Patents

Literature

139results about How to "Reduce demolition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

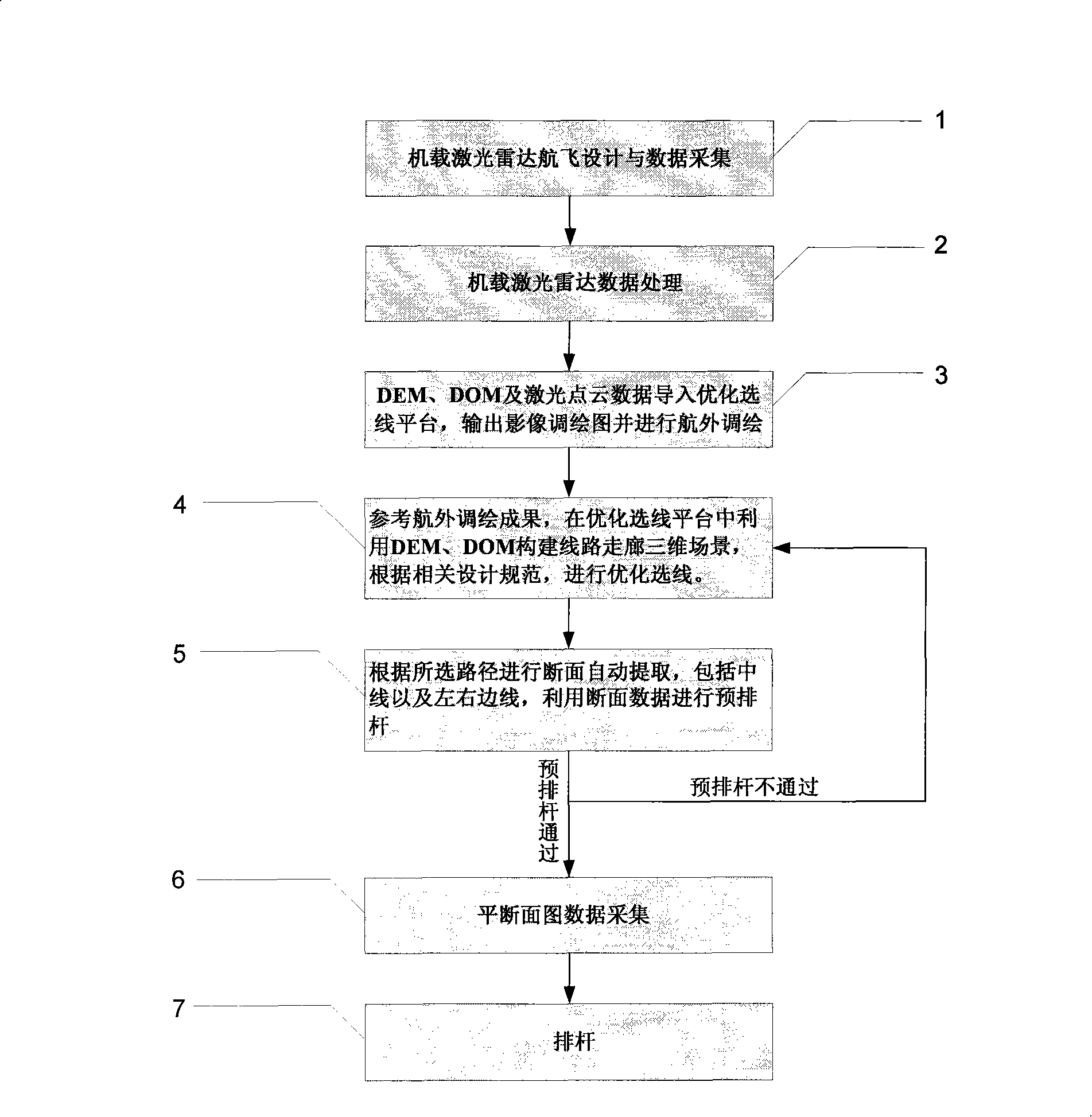

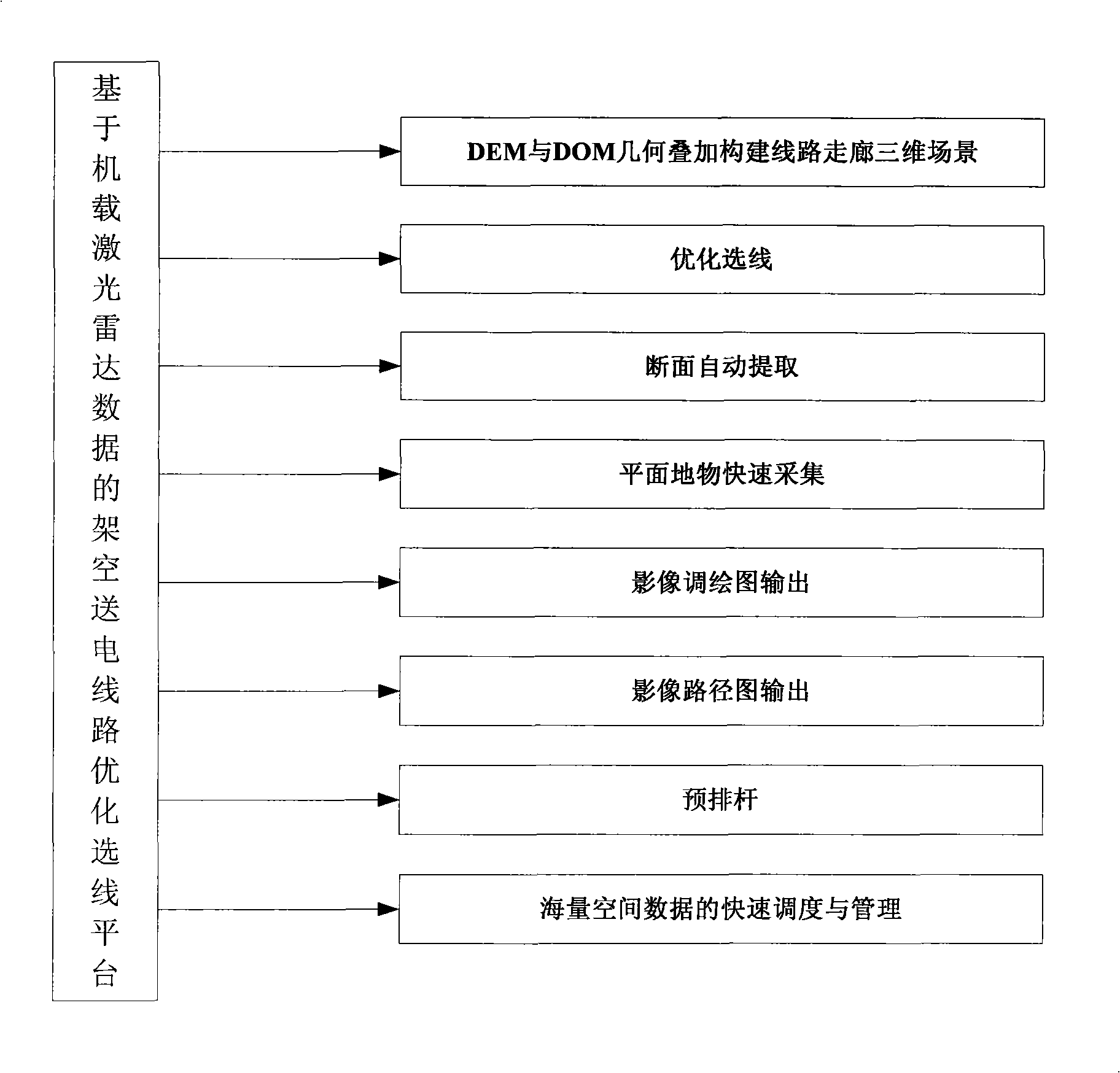

Overhead power transmission line optimized line selection method based on airborne laser radar data

InactiveCN101335431ARealistic 3D visualizationReduce configuration requirementsElectromagnetic wave reradiationApparatus for overhead lines/cablesAviationSimulation

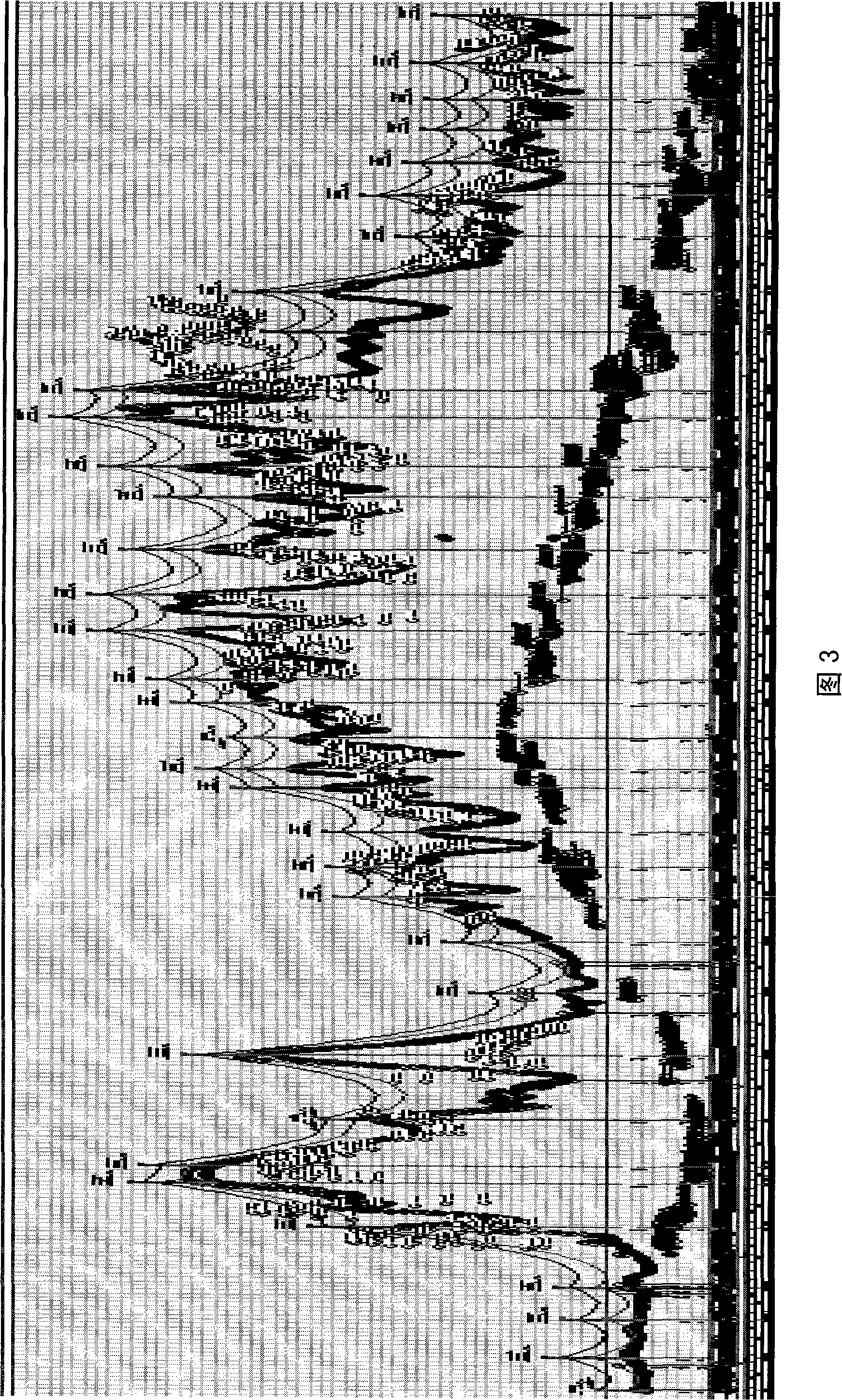

The invention discloses an optimal route selection method for overhead transmission line route. Onboard lidar equipment is adopted to acquire laser point cloud data and aerial digital photo data of the transmission line route corridor range; the onboard lidar data is processed after the wave filtering and the sorting of the laser point cloud data, and the points of the ground surface are made into a digital elevation model with high precision; then data processing is carried out by utilizing the data of the digital elevation model with high precision and ortho-rectification is carried out to the aerial photo by utilizing the internal and external orientation elements of the aerial digital photo to generate digital orthophoto maps; through the overlying of the digital elevation model and the digital orthophoto maps, the tridimensional visualization of the transmission line route corridor can be realized to optimize the transmission line route selection; finally prearrangement of power pole and power pole arrangement are carried out according to the data of plane cross sections. The route selection platform of the invention has simple operation and lifelike tridimensional scene, thus being convenient for full roaming and multi-view observation and greatly improving the efficiency of the inner plane cross section survey operation. Compared with the optimal route selection technology based on the aerial photographing measuring method, the efficiency of the inner plane cross section survey operation can be improved by about 75 percent.

Owner:GUANGXI ELECTRIC POWER IND INVESTIGATION DESIGN & RES INST

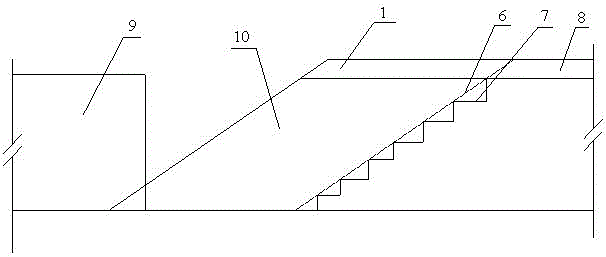

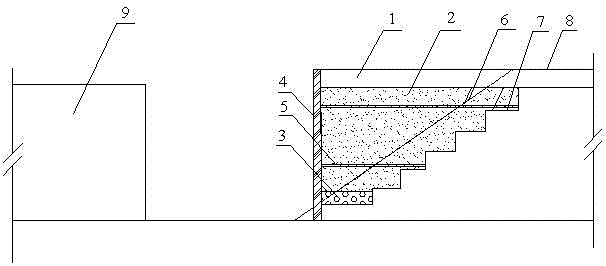

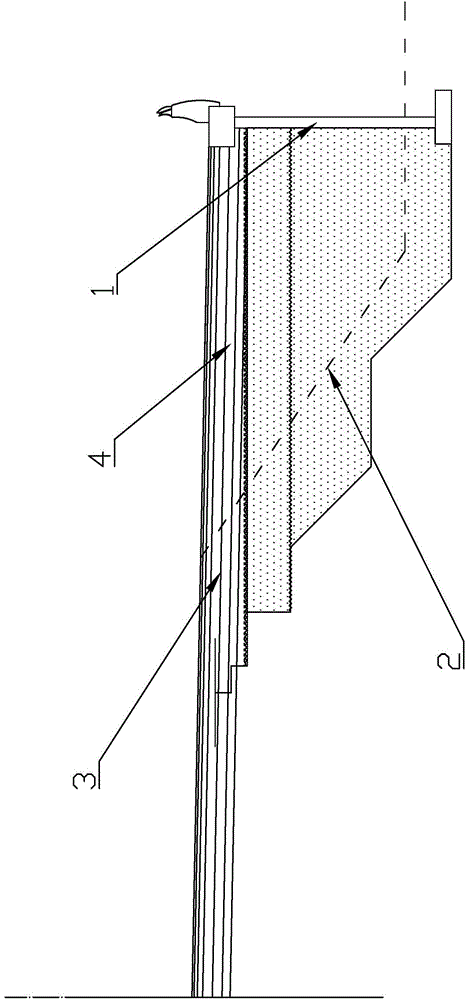

Roadbed structure applied to road widening and construction method

The invention relates to a road building structure and a construction method field. A roadbed structure applied to road widening comprises a new road layer, a filling material layer, a broken stone cushion layer, a concrete retaining wall and an original roadbed slope, wherein the original roadbed slope is finished as a step shape; the concrete retaining wall is arranged on the reciprocal nth step of the step-shaped roadbed slope; the surface of the reciprocal n-1th step of the step-shaped roadbed slope is an inclined surface; the broken stone cushion layer is laid on the surface of the bottom layer of the step-shaped roadbed slope; the filling material layer and the new road layer are arranged at the upper part of the broken stone cushion layer in sequence; and the filling material layer is prepared by cement, silicon fume powder, kieselguhr, expanded perlite, water, a water reducing agent, rubber powder, planet fibers, a foaming agent and a micro foam agent. The roadbed structure can be applied to the road widening, can perform the vertical filling to save the land and to reduce the demolition, can largely reduce the filling load to reduce the differential settlement of new and old roadbeds in soft-foundation road sections, and is short in construction period.

Owner:河南华泰新材科技股份有限公司

Parallel construction method for shield arrival tunnel portal ring beam and shield crossing station

ActiveCN103032078AReduce reservationReduce demolitionUnderground chambersTunnel liningSocial benefitsArchitectural engineering

The invention relates to the field of tunnel shield construction, in particular to a parallel construction method for a shield arrival tunnel portal ring beam and a shield crossing station. According to the parallel construction method for the shield arrival tunnel portal ring beam and the shield crossing station, the problems of long construction period and high cost because tunnel portal ring beam construction is carried out after the shield tunnel of the traditional station is finished are solved. The parallel construction method for the shield arrival tunnel portal ring beam and the shield crossing station comprises the following steps of: reserving a pump pipe on a middle plate and a top plate of the station; during shield arrival, carrying out secondary after-grouting to the back of a pipe piece by polyurethane; cancelling zero ring pipe piece splicing; after a shield tail leaves the tunnel portal ring beam, overlaying I steel on tunnel portal ring steel; welding a steel plate on the I steel; erecting a groined type rack platform on the tunnel portal steel ring; binding the tunnel portal ring beam reinforcing steel bar; installing an annular template and an end tip template; and directly pouring tunnel portal ring beam concrete by a station embedded pump pipe. Tunnel portal ring beam and shield tunneling can be synchronously carried out, and the influence on the shield tunneling by the tunnel portal ring beam construction is avoided. The parallel construction method for the shield arrival tunnel portal ring beam and the shield crossing station has the advantages of simple technology, advanced technology, flexible working procedure regulation, no construction interference and favorable economic benefit and social benefit.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

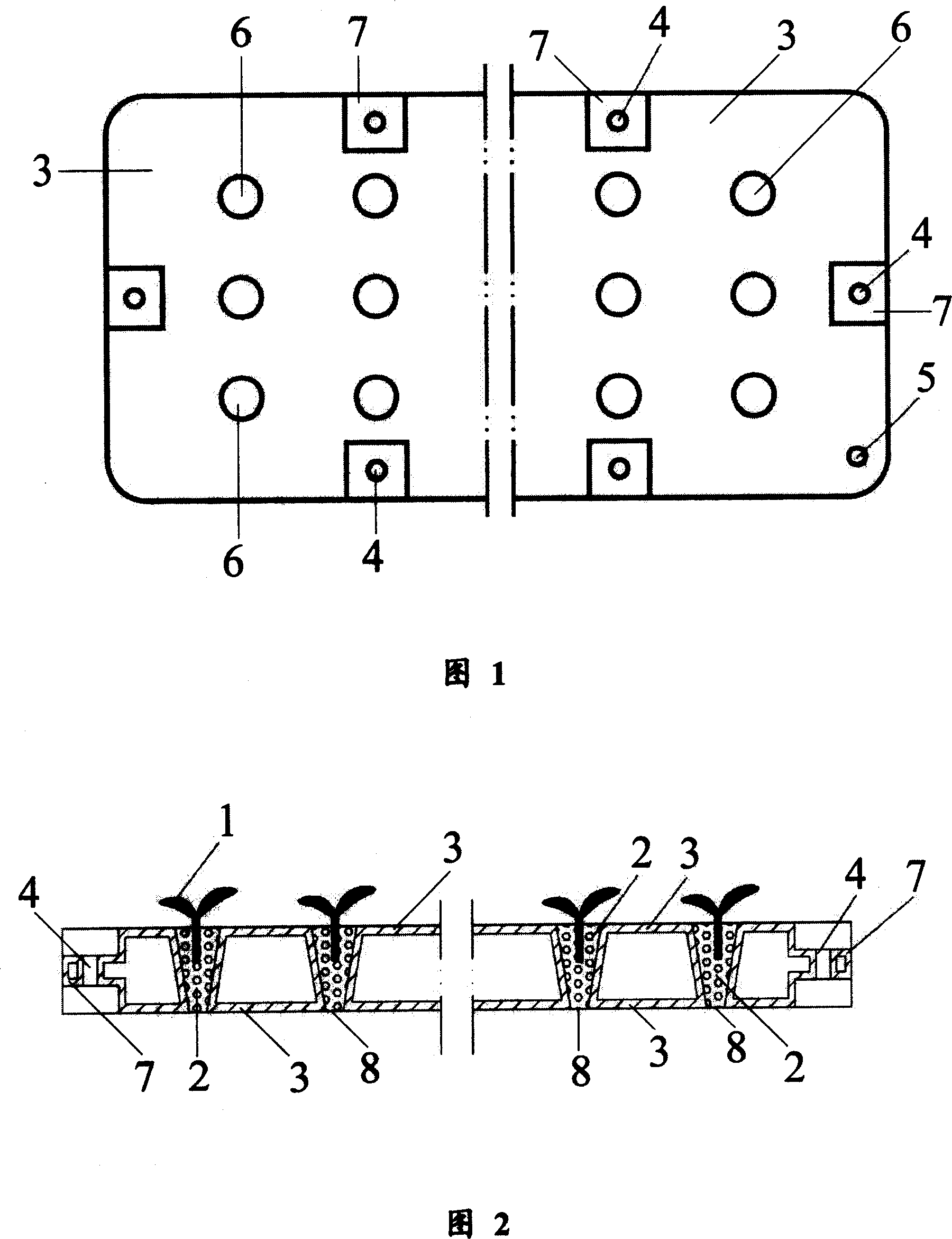

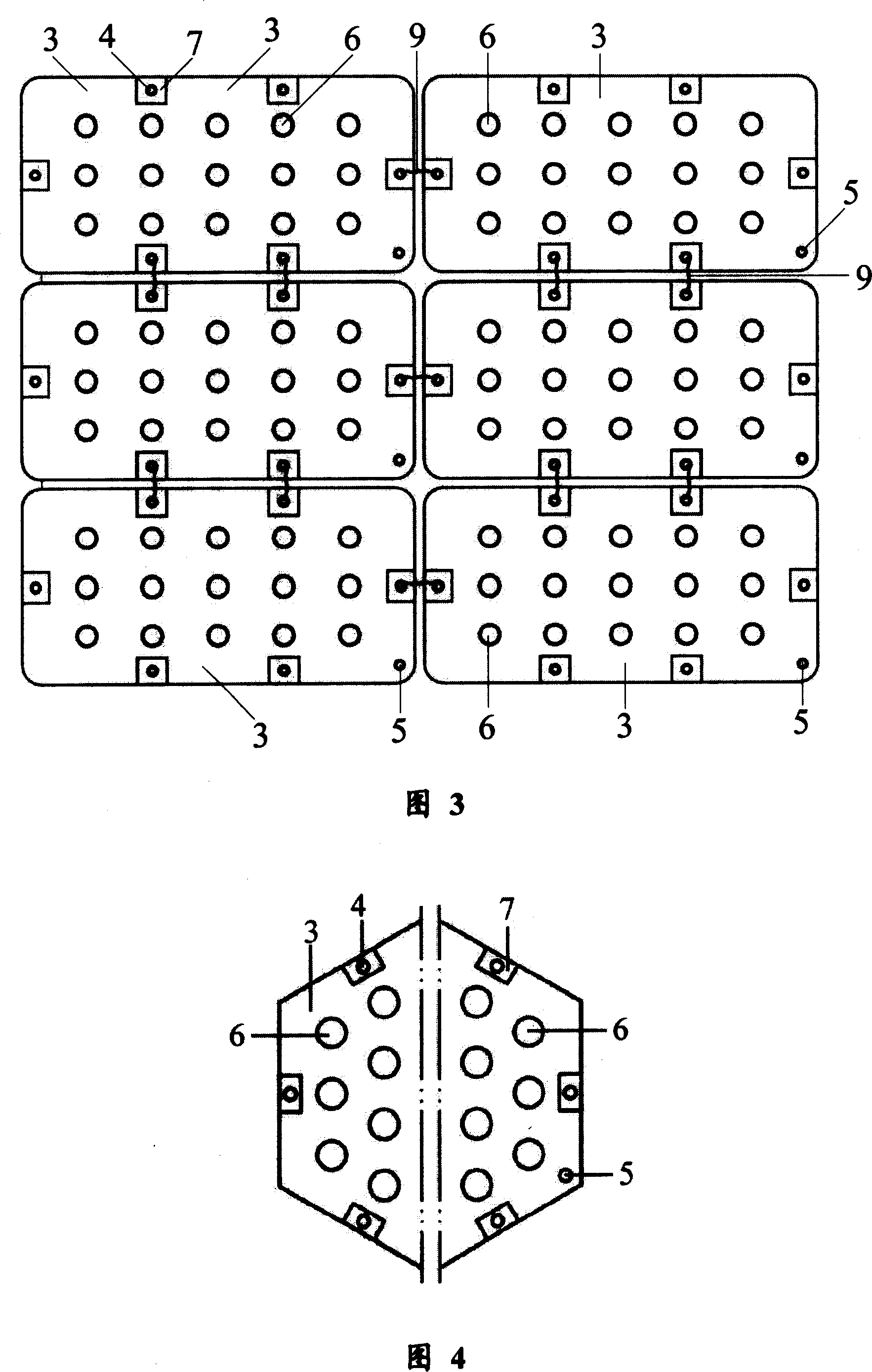

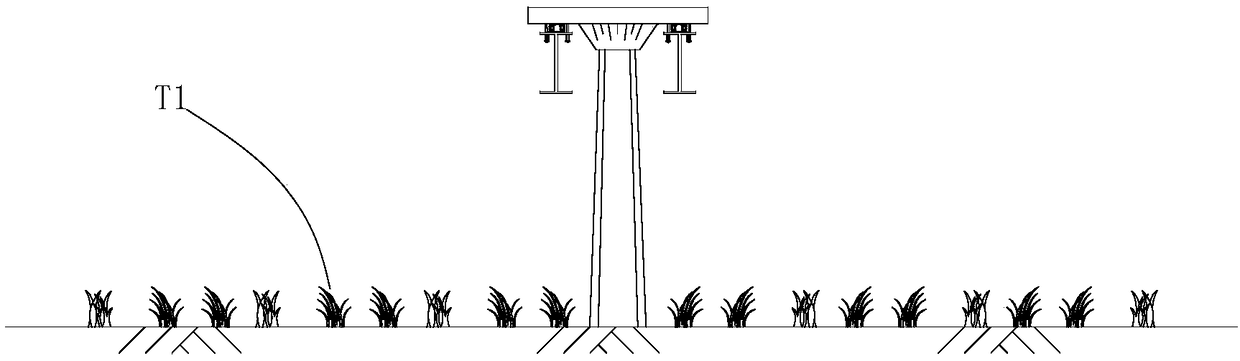

Rise and fall artificial floating floor of plants for biological treating sewage, preparation method and method of application

InactiveCN101003408AInhibit algae growthPrevent eutrophicationSustainable biological treatmentBiological water/sewage treatmentSurvival periodRoot system

This invention discloses a method for producing rise-fall artificial plant floating bed for wastewater biological treatment. The main body of the floating bed is hollow and sealed, and a planting groove is set on the main body. Filler and plants are placed in the planting groove. A support is set in the planting groove, which is connected with water body. Bed connectors are placed surrounding the main body of the floating bed. At least two main bodies are combined to form the floating bed, which is placed on the water surface. The roots of the plants on the floating bed can realize filtration, absorption and adsorption of pollutive substances in wastewater. The floating bed is sinked into the non-frozen layer below water surface in winter, and taken out of water surface inspring. The plants are left for further filtration, absorption and adsorption of pollutive substances in wastewater. This invention has such advantages as short project period, and rapid acting. Plants of the floating bed have a survival period of more than 8 months / year. The planting can match city landscape, thus are good for city afforestation, and can reduce secondary assembly cost. The floating bed just needs replanting in spring.

Owner:TIANJIN WATER CONSERVANCY INST

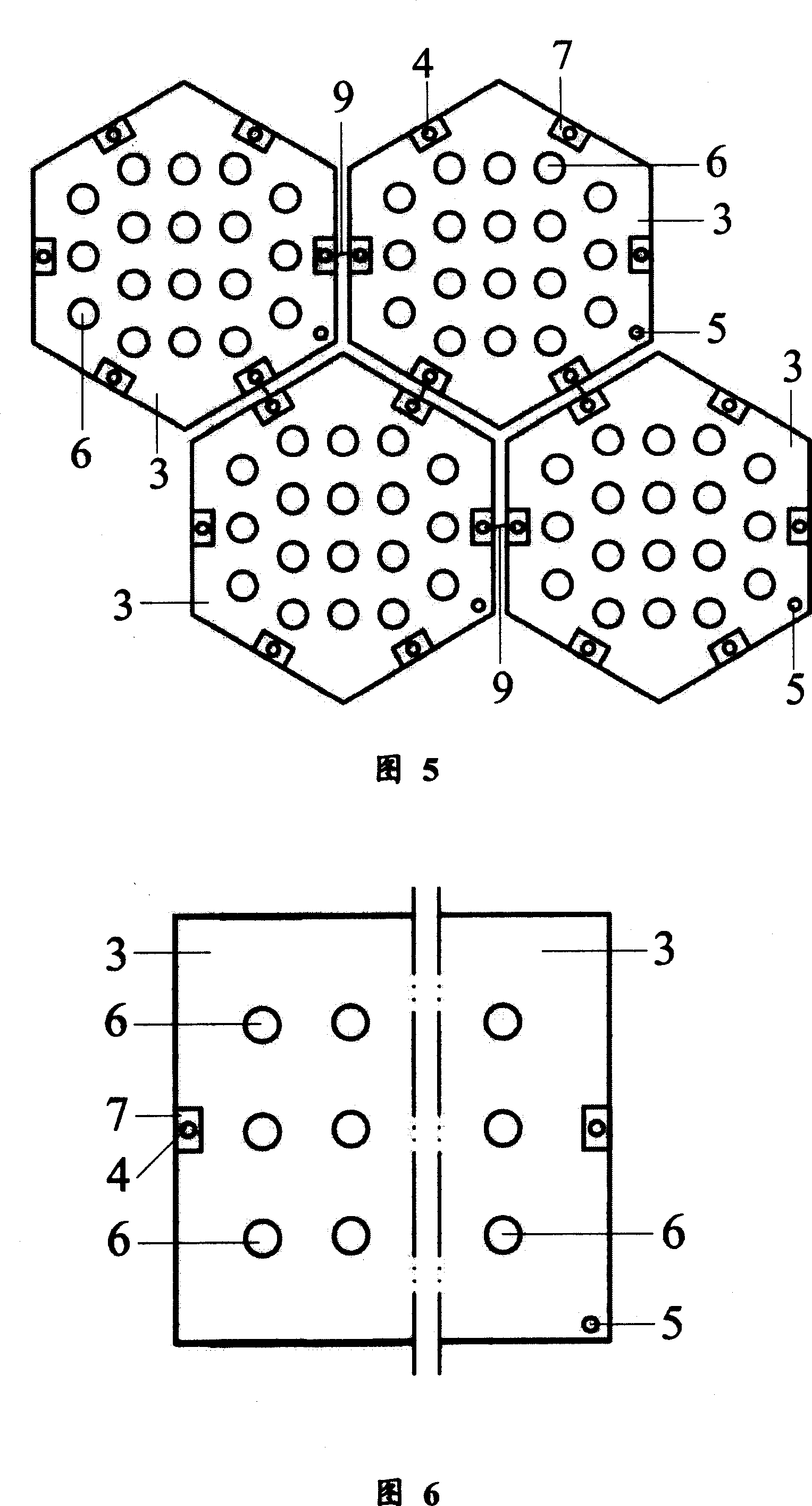

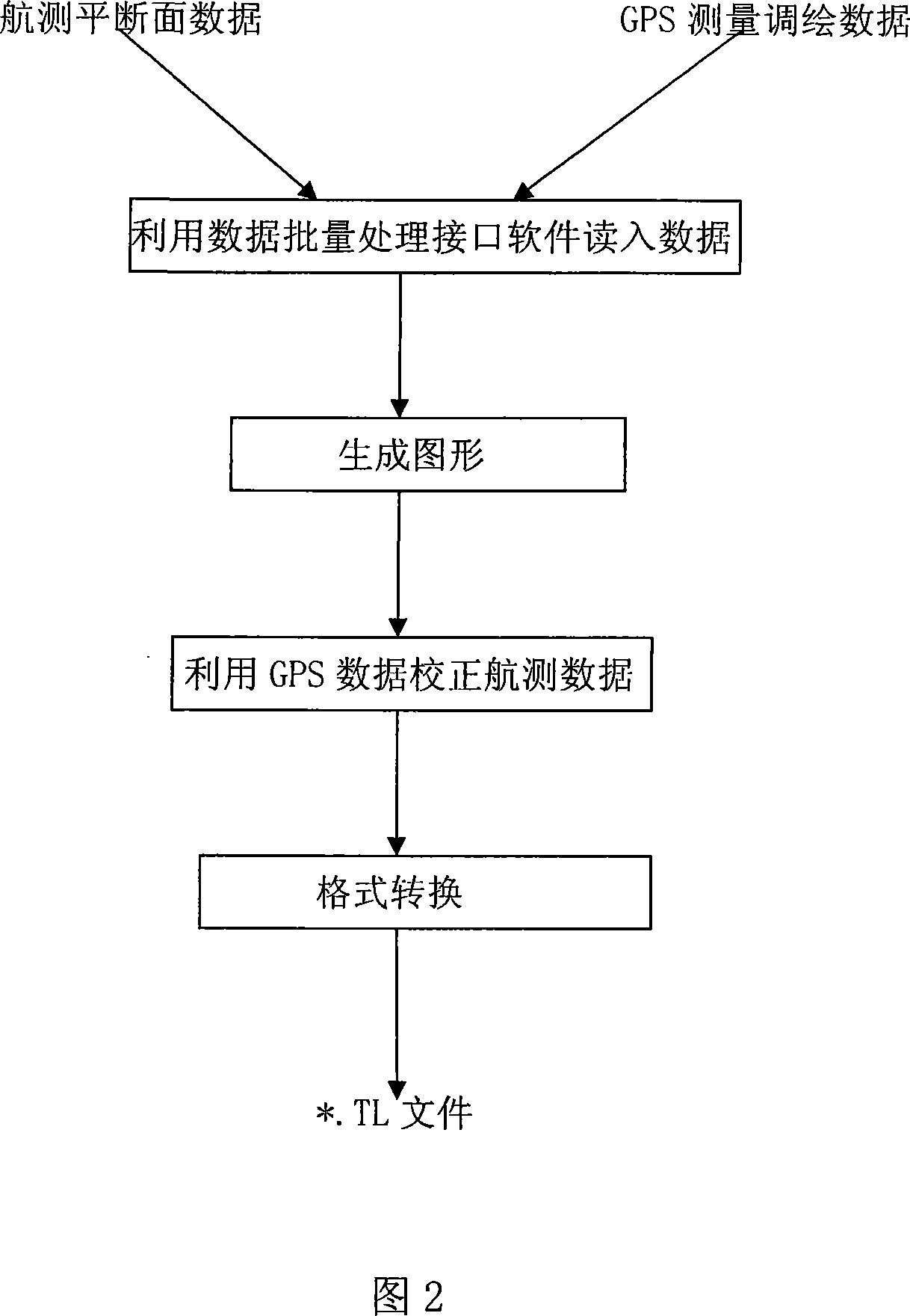

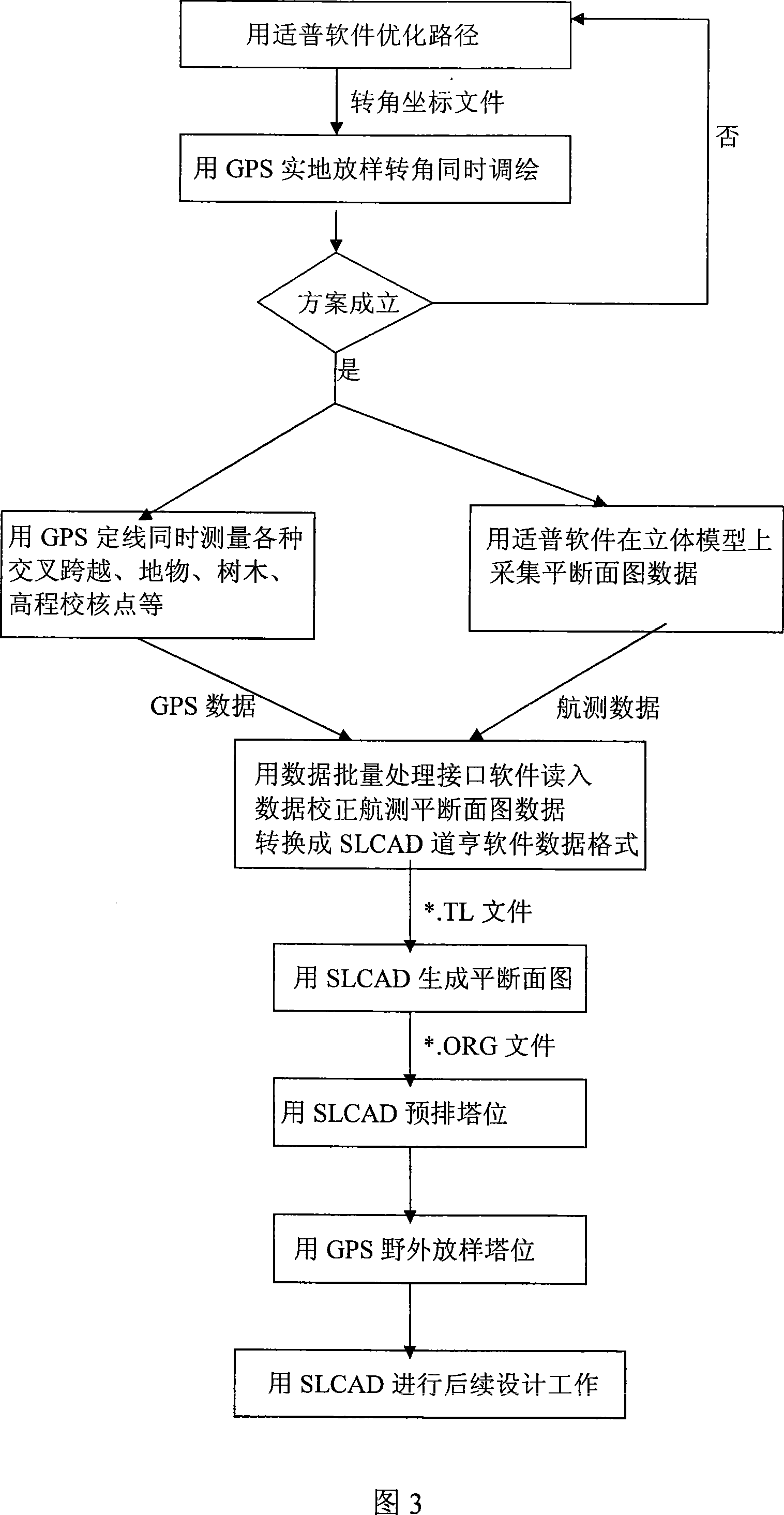

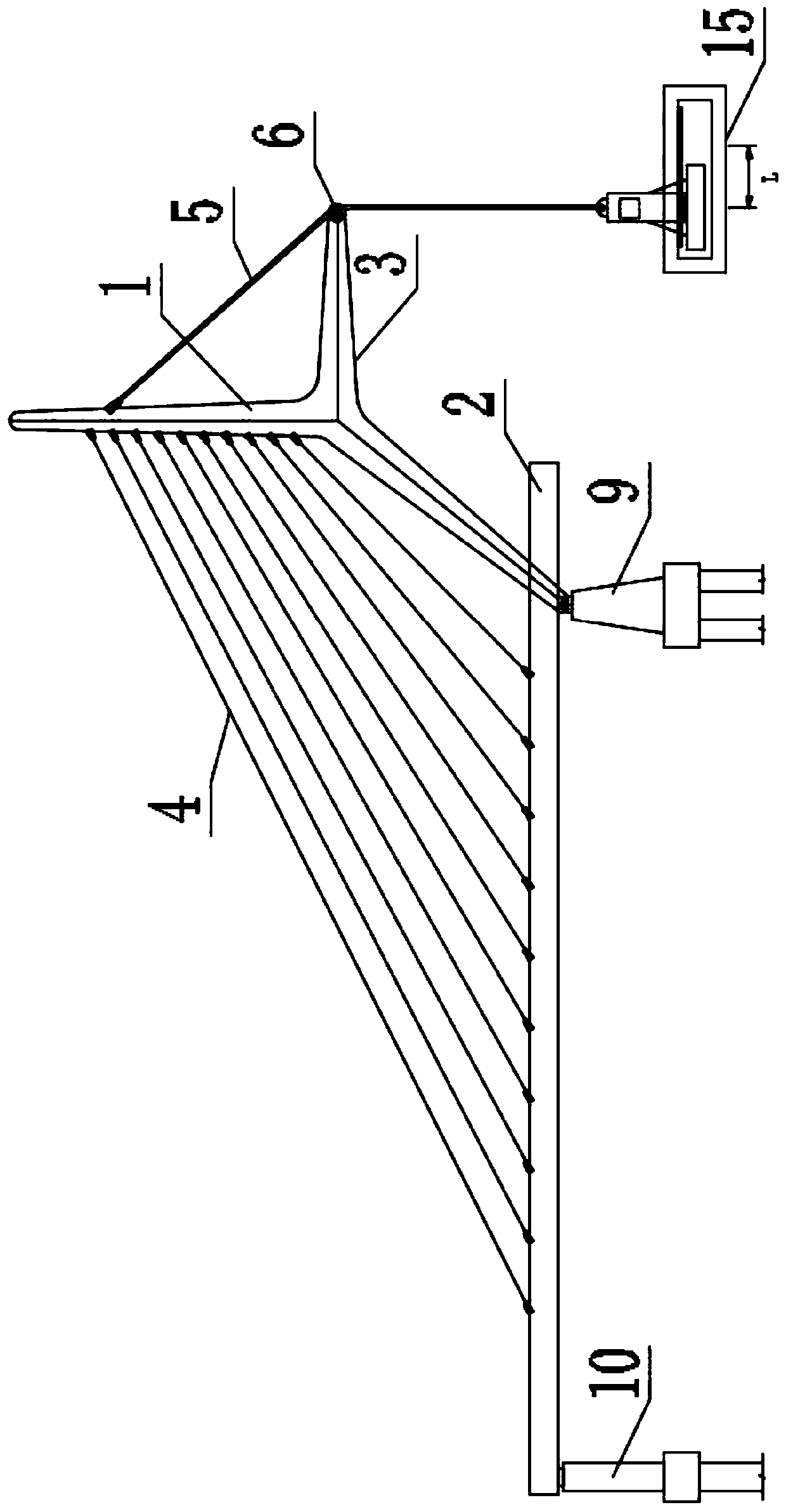

Powerline surveying and designing inside and outside trade integration method using full digitisation photogrammetric technology

ActiveCN101178310ALow costSave steelPhotogrammetry/videogrammetrySpecial data processing applicationsSocial benefitsSurveyor

The present invention relates to a method for integrating the survey and design of power transmission lines with internal and external work using all-digital photogrammetry technology. The present invention is improved on the basis of the prior art. Plane section data, after field measurement and adjustment, use the data batch processing software interface to input the plane section data into the Daoheng software platform. The invention has the beneficial effects of low cost, high work efficiency, reduced labor intensity, less personnel investment, reliable quality, easy popularization and application, and remarkable economic and social benefits.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

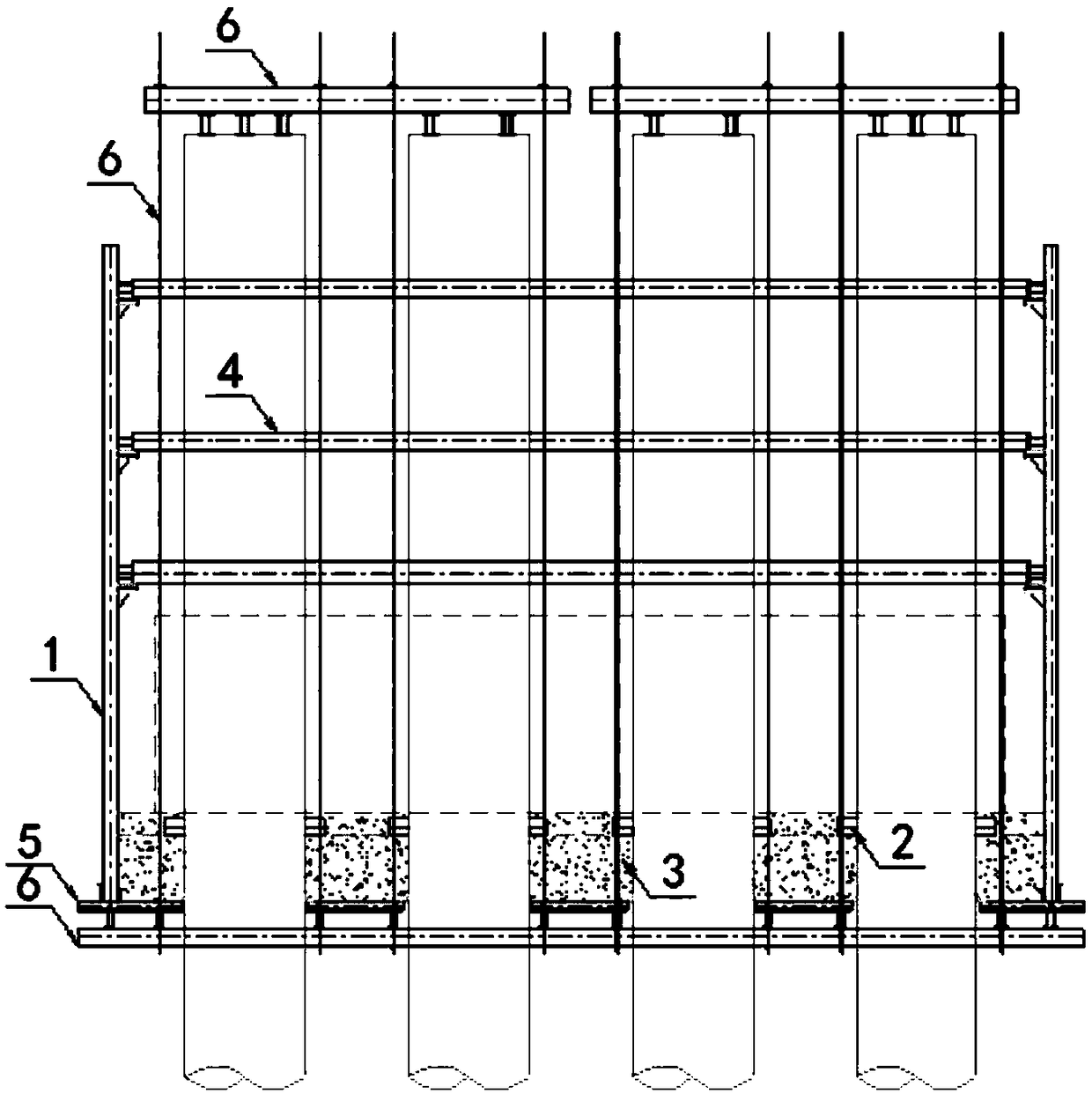

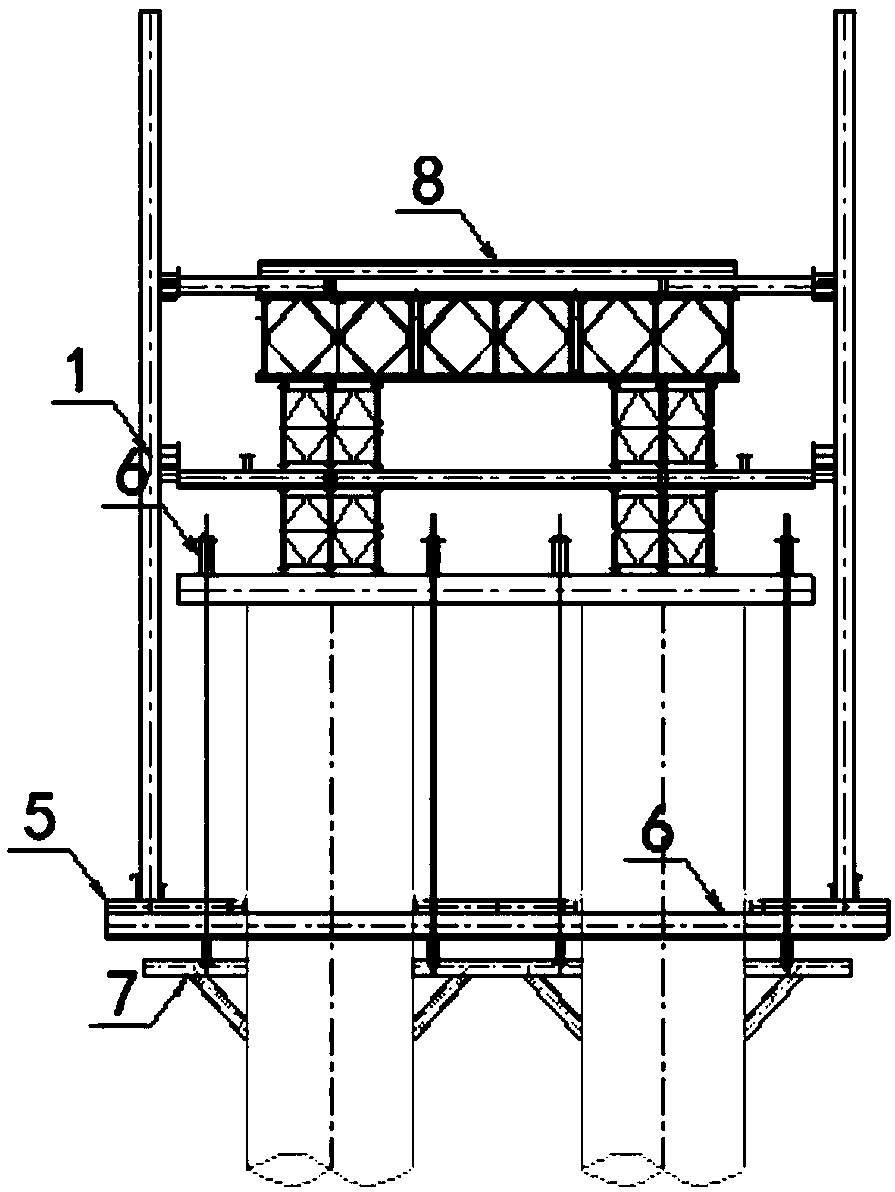

Construction method of deep water high pile bearing platform steel hanging box cofferdam

The invention discloses a construction method of a deep water high pile bearing platform steel hanging box cofferdam. The construction method comprises the following steps: 1) design of a steel hanging box cofferdam: Larson steel plate piles are adopted as wall plates of the steel hanging box cofferdam; 2) assembly and placement of the steel hanging box cofferdam: the steel hanging box cofferdam adopts high assembly and overall placement technologies; 3) bottom cover concrete construction: a bottom cover construction process is performed twice; after primary bottom covering, water in the steelhanging box cofferdam is extracted to a bottom cover surface; and then, the secondary bottom cover concrete casting is performed; and 4) disassembly of the steel hanging box cofferdam: after a bearing platform and part of underwater piers are constructed, the water is injected in the steel hanging box cofferdam to reach balanced inner and outer water levels; and the steel hanging box cofferdam isdisassembled. In the construction method, through the Larson steel plate piles as the wall plates of the steel hanging box cofferdam and twice bottom cover construction process, the construction progress can be accelerated, the economical cost is saved, and the engineering quality is guaranteed.

Owner:CHINA RAILWAY 23RD BUREAU GRP NO 1 ENG

Construction method for widening road in rapid erection manner

InactiveCN104131502AEliminate differential settlementImprove stabilityRoadwaysEngineeringPlastic film

The invention discloses a construction method for widening a road in a rapid erection manner. The construction method comprises the following steps: excavating a foundation pit, excavating steps, removing an original protection project, cutting the slope of the existing side slope roadbed, excavating stairs, mounting a protecting wall which is vertical to an original road in a side slope or at the bottom of the side slope, zoning the roadbed and mounting formworks, preparing cast-in-place foam light weight soil, pouring the foam light weight soil layer by layer from bottom to top to a height of design requirements, covering a plastic film on the surface of the foam light weight soil for preserving moisture and curing after the pouring is completed, and removing the formworks. According to the construction method disclosed by the invention, the characteristics of good construction property, good light weight property, good independence after solidification, and the like of the cast-in-place foam light weight soil are used, the road is rapidly widened in an erection manner, the purposes of eliminating the differential settlement of new and old roadbeds of spliced road segments, improving the stability of the roadbeds, saving the land, reducing the quantity of removal and reducing the comprehensive building cost are achieved, the construction process is simple, the construction method is rapid, simple and convenient, and the construction period is shortened.

Owner:GUANGDONG SHENGRUI TECH CO LTD

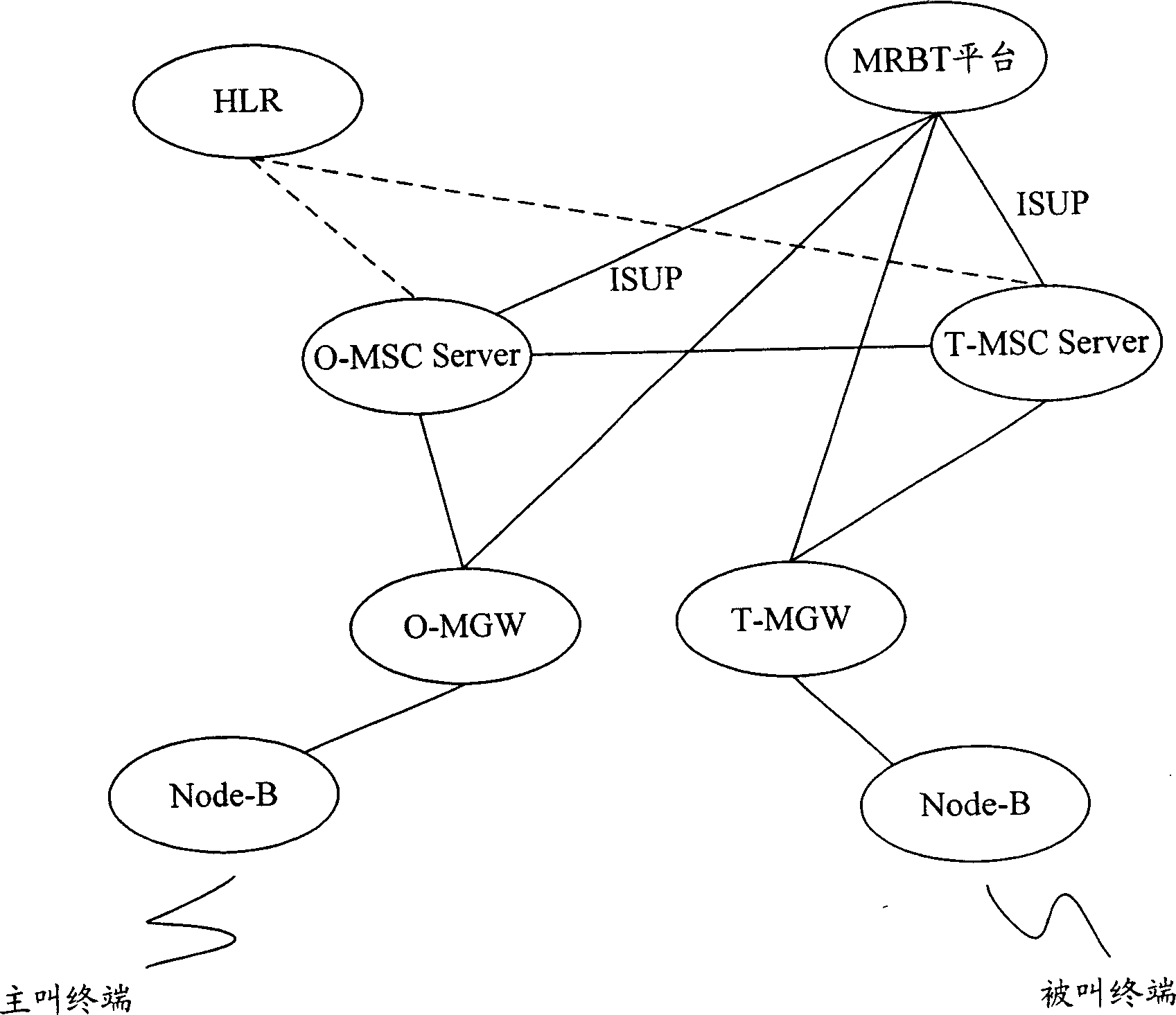

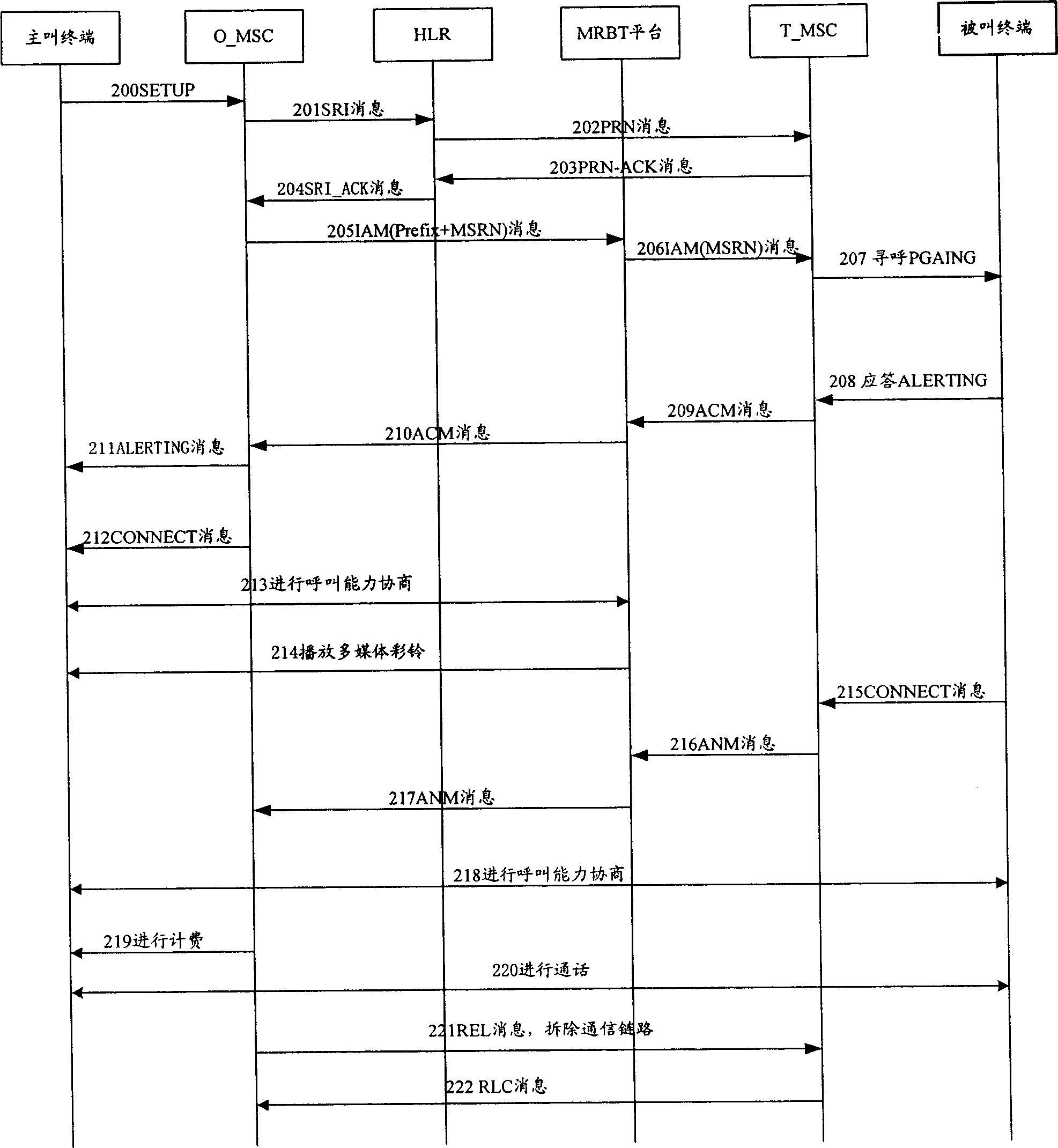

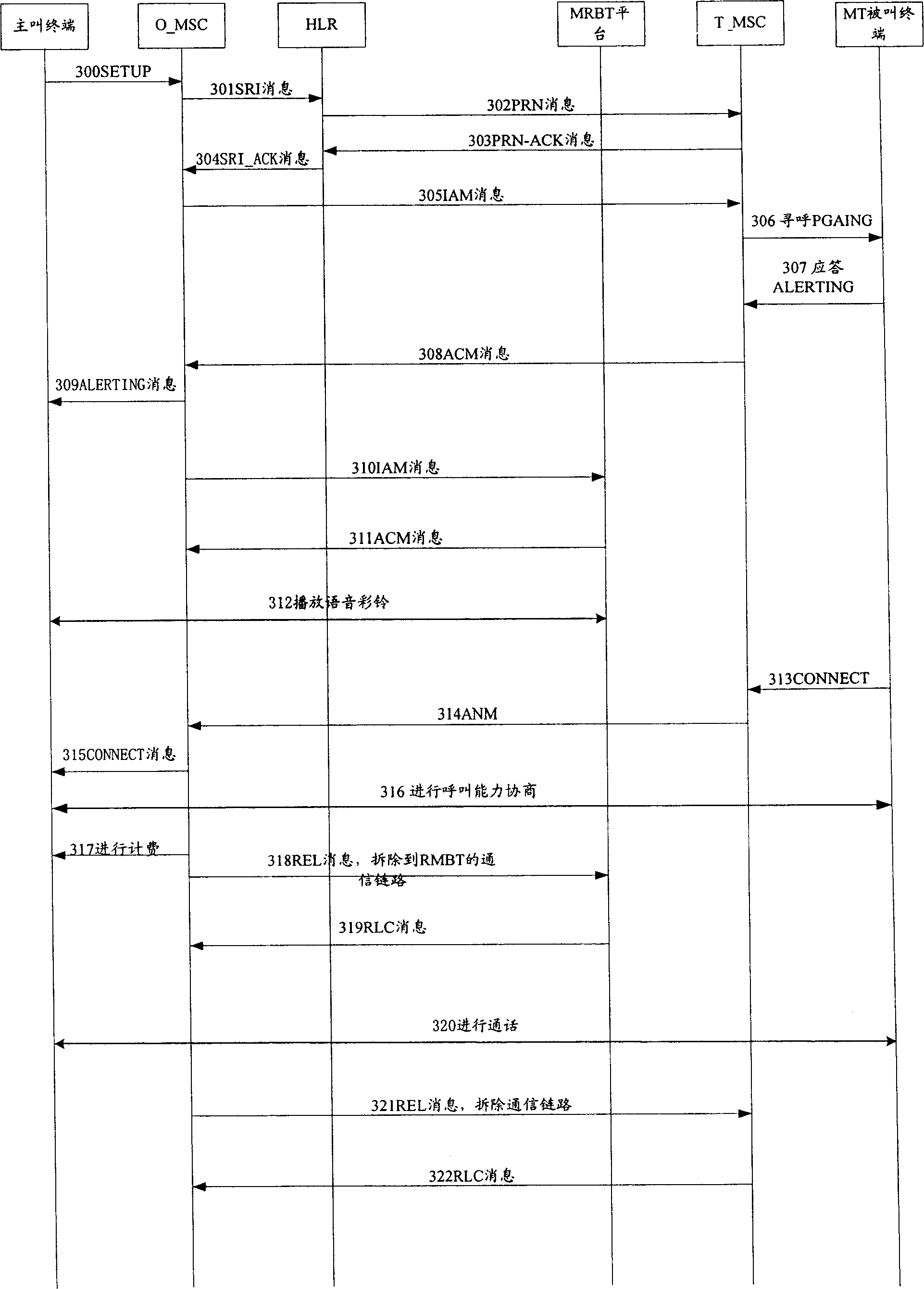

System and method for realizing multimedia color ring service

ActiveCN1859496AWith VIG functionRealization of Multimedia Ring Back ToneSpecial service for subscribersRadio/inductive link selection arrangementsService systemTelecommunications link

The present invention discloses realizing multimedia coloring ring back tone (CRBT) service system. It contains mobile switching center (MSC), multimedia gateway (MGW) and home location register (HLR) home location register (HLR), multimedia ringing back tone (MRBT) platform storing multimedia coloring ring back tone (CRBT) in 3 G communication network, said platform with built-in video intercommunication gateway (VIG), MRBT platform respectively connected with MSC and MGW in 3 G communication network. The present invention also discloses a realizing multimedia coloring ring back tone (CRBT) service method. When calling terminal through MSC called terminal success to calling connected, establishes communication link from calling terminal through MGW to MRBT platform, MRBT platform through said established communication link playing multimedia coloring ring back tone (CRBT) to calling terminal.

Owner:HUAWEI TECH CO LTD

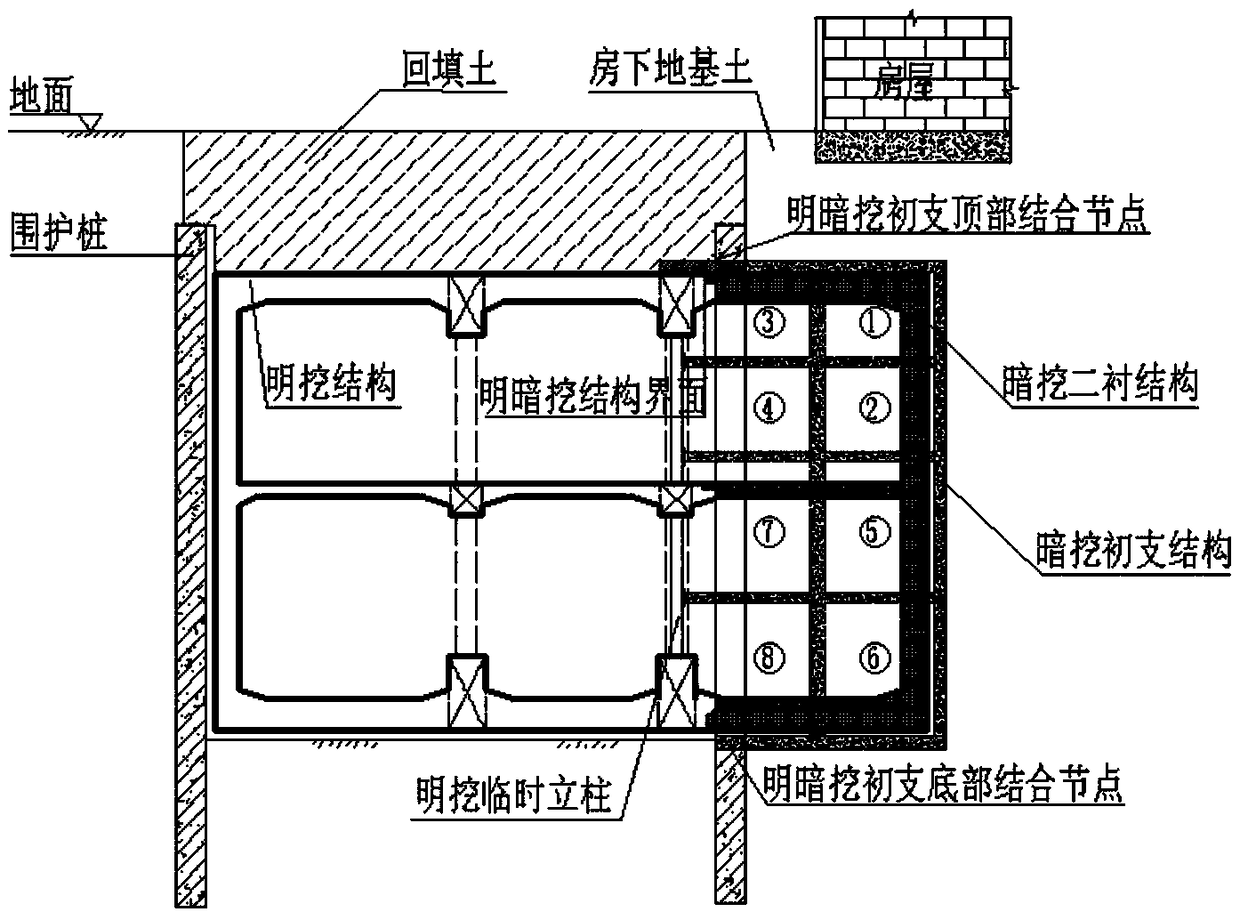

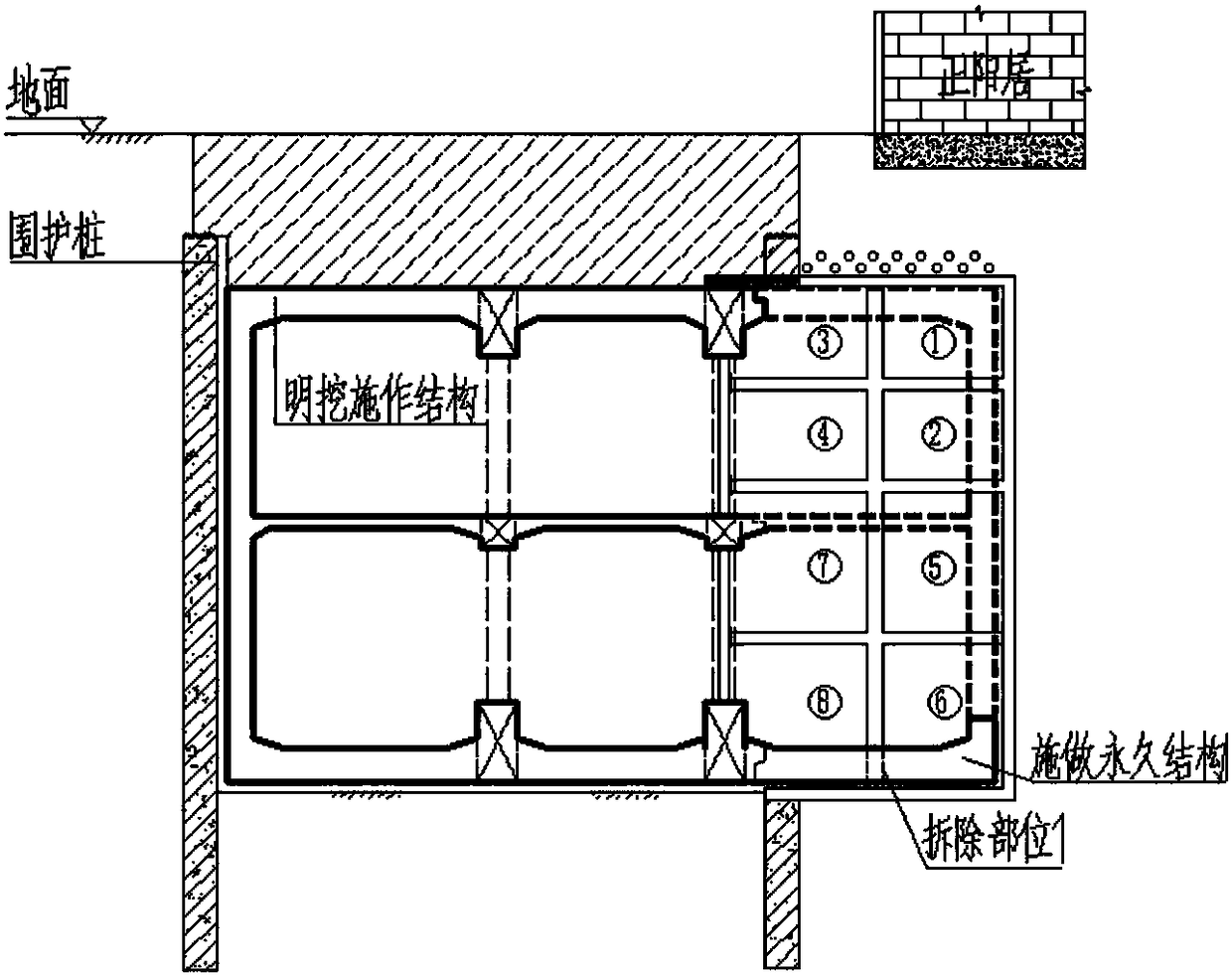

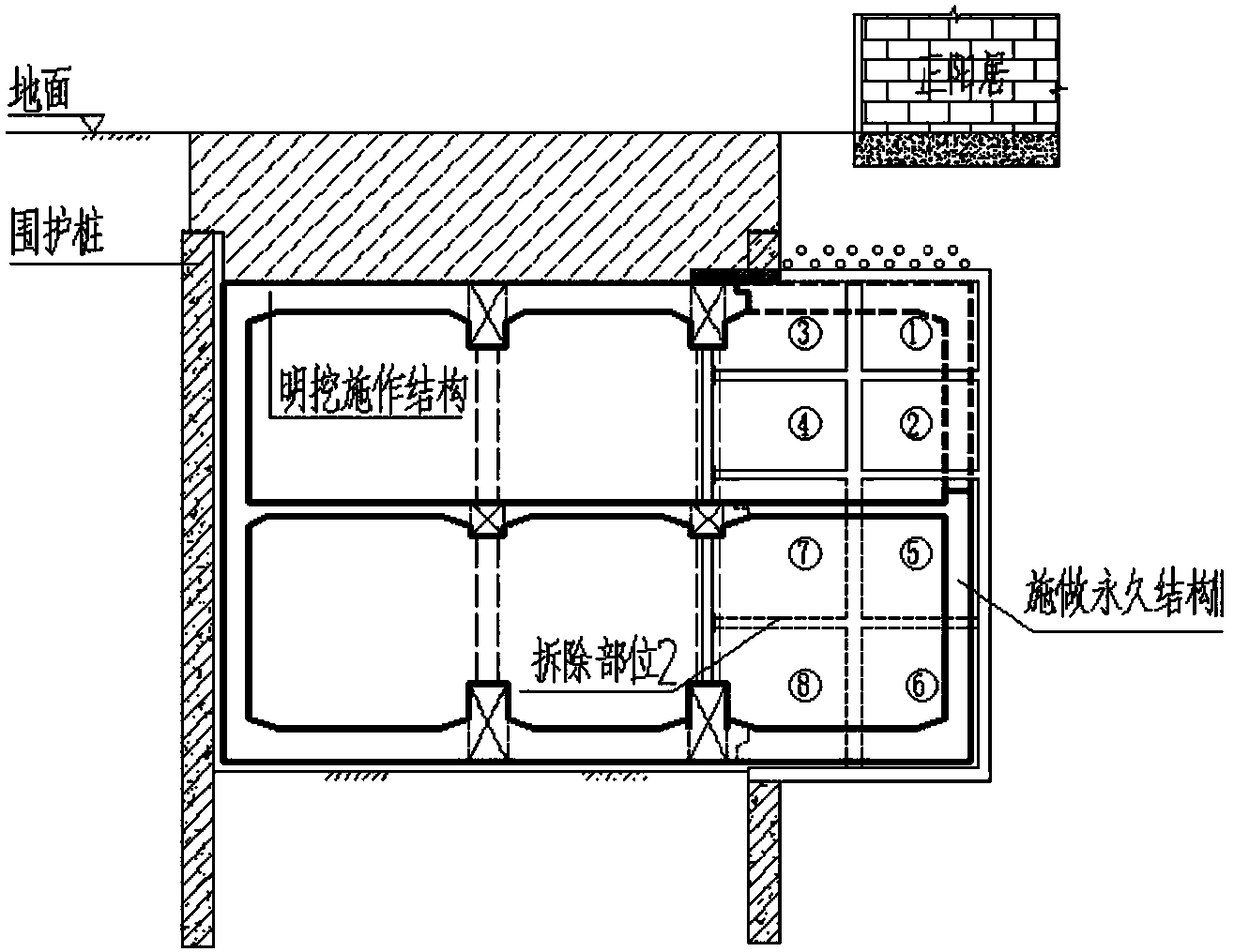

Method for constructing underground structure by combining light-shade excavation with ground matter removal avoidance

InactiveCN108286266AReduce demolitionGuarantee the progress of the projectArtificial islandsUnderwater structuresEnvironmental geologyStructure system

The invention discloses a method for constructing an underground structure by combining light-shade excavation with ground matter removal avoidance. The method comprises the following steps: light-shade excavation construction ranges and boundary points of the underground structure are determined; light excavation is performed; primary support construction and branch excavation are performed on nodes reserved in light excavation; primary supports are removed; and a waterproof system and a secondary lining are constructed. Compared with a full-light excavation method, the method reduces removal, and guarantees the engineering progress; meanwhile, the house removal expense is hundred million Yuan, so that the engineering investment is saved; the underground structure system is kept invariable without influencing ground functions; the removal quantity is reduced; the construction garbage and the resource waste are reduced; and the construction cost is reduced.

Owner:CHINA RAILWAY FIRST GRP SECOND ENG CO LTD

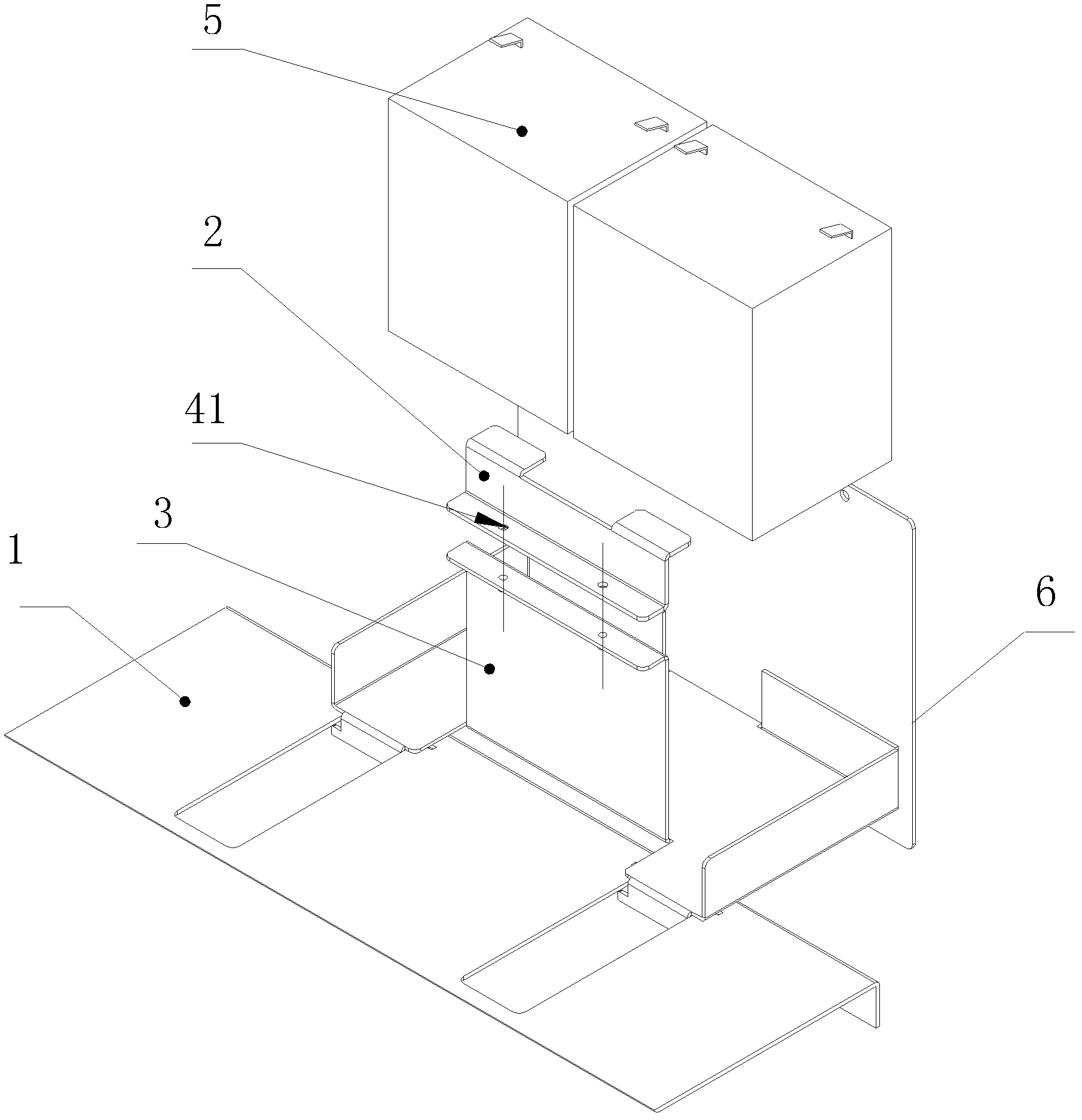

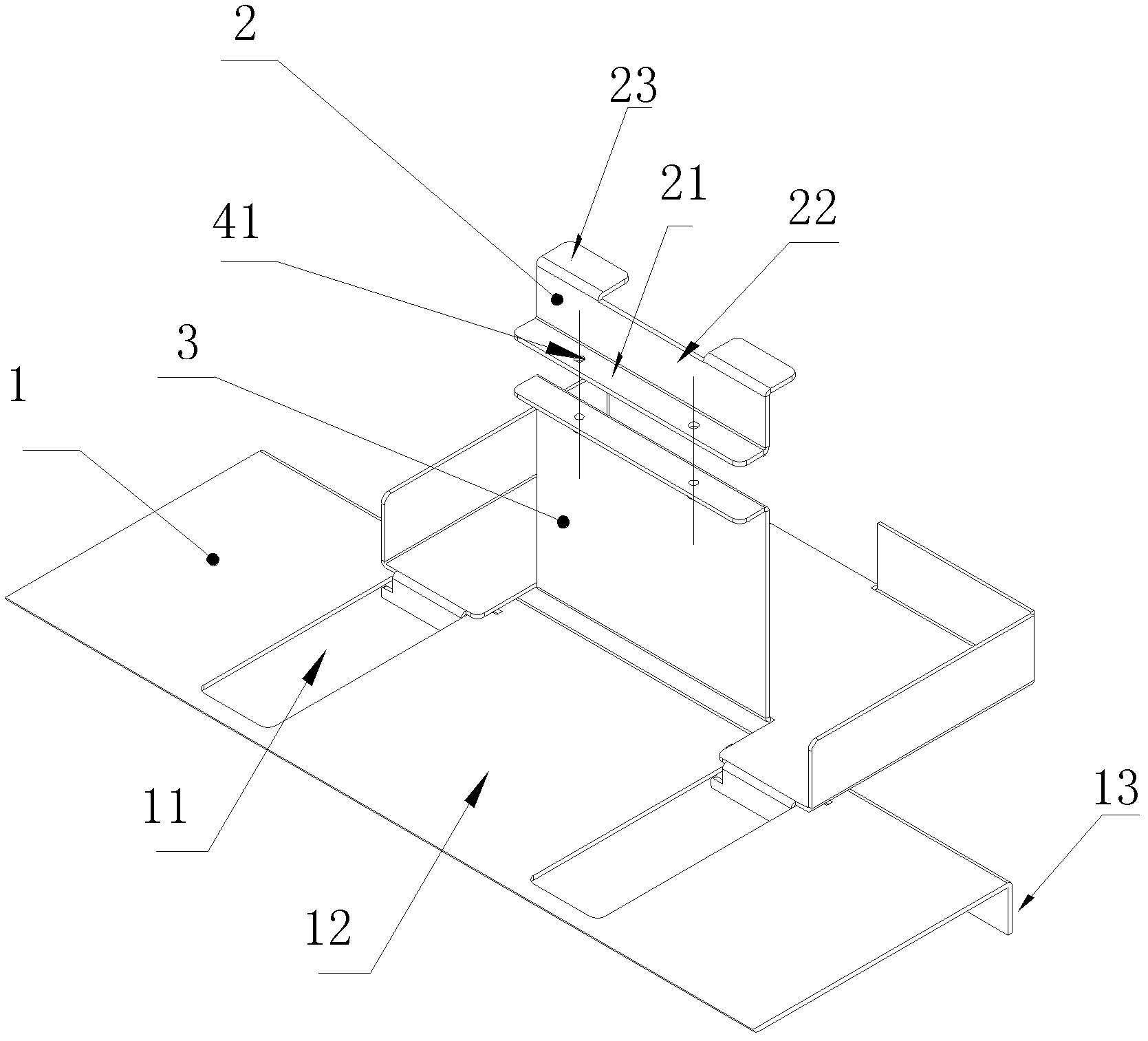

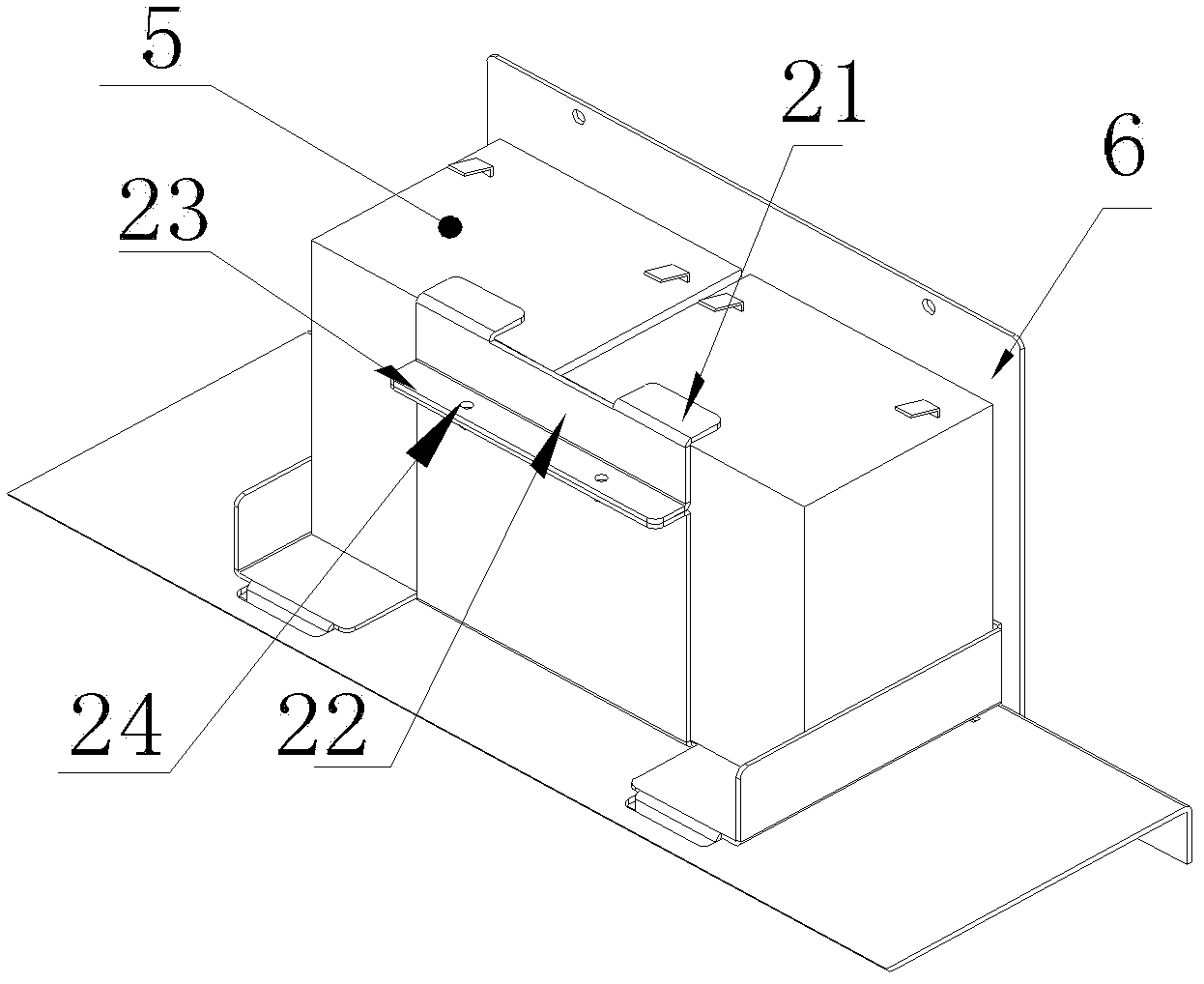

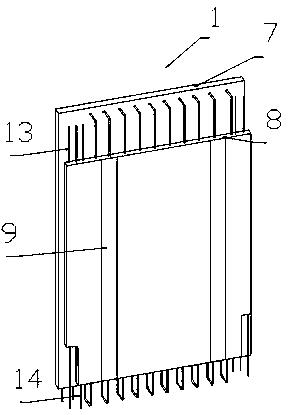

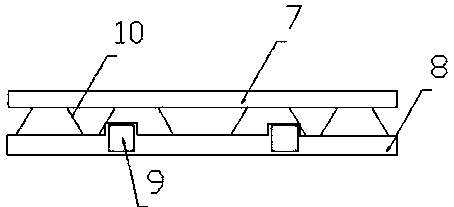

Pull box assembly for replacing battery and method for replacing the battery

ActiveCN103187546ASimple structureEasy to install and disassembleCell component detailsEngineeringElectrical and Electronics engineering

The invention provides a pull box assembly for replacing a battery, comprising a battery pull box, a pull box fixing plate and a battery fixing plate, wherein the battery pull box has a sliding structure, a pull spacing structure, a battery spacing structure and a pull handle; the pull box fixing plate has a chute structure and a battery pull box fixing hole; the battery fixing plate has a battery fixing hole; the sliding structure of the battery pull box is matched to the chute structure of the pull box fixing plate, and the battery pull box is prevented by the pull spacing structure of the battery pull box from being released from the pull box fixing plate; and the battery spacing structure of the battery pull box and the battery fixing hole of the battery fixing plate together restrict the displacement of the battery in the forward-back, left-right and up-down six directions. The pull box assembly has advantages of simple structure and simple battery replacing steps, and greatly raises convenience in a battery replacing process.

Owner:BEIJING AEONMED

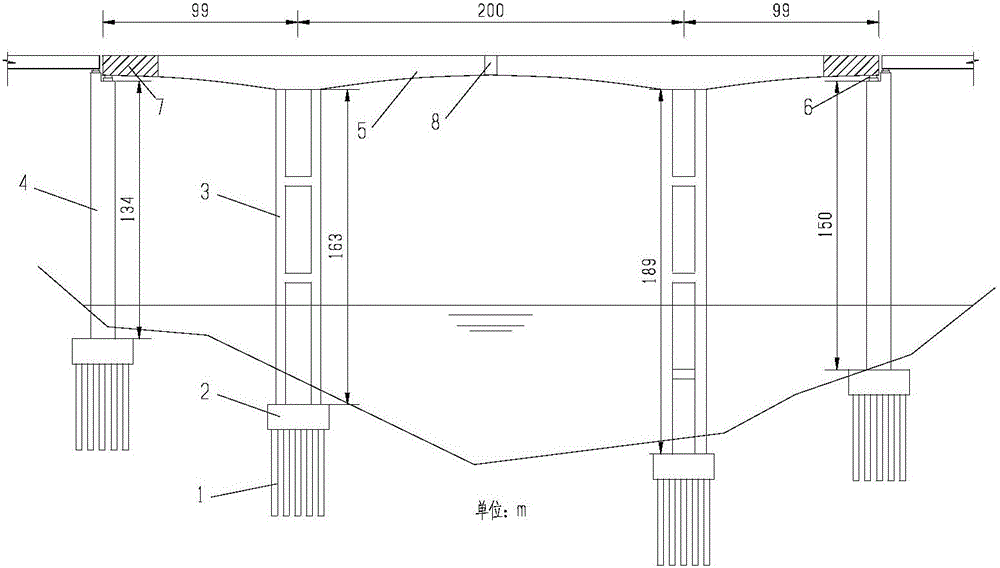

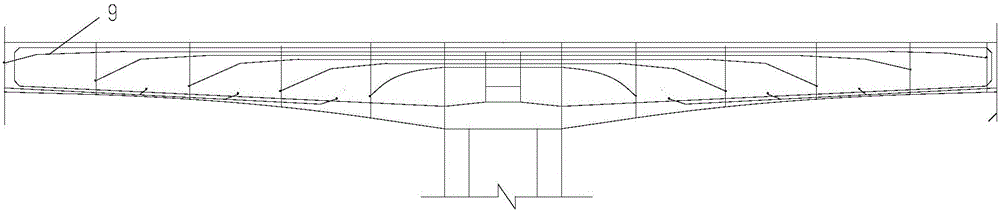

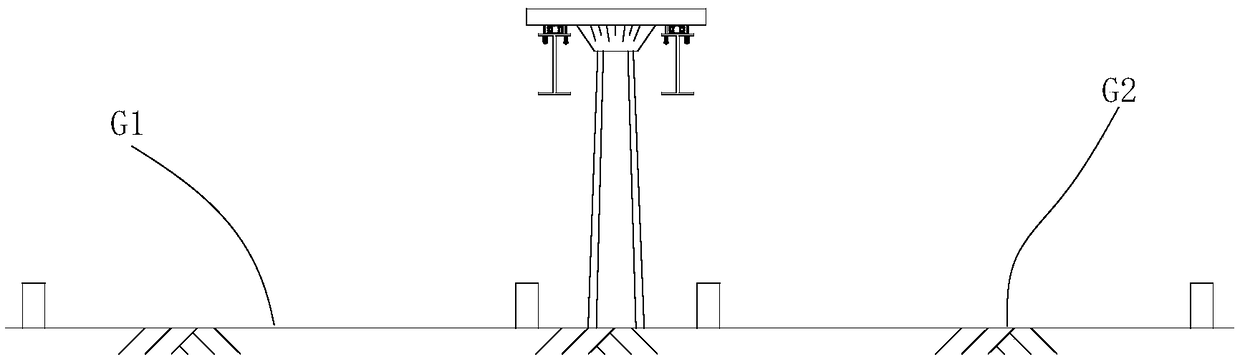

Prestressed concrete continuous rigid frame bridge with complete cantilever-construction and construction method thereof

InactiveCN106758871AReduce designReduce demolitionBridge erection/assemblyTension compressionPre stress

The invention discloses a prestressed concrete continuous rigid frame bridge with complete cantilever-construction and a construction method thereof. The prestressed concrete continuous rigid frame bridge with the complete cantilever-construction comprises a foundation, a bridge cushion cap, a main pier of bridge, an abutment pier, a main girder, an abutment pier tension-compression bearing, a side span counterweight segment and a main span closure segment; a side span closure segment is not installed in the prestressed concrete continuous rigid frame bridge with the complete cantilever-construction; the ratio of midspan and to side span is less than 0.5, the abutment pier tension-compression bearing is arranged at the top of the abutment pier, the side span counterweight segment is arranged on the side span. The mechanical properties of the prestressed concrete continuous rigid frame bridge with the complete cantilever-construction are mainly achieved by reasonable configuration of prestress and temporary counterweight during the construction of the complete cantilever. The prestressed concrete continuous rigid frame bridge with the complete cantilever-construction and the construction method do not have the process of the side span closure segment, the construction steps are simplified, the construction workload is reduced, the construction period is shortened and the construction risk of a high pier support is reduced.

Owner:HUNAN UNIV OF SCI & TECH

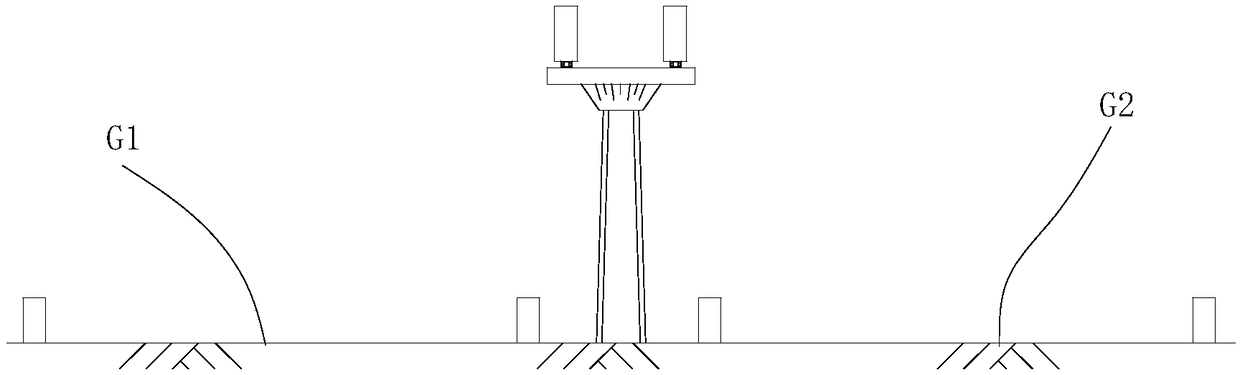

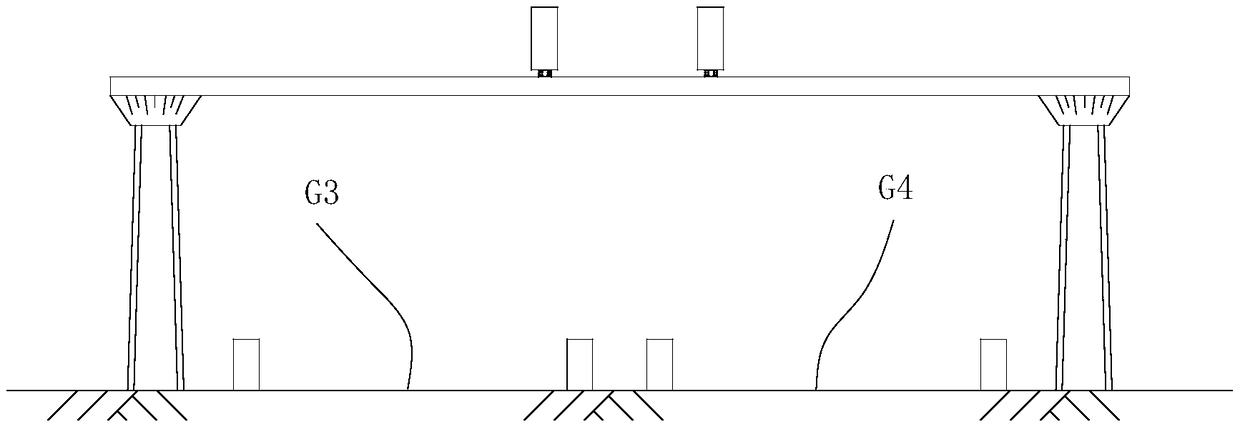

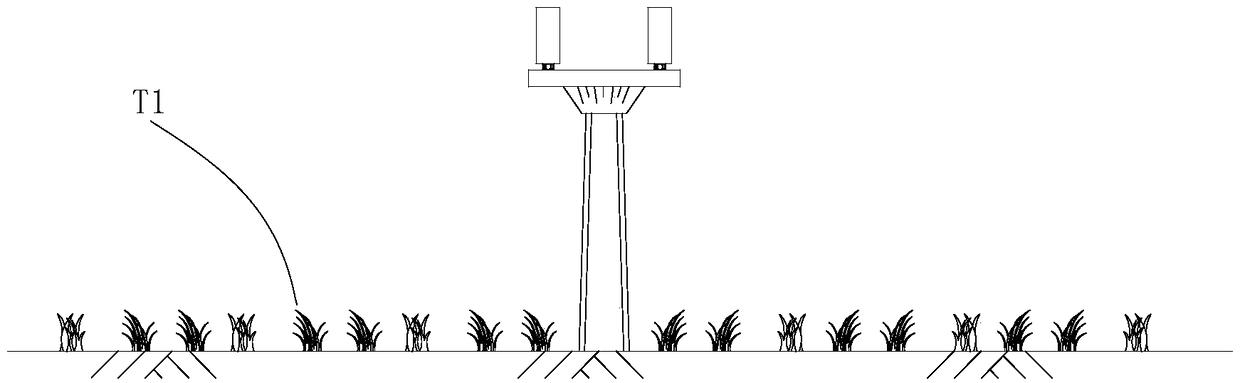

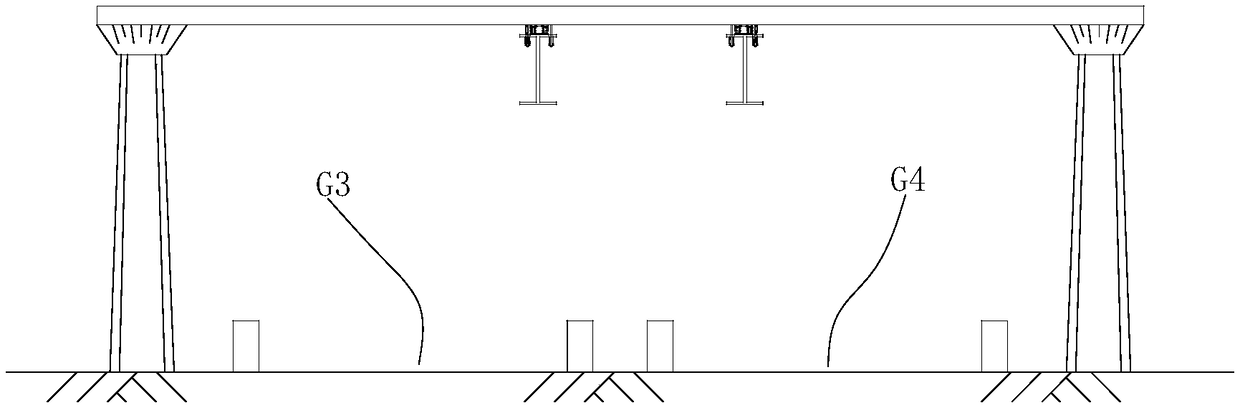

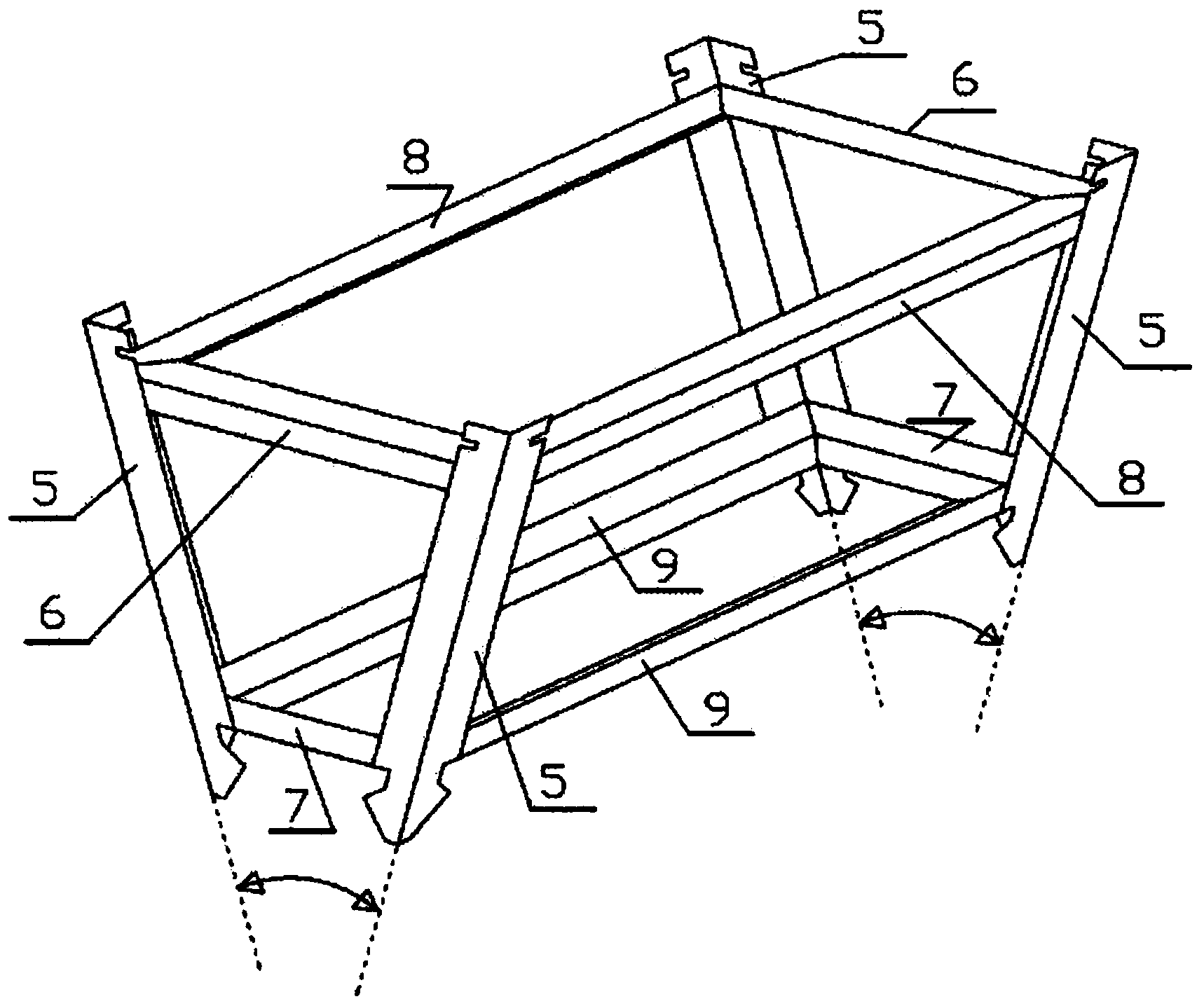

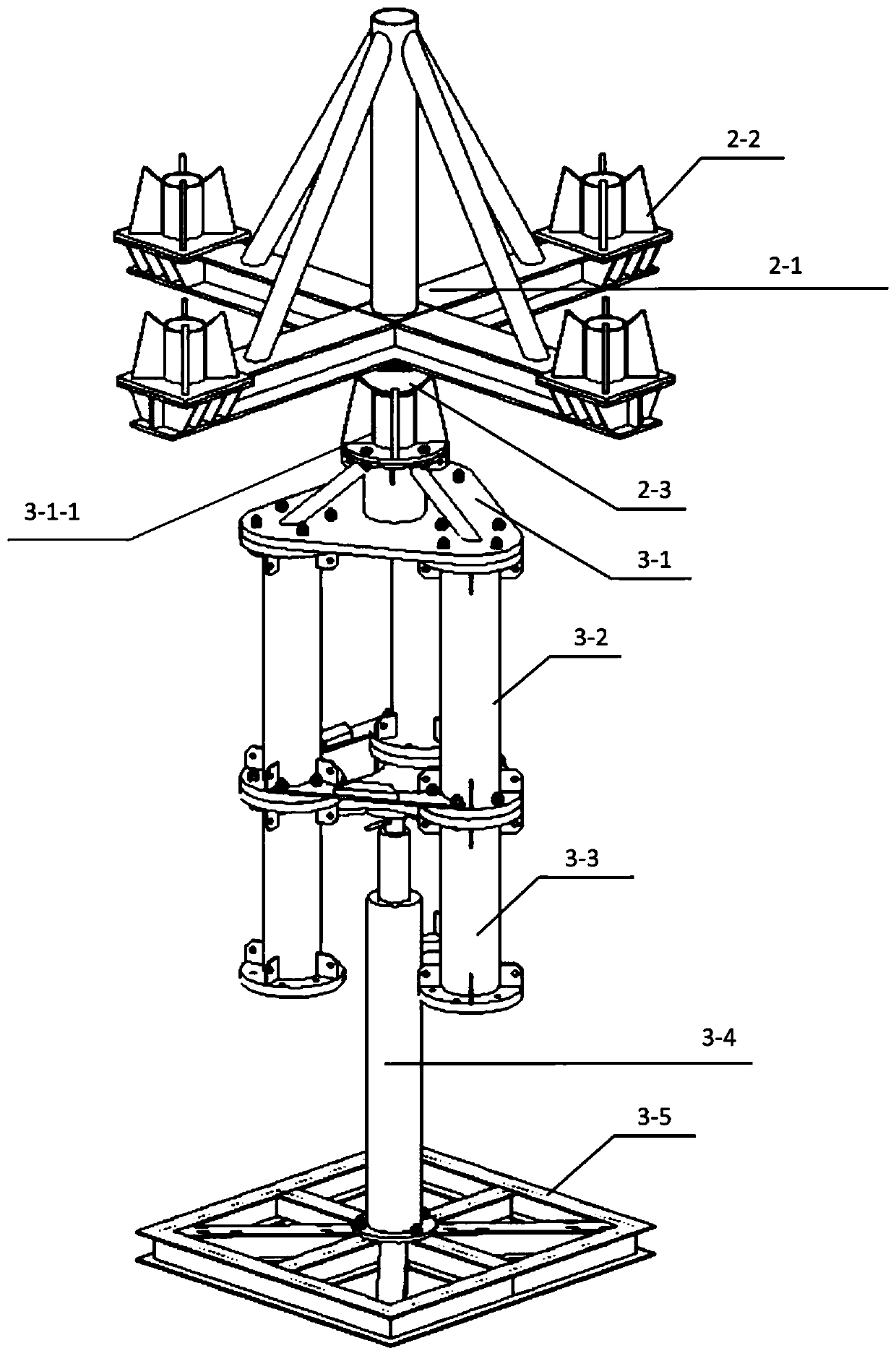

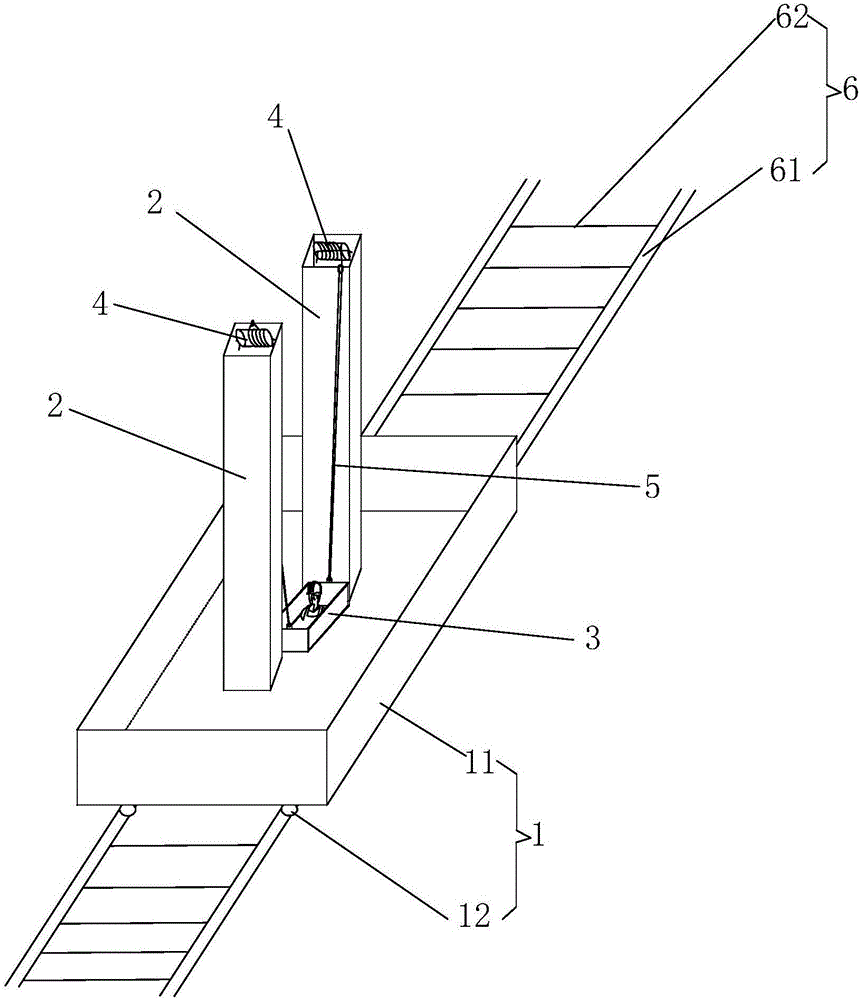

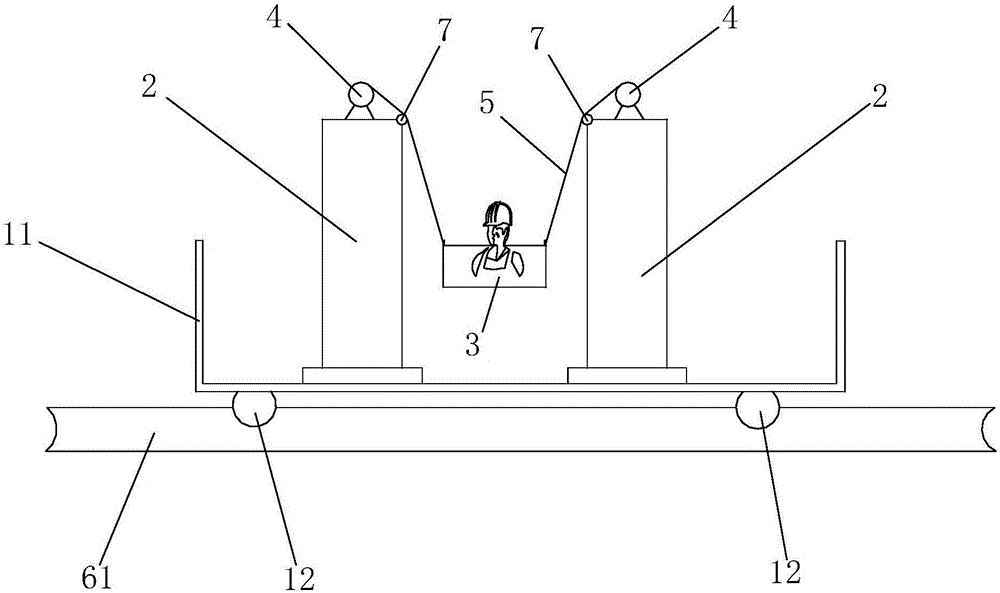

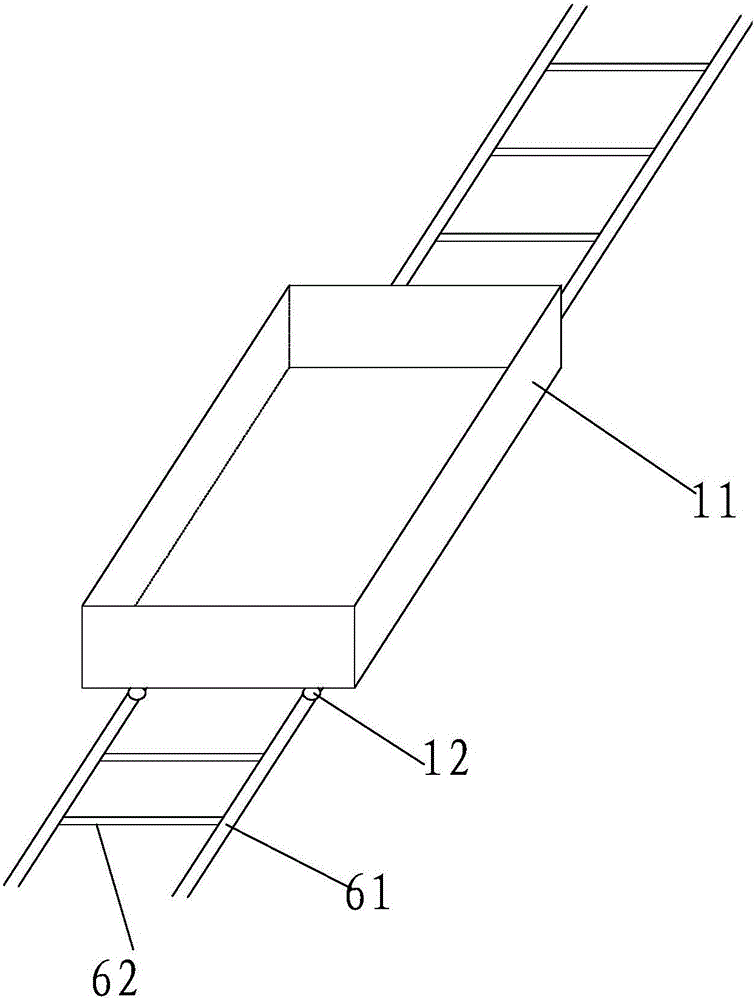

A straddle-type logistics monorail transportation system

The patent discloses a straddle-type logistics monorail transportation system, which belongs to the field of monorail transportation. By proposing a straddle-type logistics monorail transportation system, using straddle-type logistics monorail girder bridge system, straddle-type logistics monorail vehicle system, straddle-type logistics monorail switch system, straddle-type logistics monorail loading and unloading system and straddle-type logistics monorail signal system, solve the problems of short distance, large size, high cost and low speed of the existing maglev transportation, and achieve the goal of long distance, lightweight, low cost and high speed straddle-type logistics monorail transportation system.

Owner:BEIJING JIAOTONG UNIV

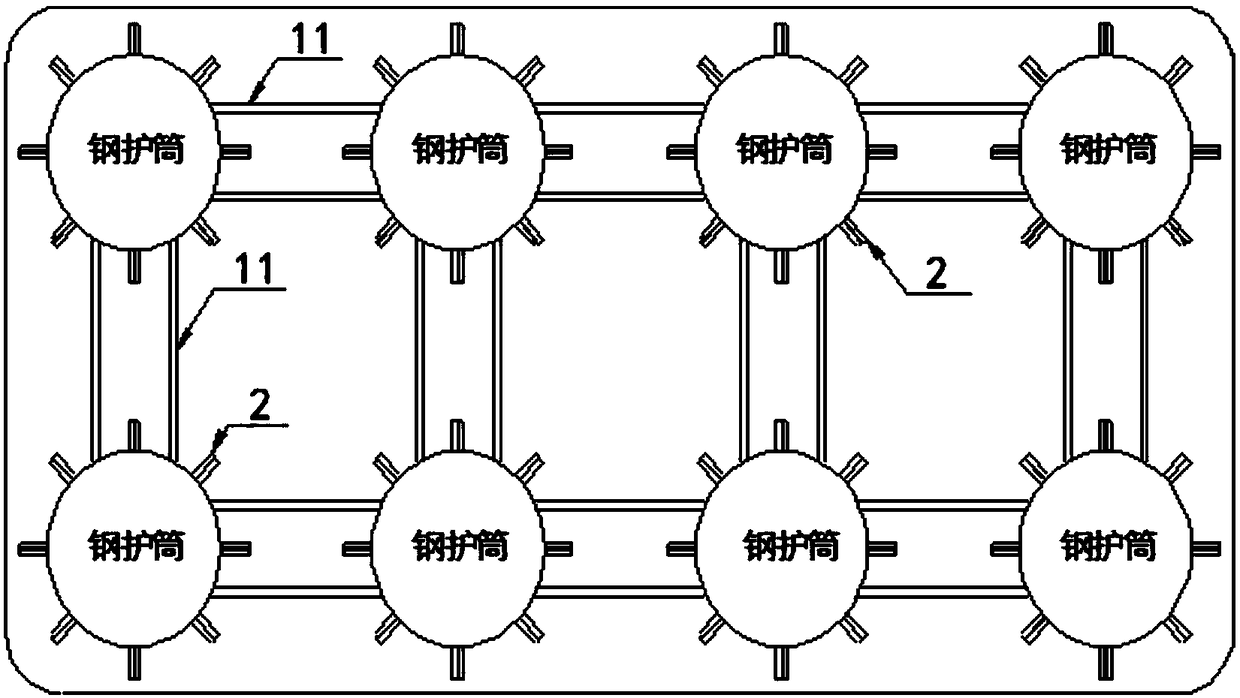

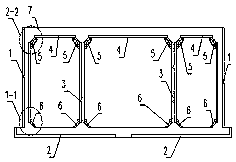

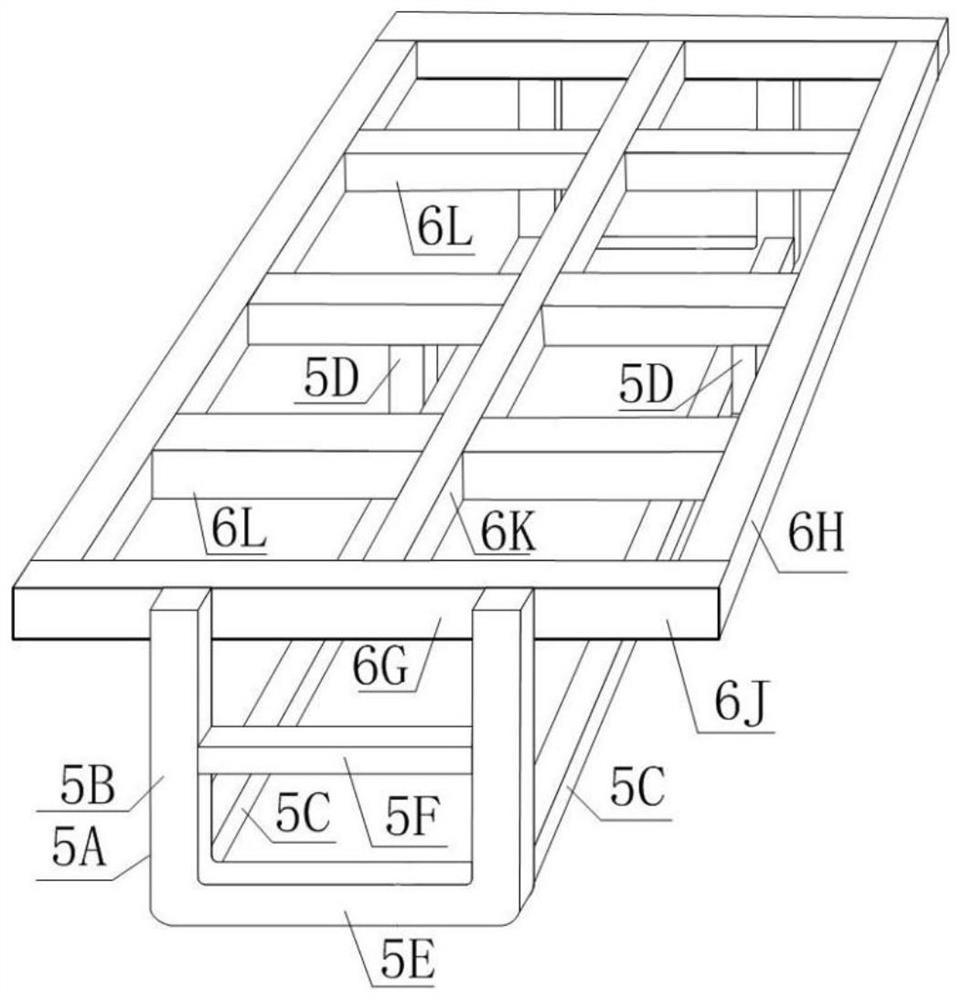

Full-fracture surface supporting-free overlapped fabricated type comprehensive pipe gallery structure and construction method

ActiveCN108708394ASolve the problem of interfering constructionReduce handlingArtificial islandsUnderwater structuresRebarWall plate

The invention relates to a full-fracture surface supporting-free overlapped fabricated type comprehensive pipe gallery structure and a construction method. The structure comprises a fabricated overlapped top plate, a fabricated overlapped base plate, a fabricated side wall plate and a fabricated inner wall plate; the side wall plate is formed by a side wall inner sheet plate and a side wall outersheet plate, and steel tie bars are arranged between the side wall inner sheet plate and the side wall outer sheet plate; and the upper and lower ends of the side wall inner sheet plate are provided with reserved extending-out reinforcing steel bars, the lower end of the side wall outer sheet plate is provided with reserved extending-out reinforcing steel bars, and the inner wall plate is formed by overlapping two wall plates. A vertical-support-free method for assembling an overall concrete pipe gallery is provided for solving the problems that an existing technology for assembling the overall comprehensive pipe gallery has the problems that a vertical support has interference in construction, axillary corner construction is difficult, and the installing field slope limitation exists; andaccording to the method, a self-designed stiffened axillary corner pouring formwork is mainly adopted, and the formwork capable of achieving supporting-free installation and capable of solving the problem about axillary corner pouring is achieved in cooperation with wallboard structure construction adjustment.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD

Suspension-type logistic monorail transportation system

The patent discloses a suspension-type logistics monorail transportation system, belonging to the monorail transportation field. By proposing a hanging logistics monorail transportation system, and byadopting the a suspension-type logistic monorail girder bridge system, a suspension-type logistic monorail girder bridge system suspended logistics monorail vehicle system, a suspension-type logistics monorail switch system, a suspension-type logistics monorail loading and unloading system and suspended logistics monorail signal system, the problems of short distance, large size, high cost and low speed of the existing maglev transportation are solved, and the goals of long distance, lightweight, low cost and high speed suspension logistics monorail transportation system are achieved.

Owner:BEIJING JIAOTONG UNIV

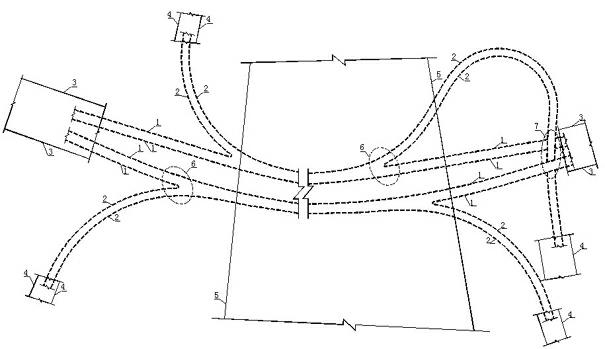

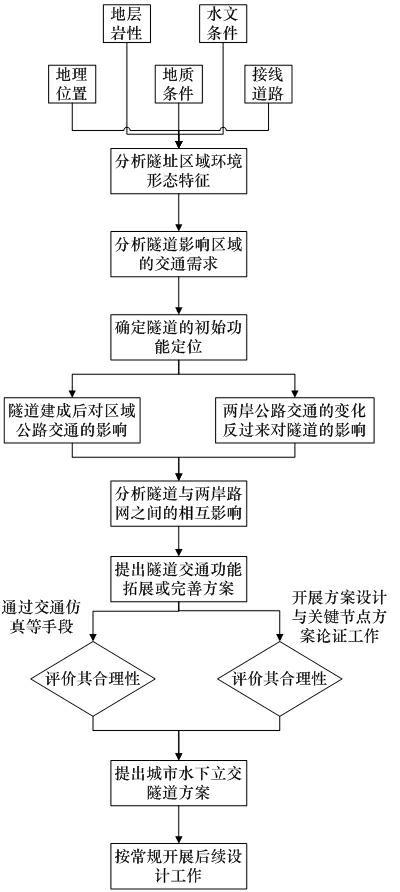

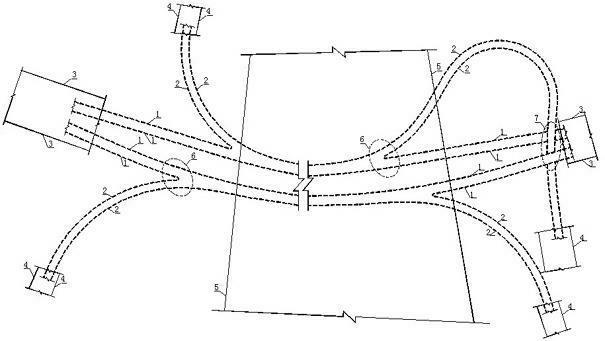

Urban underwater overpass tunnel system

InactiveCN102587417AIncrease profitFull play of traffic functionsArtificial islandsRoadwaysEngineeringUtilization rate

The invention discloses an urban underwater overpass tunnel system, which comprises a mainline tunnel and ramp tunnels. The mainline tunnel downwards penetrates into a water system, two ends of the mainline tunnel are connected with ground connection roads, one end of each ramp tunnel is connected with the mainline tunnel while the other end of the ramp tunnel is connected with another surface road, and an underground flyover crossing relation is formed between the mainline tunnel and the ramp tunnels or among the ramp tunnels. The urban underwater overpass tunnel system is structurally characterized in that under the premise that new underwater corridors are not added and the position of the mainline tunnel is not changed, the ramp tunnels are added, one end of each ramp tunnel is connected with the mainline tunnel while the other end of the ramp tunnel is connected with the other surface road, so that an underground overpass is formed, the utilization rate of underwater corridors is increased to the greatest extent, and traffic functions of the tunnels are sufficiently realized.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Large steel bridge deck and manufacture method thereof

ActiveCN103920974AAvoid damageReduce demolitionArc welding apparatusBridge structural detailsEngineeringSurface plate

The invention relates to a large steel bridge deck and a manufacture method thereof. The large steel bridge deck is made by welding a plurality of steel bridge deck blocks. Each steel bridge deck block is made by welding two or more steel bridge deck units. Each steel bridge deck unit is composed of a plurality of U-shaped ribs and a face plate; the U-shaped ribs are welded on the face plate at equal intervals; a transverse partition joint plate is welded to the U-shaped ribs and the face plate. The large steel bridge deck has the advantages that operation is simple, and the single-side welding double-side forming technique with high requirements on operating skill is avoided; welding materials are saved, expensive waterproof ceramic pads are not used, and gas shielded welding wires and protective gases are not used; no rigid jig plate is used, steel is saved, damage of the face plates by the jig plates is avoided, and great amount of work such as dismantling the jig plates and repairing is decreased.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

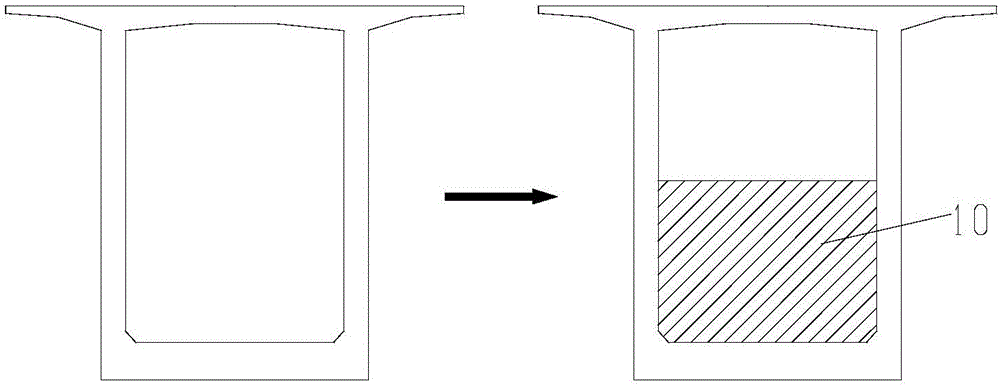

Method for rebuilding diversion tunnel body into flood discharging tunnel body

ActiveCN103388322AReduce demolitionGuaranteed functional requirementsBarrages/weirsReinforced concreteRebar

The invention discloses a method for rebuilding a diversion tunnel body into a flood discharging tunnel body. The method comprises the steps of 1, excavating the section of the original diversion tunnel body to the designed expanding excavation section of the flood discharging tunnel in an expanding mode; 2, mounting vertical reinforcing steel bars at tunnel edge walls; 3 pouring tunnel edge wall and tunnel top arch concrete according to construction demands; and 4, after the diversion is finished, pouring bottom plate concrete on an original diversion tunnel bottom plate, wherein the bottom plate concrete is poured in two layers from bottom to top, the pouring elevation of the lower concrete is higher than that of embedded steel plates; after the pouring of the lower layer concrete is finished, the upper layer concrete is poured after the reinforcing steel bars needed to be mounted in the upper layer concrete are welded with the embedded steel plates; the top face elevation of the upper layer concrete is the bottom plate elevation of the flood discharging tunnel after rebuilding; the strength level of the lower layer concrete is lower than that of the upper layer concrete. The method for rebuilding the diversion tunnel body into the flood discharging tunnel body has the main advantages of omitting the demolishing of poured reinforcing steel bar concrete in the built diversion tunnel, and ensuring the function demands on the tunnel in different periods.

Owner:YELLOW RIVER ENG CONSULTING

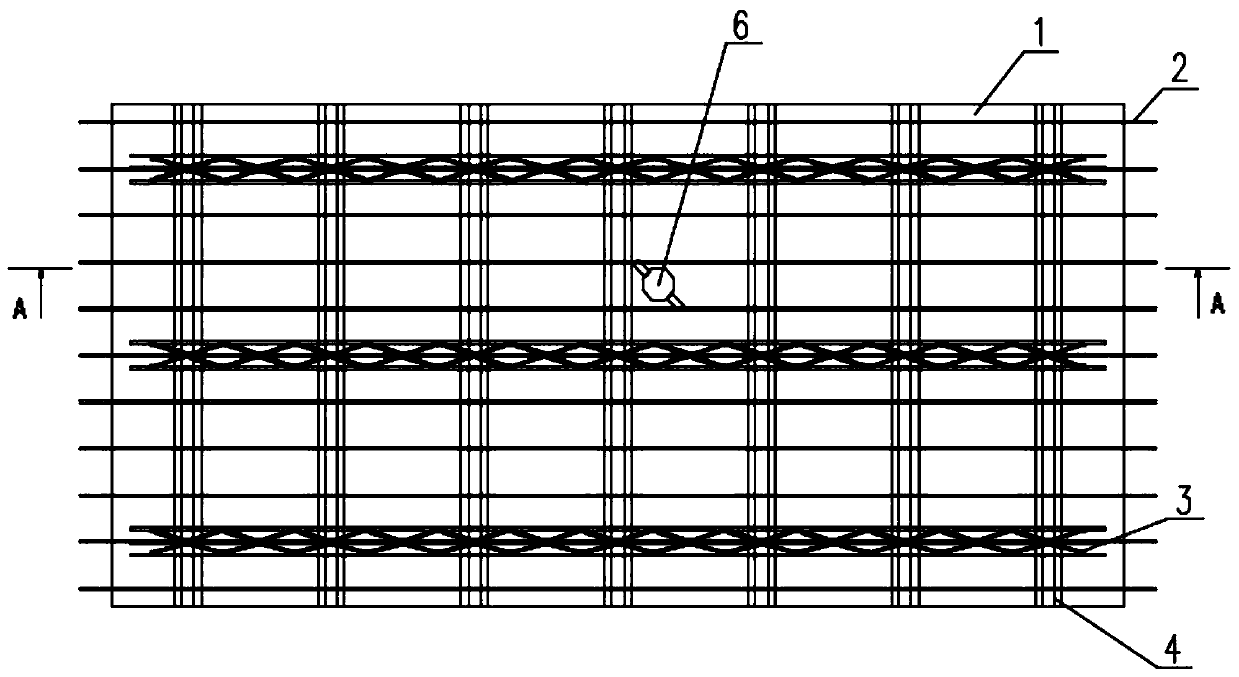

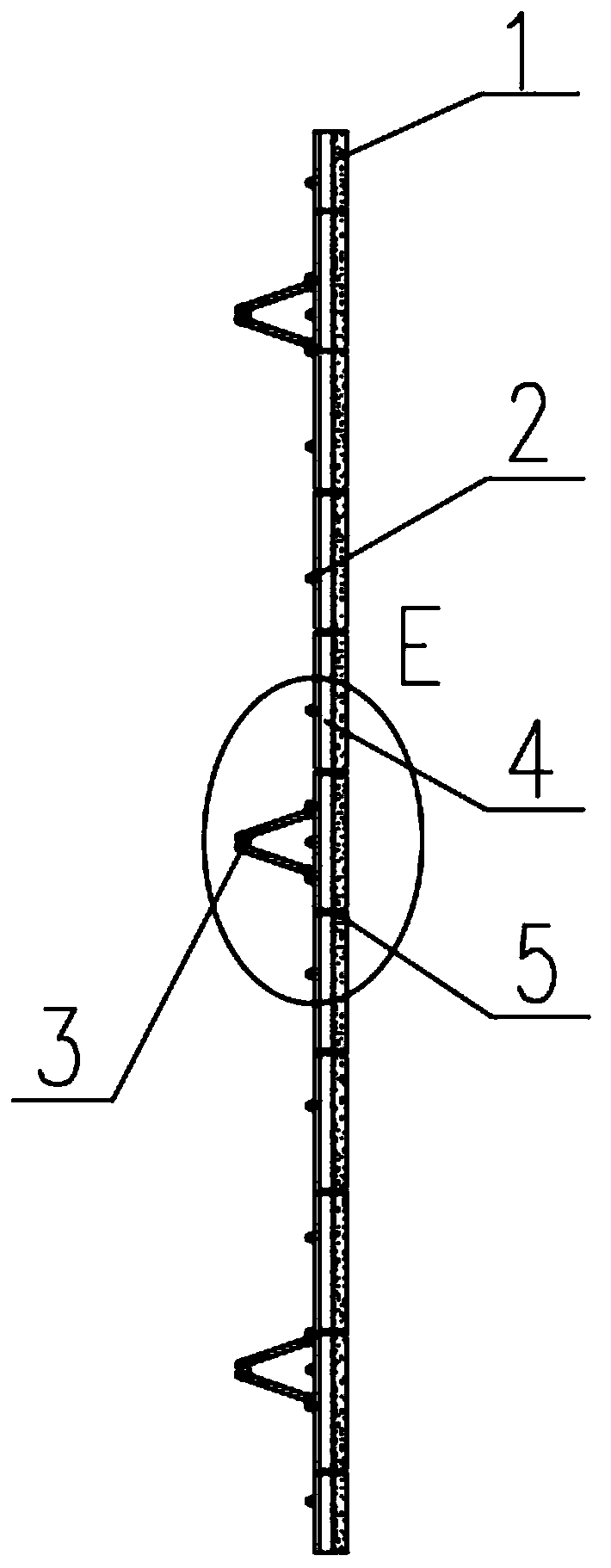

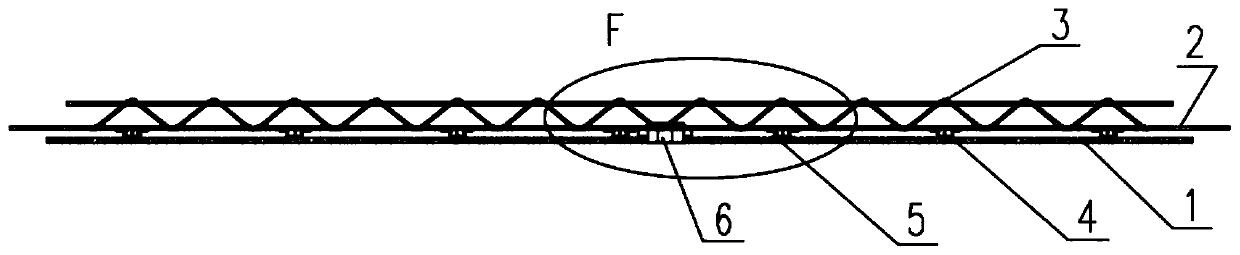

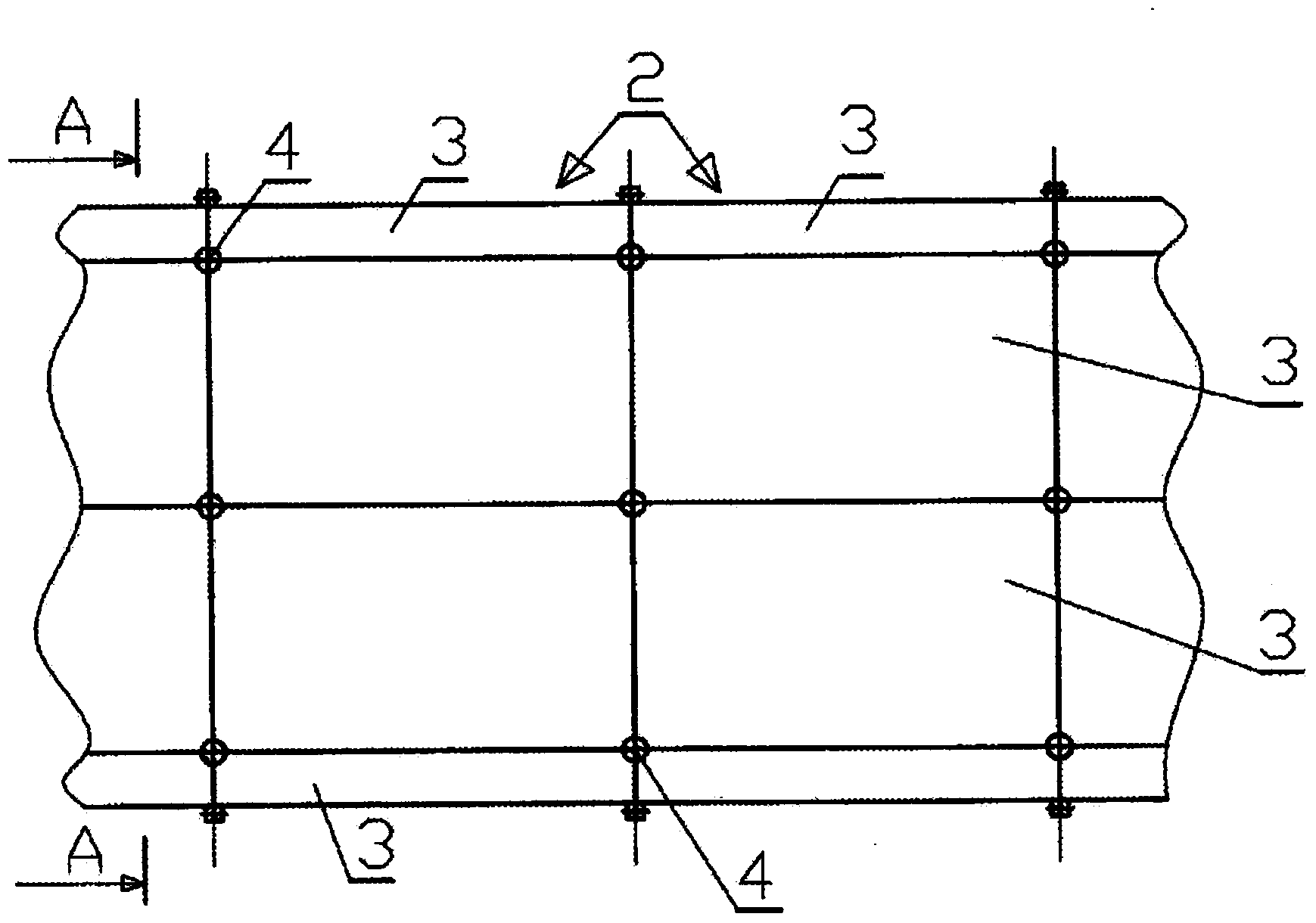

Prefabricated composite floor component

The invention discloses a prefabricated composite floor component which comprises high-precision dismounting-free form boards, combined formed steel bar products and connecting screws. The bottom faceof a floor is formed by the multiple high-precision dismounting-free form boards, rectangular grooves are adopted by the single faces of the high-precision dismounting-free form boards to achieve galling, the combined formed steel bar products are placed above the bottom face of the floor and are connected together through n-shaped profile steel, the open sides of the n-shaped profile steel are connected to the bottom faces of the combined formed steel bar products, concrete is poured after the closed sides of the n-shaped profile steel are connected with the galling faces of the rectangulargrooves of the floor through connecting screws, and a prefabricated is formed. Reserved wire box wire pipes are arranged on the high-precision dismounting-free form boards and in the combined formed steel bar products. According to the prefabricated composite floor component, the concept is ingenious, the structure is compact and reasonable, prefabricated parts are thin and light, lifting and transporting are facilitated, cost is reduced, by means of the design of the dismounting-free form boards, workloads are reduced, and the requirement for high levelness of a combined beam is guaranteed.

Owner:高慧静

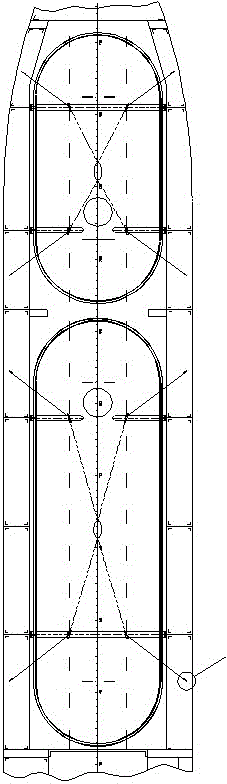

Method for positioning liquid tank quickly and accurately during building of liquefied ship

The invention relates to a method for positioning a liquid tank quickly and accurately during the building of a liquefied ship. The method comprises the following steps: setting a guide plate and a lifting point on the liquid tank separately; mounting a detachable guide device in the mounting position of the liquid tank on a ship body segment; welding an operating eye plate on a deck, connecting a steel wire rope on hoisting equipment on the lifting point to lift the liquid tank above the mounting position, and connecting a chain block with the lifting point and the operating eye plate separately to position the liquid tank; pouring epoxy resin at the mounting position of the liquid tank, starting the hoisting equipment to enable the liquid tank to fall down, controlling the falling stability of the liquid tank by the chain block, and enabling the guide plate to clamp in the specially designed guide device; enabling the liquid tank to fall down to the mounting position quickly under accurate control; dismantling the steel wire rope and the chain block and dismantling the reusable guide device. The one-time positioning method provided by the invention has the characteristics of accuracy and quickness in hoisting, and the dismantled guide device can be reused repeatedly after hoisting.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

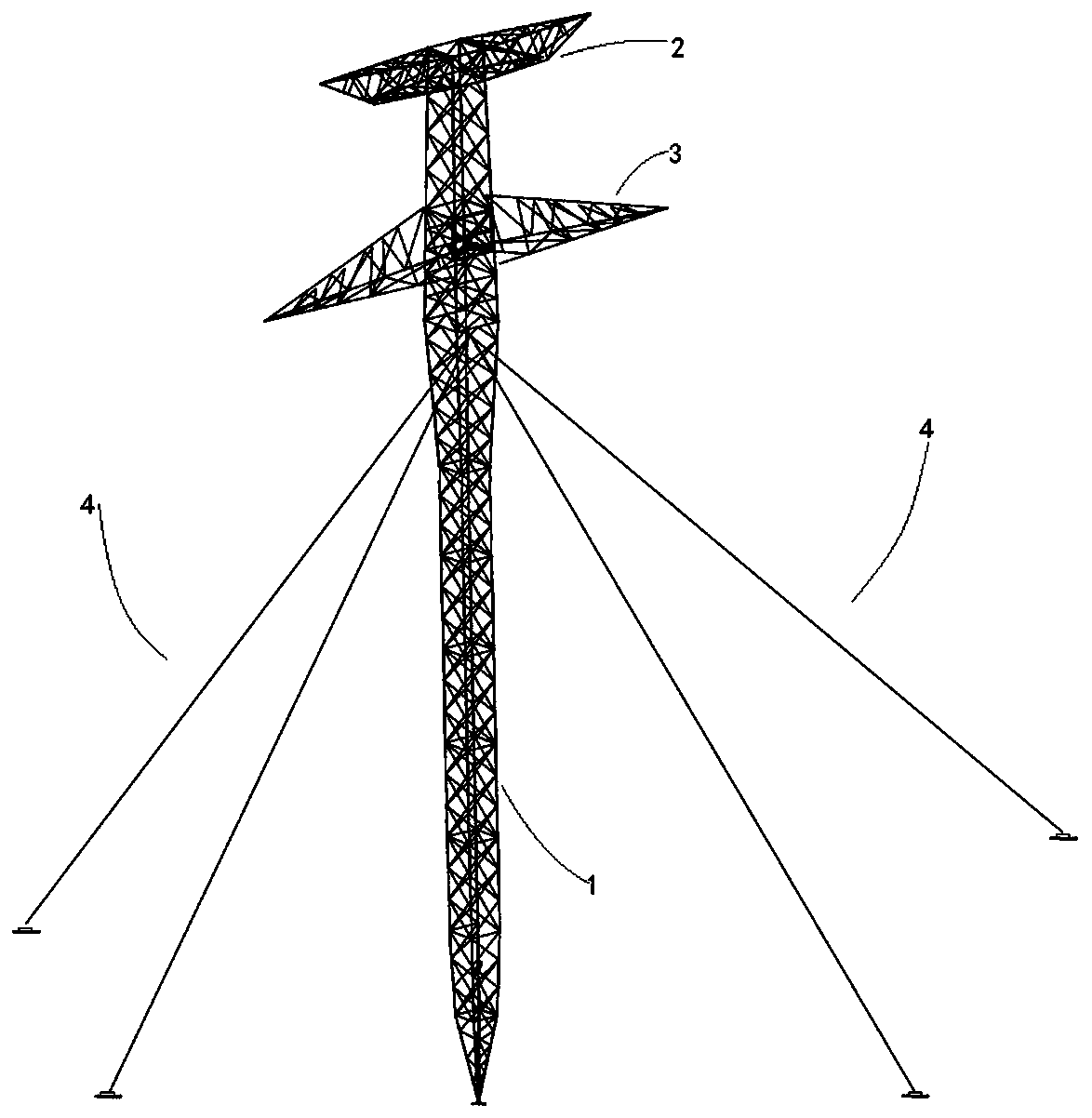

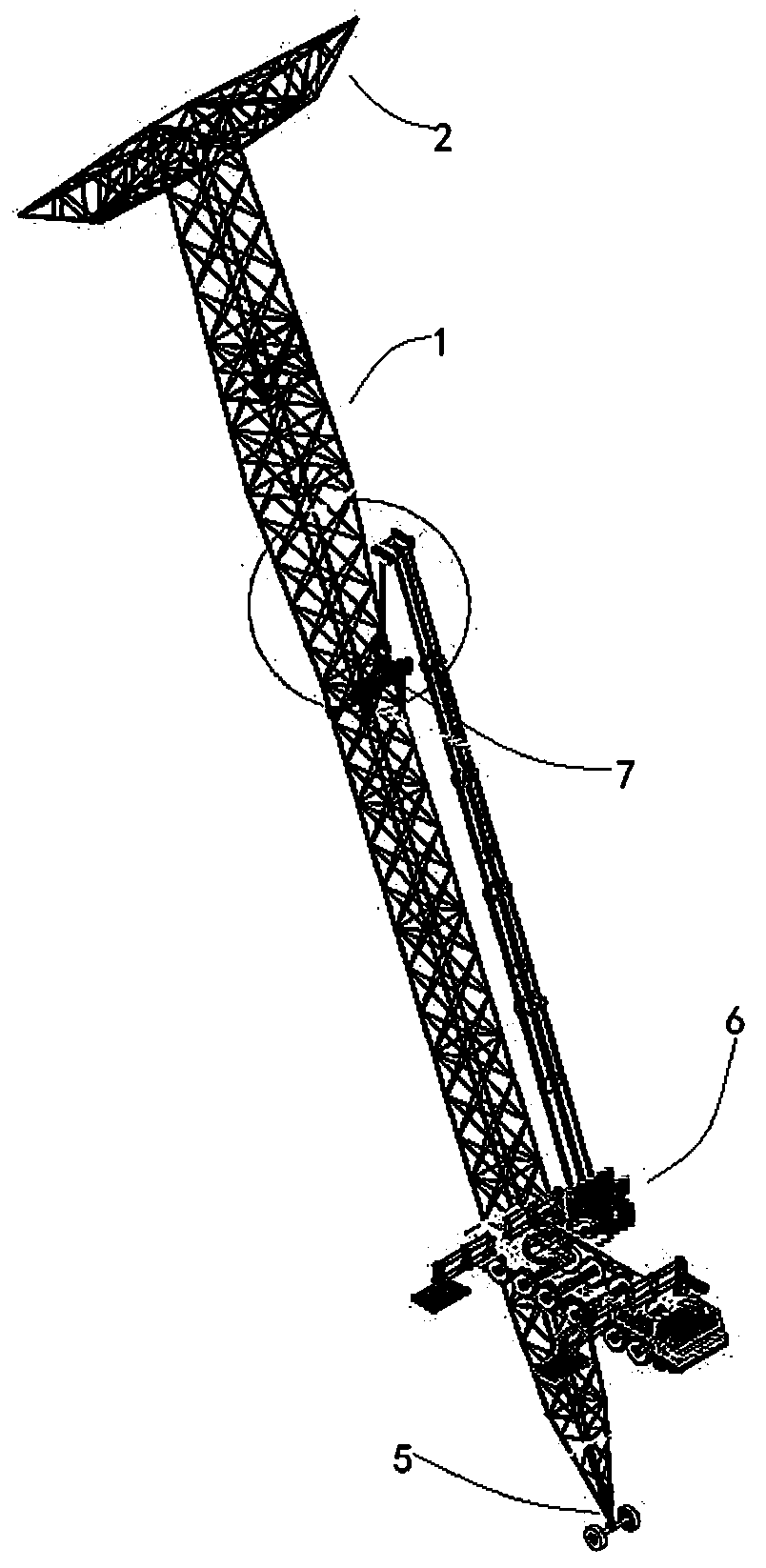

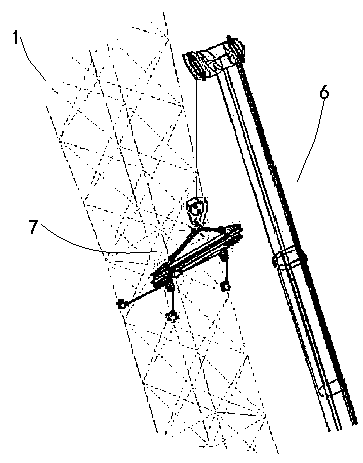

Hoisting method of transmission line guyed tower shaped like Chinese character 'gan'

ActiveCN109236012AReduced tonnage requirementsAvoid damageTowersLoad-engaging elementsMaterial defectChinese characters

The invention relates to the field of iron tower hoisting, in particular to a hoisting method of a transmission line guyed tower shaped like a Chinese character 'gan'. The hoisting method includes thefollowing steps of S1, ground assembling; S2, hoisting of a tower body and an upper cross arm; S3, unhooking; S4, mounting of a stay wire; S5, hoisting of a lower cross arm; S6, adjusting of the mounting precision of the tower body. According to the structural characteristics of the guyed tower shaped like the Chinese character 'gan', the four parts are assembled respectively on the ground firstly before being hoisted, a split type assembling and erecting method is adopted, the tonnage requirement of a hoisting machine is lowered, damage to plants is reduced, the influences on an ecological system are greatly reduced, and meanwhile the construction cost is also reduced. Ground tower assembling cooperates with tire type hoisting machine tower erecting, most work of iron tower assembling iscompleted on the ground, tower material defects can be found and overcome in the ground assembling process, and construction quality control is superior to that of derrick tower assembling and erecting.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

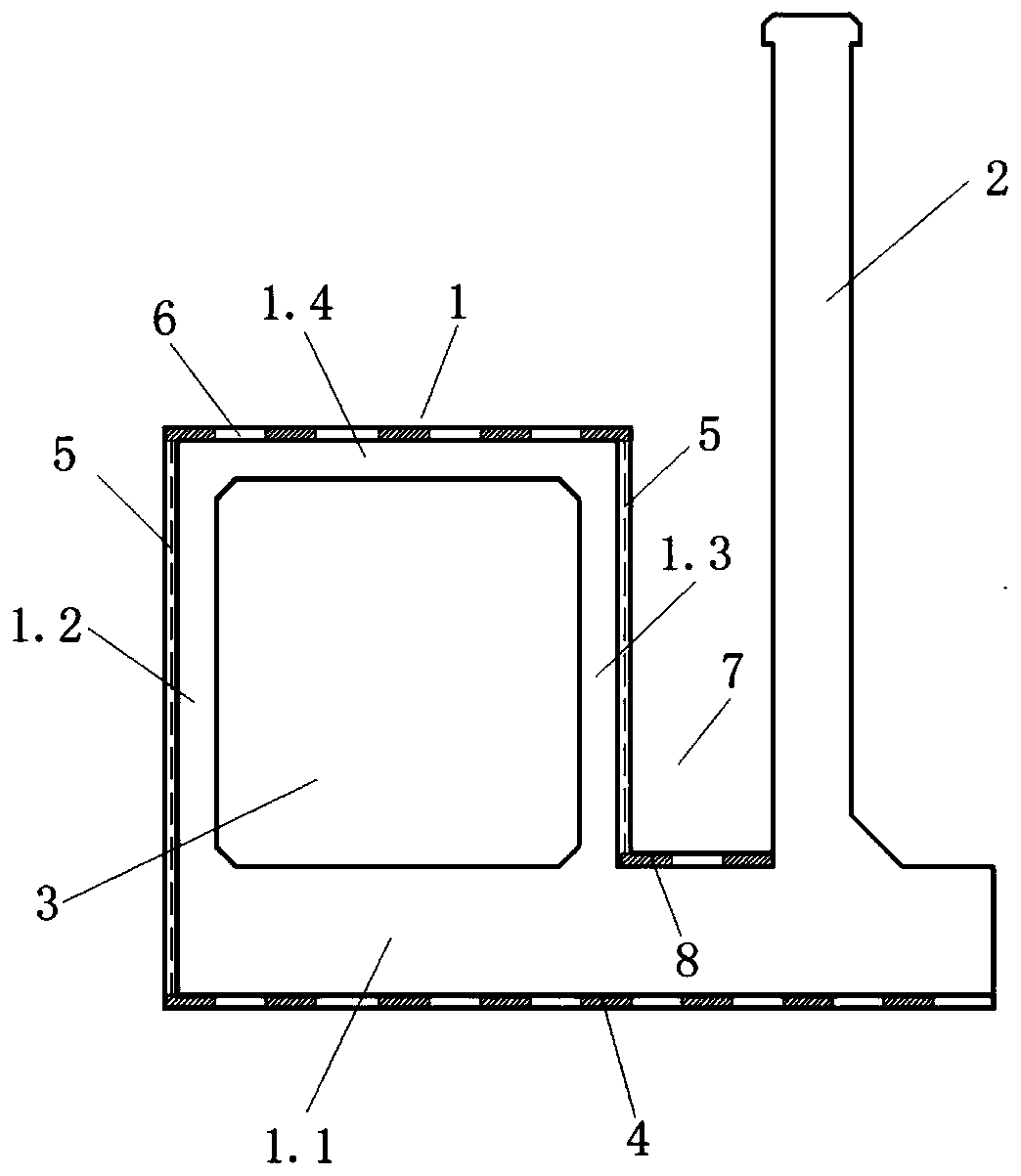

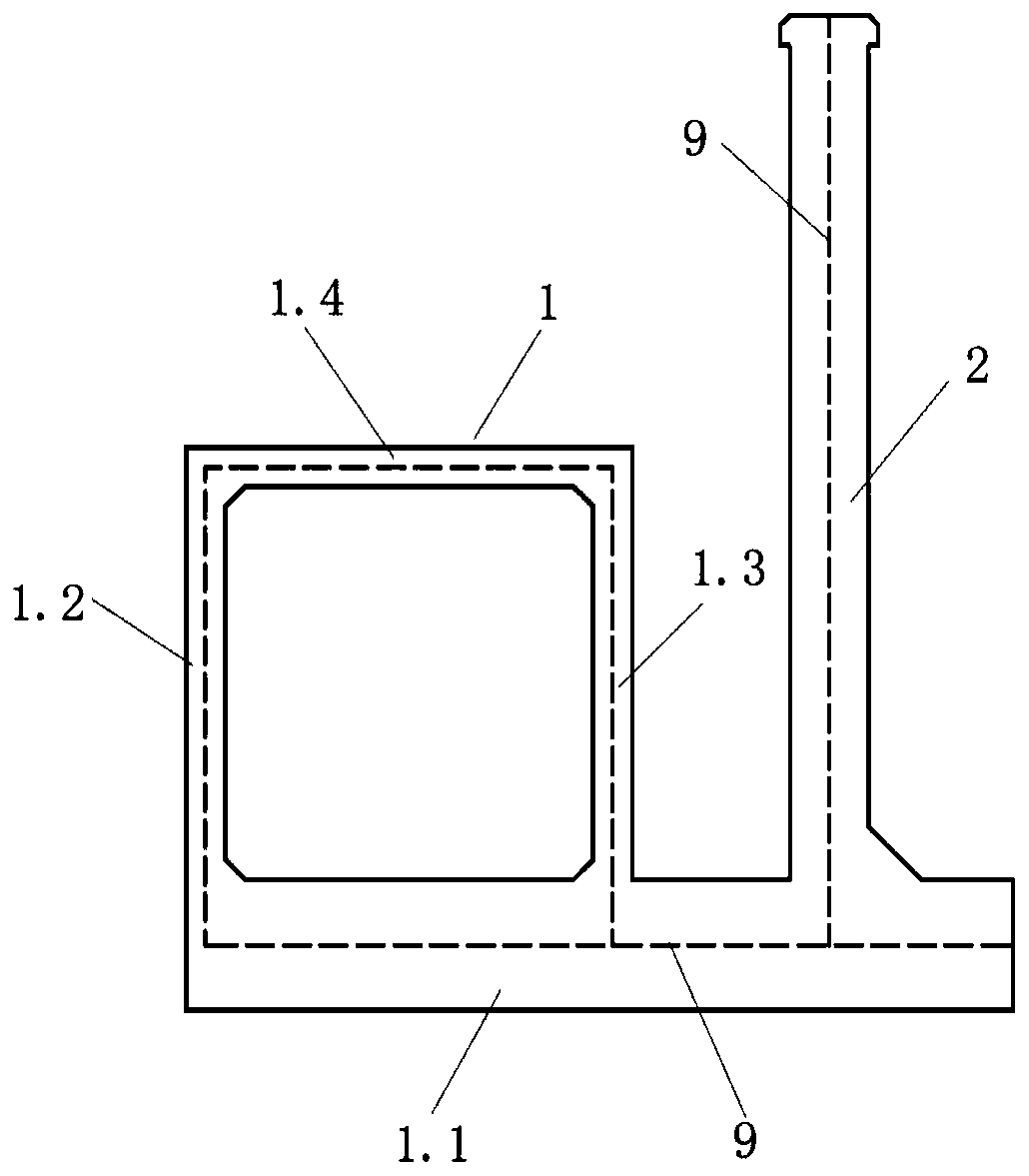

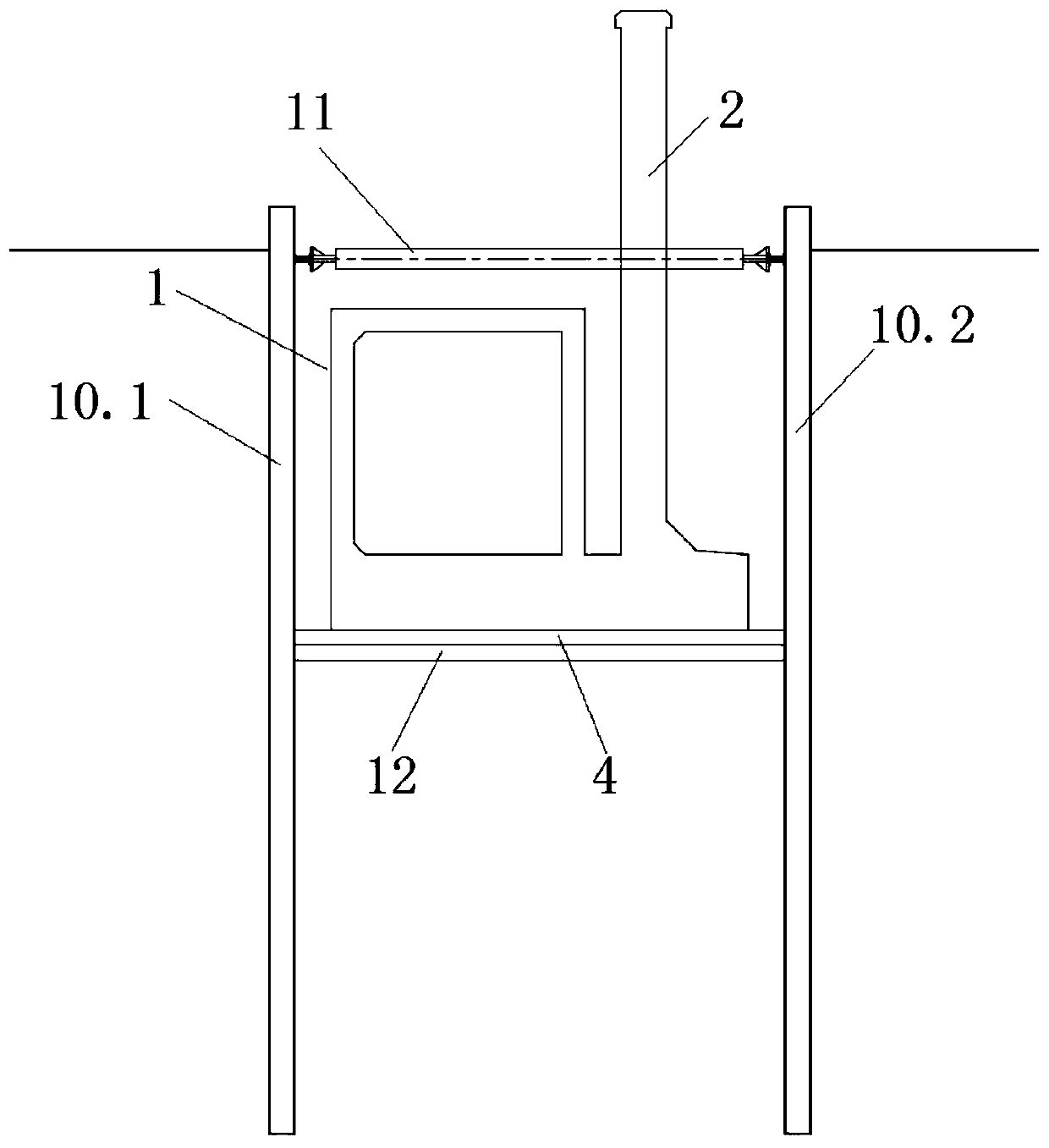

Electric power pipe rack and anti-flooding wall co-building structure and construction method thereof

PendingCN110306595AImprove securityImprove standardsDamsArtificial islandsStructure of the EarthArchitectural engineering

The invention discloses an electric power pipe rack and anti-flooding wall co-building structure and a construction method thereof. The structure comprises an electric power pipe rack body and an anti-flooding wall; the electric power pipe rack body comprises a bottom plate, a first pipe rack side wall, a second pipe rack side wall and a pipe rack top plate; the first pipe rack side wall is arranged on the side in the width direction of the bottom plate; the anti-flooding wall is arranged on the other side in the width direction of the bottom plate; the second pipe rack side wall is arranged on the middle portion of the bottom plate; the pipe rack top plate is arranged on the top face between the first pipe rack side wall and the second pipe rack side wall; and a hollow channel for a pipeline to pass through is defined among the bottom plate, the first pipe rack side wall, the pipe rack top plate and the second pipe rack side wall. The structure intensively utilizes the city building land, improves the electric power pipe rack building safety and standard, shortens the construction period, reduces the engineering investments and reduces disassembling of rooms for along-the-line dike management.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

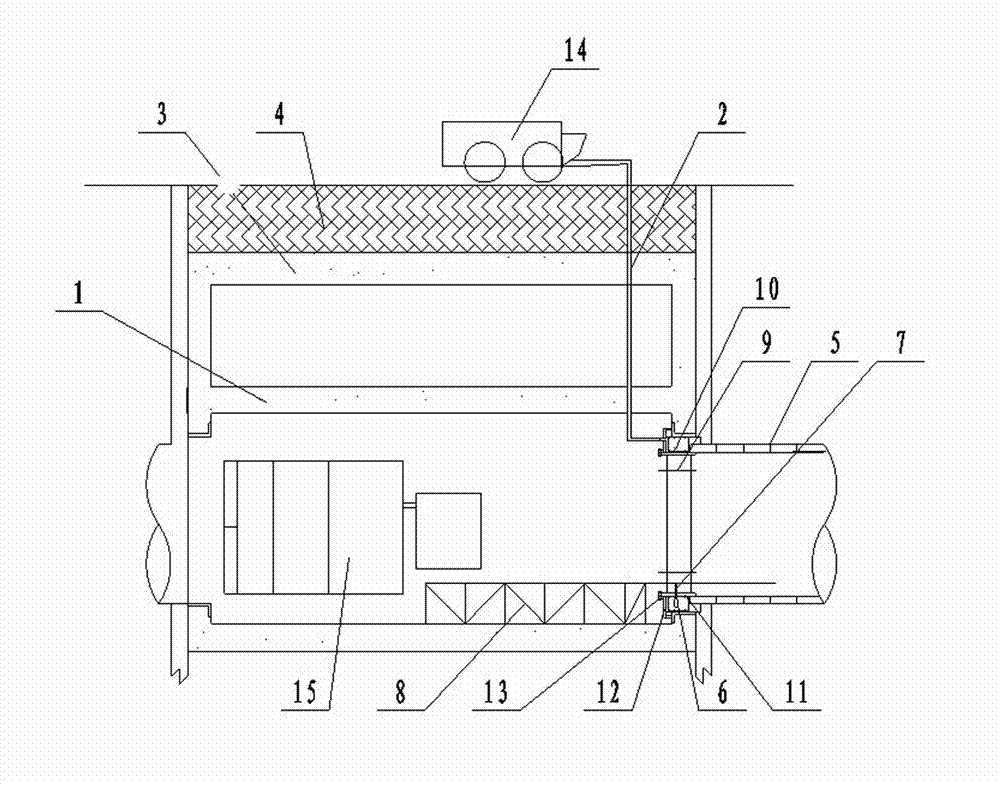

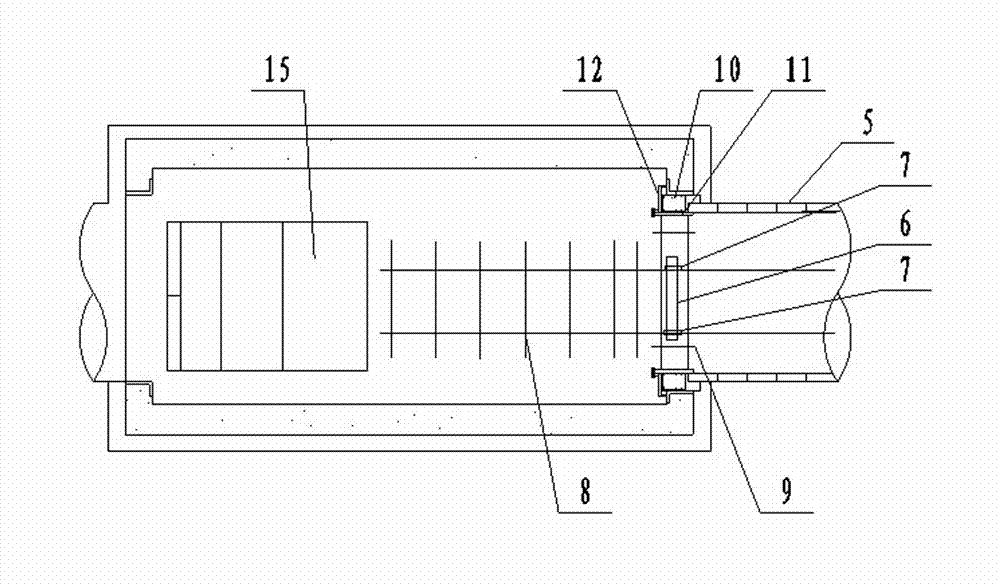

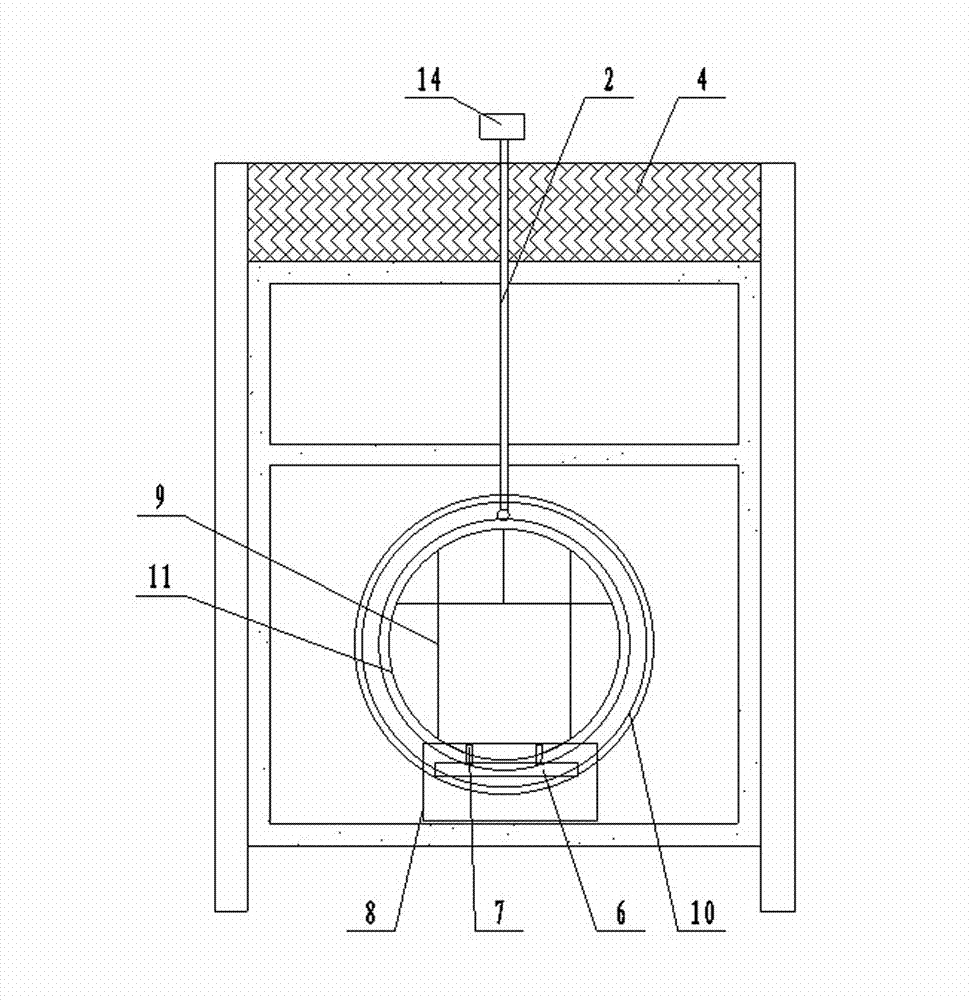

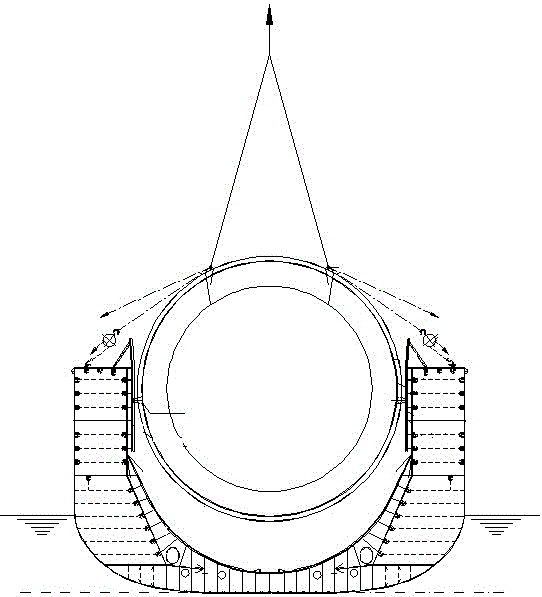

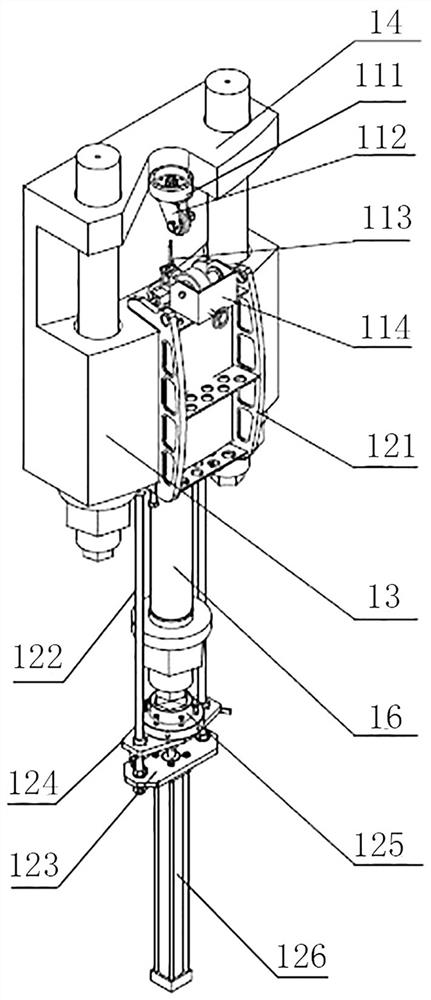

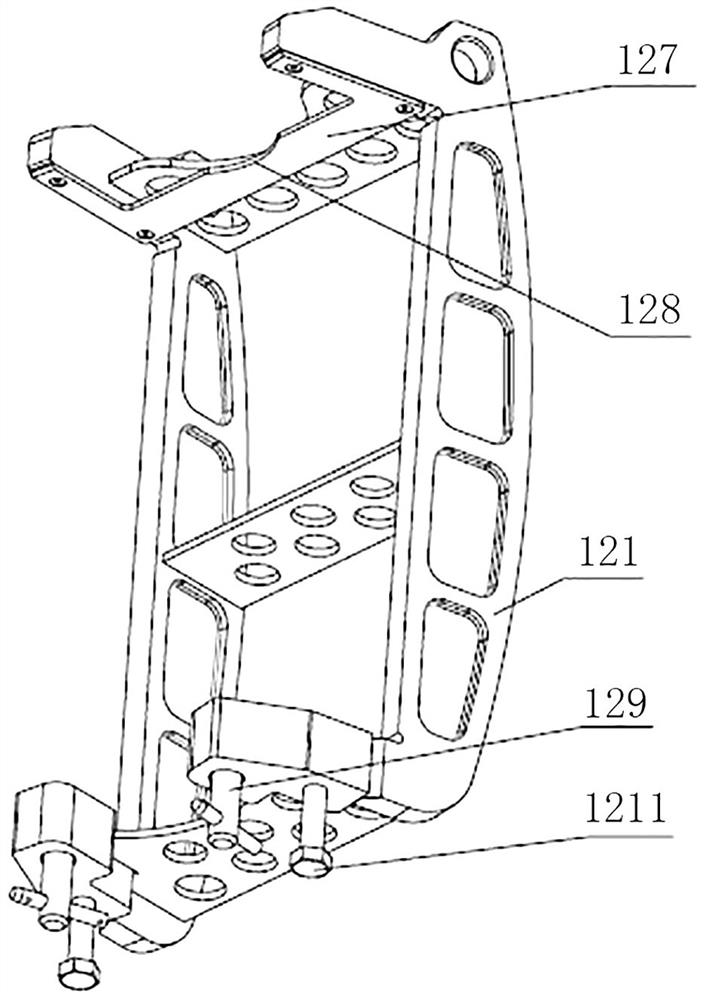

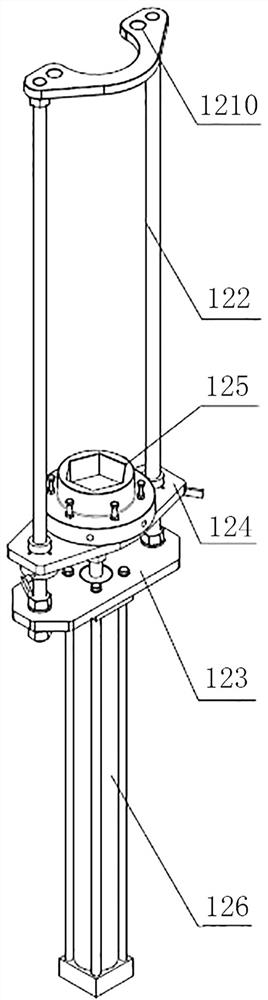

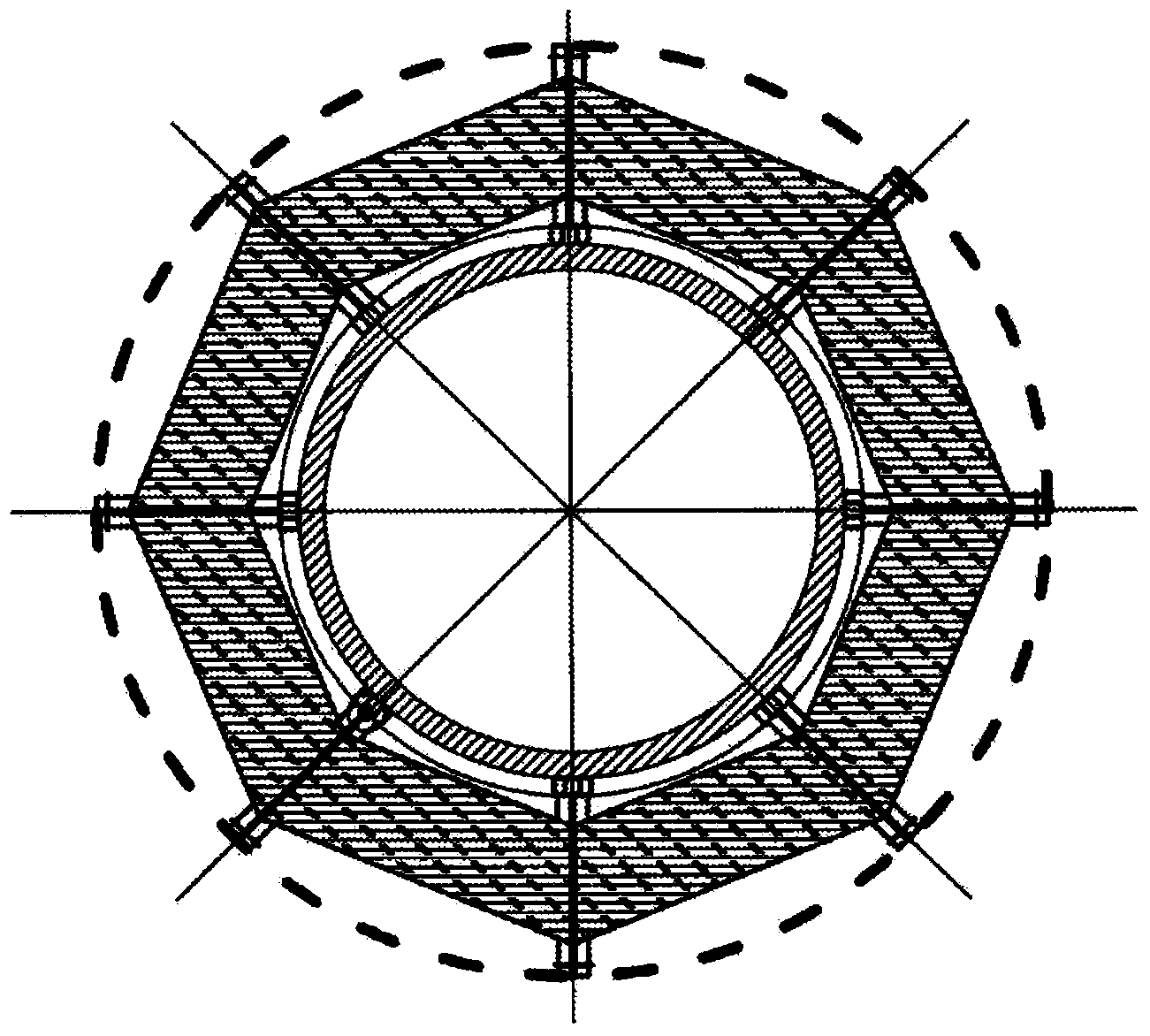

Radioactive environment large-scale shield main pump integral dismantling device and dismantling process

InactiveCN111963486ASave critical path timeReduce disassemblyPump componentsPortable grinding machinesNuclear engineeringNuclear power

The invention provides a radioactive environment large-scale shield main pump integral dismantling device and dismantling process and belongs to the technical field of nuclear power station large-scale shield main pump maintenance. The radioactive environment large-scale shield main pump integral dismantling device comprises a main bolt pneumatic disassembling and assembling tool, an upper C-typering internal residual liquid draining tool, an upper C-type ring cutting tool, a pump case shielding protective tool and an impeller shielding and rotor locking tool. The radioactive environment large-scale shield main pump integral dismantling device is easy to operate and capable of safely and efficiently completing dismantling of a large-scale shield main pump.

Owner:SANMEN NUCLEAR POWER CO LTD

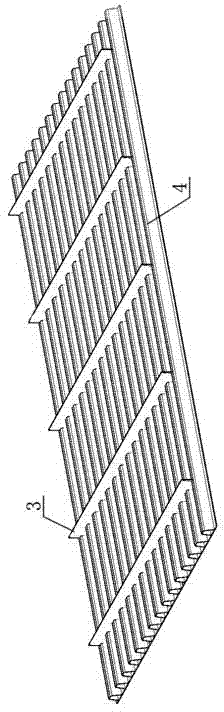

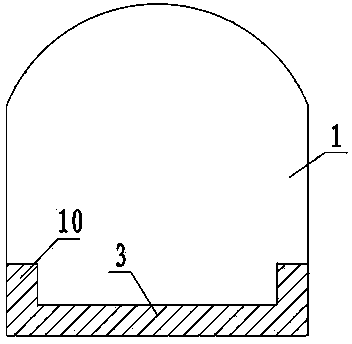

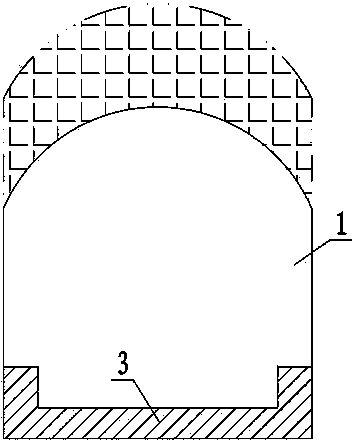

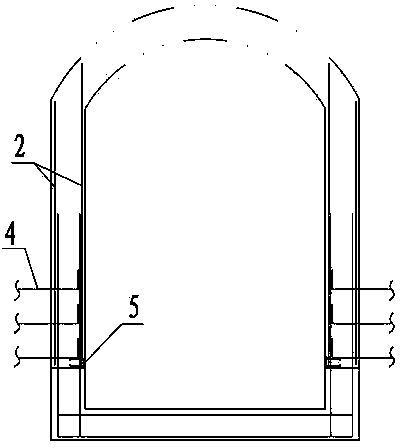

Modular removable thermal insulation

InactiveCN104321579ASimplify the installation processReduce demolitionThermal insulationNuclear energy generationNuclear powerThermal insulation

The present invention relates generally to the thermal insulation technology, and more particularly to a thermal insulation for equipment at nuclear power plants (NPPs). The advantages of the present invention includes the widening of the field of application; the simplification of both installation and dismantling of the thermal insulation modules; an increase in the isothermality of an equipment to be thermally insulated; a uniform distribution of a temperature field within the thermal insulation volume along the length thereof; and the possibility of monitoring the state of the equipment body without need to remove the thermal insulation modules.

Owner:鲍里斯·弗拉基米劳维奇·柯拉基诺夫

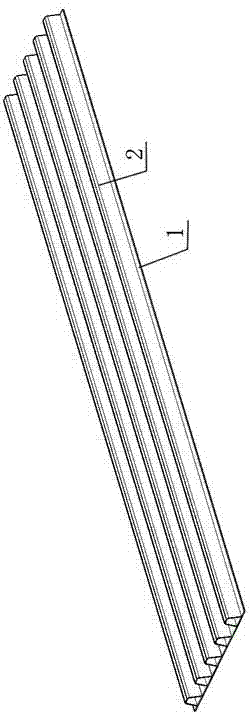

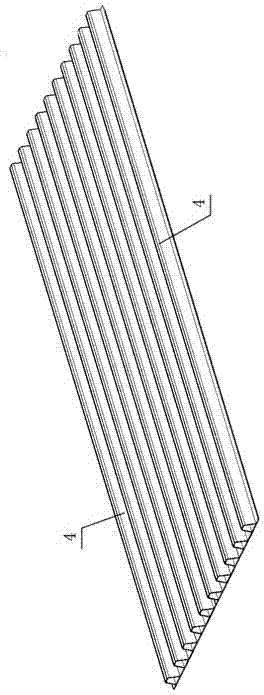

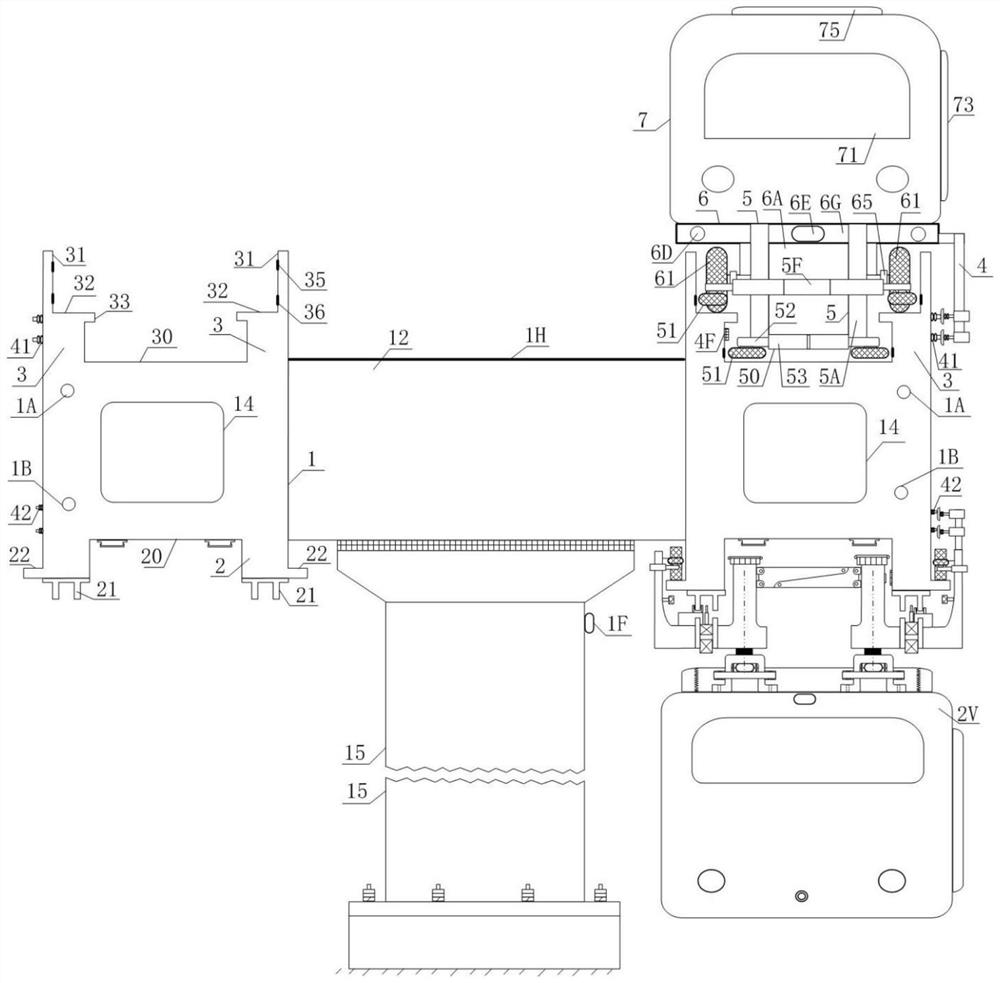

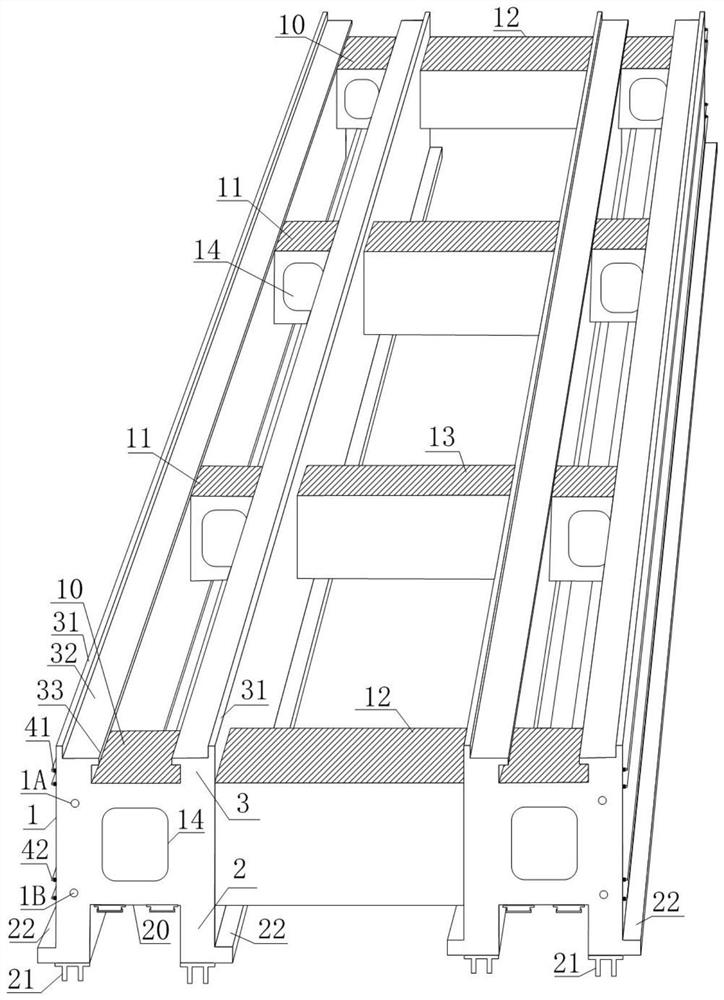

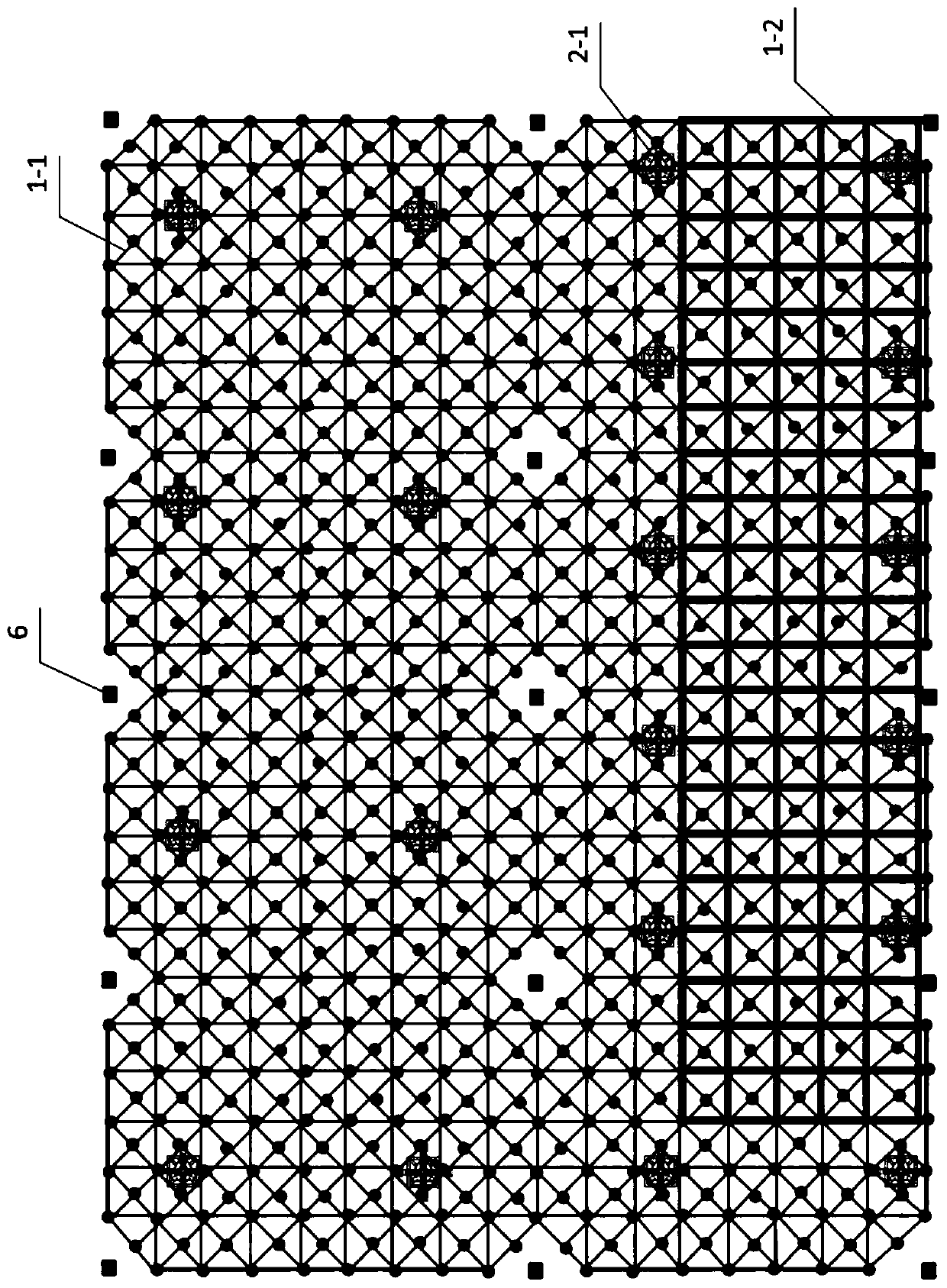

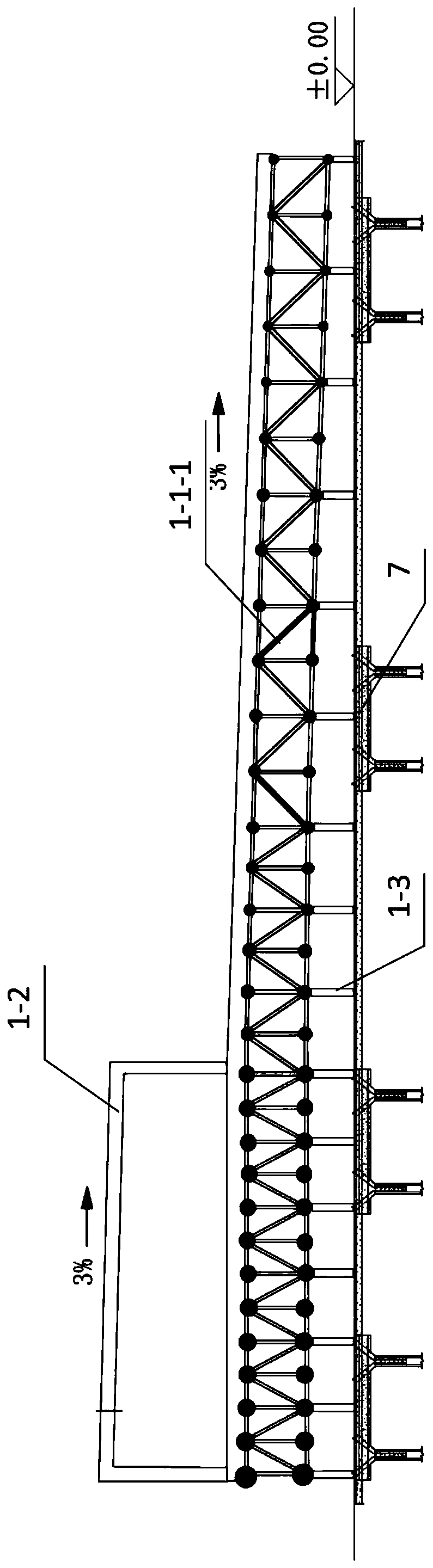

High-speed bus public transportation system based on composite special-shaped flange track

PendingCN114872747ALight weightEmission reductionElectrodynamic brake systemsRailway system combinationsLogistics managementMechanical engineering

The invention relates to a high-speed bus public transportation system based on a composite special-shaped flange track, in particular to an unmanned high-speed bus public transportation system based on an upper composite special-shaped flange track and a lower composite special-shaped flange track of an H-structure base beam (1), which comprises a composite special-shaped flange track system, a high-speed bus and an operation central cloud platform, the invention provides a three-dimensional intelligent traffic solution that the urban up-and-down three-dimensional rail high-speed bus and high-speed intelligent logistics system share the rail.

Owner:山东启和云梭物流科技有限公司

Large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method

ActiveCN110820950AReduced ground assembly heightGuaranteed installation qualityLifting framesBuilding constructionsButtressArchitectural engineering

The invention discloses a large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method. The method comprises the following steps that 1, acorresponding number of jacking foundations are constructed on a terrace according to a plurality of set jacking point locations; 2, after the terrace is hardened, ground splicing and acceptance inspection of combined steel structures are performed; 3, jacking equipment is installed, and jacking is performed; 3.1, ground assembling of crossed joists is performed on the multiple set jacking pointlocations; 3.2, the crossed joists are lifted to the positions of net rack upper chord balls; 3.3, hemispherical hinged supports are concentrically welded to the bottoms of the crossed joists; 3.4, the combined steel structures achieve supporting conversion from net rack lower chord balls supported by buttresses to the net rack upper chord balls supported by jacking frames through a jack; 3.5, synchronous jacking is performed; 3.6, supplementing and splicing installing of net rack support position balls and connecting rod pieces thereof can be performed, and then the whole structure falls backin position. Overhead operation can be greatly reduced, and safety and reliability are achieved.

Owner:中建六局第一建设有限公司 +1

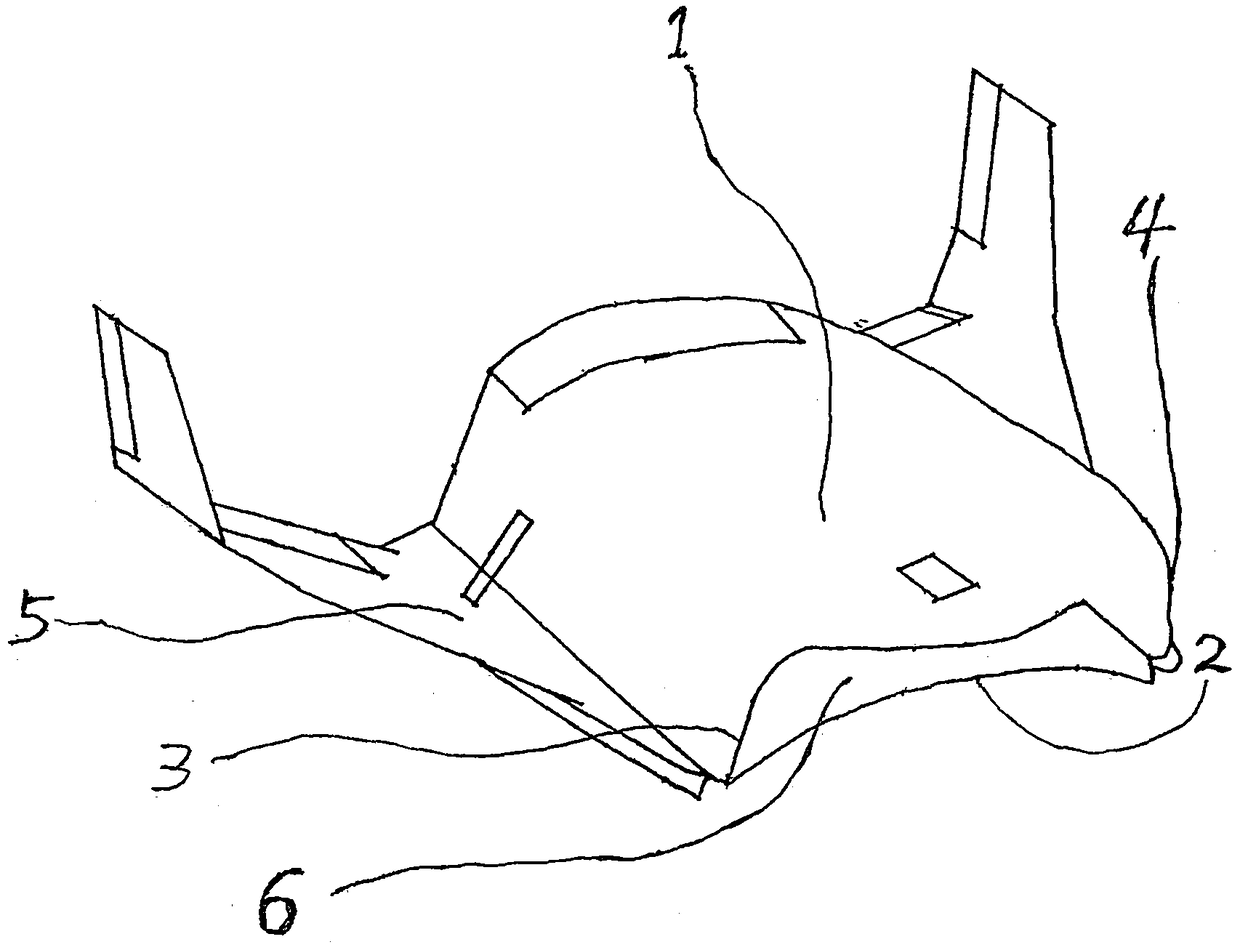

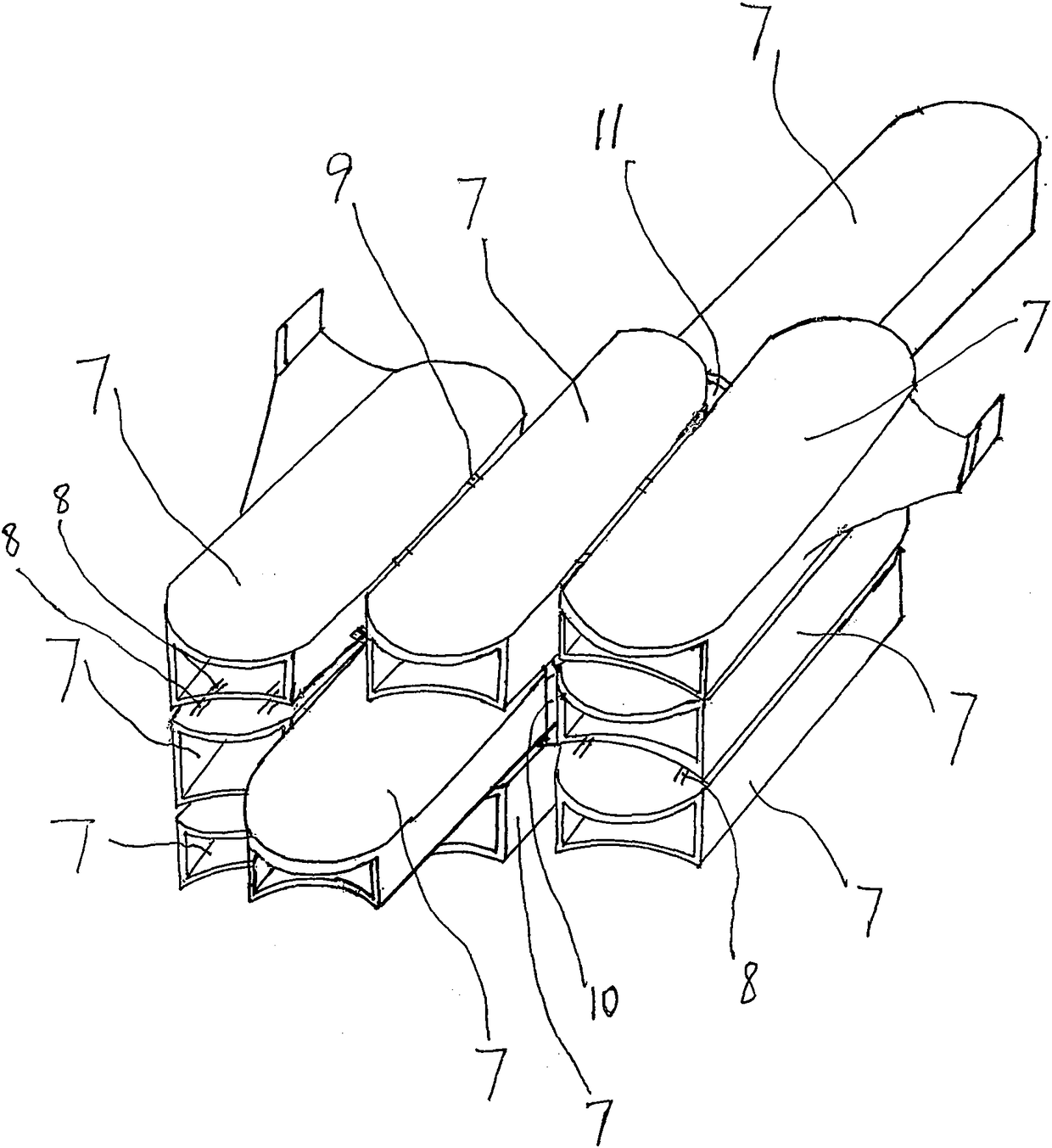

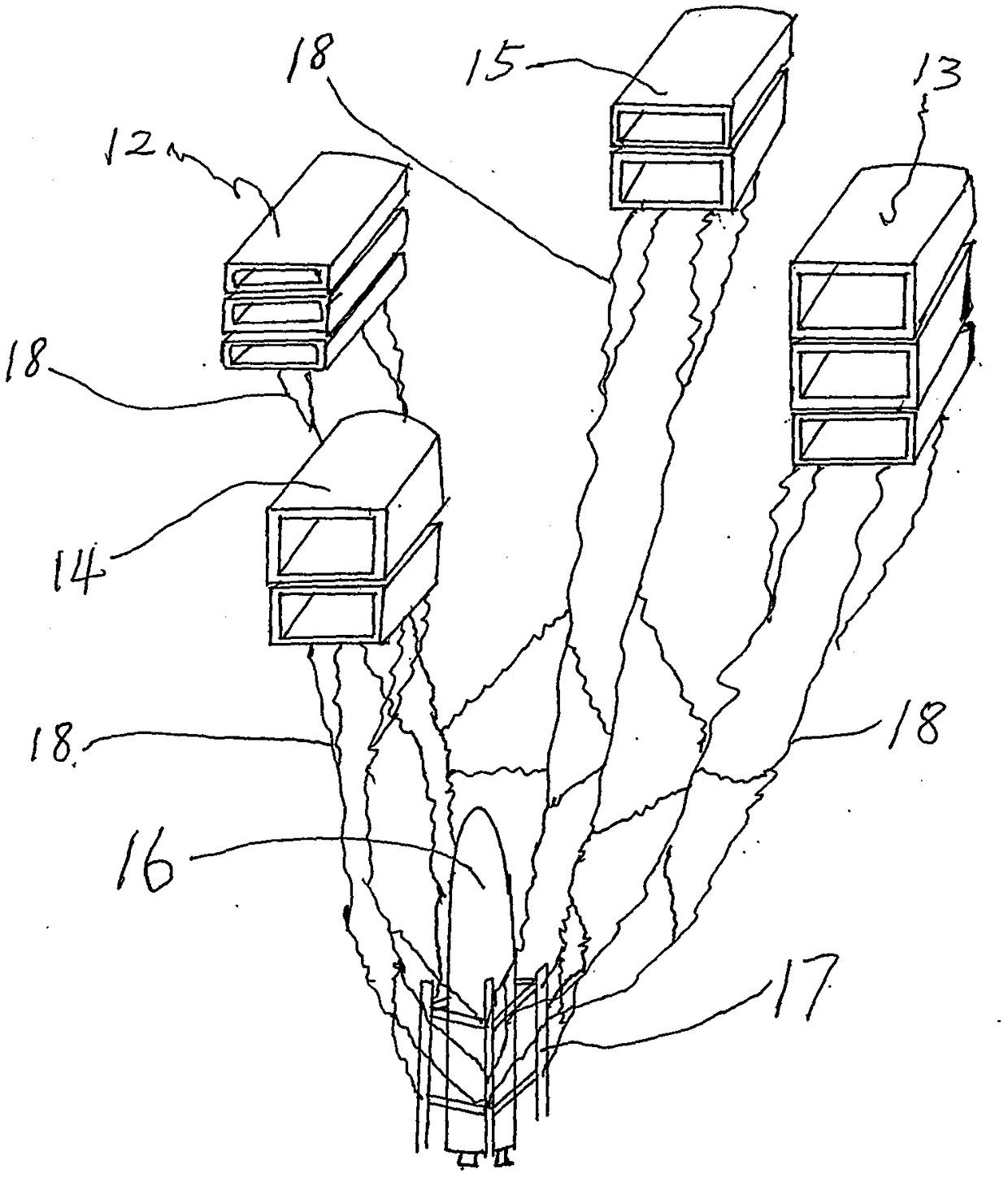

Large airship composed of multiple airships and airship ring rotationally flying around earth

Disclosed are a large airship composed of multiple airships and an airship ring rotationally flying around the earth. The invention provides two types of aviation air vehicles composed of multiple airship units and with the performance improved by times and relates to the large airship and a whole circle of the airship ring rotationally flying around the whole earth in the air like a hula hoop, wherein a forward and backward two-way electric drive vacuum pipeline high-speed train passenger and cargo transportation system is arranged in the airship ring, and the system can be used for metropolis ground passenger transportation as well; the whole airship ring can be added and expanded, and the local structures of the airship ring can be separated and connected again; the large airship and the airship ring are used for climate and air temperature manual control, air residence and sightseeing, sunshine power generation and wind power generation, the large airship is composed of ten airships, the airship ring is composed of tens of thousands of airships, and the energy consumption and exhaust pollution of each airship are much lower than those of an airplane.

Owner:杨福顺

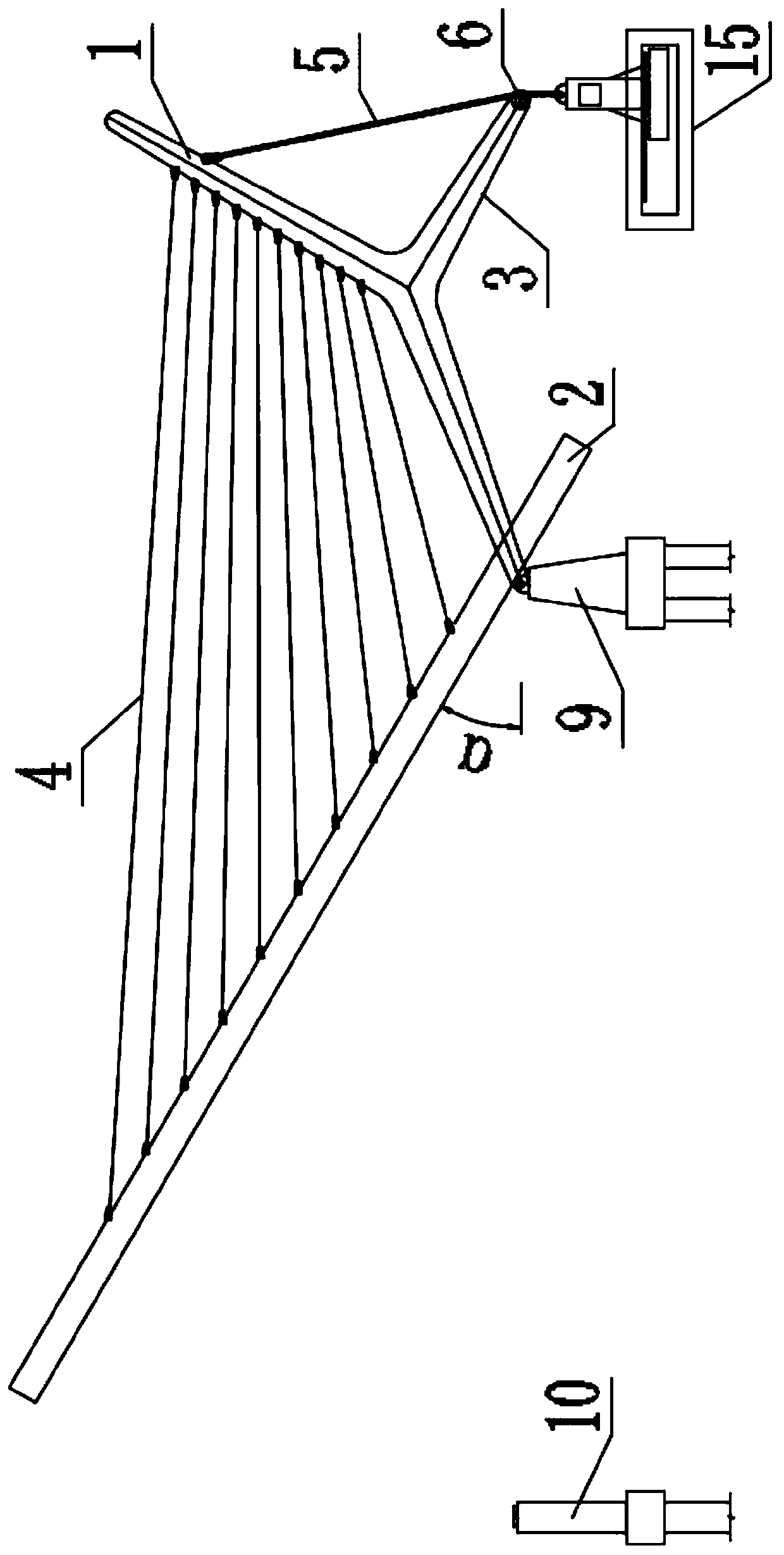

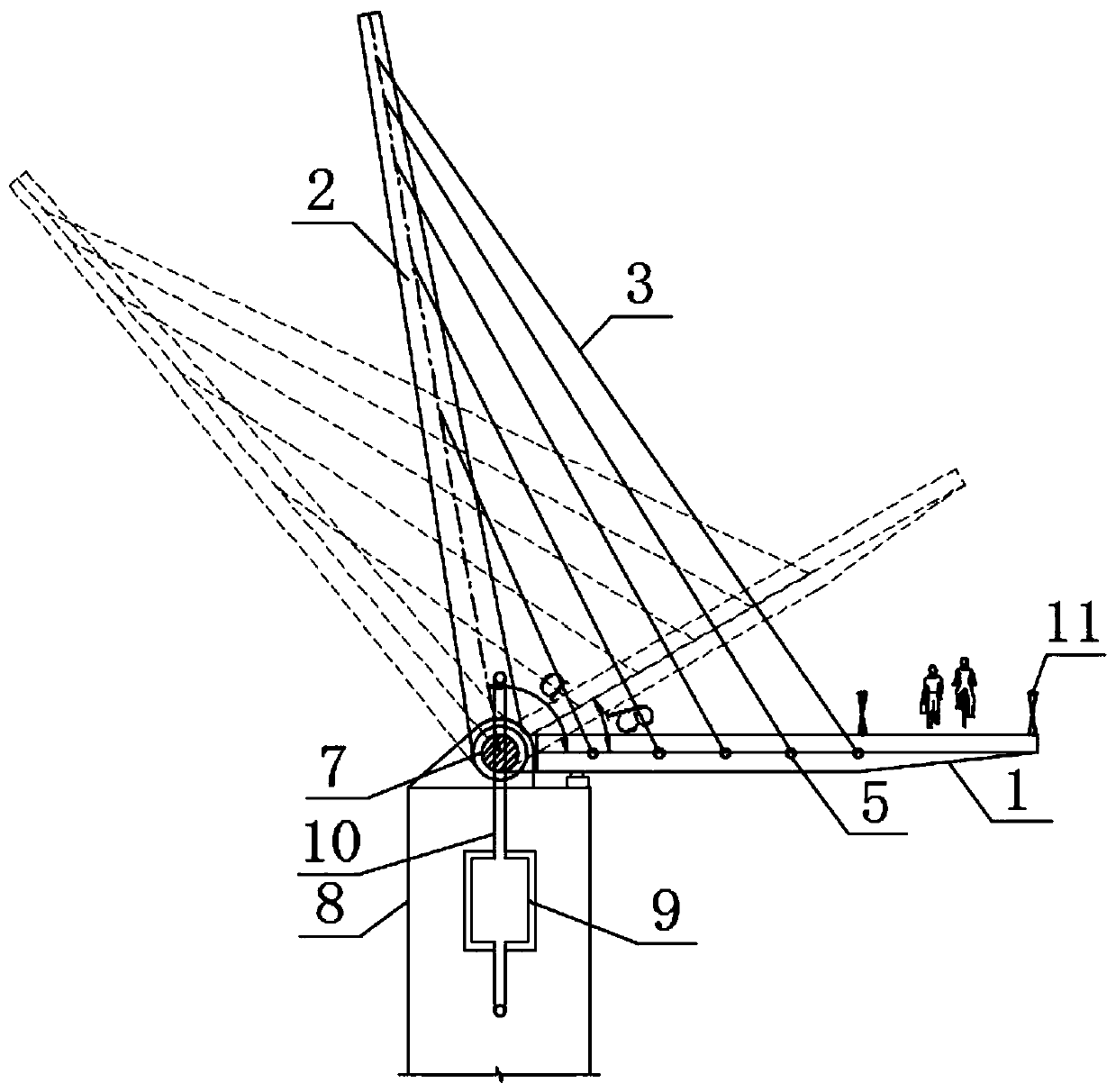

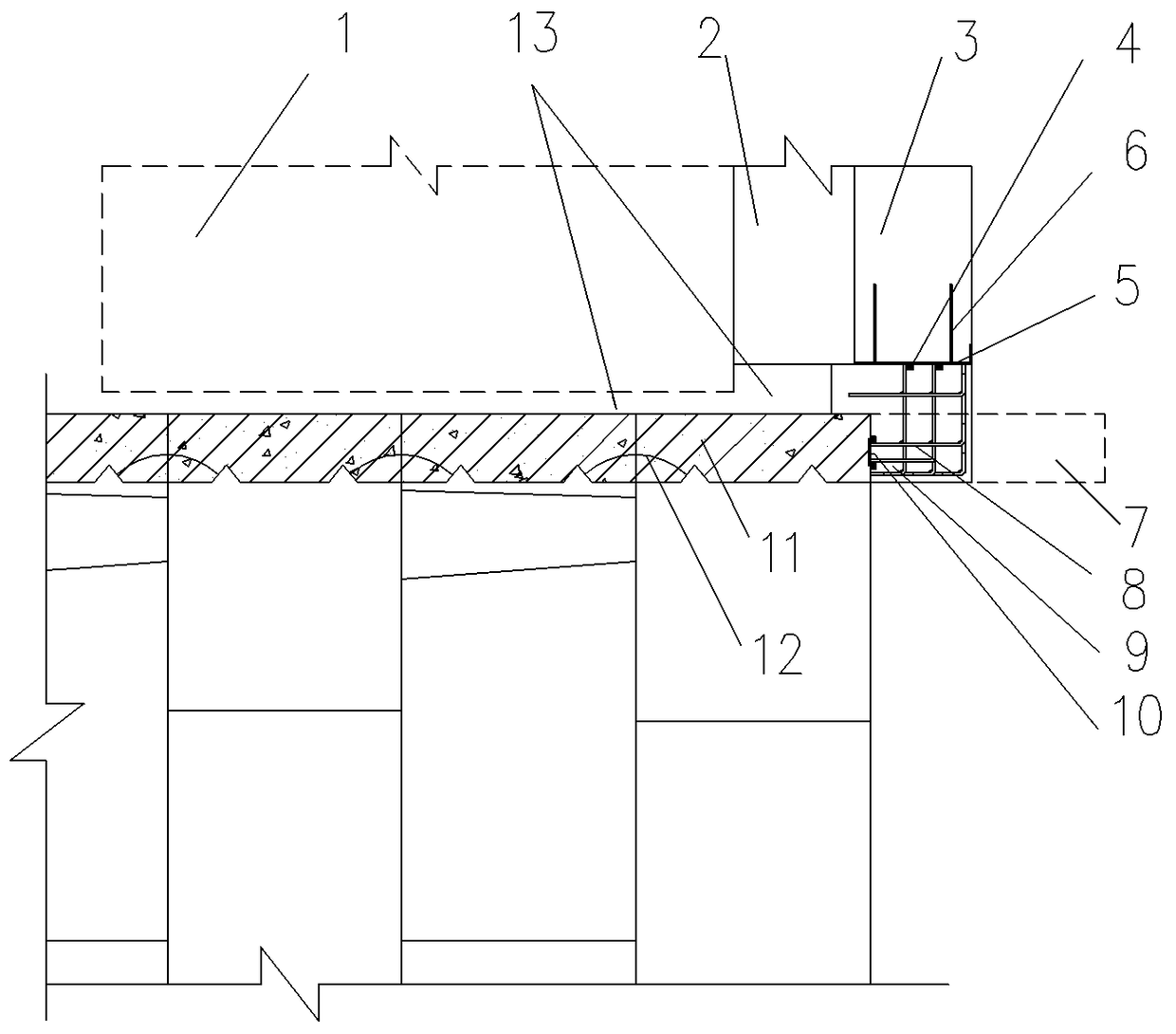

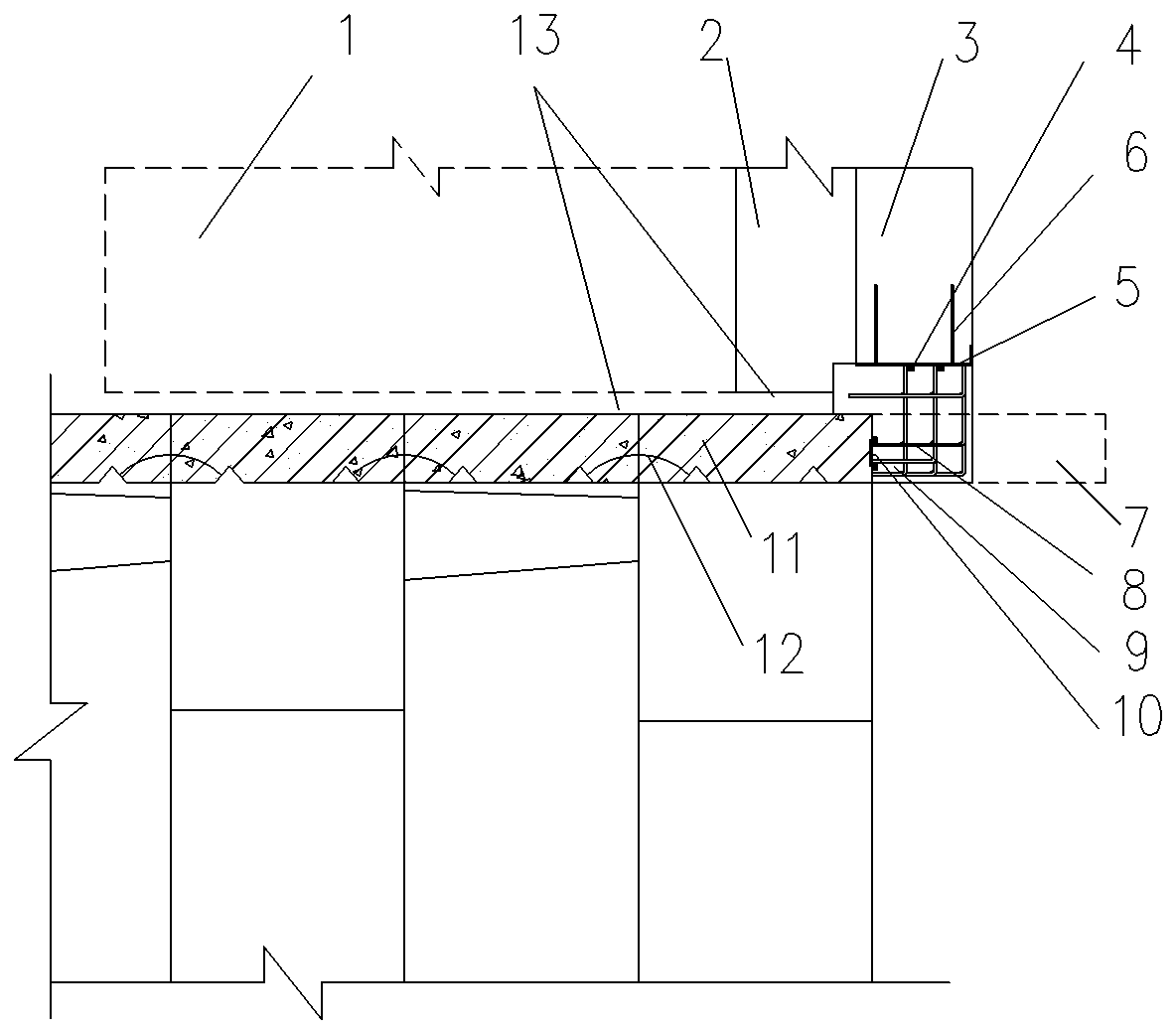

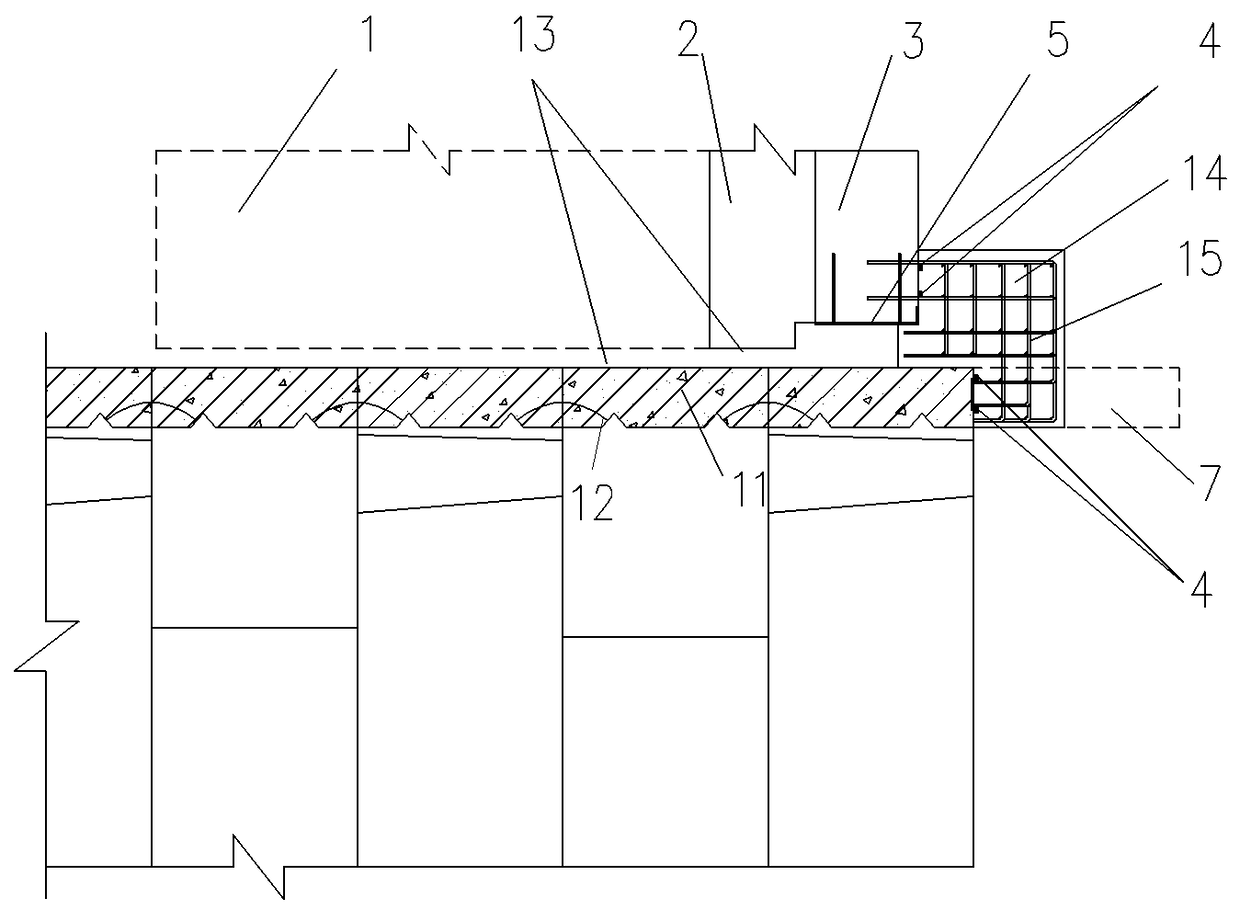

Folding-tower-type cable-stayed bridge with openable deck

The invention discloses a folding-tower-type cable-stayed bridge with an openable deck. The bridge comprises a steel folding tower, a steel main beam, a rotation system, an anchor sliding system, a concrete main pier and a concrete side pier, wherein the rotation system comprises a stay cable, a folding tower back cable, a tower cable rotating hinge, a back cable tensioning system device, a beam pier rotating hinge and a tower pier rotating hinge, the anchor sliding system comprises a movable anchoring structure, a horizontal movable box chamber, a horizontal steel slide way and a tetrafluoroethylene steel slide block, the front surface of the steel folding tower is connected with the steel main beam through the stay cable, and the back surface of the steel folding tower is connected withthe movable anchoring structure through the folding tower back cable bypassing the tower cable rotating hinge. According to the bridge, the special achieving scheme of the navigation clearance limit requirement is met, the subtle mechanical balance is achieved through the reasonable arrangement of the cables and the towers, the rotation of the steel folding tower is directly realized through vertical-direction tensioning of the folding tower back cable tensioning system device and horizontal sliding of the movable anchoring structure, and opening of the steel main beam bridge deck is indirectly realized.

Owner:广州揽睿路桥设计有限公司

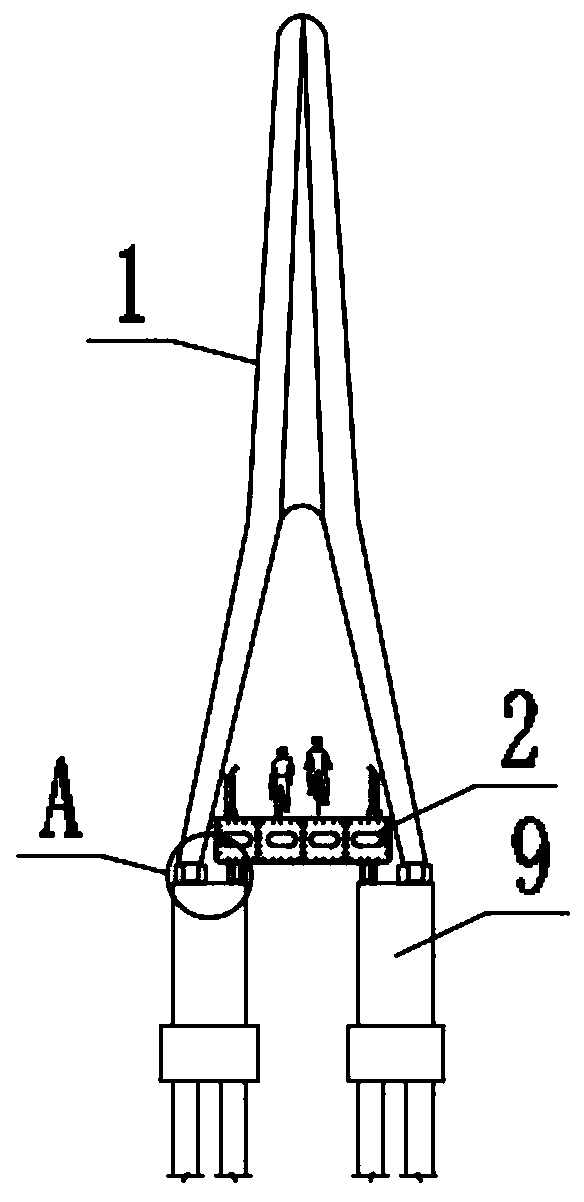

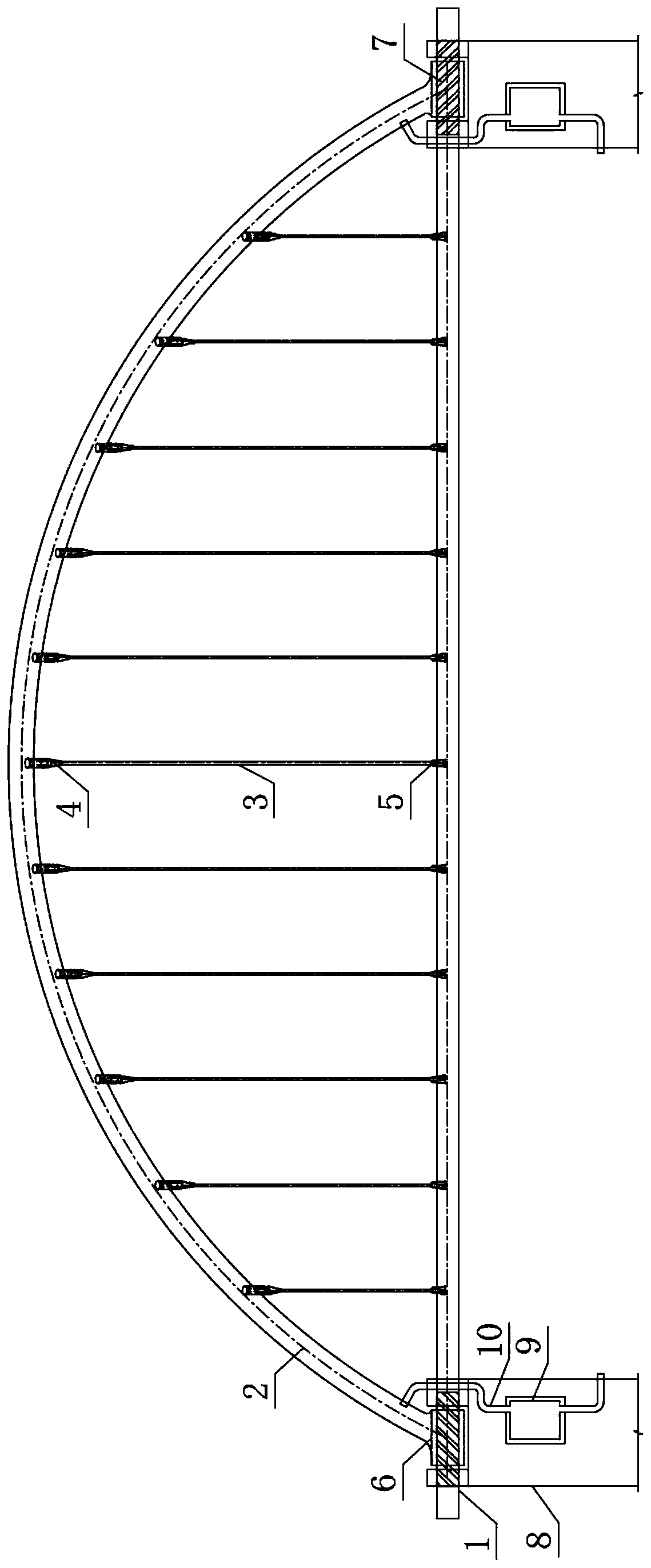

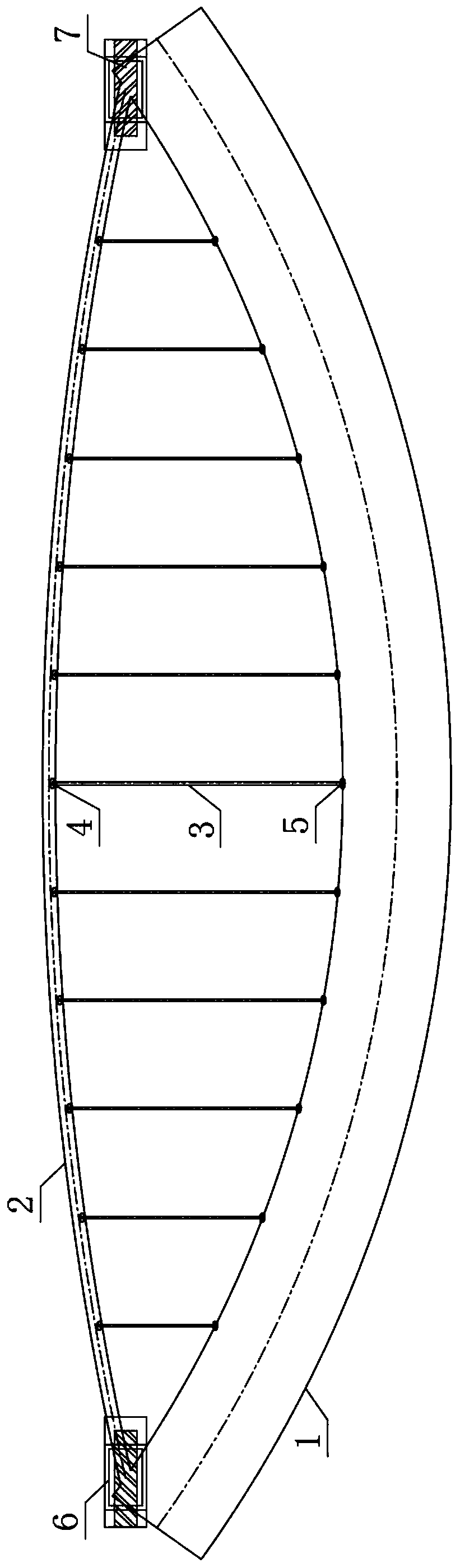

Bridge deck openable swing type inclined tied arch bridge

PendingCN110804932AMeet openAchieve openBascule bridgesBridge structural detailsArchitectural engineeringBridge deck

The invention discloses a bridge deck openable swing type inclined tied arch bridge. The bridge deck openable swing type inclined tied arch bridge comprises a curved steel main beam, an inclined steelpipe arch rib, tied arch suspenders, tied arch rotating hinges, tied arch rotating shafts, tied arch piers, an intelligent water pump device and a water pump device water pipe. The bridge deck openable swing type inclined tied arch bridge meets the special implementation scheme of the navigation clearance limit requirement, the inclined steel pipe arch rib and the curved steel main beam are connected through the multiple tied arch suspenders, the inclined steel pipe arch rib is connected with the two ends of the curved steel main beam, and the tied arch rotating hinges and the tied arch rotating shafts are arranged below the inclined steel pipe arch rib and the curved steel main beam; and the intelligent water pump device arranged in the tied arch piers pumps river water into the inclinedsteel pipe arch rib step by step, along with rising of the water level of injected water, after the gravity center of the inclined steel pipe arch rib moves to the critical value, the tied arch bridge integrally achieves automatic rotation, and therefore opening of a bridge deck is achieved.

Owner:广州揽睿路桥设计有限公司

Shield machine access hole connector processing structure and method thereof

PendingCN108119159AReduce demolitionReduce disturbanceUnderground chambersTunnel liningEngineeringStructure system

The invention relates to a shield machine access hole connector processing structure and a method thereof. As shield launching and receiving in a deep foundation pit under the special complicated geological condition has certain engineering risk, a post-poured externally-coated ring beam is constructed in a segmental lining and foundation pit range outwards from an outline of a shield access holeto the periphery to replace a traditional built-in ring beam structure. In order to disturb a access hole connector position and the periphery as little as possible and disassemble spliced duct piecesat the connector position as little as possible, the shield machine access hole connector processing structure disclosed by the invention utilizes an externally-coated ring beam type, so that bearingand sealing capacity of the spiced duct pieces and back grouting is given to full play; a balance stable structure system is utilized, the externally-coated ring beam is arranged based on the balancestable structure system to assist further receiving opening and connector sealing treatment, and structural safety and waterproof reliability at a shield machine access hole are ensured.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

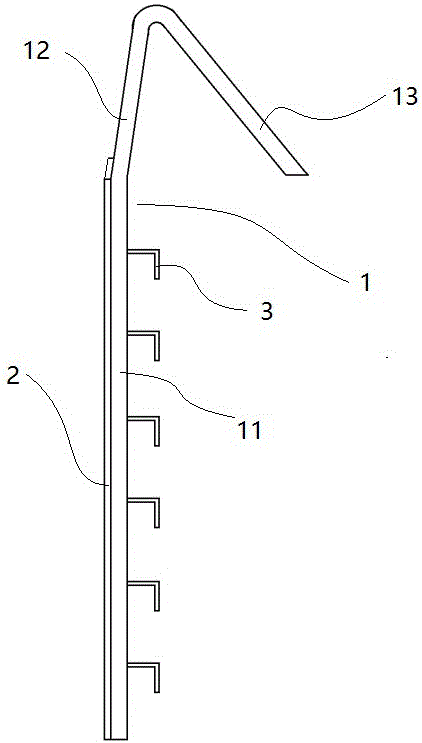

Mechanical automatic lifting slipway scaffold assembly

The invention relates to a mechanical automatic lifting platform scaffolding tool, including a mechanical hoisting device for enabling the scaffolding tool to realize translational movement along the horizontal direction, and for hoisting and driving the hanging basket containing construction personnel to rise or fall. In the present invention, through the cooperation of the walking mechanism and the mechanical hoisting device, operations such as paint spraying, weld seam welding and grinding, and high-altitude hanging code removal at all positions of the hull plate are realized. The mechanical self-elevating scaffold is easy to use and avoids repeated times of fixed scaffold The cumbersome workload caused by erection and dismantling, and compared with the fixed hanging basket high-altitude operation, it does not require welding brackets, thus reducing the welding, dismantling, and grinding operations of the brackets. Between the above content, this device is conducive to greatly reducing on-site construction work quantity, improve construction efficiency, and reduce ship manufacturing costs.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com