Patents

Literature

203 results about "Pressboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressboard is a class of cellulose-based material constructed of several layers (plies) of paper which, when compressed using a combination of heat and pressure, form a stiff, dense material in a range of weights. Pressboard has been widely used in traditional school and office products such as spiral-bound notebooks and three-ring binders, but its unique physical characteristics lend itself readily to a variety of end-uses, including (but not limited to) document storage, filing supplies (classification and file folders), report covers, folding cartons, tags, labels, and industrial applications. It is commonly used to make the back panels of radios and some televisions. Pressboard may be converted using a number of different techniques (scoring, folding, die-cutting), and accepts a range of value-add decorating techniques (coating, foil-stamping, screen-printing, and embossing). Pressboard may contain recycled fiber content (including post-consumer waste), and is typically itself recyclable and biodegradable, making it an environmentally-sound choice for those seeking an alternative to petroleum-derived substrates.

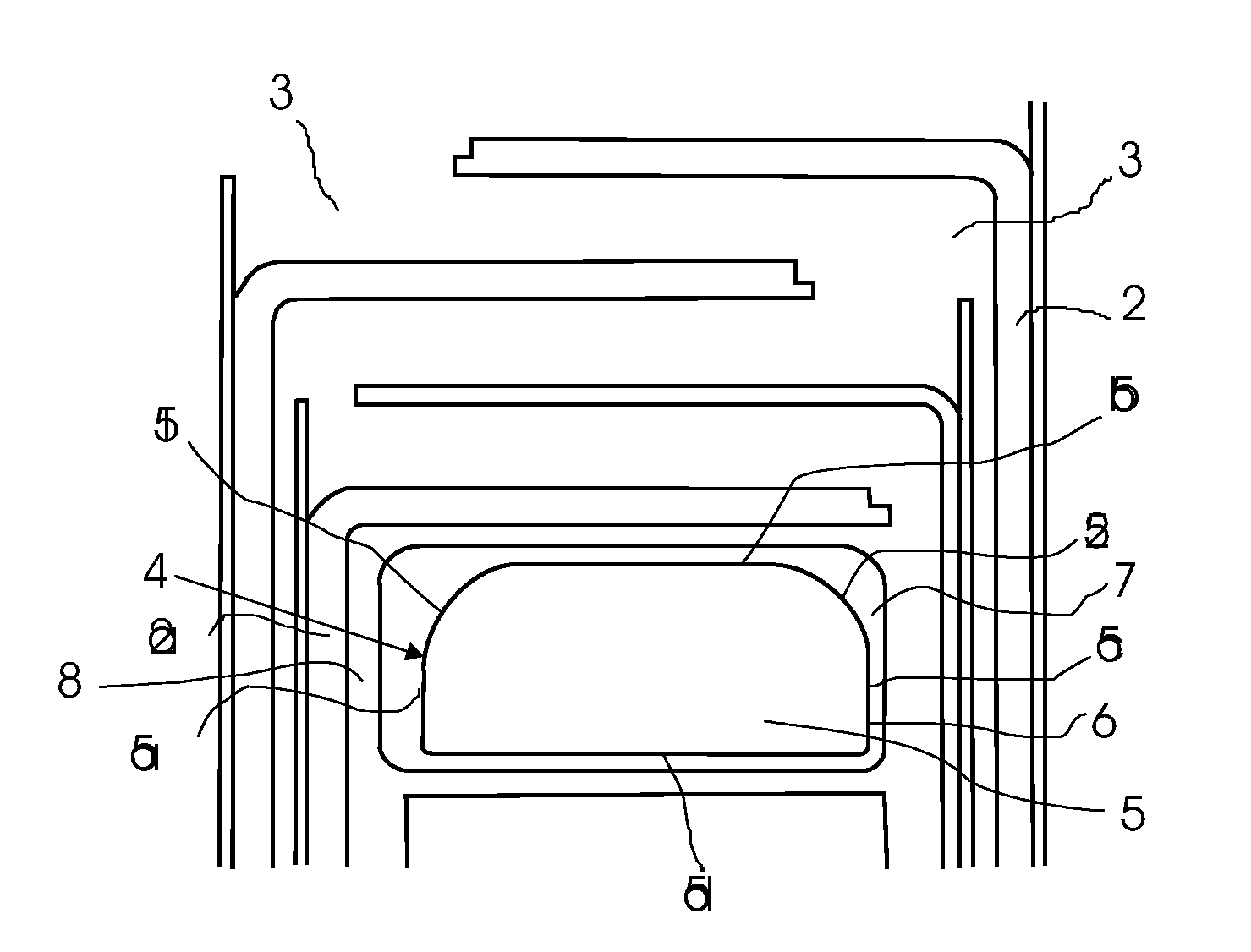

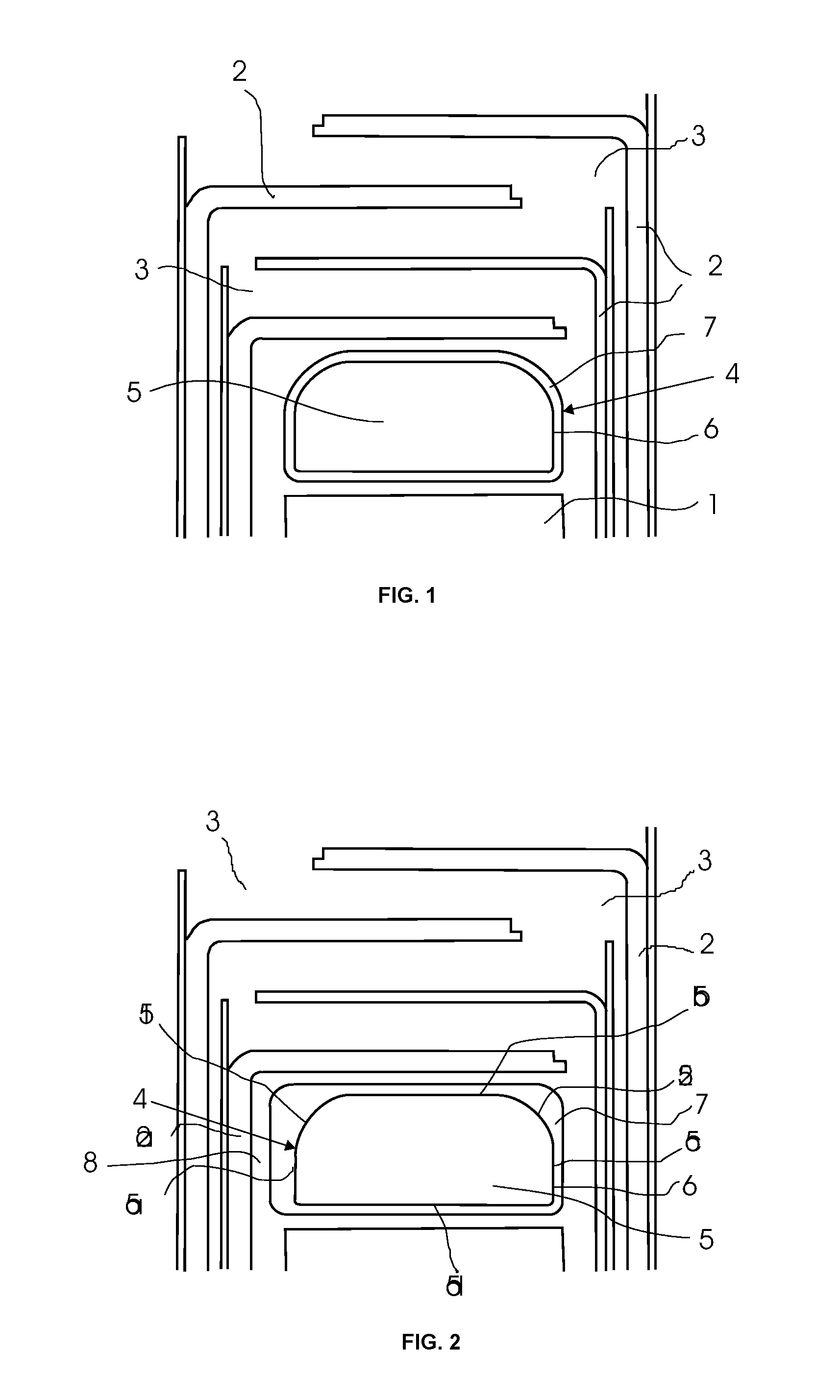

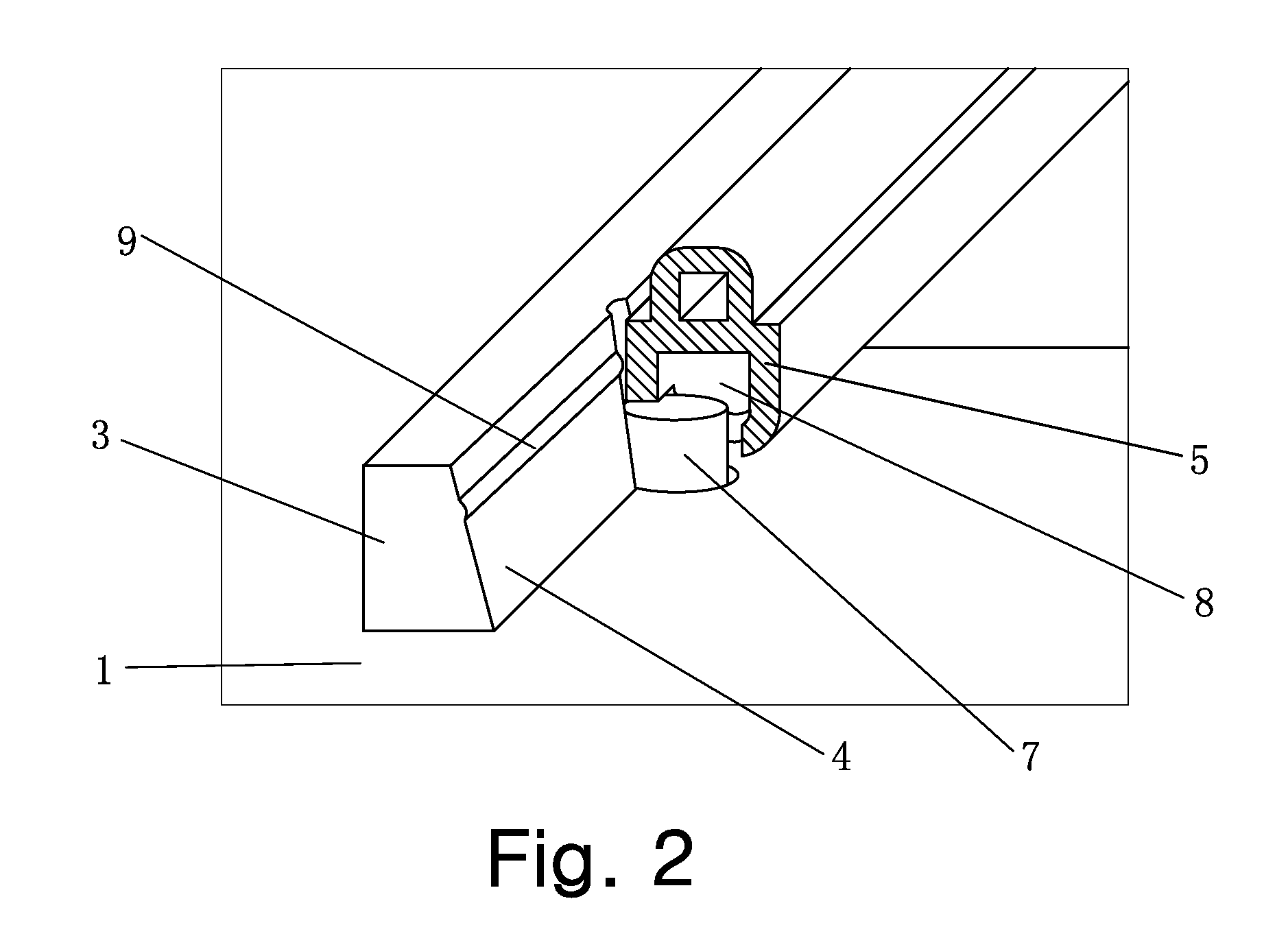

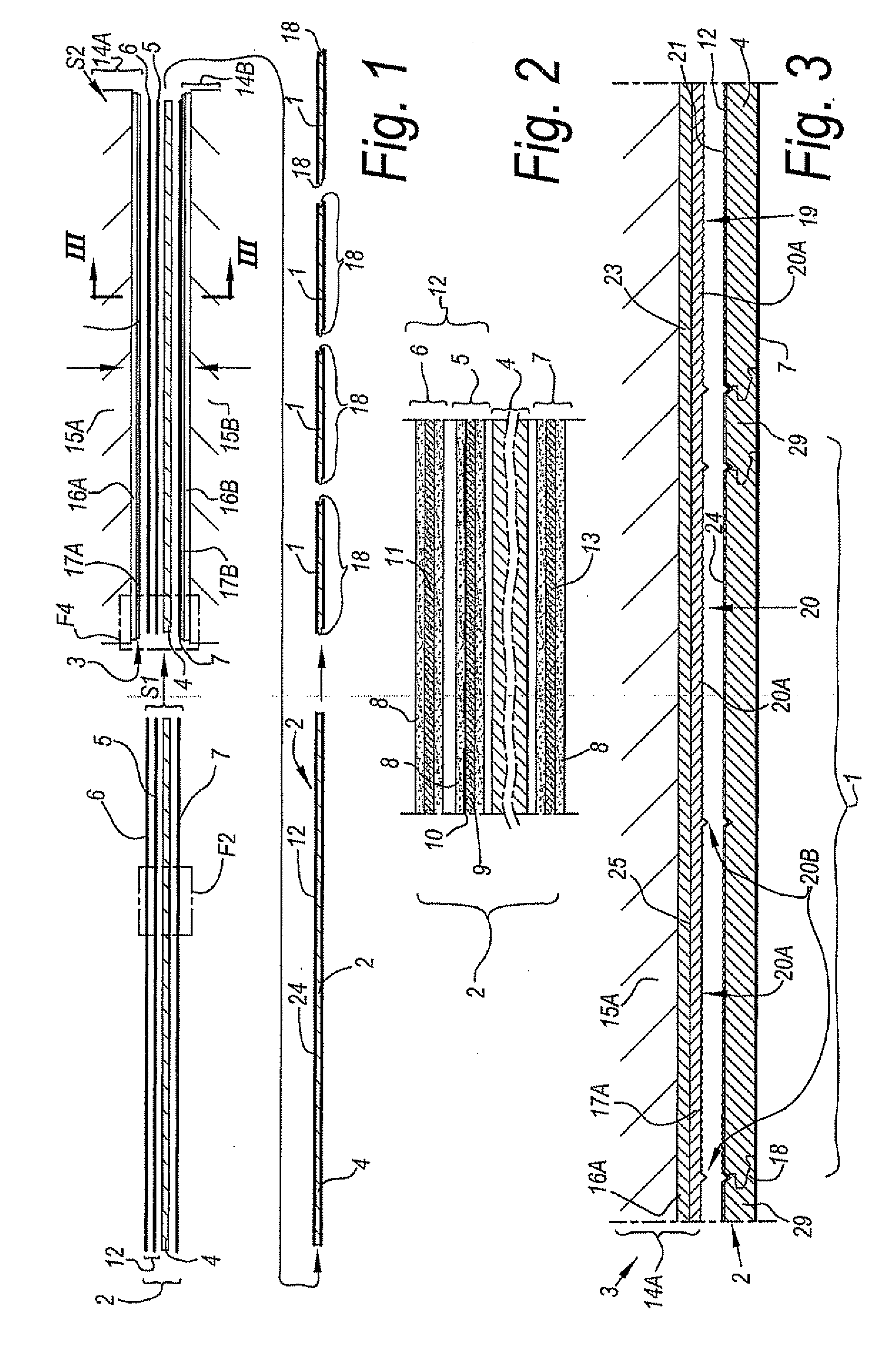

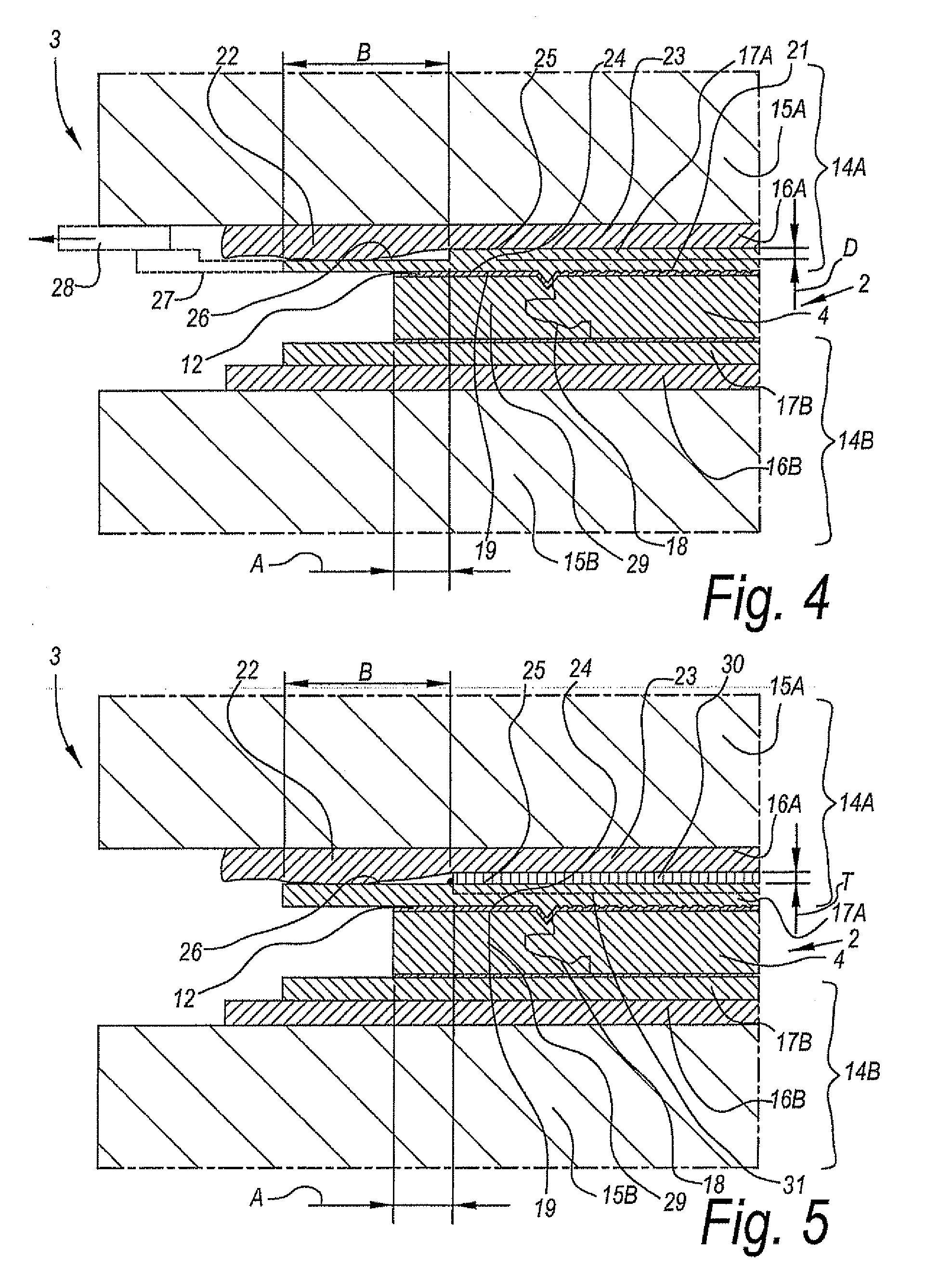

Sandwich panel and method of manufacturing same

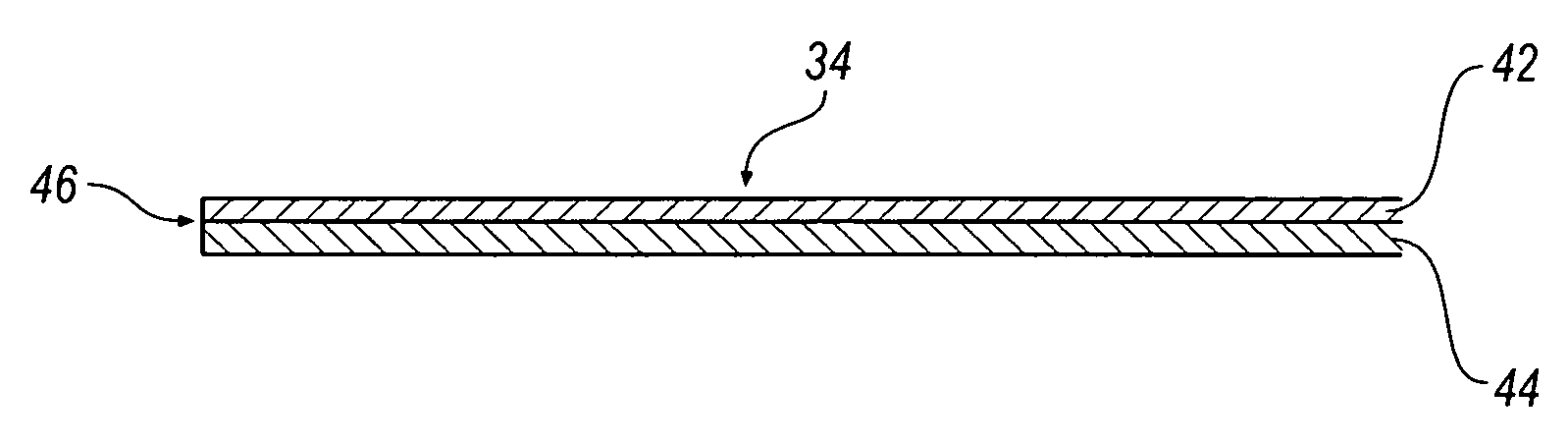

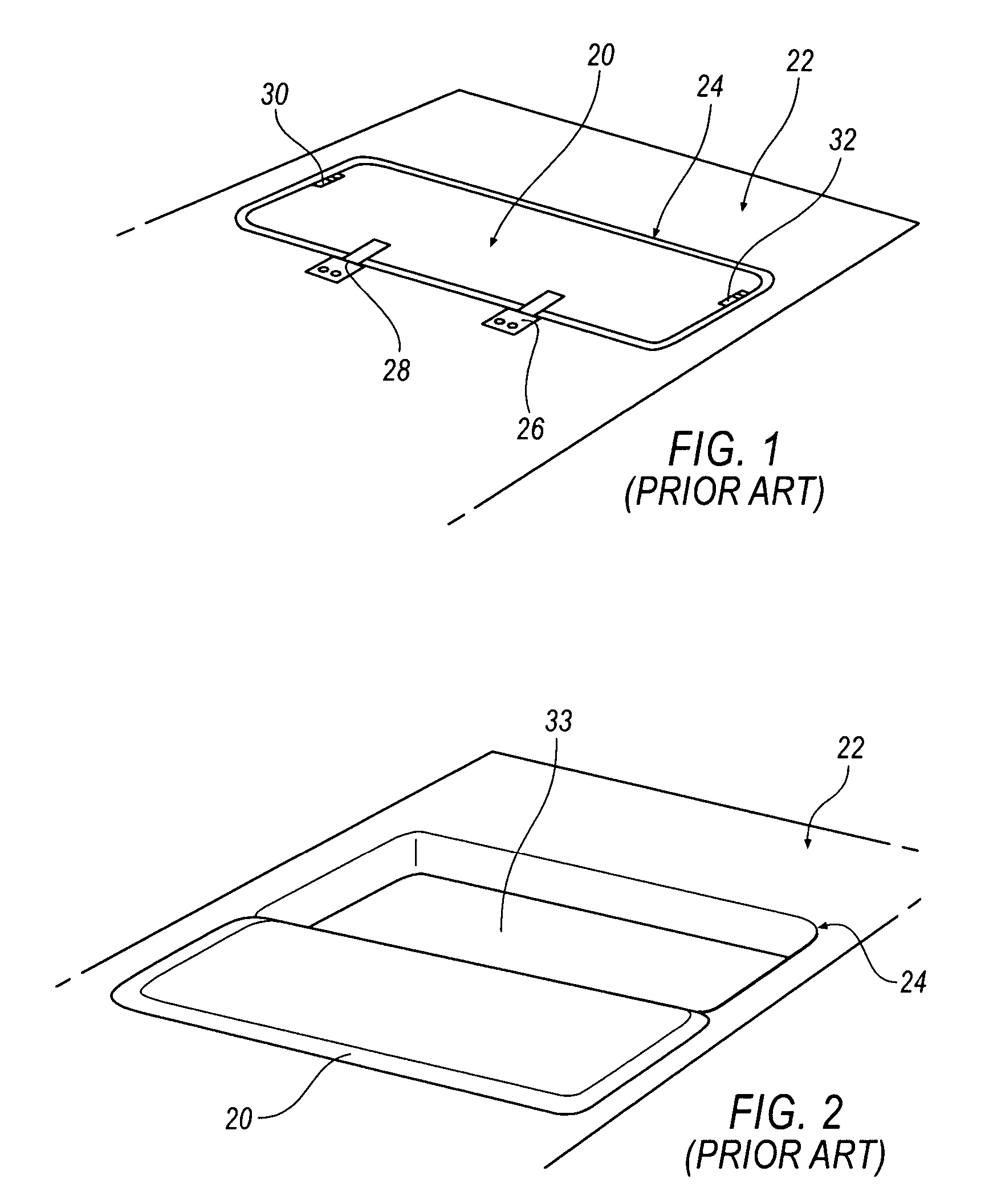

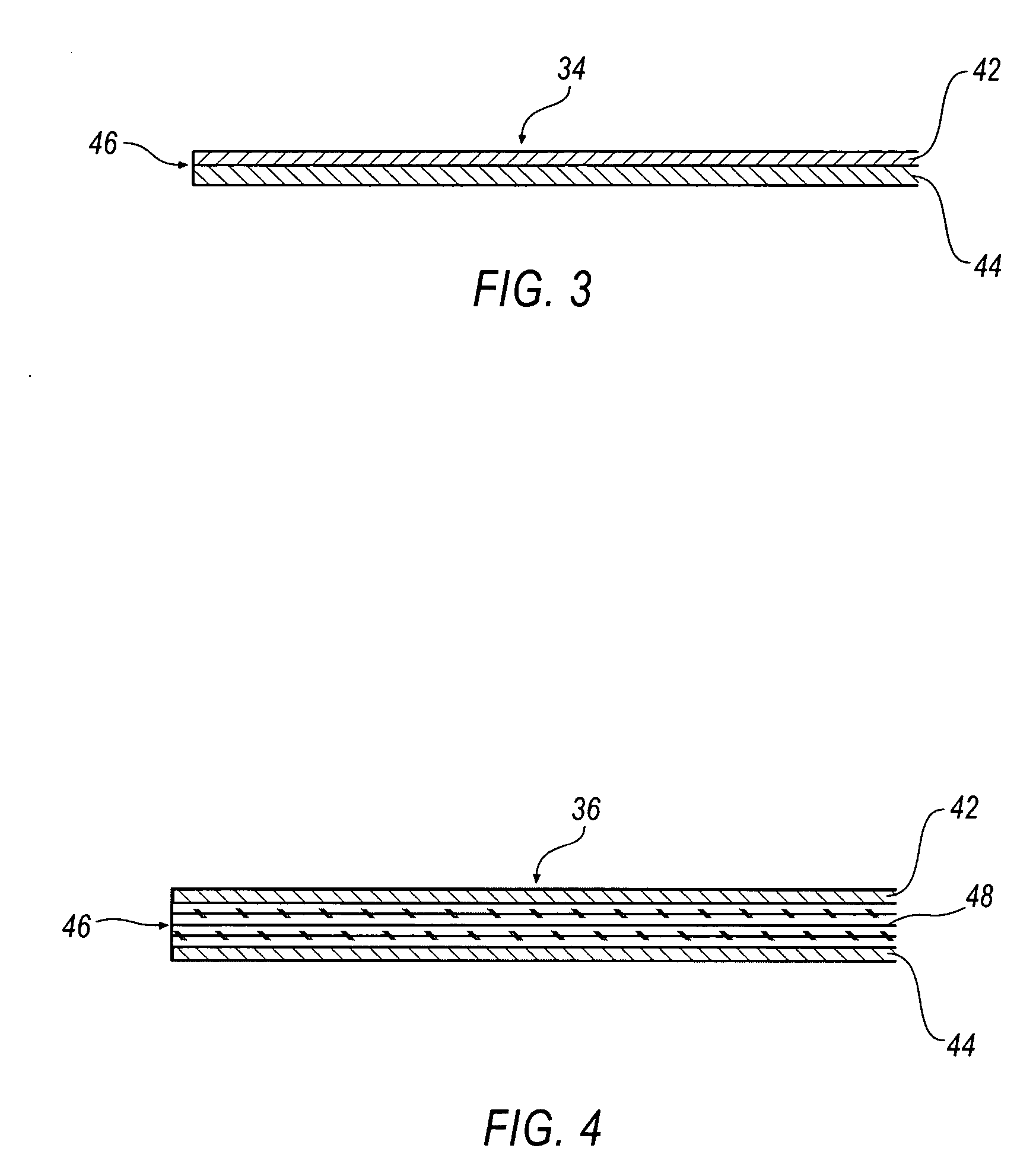

InactiveUS20060008609A1Improve reliabilityImprove fit and finish of the panelCellulosic plastic layered productsPaper/cardboard layered productsSandwich boardPressboard

A sandwich panel having a pair of skins and an intermediate substrate secured between the two skins creating a structural panel. The skins may be a pressboard material and a covering material may be applied to the skins forming an exterior surface. Selectively, the skins may be covered with a material. Further, an edge member may be provided that is engaged around the peripheral edge of the intermediate substrate. The edge member may include an engaging member and the engaging member may include anti-reverse fins. The edge member may also trap the covering material. A method of manufacturing a sandwich panel for an automobile where two skins of predetermined size and shape are provided. The two skins are attached to each other forming a structural panel. An intermediate substrate may be provided and attached between the skins. Further, an edge member may be provided and attached to the periphery of the structural panel.

Owner:GRUPO ANTOLIN NORTH AMERICA

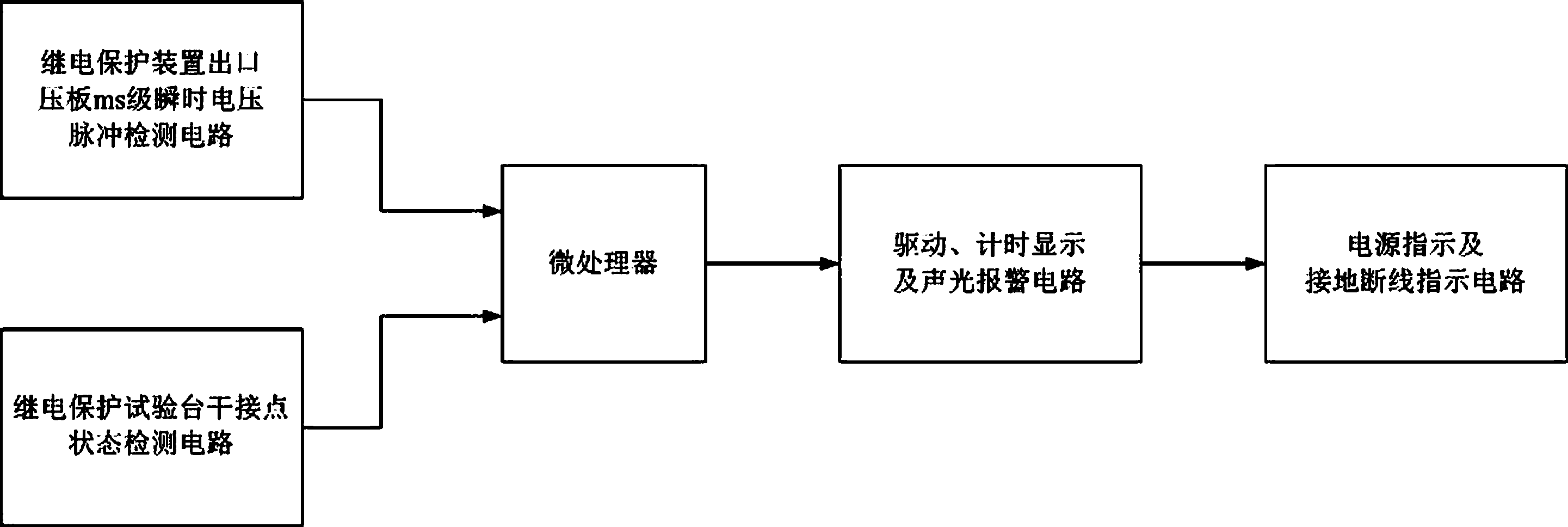

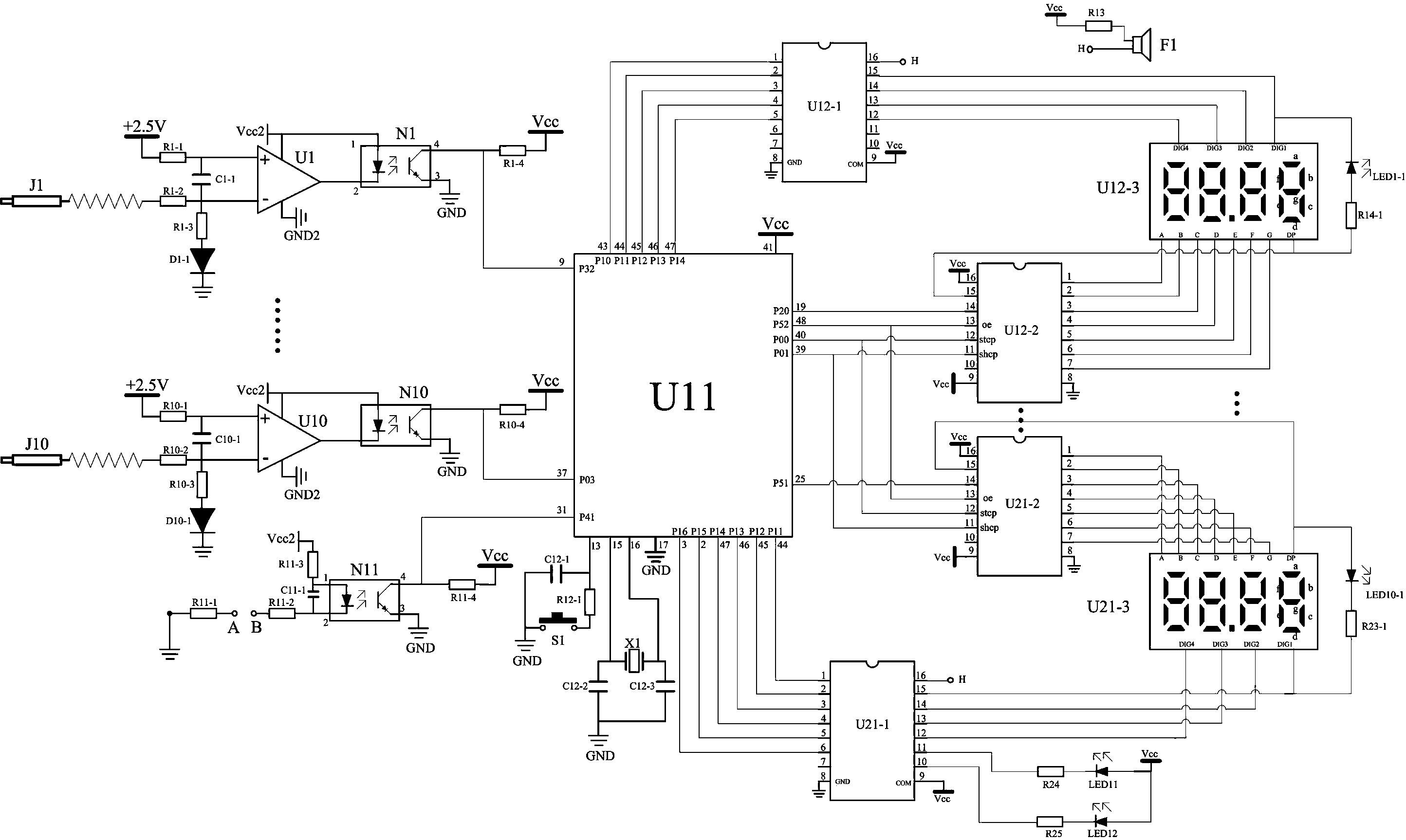

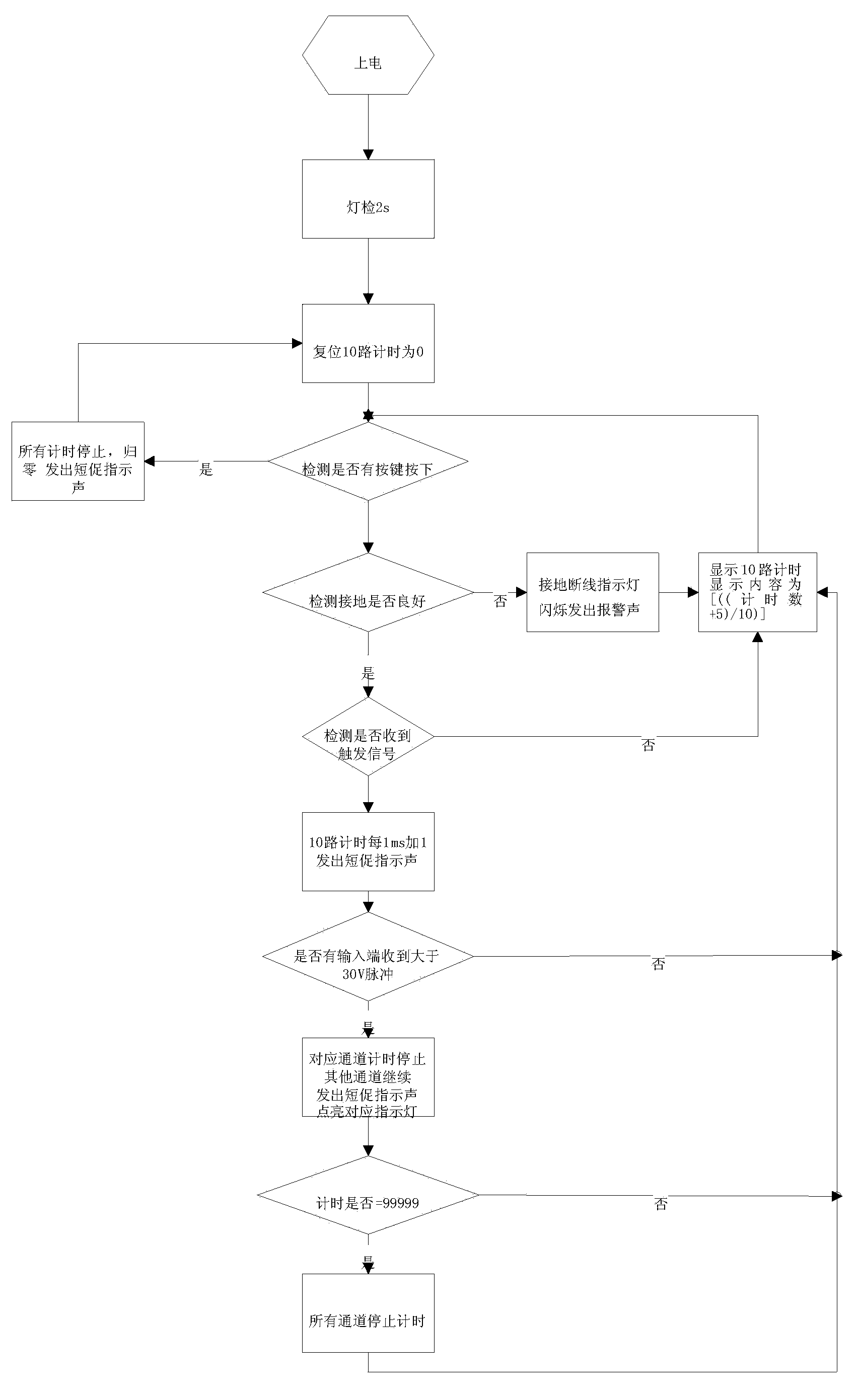

Relay protection device pressboard outlet logic detection apparatus

The invention relates to a relay protection device pressboard outlet logic detection apparatus. The logic detection apparatus comprises a relay protection device outlet pressboard ms-level instantaneous voltage impulse detection circuit, a relay protection test-stand dry contact state detection circuit, a microprocessor, a drive, timing display and sound-light alarm circuit and a power indication and grounding disconnection indication circuit, wherein the output terminals of the relay protection device outlet pressboard ms-level instantaneous voltage impulse detection circuit and the relay protection test-stand dry contact state detection circuit are connected with corresponding input terminals of the microprocessor respectively; the output terminal of the microprocessor is connected with the input terminal of the drive, timing display and sound-light alarm circuit; the input terminal of the power indication and grounding disconnection indication circuit is connected with the output terminal of the drive, timing display and sound-light alarm circuit. The advantages of the logic detection apparatus are that: detection accuracy and sensitivity are high, and wiring and operation are simple.

Owner:STATE GRID CORP OF CHINA +1

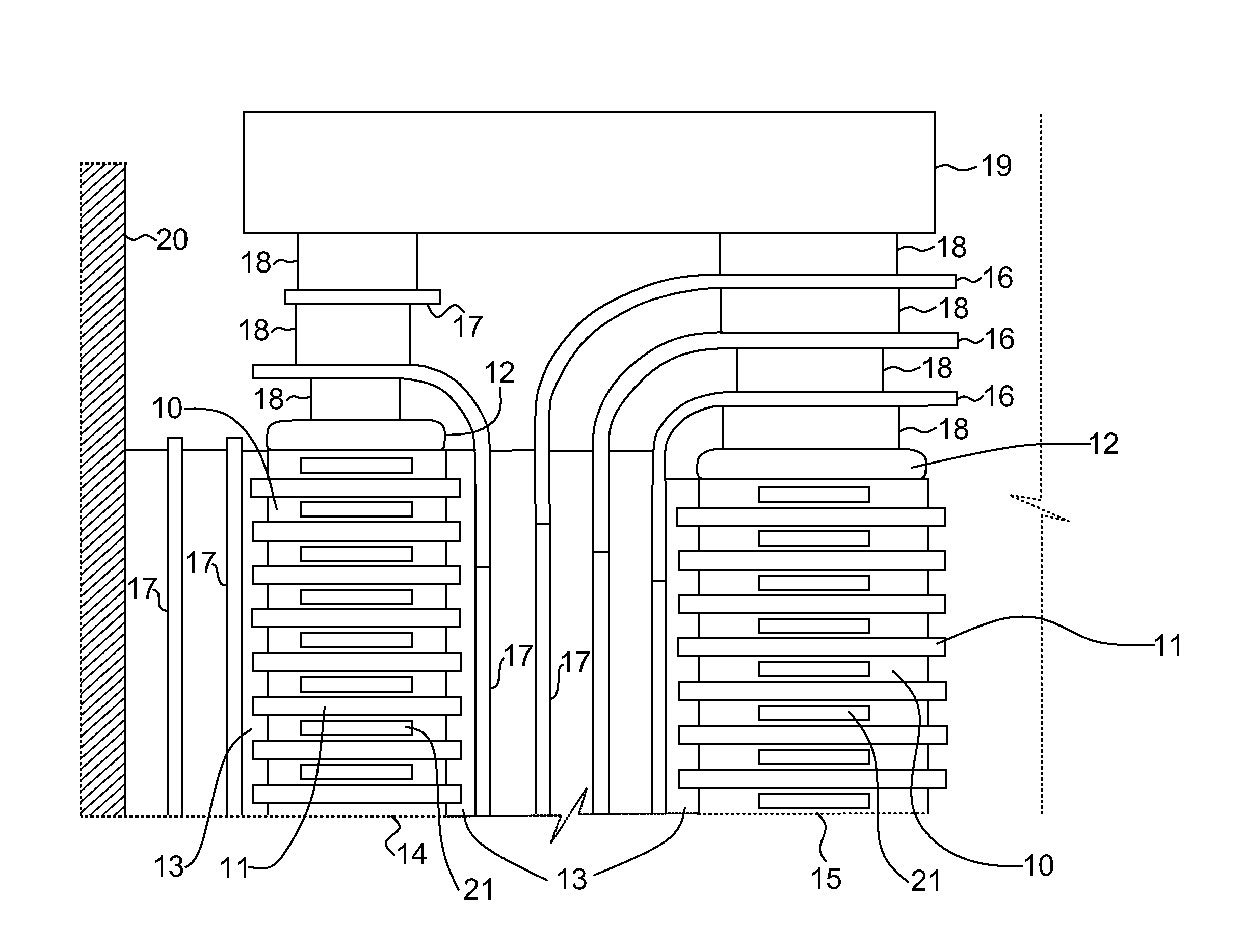

High voltage transformer with a shield ring. a shield ring and a method of manufacture same

ActiveUS20100007452A1Reduce electrical stressHigh propertyTransformers/inductances casingsTransformers/inductances magnetic coresInsulation layerPressboard

A high voltage transformer including a transformer housing. Internal components and provided in the transformer housing. The internal components are submerged in transformer oil and are provided with insulation for insulating a high voltage winding end. The insulation includes a shield ring arranged above the winding end and a pressboard structure formed in a zigzag pattern arranged around the winding end. The shield ring includes a core covered with a conducting layer and a continuous solid insulation layer outside the conducting layer. The insulation layer includes integrated solid insulation sections of which at least some among themselves having varying thickness. Also a shield ring and a method of manufacture the shield ring.

Owner:HITACHI ENERGY SWITZERLAND AG

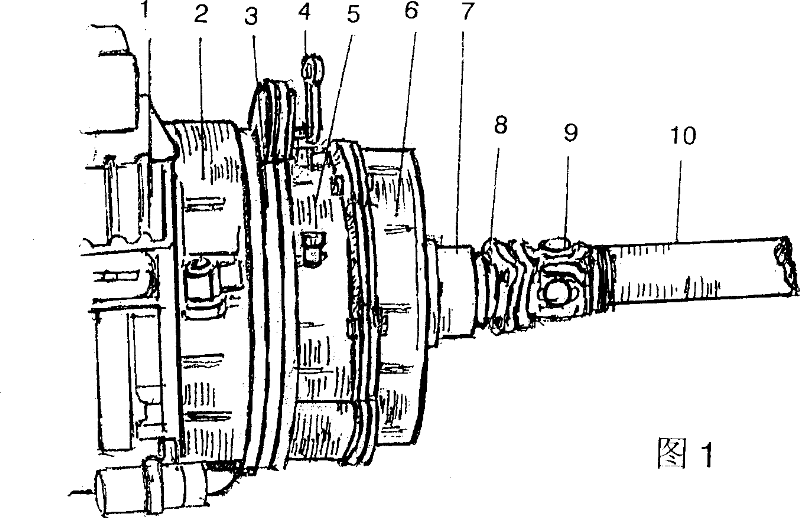

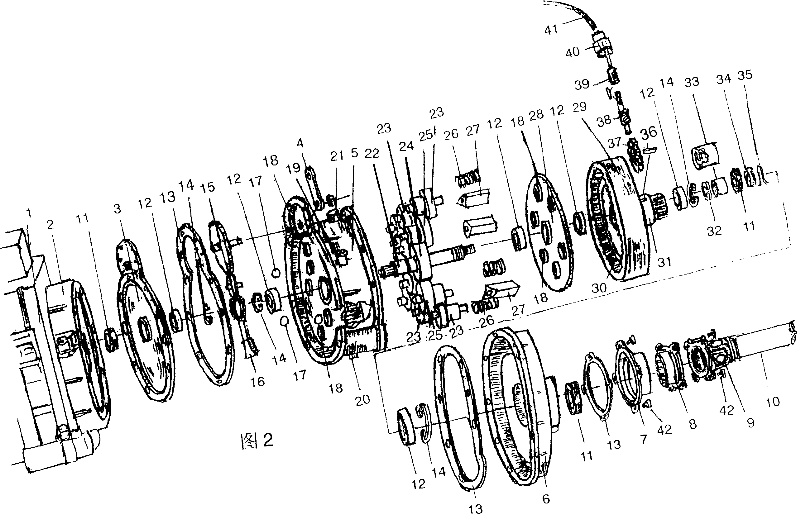

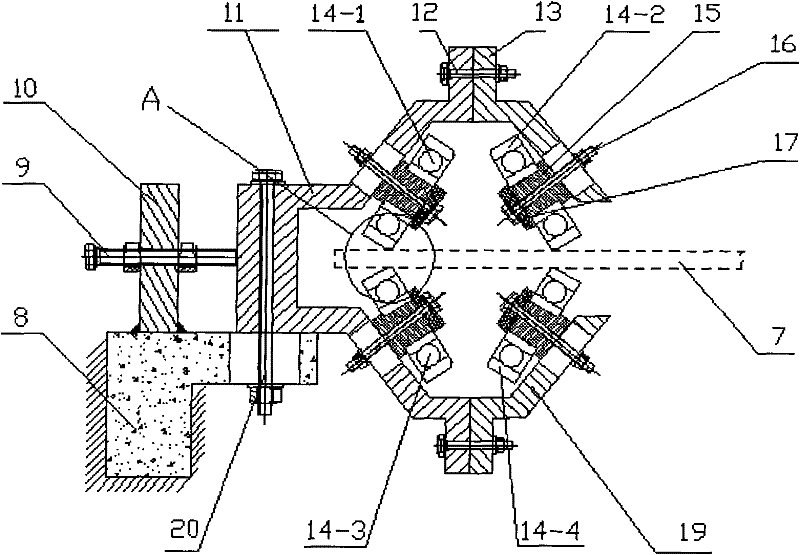

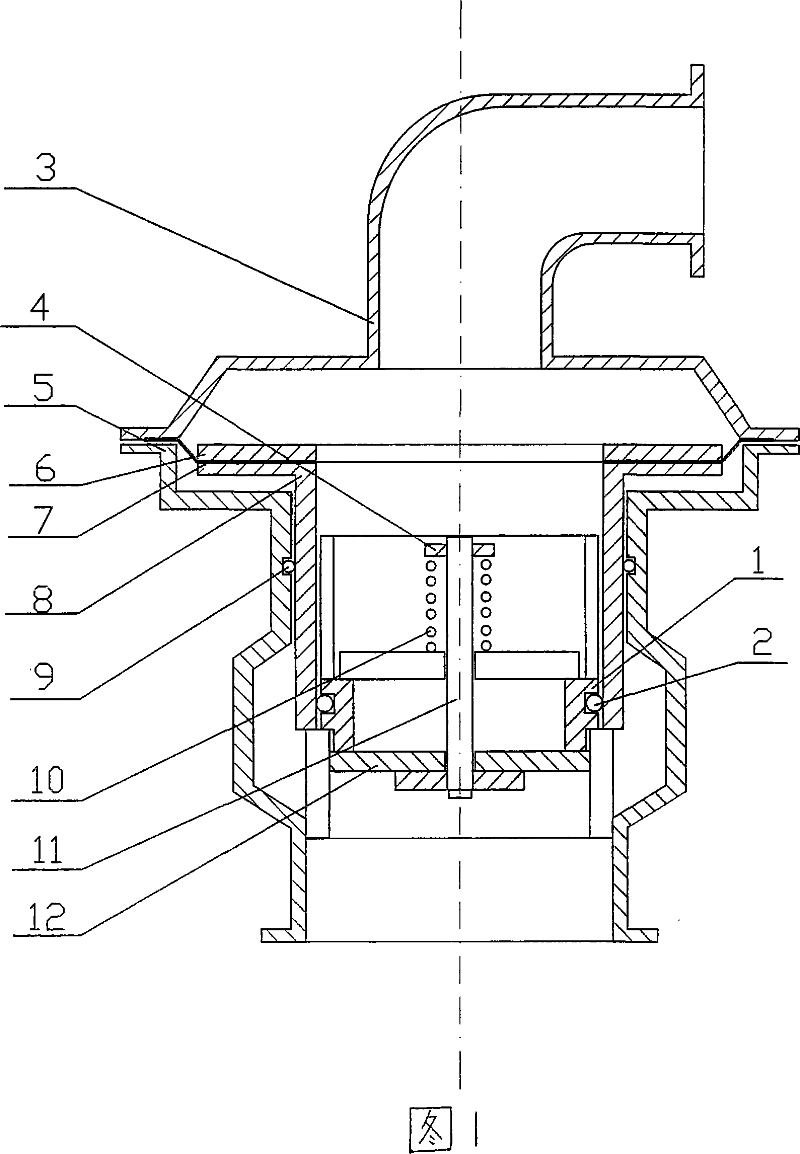

Cylinder-shaped speed-changing box

A round gear box, which relates to a new type round speed-shifting mechanism. A shrouding disc is connected with the engine, which is connected with a H-shape carrier, a fixed rack in the internal plane of the shrouding disc is connected with a fixed flat plate, a rotating disc is on the outside, which is provided with internal teeth, central outside is provided with output shaft hull, the H-shape carrier is connected with the casing, the output shaft hull passes through the casing incircle, the input shaft passes through the center of discs, a drive gear is fixed on the input shaft between the H-shape carrier and the fixed flat plate, a plurality of mid-gears are provided in periphery of the drive gear, and a plurality of lifting speed gears are provided outside of the mid-gears, a shift pulling plate out of the machine actuates a shifting wheel on the input shaft, a shift pressboard is actuated to press a isolation steel ball, different lifting speed gears are made up-down to do open-close movement with the inner teeth of the rotating disc, and speed transmission is realized via the output shaft hull. Cost of the invention is low, structure is simple, slewing range is wide, which is durable, and can be conjoined with engines, it is easy to operate, it can also be used without engaging apparatus, physical property of the round body is prior than the square body, which can realize the simplest and practical manual shifting, automatic shifting, manual-auto integral shifting and button-press shifting.

Owner:石铭正

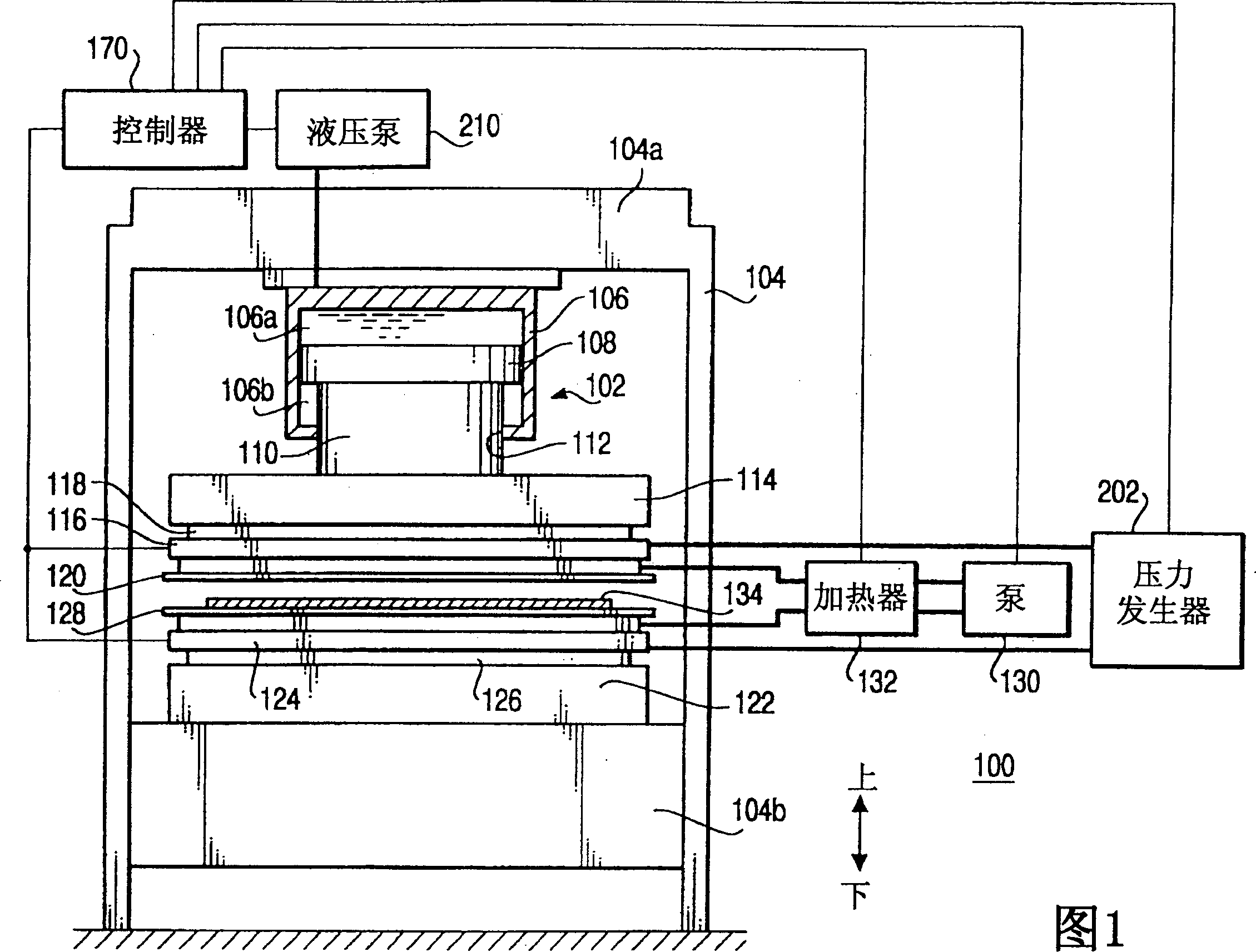

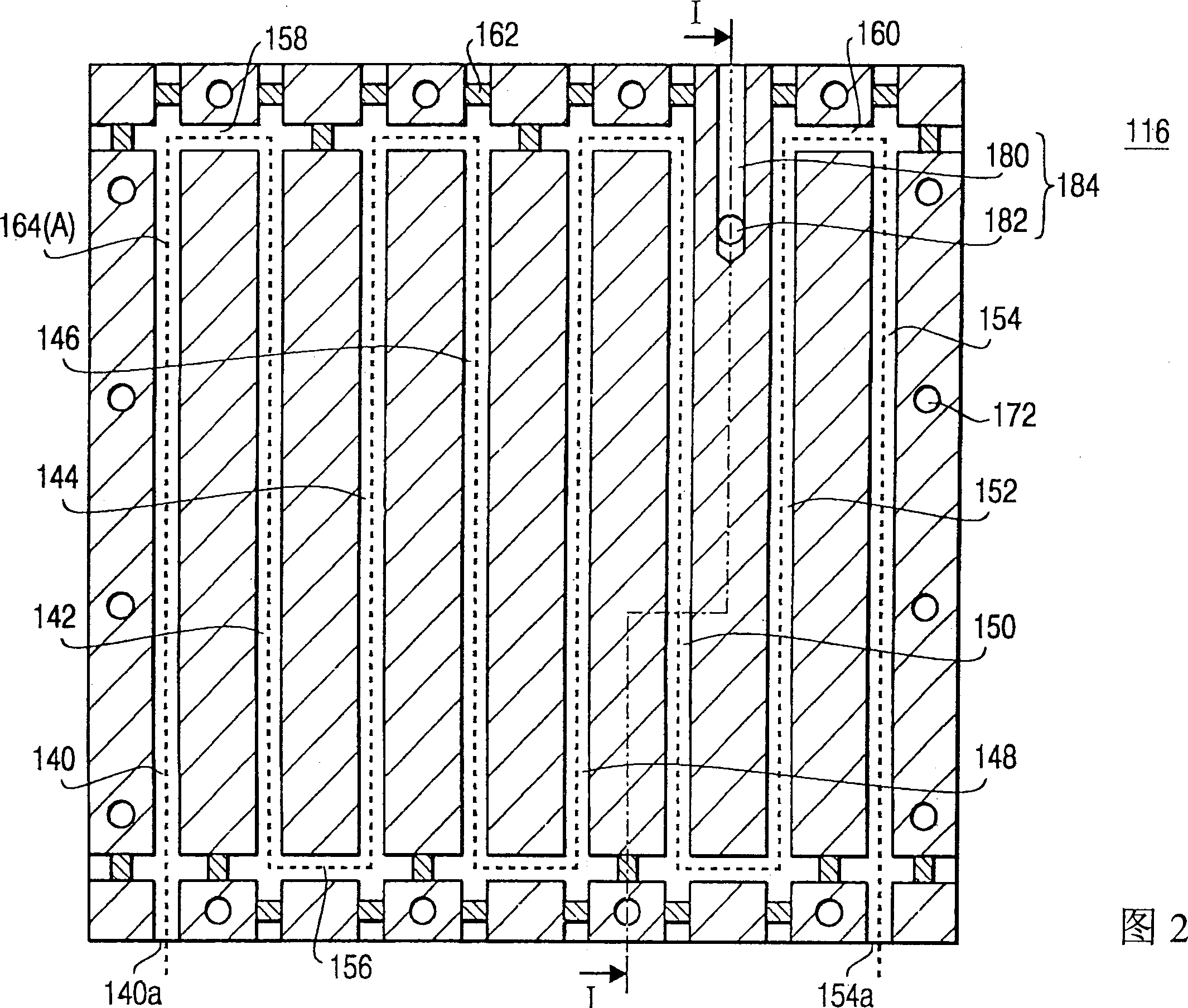

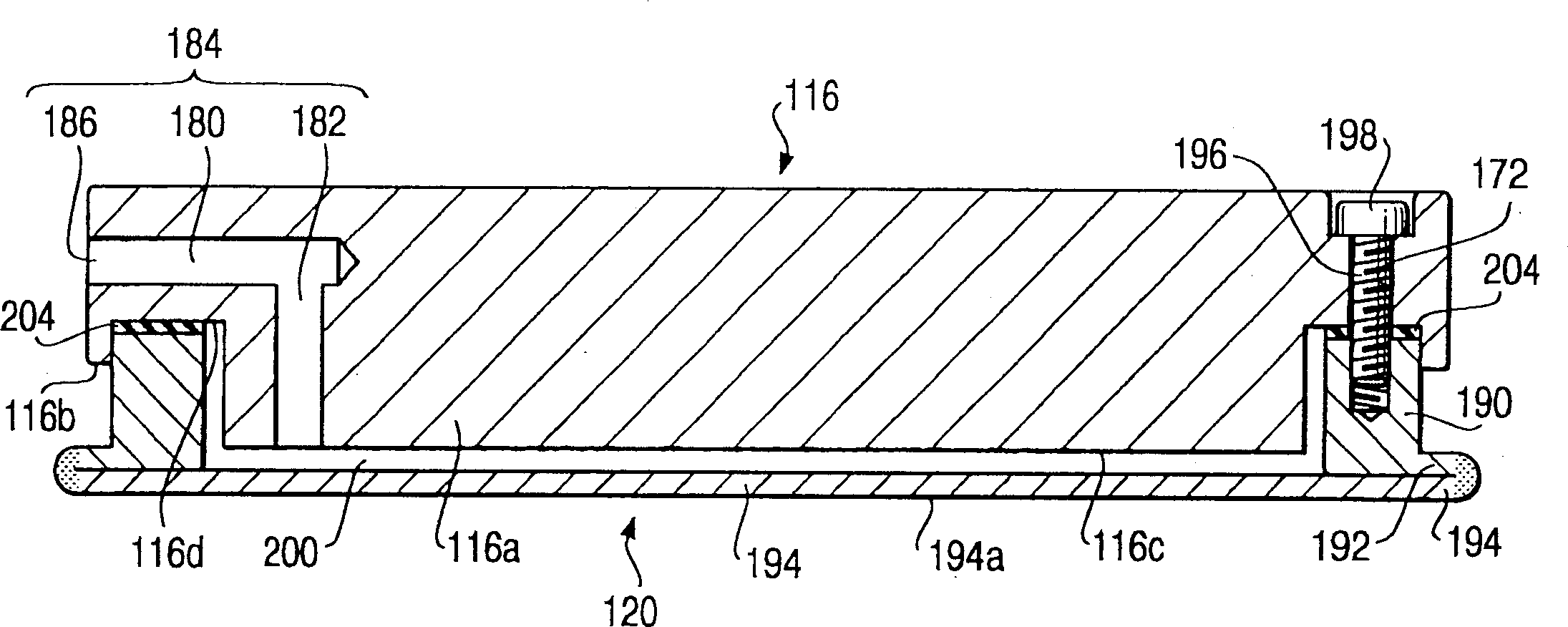

Method and apparatus for pressing component

InactiveCN1406743AImprove thermal conductivityMultilayer circuit manufacturePressesLiquid layerPressboard

A pressing device including a platen for pressing a workpiece is provided, which has a pressing plate provided between the platen and the workpiece to press the workpiece instead of the platen when the platen is moved toward the workpiece, and a liquid layer formed between the pressing plate and the platen to transfer a force for pressing the workpiece with a required pressure to the pressing plate from the platen through the liquid layer. The platen is a heating platen heatble to a temperature sufficient to heat the workpiece to a temperature required for pressing, and the liquid layer is filled with heat transfer oil. The pressing plate is metal plate with a mirror finished surfaces.

Owner:KITAGAWA SEIKI

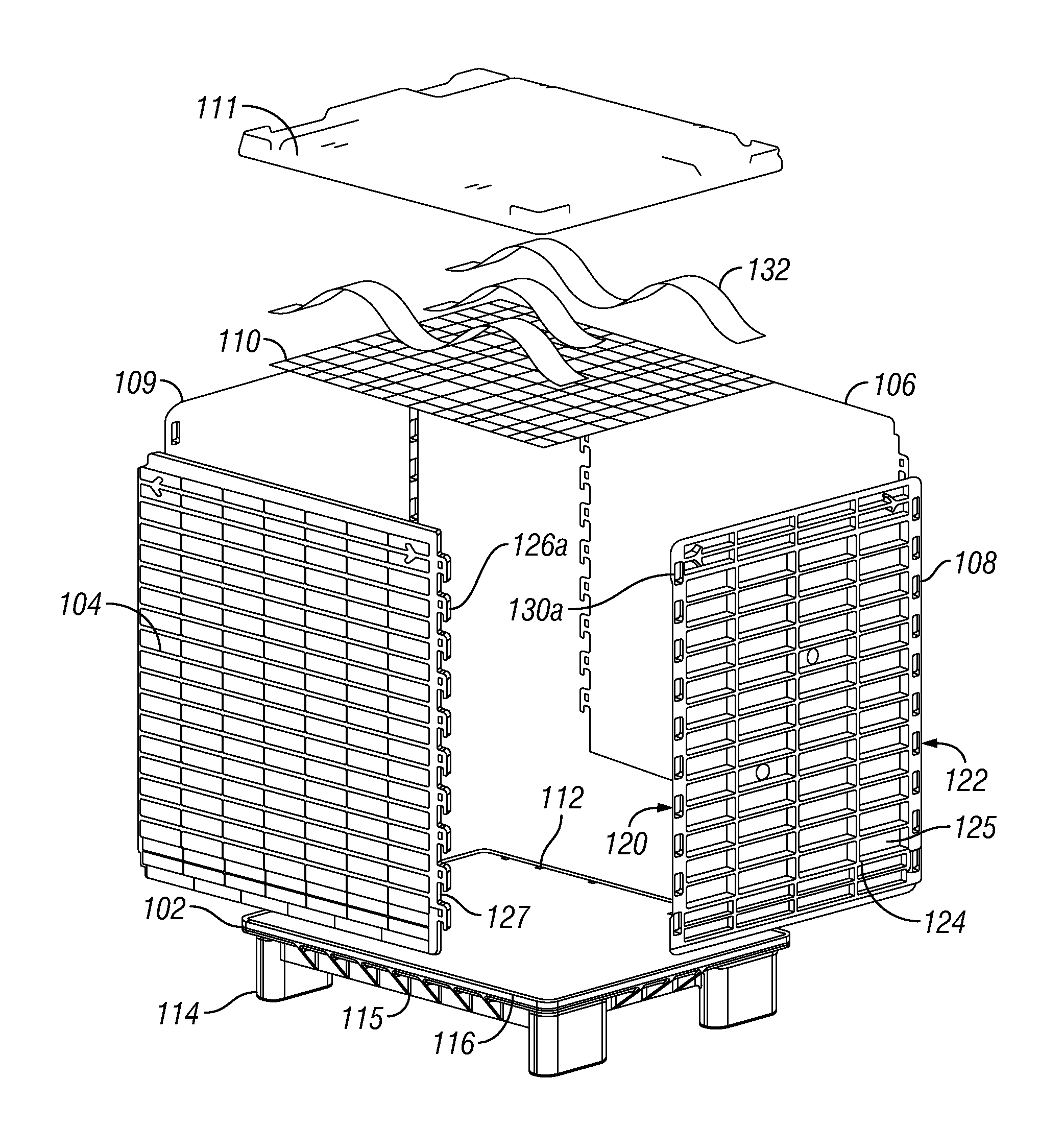

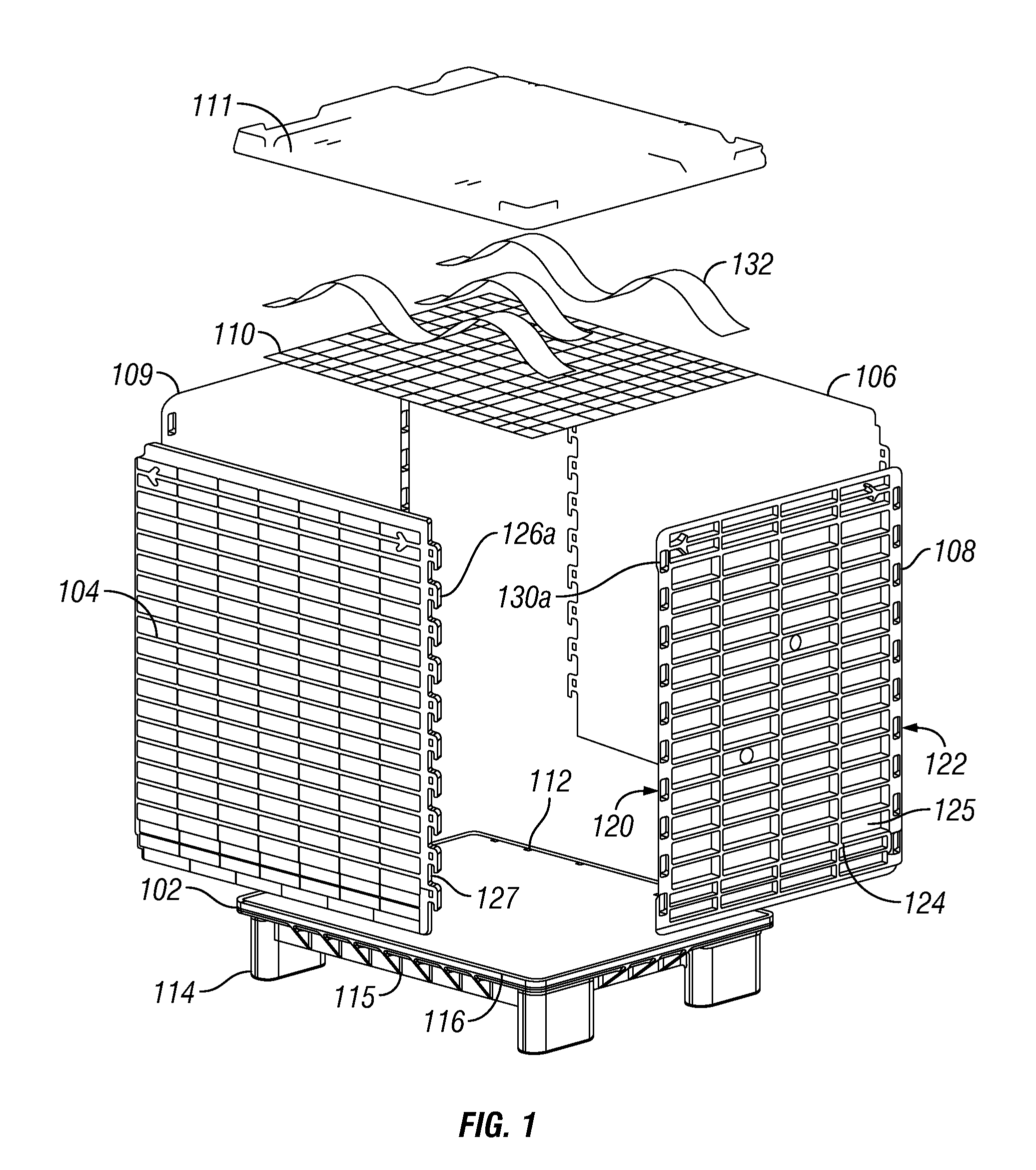

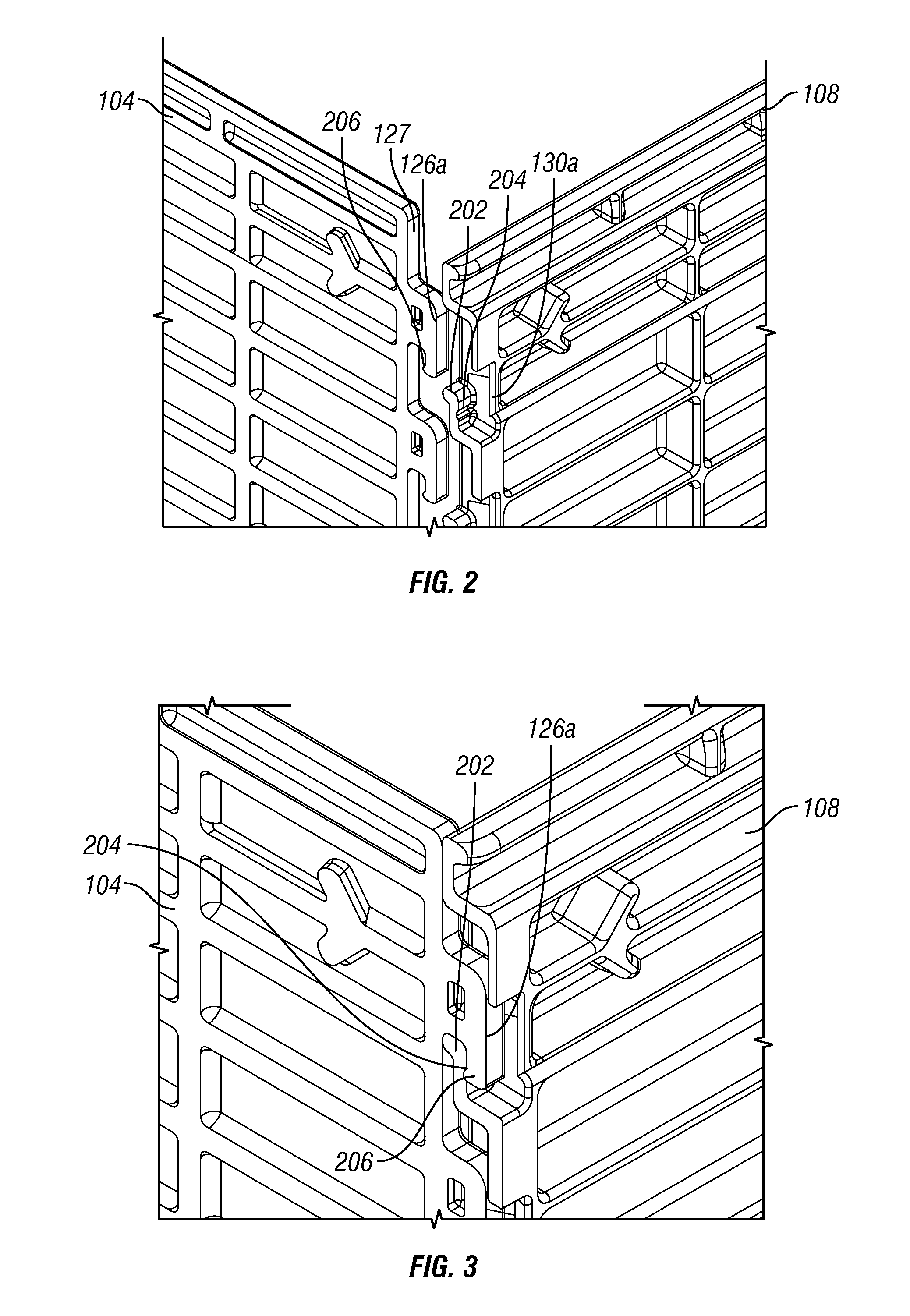

Collapsible cheese container

Embodiments described herein provide a system for molding cheese having a pressboard for compressing cheese in a cheese mold. The pressboard includes spring alignment features to align a set of leaf springs that help ensure even compression of the cheese.

Owner:BUCKHORN

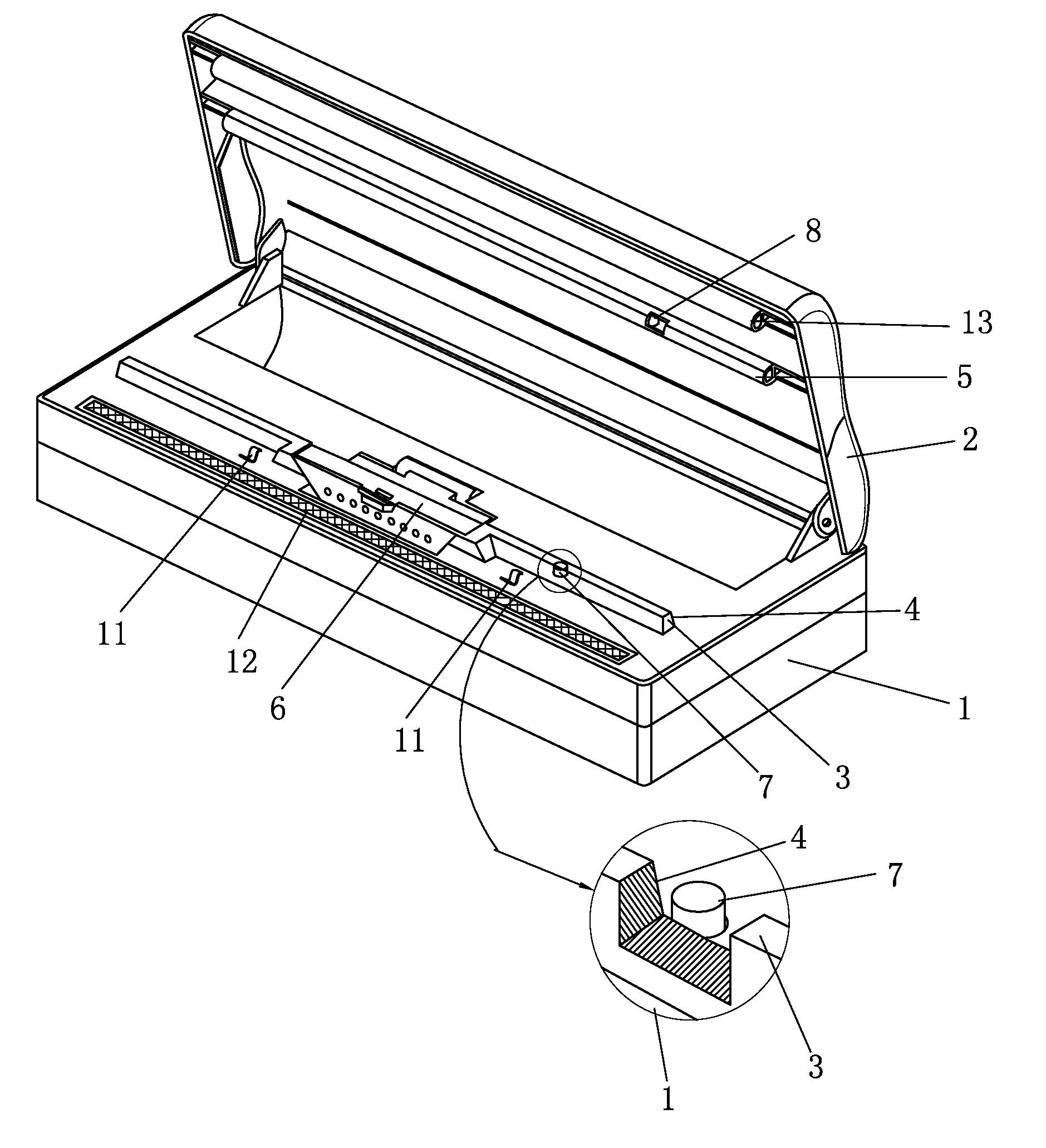

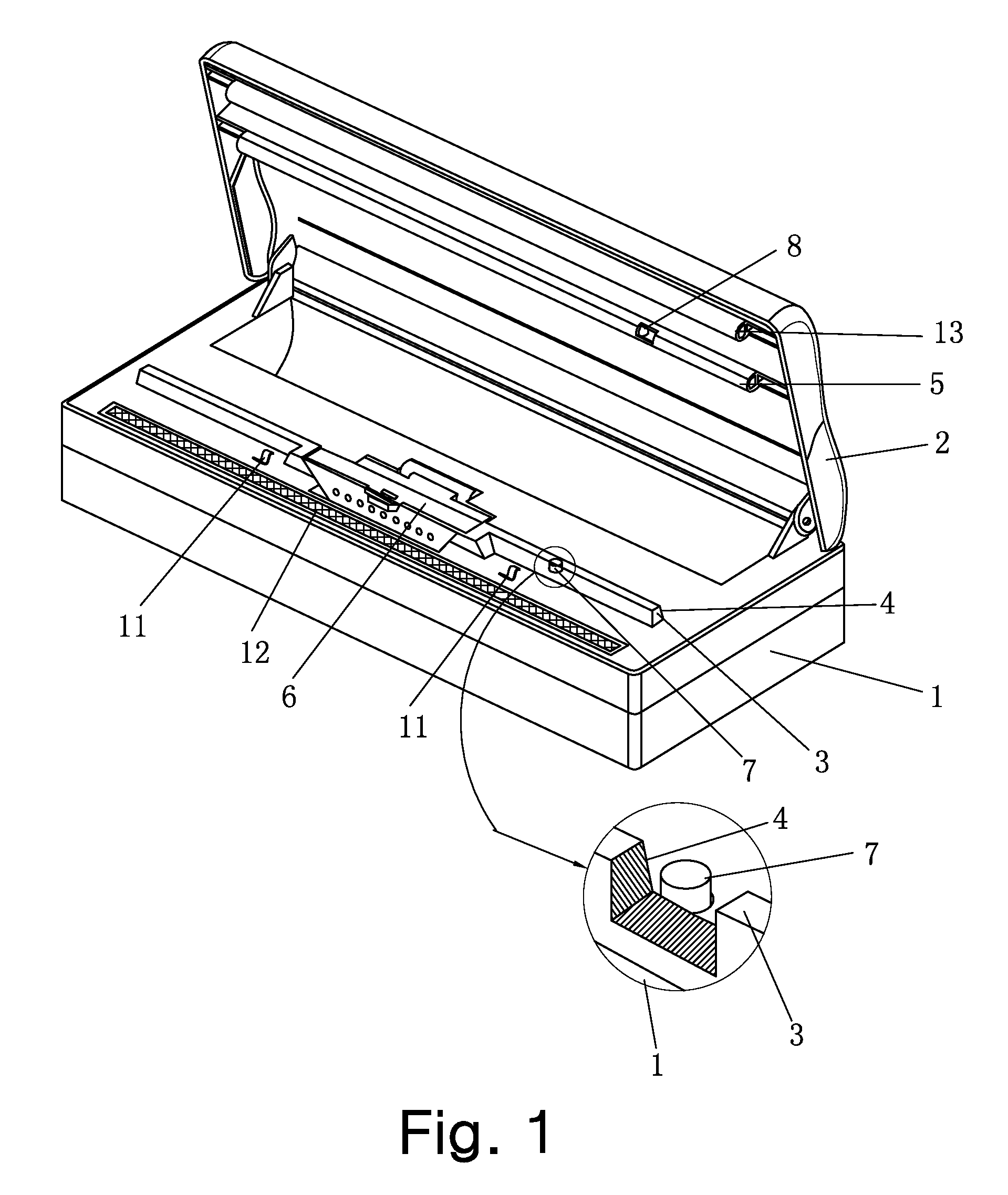

Easy-to-operate bag sealer

InactiveUS20110126986A1Simple designIncrease friction forceMechanical control devicesPackaging under special atmospheric conditionsPressboardEngineering

The item is an easy-to-operate bag sealer that can inflate as well as vacuum, for normal household use, to keep foodstuff fresh. In the front portion of the surface of the body is the bottom frictional pressboard bar that has a frictional surface on one side. Under the cover, facing the frictional surface of the bottom frictional bar is fitted with the upper frictional pressboard bar for vacuuming or inflating. The diagonal frictional force produced by the frictional surface of the bottom frictional pressboard bar and that of the upper frictional pressboard bar is enough to enable the cover to stay closed during the process of realizing the vacuuming and inflating functions. A heat wire is located in parallel to and in the front of the bottom frictional pressboard bar and under the cover is fitted with another coordinating pressboard bar for bag sealing. Also included is an indirect switch to be pressed down to activate the vacuuming and inflating functions control, placed underneath the body, through a hole opened on the body at a corner position formed by the bottom frictional pressboard bar and the surface of the body. Under the cover, at the exact position facing the hole on the body through which the indirect switch is protruding, a cave-like opening is made on the upper frictional pressboard bar or wherever deemed appropriate. The coordinating factor of this cave-like opening and the indirect switch has a procedural function to control the activation of vacuuming and inflating.

Owner:CHEUNG PO HA

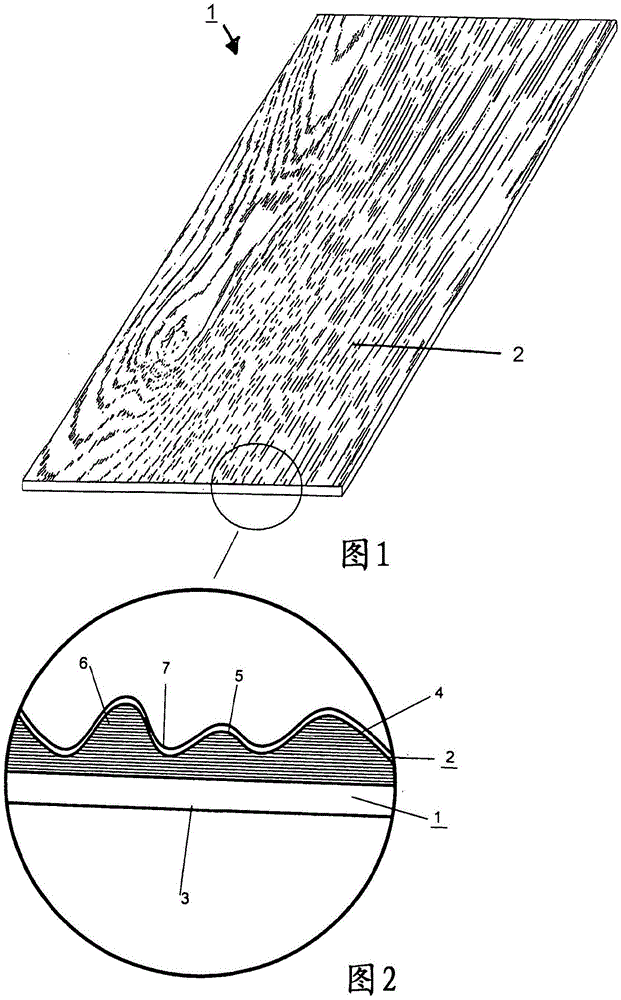

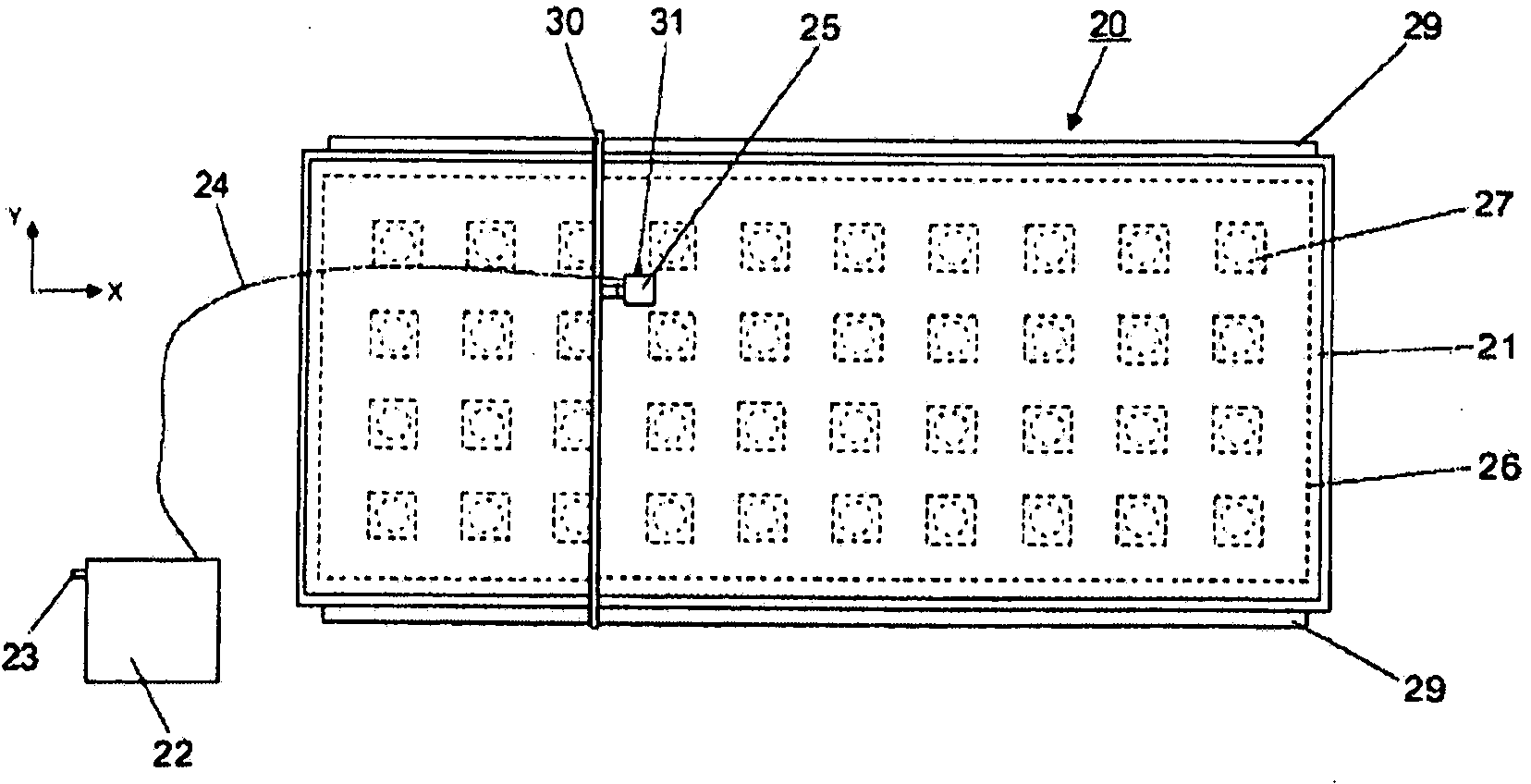

Method and device for producing a three-dimensional surface structure of a pressing tool

InactiveCN105473315AEasy to manufactureGood repeatabilityAdditive manufacturing apparatusOrnamental structuresCredit cardCheque

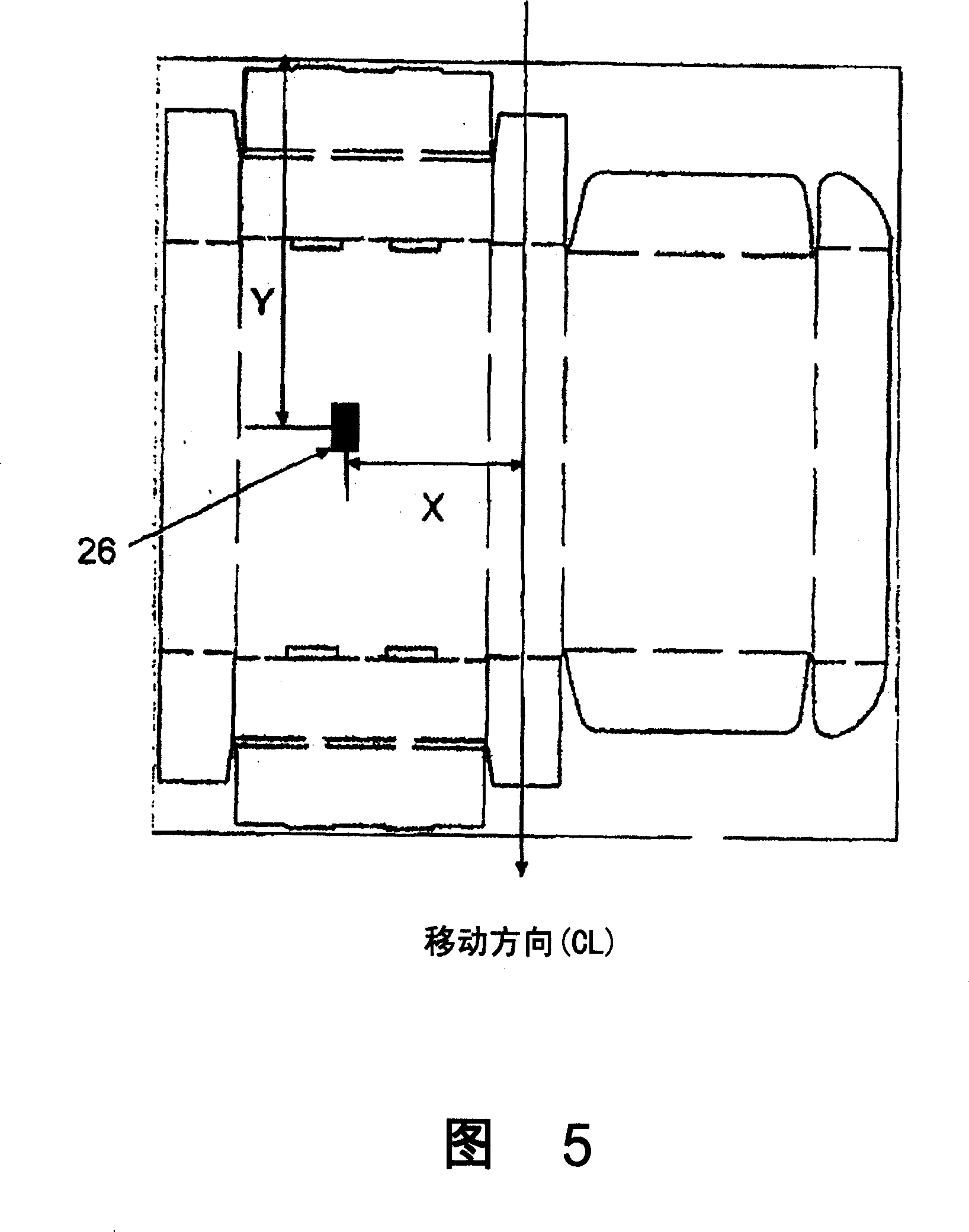

The invention relates to a method for producing a surface structure of a pressing tool, in particular a pressing plate or endless belt, for pressing material plates, plastic films, separating films, PVC surfaces, LVTs (luxury vinyl tiles), cheque cards, passports, credit cards, or plastic cards, comprising the following steps: providing and using digitised data of a 3-D topography of a surface structure, creating digitised data of individual 2-D layers of the 3-D topography, and using the digitised data of the 2-D layers to guide a processing head (28) and / or position the processing head in an xy-plane, or to move a work table (21) in the plane spanned by an x-y coordinate system in relation to a stationary processing head, in order to connect a layer material to an existing carrier material or an already completed layer on the basis of the digitised data of the 2-D layers.

Owner:HUECK RHEINISCHE

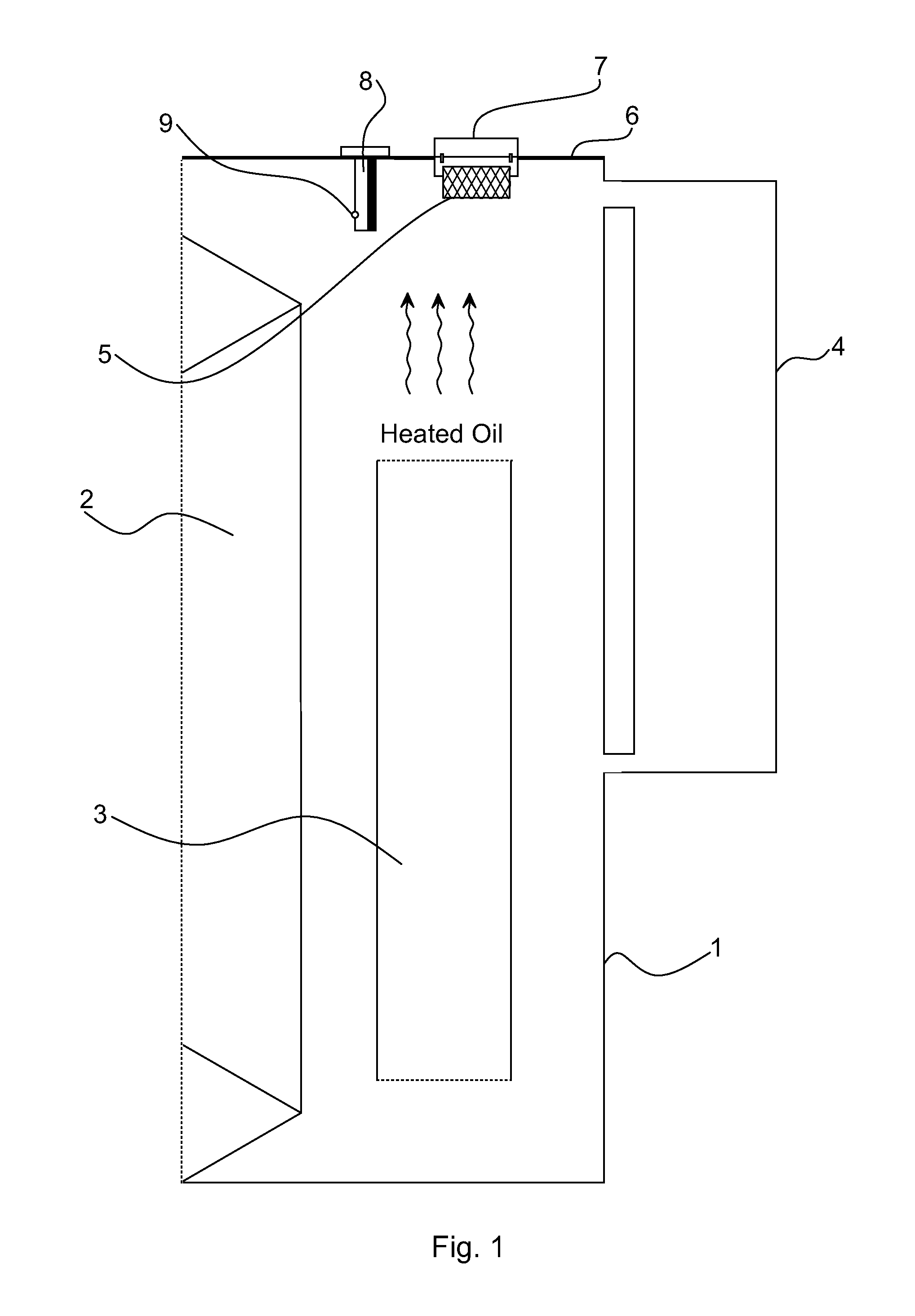

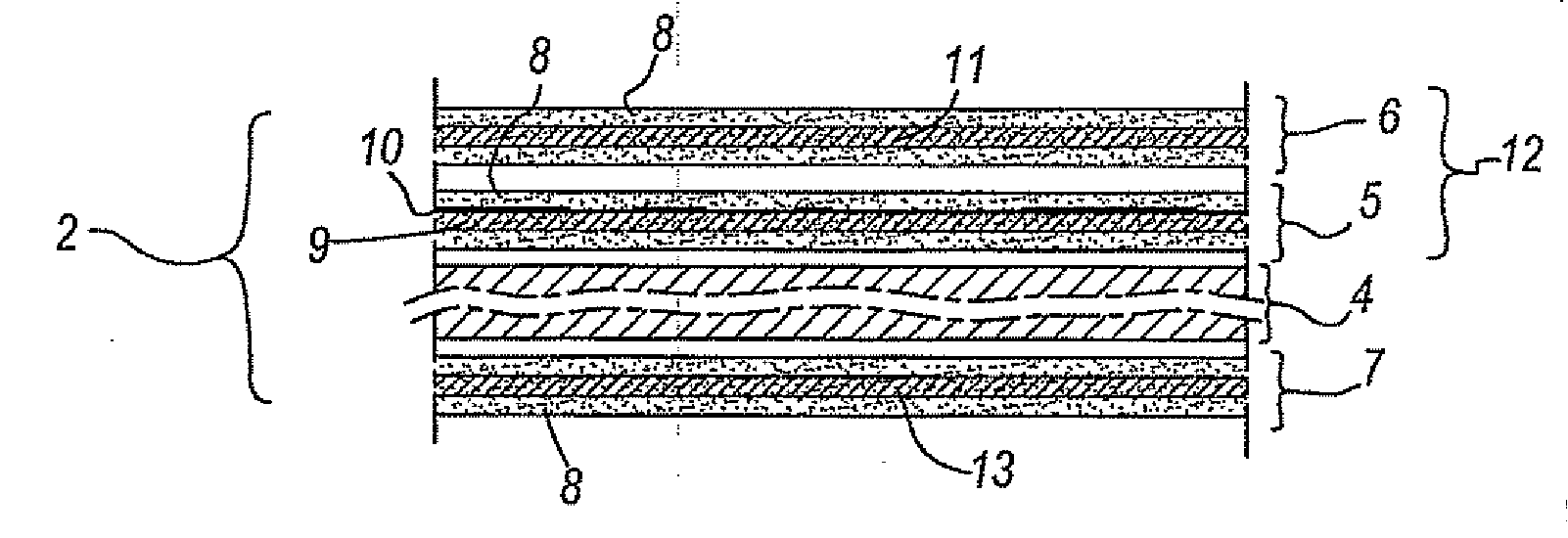

Predicting The Remaining Life Of A Transformer

InactiveUS20130243033A1Thermometer detailsTransformers/inductances coolingElectrical conductorPressboard

Method of assessing the remaining lifetime of a transformer operating at temperatures above IEC 60° C. / 65° C. / 78° C. or IEEE 65° C. / 65° C. / 80° C. including a core, a winding conductor covered by high temperature insulation material and pressboard material arranged as an insulation barrier and / or a supporting structure. The covered winding conductor and the pressboard material are immersed in a fluid having a fire point of at least 300° C. The method includes at least twice measuring the temperature of the fluid at its top surface and registering the time of each measurement and assessing the remaining lifetime of the transformer as a function of the measured temperatures and the corresponding registered times, and / or obtaining a sample of pressboard material that has been in contact with the fluid at its top surface and analysing the sample to assess the remaining lifetime of the transformer.

Owner:ABB TECH AG

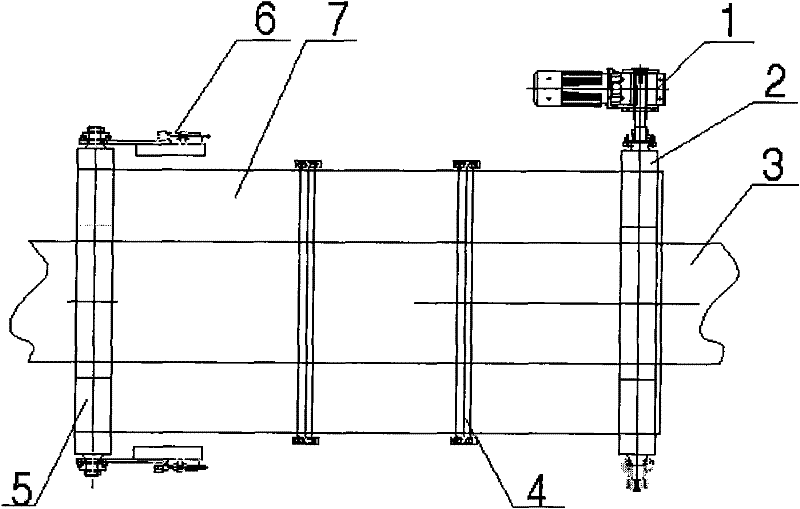

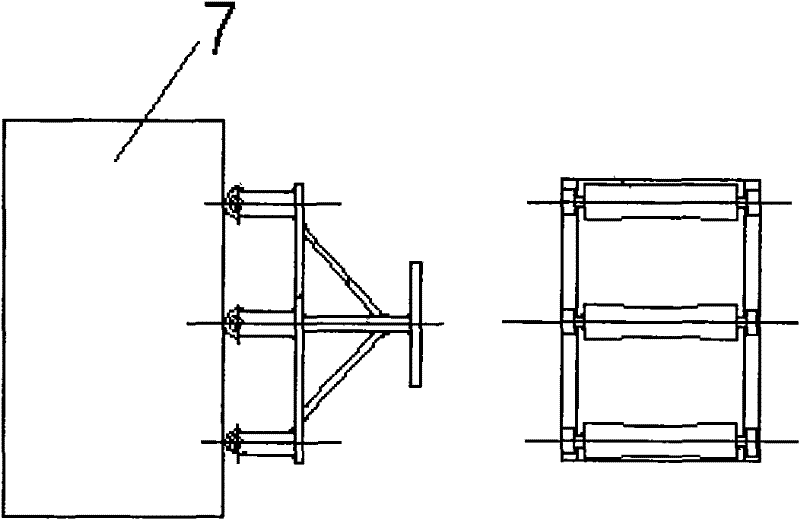

A belt online adjusting device capable of preventing belt deviation

ActiveCN102161422APrevent deviationDoes not affect tensionConveyorsWebs handlingPressboardEngineering

A belt online adjusting device capable of preventing belt deviation comprises pinch rollers, pinch roller support components and pinch roller angle adjusting components, wherein the pinch roller support components allow the pinch rollers to be arranged above and below a belt in a symmetrical V-type manner and simultaneously execute the belt positioning from above, below, left and right. The device in the invention avoids the problems of band steel deviation, folding of band threading and piling-up of steels, which are caused by the floating movement and deviation of the belt; wedge-shaped shafts enable the pinch rollers to execute three-dimensional 360-degree adjustment and are connected with the pressboards through key slots, thereby guaranteeing the synchronized adjustments of the pinch rollers and the pressboards and accordingly improving the adjustment speed; and the pinch rollers can prevent the edge damage after the belt deviates. The device in the invention has a small request for installation positions, is capable of online change and adjustment and can be widely applied to belt conveying equipment of galvanizing machine sets or other machine sets in the industry of cold rolling.

Owner:BAOSHAN IRON & STEEL CO LTD

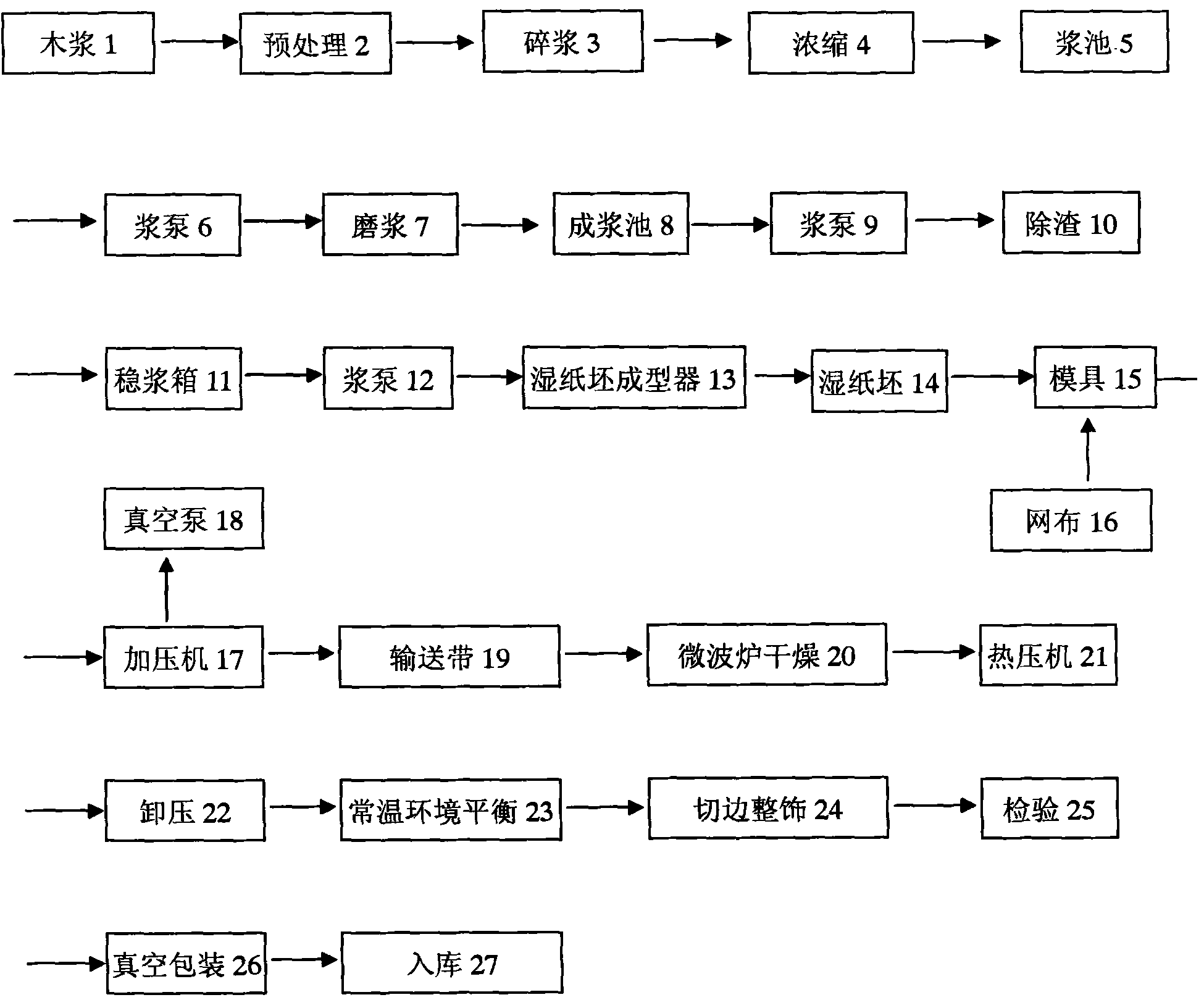

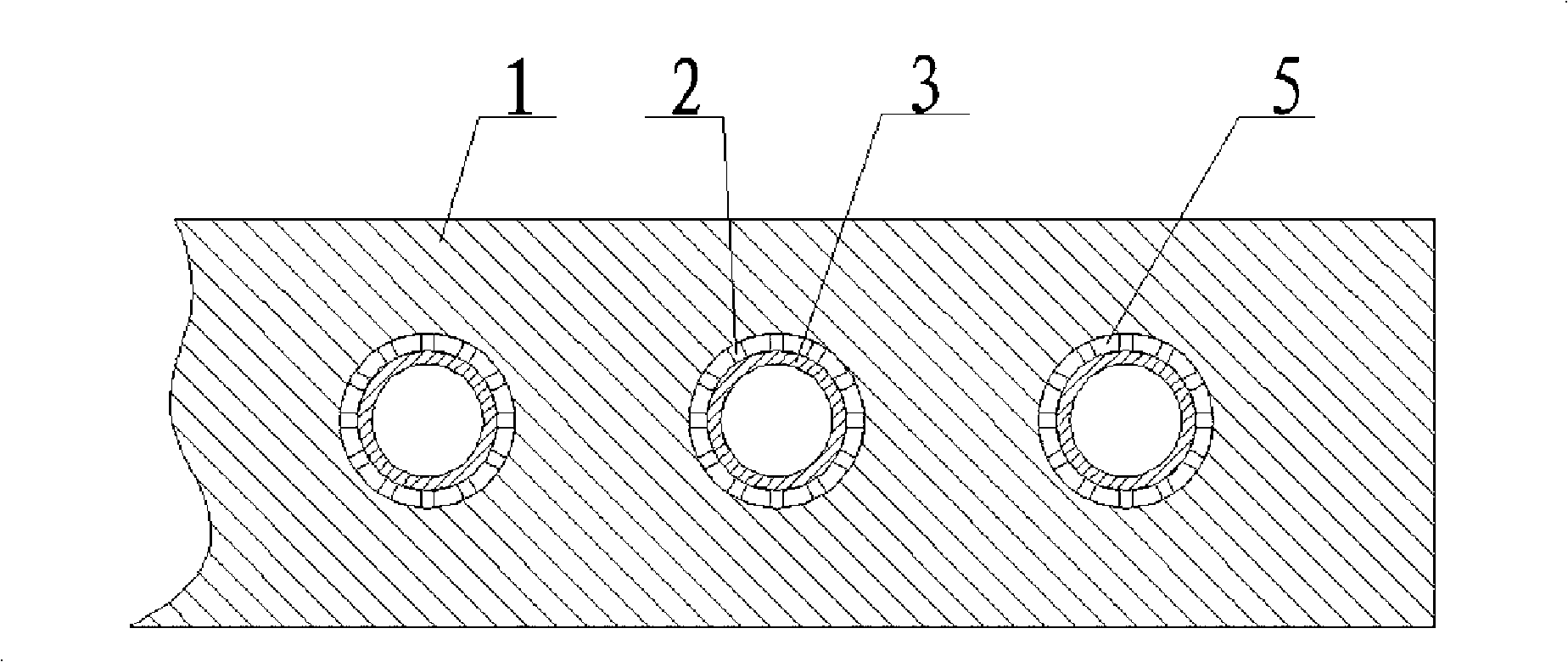

Drying process of super thick insulated pressboard

ActiveCN101781869AReduce processing linksReduce secondary pollutionFibreboardPulp beating/refining methodsCardboardPressboard

The invention belongs to a drying process of a super thick insulated pressboard. In the process, 0.5-0.7 percent pulp is prepared by insulation pulp through conventional treatment, enters a pulp stabilization box and is sent into a wet ground paper forming device through a pulp pump, a prepared wet ground paper is sent into a die which is sleeved with an inner net and is sent into a pressurizer with the die together for water extrusion with the pressure of 0.7-0.9MPa, a vacuum pump assists with water suction and absorption, the wet ground paper is taken out when the moisture achieves 40-50 percent, is sent into a micorwave drying box to be dried through a conveyor belt and is pulled out and sent into a hot press to be dried with the temperature of 115-125 DEG C when being dried with the water content of 25-35 percent, the drying time is determined by the thickness, the wet ground paper is dried until the pressboard water content achieves 4-6 percent and enters a half finished chamber to be in balance treatment for 3-5 days after board disassembly, the paper is treated by edge trimming and finishing and is packaged to be put into a storage after passing the inspections.

Owner:XINSHAO GUANGXIN ELECTRICAL INSULATING MATERIALS

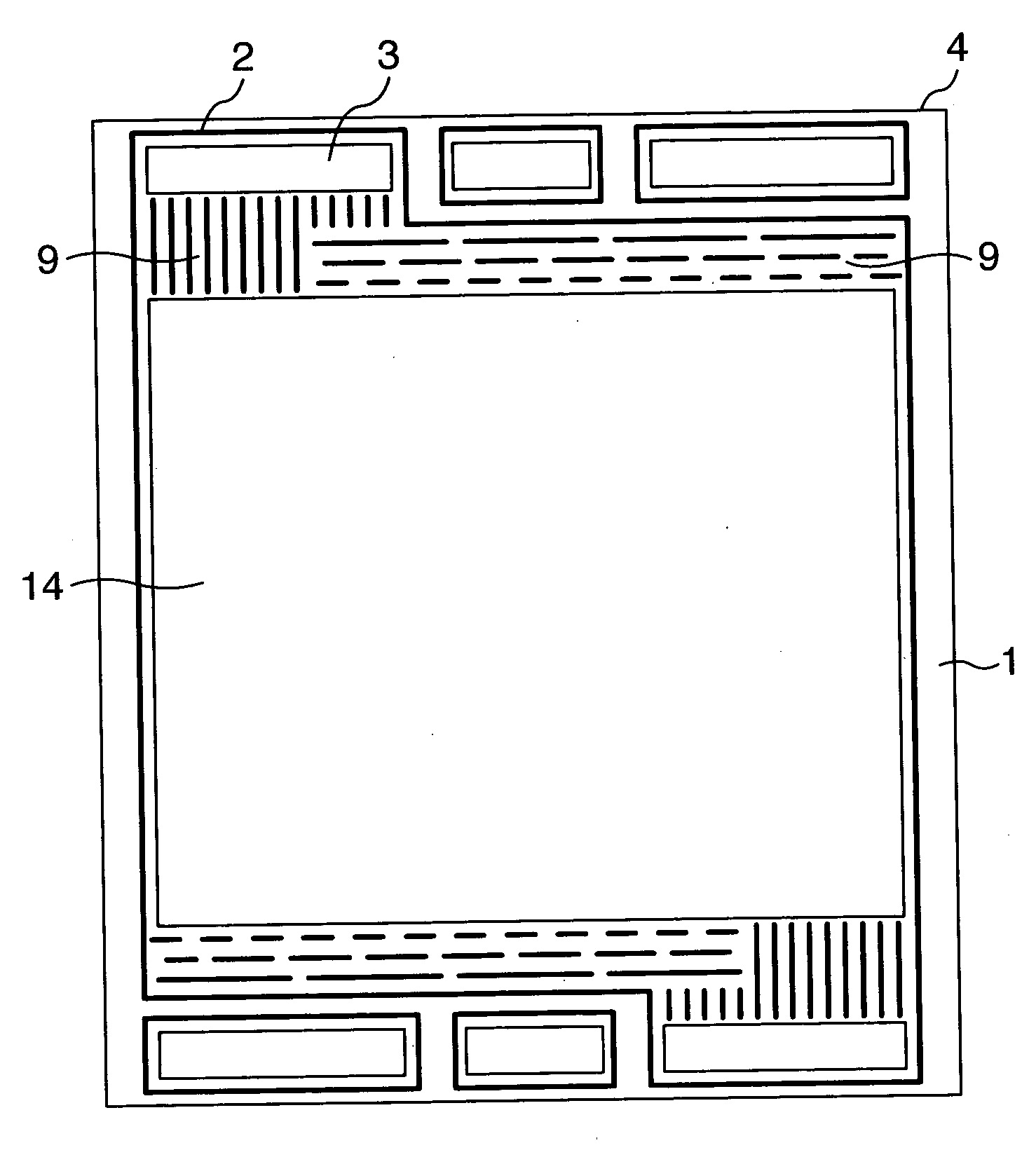

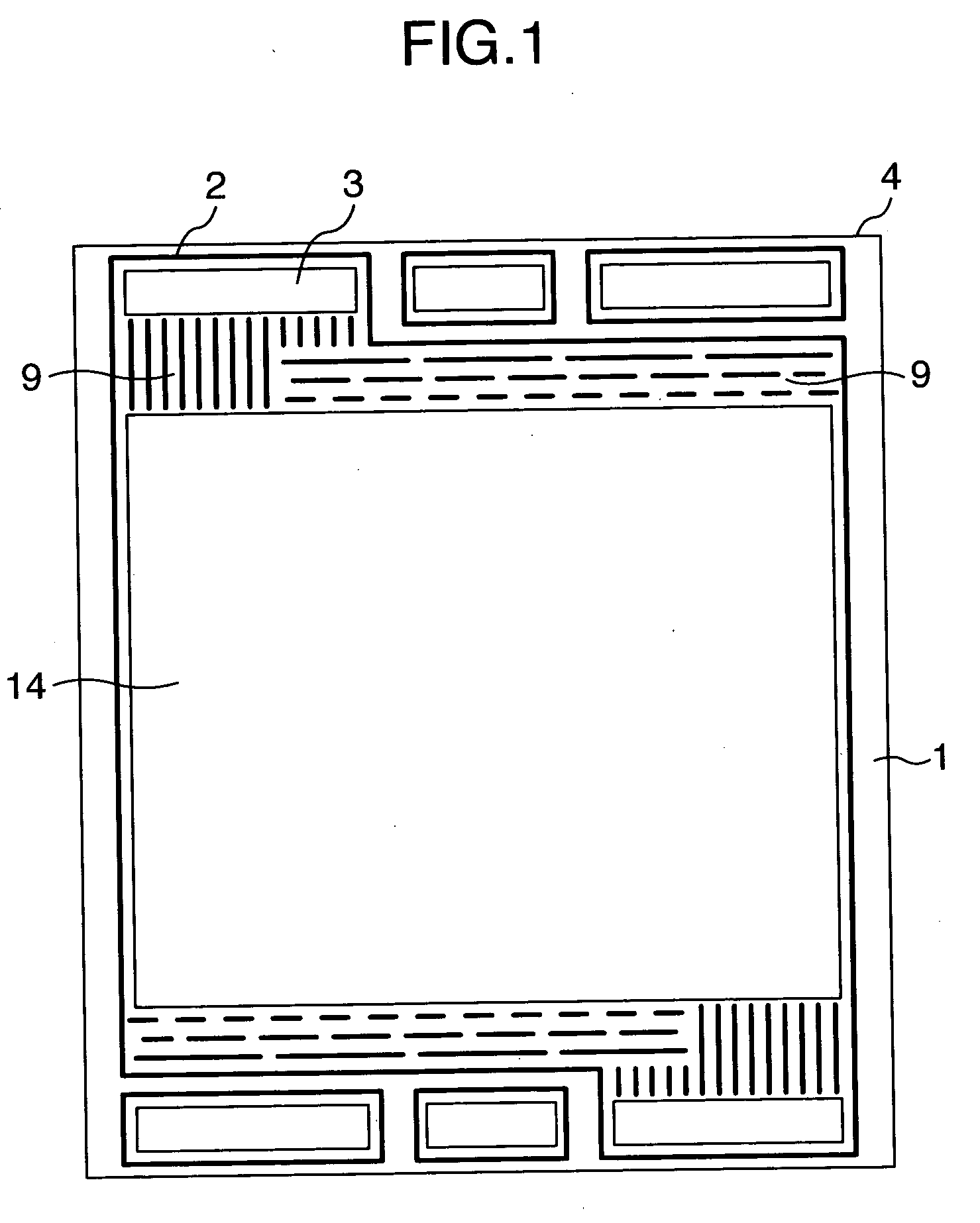

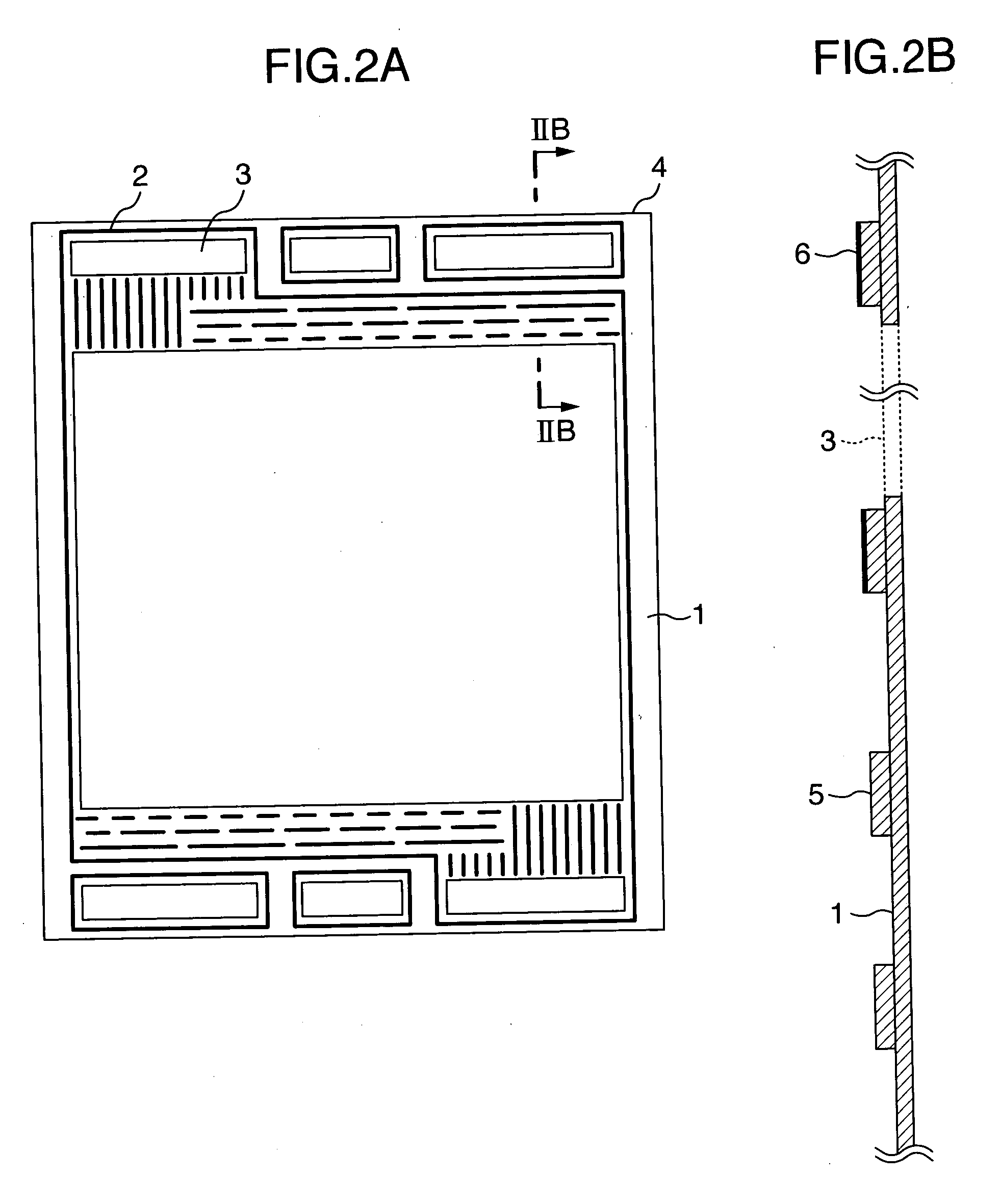

Separator for fuel cell and fuel cell using it

InactiveUS20060127744A1Sufficient sealing characteristicIncrease reaction pressureFuel cell auxillariesCell component detailsElastomerFuel cells

The present invention provides a separator for a fuel cell constructed using a metallic pressed plate, in which a gas channel from a manifold to an electrode surface is formed simply, and a good sealing characteristic is realized. The separator is comprised of a metallic pressed plate, a resinous frame member, and a sealing frame having a sealing material integrated therewith, and a channel for introducing a gas from the manifold to an electrode surface is formed by a metallic surface, the sealing material and a resinous surface. An elastomer such as a rubber is used for the sealing material. Thus, the gas channel from the manifold to the electrode surface can be formed simply, and an excellent sealing characteristic to the gas and water is obtained.

Owner:HITACHI LTD

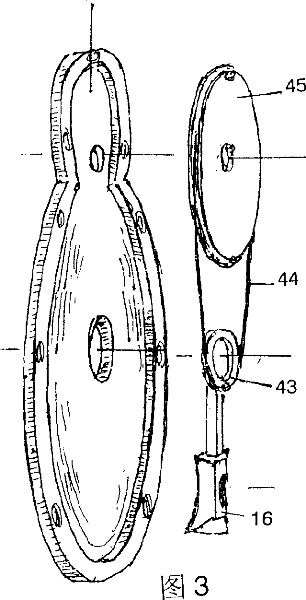

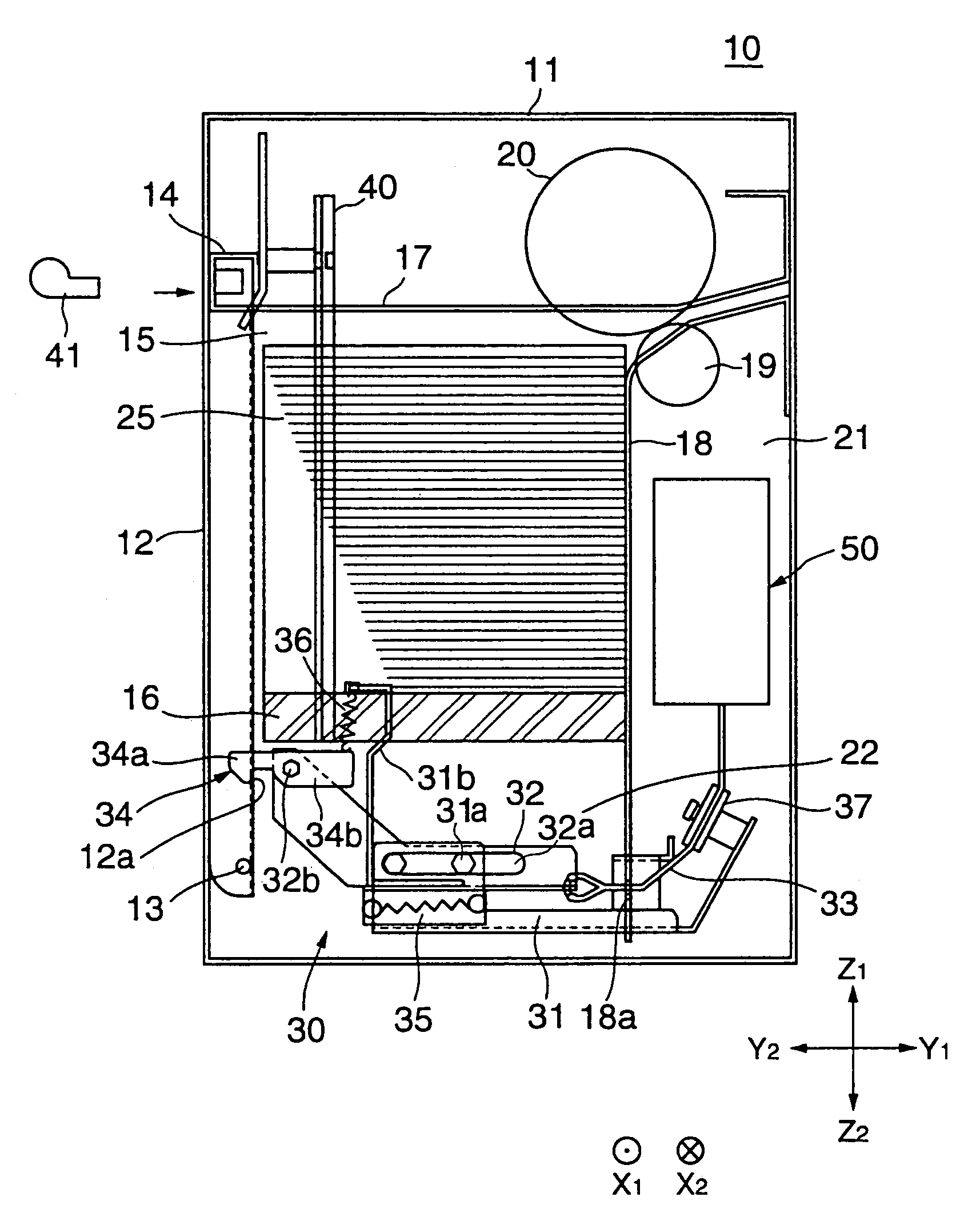

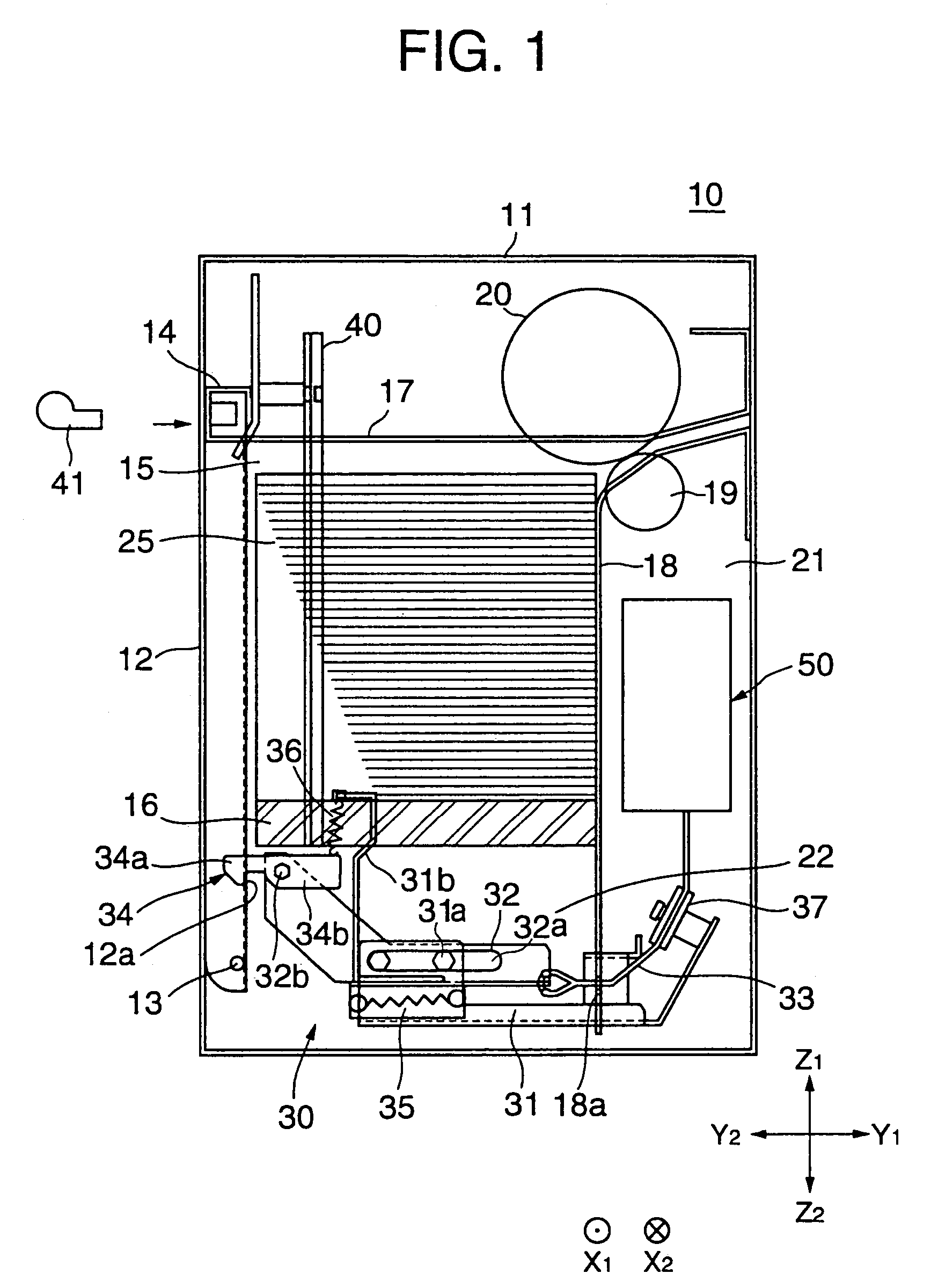

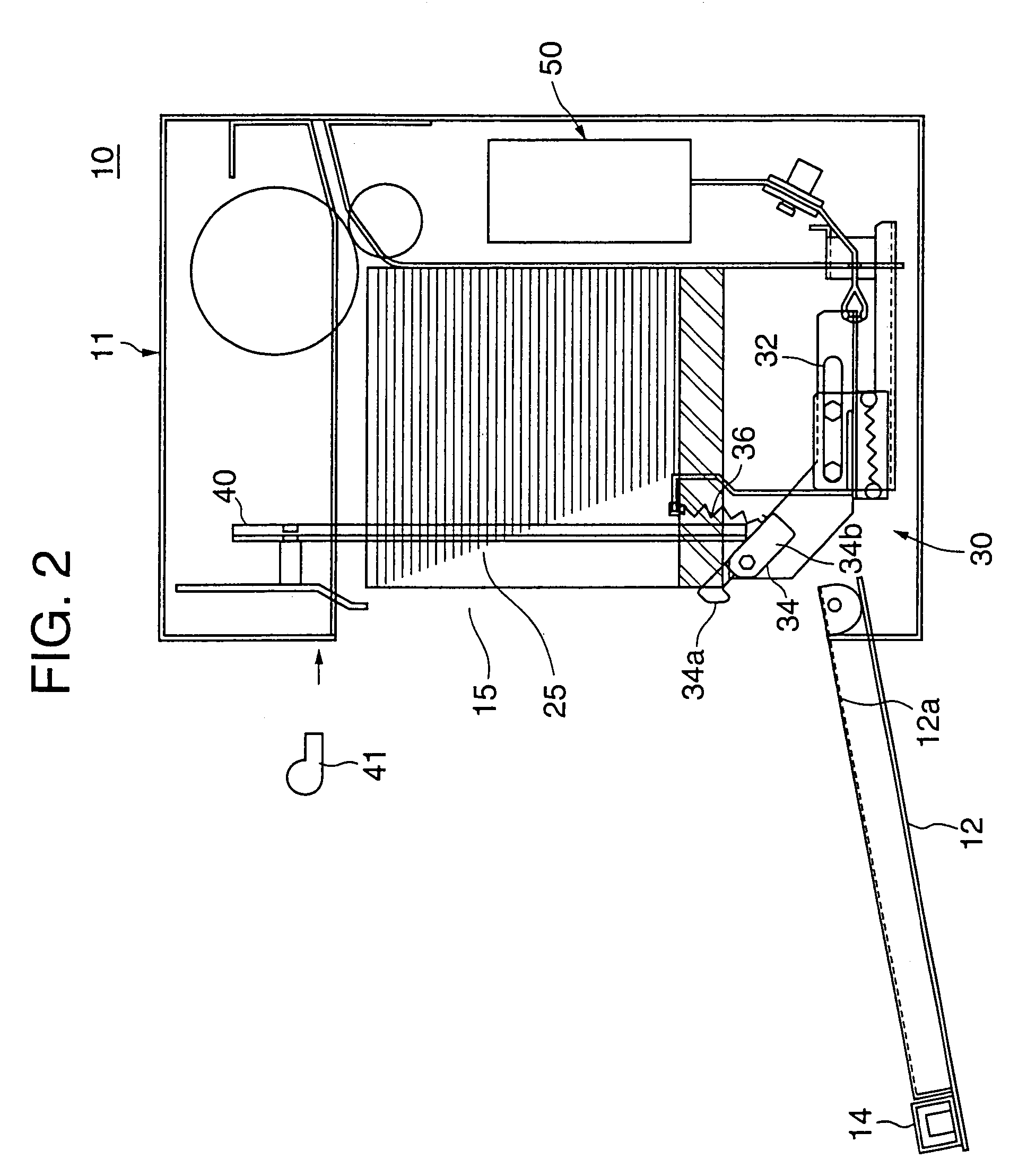

Theft-prevention ink pack device, and treasure safe having the same

InactiveUS7100520B2Improve operational reliabilityEasy to assembleAlarms with smoke/gas/colored-powderBank protection devicePressboardCoil spring

A theft-prevention ink pack device is provided, comprising a support member (70) having support lugs (73a, 74a, 75a, 75b) within a case (130) having ink spouts (66) and knife edges (69), a tray member (80) supported by the lugs (73a, etc.), spaced from the knife edges (69), an ink pack (90) placed on the tray member (80) and having a bag (92) containing ink (91), a pressboard (100) positioned behind the ink pack (90), and conical compression coil springs (120, 121) for pushing the pressboard (100). When the support member (70) is moved as it is pulled, the support provided by the support lugs (73a, etc.) of the tray member (80) is cancelled to cause the tray member (80) to fall down and the ink pack (90) is broken by the knife edges (69) and urged under pressure by the spring forces of the springs (120, 121) via the pressboard (100) to cause the ink to spurt through the ink spouts (66).

Owner:FUJITSU LTD

Chemical machinery grinding equipment

InactiveCN1471141ASemiconductor/solid-state device manufacturingLapping machinesPressboardEngineering

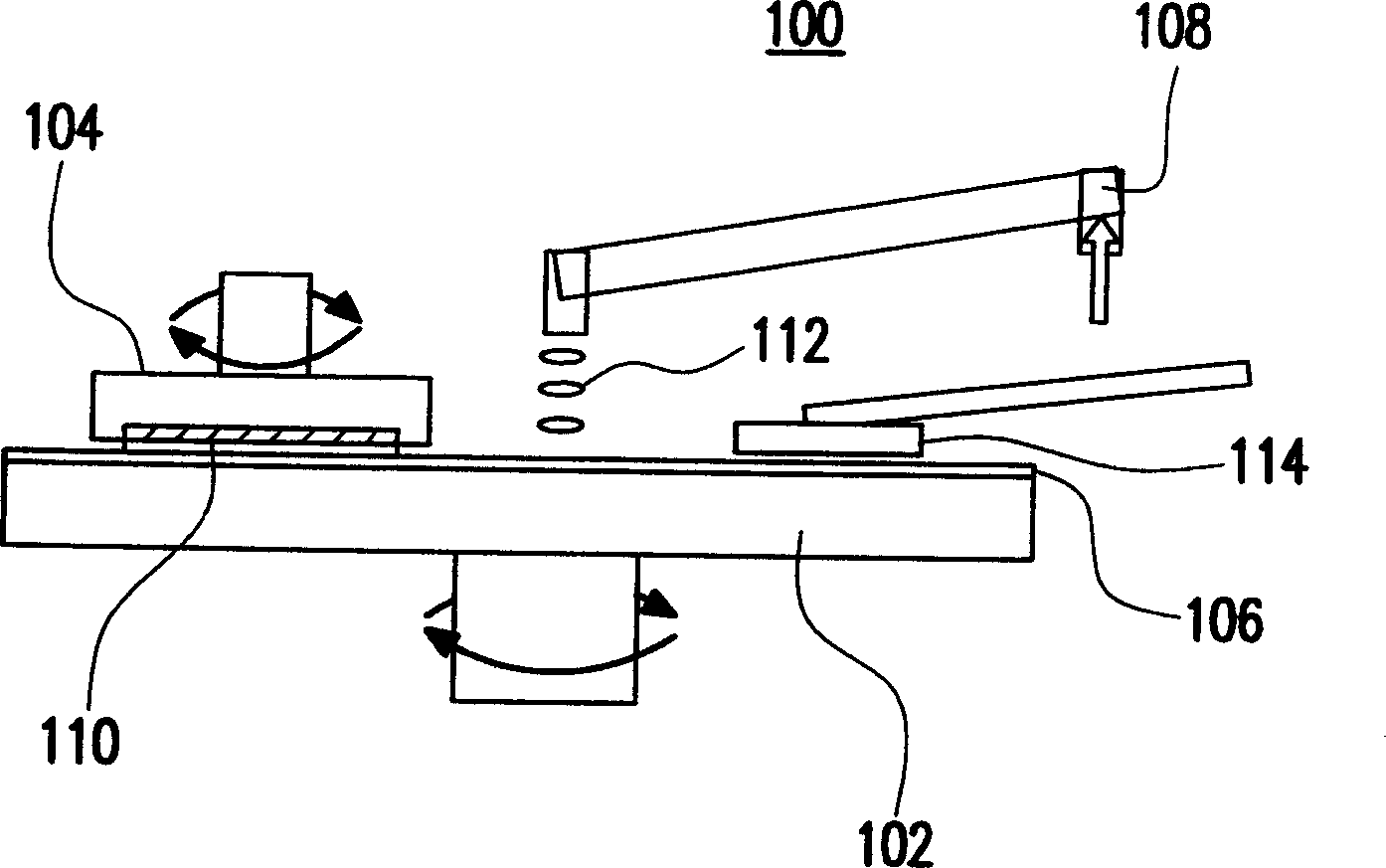

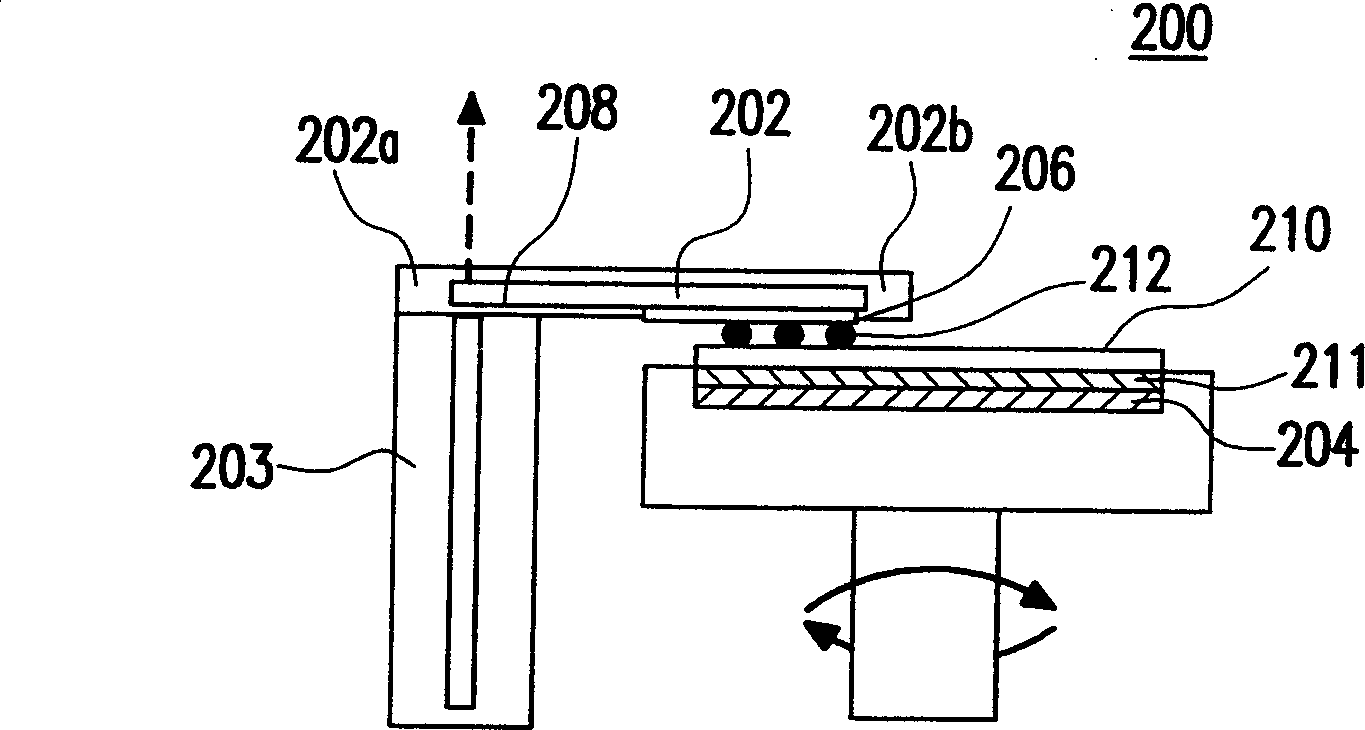

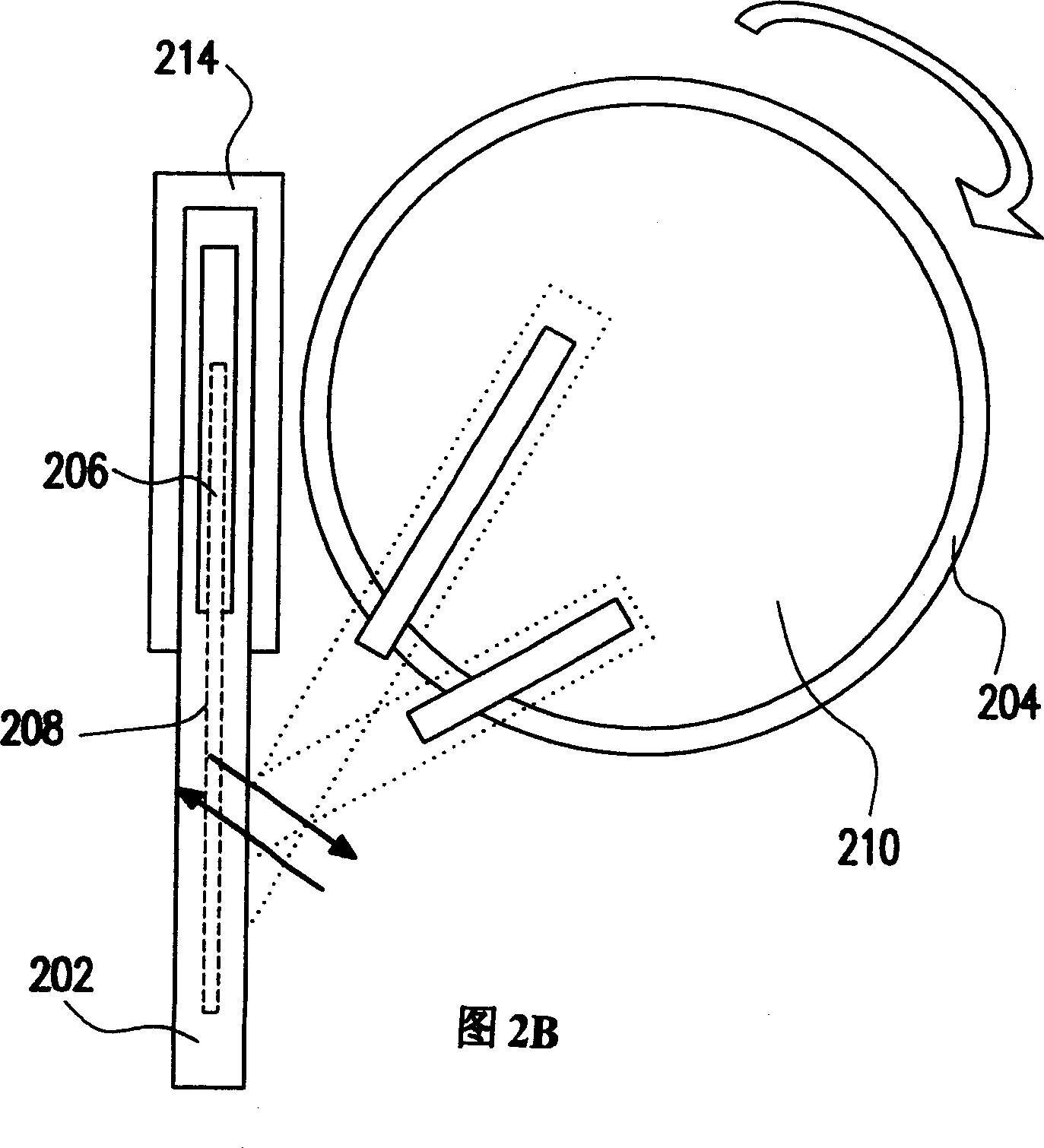

The invented chemical mechanical polishing (CMP) device is suitable to present manufacturing technique. Slim grinding pressboard with size less than the size of wafer is utilized in the invented CMP device. Thus, the layout can be pressed and space can be used effectively so as to reach high yield and effective production management. The CMP device can select diversified grinding pad and / or grinding pulp, thus, flexible manufacturing procedure can be arranged by the CMP device.

Owner:UNITED MICROELECTRONICS CORP

Electric shredder

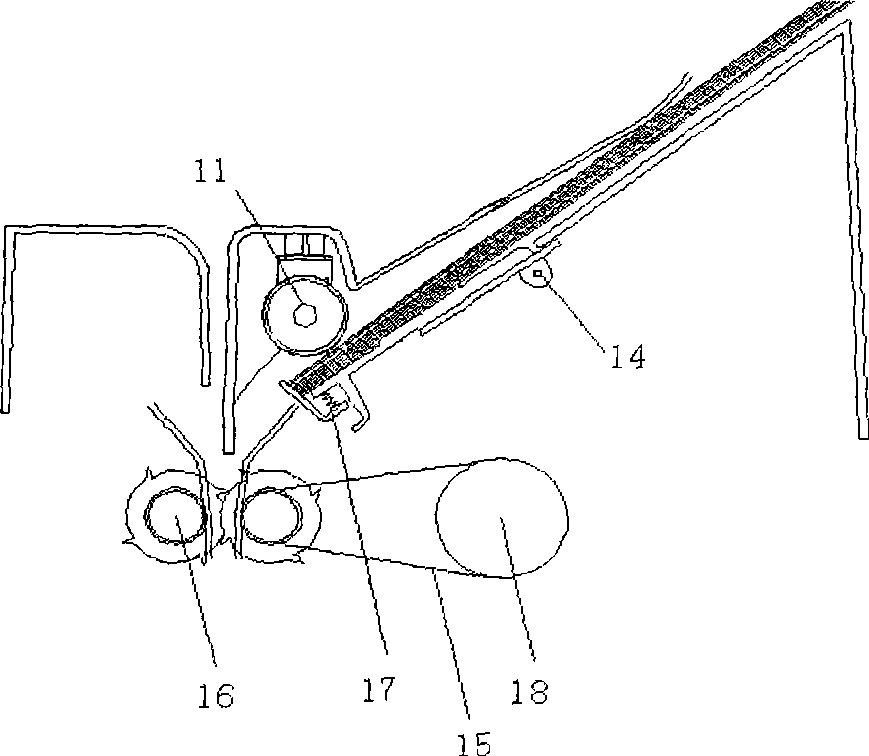

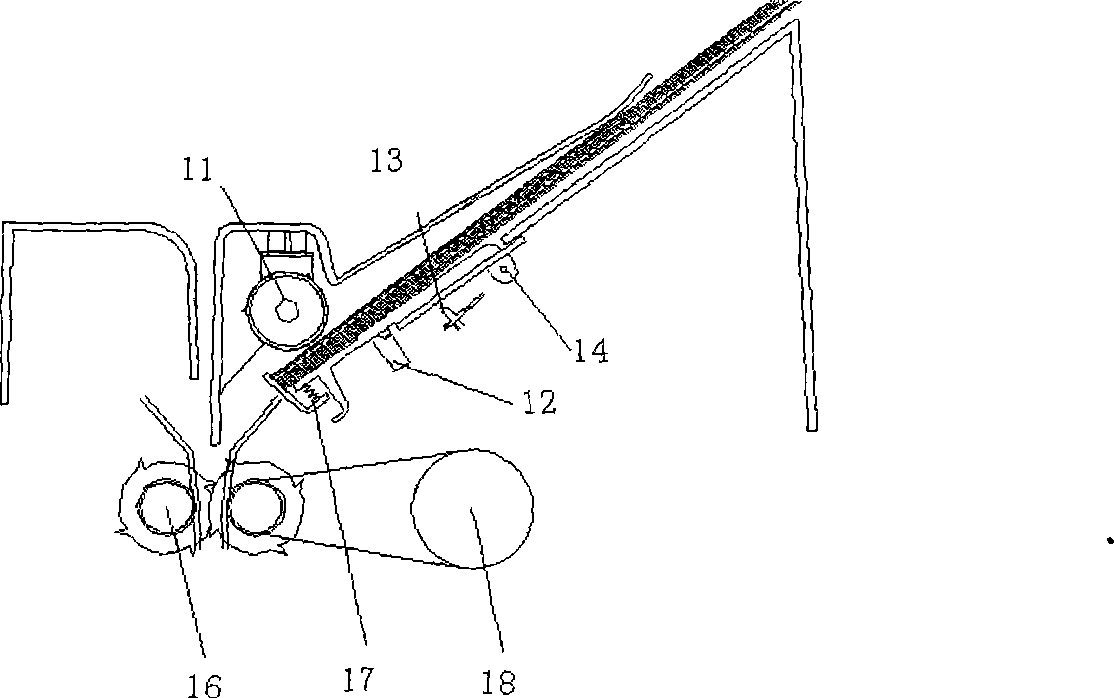

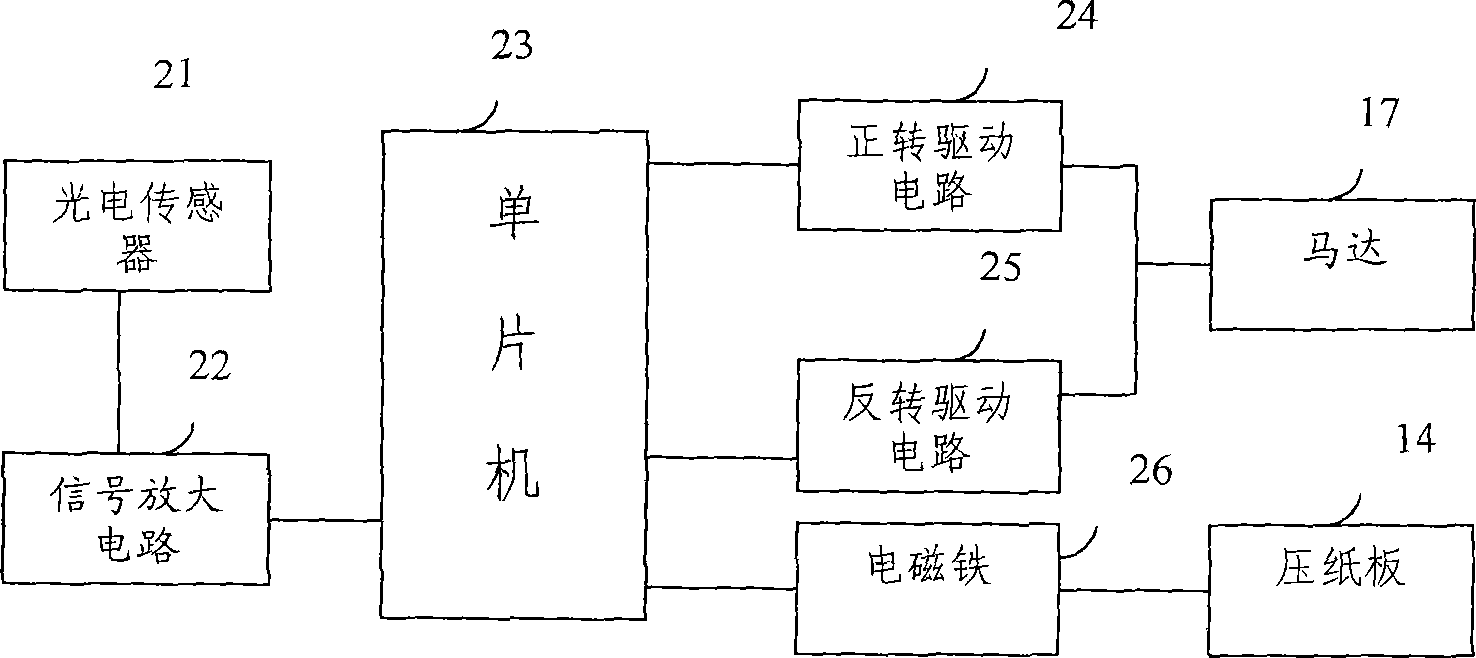

ActiveCN101518753AReduce stepsImprove work efficiencyGrain treatmentsArticle feedersMicrocontrollerCardboard

The invention relates to an electric shredder which comprises a singlechip, a positive rotation drive circuit, a reverse rotation drive circuit, a motor, a sensor and a lifting controller, wherein the singlechip is connected with the positive rotation drive circuit and the reverse rotation drive circuit which are simultaneously connected with the motor; the lifting controller is arranged at the bottom of a pressboard, and the sensor is arranged at a paper feeding hole of a press board of the shredder and connected with the singlechip. The press board is far from a paper feeding roller when no paper needs to be shredded, the sensor sends a signal to the singlechip when paper needs to be shredded, the singlechip sends a control signal to the lifting controller according to a set command, and the lifting controller releases fixation to the press board and puts the paper to be shredded to be close to the paper feeding roller by utilizing the force of a spring, thereby the shredder conveniently realizes automatic paper feed, reduces the paper shredding operation for operators and enhances the work efficiency of the operators.

Owner:ROYAL SOVEREIGN QINGDAO

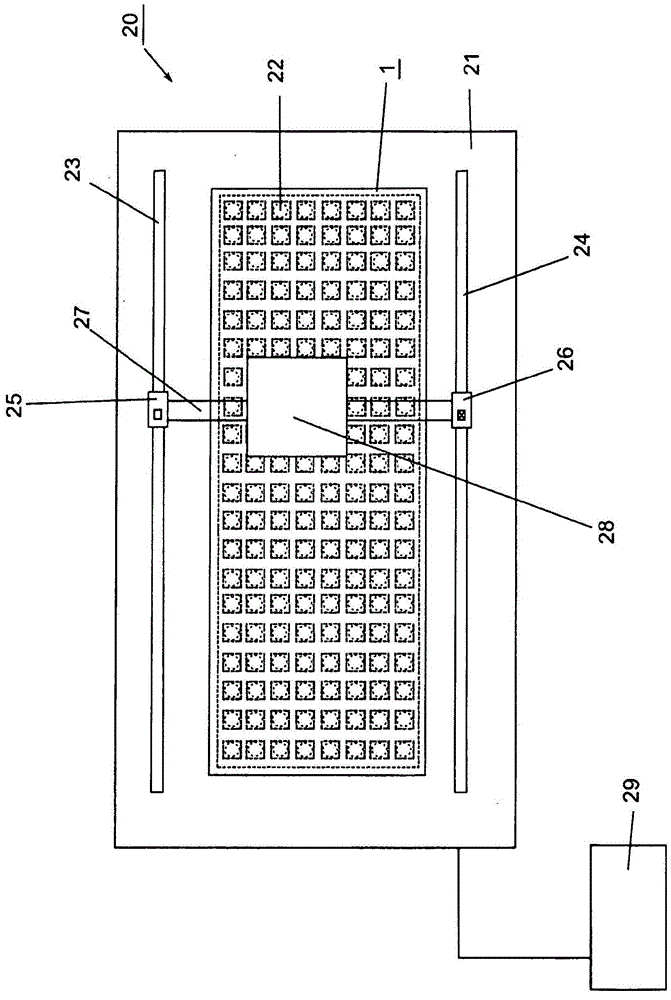

Method for inserting RFID tags in corrugated cardboard

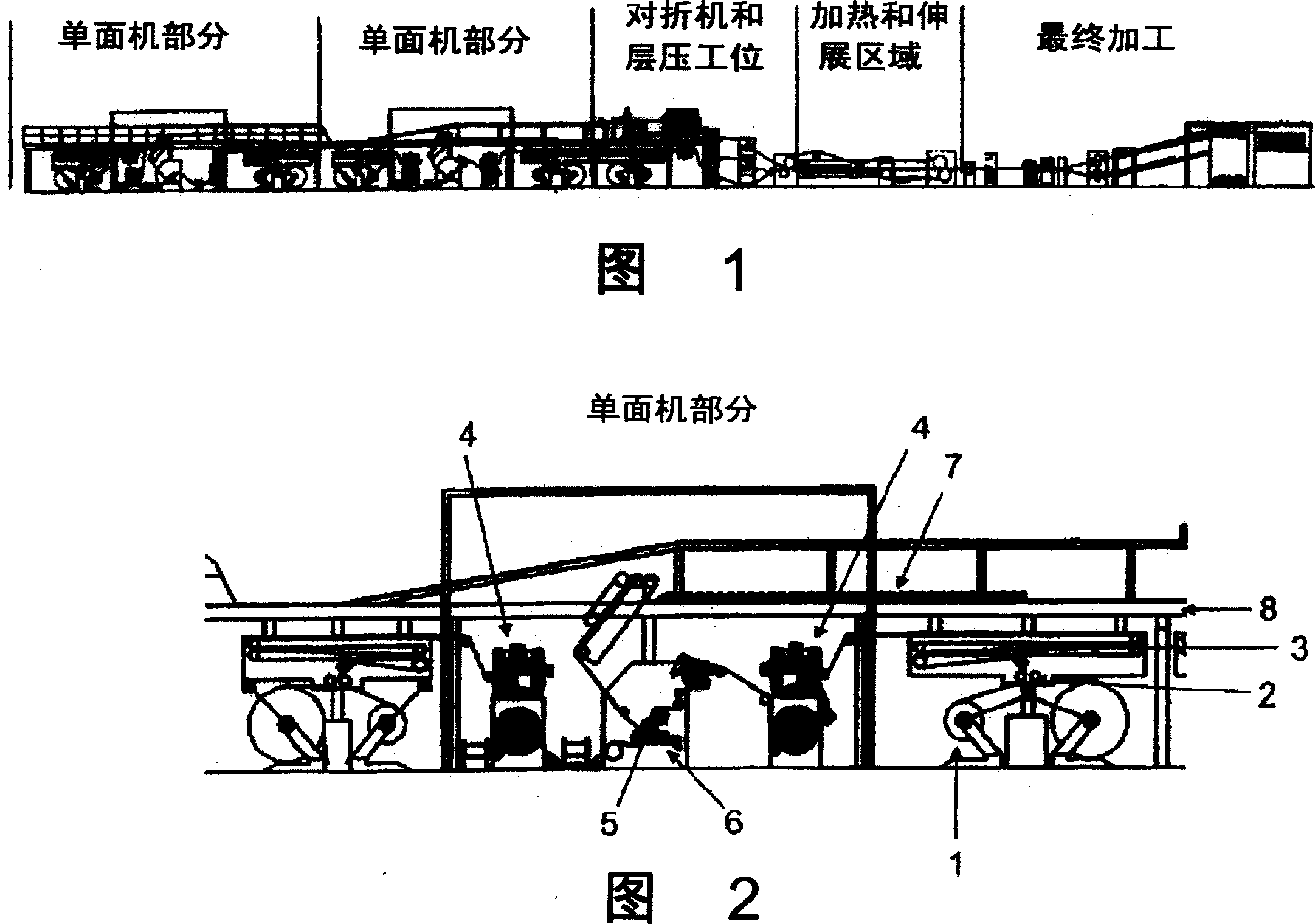

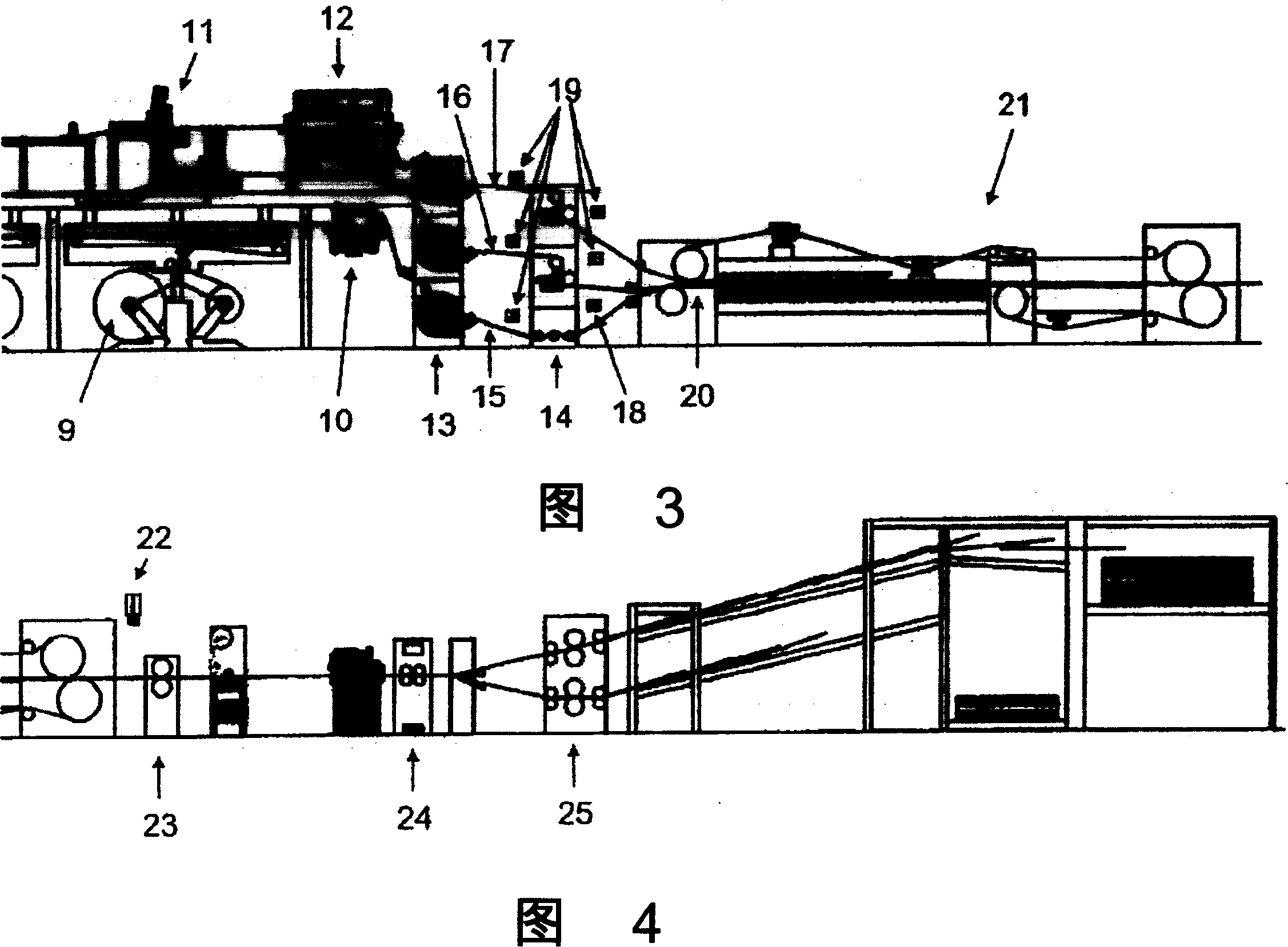

ActiveCN101024314ASimplified orientationAccurately determineContainer decorationsLevel indicationsCardboardPressboard

The present invention relates to a method, apparatus and system of manufacturing or equipping pressboard to embed information carrier between two layers of material, and the pressboard material manufactured in this way and a package. The invention especially relates to embedding an information carrier into a wave pressboard, which considers a cut made in lateral direction later, a distance of position for across cutting to position for applying information carrier, and the movement of the ventral board material between the applying position and the across cutting position.

Owner:得克斯马格贸易有限公司

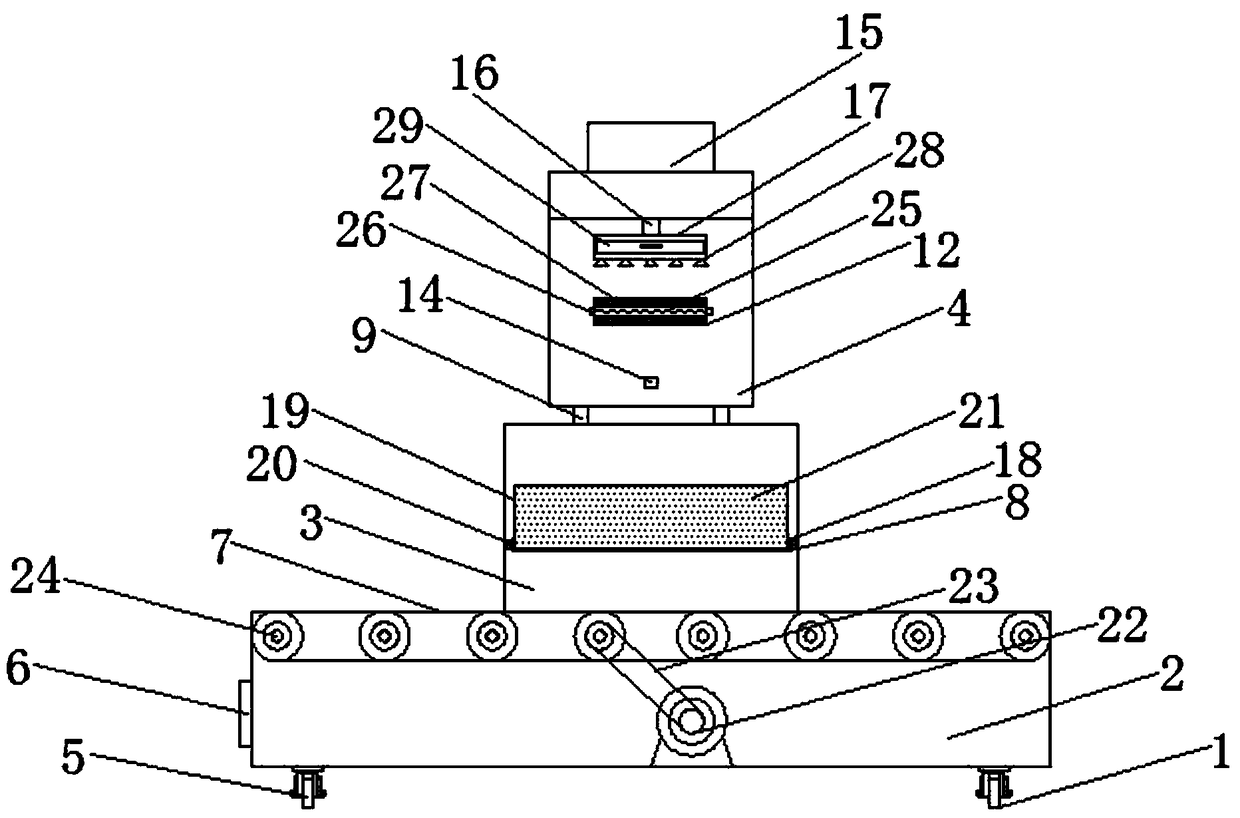

Using method of logistical packaging bag sealing device

InactiveCN108750219AEasy to transportEasy to cleanWrapper twisting/gatheringPackaging automatic controlPressboardArchitectural engineering

The invention discloses a using method of a logistical packaging bag sealing device. A base is arranged at the bottom of the device; a programmable program controller is mounted on the front of the base; support plates are mounted at two sides of the top of the base; electric push rods are mounted at two inner sides of the support plates; a bracket is mounted at the tops of the electric push rods;a left electric cylinder is mounted at the left side of the bracket; a hot pressboard is mounted at one end of the left electric cylinder; a right electric cylinder is mounted at the right side of the bracket; a bearing plate is mounted at one end of the right electric cylinder; fixed parts are mounted at the inner sides of the support plates; fixed plates are arranged at the bottom ends of the fixed parts; L-shaped expansion plates are mounted in the fixed plates; fixed knobs are mounted at two ends of one sides of the fixed plates; and truckles are mounted at the bottom of the base. According to the device, the fixed plates are fixedly connected with the L-shaped expansion plates through the fixed knobs, so that the connection is firm; through the fixed knobs, the expansion and shortening of the L-shaped expansion plates can be realized, so that the clamping distances can be properly adjusted according to the sizes of packaging bags, simplicity and practicability are provided, and application range of the device is enlarged.

Owner:FUYANG FUBAO INSTR MACHINE TOOL FACTORY

Low type bidirectional pressure regulating tower

ActiveCN101037870ALower the altitudeLow costPipe elementsService pipe systemsPressure risePressboard

The invention discloses a low type bidirectional pressure regulating tower which comprises an upper case body and a lower case body with a seal ring, the lower case body is provided with a movement control assembly and a fixing tower ring with a seal ring, the movement control assembly is composed of a diaphragm pressboard, a control diaphragm, a guide piston, a spring, a piston rod and a one-way seal board. The control diaphragm is tightly pressed on the guide piston by the diaphragm pressboard, and the peripheral edge of the control diaphragm is tightly pressed on the lower case body by the upper case body, the one-way seal board is fixedly coupled with the piston rod integrally, and the lower end surface of the one-way seal board pressed on the seal valve seat of the guide piston by a spring baffle and the spring, while the upper end surface of the one-way seal board is pressed on the fixing tower ring. By arranging the guide piston, the invention can greatly lower the height of the bidirectional pressure regulating tower which must be arranged according to the height of the water line, save the engineering cost, lower or eliminate the water hammer pressure rising in the pipe, thereby preventing the pressure pipe from damage caused by bearing overhigh water pressure, or supplementing the collapsing cavity possibly generated by negative pressure to prevent the possible water hammer due to cavity collapsing.

Owner:杨硕

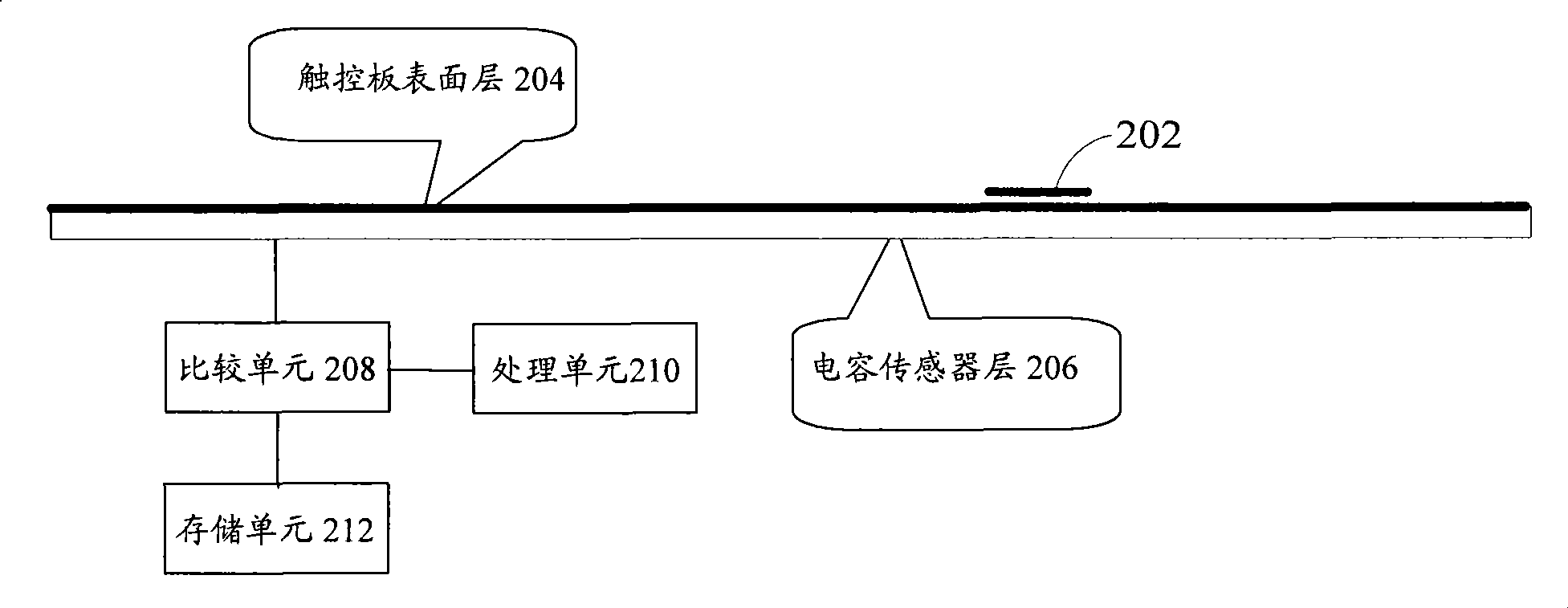

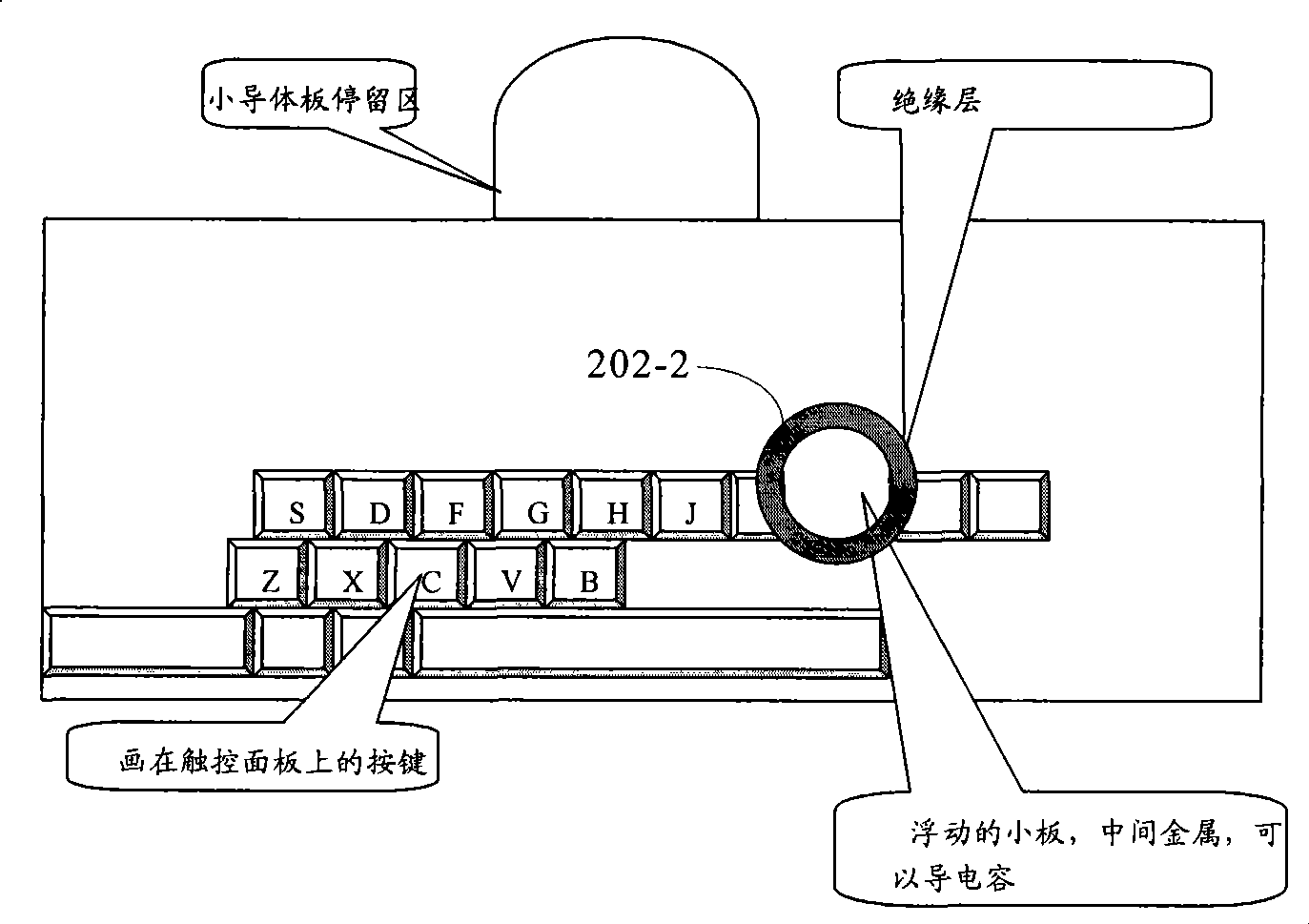

Input device, method and notebook computer

ActiveCN101458576AReduced integration areaNo slippageDigital data processing detailsInput/output processes for data processingCapacitancePressboard

The invention provides an input device, an input method and a notebook computer. The device includes: a locating plate which has a conducting layer on bottom; a touch control panel which connects with the locating plate, area of the touch control panel is larger than bottom area of the conducting layer of the locating plate, the locating plate slides on the touch control panel; a first capacitance sensing layer which connects with the touch control panel and connects with the locating plate through the touch control panel for sensing a first area value on the touch control panel generated by the user's input operation in a first time; a first comparing unit which connects with the first capacitance sensing layer, compares the first area value and a waited-compared value for generating a comparing value; a processing unit which connects with the first comparing unit and judges the input operation whether being input by mouse or keyboard according with the comparing value. The device, the method and the notebook computer provided by the invention can solve problem of distinguishing position moving operation on the touch control panel and keyboard pressboard knocking input, blend the touch control panel and the keyboard fully, and has more higher input precision.

Owner:LENOVO (BEIJING) LTD

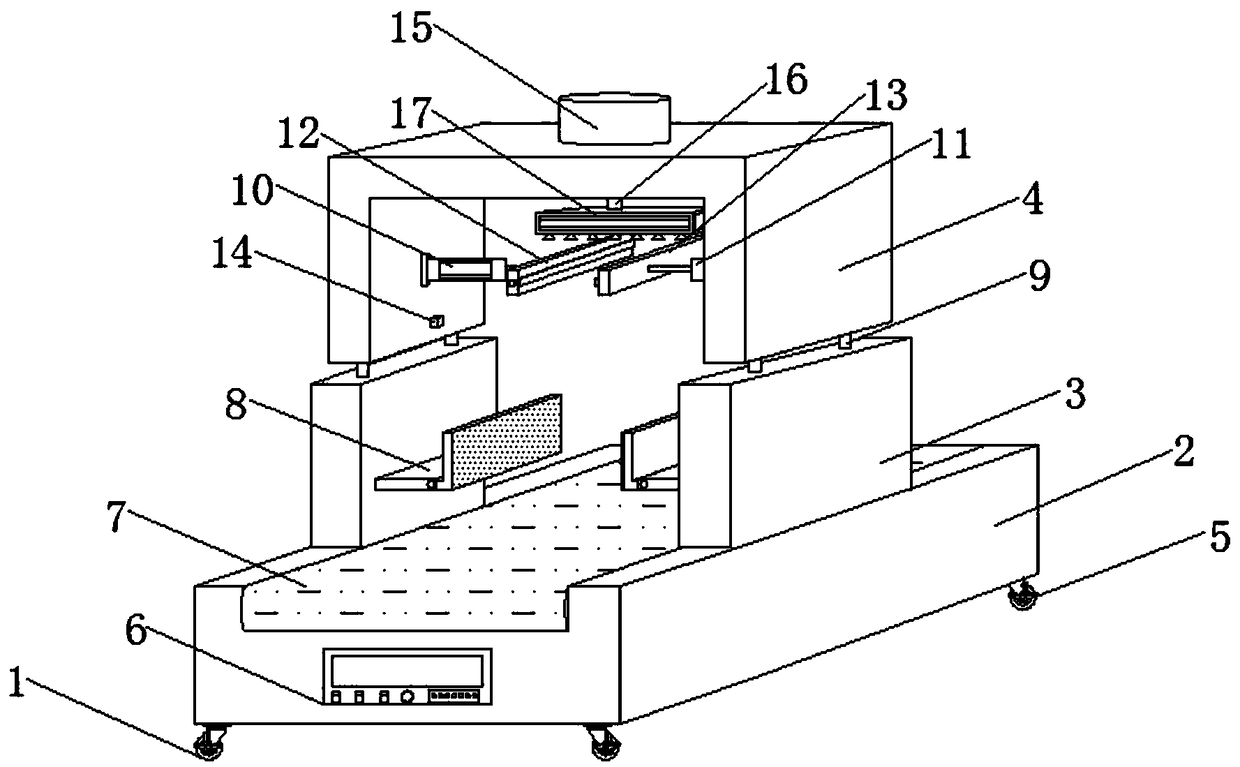

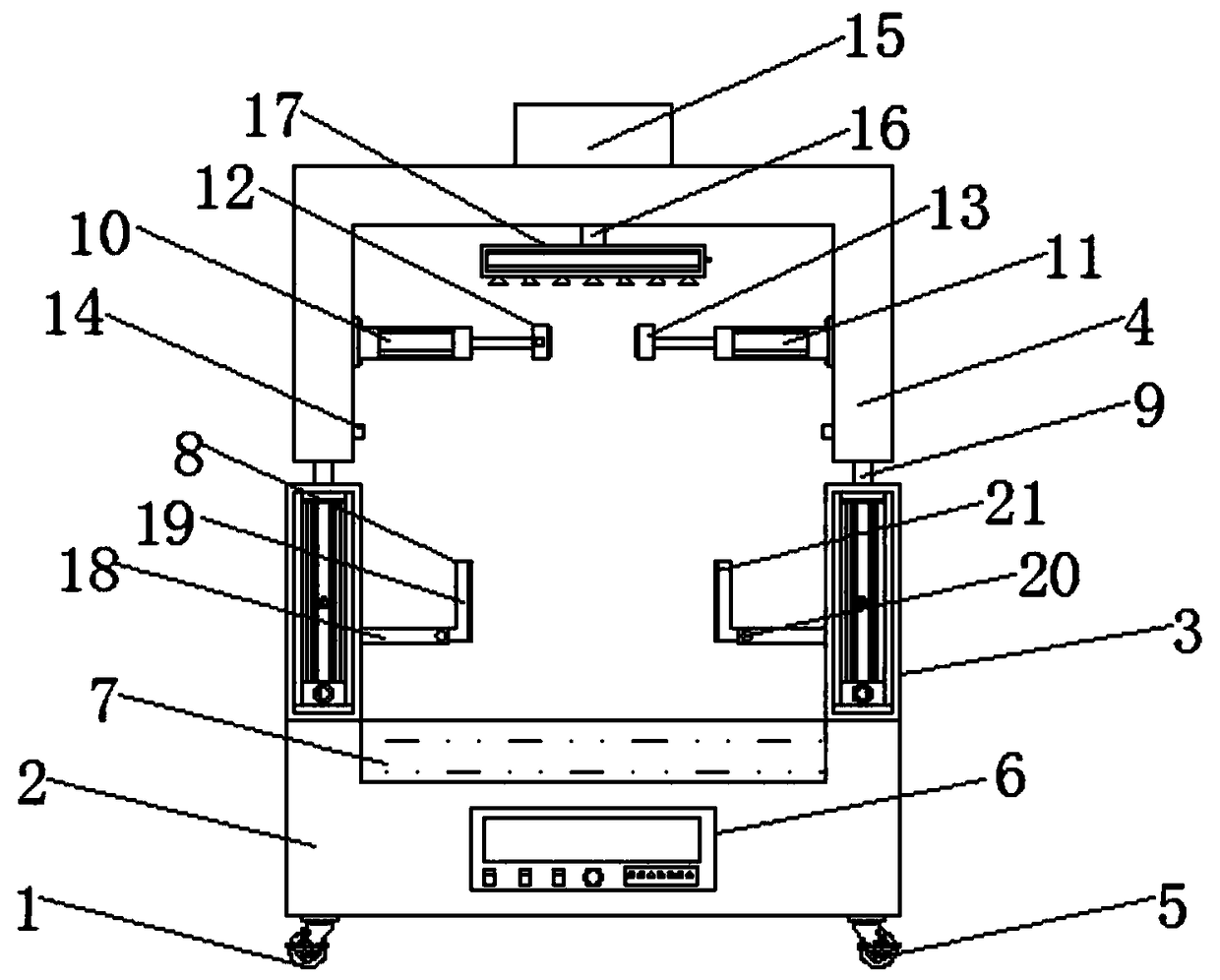

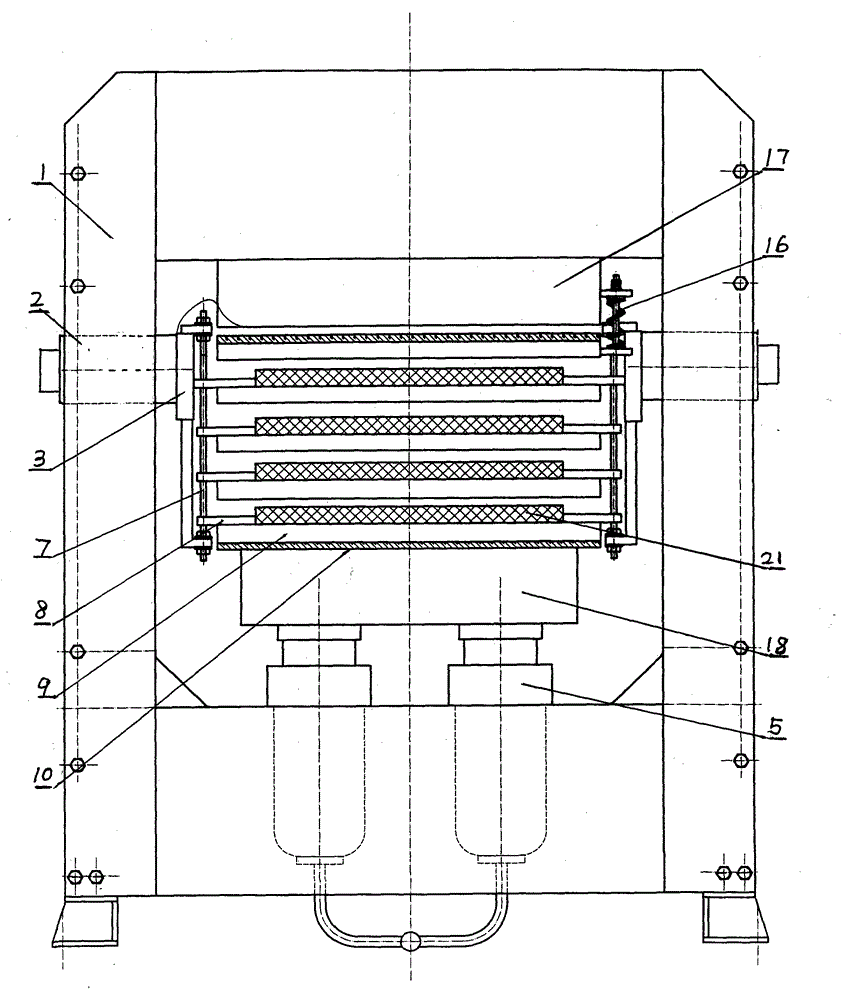

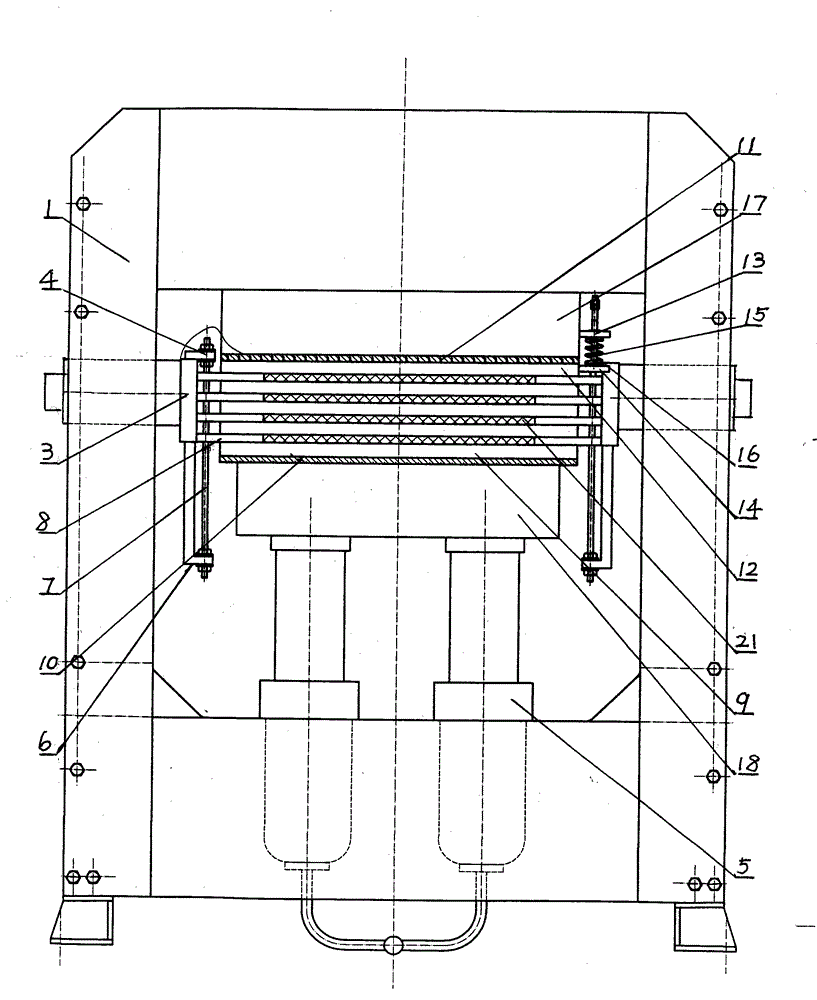

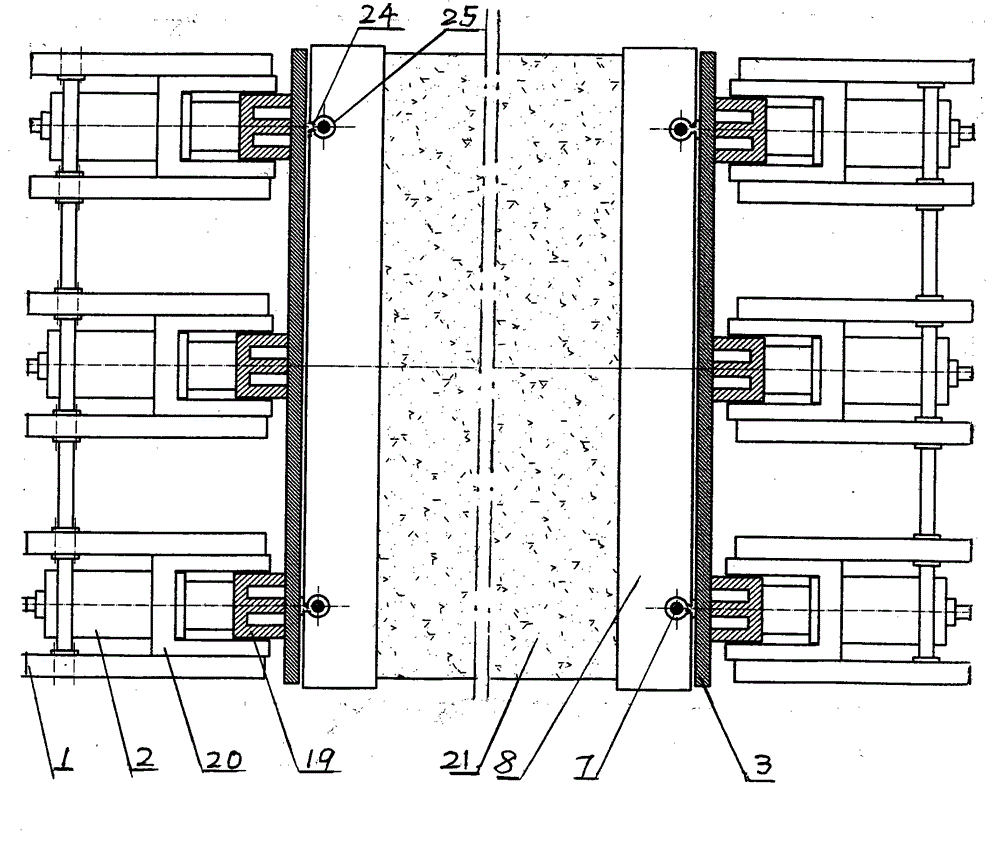

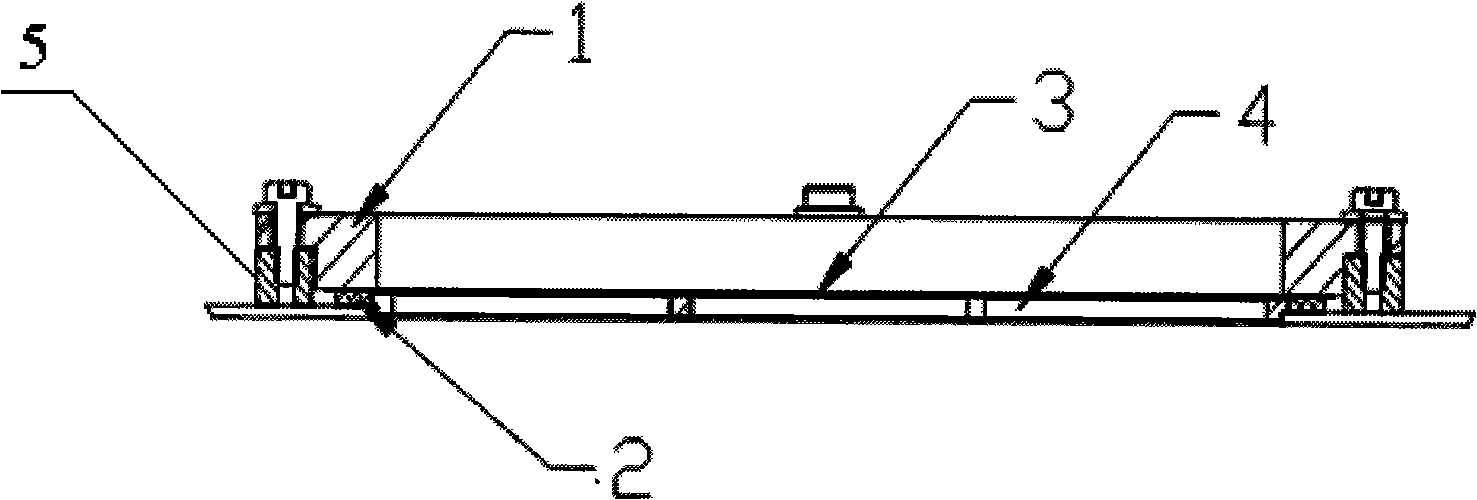

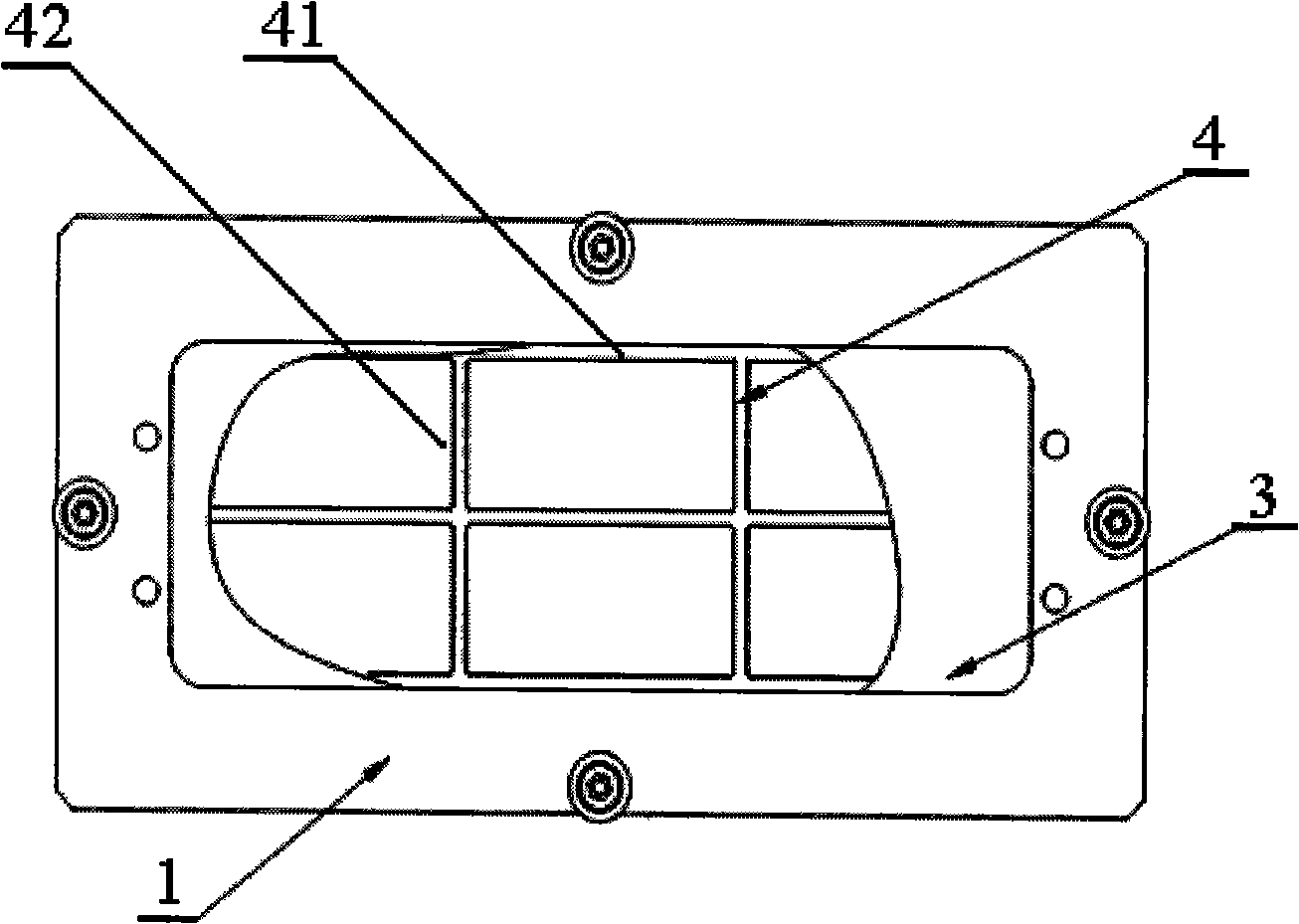

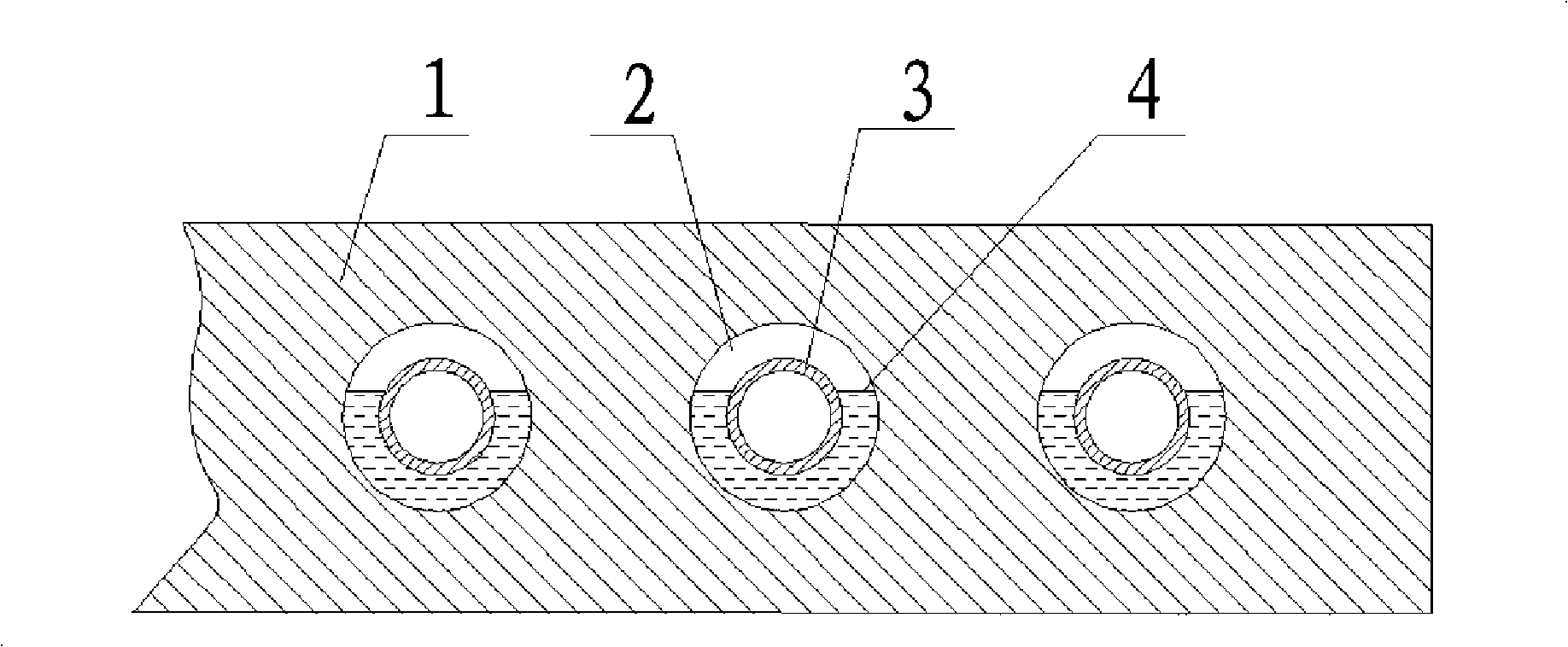

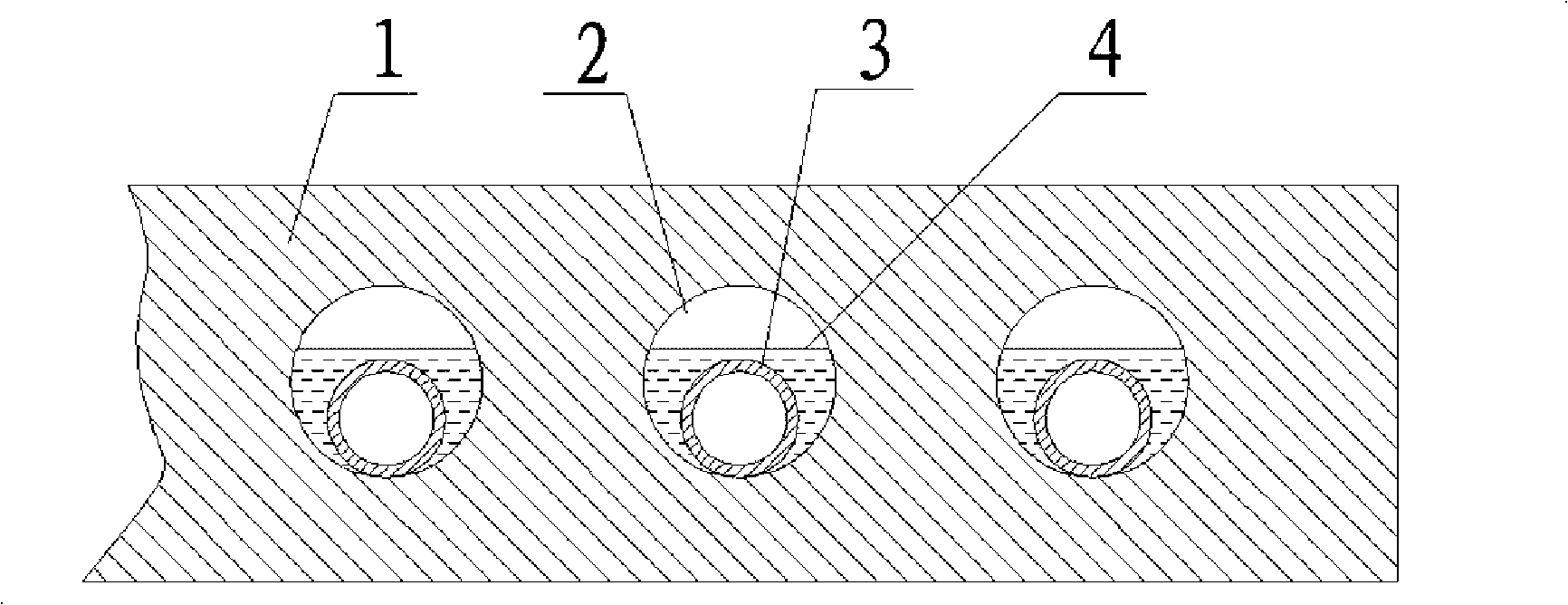

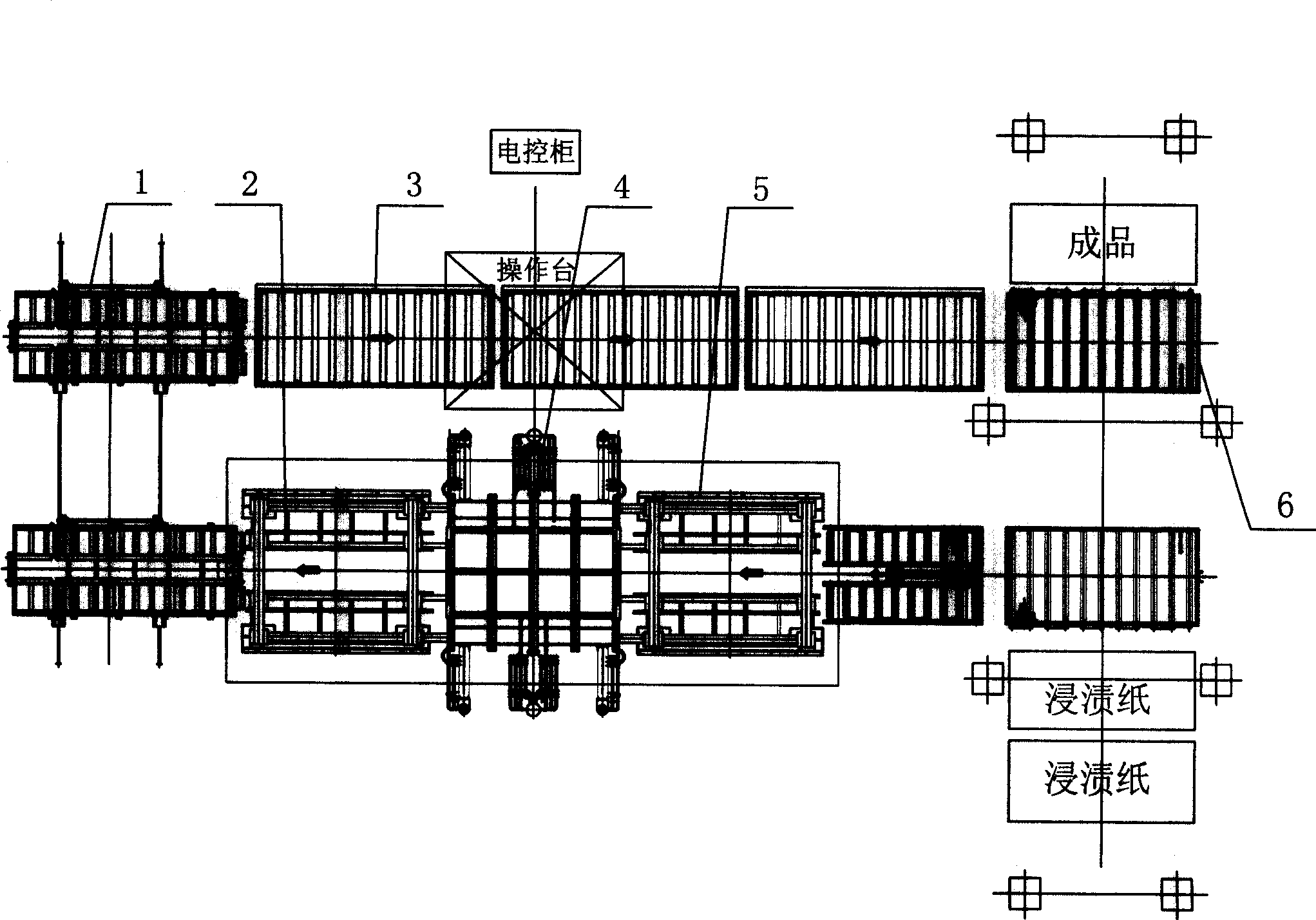

Hot press for bamboo floor

The invention discloses a hot press for a bamboo floor and relates to technical equipment for producing bamboo-laminated bamboo floor products. The hot press for the bamboo floor comprises a stand, master cylinders, an upper crossbeam, a lower crossbeam, an upper insulation board, a lower insulation board, multiple layers of hot pressboards, a side cylinder, guide pull rods, multiple layers of side pressboards, a hydraulic system and an electronic control system, wherein the side pressboards penetrate the guide pull rod. The hot press for the bamboo floor has the advantages that I, tons of weak positive pressure is provided through a compression spring arranged between the upper crossbeam and a top layer hot pressboard to create a side pressure condition, and therefore, the high-quality bamboo floor can be produced; II, both side faces of each guide pull rod are respectively provided with trapezoidal gaps according to a new design; each side pressboard is provided with a through hole matched with the related guide pull rod and provided with a side opening; the width of the side opening of each through hole can allow the related trapezoidal gap of the guide pull rod to partially pass in the manner of matching, and therefore, the side pressboards can be replaced without entirely detaching the guide pull rod. The hot press for the bamboo floor is convenient, cannot delay the production and is in favor of the improvement of the production efficiency.

Owner:QINGDAO GUOSEN MACHINERY

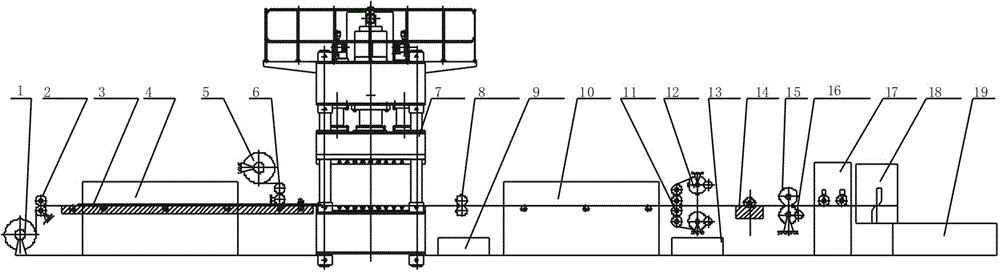

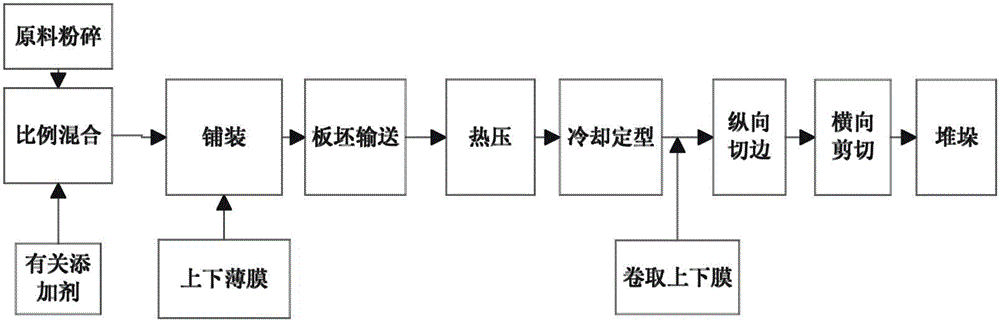

Device and method for preparing paper and plastic composite plate for steel roll package

InactiveCN102744952AMeet packaging requirementsMeet the requirements of outdoor storageLamination ancillary operationsLaminationMolded pulpPressboard

The invention relates to a device and a method for preparing a paper and plastic composite plate for a steel roll package. A hot press serves as a core, the device is provided with a coiling and recoiling device, a paving device, a cooling device, a coiling device, a mobile trolley, a plate drawing device, a plate cutting device, an automatic stacking device and the like, the working pressure of the hot press, the slide block stroke, the hot pressboard temperature control, the paper and plastic plate movement working speed and the shearing plate specification can be adjusted according to a technical process through hydraulic control, programmable logic controller (PLC) electronic control and frequency conversion control, and a fixed-travel molding technical way of the hot press can be finished. Paper and plastic wastes are changed into a composite plate, the manufacturing cost is relatively low, and the source of the raw materials is wide; and compared with the current paper and plastic (aluminum) composite material which is difficultly separated and reused, the material provided by the invention is convenient to reclaim and reuse and can be also naturally degraded after being used and the environmental protection is facilitated.

Owner:武汉市江夏区江南实业有限公司

Explosion-proof apparatus of inflating switch cabinet

The invention relates to anexplosion-proof equipment, particularly to an explosion-proof equipment for charging the air chamber of the switchboard. The explosion-proof equipment of the charging switchboard includes a rupture membrane frame, comprising a frame and a blocked side of the partition frame port arranged on the frame, wherein a pressure release port is arranged on the air chamber of the charging switch and the frame is arranged on the pressure release port; a sealing ring, arranged on the outside of the rupture membrane frame and the circumference of the pressure release port; a rupture membrane, arranged on the sealing ring for sealing the frame port of the frame; a pressboard, fastened on the circumference of the pressure release port for fastening the rupture membrane and the sealing ring on the circumference of the pressure release port. The device can prevent the explosion accident of the air chamber when the air in the air chamber of the charging switchboard releases with certain pressure.

Owner:SHANGHAI PINGGAO TIANLING SWITCHGEAR CO LTD +1

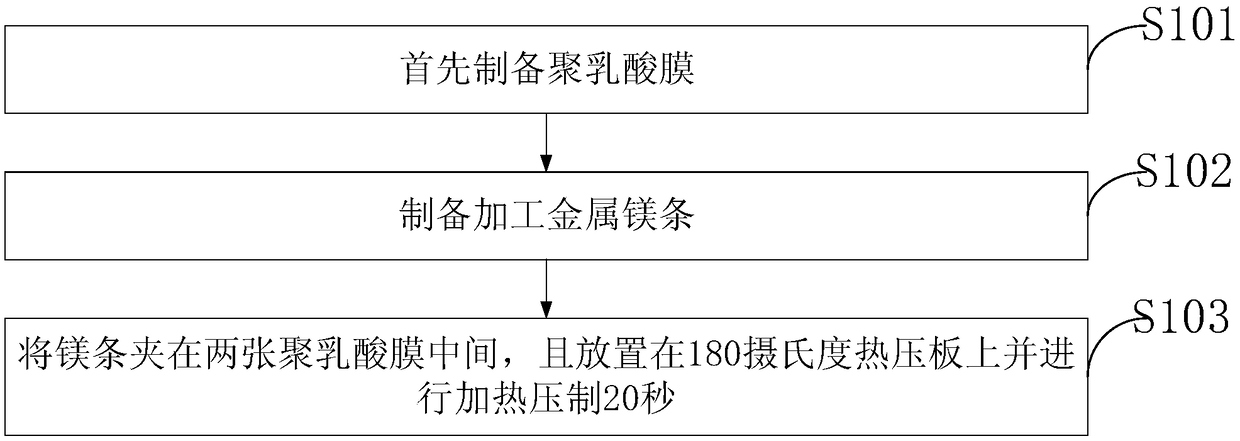

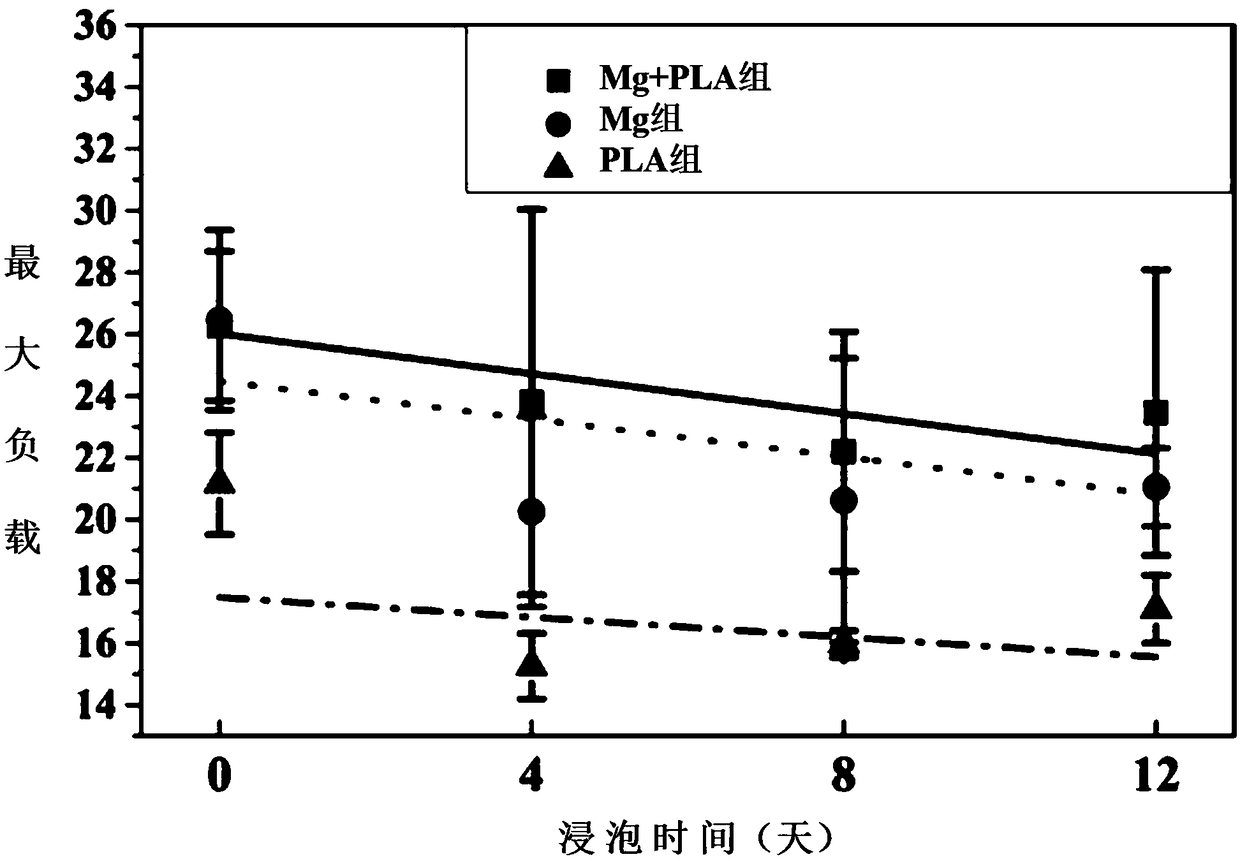

Biodegradable compound type guided bone regeneration barrier membrane and preparation method thereof

InactiveCN108379656AEasy mechanical strengthEasy to operateTissue regenerationProsthesisPressboardBiocompatibility Testing

The invention belongs to the technical field of medical materials, and discloses a biodegradable compound type guided bone regeneration barrier membrane and a preparation method thereof. The biodegradable compound type guided bone regeneration barrier membrane comprises a biomedical magnesium rod and polylactic acid membranes pressed on the upper and lower faces of the magnesium rod. The method comprises the steps that the magnesium rod is clamped between two polylactic acid membranes, placed on a 180-DEG C hot pressboard, and conducted with hot pressing for 20 seconds. The biodegradable compound type guided bone regeneration barrier membrane and the preparation method thereof have the advantages that the novel bio-barrier membrane with good biocompatibility, capacity of selectively guiding the regeneration of tissues, certain mechanical strength, biodegradability, degradation rate coordinating with a process of bone tissue regeneration and other characteristics, the preparation technology is simple, and the cost is low.

Owner:SHANDONG FIRST MEDICAL UNIV & SHANDONG ACADEMY OF MEDICAL SCI

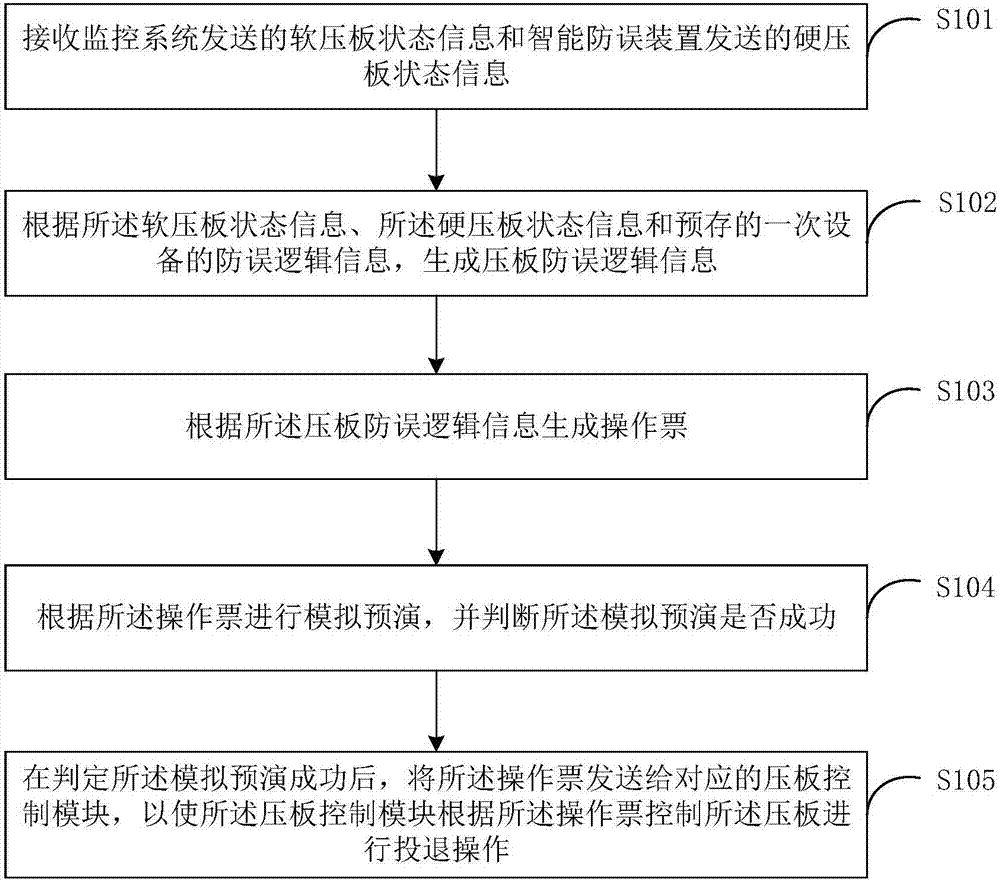

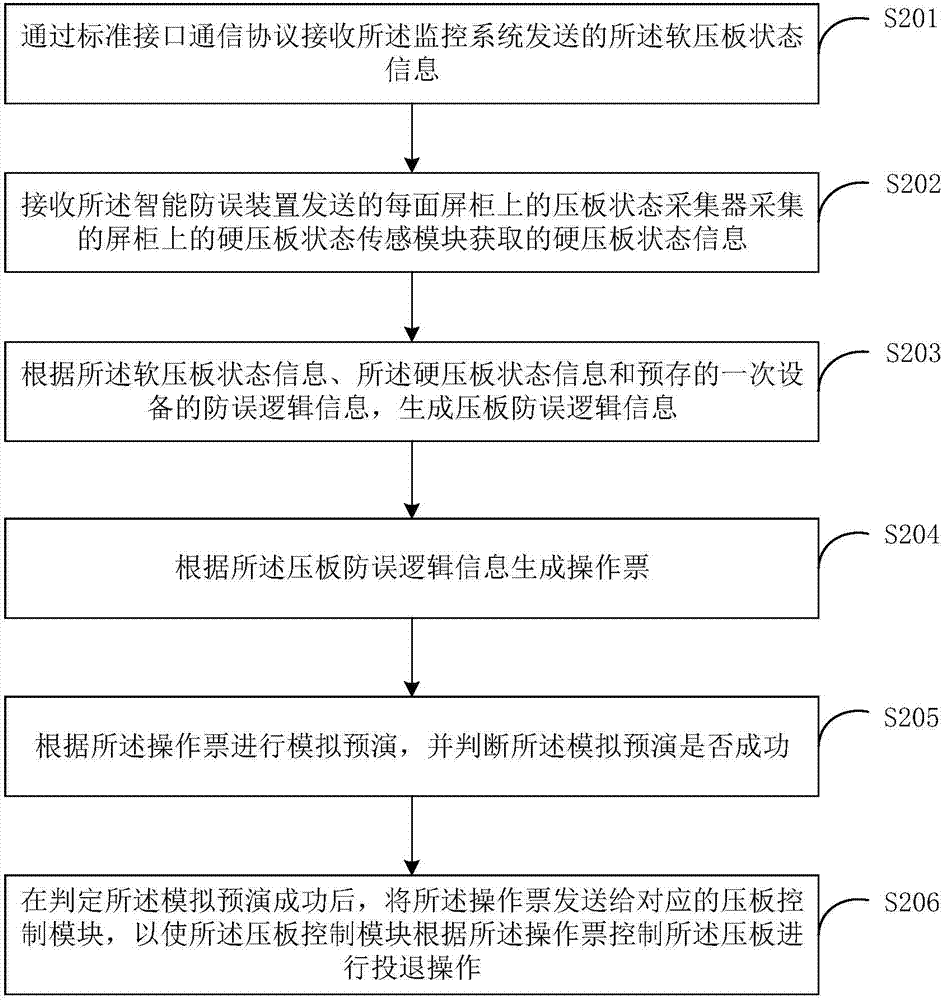

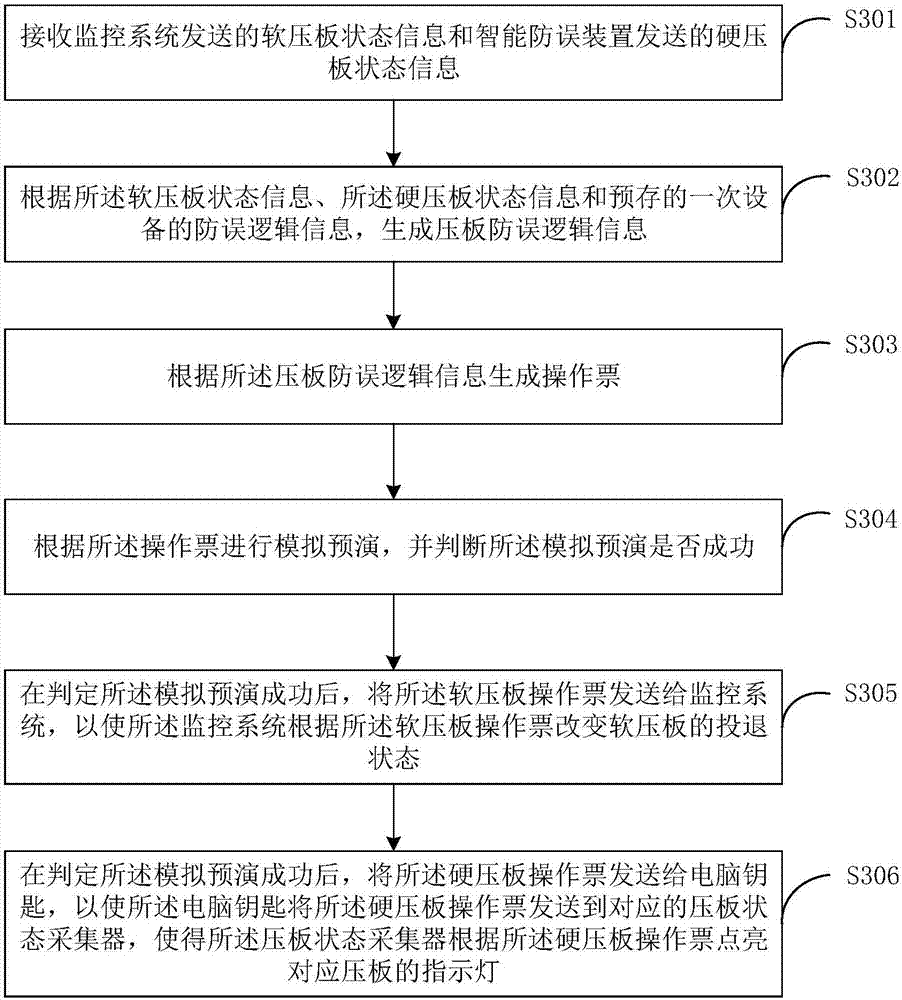

Transformer station pressboard anti-error operation method and device

ActiveCN107546854APrevent mis-casting and false-returningImprove management efficiencyCircuit arrangementsInformation technology support systemPressboardMonitoring system

The invention is suitable for the technical field of electric power equipment and discloses a transformer station pressboard anti-error operation method and device. The method comprises steps that thesoft pressboard state information sent by a monitoring system and the hard pressboard state information sent by an intelligent anti-error device are received; the pressboard anti-error logic information is generated according to the soft pressboard state information, the hard pressboard state information and the pre-stored anti-error logic information of primary equipment; an operation bill is generated according to the pressboard anti-error logic information; simulation rehearsal is carried out according to the operation bill, and whether simulation rehearsal succeeds is determined; after simulation rehearsal succeeds, the operation bill is sent to a corresponding pressboard control module to make the pressboard control module control a pressboard according to the operation bill for carrying out switching operation. The method is advantaged in that real-time pressboard state monitoring can be realized, the pressboard error switching phenomenon can be prevented, pressboard managementefficiency is improved, and safe operation of the power grid is guaranteed.

Owner:STATE GRID CORP OF CHINA +1

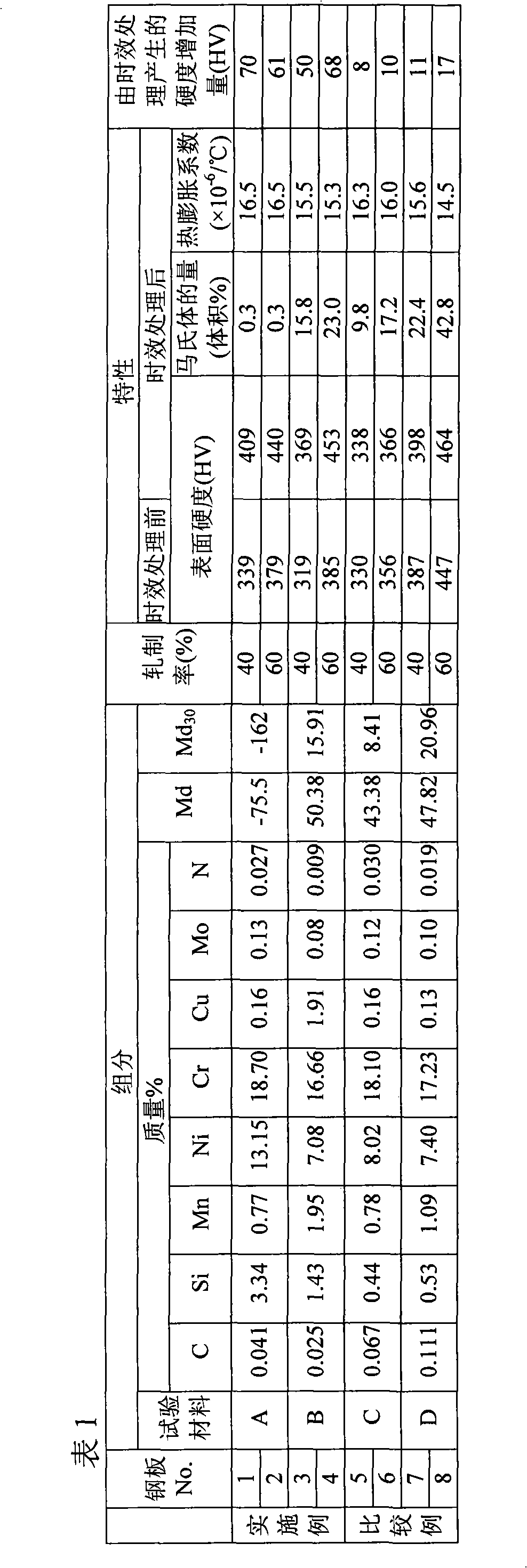

Austenite stainless steel plate for pressboard

InactiveCN101314836AEasy to manufactureImprove flatnessFurnace typesMultilayer circuit manufacturePressboardStability index

The invention relates to an austenitic stainless steel plate for pressure plate. The invention provides a new pressure plate material; the material is able to easily produce the pressure plate which has both planeness and hardness that are difficult to exist at the same time and has coefficient of heat expansion in the same degree with the coefficient of heat expansion of the copper. The invention provides an austenitic stainless steel plate for pressure plate, comprising 1.0 mass% to 4.0 mass% Si, 10.0 mass% to 25.0 mass% Cr, 5.0 mass% to 15.0 mass% Ni, less than 0.3 mass% (containing 0 mass%) C+N, less than 5 mass% (containing 0 mass%) Mn, less than 5 mass% (containing 0 mass%) Cu, less than 5 mass% (containing 0 mass%) Mo and the excess being Fe and unavoidable impurity; and the austenitic stability index Md30 (degree centigrade) of the stainless steel plate expressed by the following formula is less than 25. Md30 (degree centigrade)=551-462(C+N)-9.2Si-8.1Mn-29(Ni+Cu)-13.7Cr-18.5Mo...(1).

Owner:NISSHIN STEEL CO LTD

Formaldehyde-free environment-friendly chipboard and manufacturing method thereof

InactiveCN107363964AReduce releaseAchieving the goal of formaldehyde-freeProtein adhesivesGlue/gelatin preparationSurface layerPressboard

The invention discloses a formaldehyde-free environment-friendly chipboard. A non-formaldehyde adhesive is adopted, a soybean-based protein adhesive is adopted for a surface layer and a bottom layer, and a soybean-based protein adhesive or an isocyanate adhesive is adopted for a core layer. The formaldehyde emission amount of the formaldehyde-free environment-friendly chipboard is far lower than 1.5 mg / L specified by the national standard grade E1, and the formaldehyde-free environment-friendly chipboard is developed. The invention further provides a manufacturing method of the formaldehyde-free environment-friendly chipboard. The manufacturing method comprises the main steps of (1) adhesive applying, (2) pavement, (3) hot pressing and (4) edge cutting. In the adhesive applying and pavement working sections, corresponding adhesive applying of the surface layer and the core layer and pavement of three layers of structures are adopted, and meanwhile, the soybean-based protein adhesive is adopted for the surface layer and the bottom layer, so that the problem of board sticking caused by the condition that during hot pressing, isocyanate flows into a hot pressboard through gaps is solved. In addition, in subsequent hot pressing, the problems that isocyanate does not have initial adhesiveness, consequently chipboard shifts, and edge subsiding and the like are produced are solved. Through combination of the modes, development of the formaldehyde-free environment-friendly chipboard is achieved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

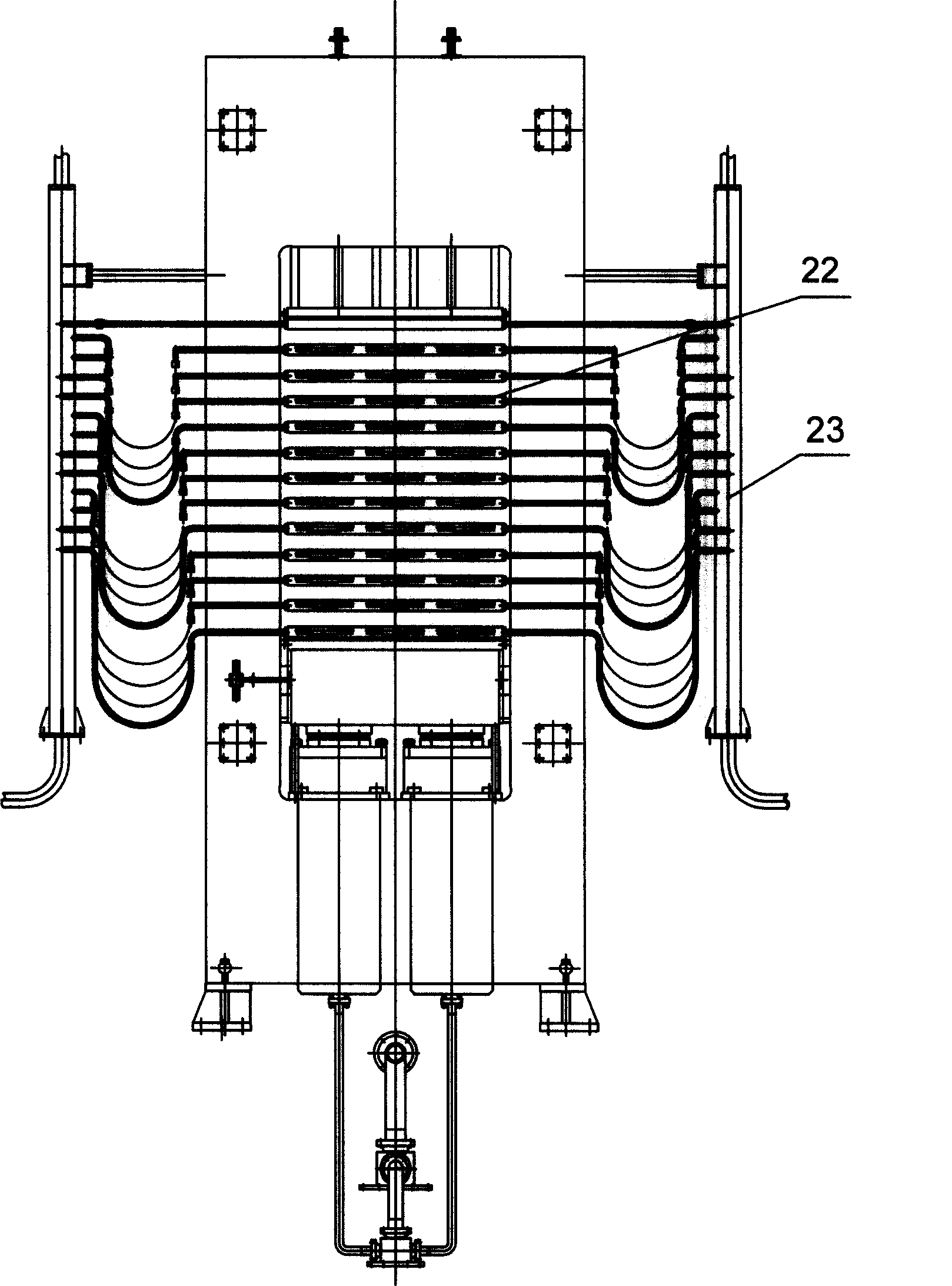

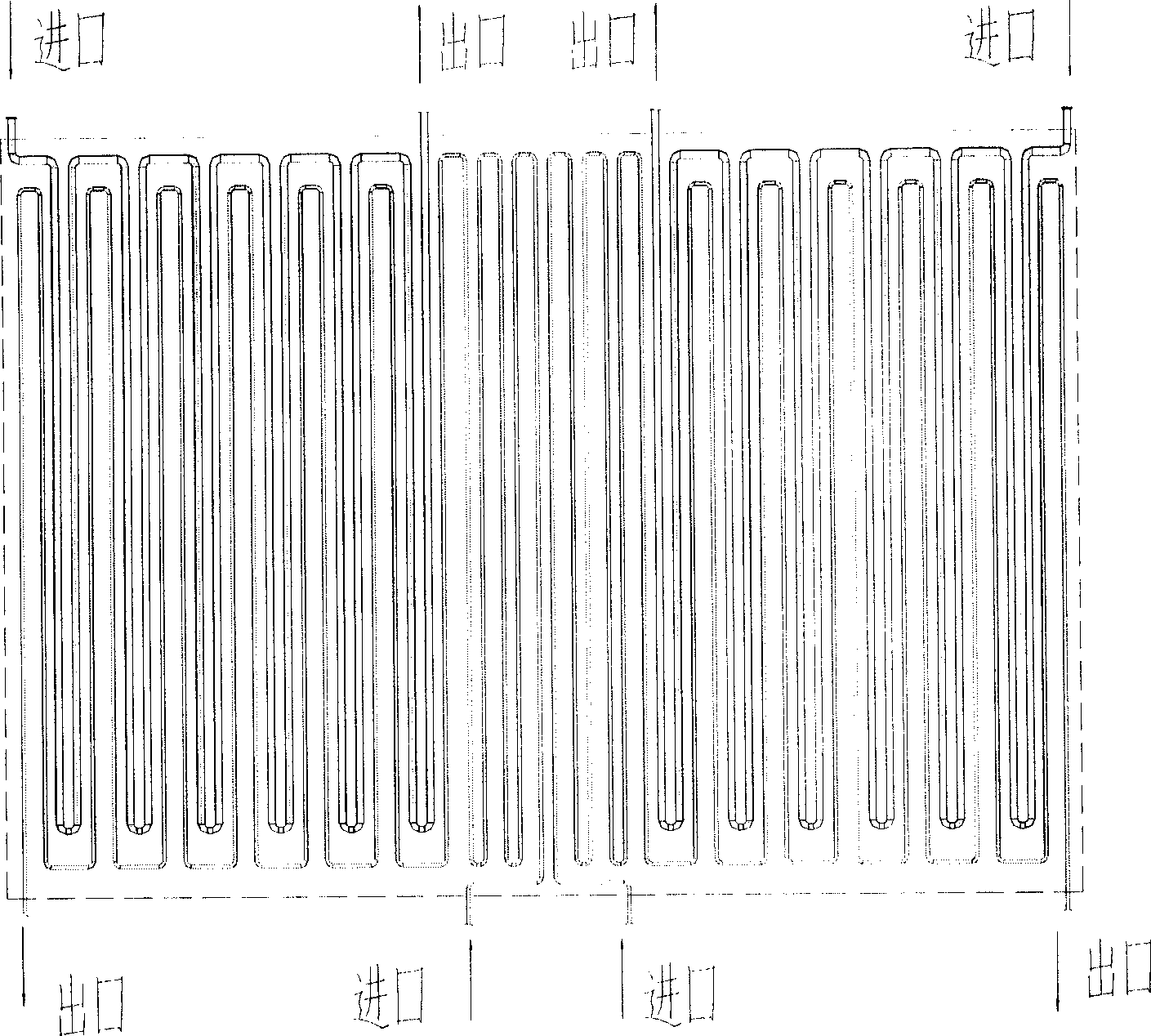

Isothermal hot pressing board

The invention discloses an isothermal hot pressboard, which is characterized in that a cavity is positioned in the hot pressboard and working medium and a heating device immersed in the working medium are arranged in the cavity; wherein, the working medium in the cavity is in two phase saturation state of gas and liquid; the liquid-phase working medium is gasified by absorbing the thermal energy of the heating device, while the gas-phase working medium is condensed by releasing thermal energy to the cavity wall, thus the working medium transfers the thermal energy released by the heating device to the cavity wall which is used as the body of the hot pressboard; because the thermal energy absorbed and released by the working medium is latent heat of phase change, the temperature in the cavity is equal, thus the isothermal hot pressboard is realized. The isothermal hot pressboard can be used as the hot pressboard of artificial board presses, copper clad laminate presses, decorative laminated sheet based on thermosetting resins presses, vacuum film laminating presses, positive-negative film laminating presses, flat vulcanizing machines, hot-press printing machines and other hot presses.

Owner:臧登志

Fire-proof board heat-pressing production chain

InactiveCN101480807AUniform temperatureShorten the timePlywood pressesVeneer pressesProduction lineAutomatic control

The invention provides a hot pressing production line for a fireproof board, which at least comprises a press. A plurality of hot pressboards are arranged on the press; pipelines on each hot pressboard are provided with four outlets and four inlets; the four outlets and the four inlets are respectively and uniformly distributed at two sides of each hot pressboard, and are oppositely distributed in a way of crossing from top down; the hot pressing production line for a fireproof plate further comprises a vacuum chunk carriage; a set of chunks and a set of liner plate chunks used for sucking liner plates and common chunks used for sucking non-liner-plate plates are newly arranged on the vacuum chunk carriage; the newly-arranged chunks are connected to the vacuum chunk carriage through an air cylinder structure; and the vacuum chunk carriage controls the motions of each set of chunks through an electric motor. The heating cooling structure adopts the four-outlet and four-inlet structure so as to guarantee the uniform temperature of hot pressboards, automatically control the temperature difference in a reasonable range (temperature difference of 3 DEG C, for example), adopts two sets of vacuum chunk structures to work, reduces the time of separating spreading boards, greatly reduces the labor intensity of spreading boards, and greatly improves the automatization of the whole line.

Owner:SUZHOU XINXIELI MACHINE MFG

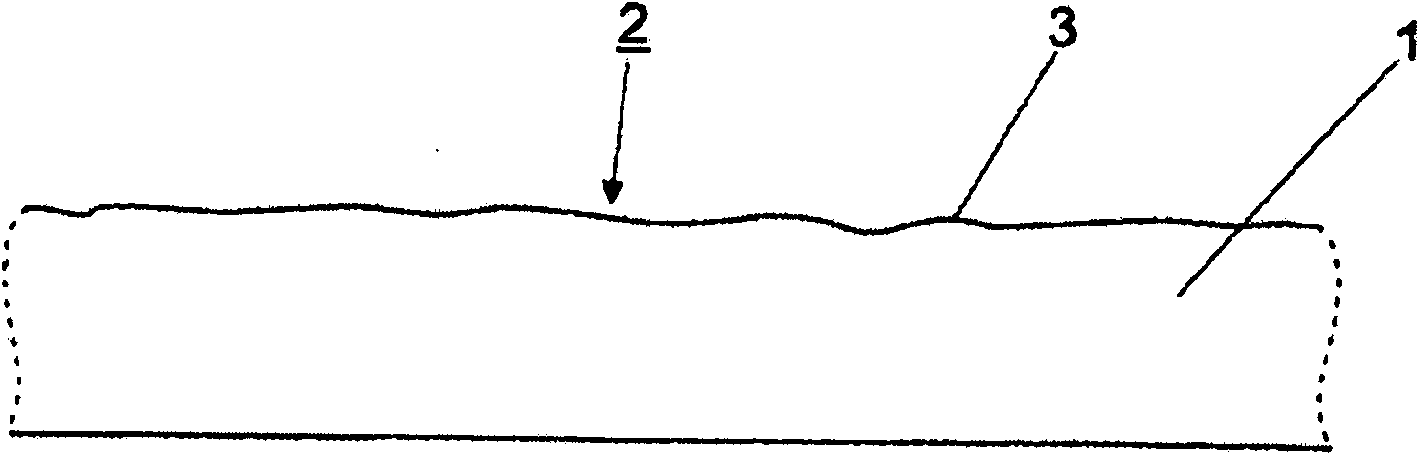

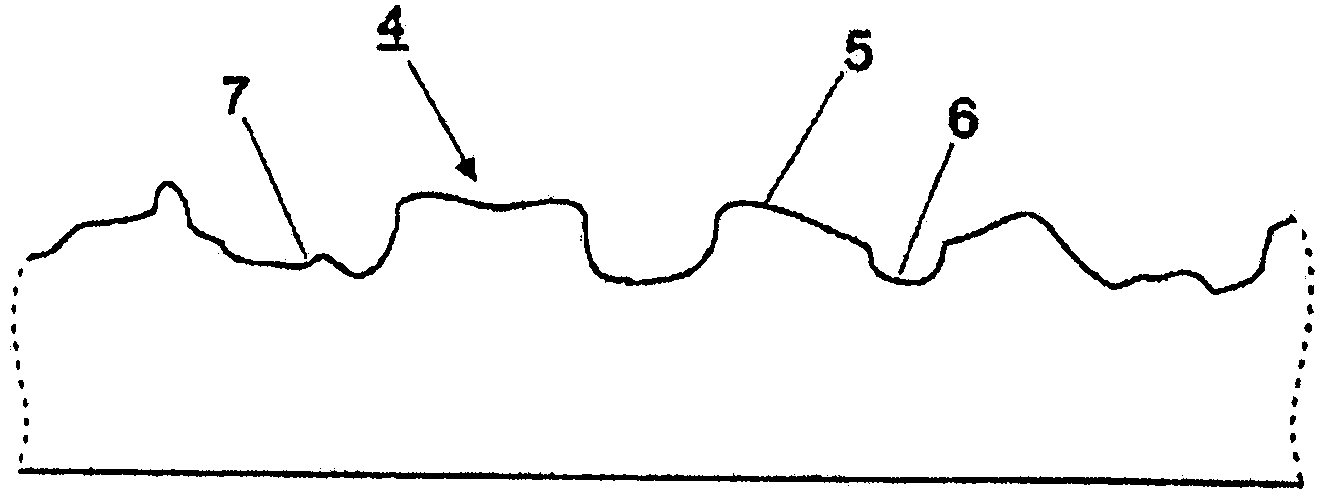

Method for producing a surface structure using a water-jet device

InactiveCN104245349ARigid fasteningSmall structured precisionDecorative surface effectsSpecial ornamental structures3d topographyParticle board

The invention relates to a method for producing a surface structure (4) of a workpiece (1) in the form of a pressed sheet, endless belt, or cylindrical embossing roller using at least one water-jet device with a machining head (25). The method according to the invention allows workpiece surfaces (2) to be machined in an environmentally friendly and inexpensive manner such that the 3D topography of a surface structure of a template or of the negative of the template is reproduced. The surface (2) of the workpiece (1) is partially removed using a water-jet device in the method according to the invention. Using the pressed parts machined in this manner, different materials can be pressed for example, such as particle boards with support films, wherein the 3D topography of the surface structure is reproduced on the surface of the pressed material.

Owner:HUECK RHEINISCHE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com