High-pressure connecting rod type bellows globe valve

A bellows globe valve, connecting rod type technology, applied in the field of globe valves, can solve the problems of single structure and short service life of bellows globe valve, avoid valve stem vibration, avoid frequent replacement, improve sealing and durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

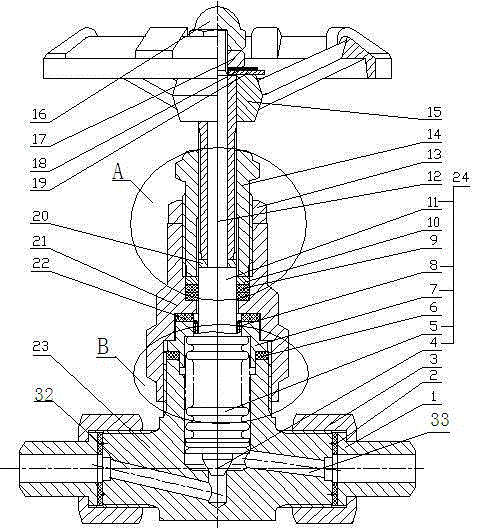

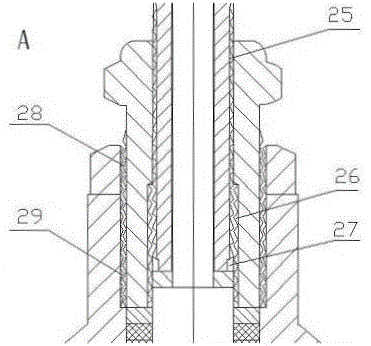

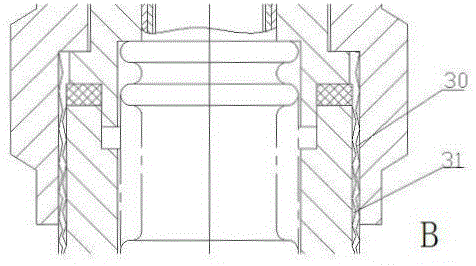

[0016] As shown in the figure, a high-pressure connecting rod bellows stop valve includes a valve body 23, a valve seat 21, a valve cover 14, and a hand wheel 15. An inlet 32 and an outlet 33 are provided on both sides of the valve body 23. The valve body The inlet 32 and the outlet 33 are provided with a connecting pipe 1, and a sealing gasket 2 is provided between the connecting pipe 1 and the inlet and outlet of the valve body 23, and the connecting pipe 1 is fixedly connected with the valve body 23 through a connecting nut 3, The valve body 23 is provided with a bellows assembly 24. The bellows assembly 24 includes a valve core 4, a bellows 5, a bellows welding sleeve 7, a welding bush 8, and a valve stem 11. The bellows 5 One end is connected with the valve core 4, the other end is connected with the bellows welding sleeve 7, the valve stem 11 is connected to the valve core 4 through the bellows welding sleeve 7 and the bellows 5, and the valve stem 11 and the bellows ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com