Fuel injector drive system

A fuel injection device and drive system technology, which is applied in the field of drive systems and fuel injection device drive systems, can solve the problems of reducing fuel injection quality and inaccurate positioning, and achieve the goals of ensuring accuracy, enhancing adaptability, and overcoming uncertainty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

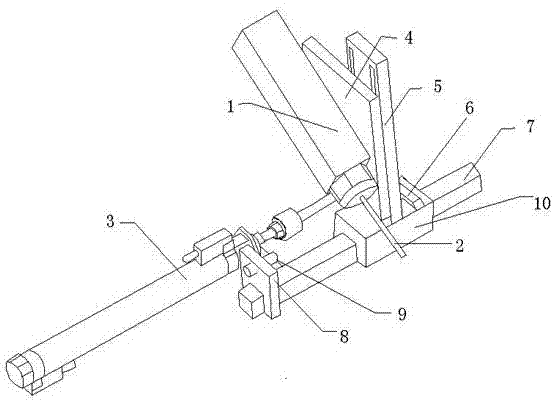

[0016] figure 1 It is a structural schematic diagram of an embodiment of the present invention.

[0017] Such as figure 1 As shown: the rotary fuel injection device includes a fuel injection needle 2, an oil supply device 1 for supplying oil to the fuel injection needle 2, a rotating shaft seat that forms the oil injection space of the rotating shaft, and can drive the fuel injecting needle 2 along the axial direction of the rotating shaft The driving system of the fuel injection device that performs reciprocating motion on the shaft seat, wherein the shaft seat is provided with a shaft and a cavity of the shaft driving device, the shaft driving device is fixed in the shaft driving device cavity on the shaft seat, and the shaft is suspended on the shaft In the rotating shaft cavity of the seat, the cross section of the rotating shaft cavity is a U-shaped long groove, and the rotating shaft is horizontally arranged in the U-shaped long groove, and it does not contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com