Patents

Literature

66results about How to "Limited travel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

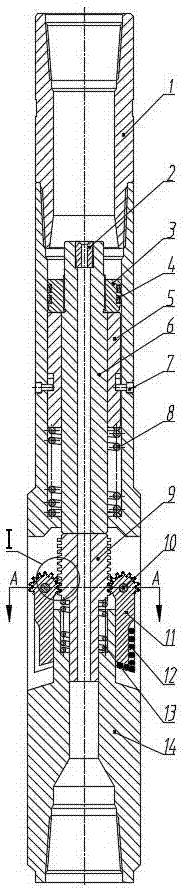

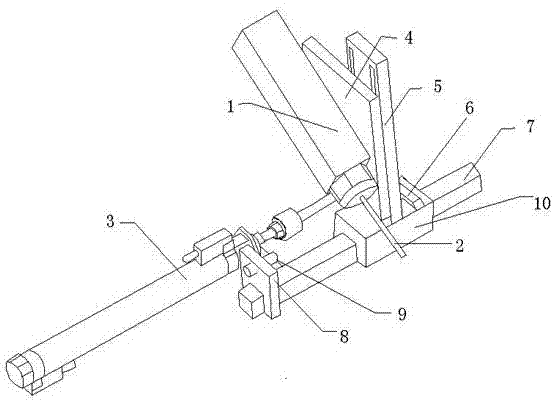

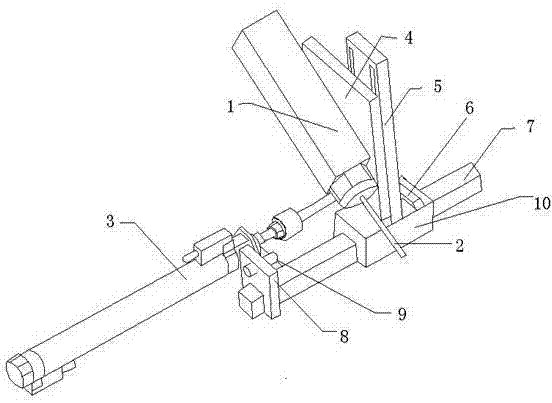

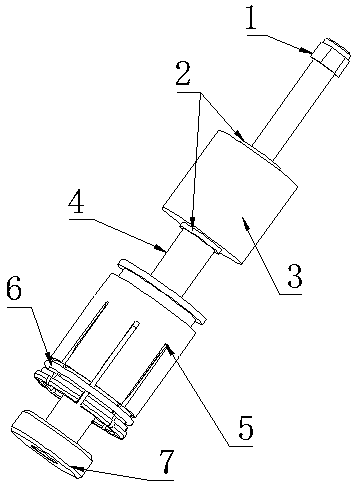

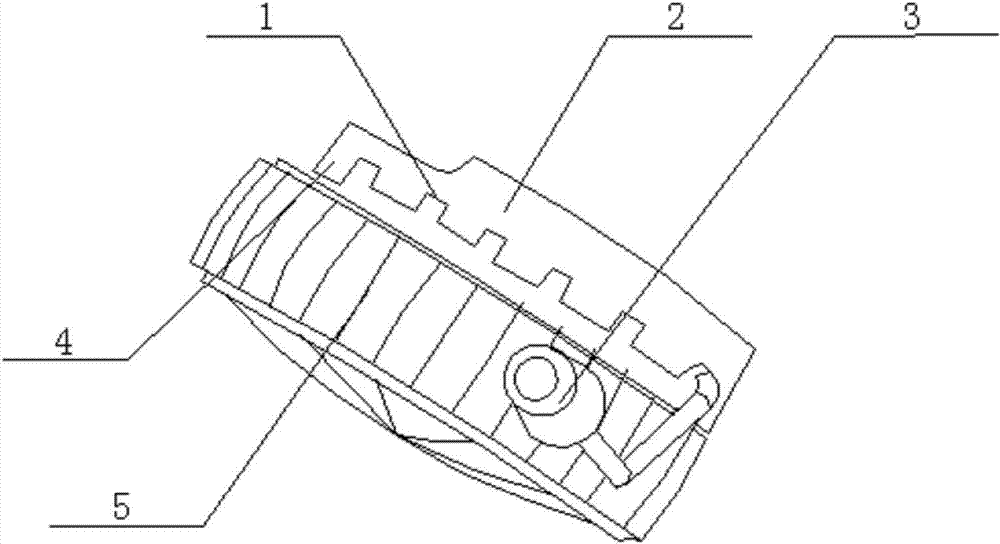

Variable-diameter hydraulic cutter capable of realizing continuous cutting of sleevings with different diameters through gear and rack transmission

InactiveCN107218007ASimple structureAccurately control the opening angleBorehole/well accessoriesGear wheelUpper joint

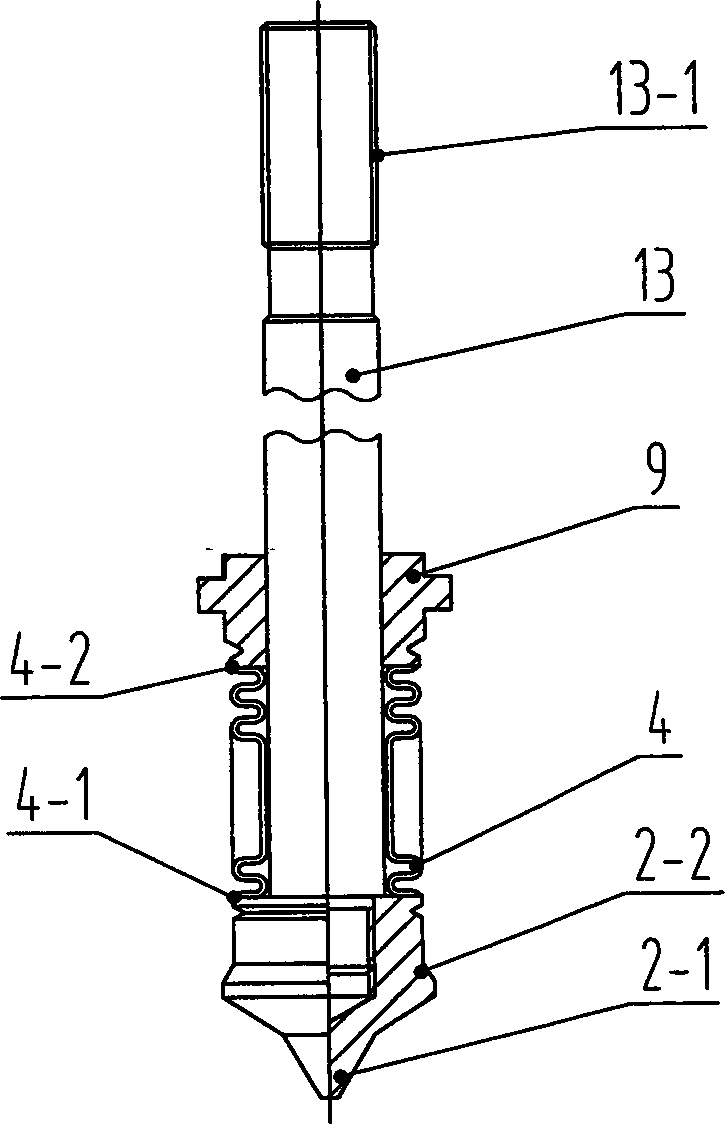

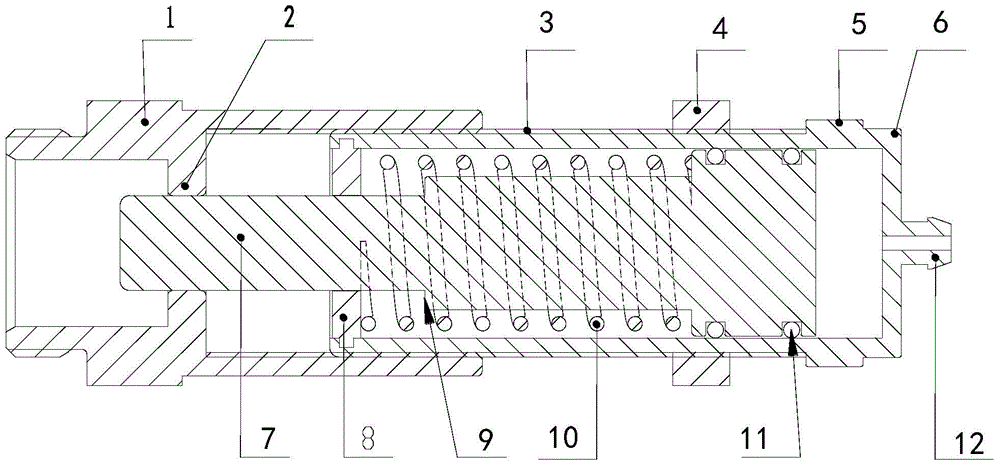

The invention relates to a variable-diameter hydraulic cutter capable of realizing continuous cutting of sleevings with different diameters through gear and rack transmission in the abandoned well operation process. The technical scheme of the cutter is that an upper joint is connected with a housing by threads; a spraying nozzle is located in a piston push rod and connected with the push rod by the threads; an upper spring, a turning mechanism and a piston are mounted on the piston push rod sequentially and arranged inside the housing; cutter knives are arranged uniformly in the circumferential direction and connected with the housing by hinge pins, gear structures of the upper parts of the cutter knife bodies are meshed with a cylindrical rack, the rack and the gears can transmit, and too large displacement of the cutter knives is limited while the opening degrees of the cutter knives are accurately controlled. According to the variable-diameter hydraulic cutter, the piston and the turning mechanism are pushed by the throttling action, gear and rack transmission is matched so as to realize continuous cutting of the sleevings with different diameters, trip times are reduced, the abandoned well operation time is saved, and the sleeving cutting efficiency and the operation reliability in the abandoned well operation process are improved greatly.

Owner:SOUTHWEST PETROLEUM UNIV

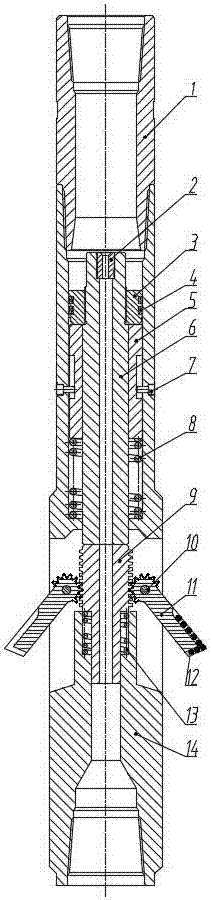

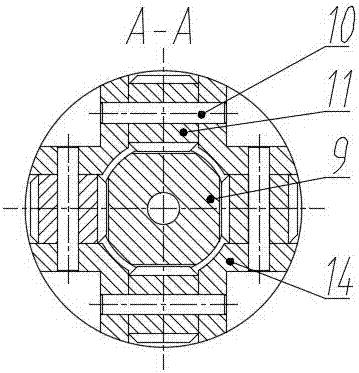

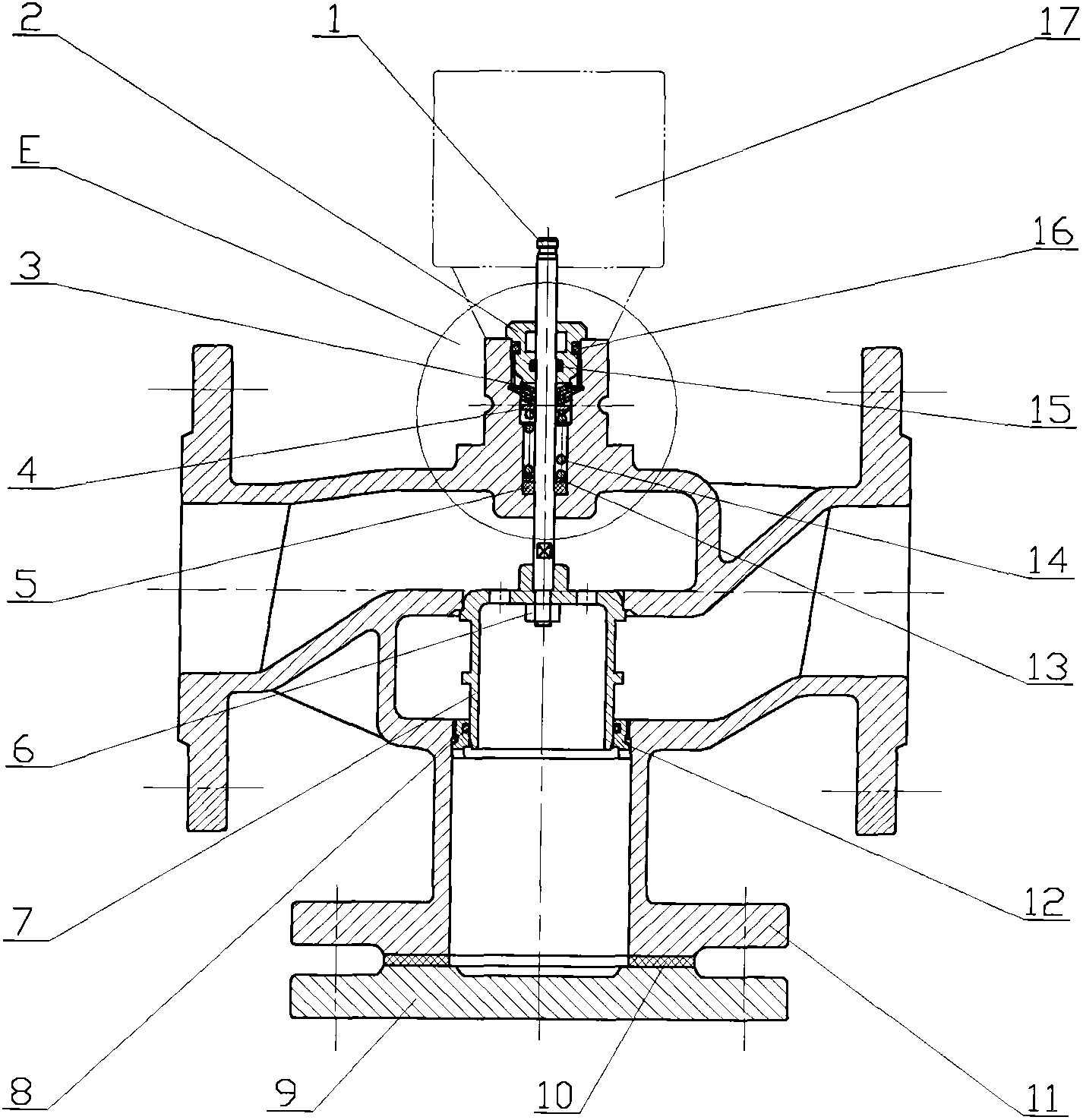

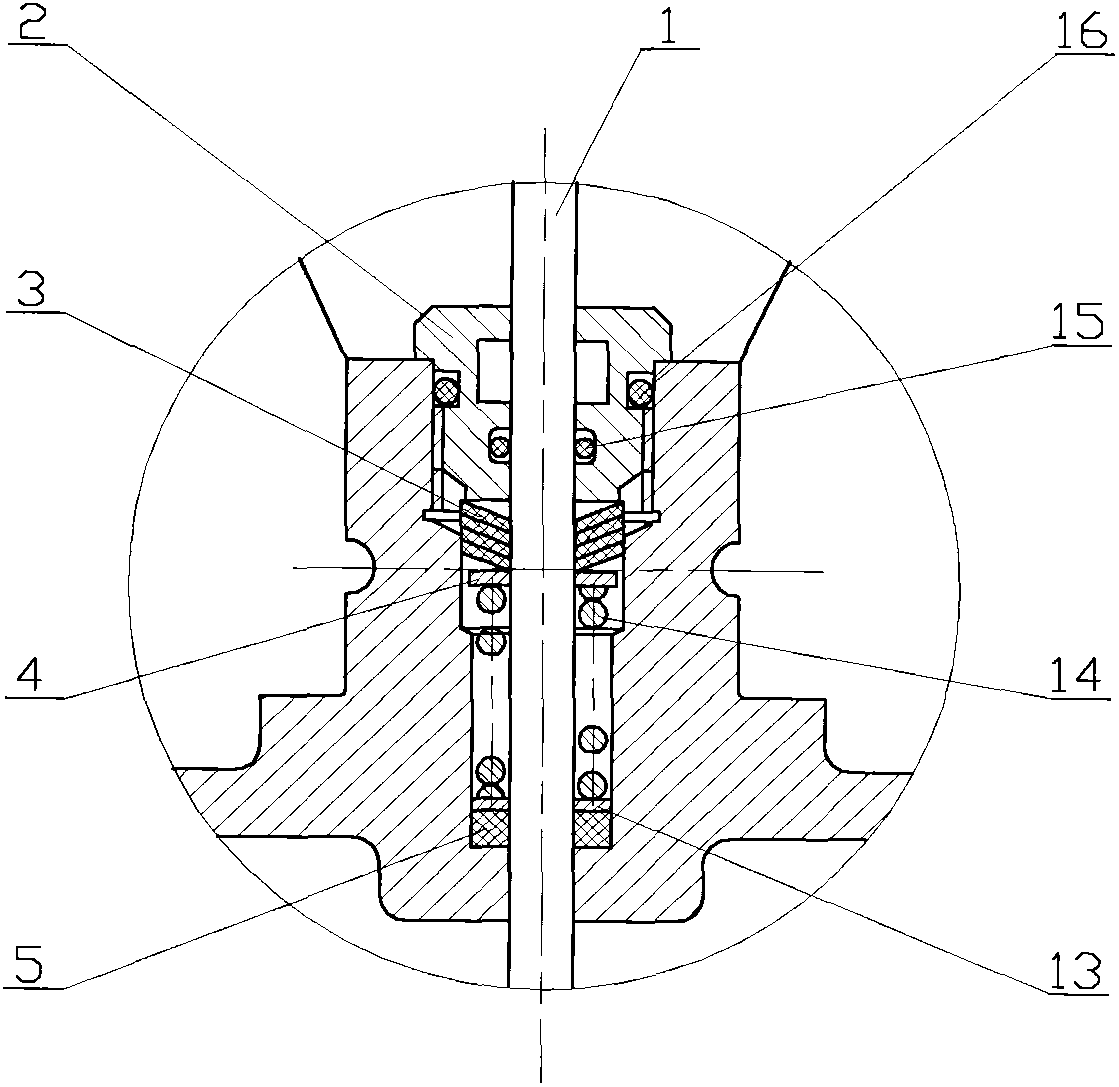

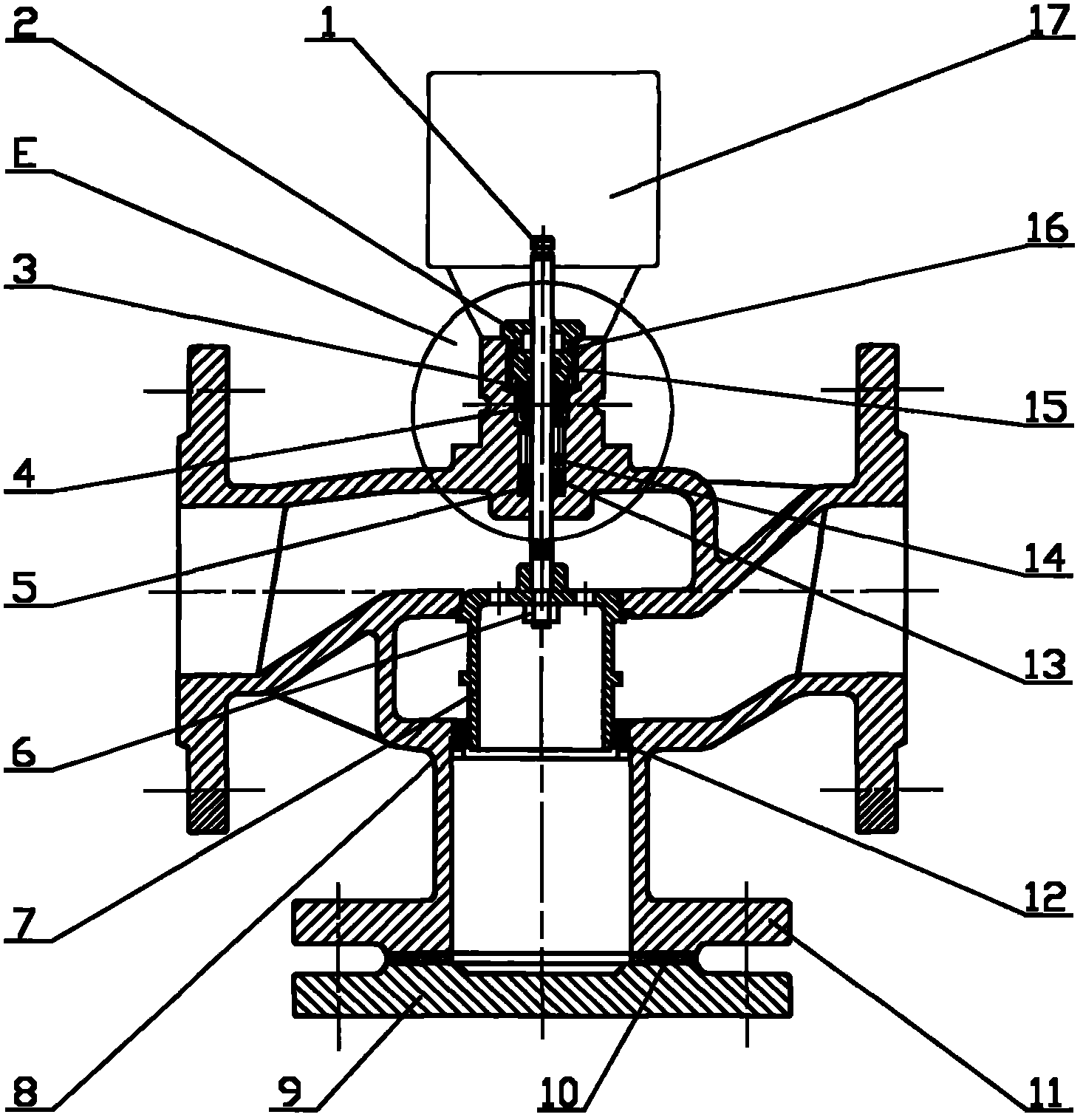

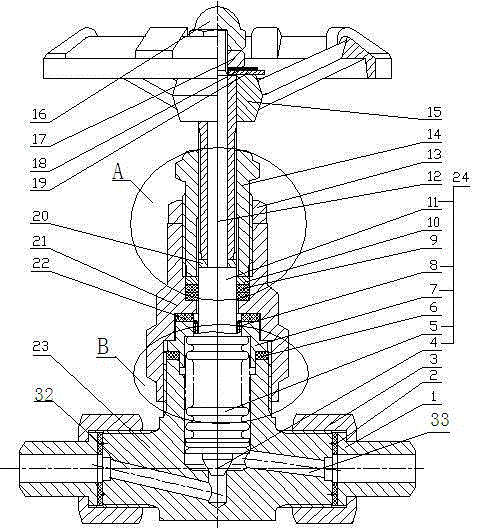

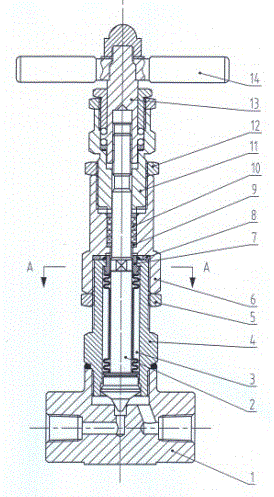

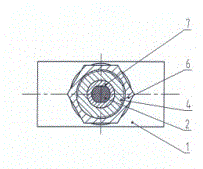

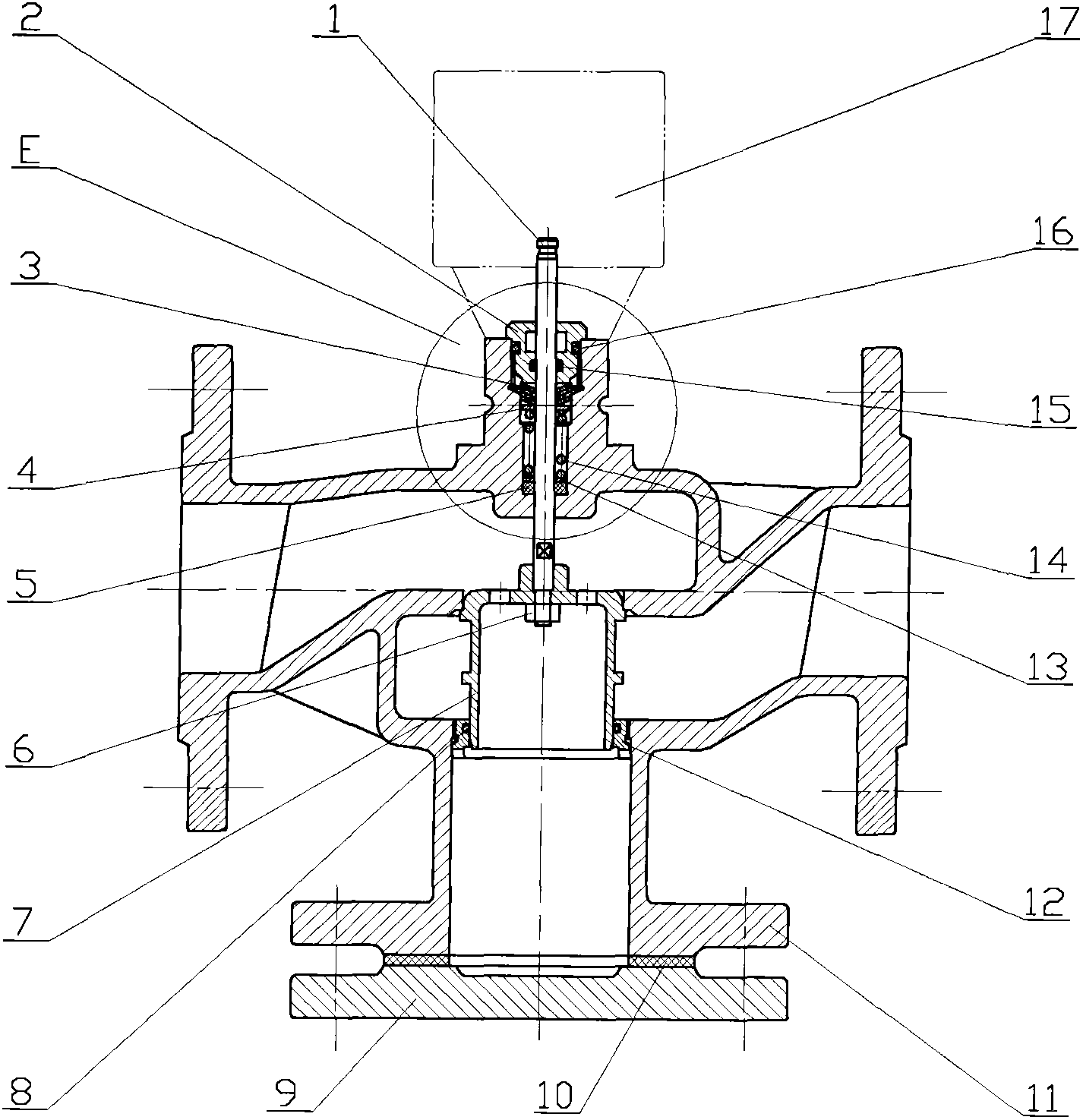

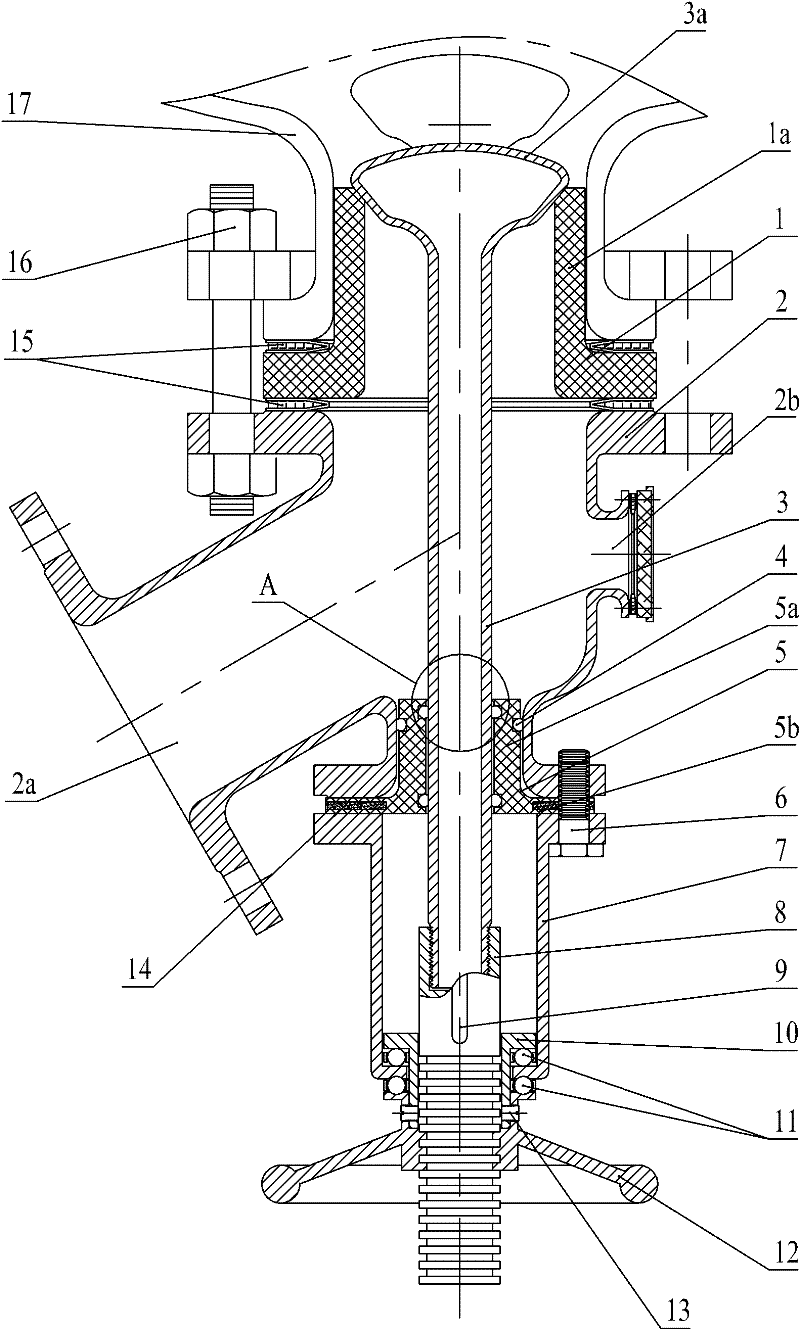

External-pressure type bellows globe valve with non-rotating valve rod

The invention relates to an external-pressure type bellows globe valve with a non-rotating valve rod. The external-pressure type bellows globe valve with the non-rotating valve rod is composed of a valve body, a valve core, a special metal bellows, a valve seat, a valve cover, a flange, filling, the valve rod and an adjusting part. The external-pressure type bellows globe valve with the non-rotating valve rod comprises a quadruple sealing mode which is achieved by closing the valve, opening a stop back seal structure, forming a metal shield when the periphery of the special metal bellows is pressed and filling heat resisting materials. The valve core stop back seal structure is formed after the valve is opened, and the valve rod is matched with a valve rod nut with a rolling rotation steel ball to achieve a non-rotating vertical motion structure. When in use, the external-pressure type bellows globe valve with the non-rotating valve rod has a small friction force and very little abrasion loss, thereby being good in sealing performance, safe, reliable, long in service life, easy to operate and particularly applicable to high-temperature, high-pressure, radioactive, flammable and explosive mediums and places which have damage on aspects such as health, security and environment.

Owner:JIANGSU XINGHE VALVE +1

Driver of window lock

ActiveCN102011512AImprove securityAvoid affecting the effect of useBuilding locksGear wheelRack and pinion

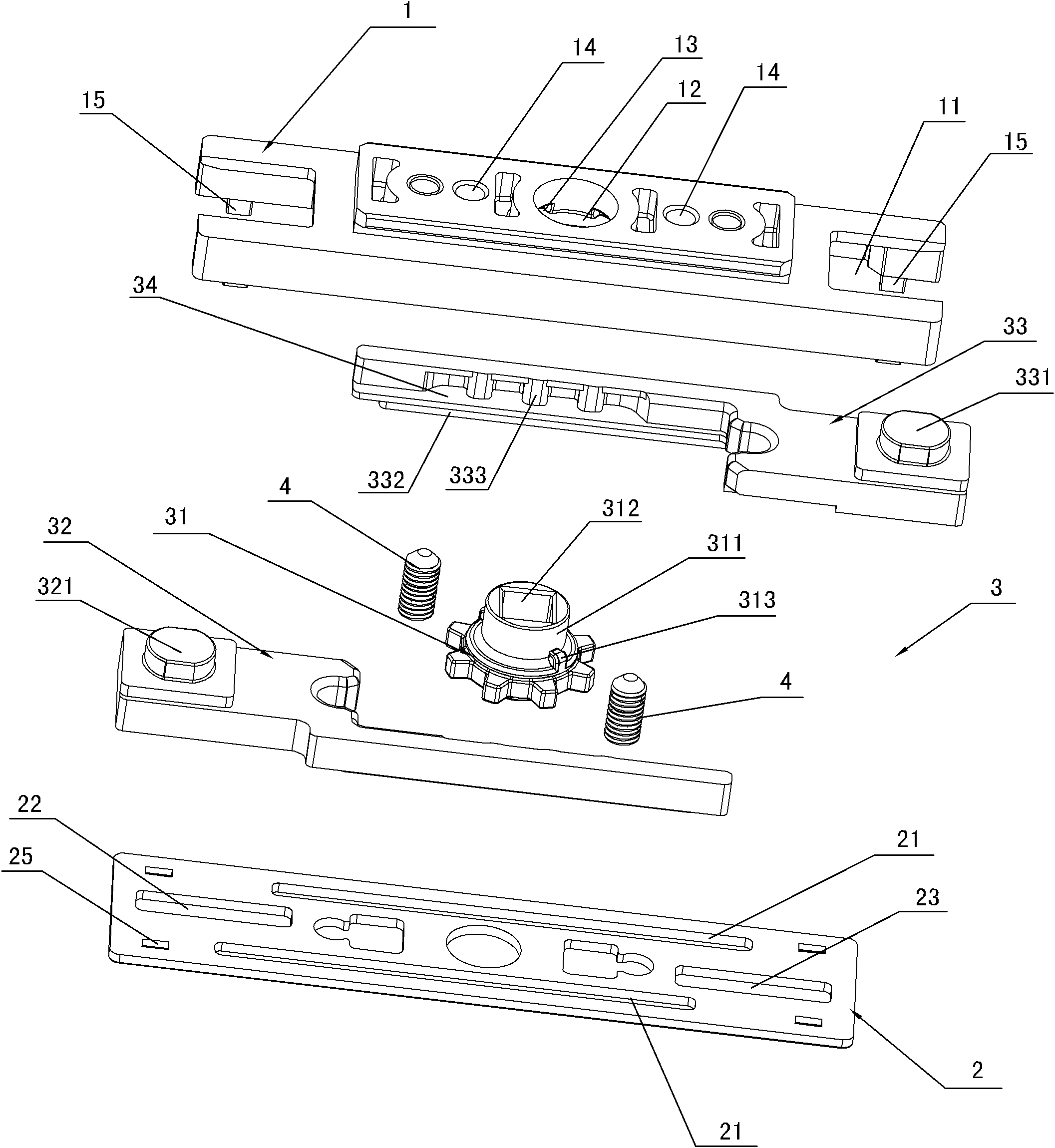

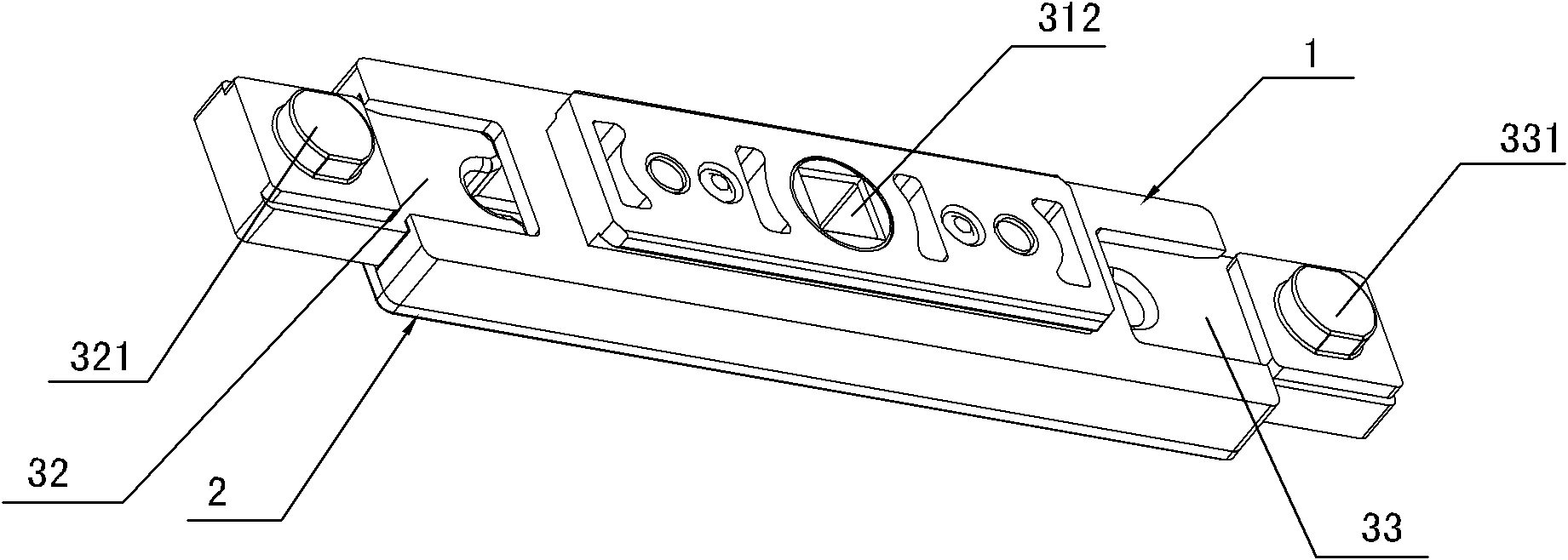

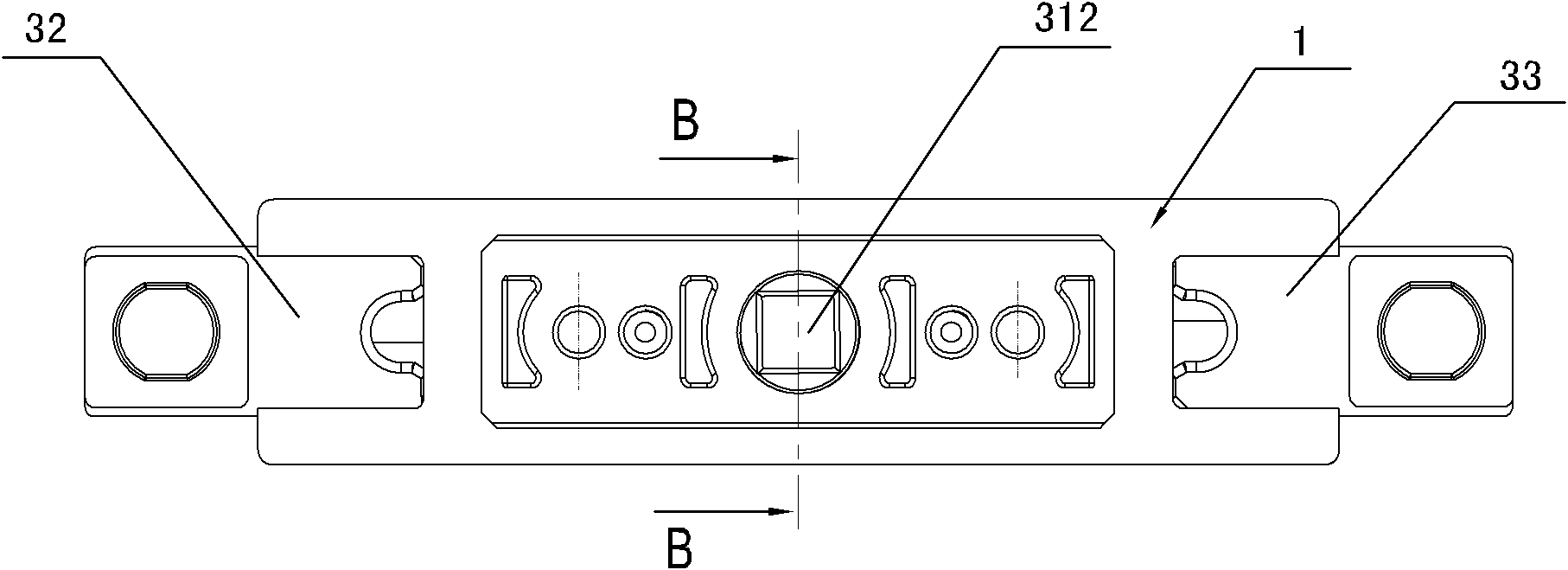

The invention discloses a driver of a window lock. The driver comprises a main body and a base plate, wherein the main body is provided with a gearing which comprises a driving gear, a first driving rod and a second driving rod; one end surface of the driving gear is provided with a cylinder bulge which is jointed with a through hole arranged on the main body in an embedding mode; the inside surfaces of the rod parts of the first driving rod and the second driving rod are respectively provided with a rack meshed with the tooth part of the driving gear; guiding limit ribs, which are located bybeing matched with guiding limit grooves arranged at two sides of the base plate, are respectively arranged below the rod parts of the first driving rod and the second driving rod; and the end edges of the first driving rod and the second driving rod are respectively provided with a connecting bulge, and the connecting bulges are located by being matched with displacement slots arranged at two ends of the main body. The driver provided by the invention has the advantages that the tooth part and rack of the driving gear are mutually matched, the guiding limit ribs and the guiding limit groovesare mutually matched, and the cylinder bulge is jointed with the through hole in an embedding mode, thereby enabling the bidirection displacement of the first driving rod and the second driving rod to be realized under the action of external force.

Owner:联程机械(宁波)有限公司

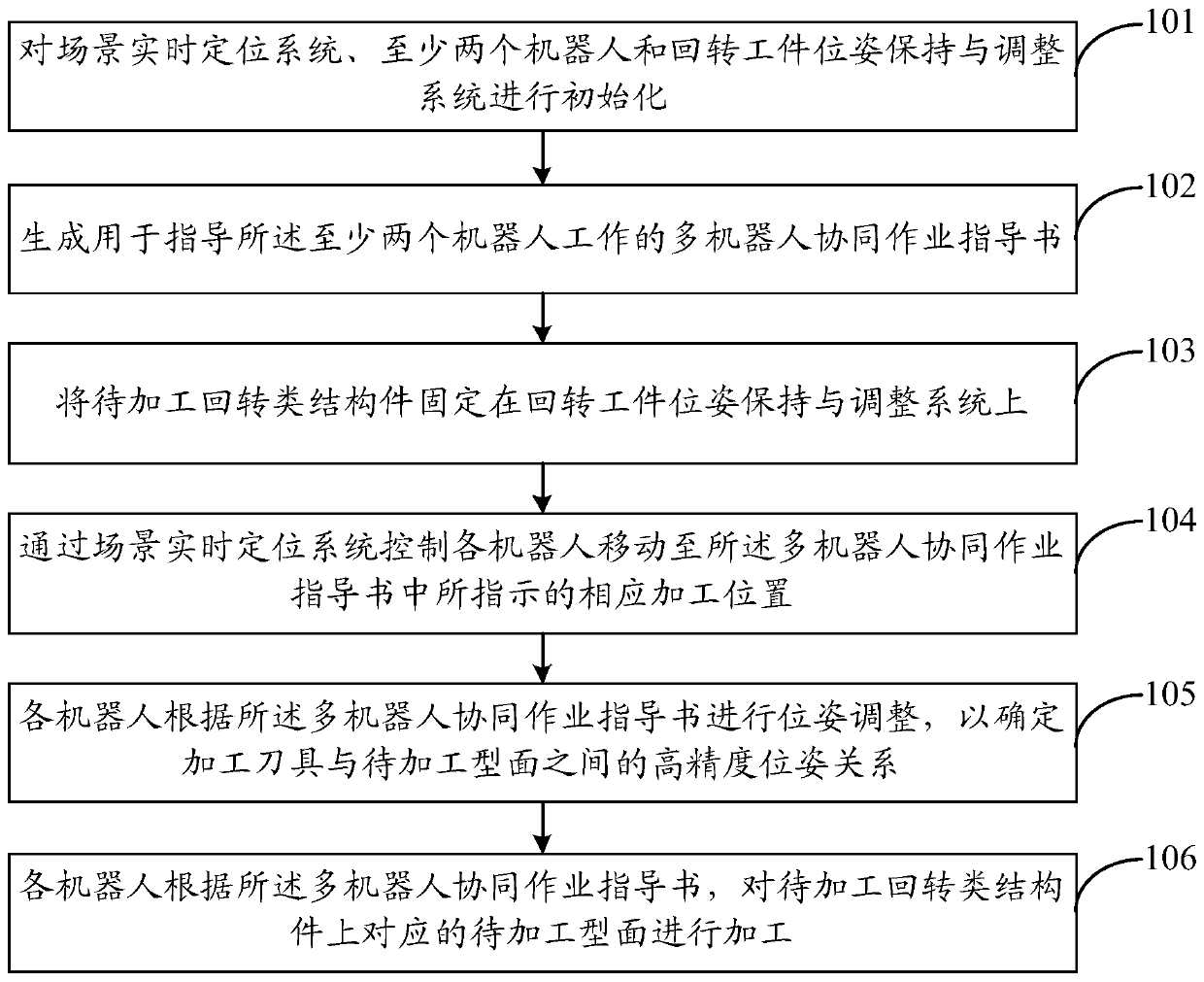

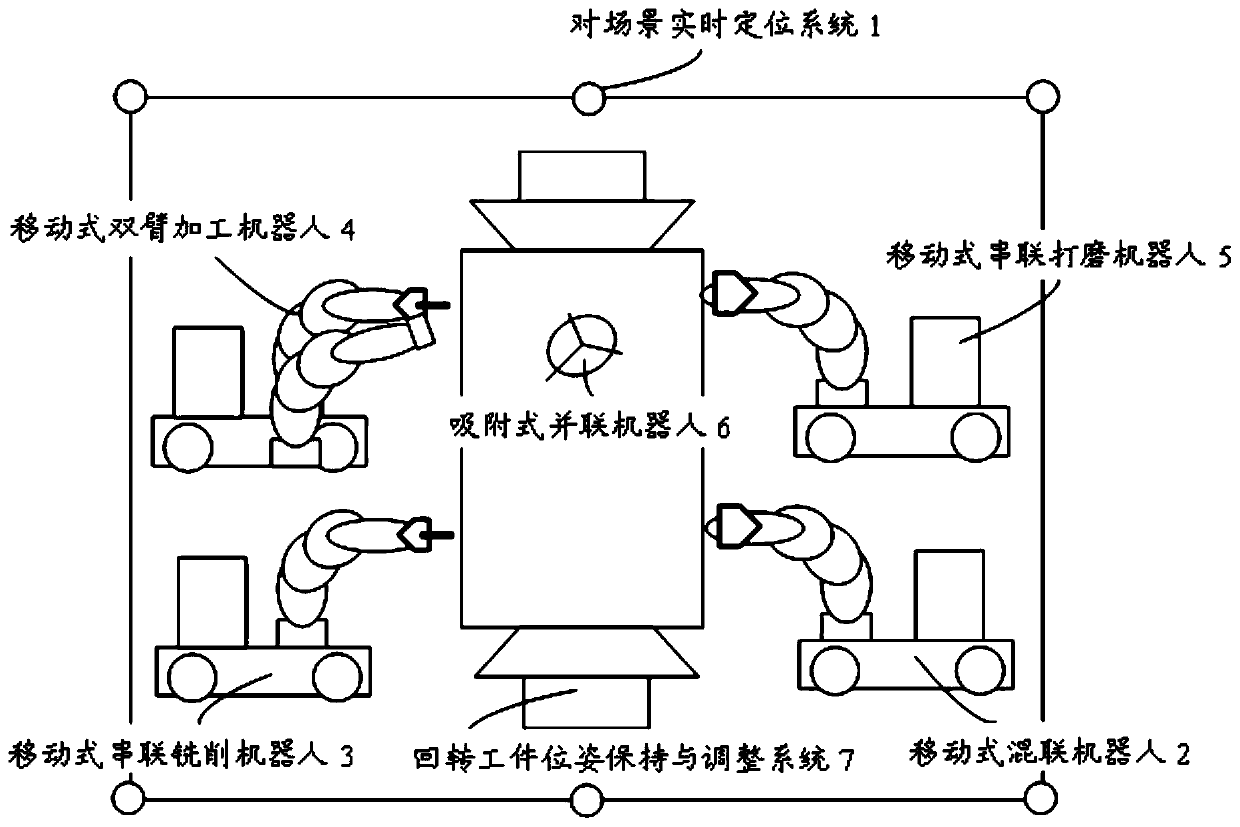

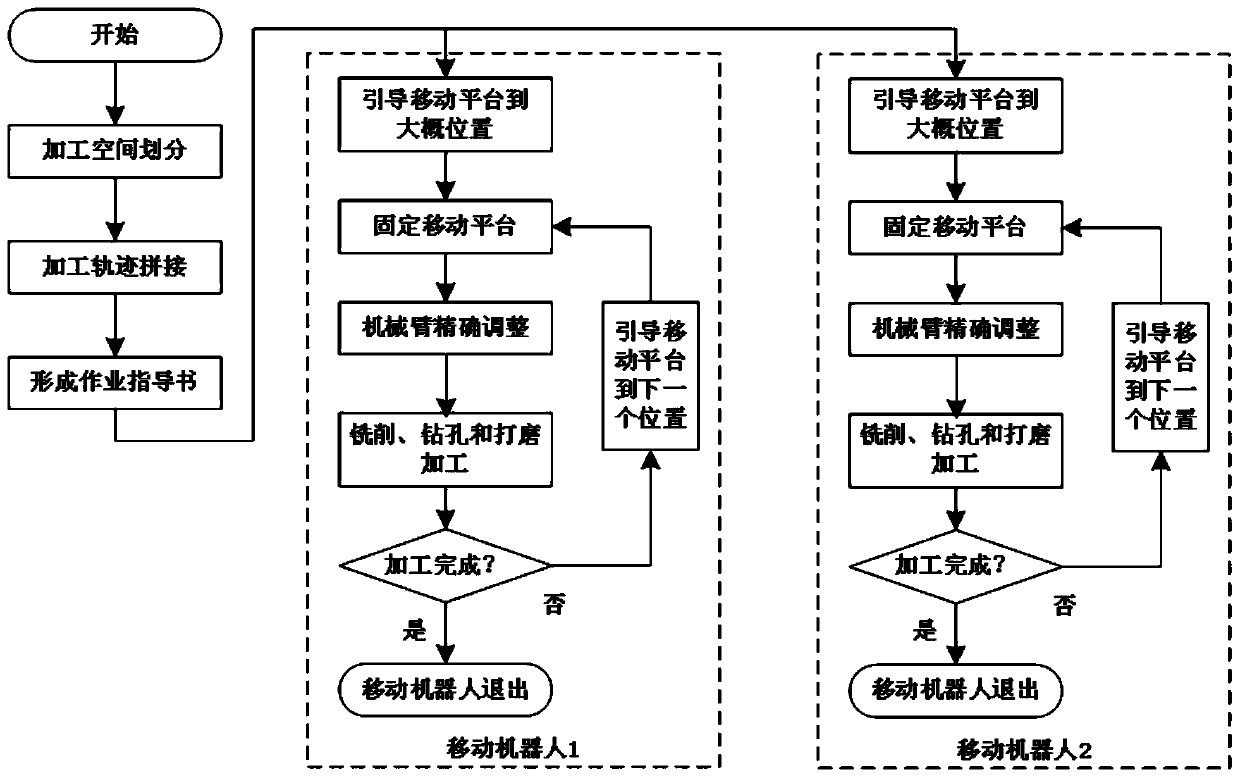

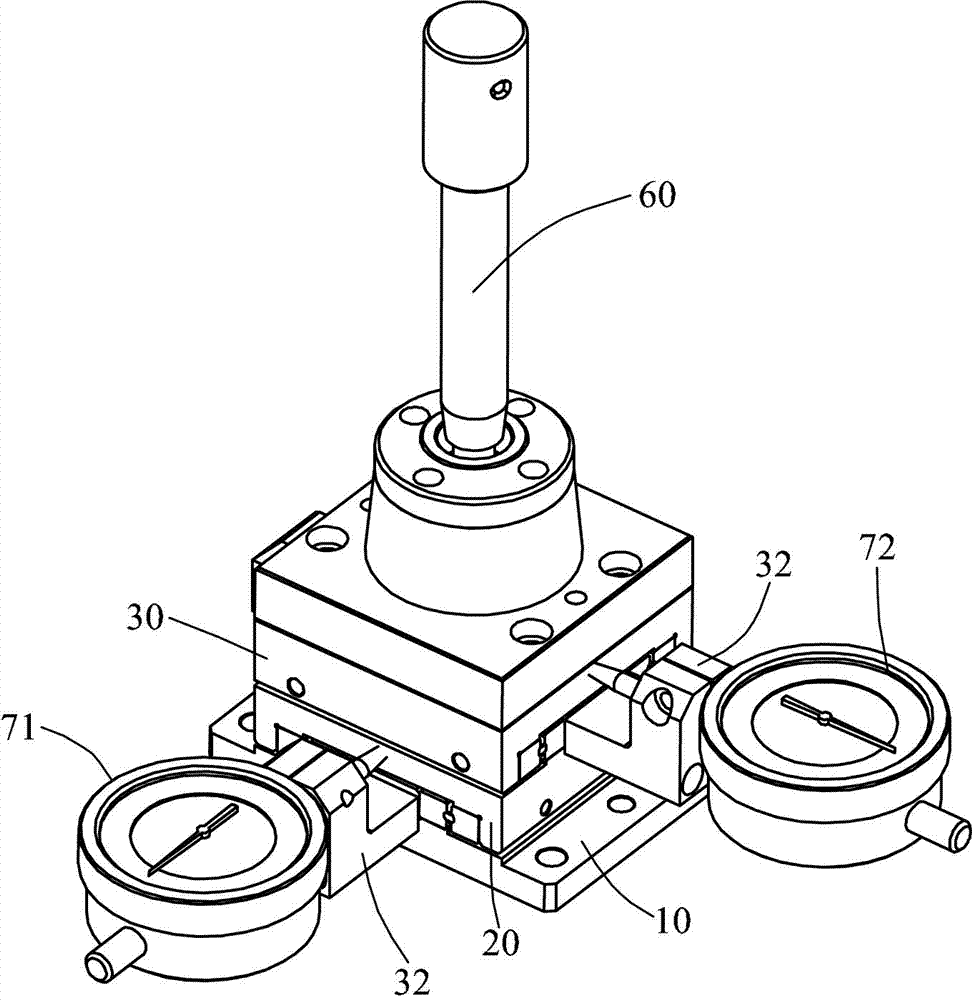

Multi-robot machining method for rotary structural part

ActiveCN109849019AIncrease the level of automationImprove processing efficiencyProgramme-controlled manipulatorGripping headsRobot machiningEngineering

The invention discloses a multi-robot machining method for a rotary structural part. The multi-robot machining method for the rotary structural part comprises the following steps: initializing a real-time scene location system, at least two robots, and a rotary workpiece position-posture keeping and adjustment system; generating multi-robot collaborative operation instruction; fixing the rotary structural part to be machined to the rotary workpiece position-posture keeping and adjustment system; controlling the robots to move to corresponding machining positions through the real-time scene location system; carrying out position-posture adjustment by the robots according to the multi-robot collaborative operation instruction to determine a high-accuracy position-posture relationship betweena machining tool and profiles to be machined; and machining the corresponding profiles to be machined on the rotary structural part to be machined by the robots according to the multi-robot collaborative operation instruction. Through the multi-robot machining method for the rotary structural part, parallel milling, drilling and grinding for a plurality of machining surfaces on a large rotary structure are realized; and due to a parallel operation method, the automation level and the machining efficiency of the large rotary structure can be effectively increased.

Owner:BEIJING SATELLITE MFG FACTORY +1

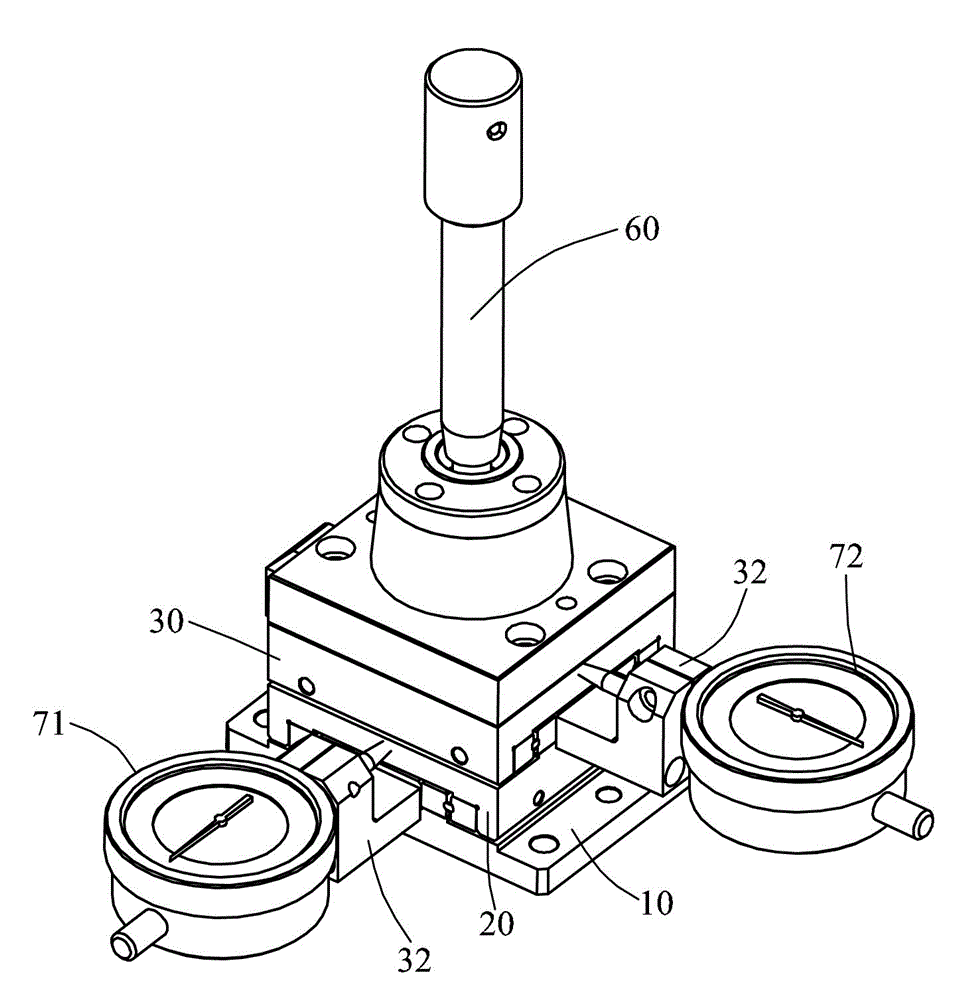

Installation hole detection device

InactiveCN102735133AAccurate measurementSimple structureMechanical measuring arrangementsEngineering

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

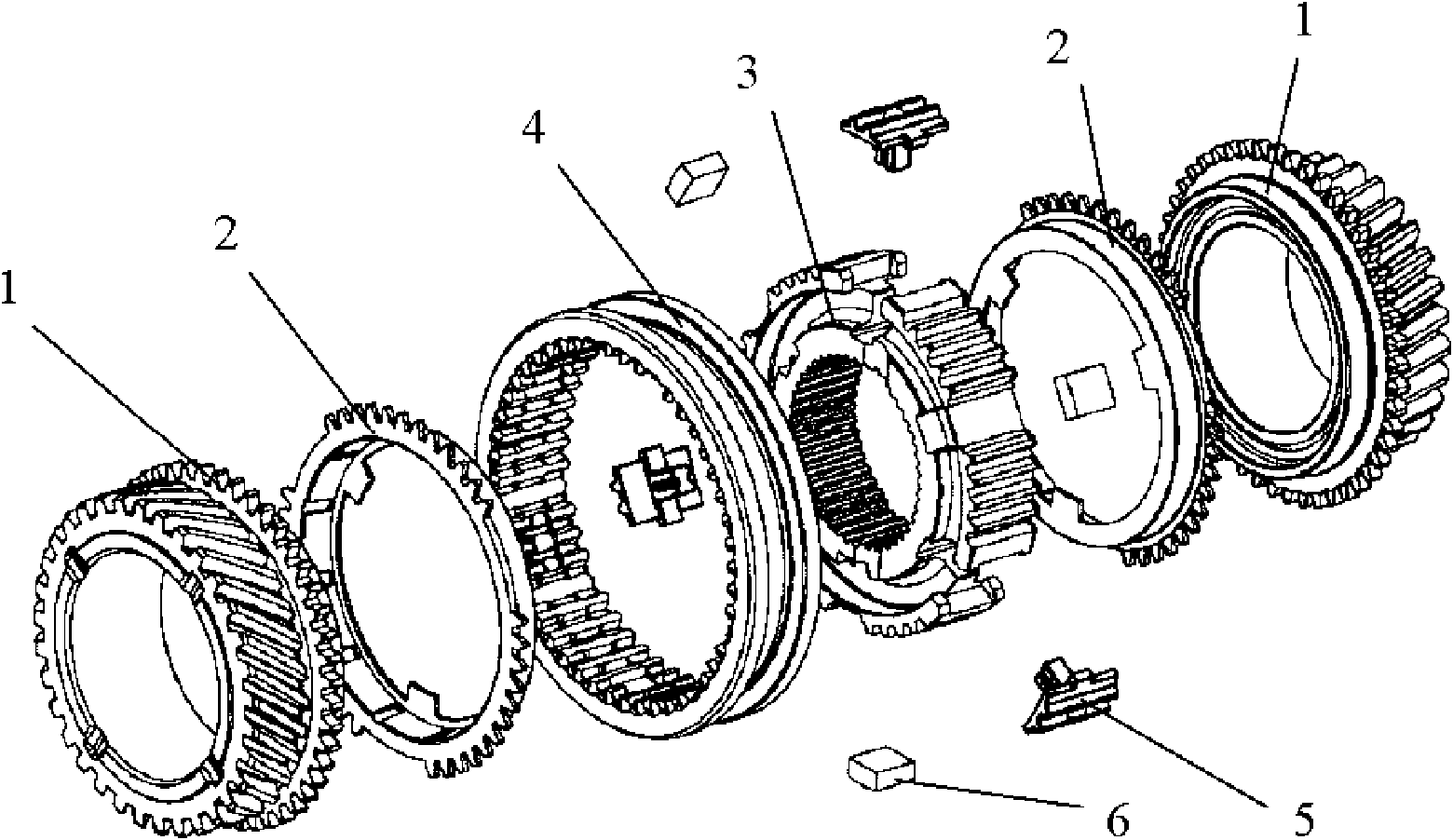

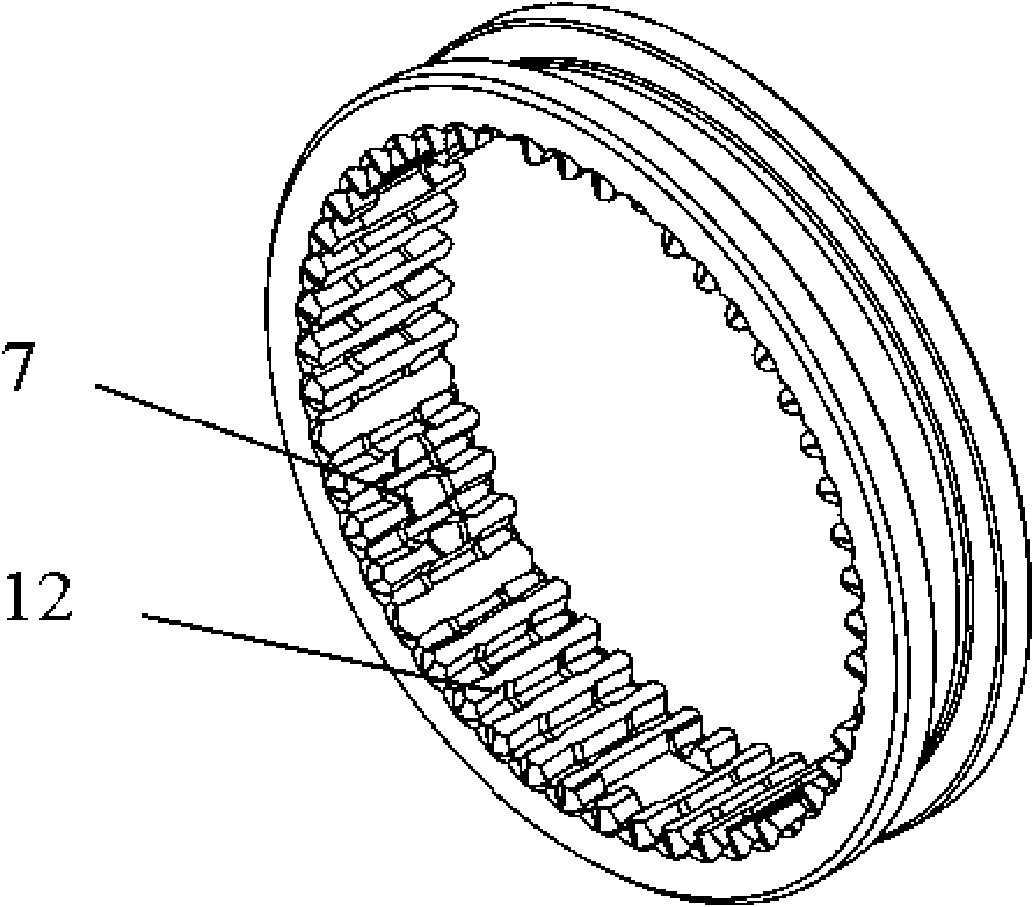

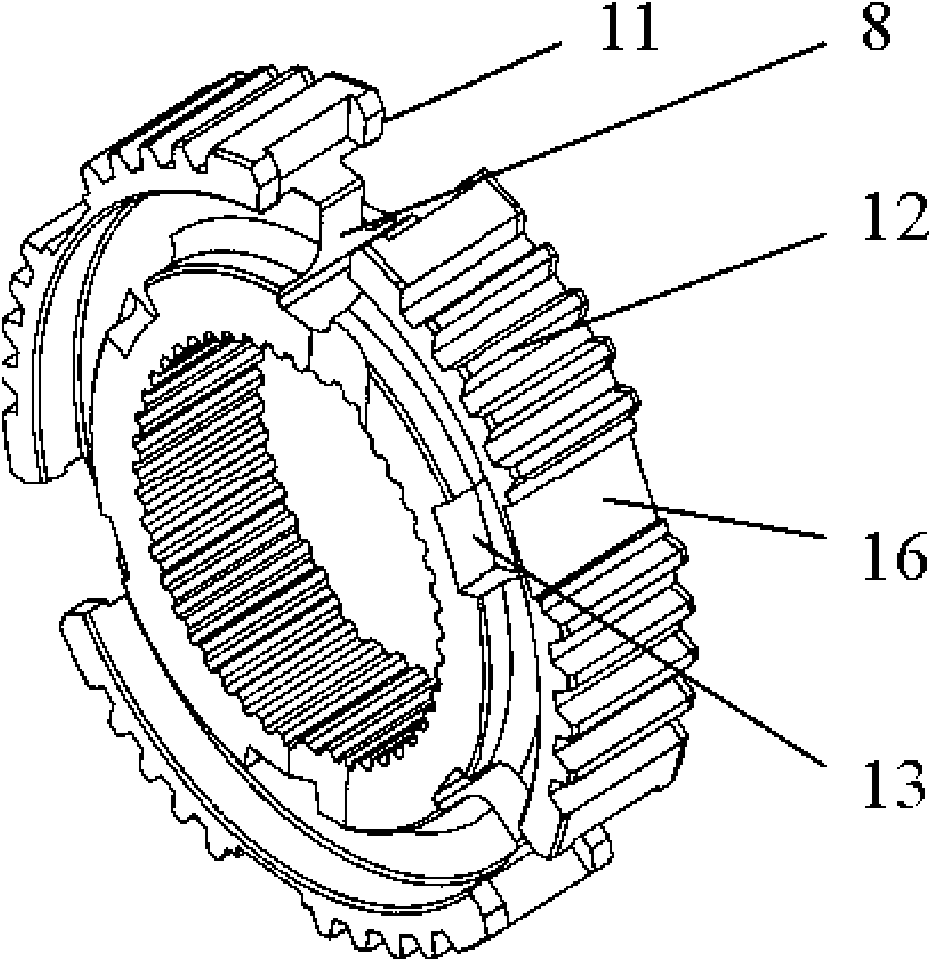

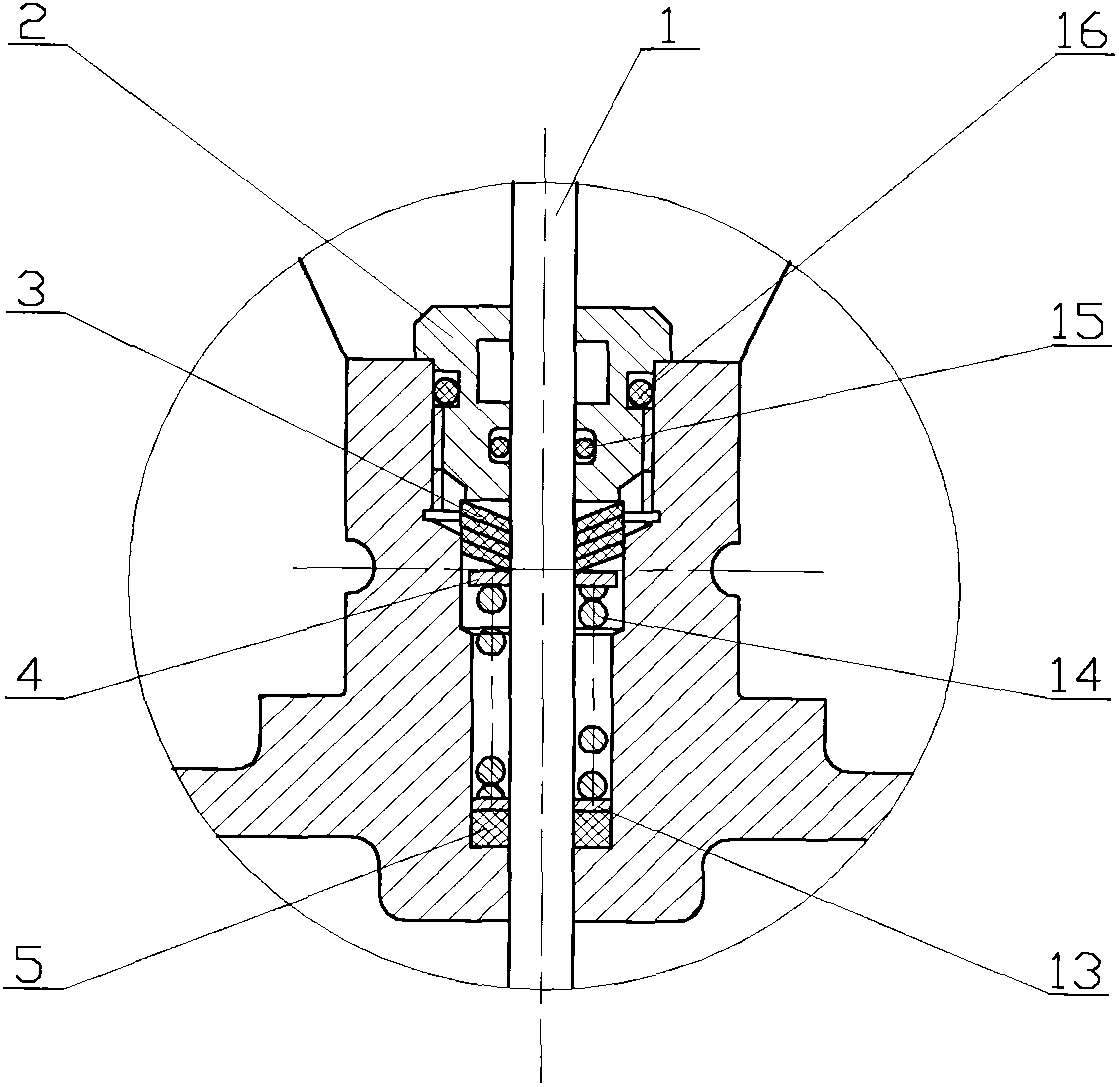

Fixed stroke synchronizer

ActiveCN101655163ALimited travelConditions that affect failureSlide valveGearing detailsEngineeringMechanical engineering

The invention relates to a fixed stroke synchronizer in the technical field of automotive engineering, comprising conjunction gears, synchronizer rings, a gear hub, a gear sleeve, an integrated moduleand a positioning device. The integrated module is arranged on the outer edge of the gear hub and clamped on the gear sleeve; the positioning device is arranged on the inner edge of the gear sleeve which is sleeved on the gear hub; and the two synchronizer rings and the two conjunction gears in the same structures are sequentially sleeved at both sides of the gear sleeve from interior to exteriorin a mirrorsymmetry mode. The synchronizer with the anti-extrusion integrated module simplifies the structure, eliminates shifting failures, even synchronizer failures due to the extrusion of a steelball of the integrated module out of the gear sleeve while shifting and effectively lowers noise generated during shifting.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Electromagnetic valve with differential pressure resistance valve core

ActiveCN102537484APrecise positioningLimited travelOperating means/releasing devices for valvesDifferential pressureMechanical engineering

An electromagnetic valve with a differential pressure resistance valve core is composed of a valve rod, a press cap, a V-shaped sealing ring, a gasket, a sealing pad, a nut, a valve core, a large O-shaped ring, a stifle, a sealing gasket, a valve body, a valve core seat, a small sealing ring, a spring, a small O-shaped ring, a middle O-shaped ring and an electromagnet. The valve core is in a thin-wall cylindrical shape, one end of the valve core is open, the other end is provided with an end face plate, a step connected with the valve rod is positioned in the center of the end face plate, and through holes are arranged on the periphery of the step. A blocking shoulder is arranged at the periphery of the valve core to limit journey of the valve core to improve sealing performance. Under the action of the electromagnet, an upward-moving valve on the valve core is in a close state, pressure water is filled with the valve core and a cavity communicated with the valve core, the sum of axial force stressed on the valve core is nearly zero, pressure difference inside and outside the cylinder wall of the valve core is large, axial force stressed on in the cylinder wall is enough to enable the thin wall of the valve core to expand and deform, and sealing between the valve core and the valve is reliable. When the valve core moves downwards, the valve is open, and water pressure has no side effects on the valve core.

Owner:ZHEJIANG HENGSEN IND GROUP

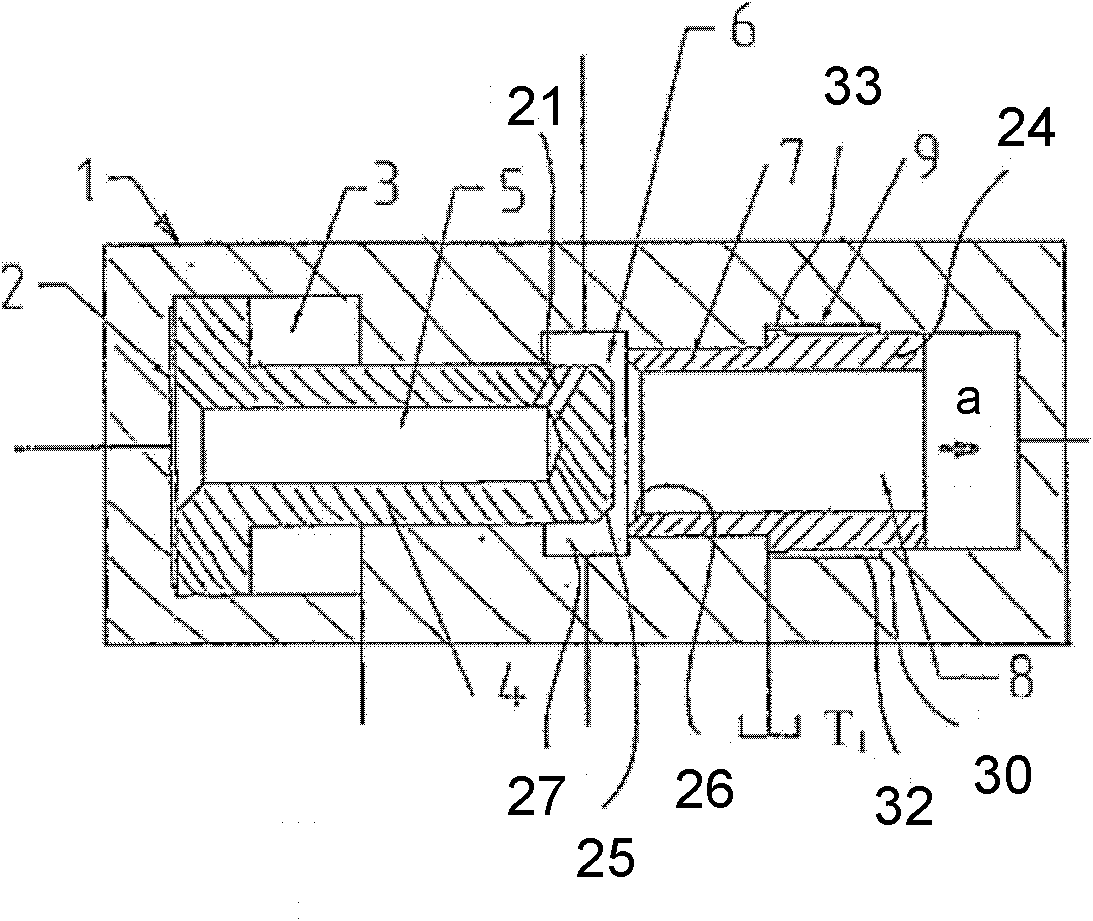

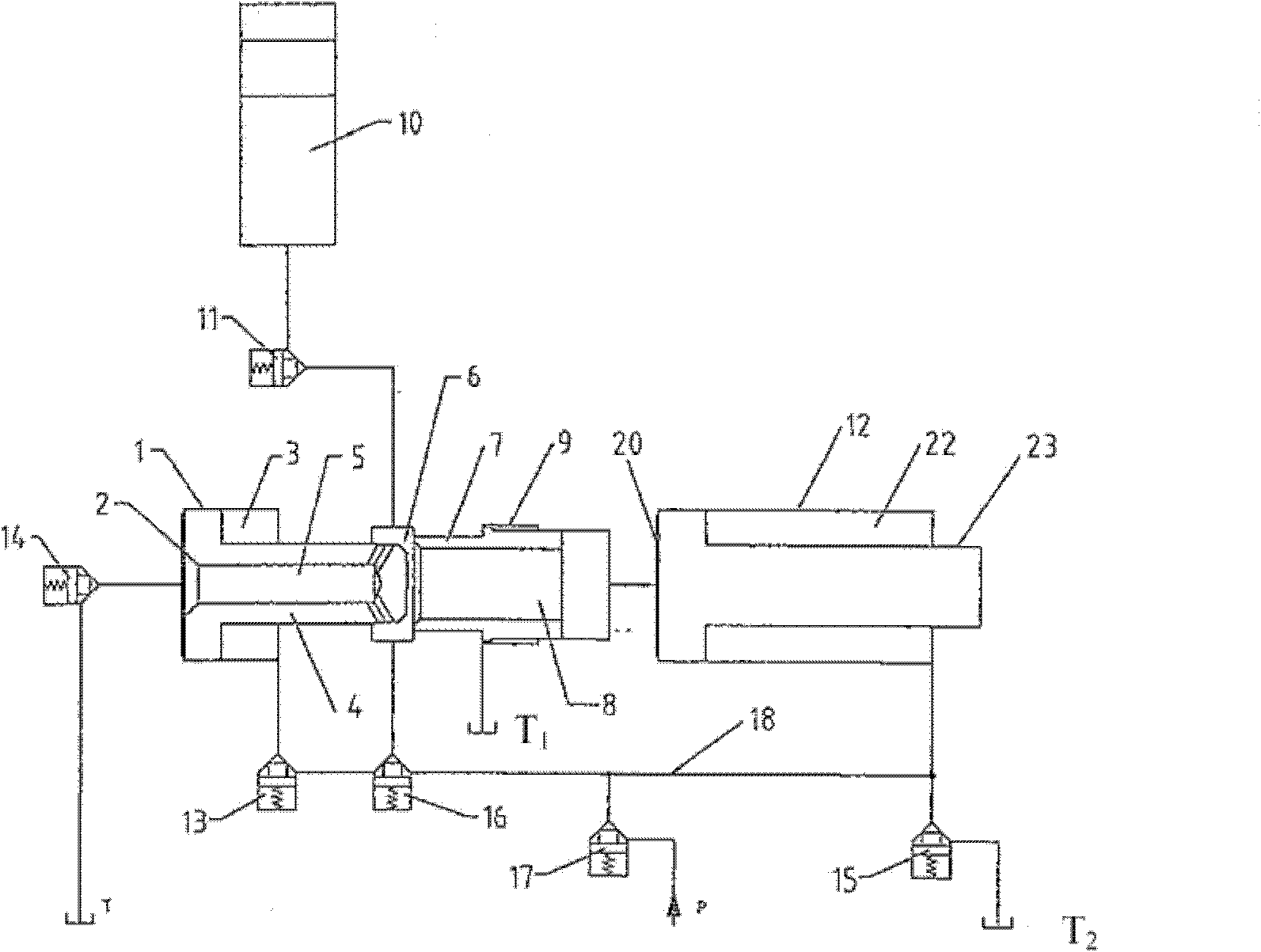

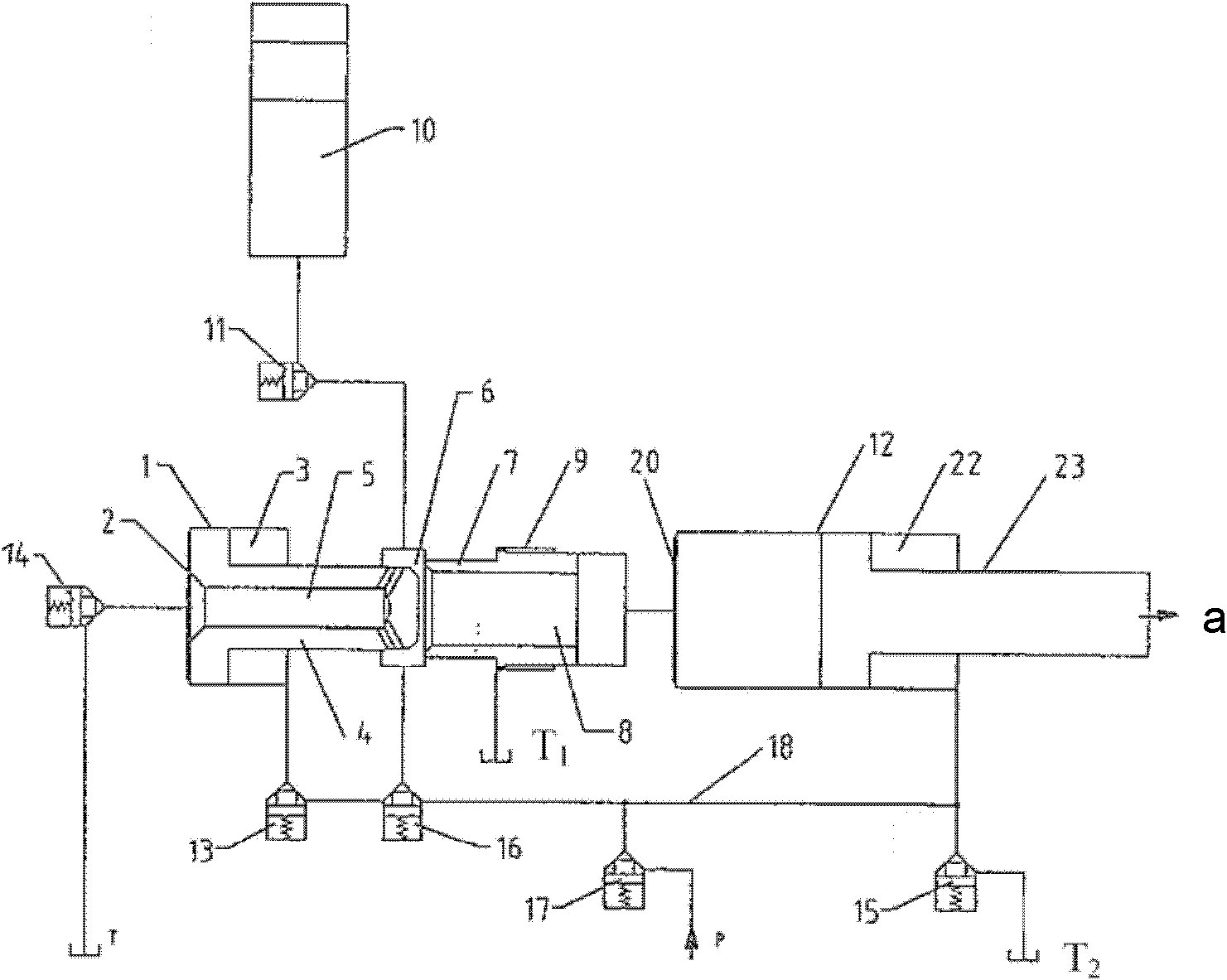

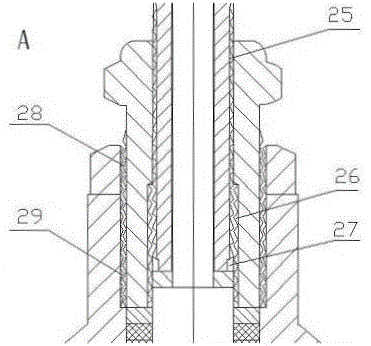

Pressure booster and diecasting arrangement

ActiveCN102256726ALarge circulation sectionGuaranteed uptimeServometer circuitsFluid-pressure convertersPistonValve seat

A pressure booster (1) for a diecasting machine comprises a pressure booster piston (4) having a valve seat (7), wherein the pressure booster piston (4) interacts with the valve seat (7) to form a shut-off or non-return valve (6). The valve body (24) is displaceable to a limited extent in the axial direction (a) and can be retained hydraulically in a starting position. (Figure 1)

Owner:BUHLER DRUCKGASS AG

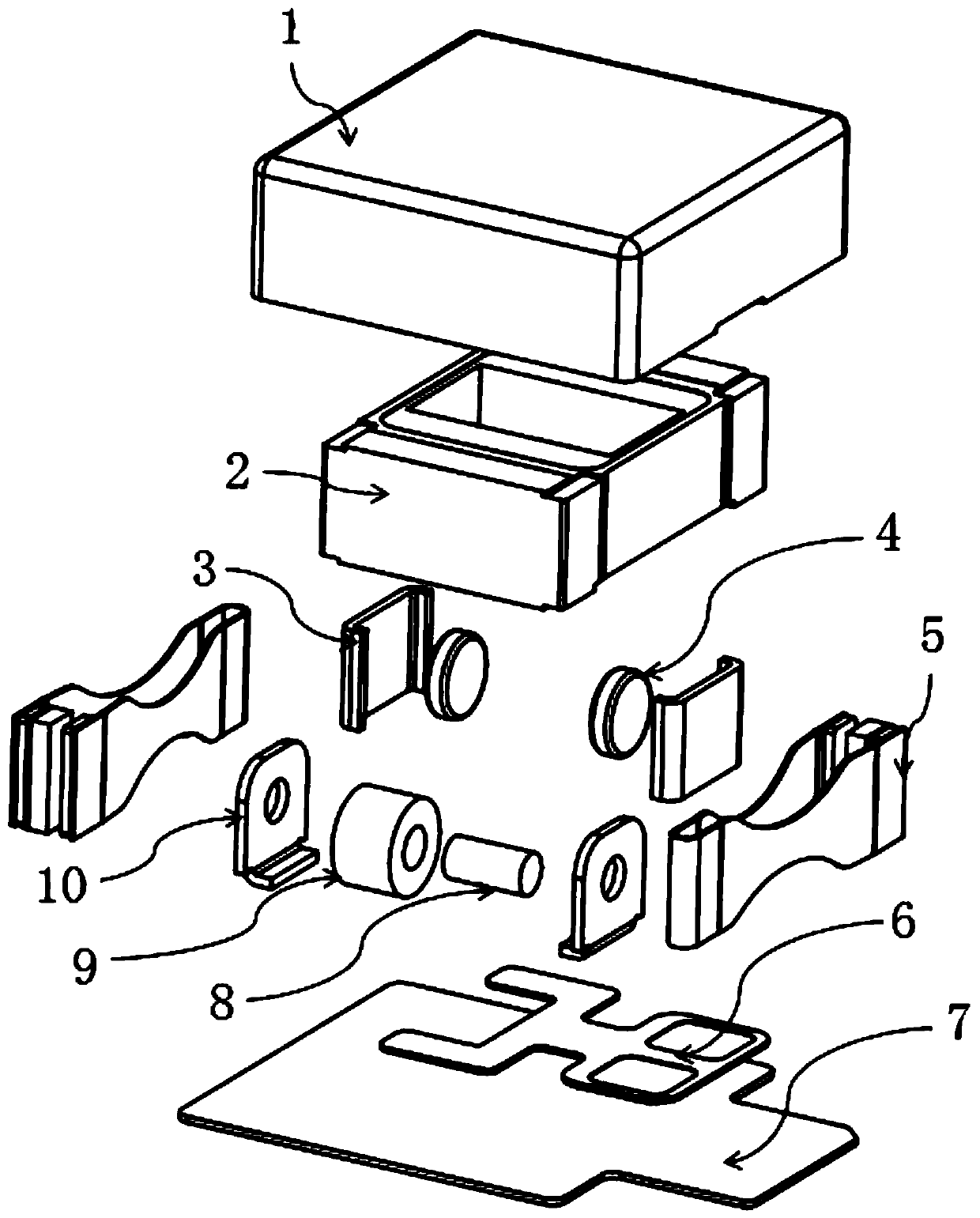

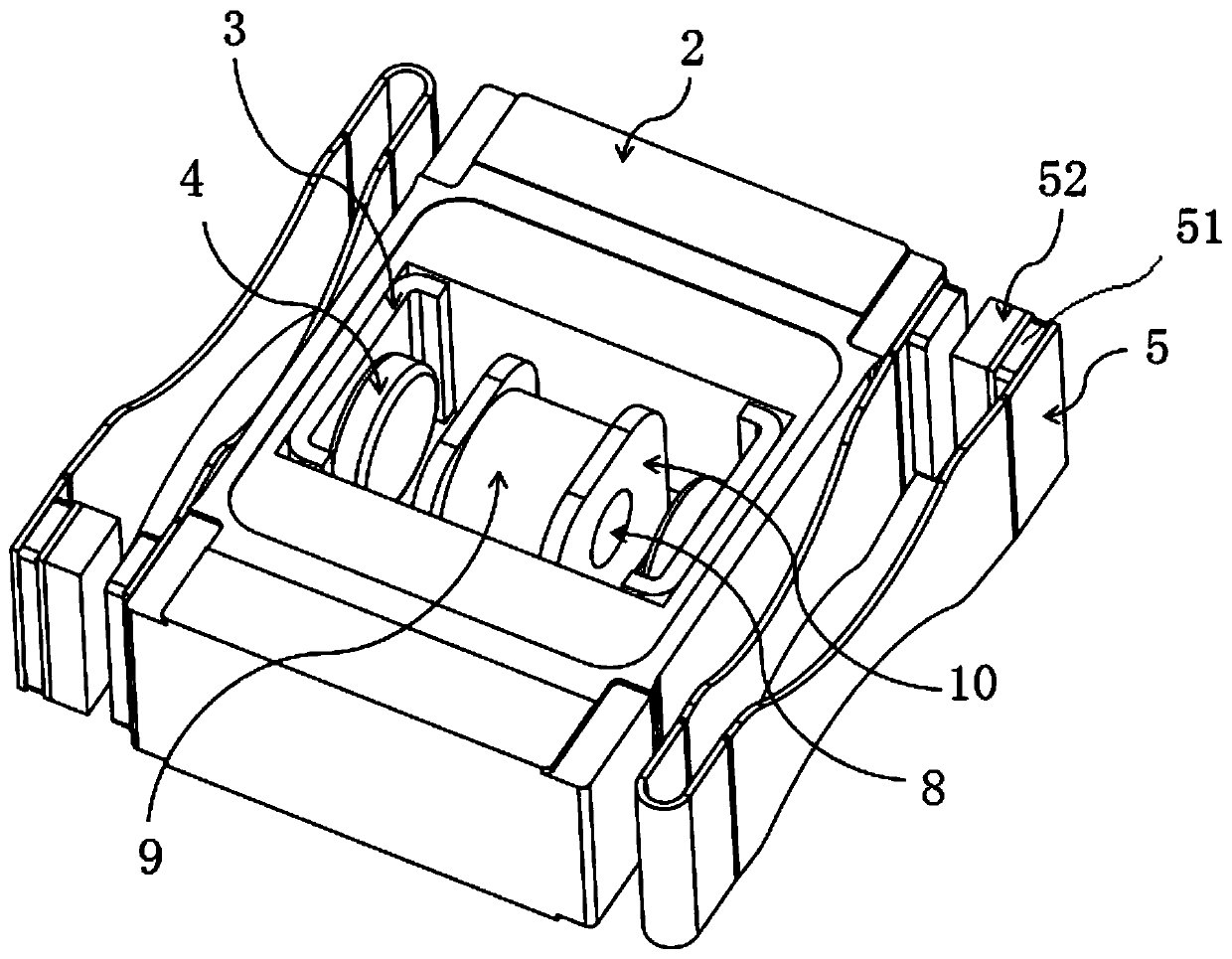

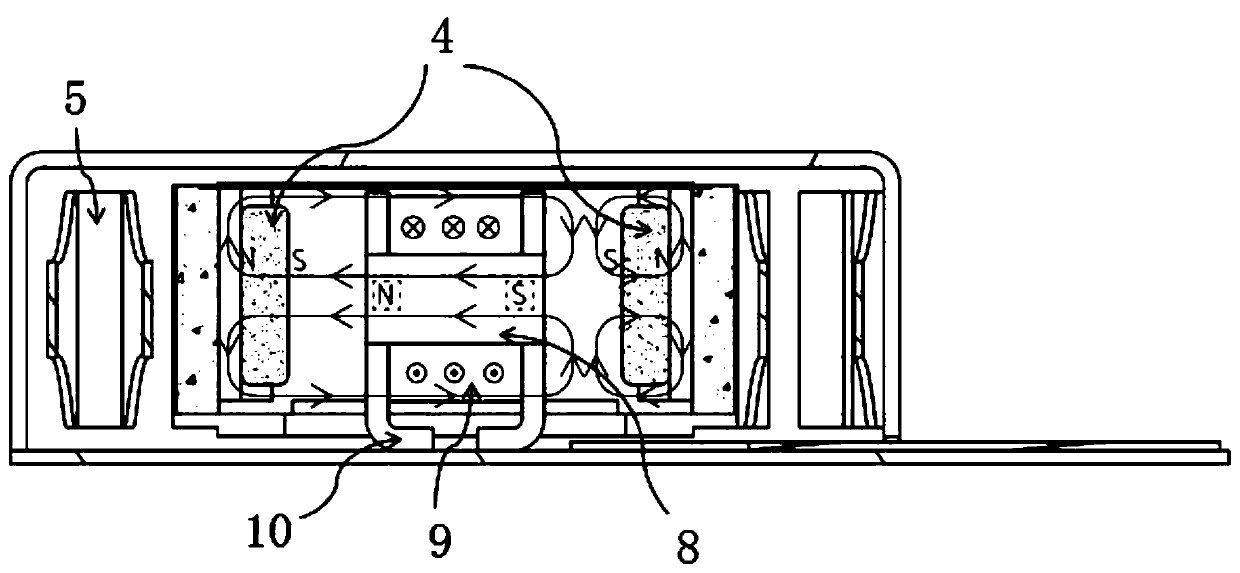

Electromagnet-type horizontal linear vibration motor and implementation method thereof

InactiveCN111146916AGreat driving forceEasy to installReciprocating/oscillating/vibrating magnetic circuit partsElectric machineMotor vibration

The invention discloses an electromagnet-type horizontal linear vibration motor. The motor comprises a motor shell, and a bracket is connected to the lower portion of the motor shell. A stator assembly is connected above the bracket, and the stator assembly comprises a circuit board and a coil. The circuit board is connected above the bracket, and the coil is arranged on the circuit board; the coil is connected with the circuit board through spot welding, and a vibrator assembly is arranged in the machine shell; the vibrator assembly comprises a mass block, a cavity is formed in the mass block, magnetic steel is connected to the two ends of the interior of the cavity, the coil is located between the two magnetic steel, and the mass block is connected with the motor shell through a spring piece. The invention further discloses an implementation method of the electromagnet-type horizontal linear vibration motor. According to the invention, an iron core, the coil and a yoke form an electromagnet structure, and the electromagnet structure and the circuit board form a circuit; after an alternating current is connected, an alternating magnetic field generated by the electromagnet interacts with magnetic fields generated by the magnetic steels on the two sides to drive the vibrator assembly to vibrate along the X axis, so the driving force of motor vibration is increased.

Owner:ZHEJIANG DONGYANG CHENGJI ELECTRO MECHANICS CO LTD

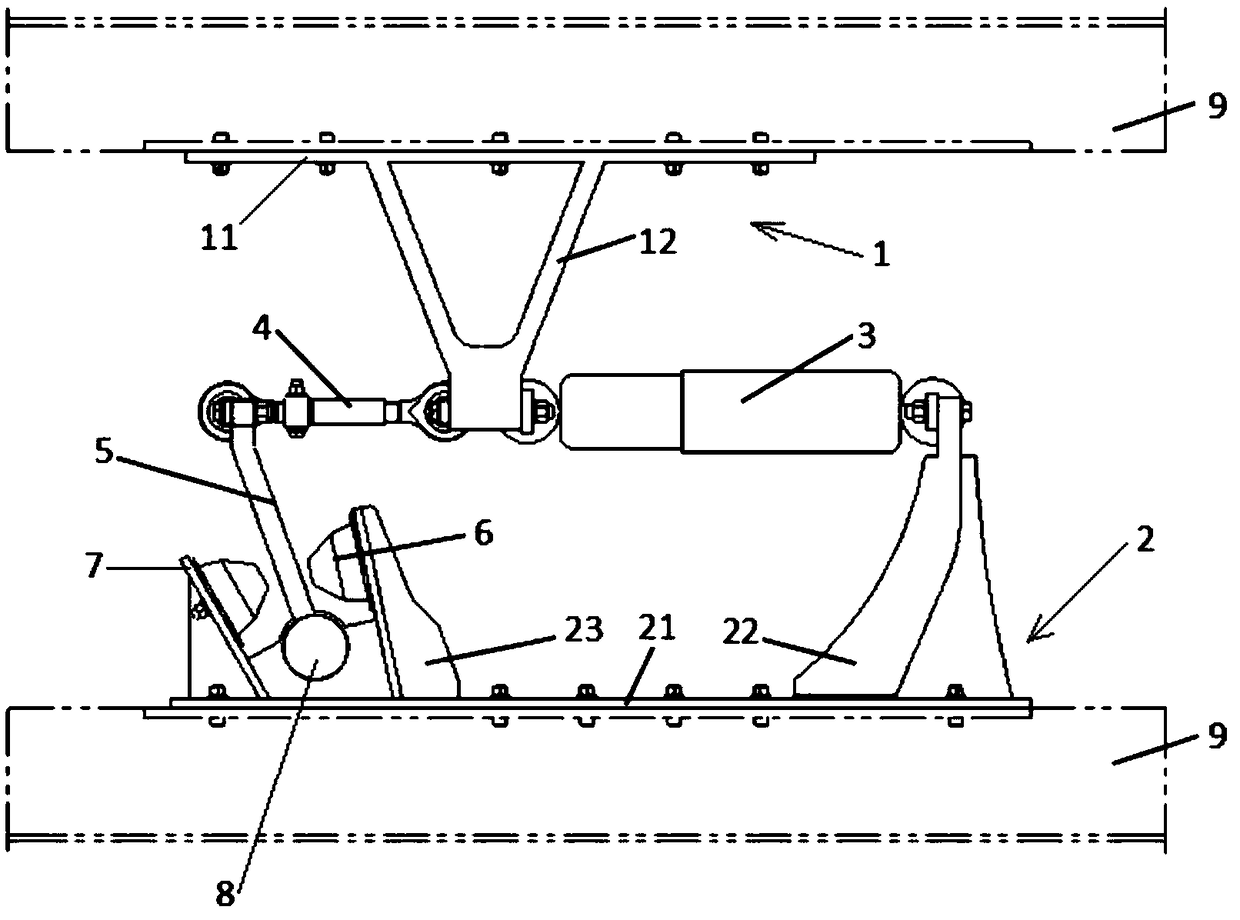

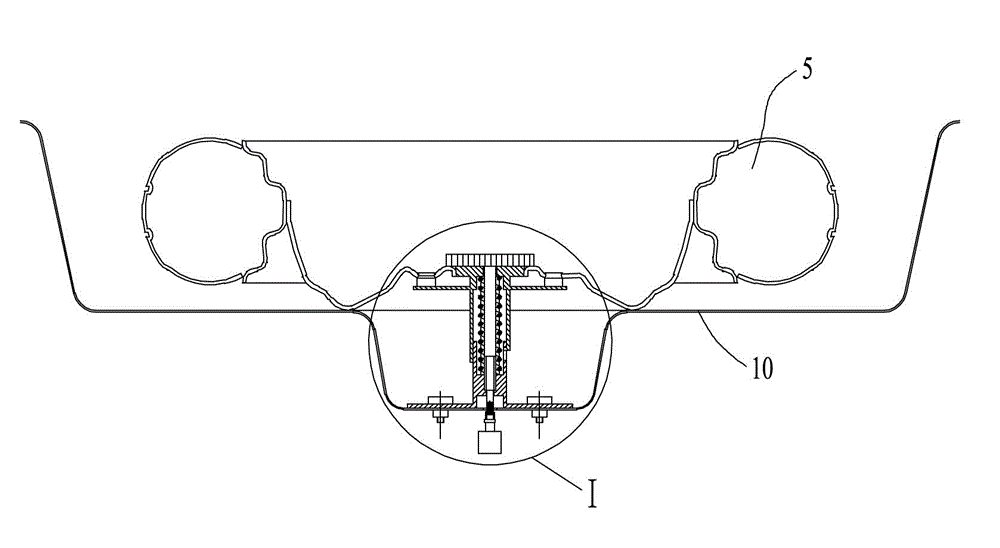

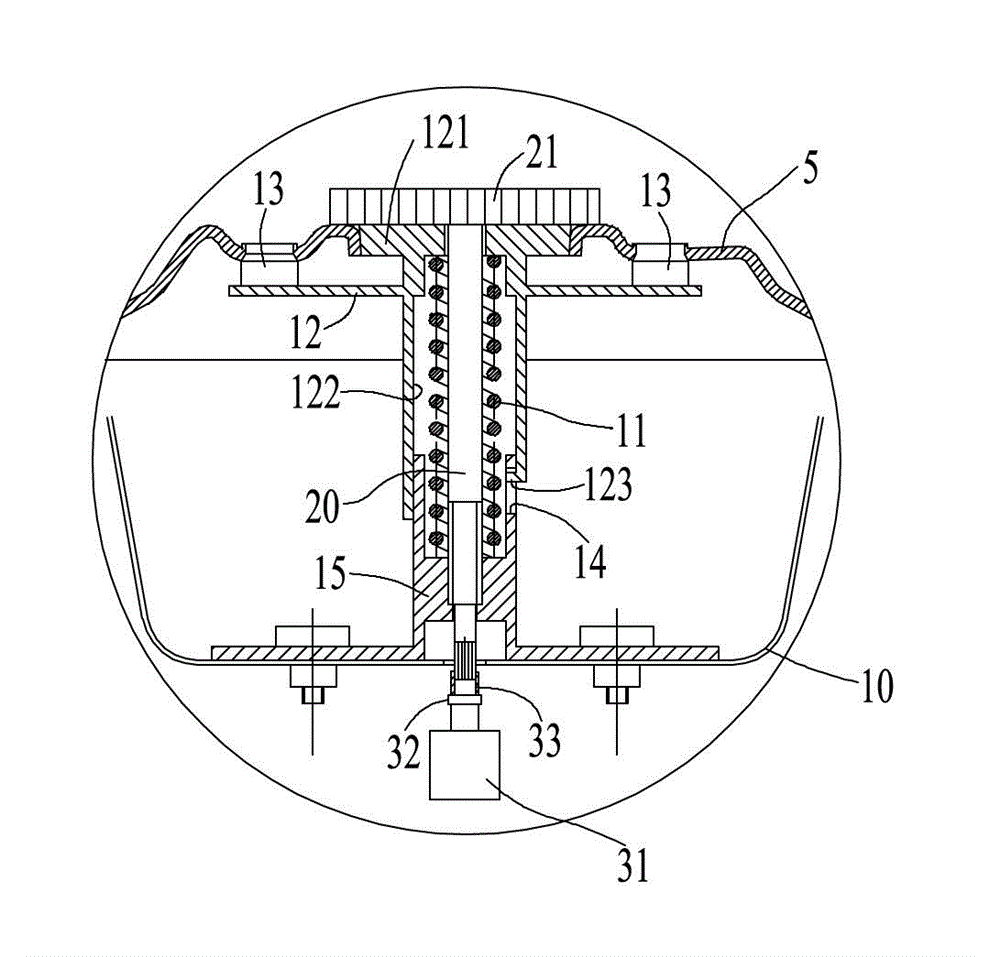

Workshop vibration damping device for rail vehicle and rail vehicle

PendingCN109334702ALimited travelLimit rotation angleRailway wheel guards/bumpersRailway couplingsRelative motionLateral displacement

The invention provides a workshop vibration damping device for a rail vehicle and the rail vehicle. The workshop vibration damping device comprises a first mounting seat, a second mounting seat, a vibration damper, a connecting rod assembly and a rotating arm. The first mounting seat comprises a first mounting plate and a first supporting seat, wherein the first supporting seat is mounted on one side of the first mounting seat. The second mounting seat comprises a second mounting plate, a second supporting seat and a third supporting seat, wherein the second supporting seat and the third supporting seat are mounted on the second mounting plate. The vibration damper is arranged in parallel between the first mounting plate and the second mounting plate, the second supporting seat is hinged to one end of the vibration damper, and the other end of the vibration damper is hinged to one side of the first supporting seat. One end of the connecting rod assembly is hinged to the other side opposite to the first supporting seat, and the other end of the connecting rod assembly is hinged to one end of the rotating arm. The other end of the connecting rod assembly is hinged to one end of the rotating arm, and the third supporting seat is hinged to the other end of the rotating arm. Transverse stoppers are arranged on both sides, in the rotating direction of the rotating arm, of the third supporting seat so as to limit the rotating angle. According to the workshop vibration damping device for the rail vehicle and the rail vehicle, the relative motion between two adjacent carriages can be attenuated, transverse vibration reduction is realized, and the maximum lateral displacement is limited.

Owner:CRRC QINGDAO SIFANG CO LTD

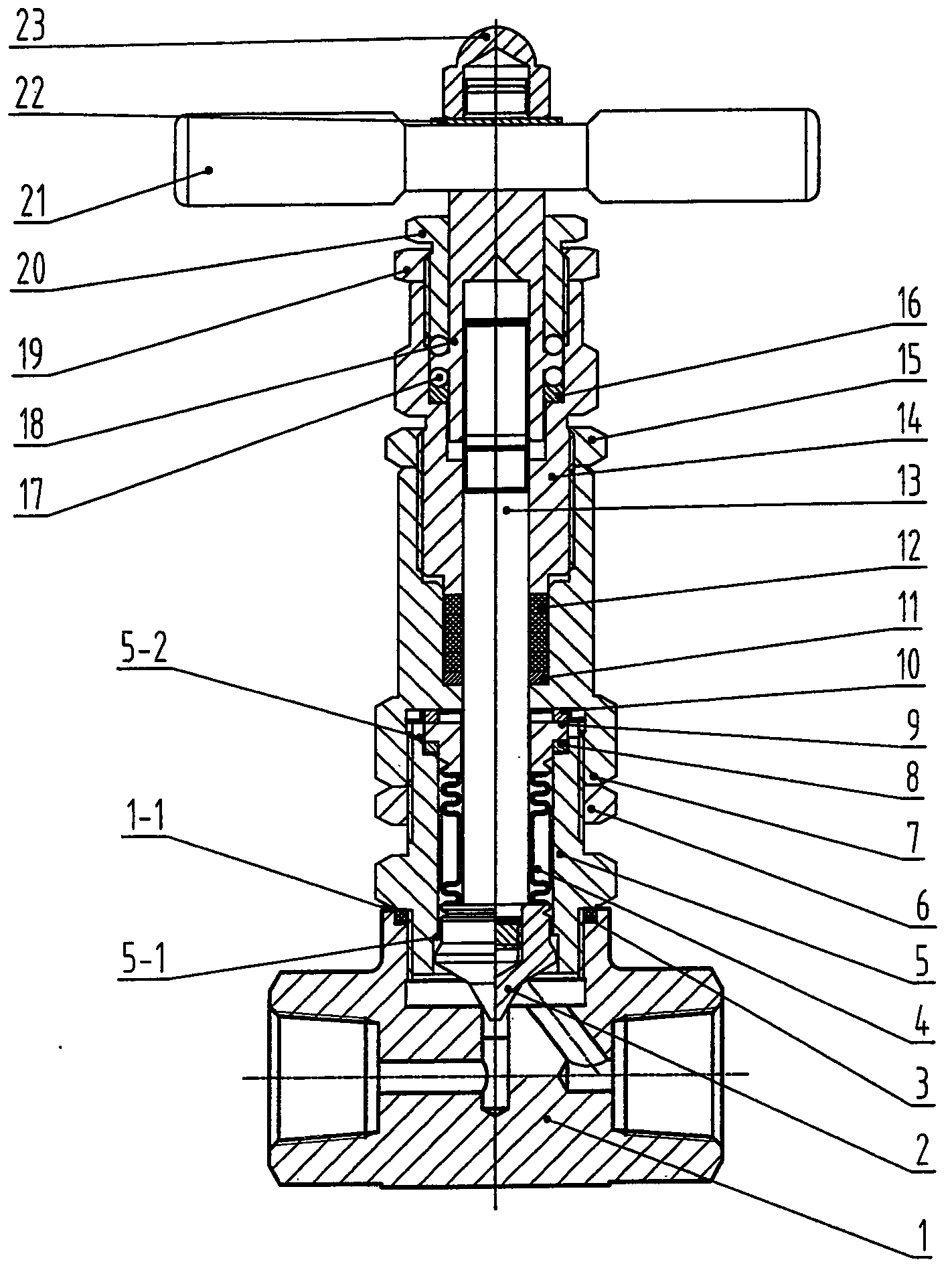

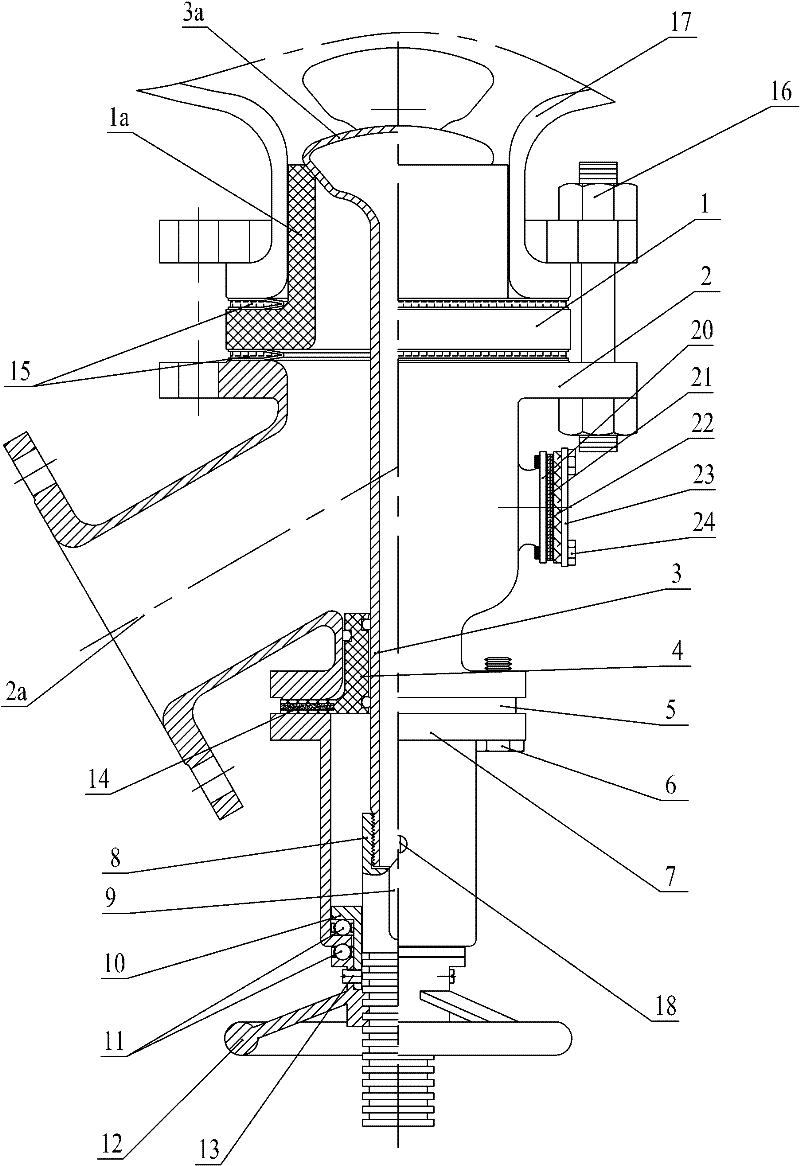

High-pressure connecting rod type bellows globe valve

A high-pressure connecting rod type bellows globe valve comprises a valve body, a valve base, a valve deck and a hand wheel. A bellows assembly is arranged inside the valve body and comprises a valve element, a bellows, a bellows welding sleeve, a welding bush and a valve rod. One end of the bellows is connected with the valve rod, and the other end of the bellows is connected with the bellows welding sleeve. A red copper sealing gasket is arranged between the valve body and the bellows welding sleeve. A sealing gasket is arranged between the valve base and the bellows welding sleeve. A filler pressing pad and a filler are sequentially arranged between the valve deck and the valve base. A jacking rod is arranged inside the valve deck. One end of the jacking rod is connected with the valve rod, and the other end of the jacking rod is provided with the hand wheel. The valve rod and the jacking rod are adopted for forming a connecting rod type pull-up device, and meanwhile the valve rod and the jacking rod are protected against corrosion through quadruple sealing of the red copper sealing gasket, the bellows, the sealing gasket and the filler; and assembly and replacement are more convenient, and sealing performance, high temperature resistance, high pressure resistance and corrosion resistance are better.

Owner:YANGZHONG VALVE FACTORY CO LTD

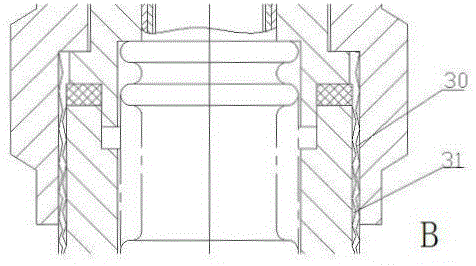

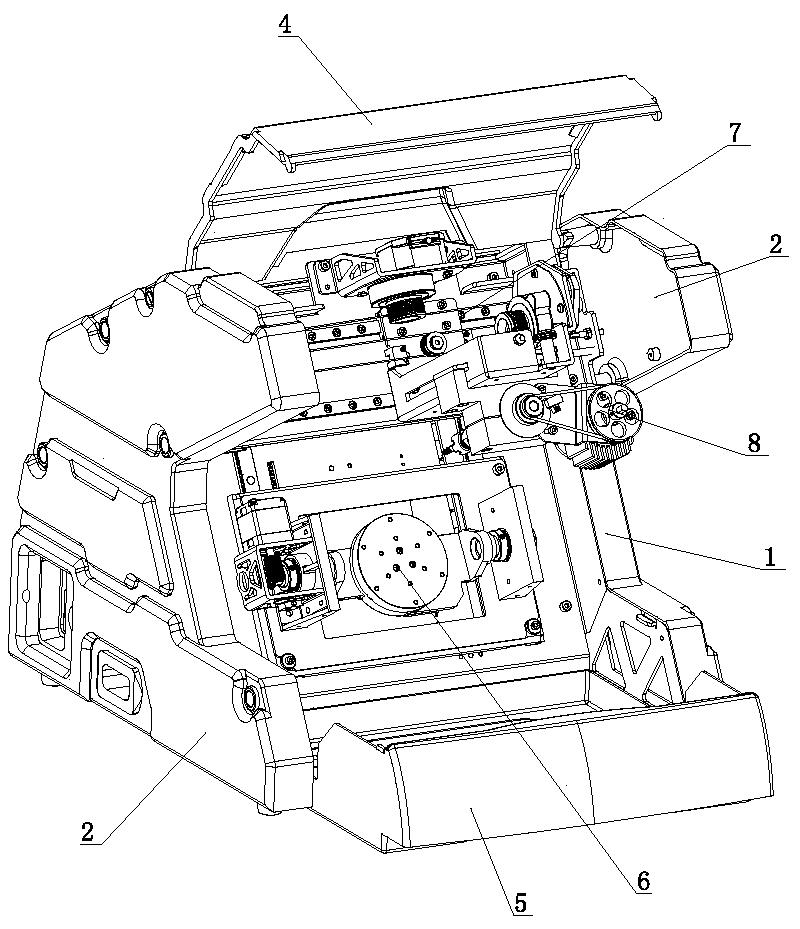

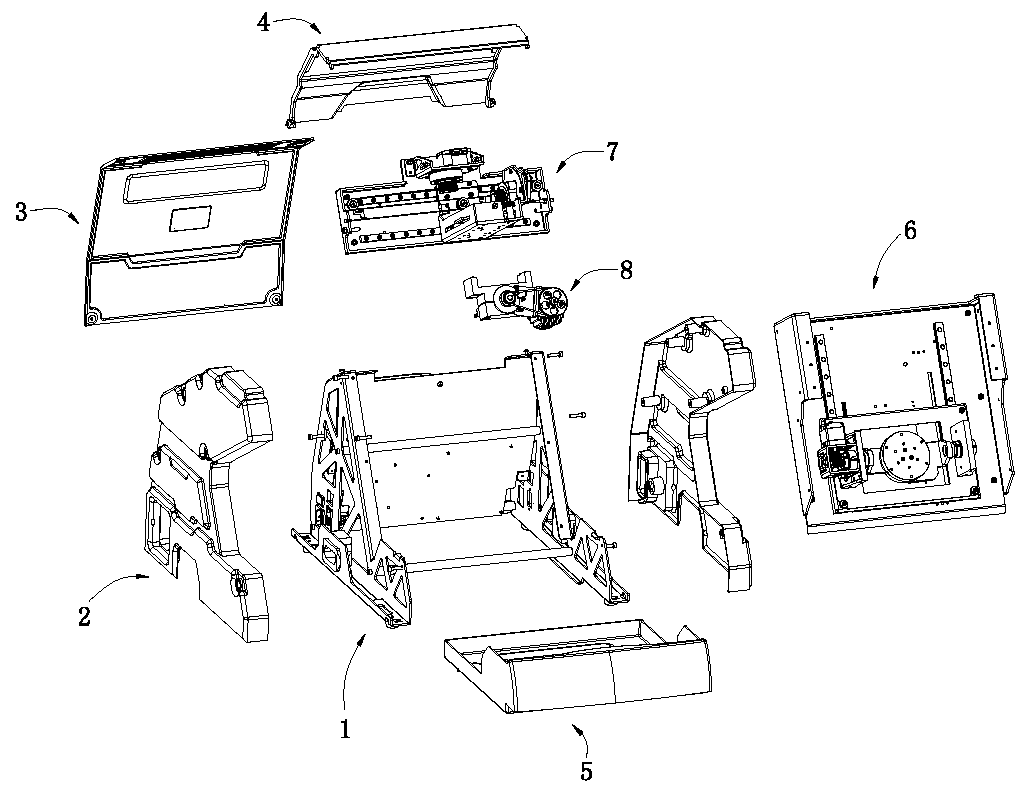

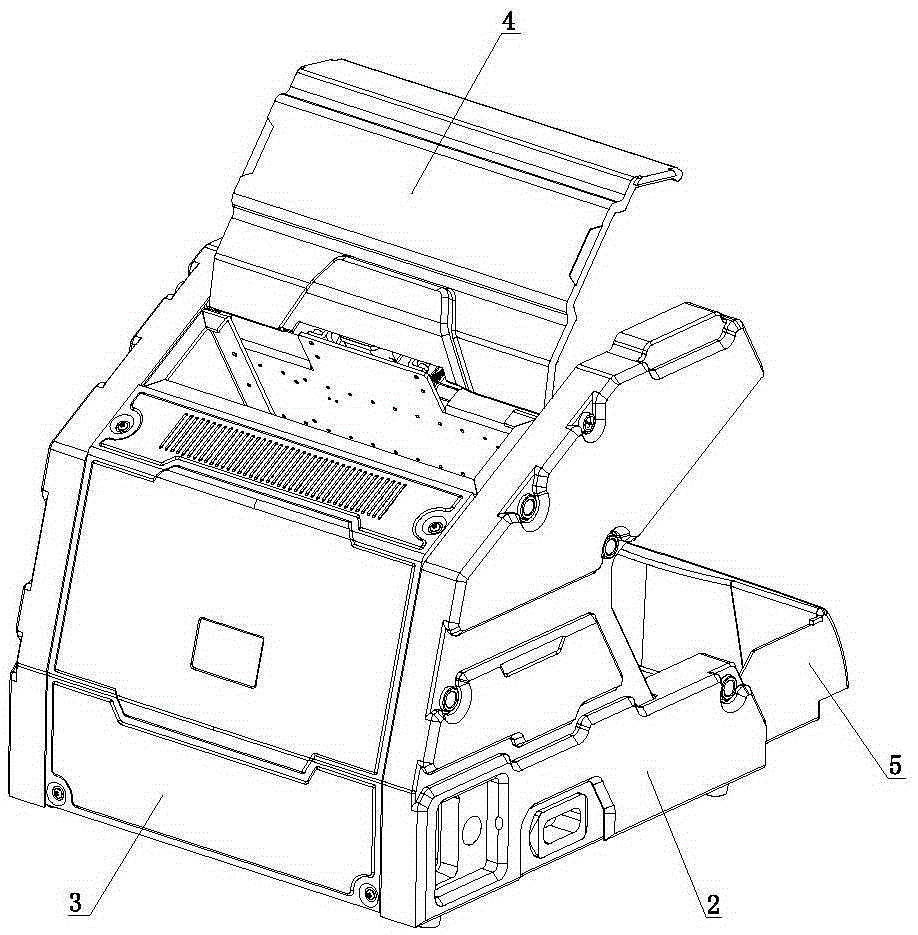

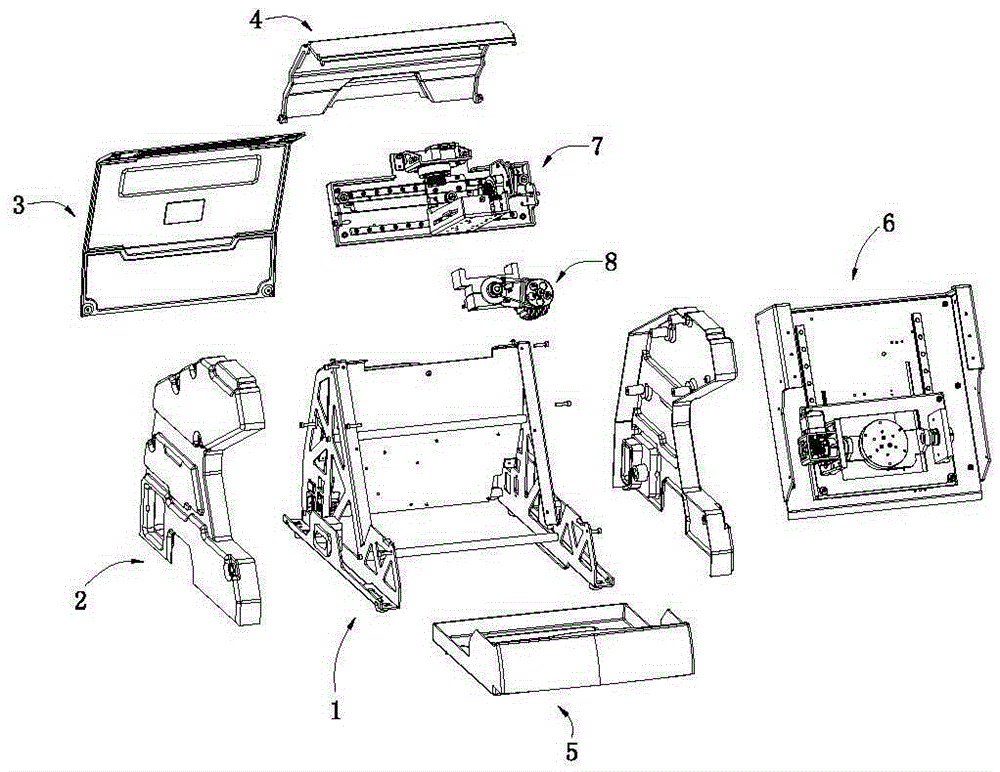

A five-axis CNC machining center

ActiveCN105364491BHigh strengthImprove bending resistanceOther manufacturing equipments/toolsLarge fixed membersNumerical controlDrive motor

The invention discloses a five-axis numerical control machining center which comprises a machine frame, side covers, a rear cover, a protective cover, a material supporting device, a working table device, a standing arm device and a spindle device, wherein the side covers are matched with bayonets on the machine frame through buckles and are connected and fastened through bolts; the rear cover is mounted on the machine frame; the protective cover is hinged to the side covers; the material supporting device is arranged on the machine frame in a sliding way; the working table device is fixed on the machine frame; the standing arm device is fixed on the working table device; and the spindle device is fixed on the standing arm device. According to the five-axis numerical control machining center, the supporting stability of the machine frame is improved, and the side covers can be positioned better and fixed firmly when mounted; scraps are convenient to clean, the material supporting device is spaced, and meanwhile movement of the material supporting device is guided better; both horizontal motion and rotation can be realized, the horizontal motion guiding property is good, a fourth-axis sliding seat can be guided initially, the moving accuracy of a fifth-axis sliding seat is high, and heat of a diving motor can be dissipated better.

Owner:烟台前创软件科技有限公司

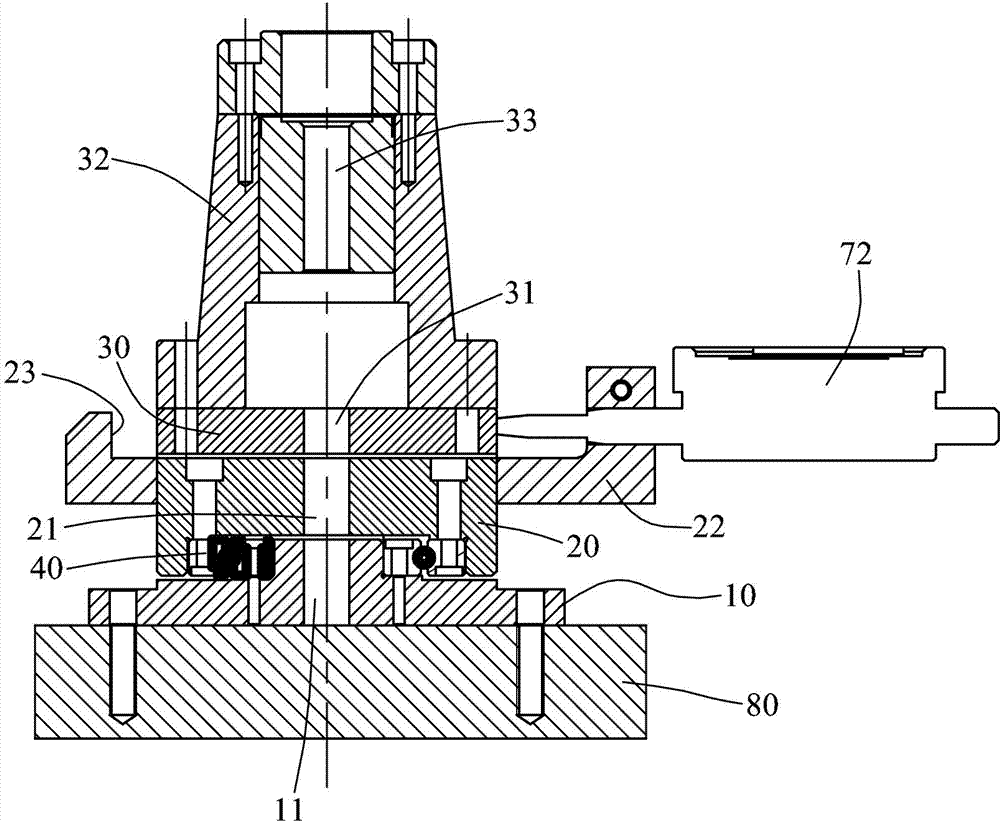

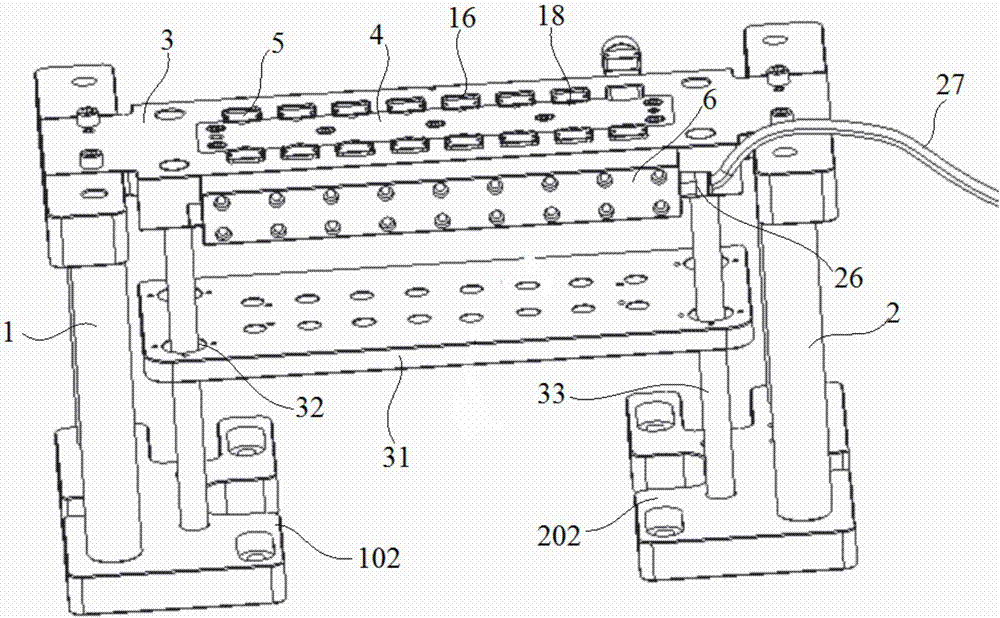

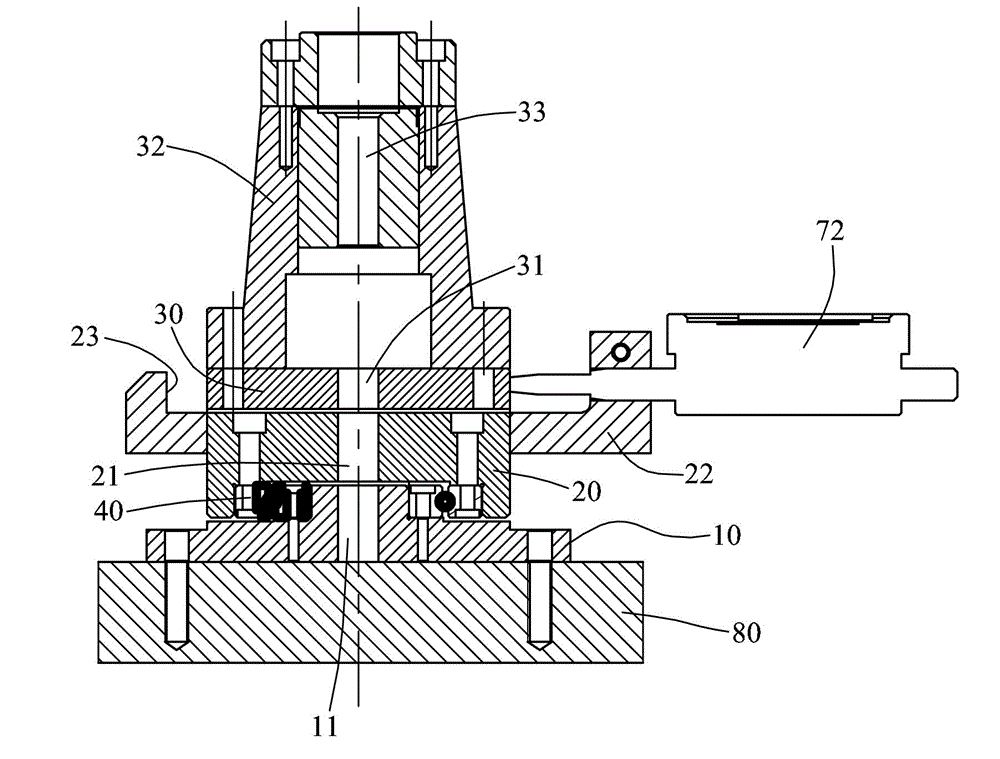

Hydraulic type clamp used for machining antenna brackets of tablet personal computer

InactiveCN107498348ALimited travelGuaranteed accuracyPositioning apparatusMetal-working holdersTablet computerPersonal computer

The invention discloses a hydraulic type clamp used for machining antenna brackets of a tablet personal computer. The hydraulic type clamp comprises a left supporting seat, a right supporting seat, a fixing plate, a locating plate, a clamping head and a pressure mechanism; the two ends of the fixing plate are fixedly connected with the left supporting seat and the right supporting seat correspondingly; the locating plate is fixedly connected with the fixing plate; a hydraulic oil hole is formed in one side surface of the pressure mechanism; one face, provided with clamping teeth, of a rack faces an arc-shaped clamping claw, the arc-shaped clamping claw is installed on the lower surface of a movable plate, and the front end of the arc-shaped clamping claw is embedded in the clamping teeth of the rack; a vertical clamping groove is formed in the inner side surface of a sliding block, and the sliding block is connected with a guiding strip through the vertical clamping groove in a clamping mode and is fixedly connected with the rack; and the lower end of a limiting screw rod penetrates through a pushing block from top to bottom and then is embedded in a center through hole of a pushing rod of a top plate air cylinder, and the limiting screw rod is sleeved with a limiting nut. According to the hydraulic type clamp used for machining the antenna brackets of the tablet personal computer, the stroke of the top plate air cylinder can be limited by arranging a limiting stud and the limiting nut, so that the rising stoke of the movable plate is in accordance with need, each rising stroke of the movable plate is fixedly consistent, and the machining precision is ensured.

Owner:KESEN SCI & TECH DONGTAI CO LTD

Pneumatic oil limiting device of mixed firing engine

InactiveCN104153895AMeet the requirements of economic operationLimited travelInternal combustion piston enginesEngine controllersEngineeringOil and natural gas

The invention relates to an oil supply amount limiter device of a diesel oil and natural gas mixed firing engine. The device comprises a connecting seat and an air cylinder connected with the connecting seat. The air cylinder comprises a cylinder body and a piston, a piston limiting check ring is arranged in the cylinder body, adjusting threads are arranged on the outer wall of the cylinder body, an air tap is arranged at one end of the cylinder body, a limiting step is arranged on a piston rod of the piston, the position, arranged in the cylinder body, of the piston rod of the piston is sleeved with a piston resetting spring, one end of the piston resetting spring is fixed to the piston limiting check ring, and the other end of the piston resetting spring is fixed to the piston. The connecting seat is of a through cavity, a piston locating hole supporting the piston rod is formed in the connecting seat, one end of the connecting seat is provided with outer threads and is connected with an engine oil pump in a matched mode, and the other end of the connecting seat is provided with inner threads and is connected with the outer threads on the outer wall of the cylinder body in a matched mode. The device is a diesel oil and natural gas engine oil supply amount limiting device, under the mixed firing mode, due to the fact that the limiting step and the resetting spring are arranged on the piston rod of the piston, the stroke of the piston is effectively limited, and the economical running requirement of the engine is met.

Owner:周继光

Spare tire fixing device

The invention discloses a spare tire fixing device. The spare tire fixing device comprises a spare tire bracket connected with an automobile body and a locking rod in threaded engagement with the spare tire bracket for fixing the spare tire on the spare tire bracket. The spare tire fixing device further comprises a drive device which drives the locking rod to rotate with own axis as an axle. The locking rod can be matched and connected with a power output part of the drive device moveably along the own axis. The power output part of the drive device is connected with the locking rod in an axial sliding manner so that the locking rod does not interfere with the drive device in the axial direction in the process of rotating to lock the spare tire, and thereby, smooth work of the locking rod is ensured.

Owner:GREAT WALL MOTOR CO LTD

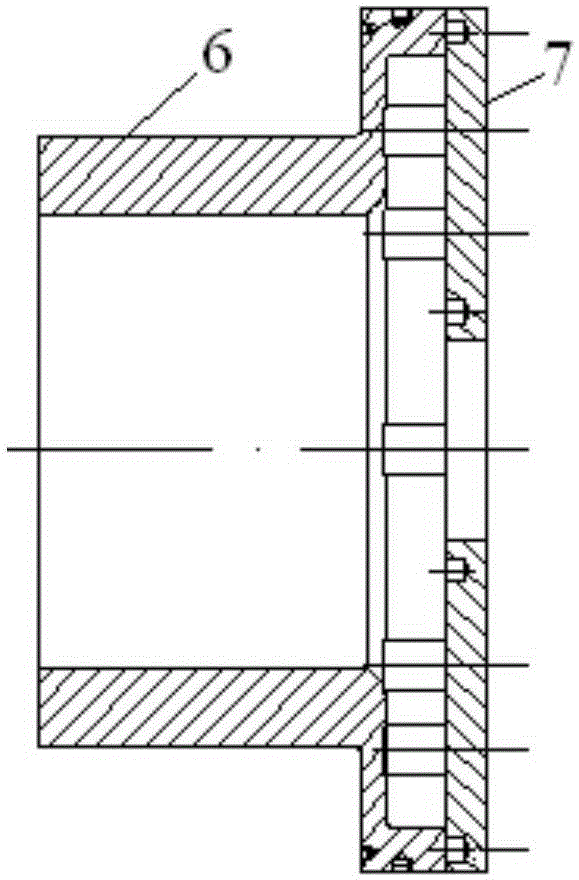

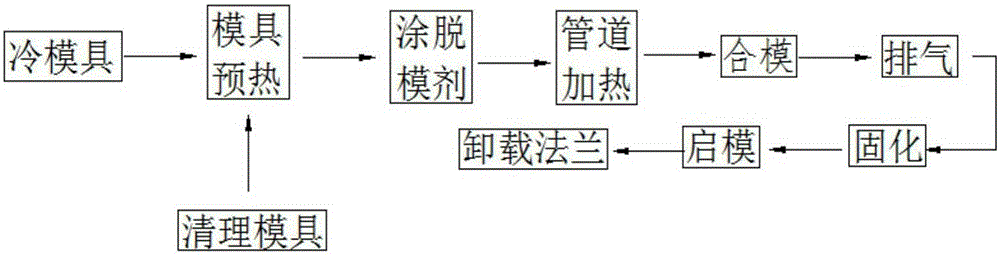

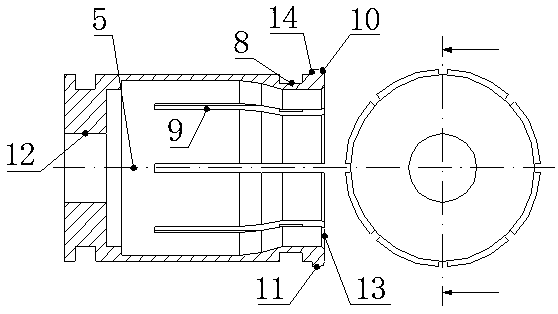

Non-metal pipe flange connector

ActiveCN105221885AQuality improvementEliminates problems with solder connectionsPipe connection arrangementsEngineeringFlange

The invention discloses a non-metal pipe flange connector aiming at solving the problem of non-metal pipe connection and achieving the purposes that production efficiency is improved, and the quality of a non-metal pipe joint is improved. According to the technical scheme, the non-metal pipe flange connector comprises a rack, the rack is fixedly provided with a guide rod, one end of the guide rod is sleeved with pipe fixing clamps, and the other end of the guide rod is sleeved with a rotating shaft support; the pipe fixing clamps and the lower end of the rotating shaft support are both provided with transmission mechanisms; the portion, between the pipe fixing clamps and the rotating shaft support, of the rack is fixedly provided with a sleeve, and a left flange die is fixedly arranged in the sleeve; the rotating shaft support is provided with a jacking shaft mechanism, and a right flange die and a push disc are sequentially connected to the jacking shaft mechanism from inside to outside, and the jacking shaft mechanism can rotate to make the right flange die combined with or separated from the left flange die; the inner end of the jacking shaft mechanism is provided with a heating device, and the inner end of the jacking shaft mechanism can stretch into a non-metal pipe; and the pipe fixing clamps, the left flange die, the right flange die and the jacking shaft mechanism are located on the same axis.

Owner:XI'AN PETROLEUM UNIVERSITY

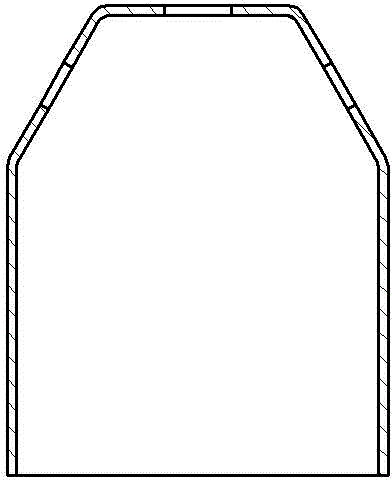

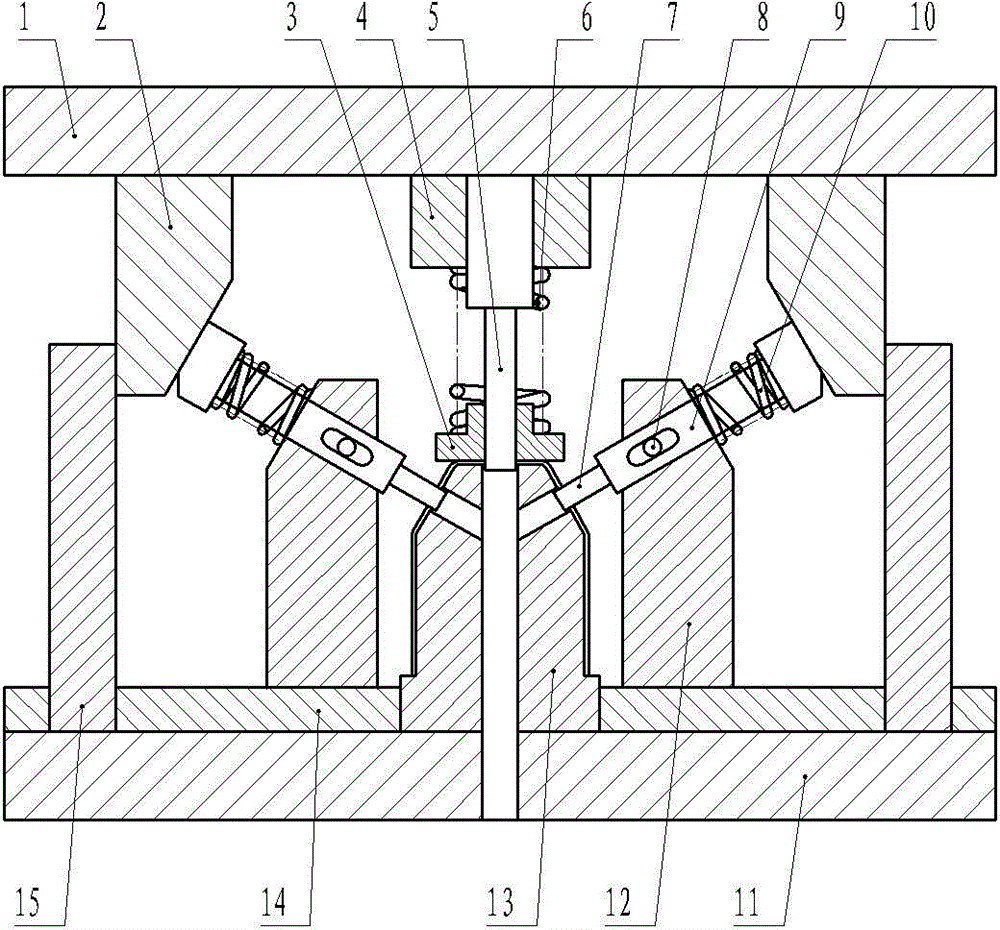

Punching die for shield

InactiveCN104826923AEasy clampingIncrease productivityPerforating toolsMetal-working feeding devicesPunchingSlide plate

The invention discloses a punching die for a shield, and relates to the technical field of punching die manufacturing. The punching die for the shield comprises an upper die base and a lower die base; the lower end of the upper die base is provided with a punch holder and a first punch; a discharging plate sleeves the lower part of the first punch; a discharging spring is arranged between the discharging plate and the punch holder; the upper end of the lower die base is provided with a workpiece locating block and two supporting shoes; a sliding plate penetrates through each supporting shoe; each sliding plate is provided with a second punch extending to the workpiece locating block; the upper part of each sliding plate is provided with a limiting boss; a reset spring is arranged between each limiting boss and the corresponding supporting shoe; the outer side of each supporting shoe is provided with a baffle; a stamping block of which the upper end is fixedly connected with the upper die base is arranged between each baffle and the corresponding supporting shoe; the outer side of each stamping block is abutted against the corresponding baffle; the inner side of each stamping block is provided with an oblique plane in compression joint with the corresponding limiting boss. Compared with the prior art, the punching die disclosed by the invention has the characteristics that the shield is arranged on the workpiece locating block, punching processing is performed on the shield by the first punch and the second punches simultaneously, the shield can be easily clamped, and the production efficiency is high.

Owner:GUANGXI WUZHOU YUNLONG PORT & SHIP MACHINERY MFG

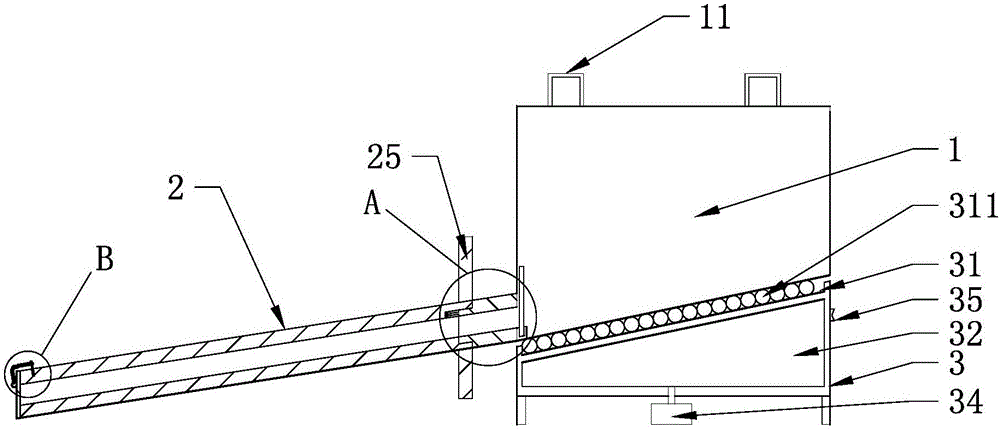

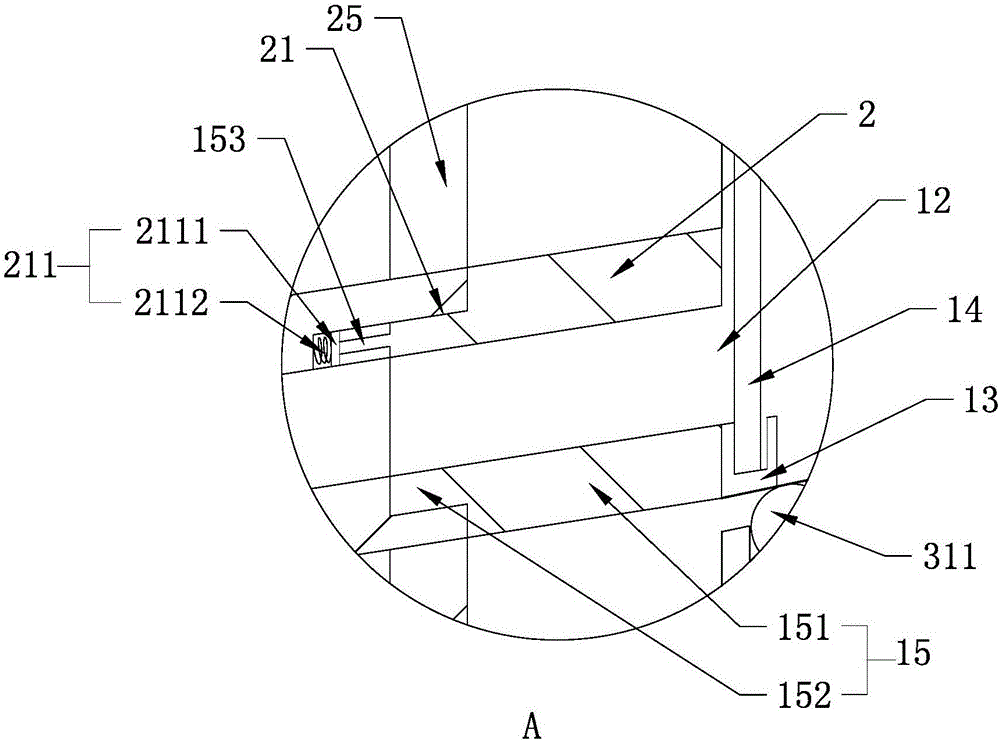

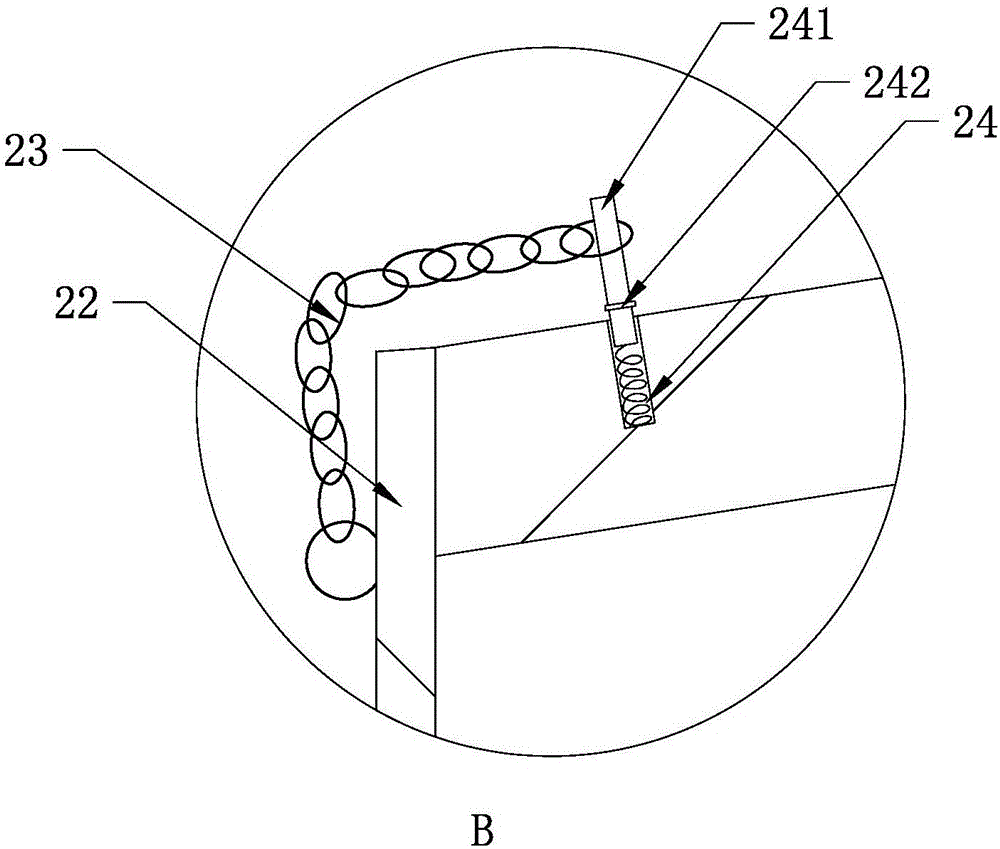

Secondary structure concrete transportation tool capable of being manufactured on site

ActiveCN106335796ALabor savingImprove work efficiencyLarge containersLoading/unloadingEngineeringMechanical engineering

The invention discloses a secondary structure concrete transportation tool capable of being manufactured on site. The tool comprises a hopper, a pump pipe and a base; hanging rings are arranged at the top of the hopper; a discharging port is formed in the lower part of the hopper; a baffle is arranged in the hopper; the discharging port is connected with a discharging pipe; a circular concave port allowing the discharging pipe to be clamped is formed in one end of the pump pipe; a normally-closed switch is arranged at the bottom of the concave port and comprises an elastic piece and a reset spring; a bulge capable of abutting against the normally-closed switch is arranged on the discharging pipe; a stop plate is arranged on the pump pipe; a groove is formed in the base; a plurality of balls bulging out of the groove are arranged in the groove; a positioning plate is hinged to the base; a sliding groove is formed in the positioning plate; a driving rod is connected in the sliding groove; a gas cylinder is connected onto the driving rod; a normally-opened switch is arranged on the base; and the normally-opened switch, the normally-closed switch, the gas cylinder and a power supply are connected in series. According to the tool, the hopper is placed on the base by the aid of a tower crane and is mounted automatically, the whole process is labor-saving, the labor is saved, construction is facilitated, and the working efficiency is improved.

Owner:ZHONGTIAN CONSTR GROUP

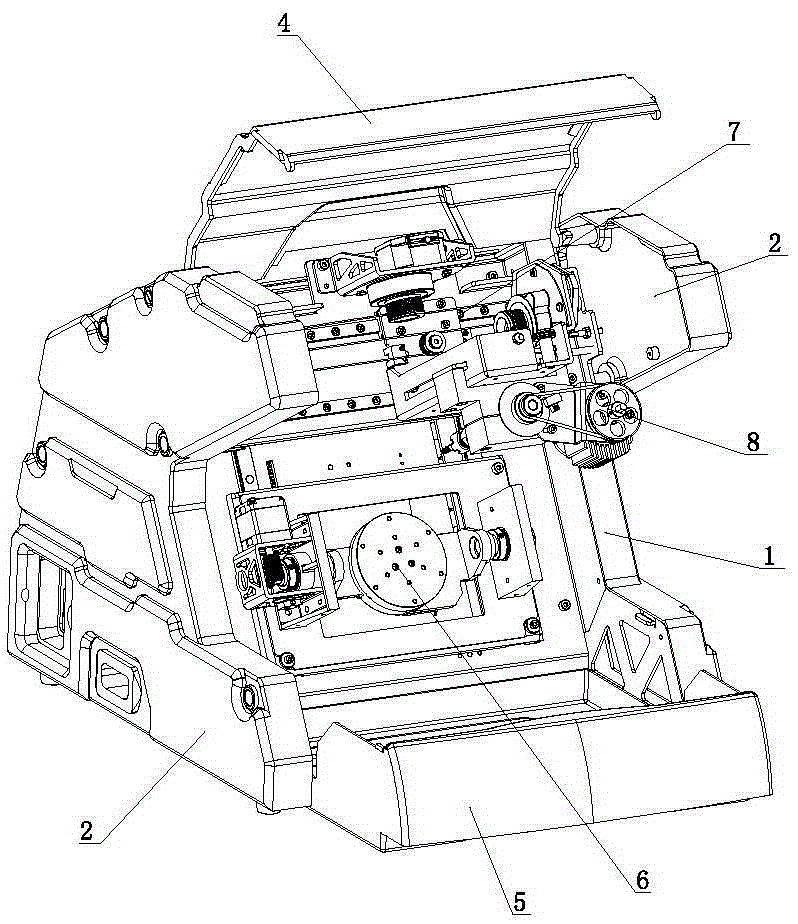

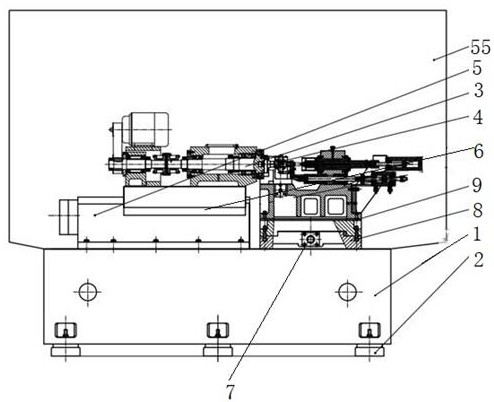

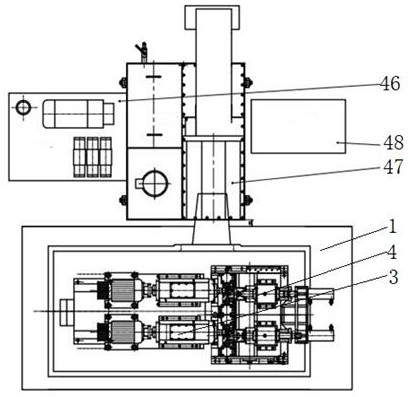

Five-axis numerical control machining center

ActiveCN105364491AHigh strengthImprove bending resistanceOther manufacturing equipments/toolsLarge fixed membersNumerical controlEngineering

The invention discloses a five-axis numerical control machining center which comprises a machine frame, side covers, a rear cover, a protective cover, a material supporting device, a working table device, a standing arm device and a spindle device, wherein the side covers are matched with bayonets on the machine frame through buckles and are connected and fastened through bolts; the rear cover is mounted on the machine frame; the protective cover is hinged to the side covers; the material supporting device is arranged on the machine frame in a sliding way; the working table device is fixed on the machine frame; the standing arm device is fixed on the working table device; and the spindle device is fixed on the standing arm device. According to the five-axis numerical control machining center, the supporting stability of the machine frame is improved, and the side covers can be positioned better and fixed firmly when mounted; scraps are convenient to clean, the material supporting device is spaced, and meanwhile movement of the material supporting device is guided better; both horizontal motion and rotation can be realized, the horizontal motion guiding property is good, a fourth-axis sliding seat can be guided initially, the moving accuracy of a fifth-axis sliding seat is high, and heat of a diving motor can be dissipated better.

Owner:烟台前创软件科技有限公司

Angle bracket installation riveting point seat and riveting point device of photovoltaic module frame

PendingCN112775251APrevent collapseAvoid deformationMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention relates to a angle bracket installation riveting point seat and riveting point device of a photovoltaic module frame. The angle bracket installation riveting point seat of the photovoltaic module frame comprises a supporting core, wherein the supporting core comprises an opening supporting part and an inner cavity supporting part, the opening supporting part can be matched with an opening fastening part of the photovoltaic module frame, and the inner cavity supporting part can be matched with a cavity of the photovoltaic module frame. According to the angle bracket installation riveting point seat, by arranging the opening supporting part and the inner cavity supporting part which are matched with the photovoltaic module frame, support is provided for riveting point processing of the photovoltaic module frame, collapse and deformation of the photovoltaic module frame are prevented, and the qualified rate of finished products of the photovoltaic module frame is improved; the phenomena of slab staggering and angle seams during splicing of long frames and short frames caused by collapse and deformation of the photovoltaic module frame are avoided, and the assembly quality of the photovoltaic module frame is improved; and the locking force of an angle bracket and the photovoltaic module frame is improved, and the assembly firmness and reliability of the photovoltaic module frame and the angle bracket are improved.

Owner:CITIC BOHAI ALUMINUM IND HLDG COMPANY

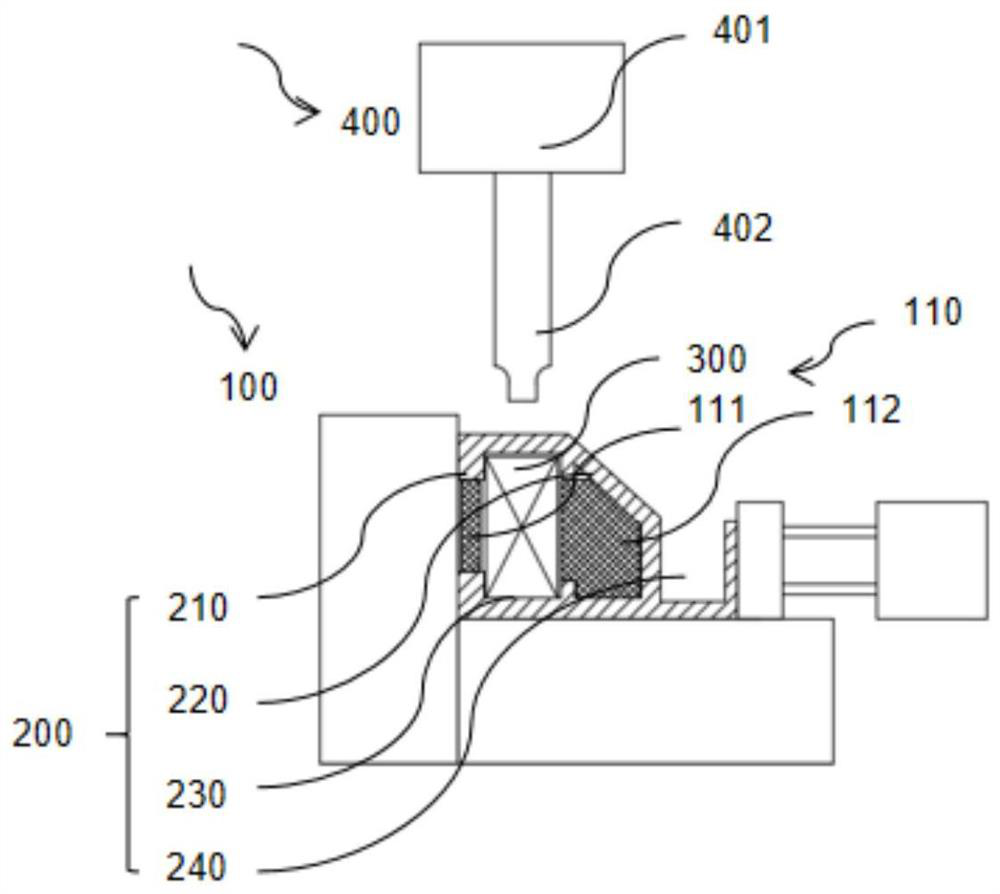

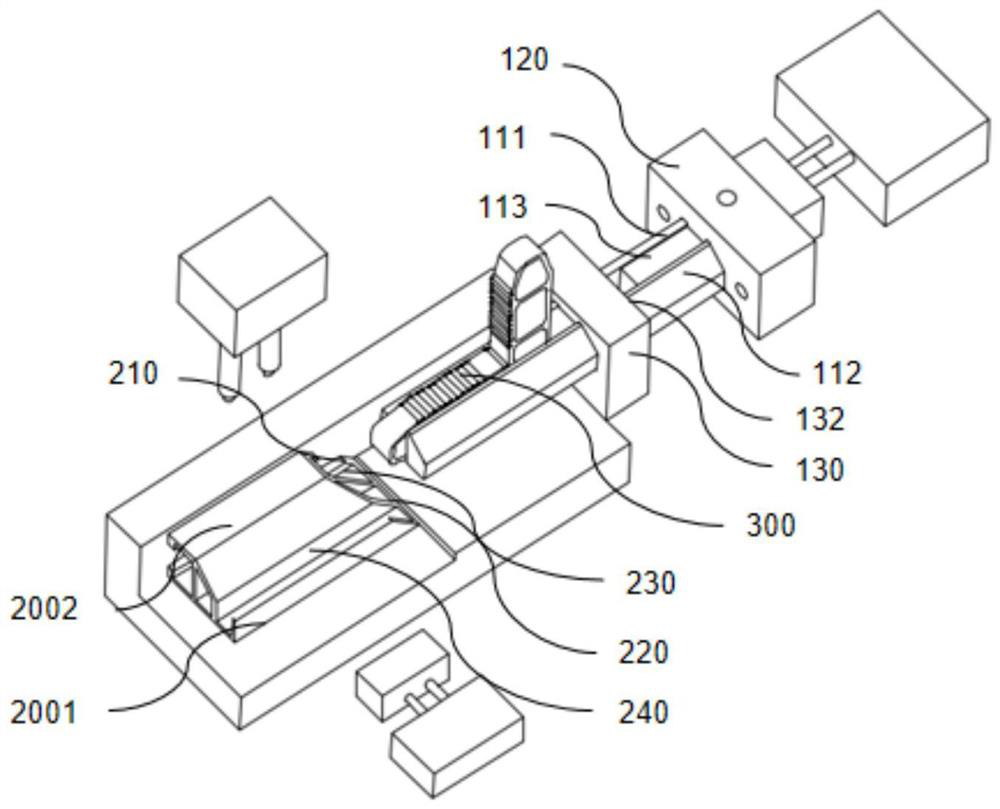

Fuel injector drive system

The invention discloses a driving system of a fuel injection device, which comprises a driving cylinder and a connecting plate, wherein the top end of the piston of the driving cylinder is fixedly connected with the connecting plate, and the fuel spraying device is fixed on the connecting plate, and is characterized in that, The drive system of the fuel injection device also includes a slide block and a guide rail, the guide rail is fixed on the operating platform, it is arranged parallel to the piston, and the slide block is arranged at the bottom end of the connecting plate, and the slide block is provided with a Grooves for a slip fit. The present invention effectively ensures the accuracy of positioning, effectively overcomes the uncertainty of the position of the oil outlet of the fuel injection needle, and ensures the quality of the product. The relative sliding fit realizes the up and down movement of the fuel injection device and enhances the adaptability of the fuel injection device to different products and fuel injection requirements.

Owner:SIP GOLDWAY TECH

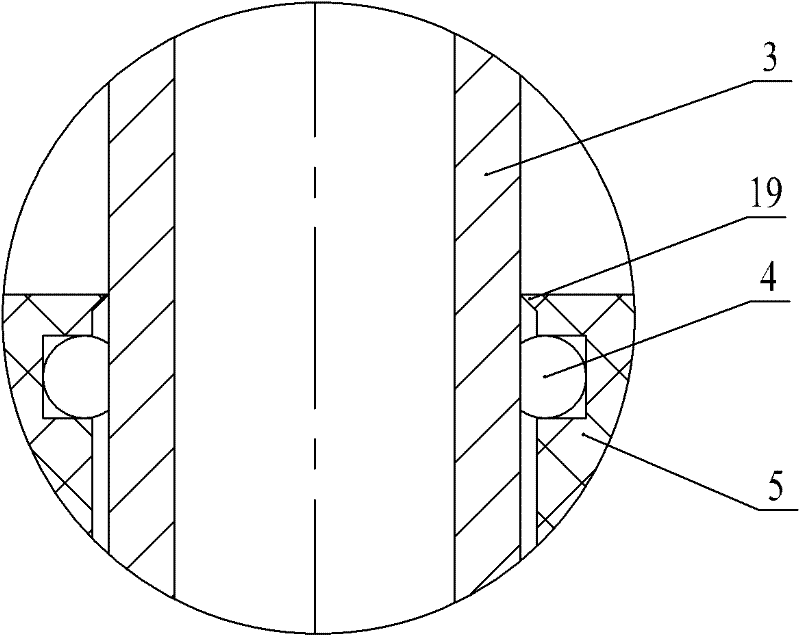

Valve rod irrotational structure of corrugated pipe check valve

InactiveCN104089035AGood sealing performanceProtective ToleranceSpindle sealingsOperating means/releasing devices for valvesCheck valveEngineering

A valve rod irrotational structure of a corrugated pipe check valve comprises a valve body, a valve rod, a metal corrugated pipe, a valve base, an anti-rotation flange, a valve cover, filler, a pressing bearing shell, an opening-closing threaded sleeve, a hand wheel or a handle and the like. The valve rod irrotational structure is characterized in that one end of the metal corrugated pipe is welded to the valve rod in a sealed mode, the other end of the metal corrugated pipe is welded to the anti-rotation flange in a sealed mode, an inner offset circle hole of the anti-rotation flange is matched with an offset circle of the valve rod, a corrugated pipe assembly is formed and arranged amount the valve body, the valve base, the valve cover, the filler, the pressing bearing shell and the opening-closing threaded sleeve, the opening-closing threaded sleeve drives the valve rod to move up and down linearly without rotation, when a valve is opened, stopping reverse sealing, metal corrugated pipe shielding sealing and filler sealing are achieved, and accordingly the corrugated pipe check valve can be used in high-temperature and high-pressure environments and is high in reliability.

Owner:JIANGSU XINGHE VALVE +1

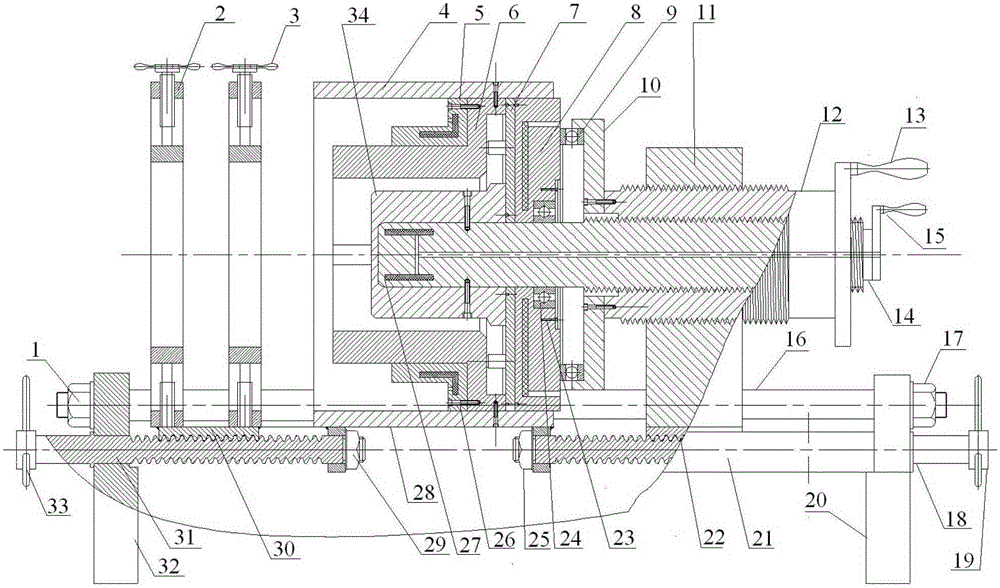

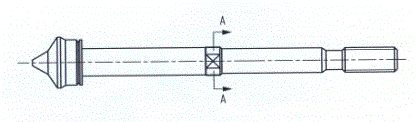

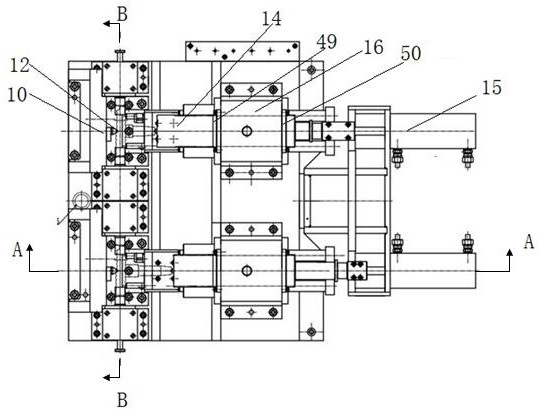

Special machine for fine boring of pin holes in crankshafts

ActiveCN113458430AMeet the machining accuracy requirementsMeet the needs of mass productionTailstocks/centresFeeding apparatusJackshaftCrank

The invention discloses a special machine for fine boring of pin holes in crankshafts. The special machine comprises a machine body, wherein a shock pad is arranged at the bottom of the machine body; a boring mechanism for driving a cutter to feed for boring and a clamp for pre-positioning, feeding, positioning and clamping the crankshafts are arranged on the upper portion of the machine body in the length direction; a hydraulic sliding table is arranged below the boring mechanism; a sliding saddle of the hydraulic sliding table is fixedly connected with the boring mechanism and drives the boring mechanism to finish feeding motion; a clamp adjusting mechanism is arranged at the bottom of the clamp; and the bottom of the clamp is fixedly connected with the clamp adjusting mechanism. According to the special machine, pre-positioning, feeding, positioning, clamping, boring and discharging processes of the crankshafts are automatically finished in one working cycle, fine boring of the pin holes and chamfering of hole ends are finished, the production takt is smaller than or equal to 35 seconds per 2 pieces, and the boring precision and the roughness meet grinding requirements; and the machining requirements of high efficiency and high precision of parts are met, the special machine is suitable for mass production, and the crankshafts with different diameters can be machined by adjusting the center distance between the pin holes and the crankshafts.

Owner:NANJING INST OF TECH

Electromagnetic valve with differential pressure resistance valve core

ActiveCN102537484BLimited travelImprove sealingOperating means/releasing devices for valvesDifferential pressureAxial force

An electromagnetic valve with a differential pressure resistance valve core is composed of a valve rod, a press cap, a V-shaped sealing ring, a gasket, a sealing pad, a nut, a valve core, a large O-shaped ring, a stifle, a sealing gasket, a valve body, a valve core seat, a small sealing ring, a spring, a small O-shaped ring, a middle O-shaped ring and an electromagnet. The valve core is in a thin-wall cylindrical shape, one end of the valve core is open, the other end is provided with an end face plate, a step connected with the valve rod is positioned in the center of the end face plate, and through holes are arranged on the periphery of the step. A blocking shoulder is arranged at the periphery of the valve core to limit journey of the valve core to improve sealing performance. Under the action of the electromagnet, an upward-moving valve on the valve core is in a close state, pressure water is filled with the valve core and a cavity communicated with the valve core, the sum of axial force stressed on the valve core is nearly zero, pressure difference inside and outside the cylinder wall of the valve core is large, axial force stressed on in the cylinder wall is enough to enable the thin wall of the valve core to expand and deform, and sealing between the valve core and the valve is reliable. When the valve core moves downwards, the valve is open, and water pressure has no side effects on the valve core.

Owner:ZHEJIANG HENGSEN IND GROUP

Installation hole detection device

InactiveCN102735133BAccurate measurementSimple structureMechanical measuring arrangementsEngineering

Owner:TIANJIN BOXIN AUTOMOBILE PARTS

Anti-cutting installation tool for blind hole rubber ring

InactiveCN110091281AEasy to installAvoid the risk of being cutMetal-working hand toolsRubber ringScrew thread

The invention discloses an anti-cutting installation tool for a blind hole rubber ring. The anti-cutting installation tool comprises a guide rod, a scaling mechanism, an elastic ring and an expansionmandrel; the scaling mechanism is cylindrical; the lower part of the cylinder wall is provided with a groove in the axial direction; the lower end of the cylinder wall is provided with a step and an annular groove in the radial direction; the scaling mechanism is arranged at the lower section of the guide rod in a sleeving mode; the elastic ring is installed in the annular groove; and the expansion mandrel is fixed at the lower end of the guide rod through threads. The retractable scaling mechanism is designed, the sealing rubber ring is expanded and fixed in an inner rubber ring groove and then is filled with a sealing element, so that the problem of cutting off part of the rubber ring at the port when a sealing part is installed due to the fact that the sealing rubber ring cannot be centered in the sealing groove can be solved; and through the use of the device, a traditional installation method of the sealing rubber ring in the inner rubber ring groove can be improved, the risk thatthe rubber ring is cut after being installed is avoided, and the safety performance of a sealed product is improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Seal baiting valve

ActiveCN102094982BIngenious structureReasonable structureSpindle sealingsLift valveEngineeringValve seat

Owner:WUXI KINGREITER ANTISEPTIC EQUIP

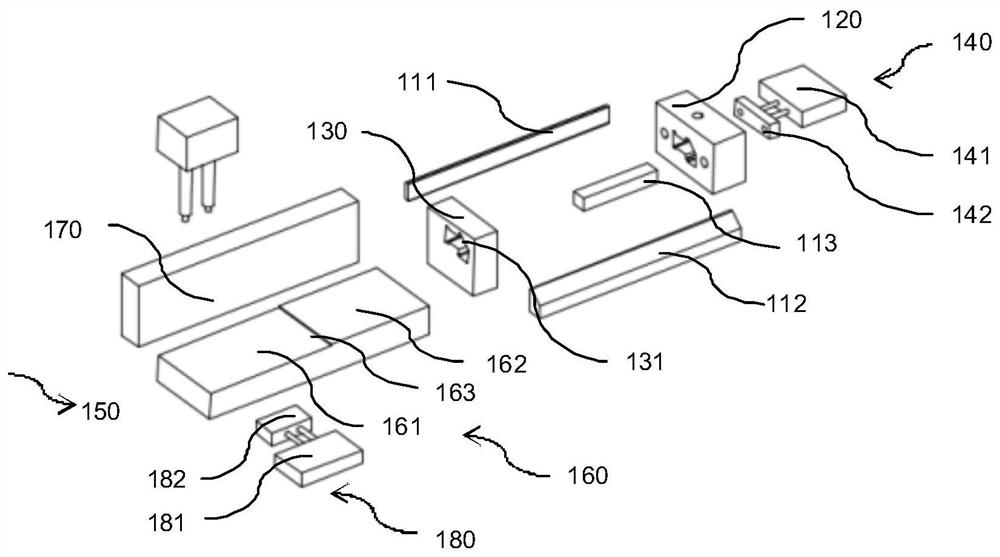

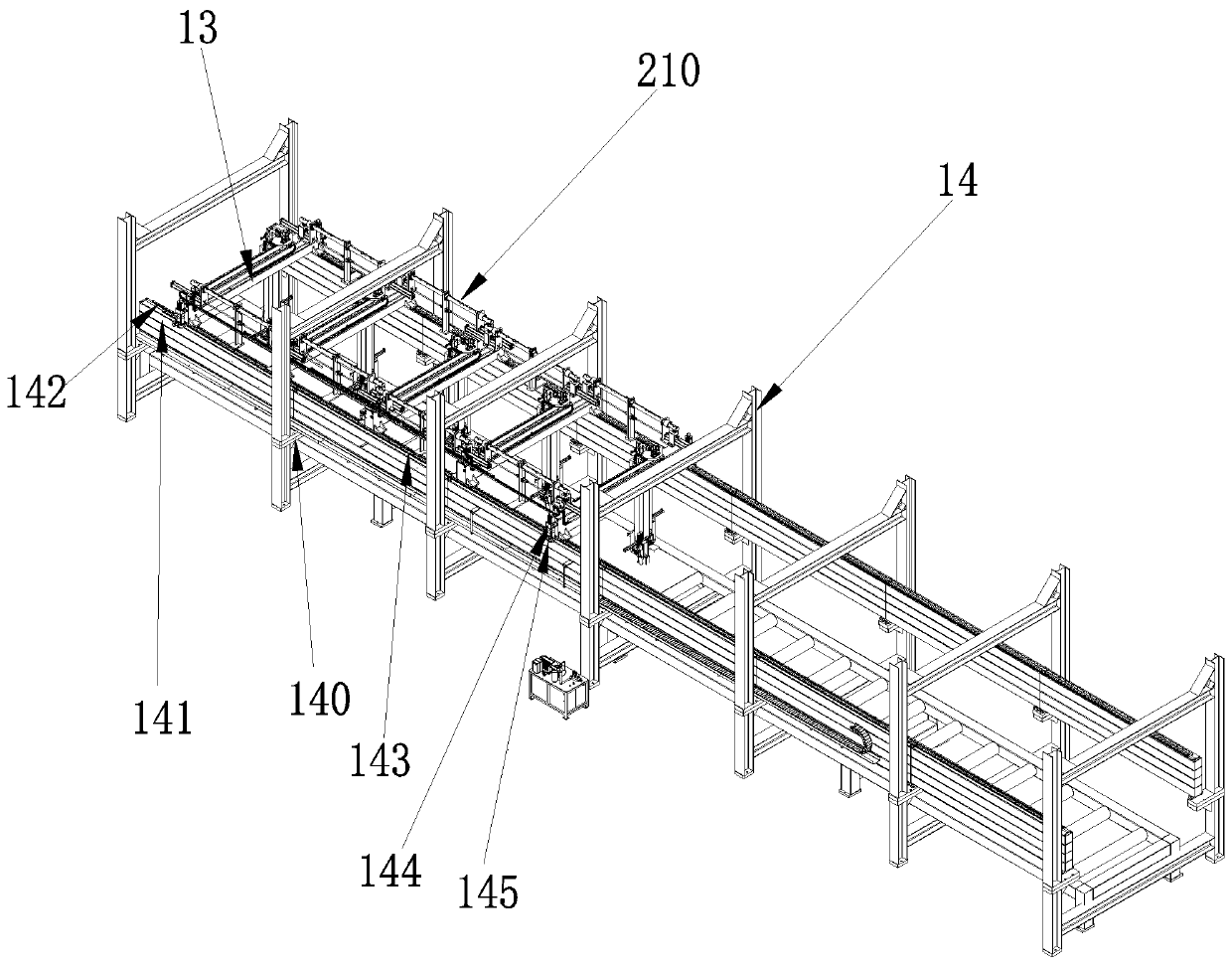

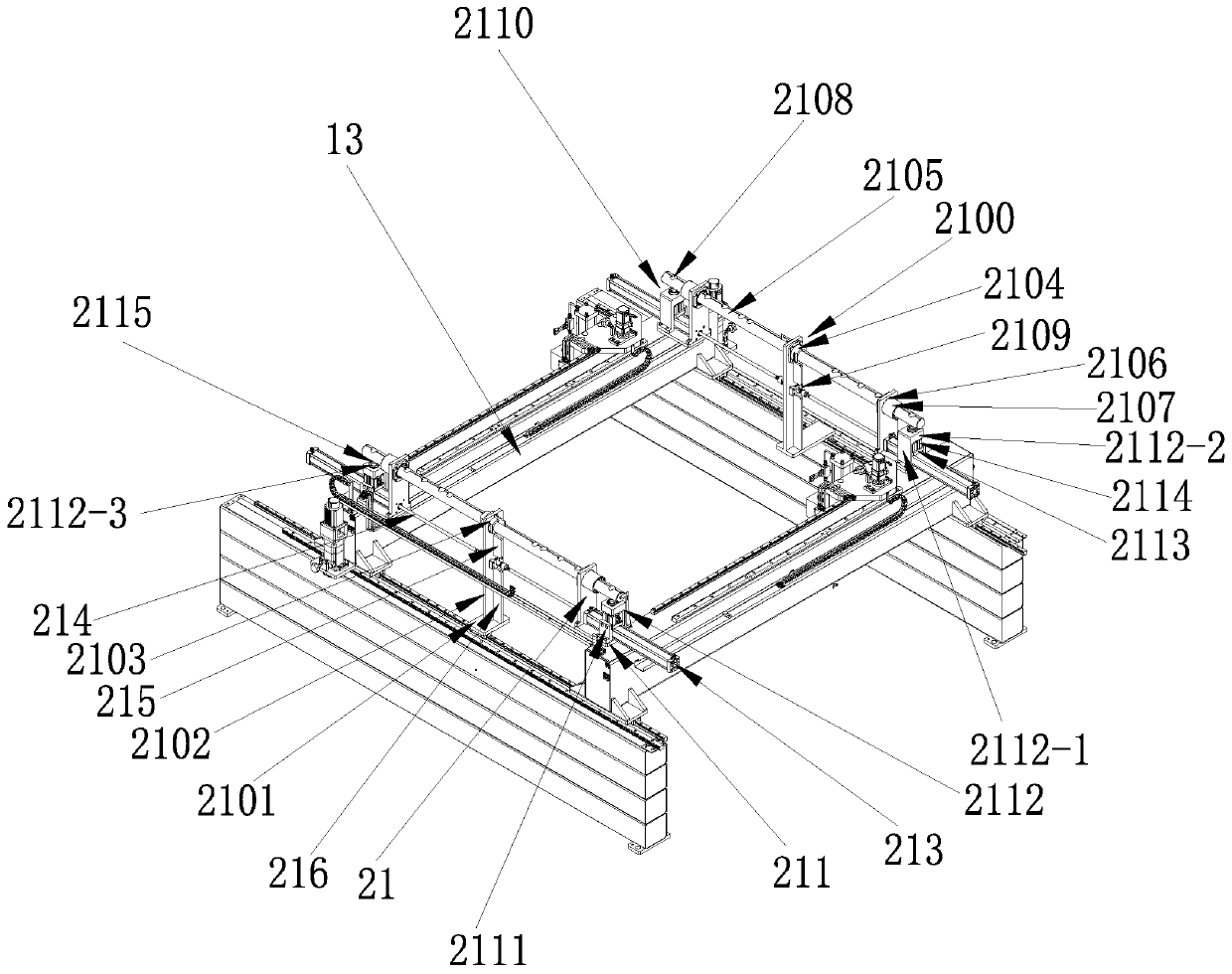

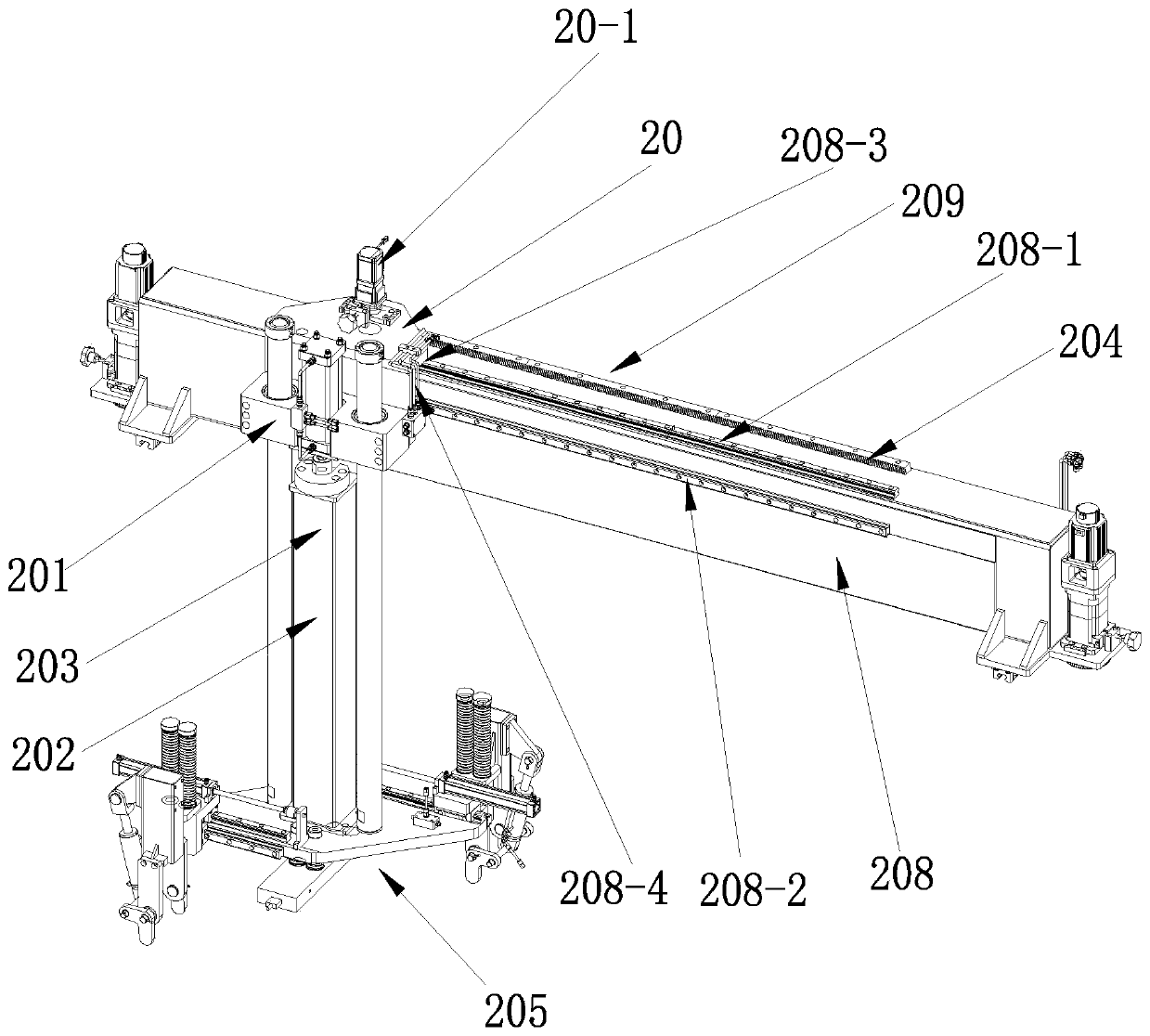

Truss type servo-transfer guide rail assembly

InactiveCN111300379AImprove processing efficiencySimple structureProgramme-controlled manipulatorGear wheelElectric machinery

The invention relates to a truss type servo-transfer guide rail assembly. The truss type servo-transfer guide rail assembly comprises a plurality of trusses and a plurality of grabbing and conveying devices; the two bottom sides of each truss are each provided with a truss supporting seat; each truss supporting seat is provided with a truss supporting block; the plurality of trusses are connectedby virtue of the supporting blocks; each truss supporting block is provided with a horizontal sliding rail; the plurality of grabbing and conveying devices are slidably connected to the horizontal sliding rails; a regulating mechanism is arranged between adjacent grabbing and conveying devices; one side of each horizontal sliding rail is provided with a first gear rack; one side of each grabbing and conveying device is provided with a driving motor; the lower side of the bottom of each driving motor is in transmission connection with a first gear; and each first gear is engaged with the corresponding first gear rack. The truss type servo-transfer guide rail assembly provided by the invention is simple in structure, convenient and practical, can implement feeding and material transfer treatment by virtue of the plurality of grabbing and conveying devices which are arranged, and greatly improves the efficiency of machining of steel plates by division of coordination work of a plurality of manipulators.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Heightened gear plate limiting device for hay mower

The invention discloses a heightened gear plate limiting device for a hay mower. The heightened gear plate limiting device comprises a heightened gear plate, two or more saw teeth are arranged on the periphery of the heightened gear plate, the saw teeth are in matched connection with an adjusting handle, and the outer side face of the heightened gear plate is connected with coaxial hay mower rear wheels; the saw teeth are arranged on the periphery of the heightened gear plate, axial extending segments are arranged on the two saw teeth at the left end and the right end, and the axial distance between the extending segments and the hay mower rear wheels is smaller than the diameter of the adjusting handle. Through the extending segment structures at the left end and the right end, on the basis of not additionally increasing the limiting, the axial distance between the extending segments and the hay mower rear wheels is reduced, and therefore the adjusting handle cannot be separated from the device, the stroke of the adjusting handle is limited, and the peril incidents caused by grounding of blades controlled by the heightened gear plate are prevented.

Owner:陈斌

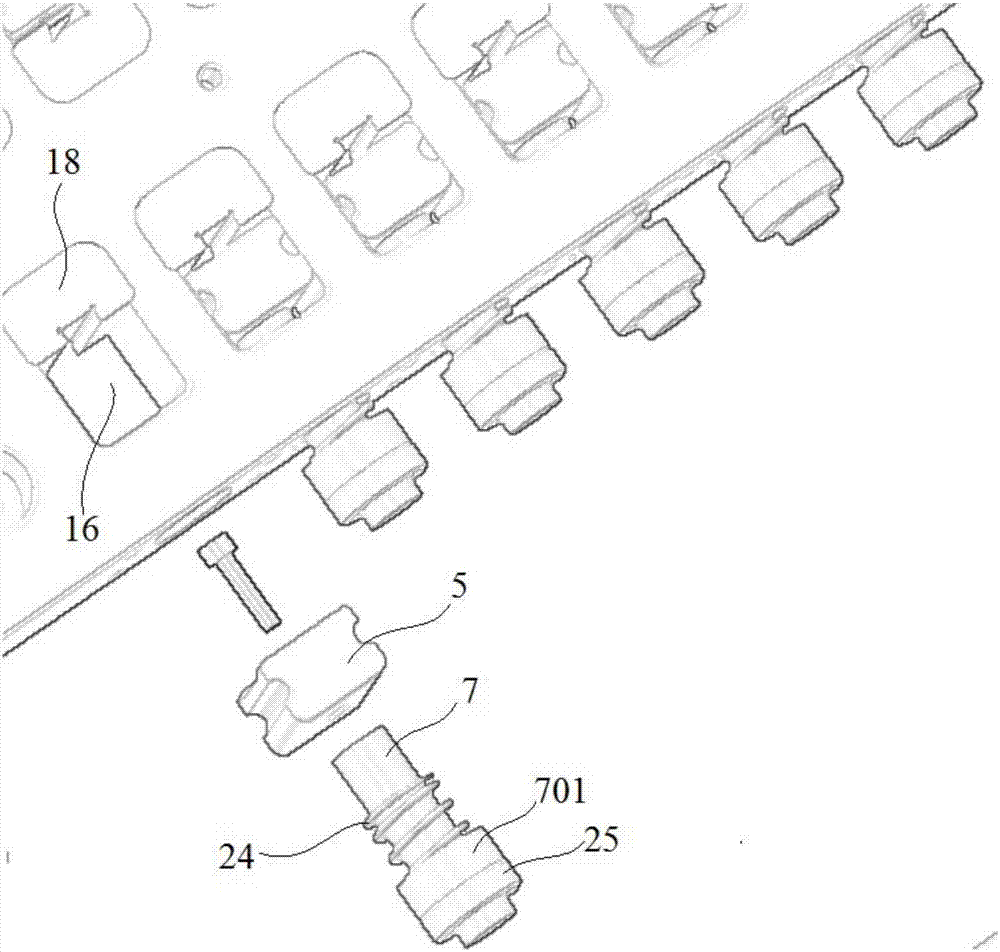

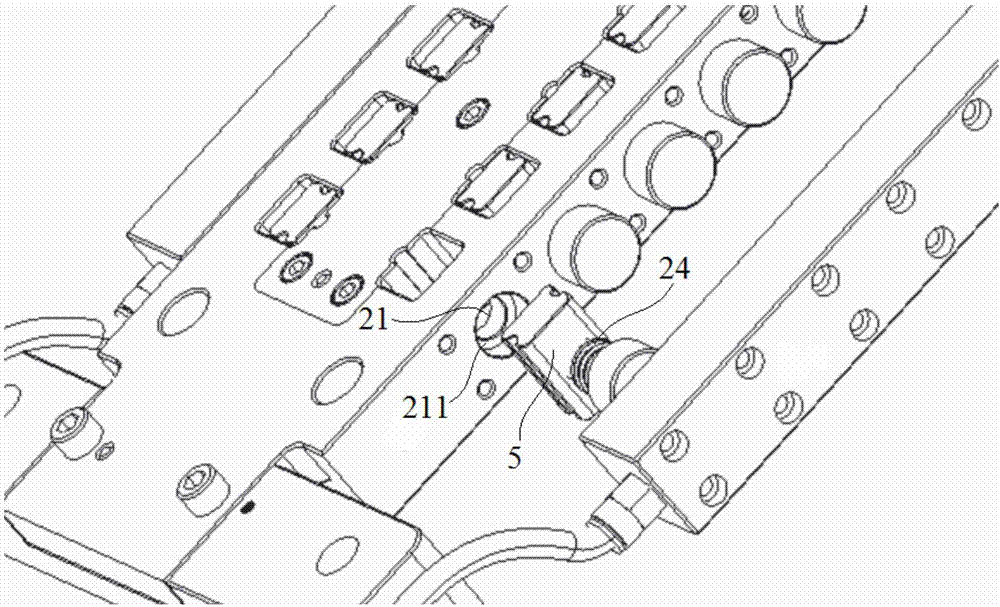

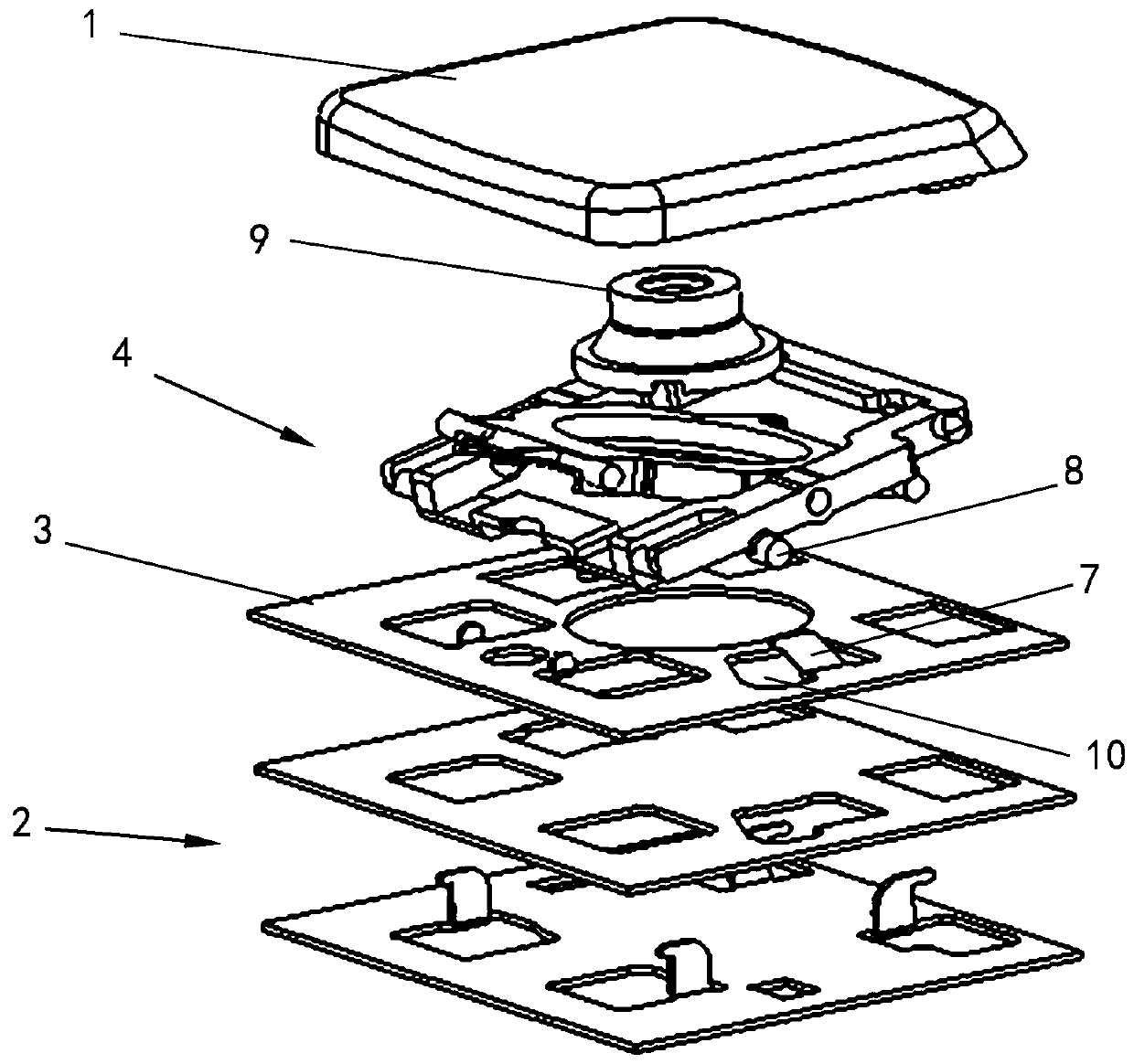

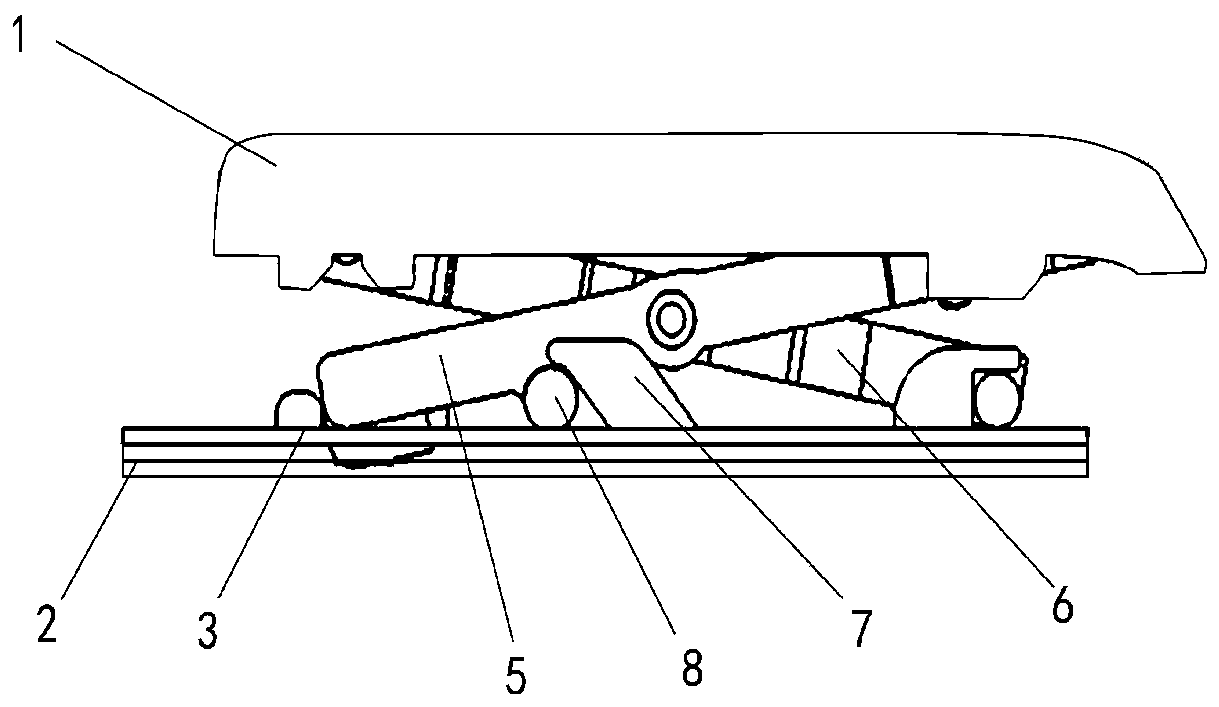

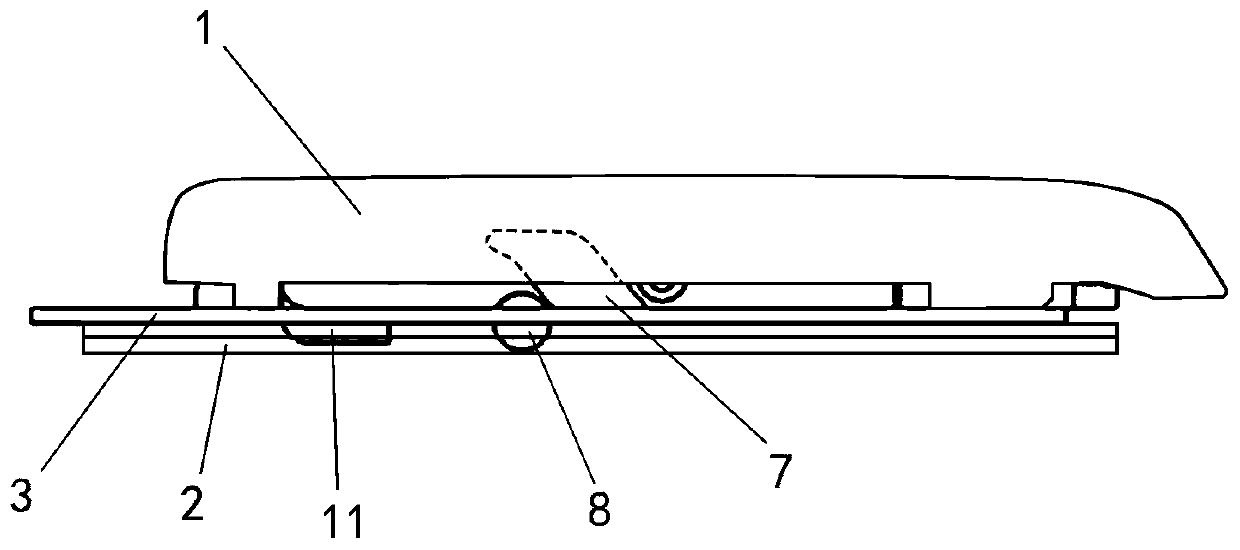

Key mechanism and electronic equipment

ActiveCN111508751AControl altitudeLimited travelHigh-tension/heavy-dress switchesAir-break switchesKey pressingStructural engineering

The embodiment of the invention provides a key mechanism and electronic equipment. The key mechanism comprises a key cap, a conductive base and a lifting assembly which abuts against the key cap and the conductive base, and the lifting assembly descends together in the process that the key cap is pressed from a first position to descend to a second position and accumulates restoring force so as tobe used for pushing the key cap to do ascending motion towards the first position, wherein the height, relative to the conductive base, of the first position meets a specific threshold value; the lifting assembly comprises a first stopping part and a second stopping part, the first stopping part and the second stopping part abut against each other at least when the key cap is located at the firstposition, force is applied to the lifting assembly so as to offset part of the restoring force, and it is guaranteed that when the key cap rises to the first position, the key cap stops rising continuously. The key mechanism provided by the embodiment of the invention can effectively control the height of the key, and supports the light and thin design of the electronic equipment.

Owner:HEFEI LCFC INFORMATION TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com