Mesoporous silicon film and two-step preparation method and application thereof

A technology of mesoporous silicon and multi-layer pores, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve problems such as complex equipment structure, secondary pollution, waste of energy, etc., and achieve Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

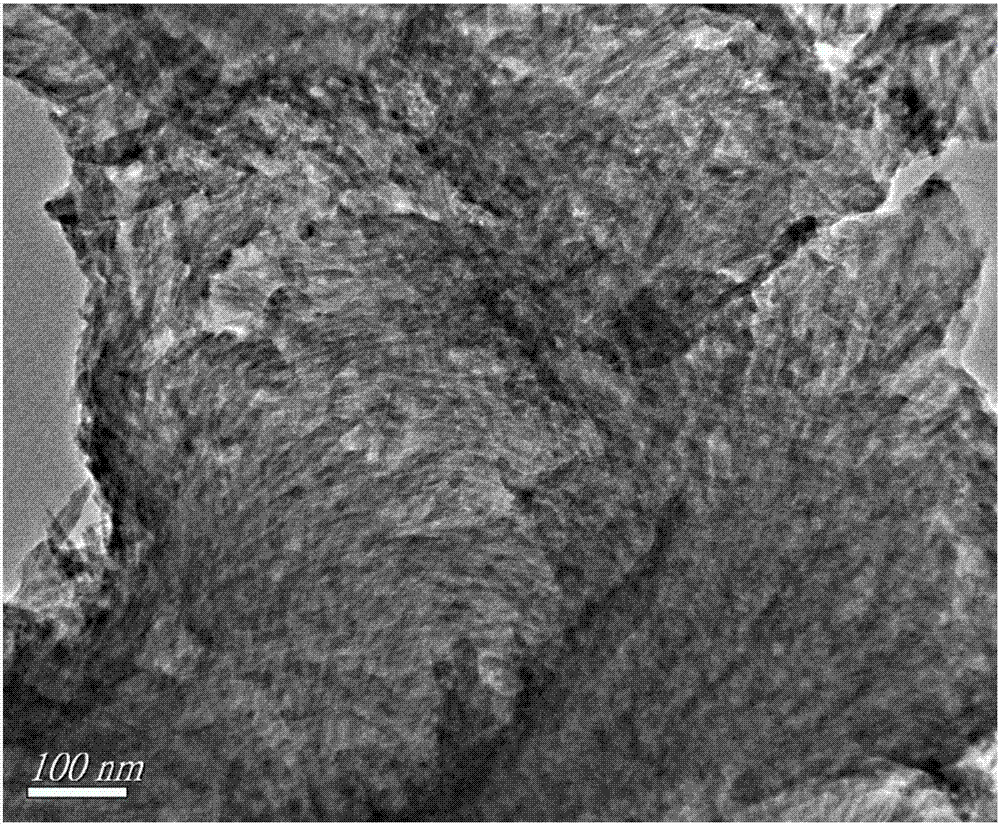

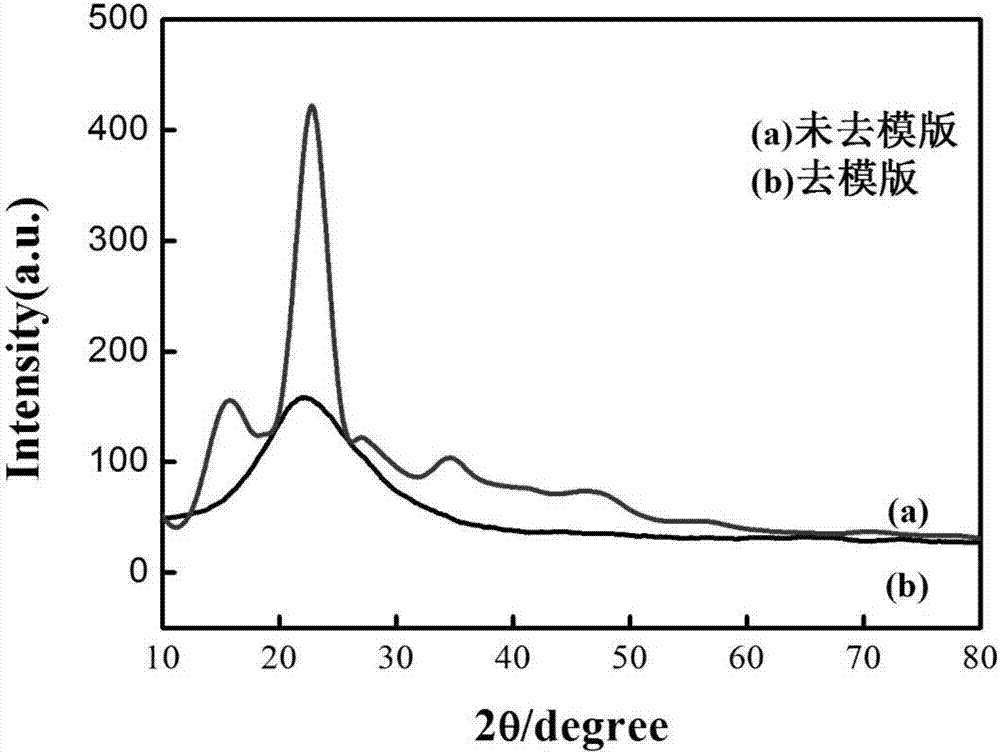

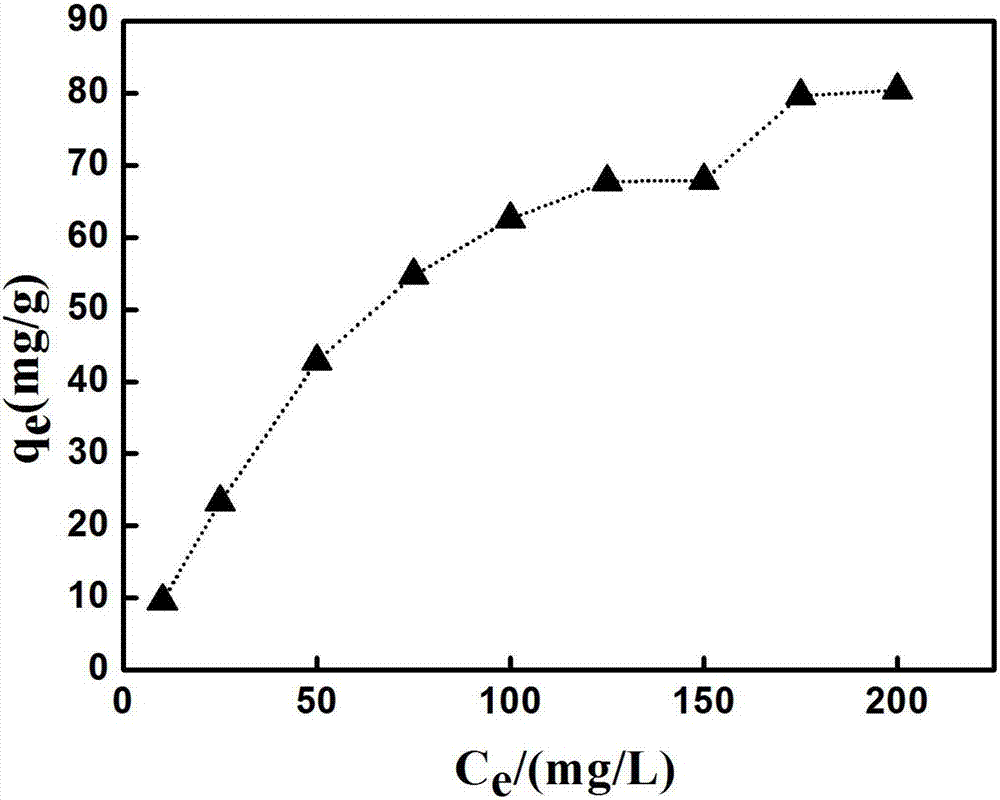

[0044](1) Take 10g of commercially available cotton and place it in 150mL of sulfuric acid solution with a mass fraction of 50%, then stir and react at 35°C for 2h, then transfer it to a beaker, dilute to 600mL with distilled water, then let stand overnight to separate layers, pour Remove the supernatant, centrifuge the suspension, wash with distilled water three times to remove the amorphous substance, transfer the suspension to a dialysis membrane for dialysis for 1 to 4 days, adjust the pH to 2.4, then sonicate for 10 minutes, and dilute to obtain nanocrystalline cellulose crystals (NCC) for use;

[0045] (2) Pipette 10 mL of NCC obtained in step (1), sonicate for 20 min, place in a round bottom flask, add 100 mg of glucose, stir for 30 min, then add 410 μL of tetraethyl silicate (TEOS), and stir for 2 h at 60 ° C , poured into a watch glass and dried in a water bath at 20°C for 1-2 days;

[0046] (3) Calcining the mesoporous silicon membrane synthesized in step (2) for 5 ...

Embodiment 2

[0060] (1) Take 10g of commercially available cotton and place it in 150mL of sulfuric acid solution with a mass fraction of 60%, then stir and react at 45°C for 3h, transfer it to a beaker, dilute to 600mL with distilled water, then let it stand overnight to separate layers, pour Discard the supernatant, centrifuge the suspension, wash with distilled water three times to remove the amorphous substance, transfer the suspension to a dialysis membrane for dialysis for 1 to 4 days, adjust the pH to 2.3, then sonicate for 10 minutes, and dilute to obtain nanocrystalline cellulose crystals (NCC) for use;

[0061] (2) Pipette 10 mL of NCC obtained in step (1), sonicate for 20 min, place in a round bottom flask, add 150 mg of glucose, stir for 30 min, then add 410 μL of tetraethyl silicate (TEOS), and stir for 2 h at 55 ° C , pour into a watch glass and dry in a water bath at 25°C for 1-2 days;

[0062] (3) Calcining the mesoporous silicon membrane synthesized in step (2) at 520° C....

Embodiment 3

[0076] (1) Take 10g of commercially available cotton and place it in 150mL of sulfuric acid solution with a mass fraction of 70%, then stir and react at 55°C for 4h, then transfer it to a beaker, dilute to 600mL with distilled water, then let it stand overnight and pour Remove the supernatant, centrifuge the suspension, wash with distilled water three times to remove the amorphous substance, transfer the suspension to a dialysis membrane for dialysis for 1 to 4 days, adjust the pH to 2.5, then sonicate for 10 minutes, and dilute to obtain nanocrystalline cellulose crystals (NCC) for use;

[0077] (2) Pipette 10 mL of NCC obtained in step (1), ultrasonicate for 30 min, place in a round bottom flask, add 200 mg of glucose, stir for 30 min, then add 410 μL of tetraethyl silicate (TEOS), and stir for 2 h at 60 °C , pour into a watch glass and dry in a water bath at 25°C for 1-2 days;

[0078] (3) Calcining the mesoporous silicon membrane synthesized in step (2) at 540° C. for 8 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com