Fire-proof board heat-pressing production chain

A production line and fireproof board technology, which is applied in the direction of veneer presses, plywood presses, flat products, etc., can solve problems affecting the quality of fireproof boards, uneven temperature of hot-pressed boards, etc., to reduce time, improve automation, and reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below.

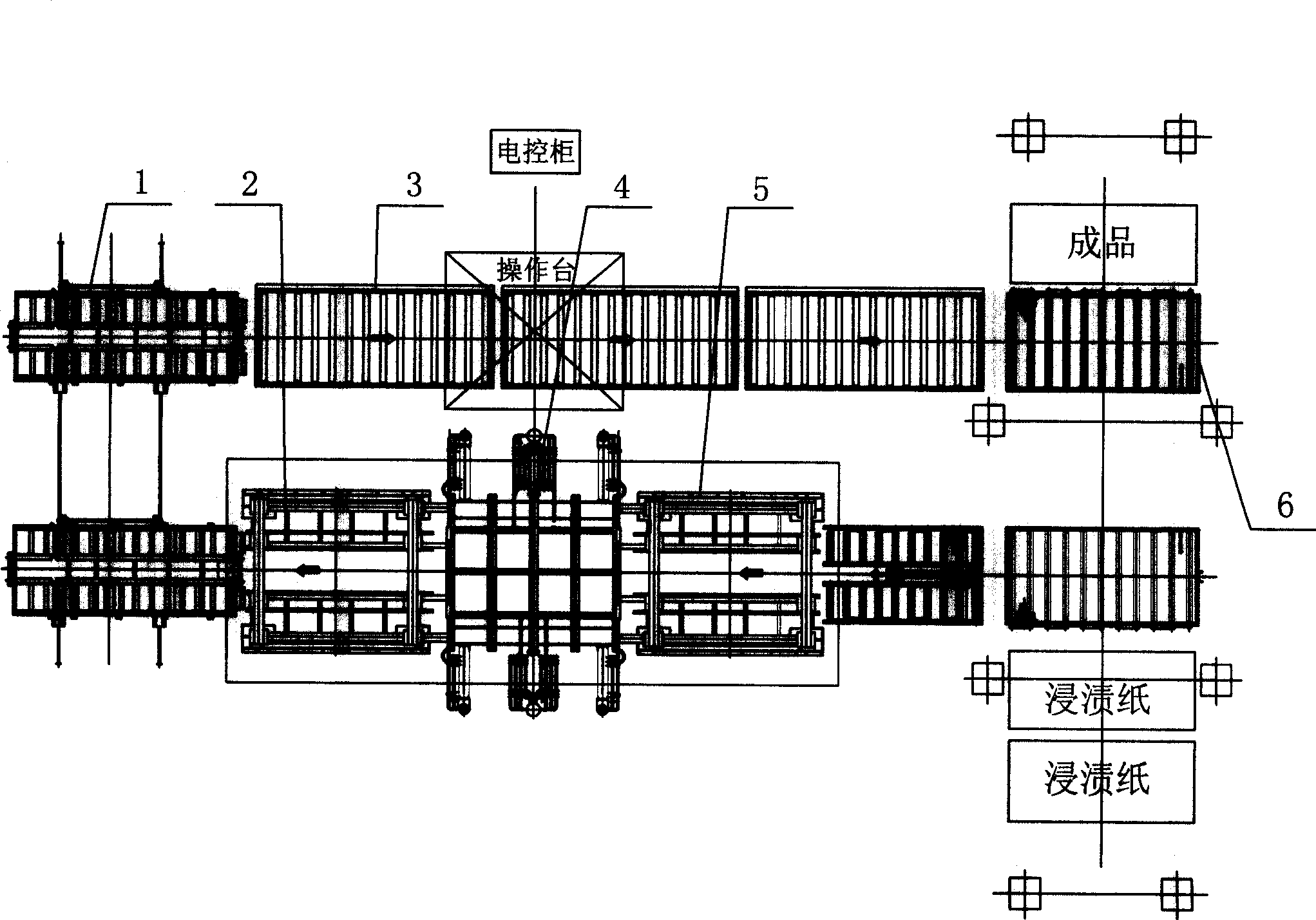

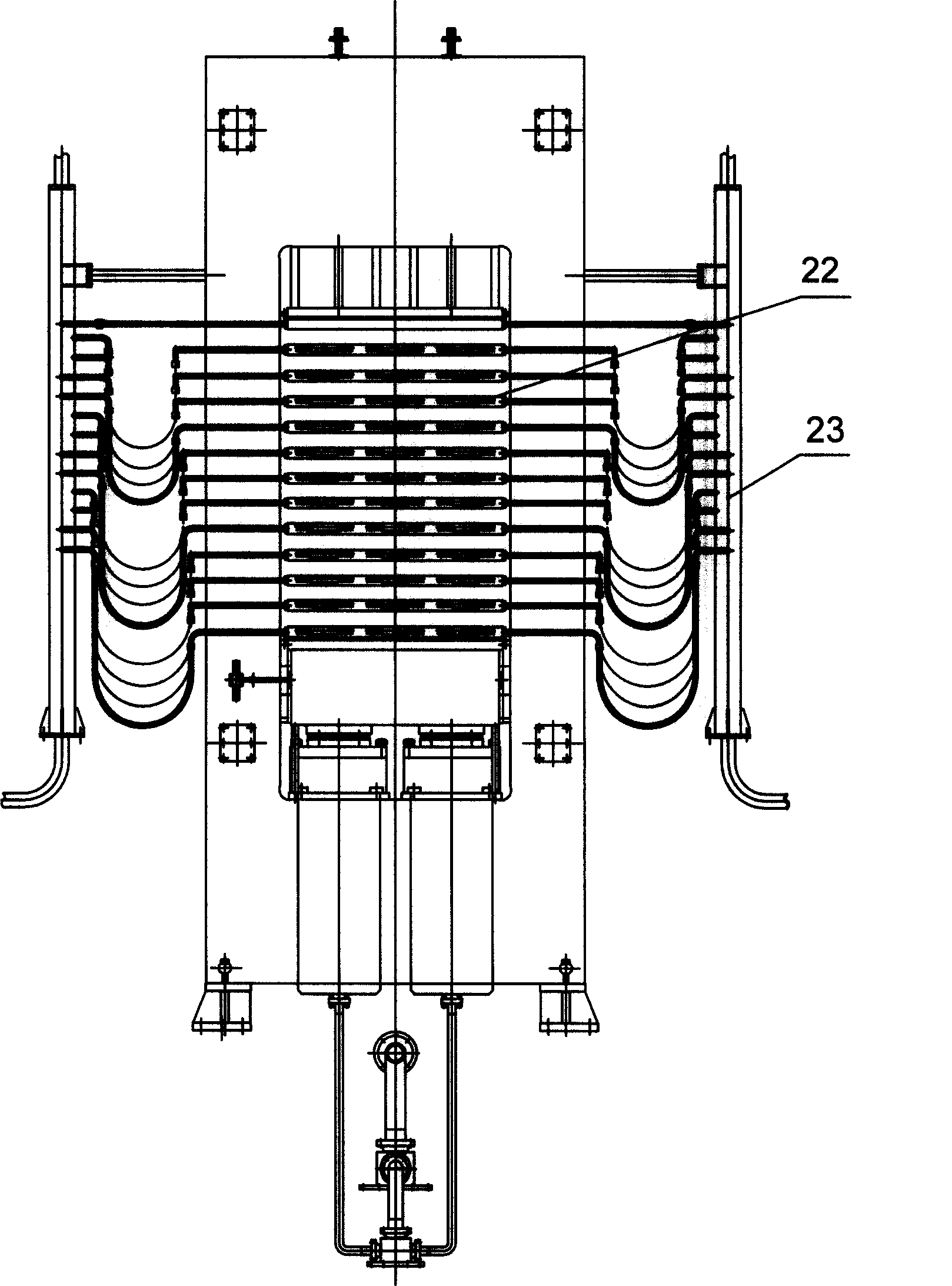

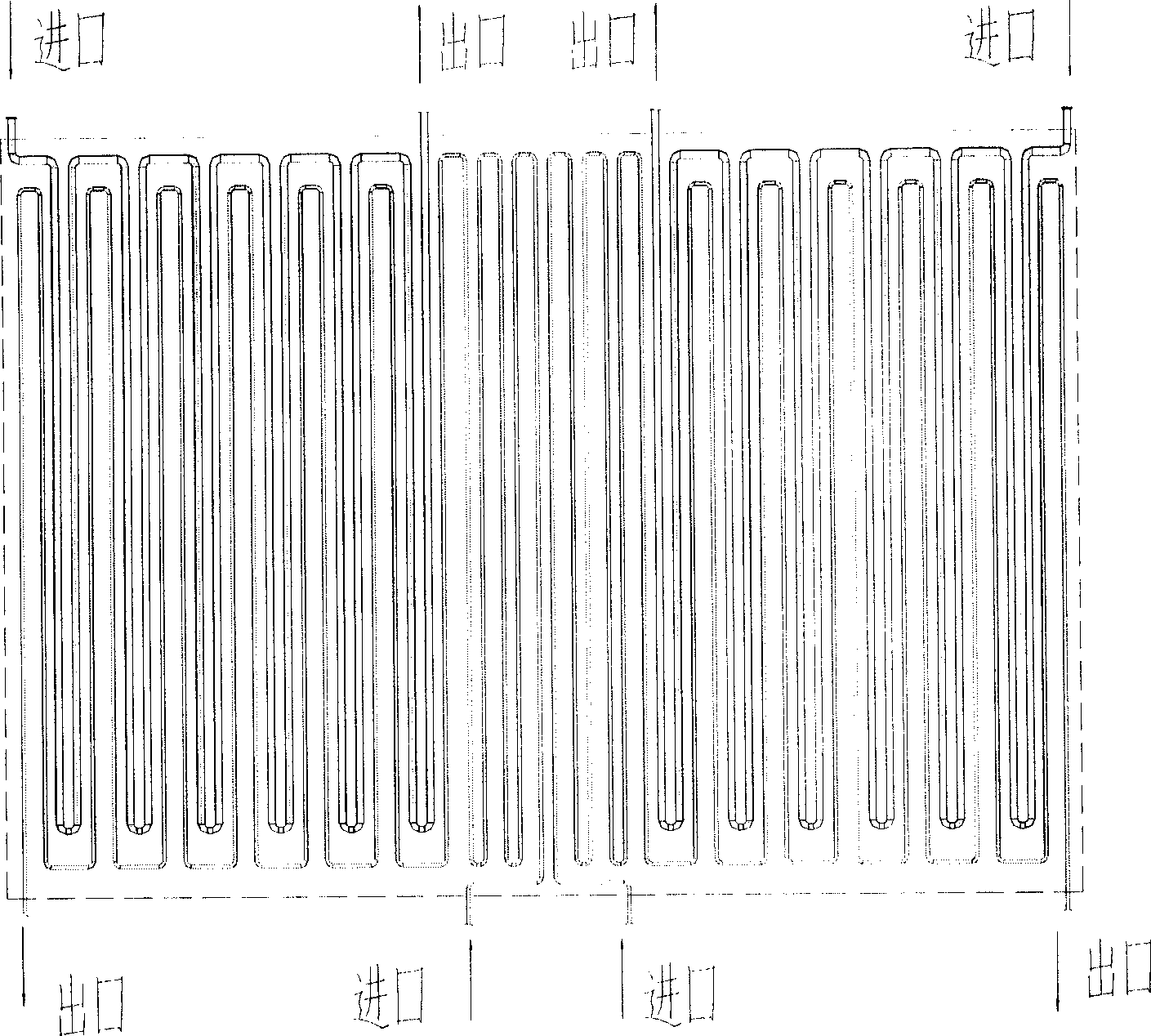

[0016] Compared with the prior art, the hot-pressing production line of the fireproof board of the present invention mainly improves the pipeline on the hot-pressing plate and adds a group of suction cups to the sports car of the vacuum suction cup. see figure 2 , which is a schematic structural diagram of the press of the present invention. The hot-pressing plate group 22 on the press is used for pressing the plates, and one hot-pressing plate group 22 corresponds to the pressing work of one plate. A heating and cooling system is arranged on each hot pressing plate in the hot pressing plate set 22 . see image 3 , which is a heating and cooling system formed by pipelines on a hot plate. The pipelines on each layer of the hot-pressing plate are divided into four outlets and four inlets, and the four outlets and four inlets are evenly distributed on both sides of the hot-pressing plate respectively, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com