Patents

Literature

216results about How to "To achieve the goal of cost reduction and efficiency increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cold-bending roller welding repair method

ActiveCN102441760ACutting costsTo achieve the goal of cost reduction and efficiency increaseArc welding apparatusNondestructive testingEngineering

The invention relates to a cold-bending roller welding repair method, which includes the steps: firstly, performing crack depth and length flaw detection for cracking and damaged positions; secondly, grinding and back chipping the cracking and damaged positions of surfaces of rollers; thirdly, warming and preheating the rollers; fourthly, performing repair welding by means of overlaying process; fifthly, performing post-welding heat treatment; sixthly, performing machining according to requirements of drawings; and seventhly, performing nondestructive testing and hardness testing. The service life of a repaired roller is the same as that of a newly made roller, the surface hardness of the repaired roller reaches HRC (Rockwell hardness) 56-60, and the expense of an end user for using the rollers is reduced.

Owner:SHANXI DINGRONG COLD FORMED SECTIONS

Welding repairing method for rolls

InactiveCN103481012ACutting costsTo achieve the goal of cost reduction and efficiency increaseHardnessMachining

The invention relates to a welding repairing method for rolls. The welding repairing method is characterized by comprising the following steps of (1) performing flaw detection on depths and lengths of fractures of cracked and damaged portions, and performing polishing and back chipping on the cracked and damaged portions of surfaces of rolls; (2) performing pre-heating treatment on the rolls; (3) performing repairing welding by using a surfacing process; (4) performing heat treatment after welding; (5) machining according to the requirement of a drawing; and (6) performing nondestructive testing and hardness measurement. According to the welding repairing method, the damaged rolls are repaired by a series of industrial means and processes. According to tracking statistics, the service lives of the repaired rolls are the same with those of new rolls, the surface hardness of the repaired rolls reaches HRC 56-60, so that the cost of a use unit on the rolls can be greatly reduced, and the purpose of reducing cost and increasing efficiency is achieved.

Owner:湖州市银鑫轧辊有限公司

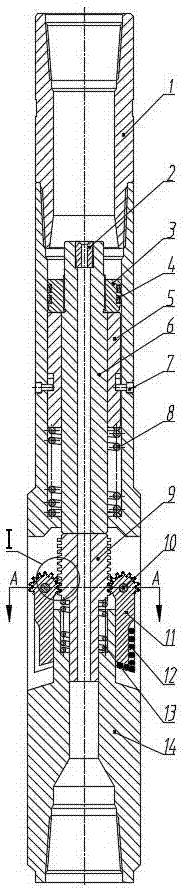

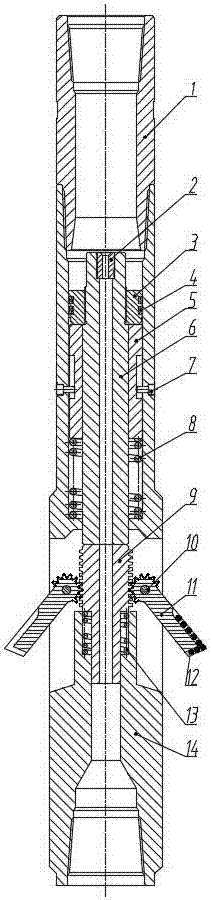

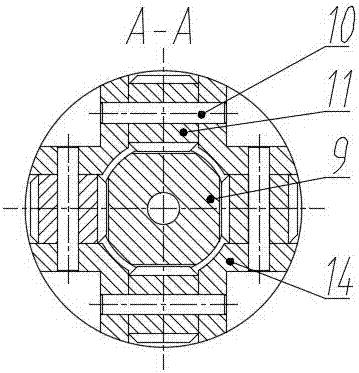

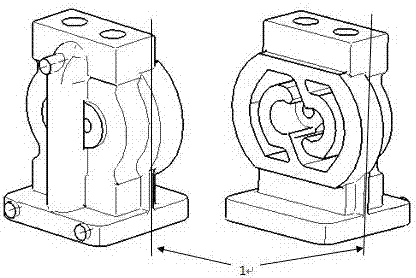

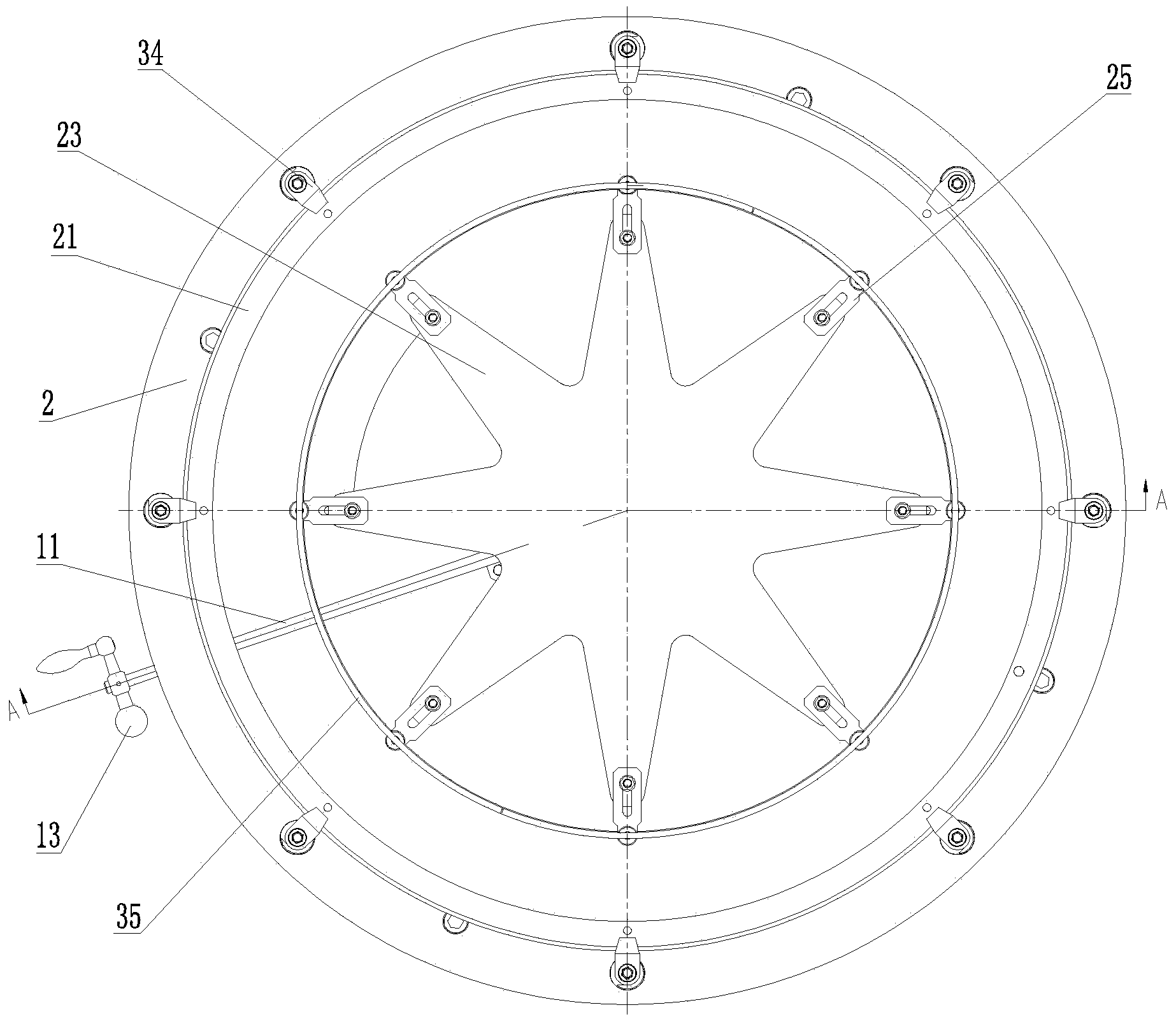

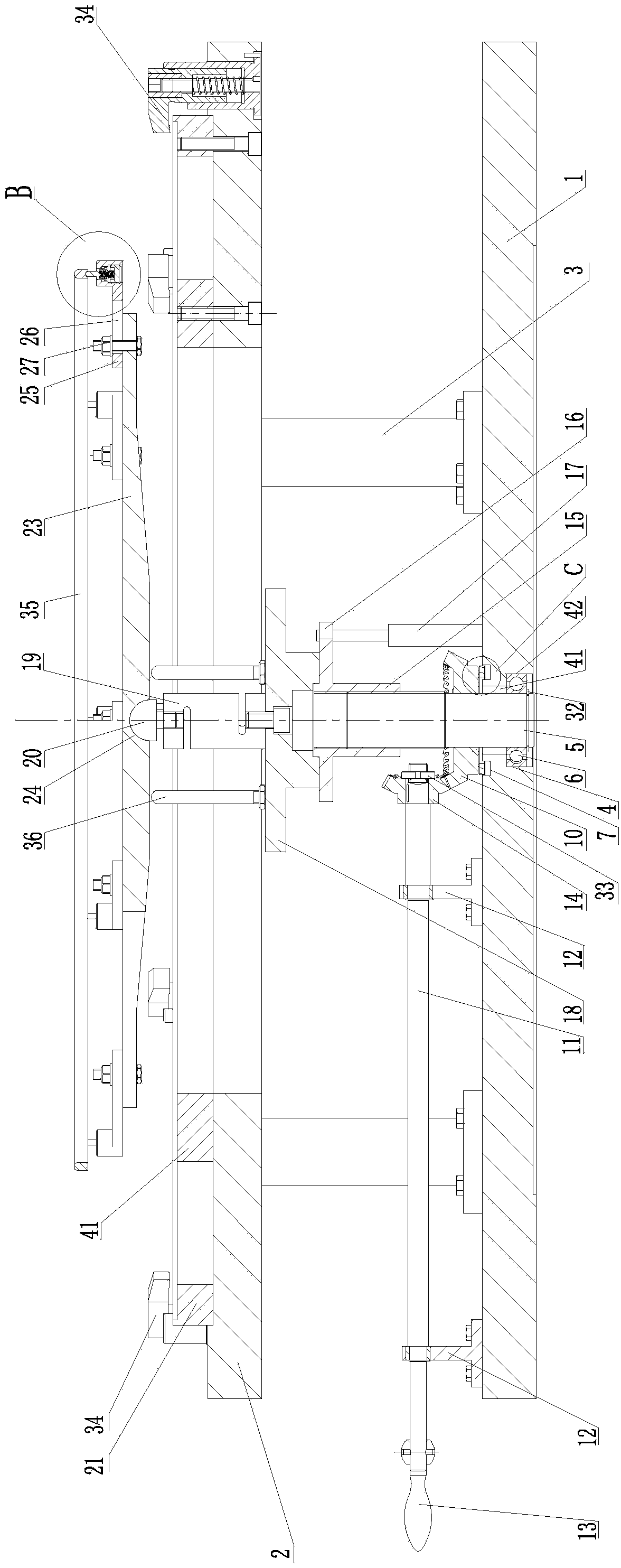

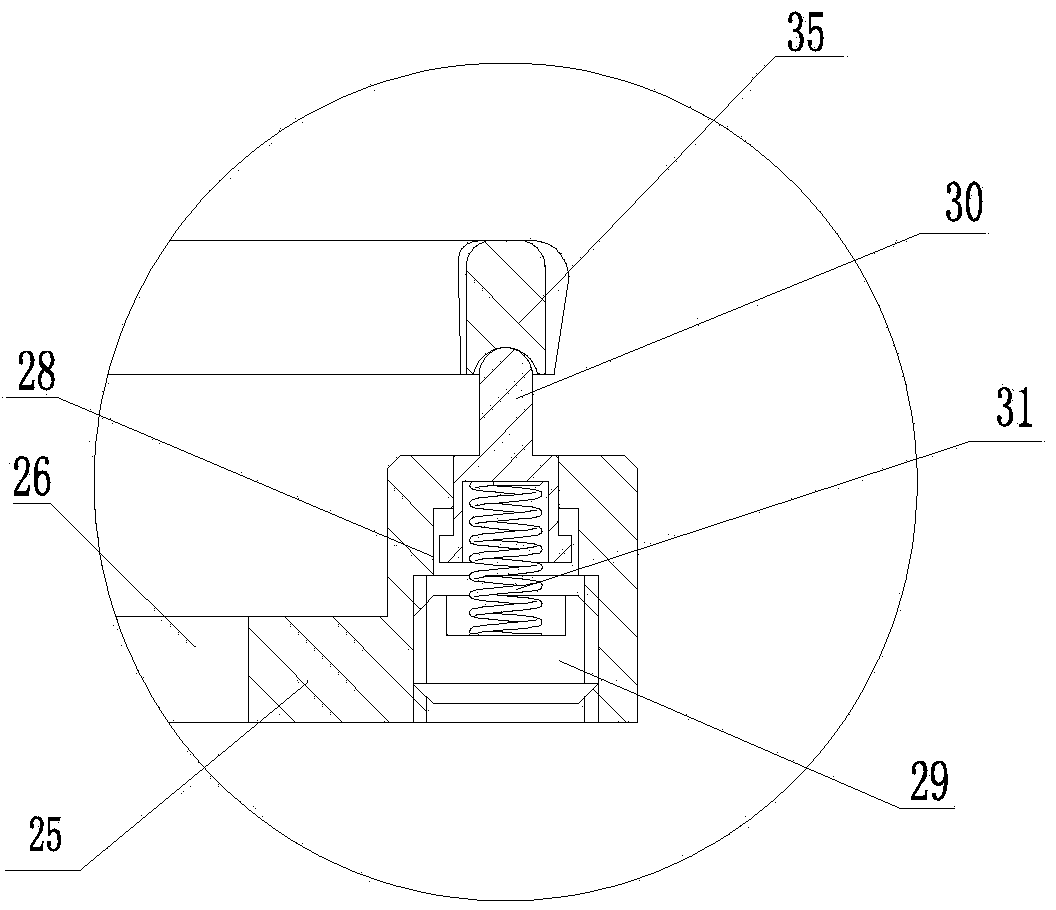

Variable-diameter hydraulic cutter capable of realizing continuous cutting of sleevings with different diameters through gear and rack transmission

InactiveCN107218007ASimple structureAccurately control the opening angleBorehole/well accessoriesGear wheelUpper joint

The invention relates to a variable-diameter hydraulic cutter capable of realizing continuous cutting of sleevings with different diameters through gear and rack transmission in the abandoned well operation process. The technical scheme of the cutter is that an upper joint is connected with a housing by threads; a spraying nozzle is located in a piston push rod and connected with the push rod by the threads; an upper spring, a turning mechanism and a piston are mounted on the piston push rod sequentially and arranged inside the housing; cutter knives are arranged uniformly in the circumferential direction and connected with the housing by hinge pins, gear structures of the upper parts of the cutter knife bodies are meshed with a cylindrical rack, the rack and the gears can transmit, and too large displacement of the cutter knives is limited while the opening degrees of the cutter knives are accurately controlled. According to the variable-diameter hydraulic cutter, the piston and the turning mechanism are pushed by the throttling action, gear and rack transmission is matched so as to realize continuous cutting of the sleevings with different diameters, trip times are reduced, the abandoned well operation time is saved, and the sleeving cutting efficiency and the operation reliability in the abandoned well operation process are improved greatly.

Owner:SOUTHWEST PETROLEUM UNIV

Mixed child-mother core assembly molding technology

ActiveCN107350429ASlow down depreciationIncrease the number ofAdditive manufacturing apparatusFoundry mouldsUltimate tensile strengthProduct Part

The invention discloses a mixed child-mother core assembly molding technology. A 3D printing molding technology and a sand mixing molding technology are combined, a part which is close to a product part having a plurality of structural features adopts 3D printing, and the other parts which have less structural features adopt the traditional sand mixing molding technology method, therefore an assembled sand mold which works through cooperative using of a mother core and a child core is formed. Based on the advantages of an original 3D printing molding technology, a traditional sand mixer production technology is introduced, the two molding technologies are combined with each other, further the cost of raw materials and the equipment investment cost are lowered, and meanwhile, child-mother separated core combination is conducted on a sand molding part which is brought out of a casting and the mold thickness which is brought out of a casting system and improves the strength so as to widen thinking for later multi-technology combination; the number of castings in a single sand box is increased, the sand box utilization ratio and the production efficiency are improved, the dependence on manual work is reduced at the same time, the cost of 3D printing raw materials and the depreciation of the equipment are reduced, and meanwhile, waste of molten iron is avoided, and the purposes of cost reduction and efficiency improvement are achieved.

Owner:四川共享铸造有限公司

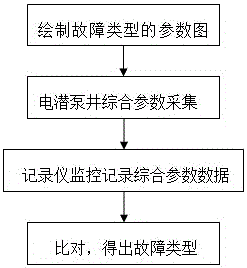

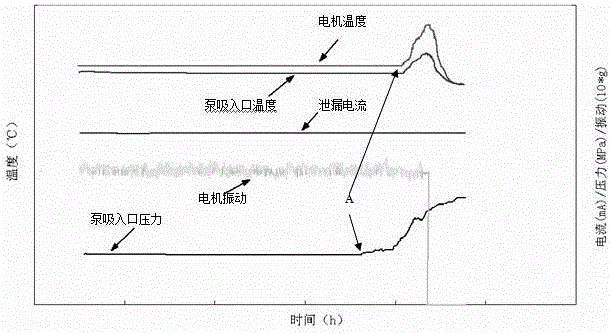

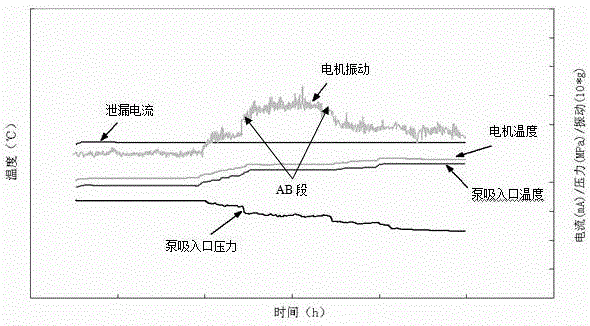

Parameter diagnosis and analysis method for electric submersible pump well working condition instrument

InactiveCN105781527AImprove accuracy and failure recoveryExtend the pump inspection cycleSurveyConstructionsInlet temperatureMotor vibration

The invention discloses a parameter diagnosis and analysis method for an electric submersible pump well working condition instrument. The method comprises steps as follows: a parameter curve chart of a typical electric submersible pump well fault type is drawn firstly; six groups of parameters including pump inlet temperature, motor winding temperature, pump inlet pressure, pump outlet pressure, leakage current and motor variation frequency are collected by the working condition instrument; pump working condition data are recorded and monitored by a recording instrument in real time; when an electric submersible pump well breaks down, the fault type is determined after comparison of a parameter curve acquired by the working condition instrument and the parameter curve chart. According to the parameter diagnosis and analysis method for the electric submersible pump well working condition instrument, the parameter curve chart of the typical electric submersible pump well fault type is drawn, so that when the electric submersible pump well breaks down again, the fault type can be determined rapidly and accurately, the working condition diagnosis accuracy rate and the fault recovery rate of the electric submersible pump are increased, meanwhile, by virtue of comparison with the chart, pre-warning and treatment are performed in time, the pump inspection period of an oil well is prolonged, the frequency of pump inspection and well repair is reduced, and the purpose of cost reduction and benefit increase is achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Ni-P alloy coating continuous casting crystallizer copper plate and preparation process thereof

ActiveCN102773432AImprove bindingReduced hot cracking tendencyMetal layered productsAlloy coatingCopper

The invention discloses a continuous casting crystallizer copper plate plating layer and a preparation process thereof. The Ni-P crystallizer copper plate plating layer comprises a crystallizer copper plate base body, wherein an Ni-P alloy layer is plated on the surface of the crystallizer copper plate base body, and contains nickel with the mass ratio being 95 percent to 99.7 percent, and phosphorus with the mass ratio being 0.3 percent to 5 percent. The preparation process of the continuous casting crystallizer copper plate plating layer comprises the following steps of: a, preplating the base body; b, preparing composite electroplate liquid containing Ni-P materials in a plating bath; and c, electroplating the Ni-P alloy layer. Due to the adoption of the scheme, the defects of low steel production, large abrasion, frequent repair of the continuous casting crystallizer copper plate can be overcome, and the continuous casting crystallizer copper plate plating layer with uniform densification, favorable binding force, low heat crack tendency, small internal stress, excellent wear-resisting property and long life cycle is obtained.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

Cold bend roller welding repairing method

InactiveCN103612000ACutting costsTo achieve the goal of cost reduction and efficiency increaseArc welding apparatusHardnessEngineering

The invention relates to a cold bend roller welding repairing method. The cold bend roller welding repairing method comprises the steps of (1) detecting the depth and length of a fracture in the fracture and damaged portion, and carrying out grinding and back gouging on the fracture and damaged portion on the surface of a roller, (2) carrying out heating pre-heating processing on the roller, (3) carrying out welding repairing through a surfacing process, (4) carrying out heating processing after welding, (5) carrying out machining according to drawing requirements, and (6) carrying out damage-free detection and hardness detection. The cold bend roller welding repairing method repairs the damaged roller through a series of industrial measures and procedures, tracking statistics shows that the service life of the repaired roller is the same as that a newly made roller, the surface hardness reaches HRC56-60, the expenses on the aspect of roller usage is largely reduced for use enterprises, and therefore the purposes of reducing cost and increasing benefits are achieved.

Owner:湖州市银鑫轧辊有限公司

Production method of high-carbon martensitic gas valve steel 85Cr18Mo2V silver bright bar material

InactiveCN108220750AEasy to shapeImprove distributionProcess efficiency improvementWire rodElectric arc furnace

The invention provides a production method of a high-carbon martensitic gas valve steel 85Cr18Mo2V silver bright bar material, wherein the production method includes the following steps: adding steelscrap, high-carbon ferrochromium and other alloying materials in an electric-arc furnace, and carrying out alloy melting initial smelting; smelting with a steel ladle refining furnace; carrying out vacuum refining with a VD furnace; carrying out continuous casting with an arc square billet continuous casting machine; carrying out electroslag remelting; carrying out high speed wire rolling; annealing; straightening, polishing, inspecting and putting in storage. The production method of the gas valve steel 85Cr18Mo2V silver bright bar material adopts the metallurgical technology means of mothermaterial continuous casting and electroslag remelting to produce a steel billet, overcomes the problem of difficult continuous casting due to large high temperature deformation resistance of 85Cr18Mo2V, improves the morphology and distribution conditions of primary carbide, reduces various metallurgical defects, such as segregation and loosening, in the billet, effectively refines the structure ofthe original billet, greatly saves energy consumption and reduces the production cost; the production efficiency is greatly improved by using electroslag steel ingot one-heating forming; and steel wire rods are processed by grinding, pollution of pickling solutions and other problems are not generated, and the purposes of reducing the cost and increasing the efficiency are achieved.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

Measuring device for gap of guide blade edge plates

InactiveCN103630103AApplicable external force application functionAccurate measurement dataMeasurement devicesAviationEngineering

A measuring device for the gap of guide blade edge plates belongs to the technical field of aviation motors. The measuring device for the gap of the guide blade edge plates is provided with a transmission mechanism, a force applying mechanism and a positioning mechanism and realizes the effect that the stable and accurate gap measuring data of the guide blade edge plates are obtained under the condition that an external force is applied to the guide blades. The device utilizes multiple uniformly distributed thimbles and a support gasket to realize the effect that the same-level guide blades are subjected to the external force with the uniform size at the same time; the design concept of piling adjusting cushion blocks is adopted, and the aim that one device is suitable for the external force applying function for the multi-level guide blades in the same receiver is realized. The measuring device comprises a chassis, wherein a lifting supporting mechanism, the force applying mechanism and the positioning mechanism are arranged on the chassis; the lifting supporting mechanism is formed by a screw rod, a screw barrel, a guide pin, a dynamometer seat, a sensor for a dynamometer, a press pillar, an angle frame, a guide plate, the thimbles and the support gasket. The force applying mechanism is formed by a first bevel gear, a second bevel gear, a rotary shaft and a support; the positioning mechanism is formed by a base with a through hole, a positioning ring and a hook-shaped press plate.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

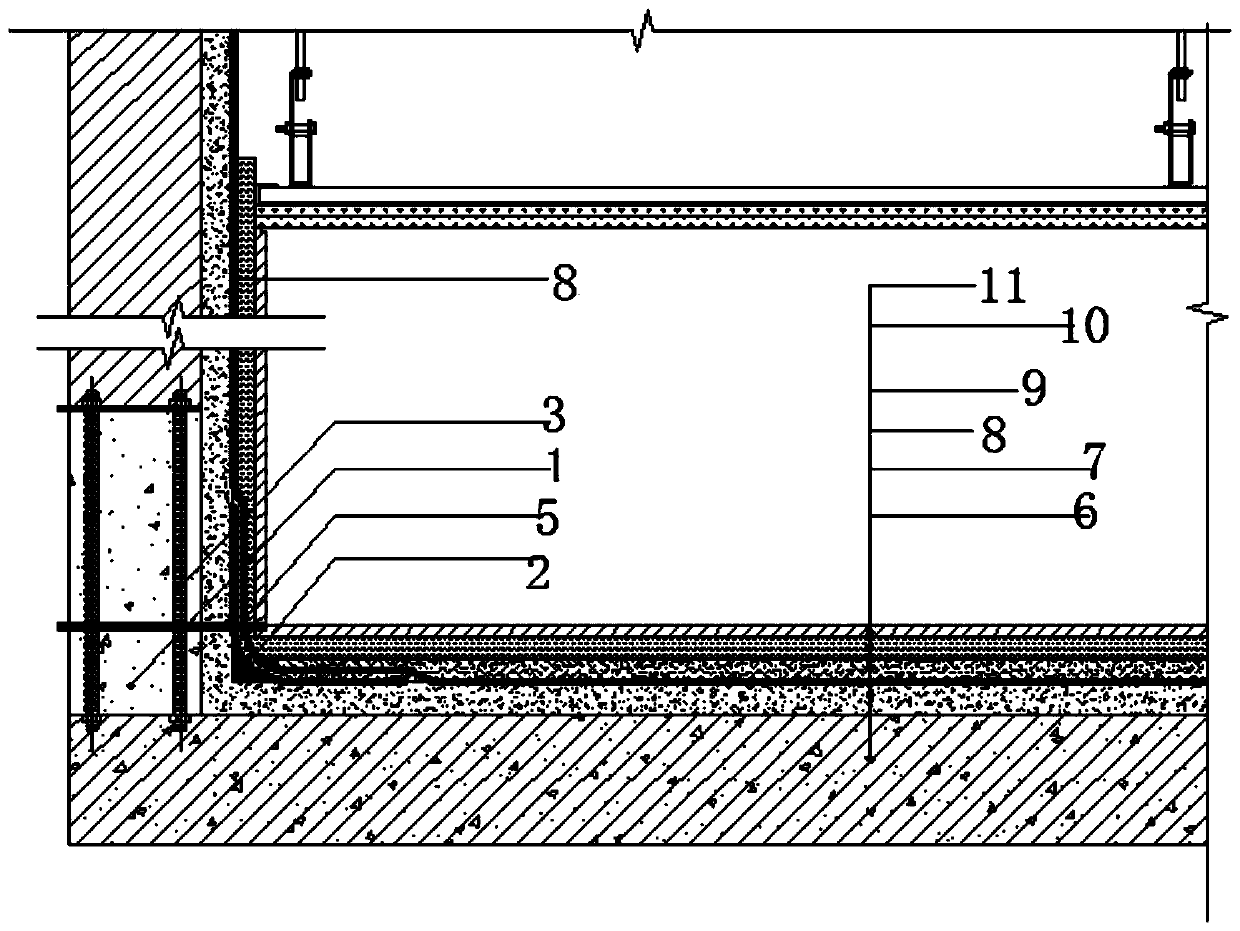

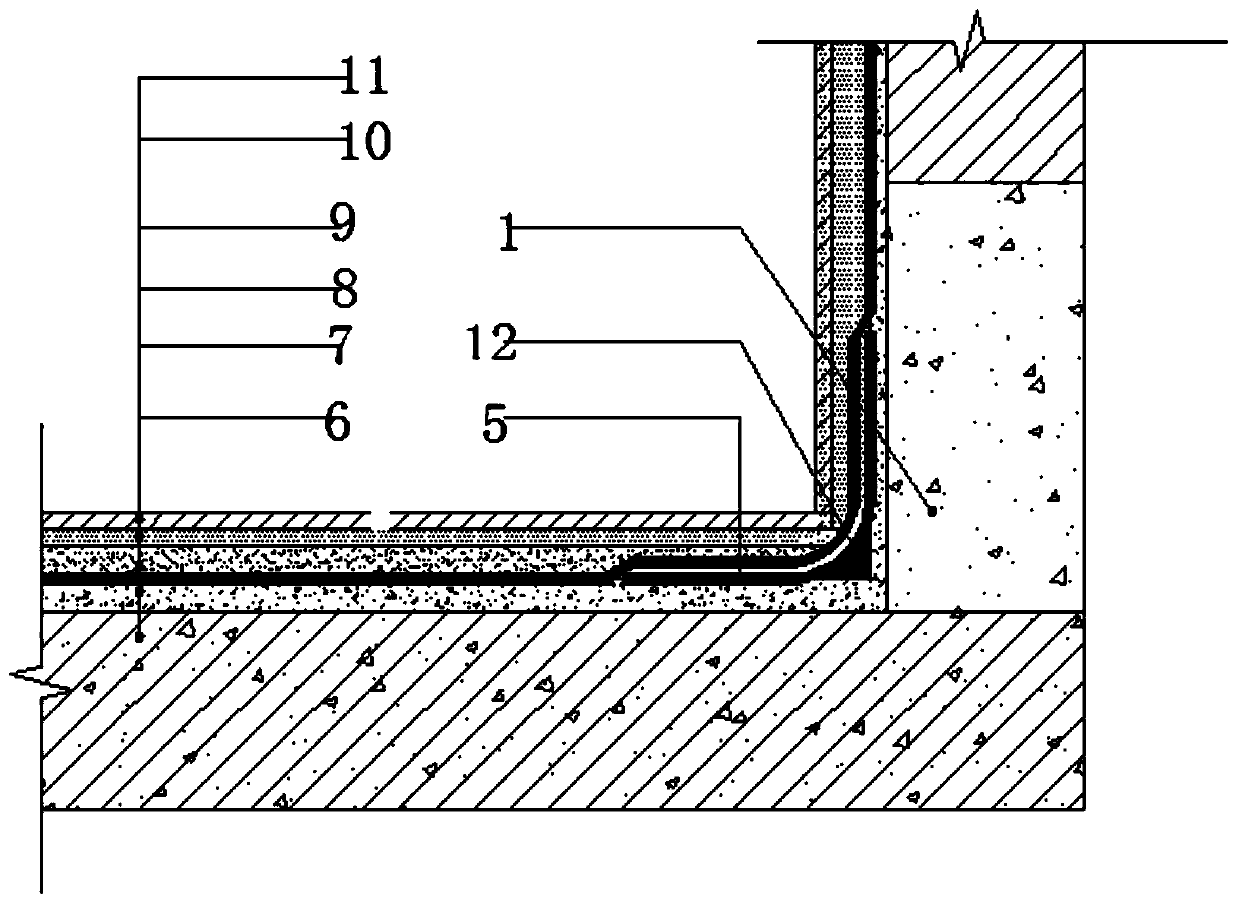

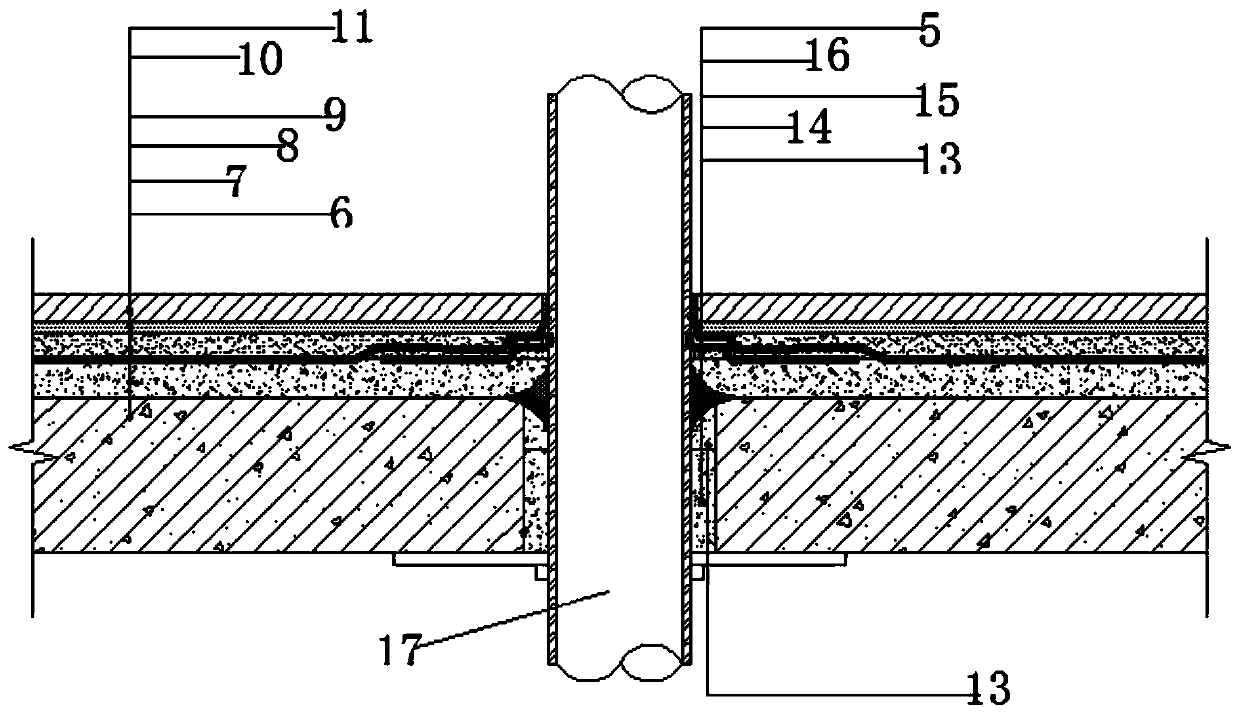

Indoor waterproof structure and construction method thereof

PendingCN110093989AAvoid the problem of water seepageTo achieve the goal of cost reduction and efficiency increasePipesBuilding insulationsUnderfloor heatingEngineering

The invention discloses an indoor waterproof structure. The indoor waterproof structurecomprisesa wall surface waterproof structure, a wall surface and ground corner waterproof structure, a board penetrating floor waterproof structure, a floor drain outlet waterproof structure, a shower room partition lower part water barrier waterproof structure, a threshold stone lower part water barrier waterproof structure, abathtub lower part water barrier waterproof structure, a water supply opening waterproof structure, abathroom with underfloor heating waterproof structure, asame floor drainage bathroom waterproof structure, and a bathroom near curtain wall sidewater barrier waterproof structure. According to theindoor waterproof structure and construction method thereof, the problem of water seepage caused by reasons such as coarse design of an indoor waterproofing system, irregular construction, and inadequate control is avoided, and achieves the purposes of cost lowering and efficiency improving are achieved.

Owner:GOLD MANTIS CONSTR DECORATION

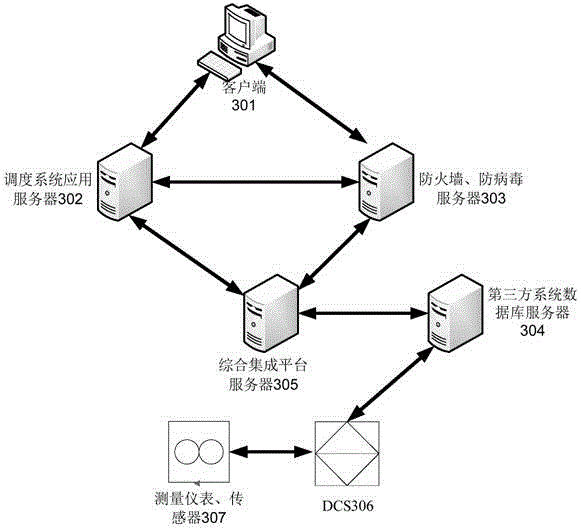

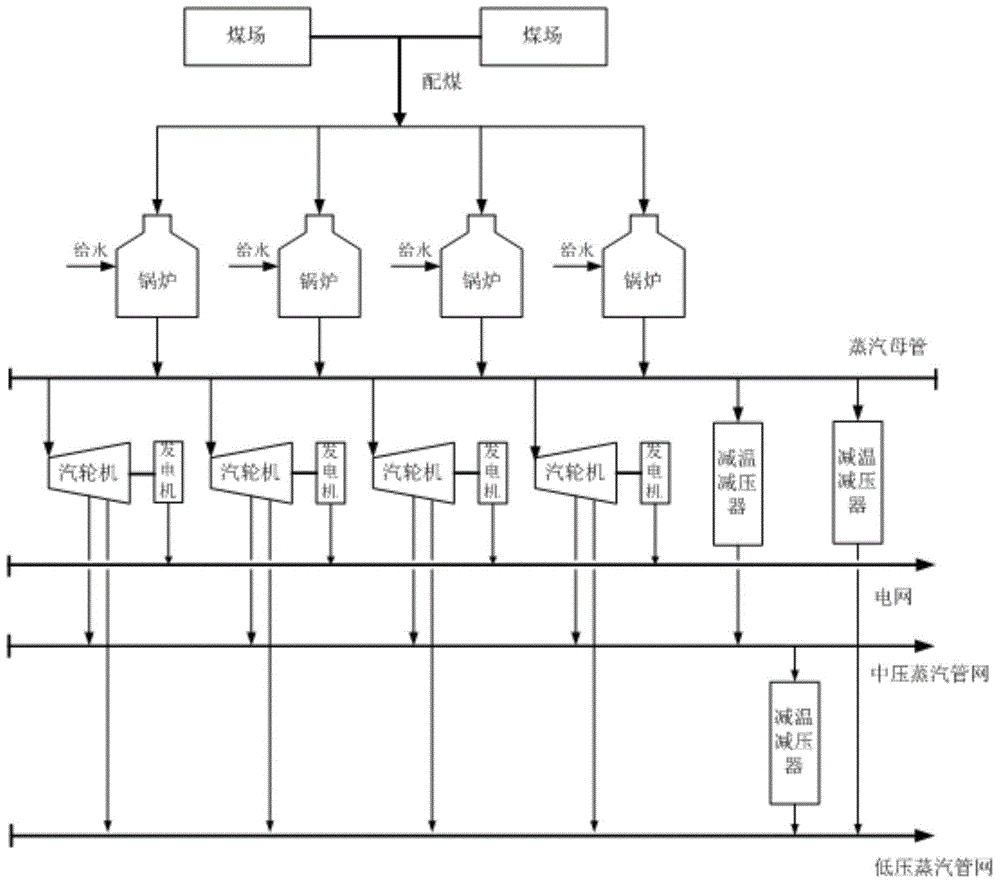

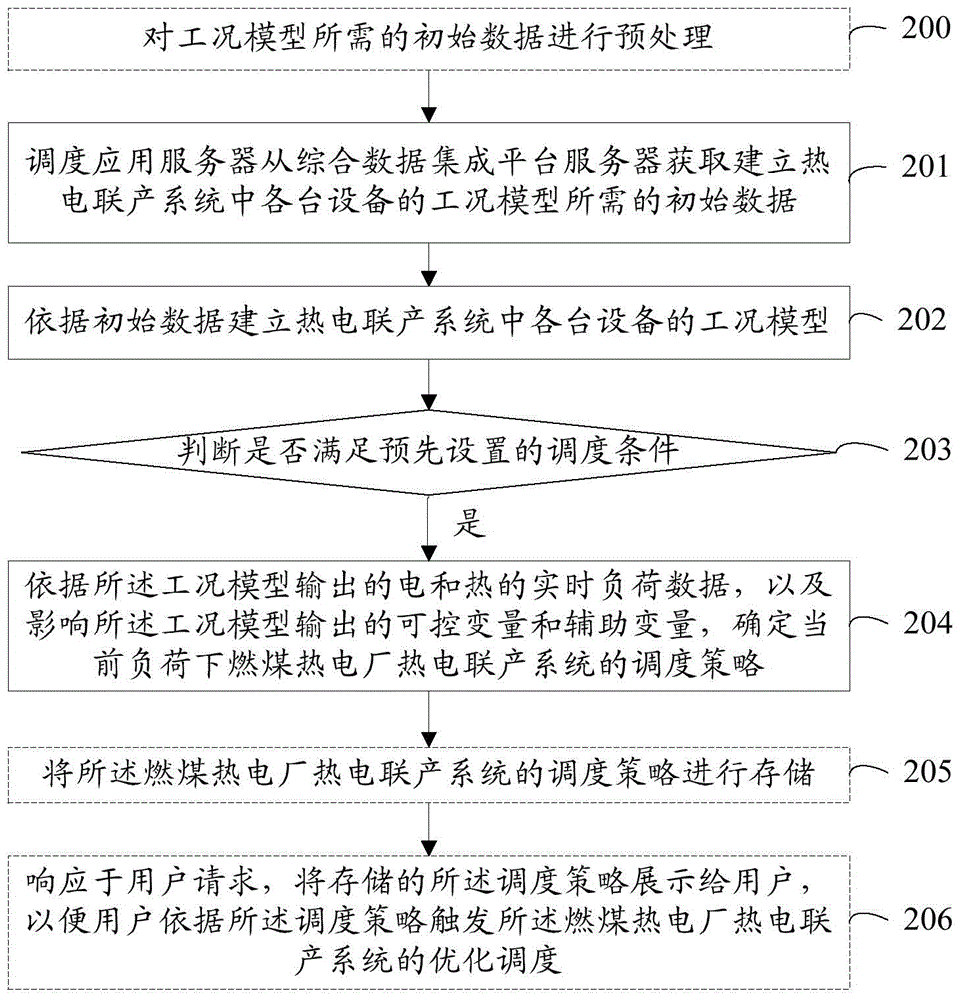

Scheduling method, server and system of combined heat and power generation system of fire coal thermal power plant

ActiveCN104102211AImprove accuracyImprove economyEnergy industryCombined combustion mitigationCogenerationSynthetic data

The application provides a scheduling method, a scheduling server and a scheduling system of a combined heat and power generation system of a fire coal thermal power plant. The scheduling method of the combined heat and power generation system of the fire coal thermal power plant is deployed on the scheduling application server in the scheduling system of the combined heat and power generation system of the fire coal thermal power plant, and includes: obtaining initial data needed by building working condition models of all devices in the combined heat and power generation system from a synthetic data integration platform, and building the working condition models of all the devices in the combined heat and power generation system according to the initial data; judging whether preset scheduling conditions are met or not, and if yes, confirming a scheduling policy of the combined heat and power generation system of the fire coal thermal power plant under a current load according to real-time power and heat load data output by the working condition models, and controllable variables and auxiliary variables, which influence outputting of the working condition models. According to the scheduling method, the scheduling server and the scheduling system of the combined heat and power generation system of the fire coal thermal power plant, scheduling problems are considered by integrating blending coal, a boiler, a turbine generator and a temperature and pressure reducer together, and a scheduling scheme can be globally optimized.

Owner:ZHEJIANG SUPCON SOFTWARE +1

Cooling and annealing process of solar cell

InactiveCN105720135AReduce thicknessReduce lattice damageFinal product manufactureSemiconductor/solid-state device manufacturingFilling factorSolar cell

The invention discloses a cooling and annealing process of a solar cell. The cooling and annealing process comprises the following steps of (1) diffusing to enter a boat; (2) oxidizing; (3) diffusing and introducing a source in a low-temperature state; (4) diffusing and pushing a junction in a high-temperature state; (5) taking out a silicon wafer out of a furnace, cooling the silicon wafer, and stabilizing the temperature of a furnace tube; (6) throwing the silicon wafer into the furnace for second times, and carrying out low-temperature annealing; and (7) diffusing to get out of the boat. By the cooling and annealing process, a diffusion dead layer is reduced, thermal defect caused by high-temperature reaction is reduced, and thus, the conversion efficiency of the solar cell is improved; particularly, the open-circuit voltage is obviously increased and is higher than that of a traditional process by 2mV, a filling factor is also improved, and thus, the conversion efficiency of the battery cell is obviously improved; and the thickness of a PN-junction dead layer of the silicon wafer surface after diffusion is reduced, lattice damage brought by high-temperature diffusion is reduced, and minority carrier lifetime is prolonged.

Owner:江苏彩虹永能新能源有限公司

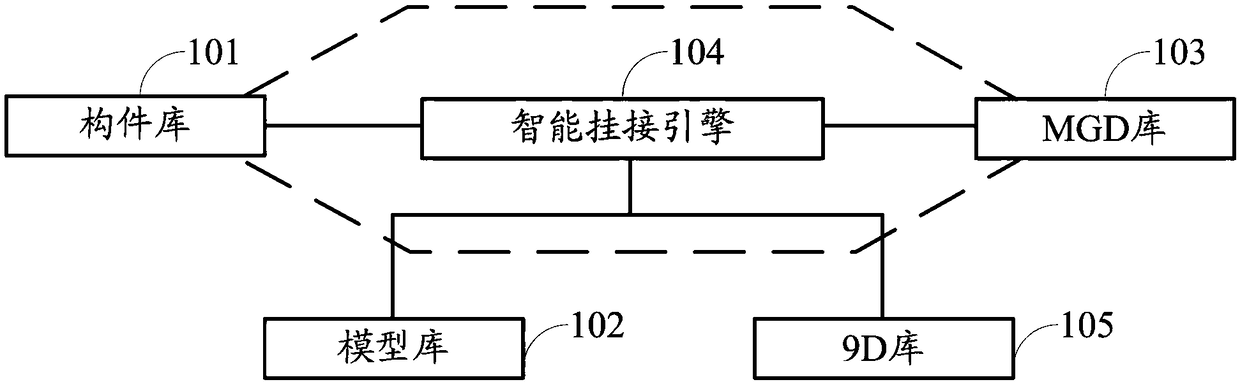

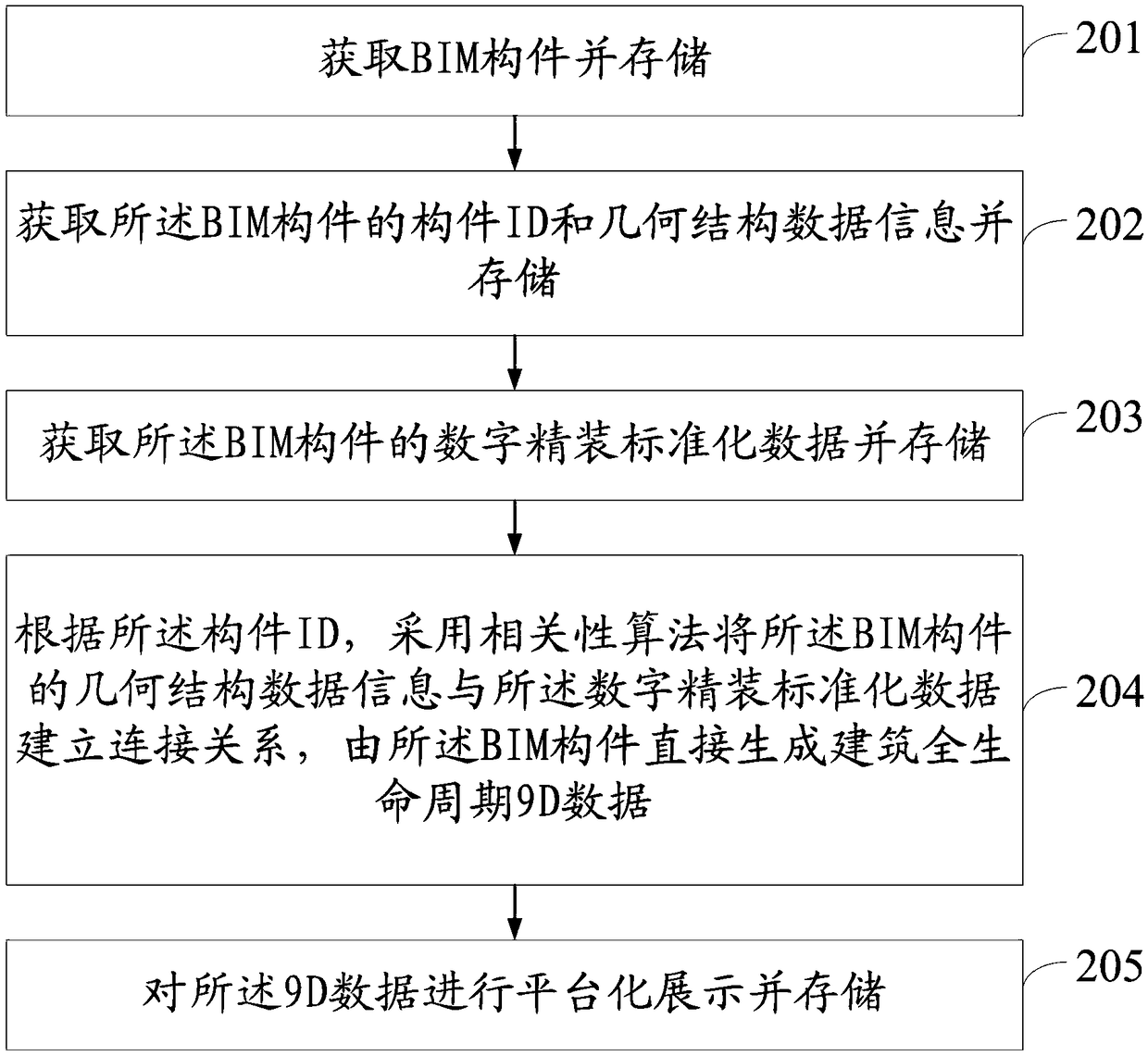

Full-life-cycle building information management system and method

ActiveCN108763714AEasy to useRefined Construction GuidanceGeometric CADDesign optimisation/simulationFull life cycleData information

The invention discloses a full-life-cycle building information management system and method. The system includes a component library, a model library, a 9D library, an MGD library and an intelligent hitching engine. The intelligent hitching engine can employ a correlation algorithm to establish connection relationships on geometric data information of BIM (Building Information Modeling) componentsand digital fine-decoration standardization data according to component ID, hitch project information, processes and resources of an engineering project at all different stages in a full life cycle to a BIM model, directly generate 9D data of the full life cycle of a building by the BIM components, and carry out platform display. Therefore, the system can be conveniently used by all participationparties of the project, and provide refined construction guidance for all the stages in the life cycle of the building, and achieves the purpose of cost reducing and efficiency improving.

Owner:北京唐吉诃德科技有限公司

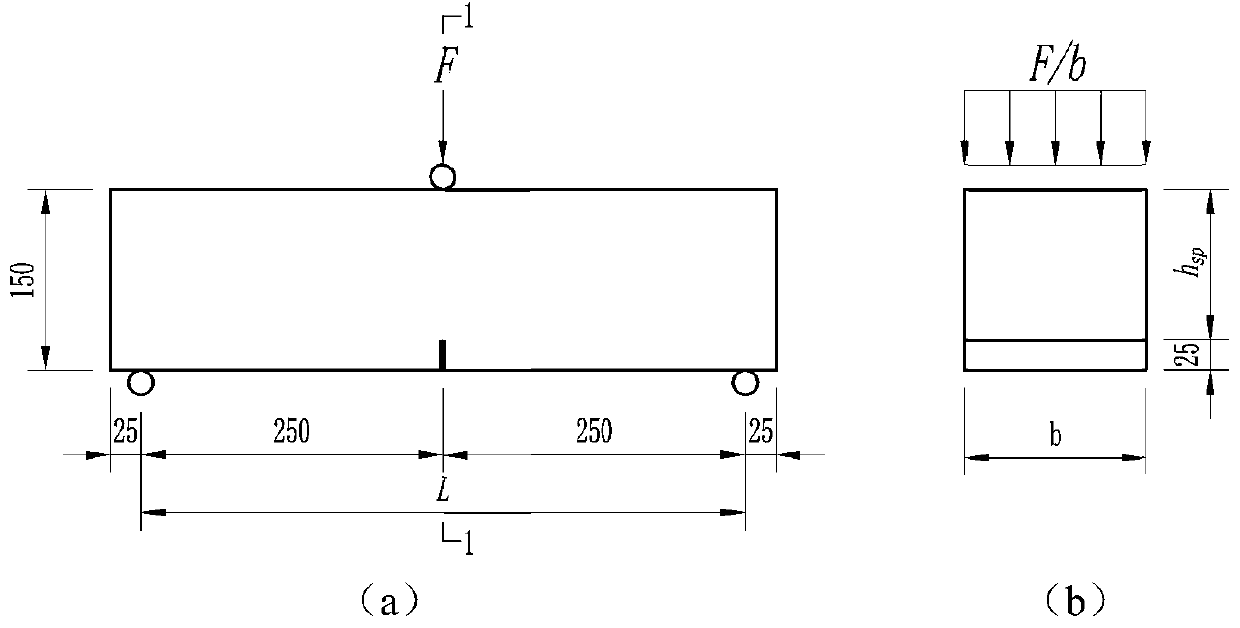

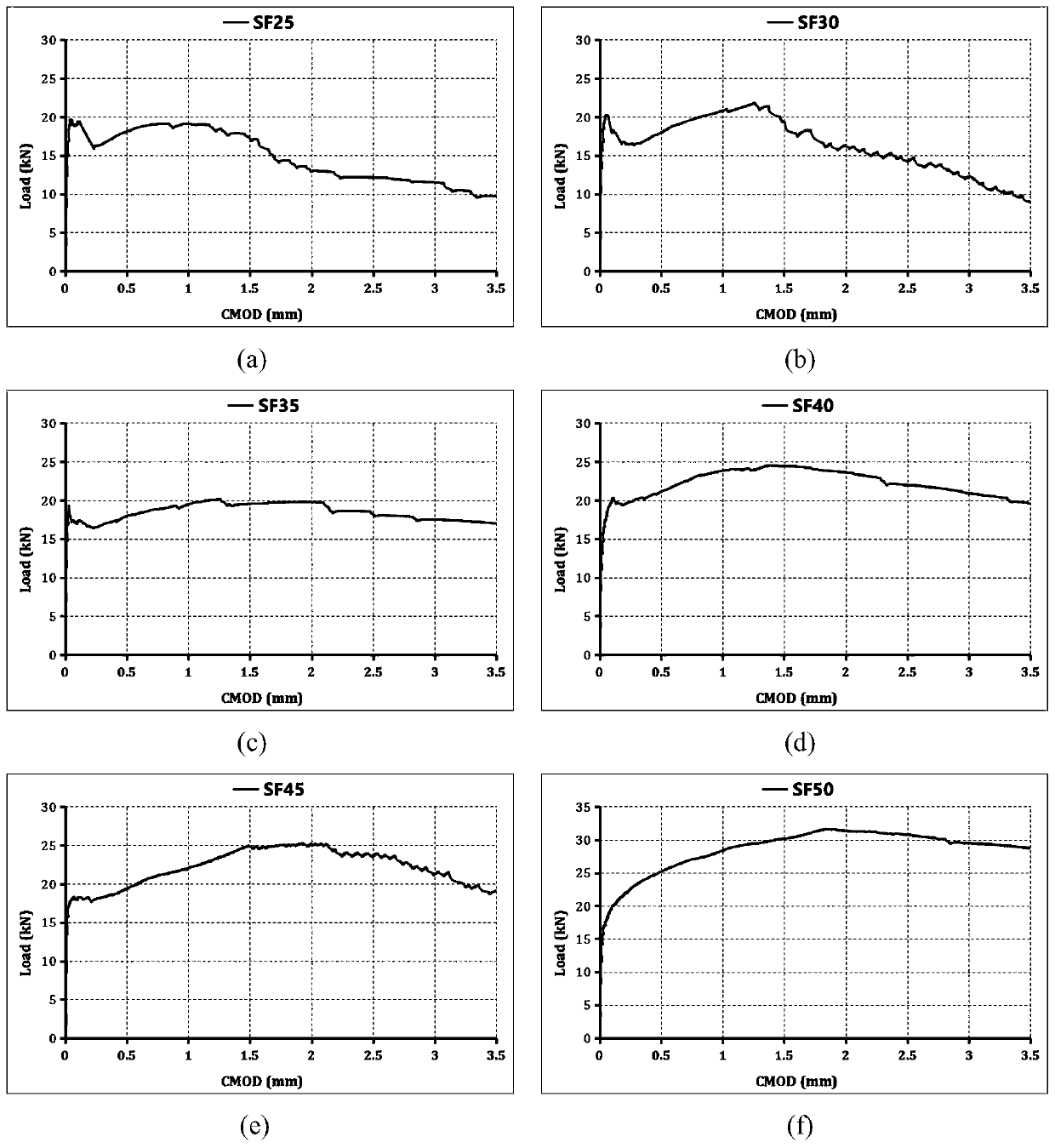

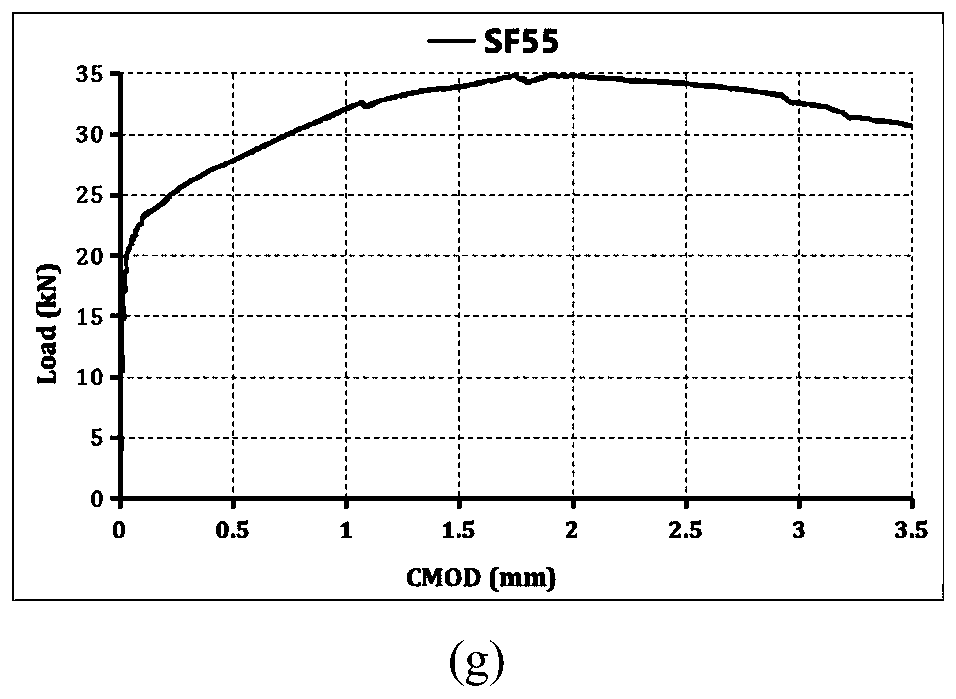

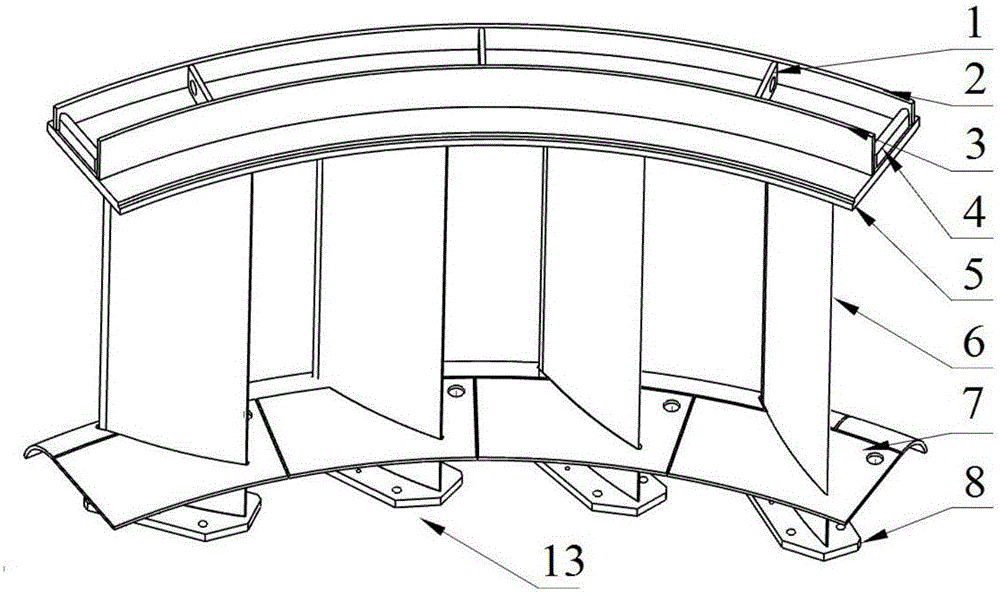

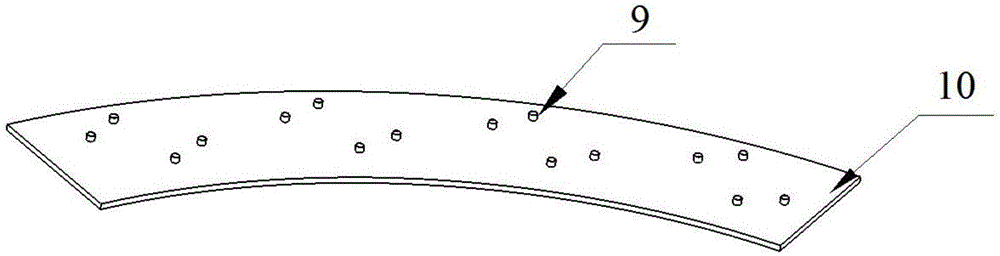

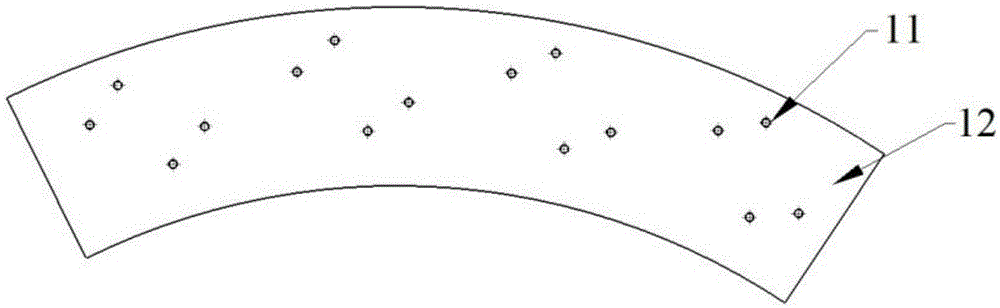

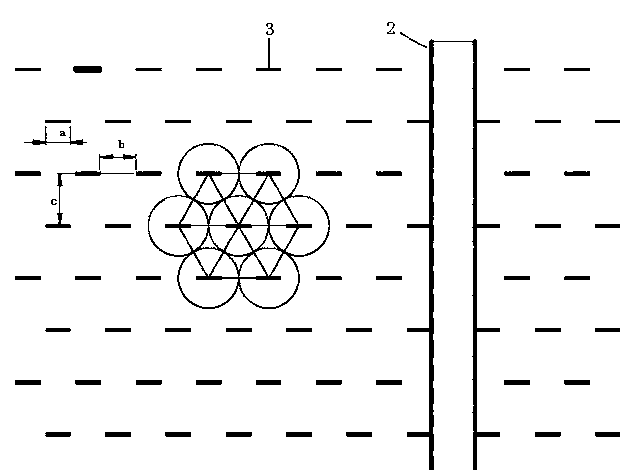

Steel bar-steel fiber concrete shield segment normal section bearing capacity and reinforcement measuring method

ActiveCN111220467AReflects the stress-strain relationshipEmbodies the strengthening and toughening mechanismMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesResidual strengthRebar

The invention discloses a steel bar-steel fiber concrete shield segment normal section bearing capacity and reinforcement measuring method, which is characterized by taking an elastic flexural-tensileresidual strength value obtained through an open beam three-point bending test as a basic parameter of a material constitutive model, converting the elastic flexural-tensile residual strength obtained by the test into axial-tensile residual strength under a constitutive model; determining the axial force and the bending moment of the steel fiber reinforced concrete on the normal section of the shield segment according to the tensile strength and the stress distribution function of the steel fiber reinforced concrete; and then, considering steel bar configuration, establishing a steel bar-steel fiber concrete shield segment normal section ultimate bearing capacity balance equation set, and determining ultimate bearing capacity or steel bar configuration on the shield segment normal section. Therefore, the method not only can be used for determining the ultimate bearing capacity, but also can be used for determining the steel bar configuration, a steel bar-steel fiber reinforced concrete structure normal section bearing capacity measuring and calculating system is further perfected, and full exertion of the advantages of the steel bar-steel fiber reinforced concrete structure and application and popularization in other fields are facilitated.

Owner:中铁科学研究院有限公司 +1

Erecting welding technological method for single-upper-ring type large segmented stand ring with sole plates

ActiveCN105057855AReduce weightReduce difficultyArc welding apparatusProcessing costWelding deformation

The invention relates to an erecting welding technological method for a single-upper-ring type large segmented stand ring with sole plates. A sole plate positioning template and positioning pipes are used for precise positioning; and after splice welding of a lower guide plate, fixed guide vane mounting holes are perforated in a matched mode, and then fixed guide vanes are inserted. The key process problems of stand ring welding deformation, sole plate assembly positioning, sole plate combining through hole processing cost, the production cycle and the like are solved through an auxiliary lower ring, the sole plate positioning templates and the positioning pipes, and the production cost and the production cycle are reduced. According to the stand ring manufactured through the technological method, the problems of assembly positioning, the production cost, welding deformation and the like are effectively solved, and construction site installation requirements are met; the subsequent production cycle and processing cost are greatly reduced, economy and practicability are both considered, and the purposes of lowering cost and improving effects are achieved.

Owner:HARBIN ELECTRIC MASCH CO LTD

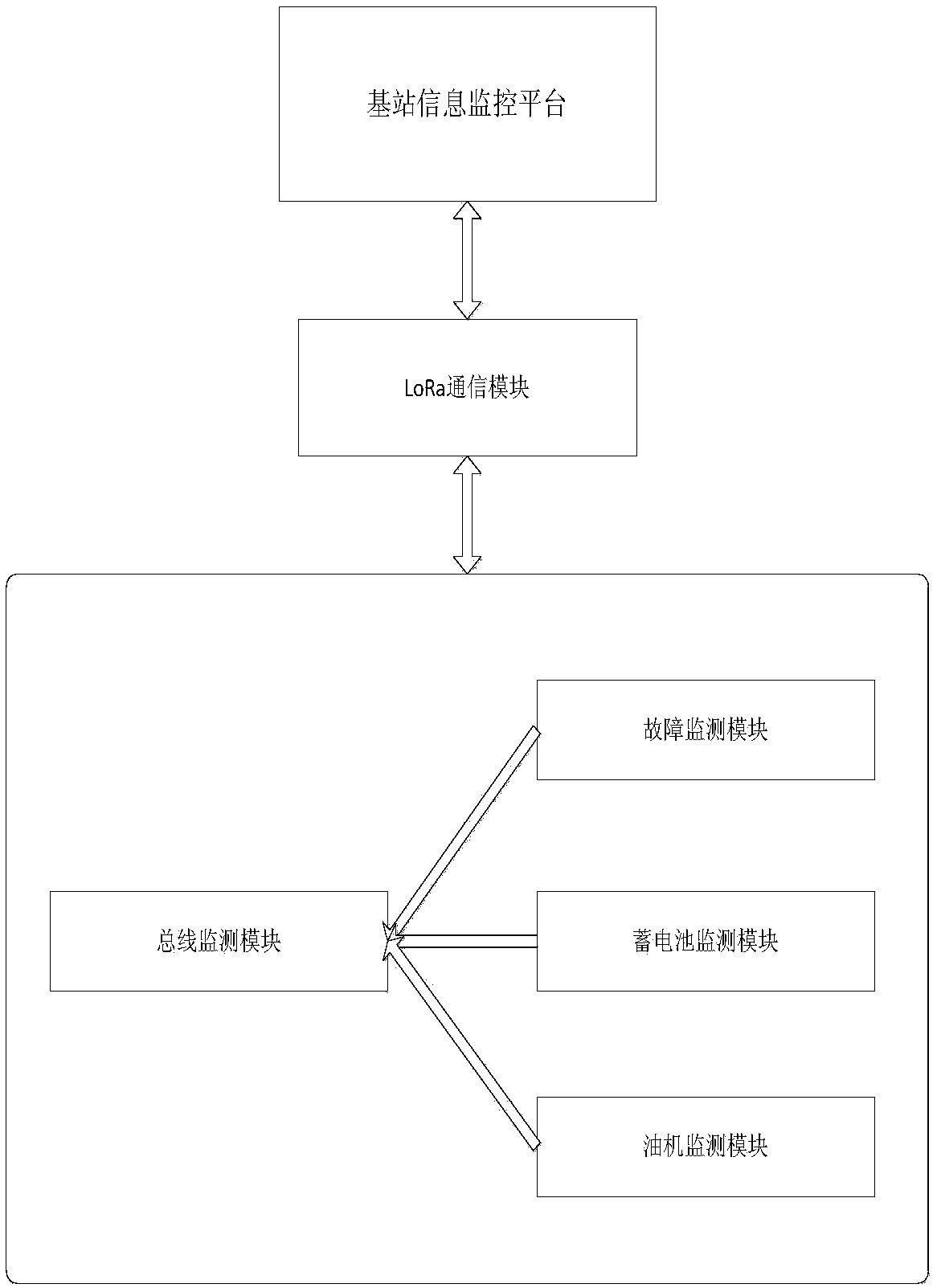

Internet-of-things-technology-based base station oil engine management system and method

InactiveCN107942862AAccurate statistics of power generation timeCalculate the cost of power generationProgramme controlComputer controlControl engineeringPower grid

The invention discloses an internet-of-things-technology-based base station oil engine management system comprising a base station information monitoring platform, a storage battery monitoring module,an oil engine monitoring module, and a bus monitoring module. The base station information monitoring platform is used for collecting operating information of base station equipment and operating equipment in the base station. The storage battery monitoring module is used for controlling connection or disconnection between a storage battery and a power supply bus and collecting electricity quantity information and charging and discharging information of the storage battery. The oil engine monitoring module is used for controlling connection or disconnection between oil engine power supply anda power supply bus and collecting power generation information of the oil engine. The bus monitoring module is used for monitoring power consumption of a base station and determining a total input line power source. According to the invention, the storage battery, the commercial power grid, the generation oil engine, and the cloud platform are connected by the sensor; statistics of the power generation time of the oil engine is carried out precisely; the oil engine power generation tasks are allocated; and problems of virtual high oil consumption caused by fault reporting and increasing of oil costs are solved.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

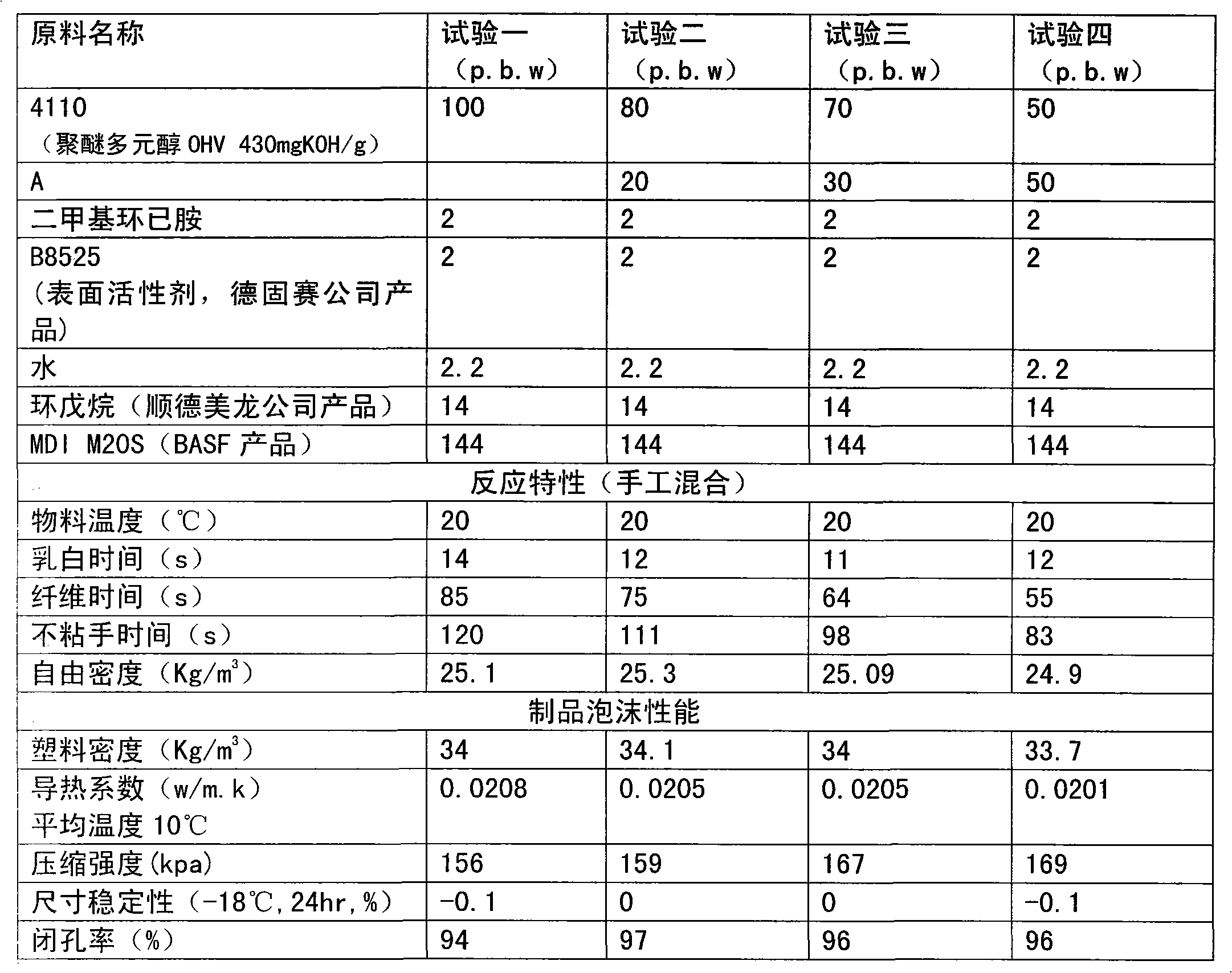

Waste polyurethane foam aminolysis recycling method

InactiveCN103012838ASolve pollutionTo achieve the goal of cost reduction and efficiency increasePlastic recyclingMechanical crushingPolyol

The invention relates to a waste polyurethane foam aminolysis recycling method, which comprises: a, removing surface attachments of waste polyurethane products; b, carrying out cutting or mechanical crushing on the surface attachment-removed waste polyurethane products into small blocks; c, preparing a mixture of regeneration polyol and aromatic amine; and d, preparing the mixture of the regeneration polyol and the aromatic amine into combination polyether for hard foam, and carrying out foaming. According to the present invention, a chemical recovery method is adopted to decompose waste polyurethane products, and processing utilization is performed, such that an environment pollution problem caused by the polyurethane foam is solved.

Owner:绍兴广佳庄鑫建材制造有限公司

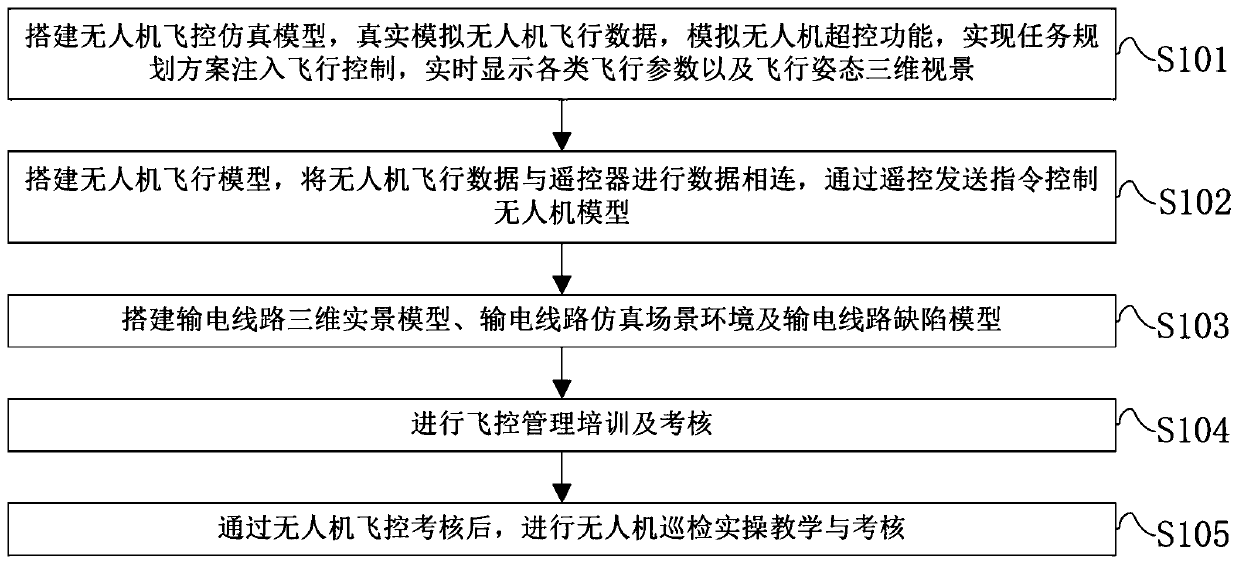

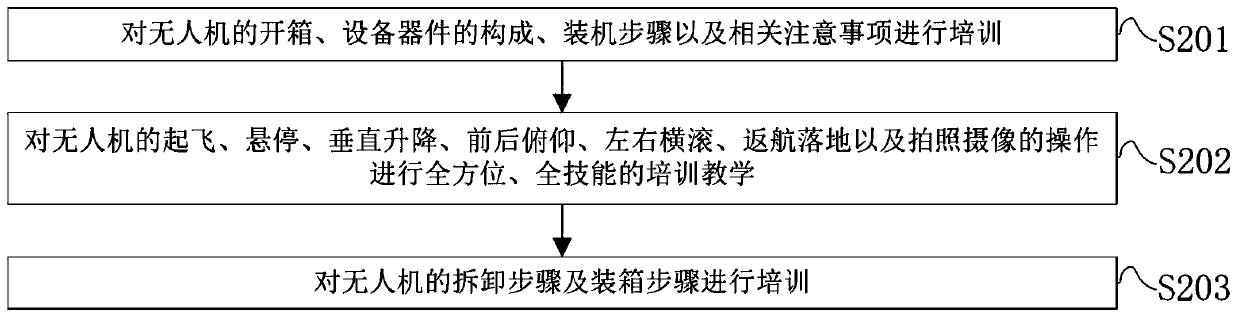

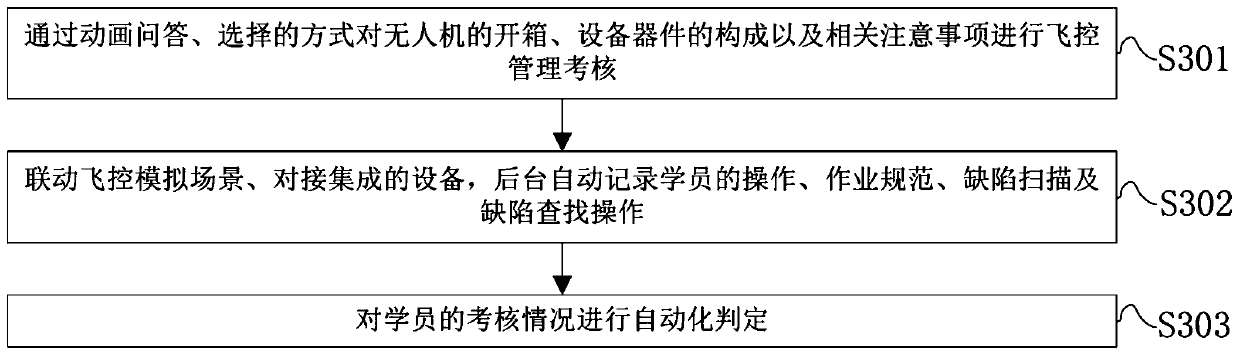

Power transmission line unmanned aerial vehicle simulation training method based on VR technology and system

InactiveCN111429772AAvoid damageIncrease line inspection professionalsCosmonautic condition simulationsSimulator controlSimulationUncrewed vehicle

The invention relates to a power transmission line unmanned aerial vehicle simulation training method based on a VR technology and a system thereof. The method comprises the steps that an unmanned aerial vehicle flight control simulation model is built, an unmanned aerial vehicle override function is simulated, task planning scheme injection flight control is achieved, and various flight parameters and flight attitude three-dimensional scenes are displayed in real time; an unmanned aerial vehicle flight model is built; a power transmission line three-dimensional live-action model, a power transmission line simulation scene environment and a power transmission line defect model are built; flight control management training and assessment are carried out; and after the unmanned aerial vehicle flight control assessment is passed, unmanned aerial vehicle inspection practical operation teaching and assessment are performed. According to the invention, after flight control management training examination of students is qualified, unmanned aerial vehicle inspection practical operation training examination is carried out, so that the students are prevented from damaging the unmanned aerialvehicle due to unskilled flight control operation, the trained students are enabled to comprehensively grasp the key technology of unmanned aerial vehicle inspection according to a standardized process, and effective assistance is provided for lean management of a power grid.

Owner:云南电网有限责任公司输电分公司

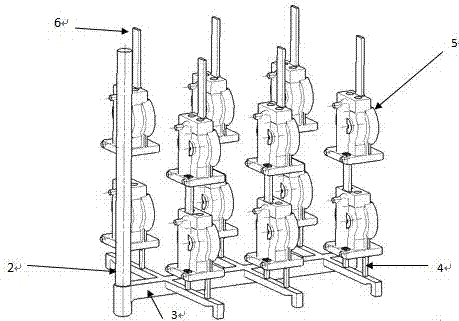

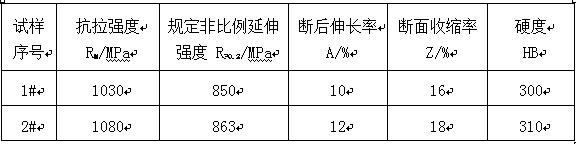

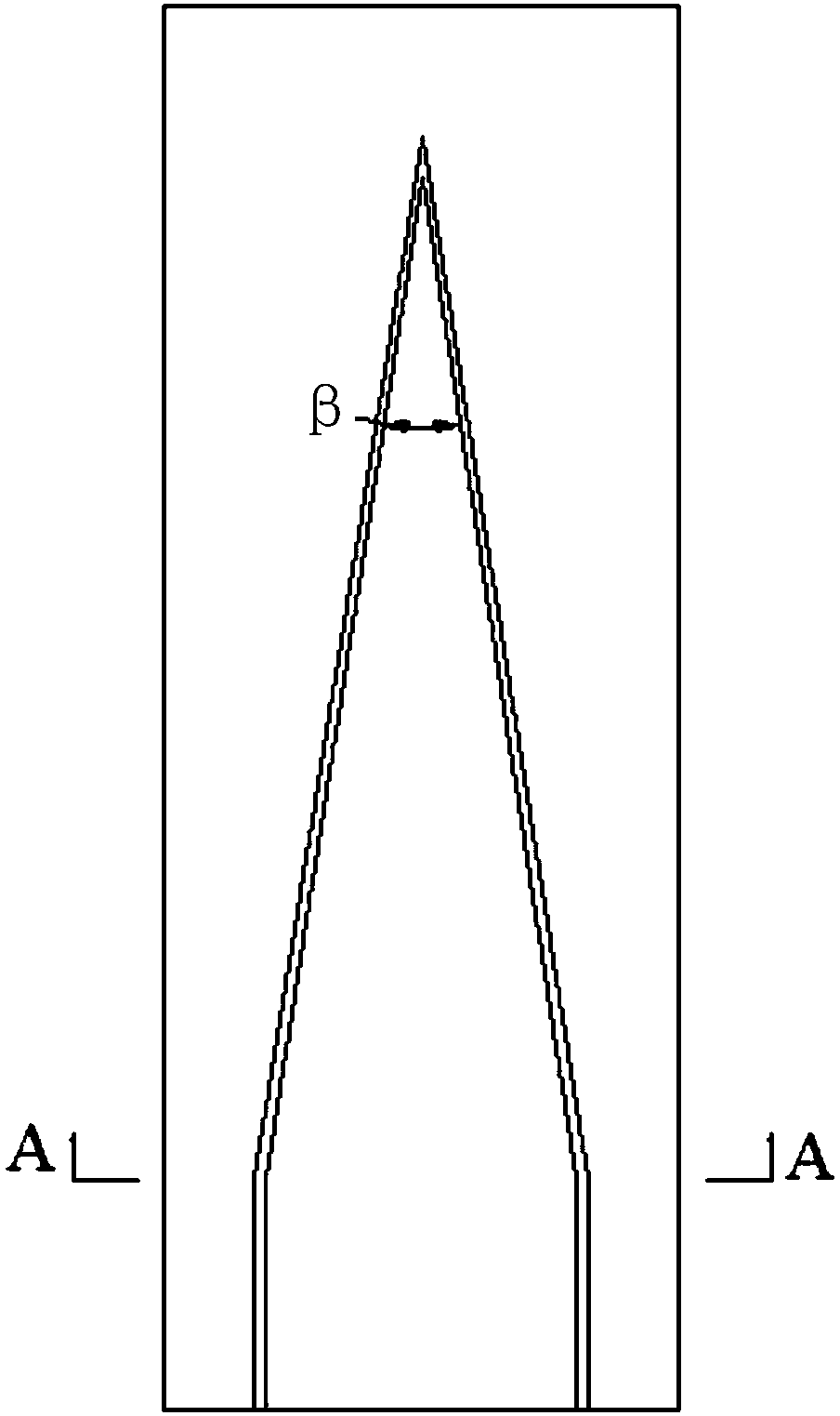

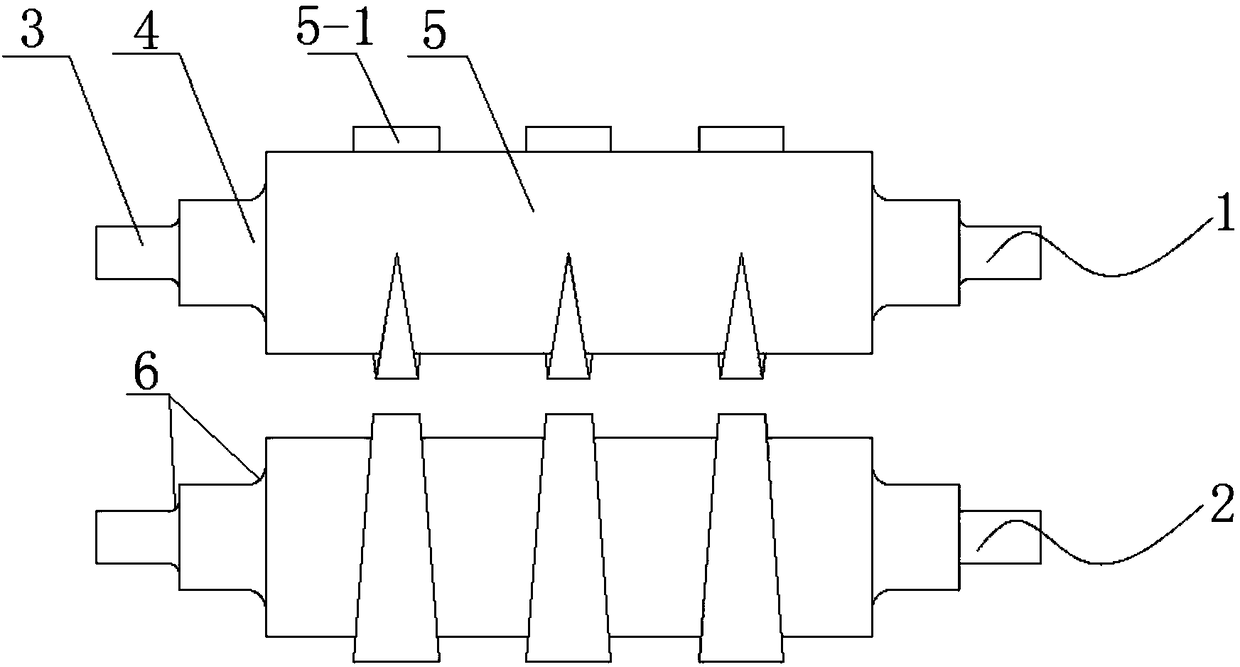

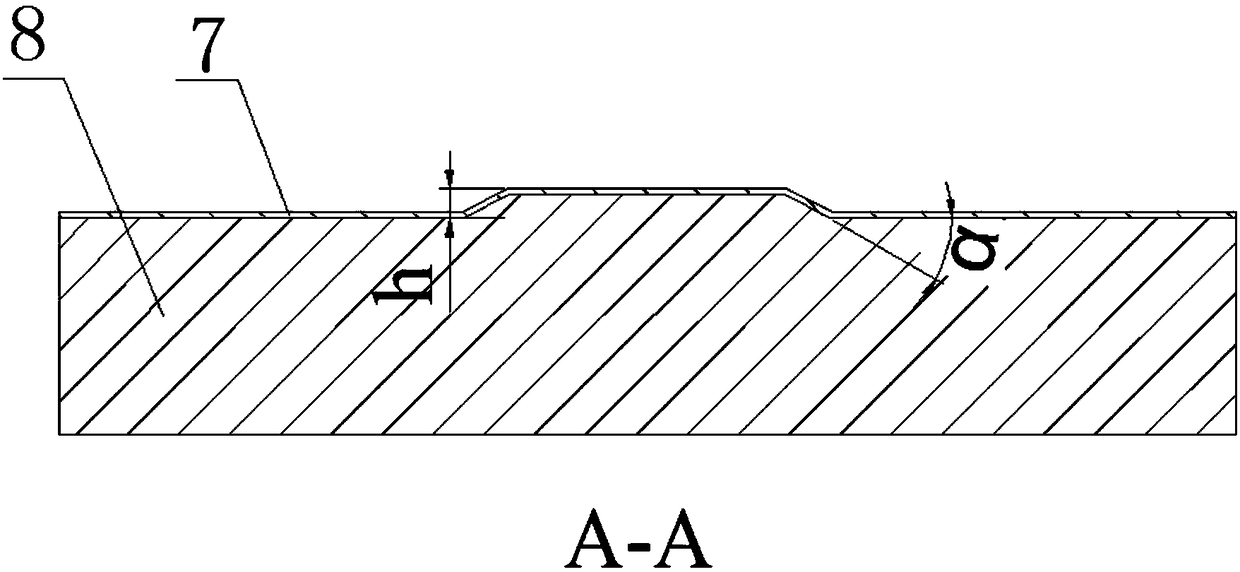

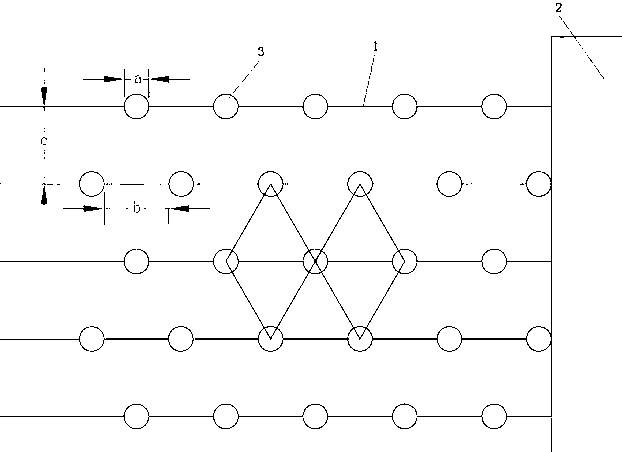

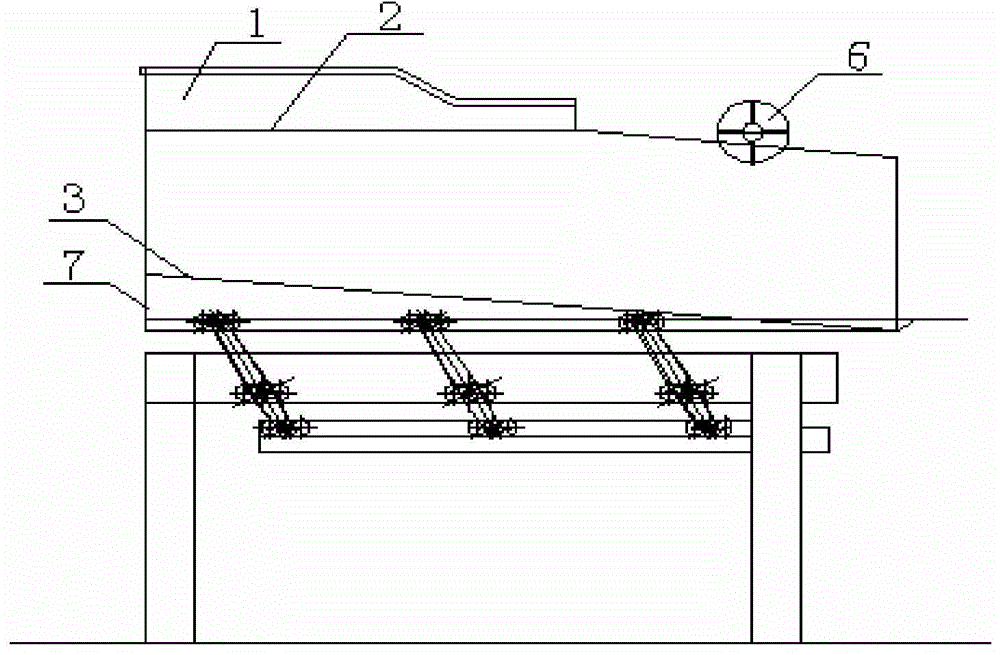

Roller applicable to cross wedge rolling shaft type parts and production technology

The invention relates to a roller and a production technology, in particular to a roller applicable to cross wedge rolling shaft type parts and a production technology. The roller is prepared from chemical ingredients comprising 1.8-2.2% of C, 0.4-0.60% of Si, 0.8-1.2% of Mn, 0.03% or less of P, 0.025% or less of S, 1.2-1.6% of Cr, 1.6-2.0% of Ni, 0.6-0.8% of Mo, 0.2-0.4% of V, 0.2-0.4% of Nb andthe balance Fe and a small amount of residual elements, then, two-furnace smelting is carried out, yttrium-based rare earth alterant is added, and a special heat treatment technology is carried out, so that the roller is obtained. The phenomenon that carbide exists in a discontinuous (granular) state is changed by optimally allocating the chemical ingredients, particularly adding niobium and vanadium, and the microscopic structure of the roller is improved. Meanwhile, by adding the yttrium-based heavy rare earth alterant for purifying molten steel in the steel melting process, the purity is improved, the comprehensive mechanical property of the roller is improved, the yield and quality of rolled products are improved, the service life of the roller is prolonged, and the purposes of cost decreasing and benefit increasing for enterprises are achieved.

Owner:湖州中杭轧辊有限公司

Method for treating backflow fracturing fluid reclaimed from exploitation of shale gas

ActiveCN104445522AReduce pollutionEmission pollution zeroWaste water treatment from quariesWater treatment parameter controlFracturing fluidWater resources

The invention discloses a method for treating the backflow fracturing fluid reclaimed from exploitation of shale gas. The method comprises the following steps: (S1) detecting the content of ions in the backflow fracturing fluid, and filling the backflow fracturing fluid which is up to the standard in a container for later use, wherein if the content of K<+> is controlled to be less than or equal to 1,500mg / L, the content of Ca<2+> is controlled to be less than or equal to 600mg / L, the content of Na<+> is controlled to be less than or equal to 2,000mg / L, the content of Mg<2+> is controlled to be less than or equal to 1,000mg / L, the content of NH<4+> is controlled to be less than or equal to 600mg / L, the content of total Fe is controlled to be less than or equal to 25mg / L, the content of Cl<-> is controlled to be less than or equal to 3,000mg / L, the content of Al<3+> is controlled to be less than or equal to 30mg / L, the content of SO4<2-> is controlled to be less than or equal to 200mg / L, and the content of COD is controlled to be less than or equal to 300mg / L, the backflow fracturing fluid is deemed to be up to the standard; and (S2) carrying out comparison test on the backflow fracturing fluid which is up to the standard and is filled in a container for later use with two formulas before the backflow fracturing fluid is injected underground to be used for fracturing, and evaluating the kinematic viscosity of slippery water. The method disclosed by the invention is particularly suitable for treating the backflow fracturing fluid immediately after the backflow fracturing fluid is reclaimed or without exceeding 10 days after the backflow fracturing fluid is reclaimed and stored. By adopting the method, various mechanical impurities, ions and bacteria affecting the reclamation of the backflow fracturing fluid can be removed, the treated backflow fracturing fluid can meet the reuse requirement, the water consumed for exploiting the shale gas can be reduced greatly, and the win-win goal of reducing cost and protecting environment can be realized.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Method for preparing SE (Selective Emitter) solar cell by utilizing sectional type mask graph

InactiveCN103219430AGuaranteed or improved conversion efficiencyLess materialFinal product manufactureSemiconductor devicesBiochemical engineeringSolar cell

The invention discloses a method for preparing an SE (Selective Emitter) solar cell by utilizing a sectional type mask graph. The method comprises the step of forming an SE mask graph on a diffusing surface by utilizing an SE etching mask sizing agent, wherein the part, which corresponds to a thin grid line, of an SE mask is in a sectional type discontinuous shape, thus forming a sectional type SE mark coating covering region. According to the method for preparing the SE solar cell by utilizing the sectional type mask graph, the traditional straight-through type SE mark coating covering region is changed into multiple sectional type SE mark coating covering regions according to a certain rule through an SE etching mask, the purpose that the transfer efficiency of a battery piece is guaranteed or improved is achieved, meanwhile, the dosage of the SE sizing agent is reduced, and the production cost is reduced.

Owner:TIANWEI NEW ENERGY HLDG

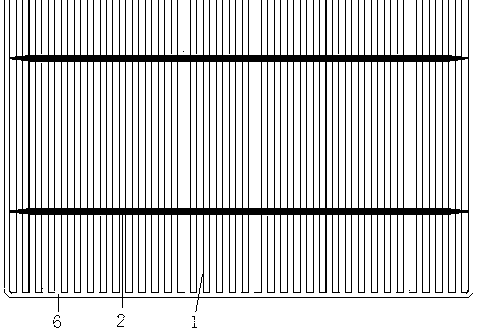

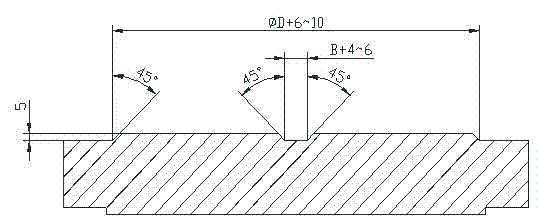

Machining method of heat exchanger tube plate build-up welding

InactiveCN103894838AEasy to operateImprove efficiencyArc welding apparatusOther manufacturing equipments/toolsEngineeringComposite plate

As the number of tube plate build-up welding composite layers of a composite plate heat exchanger increases, a traditional direct build-up welding mode wastes labor and time. The invention provides a machining method of heat exchanger tube plate build-up welding. In the machining method, the method that machining is performed firstly and then build-up welding is conducted is used for machining, therefore, operation is more convenient, and the efficiency is greatly increased; firstly machining is conducted according to the method, the external diameter of a tube plate sealing surface is reduced by 6-10 mm, the depth of the tube plate sealing surface is 5 mm, and 45-degree chamfering is conducted on the tube plate sealing surface, the width of a partition plate groove is increased by 4-6 mm, the depth of the partition plate groove is 5 mm, the two sides of the partition plate groove are chamfered by 30-60 degrees, and a 3-5 mm stainless steel composite layer is formed in a build-up welding mode. According to the method, the purposes of energy conservation, consumption reduction, cost decreasing and efficiency increasing are achieved.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

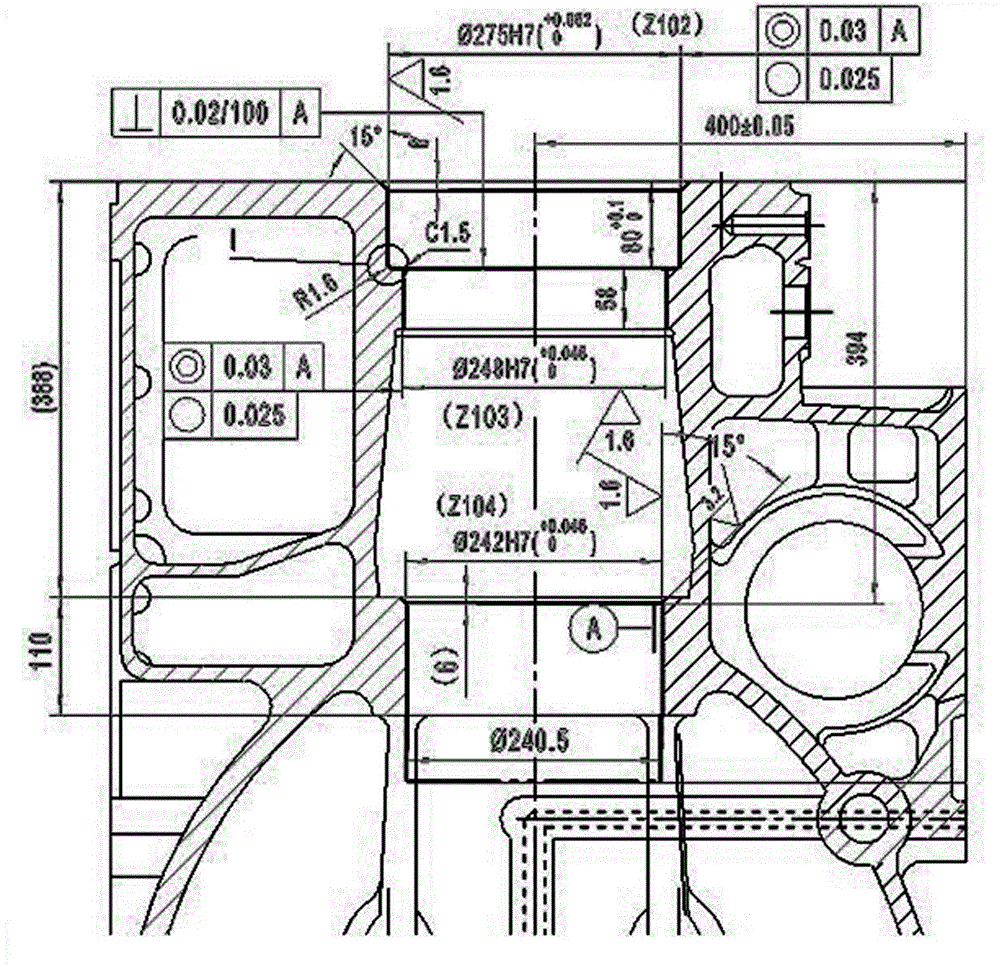

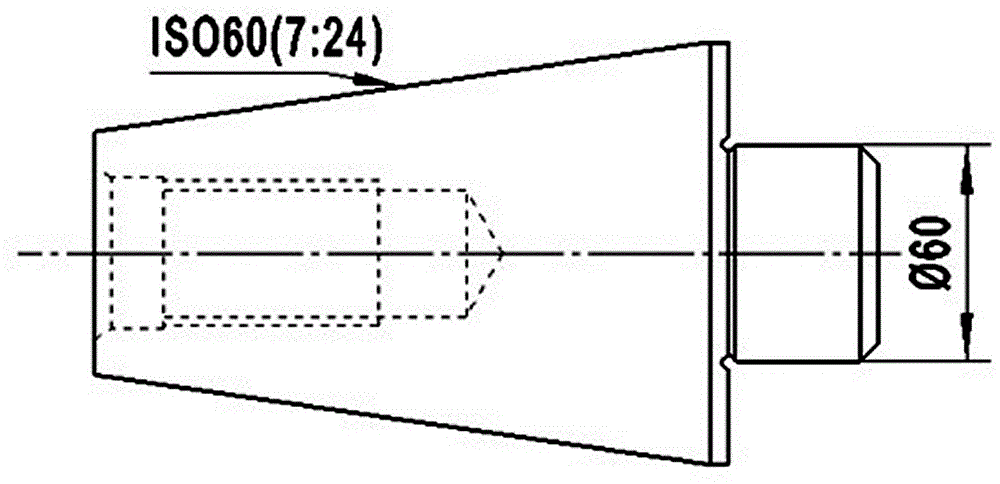

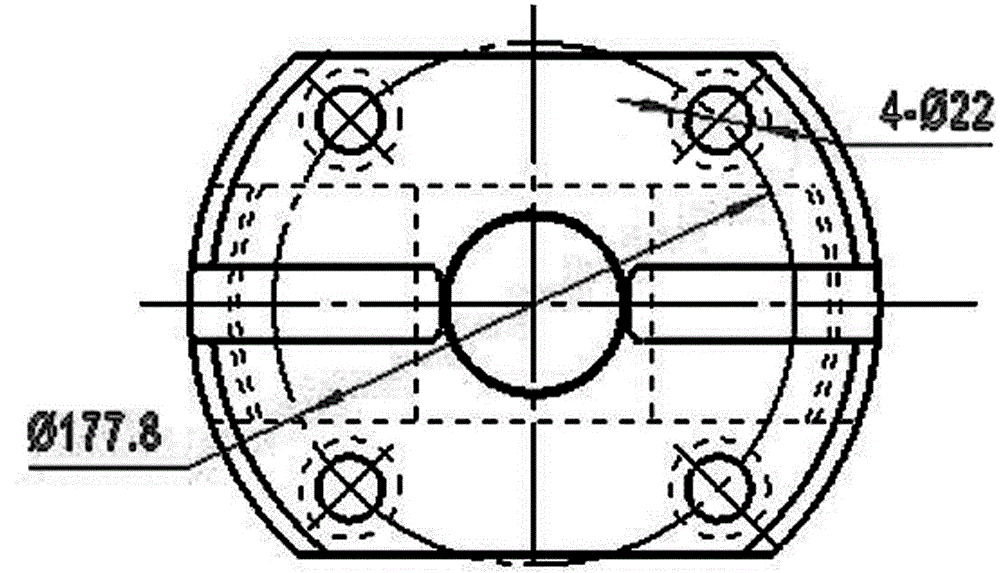

Method for machining cylinder holes in diesel engine body

ActiveCN104858471AReduce in quantityImprove productivityBoring/drilling machinesEngineeringDiesel engine

The invention discloses a method for machining cylinder holes in a diesel engine body. The method comprises steps as follows: machining elements of the cylinder holes in the engine body are classified, analyzed one by one and allocated to rough machining combined boring tools and finish machining combined boring tools; machining elements required to be machined are machined through the rough machining combined boring tools and the finish machining combined boring tools respectively; during machining, resistance to cutting is balanced, and vibration of the tools is reduced. With the adoption of the method, the tool changing frequency and the number of the tools can be reduced, so that the tool changing time is saved, the cost decreasing and benefit increasing purposes are achieved, and the yield of the diesel engine body is increased.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

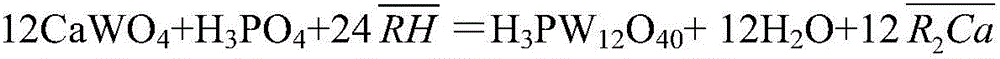

Scheelite decomposing method

The invention discloses a scheelite decomposing method. The method comprises the following steps: after cation exchange resins and phosphoric acid solution are heated and uniformly mixed, scheelite is added for decomposing; and after the decomposing reaction is finished, phosphotungstic heteropoly acid solution is obtained through filtration and separation. The method uses the cation exchange resins for cooperating with the phosphoric acid to decompose the scheelite to directly obtain the phosphotungstic heteropoly acid solution with higher purity, so that the problem of influence on the resolution ratio by wrapping of the scheelite by tungstic acid in the process of decomposing the scheelite by traditional acid is solved, the problem of equipment corrosion due to use of concentrated acid in traditional acid decomposition is overcome, and the high-efficiency clean decomposion of the scheelite is realized.

Owner:CENT SOUTH UNIV

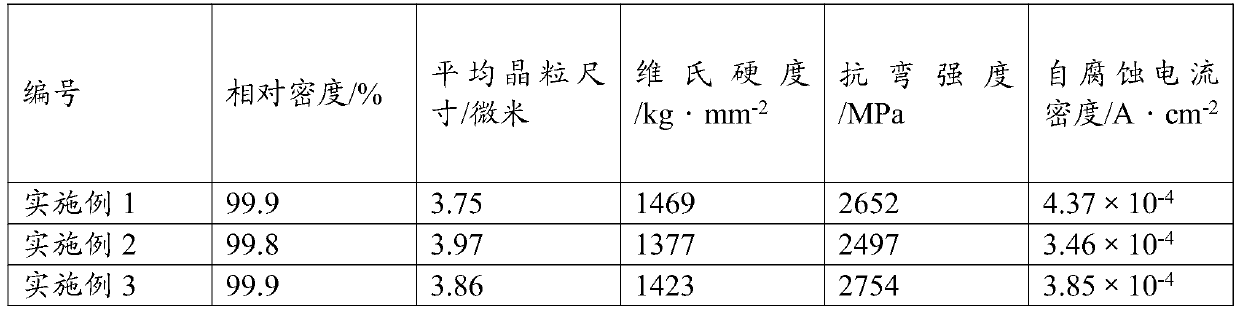

Multi-component hard alloy and preparation method thereof

ActiveCN110229989AImprove high temperature mechanical propertiesHigh feasibilityTransportation and packagingMetal-working apparatusSolid solution strengtheningCemented carbide

The invention provides a WC-(Tix, Cr1-x)3C2-(Fe, Cr)-(Ni, Cu)-Co multi-component hard alloy and a preparation method thereof, and belongs to the field of high-temperature ceramic manufacturing. According to the multi-component hard alloy and the preparation method thereof, an Fe-Cr alloy and an Ni-Cu alloy are adopted to partially replace Co as a bonding phase of a WC-based hard alloy, the solid solution strength effect is obvious and the feasibility is high; and WC is partially replaced by (Tix, Cr1-x)3C2 solid solution carbide, the cost is reduced while the effect is improved, and Co and WCsources are saved. The preparation method comprises the steps of sequentially carrying out wet ball-milling, compression forming and vacuum hot pressing sintering after WC powder, (Tix, Cr1-x)3C2 powder, Fe-Cr prealloy powder, Ni-Cu prealloy powder and Co powder are mixed. The preparation method is stable in process, high in precision, and high in repeatability, and a novel multi-component hard alloy with excellent hardness, bending strength and self-corrosion current density performance.

Owner:SHAANXI SCI TECH UNIV

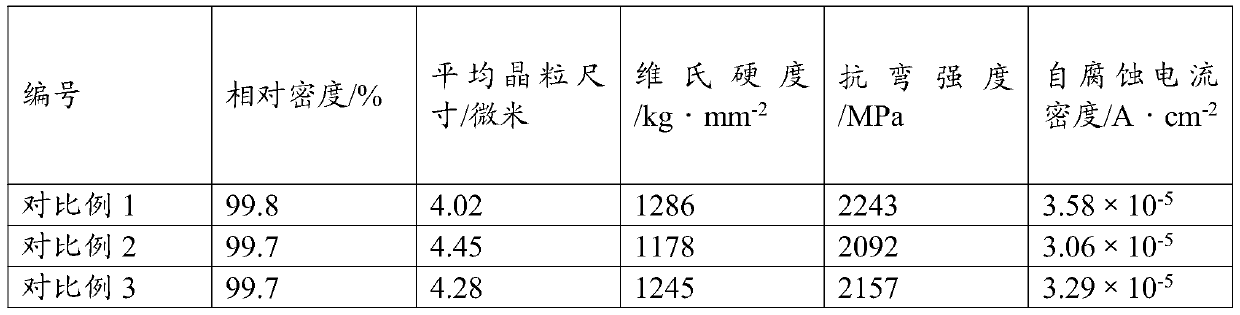

Scale inhibitor and preparation method thereof

ActiveCN104591412AGood antifouling effectInhibition formationScale removal and water softeningDiluentStrontium

The invention discloses a scale inhibitor and a preparation method thereof. The scale inhibitor disclosed by the invention is composed of modified polyepoxysuccinic acid, organic phosphonate and a diluent, wherein the mass ratio of the modified polyepoxysuccinic acid to the organic phosphonate to the diluent is (1.0 to 1.5): (1.5 to 2.0): (7.0 to 7.5). The preparation method comprises the following steps: mixing the modified polyepoxysuccinic acid, the organic phosphonate and the diluent to obtain the scale inhibitor. The scale inhibitor solution disclosed by the invention has the beneficial effects that scale inhibiting effect is good and inorganic scales such as calcium, magnesium, strontium and barium are effectively prevented from being formed; the adsorption amount of the scale inhibitor solution disclosed by the invention is low; during a process of injecting the scale inhibitor solution in a stratum, a small amount of the scale inhibitor solution is only adsorbed by minerals in the stratum, so that the utilization efficiency of the scale inhibitor can be effectively increased; the scale inhibitor solution disclosed by the invention is long in acting distance, long in validity period, and capable of reducing a construction frequency to achieve the purposes of reducing a cost and improving effects.

Owner:CHINA NAT OFFSHORE OIL CORP +1

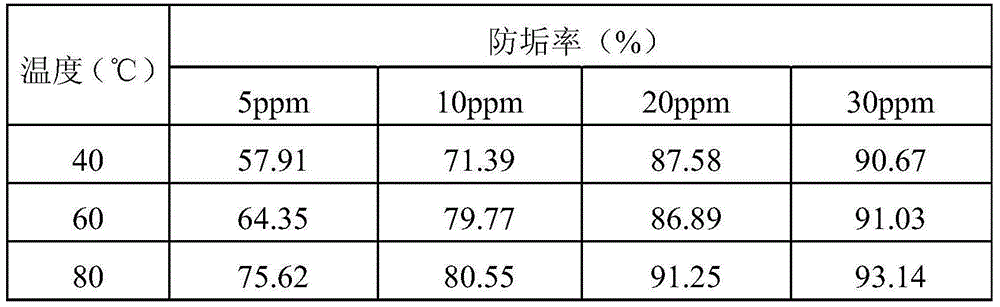

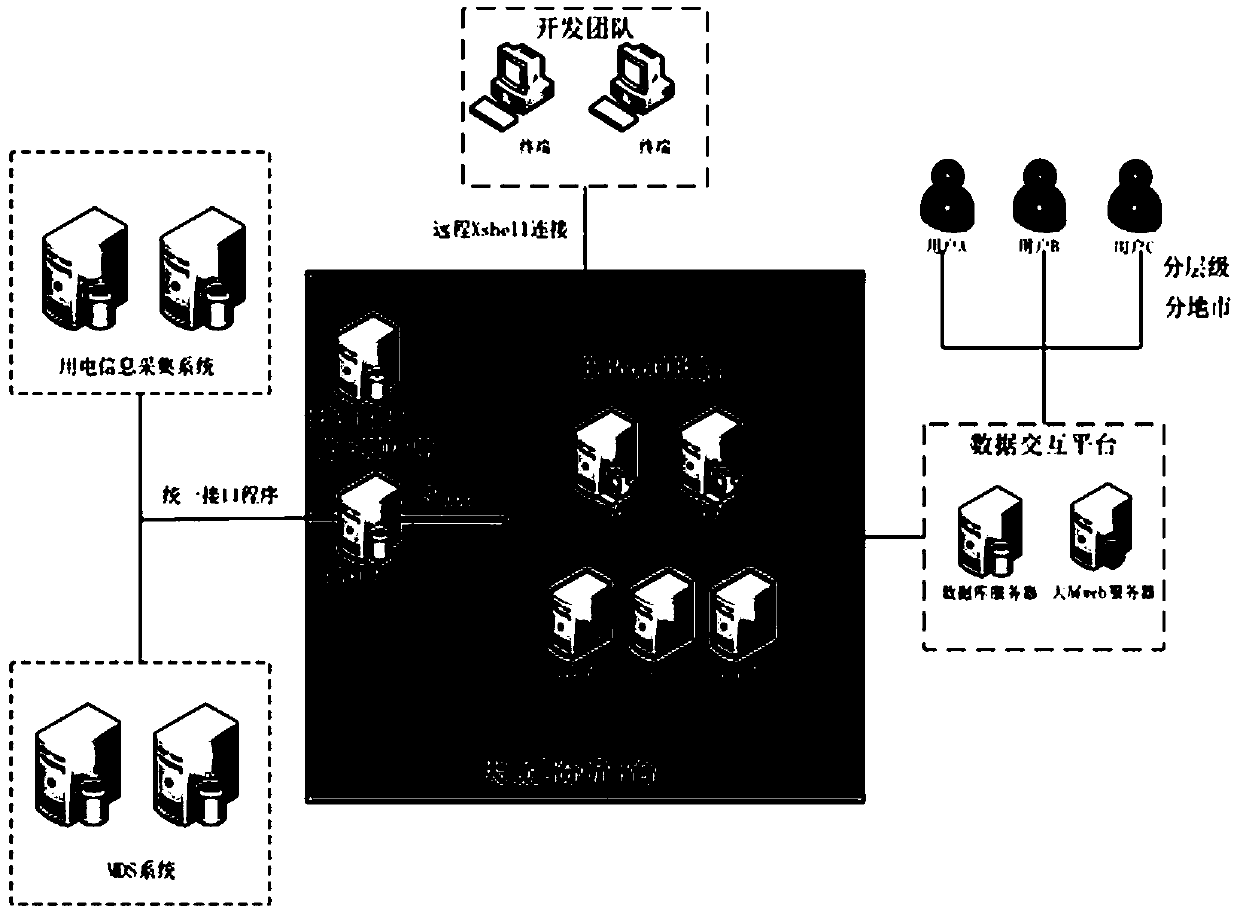

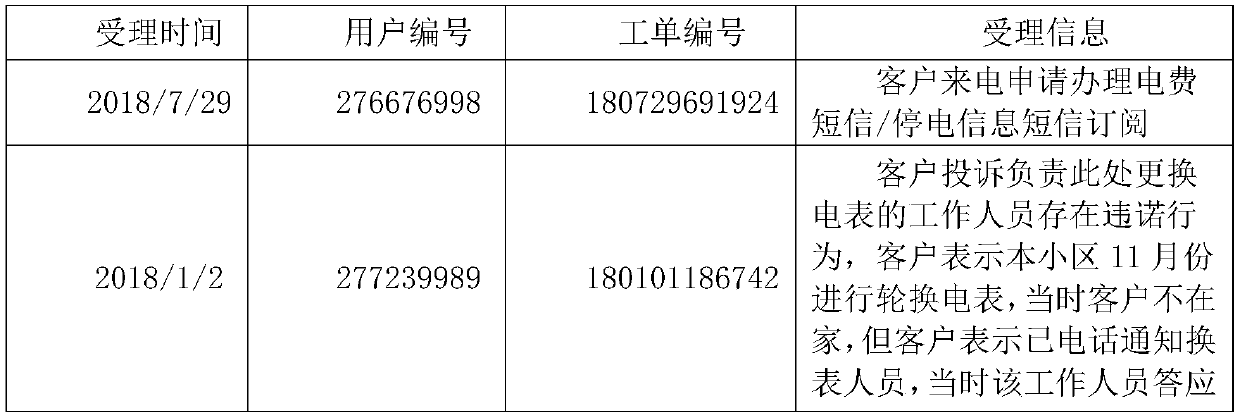

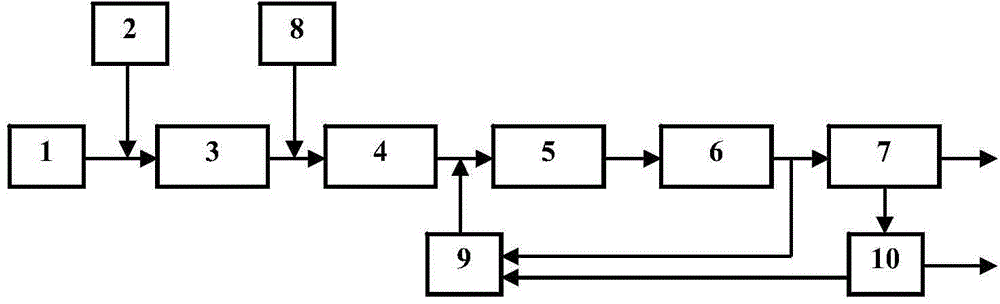

Distribution network accurate investment strategy method based on customer demands

ActiveCN110765268AImprove accuracyImprove experienceNatural language data processingResourcesDistribution transformerPower grid

The invention discloses a distribution network accurate investment strategy method based on customer demands. The method is based on the relationship between customer appeals and a power grid structure. Evaluating models such as an AHP and a fuzzy weight matrix are used; an algorithm for supporting the precise investment work of the distribution network according to the quantitative distribution transformer reliability index is provided; according to the algorithm, the customer appeal and the reliability identification result of the power grid operation structure are fused, the distribution transformer with strong customer appeal and poor operation state is preferentially invested, the customer service level can be improved, the operation cost can be reduced, and the purpose of accurate investment of the distribution network is further achieved.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +3

Acrylonitrile wastewater treatment method

ActiveCN105271605AImprove removal efficiencyWater up to standardMultistage water/sewage treatmentAcrylonitrileTherapeutic effect

The invention belongs to the technical field of industrial wastewater treatment, and concretely relates to an acrylonitrile wastewater treatment method. The method comprises the steps of homogenization, acidification, denitrification, nitrification and deposition. TMPD wastewater with very good biodegradability can be supplemented in the acrylonitrile wastewater treatment process as a carbon source, so the COD and total nitrogen treatment effect of acrylonitrile wastewater by a system is improved, and the problem of difficult standard reaching of direct treatment of the TMPD wastewater is solved, that is, purposes of waste control by waste, cost reduction and effect improvement are realized; and a new approach is provided for standard reaching treatment of the acrylonitrile wastewater. The method has the characteristics of simple flow and low running cost.

Owner:CHINA PETROLEUM & CHEM CORP

Method for producing stalks by expanded stems

ActiveCN104872811AReasonable structureGood uniformity of stemsTobacco treatmentHorticultureMouthfeel

The invention relates to a method for producing stalks by expanded stems. The method includes steps of pretreating the expanded stems, arranging the stalks and slicing, ordering and cutting the stalks, burdening, drying, sorting and flavoring and the like. The stalks are mixed into cigarette, tar and CO release can be effectively reduced, the cigarette is little irritant, soft in smoke and comfortable in taste, smoking quality is greatly improved, stability of the cigarette is improved remarkably, cigarette quality is improved, application range of the stalks in the cigarette is broadened, utilization rate is increased, cost is reduced and effect is improved.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

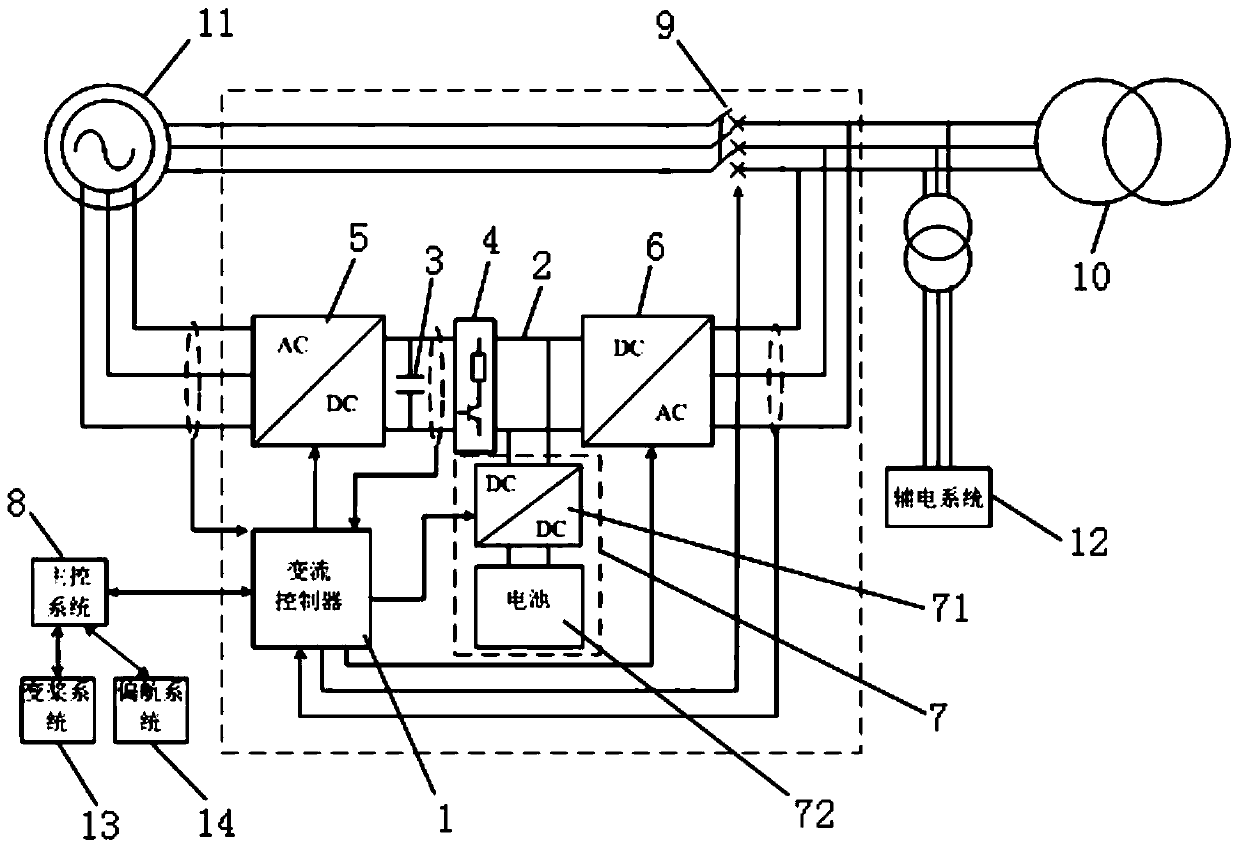

Doubly-fed wind turbine generator converter and black-start method implemented by using same

PendingCN111082461AReduce capacityTo achieve the goal of cost reduction and efficiency increaseClimate change adaptationSingle network parallel feeding arrangementsCapacitanceRotor (electric)

The invention discloses a doubly-fed wind turbine generator converter and a black-start method implemented by using the same. The doubly-fed wind turbine generator converter comprises a converter controller, a direct-current bus, a support capacitor, a Chopper circuit, a machine-side converter, a grid-side converter and a standby power supply system. The direct-current bus is connected between themachine-side converter and the grid-side converter; the support capacitor, the Chopper circuit and the standby power supply system are sequentially connected to the direct-current bus; the machine-side converter, the standby power supply system and the grid-side converter are respectively connected with the converter controller, the converter controller is respectively in communication connectionwith a main control system and a grid-connected circuit breaker, and the converter controller monitors a converter-side alternating-current signal, a converter-side alternating-current signal and a direct-current bus voltage. The standby power supply system capable of being used as a black-start power supply is integrated in the converter, electric energy and auxiliary power supply system power supply required for establishing excitation voltage for a generator rotor are provided, and the problems that existing black-start equipment is high in price, complex in structure and low in utilization efficiency are solved.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com