Austenite stainless steel plate for pressboard

A stainless steel plate and austenitic system technology, applied in the field of austenitic stainless steel, can solve the problems of hardness, inability to manufacture pressing plates, and copper foil breakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

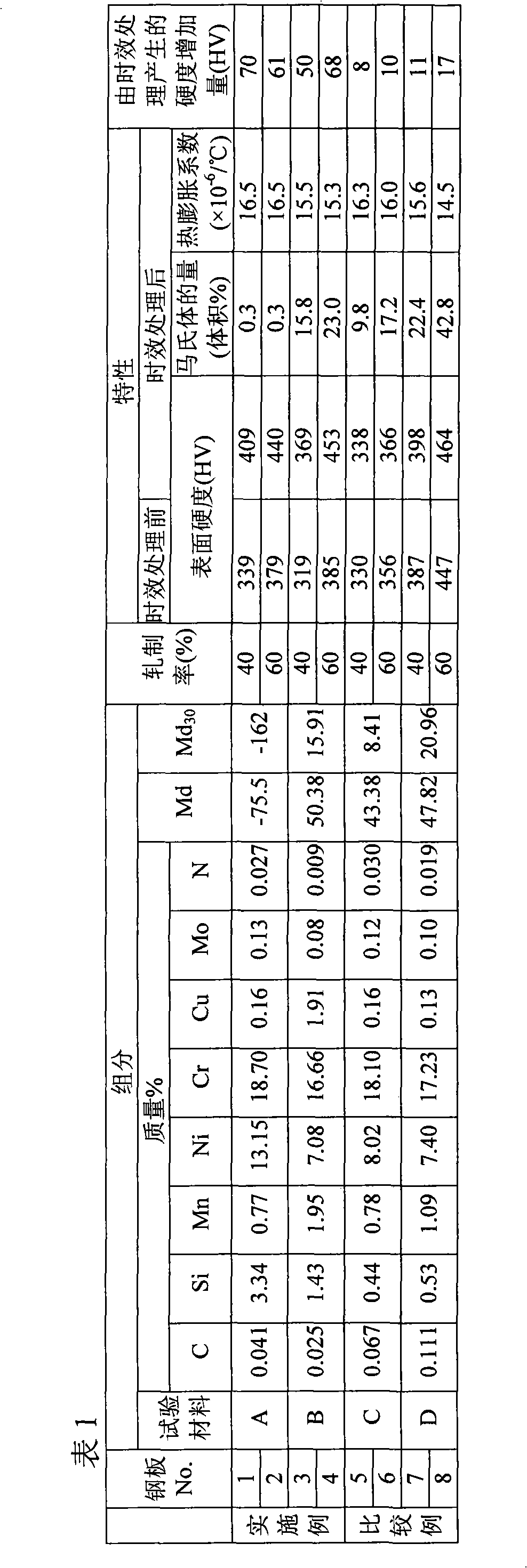

[0075] The following examples are given to describe the present invention in detail, but the present invention is not limited to the following examples.

[0076] i) Manufacture of pressing plate

[0077] 1. Manufacture of steel plate

[0078] 80 t of test materials each having the compositions shown in A to D of Table 1 were vacuum-melted in an electric furnace, and steel ingots having a thickness of 200 mm were cast. The obtained steel ingot was subjected to hot rolling to manufacture a hot-rolled sheet having a thickness of 3.0 mm. These hot-rolled sheets were annealed, pickled, and then cold-rolled to produce cold-rolled sheets with a thickness of 1.5 mm or 1.0 mm. These cold-rolled sheets were annealed, pickled, and then cold-rolled to obtain 0.6-mm-thick steel sheets Nos. 1 to 8 made of austenitic stainless steel in Examples or Comparative Examples.

[0079] 2. Aging treatment

[0080] Cut the steel plates No.1 to 8 into 500mm×500mm, sandwich them between two 600mm×60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com