Alloy powder semi-continuous ingot preparation production device and production method

A technology for alloy powder and production equipment, applied in the field of production equipment for semi-continuous ingot making of alloy powder, can solve the problems of inability to realize large-scale production of alloy ingots, low production efficiency, low product performance, etc., to promote large-scale production, reduce Production energy consumption and cost, effect of tonnage reduction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

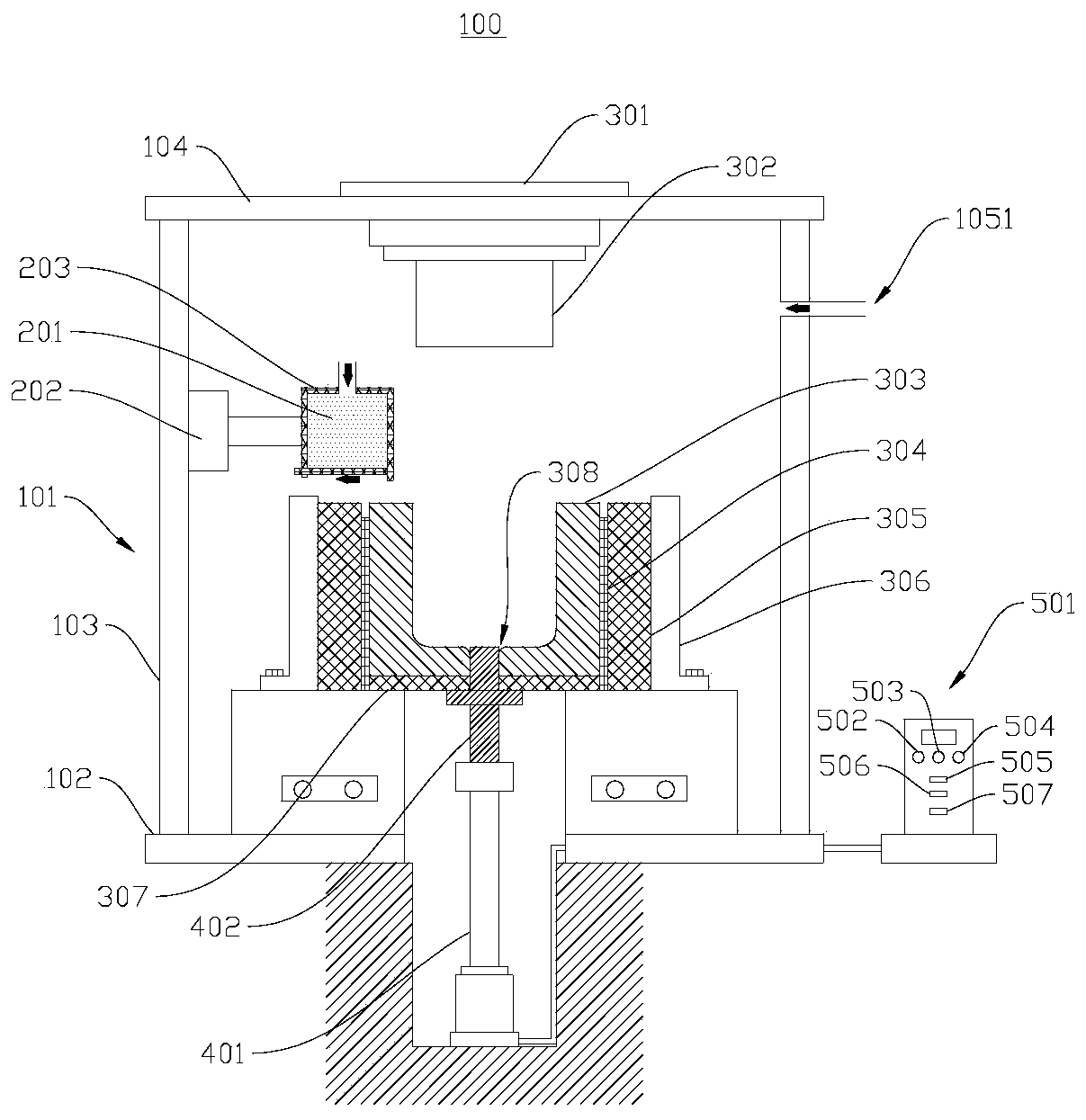

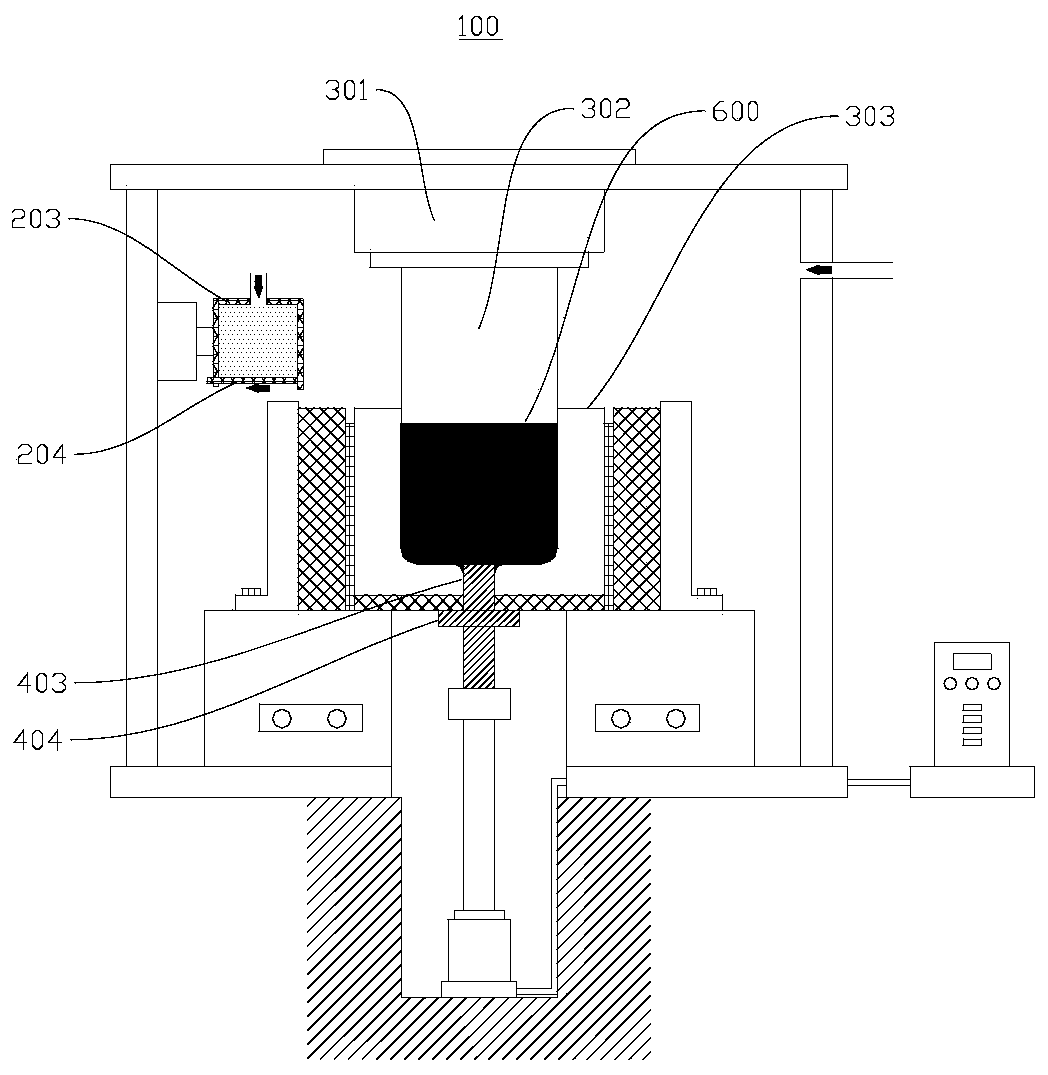

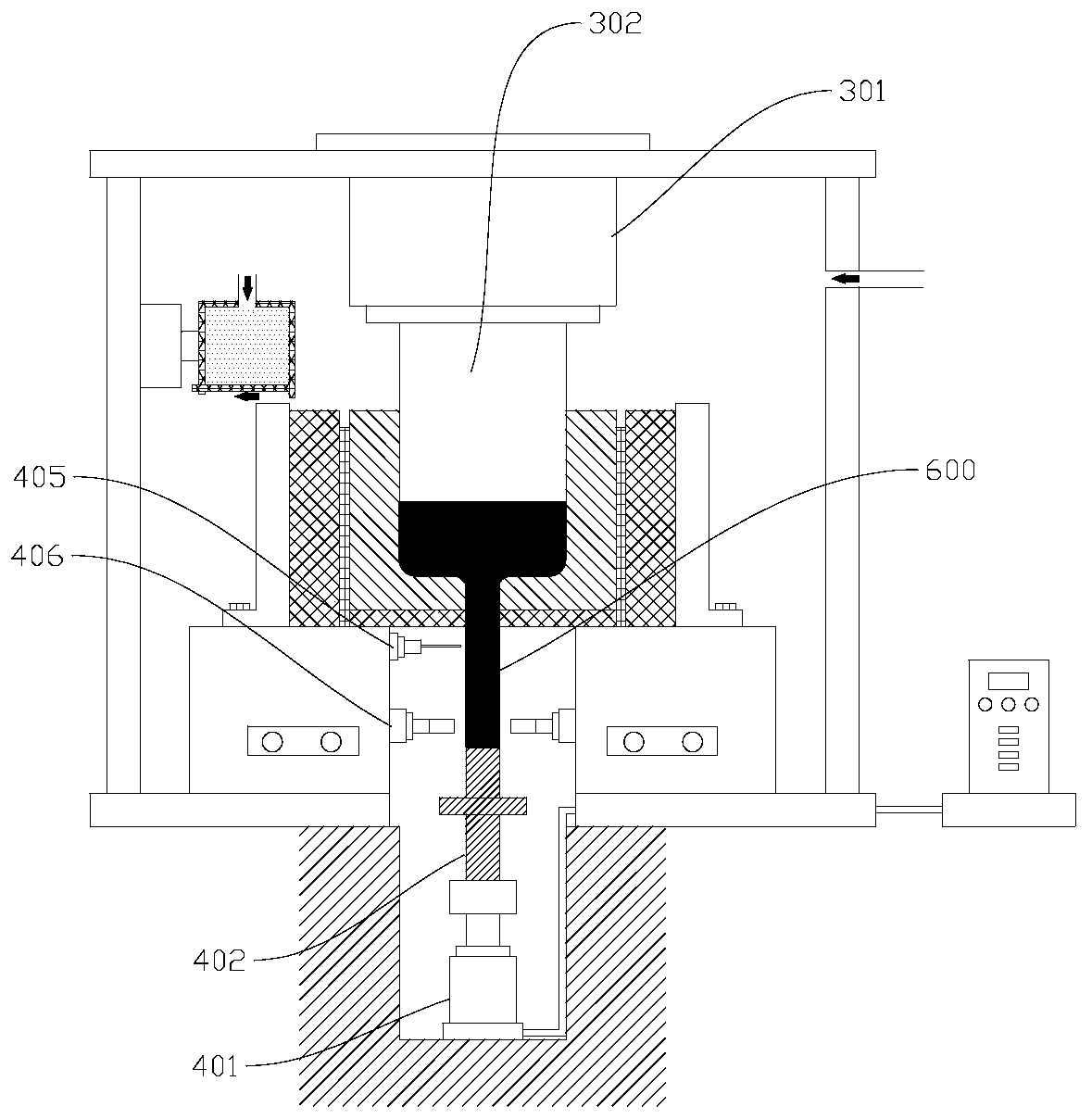

[0032] Please refer to Figures 1 to 3 , the production equipment 100 of the alloy powder semi-continuous ingot making of the embodiment of the present invention includes: a casing 101, a powder feeding system, an extrusion system and a back pressure system arranged in the casing 101, and a control powder feeding system, extrusion Electric control box 501 for system and back pressure system work.

[0033] The casing 101 of the embodiment of the present invention is a sealed casing, so that the entire production process is carried out in a sealed environment filled with inert gas, so as to prevent the alloy from reacting with oxygen during the preparation process. Such as figure 1 In the shown embodiment, the casing 101 includes a base 102 , a vertical plate 103 and a top base 104 , the base 102 is fixed on the ground, and the base 102 and the top base 104 are connected and fixed through the vertical plate 103 . The casing 101 in the figure is only for illustration, and its s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com