Opening weft insertion mechanism applicable to multilayer fabric weaving

A technology for a weft insertion mechanism and a multi-layer fabric is applied in the field of an open weft insertion mechanism and an open weft insertion mechanism for a loom, and can solve the problems such as the inability to make more than seven layers of multi-layer fabrics, the limited thickness of the multi-layer fabrics, and the like. Improve design diversity, avoid bending wear and breakage, and increase the effect of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

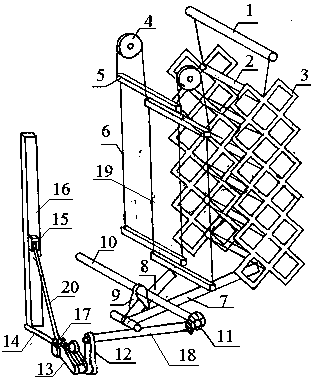

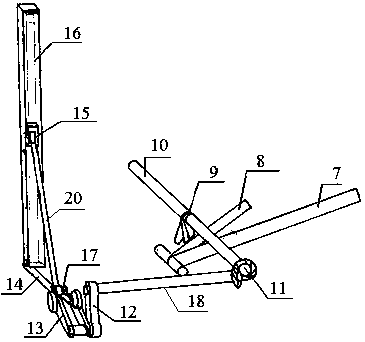

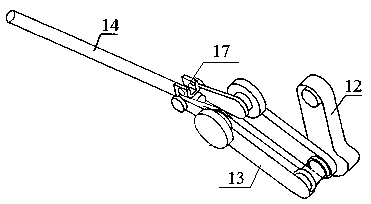

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail, see accompanying drawing.

[0019] A shedding weft insertion mechanism suitable for weaving multi-layer fabrics, comprising a heald frame in a loom, a shedding device and a weft insertion device, said shedding device is composed of more than two layered rollers 2 and two diamond-shaped lifting mechanisms 3 The number of layered rollers 2 can be determined according to the thickness of the woven fabric. The diamond-shaped lifting mechanism 3 is an integral mechanism formed by hinged steel sheets through bolts, nuts and gaskets. The layering rollers 2 are arranged in parallel and are respectively located between two rhombic elevating mechanisms 3 . Each layering roller 2 will carry the warp yarns of each layer respectively, forming a plurality of sheds when the rhombus elevating mechanism 3 is opened once. The two ends of the layered roller 2 are respectively connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com