Hoisting method of transmission line guyed tower shaped like Chinese character 'gan'

A hoisting method and transmission line technology, applied in the direction of transportation and packaging, towers, building types, etc., can solve the problem of hoisting platform area and flatness, high width of approach road, heavy preparation work on the construction site, large vegetation damage area, etc. problems, to achieve the effect of improving the level of construction mechanization, improving the utilization rate of mechanical equipment and construction efficiency, and controlling the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

[0031] The invention is a method for hoisting a dry-shaped guyed tower of a power transmission line, and the implementation process includes the following steps:

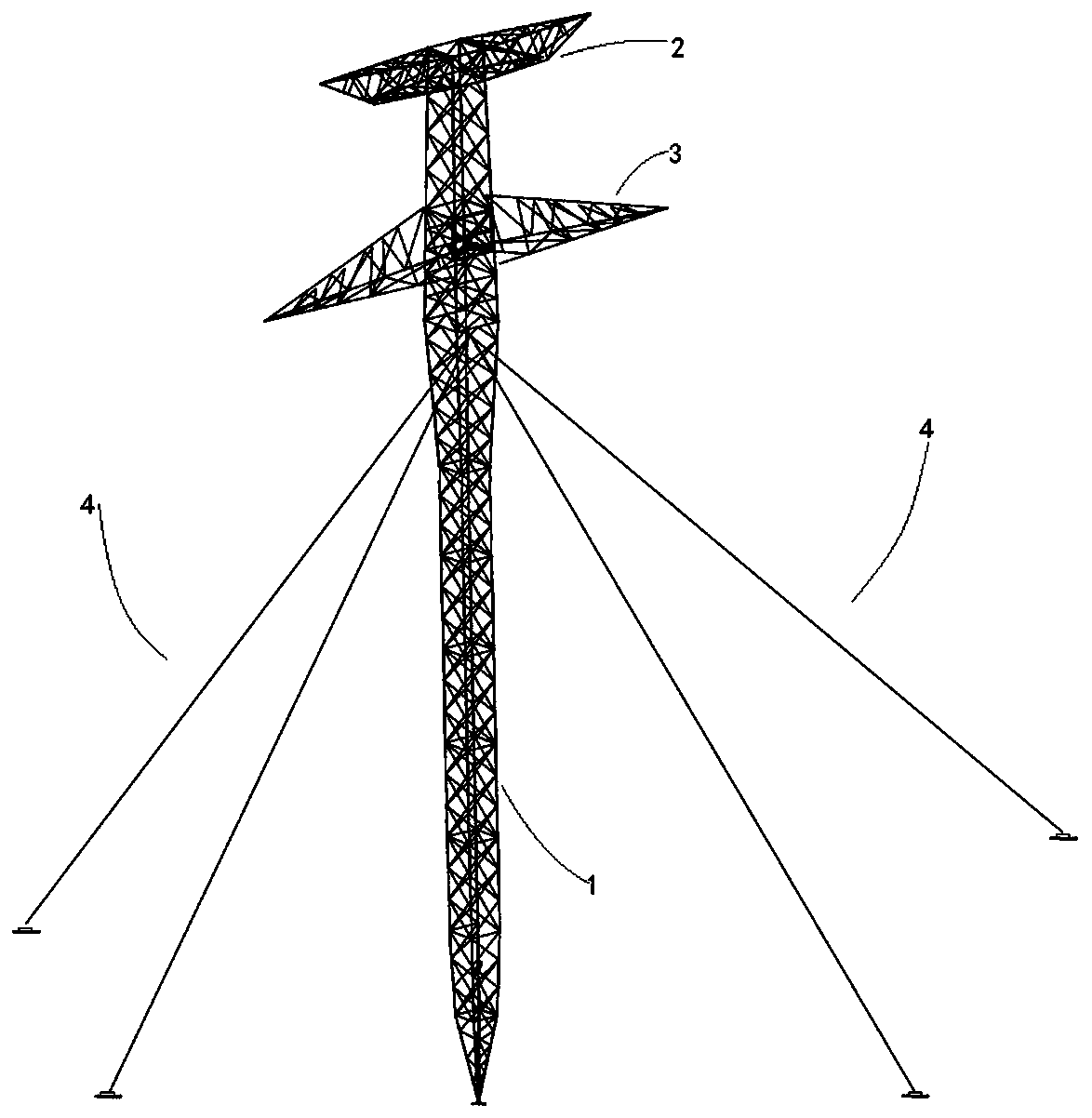

[0032] S1. Ground assembly: transport the tower materials to the tower position, assemble the tower body 1 and the lower cross arm 3 on the ground with a truck-mounted crane, and assemble the upper cross arm 2 directly on the top of the tower body 1. Because the connecting frame of the formal guy wire 4 protrudes from the tower body 1, two formal guy wires 4 are installed on its upward side after the tower body 1 is assembled, and two temporary guy wires are installed on its downward side;

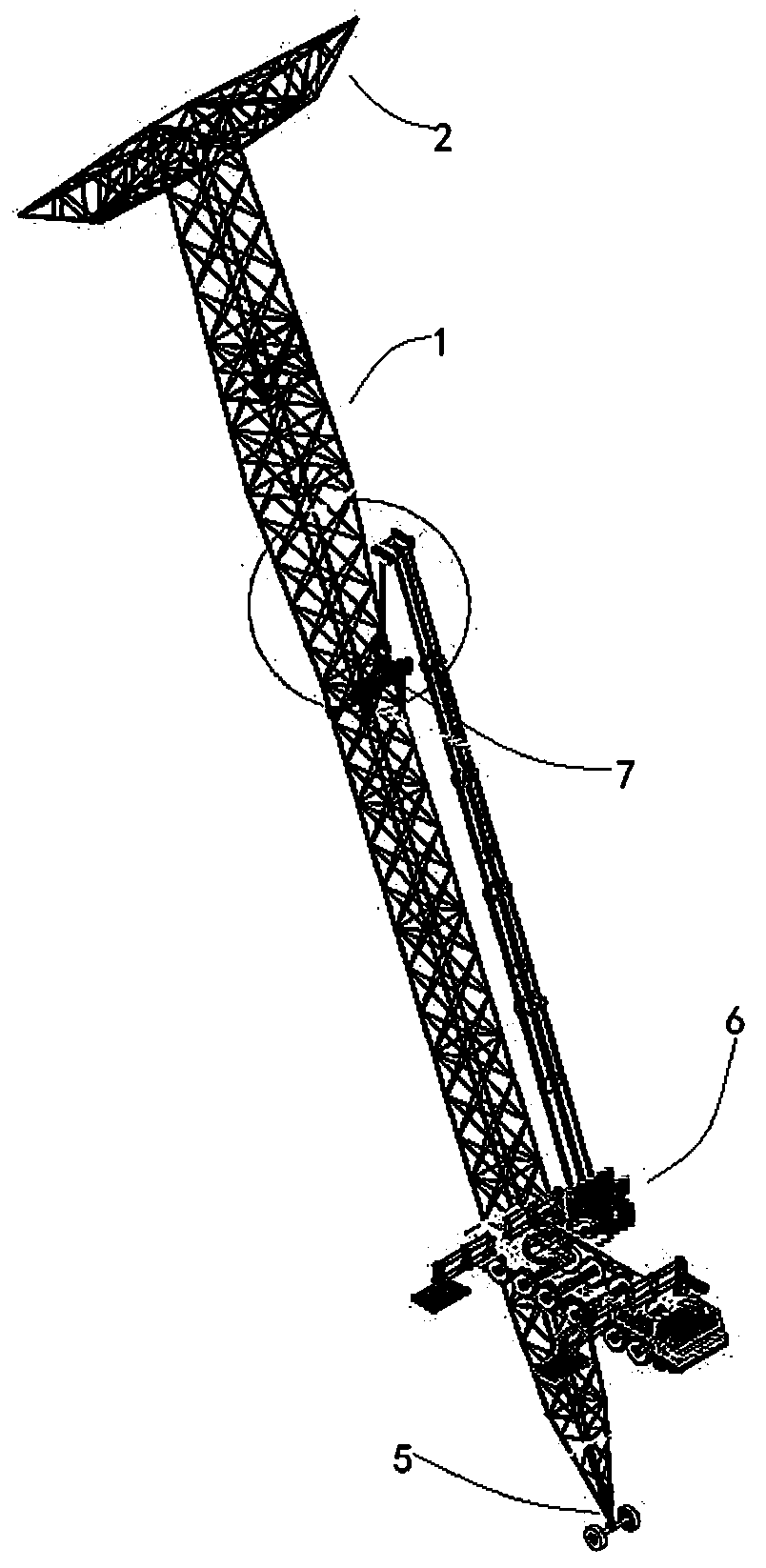

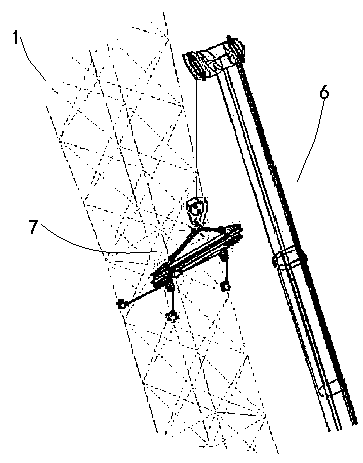

[0033] S2. Lift the tower body 1 and the upper cross arm 2: determine the lifting point on the tower body 1, and the height of the lifting point on the tower body 1 is 0.1m higher than the nominal height of the tower bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com