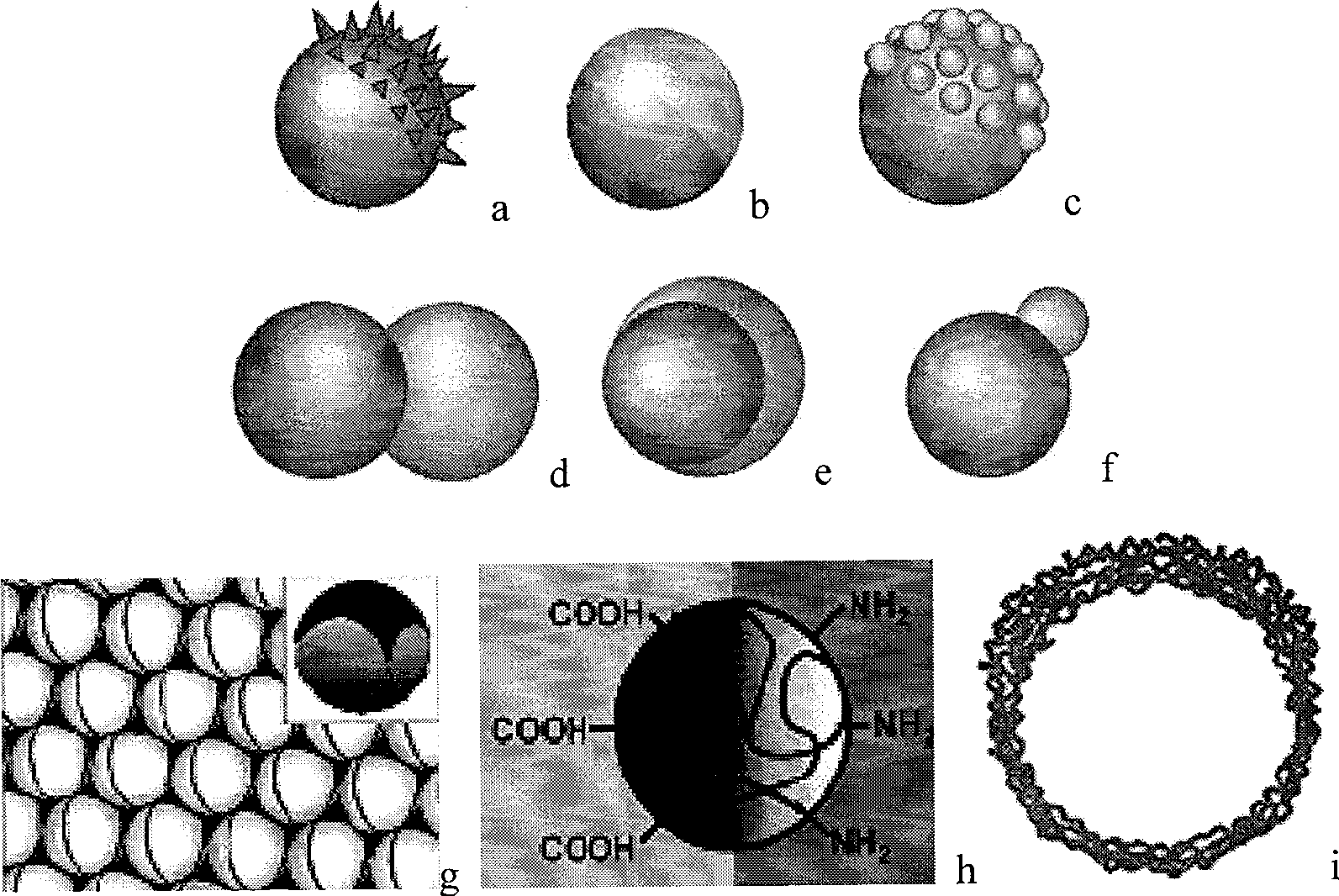

Method for preparing asymmetric polymer microsphere by using optically active polymer microsphere in UV light field

A photoactive polymer, polymer technology, applied in the field of preparation of functional polymer microspheres, can solve problems such as asymmetric spheres that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

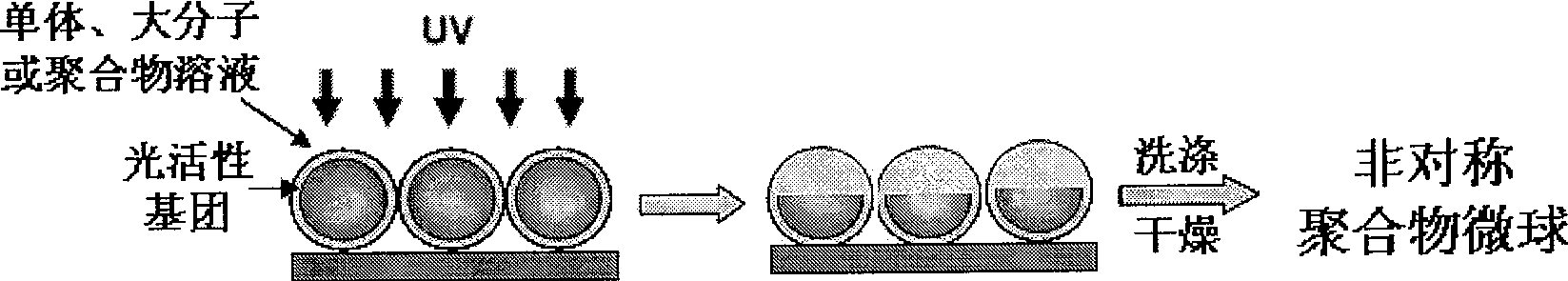

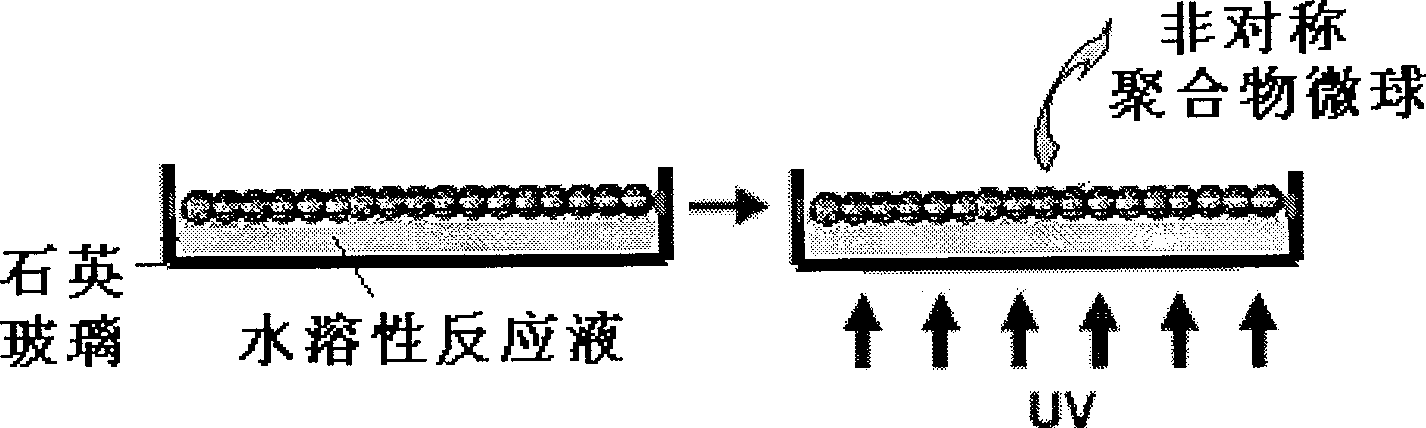

Method used

Image

Examples

Embodiment 1

[0091]After adopting the conventional dispersion polymerization method to react for 5 hours, within 10 to 15 minutes, add dropwise an acetone solution of 4-acrylate-based benzophenone (BPA) in the reactor (BPA accounts for 4% by mass of styrene), and continue The reaction ended after 5h. The obtained reaction solution was centrifuged, washed with methanol for 3 times, and the product was dried to obtain polystyrene (PSt) microspheres containing a hydrogen abstraction type photoinitiator benzophenone group on the surface, and the particle size of the microspheres was 1.0 μm for SEM observation and analysis. , with a coefficient of variation of 5%.

[0092] The above-mentioned monodisperse PSt microspheres were suspended and dispersed in ethanol, and the concentration of the microspheres was 4 wt%.

[0093] Drop 0.4ml of 5wt% dextrose aqueous solution onto a quartz glass sheet (20mm × 20mm × 1mm), spin coat it with 3000rpm speed for 15s on the desktop glue homogenizer, and coat...

Embodiment 2

[0097] As in Example 1: after reacting for 5 hours, add dropwise an acetone solution of 4-methacrylate-based benzophenone (BPMA) in the reactor (BPMA accounts for 6% of the mass percentage of styrene), to obtain a surface containing The hydrogen type photoinitiator PSt microsphere of benzophenone group has a particle size of 2.3 μm and a coefficient of variation of 1.3%.

[0098] The monodisperse PSt microspheres were suspended and dispersed in methanol, and the concentration of the microspheres was 5 wt%.

[0099] As in Example 1: Arranging and fixing PSt microspheres on a quartz glass substrate coated with a glucose film.

[0100] Drop 0.5ml, 10wt% polyacrylamide (PAM) aqueous solution onto the surface of the above-mentioned arrayed microspheres, and place it under a 375W high-pressure mercury lamp to illuminate for 40min with a light intensity of 55w / m 2 . After illumination, the microspheres were post-treated according to the method in Example 1 to remove unreacted PAM. ...

Embodiment 3

[0102] Prepare, arrange and fix PSt microspheres with Example 2.

[0103] Drop 0.1ml, 30wt% chitosan aqueous solution onto the arrayed microspheres, place it under a 375W high-pressure mercury lamp for 10min, and the light intensity is 100w / m 2 . After illumination, the microspheres were post-treated according to the method in Example 1 to remove unreacted chitosan. After SEM observation, the surface morphology of the modified area of the microspheres was obviously different from that of the unmodified area. The microspheres can be distributed at the interface of n-hexane / water phase, the interfacial tension of n-hexane / water suspended with the modified microspheres is significantly reduced to 22 millinewtons / meter, and the obtained microspheres are amphiphilic spheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com