Patents

Literature

185results about How to "No phase change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

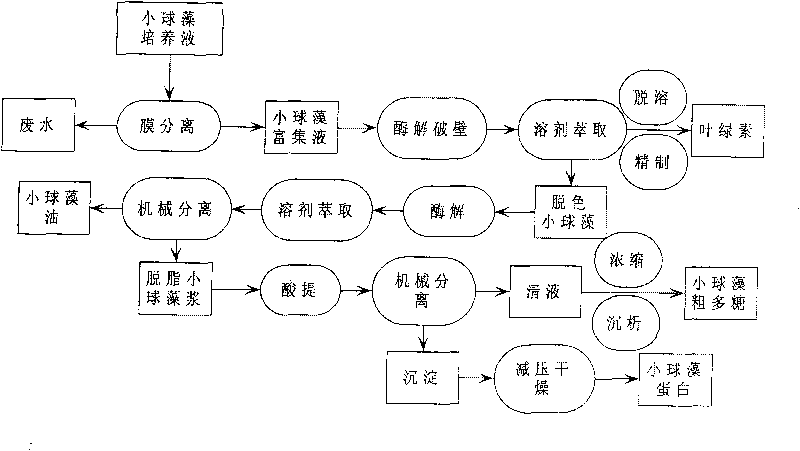

Method for continuously extracting functional components of chlorella vulgaris

InactiveCN101736045AEasy to keep activeReliable operationPeptide preparation methodsNatural dyesSolventChemistry

The invention relates to a method for continuously extracting functional components of chlorella vulgaris, which comprises the steps of enriching the chlorella vulgaris through the membrane separation technology, obtaining concentrated slurry of the chlorella vulgaris, adding a proper enzyme in a liquid phase system for wall-breaking, and using a solvent for extracting chlorophyll from chlorella vulgaris solution after wall-breaking, thereby being capable of obtaining a functional pigment product and reducing the color value of follow-up products; and firstly carrying out enzymatic hydrolysis on a water phase of the chlorella vulgaris after decoloring, then using the solvent for extracting functional grease, extracting active polysaccharides from the obtained degreased chlorella vulgaris by using the acid method, and then drying the other parts for obtaining crude proteins of the chlorella vulgaris. The main products comprise the chlorophyll, the active polysaccharides of the chlorella vulgaris, the functional grease of the chlorella vulgaris, the proteins of the chlorella vulgaris and the like, and the method optimizes the process on the basis of ensuring the activity of the functional components of the chlorella vulgaris, thereby obtaining high yield and reducing production cost.

Owner:BOHAI UNIV

Method for extracting collagen peptide from fish scales

InactiveCN101886106AAvoid pollutionPromote absorptionCosmetic preparationsAntipyreticBiotechnologyCollagenan

The invention discloses a method for extracting fish scale collagen peptide. Fish scales are taken as a raw material, and the method comprises the following steps of: cleaning the fish scales, blending with water, and heating for sterilization; performing degreasing and enzymolysis by using biological enzyme; further performing enzymolysis by utilizing exo-protease, deactivating enzyme, filtering, decoloring, performing film separation, and drying the obtained filtrate to obtain the fish scale collagen peptide. The method has the advantages of short production period, low cost, and no toxic or harmful substance; and the obtained product has high safety and can be widely used in the fields such as cosmetics, foods, medicaments, health care products, biological synthesis and the like.

Owner:湖北远成药业有限公司

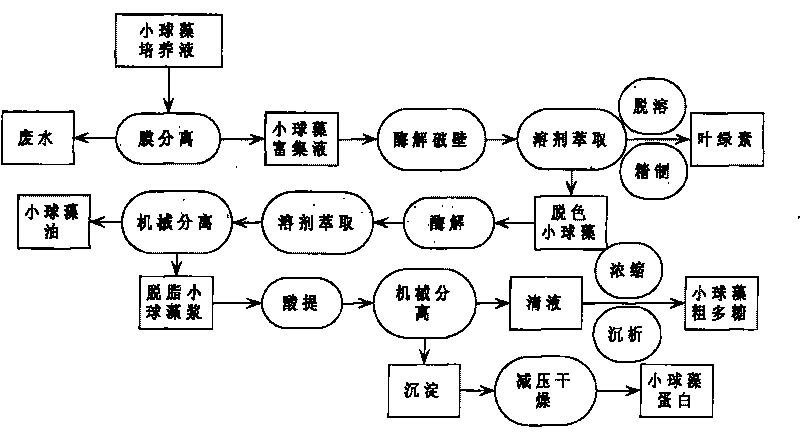

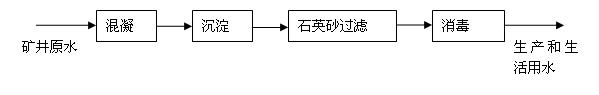

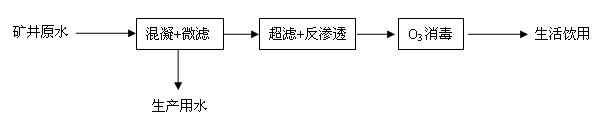

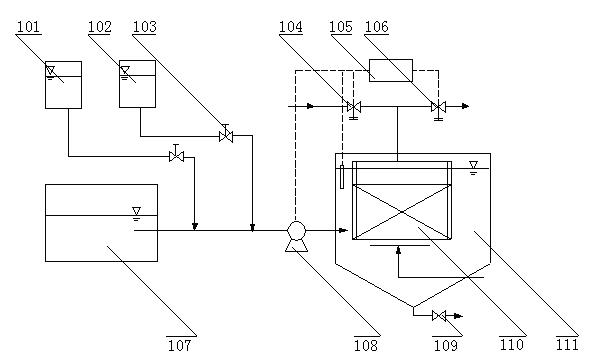

Comprehensive recycling technology for mine water with high suspended matter content and high mineralization degree

InactiveCN102491564AReduce membrane foulingRestore membrane fluxWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRaw waterChemistry

The invention discloses a comprehensive recycling technology for mine water with high suspended matter content and a high mineralization degree. A coagulating agent is added into mine raw water, so that suspended colloid fine particles in water are subjected to conventional compressive double-electric-layer destabilization, and are treated with a three-membrane gradual filtering technology consisting of first-stage microfiltration membrane filtering, second-stage microfiltration membrane filtering and third-stage microfiltration membrane filtering. After the mine raw water is subjected to first-stage microfiltration membrane filtering, effluent can meet the requirement of production under a coal mine; and after the mine raw water is subjected to second-stage microfiltration membrane filtering and third-stage microfiltration membrane filtering and is disinfected with O3, effluent can meet the requirement of daily drinking. Different reverse osmosis membrane automatic back washing technologies and back washing chemical medicament formulae are adopted according to water of different mineralization degrees, so that the problem of poor running effect of a mine water reverse osmosis system with a high mineralization degree is solved, and the effluent quality and stable running of a water treatment system are enhanced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

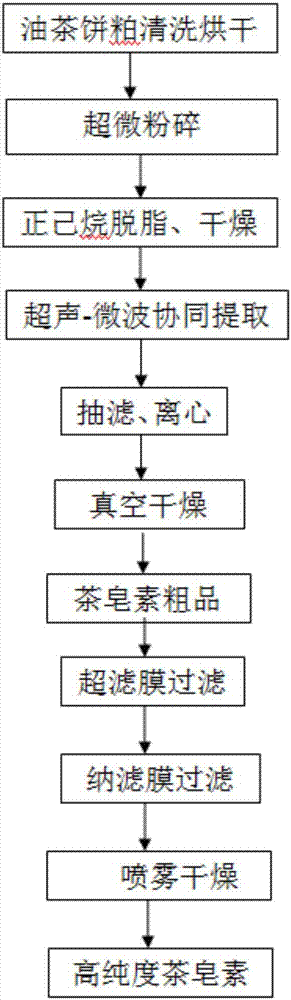

Clean extraction method of tea saponin

InactiveCN108003215ALarge specific surface areaUniform particle size distributionSemi-permeable membranesSugar derivativesCamellia oleiferaFiltration membrane

The invention provides a clean extraction method of tea saponin. The clean extraction method comprises the following steps: (1) crushing a cake of camellia oleifera, sieving, wherein the fineness is 200 to 400 meshes; (2) adding normal hexane into the cake powder of camellia oleifera according to a material-to-liquid ratio of 1:(2 to 3), heating to 60 to 70 DEG C, refluxing for 1 to 3 h, degreasing, and drying; (3) adding ethanol into the cake powder of camellia oleifera according to the material-to-liquid ratio of 1:(15 to 25), heating to 50 to 70 DEG C, and performing ultrasonic-microwave synergistic extraction; (4) suction filtering and centrifuging the extracted solution, and obtaining tea saponin extract solution; (5) drying the extract solution, and obtaining a tea saponin crude product; and (6) dissolving the tea saponin crude product, successively filtering by virtue of a hyperfiltration membrane and an organic nano filtration membrane, drying, and preparing high-purity tea saponin. By adopting the clean extraction method, the utilization rate of raw materials is increased, the extraction rate of the tea saponin can be maximally increased, the extraction time is shortened,and compared with the traditional separation process, the clean extraction method has the advantages of low energy consumption, single-level separation efficiency, simple device, no phase change, no pollution and the like.

Owner:贯虹科技有限公司

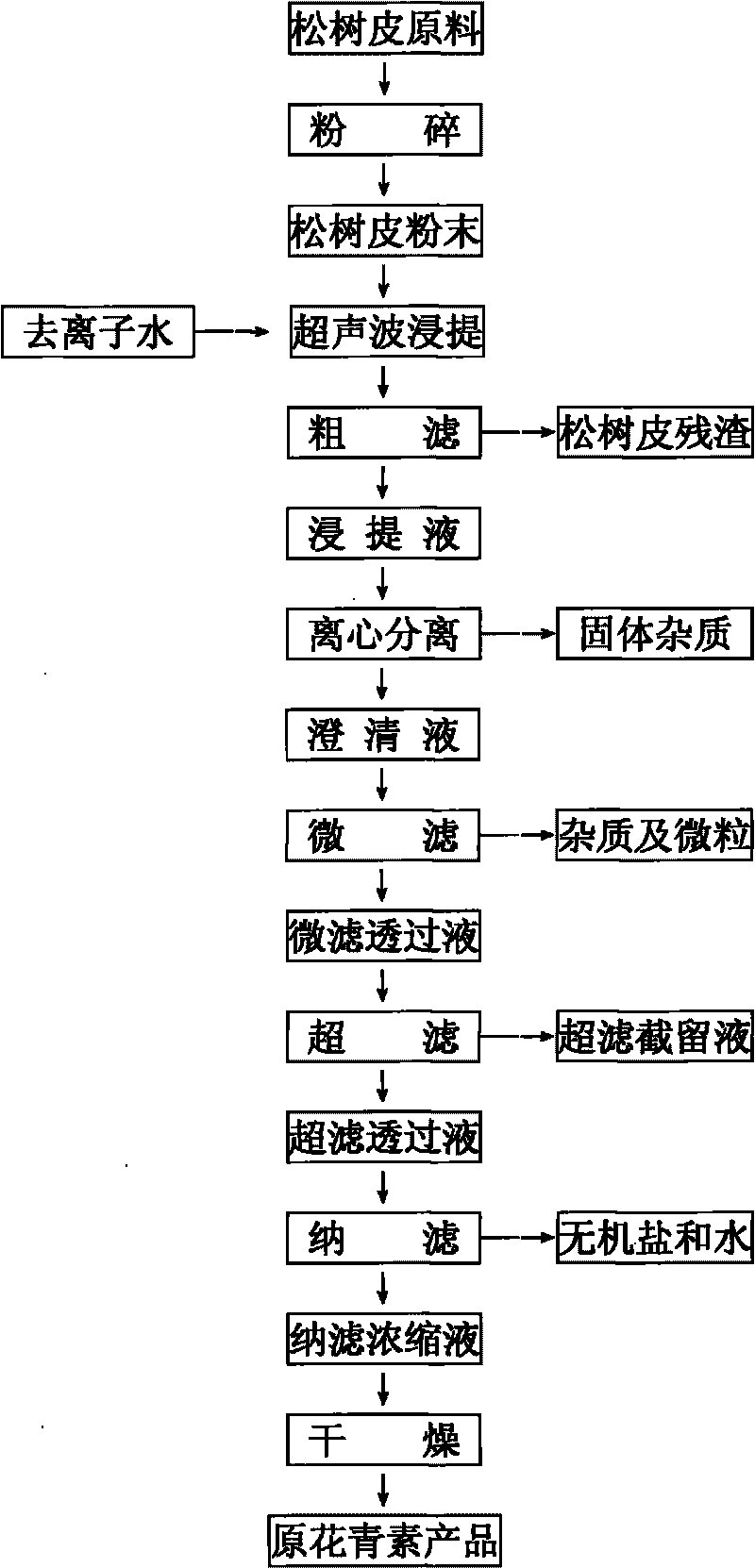

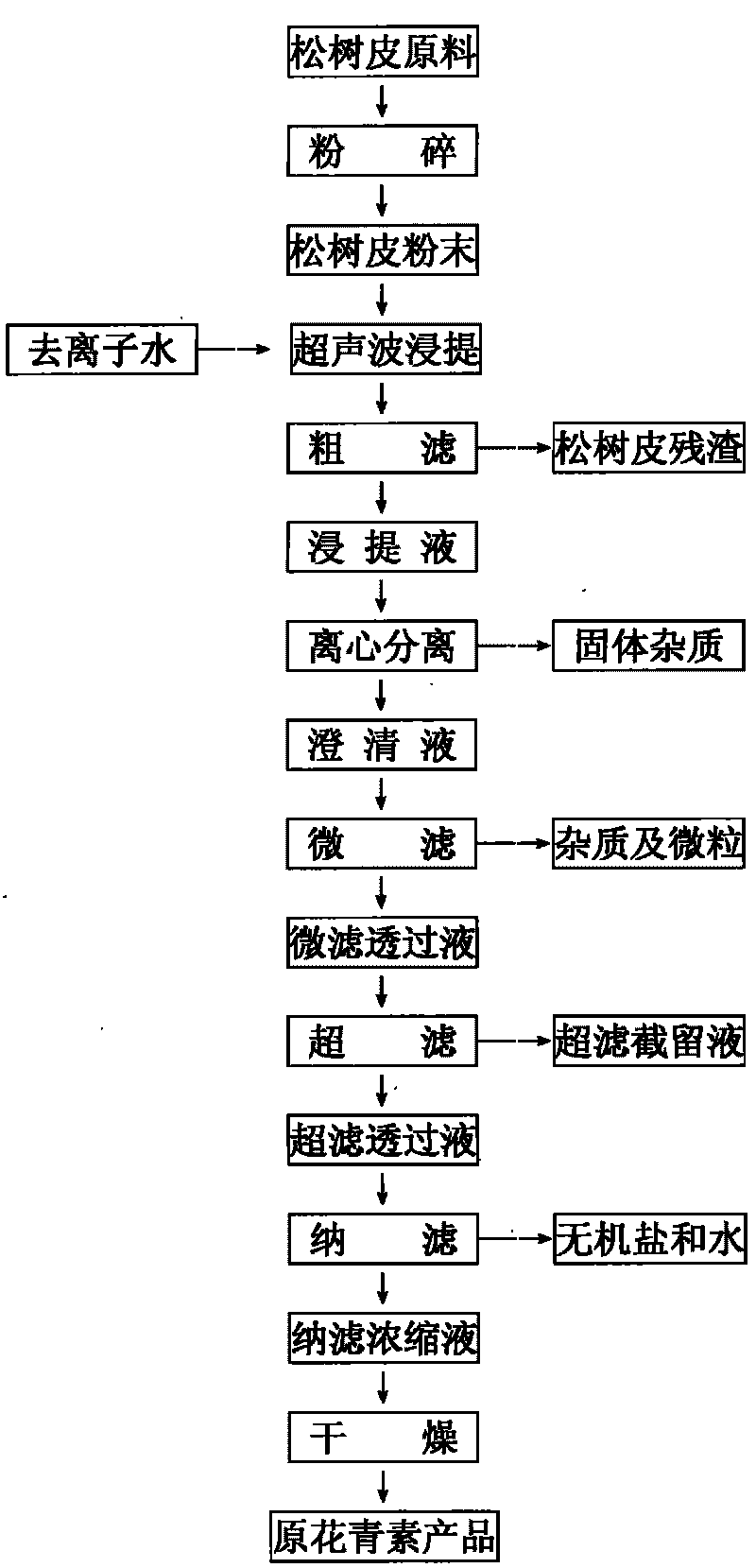

Method for extracting proanthocyanidin from pine bark by taking water as solvent

InactiveCN101701013AReduce energy consumptionImprove extraction efficiencyOrganic chemistrySolventChemistry

The invention discloses a method for extracting proanthocyanidin from pine bark by taking water as solvent. The method takes the pine bark as raw material and water as extraction solvent, utilizes ultrasonic wave technology for enhanced extraction to obtain proanthocyanidin leach liquor, uses the membrane separation technology of microfiltration for removing impurities, ultrafiltration purification and nanofiltration concentration for processing to obtain concentrated proanthocyanidin liquid, and finally obtains the proanthocyanidin product by vacuum or freeze drying. The method only takes the water as the extraction solvent, and utilizes the ultrasonic wave extraction technology and the membrane separation technology, so as to lead the whole technical process to be operated under the low temperature condition, thus not only effectively improving the extraction yield of active ingredients and ensuring bioactive substances not to be damaged, but also being safe and environment-friendly in production and having no residual chemical solvent on the product. Therefore, the proanthocyanidin is a natural and green product in the true sense, and the production method is very environment-friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

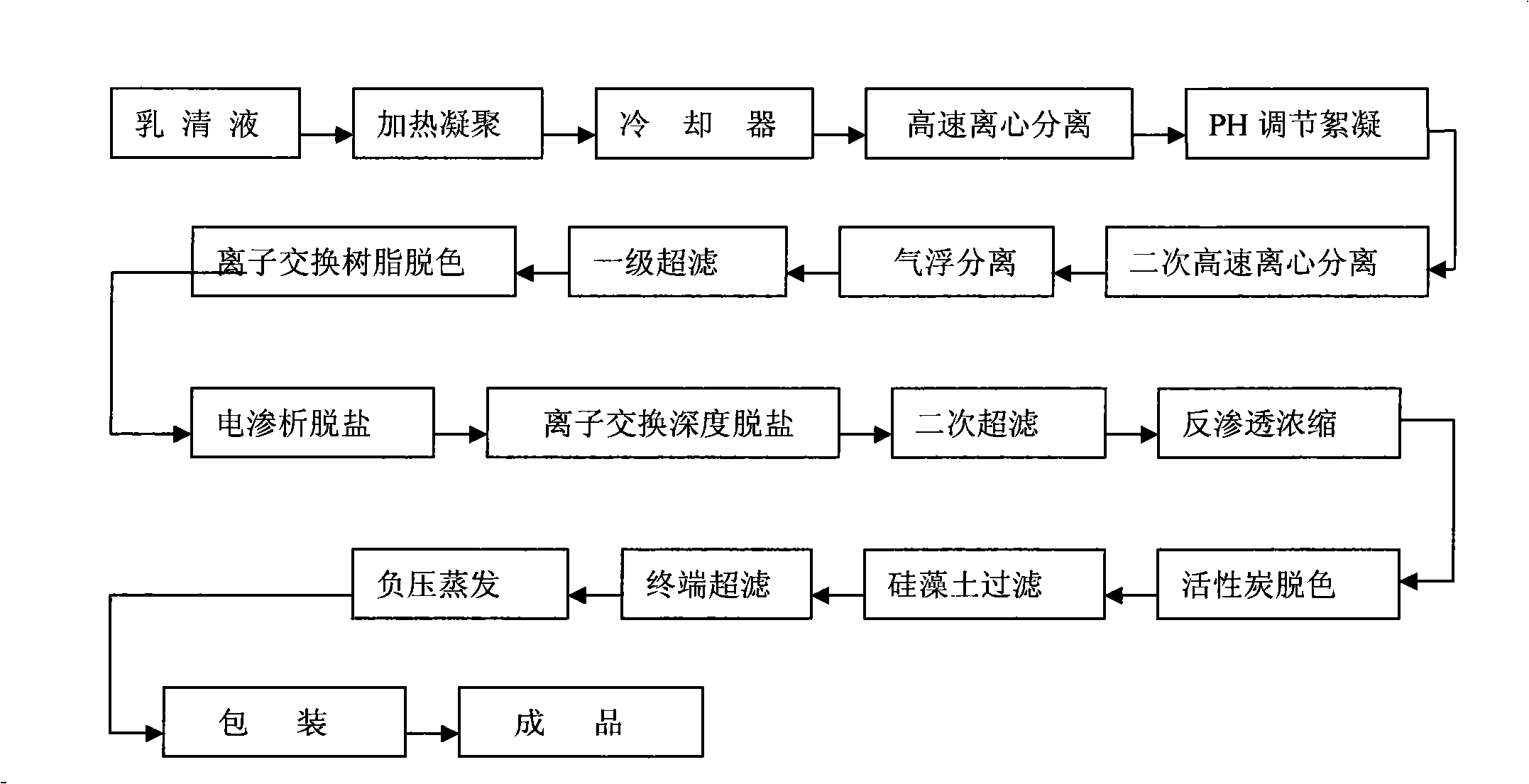

Process for extracting the soyabean oligosaccharides by air-float purification and film integration

The invention relates to a method for extracting edible oligosaccharides, specifically a method for extracting soybean oligosaccharides from soybean whey liquid by flotation purification and membrane concentration. The method comprises the following steps: thermal coagulation, cooling, high-speed centrifugal separation, pH adjustment and flocculation, secondary high-speed centrifugal separation, flotation separation, first-stage ultrafiltration, decolorization with ion exchange resin, electrodialysis desalination, further desalination with ion exchange resin, second-stage ultrafiltration, reverse osmosis concentration, activated carbon decolorization, diatomite filtration, terminal ultrafiltration and negative-pressure evaporation concentration. The invention has the advantages that: 1. based on the reasonable combination of proper molecular weight cut-off of ultrafiltration membrane and membrane assembly, operation mode and efficient cleaning, the method works continuously and stably for long time; 2. the method realizes the pretreatment by using multi-stage high-efficiency centrifugal separation technique, without using filter aids and producing pollutants, and the separated protein residue can be recycled; and 3. the method has simple process and low equipment and operation costs.

Owner:逄镜萍

Biological fermentation extracting method for hyaluronic acid

InactiveCN101914594ASolve pollutionFix security issuesChemical industryMutant preparationIon exchangeBiology

The invention discloses a biological fermentation extracting method for hyaluronic acid. The method comprises the following steps of: A, taking streptococcus as an original strain, and taking ultraviolet rays and nitrosoguanidine as mutagens; B, inoculating mutagenic strains to an agar culture medium, and culturing slant strains; C, inoculating the slant strains to a triangular flask; D, inoculating the triangular flask strains to a seeding tank according to a proportion to perform spread culture; E, sterilizing and cooling culture solution in a fermentation tank, and inoculating seeds to the fermentation tank to perform fermentation; F, inactivating the fermentation solution with heating; G, adding active carbon into the fermentation solution to filter decarburized bacteria; H, adding CPB aqueous solution into the filtrate with stirring, and standing and settling the solution; I, adding sodium chloride solution of fermentation solution volume into the sediment, and stirring the solution; J, decolorizing dissociation solution by ion exchange; K, concentrating and purifying the decolorized solution by membrane separation; L, adding ethanol into the concentrate, and separating out the sediment; and M, drying the sediment to obtain the hyaluronic acid. The method has the advantages of feasibility, simple and convenient operation, short production period, low cost, high efficiency, energy conservation and environmental protection. The hyaluronic acid can be widely used in the fields of cosmetics, food, medicaments and the like.

Owner:湖北远成药业有限公司

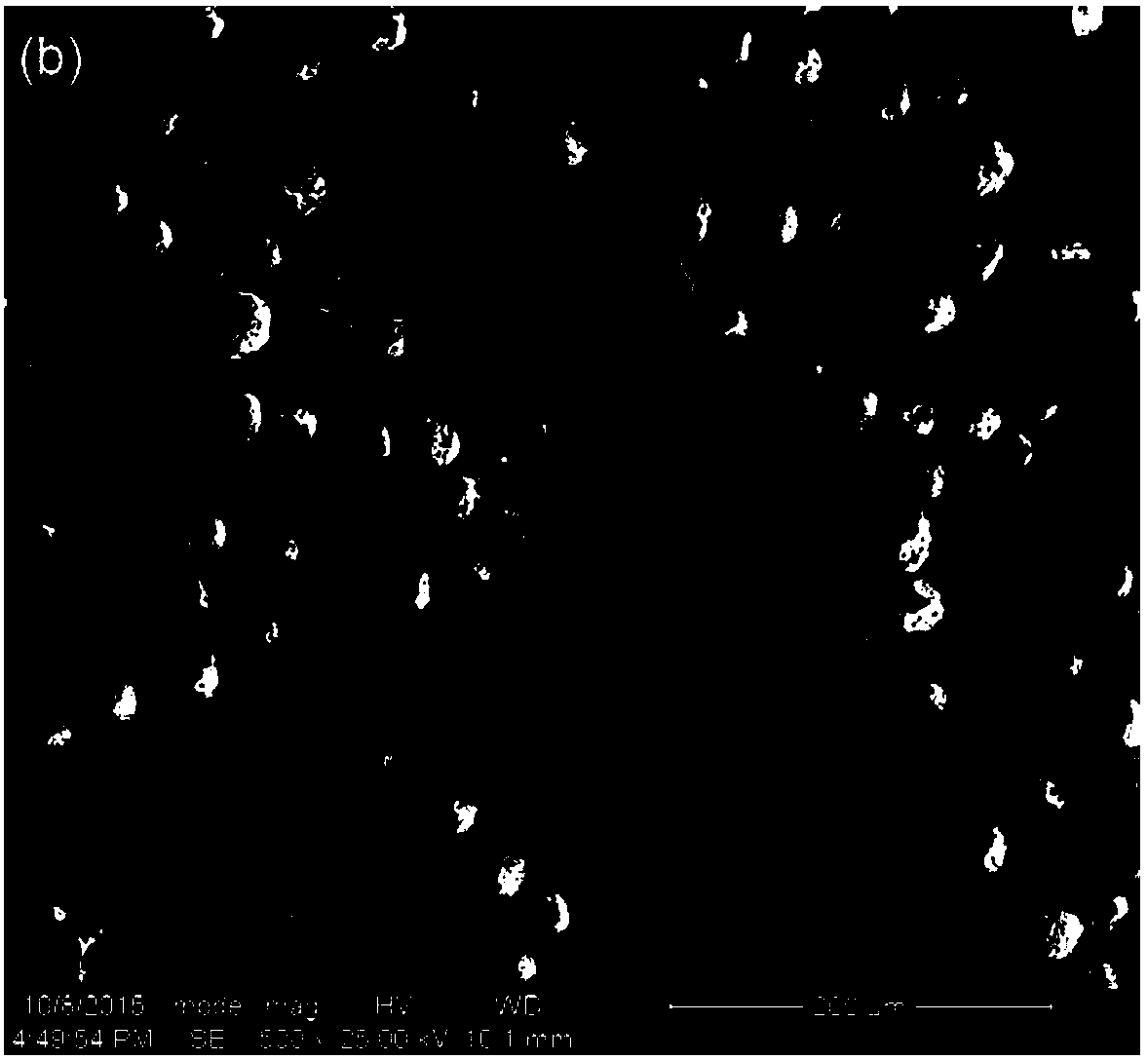

WC-Co-cBN composite hard alloy and preparation method thereof

ActiveCN107739950AGood thermal stabilityGood effect of coating modification and wetting agentTransportation and packagingMetal-working apparatusCemented carbideChemical composition

The invention belongs to the technical field of superhard cutting tools, and relates to a WC-Co-cBN composite hard alloy and a preparation method thereof. The WC-Co-cBN composite hard alloy comprisesthe following chemical components of, by weight, 70%-90% of ultrafine / nano WC powder, 3%-15% of Co powder, 0.35%-0.75% of a grain inhibitor, 1%-10.75% of cBN micro powder with a surface plated with aMo, Ni and Ti metal film with excellent high-temperature and chemical stability, and 0.25%-5% of spherical mixed powder selected from Al, Ni, Cr, Y or other combinations; and the components are prepared into the composite hard alloy through spark plasma sintering. According to the WC-Co-cBN composite hard alloy and the preparation method thereof, the grain size of the prepared alloy is small, hardness, strength and toughness is high, wear resistance is good, the difficulty that heat stability of dry cutting is low can be overcome, machining cost is reduced, and the WC-Co-cBN composite hard alloy and the preparation method thereof are particularly suitable for high-performance machining cutting tools.

Owner:GRIMAT ENG INST CO LTD

Method for reinforced ultrafiltration treatment of phenol-containing waste-water by ultrafiltration membrane

InactiveCN101157492AIncrease the amount of solubilizationHigh removal rateWater contaminantsWater/sewage treatment bu osmosis/dialysisFiltration membranePhenol

The invention discloses a method for ultra-filtration membrane strengthened ultra-filtration treatment of phenol-containing sewage. The method comprises: first adding cetylpyridinium chloride which is a cationic surfactant, and sodium carbonate into the phenol-containing sewage, stirring uniformly and standing for reaction where cetylpyridinium chloride monomer molecules produce micelles by self-assembly and then solubilize the phenol contained in the water; pumping the water to an ultra-filtration component for filtration where the cetylpyridinium chloride micelles with being solubilized the phenol contained in the water are intercepted by the ultra-filtration membrane so that the phenol contained in the water is removed. The phenol concentration in the sewage is 5mg / L-200mg / L; the addition of cetylpyridinium chloride is 20*10<-3>mol / L-30*10<-3>mol / L; the addition of sodium carbonate is 1*10<-3>mol / L-20*10<-3>mol / L; the weight of molecules intercepted by the ultra-filtration membrane is 6000-10000Dalton; the membrane operation pressure is 0.05MPa-0.20MPa. The method is carried out in an intermittent type, and the standing reaction time is 0.5-10h. In treating the phenol-containing sewage, the invention has excellent phenol removal performance, low energy consumption, simple operation, low surfactant consumption and low cost. In addition, the surfactant and the phenol can be recycled.

Owner:HUNAN UNIV

Method for extracting tea-seed oil and tea saponin by using biological method

InactiveCN102191124AMitigate the effects of dissolutionLess impuritiesSugar derivativesFatty-oils/fats refiningCentrifugationUltrafiltration

The invention relates to a method for extracting tea saponin and tea-seed oil from tea seed kernels by using a biological method. The amount of each added material is based on the weight of the tea seed kernels, and the method comprises the following steps of: cooking the tea seed kernels, crushing, liquefying and saccharifying, adjusting the pH, and performing centrifugation; for the obtained supernatant oil comprising the main components of fat and oligosaccharide, performing membrane separation to obtain crude oil, and performing alkaline refining de-acidification to obtain refined tea oil; for the subnatant water phase comprising the main components of saponin and protein, adjusting the pH, and then performing centrifugation to obtain crude tea saponin; and performing decontaminating concentration by using an ultrafiltration membrane to obtain refined tea saponin. According to the method, the tea seed kernels are reasonably used to extract the tea-seed oil and the tea saponin at the same time, the process is simple, the operation is safe, high-purity tea oil and saponin are obtained, and simultaneously secondary pollution and a great deal of wastewater cannot be generated.

Owner:武汉普赛特膜技术循环利用有限公司

Extraction method of wheat gluten peptide

InactiveCN101974592AAvoid residueGuaranteed natural whitenessPeptide preparation methodsFermentationSodium sulfitePeptide

The invention discloses an extraction method of gluten peptide. The method adopts the commercial gluten flour as the main raw material; and the method comprises the following steps: proportioning with water, adding alcohol and sodium sulfite to heat and cook, filtering to obtain filtrate, adding protease in the filtrate for enzymolysis, killing enzyme, decoloring, performing membrane separation to obtain filtrate, and drying the filtrate to obtain the gluten peptide. The method of the invention has short production period and low cost and can not generate any poisonous or harmful substance; and the obtained product has high safety and can be widely used in the fields such as food, medicines, health products and biosynthesis.

Owner:湖北远成赛创科技有限公司

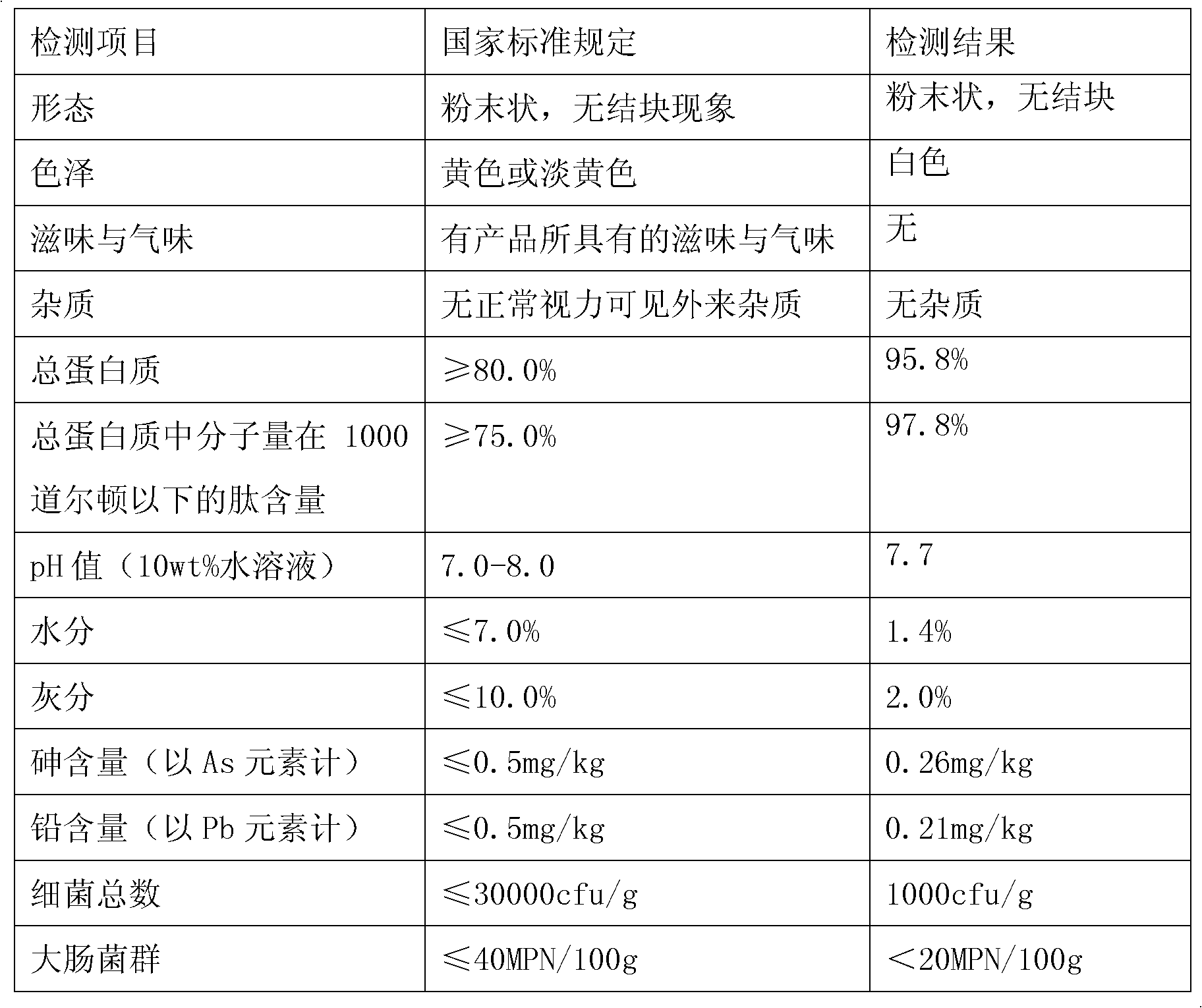

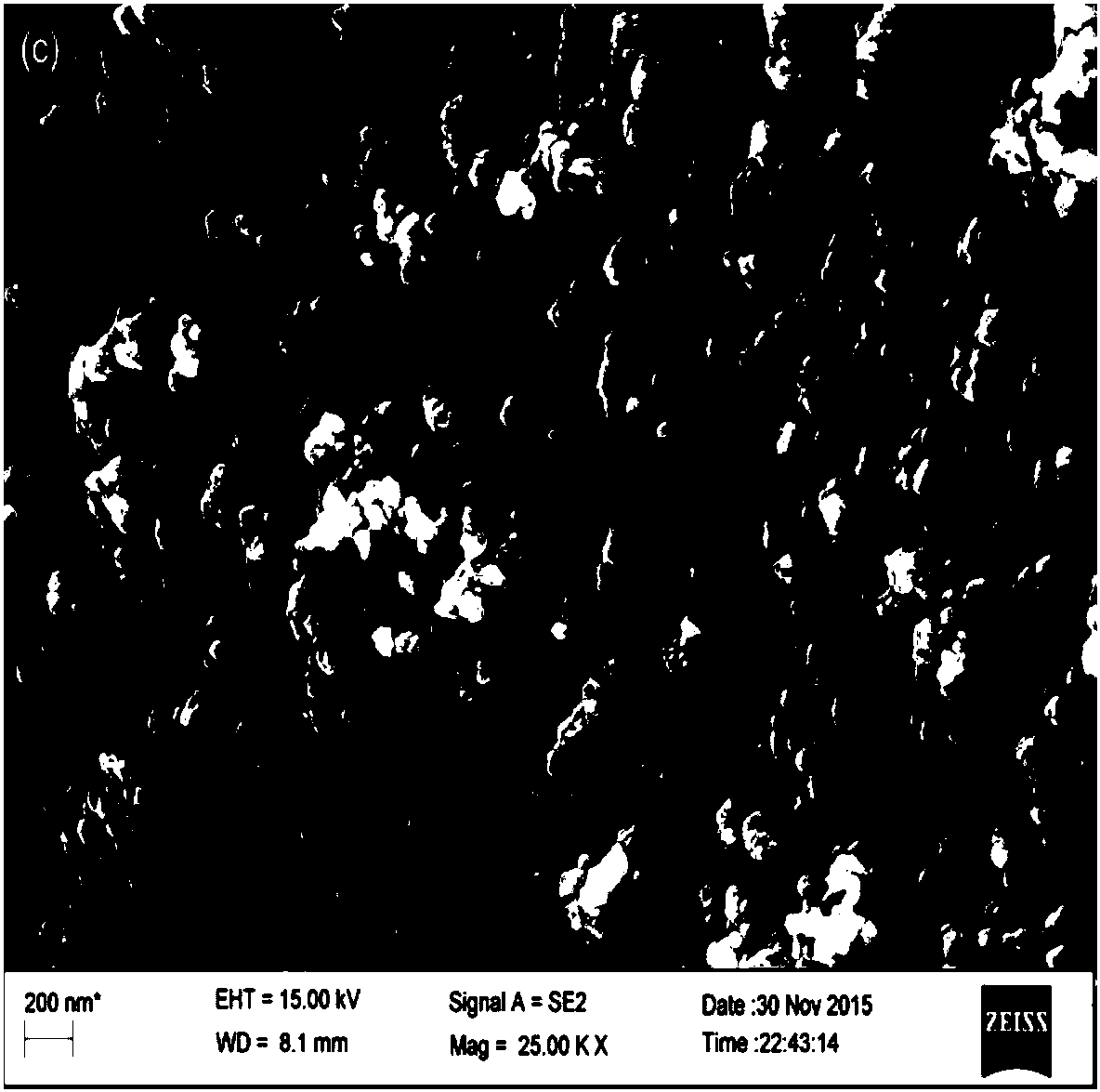

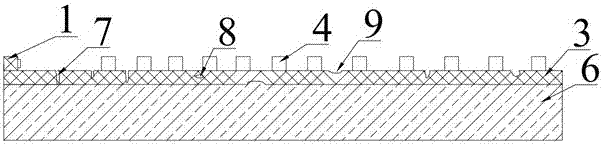

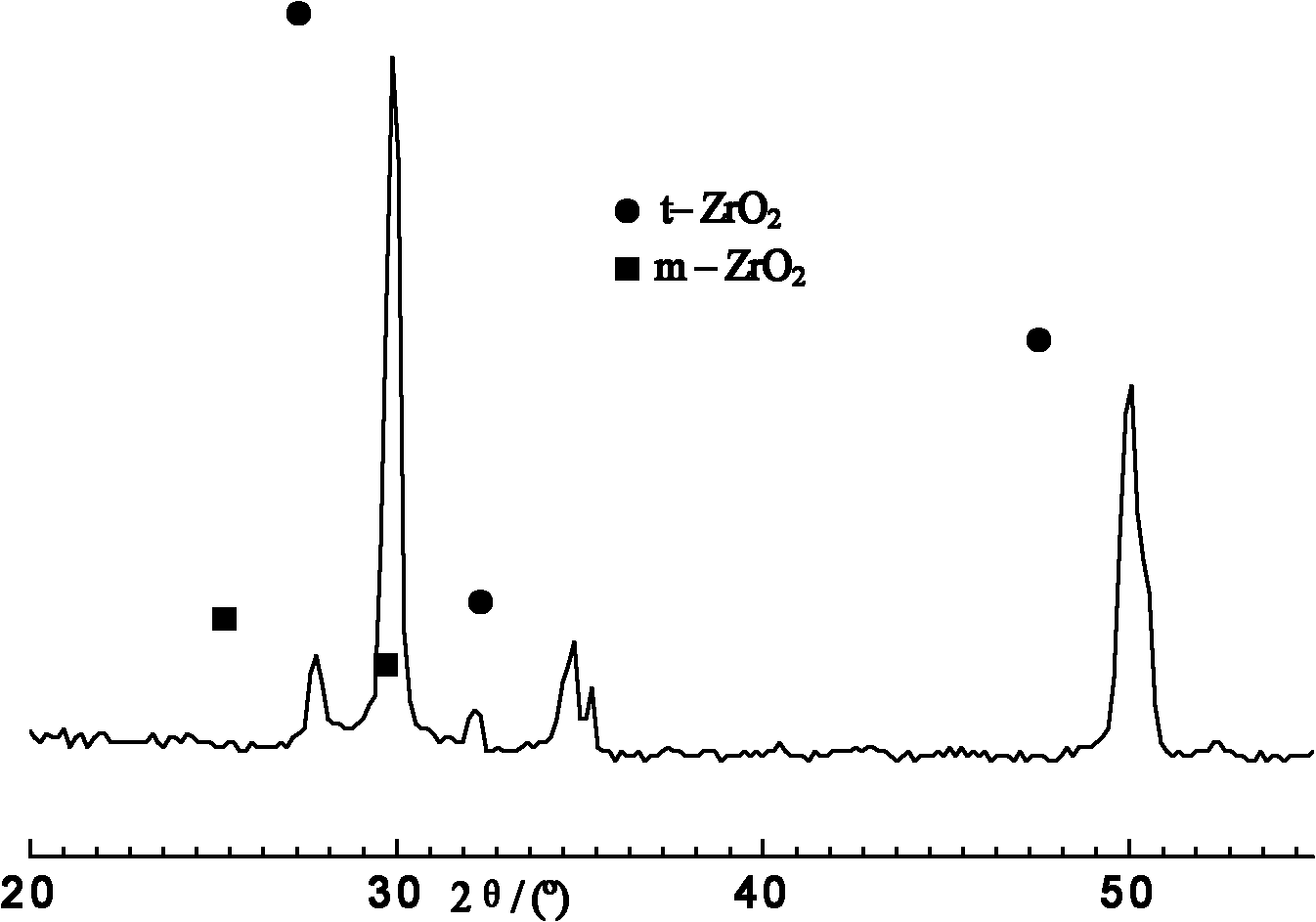

High-performance thermal barrier coating and ceramic layer thereof

ActiveCN107815633AImprove efficiencyIncrease working temperatureMolten spray coatingNano structuringThermal diffusion coefficient

The invention discloses a preparation method for a high-performance thermal barrier coating and specifically discloses a 4YSZ (4mol% Y2O3 stabilized ZrO2) thermal barrier coating and the preparation method of the 4YSZ thermal barrier coating. The 4YSZ powder which is of a fine nano-structure, uniform ingredients and a pure tetragonal phase structure is prepared utilizing a sol-spray pyrolysis synthetic process, and the 4YSZ powder is subjected to spray drying granulation, screening and atmospheric plasma spraying (APS) in sequence to prepare the coating. The high-performance thermal barrier coating prepared by the invention is of a pure tetragonal phase nano-structure with uniform ingredients, compared with a traditional YSZ casting, the high-performance thermal barrier coating has the advantages of being low in thermal diffusion coefficient, good in high temperature phase stability and thermal shock resistance, simple in preparation process and low in cost and the like; and the high-performance thermal barrier coating is more conducive to improving the efficiency and working temperature of a turbine engine, and the service life of the engine is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

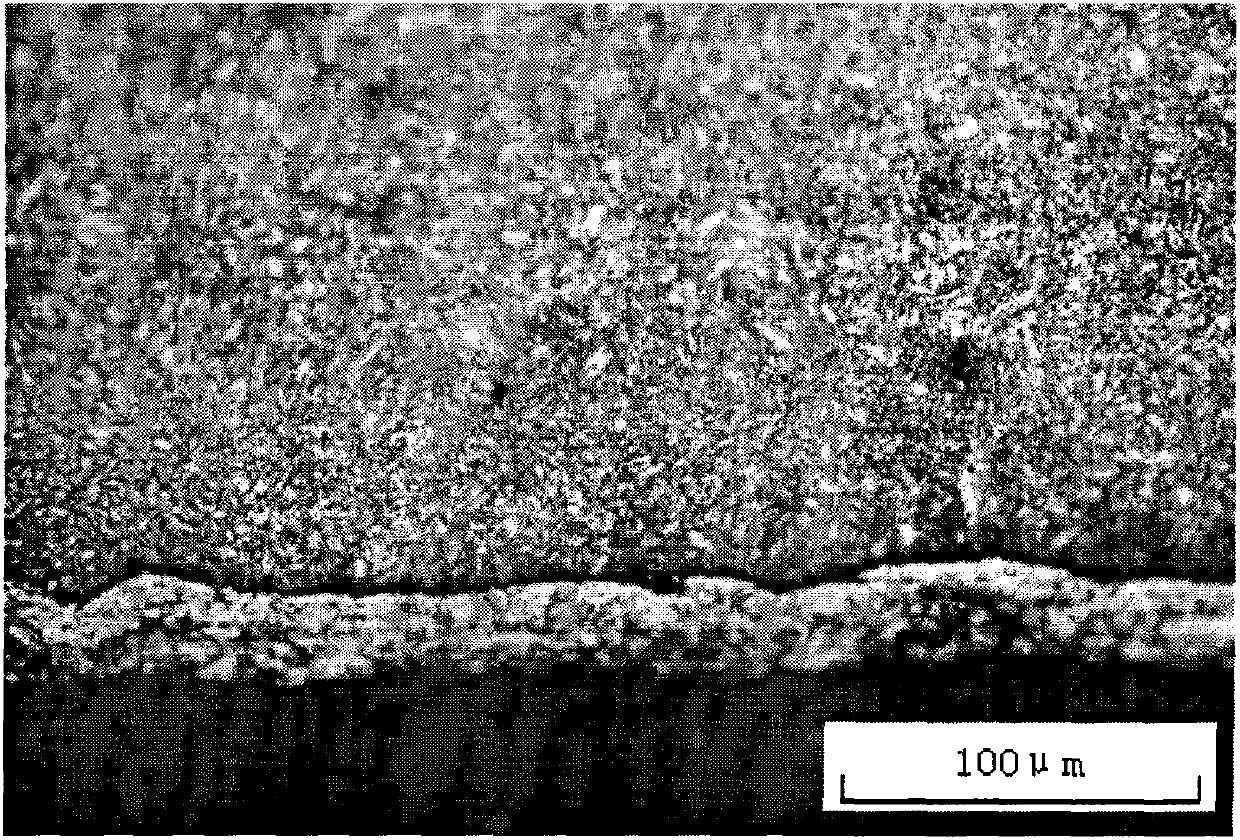

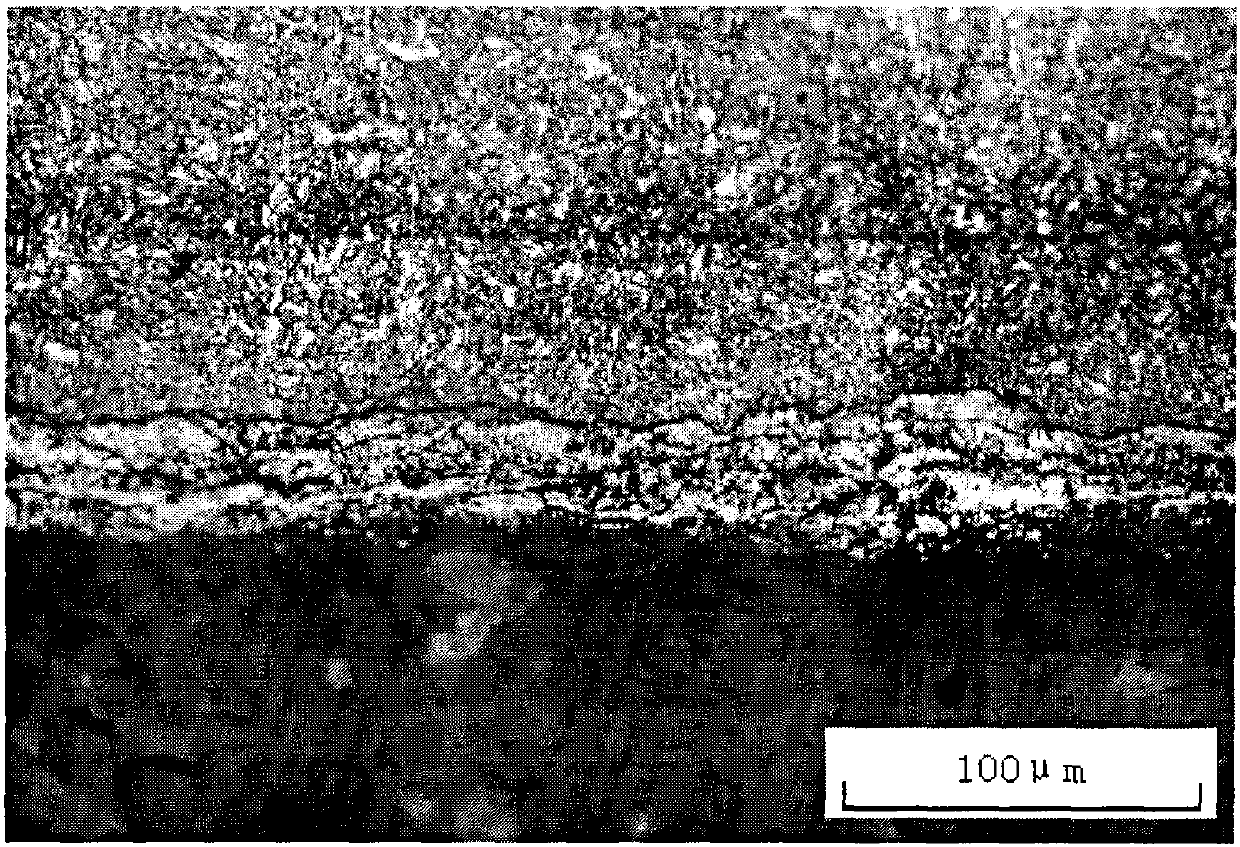

Novel low-temperature rare earth-chromium-boronizing agent

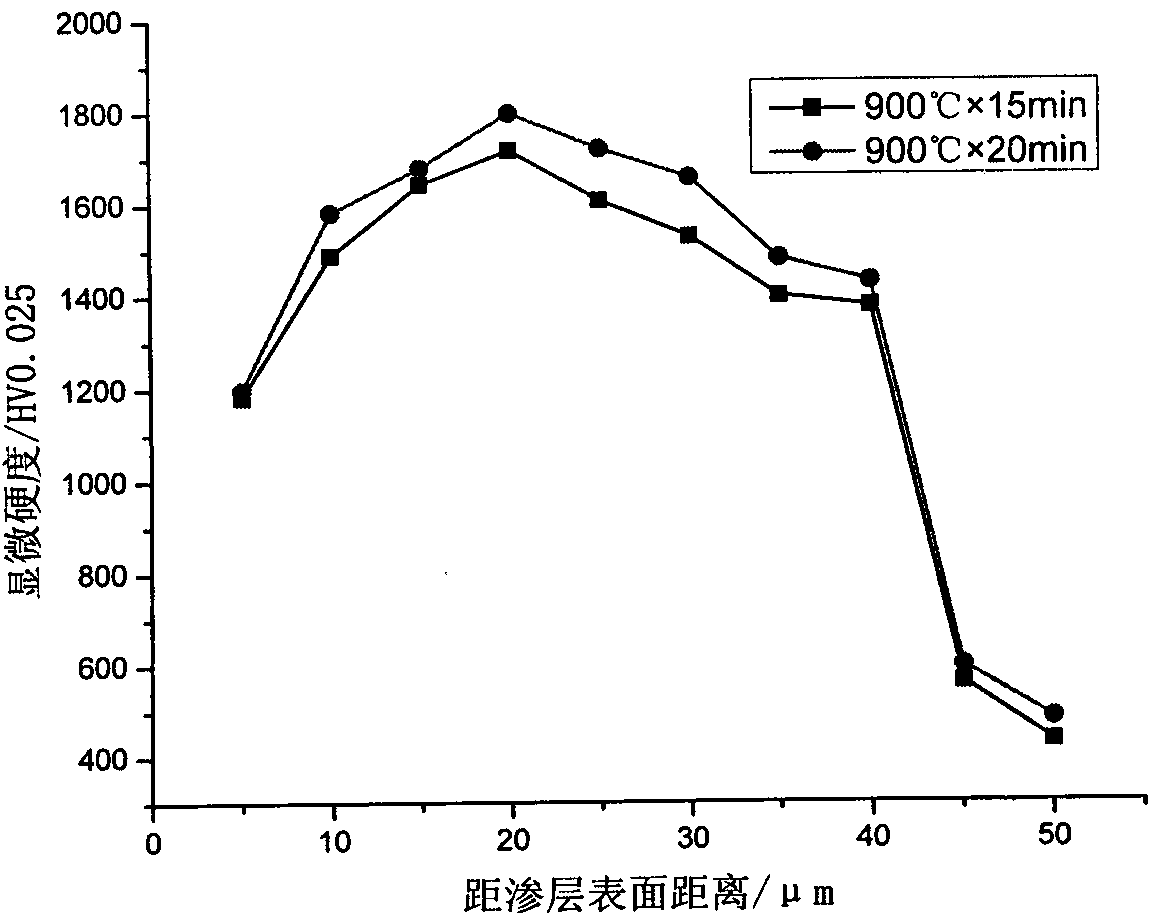

InactiveCN103343314AReduce distortionNo phase changeSolid state diffusion coatingThioureaHigh carbon

The invention discloses a novel low-temperature boron-chromium-rare earth co-permeation agent which comprises the following components in parts by content: 4.8 to 5.0 parts of high-carbon ferrochrome, 3.8 to 4.0 parts of rare earth, 6.8 to 8.4 parts of potassium fluoborate, 21.3 to 24.5 parts of aluminium oxide, 5.9 to 7.6 parts of thiourea and 53.0 to 54.5 parts of ferroboron. The co-permeation agent has the advantages that 1) a workpiece is deformed slightly and cannot generate phase-change and internal stress after being subjected to co-permeation, so that the application of the co-permeation agent on a precise part is promoted greatly; 2) a low-temperature co-permeation layer is thicker and ranges from 30 mu m to 52 mu m or so, so that the application range is wide; and 3) the cost of the low-temperature co-permeation of the boron-chromium-rare earth is lower, so that the good economical effect is obtained.

Owner:SHANDONG JIANZHU UNIV

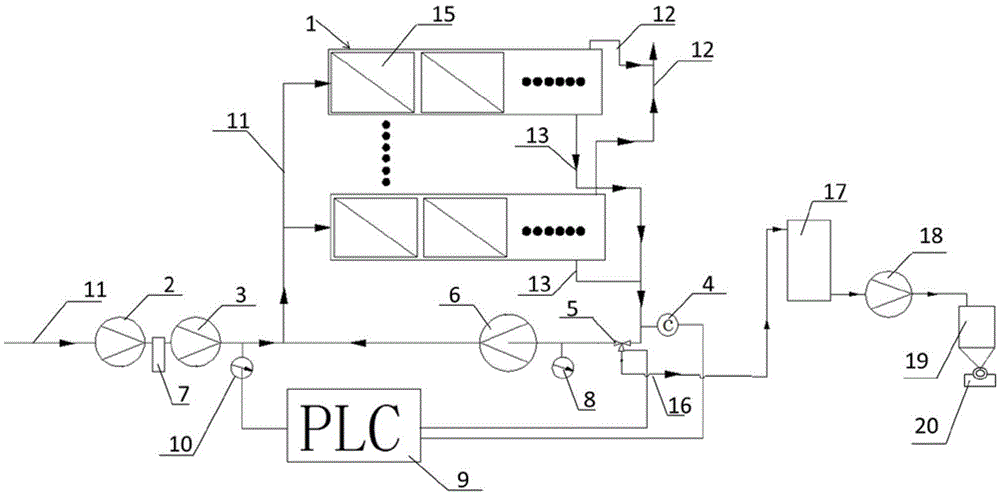

Rapid rice husk pyrolysis apparatus and matching system thereof

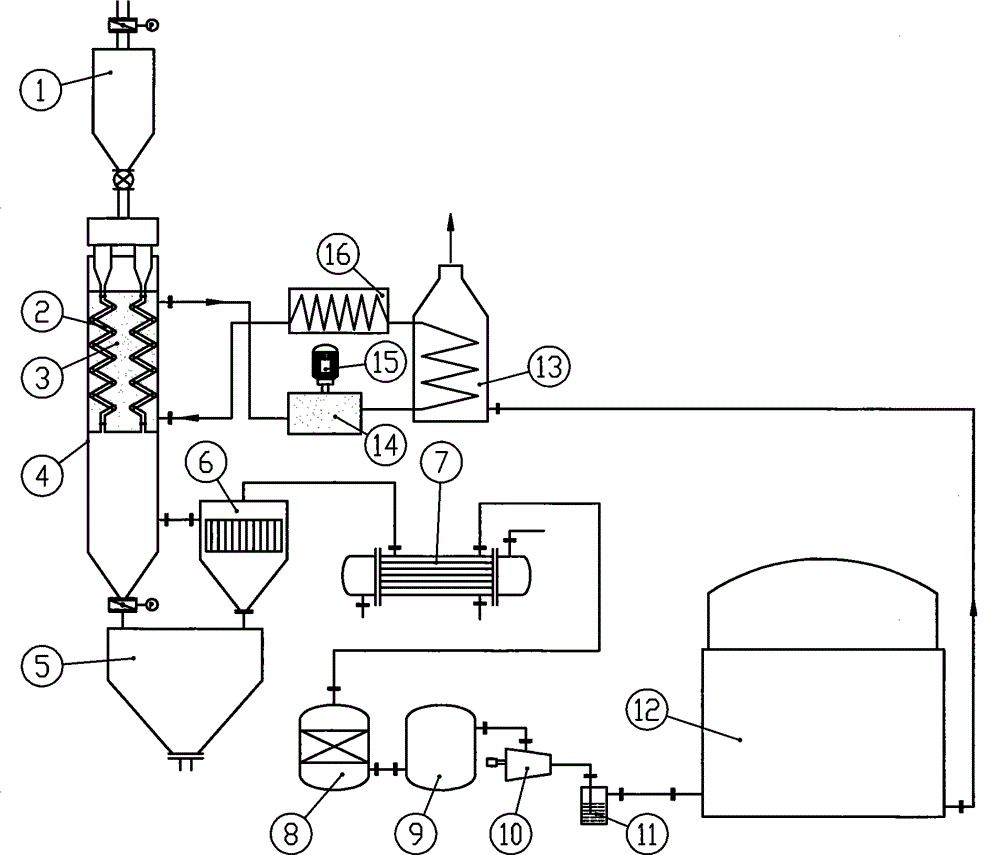

ActiveCN105400528AFast pyrolysisAchieve self-sufficiencyBiofuelsSpecial form destructive distillationScrew conveyorPyrolysis

The present invention discloses a rapid rice husk pyrolysis apparatus. According to the rapid rice husk pyrolysis apparatus, the main body of a reactor is a stainless steel housing, the upper portion is tightly provided with an vacuum material feeder through a material inlet on the upper end, the lower portion, a screw conveyor and two pneumatic gate valves maintain the reactor and outside air isolation state through a material outlet, multiple groups of molten salt heaters are vertically and densely arranged inside the reactor, a fuel gas outlet is arranged above the right side of the main body, the external is connected to a vacuum pump, a condenser and a filter, and separated combustible gas enters a combustor to combust so as to heat high temperature molten salt adopted as a thermal carrier, such that the energy self-sufficiency can be achieved. With the apparatus of the present invention, the rapid rice husk pyrolysis at the temperature of 450-650 DEG C under the total pressure of 5-15 kPa can be achieved, the natural nanometer structure of the silica inside the rice husk is not damaged, and the complete oxidation of the subsequent combustion oxidation unit impurity carbon is easily achieved.

Owner:王开辉

Aqueous toughened glass printing ink dedicated for touch screen and preparation method thereof

The invention belongs to the technical field of chemical printing ink, and specifically relates to an aqueous toughened glass printing ink dedicated for touch screen and a preparation method thereof. The aqueous toughened glass printing ink is prepared from the following raw materials in parts by weight: 6 to 28 parts of inorganic pigment, 20 to 50 parts of first glass powder frit, 10 to 40 parts of second glass powder frit, 10 to 60 parts of aqueous varnish, 0 to 2 parts of wetting dispersant, 0 to 1 part of antifoaming agent, and 0 to 2 parts of leveling agent. The printing ink can improve the surface acoustic wave signal transduction performance of touch screen glass, solves the problem that after surface acoustic waves go through tough screen glass, the signal attenuates, and has the advantages that the covering performance of the printing ink is good, the surface acoustic wave propagation speed is quick, the energy attenuation is little, no phase change happens, and the corrosion of the printing ink is weak.

Owner:郑州市亚美凯新材料有限公司

High manganese steel balance weight for frequency conversion compressor and manufacturing method thereof

InactiveCN102296252ACushion the shockUniform structurePositive displacement pump componentsFoundry mouldsSolventInverter compressor

The invention discloses a high manganese steel balance block for frequency conversion compressor and a manufacturing method thereof. The balance block is made of high manganese steel, and the weight ratio of each element in the high manganese steel is: C0.2%~1.5%, Mn13 ~25%, S≤0.1%, P≤0.1%, Si≤1%, Cr≤5%, Ni≤2%, Fe balance, the balance weight of the compressor is made by investment casting process, which can effectively guarantee the shape of the product And the size, especially the composition is controllable, the batch production capacity is large, and the production cost of the compressor balance block is effectively reduced.

Owner:JIANGMEN ZHENGKE METAL PROD

Method for extracting chondroitin sulfate

InactiveCN102153672AAvoid residueGuaranteed natural whitenessSenses disorderMetabolism disorderHazardous substanceFiltration

The invention discloses a method for extracting chondroitin sulfate. Pig nose cartilage is used as a main raw material in the method; and fine chondroitin sulfate is obtained by digestion, impurity removal, water distribution, enzymolysis, decolorization, sedimentation, enzymolysis, nano-filtration, sedimentation and drying. The product produced by using the method has high purity, any toxic or harmful substance is not produced, and the obtained product has high safety and can be widely applied to the fields of medicaments, health-care products and the like.

Owner:湖北远成赛创科技有限公司

Treatment method of lead-containing wastewater

InactiveCN102476853AFast processingEfficient treatment methodWater/sewage treatmentLow speedWater quality

The invention discloses a treatment method of lead-containing wastewater. The treatment method sequentially comprises the steps of: (1) respectively adding a membrane surfactant at a volume ratio of 3%-5% and a flowing carrier at the volume ratio of 4%-10% to a membrane solvent at the volume ratio of 85%-93% and stirring at a low speed for 10-15 min to prepare a membrane phase; (2) slowly adding an internal water phase medicament having the same volume as the membrane phase to the membrane phase and stirring at a high speed for 10-30 min to prepare a water-in-oil type emulsion; and (3) adding the prepared emulsion to the wastewater at a lead concentration of 10-1000 mg / L until the pH of an external water phase is 3.0-5.5, standing for laying after stirring at a high speed for 30-60 min, breaking the emulsion obtained after the layering through a high-voltage electric field, and separating out an oil phase and an internal water phase, wherein the discharged water can reach the national discharge standard. The treatment method of the lead-containing wastewater disclosed by the invention is fast, efficient, energy-saving and free from phase change, purifies water quality, gathers and recycles heavy metal ions and has simple equipment, convenient operation, a lead removal rate of more than 99.9% and unprecedented application foreground in the field of heavy metal wastewater treatment.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

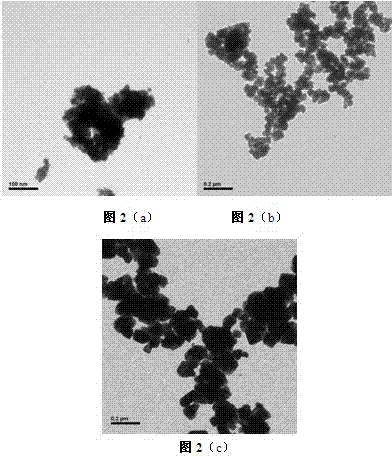

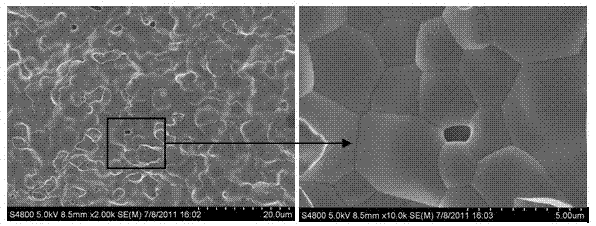

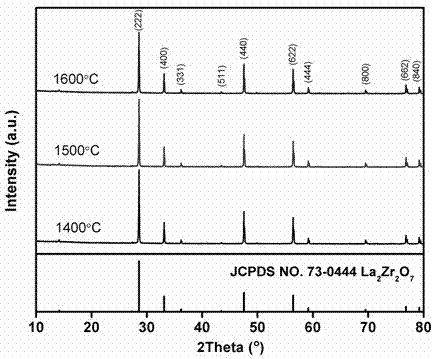

Compact pure-phase lanthanum zirconate ceramic with low thermal conductivity and high strength, and preparation method thereof

The invention discloses compact pure-phase lanthanum zirconate ceramic with low thermal conductivity and high strength, and a preparation method thereof. A chemical formula of the lanthanum zirconate ceramic is La2Zr2O7, the compactness is greater than 85%, the compression strength is 310-500MPa, the thermal conductivity and the thermal diffusion coefficient at normal temperature respectively are 1.55-1.79W / (m.K) and (0.90-0.76)*10<-6>m<2> / s; the thermal conductivity and the thermal diffusion coefficient at the temperature of 1200 DEG C respectively are 0.75-0.94W / (m.K) and (0.35-0.45)*10<-6>m<2> / s; the breaking tenacity is 1.45-1.70MPa. The lanthanum zirconate ceramic prepared according to the lanthanum zirconate ceramic preparation method provided by the invention has the advantages of low thermal conductivity, high melting point, good inoxidizability, excellent mechanical property, good high temperature-phase stability and the like, and the requirements of hypersonic velocity aerospace vehicles on the performances of high-strength thermal insulation ceramic materials can be met.

Owner:ZHEJIANG UNIV

Extraction and preparation method for licorice effective ingredients

InactiveCN103965152AHigh yield of active ingredientsHigh yieldSugar derivativesSteroidsWater dischargeLicorice acid

The invention relates to an extraction and preparation method for licorice effective ingredients, mainly to a method for simultaneously extracting effective ingredients like glycyrrhizic acid, glycyrrhiza flavonoid and a licorice flavoring agent from licorice. The method comprises the following steps: with glycyrrhizic acid as a raw material, carrying out extraction so as to obtain licorice residue and extract liquid and subjecting the licorice residue to ethanol extraction so as to obtain a crude glycyrrhiza flavonoid product; removing impurities in the licorice extract liquid by using an ultrafiltration membrane device, carrying out concentration by using a nanofiltration membrane device, subjecting a nanofiltration membrane concentrate to acid precipitation and drying a precipitate so as to obtain glycyrrhizic acid; and subjecting a supernatant produced after acid precipitation to concentration with the nanofiltration membrane device and carrying out drying so as to obtain the licorice flavoring agent. The method adopts membrane separation technology for impurity removal and concentration of the extract liquid, so working conditions are mild, product purity and quality are guaranteed, and yield of licorice effective ingredients is high; the method has the advantages of simple production flow, low cost, small pollution, reusability of a nanofiltration membrane filtrate generated in production process, reduction in consumption of raw water and great decrease of waste water discharge.

Owner:武汉普赛特膜技术循环利用有限公司

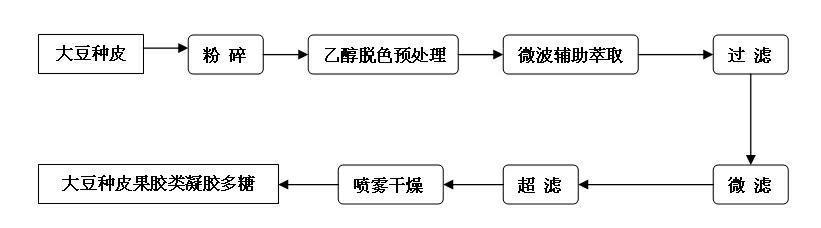

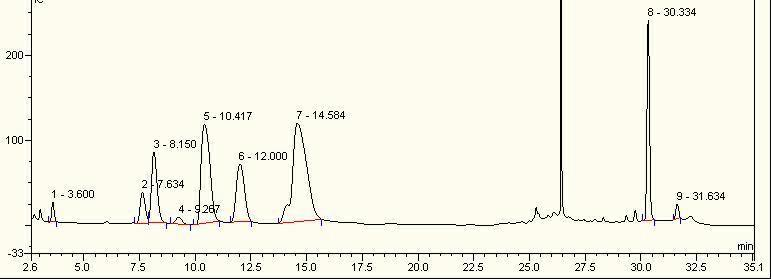

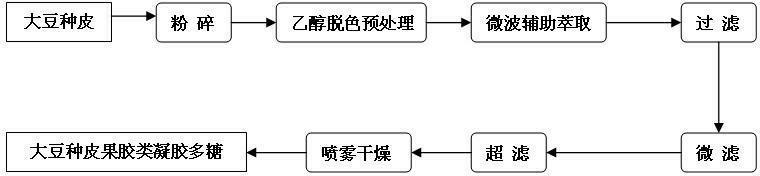

Preparation method of soybean episperm pectin gel polysaccharide

ActiveCN102492054ADepigmentationGood decolorization effectFood preparationUF - UltrafiltrationImpurity

The invention relates to a preparation method of soybean episperm pectin gel polysaccharide. The preparation method comprises the following specific steps of: firstly crushing soybean episperm, soaking and persistently stirring the soybean episperm with low concentration ethanol, filtering, recovering ethanol and drying retentate under reduced pressure; and adding ammonium oxalate or a component A to dried soybean episperm powder, carrying out microwave-assisted extraction, carrying out conventional filtering on the material liquid after microwave treatment to obtain filtrate, removing fine impurities by a microfiltration method, carrying out ultrafiltration and concentration on the obtained filtrate, and spray-drying the concentrated material liquid by an atomizer to obtain soybean episperm pectin polysaccharide solid powder, wherein the component A is a mixed solution of ammonium sulfate and a component B, and the component B is oxalic acid or EDTA (ethylene diamine tetraacetic acid) or citric acid. The method is low in production cost and high in extraction rate; and the prepared product solution is low in color value, has unique gel characteristics and can be widely applied tofood industry.

Owner:BOHAI UNIV

Extraction method of pig blood protein peptide

The invention discloses an extraction method of pig blood protein peptide. The extraction method comprises the following steps: steaming and cooking fresh pig blood used as a main raw material, mincing, adding water, adding proteinase for enzymolysis and adding flavourzyme for enzymolysis, inactivating enzyme, decolorizing, separating through a nanofiltration membrane, and performing spray drying to the obtained filtrate and obtain the pig blood protein peptide. The extraction method disclosed by the invention has the advantages of short production period, low cost, no environmental pollution and high product safety, and can be widely applied in the fields of health-care products, food, medicines and the like.

Owner:DELISI GROUP

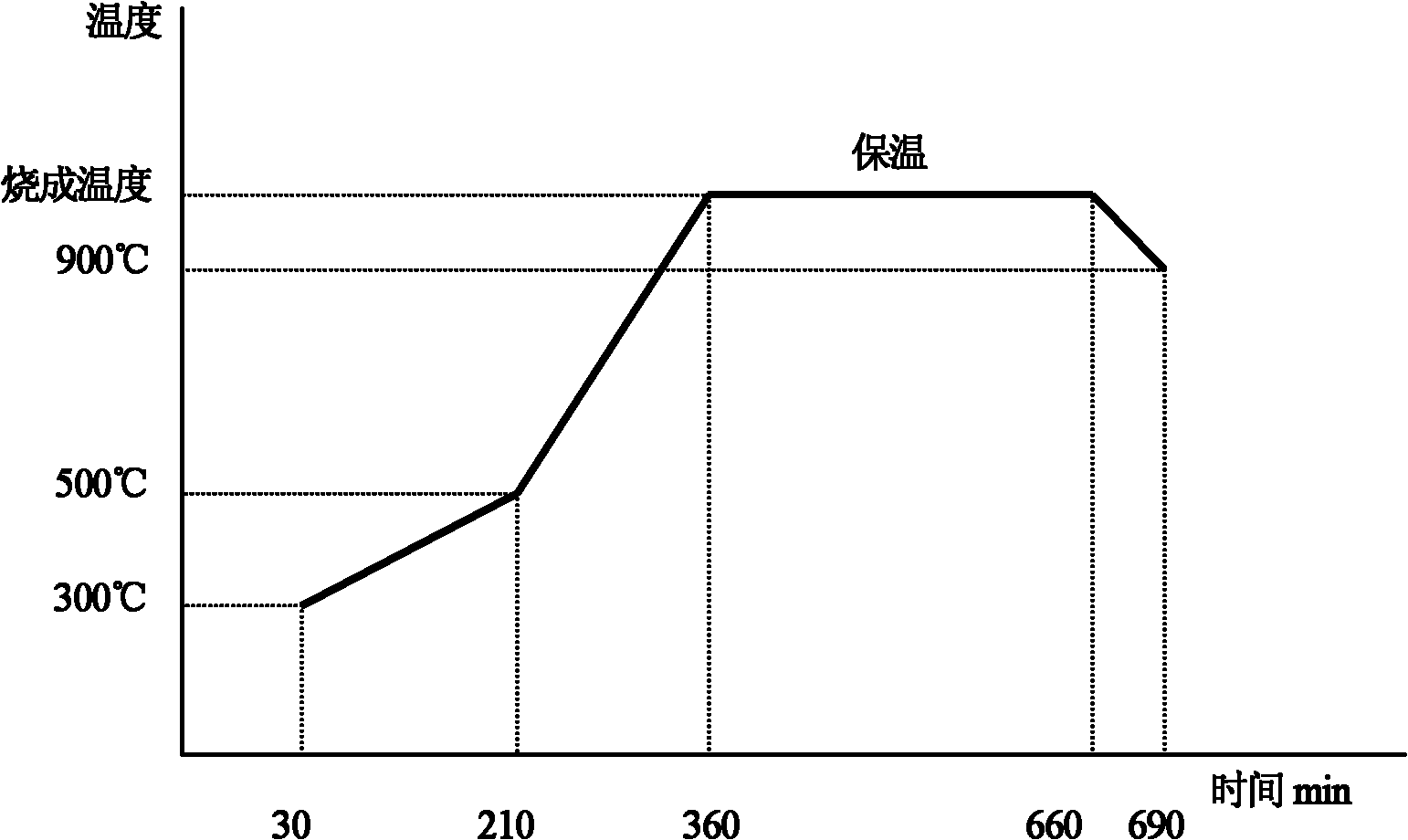

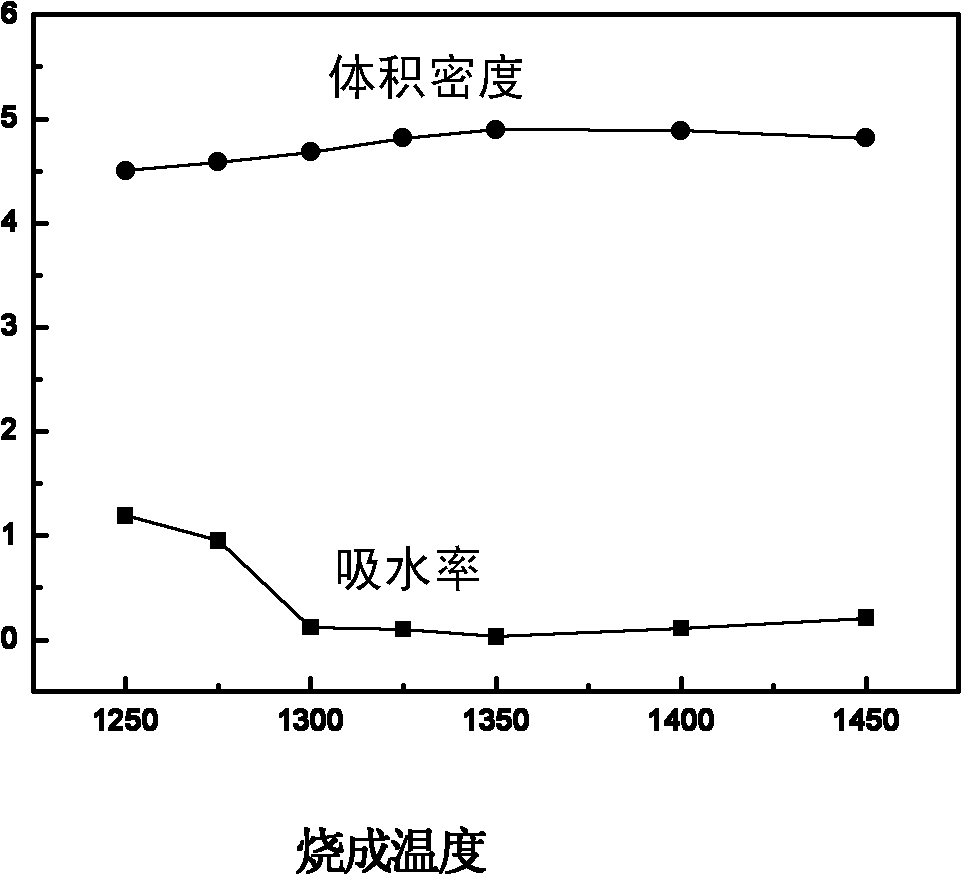

Liquid phase sintering additive for tetragonal polycrystalline zirconia ceramic material and preparation and application thereof

The invention discloses a liquid phase sintering additive for a tetragonal polycrystalline zirconia ceramic material and preparation and application methods thereof. The additive consists of a stabilizing agent and a flux, wherein the stabilizing agent is yttrium oxide; the flux is calcium-aluminium-silicon-based glass powder consisting of 40 to 50 weight percent of SiO2, 5 to 15 weight percent of CaO, 20 to 30 weight percent of Al2O3, 5 to 15 weight percent of Na2O and 10 to 20 weight percent of B2O3; and the mass ratio of the stabilizing agent to the flux is 2-5:4-6. In the sintering additive, the addition amount of the stabilizing agent accounts for 2 to 5 percent of the matrix zirconia material, and the addition amount of the glass flux accounts for 4 to 6 percent of the matrix zirconia material; under the condition of preparing the TZP material with high toughness and high chemical stability, a zirconia liquid phase sintering mechanism can be formed, the firing temperature is greatly reduced, the sintering temperature of the TZP material added with the additive is 1,400+ / -30DEG C and the breaking strength is more than 400MPa.

Owner:湖南博深实业集团有限公司

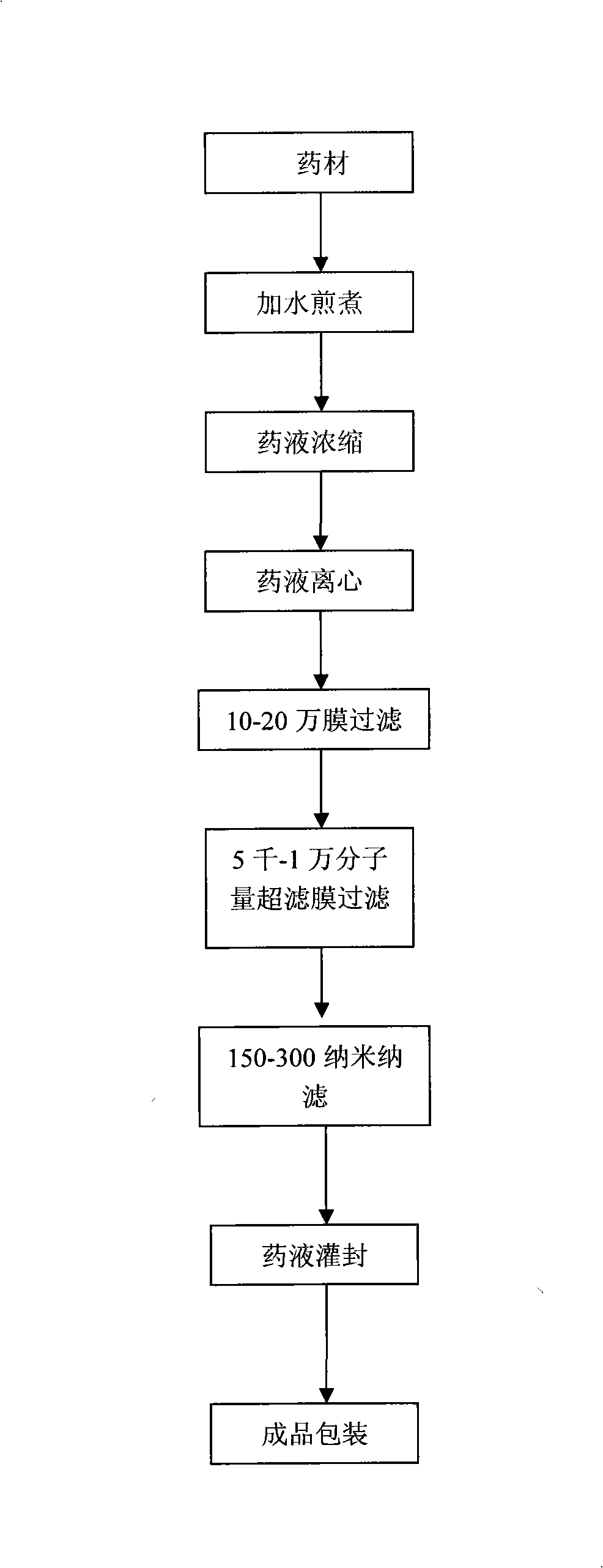

Process for preparing compound folium isatidis injection with membrane filter technique

The invention discloses a process for preparing compound dyers woad leaf injection by membrane filtration technology. The process for preparing the compound dyers woad leaf injection by membrane filtration technology is as follows: according to the prescription of the compound dyers woad leaf injection, medicine materials are decocted; medicine liquid is condensed to three times as much as formula dosage, centrifuged, filtrated directly by the membrane with large pore size, filtrated by an ultrafiltration membrane and condensed by a nanofiltration membrane, thus extracting the compound dyers woad leaf injection. The process for preparing the compound dyers woad leaf injection has following characteristics: 1. heating process is reduced to decrease the loss of effective components; 2. the process is carried out at normal temperature to prevent phase transition and pollution; 3. the ethanol extraction process in conventional technology is replaced, so cost is saved and production is kept clean; 4. extraction period is shortened and pollution sections are reduced, thus offering technological insurance for the quality of products; 4. compared with content produced by prior art, the content is increased by over two times.

Owner:SHANDONG HUAXIN PHARMA

Method for extracting L-isoleucine through whole membrane technology

ActiveCN106220521AIncrease incomeSimple processOrganic compound preparationMicroorganismsFlocculationFiltration membrane

The invention belongs to the technical field of base acid production, and discloses a method for extracting L-isoleucine through whole membrane technology. The method comprises the following steps: step 1) filtering through a micro-filtration membrane and removing impurities through flocculation; step 2) filtering through an ultra-filtration membrane, step 3) concentrating through a reverse osmosis membrane; step 4) concentrating and crystallizing. The membrane technology is combined with the flocculation agent to remove the impurities, the process is simple and feasible, and the yield and the purity of the product are greatly improved.

Owner:SHANDONG FUFENG FERMENTATION CO LTD

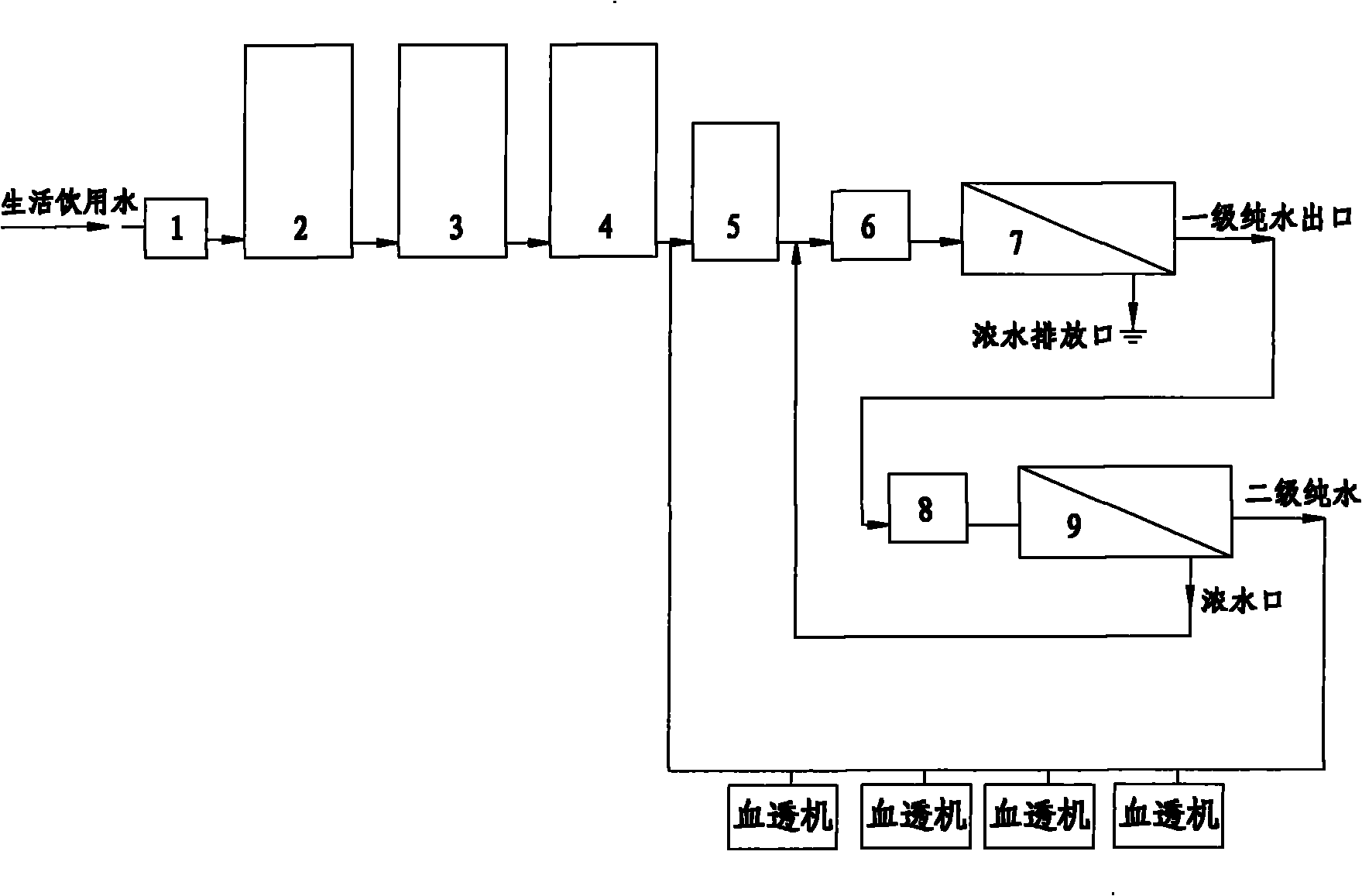

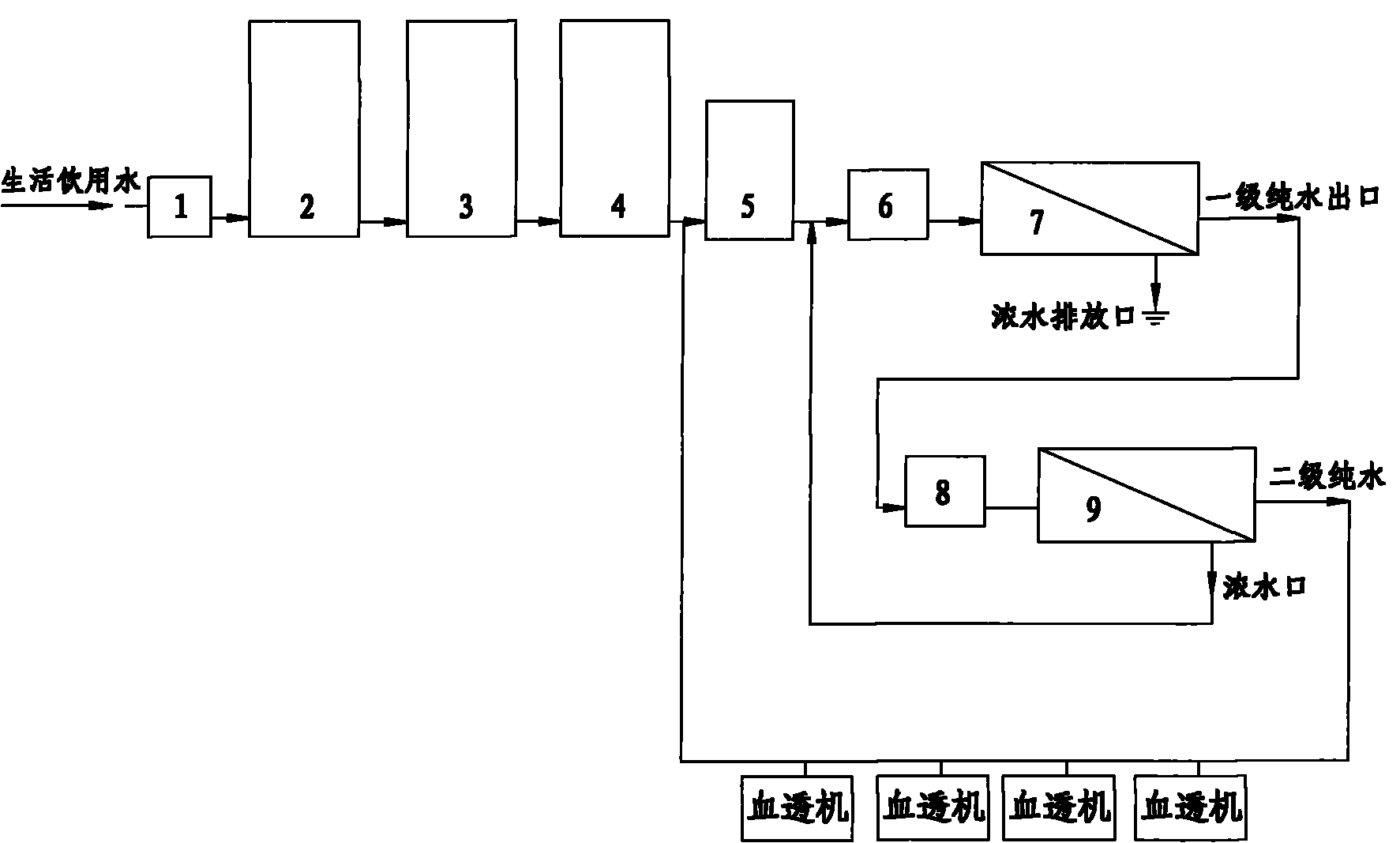

Water making device for purifying blood

InactiveCN101870526AHeat resistantImprove water purityInfusion devicesWater/sewage treatment bu osmosis/dialysisChemistryPollutant

The invention discloses a water making device for purifying blood, which can further improve the purity of water quality and the sterilization rate, and can be used for softening the water quality. The device leads pure water to be treated by reverse osmosis membrane separation again, thus ensuring the water quality to be better in accordance with the standard of hemodialysis water; and a softener is used for removing calcium and magnesium ions, thus reducing the hardness of the water. By utilizing the secondary reverse osmosis membrane separation technology, the water making device for purifying blood improves the removal rate of the device for chemical pollutant, thoroughly removes bacteria in the water, leads the quality of the hemodialysis water to reach the standard of the hemodialysis water, and reduces the treatment risk of hemodialysis patients.

Owner:盛建华

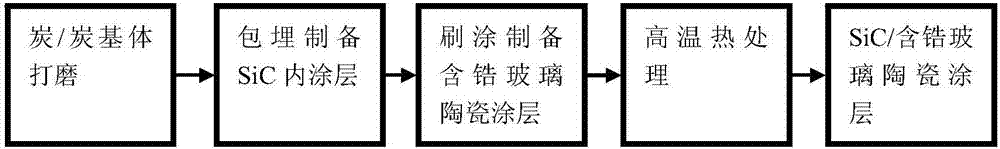

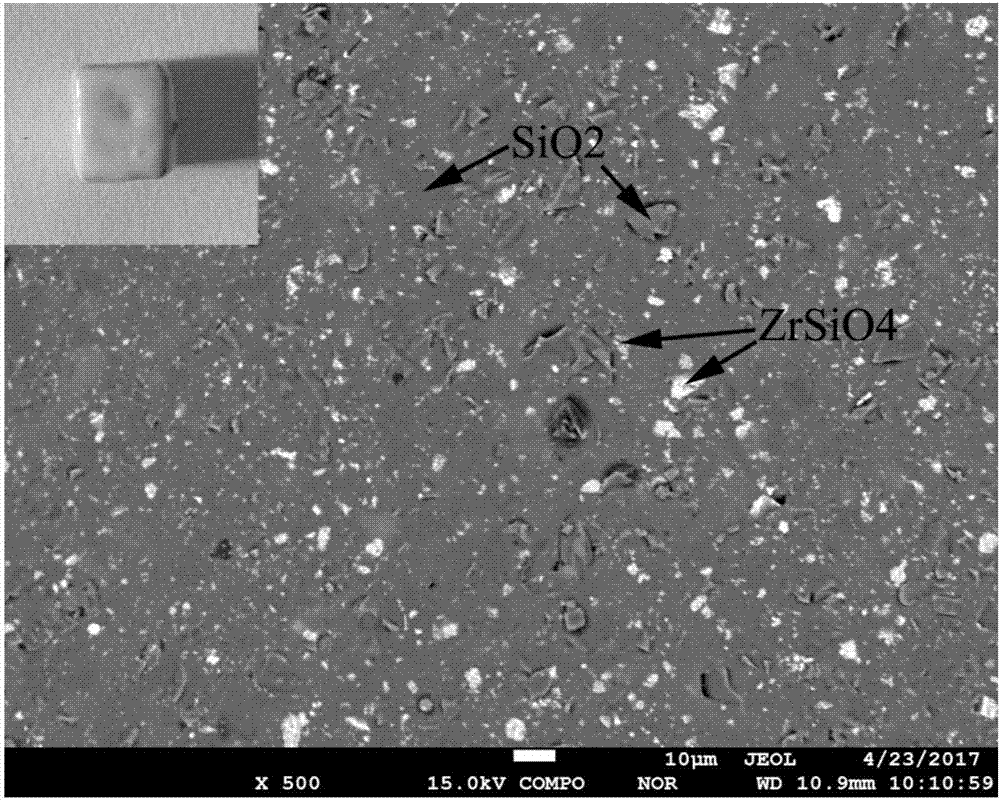

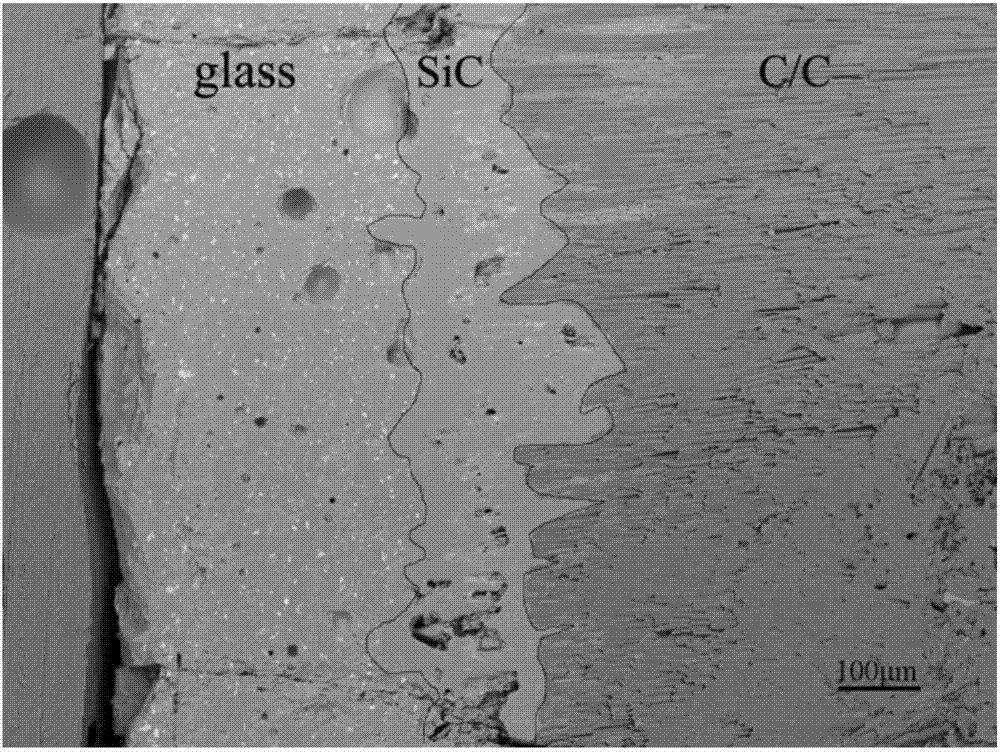

Carbon/carbon composite material with antioxidant coating, preparation method and application thereof

The invention relates to a carbon / carbon composite with an anti-oxidant coating, a preparation method and the application thereof. The carbon / carbon composite comprises a carbon / carbon composite substrate, a SiC layer and a second coating, wherein the carbon / carbon composite substrate is uniformly coated with the SiC layer; the SiC layer is coated with the second coating; the second coating is a zirconium-containing glass ceramic coating; the second coating comprises the following components by mass: 55-85% of SiO2, 5-35% of ZrO2, 2-10% of Al2O3, 5-15% of B2O3, 1-3% of Li2O and 2-6% of Y2O3. The preparation method comprises the following steps: preparing the SiC layer by a pack siliconizing process; preparing the second coating by a brushing method. The process of the invention is simple and convenient to operate; the coating is controllable in thickness, firmly and uniformly bonded to the carbon / carbon composite substrate, excellent in oxidation resistance and thermal shock resistance below 1400 DEG C, and capable of realizing industrial production.

Owner:CENT SOUTH UNIV

Enhancing ultrafiltration treatment method of compound wastewater containing cadmium and methylene blue by surfactant

InactiveCN101696049AGood removal effectGood emulsificationWater contaminantsWater/sewage treatment bu osmosis/dialysisUltrafiltrationCadmium Cation

The invention discloses an enhancing ultrafiltration treatment method of compound wastewater containing cadmium and methylene blue by surfactant, which comprises the following steps: adding lauryl sodium sulfate to the compound wastewater containing the cadmium and the methylene blue, wherein 6*10-3mol-8*10-3mol of the lauryl sodium sulfate is added to per liter of wastewater; stirring evenly and then standing still and reacting for more than a half hour; after the reaction, generating a lauryl sodium sulfate micelle with cadmium ions and methylene blue molecules; standing still and reacting, then sending the wastewater to an ultrafiltration film component for ultrafiltration process; trapping the lauryl sodium sulfate micelle and completing the simultaneous removal of the cadmium and the methylene blue in the wastewater. The method has the advantages of high removing rate, low energy consumption, no phase change, no secondary pollution, easy realization of pollutant recycling, automatic operation, and the like.

Owner:HUNAN UNIV

Equipment and method for preparing anhydrous sodium sulfate

ActiveCN105480990ANo phase changeRaise the gradeAlkali metal sulfite/sulfate dehydrationCentrifugationSalting out

The invention discloses equipment for preparing anhydrous sodium sulfate. The equipment is characterized by comprising a closed cycle membrane concentration system, a salting out system, a conveying pump and a normal temperature crystallization system which are sequentially connected; the closed cycle membrane concentration system is used for conducting concentration on inlet liquor containing sodium sulfate and discharging concentrated liquor containing supersaturated sodium sulfate, the salting out system is used for changing a sodium chloride-sodium sulfate-water ternary system in the concentrated liquor into an unstable system, the conveying pump is used for conveying the concentrated liquor discharged by the salting out system to the normal temperature crystallization system, and the normal temperature crystallization system is used for conducting normal temperature crystallization and centrifugation on the concentrated liquor conveyed by the conveying pump so as to obtain the anhydrous sodium sulfate. The invention further provides a method for preparing the anhydrous sodium sulfate. According to the method, the evaporation process is omitted, crystallization is conducted at a normal temperature, anhydrous sodium sulphate is obtained, phase change of water does not occur in the whole process, energy consumption is low in the production process, product quality is good, and the high-grade anhydrous sodium sulphate can be obtained.

Owner:SHANGHAI LYMAX ENVIRONMENTAL TECH CO LTD

Method for treating cadmium-containing waste water by intensified ultrafiltration of hollow fiber ultrafiltration membrane and foam floatation

InactiveCN1843963AGood removal effectReduce energy consumptionWater/sewage treatment by sorptionWater/sewage treatment by flotationHollow fibreFiber

The invention provides a method of disposing waste water containing cadmium with hollow fiber hyperfiltration membrane intensive hyperfiltration and floating foam, which comprises the following steps: 1) adding anionic surfactant sodium dodecyl sulfate into the waste water containing cadmium, intimate mixing, and stewing reacting, pumping the water into hyperfiltration membrane assembly for filtering with peristaltic pump, then flowing into air-float column; 2) blowing air from aeration head in the bottom of air-float column with air compressor, making yielding water obtained from step 1)flow into from the intermediate section of air-float column, with foamability of sodium dodecyl sulfate, making rudimental sodium dodecyl sulfate form bubble with adsorption capacity, to adsorb low-concentration cadmium ion remaining in water, 3) the bubble with cadmium ion obtained from step 2) floating upward, and issueing from the top of air-float column, and the water discharging from the bottom of air-float column after reaching the standard. The invention has the following merits: good removal effect, small energy consumption, simple operation, less dosage of surfactant, low cost.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com