Comprehensive recycling technology for mine water with high suspended matter content and high mineralization degree

A comprehensive treatment and salinity technology, applied in the field of coal mine water resource treatment, can solve the unsatisfactory effect of coal mine water treatment and resource utilization, affect the quality of effluent water and the operation of the water treatment system, and the reverse osmosis membrane is easy to clog and pollute and other problems, to increase the range of pollutant removal, easy automation of operation, and reduce membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

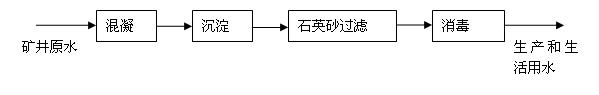

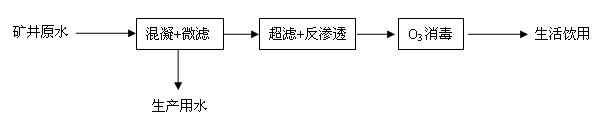

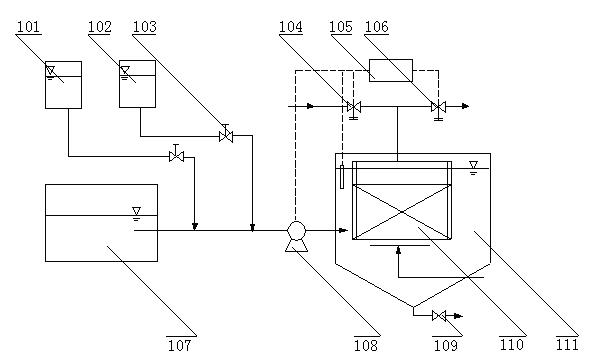

[0041] Refer to attached figure 2 , the integrated technology of high suspended solids and high salinity mine water treatment and reuse in the present invention aims at the water quality characteristics of high suspended solids and high salinity mine water, and adds coagulant to the mine raw water to make the water suspended After the colloidal particles are destabilized through the conventional treatment of the compressed electric double layer, the three-membrane filtration technology of the first stage of microfiltration membrane, the second stage of ultrafiltration membrane, and the third stage of reverse osmosis membrane is adopted.

[0042] After the mine raw water is filtered by the microfiltration membrane in the first stage, the effluent water quality can meet the needs of coal mine underground production.

[0043] After the second-stage filtration of ultrafiltration membrane and the third-stage filtration of reverse osmosis membrane, it is filtered step by step, and ...

Embodiment 2

[0059] Chemical cleaning of 208 reverse osmosis membrane third-stage filter pollution in the first-stage reverse osmosis system, with 2.0%wt STPP sodium tripolyphosphate and 0.8%wt Na 2 - EDTA blend, pH 10.0 cleaning solution designed for the removal of calcium sulfate scale and light to moderate levels of natural organic pollutants.

Embodiment 3

[0061] The first-stage reverse osmosis system 208 chemical cleaning of reverse osmosis membrane third-stage filtration pollution, using 1.0%wt sodium bisulfite, cleaning solution with a pH of 11.5, is used to remove metal oxides and hydroxides, and can be used to a certain extent extended to remove calcium sulfate, barium sulfate and strontium sulfate scale.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com