Electric shredder

A paper shredder, electric technology, applied in the direction of object separation, object supply, grain processing, etc., can solve the problems of operator inconvenience, cumbersome operation steps, and reduce the work efficiency of operators, so as to reduce operation steps and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

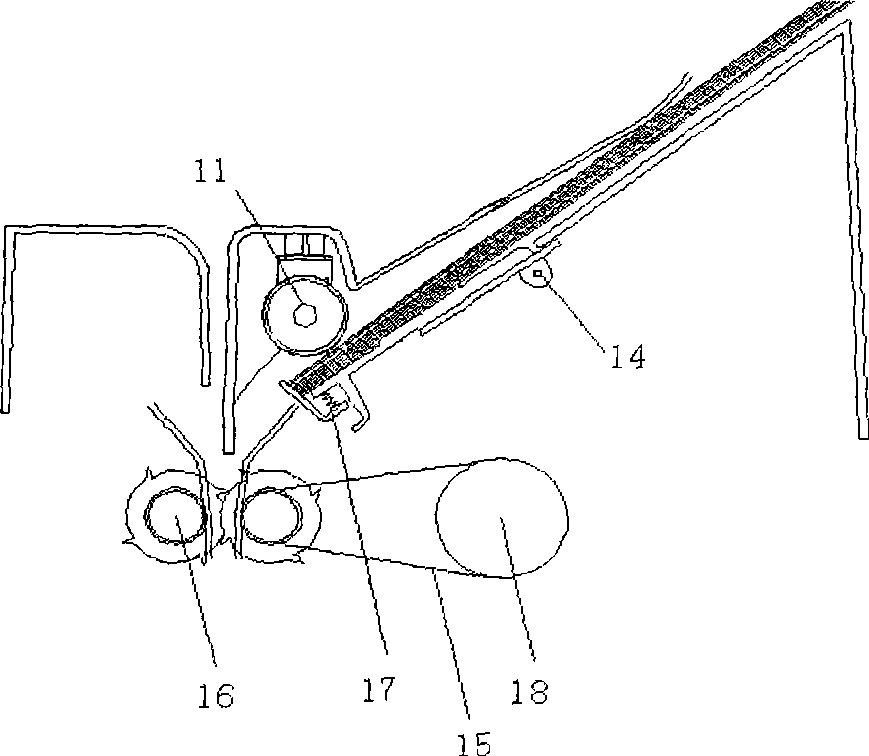

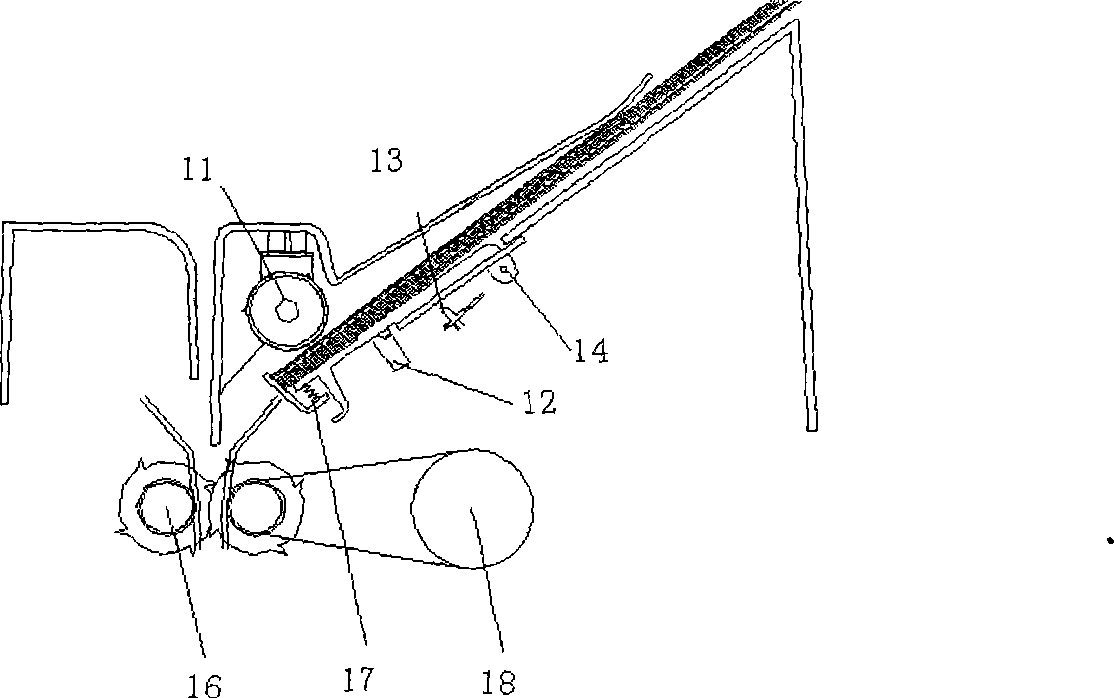

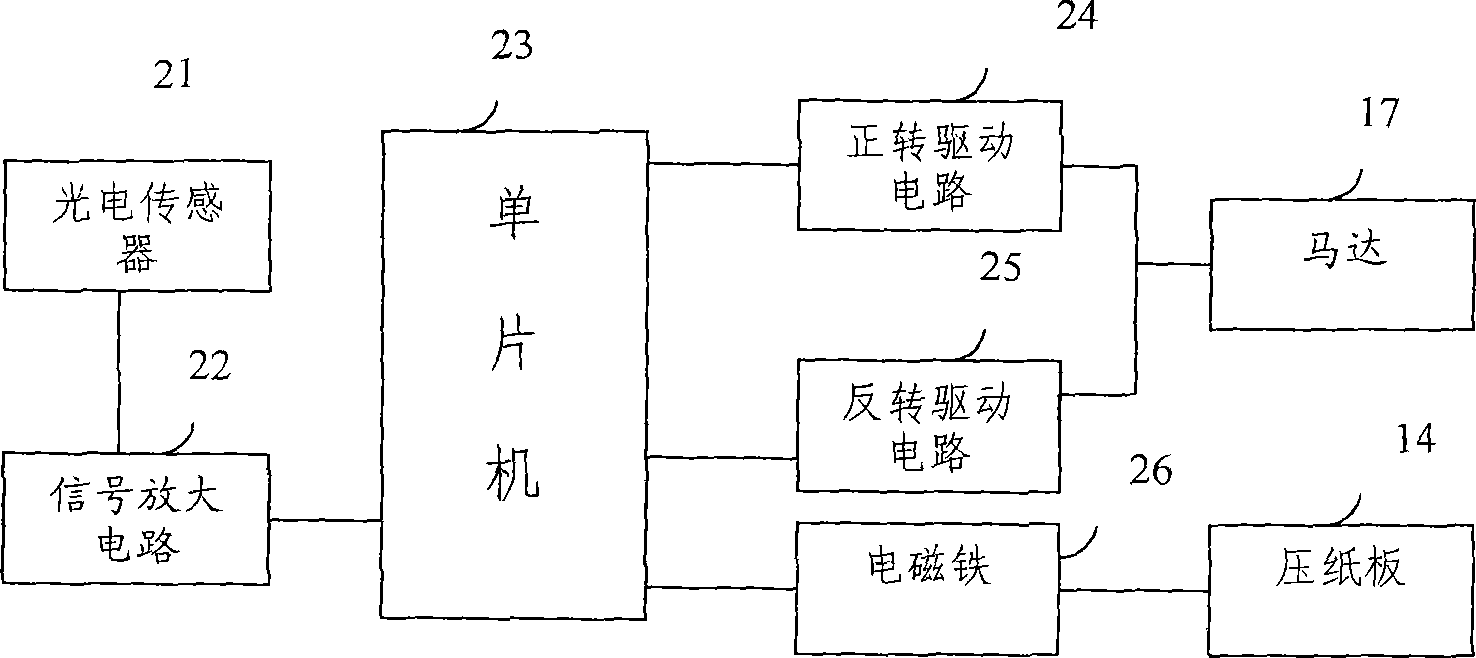

[0016] Such as image 3 and figure 2 as shown in figure 1 On the basis of the structure of the electric shredder shown, a lifting controller 12 and a sensor 13 are added. The lifting controller is installed at the bottom of the platen 14, and the sensor is installed at the paper inlet of the platen 14; in order to facilitate those skilled in the art to understand this The technical solution of the invention, this embodiment takes the lifting controller 12 as the electromagnet 26 and the sensor 13 as the photoelectric sensor 21 to specifically illustrate the technical solution of the present invention. Before the file is shredded, the photoelectric sensor 21 sends an electric signal, which is amplified by the signal amplifier ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com