Patents

Literature

157results about How to "Easy to operate continuously" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

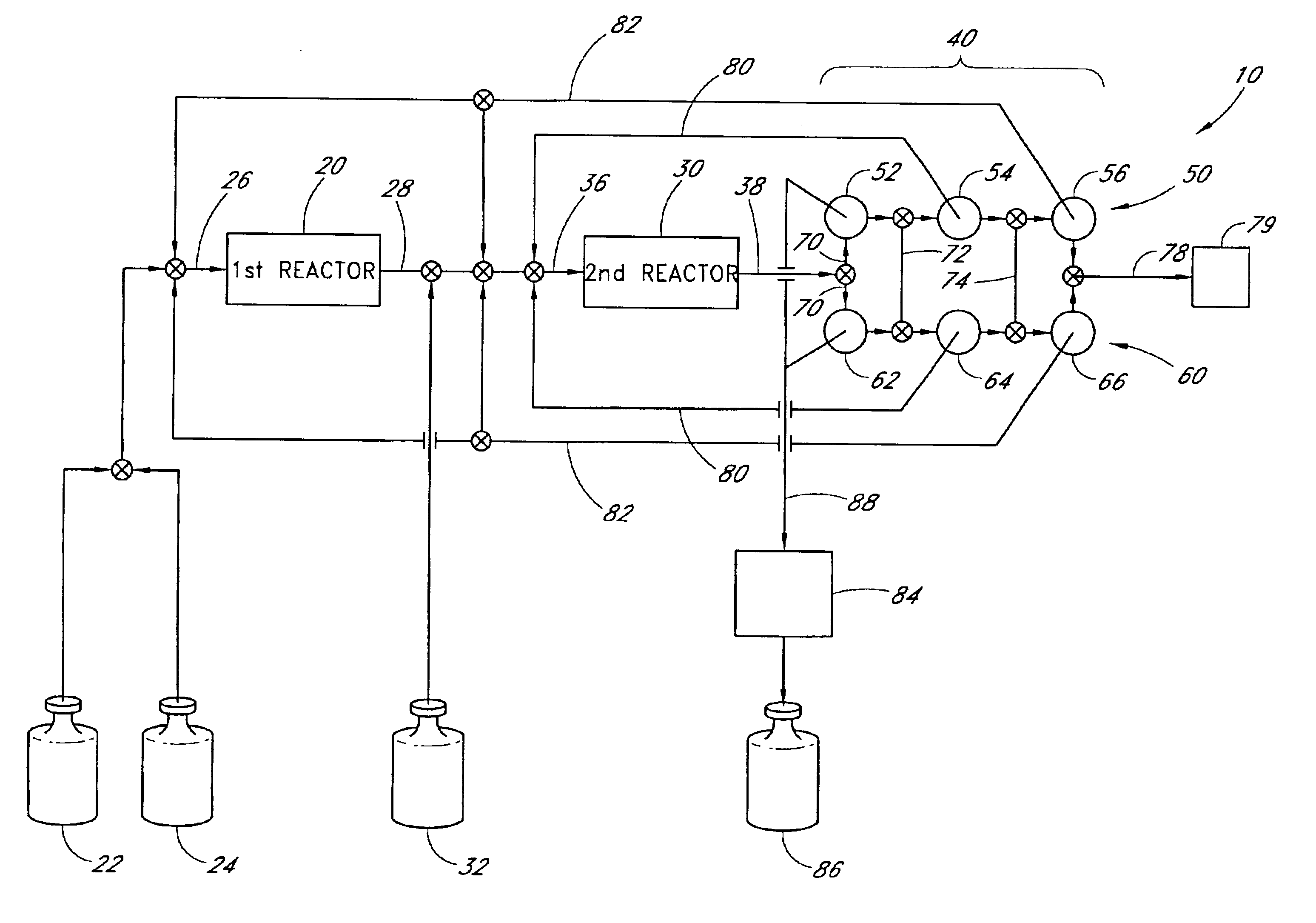

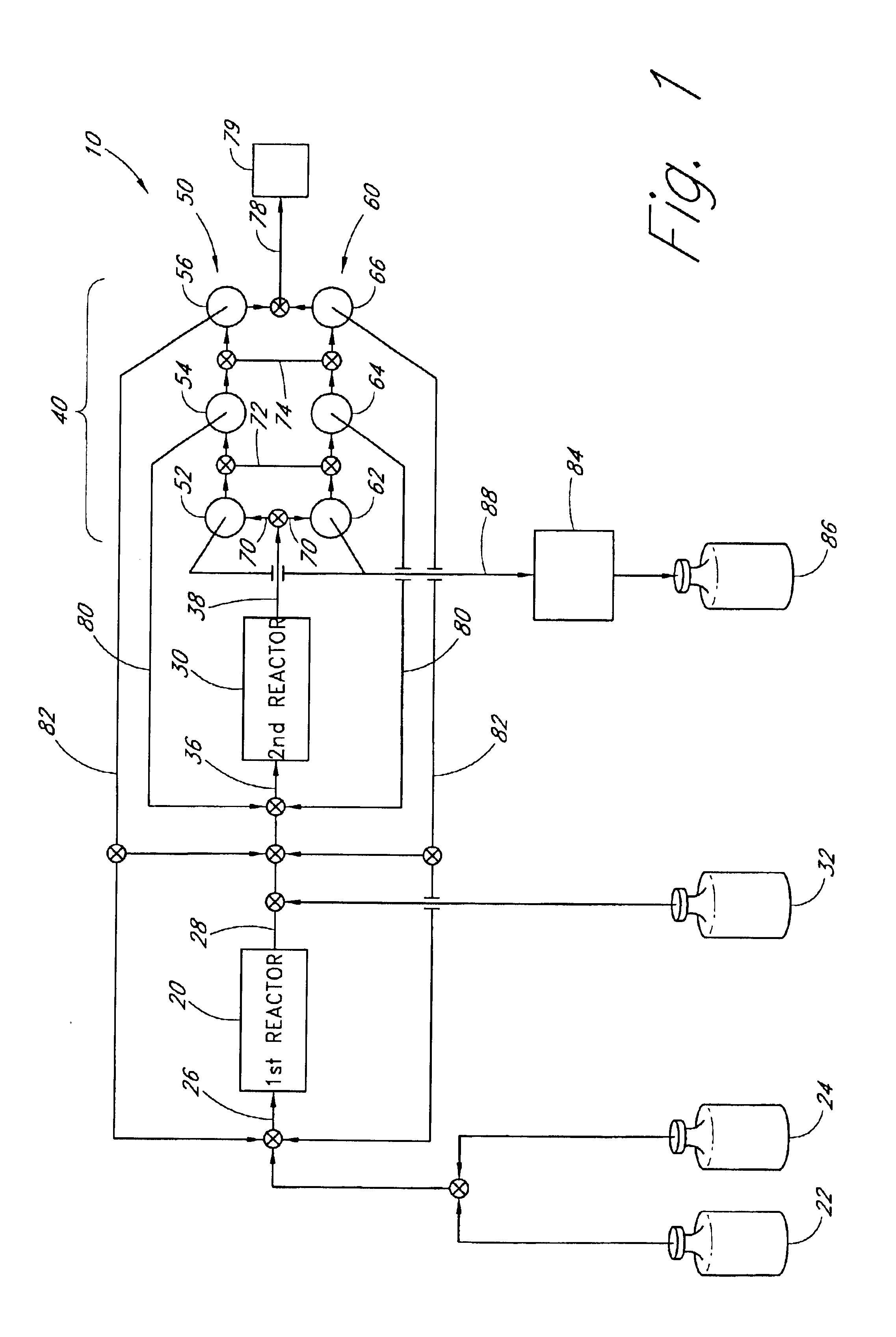

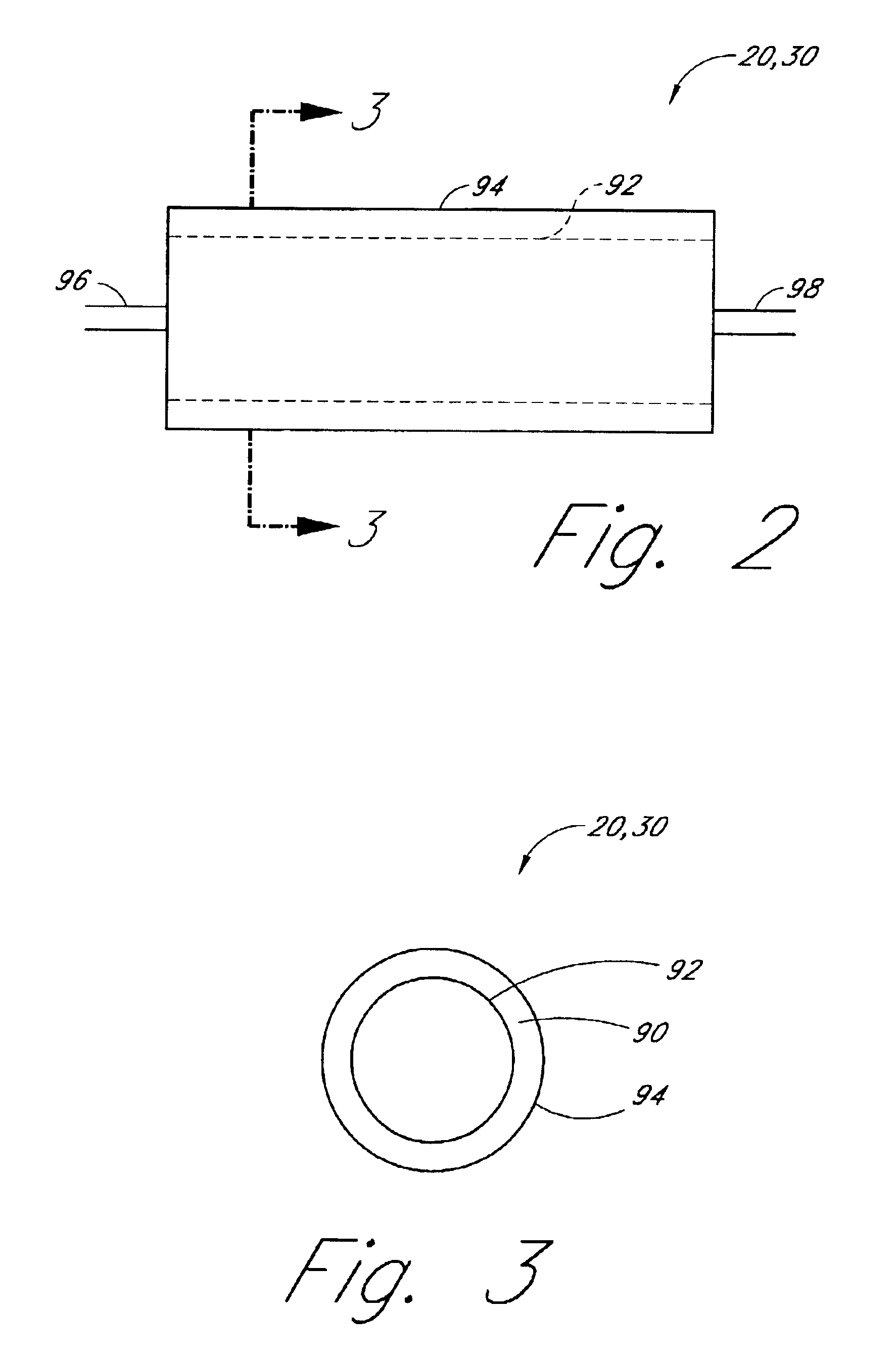

Method and apparatus for chemical synthesis

InactiveUS6858196B2Easy to operate continuouslyHighly orderedNitrogen compoundsMetal silicidesCondensation trapChemical synthesis

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM IP HLDG BV

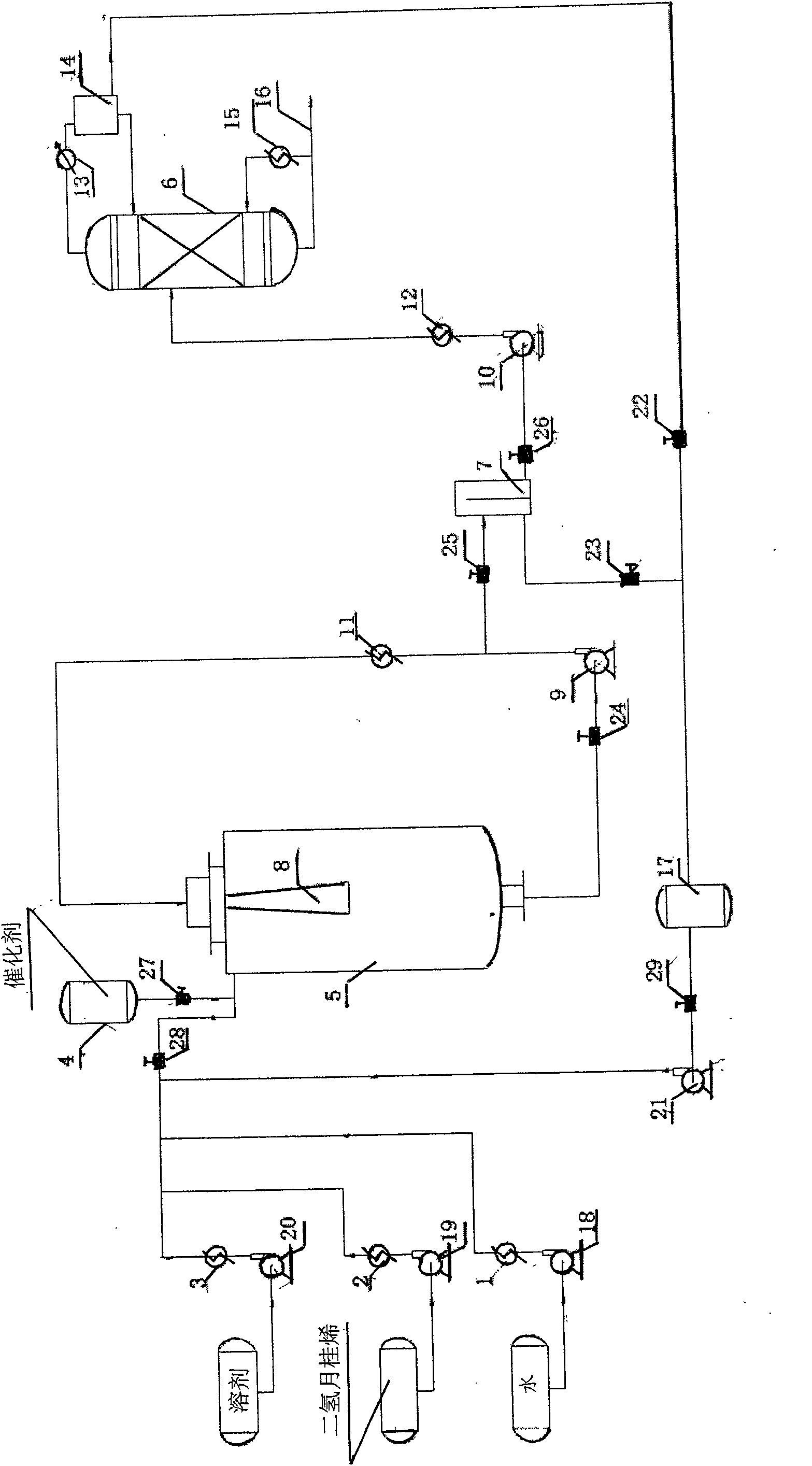

Environment-friendly process for producing dihydromyrcenol by using dihydromyrcene hydration reaction

ActiveCN101684064ASimple processReduce energy consumptionOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by hydroxy group additionHydration reactionFixed bed

The invention discloses an environment-friendly process for producing dihydromyrcenol by using a dihydromyrcene hydration reaction. The process adopts an integrated system consisting of a jet reaction device, an oil-water separation device and a rectification device. A high-speed injector is adopted in a reactor for reinforcing heat transfer and mass transfer of a reaction process; an acid (containing sulphuric acid, phosphoric acid and p-toluenesulfonic acid) is used as a catalyst and is in closed cycle; and an oil-water separator is arranged in the process flow to reduce the heat load of a rectification tower, and meanwhile the catalyst and the water phase in the oil-water separator are cycled and used in the system together so as to avoid the environment problems caused by the discharge of acid waste water. The process of the invention can improve the conversion rate of dihydromyrcene, and reduce the energy consumption and the production cost. Compared with a mechanical stirring reactor or a fixed bed reactor with the same scale, the process can improve the conversion rate of the dihydromyrcene by 1.2 to 4 times, and reduce the energy consumption of a dihydromyrcenol product per ton by more than 55 percent.

Owner:厦门中坤化学有限公司 +1

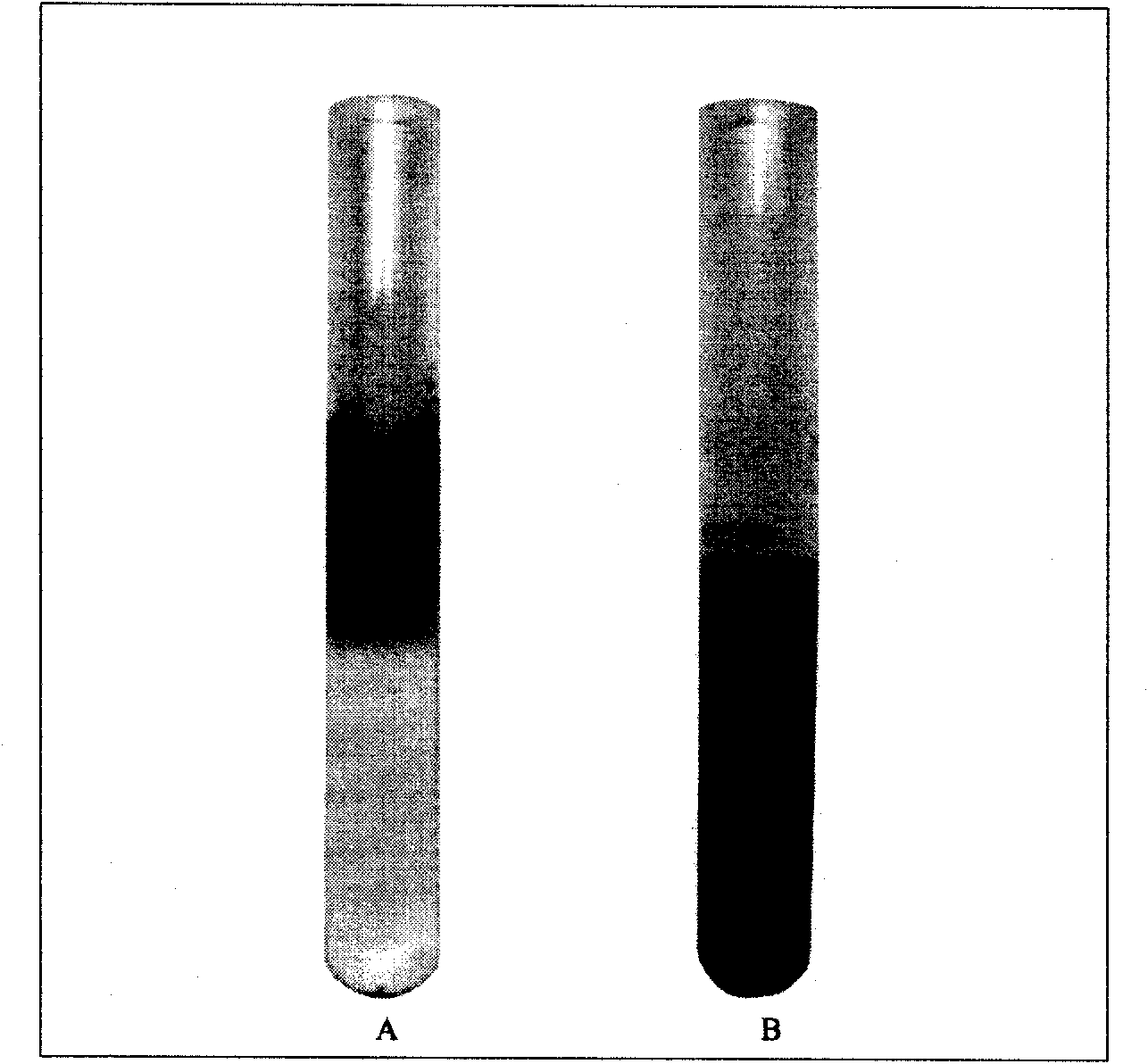

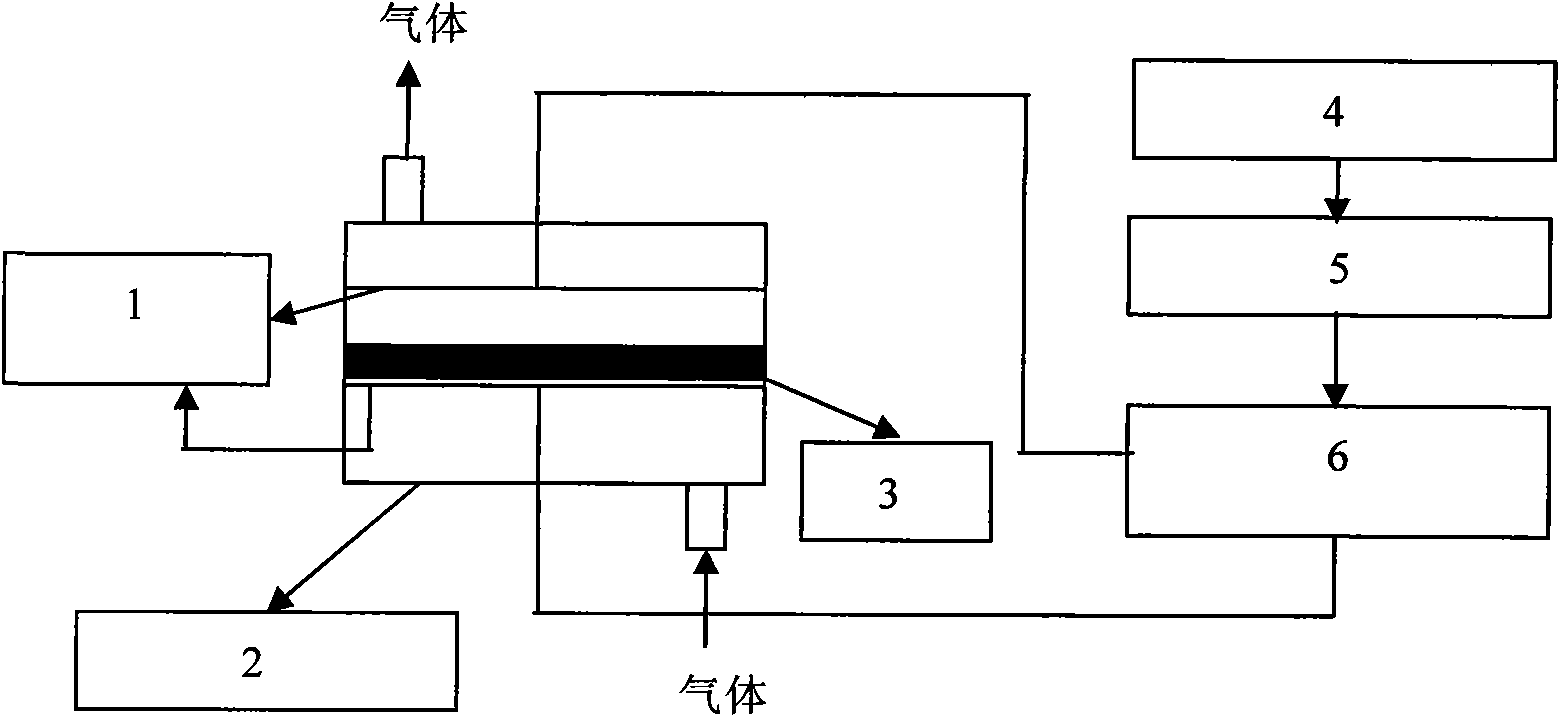

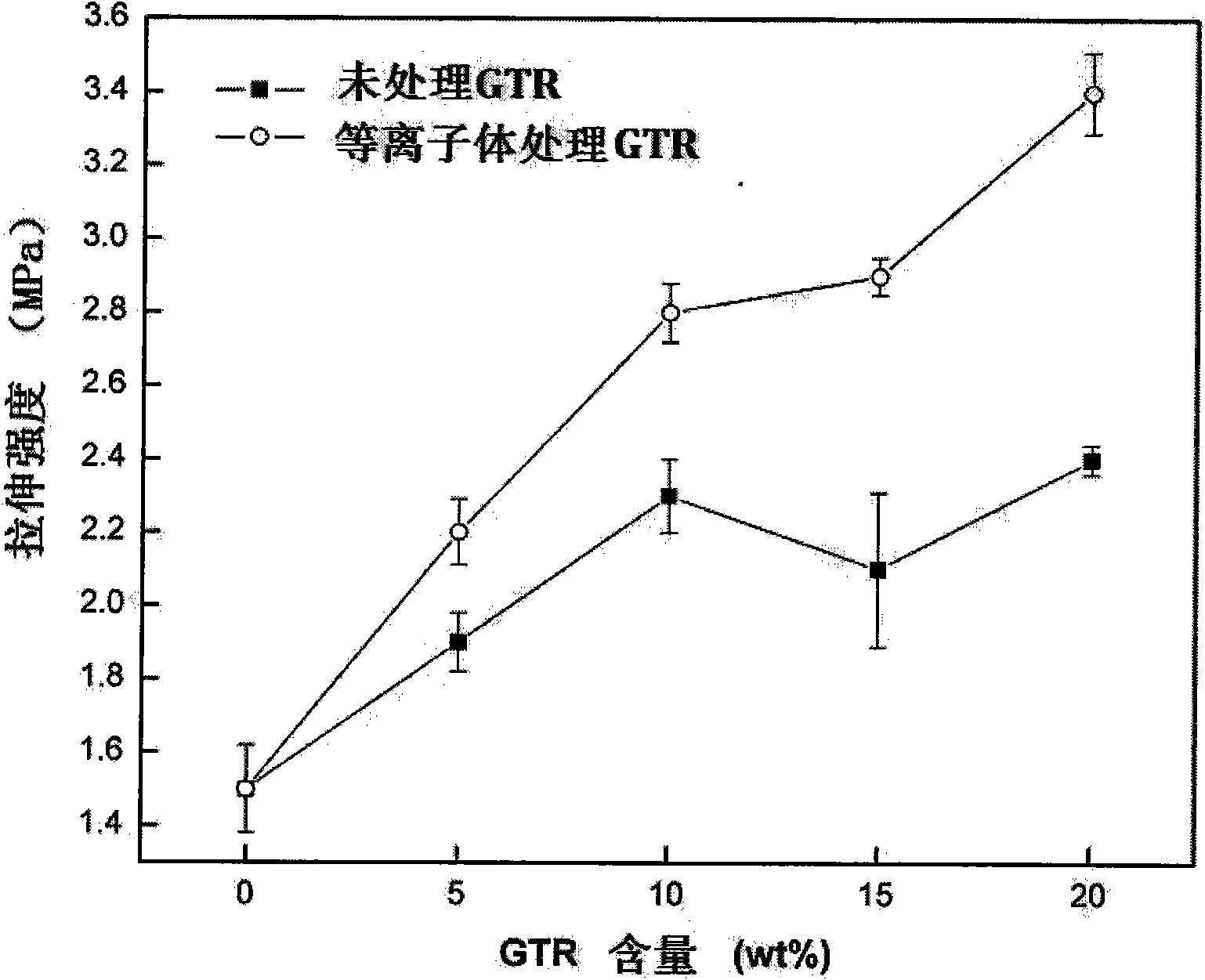

Method for improving surface hydrophilicity of waste rubber powder

The invention discloses a method for improving surface hydrophilicity of waste rubber powder, which is characterized by comprising the following steps of: putting 10 to 100 weight parts of the waste rubber powder into a plasma processing device; and jetting plasma to the surface of the waste rubber powder in an open environment with room temperature and atmospheric pressure to ensure that the waste rubber powder moves and is processed in a plasma atmosphere, wherein the power for processing the waste rubber powder is 10 to 5,000 W, and the time is 2.0 to 300 s. After the plasma processing, the surface polarity of the waste rubber powder is increased, the surface oxygen and nitrogen are increased, and the surface hydrophilicity is significantly improved. The method is a one-step method, which improves the surface property, the structure and the shape of the waste rubber powder and improves the added amount in a polymer. The method has the advantages of simple process, strong controllability, simple and convenient operation and high efficiency, needs no organic solvent and is environmentally-friendly.

Owner:SICHUAN UNIV

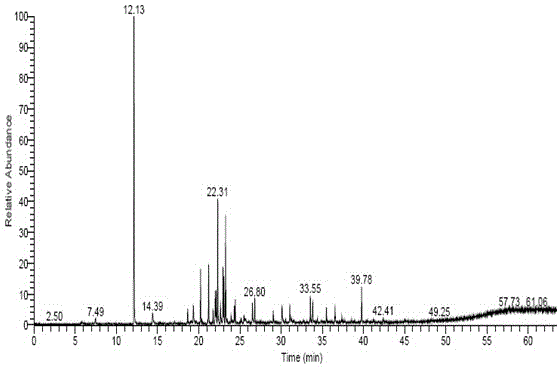

Preparation method for light-aromatic-rich bio-oil

ActiveCN104560091AAlleviate the phenomenon of secondary crackingMitigate or even avoid the phenomenon of secondary crackingLiquid hydrocarbon mixture productionMicrowave pyrolysisOil water

The invention discloses a preparation method for light-aromatic-rich bio-oil. The preparation method comprises the following steps: uniformly mixing a biomass raw material and a microwave additive, performing microwave preheating treatment, then performing microwave pyrolysis, condensing generated pyrolyzed volatile components, and performing oil-water separation to obtain the light-aromatic-rich bio-oil. The target product prepared by the preparation method disclosed by the invention is high in yield, high in component content and low in moisture content; furthermore, the process is simple, a catalyst is not required to be added, and the product can be easily separated; the preparation method is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

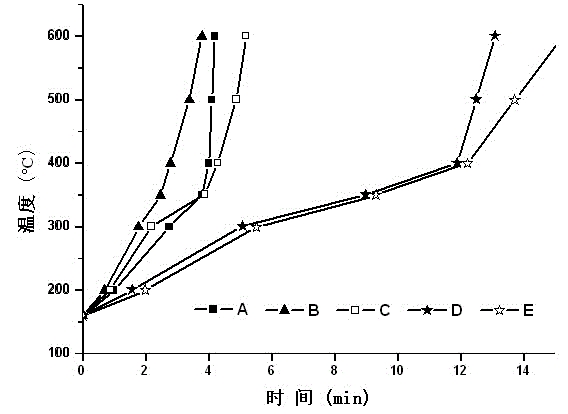

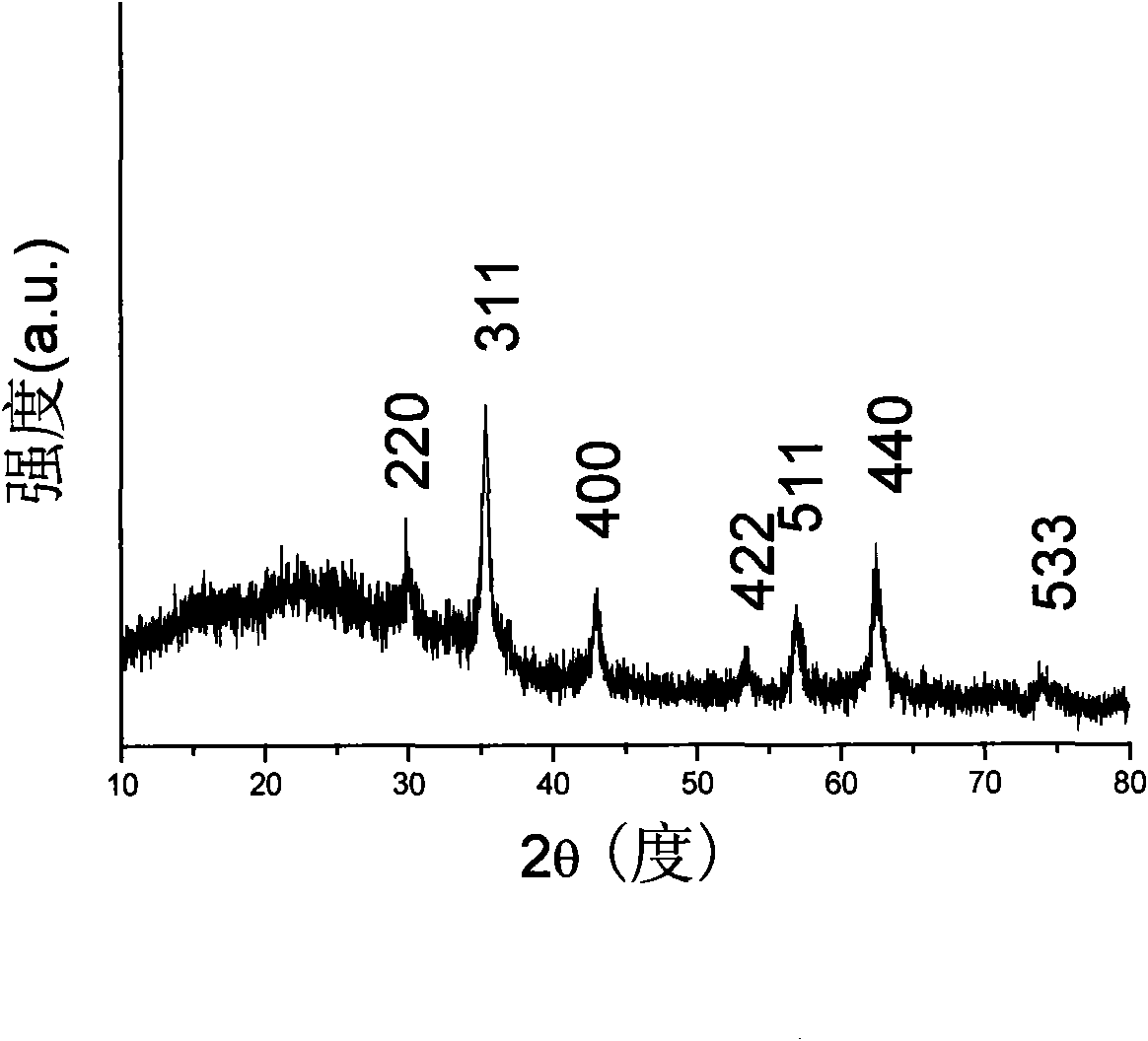

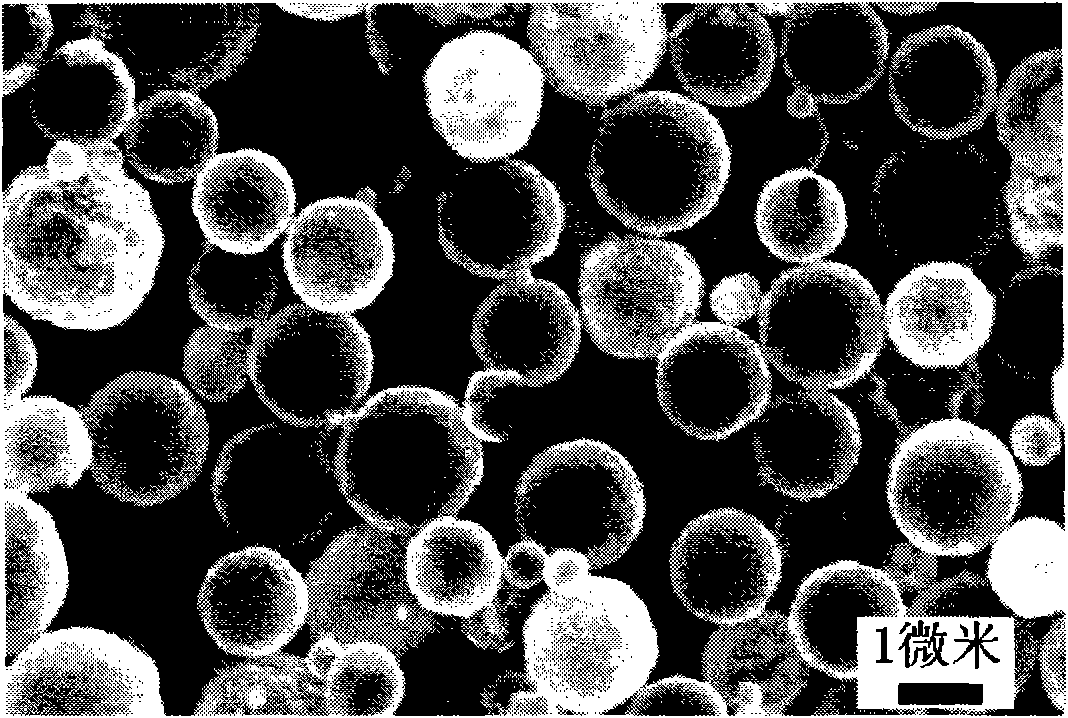

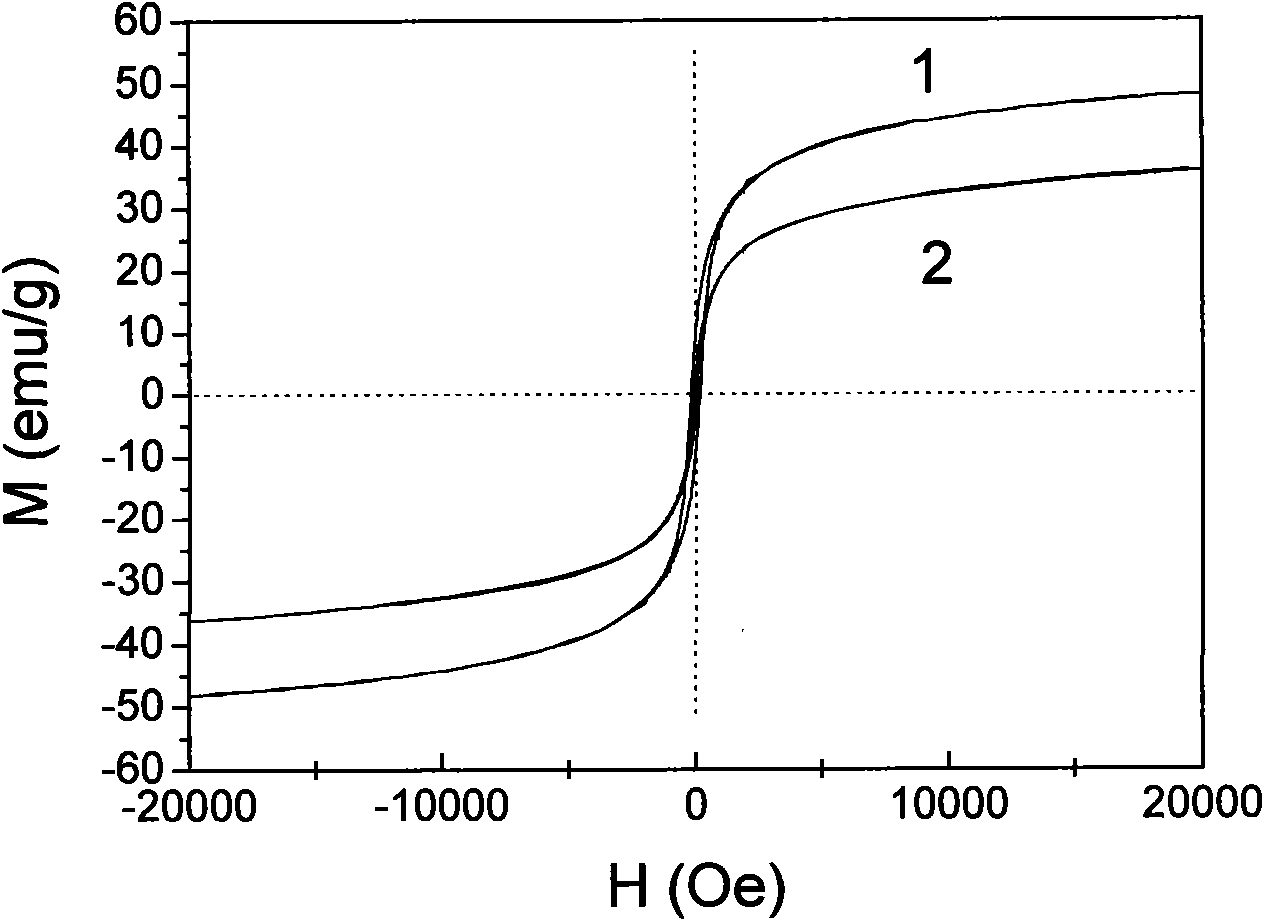

Preparation method of monodisperse-metal oxide magnetic composite microsphere resisting acid and magnetic composite microsphere

InactiveCN101596435AImprove acid resistanceShape is easy to controlEnergy based chemical/physical/physico-chemical processesMicroballoon preparationMicrosphereMagnetic separation

The invention relates to a preparation method of a monodisperse-metal oxide magnetic composite microsphere resisting acid and the composite microsphere. The method comprises the following steps: a water soluble carbon source and water soluble inorganic metal salt are dispersed in deionized water and are mixed evenly in an electromagnetic way to obtain a precursor water solution; the precursor water solution is transferred to an ultrasonic atomizer apparatus to be atomized, and atomized drips are transported to a silica tube placed in a tubular furnace by taking inert gases as the carrier gas; the flow rate of the inert gases is 0.1-15 standard liter / min, and the temperature of the tubular furnace is set to be 400-1000 DEG C; and production is collected and dried to obtain the monodisperse-metal oxide magnetic composite microsphere resisting acid. By adjusting the carbon source, a hollow microsphere or a solid core / shell microsphere can be prepared selectively. The magnetic composite microsphere has good acid resistance and can be widely applied to fields such as data storage, nuclear magnetic resonance, magnetic separation biomolecule, drug loading, water environment restoration, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

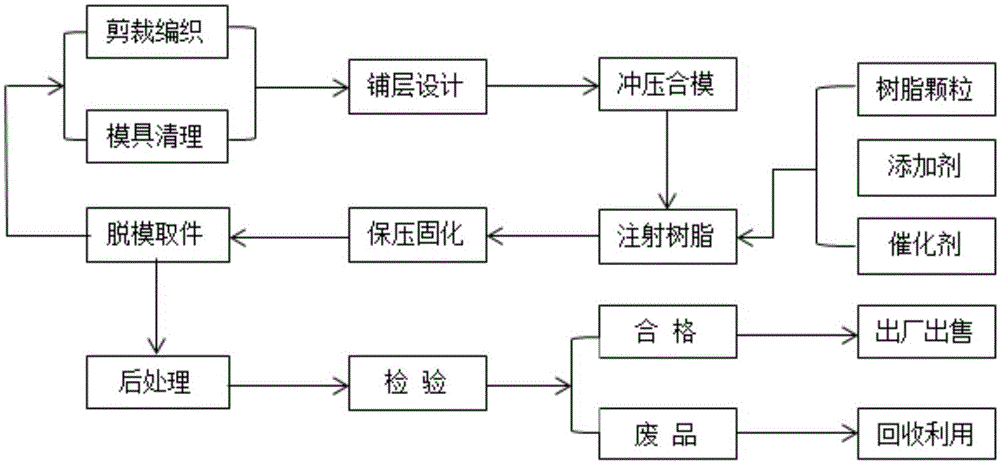

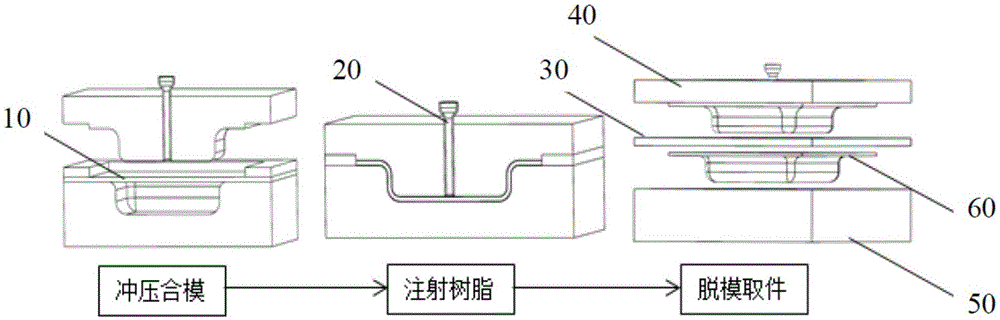

Stamping and injection integrated molding method for thermoplastic resin matrix woven composite material

InactiveCN105269835AGood soft molding performanceEasy to operate continuouslyResin matrixInjection molding machine

The invention provides a stamping and injection integrated molding method for a thermoplastic resin matrix woven composite material. The method includes the following steps of woven fabric cutting, die preparing, layer designing, stamping and die assembling, resin injecting, pressure maintaining and curing, die releasing and part taking and post-treating and inspecting. The stamping and injection integrated molding method for the thermoplastic resin matrix woven composite material integrates the stamping molding technology and the injection molding technology; reasonable layer designing can be conducted on the woven fabric according to stress features of molded parts; the flexible molding performance of the woven fabric is good; and parts with complex surfaces can be molded. Injection molding is conducted under certain pressure and temperature, and it is ensured that thermoplastic resin is fully soaked in a seam of a woven material.

Owner:SHANGHAI HUIZHONG AUTOMOTIVE MFG

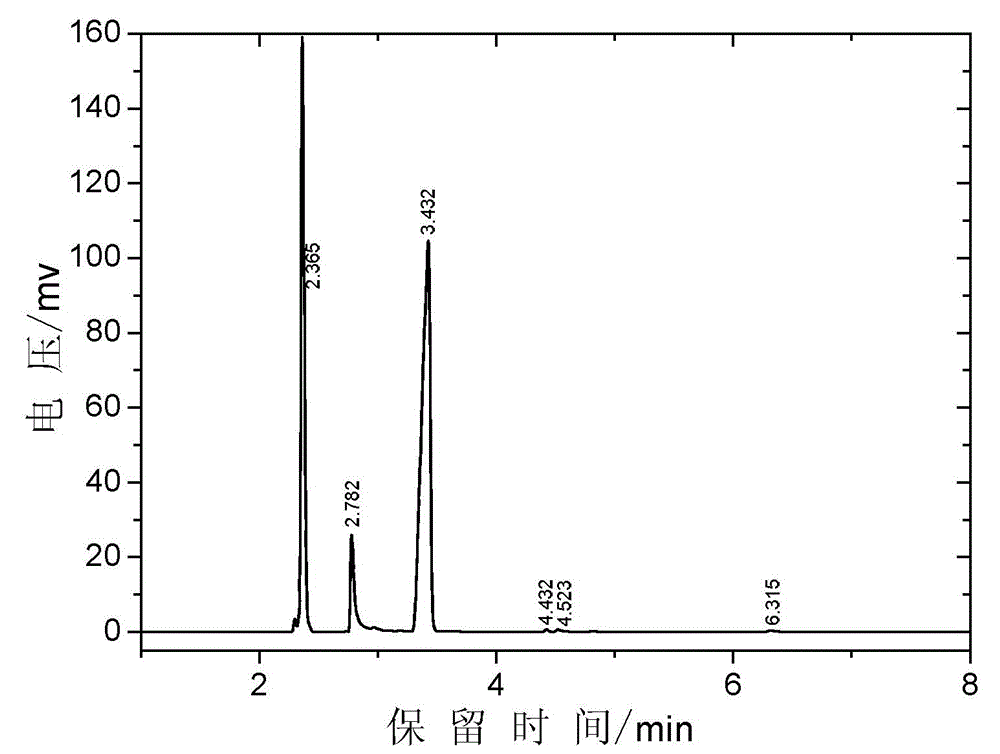

Method for preparing ultrapure fluoromethane

InactiveCN103910600AFast adsorption rateSuitable for mass productionHalogenated hydrocarbon preparationMolecular sieveActivated carbon

The invention provides a method for preparing ultrapure fluoromethane through an adsorption process. Impurities in crude fluoromethane are removed by adopting A-type molecular sieve and / or active carbon with the particle size of 1.5-3.0mm, and the A-type molecular sieve and active carbon are activated before use. Highly pure fluoromethane with the purity of above 99.99 even 99.9999% can be obtained through the preparation method, and the prepared ultrapure fluoromethane can be used in the semiconductor / electron industry as an etching gas.

Owner:SINOCHEM LANTIAN +1

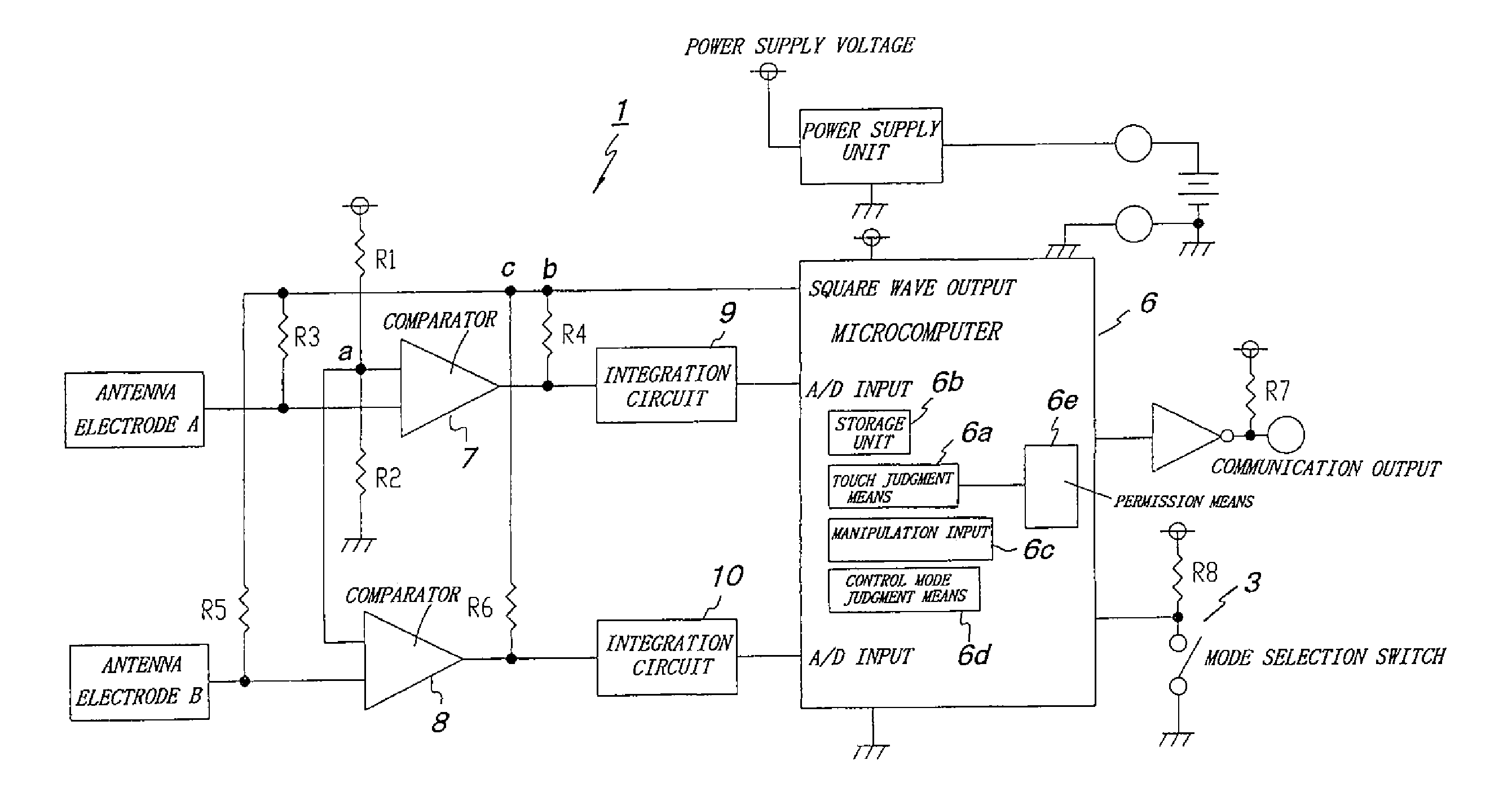

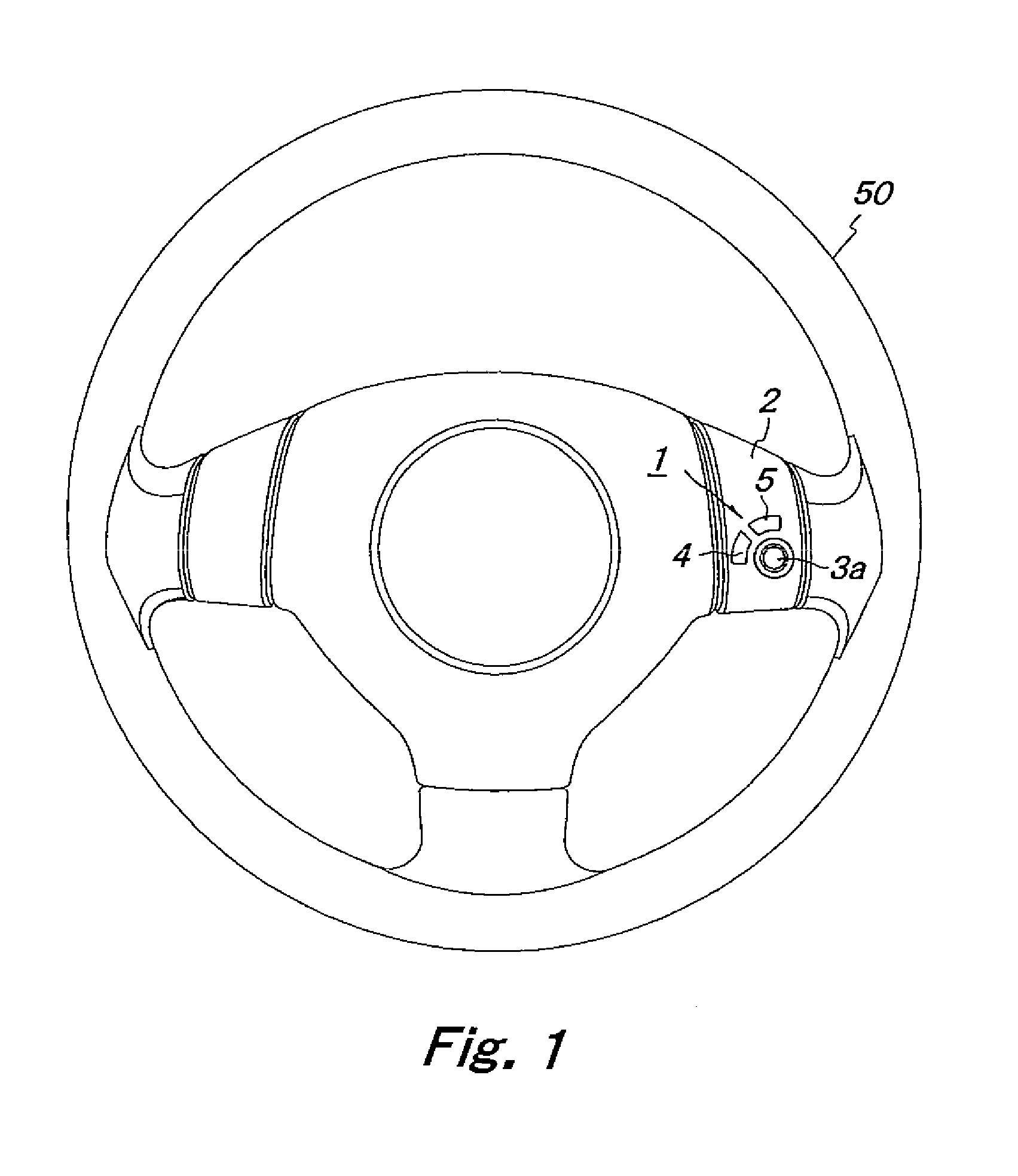

Touch sensor

ActiveUS20130135033A1Easy to operateAvoid difficult choicesElectronic switchingDriver/operatorHuman–computer interaction

Provided is a touch sensor having a simple structure and enabling a driver to appropriately and quickly manipulate the touch sensor as intended without looking at a manipulation surface of the touch sensor. The touch sensor includes: multiple electrodes; detection means for detecting touch on any of electrodes and for outputting a detection signal for each electrode; touch judgment means for judging whether each of the electrodes is touched or untouched based on the detection signal; a switch having a manipulation button; control mode judgment means for determining a control function for a controlled device in accordance with an input signal transmitted from the switch when the manipulation button is manipulated; and permission means for permitting the touch judgment means to judge touch on each electrode in response to the input signal from the switch.

Owner:U SHIN LTD

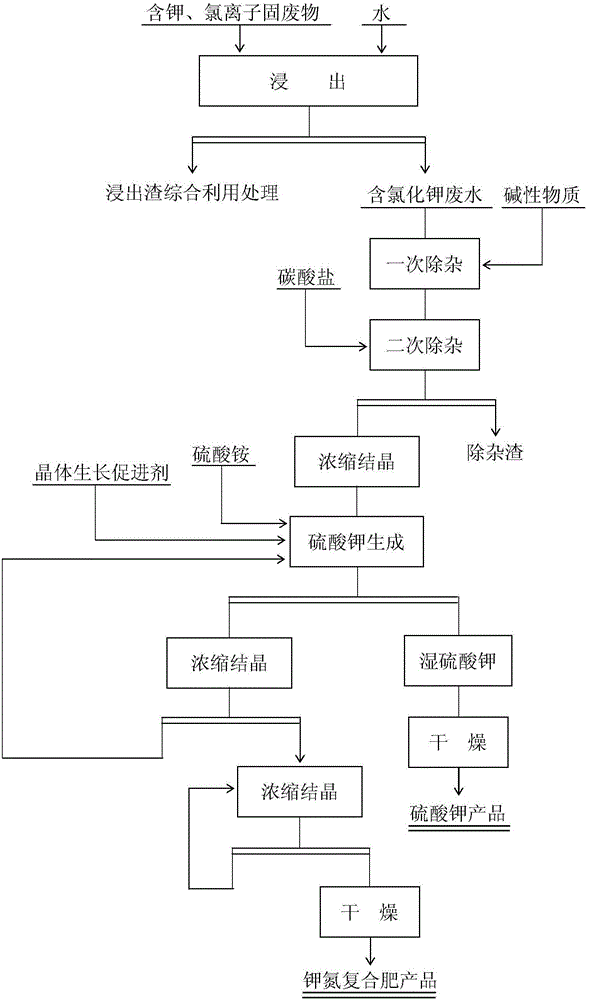

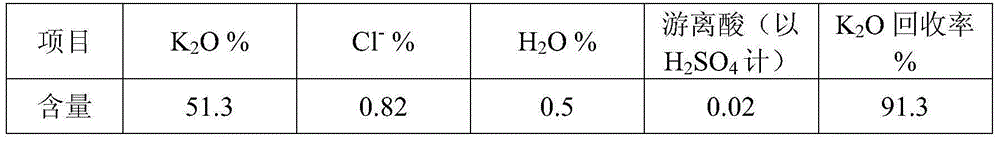

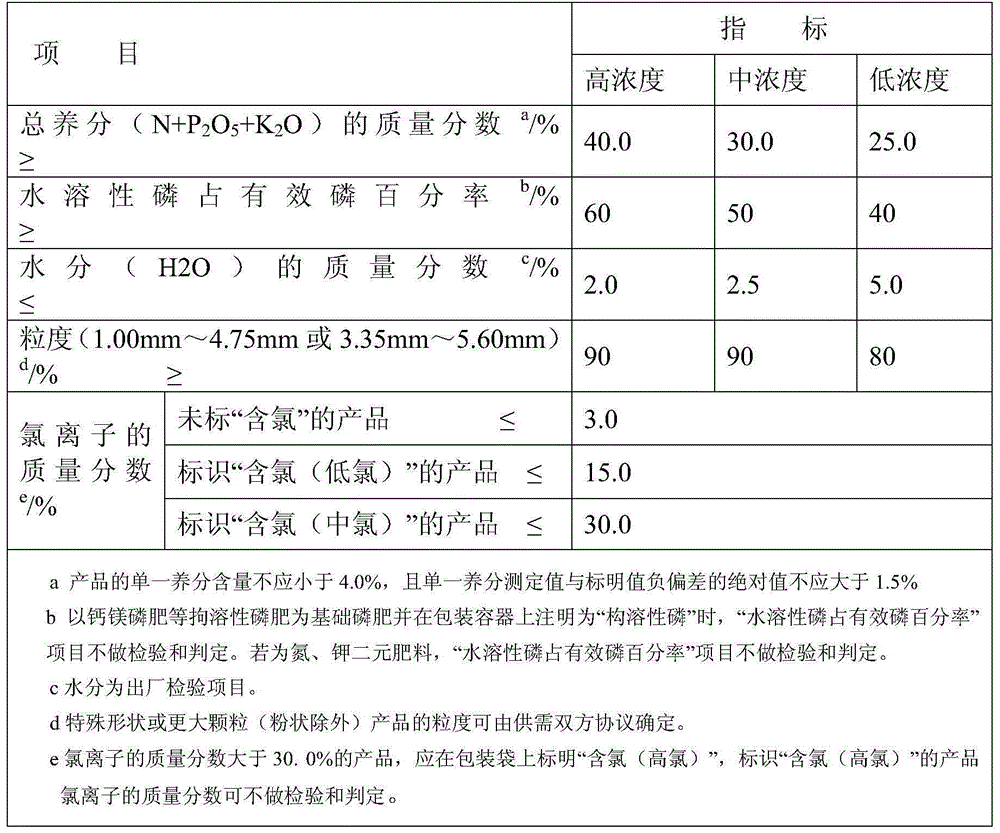

Method for producing potassium sulfate from potassium/chlorine-ion-containing solid waste

InactiveCN105110352AImprove product qualityLow costAlkali metal sulfites/sulfatesPhosphateSodium salt

The invention discloses a method for producing potassium sulfate from potassium / chlorine-ion-containing solid waste, which comprises the following steps: adding water, leaching, adding an alkaline matter and soluble carbonate for impurity removal, and concentrating to obtain a concentrated solution with the K<+> concentration of 100 g / L or above; and adding ammonium sulfate into the concentrated solution, adding a mixture of sodium tripolyphosphate, ammonium monoacid phosphate, magnesium sulfate, urea and sodium salt, reacting to obtain a potassium sulfate precipitate, carrying out solid-liquid separation to obtain wet potassium sulfate and a filtrate, drying to obtain a potassium sulfate product, carrying out concentration and crystallization on the filtrate twice, and drying to obtain a potassium-nitrogen compound fertilizer product. The method is simple and safe, has the advantages of high efficiency, lower cost and high potassium sulfate product quality, does not need any alcohol substance to perform precipitation, and meanwhile, can coproduce the potassium-nitrogen compound fertilizer which satisfies the national standard.

Owner:莫红兵 +2

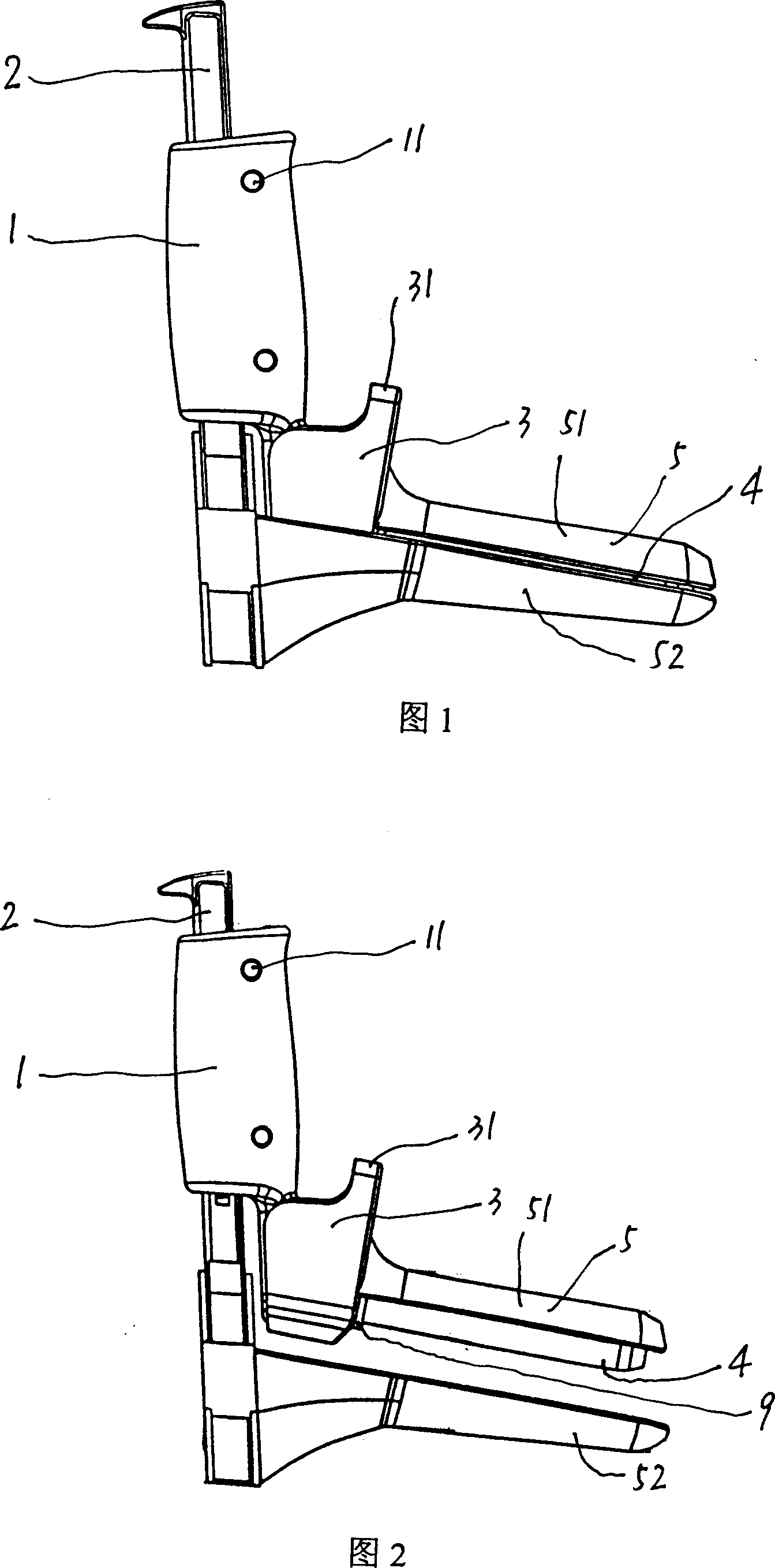

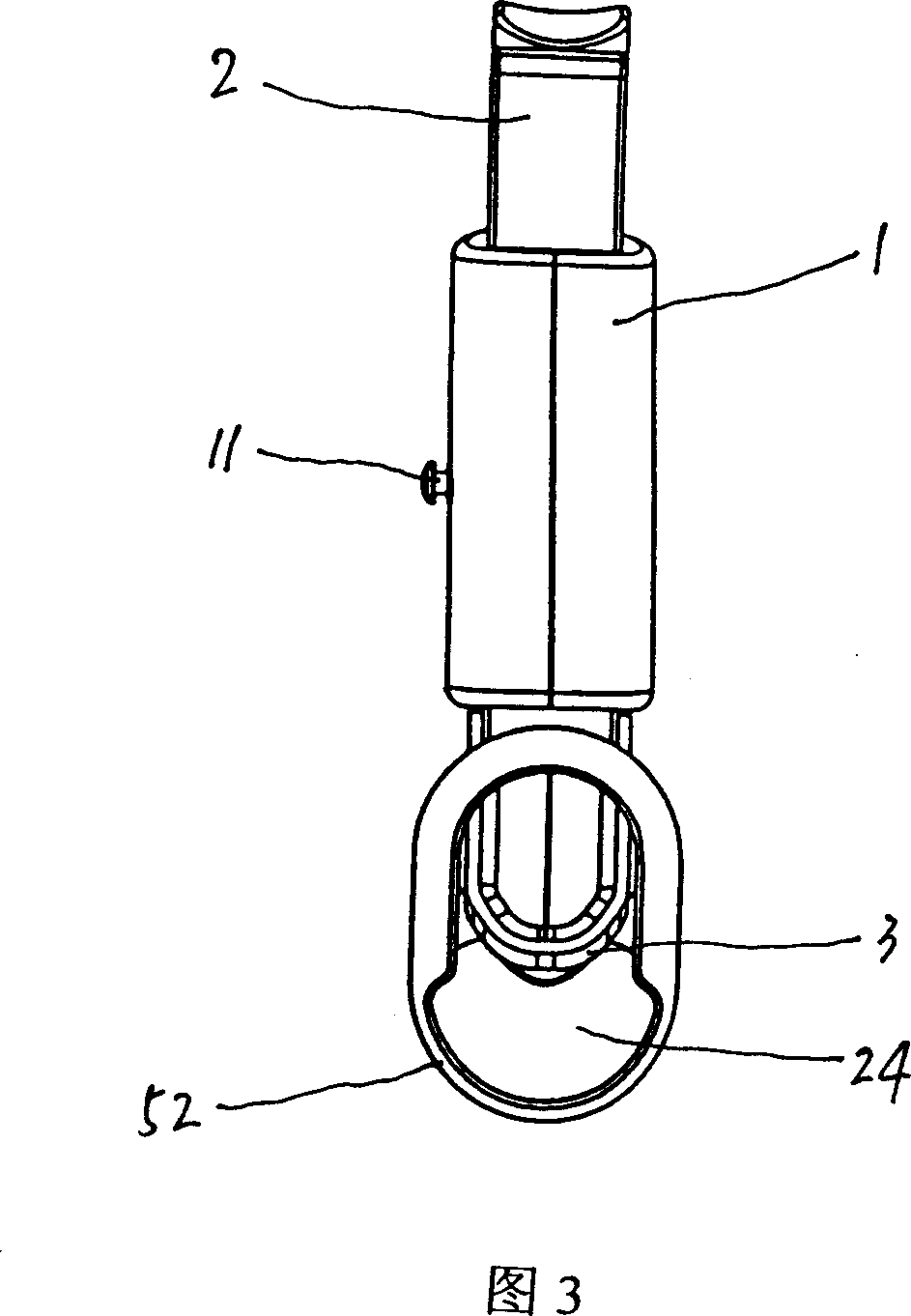

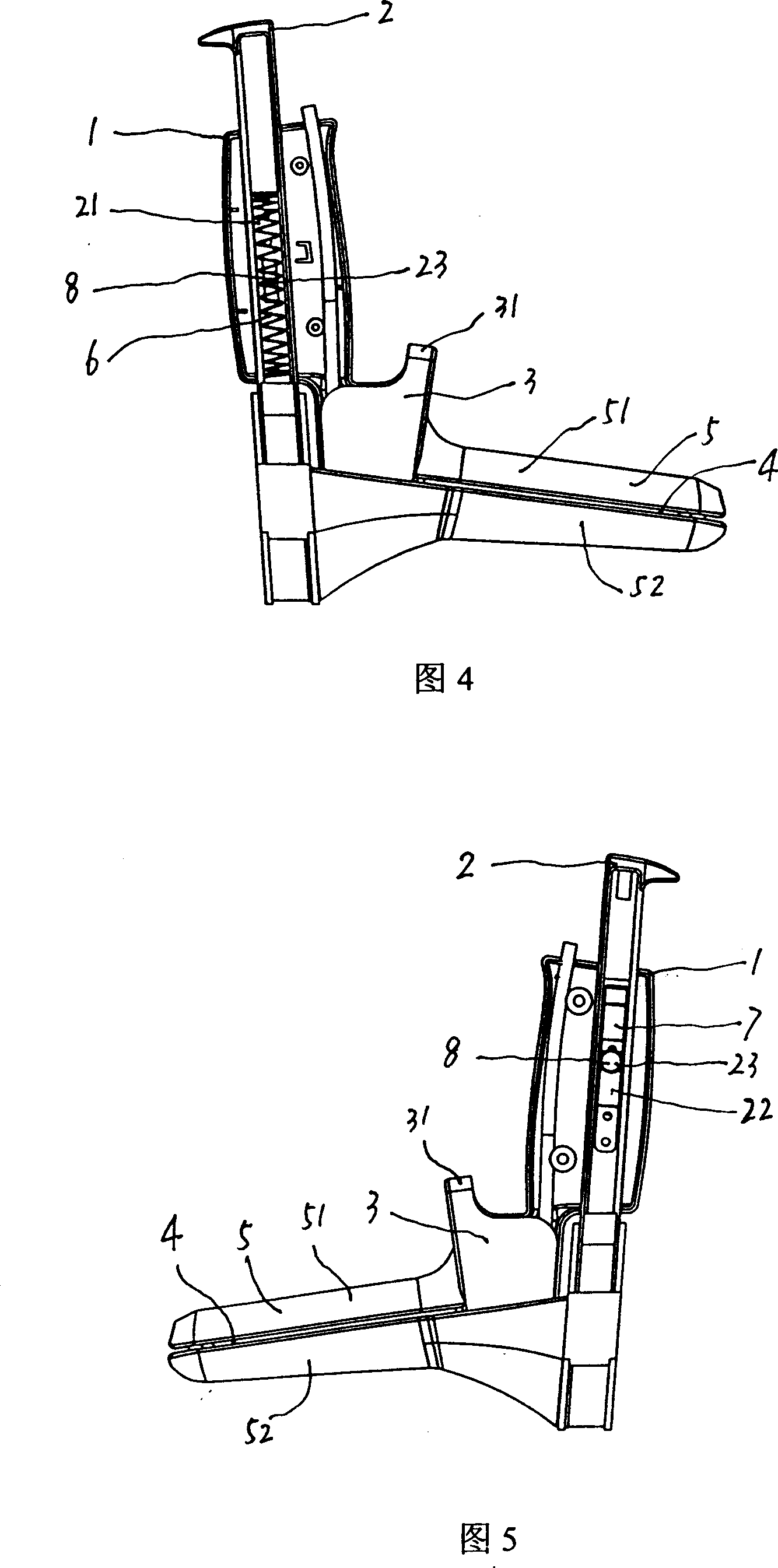

Integral electronic vaginal dilator

InactiveCN101103897AImprove accuracyImprove work efficiencySurgeryDilatorsColposcopesMechanical engineering

Disclosed is an integrated electric vagina expander, relating to a combined structure of a vagina expander and a colposcope and comprising a detector, a detector permanent seat and a spring regulating mechanism. The spring regulating mechanism is composed of a duck mouth and a duck-mouth open-close device. The duck-mouth open-close device is composed of an open-close shaft and a shell sleeved outside the open-close shaft. A spring is arranged on the open-close shaft, regulating the open and close of the duck mouth. The integrated electric vagina expander which integrates the functions of the vagina expander and the colposcope can achieve continuous operations of examination, sampling and medicine application by a doctor, greatly improving the work efficiency of the doctor; the duck mouth is opened and closed in parallel so that the pain that a patient feels is reduced. In addition the invention is simply structured and produce with low cost.

Owner:郑宇霞

Preparation method of dimethylaminoethyl acrylate and catalyst thereof

InactiveCN105330556AHigh yieldTo achieve the purpose of energy savingPhysical/chemical process catalystsOrganic compound preparationPolymer sciencePtru catalyst

The invention discloses a preparation method of dimethylaminoethyl acrylate and a catalyst thereof. Methyl acrylate and dimethylamino ethyl alcohol are used as raw materials, in a condition that a prepared modified catalyst and a polymerization inhibitor exist, a interesterification process is carried out, methanol generated from the reaction is timely removed by azeotropic distillation, obtained reaction products containing dimethylaminoethyl acrylate are distilled in a pressure reduction condition, and the dimethylaminoethyl acrylate product is obtained. The catalyst for the interesterification process is a titanate modified catalyst, and has high catalytic activity and good dissolvability; deposition does not generate in the reaction process, new impurities are not introduced, scale does not generate on the reactor wall, and the catalyst can be reused.

Owner:ZHEJIANG SATELLITE PETRO CHEM CO LTD

Preparation method of flame-retardant polyacrylonitrile fabric

InactiveCN106988121ALow costEasy to operateHeat resistant fibresGlycidyl methacrylatePhosphorylation

The invention discloses a preparation method of flame-retardant polyacrylonitrile fabric, and relates to the technical field of textile products. The preparation method includes grafting glycidyl methacrylate onto polyacrylonitrile fabric by taking benzophenone as an initiator according to an ultraviolet light grafting technology so as to introduce epoxy groups; subjecting the obtained fabric to amination and phosphorylation to finally obtain the flame-retardant polyacrylonitrile fabric. The preparation method has the advantages that the glycidyl methacrylate is grafted onto the surface of the polyacrylonitrile fabric according to the ultraviolet light grafting technology, chemical modification is combined, nitrogen and phosphorus are introduced onto the surface of the fabric by means of the active epoxy groups, and accordingly, the polyacrylonitrile fabric with the flame-retardant effect is obtained; the preparation process is simple, easy to operate and suitable for continuous production, and the product does not contain halogen and is environment friendly and free of poison.

Owner:TIANJIN POLYTECHNIC UNIV

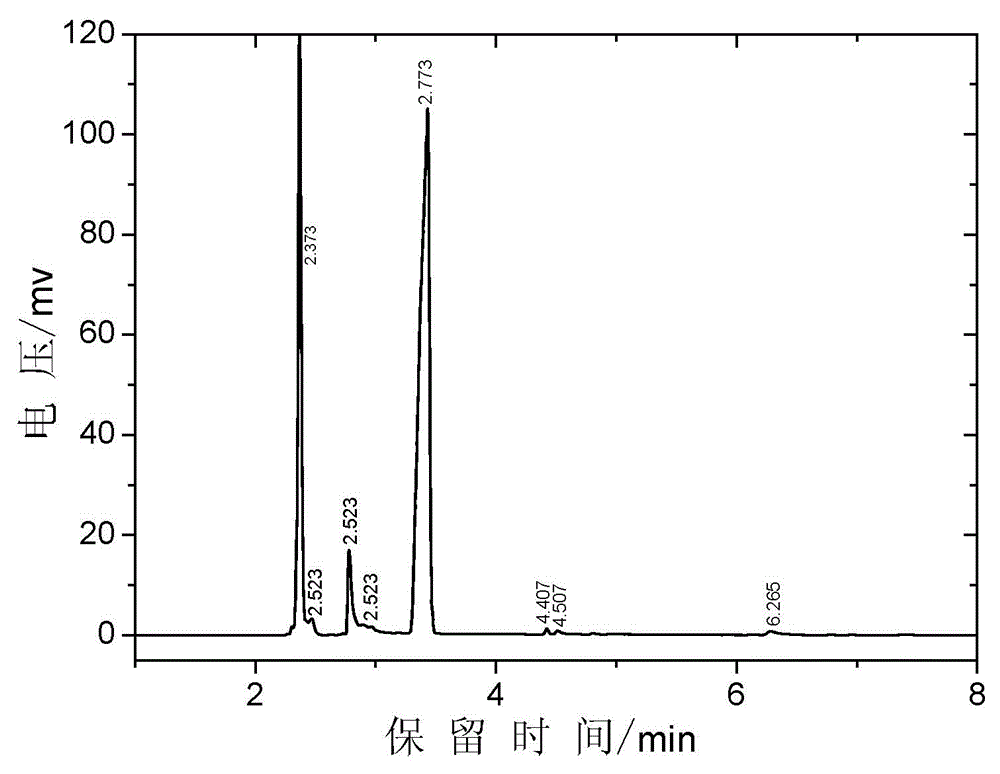

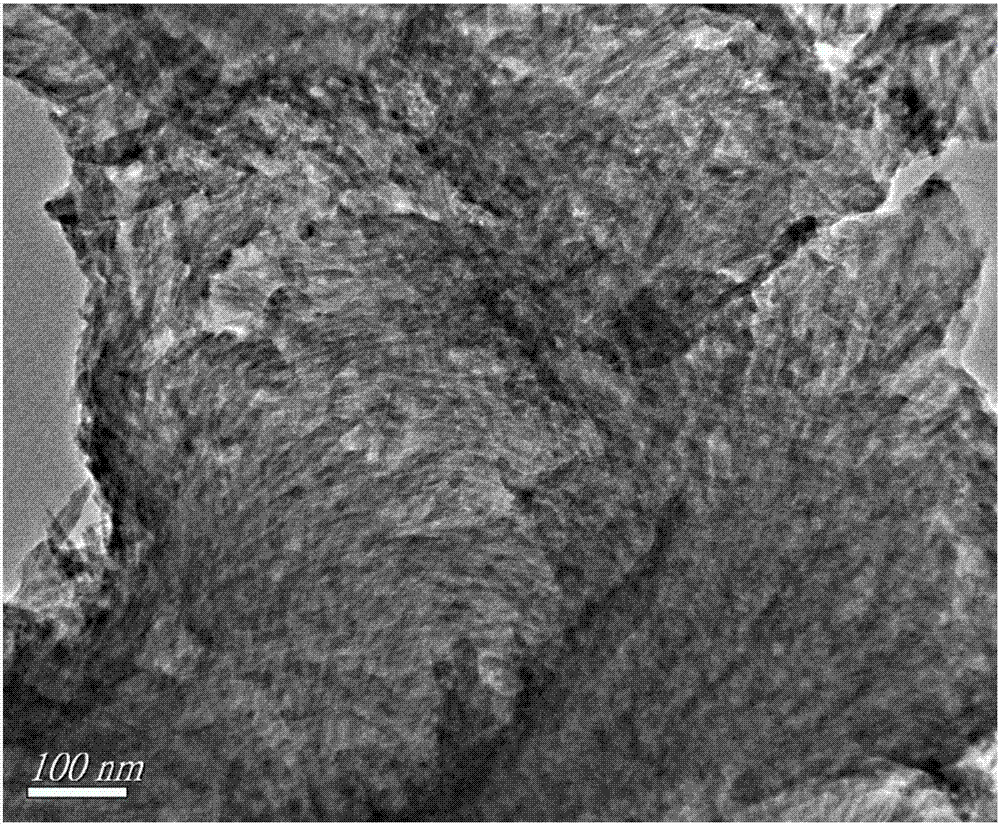

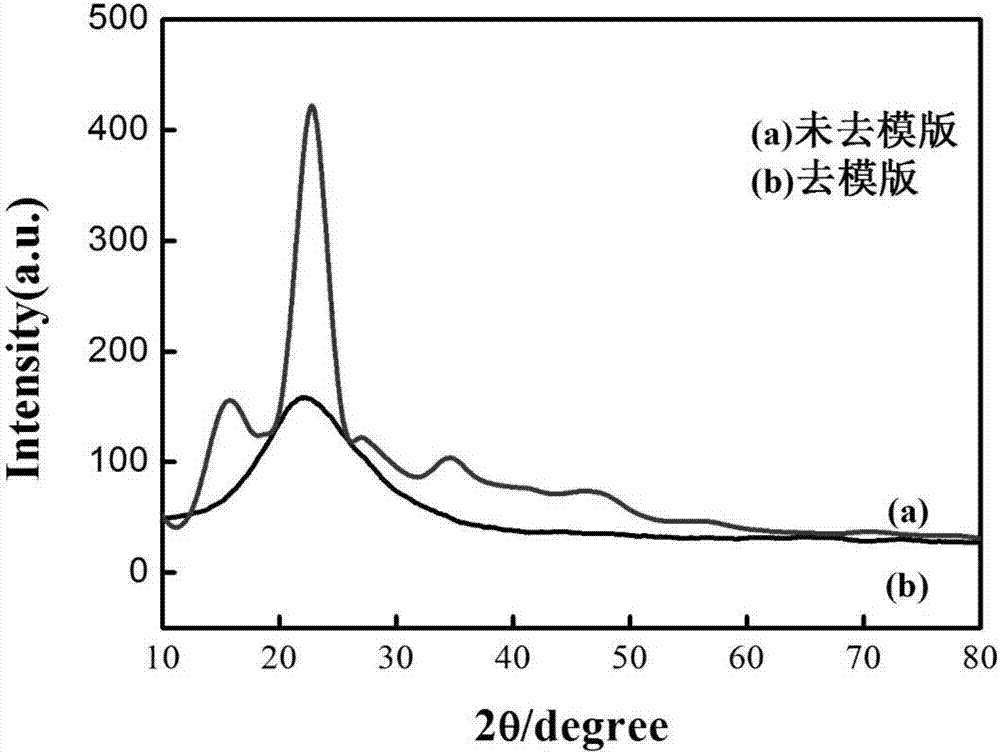

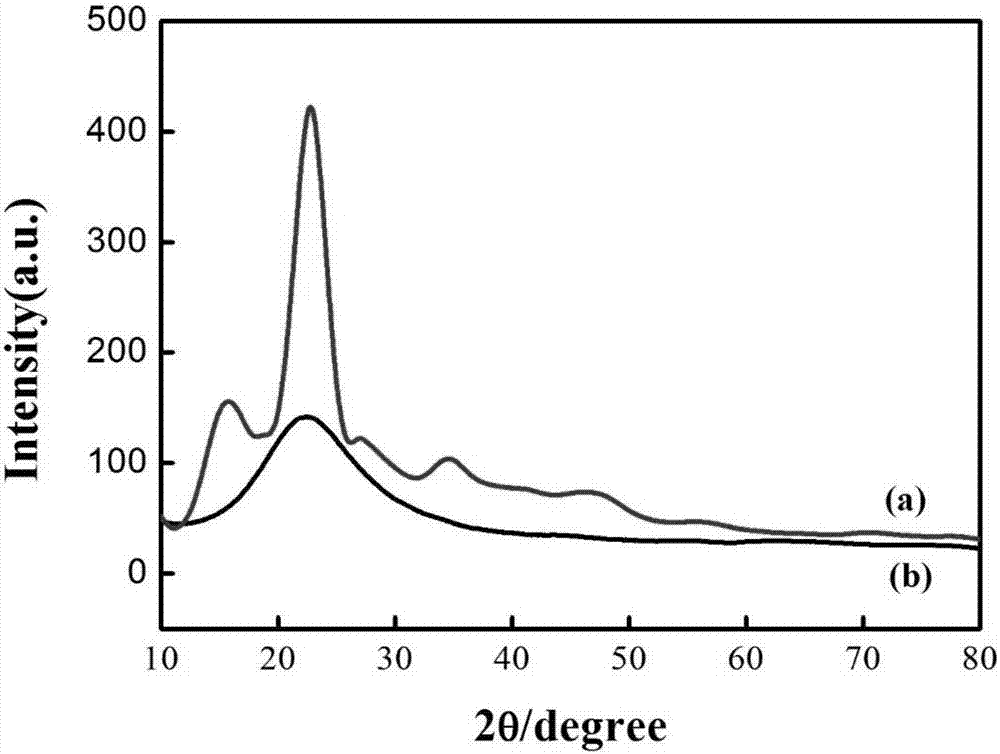

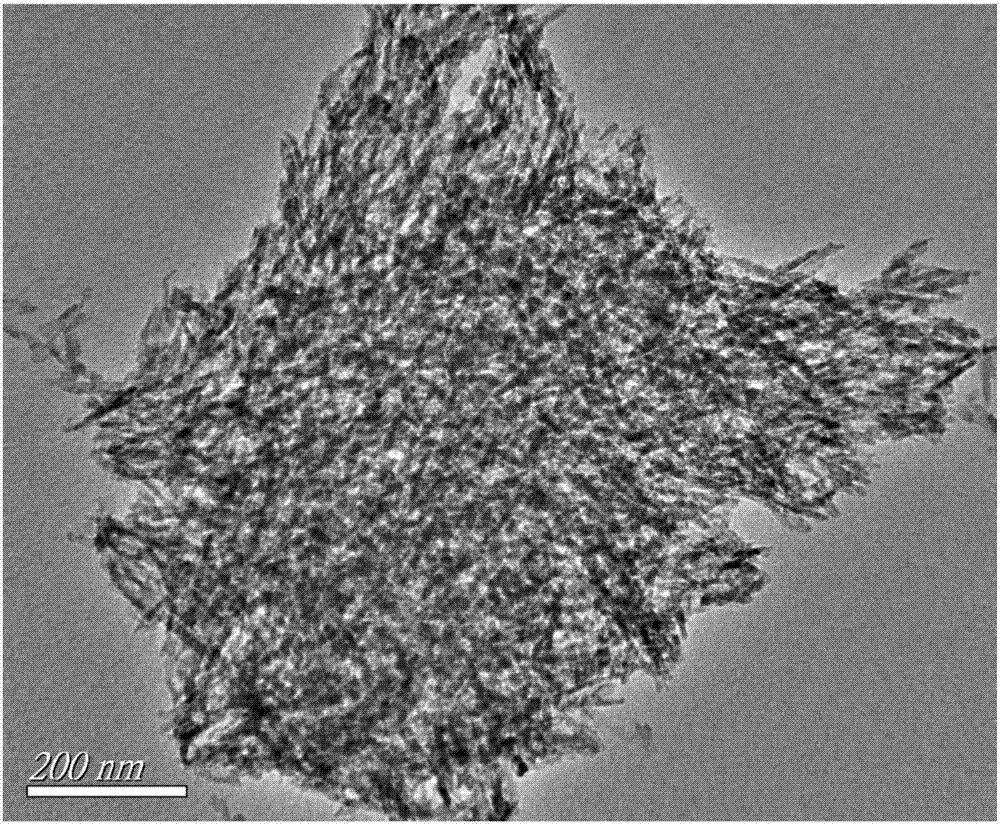

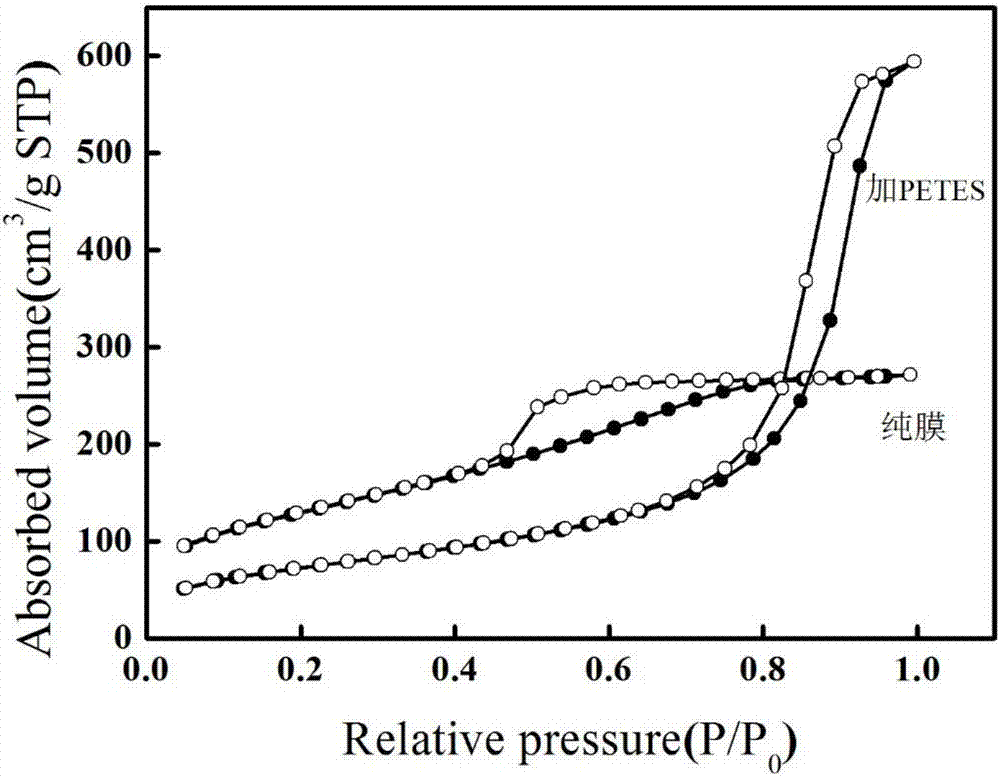

Mesoporous silicon film and two-step preparation method and application thereof

ActiveCN107082466AWide variety of sourcesEasy to operate continuouslyOther chemical processesWater contaminantsCelluloseMesoporous silica

The invention provides a mesoporous silicon film and a two-step preparation method and application thereof. The preparation method comprises the following steps: putting cotton into a sulfuric acid solution, stirring and reacting, taking out the cotton after the reaction, diluting with distilled water, standing for layering; carrying out centrifugal separation on the lower layer of a suspension, washing; carrying out dialysis on the centrifuged suspension, adjusting the pH, carrying out ultrasonic treatment to obtain nanocrystalline cellulose; carrying out ultrasonic treatment on the nanocrystalline cellulose, putting the nanocrystalline cellulose into a round-bottom flask, adding glucose, stirring evenly, adding tetraethl silicate, stirring and drying to obtain a mesoporous silicon film A; calcining the mesoporous silicon film A to obtain a mesoporous silicon film B; putting the mesoporous silicon film B into methylbenzene, introducing nitrogen, dropwise adding triethylamine, introducing nitrogen, dropwise adding Diethylphosphatoethyltriethoxysilane, sealing, and shaking to obtain a mesoporous silicon film C; putting the mesoporous silicon film C into concentrated hydrochloric acid and reacting to obtain a mesoporous silicon film D; and washing the mesoporous silicon film D and drying to obtain the final mesoporous silicon film. According to the invention, biomass cellulose is used as a template, has a wide range of sources and is green and environmentally friendly.

Owner:JIANGSU UNIV

Mesoporous silicon film and one-step preparation method and application thereof

InactiveCN106964318AWide variety of sourcesReduce energy consumptionOther chemical processesProcess efficiency improvementCelluloseDialysis membranes

The invention provides a mesoporous silicon film and a one-step preparation method and application thereof; the preparation method comprises: placing cotton in sulfuric acid solution, stirring for reaction, taking out after reaction, diluting with distilled water, and standing for layering; pouring off clear supernate, centrifugally separating lower suspension, and washing; transferring the centrifuged suspension to a dialysis membrane for dialysis, adjusting pH, ultrasonically treating to obtain nanocrystalline cellulose, and getting ready for use; ultrasonically treating the nanocrystalline cellulose, placing in a round-bottom flask, adding glucose, stirring, adding mixed liquid A of diethylphosphatoethyltriethoxysilane and tetraethyl orthosilicate, stirring, and drying to obtain mesoporous silicon film A; placing the mesoporous silicon film A in sulfuric acid solution, and removing a template to obtain mesoporous silicon film B; placing the mesoporous silicon film B in concentrated hydrochloric acid for reaction to obtain mesoporous silicon film C; flushing the mesoporous silicon film C with distilled water and absolute ethyl alcohol, and drying to obtain final mesoporous silicon film. Biomass cellulose is used as the template herein, the source range is wide, and the mesoporous silicon film is green.

Owner:JIANGSU UNIV

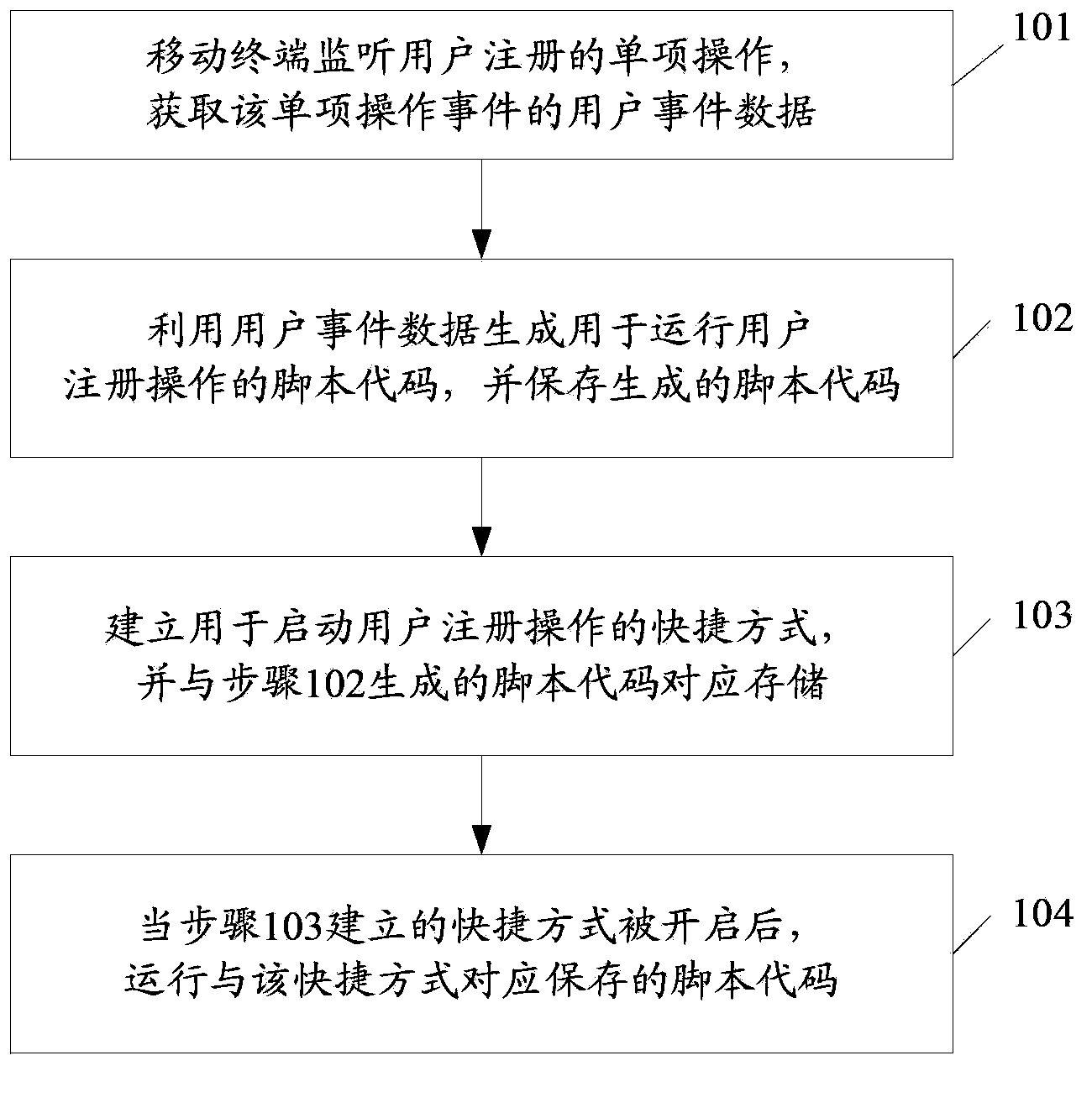

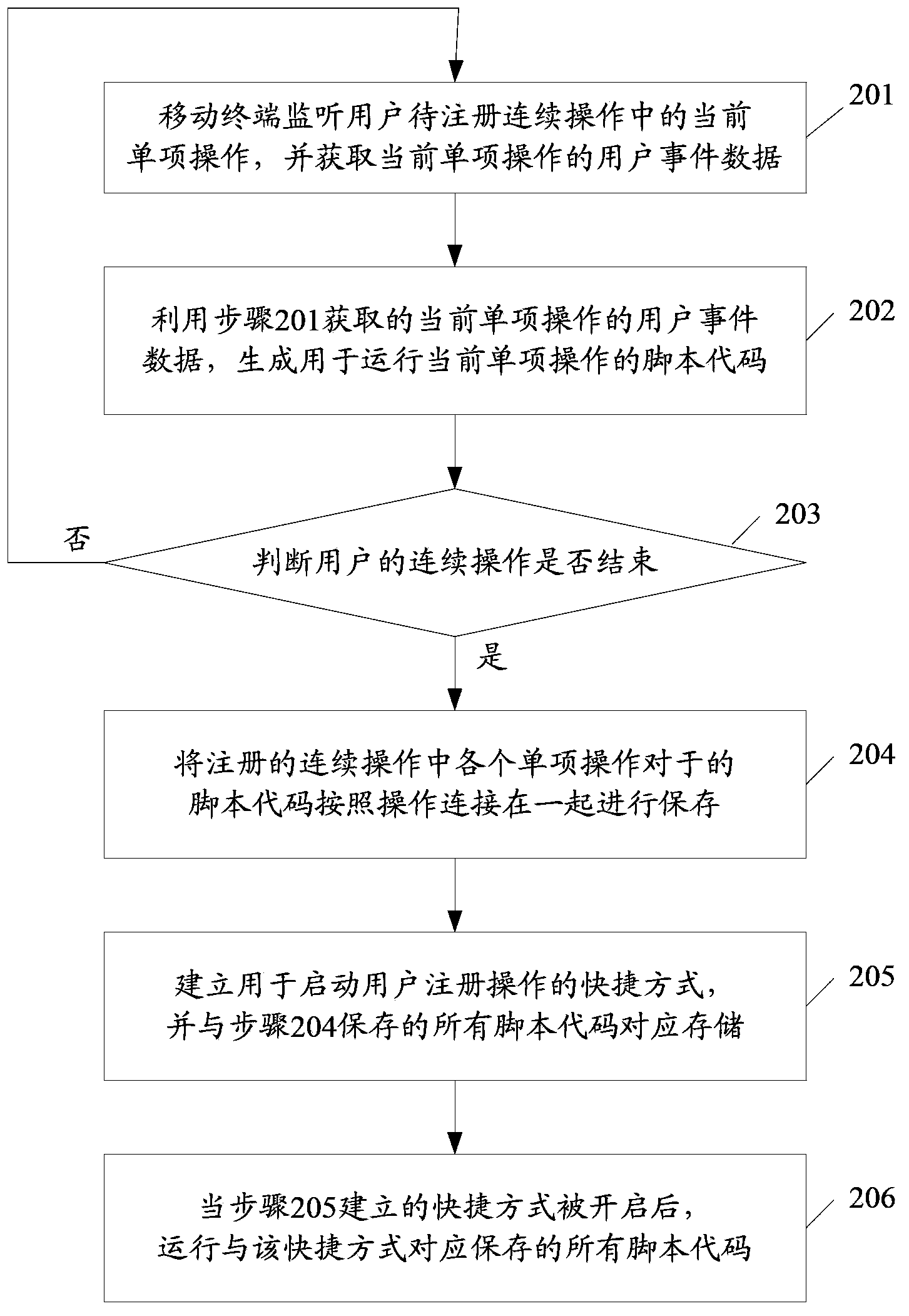

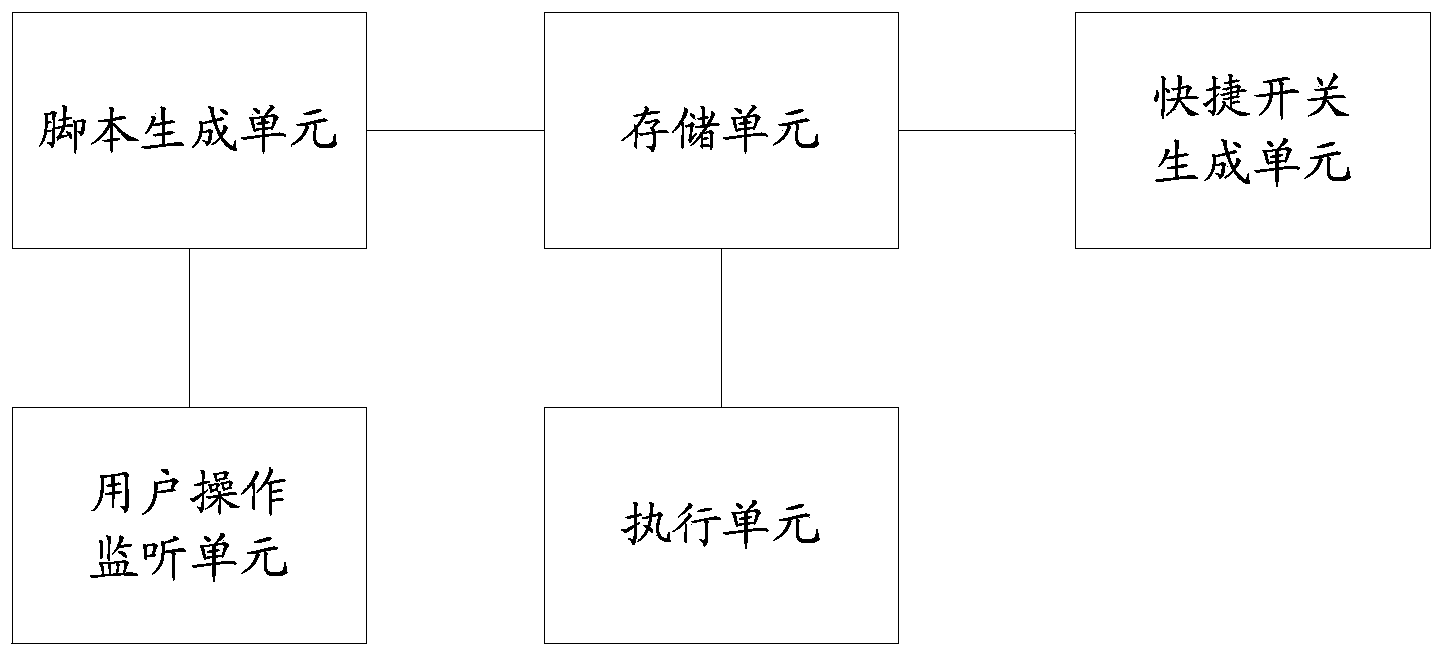

Mobile terminal and method for realizing shortcut operation of mobile terminal

InactiveCN103795835AEasy to operateImprove operational efficiencySubstation equipmentEvent dataContinuous operation

The invention discloses a mobile terminal and a method for realizing the shortcut operation of the mobile terminal. The method includes the following steps that: as for logon operation of users, the mobile terminal sequentially obtains user event data of single operation events in the logon operation, and utilizes the user event data to generate script codes for operating the single operation events, and sequentially connects the script codes of the single operation events and saves the connected script codes; and when the logon operation is started, connected script codes which are corresponding to the logon operation are operated. With the mobile terminal and the method for realizing the shortcut operation of the mobile terminal of the invention adopted, shortcut setting of complex operation can be realized, and continuous operation can be automatically memorized, repetitive and tedious operation can be reduced, and user experience can be improved.

Owner:BEIJING SAMSUNG TELECOM R&D CENT +1

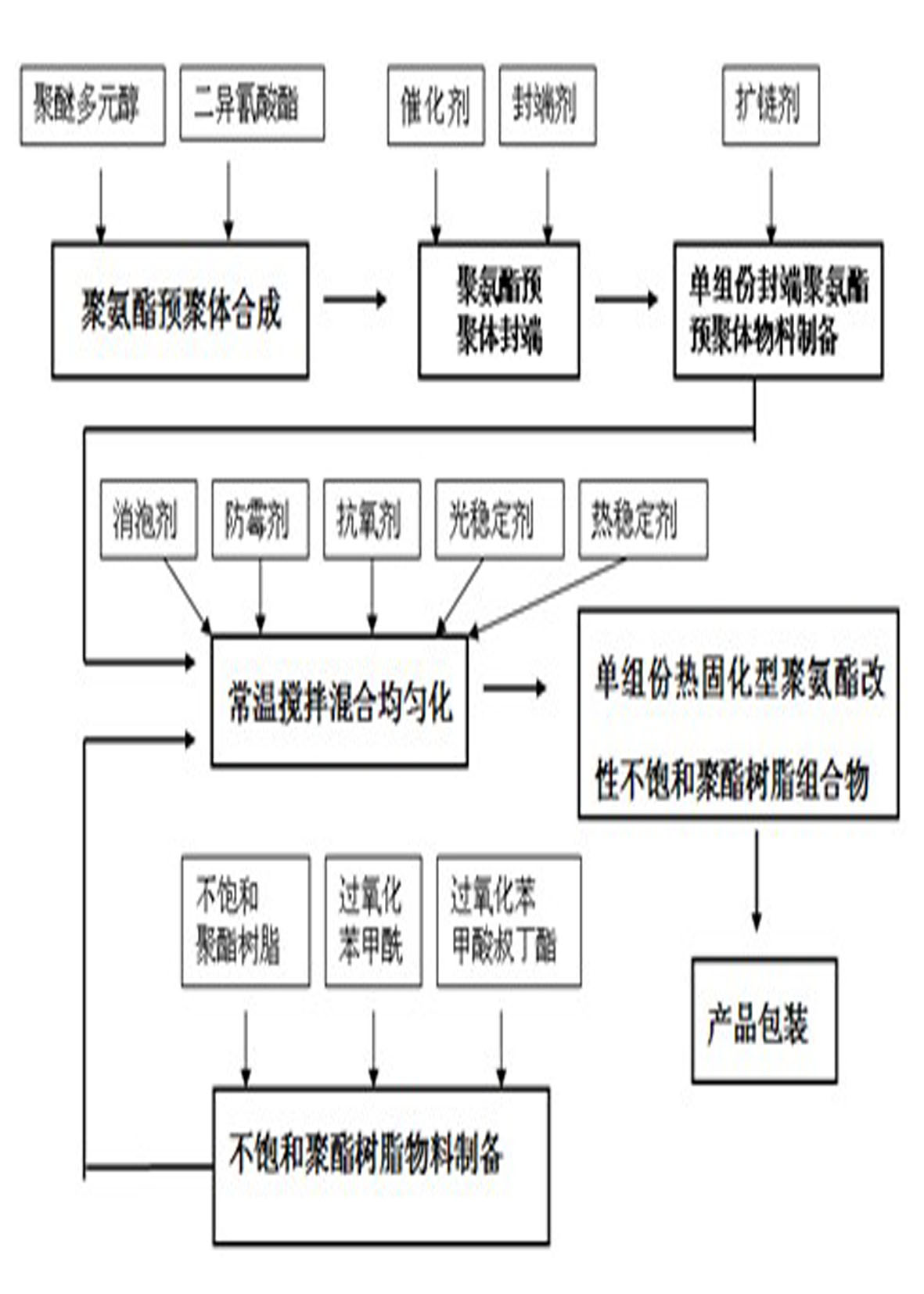

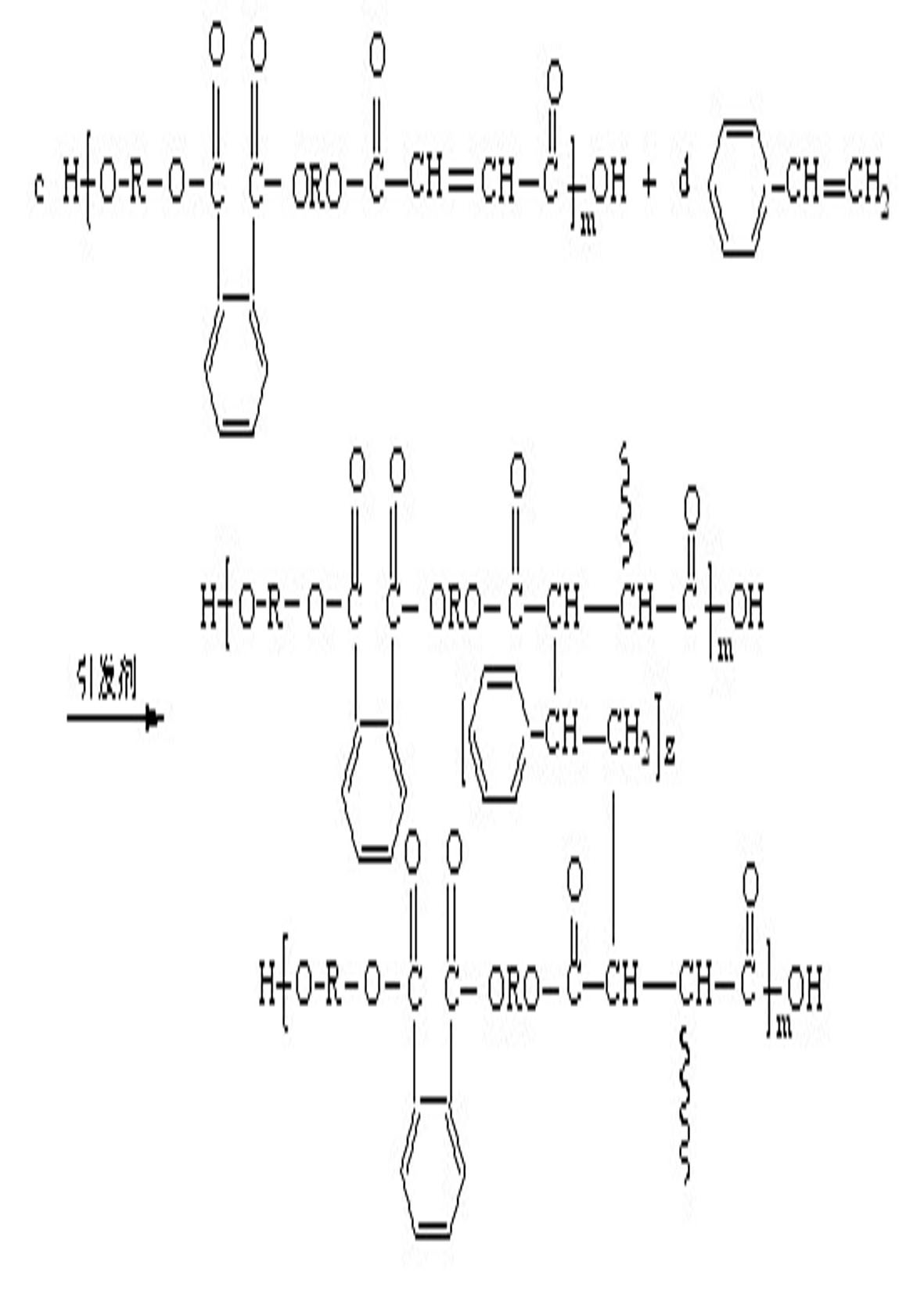

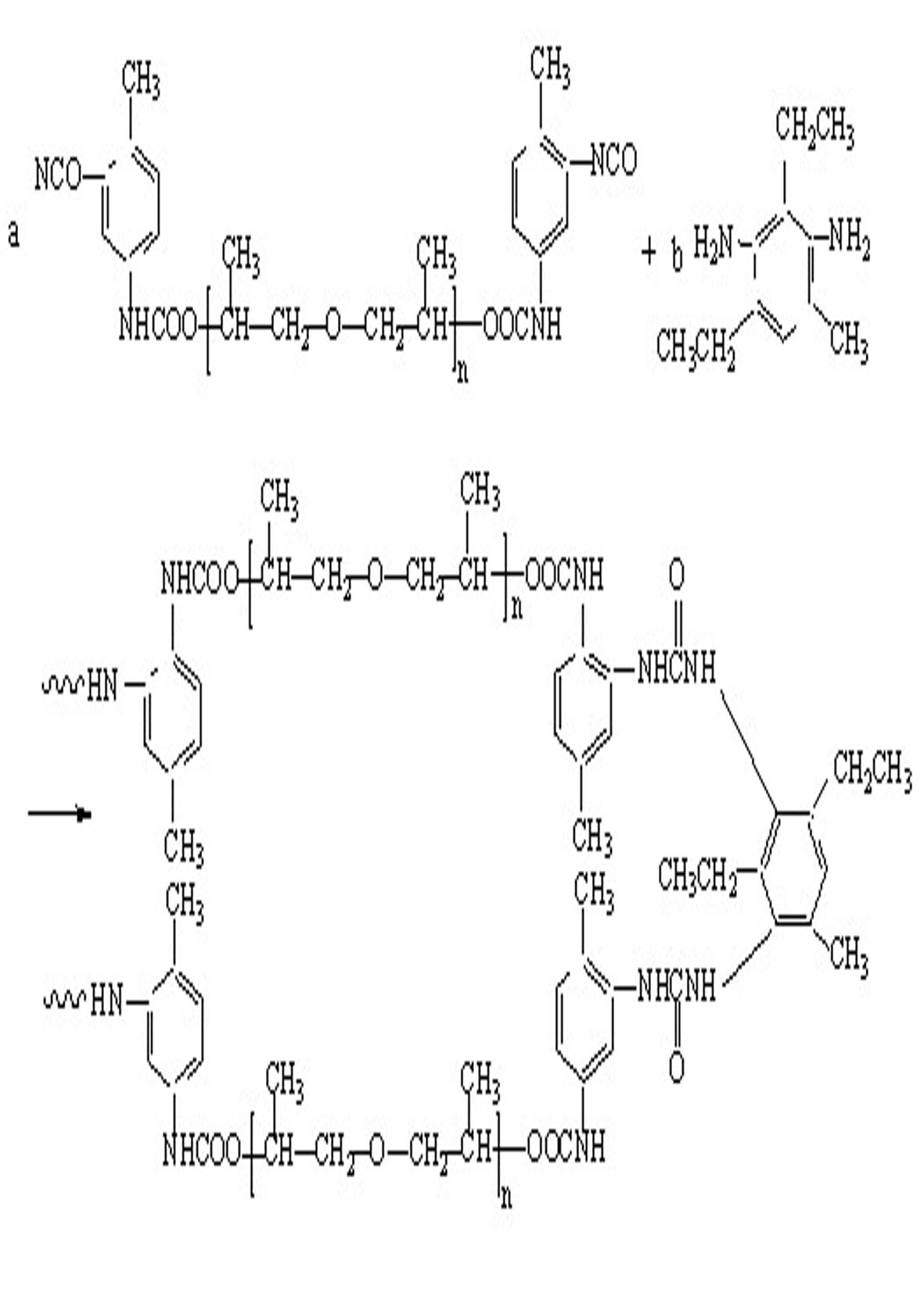

Polyurethane modified unsaturated polyester resin composition and preparation method thereof

The invention relates to a polyurethane modified unsaturated polyester resin composition and a preparation method thereof. The polyurethane modified unsaturated polyester resin composition is prepared through taking 100 parts of an unsaturated polyester resin, adding 13-25 parts of a monocomponent capped polyurethane prepolymer, adding 0.3-0.5 parts of an antioxidant, 0.3-0.5 parts of an antioxidation assistant, 0.3-0.8 parts of a thermal stabilizer, 0.3-0.5 parts of an ultraviolet ray absorbent, 0.3-0.6 parts of a mildew preventive and 0.2-0.5 parts of a defoamer, putting above materials into a mixed reactor, and stirring and uniformly mixing them at normal temperature. The composition of the invention, which can be cured to form a composition with interpenetrating networks of polyurethane macromolucules and unsaturated polyester macromolucules after heat-reacting, solves problems of bad toughness, bad impact resistance, easy cracking after curing and the like of present unsaturated polyester materials, so the composition of the invention can be applied to the building industry and the like as a thermocuring coating and an adhesive.

Owner:TAIYUAN UNIV OF TECH

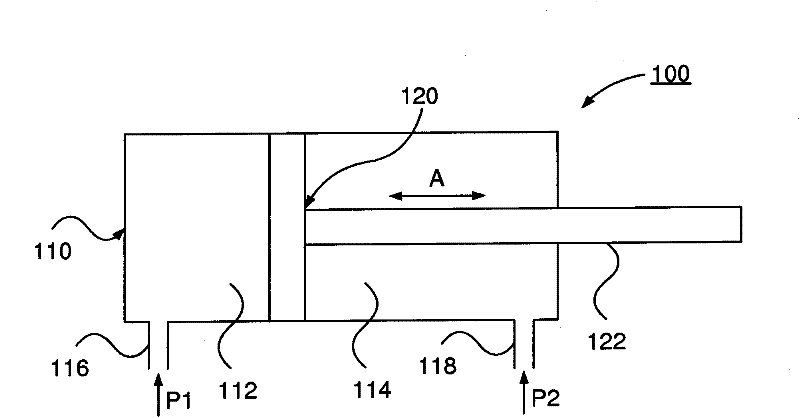

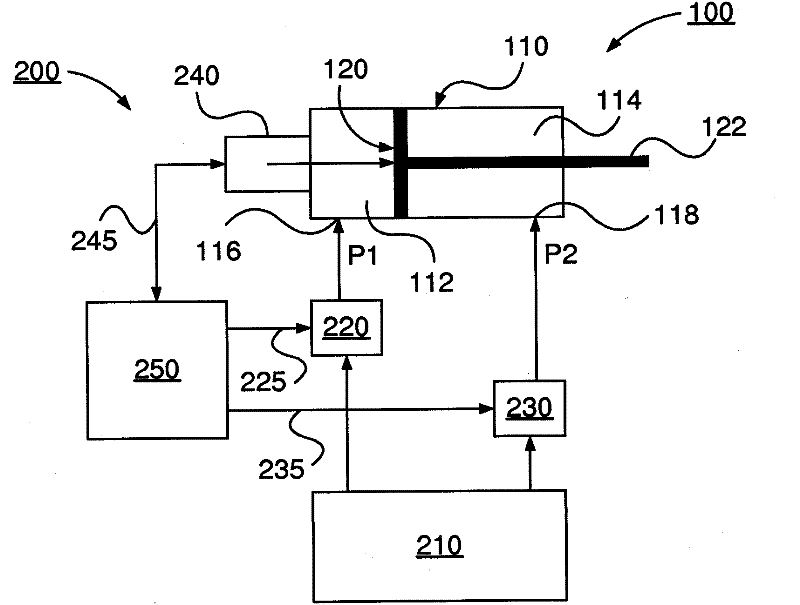

Pneumatic actuator, and system and method for controlling same

InactiveCN102227565AEasy programmingEasy to operate continuouslyServomotorsGearing controlPistonPosition sensor

The present invention relates to a pneumatic actuator comprising a cylinder and a piston arranged to reciprocate within said cylinder, said piston dividing said cylinder into a first space having a first port for passing a first gaseous medium into said first space, and a second space having a second port for passing a second gaseous medium into said second space, so as to move said piston, wherein said first gaseous medium is arranged to be provided as a first set of pulses, and said second gaseous medium is arranged to be provided as a second set of pulses, said sets being arranged to provide an impact difference for moving said piston, and at least one position sensor arranged at said pneumatic actuator to sense the position of the piston, said control of the pneumatic actuator being based upon the position of the piston. The present invention also relates to a system for controlling a pneumatic actuator. The present invention also relates to a method for controlling a pneumatic actuator. The present invention also relates to a computer program and a computer program product.

Owner:SCANIA CV AB

Method for preparing 1,1,1,2,3,3-hexafluoropropane from 1,1,1,2,3,3-hexafluoropropylene and hydrogen gas

ActiveCN101148395AReduce manufacturing costEasy to operate continuouslyHalogenated hydrocarbon preparationAlkanePtru catalyst

The process of preparing 1, 1, 1, 2, 3, 3-hexafluoro propane with 1, 1, 1, 2, 3, 3-hexafluoro propylene and hydrogen belongs to the field of hydrogenating organic halide to prepare alkane. Compound 1, 1, 1, 2, 3, 3-hexafluoro propylene and hydrogen are made to react in the presence of catalyst comprising one or several of Ni, Cu, Fe, Cr, Zn and Al and one or several of RE metal oxide, transition metal oxide and alkali metal oxide. The preparation process with non-noble metal as the main active components in the catalyst has greatly lowered cost, simple reaction process, high material utilizing rate and no pollution.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

Solid-liquid separating device and separating method

The invention discloses a solid-liquid separating device and a separating method. The solid-liquid separating device at least comprises a solid-liquid mixture holding component, an elastic porous adsorption component, an extruding component and a support component, wherein the solid-liquid mixture holding component is used for storing or conveying an unseparated solid-liquid mixture; the elastic porous adsorption component is made of a plurality of capillary tubes, is arranged on the solid-liquid mixture holding component, and is in contact with the mixture; the extruding component is used for extruding the elastic porous adsorption component; and the support component is used for supporting the elastic porous adsorption component when the elastic porous adsorption component is extruded by the extruding component, and is a porous component. By adopting the solid-liquid separating device and the separating method, solid-liquid separation can be realized without adding a large quantity of substances such as flocculating agents or introducing a large amount of mechanical energy, so that the energy consumption is low, and the treatment cost is low.

Owner:蔡子辉

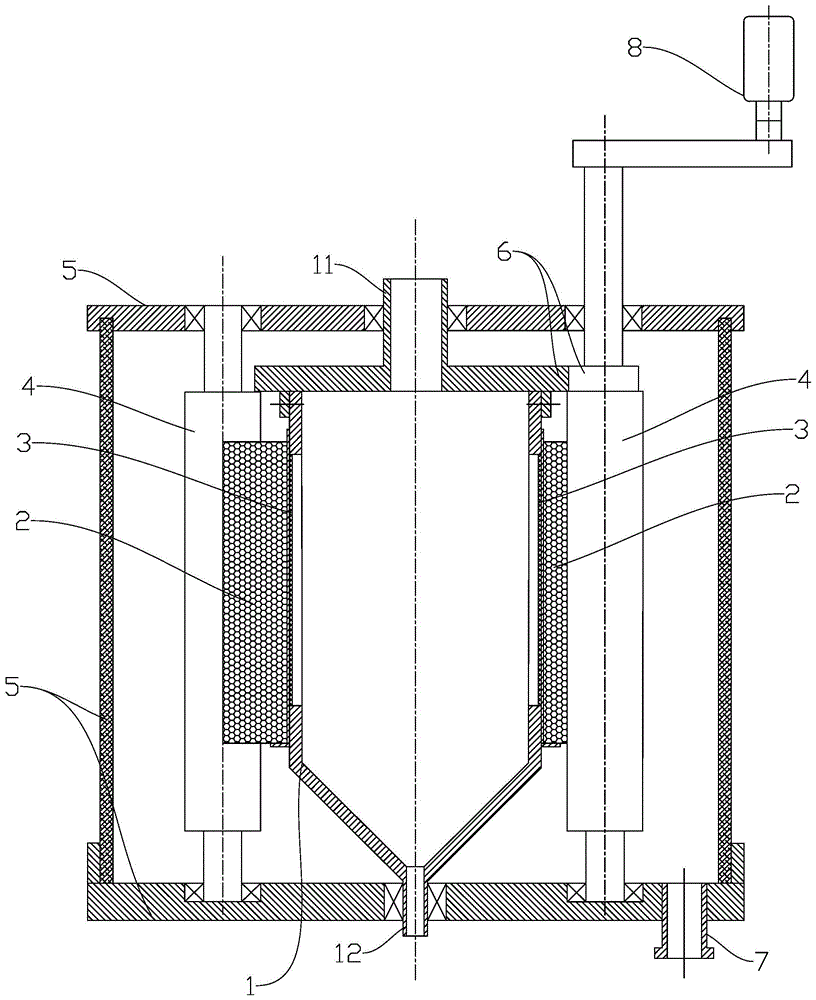

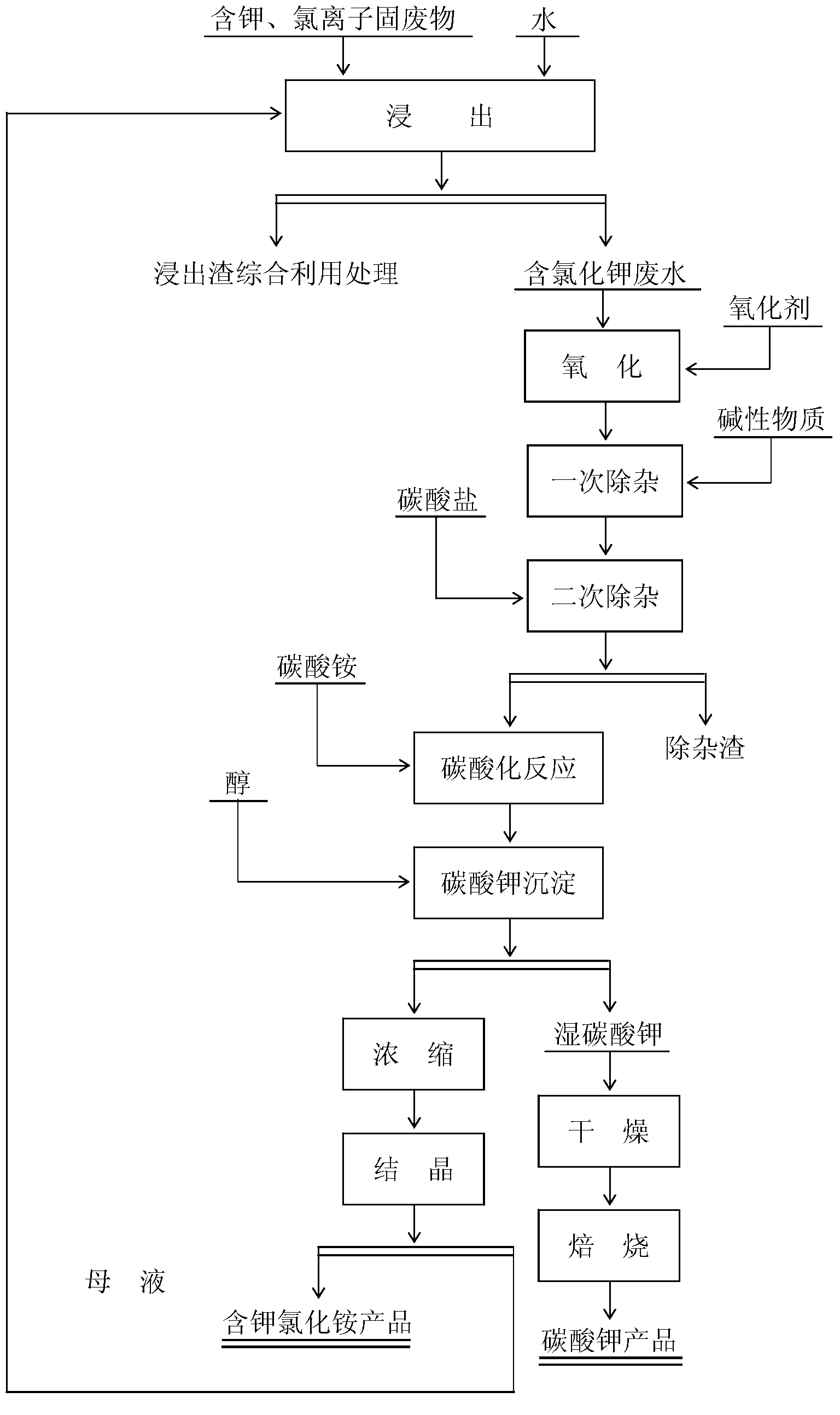

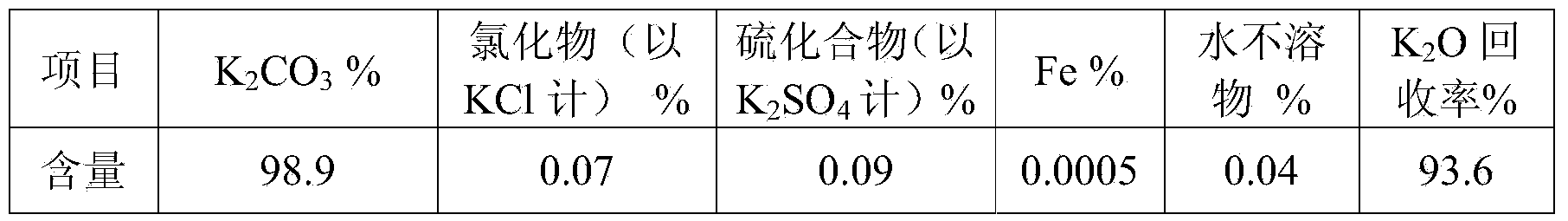

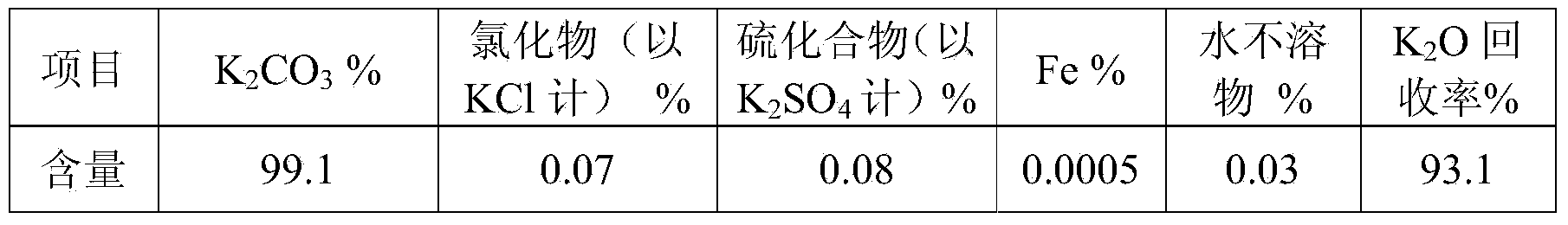

Method for producing potassium carbonate by using solid wastes containing potassium and chlorine ions

InactiveCN104291362AImprove product qualitySimple processSolid waste disposalAlkali metal carbonatesPotassium carbonateChloride potassium

The invention discloses a method for producing potassium carbonate by using solid wastes containing potassium and chlorine ions. The method comprises the following steps: leaching the solid wastes containing potassium and chlorine ions by using water, wherein potassium and chlorine ions as well as other soluble impure ions enter into water to form a mixed solution containing potassium chloride; adding an oxidizing agent into the mixed solution, then adding alkaline substances after oxidization, and adjusting the pH value and alkalinity of the solution for edulcoration for the first time; further adding a certain weight of soluble carbonate for edulcoration for the second time; carrying out solid-liquid separation; adding ammonium salt into the filtrate, and after carbonation reaction, adding alcohols to settle potassium carbonate; after precipitation reaction of potassium carbonate, carrying out solid-liquid separation; drying the filter residues to obtain a potassium carbonate product; and adding the filtrate into concentration and crystallization equipment for concentration and crystallization, and carrying out solid-liquid separation to obtain the filter residue which is an ammonium chloride product containing potassium. By virtue of the method, the recovery rate of K2O in the mixed solution containing potassium chloride in the product is less than 92.5% and the purity of potassium carbonate is not less than 96.5%.

Owner:XIANGTAN TIANZHI TECH

Preparation method of ultra-pure 1,1,1,2,3,3,3-heptafluoropropane

The invention provides an adsorption and rectification combined technology for preparation of ultra-pure 1,1,1,2,3,3,3-heptafluoropropane. An ultra-pure 1,1,1,2,3,3,3-heptafluoropropane crude product is first subjected to adsorption treatment and then subjected to rectification and purification. The prepared 1,1,1,2,3,3,3-heptafluoropropane has purity reaching 99.99%, even 99.999% or higher, and any alkene impurity less than 5 ppm. The prepared ultra-pure 1,1,1,2,3,3,3-heptafluoropropane can be used as a medicinal aerosol propellent.

Owner:中化蓝天氟材料有限公司 +2

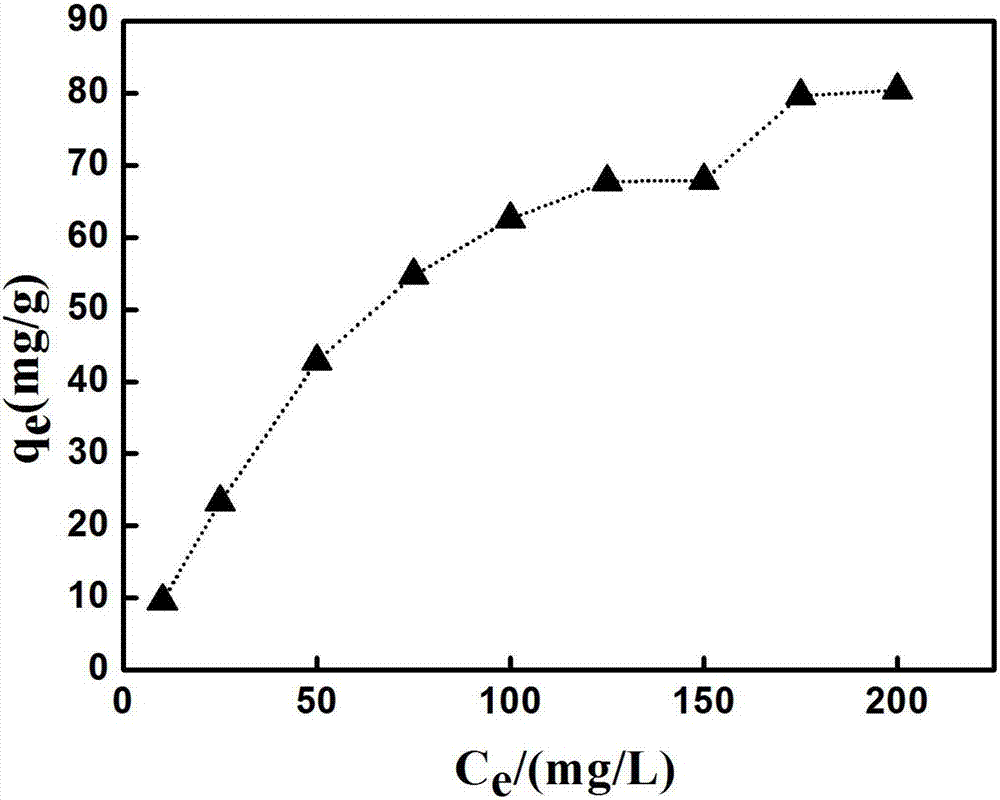

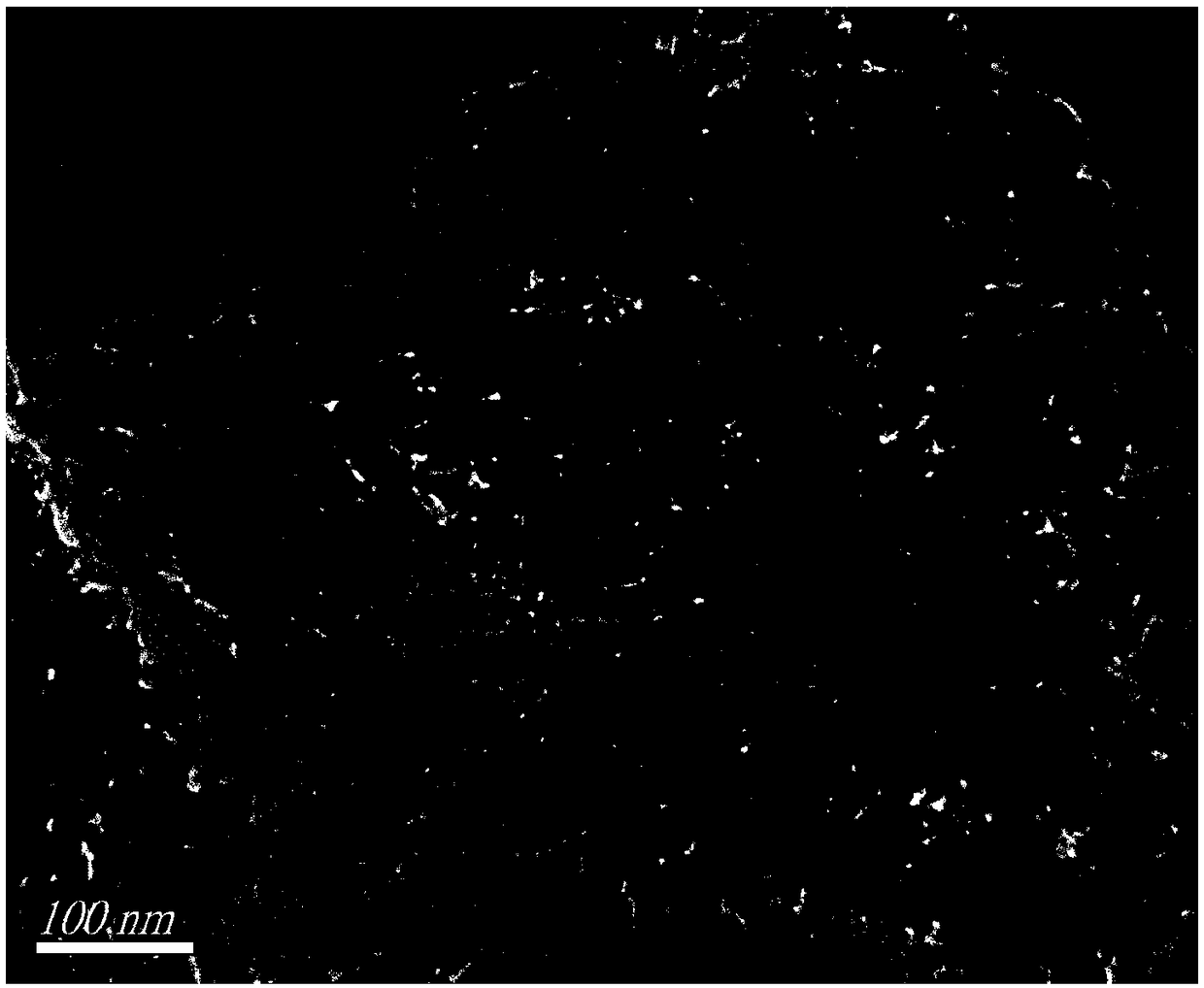

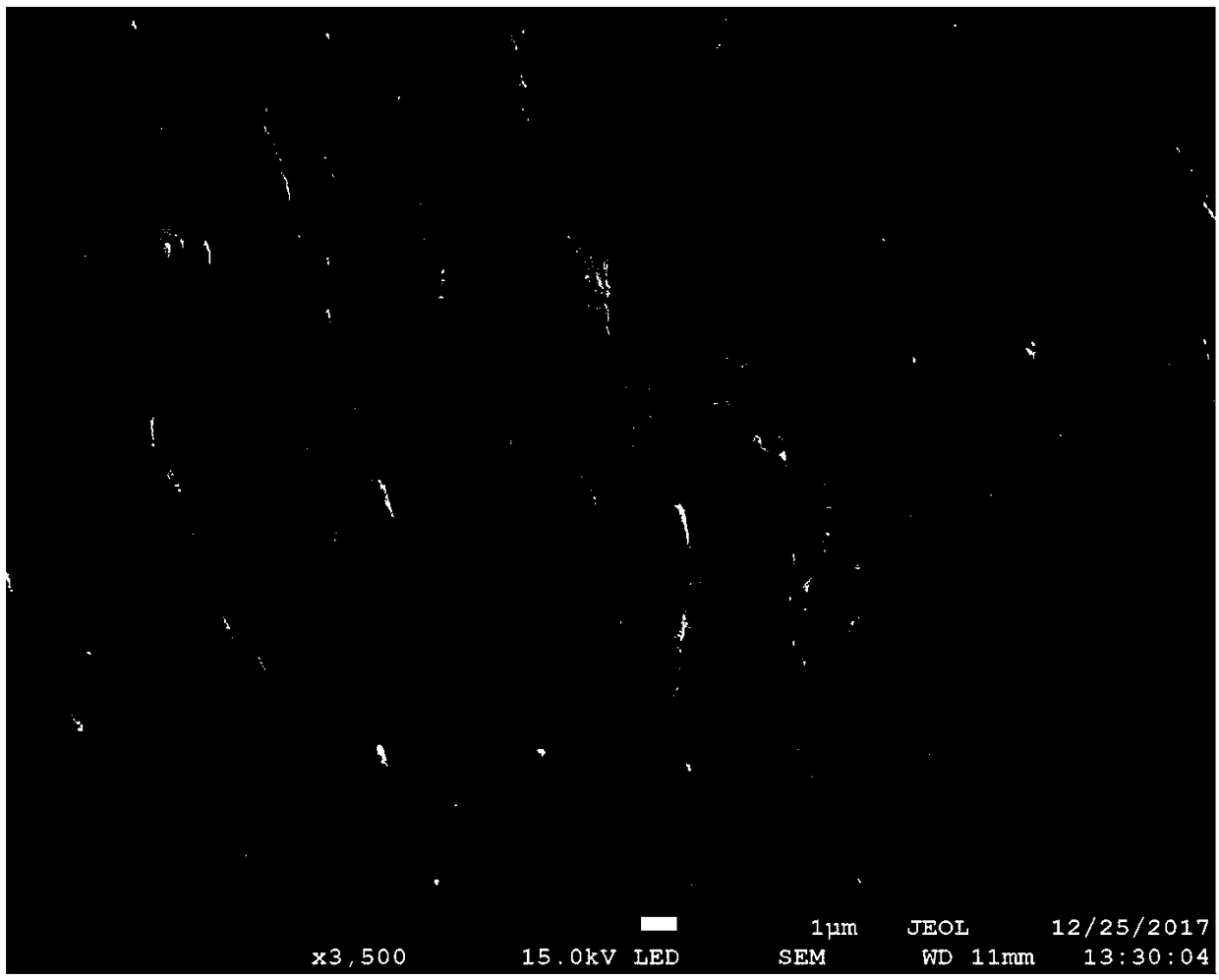

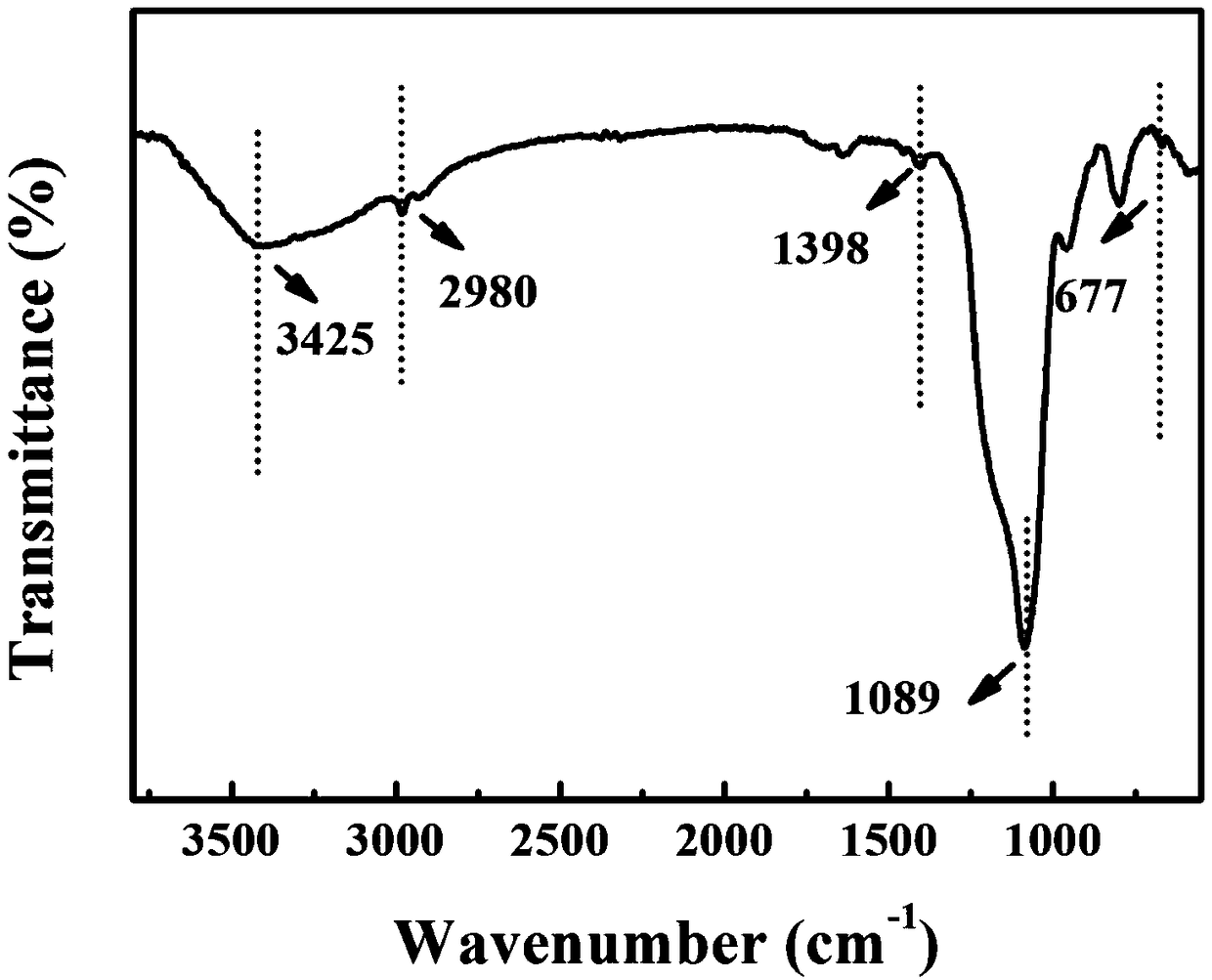

Oxidized graphene doped mesoporous silicon film, preparation method thereof and application of film

InactiveCN108325507AEasy to operate continuouslyEasy to recycleOther chemical processesProcess efficiency improvementPhysical chemistrySilicon membrane

The invention belongs to the technical field of material preparation and separation, and relates to a preparation method of an oxidized graphene doped ordered mesoporous silicon film with high lanthanum adsorption capacity and high selectivity. The one-step direct synthesis preparation method is used for adsorption and recovery of lanthanum serving as a rare earth element. Biomass nano-crystallinecellulose (NCCs) serves as a template, diethyl phosphinylidyne ethyltriethoxysilane (PETES), tetraethl silicate (TEOS) and graphene oxide (GO) are synthesized into film materials, the adsorption performance of adsorbents is greatly improved, continuous operation of the film materials is facilitated, and the film materials are easily recovered and superior to powder materials and have great advantages among various adsorption materials.

Owner:JIANGSU UNIV

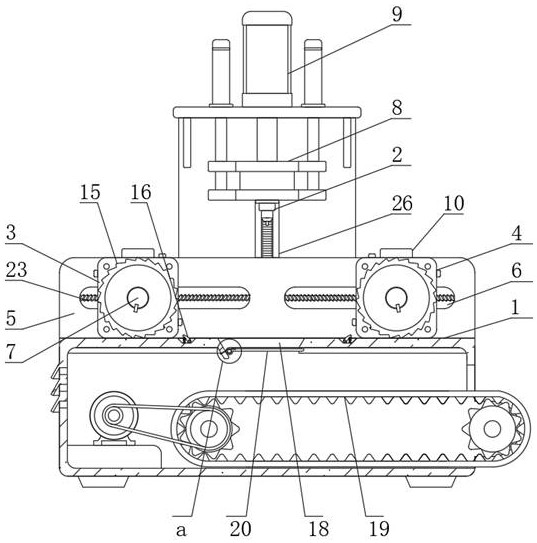

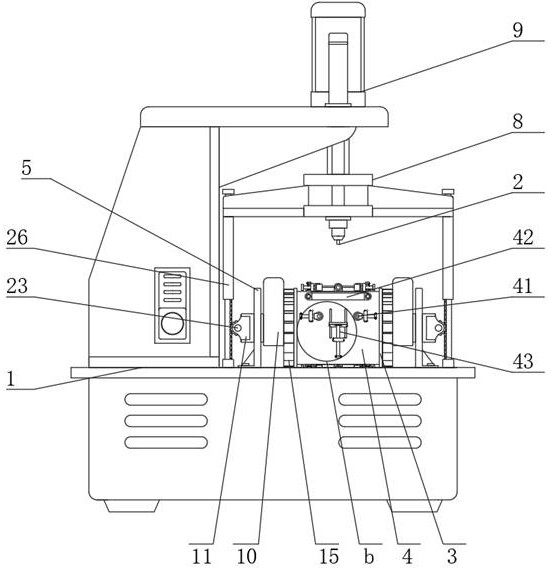

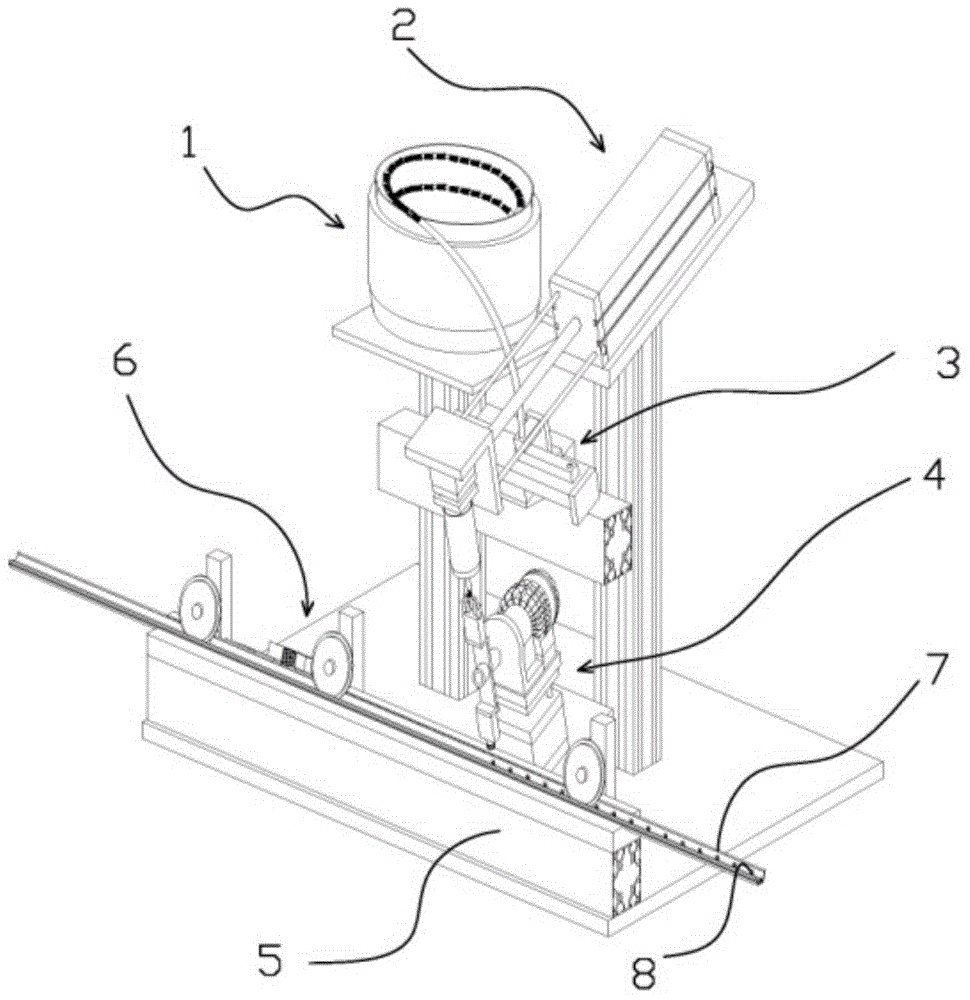

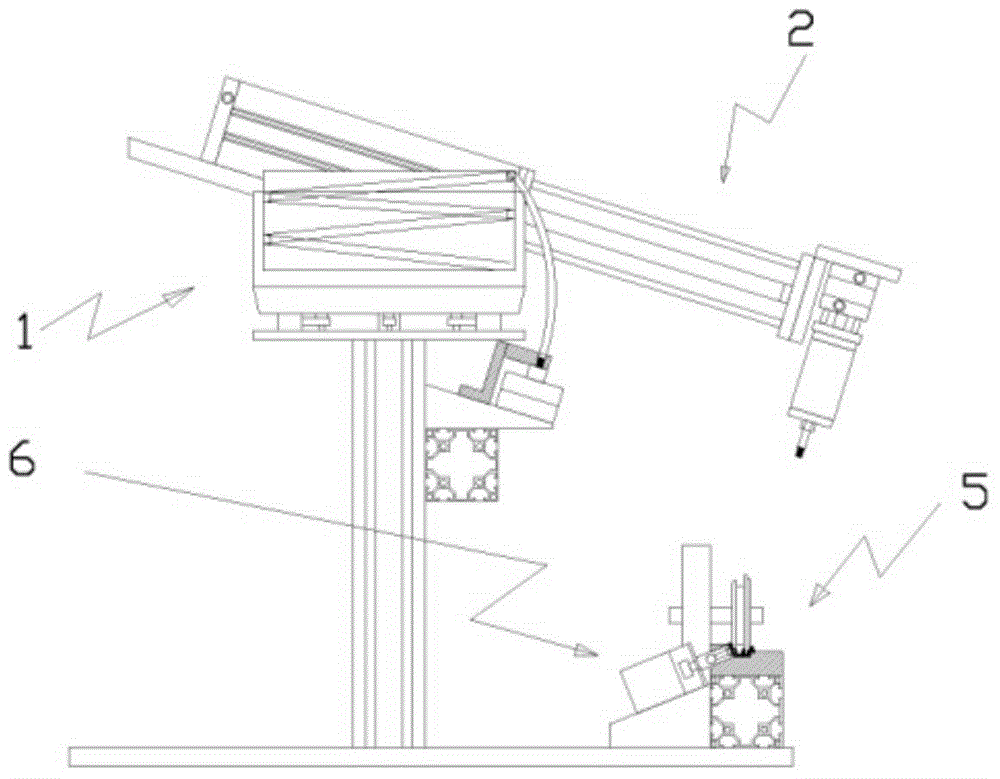

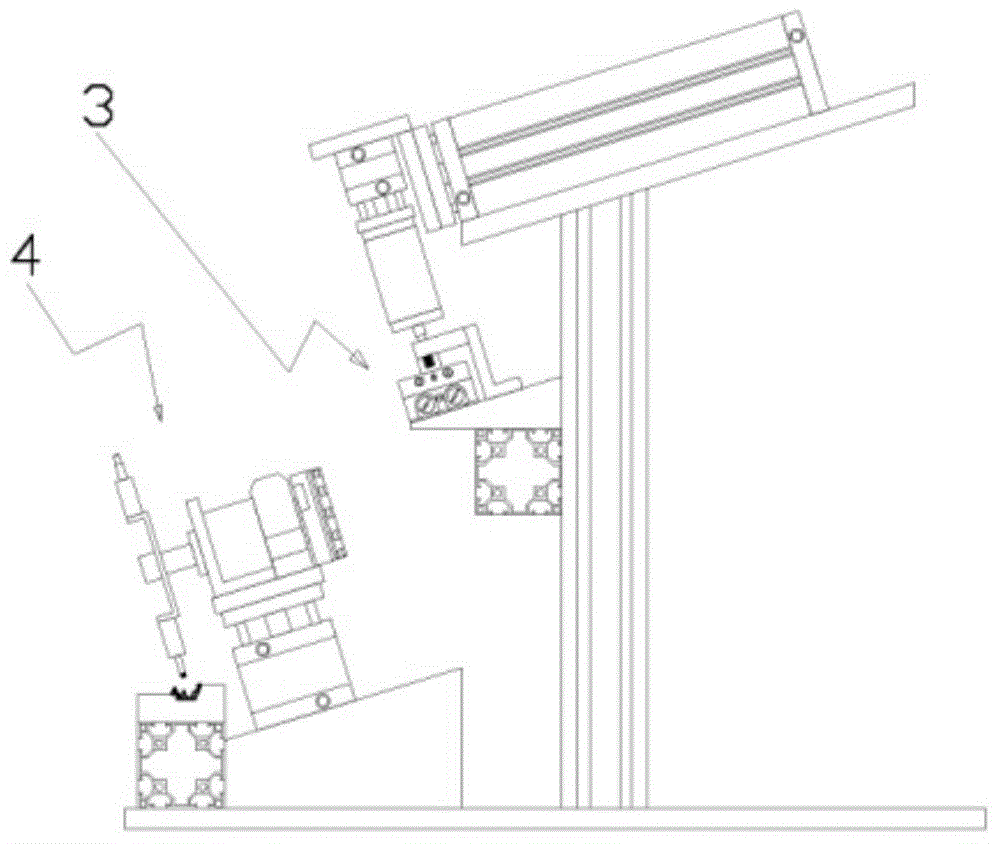

Uninterrupted operation welding positioning device capable of quickly fitting welding surface

PendingCN114289985AImprove work efficiencyEasy to run synchronouslyWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringManufacturing engineering

The uninterrupted operation welding positioning device comprises a machining platform and a welding mechanism above the machining platform, movable bearing tables are arranged on the left side and the right side of the upper surface of the machining platform correspondingly, and positioning clamping discs are arranged on the outer surfaces of the movable bearing tables; side baffles are arranged on the front side edge and the rear side edge of the machining platform correspondingly, translation sliding grooves are transversely formed in the middles of the side baffles, positioning clamping discs are arranged on the upper end face, the lower end face, the left end face and the right end face of the movable bearing table correspondingly, a movable shaft penetrates through the middles of the front end and the rear end of the movable bearing table, and the welding mechanism is installed on the inner side of the lifting movable frame. The movable bearing table capable of turning over and sliding is matched with the multi-face positioning clamping disc, so that a workpiece is slidably guided to be quickly positioned and attached, meanwhile, a multi-face station can be flexibly turned over and replaced, continuous operation of feeding and discharging and welding machining can be conveniently and continuously conducted, and the working efficiency of welding machining is improved.

Owner:江苏博格门窗有限公司

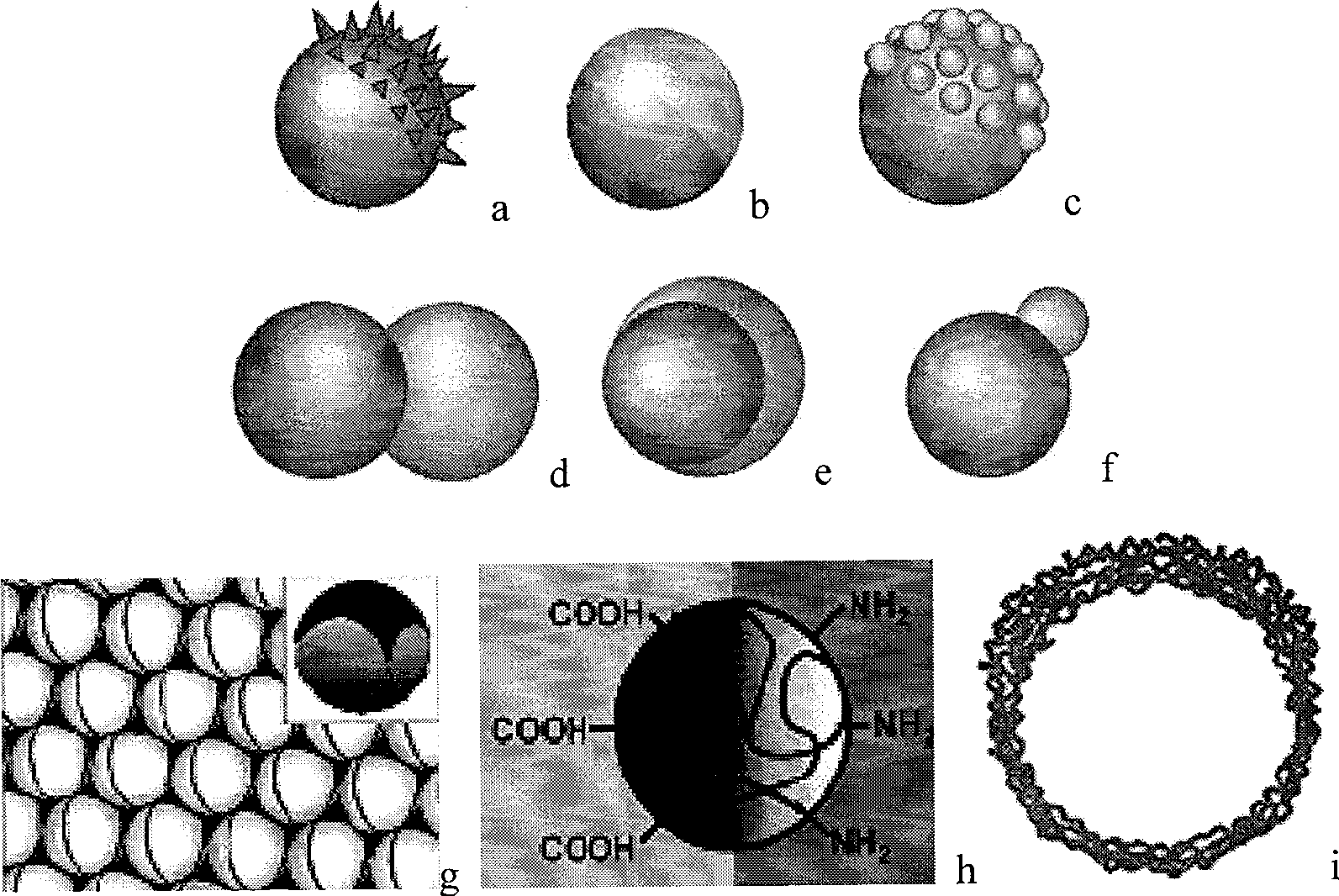

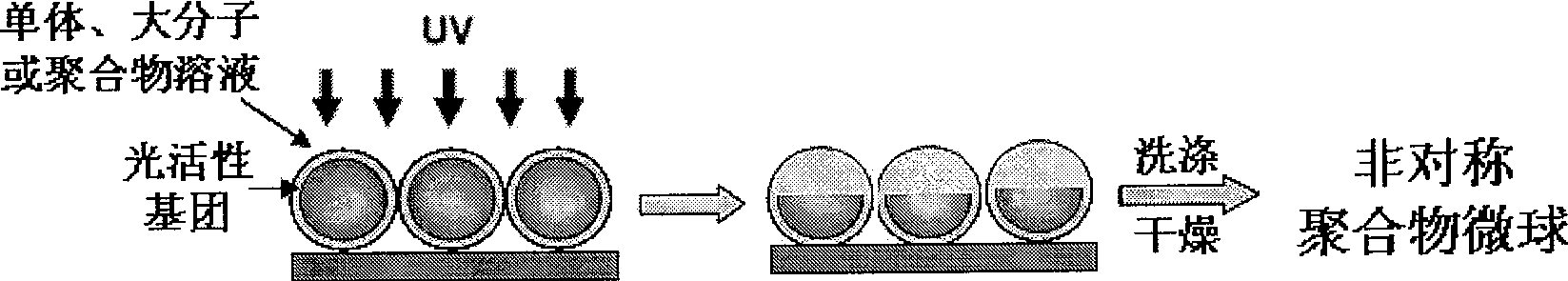

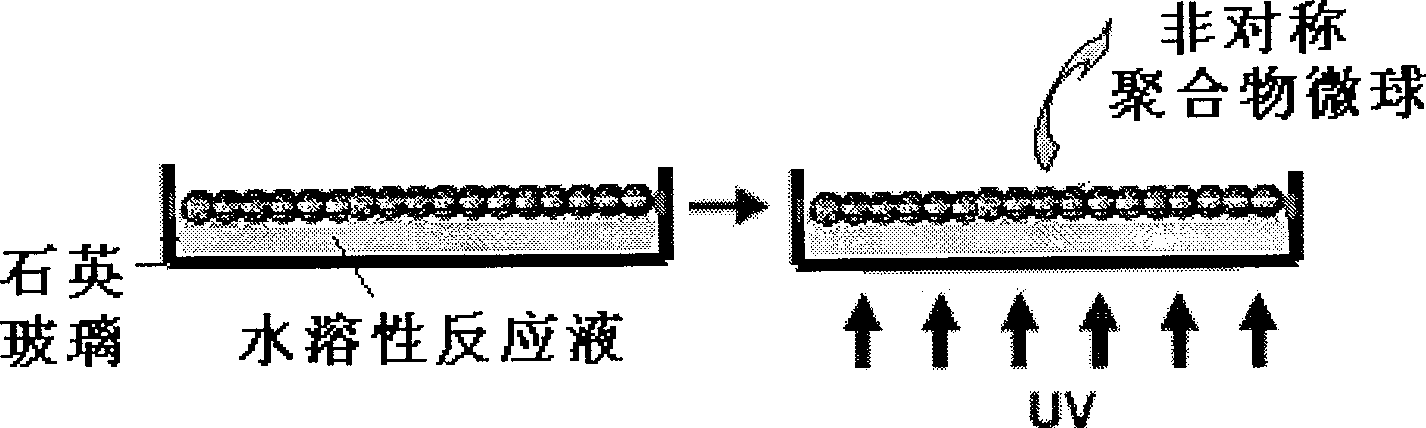

Method for preparing asymmetric polymer microsphere by using optically active polymer microsphere in UV light field

InactiveCN101423567ASolve the problem of unstable distributionQuick responseActive polymerPolymer science

The invention provides a method for preparing asymmetric polymer microspheres in a UV optical field by using optical active polymer, which belongs to the polymerization field. The invention relates to a method for preparing the asymmetric polymer microspheres from isotropic polymer of which the surface contains optical active groups in a UV optical field. Specifically, the invention is a method for preparing the asymmetric polymer microspheres by the reaction difference of optical active groups on different area surfaces of the microspheres to light along the direction of illumination. The method has the advantages of wide applicability, high reaction speed, simple technique and equipment, less investment, high security and environment protection, and the like. Moreover, one of the most apparent characteristic of optical reaction is easy implementation of continuous operation; therefore, the method can greatly improve the preparing efficiency of asymmetric polymer microsphere.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of polycarbonate

InactiveCN101928388AEasy and accurate controlThe method of controlling the flow rate of phosgene is convenient and accurateReaction rateMolecular materials

The invention relates to a preparation method of polycarbonate, belonging to the technical field of preparing high molecular material, in particular to a method for preparing polycarbonate through phosgene interface method; in the course of reaction, the flow of phosgene is controlled to correspondingly regulate the flow of alkaline solution, thus the pH value of the reaction system is controlled within a proper range so as to improve the reaction rate and the conversion efficiency of phosgene and bisphenol.

Owner:甘肃银光聚银化工有限公司 +1

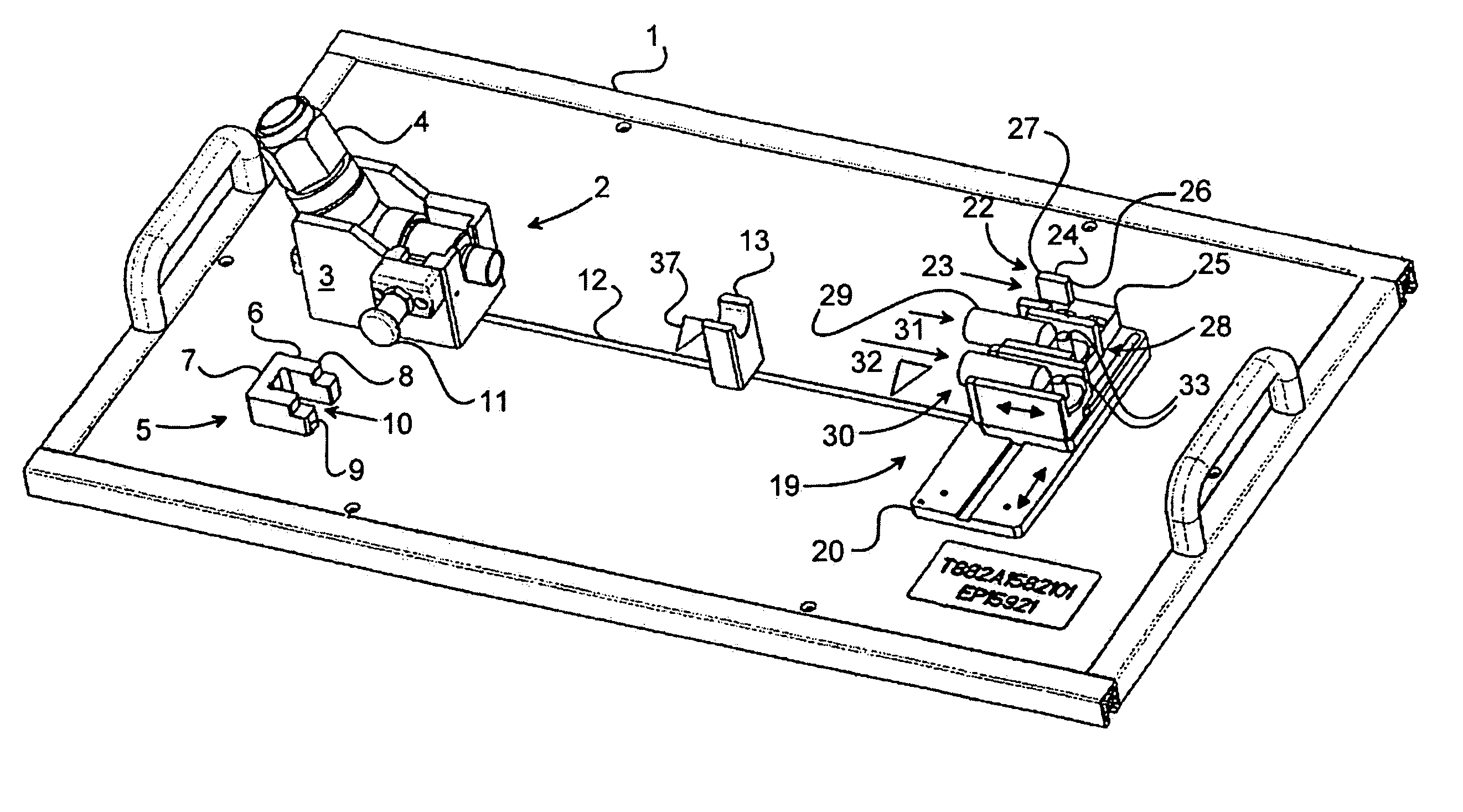

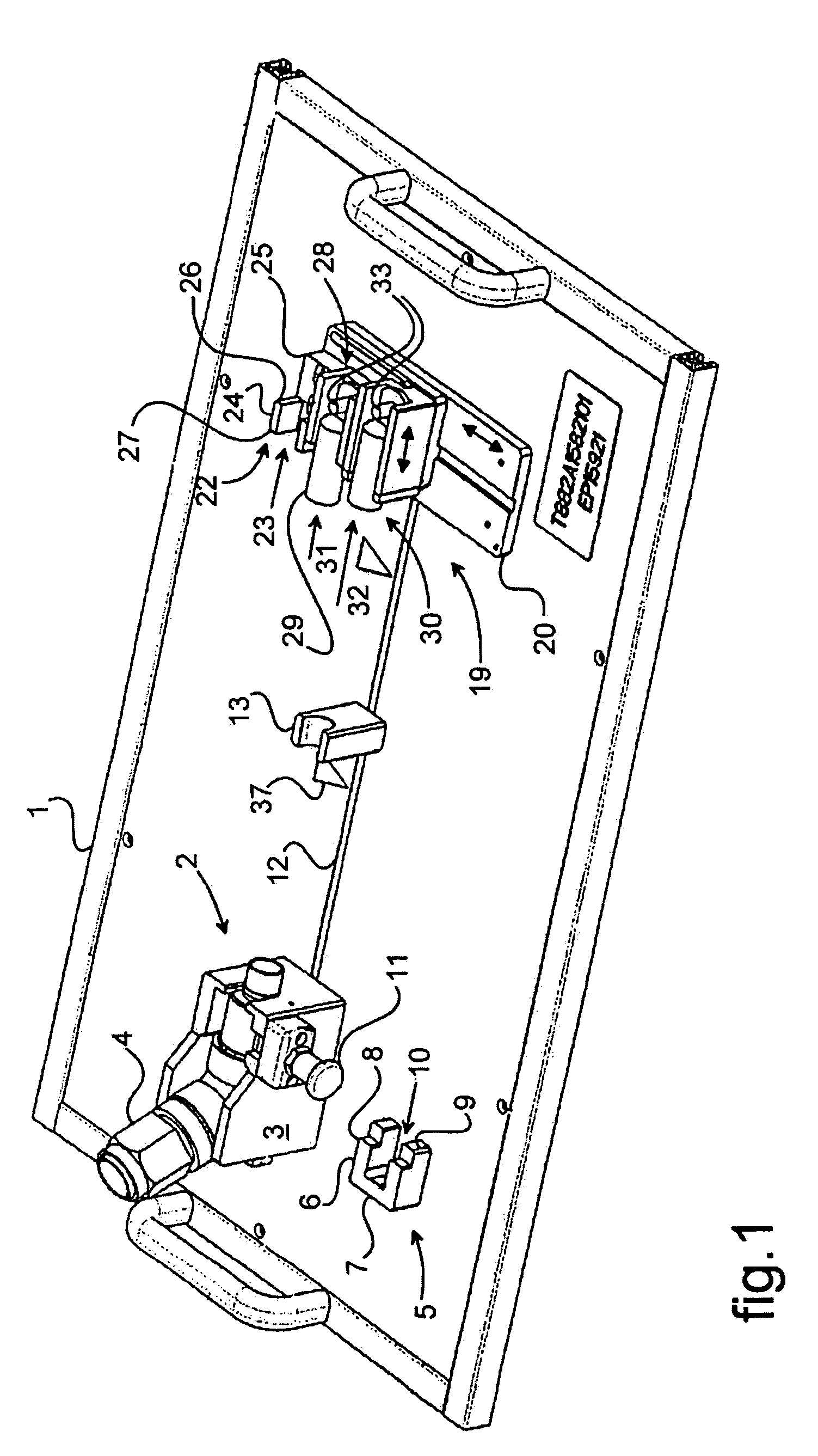

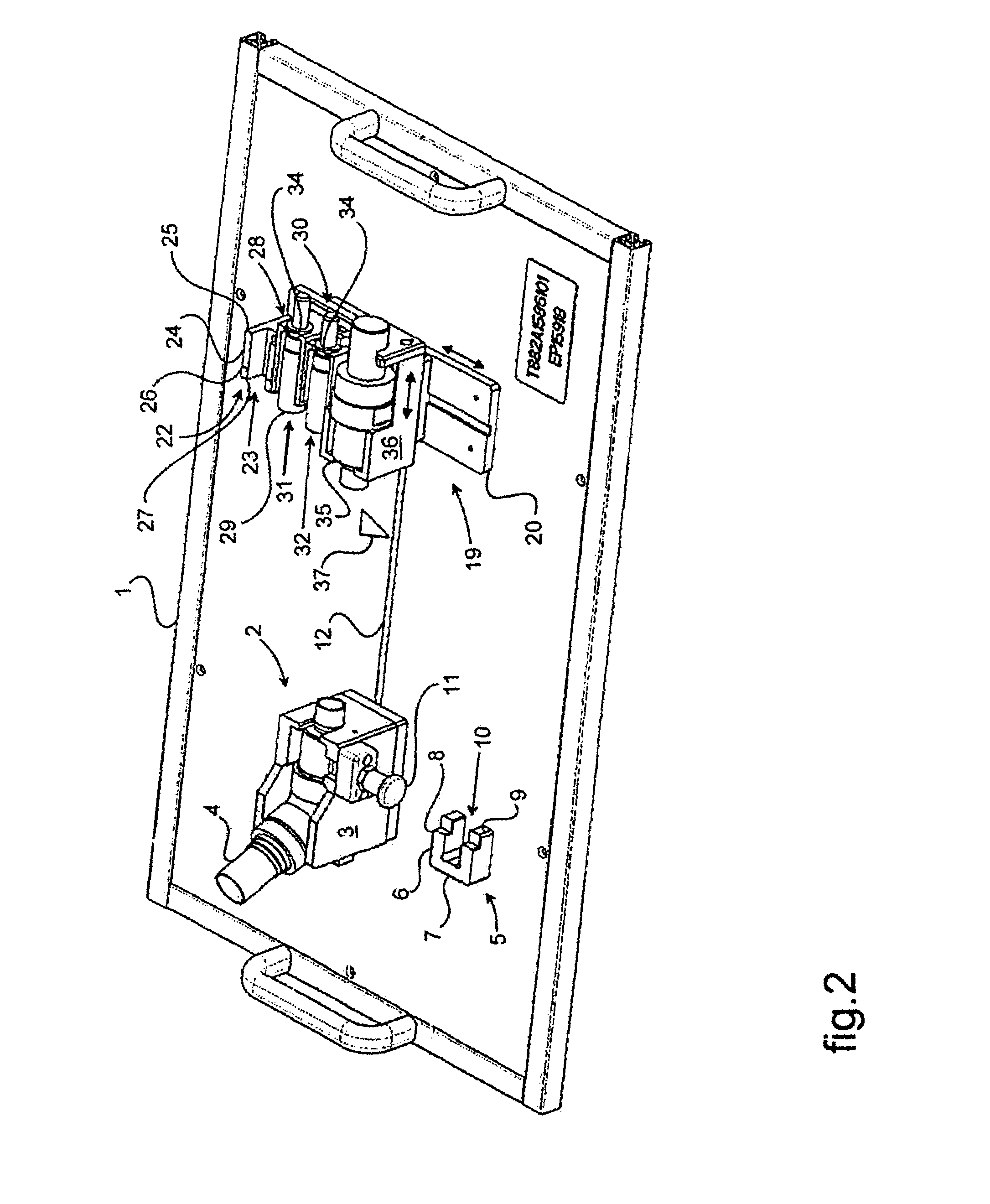

Tooling for manufacturing large-section rigid harnesses

InactiveUS7266877B2Easy to operate continuouslyEasily reliably markElectrically conductive connectionsOther manufacturing equipments/toolsElectric cablesIndustrial engineering

The invention relates to tooling for preparing a large-section harness comprising at least one cable. The tooling includes an output module (19) for receiving the terminal end of the cable. The output module (19) comprises three tools mounted on an output body (20) that is movable on a tray (1) so that each of the tools can be presented in alternation in register with the terminal end of the cable, the tools comprising a first tool (22) for marking cutting and stripping lengths for the cable, a second tool (28) for marking the position and the orientation of the terminal connection member (29), and a third tool (30) for checking that the terminal connection member (29) is in the proper position and orientation after it has been crimped to the terminal end of the cable.

Owner:EUROCOPTER

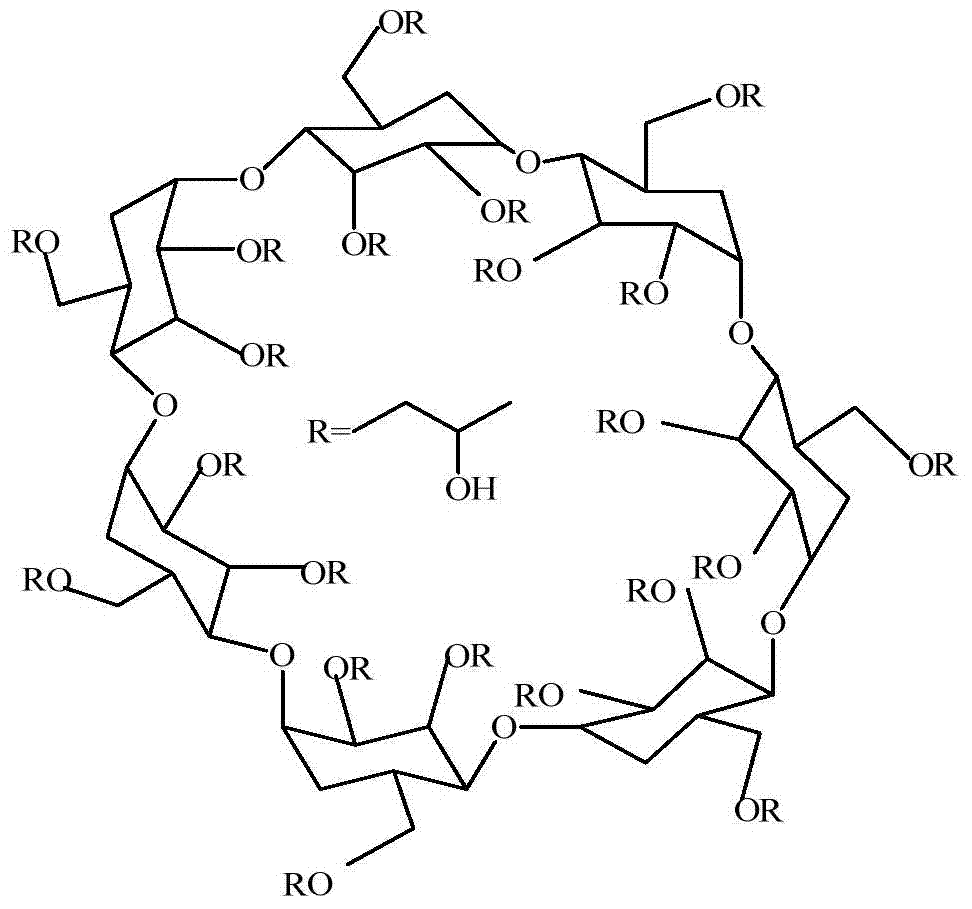

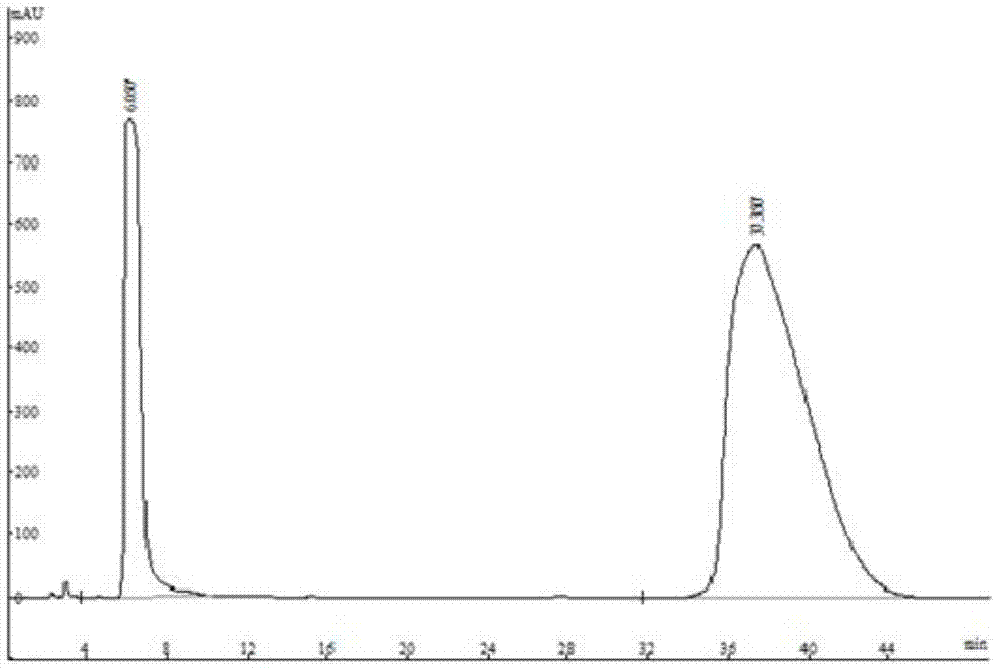

Hydroxypropyl-beta-cyclodextrin chiral composite membrane, and applications thereof

InactiveCN103752180AHigh purityNo phase changeSemi-permeable membranesOrganic compound preparationEnantiomerPolysulfone membrane

The invention discloses a hydroxypropyl-beta-cyclodextrin chiral composite membrane, and applications thereof. A preparation method of the hydroxypropyl-beta-cyclodextrin chiral composite membrane comprises following steps: a polysulfone membrane is immersed in deionized water for two days, is dried vertically in the air, is immersed in a hydroxypropyl-beta-cyclodextrin solution with a concentration of 0.02g / ml, is dried vertically in the air, and is subjected to interfacial polymerization with a 1,6-hexanedioldiisocyanate solution with a concentration of 0.012g / ml; an obtained product is collected, is washed with deionized water after volatilization of reagents on the surfaces, and is dried in that air so as to obtain a chiral composite membrane; and the chiral composite membrane is delivered into a common dialysis device, and d-p-hydroxyphenylglycine raceme solution is separated by concentration difference, wherein purity of d-p-hydroxyphenylglycine enantiomer in a permeate liquid is more than 55%. The purity of the enantiomer obtained via the preparation is relatively high; cost is low; energy is saved; environment is protected; and the preparation method is convenient for continuous operation and large-scaled industrialized production.

Owner:YUNNAN NORMAL UNIV

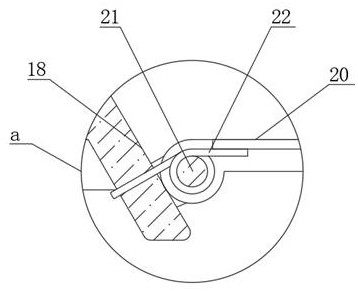

Automatic spring rotary-cutting and inserting machine for preparation of film-suspended insulating glass film stretching frame

An spring rotary-cutting and inserting machine for preparation of a film-suspended insulating glass film stretching frame comprises a spring feeding mechanism, a spring conveying mechanism, a spring taking mechanism, a rotary-cutting mechanism, a frame moving mechanism, a propping mechanism and a work bench, wherein spring feeding, conveying and taking are performed, then a rotary arm in the rotary-cutting mechanism rotates to drive a spring insertion head which is mounted on the rotary-cutting mechanism and clamps a spring to perform circular motions, so that an expansion ring on the last circle at the bottom of the spring is squeezed in the tangential direction of the circumference to become narrow and then enters flared ports in the bottom of the clamping groove of the film stretching frame via the bottle neck of a clamping groove of the film stretching frame, and the expansion ring recovers elasticity, becomes wide and is clamped and positioned in the flared ports. The rotary head of the spring taking mechanism rotates by 360 degrees, so that fractures at the bottoms of springs of the spring taking mechanism face the same direction, and the fractures of bottom rings of the inserted springs in the film stretching frame keep at the same angle. Damage of spring insertion to a sectional material of the film stretching frame is reduced, so that all the fixed springs in the film stretching frame keep in a certain direction and at a certain angle and are distributed well linearly.

Owner:伟视幕墙(上海)有限公司

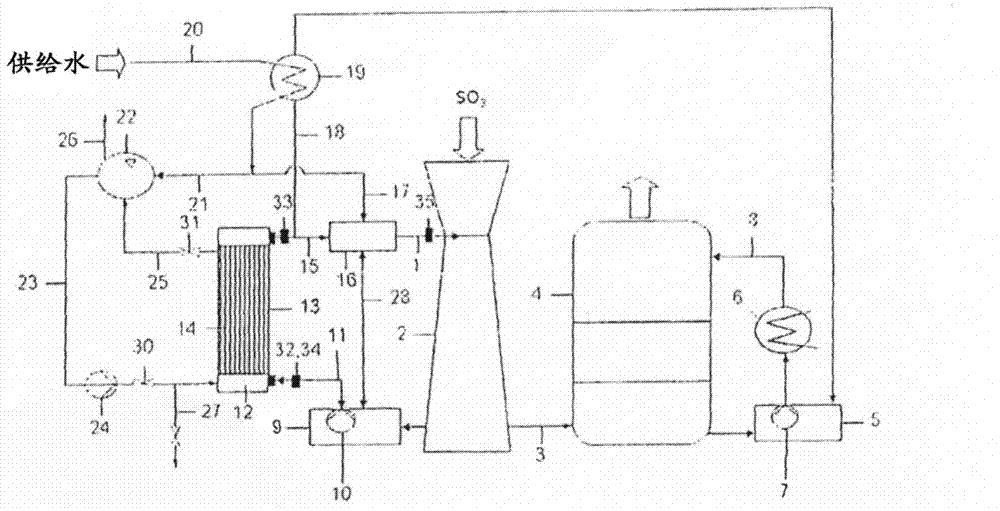

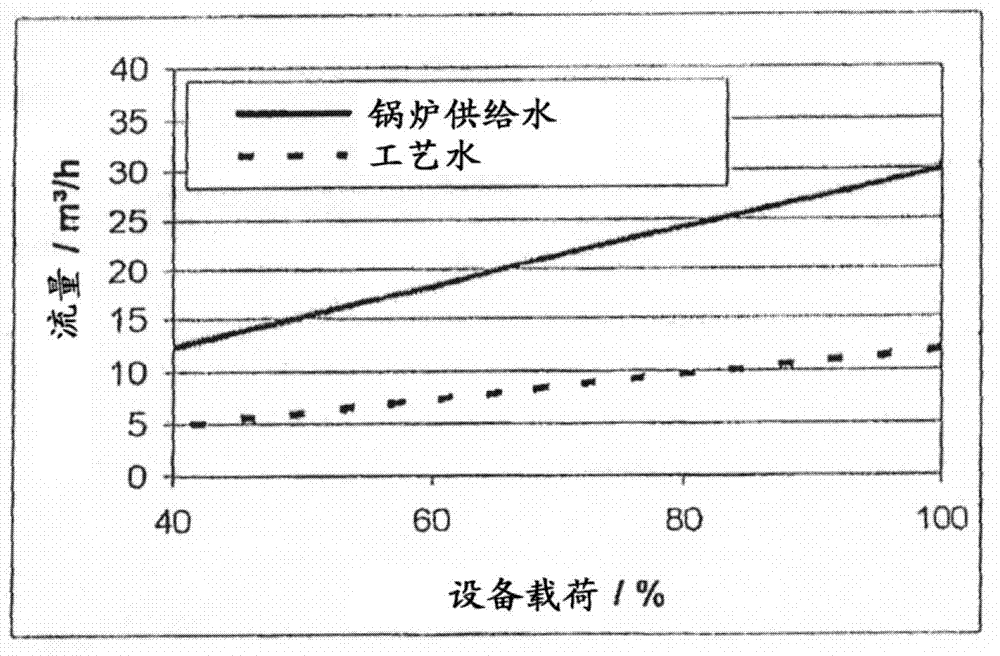

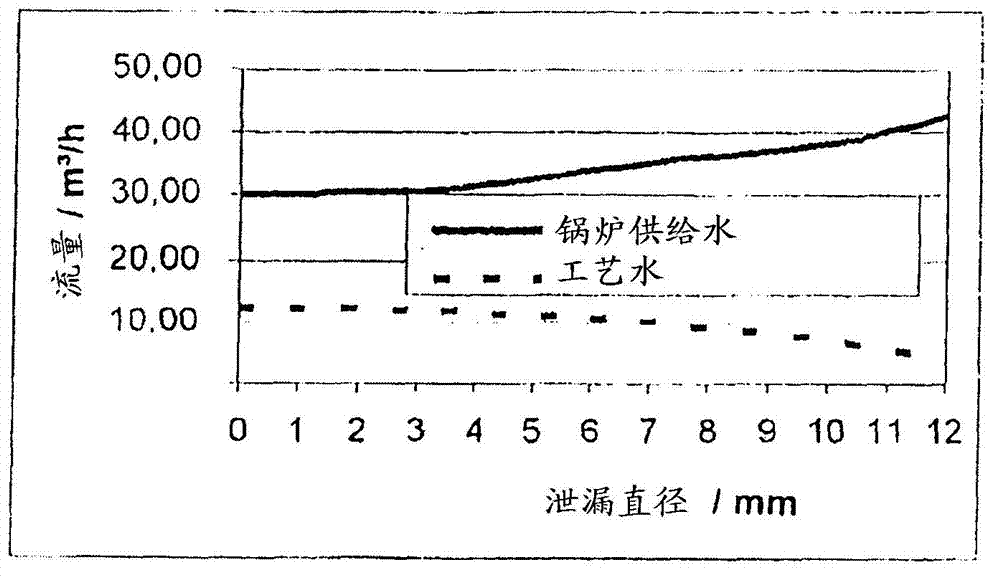

Process and plant for cooling acid

ActiveCN102741159ALess quantityIncrease flexibilitySulfur compoundsSteam useTransport mediumSteam drum

When cooling acid which is withdrawn from an absorption apparatus of a sulfuric acid plant,the acid is pumped from an acid pump tank into a heat exchanger and subsequently again supplied to the absorption apparatus,wherein water as heat transport medium is heated in the heat exchanger with the heat of the acid and is at least partly converted into steam, and wherein the water is separated from the steam.It is provided that the acid is supplied to a shell space of the heat exchanger and the water is supplied to heat transfer elements arranged in the shell space and at least partly converted into steam, that the steam generated in the heat exchanger is separated from water in a steam drum, and that the water thus obtained is recirculated to the heat exchanger by means of a pump.

Owner:METSO OUTOTEC (FINLAND) OY

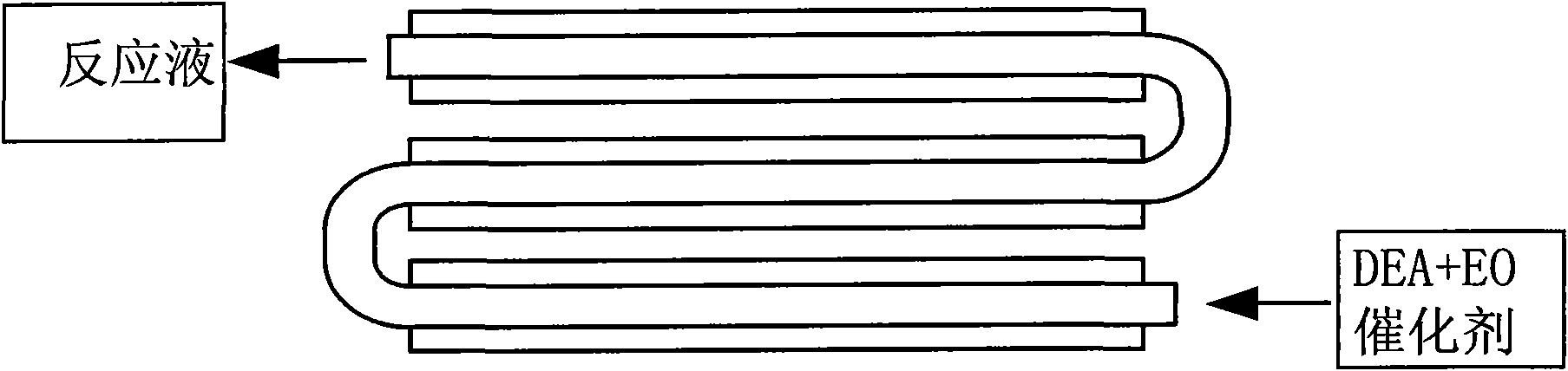

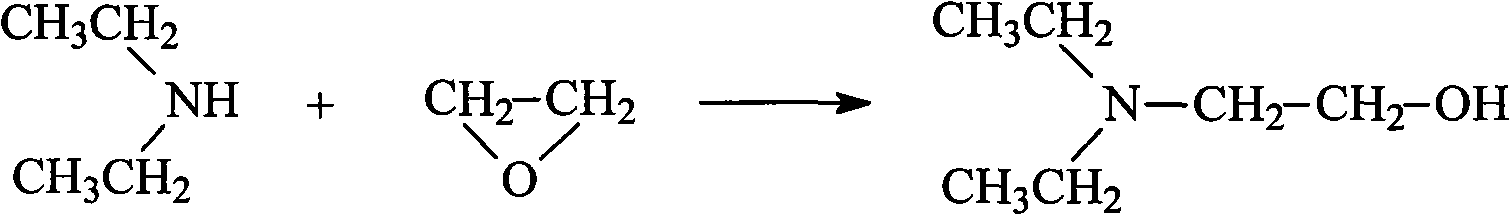

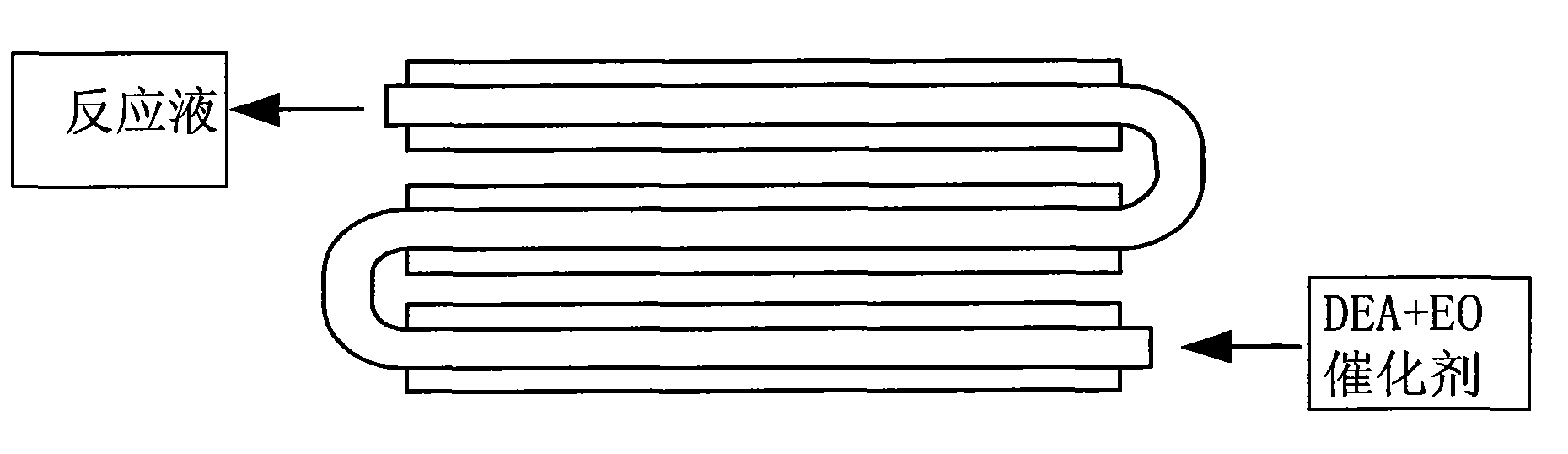

Method for synthesizing N,N-diethyl ethanolamine

ActiveCN102126966AImprove equipment utilizationAvoid side effectsOrganic compound preparationAmino-hyroxy compound preparationContinuous operationEnergy consumption

The invention discloses a method for synthesizing N,N-diethyl ethanolamine, which is to synthesize N,N-diethyl ethanolamine in one step in the presence of a catalyst by using diethylamine and ethylene oxide as raw materials, wherein the molar ratio of diethylamine to ethylene oxide in the reaction is (1-15):1, the synthesis reaction temperature is controlled to be 10 to 180 DEG C, the catalyst is added continuously at a speed of 5 to 10g / h, and the added amount is 0.1 to 2.0 percent based on the total mass of the catalyst and the two materials. The method has the following advantages that: 1) pure diethylamine instead of aqueous solution of diethylamine is used as the reaction raw material, so the energy consumption is low and the equipment efficiency is high; and 2) a tubular reactor with a jacket is adopted to transfer heat conveniently, which is favorable continuous operation.

Owner:ZHEJIANG JIANYE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com