope, practically placing a steel wire rope in the marking position and recording the marking position; setting a rope-releasing safety alerting position of the steel wire rope; taking the marking position as an original position and detecting the turning circles of a winding machine in real time; obtaining the present position of the winding steel wire rope in real time according to the original position and the turning circles of the winding machine; and limiting the winding machine to continue releasing the rope when the present position is at the rope-releasing safety alerting position. According to the control system and the control method, the information about the steel wire rope located in the rope-releasing safety alerting position can be obtained only on the basis of the detected turning circles of the winding machine, so that the continuing releasing of the steel wire rope is timely limited and the control for preventing the over-releasing of the steel wire rope is very reliable. Besides, the marking position is randomly selected, the marking efficiency is ultrahigh and the control method is suitable for a normal construction field.

Owner:XCMG CONSTR MACHINERY

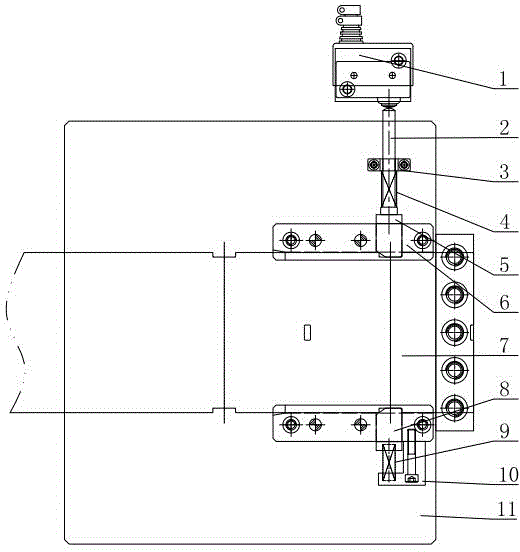

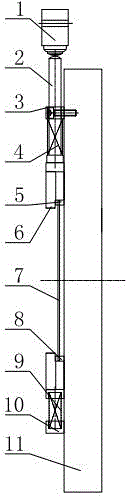

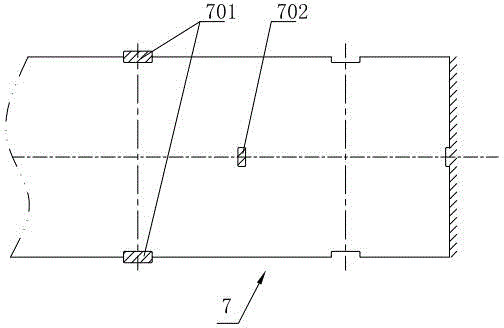

Gap part aligning and mistaken delivery detecting structure

ActiveCN104438911APrecise positioningReduce generationMetal-working feeding devicesMetal working apparatusButt jointFastener

The invention relates to a gap part aligning and mistaken delivery detecting structure. The gap part aligning and mistaken delivery detecting structure comprises a female die. A material belt conveyed by a material conveyer is arranged in the middle of the female die. The two sides of the material belt are provided with gaps which are evenly arranged at equal intervals. Symmetrical material guiding plates are fixed to the female die through fastening pieces. The material guiding plates are located on the two sides of the material belt respectively. The material guiding plate located at the upper end is provided with a first pushing block. An association pin is installed at the upper end of the first pushing block. The association pin is sleeved with a first spring. The association pin penetrates through a fixing block installed on the female die. The material guiding plate located at the lower end is provided with a second pushing block. The material guiding plate located at the lower end is further provided with a stop block of a right-angled structure through a fastening piece. One right-angled edge of the stop block is connected with the second pushing block through a second spring. The gap part aligning and mistaken delivery detecting structure further comprises a mistaken delivery detector. The mistaken delivery detector is installed on one side of the female die. A contact switch of the mistaken delivery detector is in butt joint with the head of the associated pin. The pushing blocks are connected with the corresponding gaps of the material belt in matched and clamped modes, so that the material belt achieves a good locating effect and is not prone to deviation, and rejected products can be greatly reduced.

Owner:WUXI MICRO RES

Online type automatic drilling machine

ActiveCN105772786AImprove securityImprove stabilityFeeding apparatusDriving apparatusEngineeringDrilling machines

The invention discloses an online type automatic drilling machine which comprises a rack, wherein the rack has a square structure and is internally provided with a power head mechanism, a pressure plate mechanism, a positioning clamping jaw mechanism and a power head automatic returning mechanism. The online type automatic drilling machine has the advantages that complete automation production is realized through automatic positioning and automatic drilling, the processing flow is simplified, the deepening accuracy is improved and the production efficiency of an enterprise is greatly improved.

Owner:ZHENJIANG YUJIU INTELLIGENT EQUIP LTD BY SHARE LTD

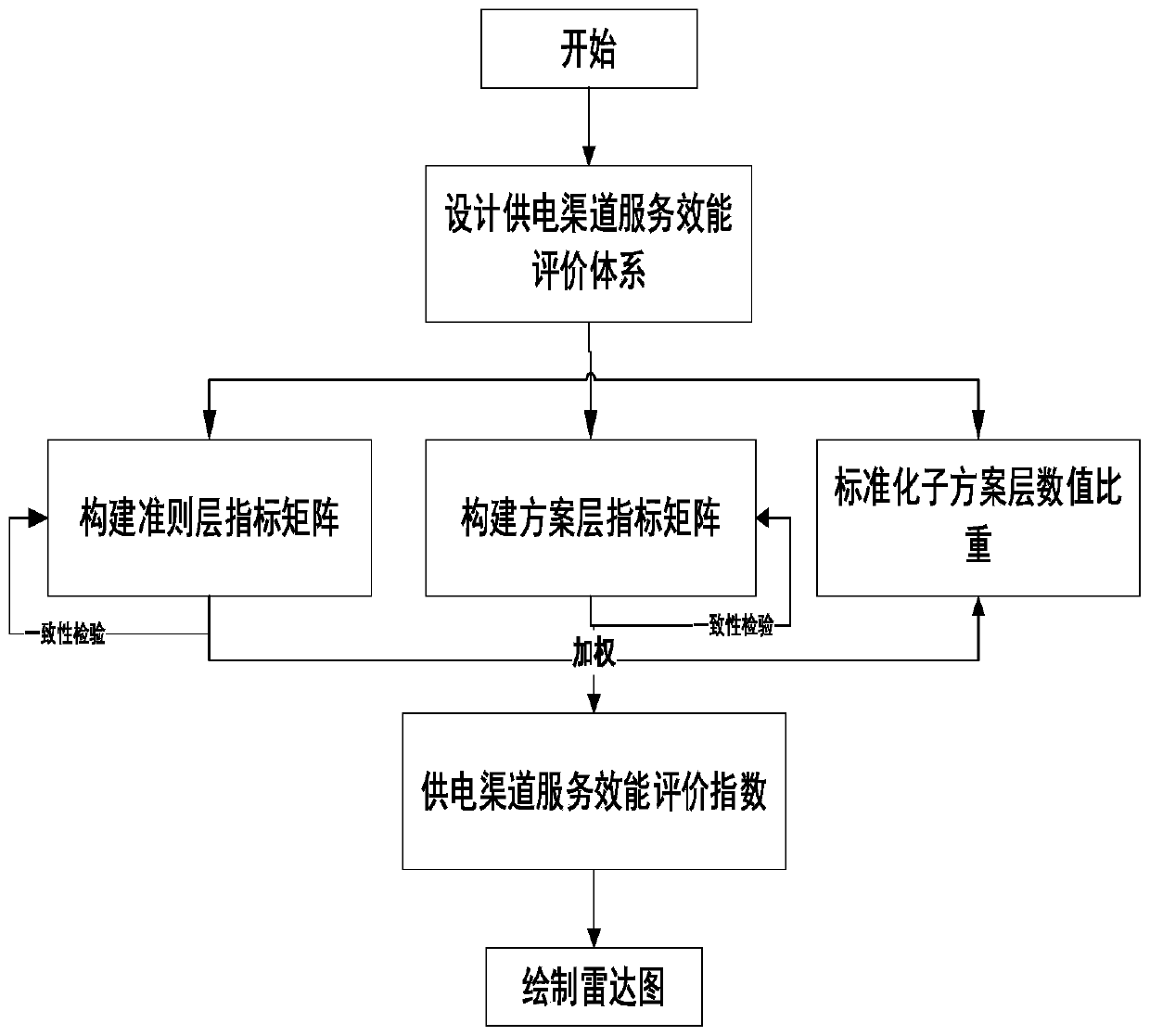

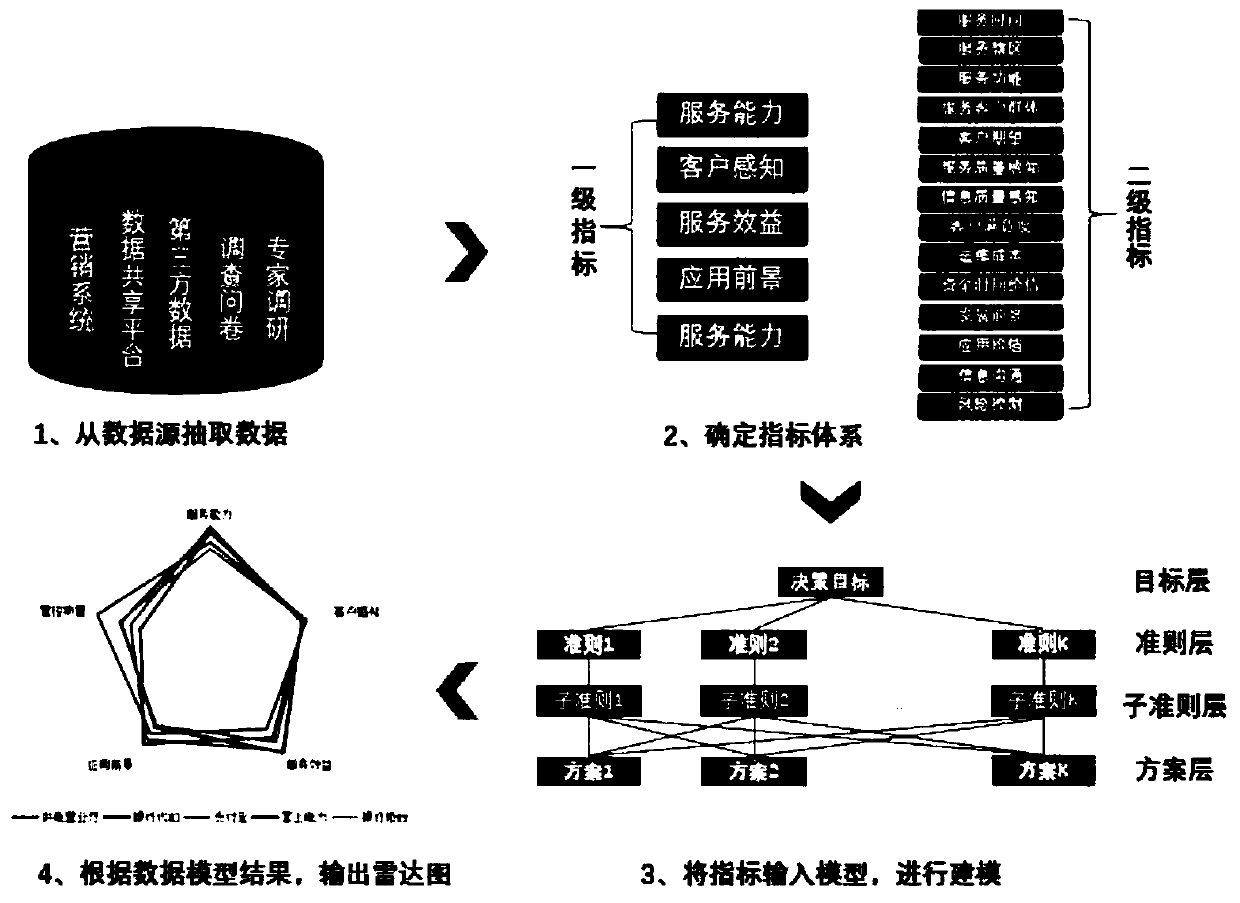

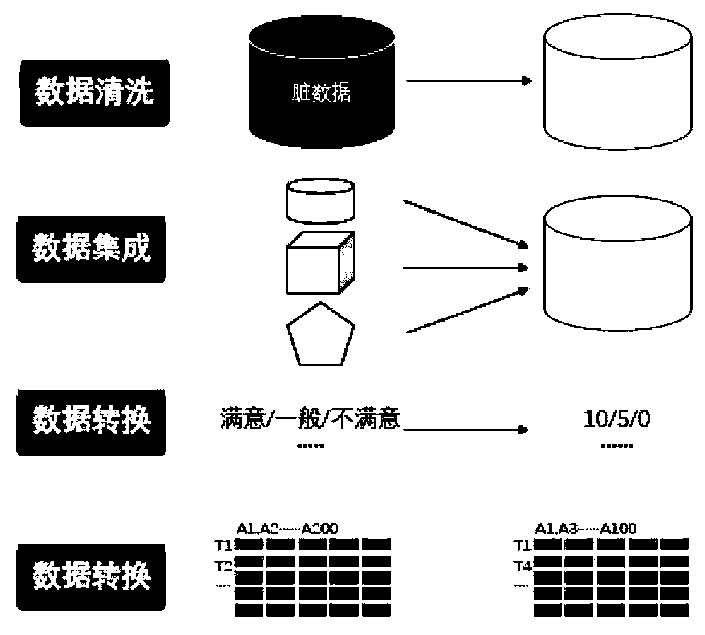

AHP-based multi-dimensional evaluation method for service efficiency of power supply channel

PendingCN111080101AImprove satisfactionTo achieve the goal of cost reduction and efficiency increaseResourcesQuality of servicePower efficient

The invention discloses an AHP-based power supply channel service performance multi-dimensional evaluation method, and belongs to the technical field of electric power. An existing evaluation scheme mainly depends on experience, is not comprehensive, rigorous and scientific enough and is prone to deviation. The invention provides basic data such as application rate, operation cost, service qualityand resource configuration based on power supply channel service. Five key index systems of service capability, customer perception, service benefit, application prospect and management and control quality are formed through quantitative analysis and inductive definition; the comprehensive evaluation score of the service efficiency of each power supply channel is calculated and output through weighted summation of an AHP analytic hierarchy process, and an index radar map is constructed, so that a decision maker can clearly observe the strength of each index of the same type of channel and analyze the reason of each data level, the optimization channel target is convenient to determine, and an optimization strategy is convenient to formulate; the scheme of the invention is comprehensive, rigorous and scientific, and deviation is not easy to generate.

Owner:NINGBO POWER SUPPLY COMPANY STATE GRID ZHEJIANG ELECTRIC POWER

Corner grinding machine tool

InactiveCN109382732AImprove grinding efficiencyRealize automatic grinding processBelt grinding machinesGrinding feedersMachine toolEngineering

The invention relates to a corner grinding machine tool. The tool is characterized by comprising a rack, a platform used for placing a to-be-ground workpiece, a platform driving mechanism and two grinding mechanisms, wherein the platform is arranged above the table top of the rack, and the positioning structure used for positioning the to-be-ground workpiece on the platform is arranged on the platform; the platform driving mechanism is used for driving the platform to horizontally slide back and forth; the two grinding mechanisms are arranged on the left side and the right side of the rear part of the rack and correspond to two grinding corners of the to-be-ground workpiece respectively; each grinding mechanism comprises a driving belt wheel and a driven belt wheel, an abrasive belt is obliquely arranged between each driving belt wheel and the corresponding driven belt wheel, and the width of each abrasive belt is larger than the height of the grinding corners of the to-be-ground workpiece. The corner grinding machine tool can be used for grinding the two side corners of the to-be-ground workpiece at the same time, and the tool can precisely grind the workpiece with the corners meeting design requirements. The corner grinding machine tool can be used for automatically grinding the two side corners of the to-be-ground workpiece at the same time, and can precisely grind the workpiece with the corners meeting the design requirements.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Woodworking cutting machine

The invention discloses a woodworking cutting machine. The woodworking cutting machine comprises a cutting machine body, wherein a handle and a bracket respectively and vertically extend outwards between a protection cover of the cutting machine body and a motor; the bracket has an L-shaped structure; an armrest handle is installed close to the vertex angle at the upper end of the bracket; a measuring scale sleeve with a hollow structure is installed on the bottom surface of the bracket; a measuring scale passes through the measuring scale sleeve; the measuring scale and the measuring scale sleeve are in drawing-pulling match; a screw hole is arranged at one end of the measuring scale; after passing through a baffle, a bolt and the measuring scale are in rotary connection; and a bolt sliding groove is arranged in the baffle. The woodworking cutting machine is simple in structure, convenient to use and applicable to flow processing enterprises with demand of cutting a lot of wood materials. With the adoption of the woodworking cutting machine, the work efficiency when cutting is greatly improved, the phenomenon of deviation does not easily happen during the cutting process, and the cutting precision is higher.

Owner:CANNY ELEVATOR

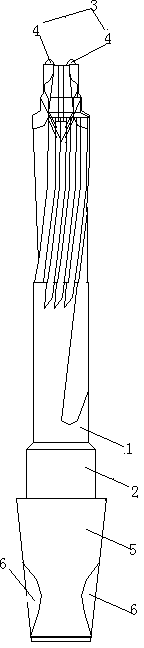

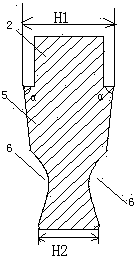

PCD spiral type reamer

The invention discloses a PCD spiral type reamer. The PCD spiral type reamer comprises a reamer body and a reamer handle, wherein a positioning structure is arranged on the top of the reamer body. The positioning structure comprises two positioning protrusions which are in a cone shape and distributed at the two ends of the top face of the reamer body. A clamping component is arranged on the outer portion of the tail end of the reamer handle, wherein the reamer handle and the clamping component are of an integral structure, the clamping component is of a circular truncated cone structure, and the ratio of the height H1 of the front end of the clamping component to the height H2 of the tail end of the clamping component is 1.5:1. Arc-shaped grooves are symmetrically formed in the two sides of the clamping component. With the central axial surface of the reamer handle as the reference plane, the front end vertex angle alpha of the clamping component is 48 degrees; due to the fact that the special positioning structure is arranged on the top of the reamer body, the reamer body is accurately positioned in the turning process and is not prone to deflection; the clamping component is arranged on the reamer handle, and therefore a tool can be effectively clamped, losses are reduced for enterprises, production cost is reduced for enterprises, and production efficiency is greatly improved for enterprises.

Owner:江苏扬碟钻石工具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com