Isothermal hot pressing board

A hot pressing plate, isothermal technology, applied in the direction of presses, manufacturing tools, etc., to achieve the effect of isothermal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

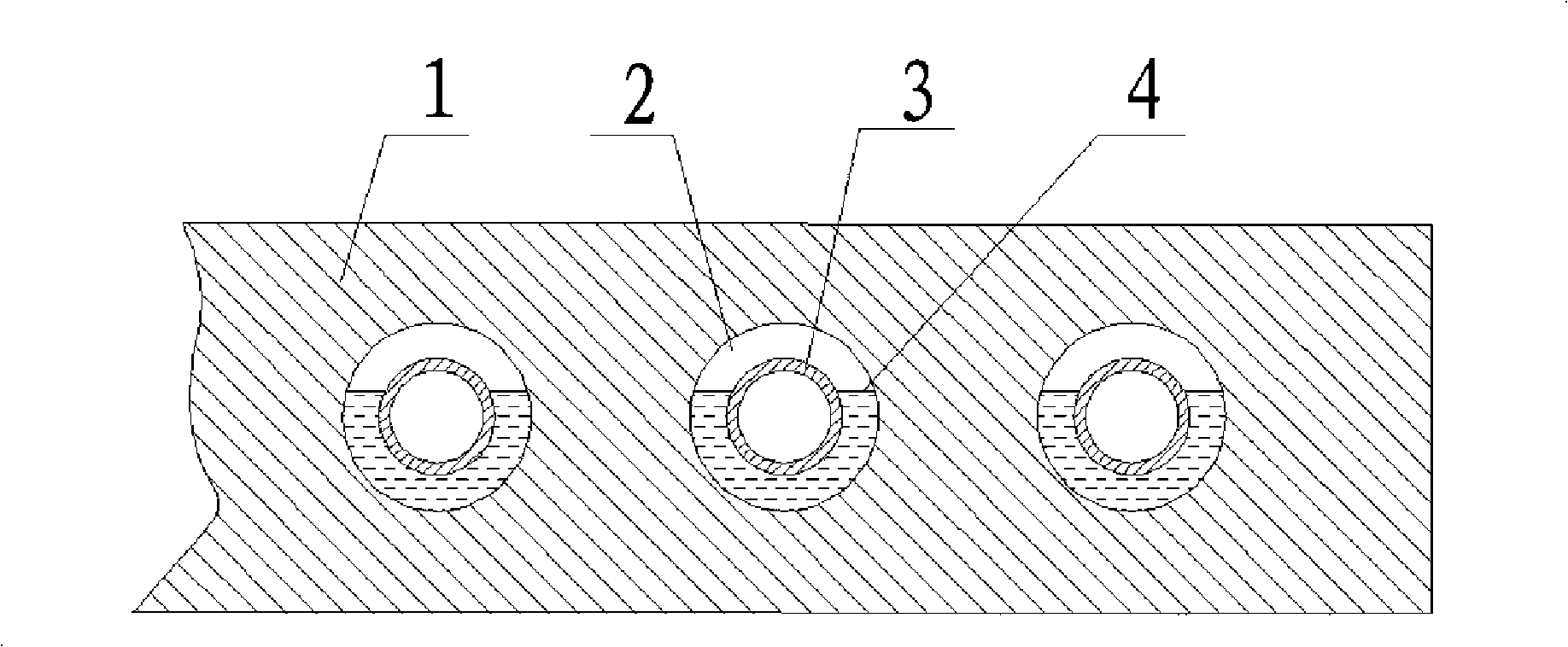

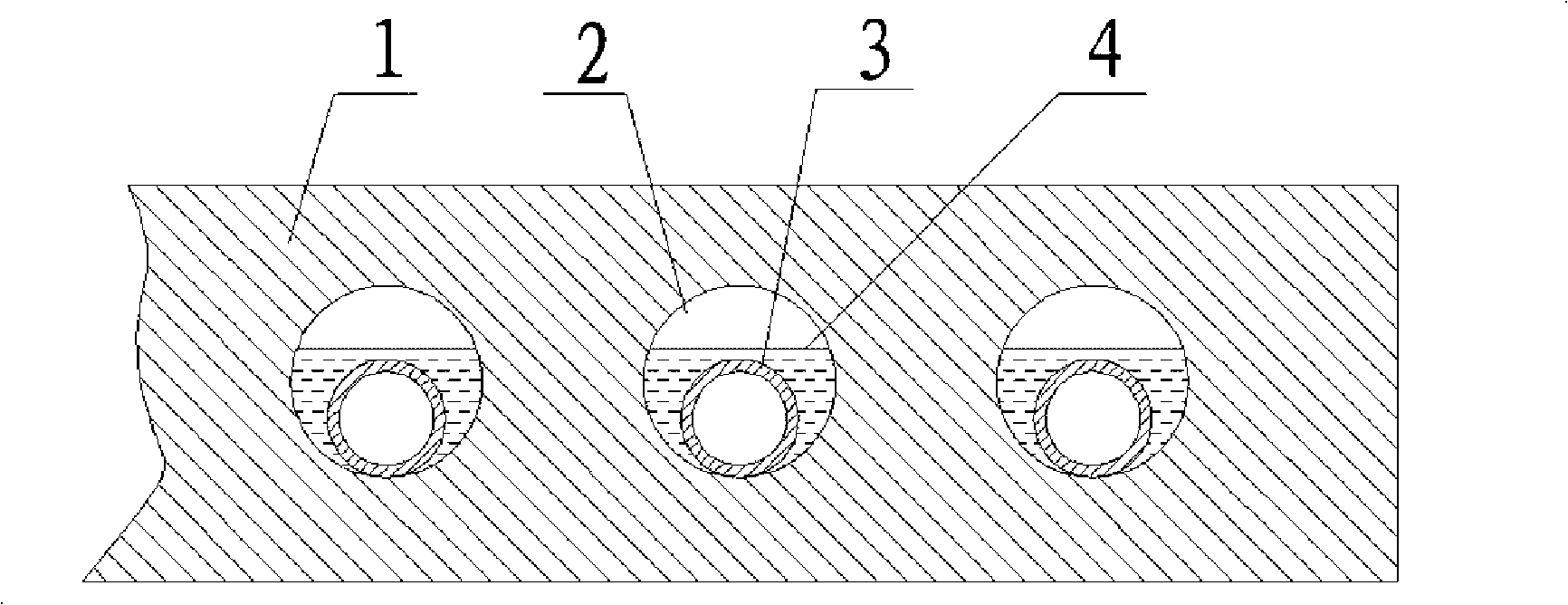

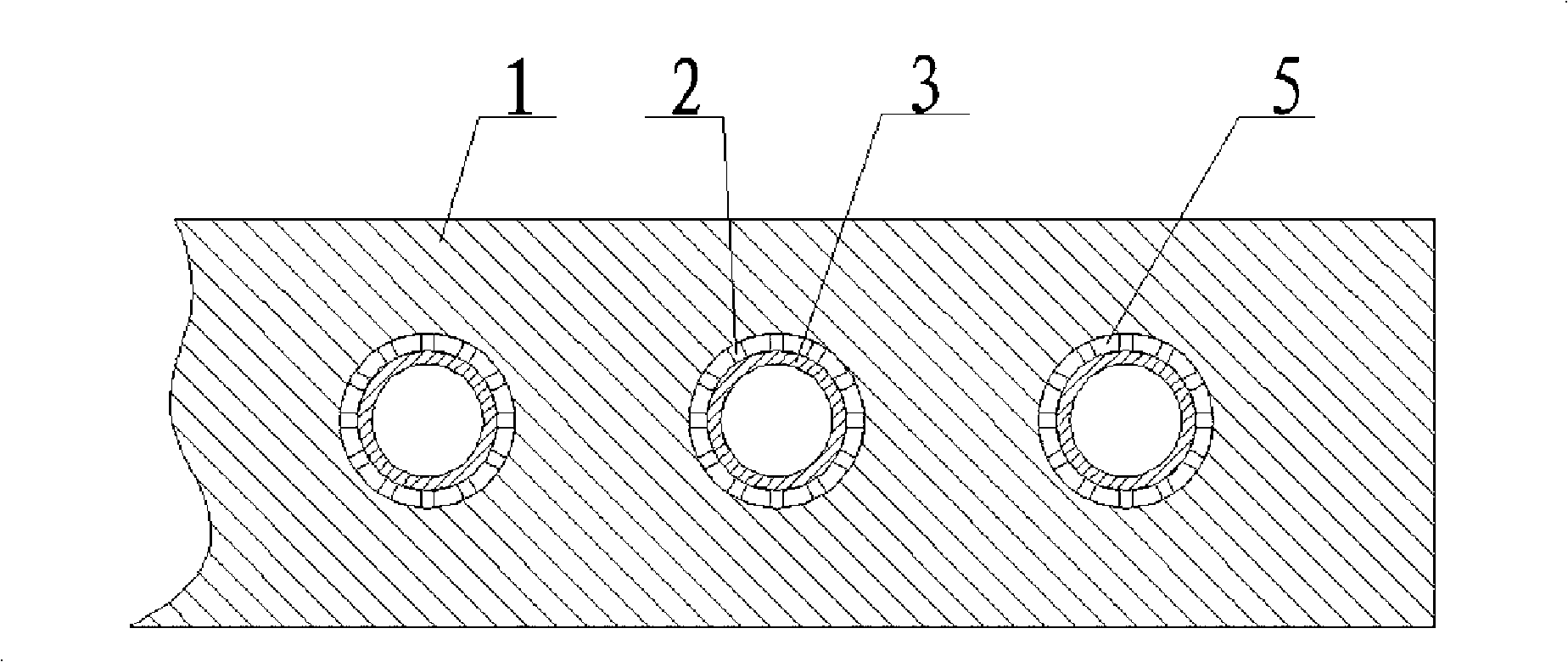

[0032] Such as figure 1 , 2 , 6, 1 is the body of the hot plate, 2 is the cavity, 3 is the heating device, 4 is the boundary line between gas phase and liquid phase of the working medium, the working medium above the boundary line is gas phase, and the working medium below the boundary line is liquid Mutually. Cavity 2 is a space formed by the inner surface of the hot platen body 1 and the outer surface of the heating device 3. There is a working medium and a heating device 3 in the cavity 2. The heating device 3 is in the working medium, that is, there is a cavity in the hot pressing plate. There is a working medium and a heating device immersed in the working medium in the cavity.

[0033]The working medium in the cavity 2 is in a state of gas-liquid two-phase saturation during operation, the liquid-phase working medium absorbs heat on the surface of the heating device 3 and boils to be vaporized, and the gas-phase working medium releases heat and condenses on the cavity w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com