Electromagnetic valve with differential pressure resistance valve core

A solenoid valve and spool technology, applied in the field of solenoid valves, can solve problems such as leakage at the through hole of the separation layer and the meshing surface of the spool, increased load to open the valve, and pressure difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

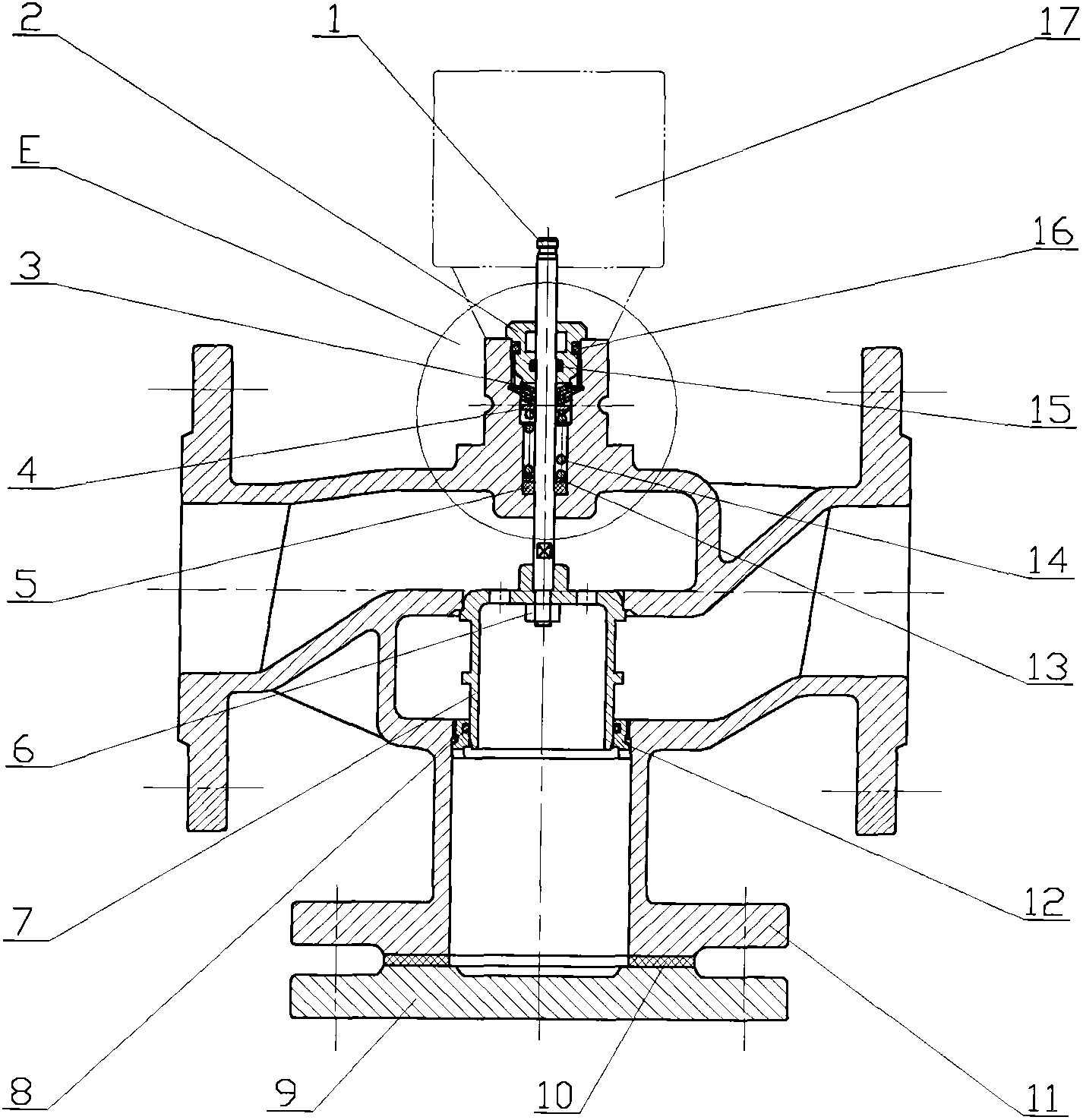

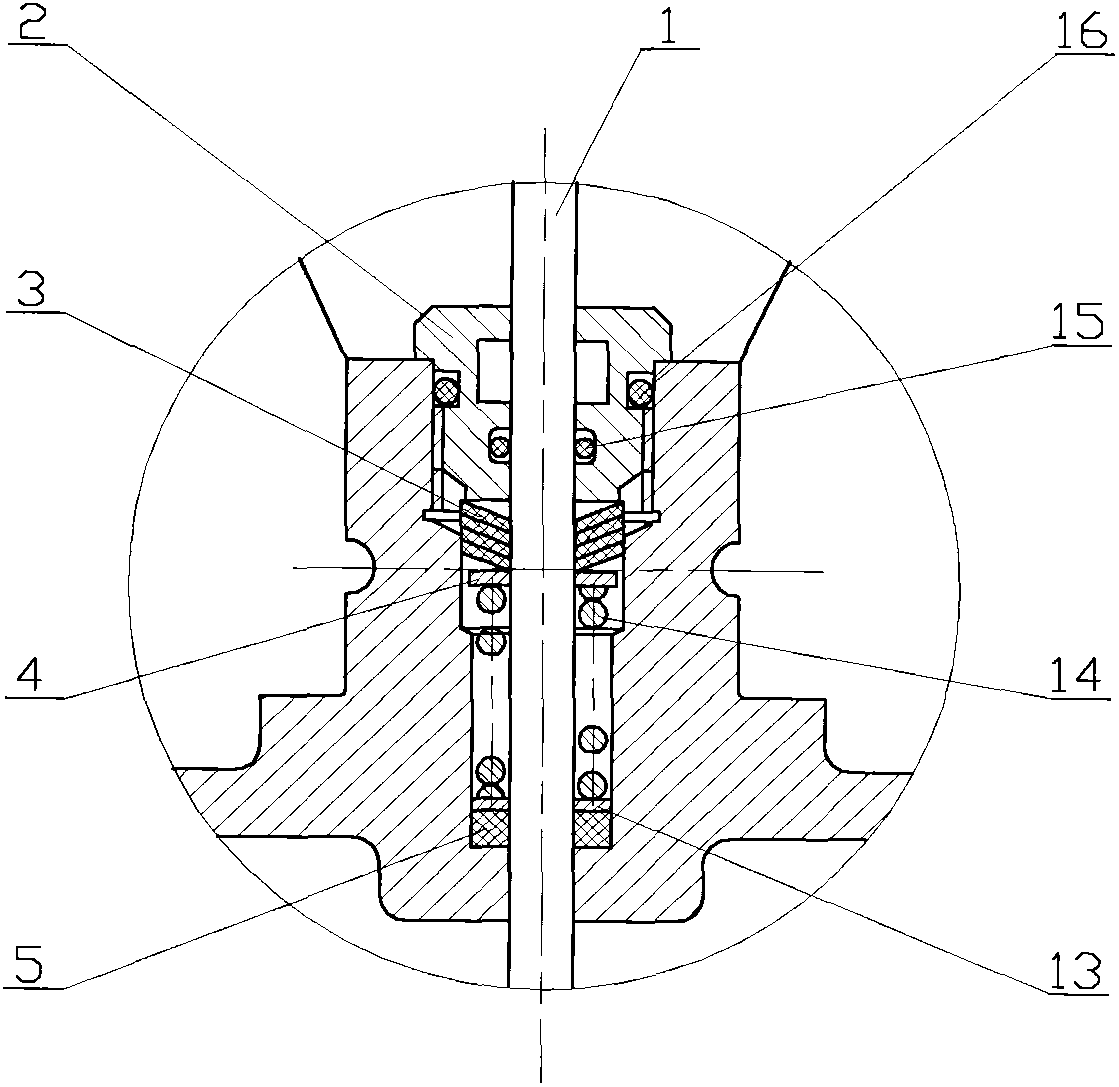

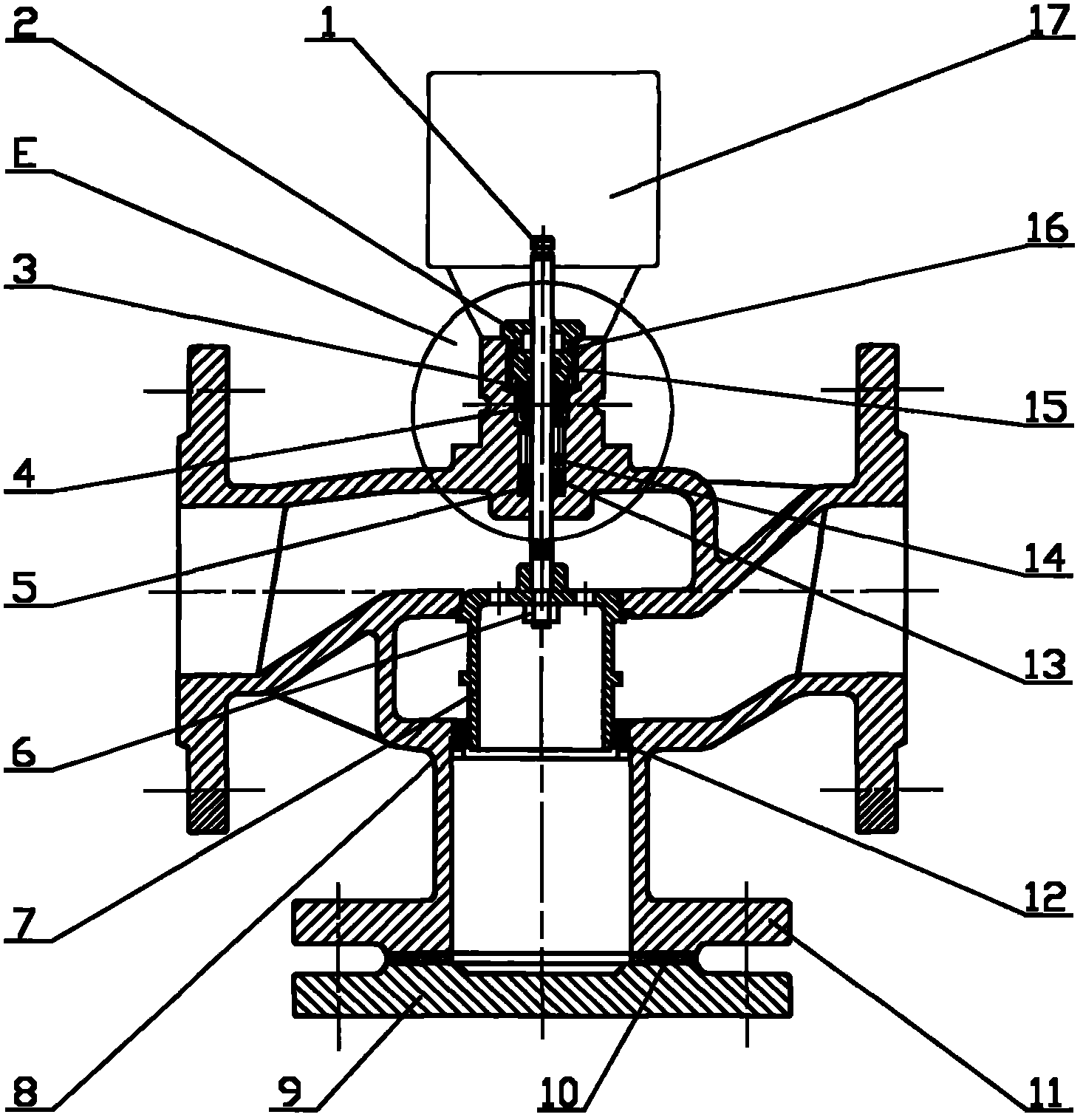

[0007] The valve body (11) is generally a T-shaped three-way structure formed by the straight-through pipe and the branch pipe intersecting. The three ports are equipped with flanges. The two ports of the valve body straight-through pipe have the same diameter. It is a plane passing through the axis, and the plane is perpendicular to the axis through which the branch pipe port runs through. There is a round hole centered on this through axis on the plane. In the section, the port of the branch pipe is lined with a sealing gasket (10) and then blocked with a stuffy cover (9). A spool seat (12) for guiding the movement of the spool (7) is provided at the junction of the inner cavity of the branch pipe port and the straight-through pipe to ensure that the spool (7) can be correctly positioned when it moves up and down. Above the round hole, that is, extending upward along the axis of the branch pipe port to the wall of the straight pipe, there is a boss for installing the valve s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com