Key mechanism and electronic equipment

A technology of buttons and keycaps, which is applied in the direction of circuits, electric switches, electrical components, etc., can solve problems such as inability to synchronize actions, the height of buttons cannot meet the design requirements of light and thin equipment, and poor coordination, so as to improve the use of tactile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

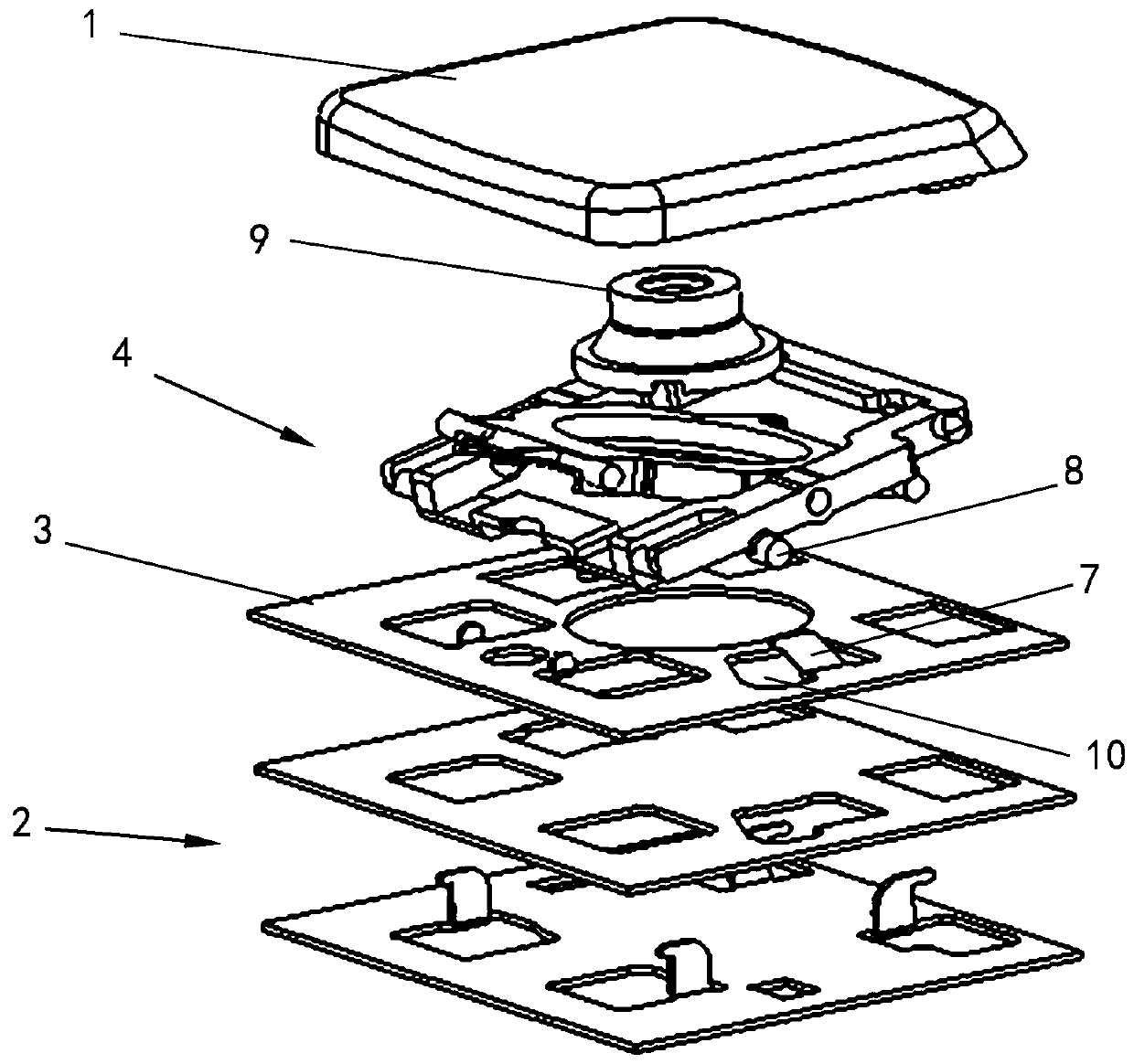

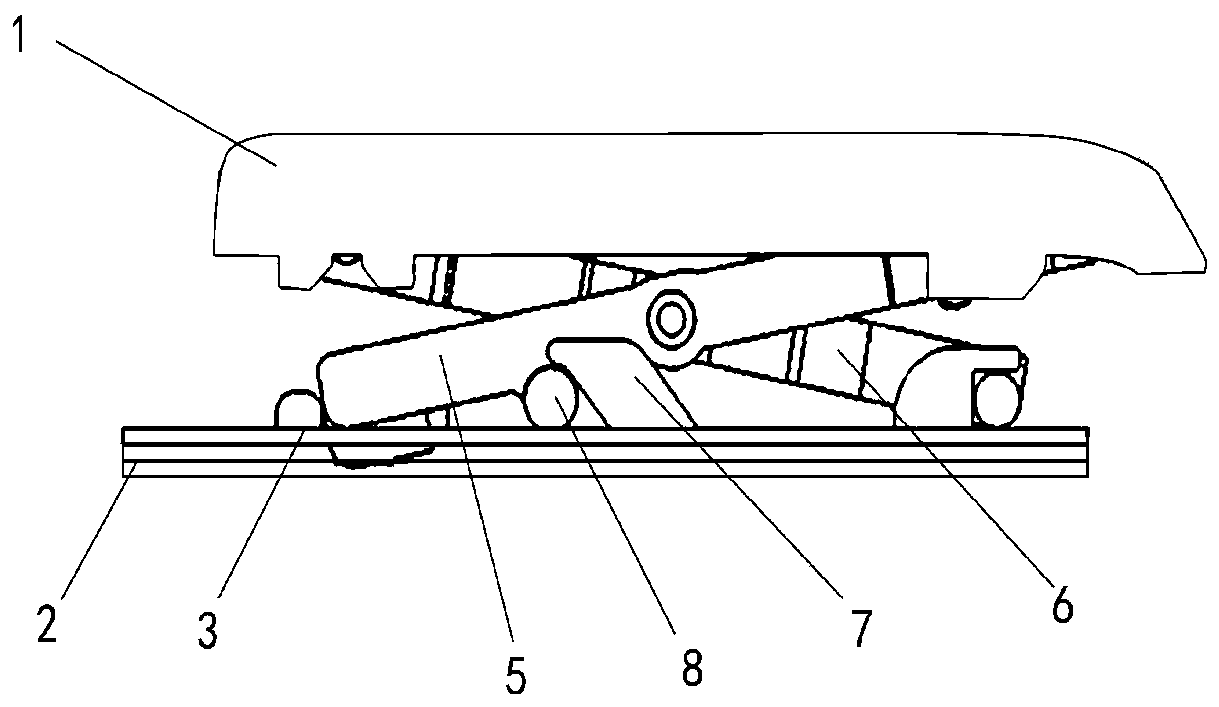

[0055] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the first stop portion 7 in this embodiment is formed by a portion of the limiting member 3 extending obliquely toward the keycap 1 , and can specifically be an inclined baffle. The second stop portion 8 is formed by extending part of the first bracket 5 toward the first stop portion 7 , and may specifically be a protruding post, such as a cylinder. The second stopper 8 is located between the first stopper 7 and the limiting member 3, and the first stopper 7 abuts against part of the second stopper 8 at least when the keycap 1 is in the first position, so as to A force towards the conductive base 2 is exerted on the lifting bracket 4 and the keycap 1 through the second stopper portion 8 . That is, at least when the keycap 1 is in the first position, the inclined surface of the first stopper 7 toward the direction of the conductive base 2 at least presses against a part of the second stopper 8, so as to ap...

Embodiment 2

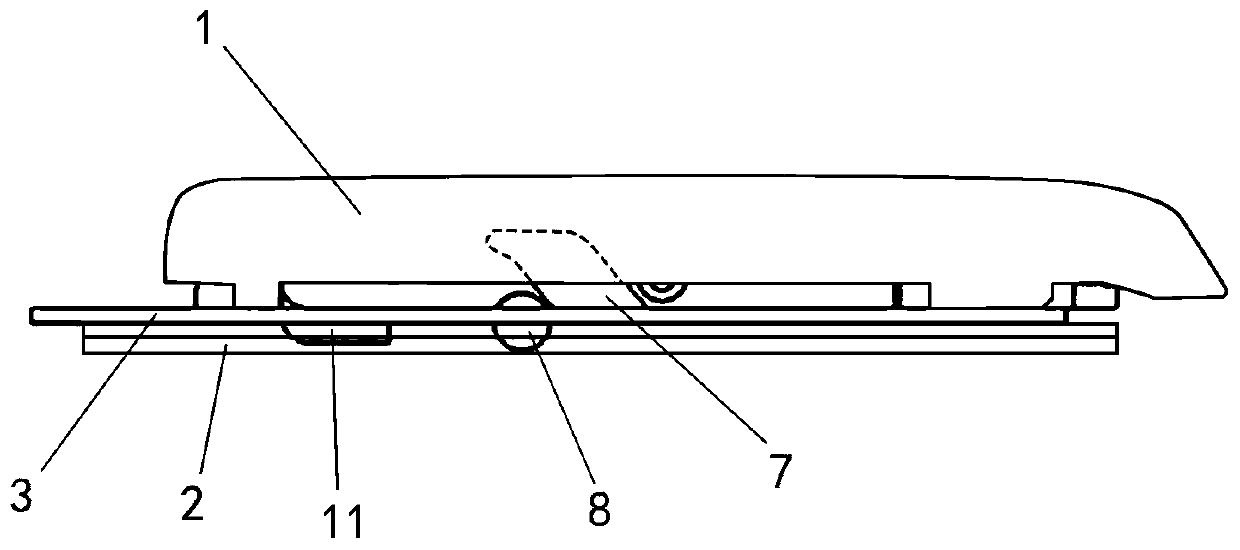

[0059] Such as Figure 5 , Figure 6 and Figure 7 As shown, the first stopper 7 in this embodiment is formed by extending part of the stopper 3 toward the direction close to the keycap 1, the first stopper 7 has a bending area, specifically as Figure 5 , Figure 6 As shown in , it is approximately in the shape of "7", wherein the part parallel to the conductive base 2 is the bending area. The second stopper 8 is formed by extending part of the first bracket 5 toward the first stopper 7, which can be specifically shown in the figure Figure 5 , Figure 7 The oblong body shown in the figure, the end of the second stopper 8 facing the limiting member 3 is inclined towards the bending area towards the limiting member 3, and at least when the keycap 1 is in the first position, it is in line with the bending area abut against each other so that the bending area can apply a force toward the conductive base 2 to the lifting bracket 4 and the keycap 1 through the second stopper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com